Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Avoid glue leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

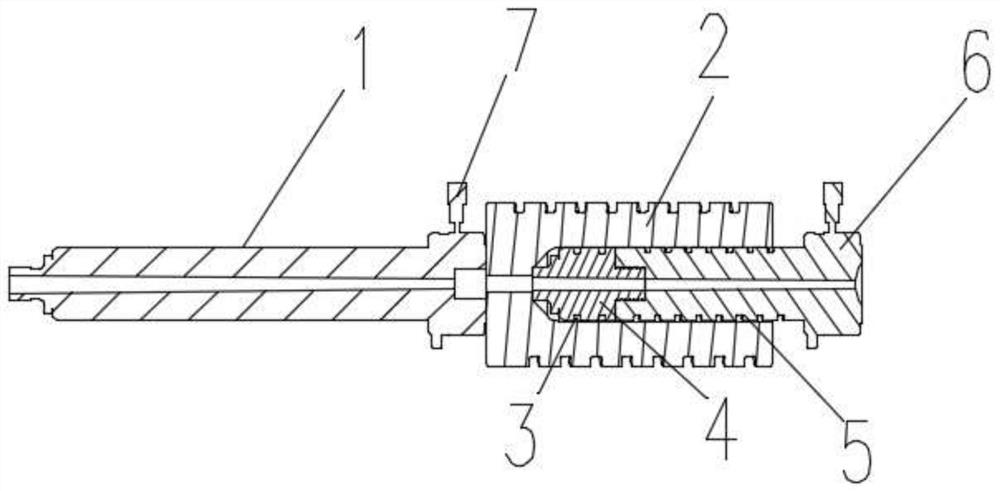

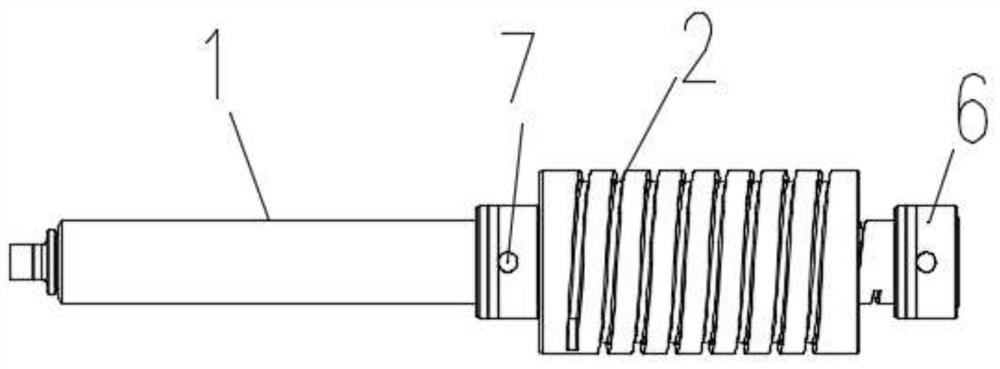

Compound extrusion unit for producing tubeless bicycles and mouth device thereof

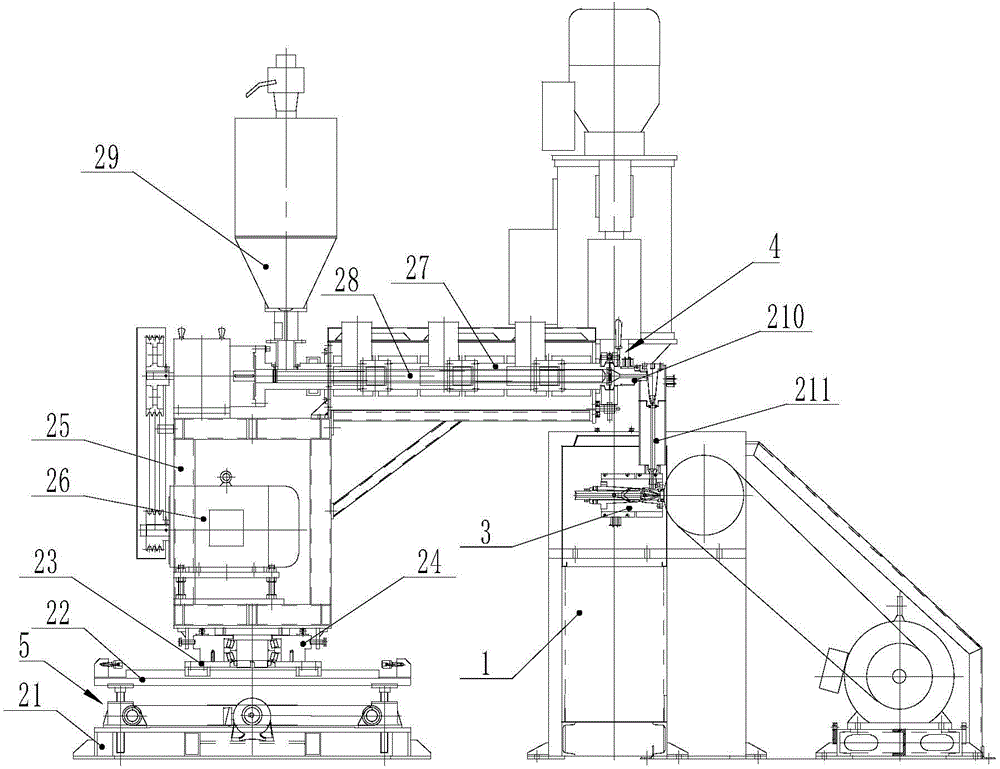

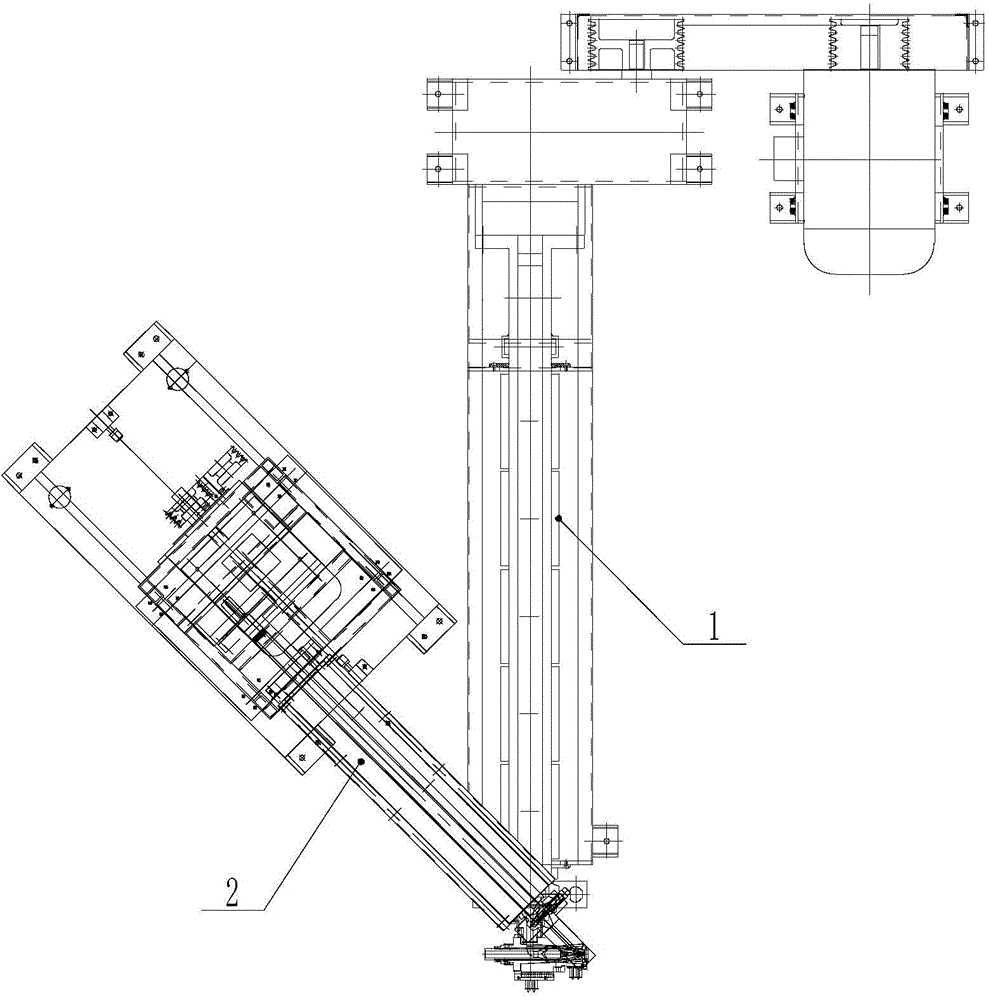

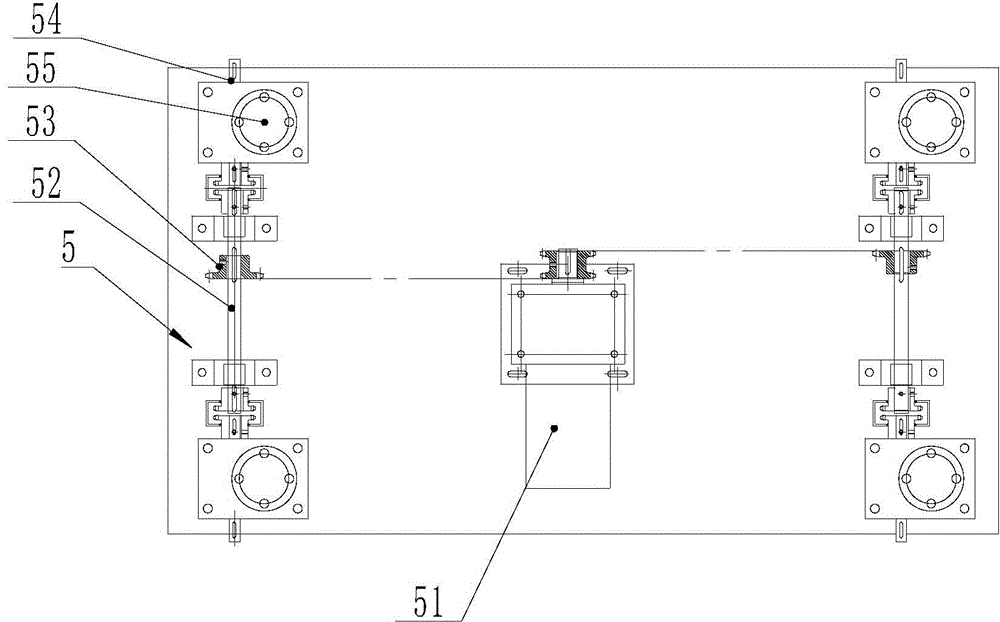

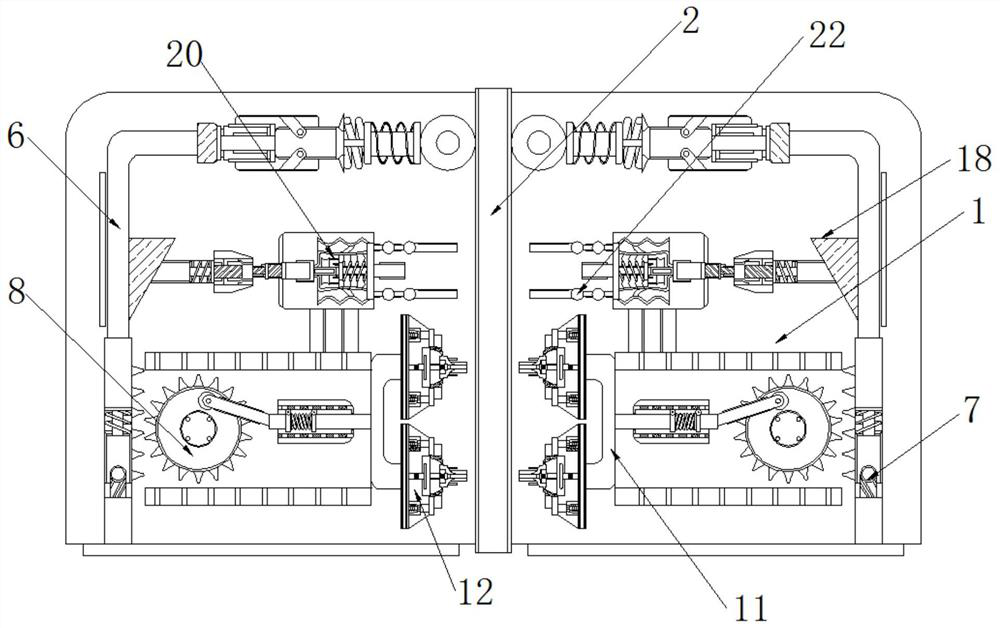

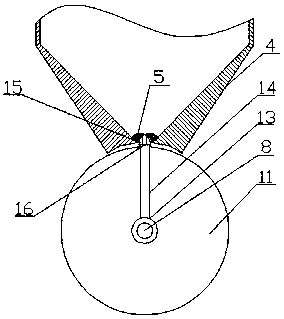

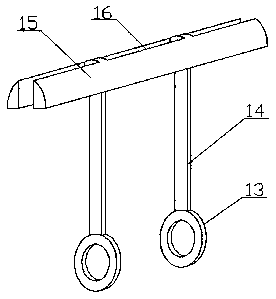

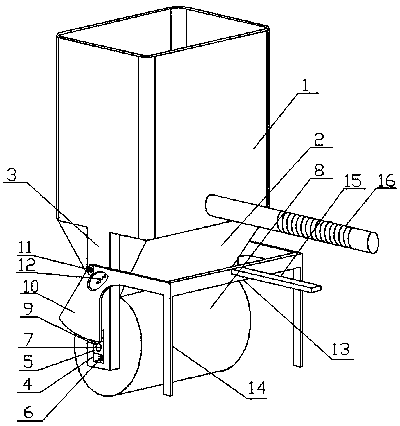

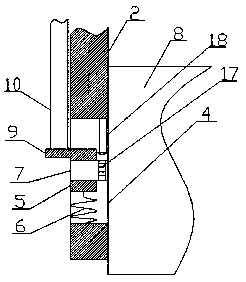

The invention provides a compound extrusion unit for producing tubeless bicycles and a mouth device thereof. According to flow direction of a sizing material, the mouth device comprises a performed mouth board, a mouth board and a mouth box, which are sequentially connected; and the mouth board is embedded in the mouth box. The performed mouth board has an integral structure; the mouth board comprises an upper mouth board and a lower mouth board, which are matched with each other; the extrusion unit comprises an extrusion system and a temperature-control system, which are connected with each other; the extrusion system comprises three compound heads and three extrusion machines which are connected with the three compound heads respectively; and three extrusion machines are arranged pickaback, and the mouth device in the three compound heads is the mouth device. The mouth device can avoid streaming and burning of the sizing material in the process of inner compounding and guarantee stable extrusion of the products; and meanwhile, the volume of the device is small and maintenance of equipment is convenient because the extrusion machines are assigned pickaback; and mold components are locked by utilizing a lock, so that locking effect is good and shaping effect of tires is also good.

Owner:东莞市力拓橡塑设备有限公司

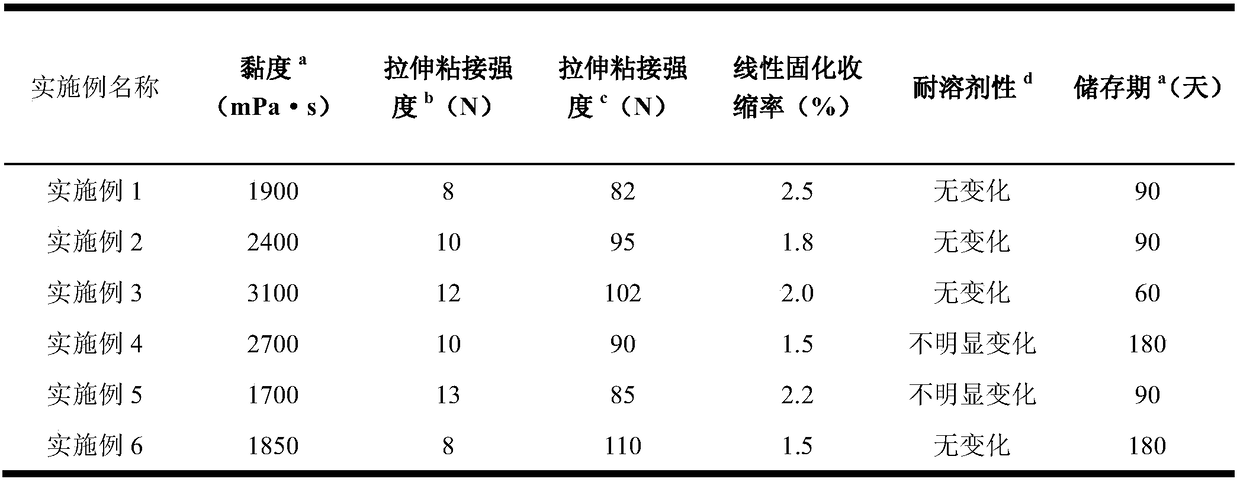

Epoxy resin-modified acrylic resin double-curing system needle adhesive and preparation method thereof

ActiveCN108753228AImprove performanceImprove curing depthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAcrylic resinAdhesive

The invention discloses an epoxy resin-modified acrylic resin double-curing system needle adhesive. The adhesive comprises the following raw materials by weight: 20-80 parts of epoxy resin, 5-60 partsof modified acrylic resin, 2-20 parts of epoxy reactive diluent, 2-30 parts of acrylate reactive diluent, 2-20 parts of latent curing agent, 0.2-5 parts of photoinitiator and 0.1-3 parts of sensitizer. A preparation method and an application of the epoxy resin-modified acrylic resin double-curing system needle adhesive are further disclosed. The epoxy resin-modified acrylic resin double-curing system needle adhesive has the advantages of 'quick drying' and 'high strength', and an adhesive condensate has the advantages of high bonding strength, small volume shrinkage, good damp heat resistanceand solvent resistance and moderate price.

