Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Avoid force imbalance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

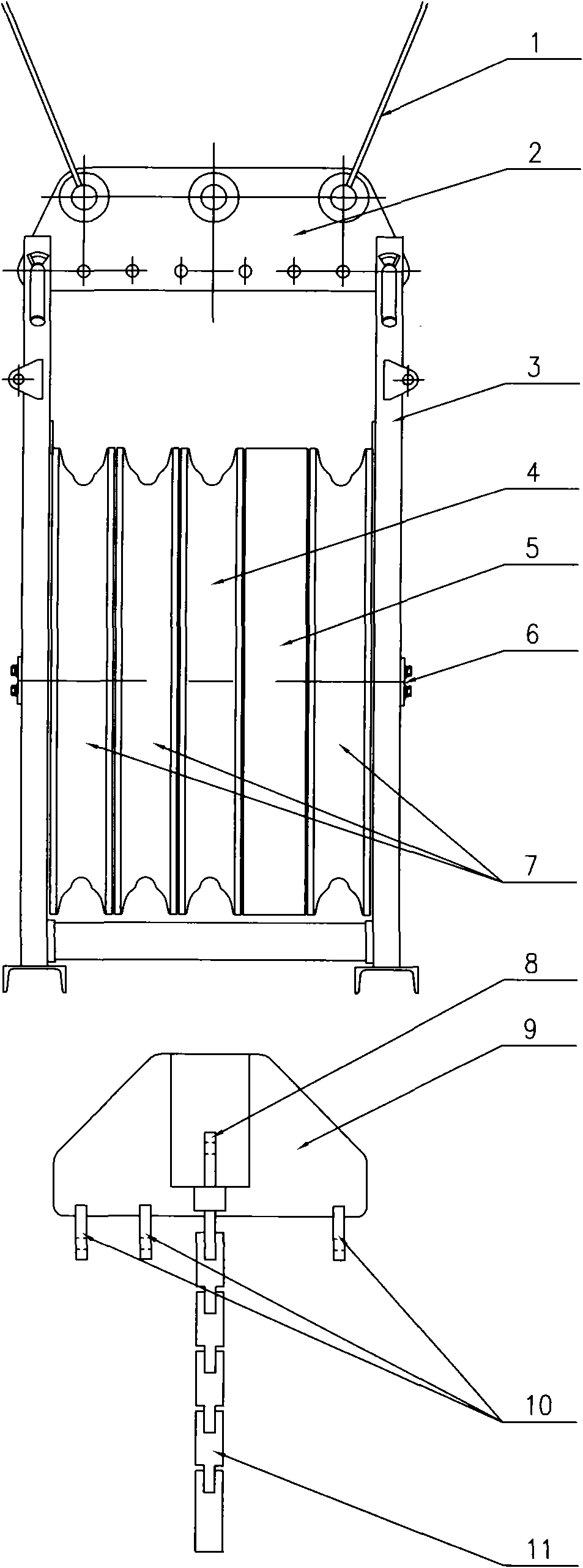

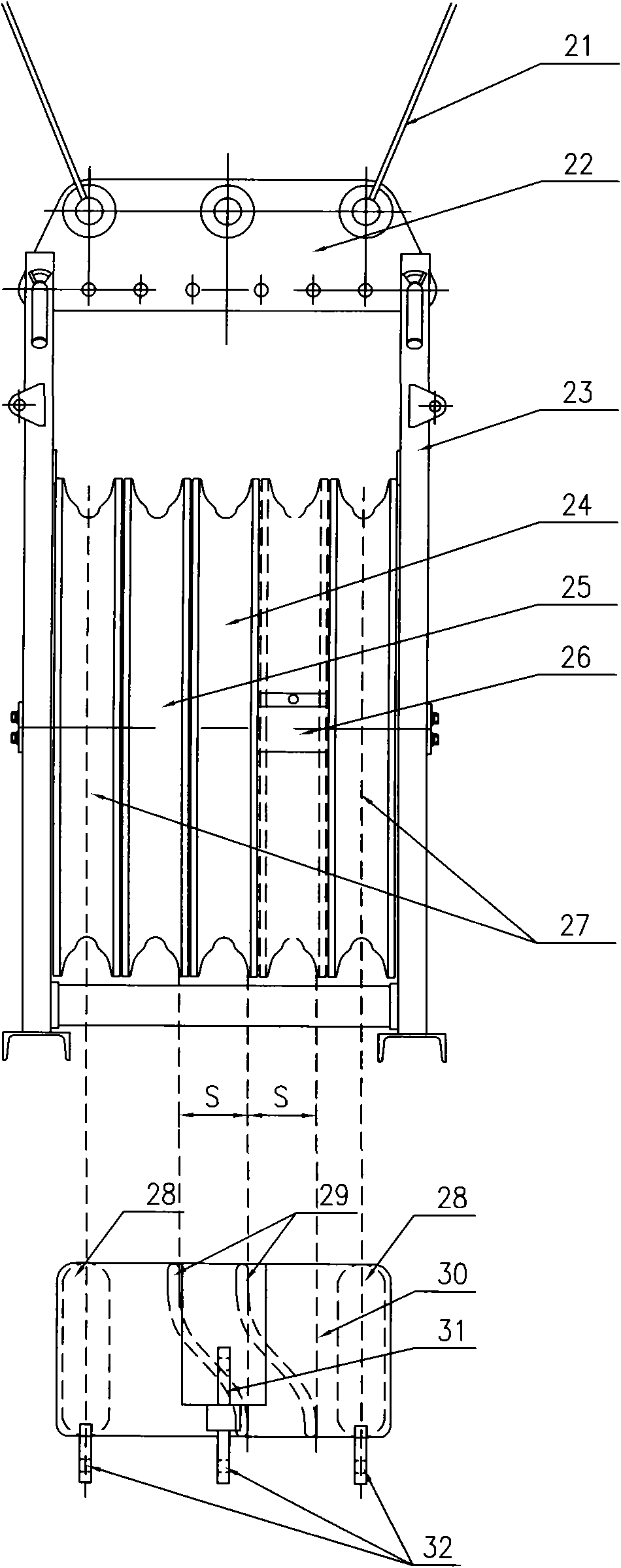

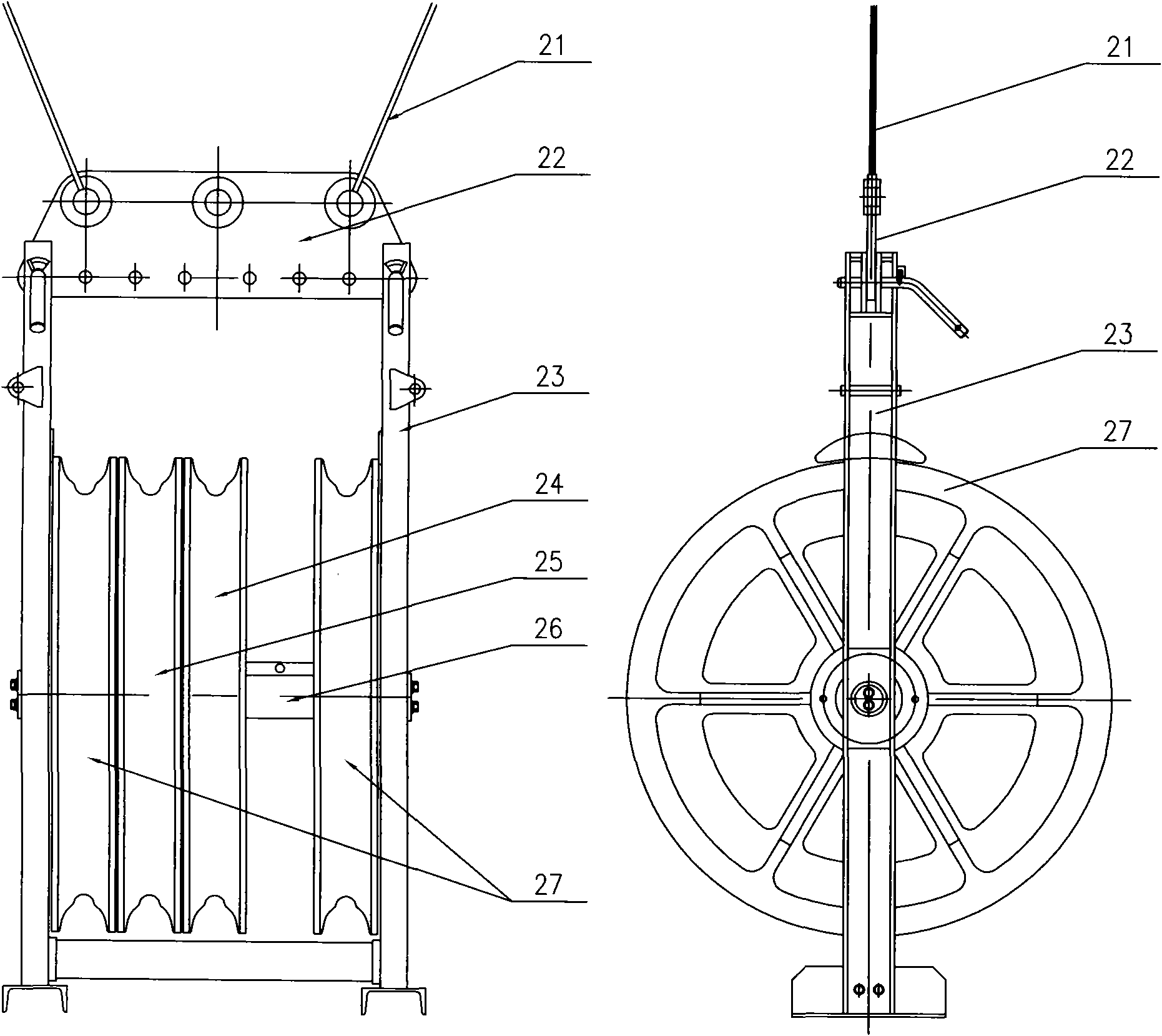

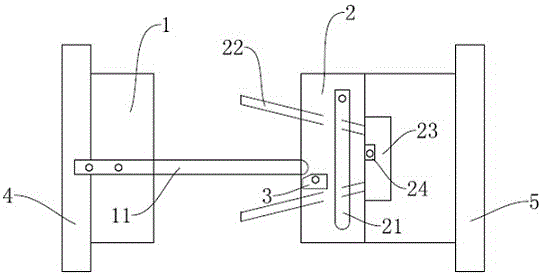

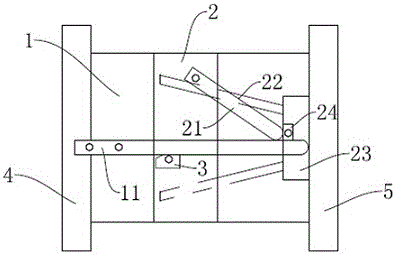

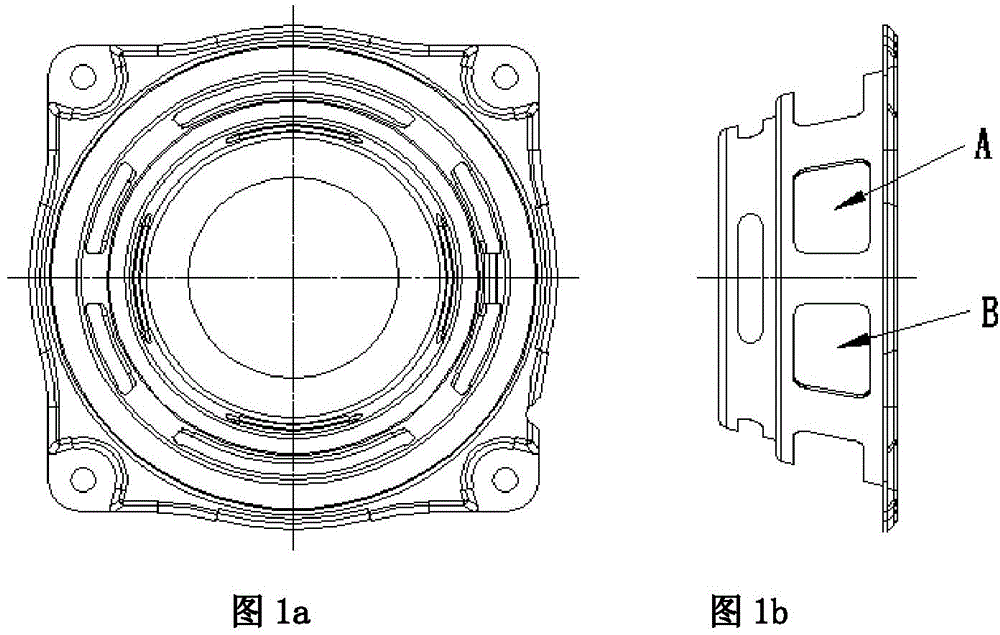

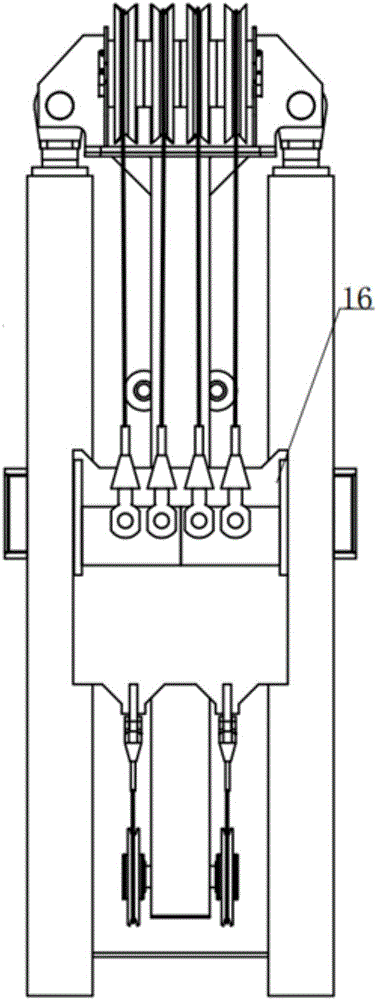

Symmetrical arrangement force balance type tackle for paying-off with a pull walking board and three wires and pull walking board

ActiveCN101789568AAvoid force imbalanceOvercoming intertwiningApparatus for overhead lines/cablesEngineeringForce balance

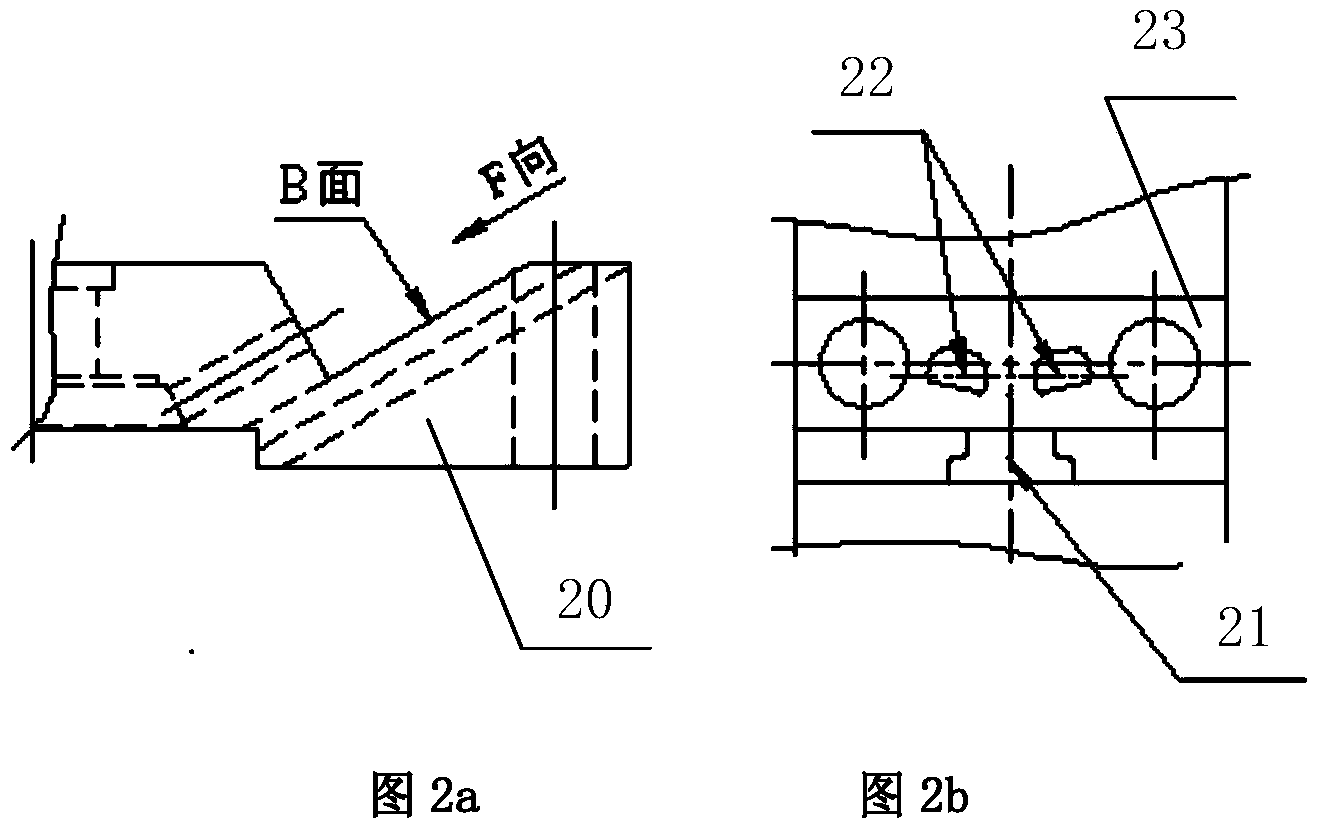

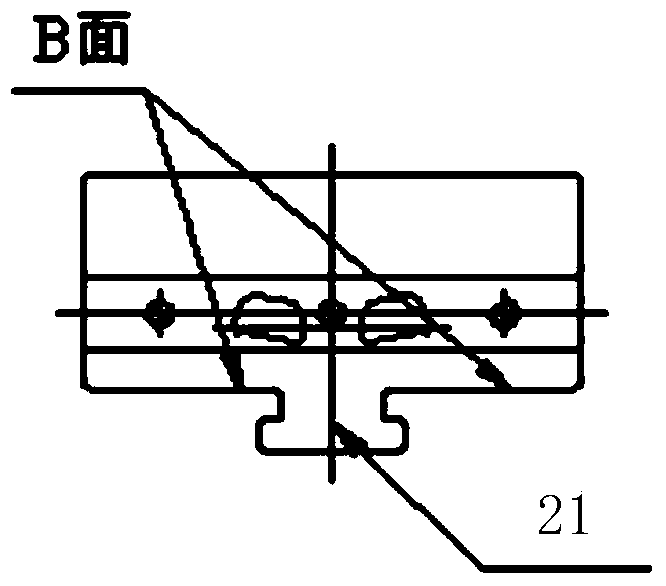

The invention relates to a tackle for paying-off and a pull walking board which can be used to ensure that the wires are symmetrically arranged and the stresses of the tackle and the walking board are balanced. The tackle is provided with a movable steel wire rope pulley and a movable wire pulley. When a hauling cable passes through the movable steel wire rope pulley of the tackle, the movable steel wire rope pulley is in the middle of the tackle so as to ensure that the stress of the tackle is balanced; when the pull walking board passes through the tackle, a guiding and pushing beam on the walking board is used to push the movable steel wire rope pulley and movable wire pulley on the tackle for paying-off to move a wheel-width distance, the movable wire pulley moves to the middle of the tackle, three wire pulleys on the tackle for paying-off are symmetrically arranged, and the three wire pulled by the pull walking board extends forward along the symmetrically arranged three wire pulleys, thus ensuring the stresses of the tackle for paying-off and the pull walking board are balanced. The tackle for paying-off and the pull walking board of the invention overcome the defects that the stresses of the general 'one-pull-three' tackle for paying-off and pull walking board are not balanced when wires are unfolded, the pull walking board and tackle for paying-off are easy to incline and overturn during construction, and the wires are intertwined.

