Internal twisted tape testing system

A testing system, a technology of spiral ties, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problem of inability to effectively verify the reliability of spiral ties, stay in the theoretical stage, and the operation of spiral ties cannot form real test conclusions, etc. problem, to achieve the effect of easy promotion, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

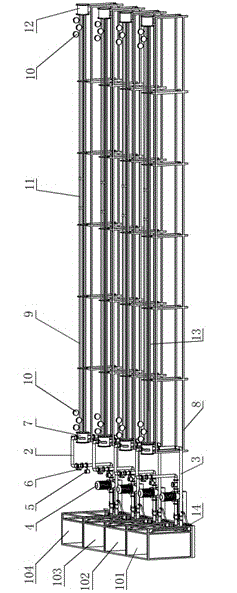

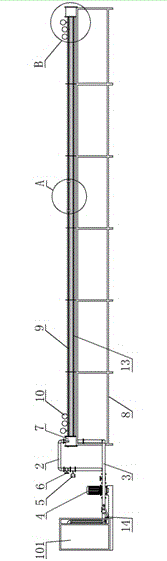

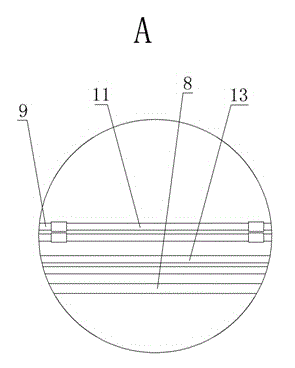

[0032] The technical solution of the present invention is further described in conjunction with the accompanying drawings and embodiments.

[0033] Such as figure 1 As shown, the present invention includes four test platforms, and each test platform includes a water tank 1, a water inlet pipe 2, an outlet pipe 3, a circulating pump 4, a flow meter 5, a pressure valve 6, a diverter box 7, a support 8, a test tube 9, Pressure gauge 10, observation tube 11, reflux tank 12, reflux branch pipe 13, main conveying pipe 14, wherein:

[0034] The water tank 1 is used to contain the medium used in the simulated use environment, and the water tanks in the four test platforms are respectively a room temperature clean water tank 101, a room temperature sludge water tank 102, a high temperature oil tank 103 and a high temperature clean water tank 104;

[0035] One end of the water inlet pipe 2 is connected to the water tank 1, and the other end is connected to the diversion tank 7, for tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com