Owner:浙江航通舟新材料科技股份有限公司

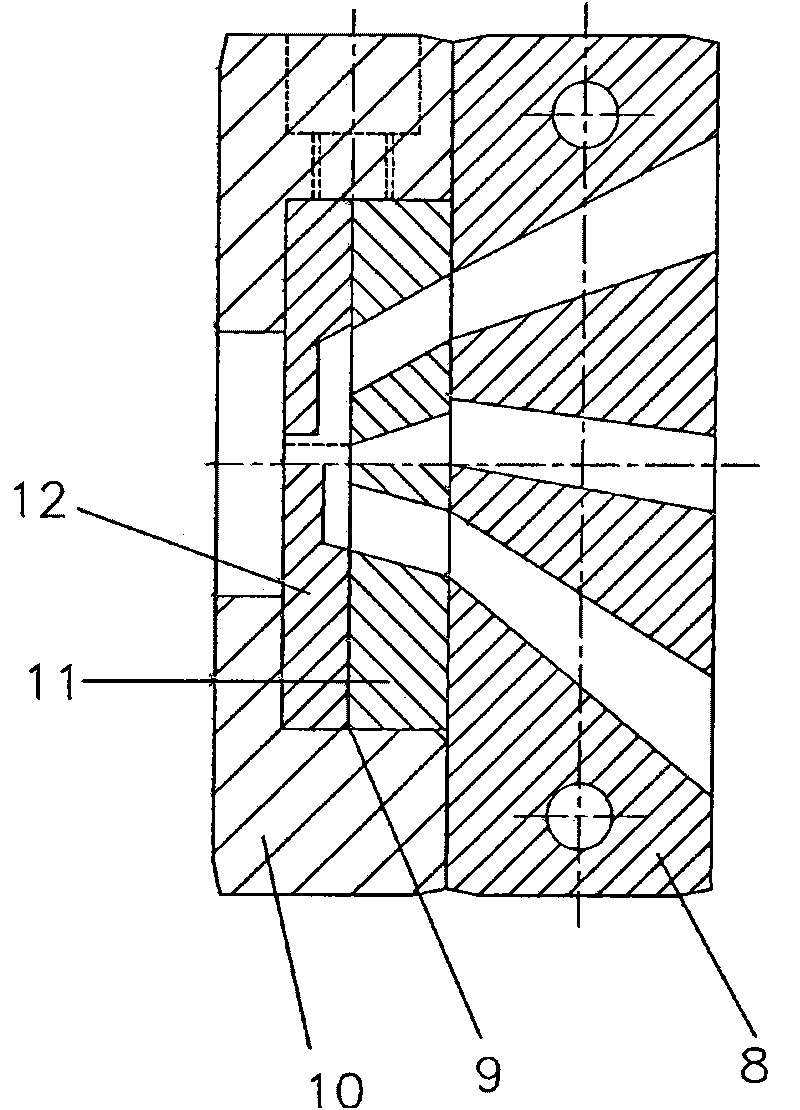

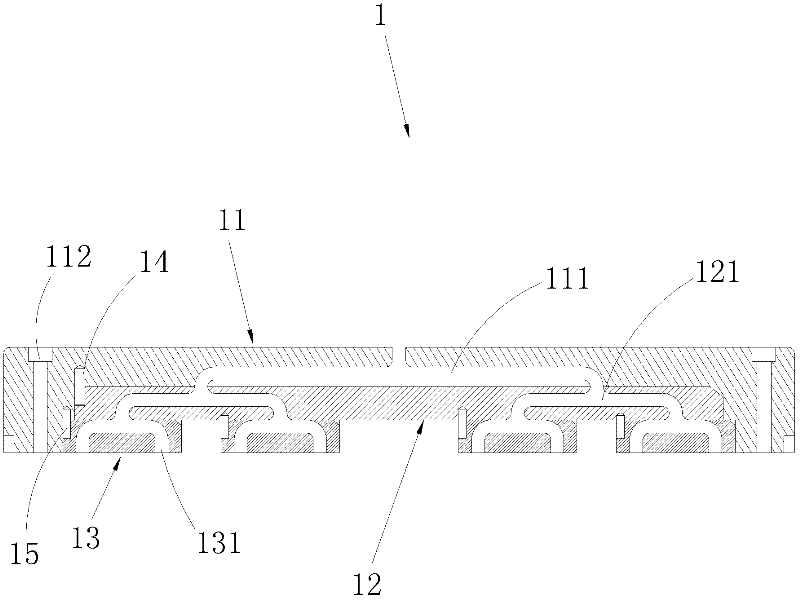

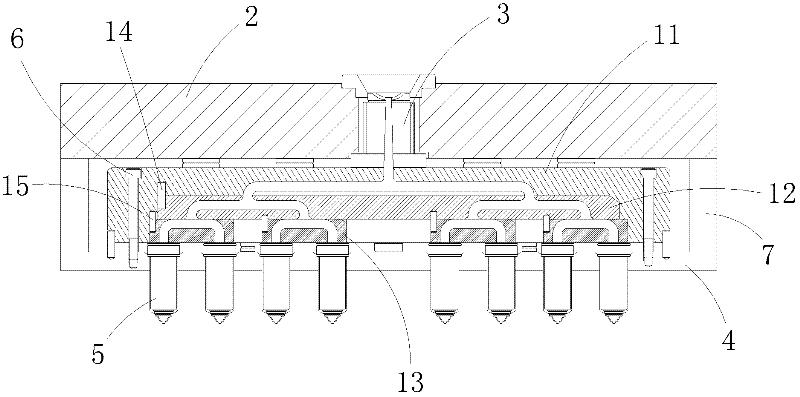

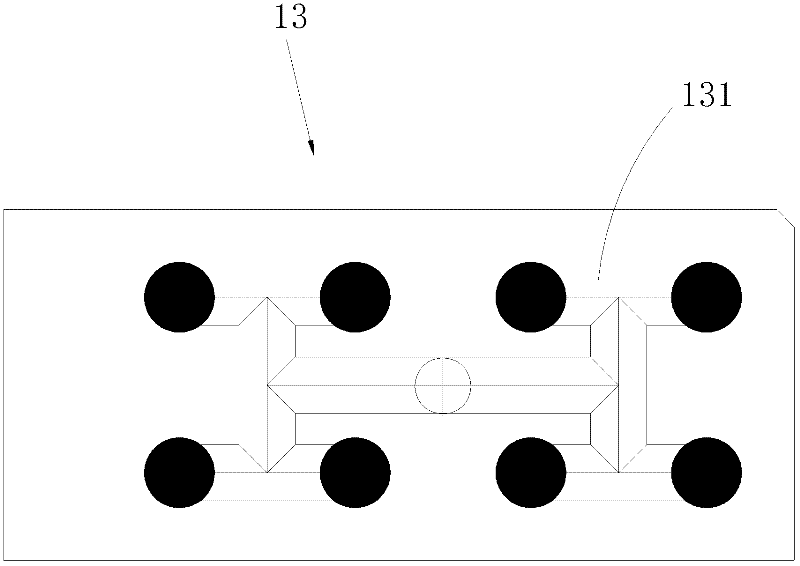

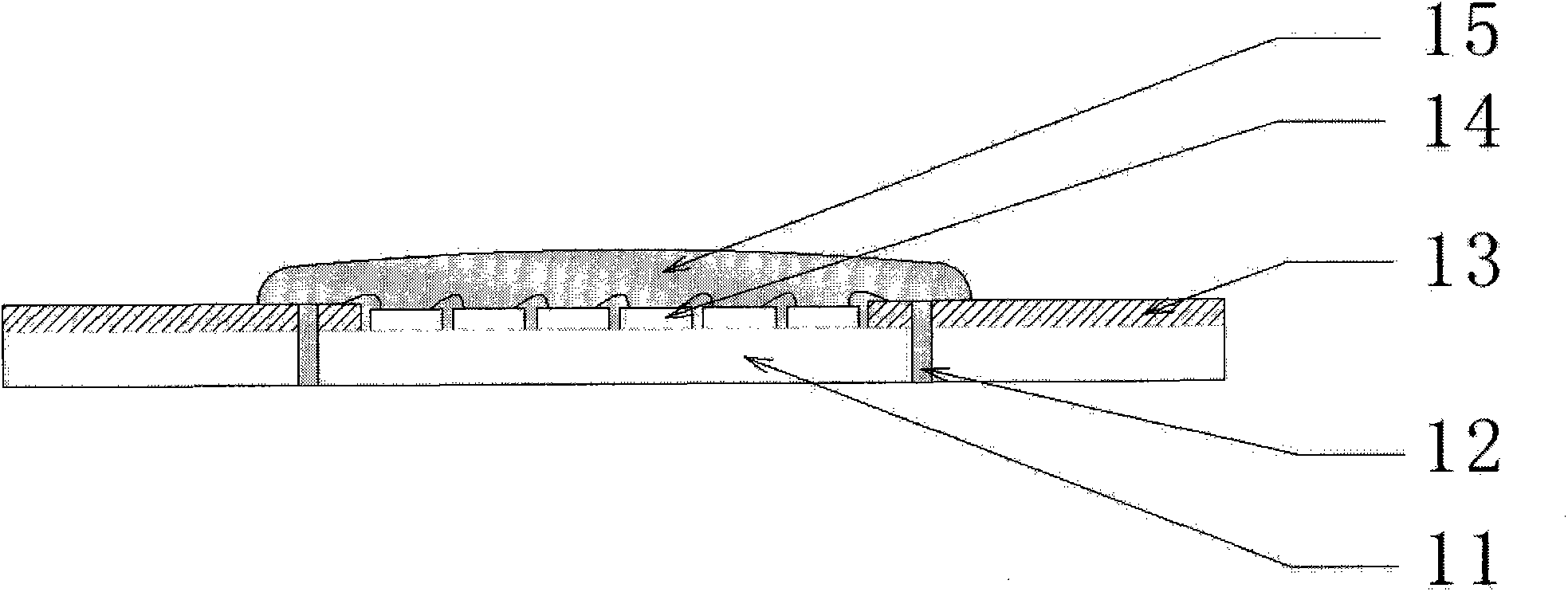

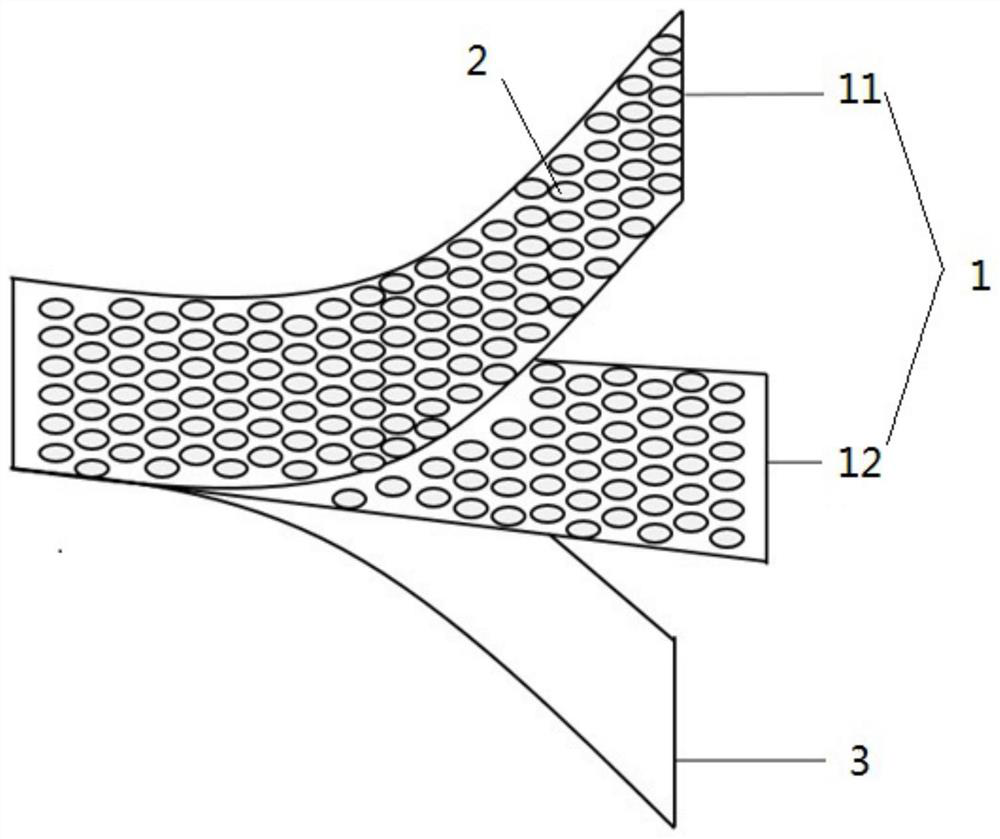

Multilayer runner spreader plate with insert, hot runner system and insert manufacture method

The invention relates to the technical field of hot runner system, and discloses a multilayer runner spreader plate with insert, a hot runner system of the spreader plate and an insert manufacture method. The spreader plate comprises a main spreader plate and at least a layer of insert set. The spreader plate and inserts of the insert set are sequentially overlapped to form a spreader plate with a multilayer structure. The main spreader plate is equipped with a main runner, and the insert set is equipped with sub-runners capable of communicating with the main runner. The spreader plate of the invention is disassembled into the main spreader plate and multilayer insert sets, and is comprised of a plurality of small units, so that a complicated runner of the spreader plate can be disassembled into a plurality of simple sub-runners to make the manufacture of the spreader plate easy and reduce manufacture costs. The runner consists of a plurality of simple sub-runners, so as to reduce a flow approach of a plastic melt in the runner, reduce injection moulding pressure, lower costs, and avoid glue leakage during spreader plate working process and material waste in spreader plate manufacture.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

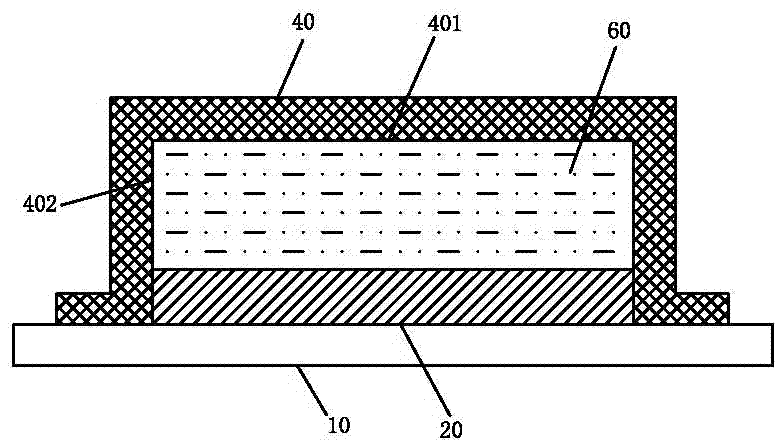

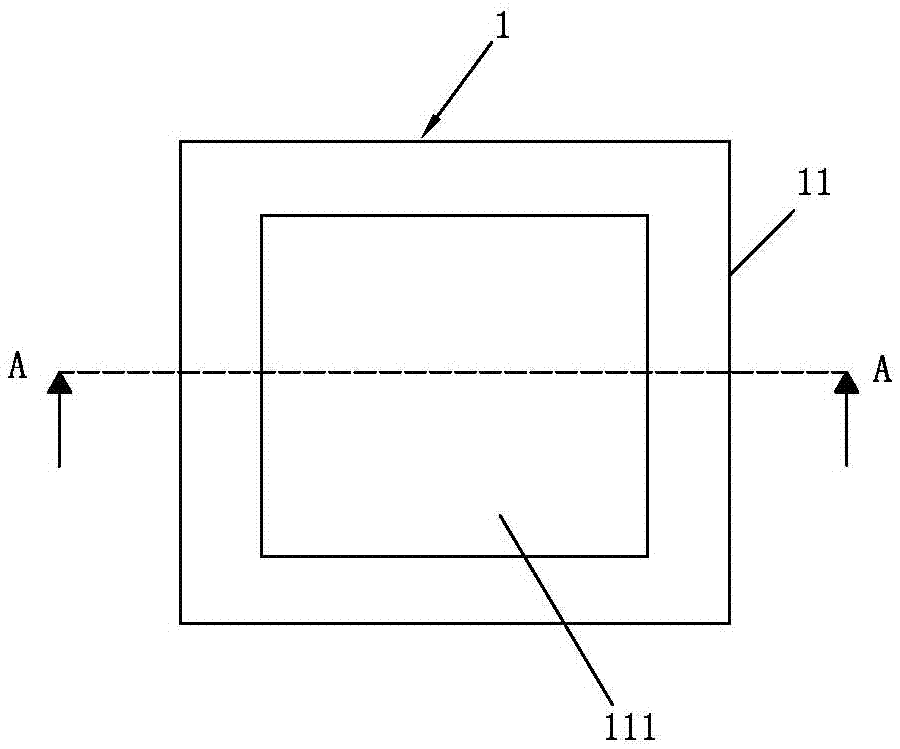

LED module COB packaging technology and structure

InactiveCN103943756AAvoid it happening againAvoid glue leakageSemiconductor devicesEngineeringElectrical and Electronics engineering

The invention discloses an LED module COB packaging technology which includes the steps: S1, conducting crystal fixing and line welding on a substrate with glue injection holes, S2, fixing the substrate to a glue injection bottom mold, S3, conducting glue injection on the glue injection holes through an accurate glue injection syringe needle, and S4 conducting mold disassembling and molding on the substrate after glue is solidified. By means of the LED module COB packaging technology, the links of dam surrounding and glue sealing of a traditional COB packaging technology are improved, the dam surrounding technology is omitted, molds are directly used for conducting glue injection molding, the efficiency of the glue sealing link is improved by three to five times relative to the efficiency in a traditional mode, and the production efficiency and the production yield are greatly improved compared with the traditional COB packaging technology. The invention further provides an LED module COB packaging structure manufactured with the technology.