Owner:CHINA ELECTRIC POWER RES INST +1

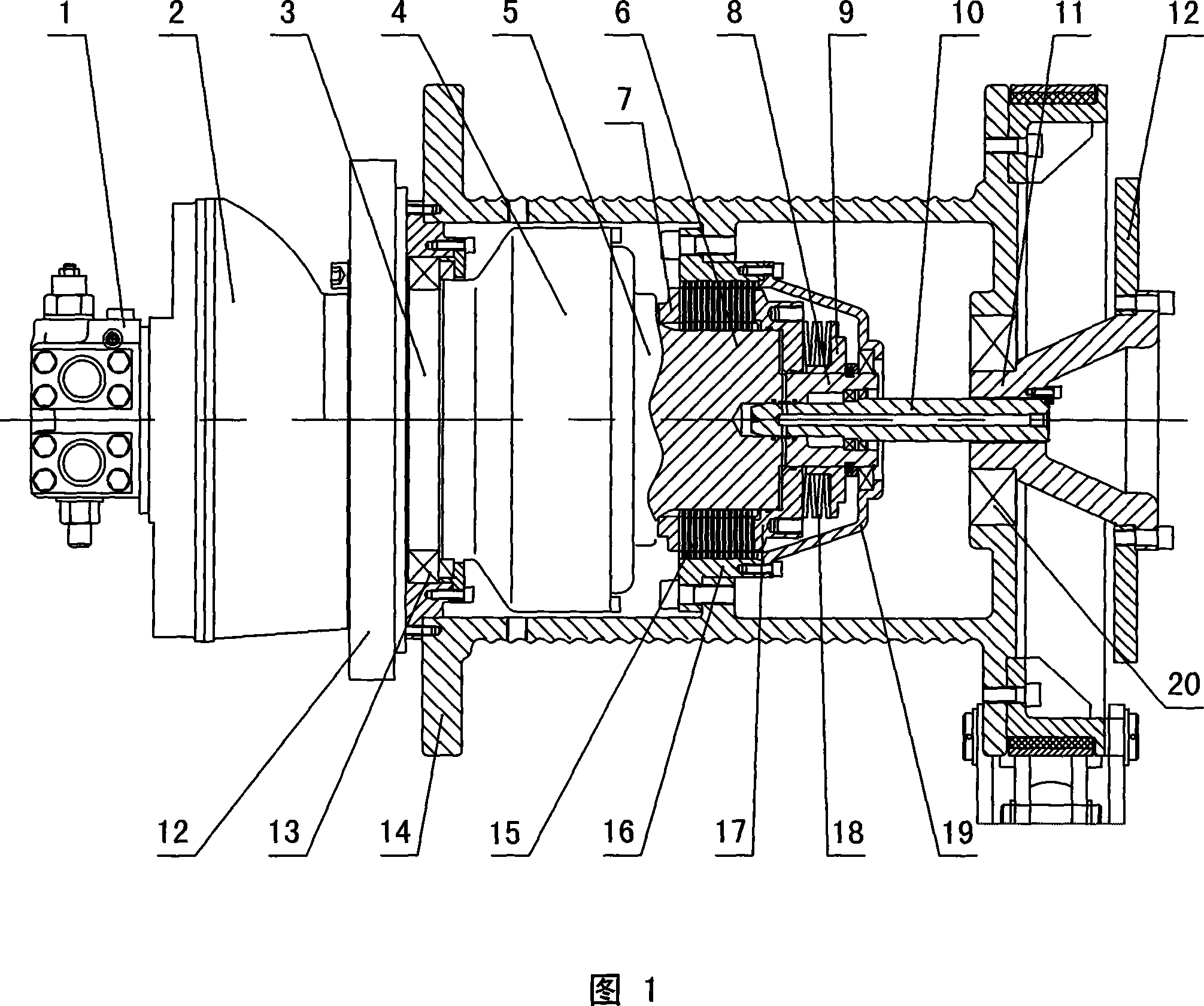

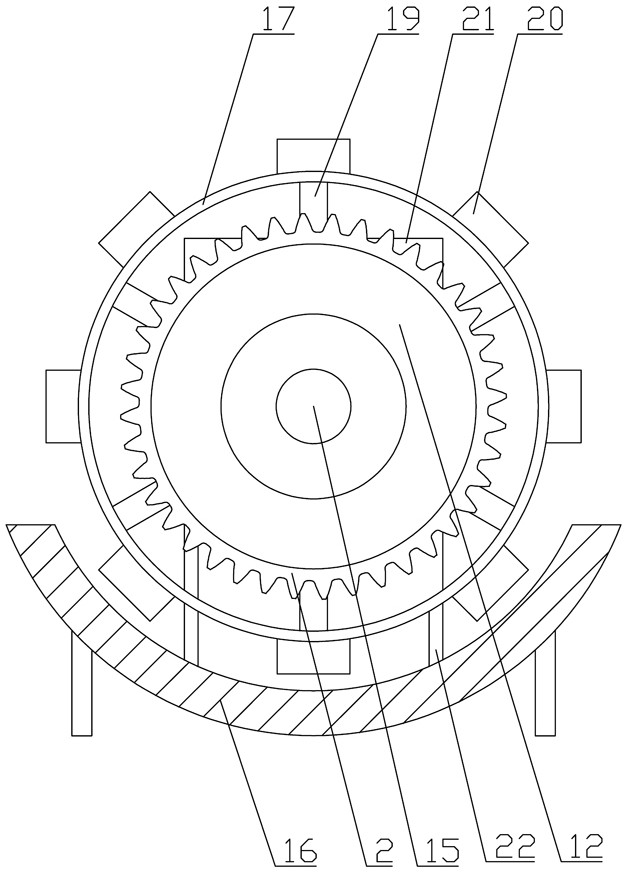

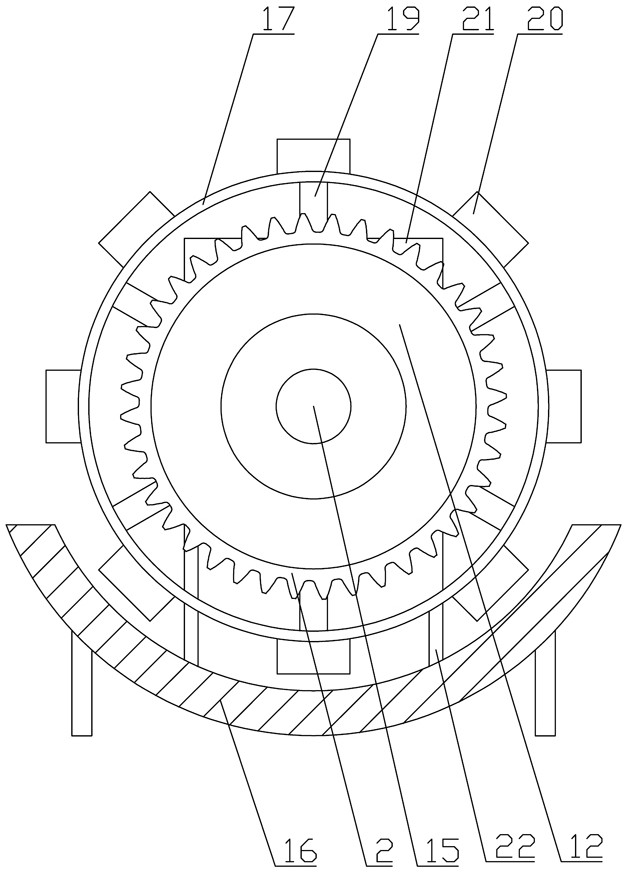

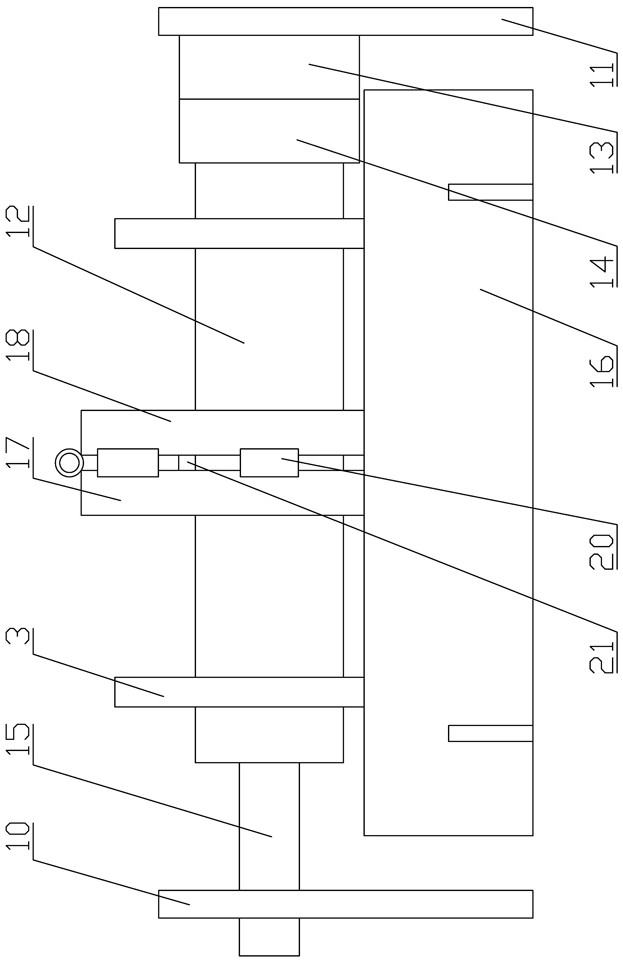

Hydraulic pressure reel cart with clutch at transmission last level

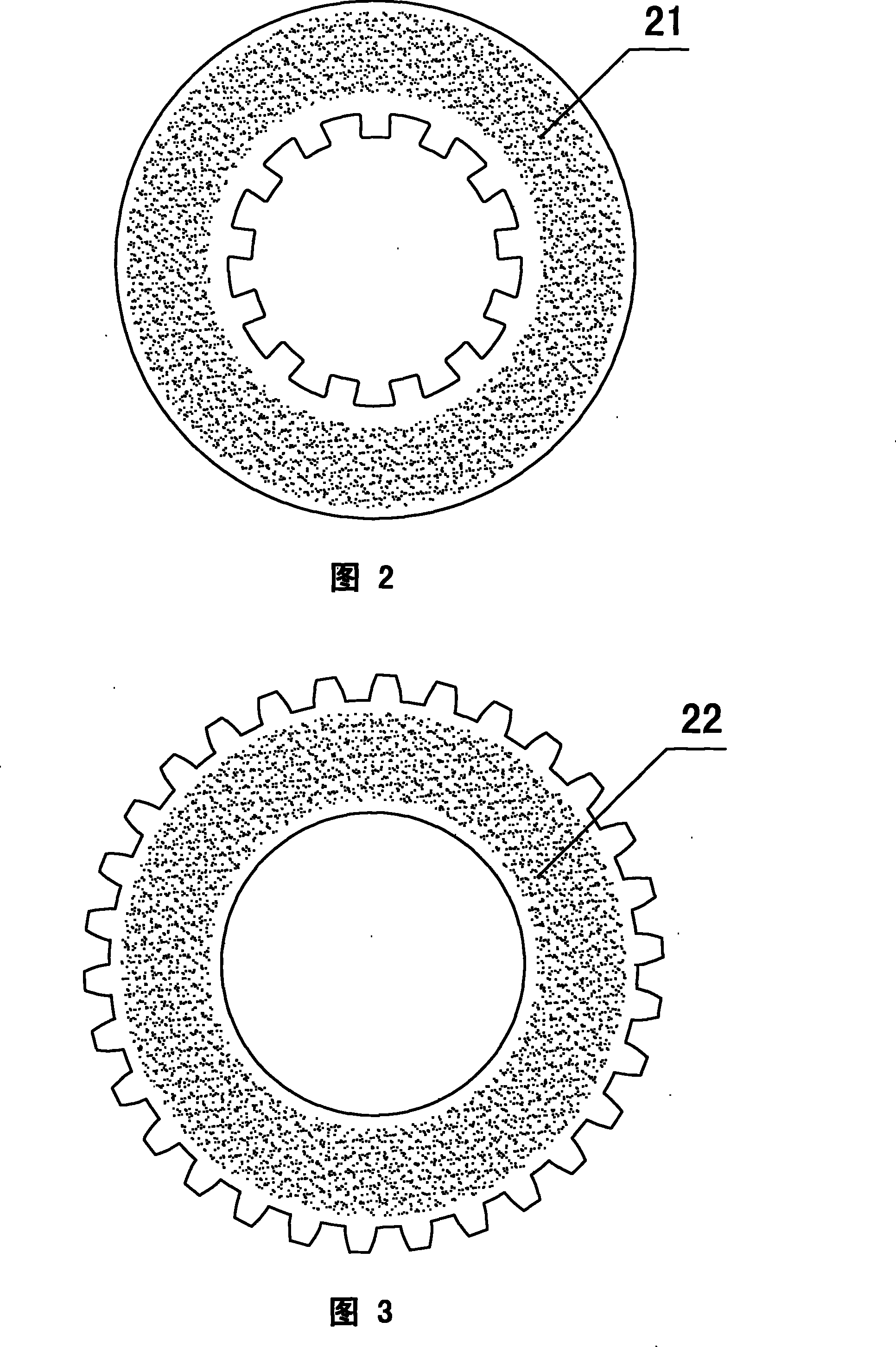

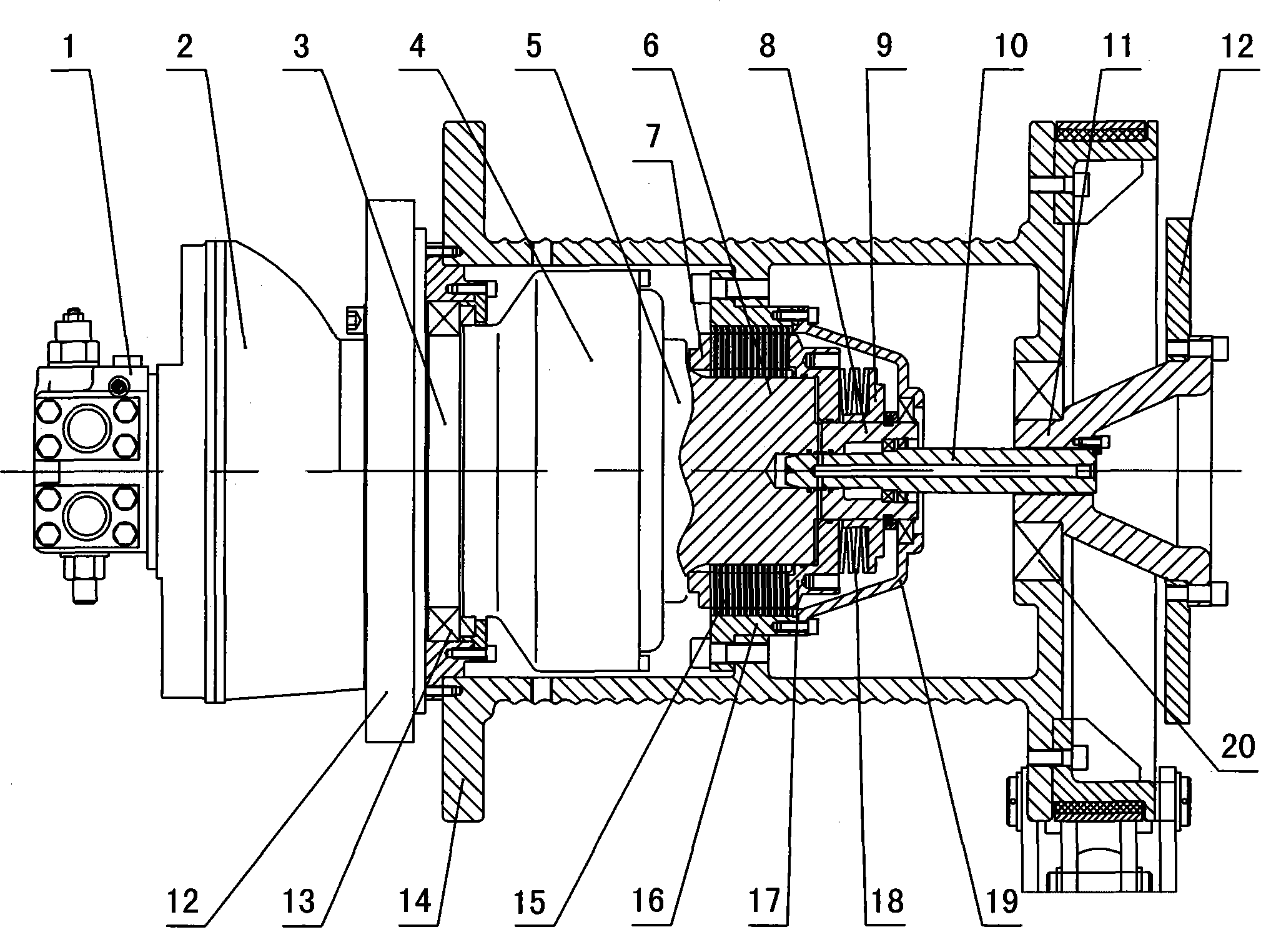

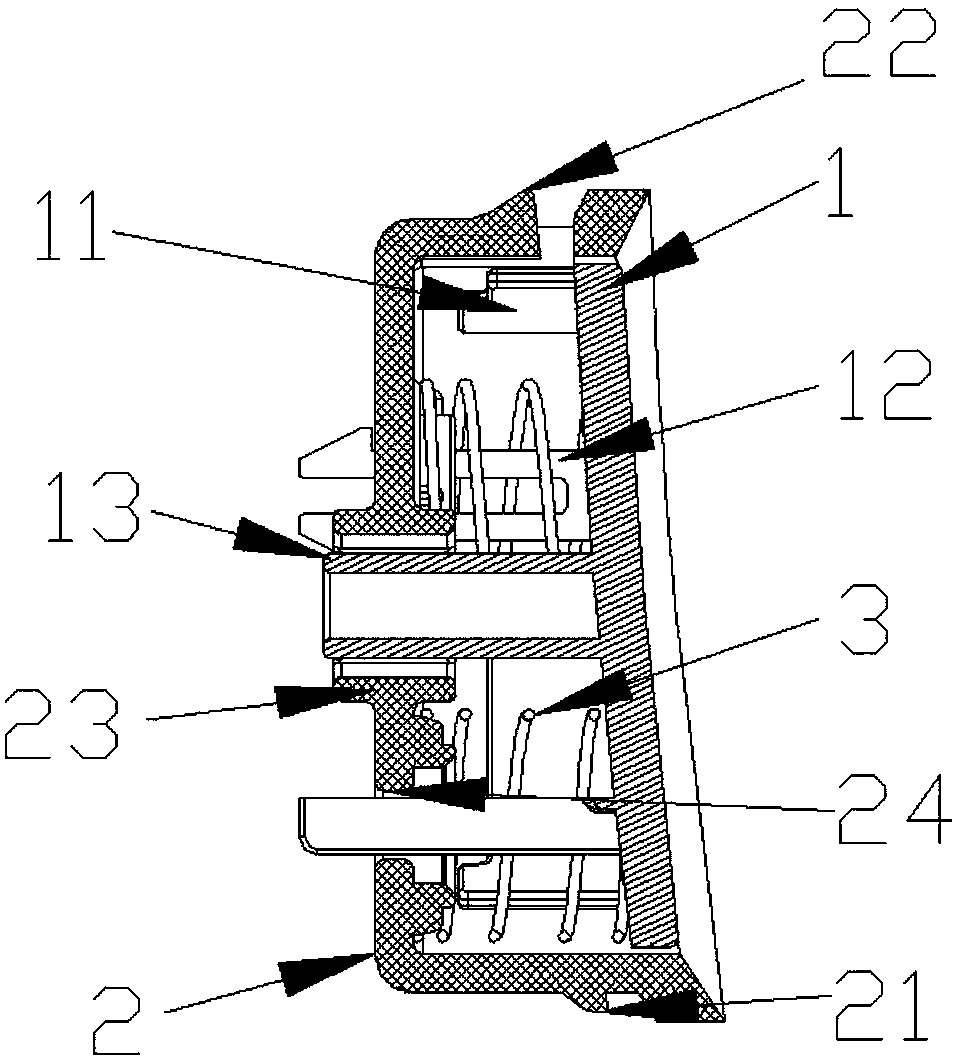

The invention discloses a hydraulic winch which is provided with a clutch at the transmission terminal. The hydraulic winch which is provided with a clutch at the transmission terminal comprises a hydraulic motor, a hydraulic brake, a planetary gear speed reducer, a hydraulic clutch, a winding drum and a hydraulic control loop which controls the work of the winding drum, wherein the hydraulic clutch arranged in the winding drum is arranged at the terminal of a system transmission chain; the planetary gear speed reducer is arranged in the winding drum, and the output end at the right side of the terminal planetary frame at the terminal of the planetary gear speed reducer is a spline shaft which is connected with a multi-plate type friction clutch; the right end of the spline shaft is the piston of a clutch control cylinder, and the planetary frame of the planetary gear speed reducer, the spline shaft of the clutch and the piston is an integrative structure. The invention effectively overcomes the problems that the present hydraulic winch is complex in connecting structure, difficult in processing and assembly, unbalance in the stress of dynamic shaft, easily worn in the connection part where a frame bearing shaft force, low in mechanical efficiency and short in service life, etc.

