AB dispenser adhesive outlet mixing valve

A mixing valve and dispensing machine technology, which is applied in the direction of valve details, valve device, valve housing structure, etc., can solve the problems of lower injection accuracy, deformation of valve channel and valve port, and inability to control the flow of glue well, to achieve The effects of improving spraying accuracy, reducing changes, saving glue and manual cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

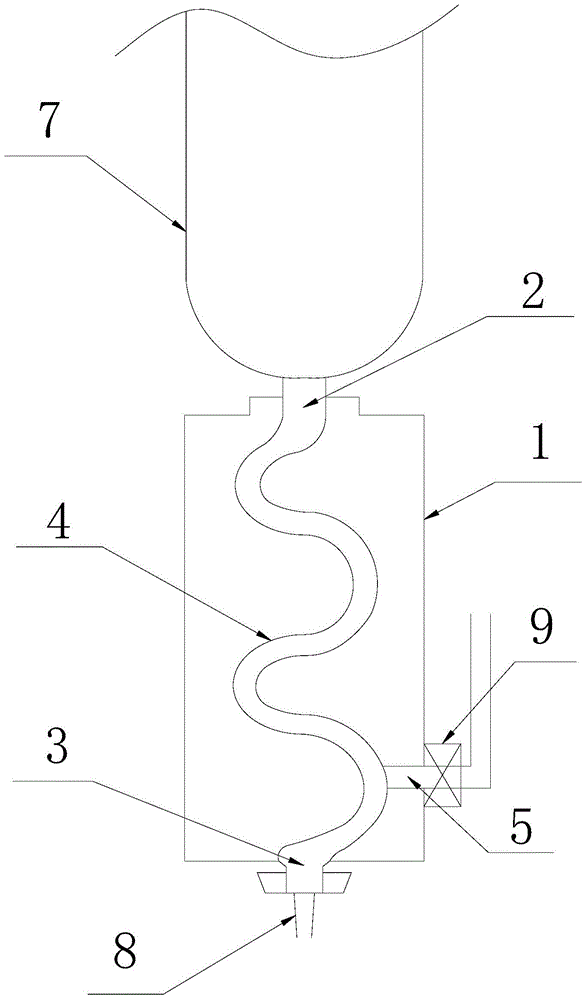

[0031] Embodiment 1: as figure 1 Shown is a specific embodiment of the AB glue dispenser glue mixing valve of the present invention, which has a valve body 1, an upper valve port 2 is opened on the top of the valve body 1, a lower valve port 3 is opened on the bottom of the valve body, and the valve body 1 There is a valve channel 4 connecting the upper and lower valve ports 2 and 3 inside, and the valve body 1 is also provided with an air inlet 5 connecting the valve channel 4 and the external air pump (not shown).

[0032] The core improvement of the present invention is that the valve channel 4 is designed with a bend, combined with figure 1 As shown, there are four bends on the valve passage 4 in this embodiment, and these bends are arc bends, but these bends are not bends with the same size and shape. In actual implementation, the specific number of bends can be determined as required, and each bend can give the glue a bearing surface against gravity.

[0033] T...