Owner:SHENZHEN JINGTAI

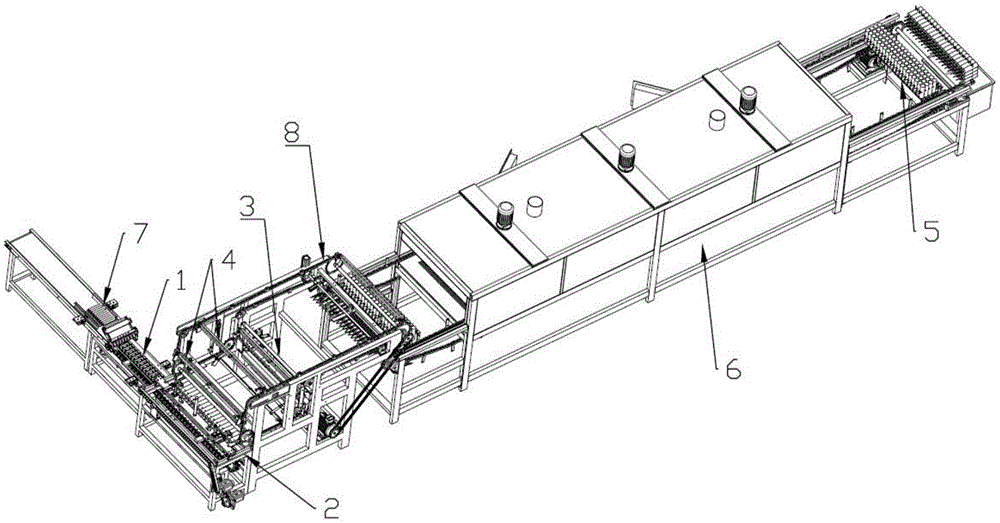

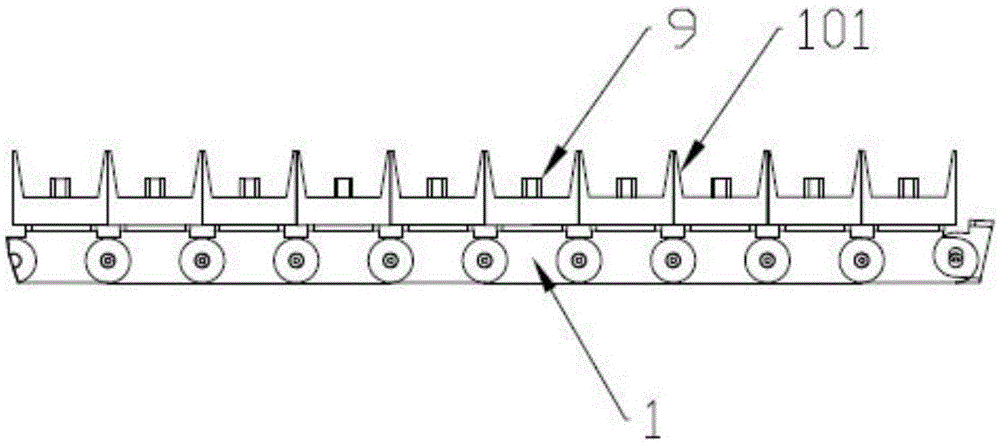

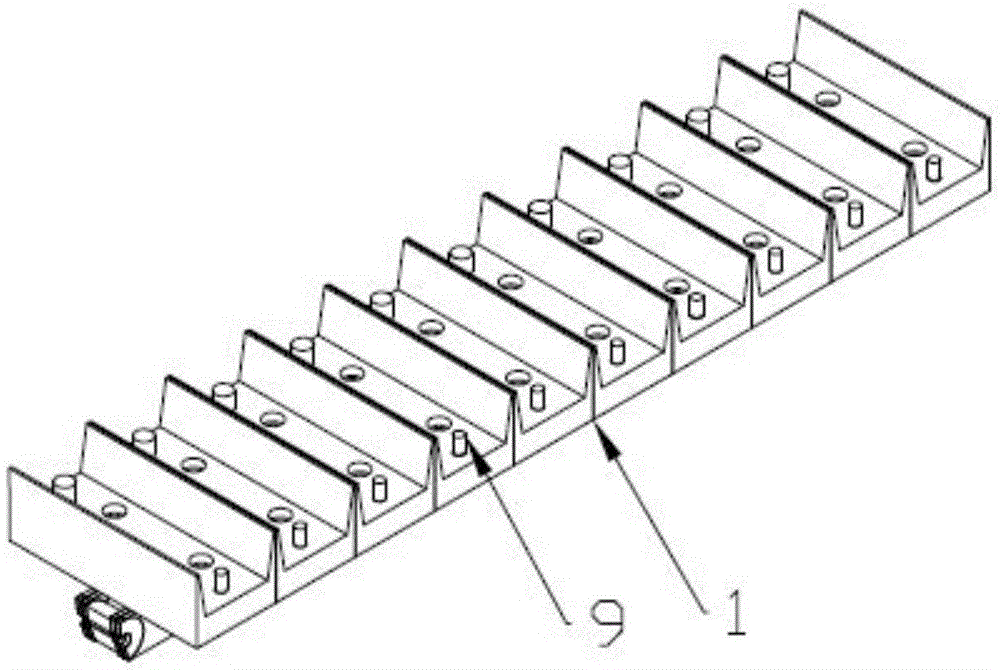

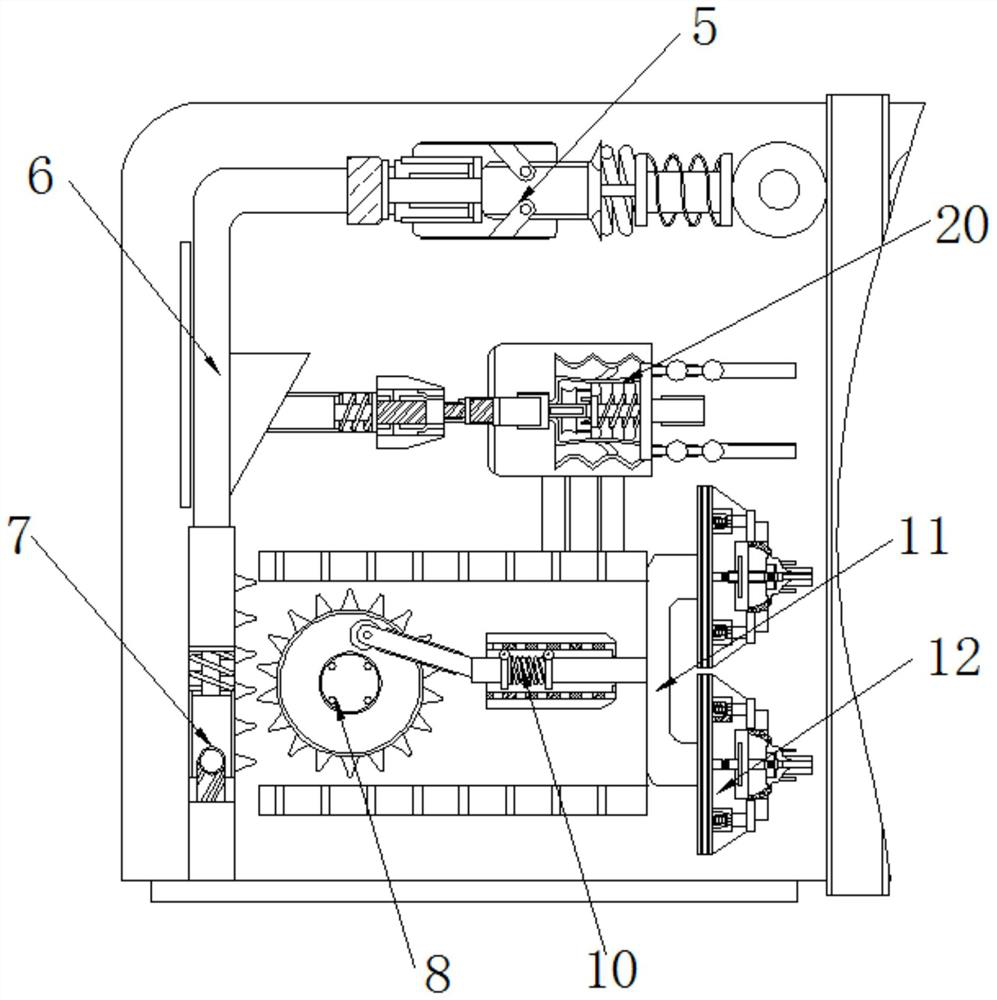

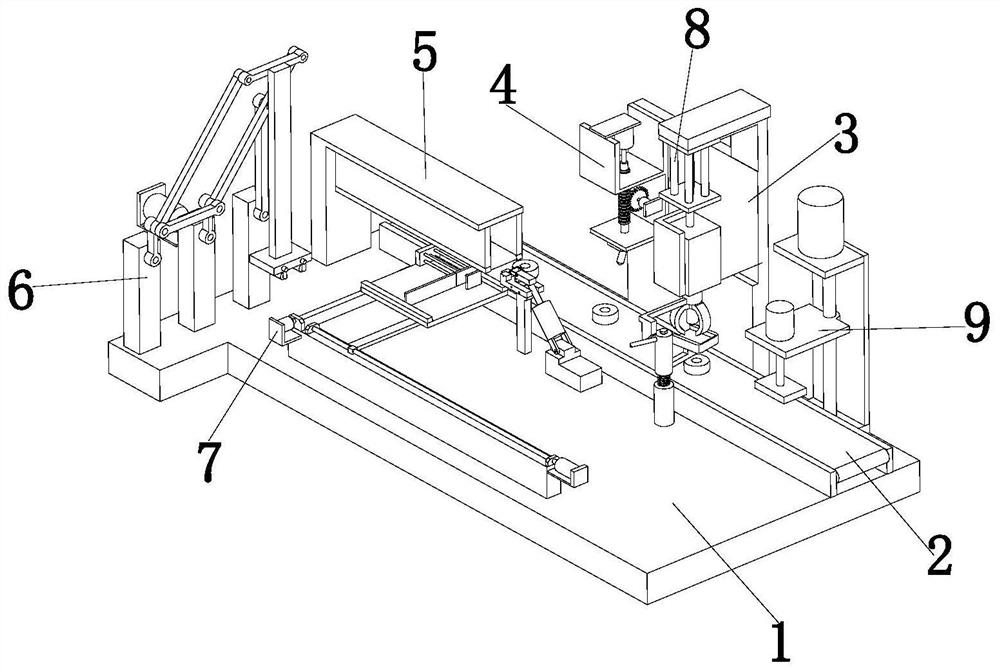

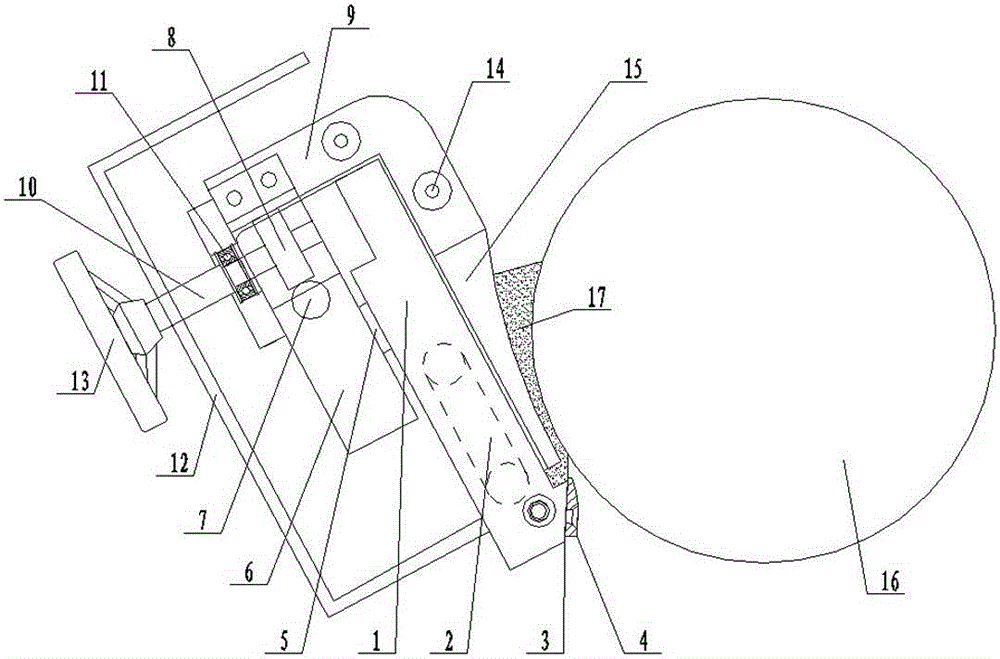

Automatic painting equipment used for Christmas tree branches

InactiveCN105521916AAvoid glue leakageHigh-efficiency automatic paintingLiquid surface applicatorsCoatingsAutomatic test equipmentEngineering

The invention relates to the field of machinery manufacturing. Automatic painting equipment used for Christmas tree branches is provided and comprises a conveying structure, a material clamping structure, a glue dispensing and positioning structure, a drying device, a material loading frame and a plurality of conveying chains, wherein one of the chains is uniformly provided with a plurality of material separating fixtures, the material separating fixture at the front end of the chain is connected with the material clamping structure, the material separating fixture at the back end of the chain is connected with the drying device, and the material separating fixture in the middle section of the chain is connected with the glue dispensing and positioning structure. According to the automatic painting equipment used for the Christmas tree branches, the Christmas tree branches are fixed to all the structures through positioning magnets and V-shaped positioning grooves and are precisely fixed to the glue dispensing and positioning fixture from the material separating fixtures; when the Christmas tree branches are arranged upwards, the working position of a glue gun on one side is straightened by a cleaning and rotating air cylinder, and painting is conducted in the up-down direction through two sets of glue guns which are distributed uniformly, so that glue is effectively prevented from being leaked on leaves; accordingly, high-efficiency, all-round and full-automatic painting is achieved. The automatic painting equipment is simple and practical in structure, and it is ensured that the automatic painting equipment is operated effectively.

Owner:江西格林自动化设备有限公司

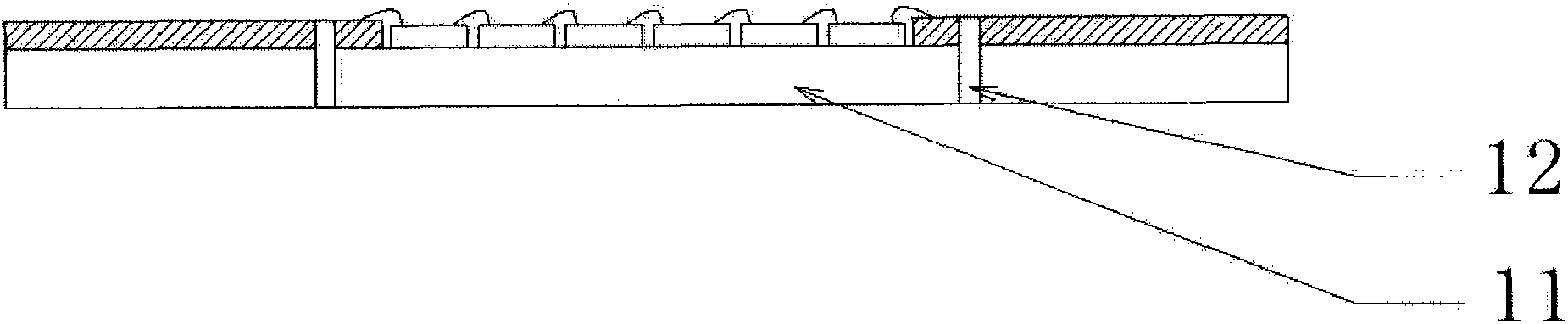

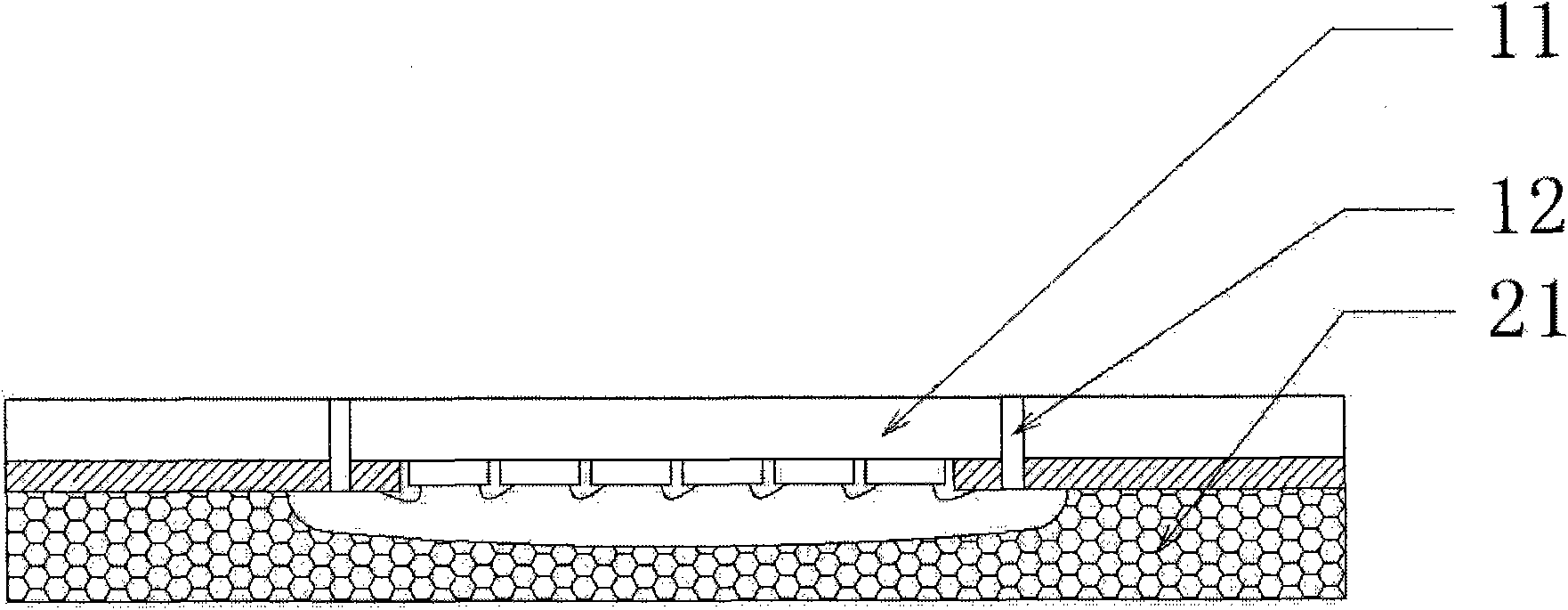

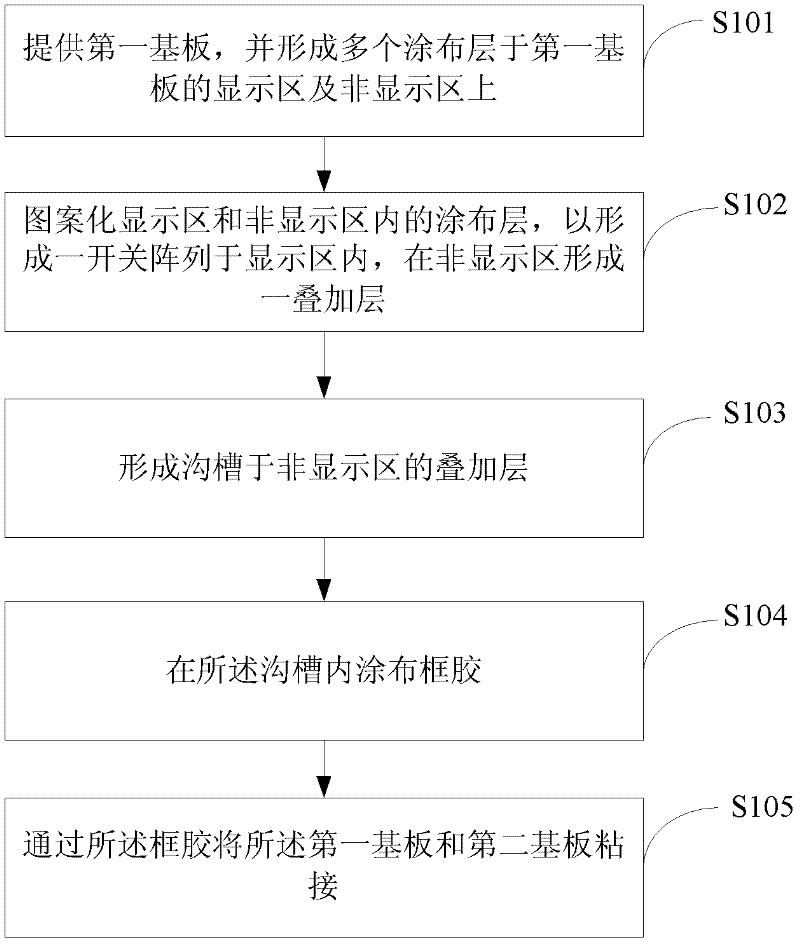

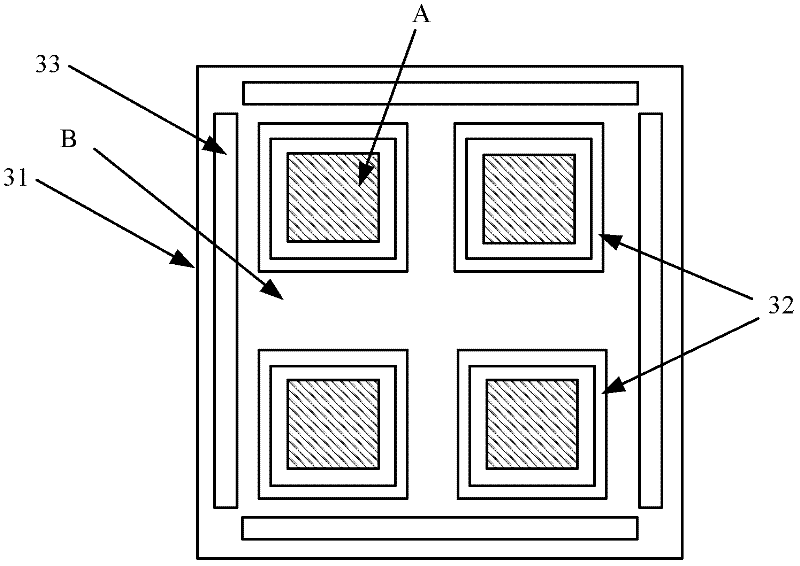

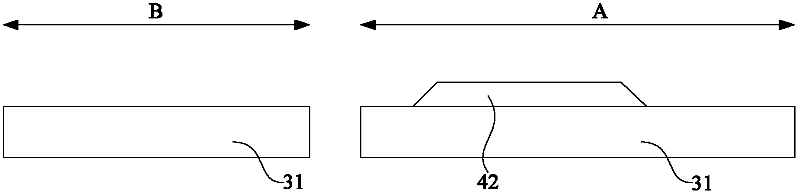

Thin-film transistor array substrate, liquid crystal display device and manufacturing method thereof

InactiveCN102411227AControl shapeHighly consistentSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The invention discloses a thin-film transistor array substrate, a liquid crystal display device and a manufacturing method thereof. The manufacturing method comprises the steps of: providing a first substrate, wherein the first substrate is provided with a display area and a non-display area, and the non-display area is located around the display area; forming a coating layer on the display area and the non-display area; respectively patterning the coating layer in the display area and the non-display area so as to form a switch array in the display area and form a superimposed layer on the non-display area, wherein the superimposed layer comprises at least one coating layer; performing exposure development to form a channel in the superimposed layer; filling frame glue in the channel; and bonding the first substrate and a second substrate by means of the frame glue. According to the invention, the shape of the frame glue can be accurately controlled, so that glue leakage can be prevented, liquid crystal can be ensured to be prevented from pollution, and box thickness is prevented from nonuniformity.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