Owner:INI HYDRAULIC

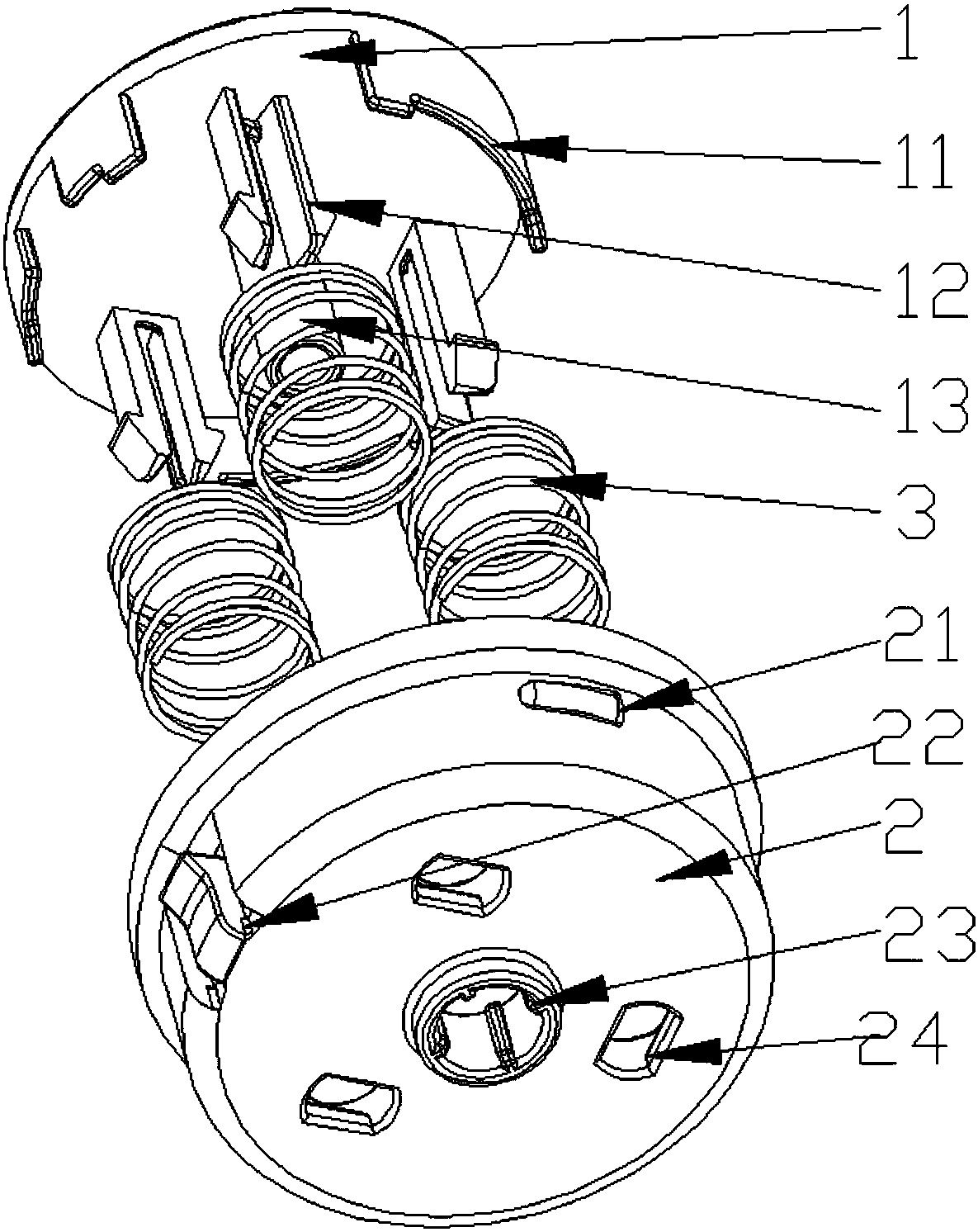

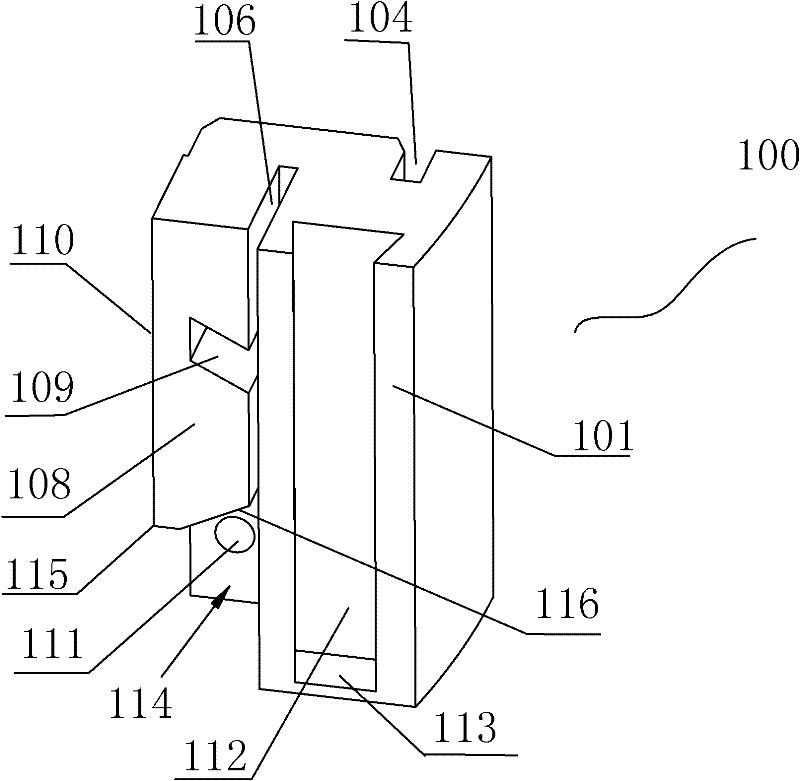

Uncovering button assembly and cookware with the same

The invention relates to a household appliance, in particular to an uncovering button assembly and cookware with the same. According to the uncovering button assembly, a pressing part is provided witha skirt rim in a shape matched with the shape of an opening, and the skirt rim extends from the inner side of the pressing part in the pressing direction, that is, the skirt rim has a guide functionin the pressing process by arranging the skirt rim and making the skirt rim matched with the opening so that the button can be prevented from being titled in the pressing process. The skirt rim is ofa discontinuous structure in the direction around the opening, and there is no skirt rim at the position, corresponding to a moving clamp buckle, of the pressing part. In order to solve the technicalproblem that in the prior art, an uncovering button assembly is prone to clamping stagnation when pressed, the uncovering button assembly not prone to clamping stagnation and the cookware with the same are provided.

Owner:GREE ELECTRIC APPLIANCES INC

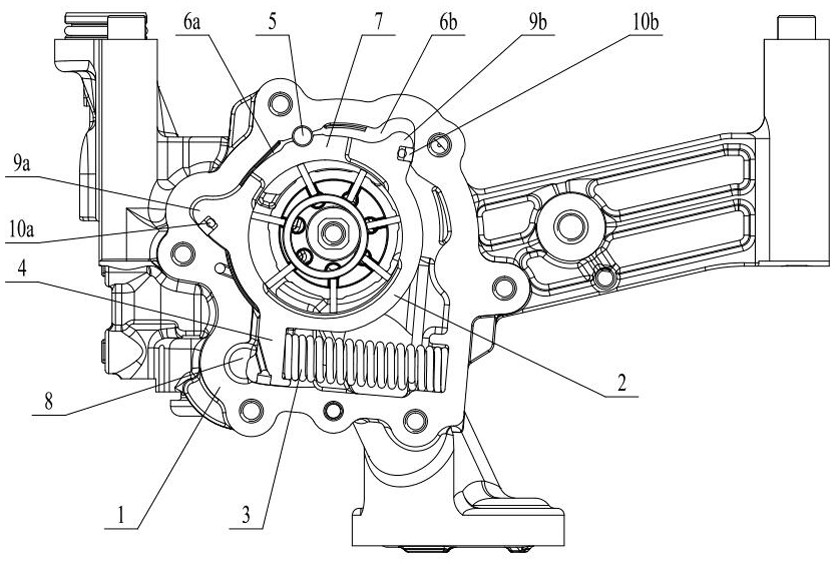

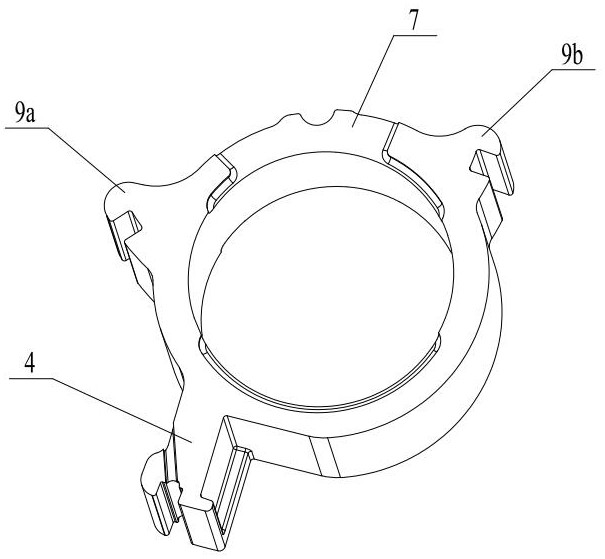

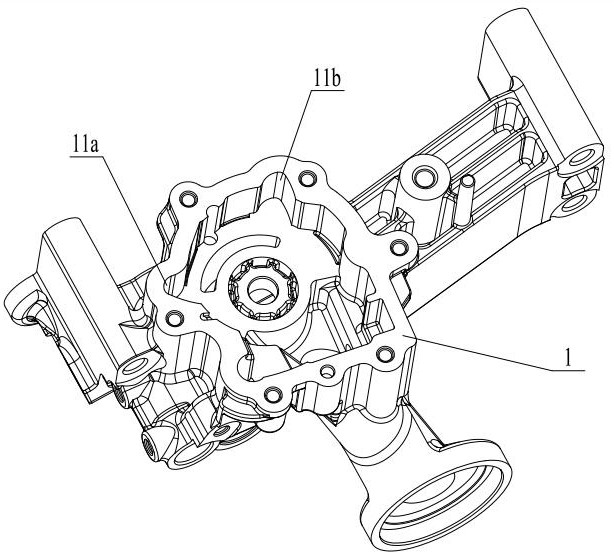

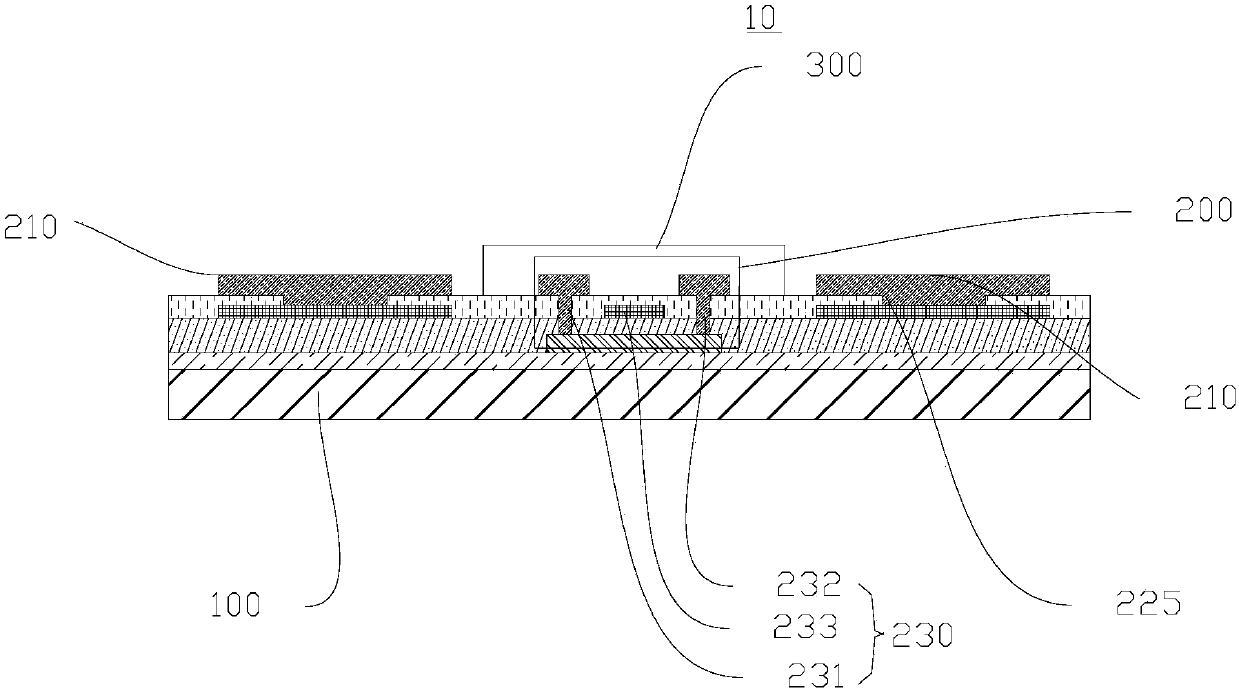

Variable displacement oil pump capable of improving volume efficiency

ActiveCN112013263AAvoid force imbalanceImprove volumetric efficiencyMachines/enginesLubricating pumpsOil canLeft lateral wall

The invention discloses a variable displacement oil pump capable of improving volume efficiency, and relates to the technical field of oil pumps. The variable displacement oil pump comprises a pump body, a pump cover, a sliding block and a spring, wherein the sliding block is fixedly connected with a spring pressing block, the two ends of the spring abut against the inner wall face of the pump body and the right side wall face of the spring pressing block correspondingly, a pin shaft is connected between the sliding block and the inner wall of the pump body, a left oil cavity is formed betweenthe outer wall of the sliding block on the left side of the pin shaft and the inner wall of the pump body, the left side of the left oil cavity is sealed, a right oil cavity is formed between the outer wall of the sliding block on the right side of the pin shaft and the inner wall of the pump body, the right side of the right oil cavity is sealed, an oil drainage groove used for communicating theleft oil cavity and the right oil cavity with a high-pressure area of a rotor cavity is formed in the end face of the sliding block, a feedback cavity is formed between the left side wall face of thespring pressing block and the inner wall of the pump body, and the feedback cavity and the left oil cavity are independent of each other. According to the variable displacement oil pump, high-pressure oil can be prevented from leaking into the feedback cavity through a gap to a great extent.

Owner:HUNAN OIL PUMP

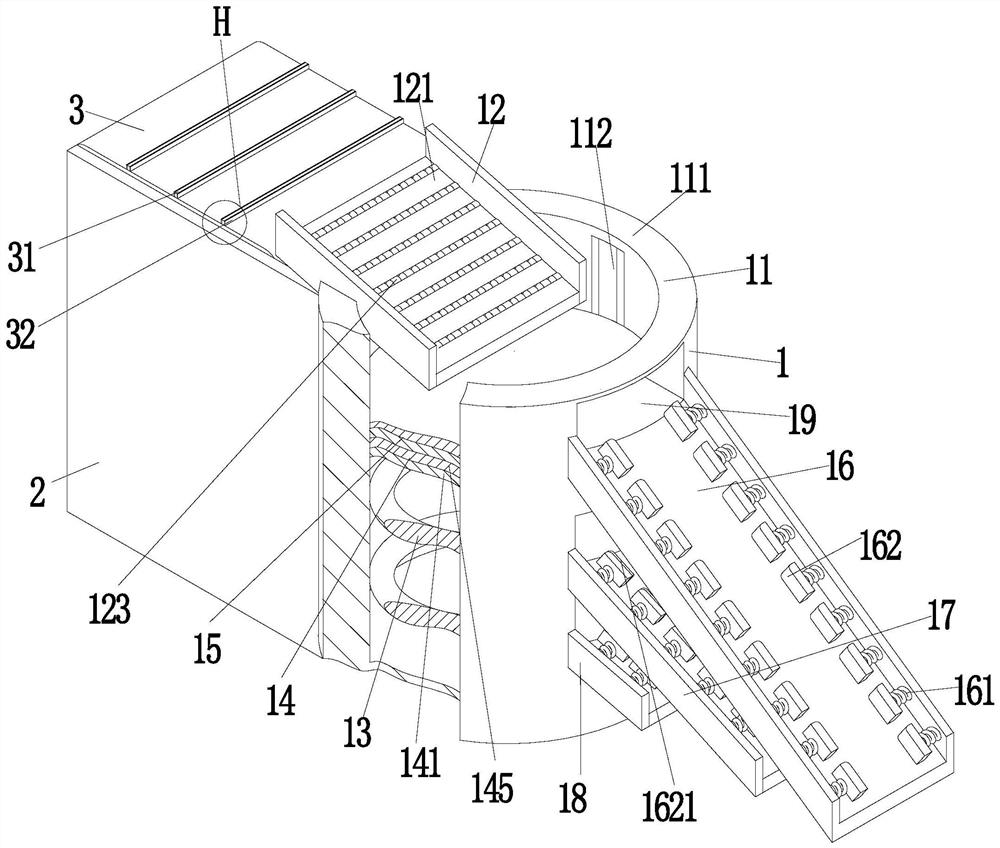

Logistics sorting robot

InactiveCN113351501AImprove efficiencyImprove sorting effectSortingLogistics managementProcess engineering

The invention relates to a logistics sorting robot which comprises a sorting device and a belt conveyor. A supporting table is fixedly installed on the left end face of the sorting device, the belt conveyor is fixedly installed at the upper side of the supporting table, and the sorting device comprises a circular cylinder, a guide plate, a positioning spring, a rotating frame, an inclined plate, a first discharging plate, a second discharging plate and a third discharging plate. By means of the logistics sorting robot, the belt conveyor is used for conveying articles, the sorting device is used for sorting the articles, and no worker is needed in the whole sorting process, so that the article sorting efficiency of the logistics sorting robot is improved; and the sorting device can quickly distinguish the quality standard of the articles according to the quality of the articles, so that the articles are quickly sorted and collected, and the purpose of improving the sorting effect of the logistics sorting robot is achieved.

