Noctilucent plastic product production equipment

A technology for plastic products and production equipment, applied in the direction of coating, etc., can solve the problems of high labor intensity, inconvenience in demoulding plastic products, and inconvenience in filtering raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

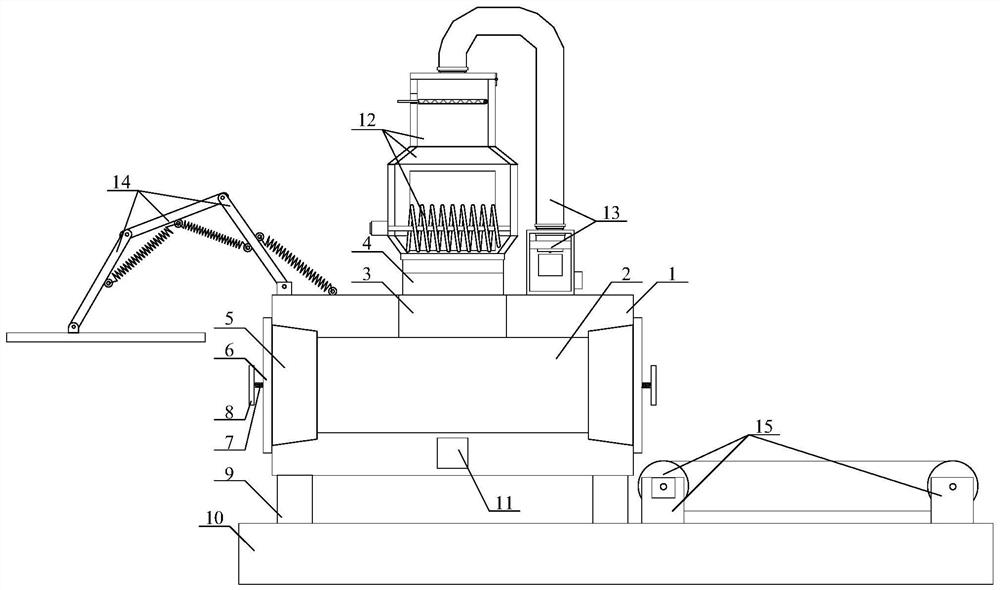

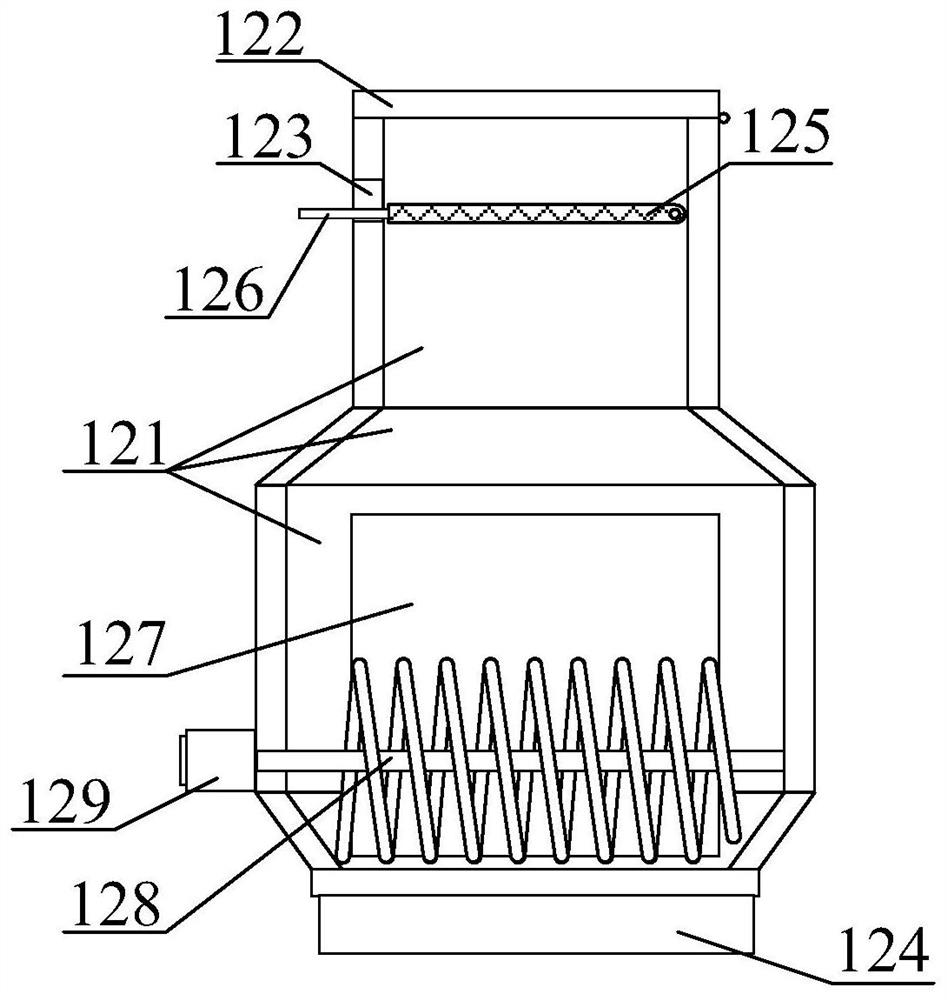

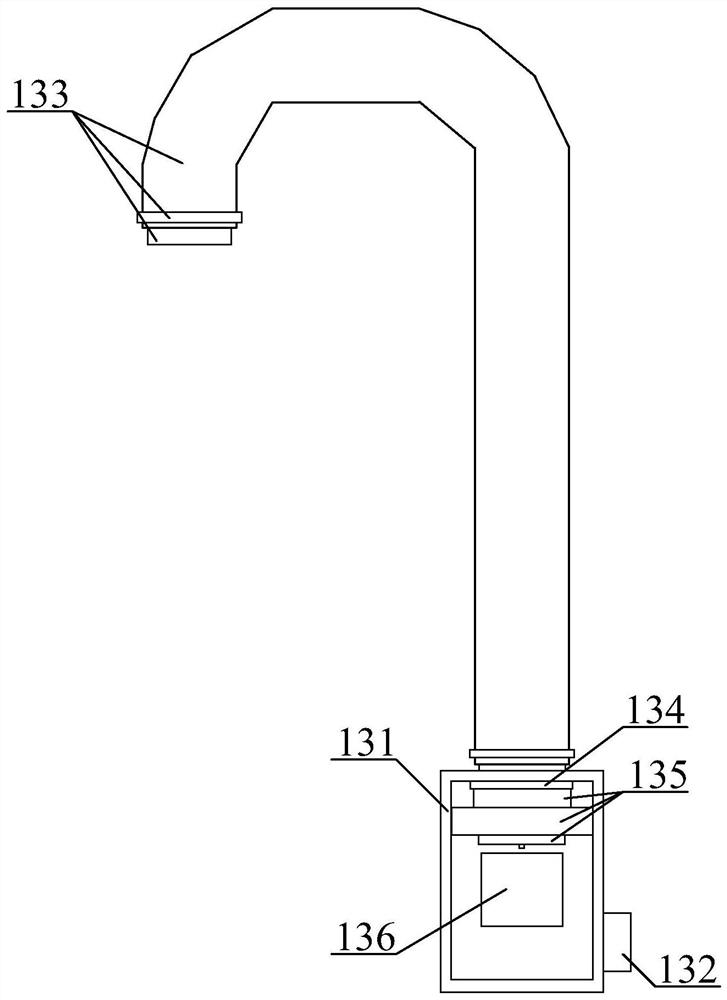

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, a luminous plastic product production equipment includes a plastic product molding body 1, a plastic mold cavity 2, a feed port 3, a feed pipe 4, a ceramic sealing plug 5, a discharge door 6, a screw rod 7, and an operating hand wheel 8. Support legs 9, workbench 10, control panel 11, raw material filtration and melting mixing bucket structure 12, raw material melting odor and anti-pollution treatment box structure 13, self-resetting finished product push rod structure 14 and artificial finished product conveyor belt structure 15. A plastic mold cavity 2 is provided in the inner middle part of the plastic product molding body 1, and a threaded blind hole is opened in the left front side of the inner middle part and the right front side of the inner middle part of the plastic product molding body 1; 3 is set on the upper midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com