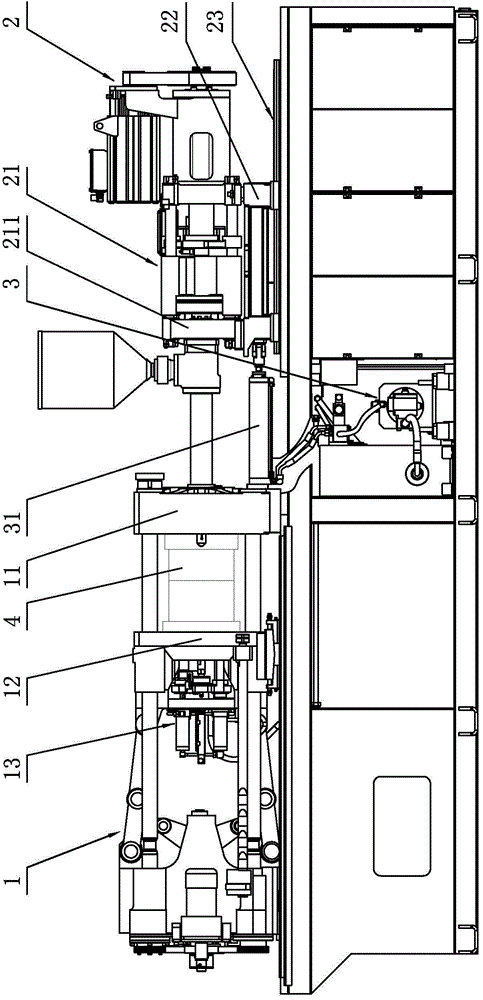

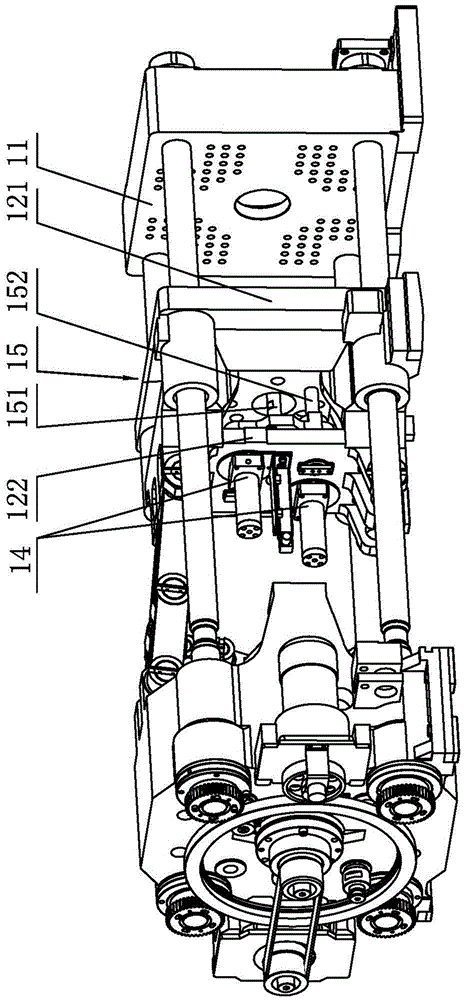

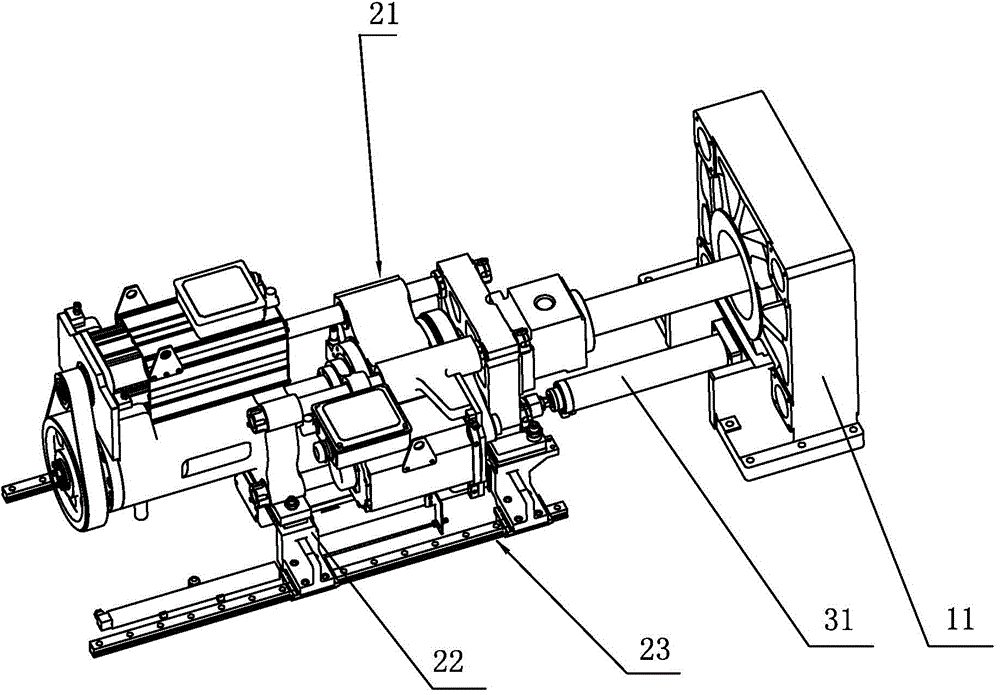

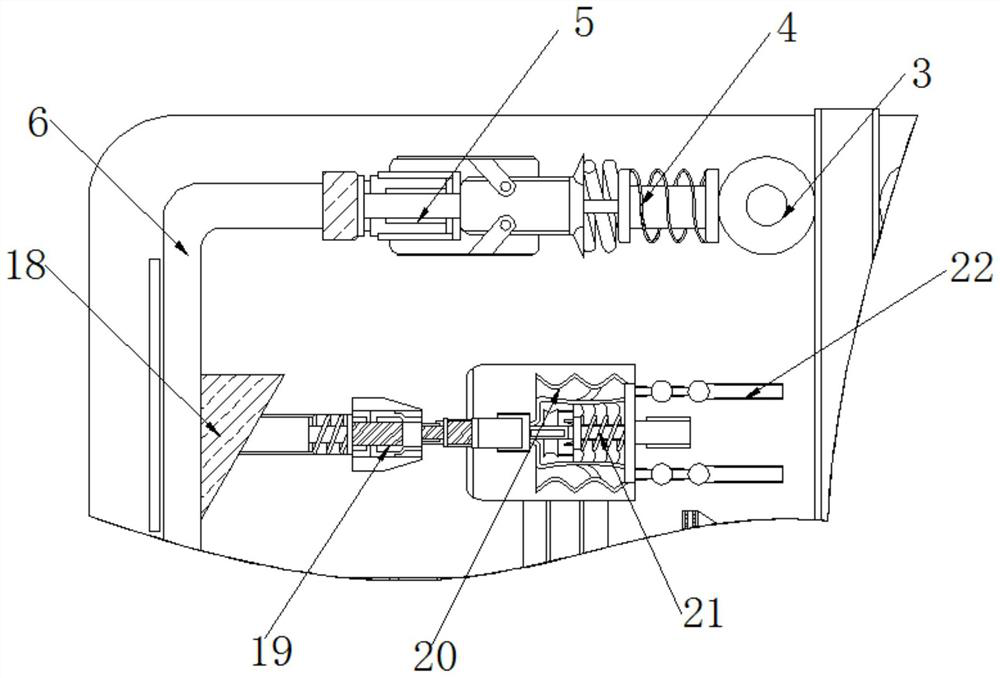

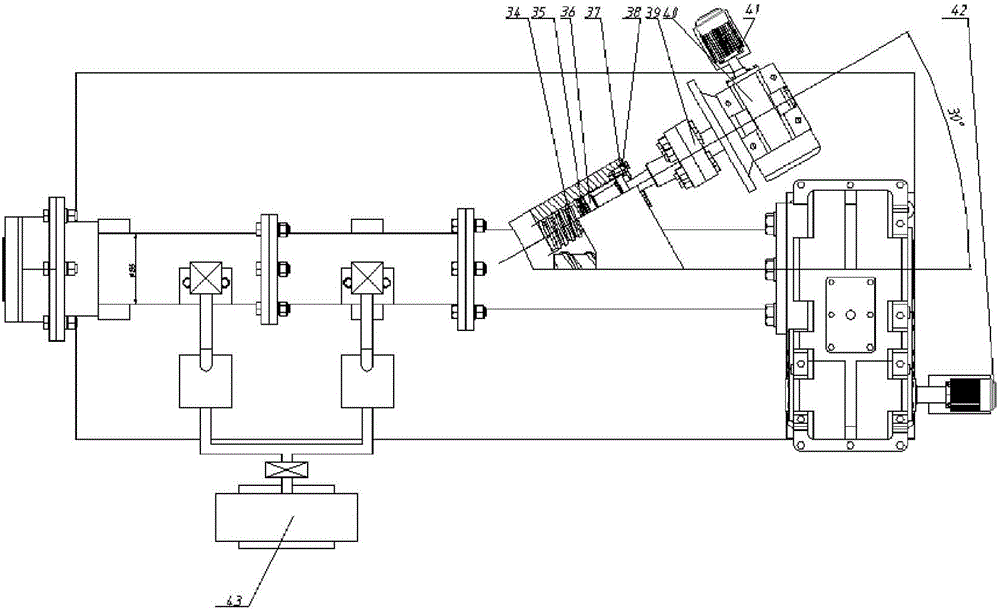

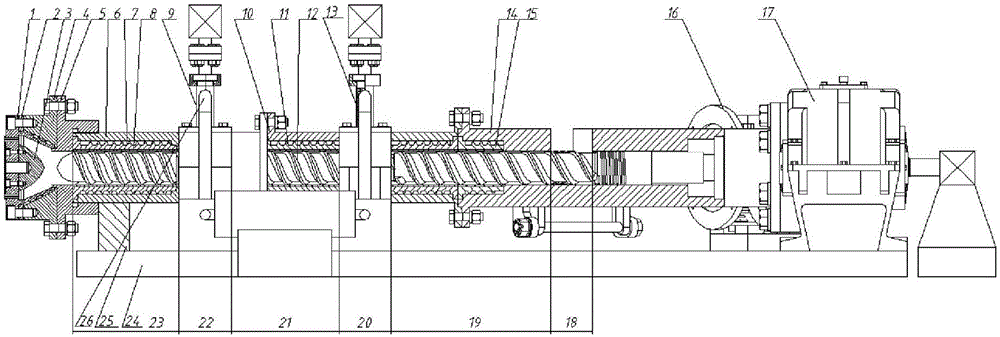

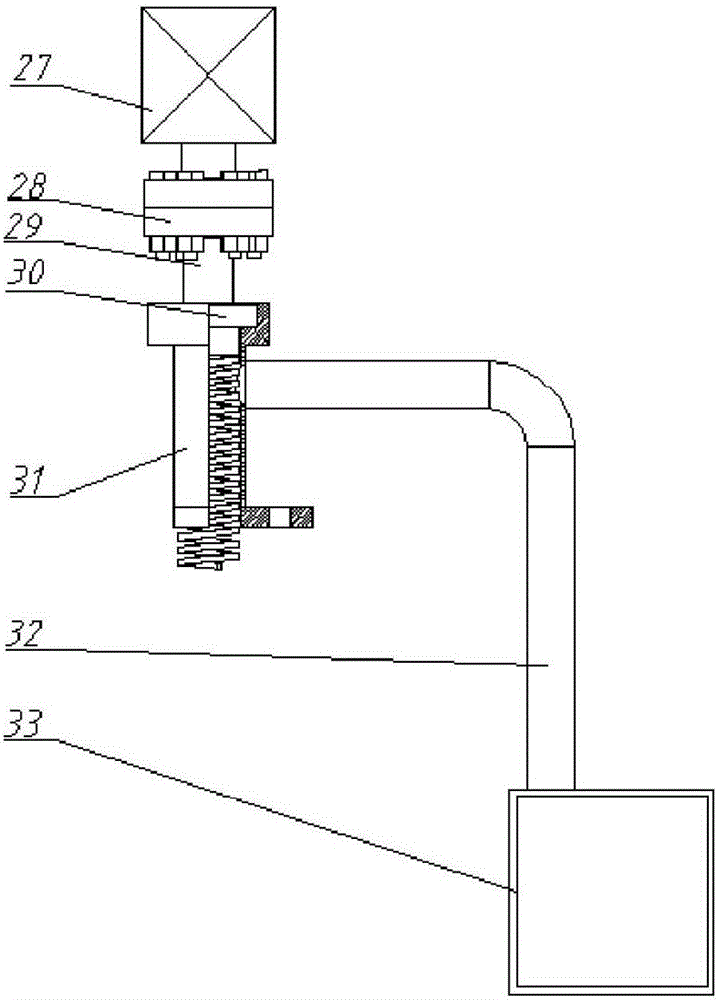

Injection moulding machine

The invention discloses an injection moulding machine which includes a die locking system and an injection moulding system, wherein the die locking system includes a fixed die plate. The injection moulding system is provided with a servo hydraulic system which is used for driving the injection moulding system to move relative to the fixed die plate. The servo hydraulic system includes a total-moving oil cylinder and a total-moving oil cylinder hydraulic control mechanism which are communicated with each other through an oil pipe. The injection moulding machine is high in universality, is high in sensitivity and control precision, can alleviate nozzle abrasion and prevent rubber leakage, is better in die compatibility and technological adaptability and is low in cost.

Owner:NINGBO ZHAFIR PLASTICS MACHINERY

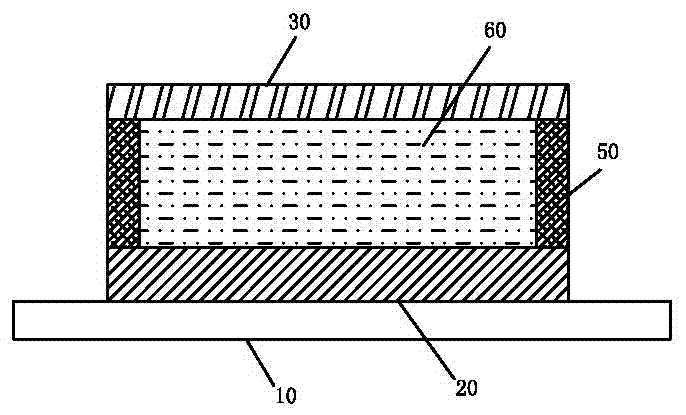

Sealing frame for sealing liquid metal, application, integrated heat dissipation structure, and electronic element

PendingCN106960830APrevent leakageIncrease stiffnessSemiconductor/solid-state device detailsSolid-state devicesLiquid stateThermal adhesive

The invention relates to the technical field of heat dissipation of electronic equipment, and specifically relates to a sealing frame for sealing liquid metal, an application, an integrated heat dissipation structure for sealing the liquid metal, and an electronic element. The integrated heat dissipation structure comprises a sealing frame and liquid metal disposed in a through hole of the sealing frame. The sealing frame comprises a frame body and thermal conduction glue layers disposed on two surfaces of the frame body. The liquid metal is integrated with the sealing frame through the die-casting technique, and is sheet-shaped liquid metal. Compared with the prior art, the structure can play a role in sealing, avoids the leakage of the liquid metal, can precisely control the size of the sealing frame and the size of the thermal conduction glue layers, improves the machining precision, greatly simplifies the preparation steps, and can achieve the batch production.