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

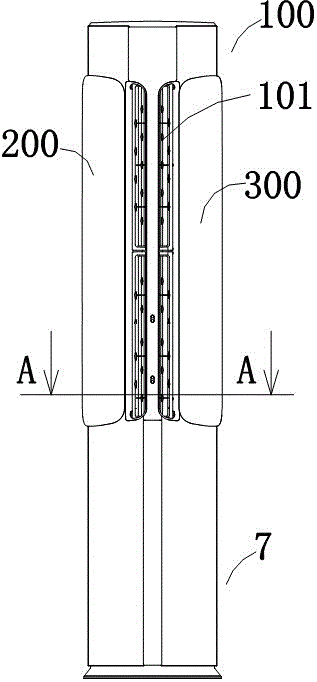

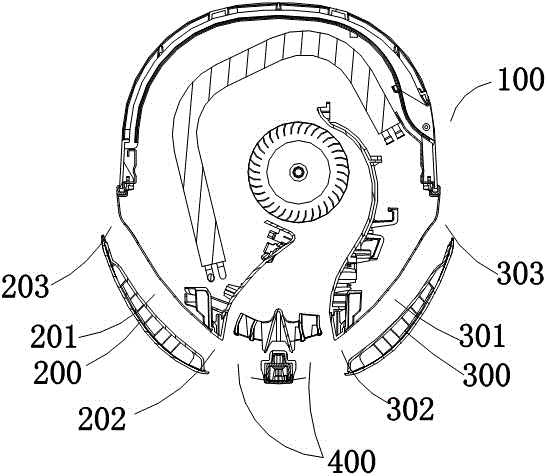

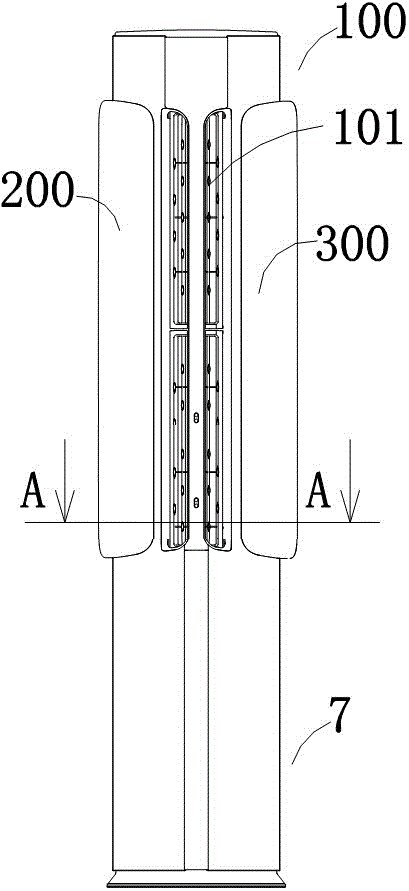

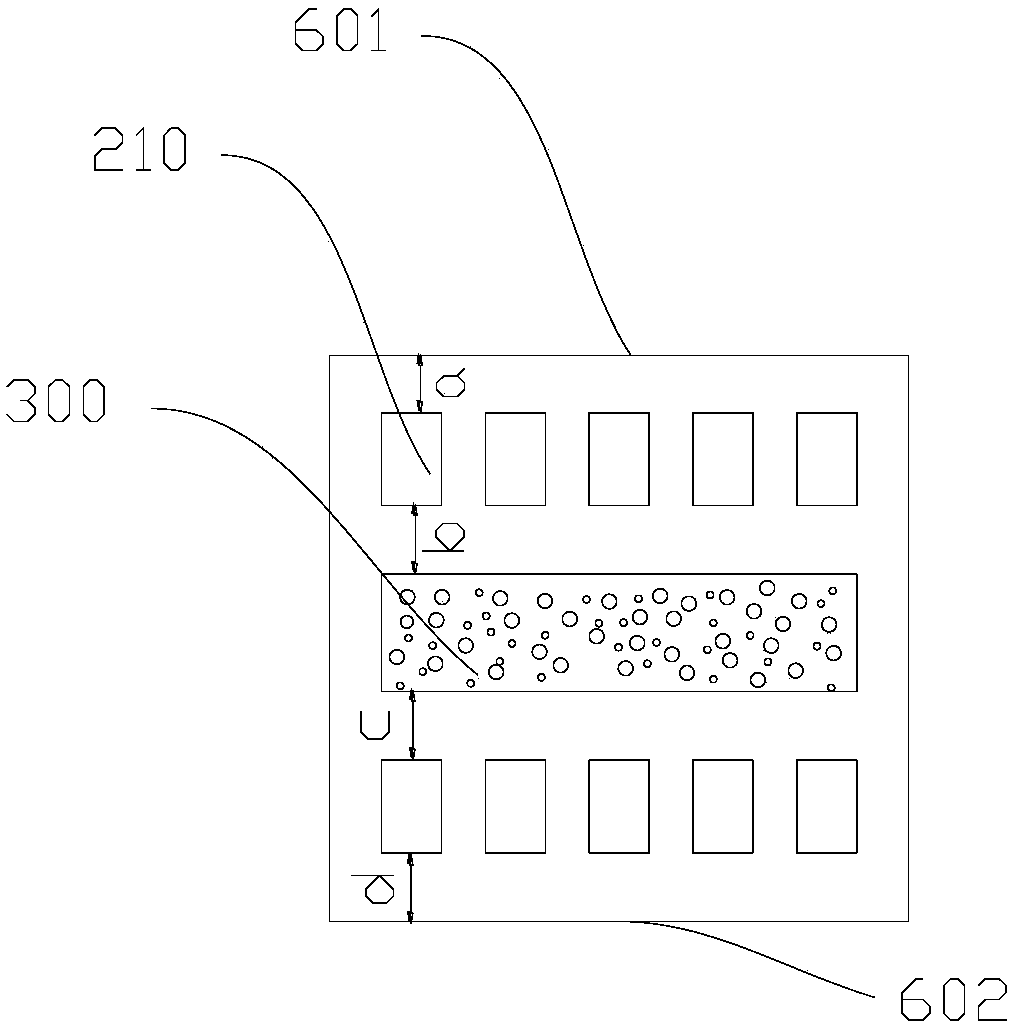

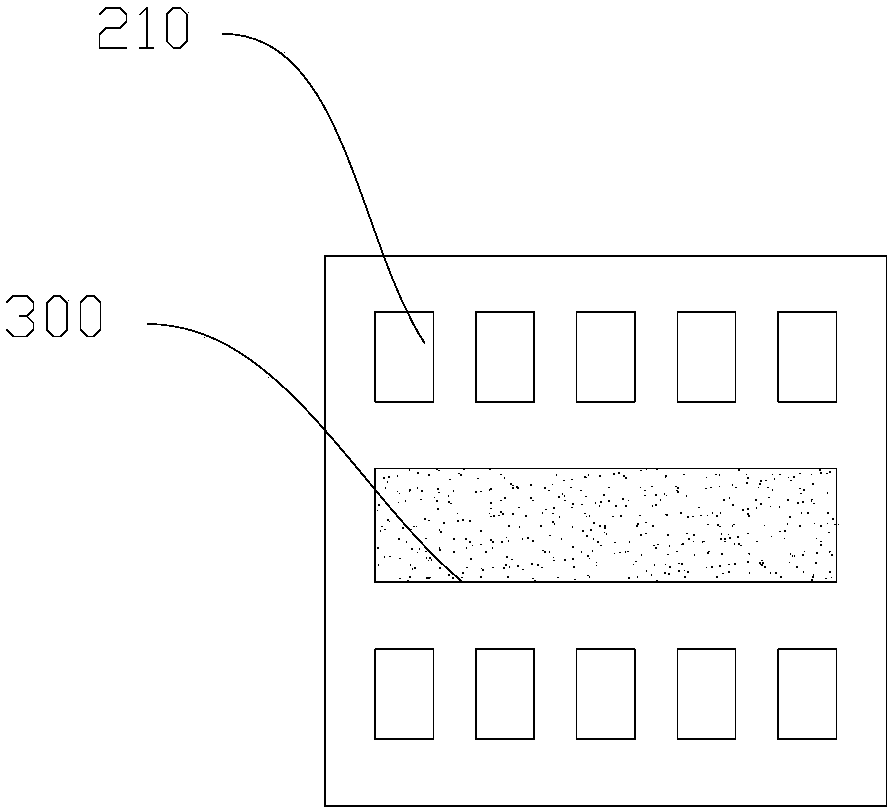

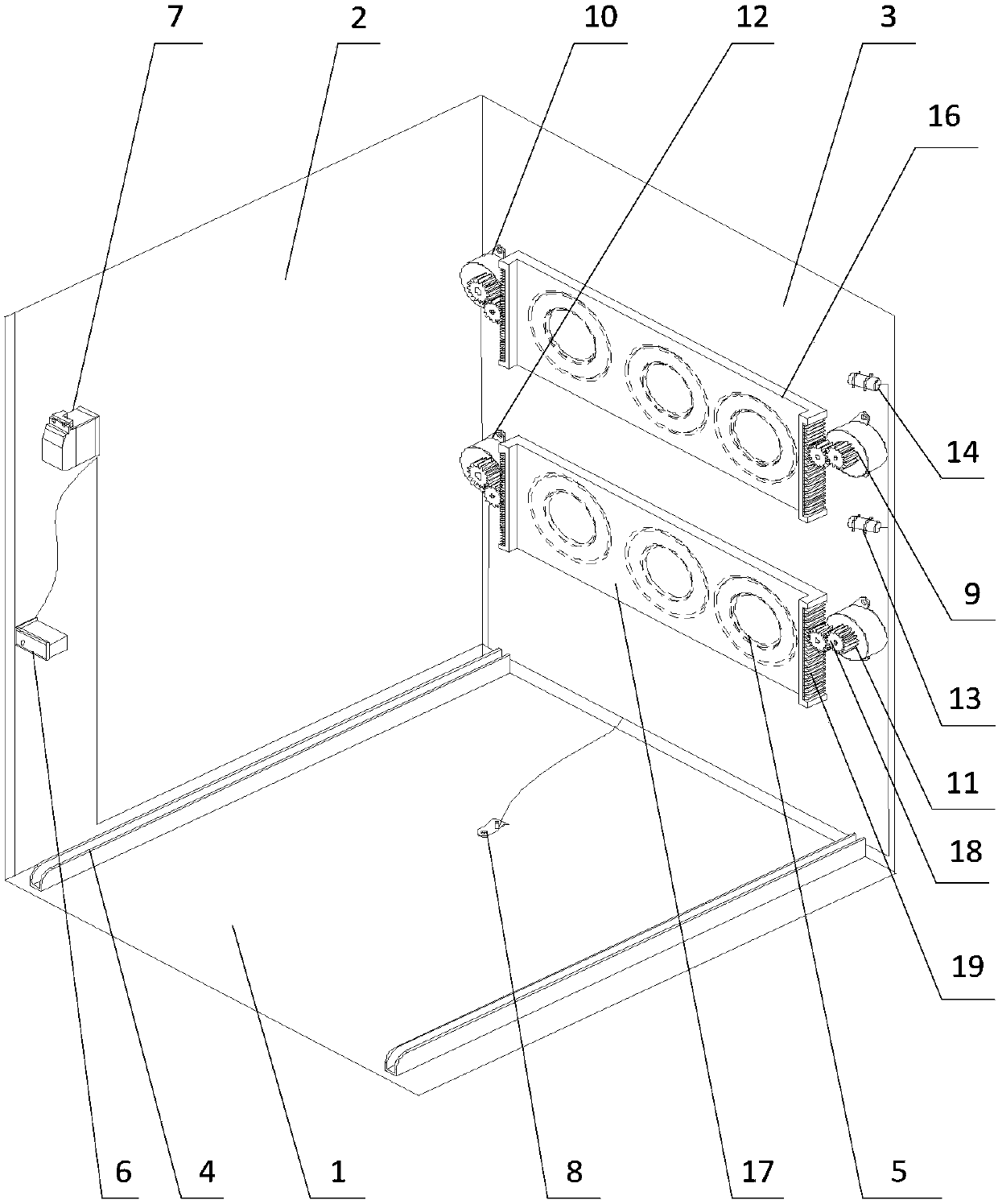

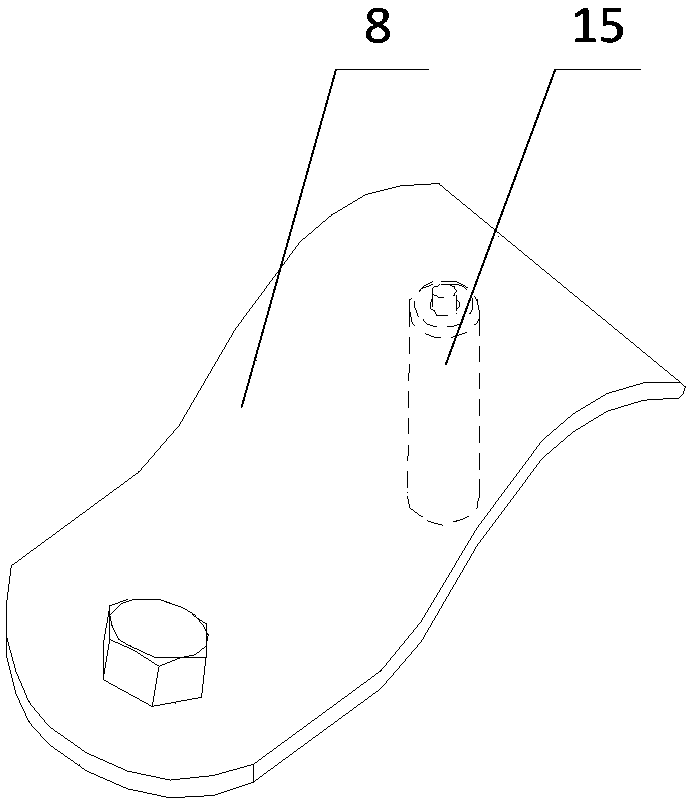

Vertical air conditioner and air deflector sliding guiding and supporting mechanism

ActiveCN106247450ASolve fluencySolve CatonLighting and heating apparatusAir conditioning systemsSliding contactLoad bearing

The invention discloses a vertical air conditioner and an air deflector sliding guiding and supporting mechanism. Air deflectors are slidably mounted on an air conditioner body through sliding mechanisms. The guiding and supporting mechanism is arranged between the corresponding air deflector and the air conditioner body. The guiding and supporting mechanism comprises an inner guide rail located on the air conditioner body and an outer guide rail located on the corresponding air deflector, the inner guide rail is provided with a supporting part for supporting the outer guide rail, and the supporting part makes sliding contact with the outer guide rail. The guiding and supporting mechanism is added between the corresponding air deflector of the vertical air conditioner and the air conditioner body on the basis of the sliding mechanisms. The sliding mechanisms are distributed at the two ends of the air deflectors and only play a role of driving. The guiding and supporting mechanism has the effects of guiding, supporting and load bearing between the air deflectors. Accordingly, the situation that stress unbalance of sliding mechanisms is caused by the action of gravity of air deflectors is avoided, and the phenomena that the air deflectors slide not smoothly, gets sluggish or even gets stuck in the moving process are avoided.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

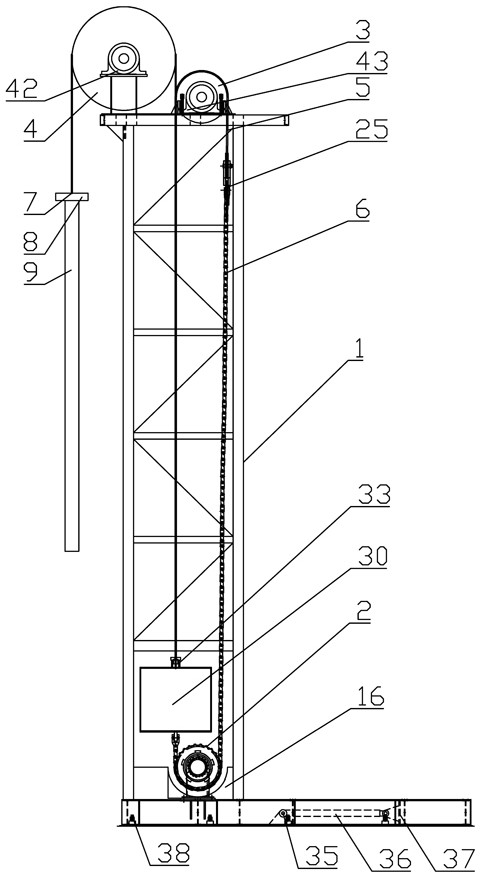

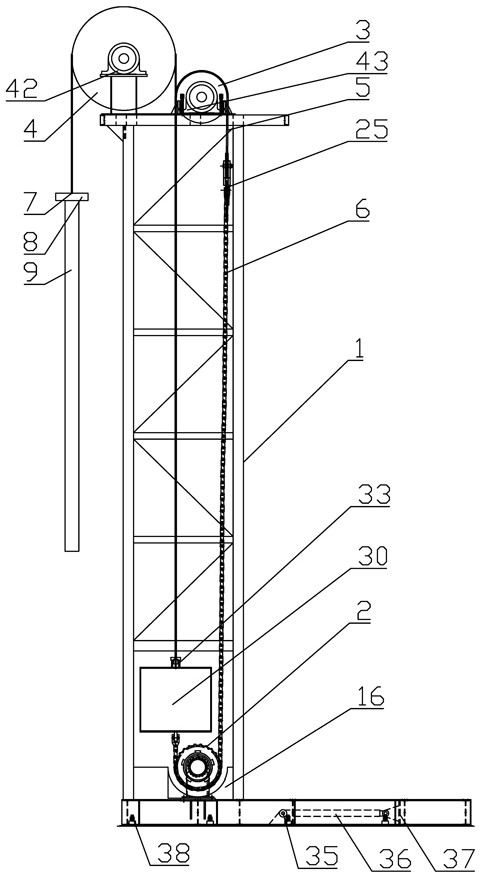

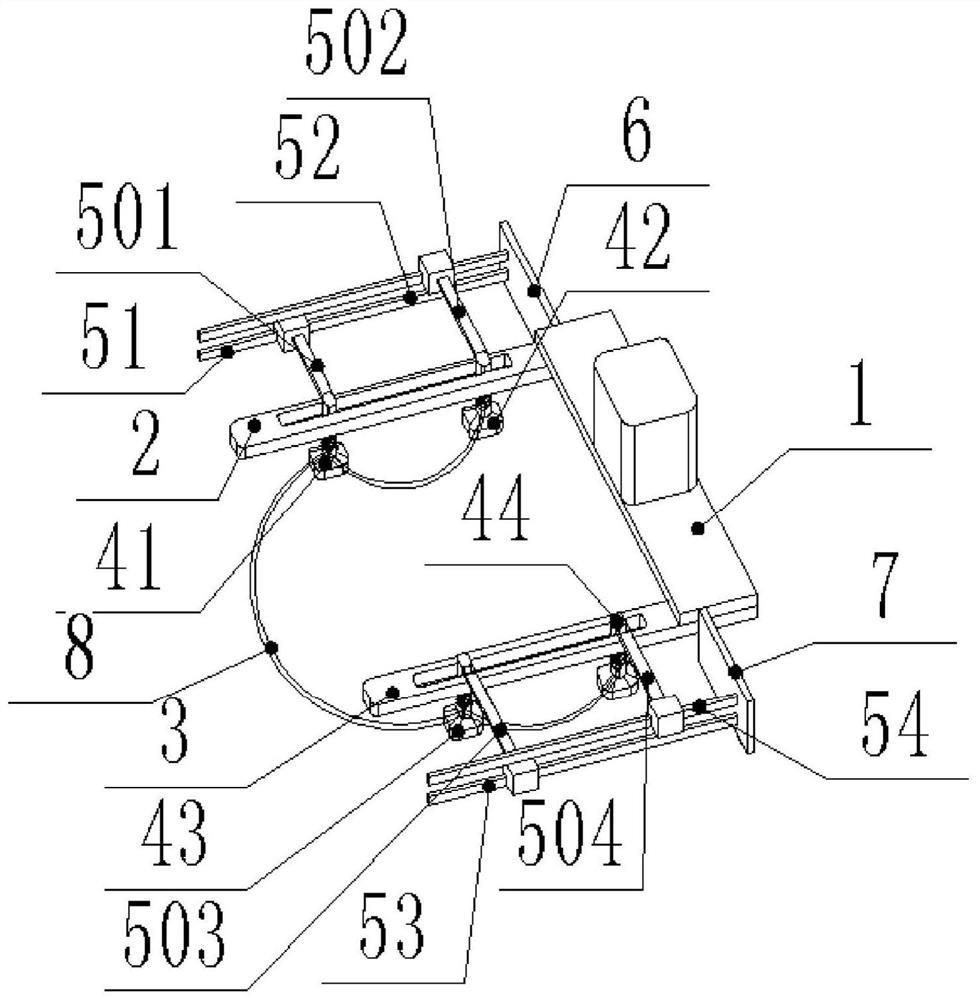

Full-intelligent vertical hydraulic pumping unit and pumping unit control method

ActiveCN111810091ARealize automatic stepless speed regulationAvoid force imbalancePortable framesDrilling rodsHydraulic motorSprocket

The invention relates to the technical field of intelligent control of pumping units, in particular to a full-intelligent vertical hydraulic pumping unit and a pumping unit control method. The full-intelligent vertical hydraulic pumping unit comprises a tower, a chain wheel, a reel, a hoisting sheave, a connecting rope, a connecting chain, a pumping rope, a polished rod eye, a rope slot ring, a first rope chain connecting part, a second rope chain connecting part, an intelligent control module and a driving device, wherein the driving device is arranged at the bottom of the tower, and the chain wheel is fixedly mounted at an output end of the driving device. The pumping unit control method comprises the following steps: the control module controls the rotating direction, the rotating speedand start and stop of a hydraulic motor; and the control module controls the flow of oil in a hydraulic station pumped into the hydraulic motor. The full-intelligent vertical hydraulic pumping unit is reasonable and compact in structure and skillful in concept. By matching the intelligent control module with the driving device, automatic stepless speed regulation, automatic setting of number of strokes and self diagnosis of operation of the pumping unit are achieved. By arranging the detachable and fixable rope slot ring, it is convenient to replace a rope slot which is worn. The full-intelligent vertical hydraulic pumping unit has the characteristics of being stable, efficient and intelligent.

Owner:合立智能装备有限责任公司

Automatic stroke number setting vertical oil pumping unit and automatic stroke number setting control method of oil pumping unit

ActiveCN111810092AEasy to replaceAdjust the tensionPortable framesDrilling rodsHydraulic motorControl engineering

The invention relates to the technical field of oil pumping unit intelligent control, in particular to an automatic stroke number setting vertical oil pumping unit and an automatic stroke setting control method of the oil pumping unit. The automatic stroke setting vertical oil pumping unit comprises a tower frame, a chain wheel, a winch wheel, a crown sheave, a connecting rope, a connecting chain,an oil pumping rope, a rope hanger, a first rope chain connecting piece, a second rope chain connecting piece, an intelligent control module and a driving device, wherein the bottom of the tower frame is provided with the driving device; and the output end of the driving device is fixedly provided with the chain wheel. The automatic stroke number setting control method comprises the steps that the control module controls the rotation direction, the rotation speed and start or stop of a hydraulic motor, and the control module controls the flow, pumped into the hydraulic motor, of a hydraulic station. According to the automatic stroke number setting vertical oil pumping unit and the automatic stroke number setting control method of the oil pumping unit, the structure is reasonable and compact, the conception is ingenious, automatic stroke number setting is achieved through the cooperation of the intelligent control module and the driving device, and the characteristics of stability, high efficiency and intelligence are achieved.