Embodiment 2

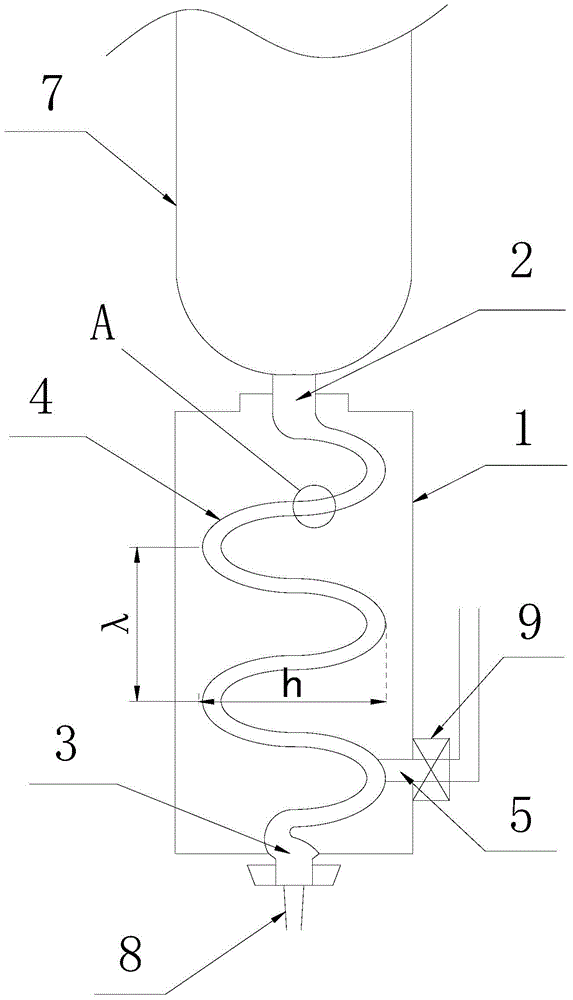

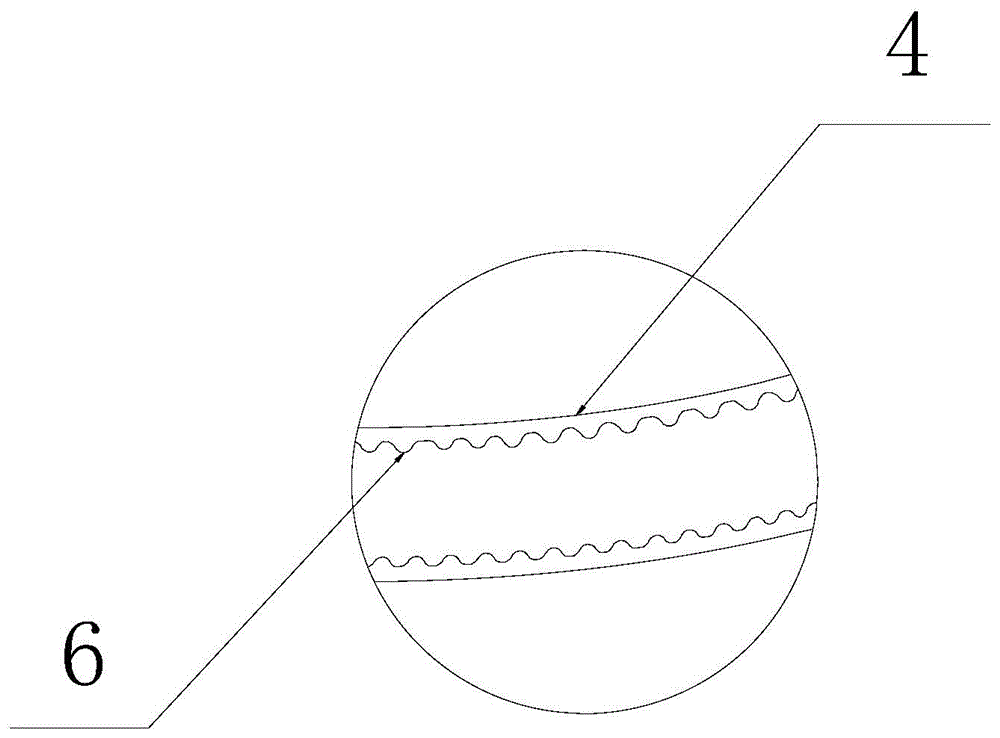

[0036] Embodiment 2: as figure 2 As shown, compared with Embodiment 1, the present invention differs in that the valve channel 4 is designed as a uniform sinusoidal waveform with five half-waves, and the ratio of the pitch λ to the amplitude h of the sinusoidal wave in this embodiment is 1 . Simultaneously combine image 3 As shown, the surface of the inner wall 6 of the valve channel 4 is a rough surface distributed with protrusions, specifically uniform and continuous corrugations, so as to improve the viscous force of the glue. The rest of this embodiment are the same as embodiment 1.

Embodiment 3

[0037] Embodiment 3: as Figure 4 As shown, the difference between the present invention and the embodiment 2 is that the valve channel 4 is designed as a uniform helical shape with nine threads, and the ratio of the pitch S to the major diameter D of the helix in this embodiment is 1. At the same time, the surface of the inner wall of the valve channel 4 in this embodiment is also designed with uniform and continuous corrugations, see image 3 shown. The rest of this embodiment are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com