Owner:广东光钛领先新材料有限公司

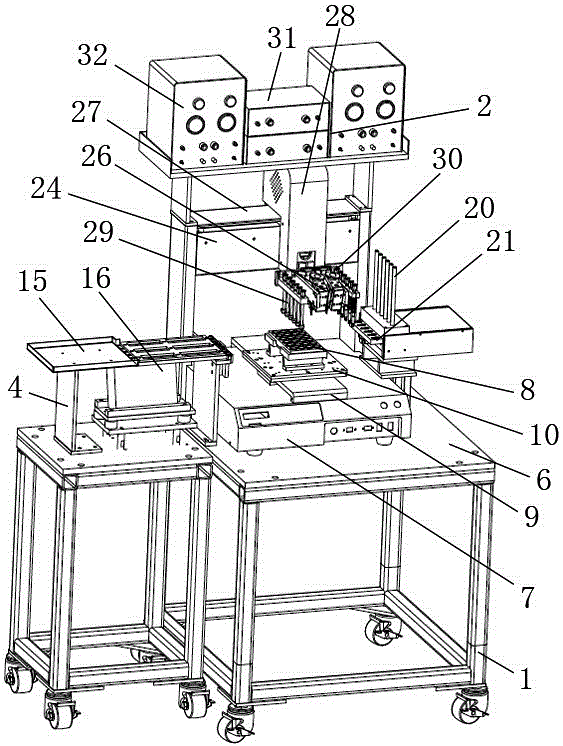

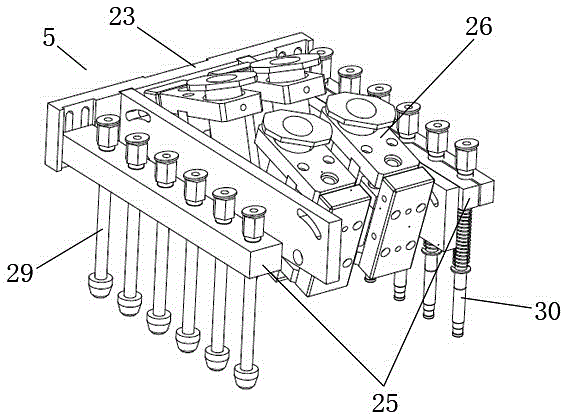

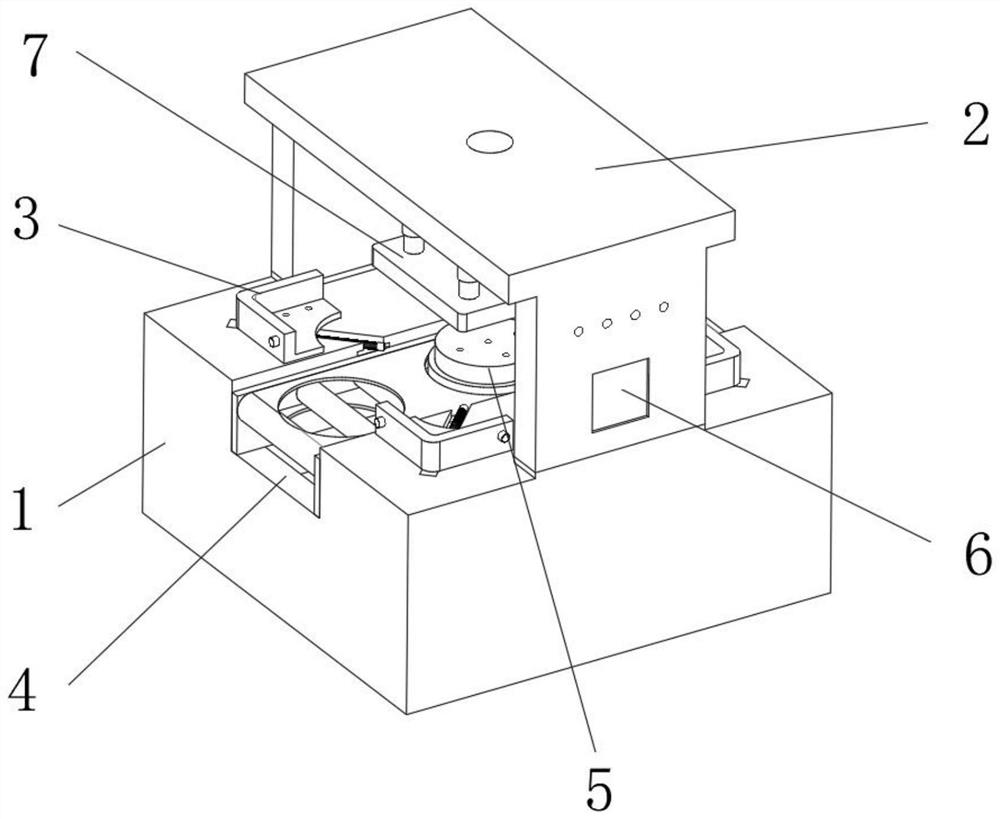

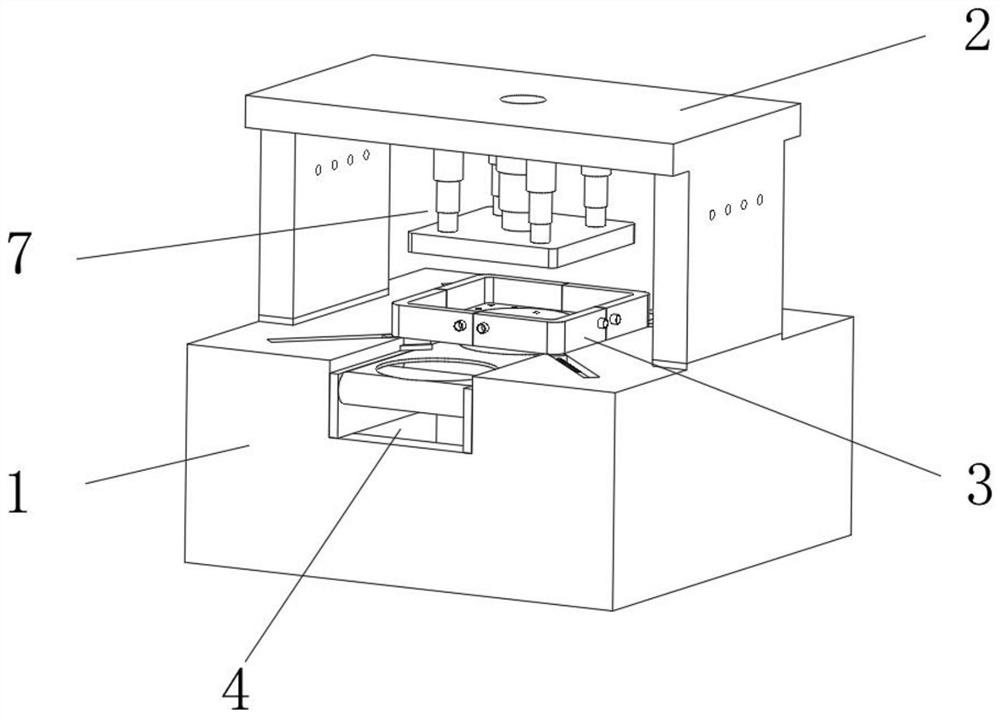

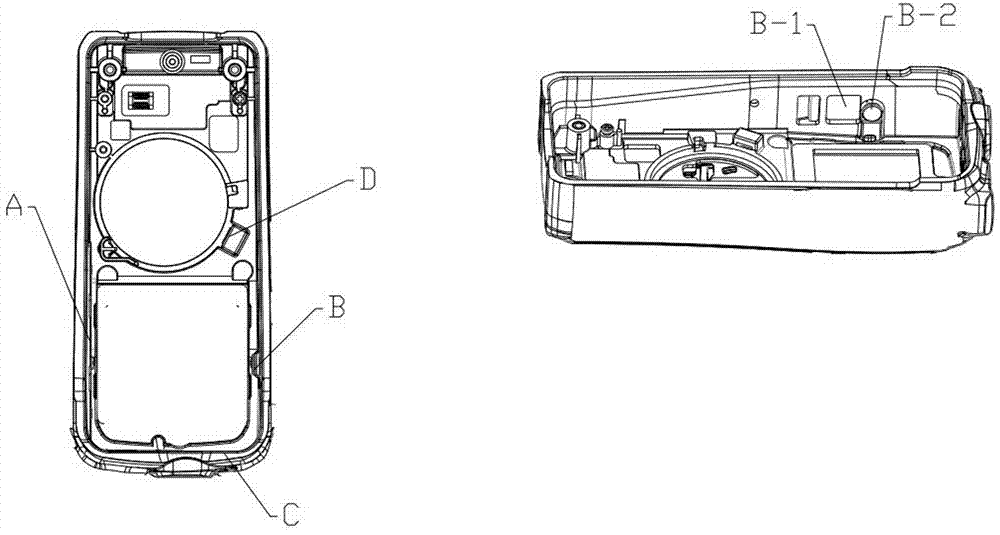

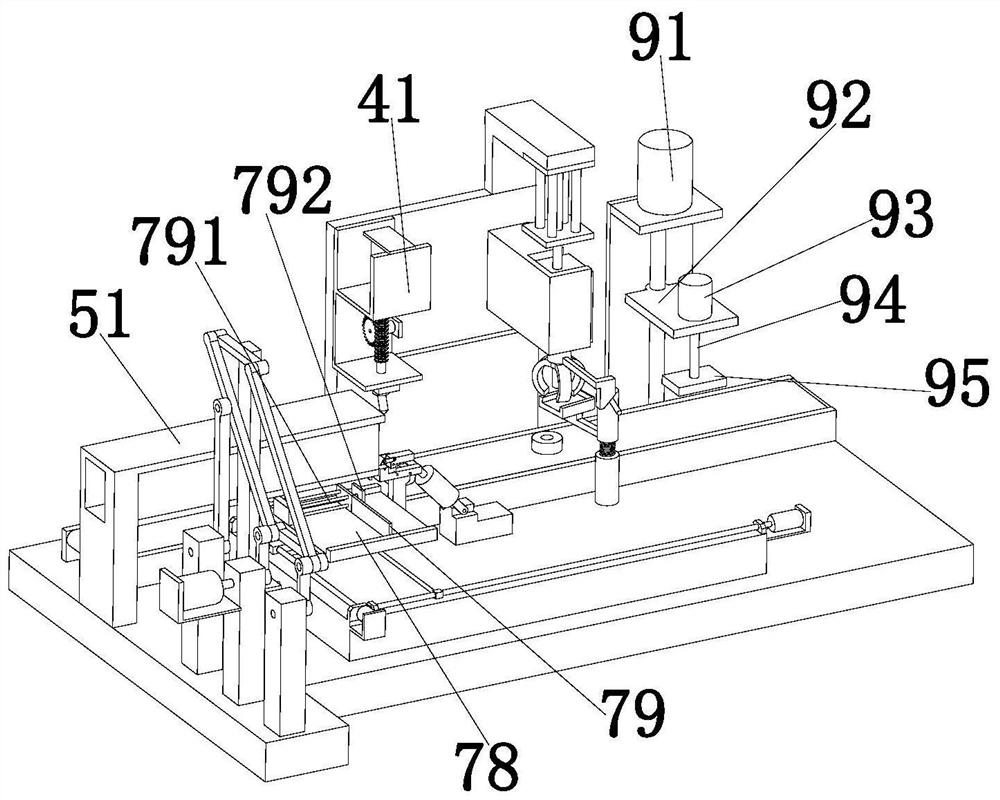

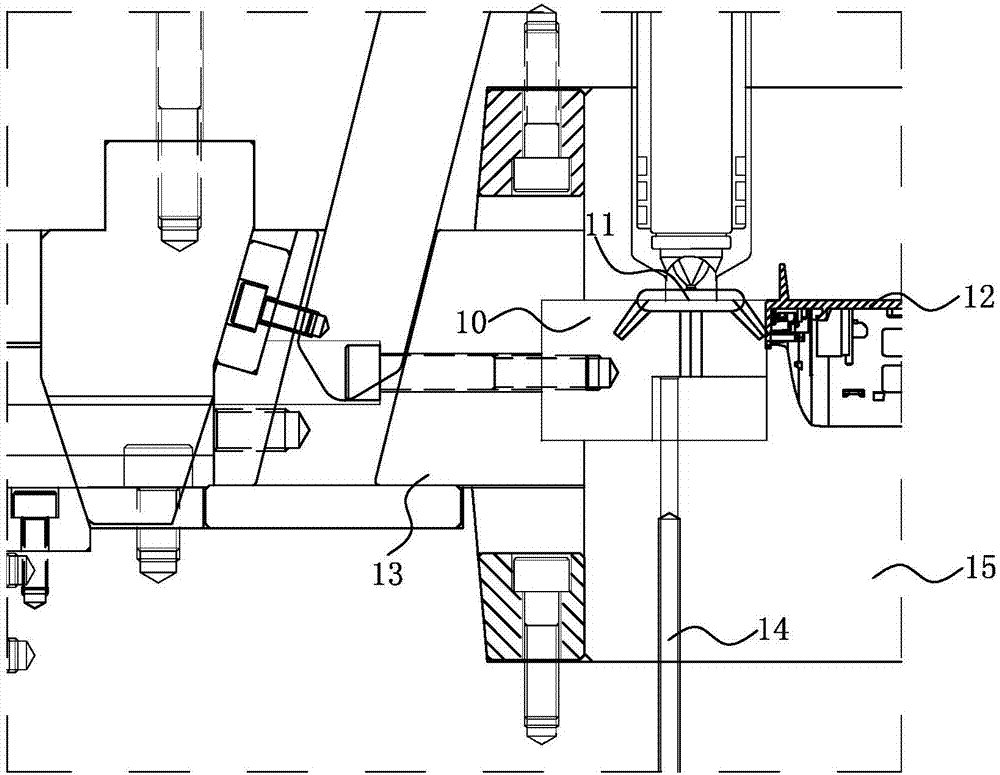

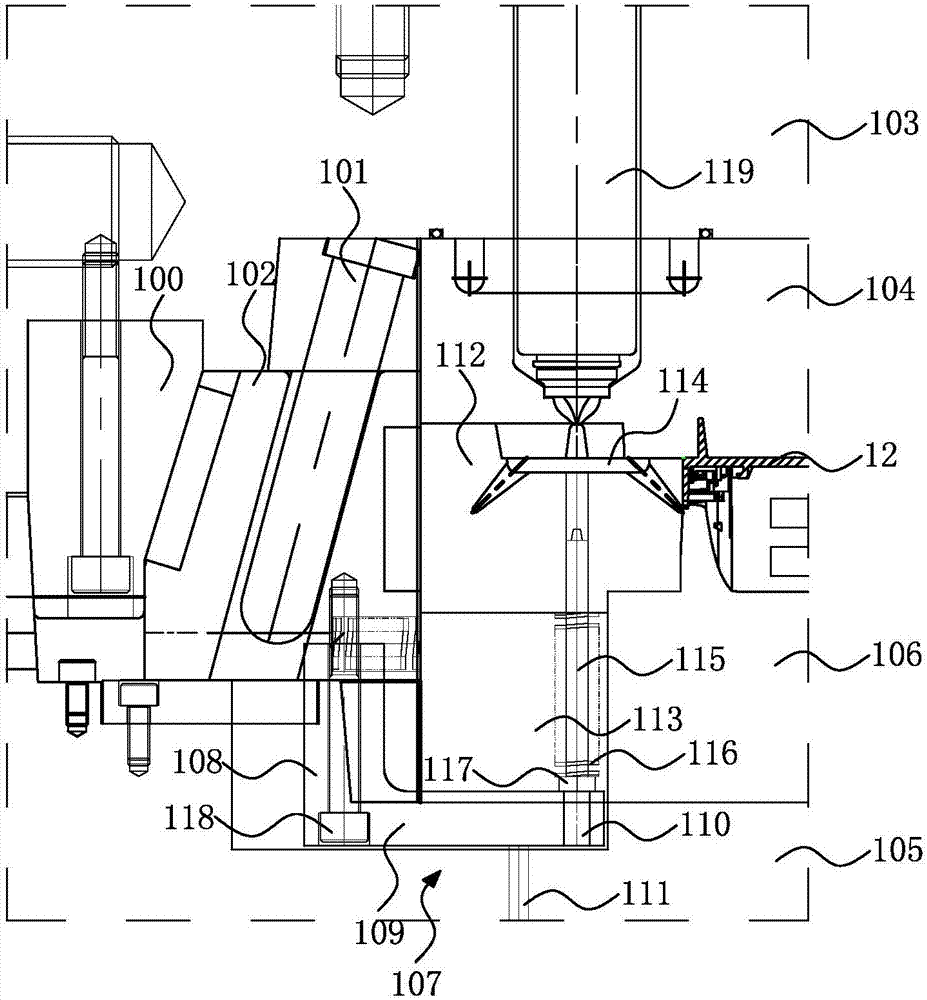

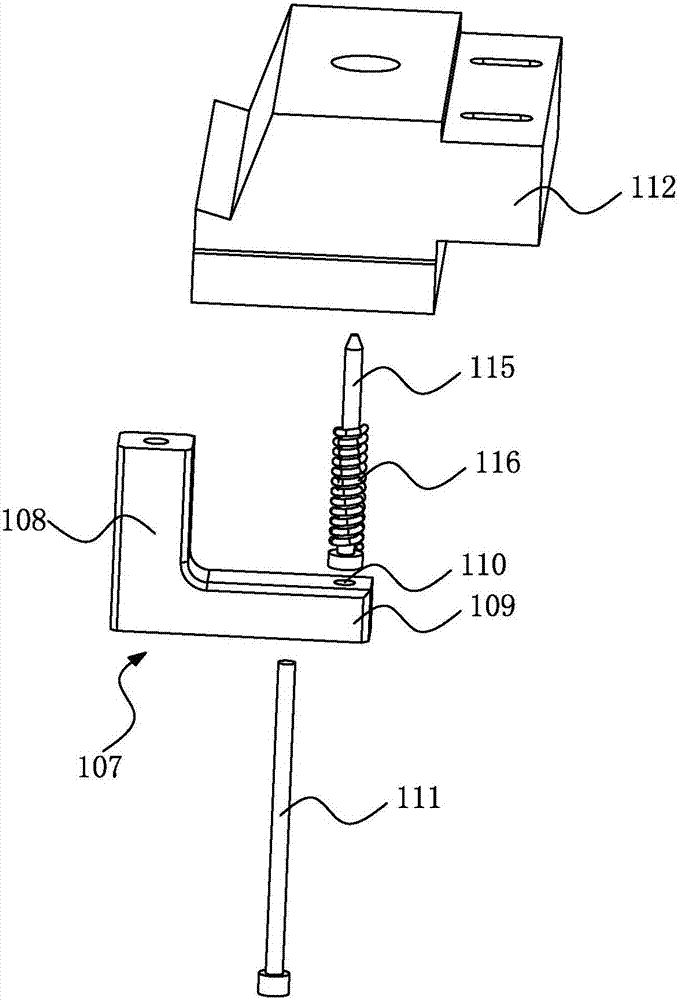

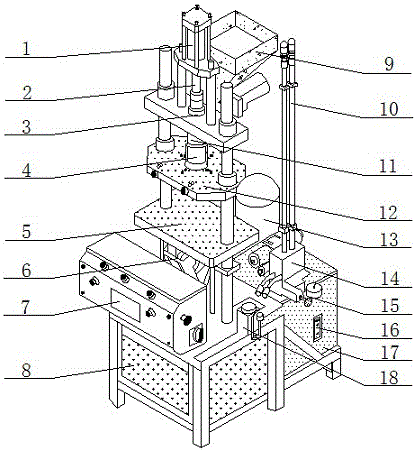

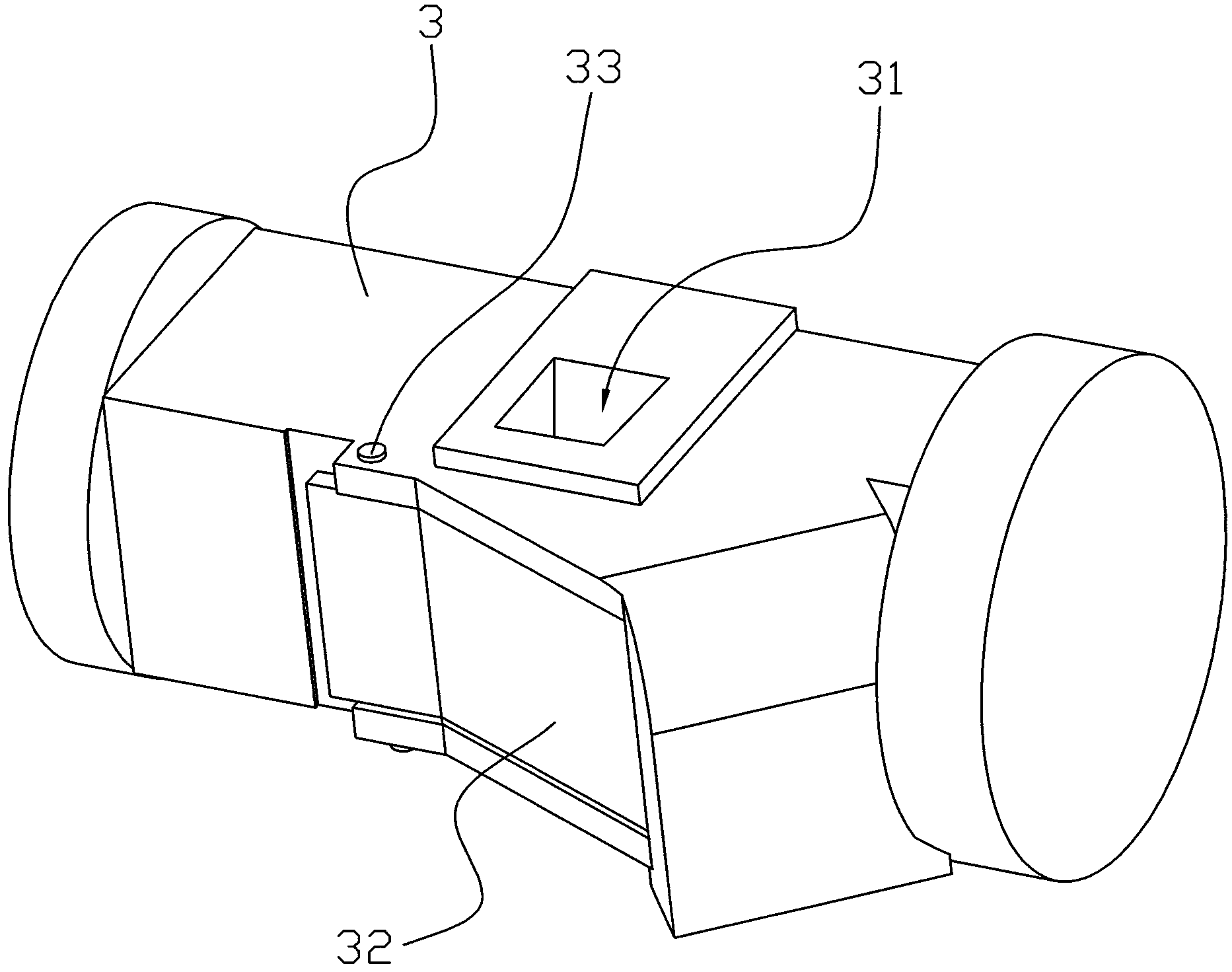

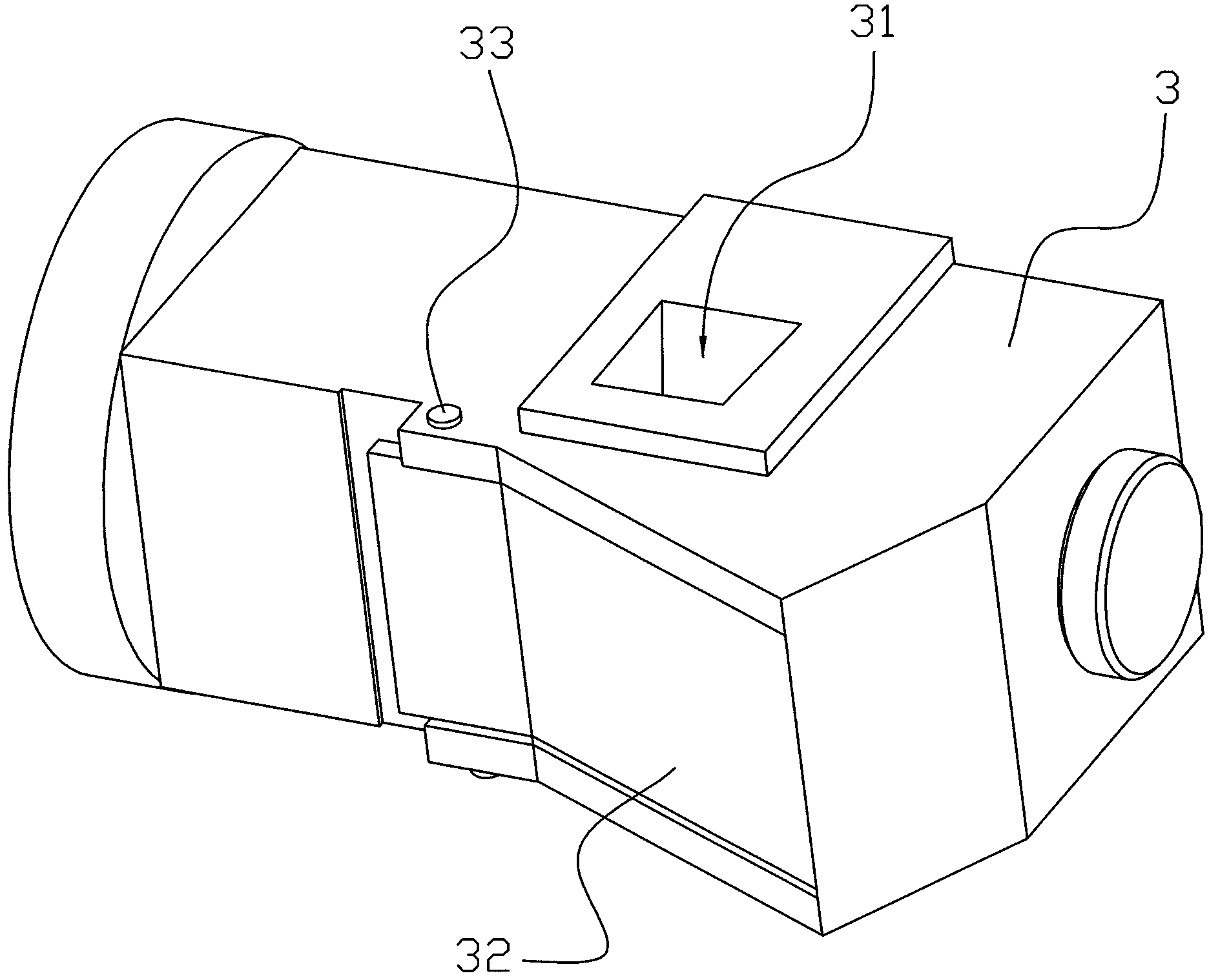

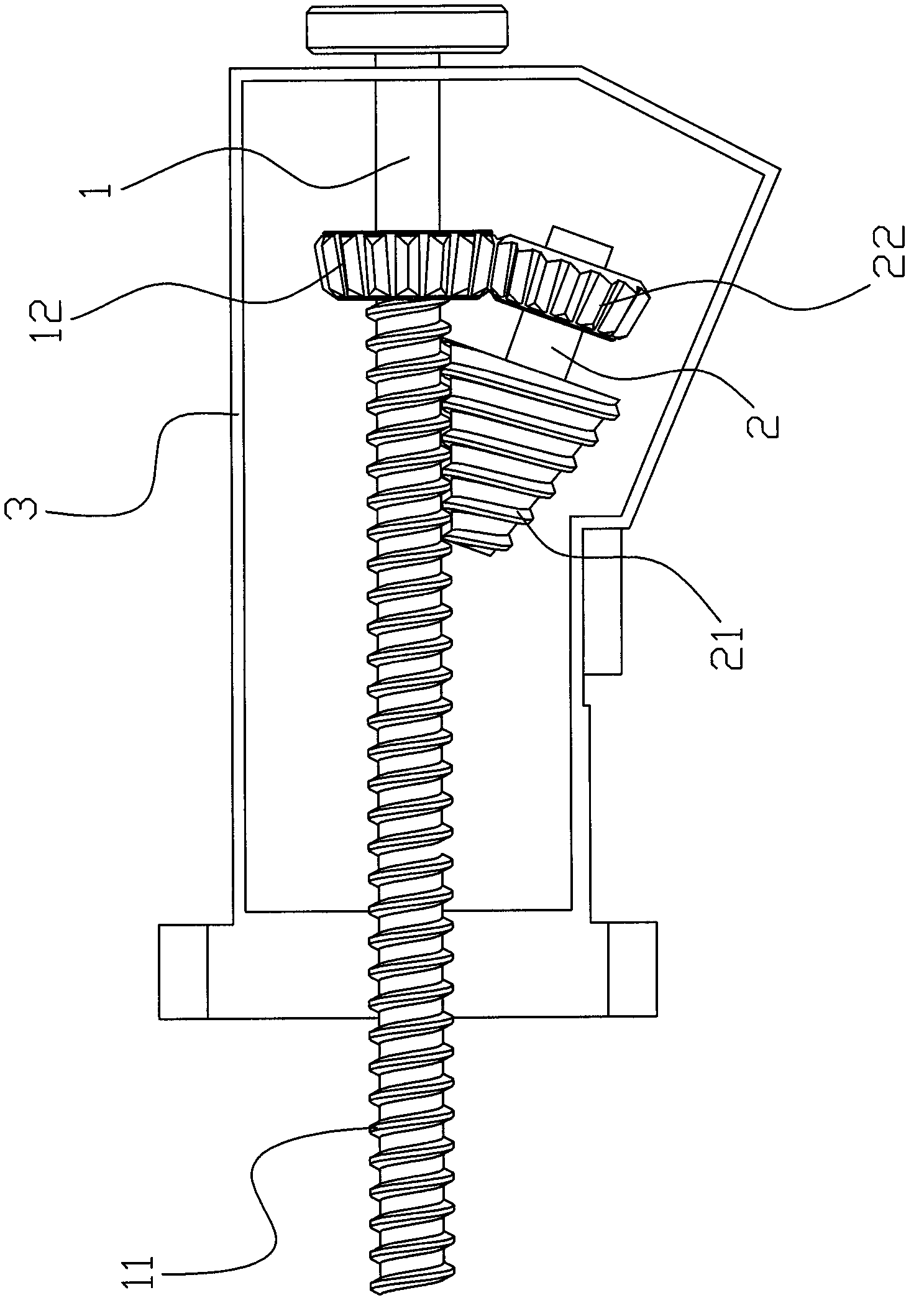

Automatic double magnetic circuit magnetic assembly device for miniature loudspeaker, and production technique adopted by device

InactiveCN105578377AReduce manufacturing costGuaranteed machining accuracyElectrical transducersProduction rateNumerical control

The invention relates to an automatic double magnetic circuit assembly device for a miniature loudspeaker with magnetic circuits, and a production technique adopted by the device. The automatic double magnetic circuit assembly device for the miniature loudspeaker is characterized by including a frame, a numerical control device, a loading device, a feeding device and a machining device, wherein a workbench is arranged on the frame; the numerical control device, the loading device, the feeding device and the machining device are all fixedly arranged on the frame; the numerical control device is fixedly arranged at the top end of the frame; the loading device is adjustably arranged on the workbench of the frame; the feeding device is arranged on the two sides of the loading device and fixed on the frame; the machining device is movably arranged on the frame. The automatic double magnetic circuit assembly device for the miniature loudspeaker provided by the invention has the beneficial effects that through the integration of feeding and machining, manual work is replaced by the automatic machine for product machining, so that the production cost is effectively reduced, the machining precision is guaranteed, the product excellence rate is greatly increased, the productivity is improved, and the production cycle is shortened.

Owner:DONGGUAN NASHENG ELECTRONICS EQUIP

Electric cable line extruder

Owner:JIANGSU JIACHENG TECH

Automatic packaging equipment for diode production

InactiveCN111987023AUniform packagingEasy to packSemiconductor/solid-state device manufacturingRubber ringRatchet

The invention belongs to the technical field of diodes, particularly relates to automatic packaging equipment for diode production. The automatic packaging equipment comprises a packaging base, wherein an accommodating groove is formed in the packaging base; rubber rings are movably connected to the positions, located on the two sides of the accommodating groove, in the packaging base; the side surfaces of the rubber rings are movably connected with elastic pushing rods; one side of each elastic pushing rod is movably connected with a push column; one side of each push column is movably connected with an L-shaped moving rod; one end of each L-shaped moving rod is fixedly connected with a ratchet column; the side surface of each ratchet column is engaged with a rotating gear; the surface ofeach rotating gear is rotationally connected with a rotating rod; one end of each rotating rod is movably connected with a pushing and pressing rod; one side of each pushing and pressing rod is fixedly connected with a U-shaped base; and a glut dispensing base is arranged on one side of each U-shaped base. When the automatic packaging equipment is used, impurities in the air can be prevented fromcorroding a chip circuit to cause reduction of electrical performance, and the service life of the diode is prolonged.

Owner:杭州穆柳商贸有限公司

Tina multi-nozzle tip hot runner system

The invention relates to a Tina multi-nozzle tip hot runner system which is characterized by comprising a flow dividing plate, a main injection nozzle, a sliding gasket, a central gasket, a center pin, an anti-rotation pin and a hot nozzle. A plurality of runners are formed inside the hot nozzle, are branched at a flange and are finally butt-jointed with nozzle tips with the same aperture; and the effect that plastic enters the main injection nozzle from a gun barrel of an injection molding machine, the flow dividing plate for flow division, the hot nozzle for flow division, the nozzle tips and a plurality of mould cavities in sequence is realized.

Owner:YUDO SUZHOU HOT RUNNER SYST

High-precision splicing type mold for injection molding machine

The invention relates to the technical field of plastic molds, and discloses a high-precision splicing type mold for an injection molding machine. The mold comprises a protective shell, a top end supporting platform, an outer side mold, a conveying mechanism and a central mold, wherein a controller is arranged on the side face of a supporting column on one side of the top end supporting platform, and a top end mold is arranged at the bottom end of the center of the top end supporting platform. A conveying belt with multiple circular holes is arranged, and therefore a central mold head can exactly pass through the circular holes in the ascending and descending process under the accurate control of the controller, and then the conveying belt cannot affect the process that the plastic mold is subjected to the mold assembling and splitting operation. Due to the fact that the controller accurately controls driving motors, a central pushing motor, hydraulic telescopic rods and conveying motors, the plastic part production process of the whole splicing type plastic mold can be accurately and efficiently operated, the whole production process can be orderly carried out, the utilization efficiency of the plastic mold can be effectively improved, the yield of plastic parts is improved, and the production efficiency is improved.