Owner:合立智能装备有限责任公司

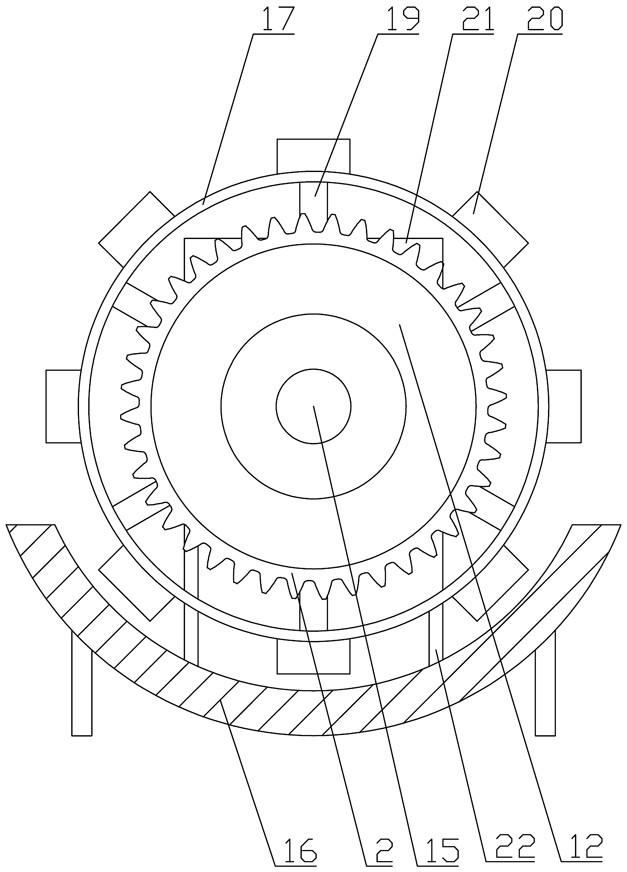

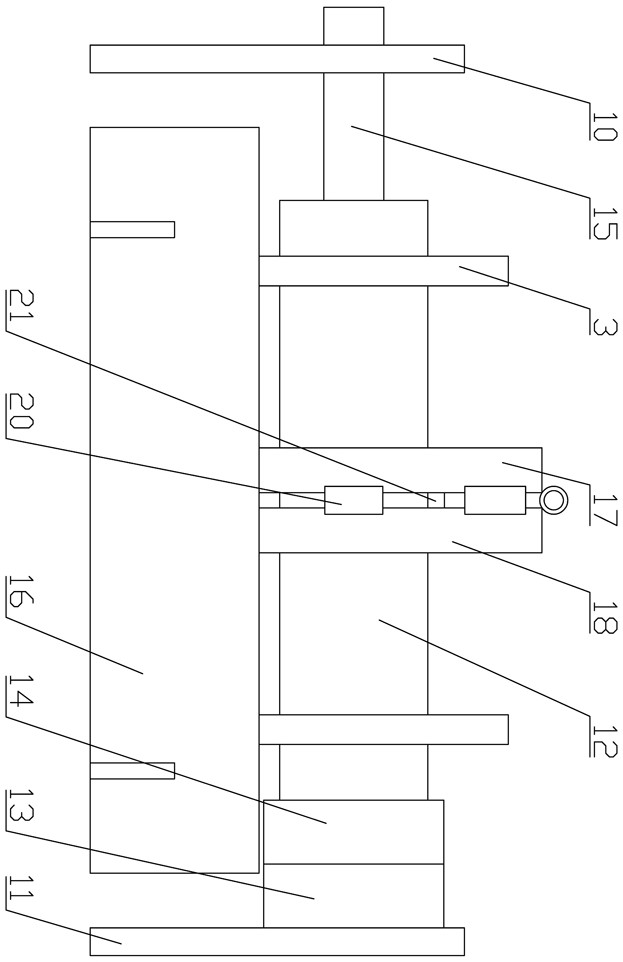

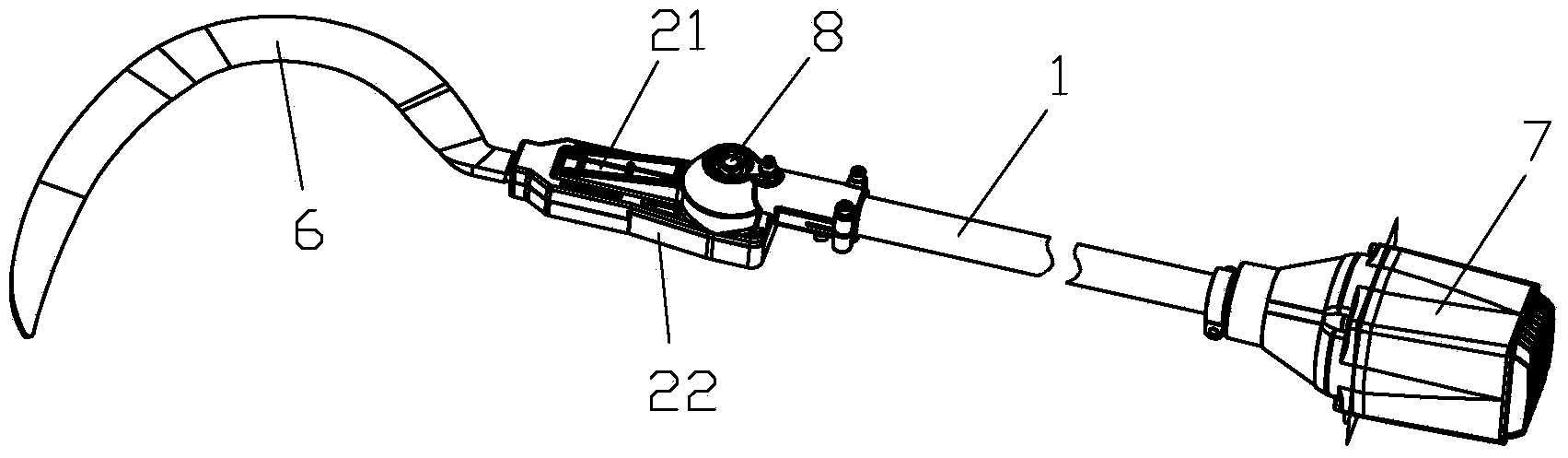

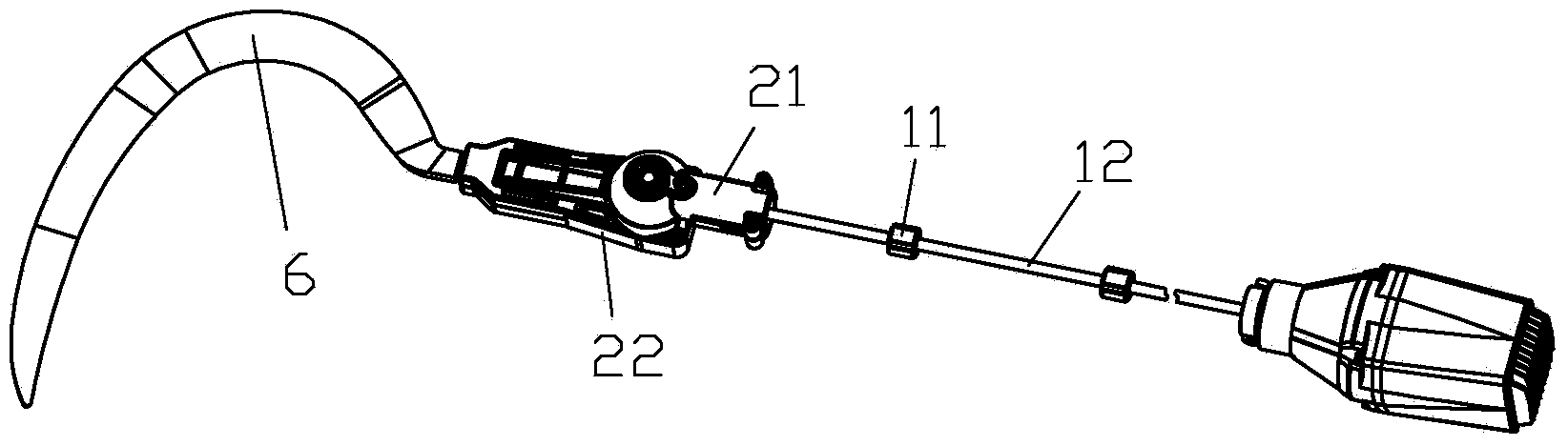

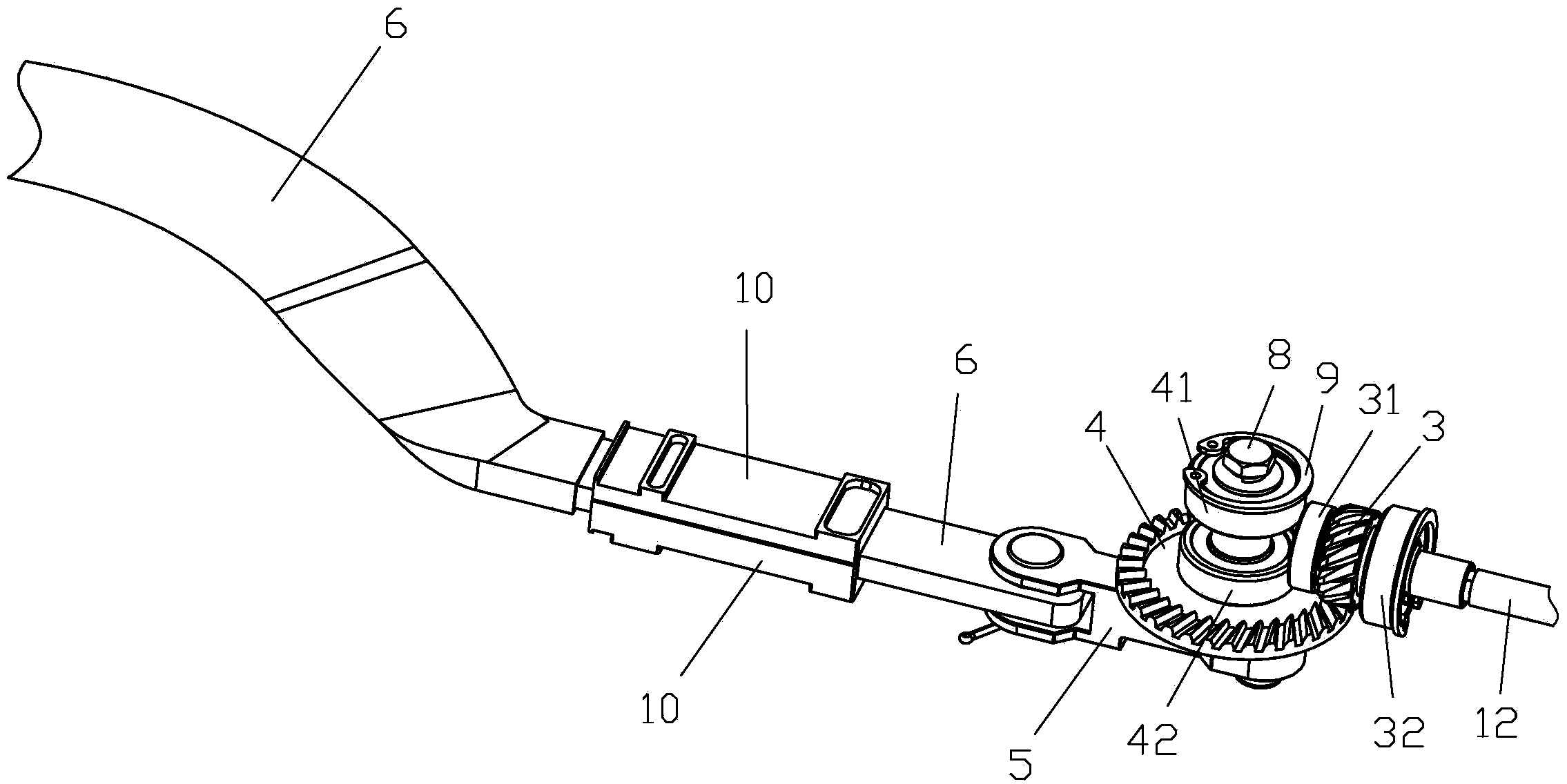

Electric palm picking machine

The invention discloses an electric palm picking machine which comprises a high branch tube and a main shell arranged at the front end of the high branch tube. The main shell is formed by an upper shell and a lower shell, a transverse tube part enabling the high branch tube to be mounted is arranged at the rear end of the upper shell, a driving bevel gear and a driven bevel gear are arranged on the upper shell, the driving bevel gear and the driven bevel gear are meshed with each other, a connecting rod is in eccentric connection with the bottom end of the driven bevel gear, a sickle is hinged to the front end of the connecting rod, the driving bevel gear is driven by a motor, a notch avoiding the driven bevel gear is formed in the transverse tube part, a front end bearing of a rotating shaft of the driving bevel gear is arranged in a hole site which is in front of the notch and corresponds to the transverse tube part, and a rear end bearing of the rotating shaft of the driving gear is located in the transverse tube part. The structure that bearings are arranged on one side of the driving bevel gear in the traditional technology is avoided, the fact that a cantilever end is formed by the driving bevel gear is avoided, the stress imbalance of unilateral stress gears and the bearings is prevented from being formed, and a whole rotating mechanism is made to run more stably.

Owner:JIANGMEN CHAOYANG PRECISION MFG

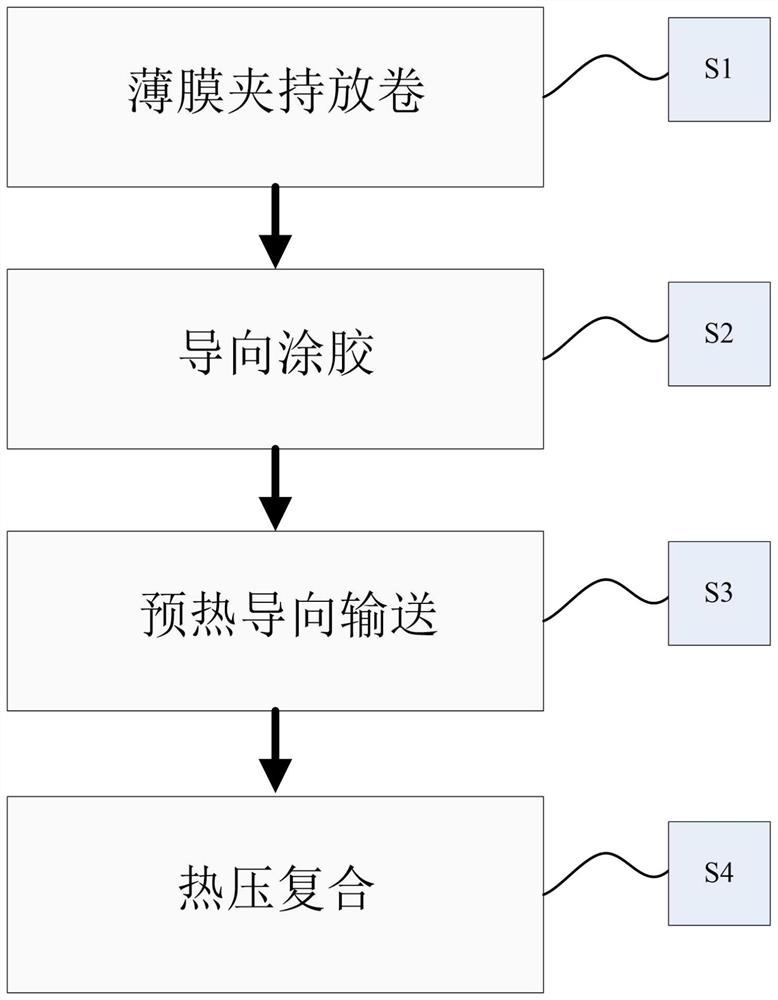

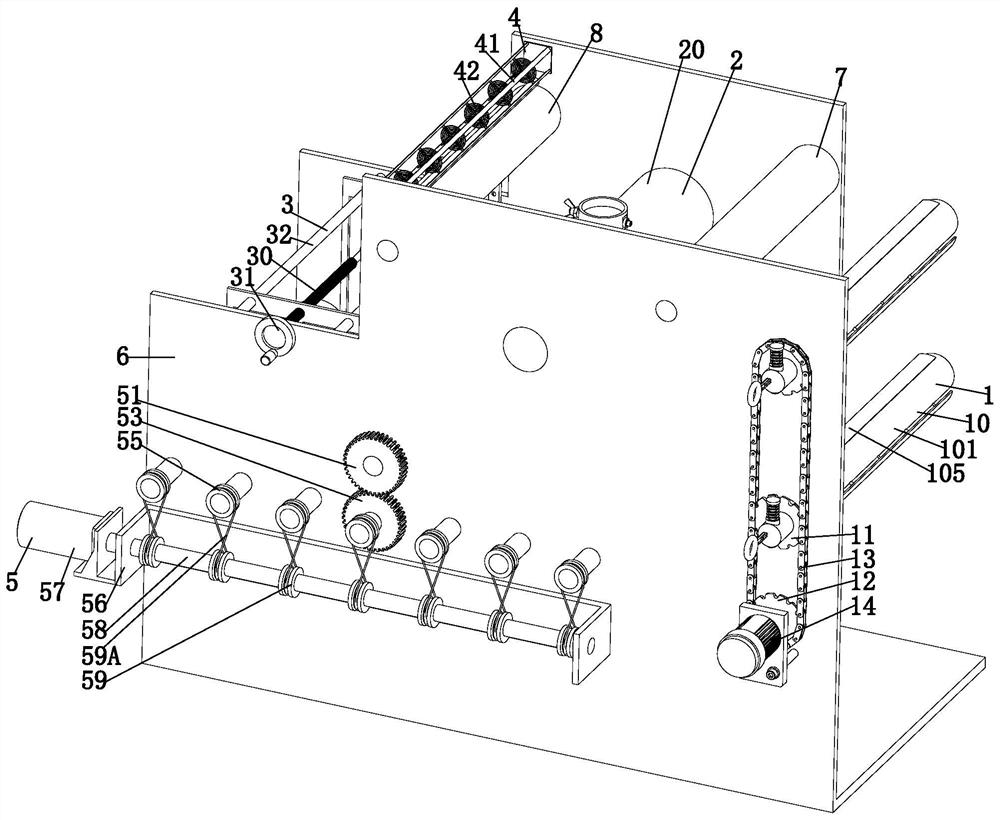

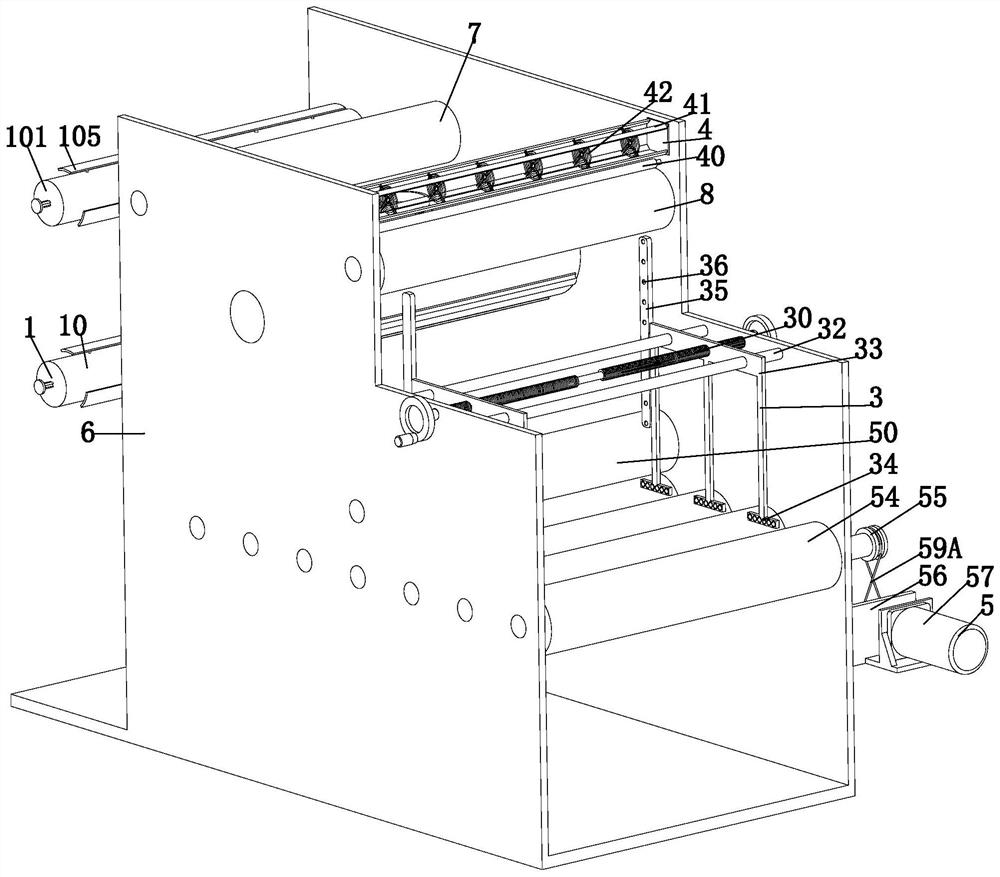

Film coating process for manufacturing packaging container

InactiveCN113500820ATension remains constantPrevent unbalanced transmission forcePaper-makingBox making operationsAdhesiveMechanical engineering

The invention provides a film coating process for manufacturing a packaging container. The film coating process comprises a winding mechanism, a coating mechanism, a guide mechanism, a drying mechanism, a conveying mechanism, a main beam plate frame, a guide roller I and a guide roller II. The film coating process solves the problems that clamping and fixing of an unwinding winding drum and a winding drum have limitation at present, and winding drums with different types and sizes cannot be clamped, so that the manufacturing of the film coating process is relatively single, and production and processing of film coating processes with different sizes cannot be realized; in the winding and unwinding processes, the execution actions cannot be synchronized, the tension in the film coating process is influenced to be constant, the film transmission stress is unbalanced, and the film is wrinkled or torn; no guide motion track exists for the transmission of paper printed matters and films, the deviation condition is easily caused after the films and the paper printed matters are compounded, and the film coating quality is influenced; and the coating of an adhesive on the surfaces of the films cannot be uniformly controlled, the coating flow speed of the adhesive cannot be controlled, and the film coating process is influenced.

