Sliding-block internal plastic filling structure

A sliding block and glue feeding technology, applied in the field of mold structure, can solve the problems of glue leakage and inability to feed glue, and achieve the effect of avoiding glue leakage and facilitating processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

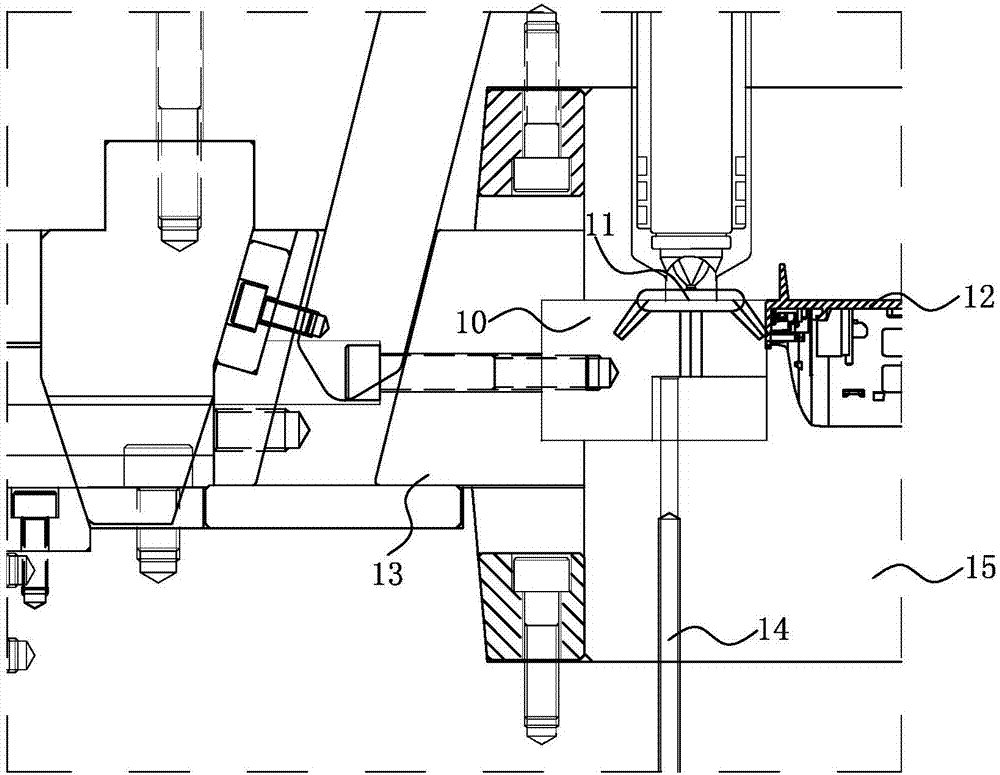

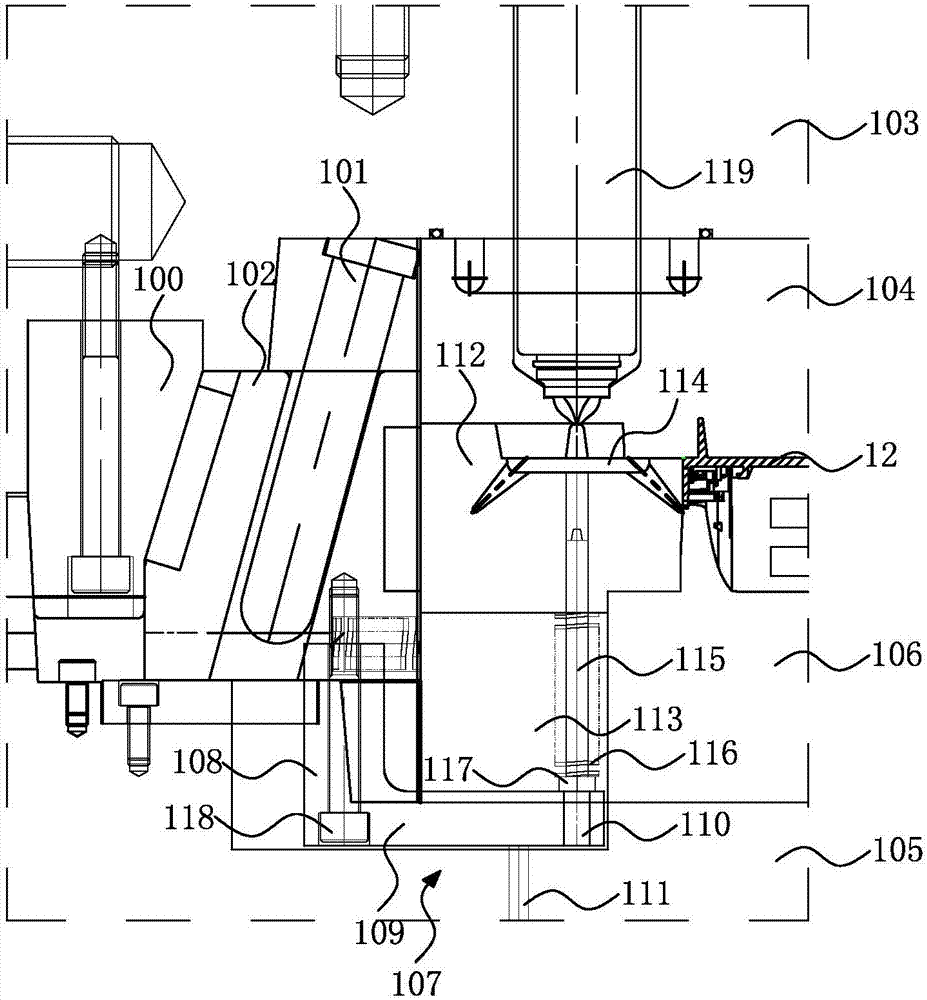

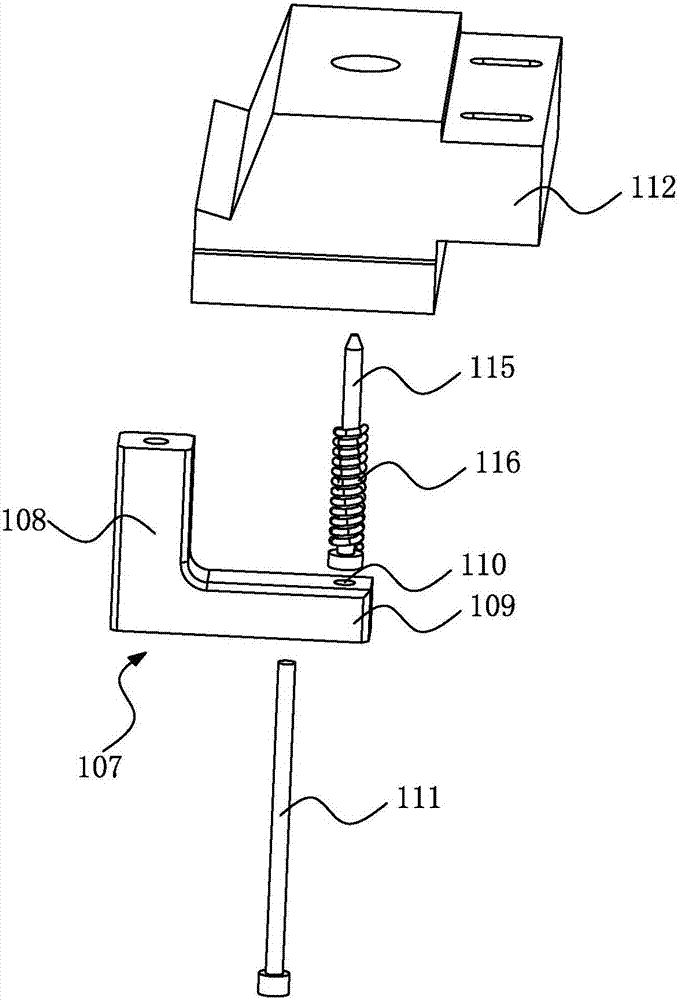

[0022] see figure 2 and image 3 shown, where figure 2 A schematic diagram of the sliding block glue feeding structure of the present invention in the mold clamping state is drawn, image 3 A three-dimensional exploded schematic diagram of a partial structure in the glue-feeding structure of the slider of the present invention is shown.

[0023] In this embodiment, the inner glue feeding structure of the slider of the present invention is applied to a plastic product 12 whose exterior surface cannot be glued into a mold. The mold includes a slider bundle 100, an inclined guide post 101, and a slider body 102. , female template 103, female mold core 104, male template 105, male mold core 106, upper ejector plate and lower ejector plate (not shown in the figure), the inner glue feeding structure of the slider includes:

[0024] Support block 107, it is located in male formwork 105 and is provided with movement stroke between male formwork 105, described support block 107 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com