Owner:武汉联镇科技有限公司

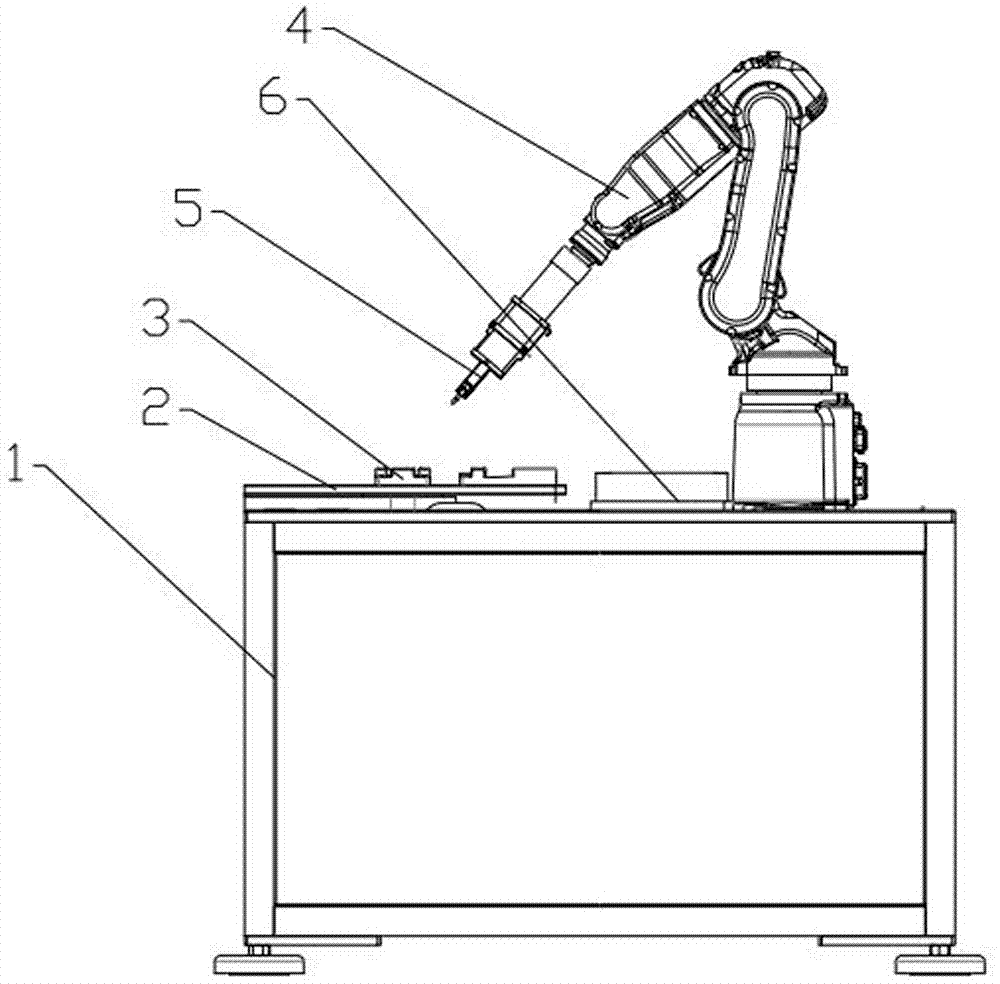

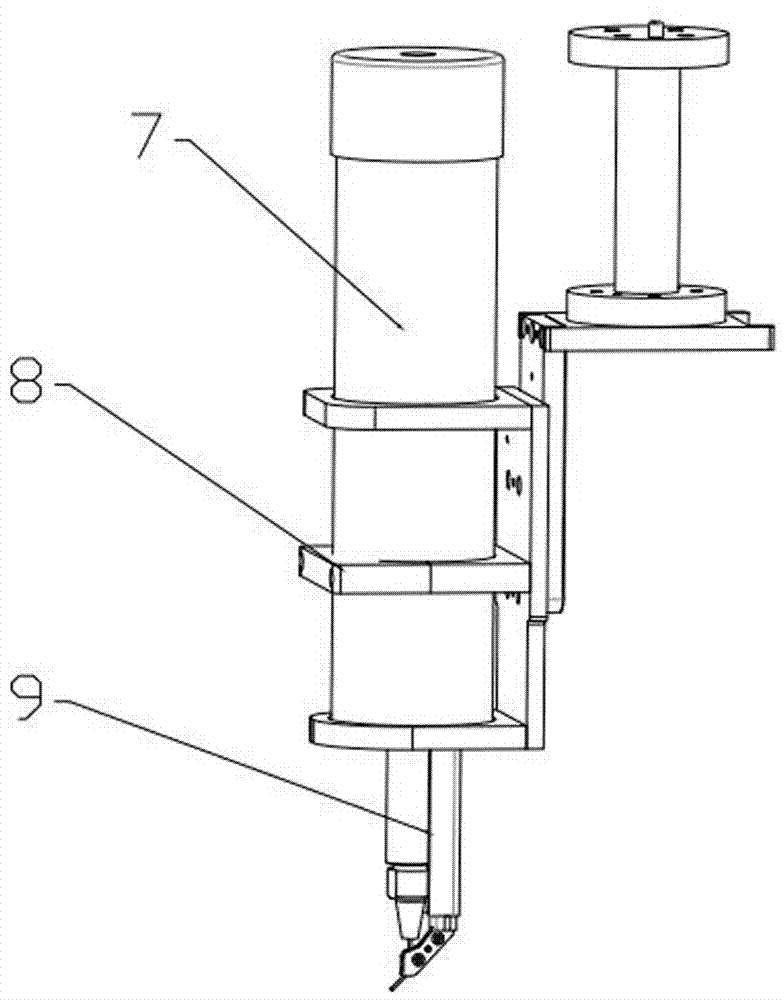

Fixed 3D glue dispensing machine

PendingCN107457156AQuick DispensingPrecise dispensingLiquid surface applicatorsCoatingsRobot handControl system

The invention discloses a fixed 3D glue dispensing machine. The fixed 3D glue dispensing machine comprises a frame, a worktable arranged on the frame, a fixing tool arranged on the worktable for fixing products to be glued, a positioning mechanism connected with the worktable for precisely driving the worktable to move in a glue dispensing position, a six-axis manipulator for driving a glue dispensing mechanism to perform three-dimensional movement, the glue dispensing mechanism fixed at an action actuation end of the six-axis manipulator for automatically dispensing glue on the products to be glued, and a control system electrically connected with the positioning system, the six-axis manipulator and the glue dispensing mechanism. The fixed 3D glue dispensing machine can realize quick glue dispensing of three-dimensional products, shortens the glue dispensing time, is accurate in glue dispensing, improves the glue dispensing efficiency, saves procedures, and improves the production efficiency.

Owner:SHENZHEN HYTERA COMM

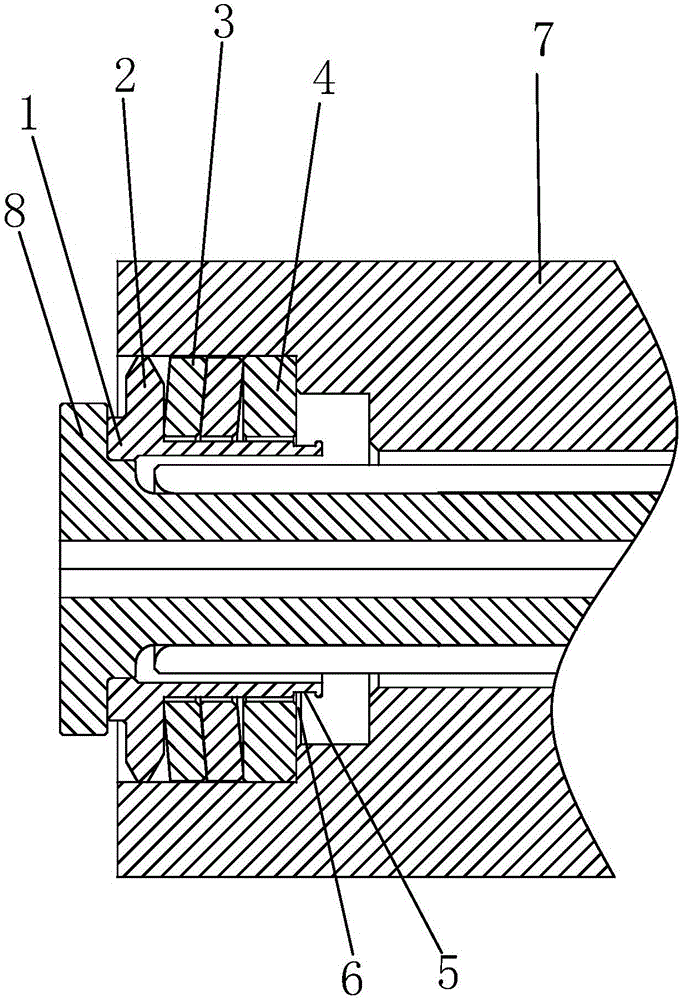

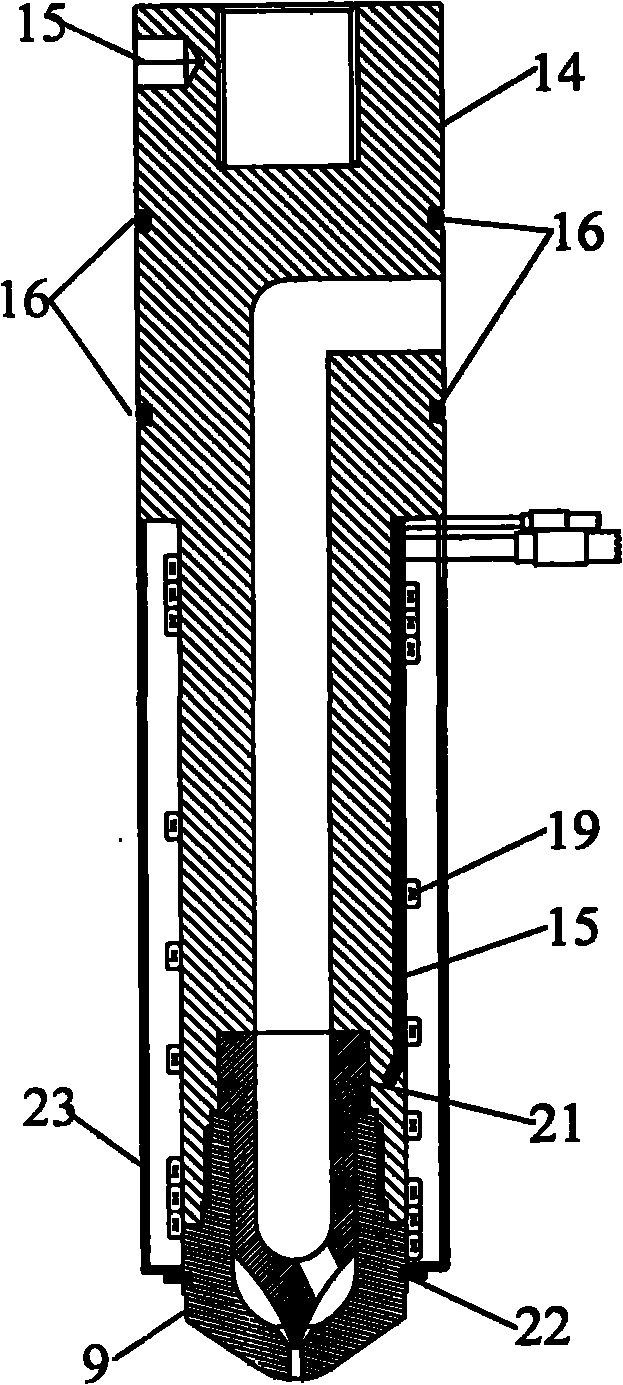

Disk spring hot nozzle bush

The invention discloses a disk spring hot nozzle bush. The disk spring hot nozzle bush comprises a hot nozzle bush body. One end of the outer wall of the hot nozzle bush body is provided with a shaft shoulder, and the other end of the outer wall of the hot nozzle bush body is provided with a clamping groove. A clamp spring is arranged in the clamping groove. A spring and a pressure-bearing gasket are arranged on the outer wall of the hot nozzle bush body and located between the shaft shoulder and the clamping spring. The hot nozzle bush body is arranged in a die mounting hole. A hot nozzle body is arranged in the hot nozzle bush body. The shaft shoulder, the spring and the pressure-bearing gasket are arranged between the hot nozzle bush body and the die mounting hole. In this way, the disk spring hot nozzle bush can play a role in protecting a die and a hot runner system against glue leakage; the bearing capacity is large; pressurization is uniform; the buffer capacity and damping capacity are high; the contact area is small; heat loss of a hot nozzle is small, and energy resources are saved; the hot runner system is good in stability.

Owner:SUZHOU HTS MOLD

Retractable hot runner system

InactiveCN101774255AReduce processing requirementsReduce residual injection pressureHot runnerEngineering

The invention discloses a retractable hot runner system. The system comprises a hot nozzle main body, a hot runner plate, a main nozzle and a driving device which is connected with the hot nozzle main body, wherein the hot nozzle main body is fixedly connected with the driving device, a hot runner hole on the hot nozzle main body is communicated with one end of a hole on the hot runner plate and the other end of the hole is communicated with a through hole on the main nozzle; the hot nozzle main body is provided with a first heating ring, a hot nozzle point and a hot nozzle gate bush and the hot nozzle gate bush is matched and fixed with the hot nozzle point and the hot nozzle main body; the hot runner plate is provided with a heating pipe and a support ring is arranged between the hot runner plate and a padding plate; and a second heating ring is wound outside the main nozzle. Compared with the prior art, the retractable hot runner system has the advantages that: the gate bush is only required to be matched with a die in position, so the die is simpler and the assembly and use of the whole hot runner system are not affected even if the processing precision on a die cavity is a little inaccurate; and meanwhile, the periphery of the gate bush contacts the die cavity exclusively, so thermal loss can be reduced.

Owner:深圳市米高科技有限公司

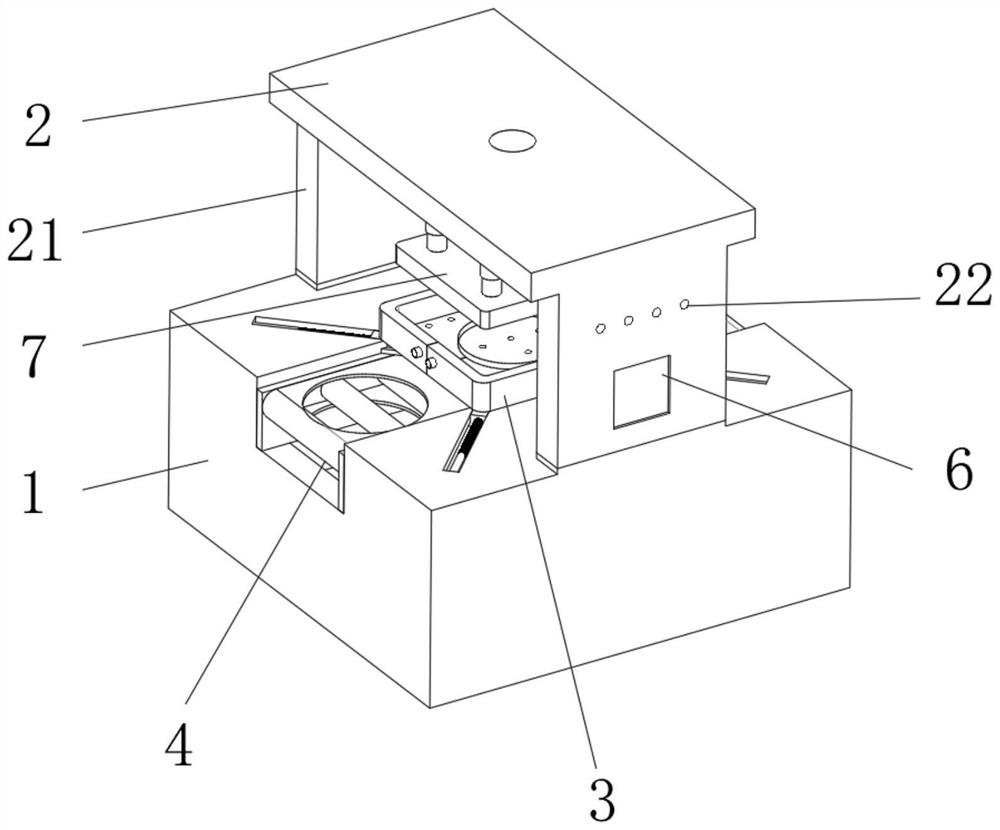

Full-automatic magnetic material assembly equipment

ActiveCN112275561ALabor savingImprove work efficiencyLiquid surface applicatorsMaterial gluingWorkbenchFully automated

The invention relates to the technical field of magnetic material assembly, in particular to full-automatic magnetic material assembly equipment which comprises a workbench, a conveying belt, a bearing plate, a ceramic tube gluing device, a feeding device, a magnetic column gluing device, a moving device, an assembly device and a pressing and sealing device. The workbench is placed on the ground,and the conveying belt is installed at the top of the workbench. The bearing plate is installed at the top of the workbench, the ceramic tube gluing device is installed on the side wall of the bearingplate, the feeding device is installed at the top of the workbench, the moving device is installed at the top of the workbench, the magnetic column gluing device is installed at the top of the workbench, and the assembly device is installed at the top of the workbench and located beside the conveying belt. The pressing and sealing device is installed at the top of the workbench and is located beside the conveying belt. According to the full-automatic magnetic material assembly equipment, inner wall gluing of a thin-wall ceramic tube and outer surface gluing of a magnetic column are conductedfor concentric assembly, so that the automatic assembly efficiency is fully automatically improved, and the phenomena of glue leakage and air holes after assembly are prevented through the pressing and sealing device.

Owner:浙江云度新材料科技有限公司

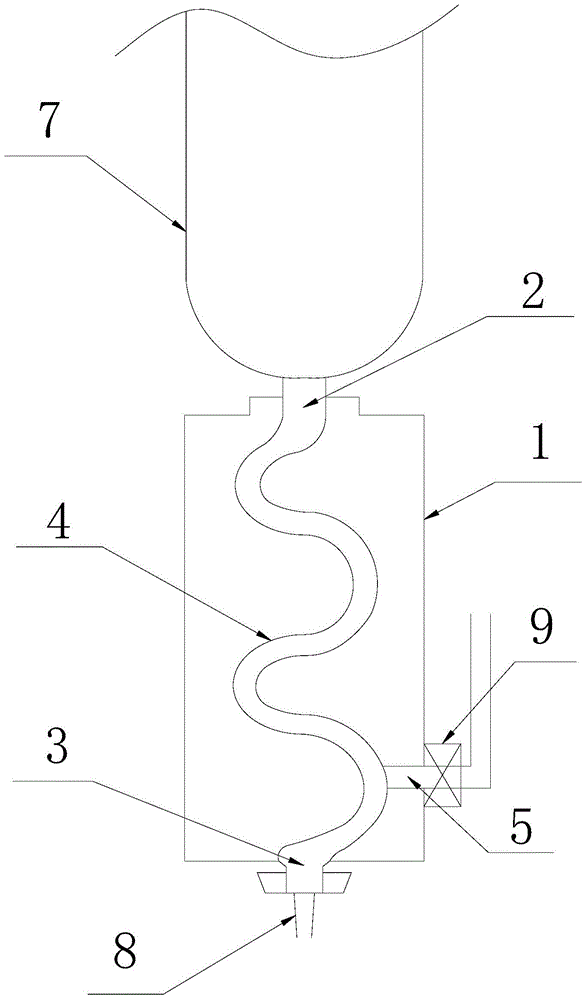

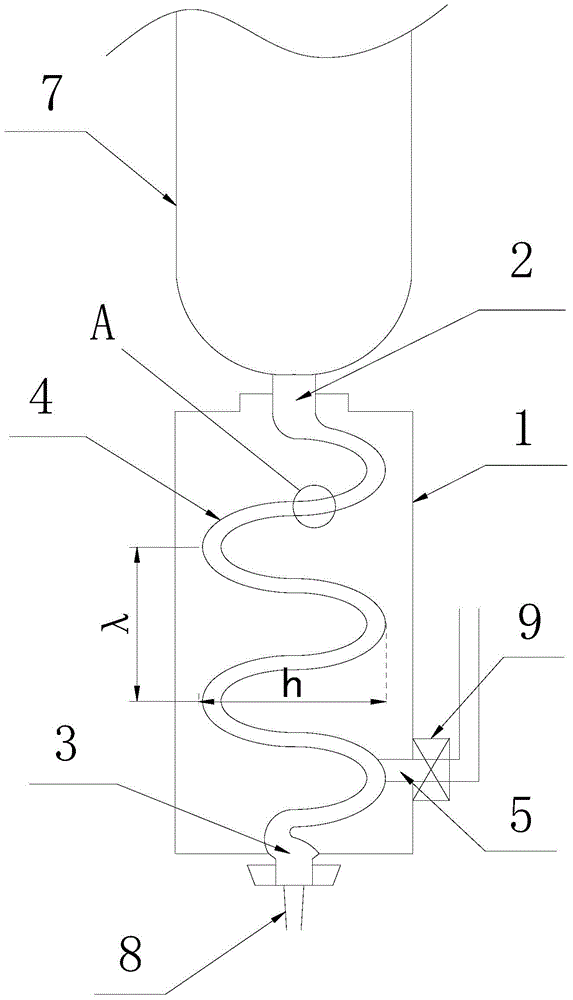

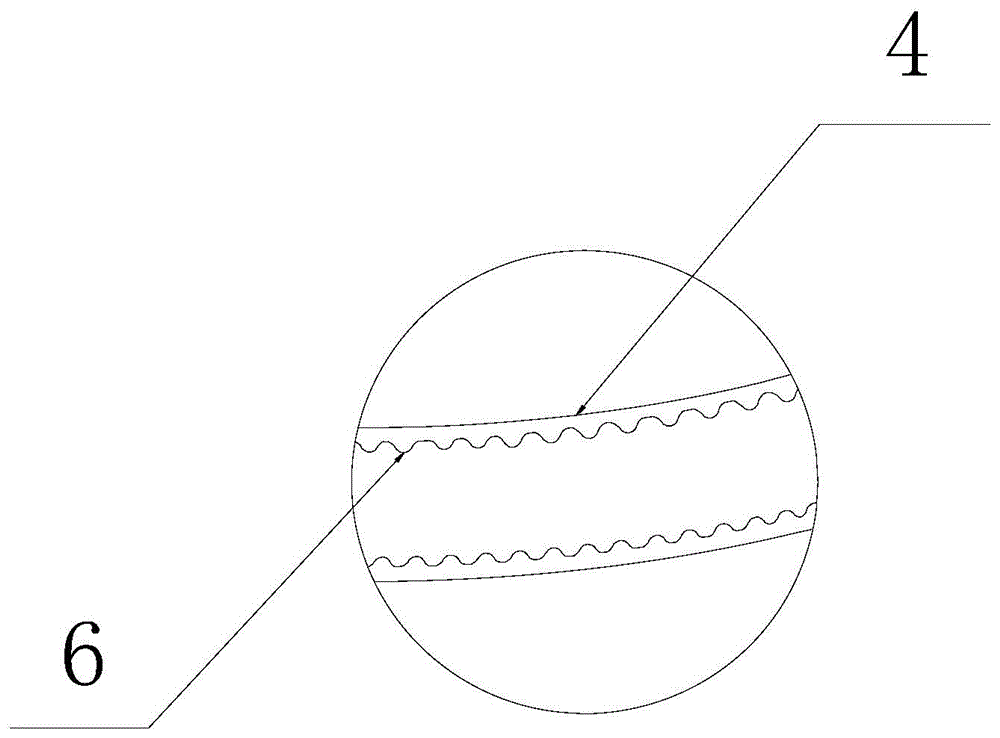

AB dispenser adhesive outlet mixing valve

The invention discloses an AB dispenser adhesive outlet mixing valve which comprises a valve body and a valve channel, wherein the valve body is provided with an upper valve port and a lower valve port, and the valve channel is formed in the valve body and connected with the upper valve port and the lower valve port. The valve body is further provided with an air inlet connecting the valve channel and an external air pump. The AB dispenser adhesive outlet mixing valve is characterized in that the valve channel is provided with one or more bent parts. Compared with a conventional adhesive outlet valve with a straight valve channel, due to the fact that the bent parts are arranged in the valve channel, certain bearing faces are provided for adhesives to resist gravity, and therefore the adhesive leakage phenomenon under the non-pressurized condition can be effectively prevented, and the adhesives and labor cleaning cost are saved; the bent valve channel and strong pressure interact with each other, the adhesives can be well stirred, the mixing effect of the adhesives in the valve channel is greatly improved, and the quality of dispensed products is further improved.