Owner:武汉众诚科技有限公司

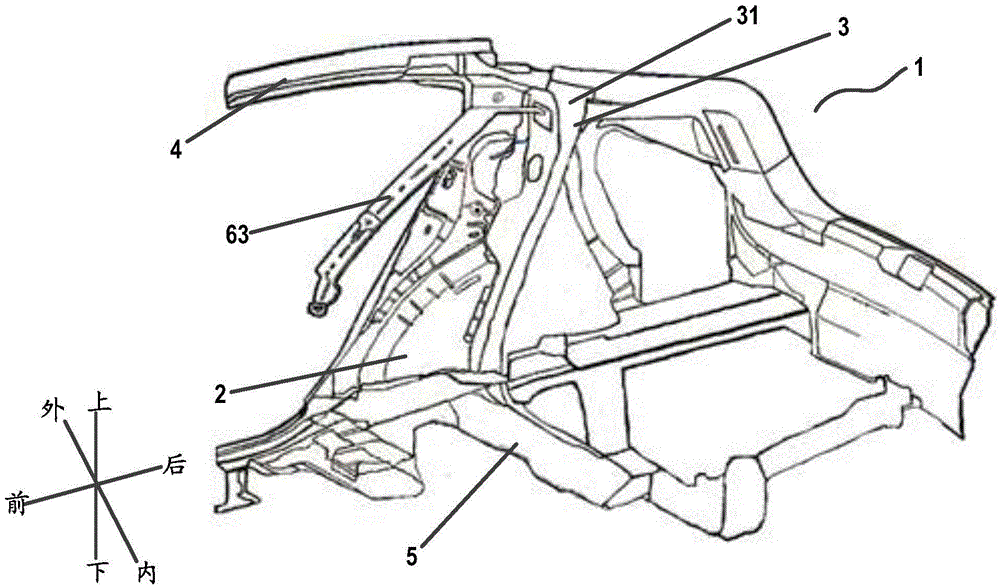

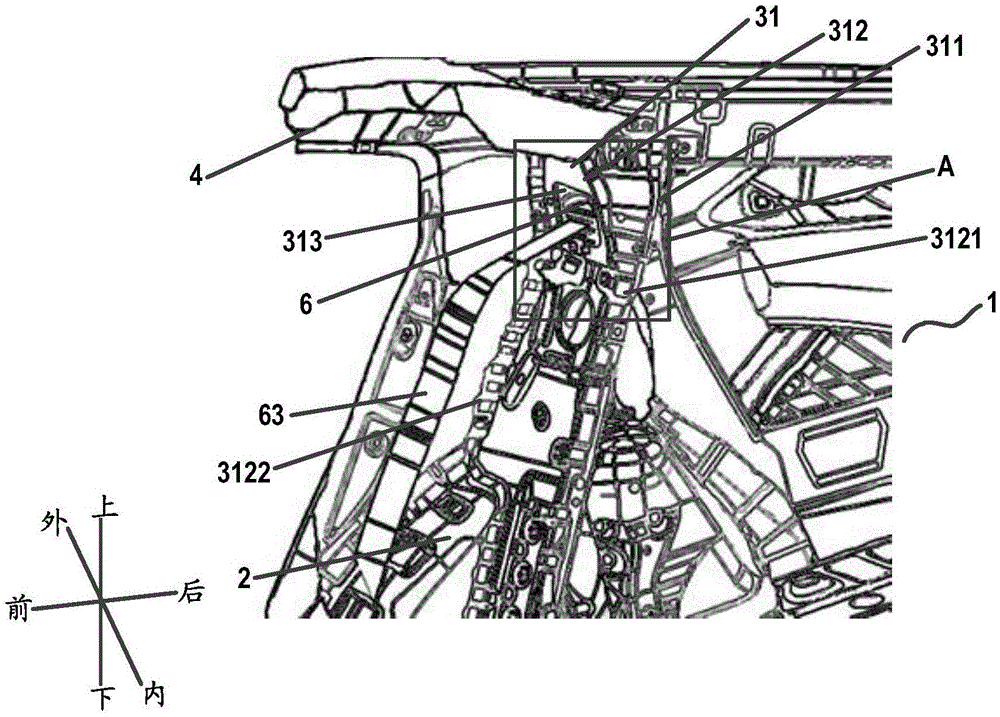

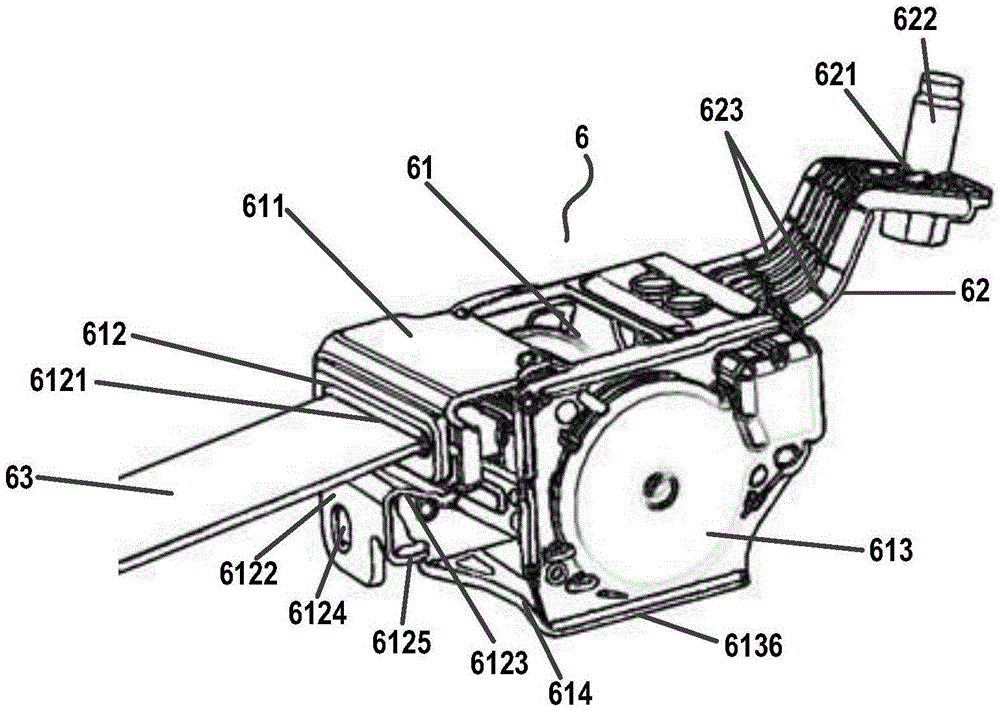

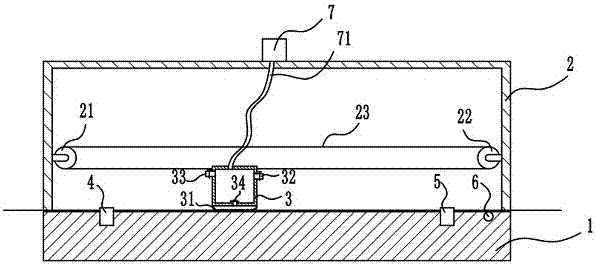

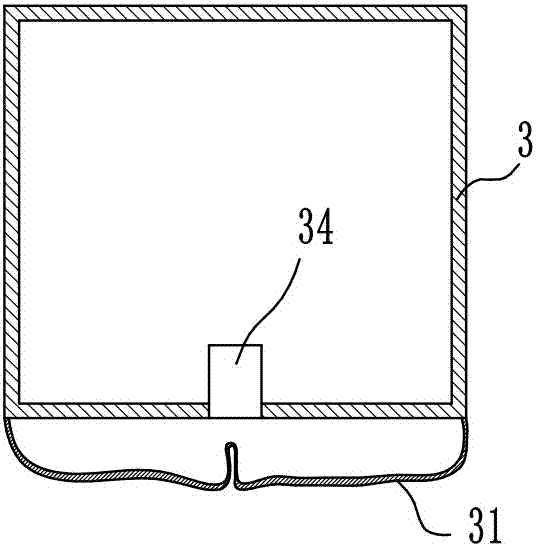

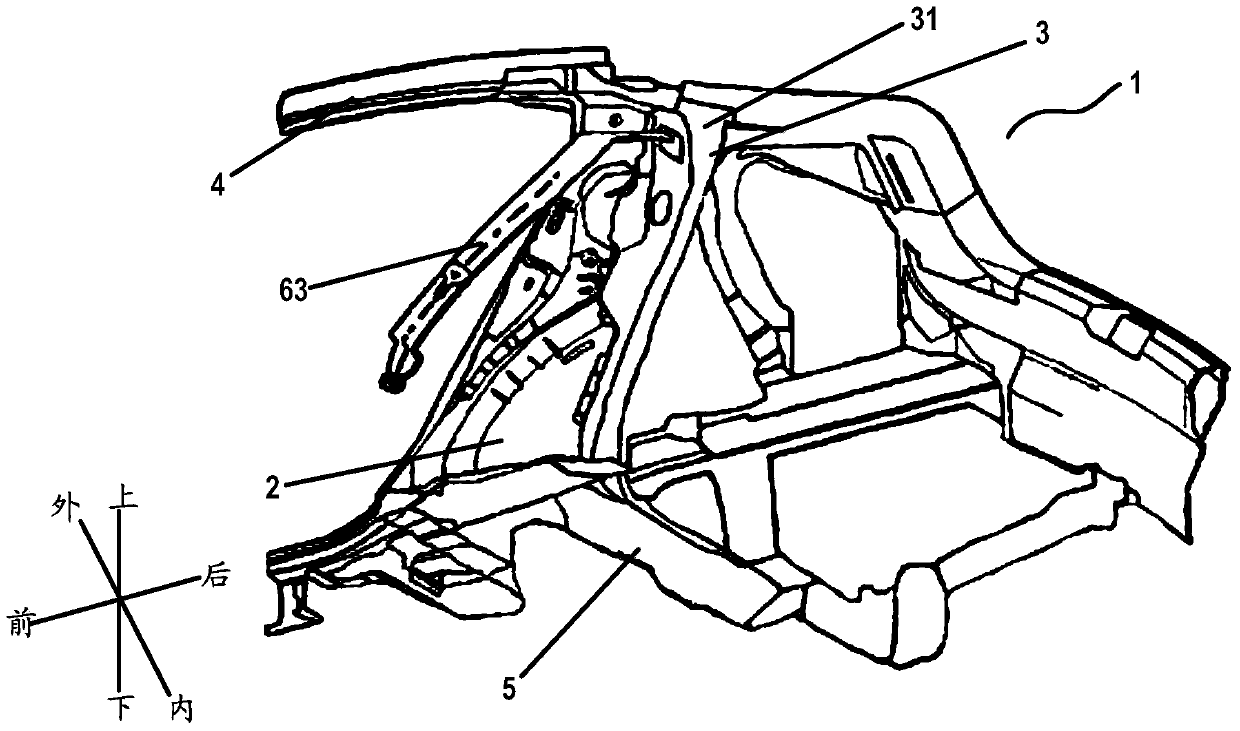

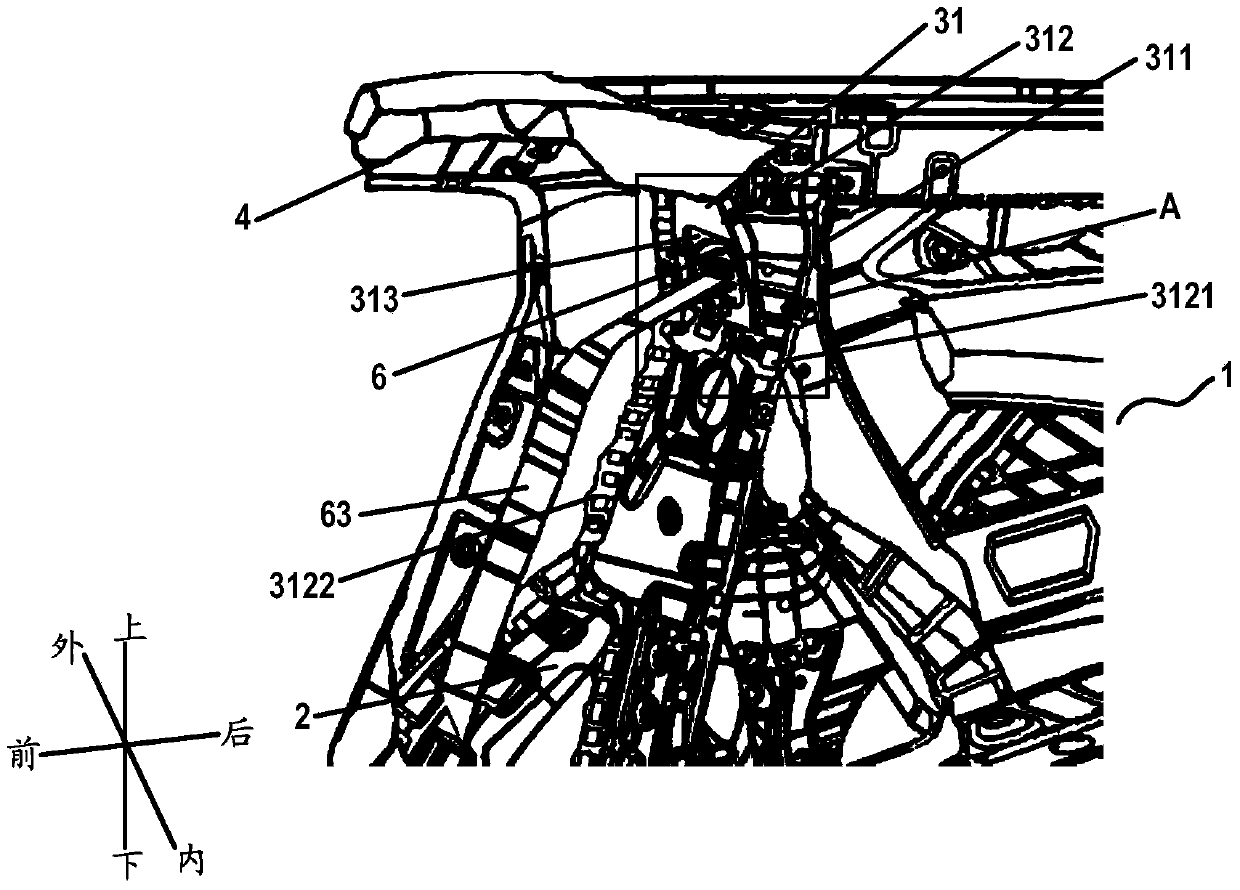

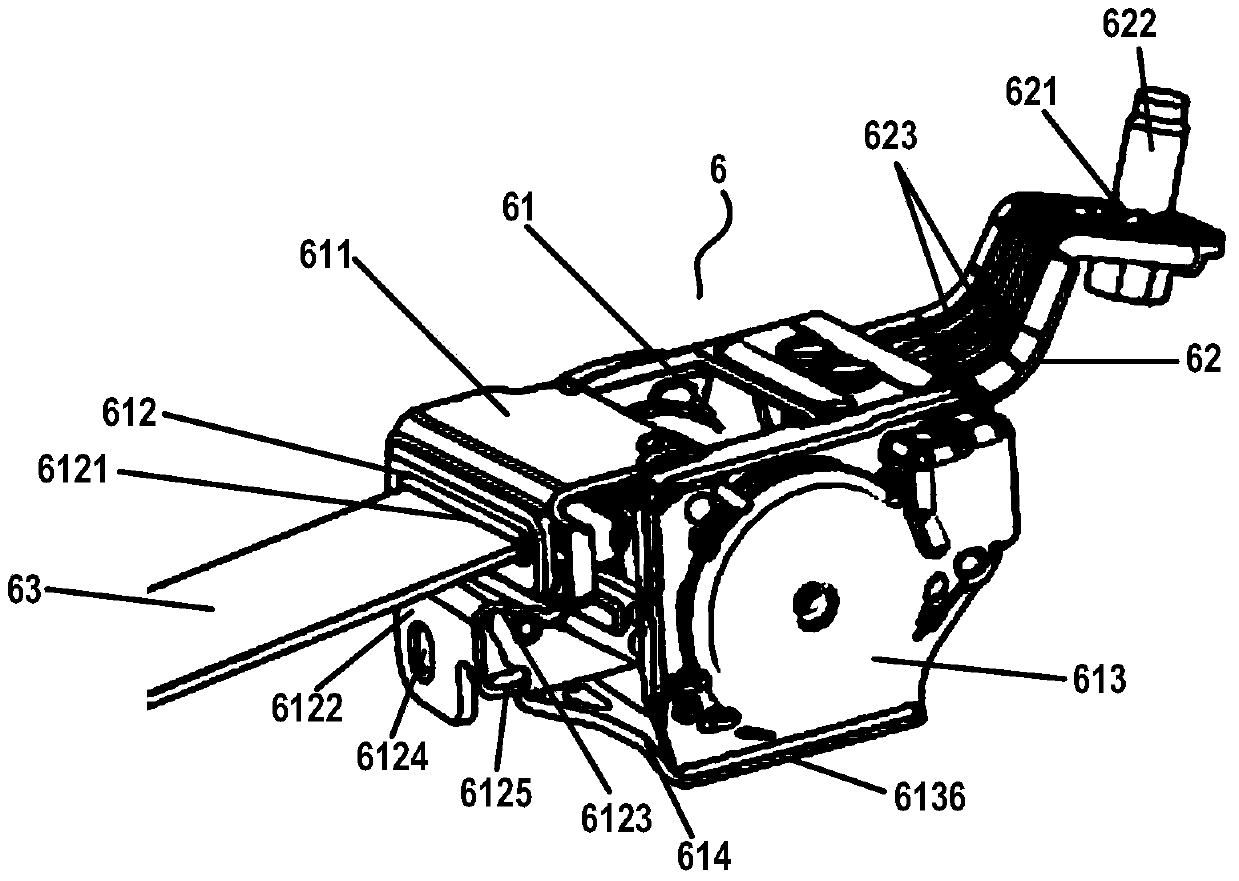

Safetybelt retractor installing structure

ActiveCN106882146AHigh strengthImprove installation strengthBelt retractorsBelt anchoring devicesShock absorberEngineering

The invention provides a safety belt retractor installing structure (3). A safety belt retractor (6) is arranged on the rear portion of a front surface opening part (313) of a hollow reinforcing structure (31) used for a shock absorber and arranged in the longitudinal direction, and a fixing piece (6122) of the safety belt retractor (6) extends forwards to outer side of the front surface opening part (313) of the reinforcing structure (31) and then is bent downwards to be fixed to the lower side of the front surface opening part (313). On the basis of the condition that the stretching direction of a safety belt is obliquely frontward and downward, the simple structure provides forward and downward supporting force for the retractor, it can be avoided that an additional guide structure and / or reinforcing component of the safety belt retractor occupies additional space in a vehicle, and as the reinforcing structure is a component existing already and additionally arranged for reinforcing the shock absorber and is a portion which is high in strength in the bodywork structure, good installation strength can be ensured.

Owner:HONDA MOTOR CHINA INVESTMENT CO LTD

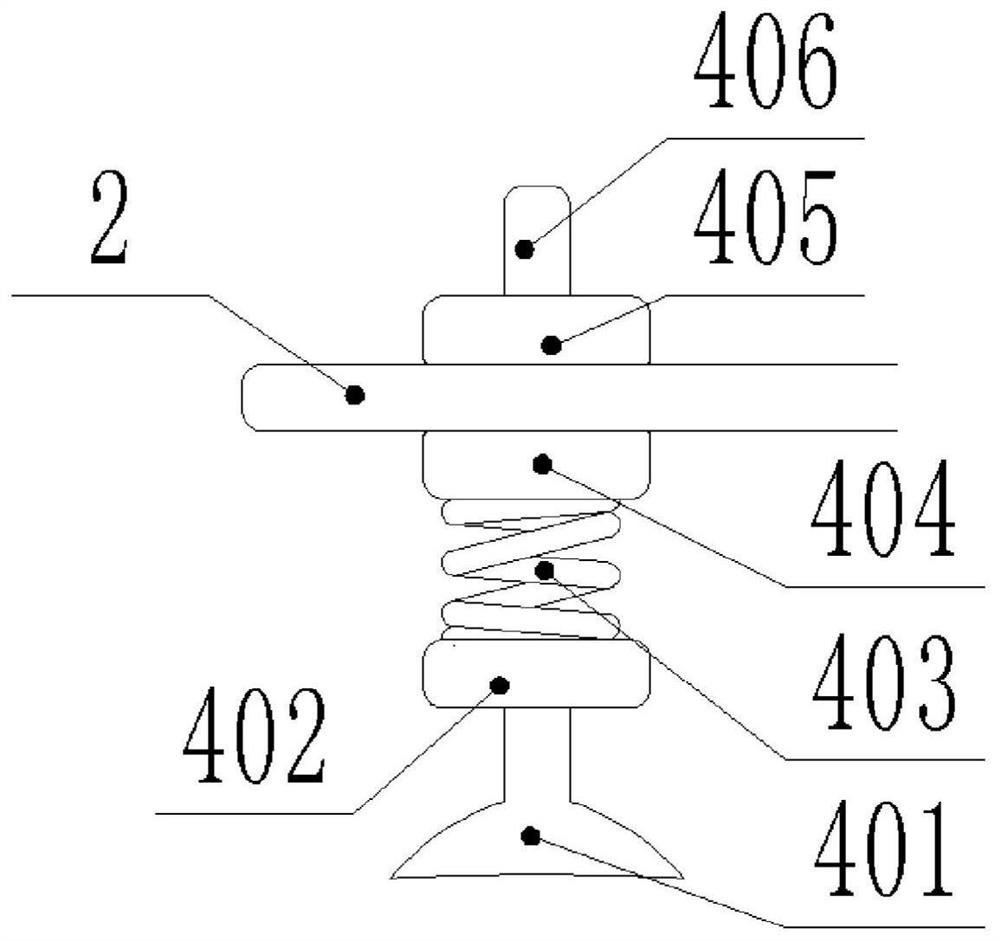

Special machining tool base for special type steel cylinder opening and machining method

PendingCN108747230AImprove stabilityAvoid force imbalanceOther manufacturing equipments/toolsEngineeringSlide plate

The invention discloses a special machining tool base for a special type steel cylinder opening. The special machining tool base comprises a medium sliding plate, a small sliding plate, a square toolrest, a first servo motor and a second servo motor. The square tool rest is in a square shape, and four tool positions are arranged at the four corners. An additional tool base is further arranged onthe medium sliding plate, located at the transverse position of the square tool rest, and provided with one tool position. The four tool positions of the square tool rest sequentially include the first tool position, the second tool position, the fourth tool position and the fifth tool position, and the additional tool base is provided with the third tool position. A turning tool is installed at the first tool position, a turning tool is installed at the second tool position, a drilling tool is installed at the third tool position, a boring tool is installed at the fourth tool position, and aturning tool is installed at the fifth tool position. The tool base is specially used for machining a cylinder opening of a transverse handle type medium-small-volume steel cylinder, one device is provided with the five tools at the same time, and the steel cylinder machining requirement can be met through one-time workpiece clamping. The invention further discloses a method adopting the above special tool base to machine the special type steel cylinder opening.

Owner:SHANDONG CONSTR HIGH PRESSURE CONTAINER

Plastic injection mold ejector pin reset mechanism

Owner:公元管道(重庆)有限公司

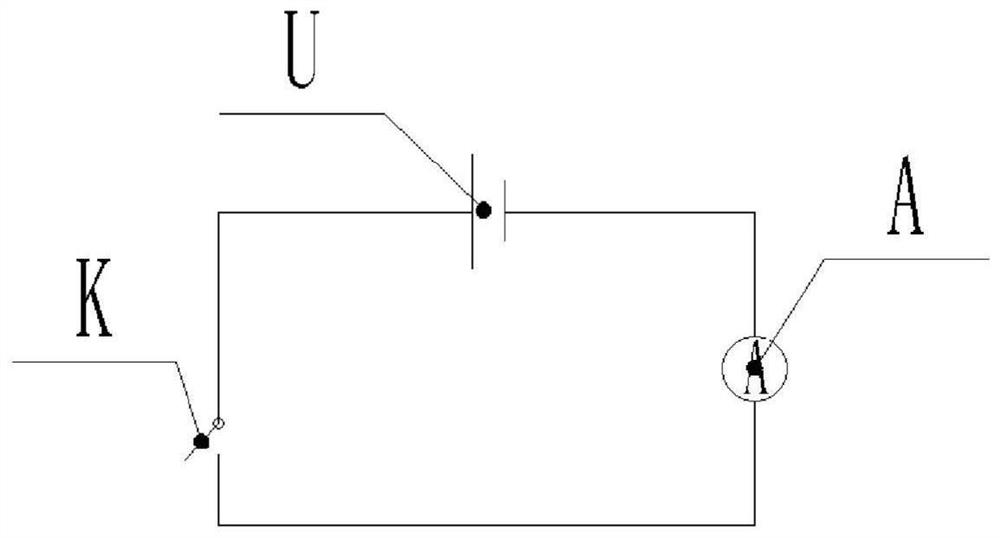

Label strengthening device for mutual inductor

PendingCN106809459AAchieve secondary fixationGuaranteed firmnessLabelling machinesStructural engineeringInductor

The invention relates to a label strengthening device for a mutual inductor. The label strengthening device is used for strengthening a label bonded to the mutual inductor. The label strengthening device comprises a sliding frame and a strengthening module arranged on the sliding frame. The sliding frame is erected on an assembly line for producing the mutual inductor. The strengthening module comprises a fixing plate, an air cylinder and a movable strengthening assembly. The fixing plate is fixed to the sliding frame. The air cylinder is erected on the fixing plate and connected with the movable strengthening assembly and drives the movable strengthening assembly to move in the direction perpendicular to the label installing plane. Compared with the prior art, the label strengthening device has the beneficial effects of being good in strengthening effect, convenient to achieve, capable of saving cost and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Vertical oil pumping unit capable of achieving automatic stepless speed regulation and automatic stepless speed regulation control method of oil pumping unit

ActiveCN111810089ARealize automatic stepless speed regulationEasy to replacePortable framesDrilling rodsSmart controlSprocket

The invention relates to the technical field of intelligent control of oil pumping units and provides a vertical oil pumping unit capable of achieving automatic stepless speed regulation and an automatic stepless speed regulation control method of the oil pumping unit. The vertical oil pumping unit comprises a tower frame, a chain wheel, a reel, a head sheave, connection ropes, connection chains,oil pumping ropes, rope hangers, a first rope-chain connecting part, a second rope-chain connecting part, an intelligent control module and a driving device, wherein the driving device is arranged atthe bottom of the tower frame; the chain wheel is fixedly mounted at the output end of the driving device. The automatic stepless speed regulation control method of the oil pumping unit comprises thefollowing steps: controlling a rotating direction and a rotating speed of a hydraulic motor through a control module, starting and stopping; and controlling flow pumped into the hydraulic motor by a hydraulic pressure station through the control module. The vertical oil pumping unit is reasonable and compact in structure and ingenious in design; through cooperation between the intelligent controlmodule and the driving device, automatic stepless speed regulation of the oil pumping unit is achieved; and the vertical oil pumping unit has the characteristics of stability, high efficiency and intellectualization.

