Automatic painting equipment used for Christmas tree branches

A technology of equipment and branches, which is applied in the field of automatic painting equipment for Christmas tree branches, can solve problems such as low efficiency, and achieve high-efficiency, all-round automatic painting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

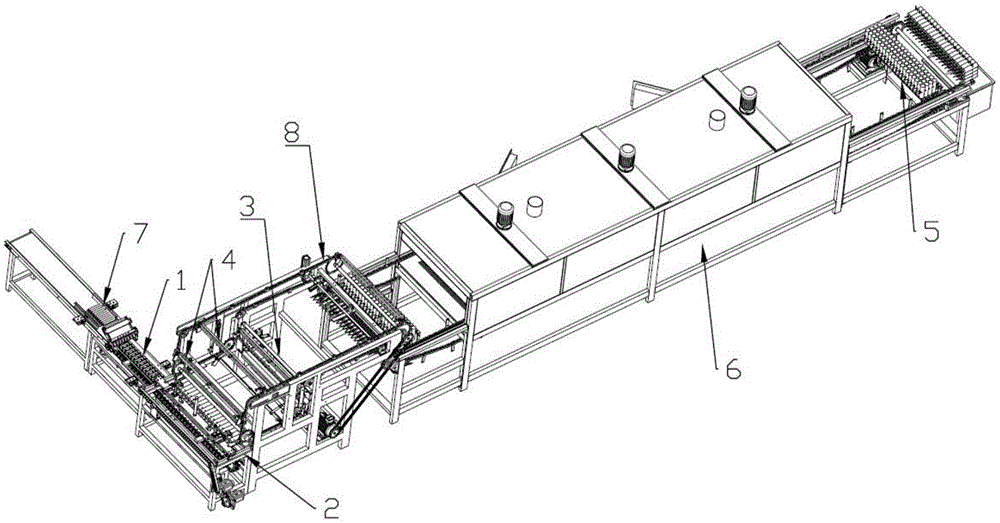

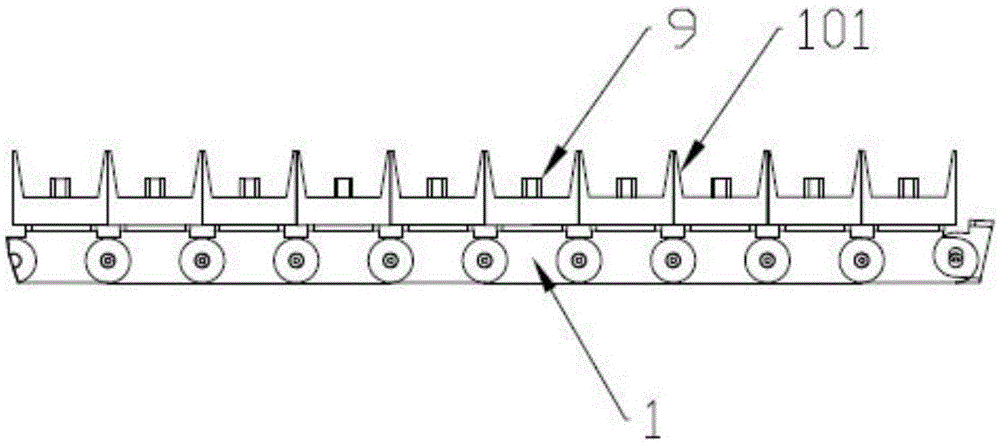

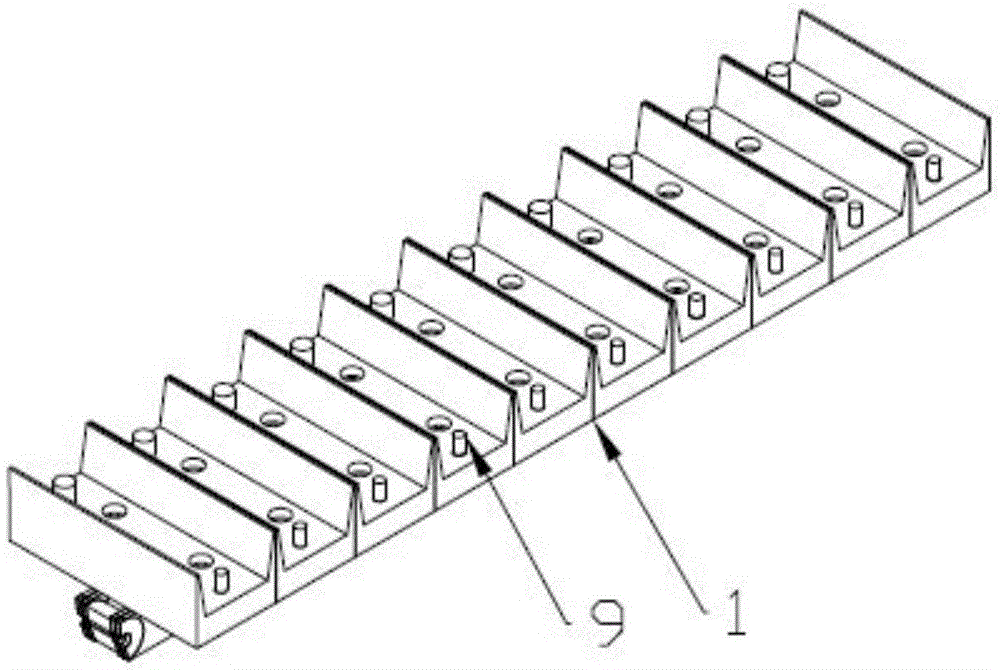

[0030] Through the following examples, combined with the attached Figure 1-15 , the technical solution of the present invention will be further specifically described.

[0031] An automatic painting equipment for Christmas tree branches, including a conveying structure 1, a material clamping structure 2, a glue dispensing positioning structure 3, a drying device 6, a charging frame 13, and a plurality of conveying chains 8, one of which is evenly arranged on the chain 8 A plurality of material distribution fixtures 4, the material distribution fixture 4 is connected to the clamping structure 2 at the front end of the chain 8, the rear end is connected to the drying device 6, and the middle section is connected with the glue dispensing positioning structure 3. The glue dispensing positioning fixture 3 includes Glue gun 302 and positioning fixture 304, described positioning fixture 304 left and right sides respectively are provided with a suspension vertical bar 305 and its fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com