Owner:苏州光宝科技股份有限公司

Knife mechanism of hot melt adhesive bonding machine

InactiveCN104399649AEasy to useUniform melt temperatureLiquid surface applicatorsCoatingsHeat conductingEngineering

The invention discloses a convenient-to-use knife mechanism of a hot melt adhesive bonding machine. The knife mechanism comprises a steel plate knife body, wherein a heat conducting oil heating cavity is defined in the steel plate knife body, a knife blade is fixedly arranged at the lower end of the steel plate knife body through a knife pressing plate, the upper end of the steel plate knife body is connected with a gear and rack plate through a dowel, a rack and a gear matched with the rack are arranged in the gear and rack plate, a sliding steel frame is arranged at the upper ends of both the steel plate knife body and the gear and rack plate, a connecting rod is arranged in the sliding steel frame through a bearing pedestal, one end of the connecting rod extends into the gear and rack plate and is connected with the gear, the other end of the connecting rod penetrates through a protective cover fixedly arranged on the steel plate knife body and is connected with an adhesive blocking plate moving hand wheel, and an adhesive blocking plate is arranged on the sliding steel frame on one side of the steel plate knife body through a fixing screw.

Owner:JIANGSU HONGYE MACHINERY

Telescopic hot runner structure, injection mold and working method thereof

InactiveCN111890641AGuaranteed tightnessSolve the problem of frequent glue leakageHot runnerHeat flow

The invention relates to the technical field of molds, and particularly discloses a telescopic hot runner structure, an injection mold and a working method thereof. The telescopic hot runner structurecomprises a connecting hot nozzle and a first hot nozzle, a second hot nozzle which can move along the edge line direction of the inner wall of the first hot nozzle is arranged in the first hot nozzle, a heating piece is arranged on the second hot nozzle, one end of the second hot nozzle extends out of an opening of the first hot nozzle, the other end of the second hot nozzle is provided with a movable transition joint for telescoping to change length, the movable transition joint is sleeved with a sealing member, the temperature of a molten material is controlled through a heating element, and then the material is conveyed to the mold through the movable transition joint, the first hot nozzle and the connecting hot nozzle in sequence for injection molding, so that the moving distance requirements of different molds in opening and closing changes can be met, meanwhile, the phenomenon of glue leakage is avoided through the sealing element, and the problem that glue leakage can occur ina hot runner structure adopted by a mold in an existing injection molding process is solved.

Owner:FOSHAN KOER TECH DEV

Pure cotton spunlace composite fabric as well as preparation method and application thereof

PendingCN112779666ASuction speed hindranceSuction speed is fastAbsorbent padsNon-woven fabricsPolymer scienceCotton fibre

The invention discloses a preparation method of a pure cotton spunlace composite fabric. The method comprises the following steps of preparing a surface layer from water-repellent cotton fibers, performing spunlace compounding on the pre-wetted surface layer and a structural layer to obtain a water-repellent all-cotton composite surface layer, preparing meshes in the water-repellent all-cotton composite surface layer by adopting a punching process, compounding the structural layer and a flow guide layer, and enabling the flow guide layer to cover the meshes in the water-repellent all-cotton composite surface layer, so that the pure cotton spunlace composite fabric is obtained. The water-repellent cotton fibers are creatively adopted to manufacture the water-repellent pure cotton surface layer, and after the water-repellent pure cotton surface layer and the structural layer are subjected to spunlace compounding, the water-repellent all-cotton composite surface layer with higher strength can be obtained, and the meshes with clearer edges are formed, so that it is guaranteed that the liquid absorption speed of the surface layer is not hindered by edge fibers of the meshes; and in addition, after the water-repellent all-cotton composite surface layer and the flow guide layer are compounded, the liquid absorption speed of the surface layer can be increased through the flow guide layer, and meanwhile the situation of glue leakage of the meshes of the surface layer can be effectively prevented.

Owner:WINNER MEDICAL CO LTD +1

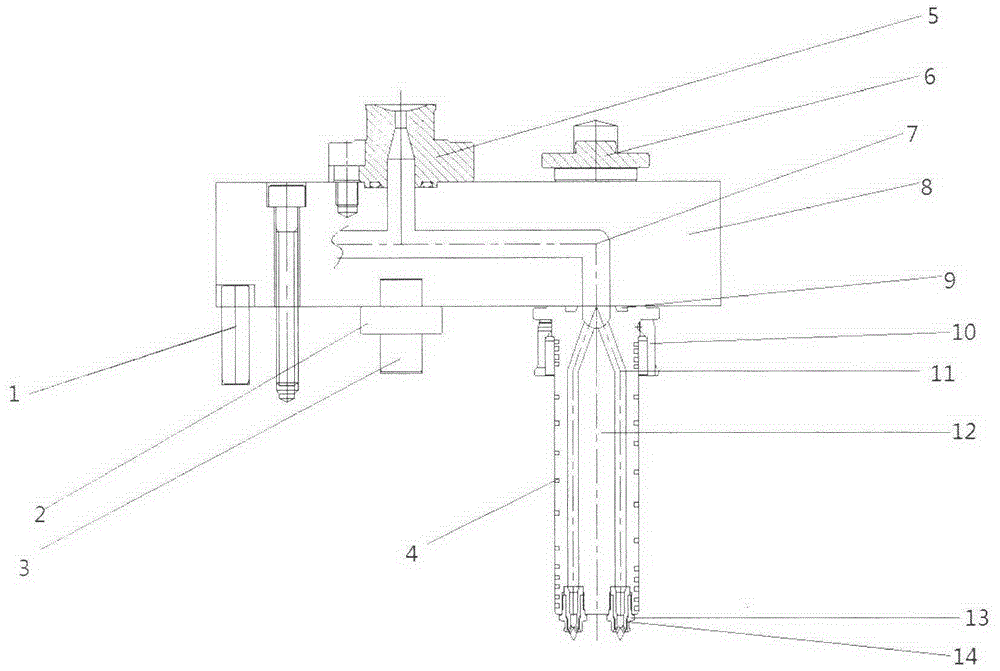

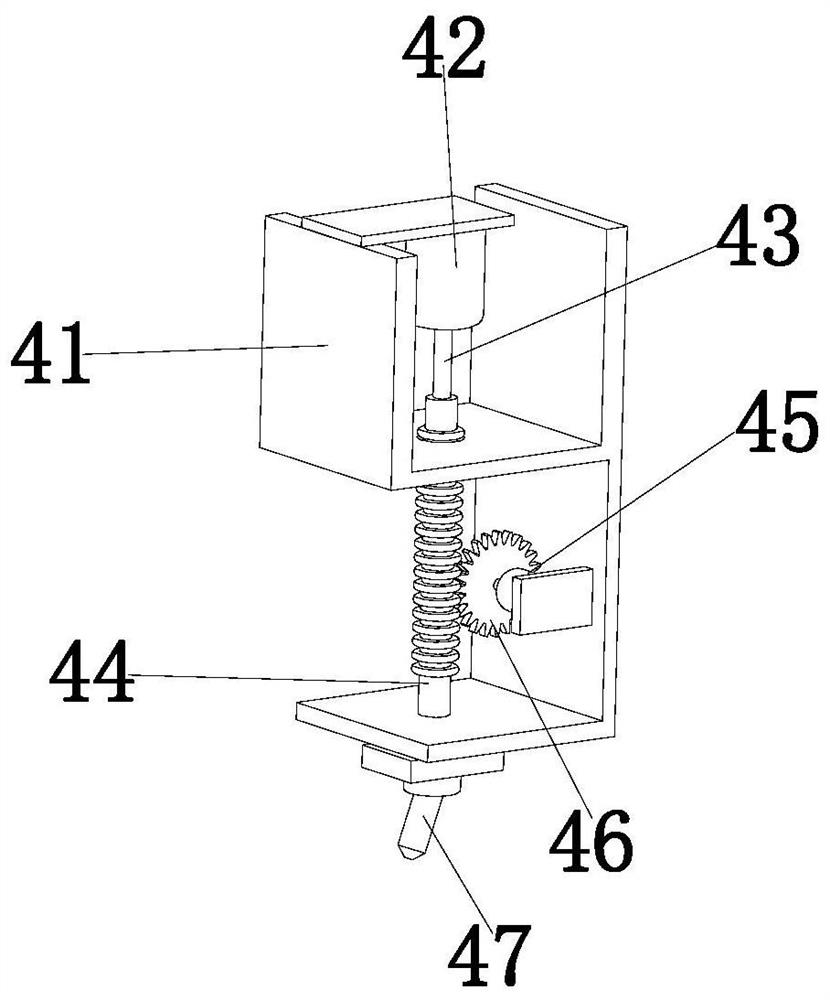

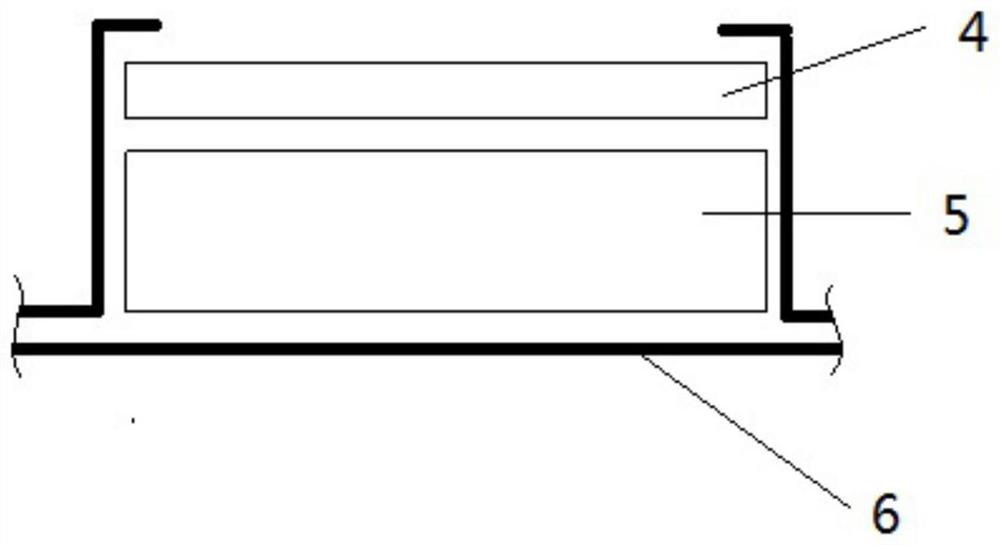

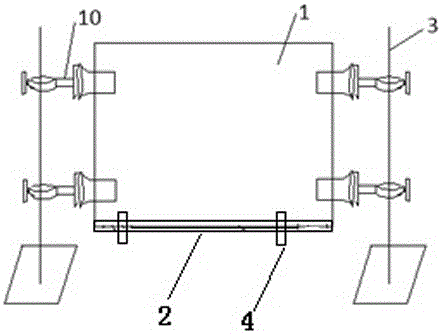

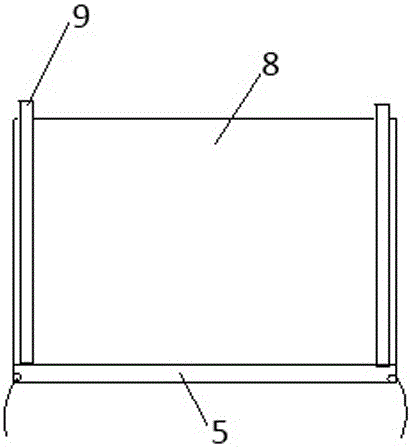

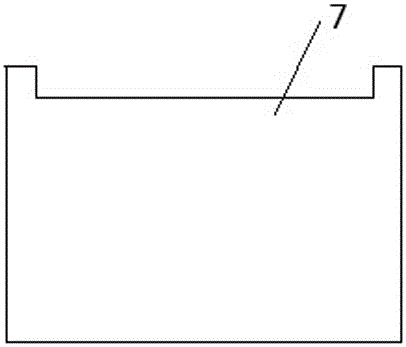

Simple glue manufacturing device for perpendicular plate electrophoresis tank

InactiveCN106512725ASimple structureEasy to assembleDispersed particle separationFixed frameSquare cavity

The invention relates to a simple glue manufacturing device for a perpendicular plate electrophoresis tank. The simple glue manufacturing device comprises a square cavity and fixed frames arranged on the two sides of the square cavity, wherein the fixed frames are connected with the square cavity through movable clamps; the square cavity comprises a front plate and a rear plate, an opening groove is formed in the top of the front plate, fixed seal strips are embedded in the left edge and the right edge of the rear plate, and a movable seal strip is clamped between the bottom of the front plate and the bottom of the rear plate; the cross section of a clamp groove is in a U shape, and the clamp groove sleeves the lower end of the front plate and the lower end of the rear plate. The simple glue manufacturing device for the perpendicular plate electrophoresis tank is good in seal performance, free of glue solution leakage, simple in structure, convenient to operate, suitable for manufacturing varieties of films and wide in application; in addition, an extra glue sealing process is avoided.