Owner:合立智能装备有限责任公司

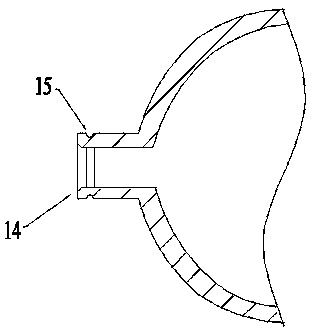

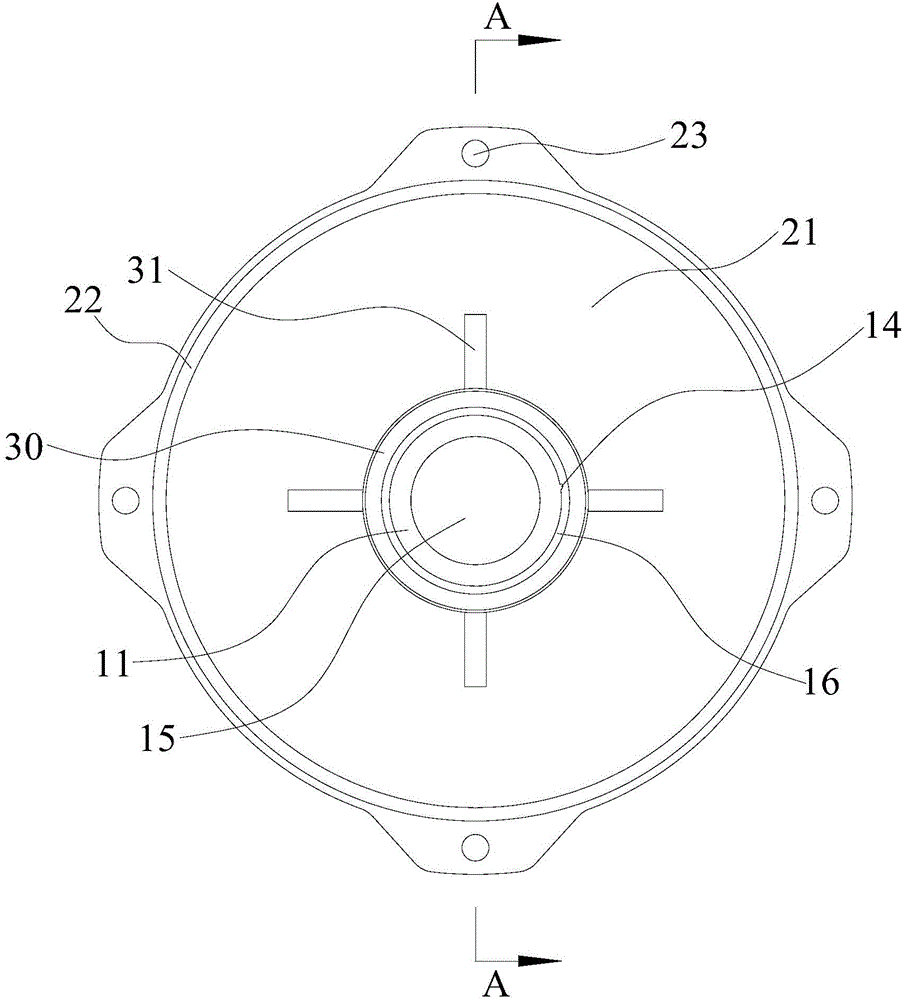

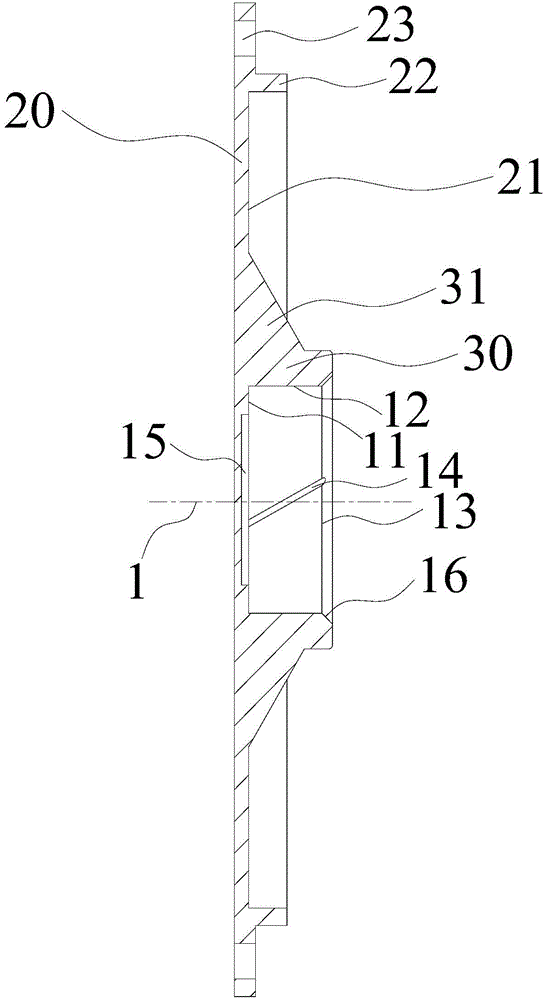

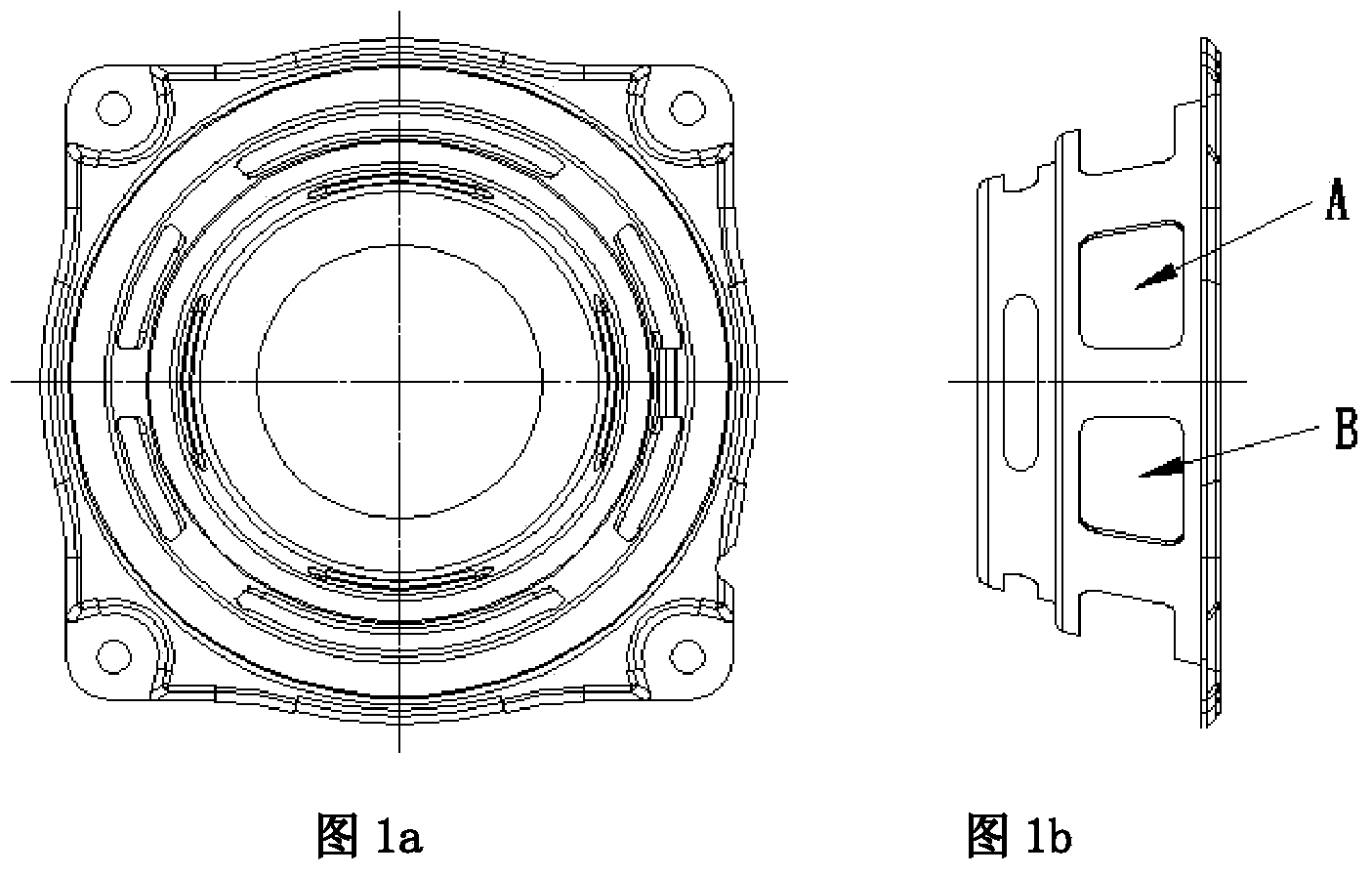

Bearing end cover and bearing seat provided with same

The invention provides a bearing end cover and a bearing seat provided with the same. The bearing end cover comprises a bearing installation blind hole provided with a hole bottom (11) and a hole wall (12), wherein the hole wall (12) forms a bearing inlet end (13); an exhaust groove (14) is arranged in the hole wall (12); the exhaust groove (14) extends in a direction from the hole bottom (11) to the bearing inlet end (13); and the exhaust groove (14) is provided with a deflection section deflecting from an extension line (1), wherein the extension line (1) is any extension line parallel to the axis of the bearing installation blind hole, on the hole wall (12). According to the technical scheme of the invention, shortening of the service life of a motor used for driving a bearing to rotate can be avoided on the basis of facilitating installation of the bearing.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

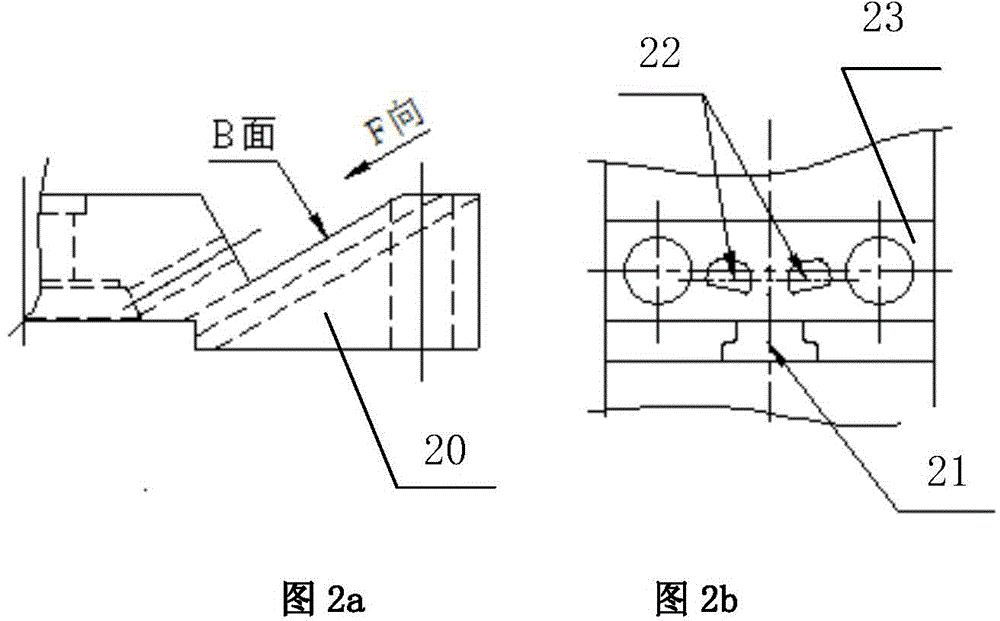

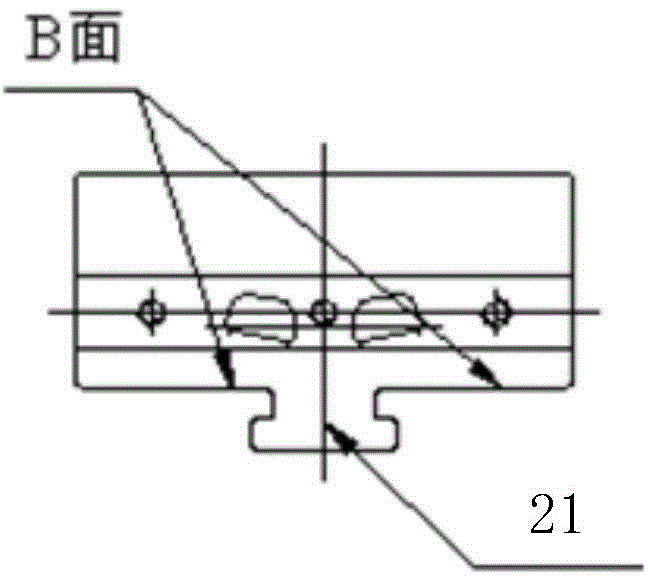

Die chute structure for oblique blanking

The invention relates to the technical field of dies and discloses a die chute structure for oblique blanking. The die chute structure is mounted between an upper die and a lower die of a die. The upper die is provided with male dies while the lower die is provided with female dies. The chute structure comprises rail plates and sliders; the rail plates are of oblique sliding surfaces provided with guide grooves; the sliders are provided with guide blocks matched with the guide grooves and further provided with male die via holes matched with the male dies. Elastic resetting devices are arranged on the sliders and used for resetting the sliders to the original positions after blanking of the male dies. Both the guide grooves and the guide blocks are of square structures. Due to the guide grooves and the guide blocks which are of the square structures, defects of unbalance stressing and shortening of die service life caused by friction force of T-shaped grooves are overcome. The die with the chute structure has the advantages of processing easiness, balanced stressing during operation and greatly prolonged service life.

Owner:WUZHOU HENGSHENG ELECTRONICS

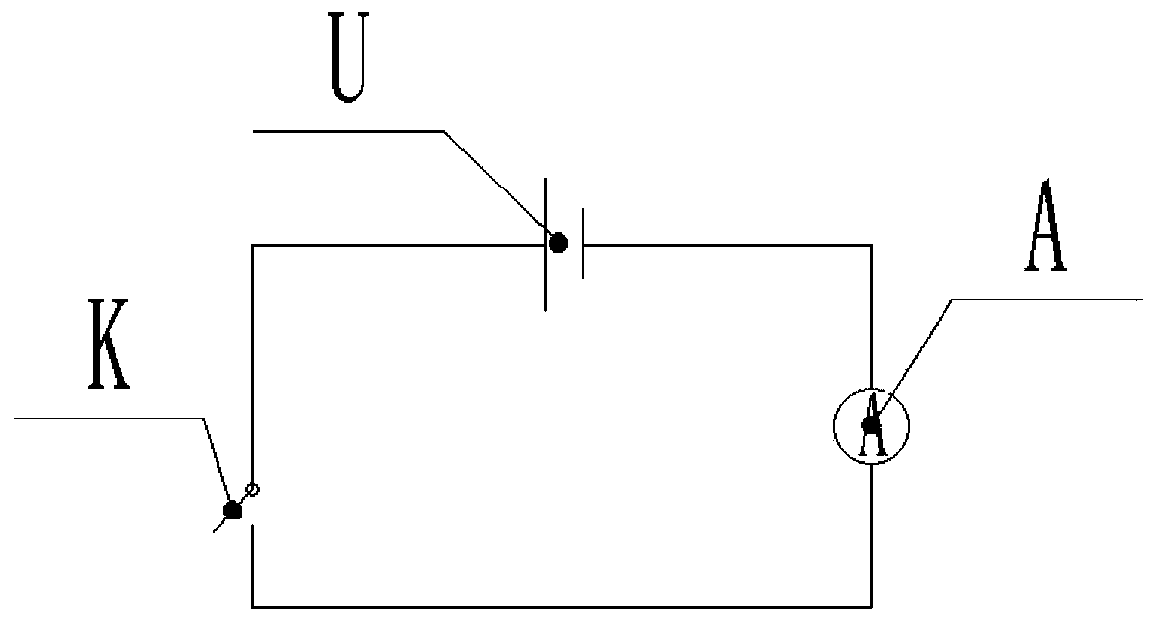

Driving circuit board and display device

PendingCN109102772APrevent static buildupPrevent breakdownTransistorSemiconductor/solid-state device testing/measurementDisplay deviceProtection layer

The invention discloses a driving circuit board and a display device. The driving circuit board comprises a substrate, and a test circuit and two connection units which are arranged on the surface ofthe substrate, wherein the two connection units are arranged at two sides of the test circuit, and a protection layer arranged on the surface of the test circuit is further included. The driving circuit board is advantaged in that lines of the test circuit can be prevented from being corroded or damaged through the protection layer.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

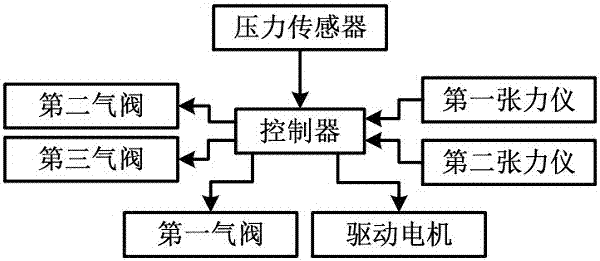

Cotton thread spinning-weaving device facilitating connection of broken threads

The invention relates to the field of textile processing equipment, in particular to a cotton thread spinning-weaving device facilitating connection of broken threads; the cotton thread spinning-weaving device comprises a thread transfer table and a gas storage box; a first tension meter and a second tension meter are mounted at the left and right ends of the thread transfer table respectively; the start positon of the gas storage box is between the first tension meter and the second tension meter and is provided with a left gas outlet, a right gas outlet and a lower gas outlet, the left gas outlet is provided with a first gas valve, the right gas outlet is provided with a second gas valve, the lower gas outlet is provided with a third gas valve, the bottom of the gas storage box is provided with a soft balloon, the bottom of the balloon is provided with wrinkles for holding thin yarns when the balloon is not inflate with compressed air, the cotton thread spinning-weaving device also comprises a pressure sensor and a controller, and the pressure sensor is disposed at the right end of the thread transfer table. At the moment when a thin yarn breaks, two yarn ends have a small spacing, the gas storage box pulls the thin yarn to bring close the two yarn ends, repair failure due to the excessive spacing of the two yarn ends is avoided, and subsequent repairing is facilitated for workers.

Owner:ZUNYI TIANYUN TEXTILE CO LTD

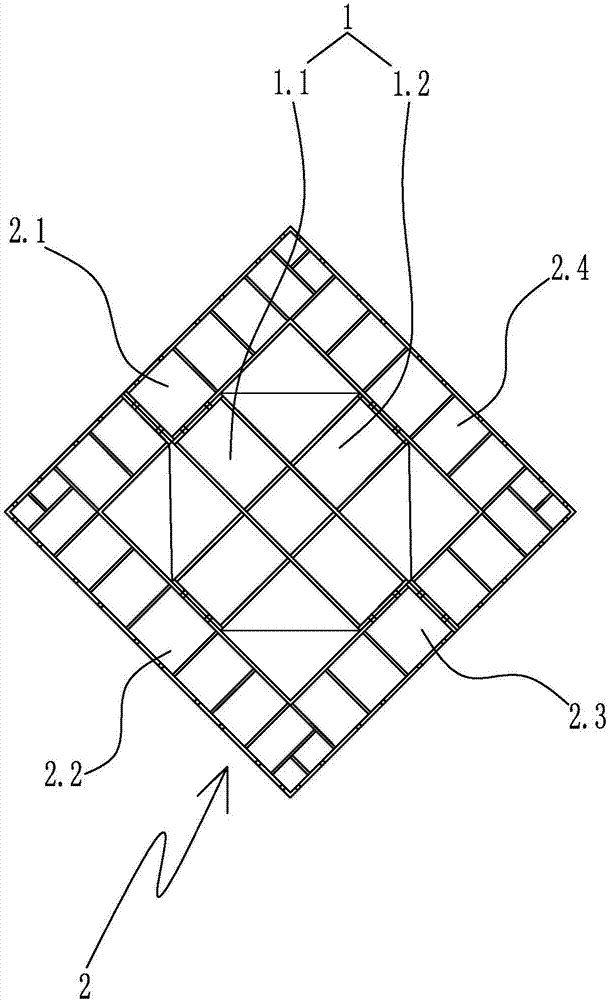

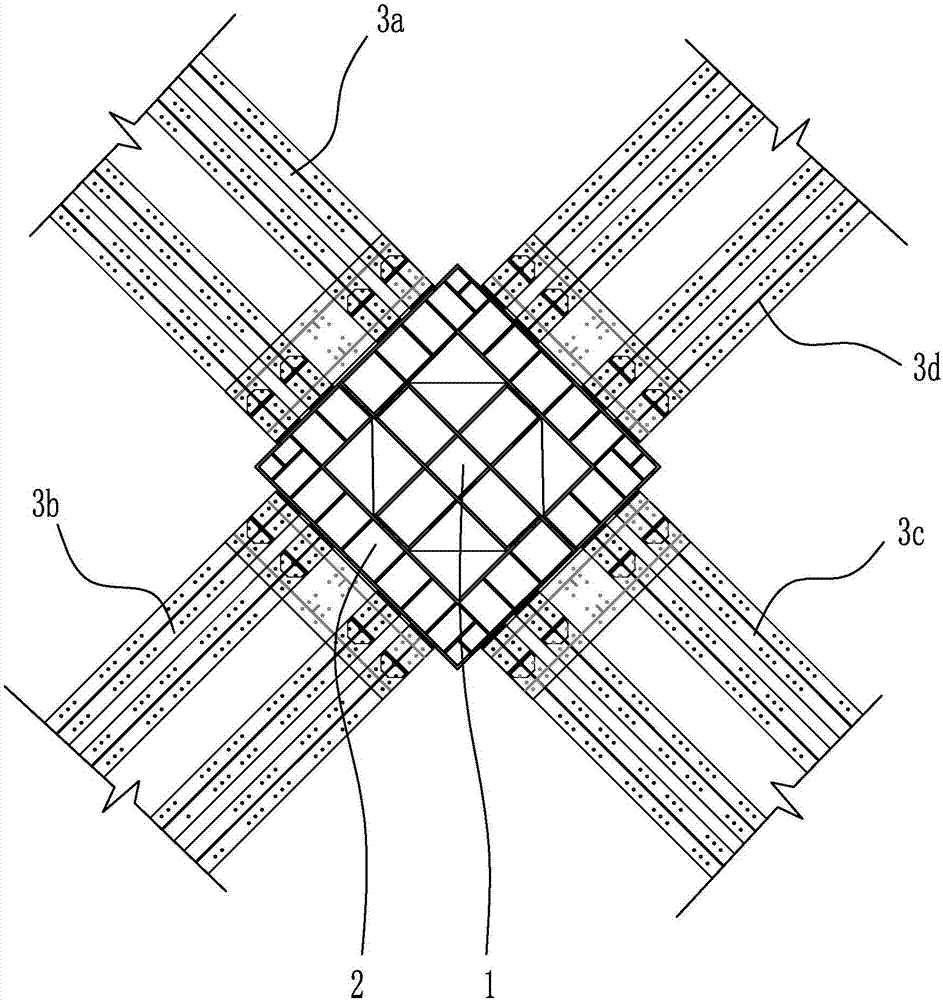

Combined type supporting force guide piece for crossed support system

The invention discloses a combined type supporting force guide piece for a crossed support system. By means of the combined type supporting force guide piece for the crossed support system, a foundation trench is supported by an internal supporting beam of an internal support in the foundation trench according to the crossed distribution condition, the problem about unbalance stress of the supporting system in the foundation trench due to the condition of avoiding the crossed condition of the internal supporting beam is solved, and construction is convenient. The combined type supporting forceguide piece comprises a force guide supporting inner core and at least one structural steel combination layers sequentially distributed on the outer side of the force guide supporting inner core frominside to outside, the force guide supporting inner core comprises a first force guide supporting rod and a second force guide supporting rod which are distributed in a crossed manner, the structuralsteel combination layers are rectangle frames or square frames, each structural steel combination layer is defined by first supporting structural steel, second supporting structural steel, third supporting structural steel and fourth structural steel, and the structural steel combination layers and the force guide supporting inner core jointly form the rectangle or square frames.

