Thin-film transistor array substrate, liquid crystal display device and manufacturing method thereof

A technology for liquid crystal displays and thin film transistors, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems affecting the display effect of liquid crystal displays, the thickness of leaking plastic boxes, and the pollution of liquid crystals, so as to improve the display effect, The effect of avoiding glue leakage and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

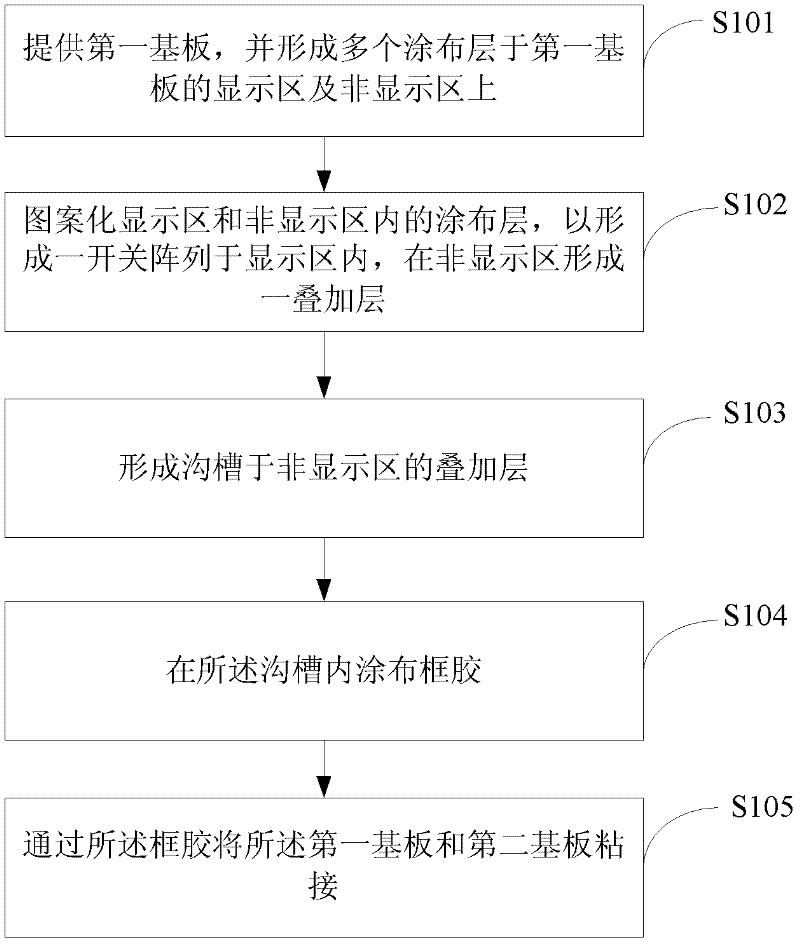

[0039] figure 1 It is a schematic flow chart of a preferred embodiment of the manufacturing method of the liquid crystal display in the present invention.

[0040] In step S101 , a first substrate is provided, and a plurality of coating layers are formed on the display area and the non-display area of the first substrate.

[0041] For example, a first metal layer, a gate insulating layer, an amorphous silicon layer, an ohmic contact layer, a second metal layer, a transparent conductive layer, and a protective layer are deposited on the first substrate.

[0042] In a specific implementation process, the first substrate is a TFT substrate. Certainly, the first substrate may also be a unified body of a TFT substrate and a CF substrate.

[0043] In step S102 , the coating layer in the display area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com