Automatic double magnetic circuit magnetic assembly device for miniature loudspeaker, and production technique adopted by device

A technology of miniature speakers and automation equipment, applied in the direction of sensors, electrical components, etc., can solve the problems of difficult to ensure product quality, low production efficiency, high product defect rate, and achieve the effect of shortening production cycle, reducing production cost, and improving quality rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

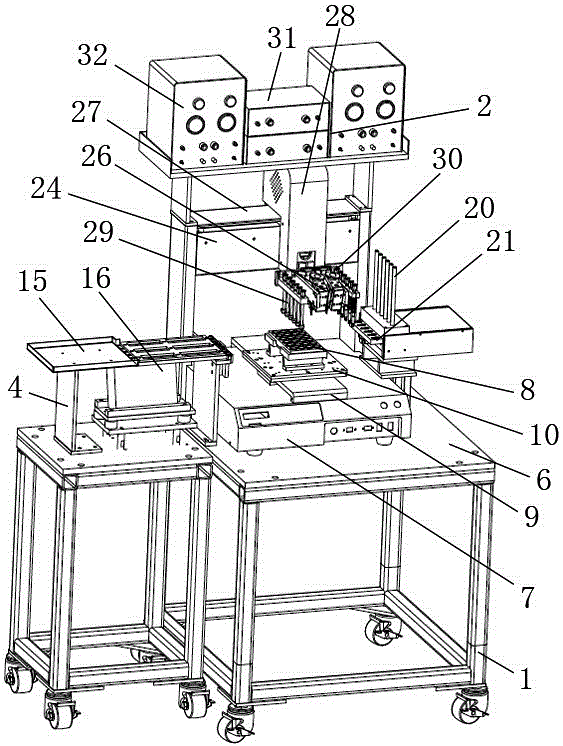

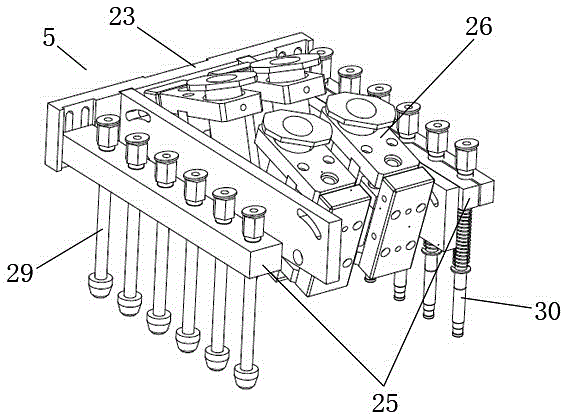

[0027] Such as Figure 1-5 As shown, a miniature magnetic circuit with magnetic speaker double magnetic circuit assembly automation equipment, including a frame 1, a numerical control device 2, a loading device 3, a feeding device 4 and a processing device 5, the frame 1 is provided with a workbench 6 , the numerical control device 2, the loading device 3, the feeding device 4 and the processing device 5 are all fixedly arranged on the frame 1, and the numerical control device 2 is fixedly arranged on the top of the frame 1 for controlling the entire automation equipment The processing process is intelligently controlled, the loading device 3 is adjustably arranged on the workbench 6 of the frame 1, and is used for loading and unloading the product material to be processed and the product after processing, and the feeding device 4 is arranged on the The two sides of the loading device 3 are fixed on the frame 1, and are used to provide the loading device 3 with various raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com