Owner:CHINESE STURGEON RES INST CHINA THREE GOR

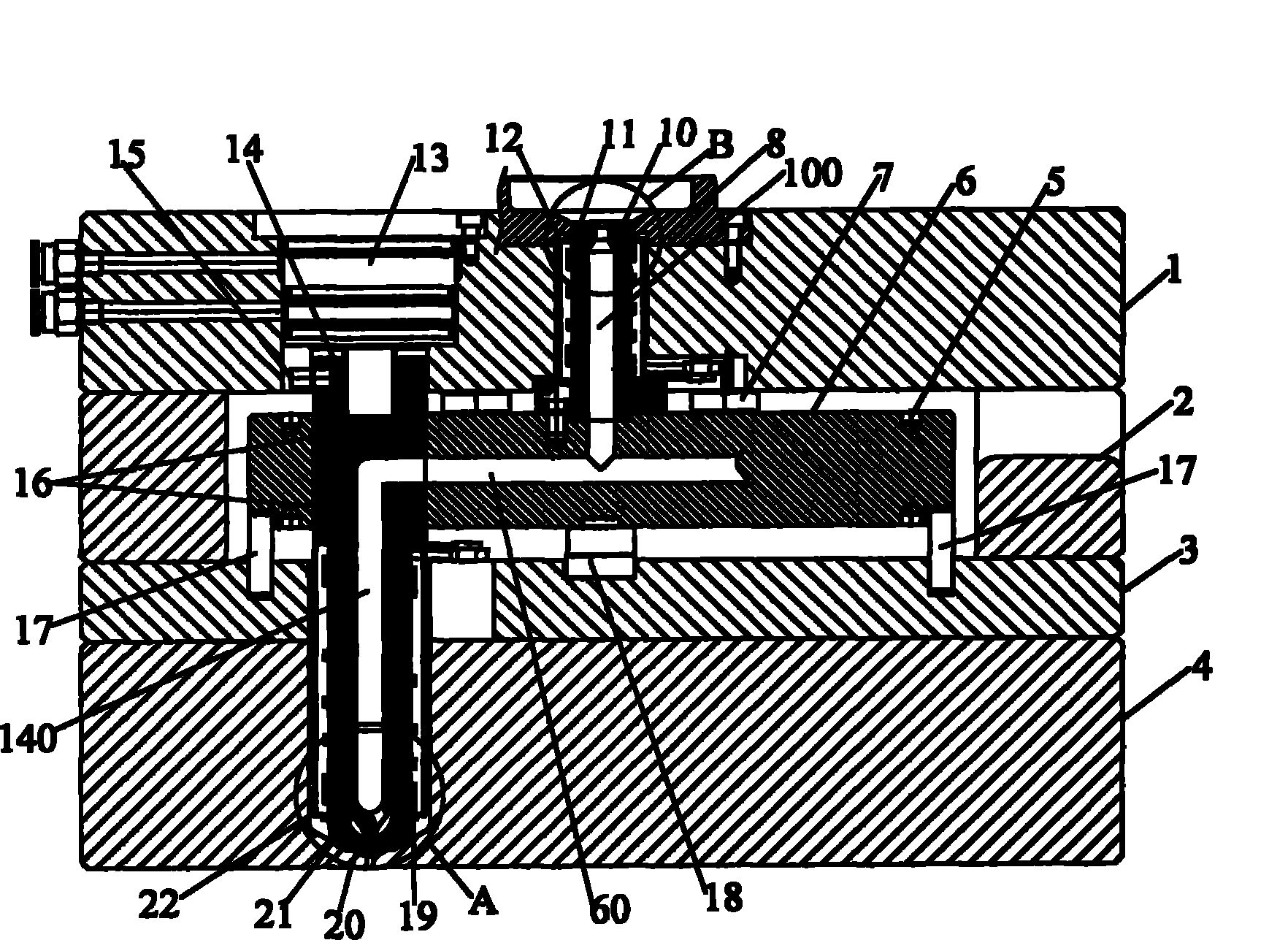

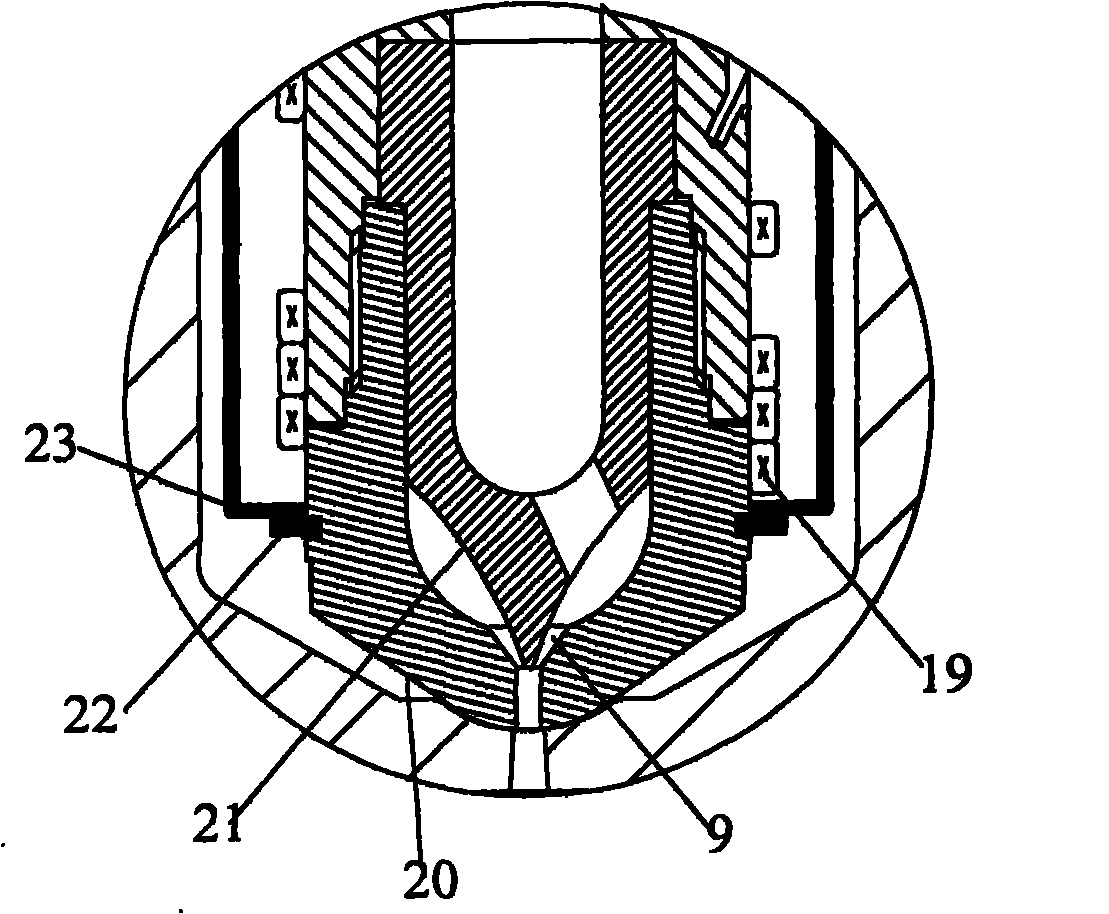

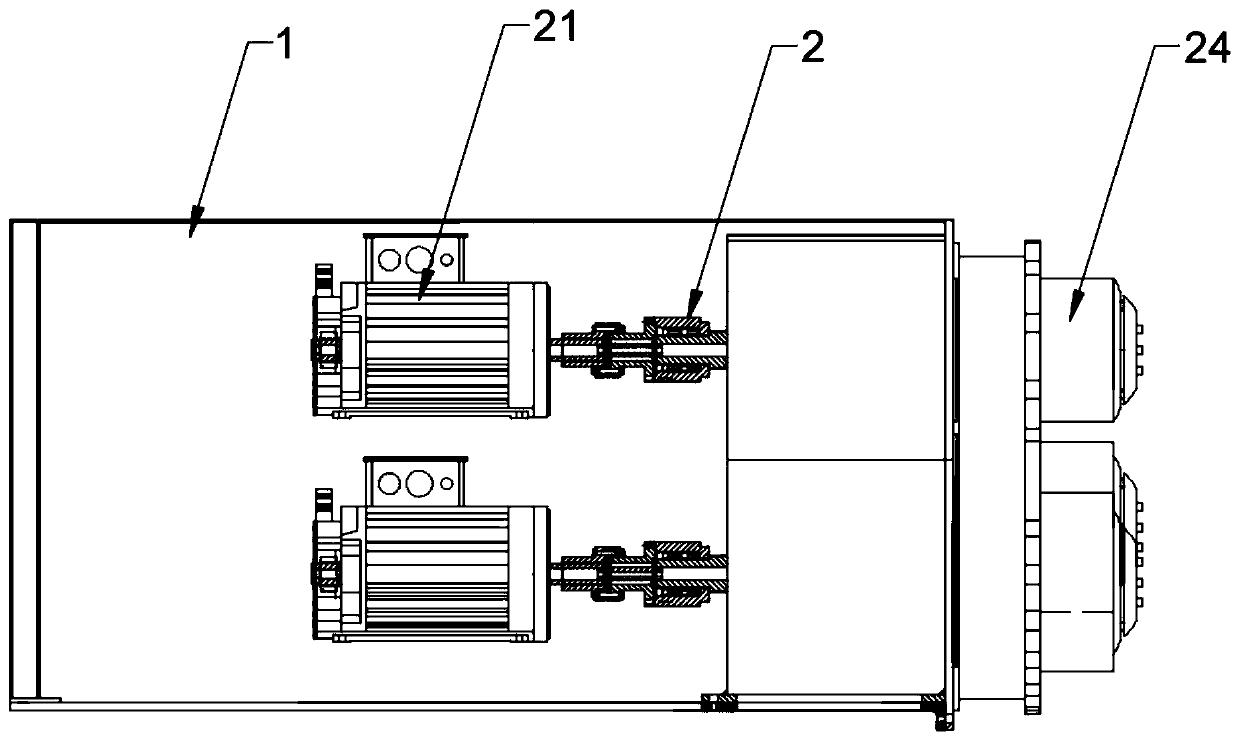

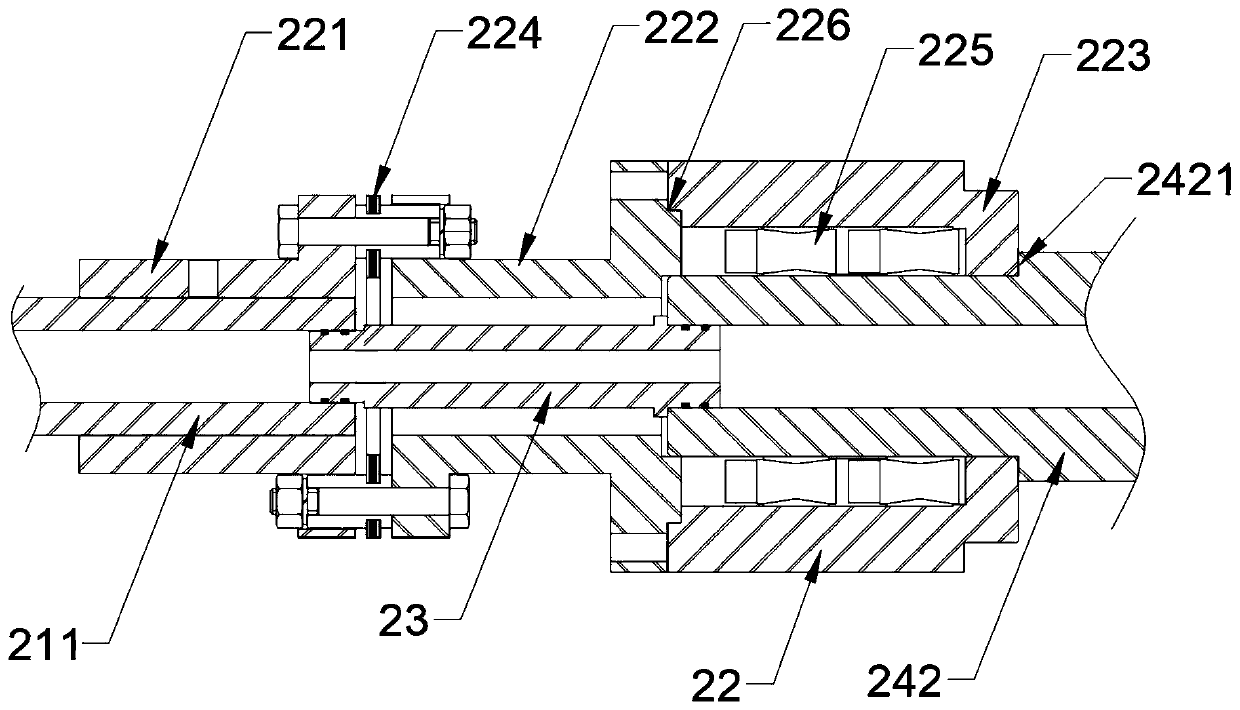

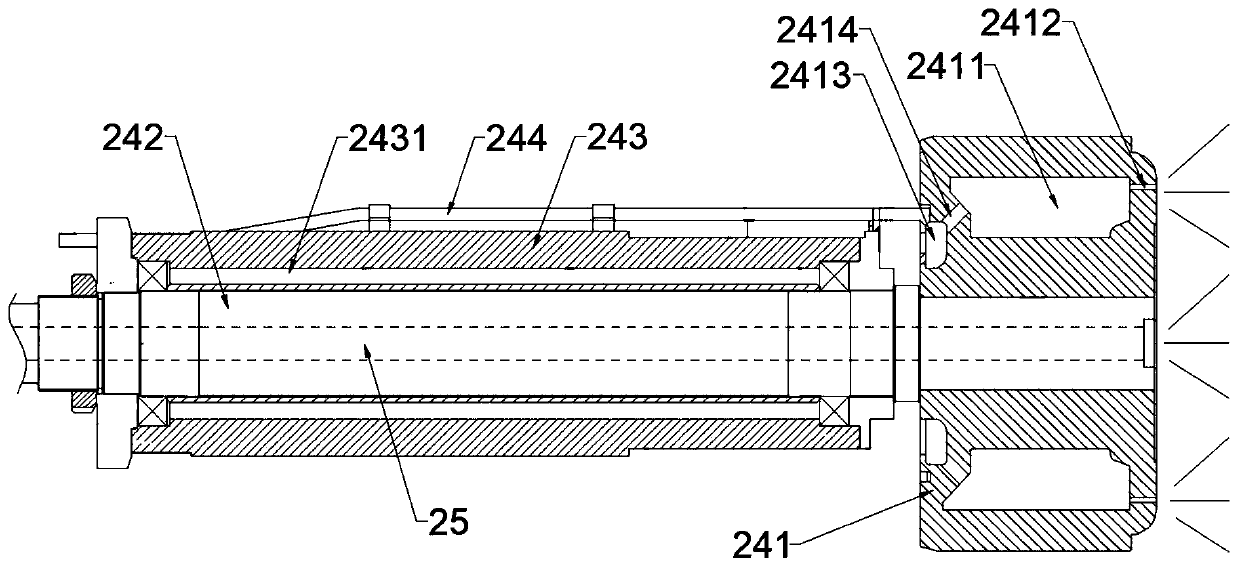

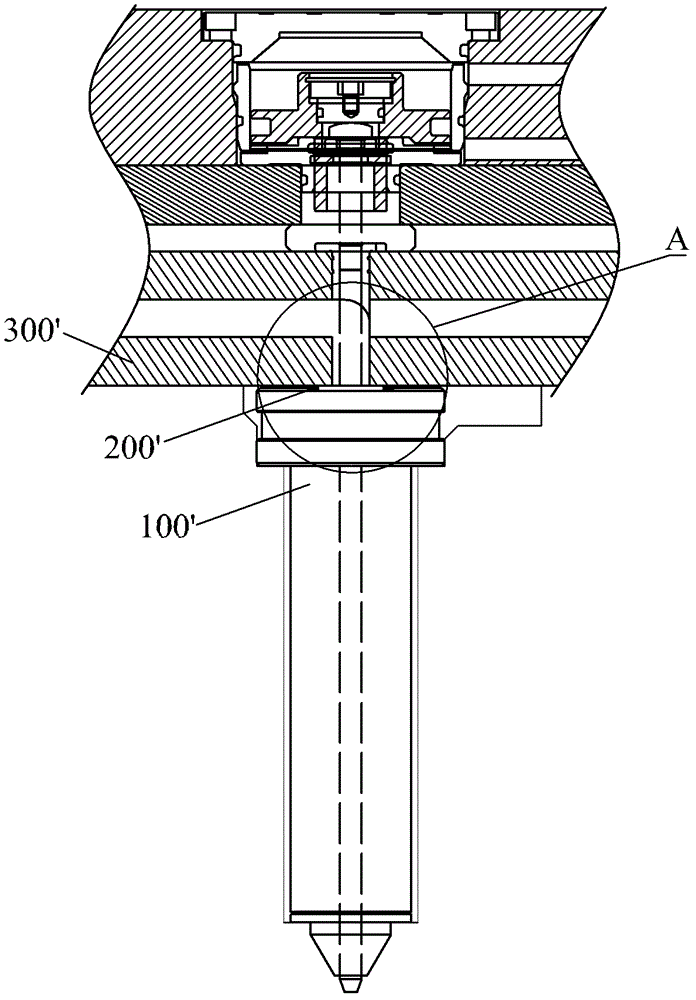

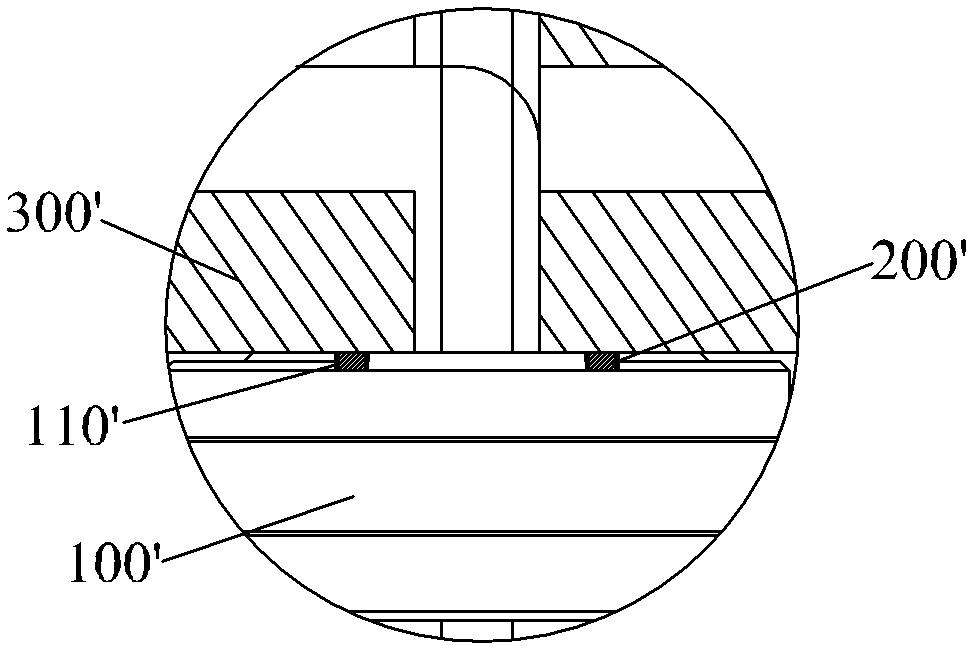

Rock wool fiberizing centrifuge

PendingCN110668690AAchieve direct driveReduce volumeGlass making apparatusGlass productionElectric machineCoupling

The invention discloses a rock wool fiberizing centrifuge. The rock wool fiberizing centrifuge comprises a frame, a plurality of centrifuging roller assemblies arranged on the frame, a split type gluespraying ring arranged around the centrifuging roller assemblies, and a glue supply mechanism for supplying glue to the centrifuging roller assemblies and the split type glue spraying ring; every centrifuging roller assembly comprises a motor, a shaft coupling, a connecting tube and a roller body; the output shaft of the motor is a hollow shaft penetrating through two ends of the motor; the output shaft of the motor is fixedly connected with the roller body through the shaft coupling; the connecting tube is located in the shaft coupling, and two ends of the connecting tube are connected withthe output shaft of the motor and the roller body correspondingly; a glue spraying tube communicated with the connecting tube is arranged in the roller body; and the output shaft of the motor, the connecting tube and the glue spraying tube in the roller body form the glue channel of the centrifuging roller assembly. The defects of large occupied space in transmission and easy slipping of an original belt are fundamentally overcome, the size of the rock wool fiberizing centrifuge is reduced, and the yield of rock wool is increased.

Owner:CHANGZHOU YINGLAI MACHINERY

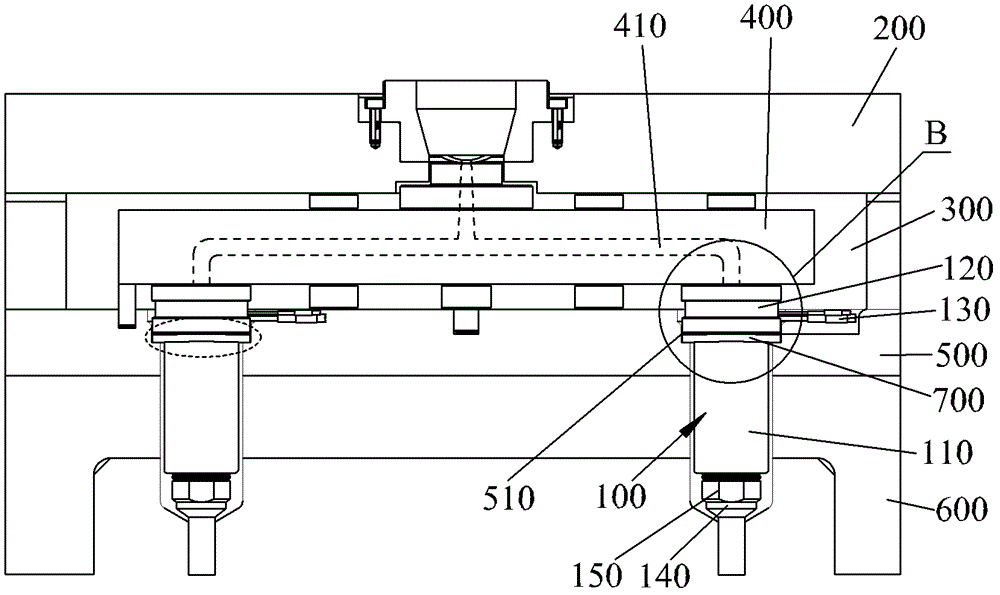

Hot nozzle installation structure of hot runner system

The invention relates to the technical field of moulds and provides a hot nozzle installation structure of a hot runner system. The hot nozzle installation structure comprises a spreader plate, a cushion plate, a front mould plate and a ladder groove which are sequentially located under the spreader plate. The ladder groove is arranged on the cushion plate and penetrates through the front mould plate. A hot nozzle comprises a body and a location sleeve sleeved at the top end of the body. The body stretches into the front mould plate from the ladder groove, the location sleeve is arranged on the step face of the ladder groove, and the top face of the location sleeve is contacted with the bottom face of the spreader plate. The hot nozzle installation structure further comprises a locking piece arranged at the bottom of the location sleeve. The locking piece elastically abuts against the location sleeve to enable the top face of the location sleeve to be in gapless fit with the bottom face of the spreader plate, and the body penetrates through the locking piece. Due to the fact that the top face of the location sleeve is in gapless fit with the bottom face of the spreader plate under the elastic abutting effect of the locking piece, glue leakage on the contact face of the location sleeve and the spreader plate is effectively avoided. Simultaneously, the hot nozzle installation structure is convenient to install and easy to dismantle.

Owner:SHENZHEN SKYWORTH PRECISION TECH

Sliding-block internal plastic filling structure

The invention discloses a sliding-block internal plastic filling structure. The sliding-block internal plastic filling structure comprises a supporting block, an ejector pin, a sliding block insert core, a pulling pin and an elastic element; the supporting block is provided with a first supporting arm and a second supporting arm which are arranged to form an right angle, the first supporting arm is connected with a sliding block body, and the second supporting arm is provided with a vertical hole; one end of the ejector pin is fixed to the interior of an upper ejector plate, the other end of the ejector pin abuts against the second supporting arm, and the other end of the ejector pin and the vertical hole are arranged in a staggered mode; the sliding block insert core is connected with the sliding block body, a male mold core and a female mold core are each internally provided with a through groove, and the sliding block insert core is internally provided with a vertical runner for achieving plastic filling molding of a plastic product; one end of the pulling pin is arranged on the second supporting arm and vertically corresponds to the vertical hole, and the other end of the pulling pin penetrates through the through grooves to stretch into the sliding block insert core to abut against the vertical runner; and the elastic element sleeves a segment of outer edge, penetrating through the through grooves, of the pulling pin. According to the sliding-block internal plastic filling structure, plastic filling is achieved through the sliding block insert core from one side face of the plastic product, the structure is suitable for the plastic product of which the appearance face can not achieve plastic filling, and the friction plastic leakage problem of the sliding block insert core and the mold cores is avoided; the mold internal plastic filling structure is low in machining difficulty and machining precision requirement and convenient to machine.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Toy injection molding machine

The invention discloses a toy injection molding machine. The toy injection molding machine comprises a feeding funnel, wherein a glue injection cylinder is arranged at one side of the feeding funnel; a glue injection piston rod is arranged at the bottom of the glue injection cylinder; a non-return valve is arranged at the bottom of the glue injection piston rod; a glue injection workbin is arranged at the bottom of the non-return valve; a glue leakage prevention device is arranged at the bottom of the glue injection workbin and is fixed on the upper surface of an upper rubber plate; a lower mold plate is arranged at the bottom of the upper rubber plate; a cooling water distributor is arranged at the bottom of a lower rubber plate on the back of an operating control box; the bottom of the operating control box is connected to an electric box; a lubricating oil pump is arranged on the top of the side wall of the electric box; an oil pipe, an oil supply motor, an oil line integrated block, an oil pressure dial gauge, an oil temperature gauge and an oil tank are arranged at one side of the lubricating oil pump. The toy injection molding machine is capable of effectively avoiding glue leakage and glue countercurrent during glue injection, monitoring the temperature of the oil tank and cooling the oil tank when the temperature of the oil tank is excessively high.

Owner:蓝灿玉

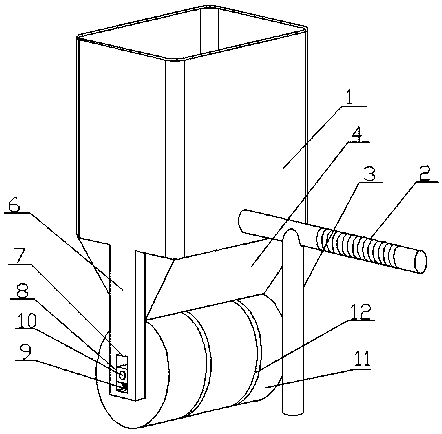

Feeding device on extruder

InactiveCN102582059AReduce extrusion pressureEliminate regurgitationEngineeringMechanical engineering

Owner:ZHEJIANG DONGBIN RUBBER MACHINERY SCREW

Vacuum assisted method and equipment for preventing outflow of rubber by screw extrusion continuous dehydration drying

The invention discloses a vacuum assisted method and equipment for preventing outflow of rubber by screw extrusion continuous dehydration drying for achieving the purpose of preventing rubber leakage in dehydration and exhausting by people using an outflow preventing exhaust device with a motor-controlled shaftless spiral device. Compared with a screw thread, the motor-controlled shaftless spiral device can generate higher downward thrust to rubber, so that the rubber slowly fills shaftless space and a spiral to reinforce the outflow preventing effect; water in the rubber escapes by being subjected to mechanical extrusion and two-time negative pressure; water escapes by two-time negative pressure, so that the rubber is dried more sufficiently; and a circuit control device does not need to be connected, so that the operation is convenient.

Owner:QINGDAO UNIV OF SCI & TECH

Press type guitar glue brushing device controllable in glue discharging amount

InactiveCN107694830AAdjust the amount of glue in timeGlue output adjustableLiquid surface applicatorsCoatingsAdhesiveBrush device

The invention discloses a press-type guitar brush gluer with controllable glue output, which comprises a glue box, a handle is provided on one side of the glue box; a conical lower glue hopper is arranged at the bottom of the glue box, There is an opening for the lower rubber at the bottom of the lower rubber opening, and an upwardly arched rubber baffle is provided on both sides of the lower rubber opening, and the rubber baffles are partially overlapped. , the lower end of the vertical plate is provided with a square groove, and a slider is arranged in the square groove. There is an annular groove as deep as the rotating shaft, and a movable ring sleeve is arranged on the rotating shaft in the annular groove, and a pressing rod is connected above the movable ring sleeve, and a rubber pressing bar is connected to the top of the pressing rod. The length of the rubber baffles is the same, and the rubber outlet bead is provided with a glue outlet longitudinally. The invention has the characteristics of not leaking glue when not brushing glue, and can timely adjust the glue output when brushing glue.

Owner:贵州谦梦乐器制造有限公司

Glue-volume-controllable glue coating device for guitar glue coating

InactiveCN107626527AThe amount of glue brushing can be adjusted in timeThe amount of glue brushing is adjustableLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a glue-volume-controllable glue coating device for guitar glue coating. The glue-volume-controllable glue coating device comprises a glue box, a taper glue discharging hopper is arranged at the bottom of the glue box, vertical plates are arranged on the two sides of the taper glue discharging hopper, square grooves are formed in the lower ends of the vertical plates, sliding blocks are arranged in the square grooves, and compression springs are arranged at the lower ends of the sliding blocks; a first rotating shaft is arranged between the sliding blocks on the two sides, and a glue coating roller is arranged on the first rotating shaft; a stress plate is arranged at the upper end of the outer side of each sliding block, each 7-shaped plate is arranged above the stress plate, corners of the 7-shaped plates are connected to the vertical plates through a second rotating shaft, tension springs are connected to the 7-shaped plates, and the other ends of the tensionsprings are connected to the vertical plates; and a connecting plate is connected between end points of the other ends of the 7-shaped plates on the two sides of a stand column, supporting feet are connected to the lower portion of the connecting plate, a horizontal hand buckling plate is arranged at the middle portion of the connecting plate, and a horizontal handle is connected to the glue box above the hand buckling plate. The glue-volume-controllable glue coating device has the beneficial effects that glue leakage is avoided when glue coating is not carried out, and the glue amount can beadjusted timely during glue coating.

Owner:贵州谦梦乐器制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com