Owner:DONGTONG ROCK SOIL SCI & TECH HANGZHOU

Improved oblique shock wave die structure for basin stand product

The invention relates to the technical field of dies, and discloses an improved oblique shock wave die structure for a basin stand product. The improved oblique shock wave die structure comprises an upper die, a lower die and a sliding chute structure arranged between the upper die and the lower die, wherein the upper die comprises an upper padding plate, an upper fixing plate and a male die; the lower die comprises a female die, a limiting block, a lower padding plate and a female die padding plate; the sliding chute structure comprises a guide rail plate and a sliding block, an oblique sliding face is arranged on the guide rail plate and provided with a guide groove, a guide block matched with the guide groove is arranged on the sliding block, and the sliding block is further provided with a male die via hole matched with the male die; the upper fixing plate is installed at the lower end of the upper padding plate, the upper end of the sliding block corresponds to the lower end of the upper fixing plate, the guide rail plate is located at the upper end of the limiting block, the female die is installed on the lower padding plate through the female die padding plate, the limiting block is installed on the lower padding plate, the sliding block is further provided with an elastic recovery device, and the guide groove and the guide block are of a square structure. The improved oblique shock wave die structure has the advantages that machining is easy to carry out, stress is balanced in the working process, and the service life of the dies is prolonged.

Owner:WUZHOU HENGSHENG ELECTRONICS

Blocking mechanism for trolley type switch cabinet contact movable baffles

InactiveCN107785808AReduce displacement deviationFlexibleSwitchgear shutters/guardsSwitchgear earthing arrangementsElectromagnetic lockPosition sensor

The invention discloses a blocking mechanism for trolley type switch cabinet contact movable baffles, and aims at solving the problem of jamming in an action process of the contact movable baffles inthe prior art. The device comprises an upper movable baffle and a lower movable baffle arranged on a separation board, an electromagnetic lock arranged on a side wall, a controller arranged on the side wall, a trolley position sensor, a first motor, a second motor, a third motor, a fourth motor, a first travel sensor and a second travel sensor which are respectively connected with the controller,and a grounding shrapnel arranged on a baseboard and fitted to the trolley position sensor, wherein the electromagnetic lock is connected with the controller. According to the scheme above, the mechanism has the advantages of being simple in structure, flexible in action, safe and reliable; and the mechanism is of great practical value and promotional value in the technical field of safety protection.

Owner:UNIV FOR SCI & TECH SICHUAN

Seat belt retractor installation structure

ActiveCN106882146BHigh strengthImprove installation strengthBelt retractorsBelt anchoring devicesSeat beltUltimate tensile strength

The invention provides a safety belt retractor installing structure (3). A safety belt retractor (6) is arranged on the rear portion of a front surface opening part (313) of a hollow reinforcing structure (31) used for a shock absorber and arranged in the longitudinal direction, and a fixing piece (6122) of the safety belt retractor (6) extends forwards to outer side of the front surface opening part (313) of the reinforcing structure (31) and then is bent downwards to be fixed to the lower side of the front surface opening part (313). On the basis of the condition that the stretching direction of a safety belt is obliquely frontward and downward, the simple structure provides forward and downward supporting force for the retractor, it can be avoided that an additional guide structure and / or reinforcing component of the safety belt retractor occupies additional space in a vehicle, and as the reinforcing structure is a component existing already and additionally arranged for reinforcing the shock absorber and is a portion which is high in strength in the bodywork structure, good installation strength can be ensured.

Owner:HONDA MOTOR CHINA INVESTMENT CO LTD

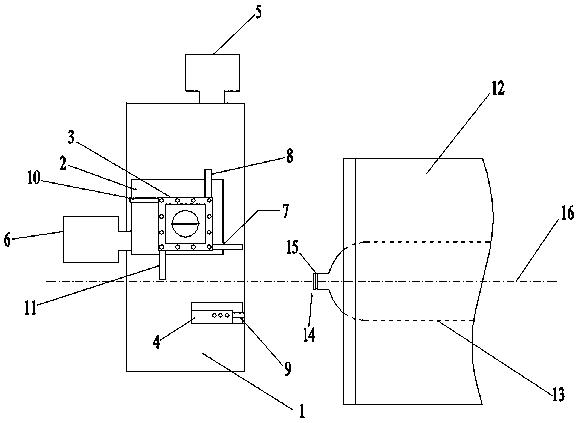

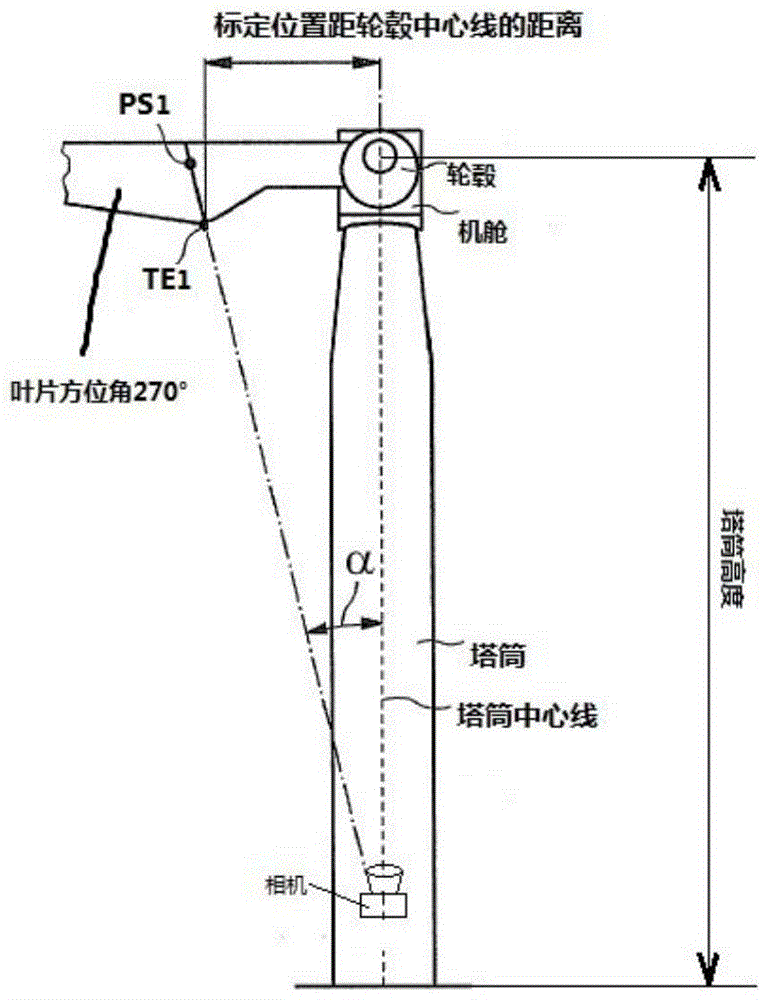

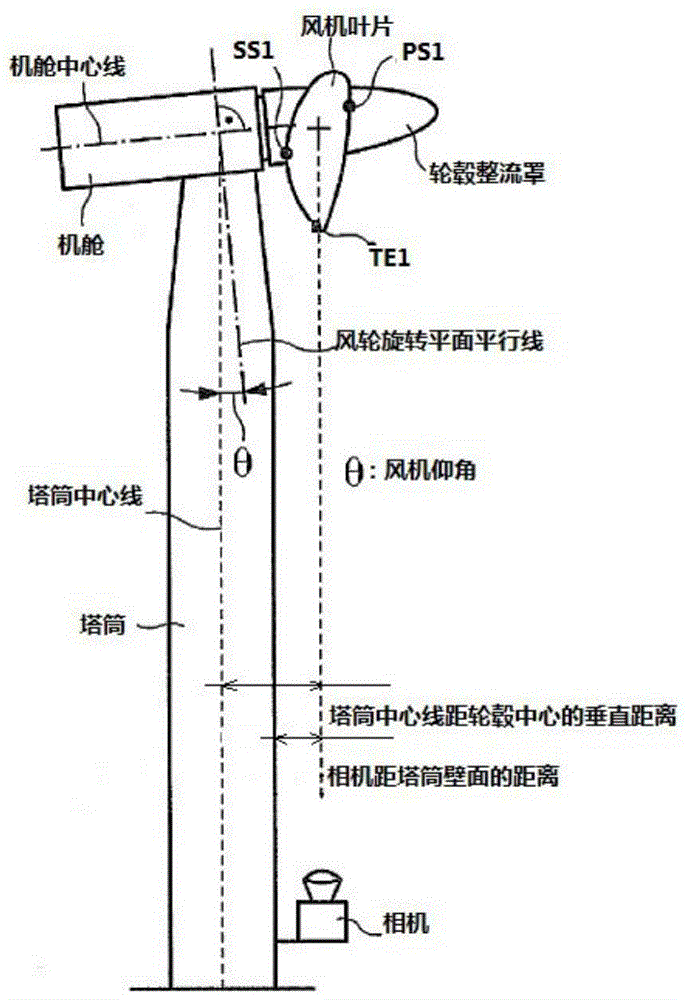

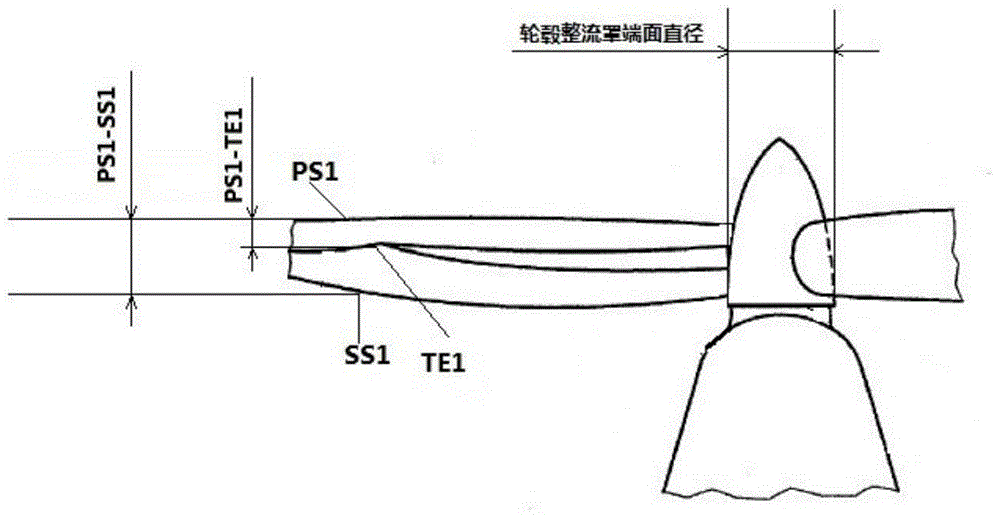

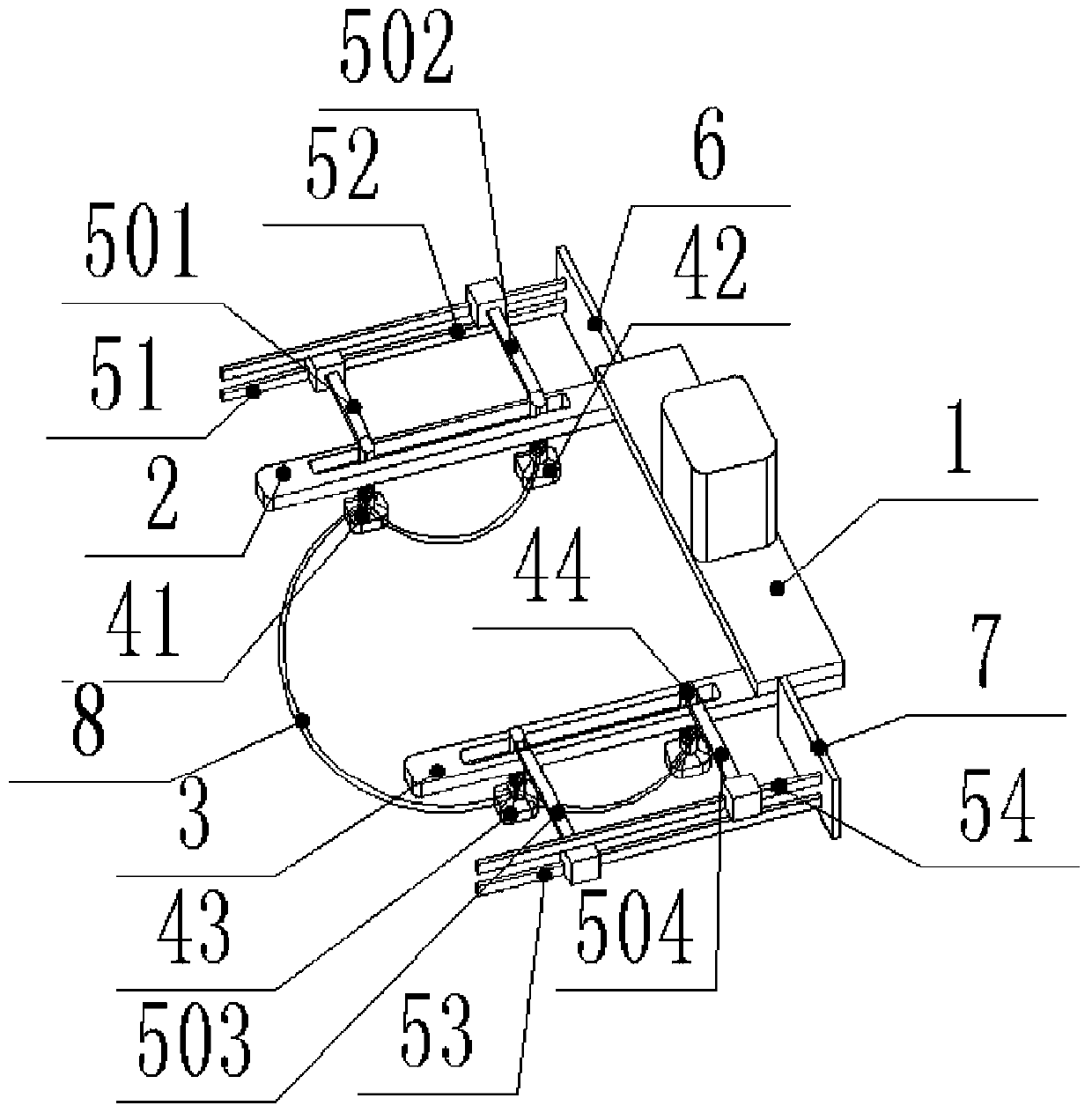

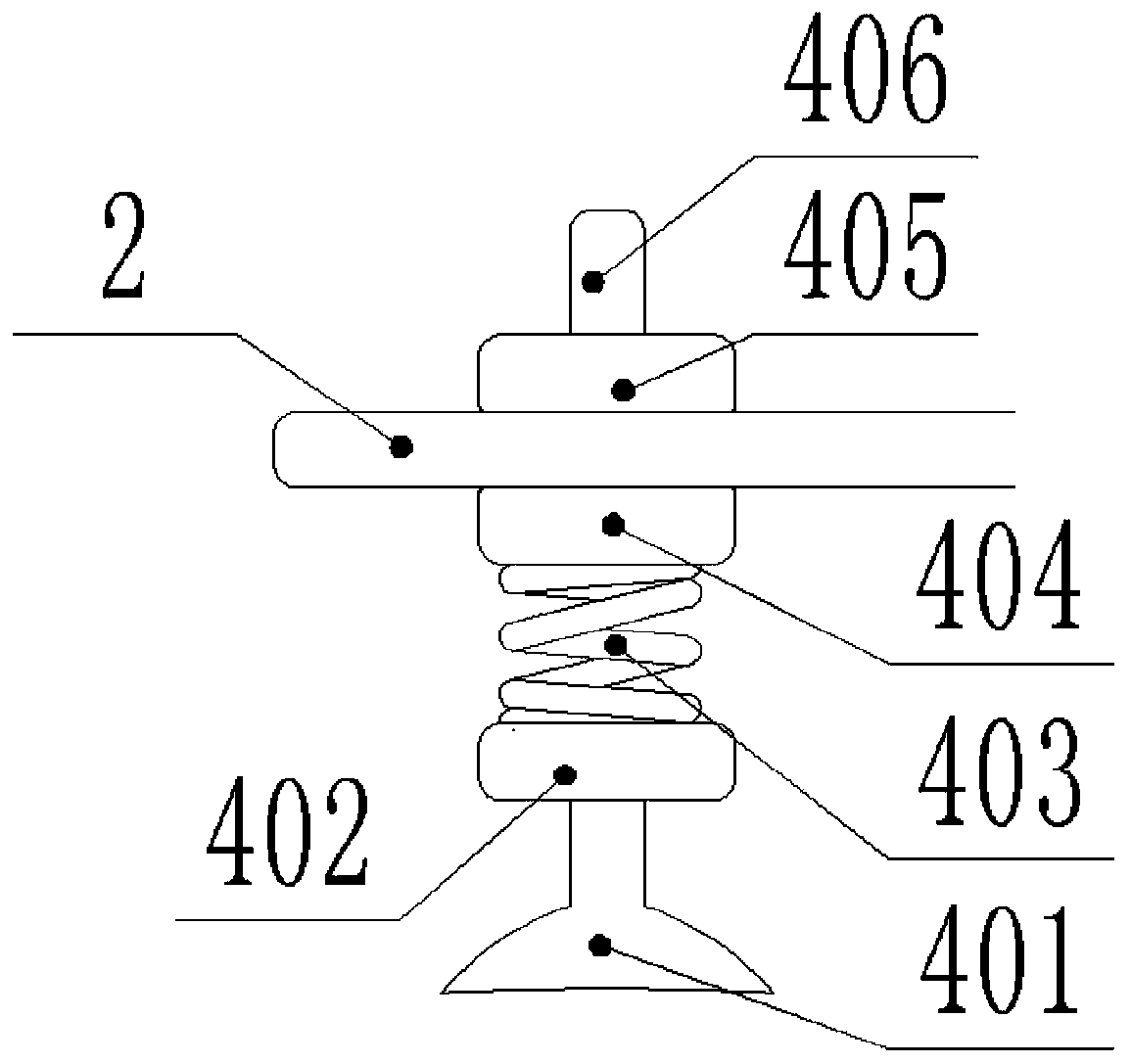

A zero-degree installation angle calibration method for fan blades

ActiveCN103982379BAvoid huge displacement deviationsAccurately determineAngles/taper measurementsMachines/enginesCalibration resultFan blade

The invention discloses a fan blade zero degree installation angle calibration method. The fan blade zero degree installation angle calibration method includes: photographing an installation position of a zero degree installation angle of an actual fan blade so as to obtain a photograph; processing the photograph; comparing the processed photograph with a three dimensional model of the fan blade to be calibrated at the zero degree installation angle; confirming whether the zero degree installation angle of the actual fan blade is correct or not by calculating a position relation among the highest point PS of a specific wing-shaped section of the fan blade to be calibrated, a trailing edge point TE of a force suction surface of the fan blade to be calibrated and the lowest point SS of the force suction surface of the fan blade to be calibrated so as to obtain a specific value Lambada which satisfies the equation that Lambada=(PS-TE) / (PS-SS); adjusting installation angles of the fan blade towards a forward direction or a negative direction according to a calibration result so as to sequentially complete installation angle calibration processes of three blades. The fan blade zero degree installation angle calibration method uses a pixel point number to confirm calibration positions on the blades, can avoid displacement deviation, is obvious in technical effect, can accurately position the calibration positions on the blades, and effectively calibrate installation angle errors among the three blades.

Owner:GUODIAN UNITED POWER TECH

Automatic milling machine

The invention relates to the field of laptop manufacturing, in particular to an automatic milling machine. The automatic milling machine comprises a placement table for placing a shell, a milling cutter device for milling waste, and a control unit, and further comprises a suction cup device; the suction cup device comprises a suction cup, a mounting plate for mounting the suction cup, a power device controlled by the control unit, and a vacuum device providing the negative pressure for the suction cups; a through groove is formed in the mounting plate, and the suction cup is slidably matched with the mounting plate through the through groove; and the suction cup is connected with the output end of the power device, and the power device drives the suction cup to move in the through groove of the mounting plate. The problem that as for the suction cup device, due to a suction cup failure, stress of the shell is unbalanced during shell taking and placing can be avoided.

Owner:重庆宇海精密制造股份有限公司

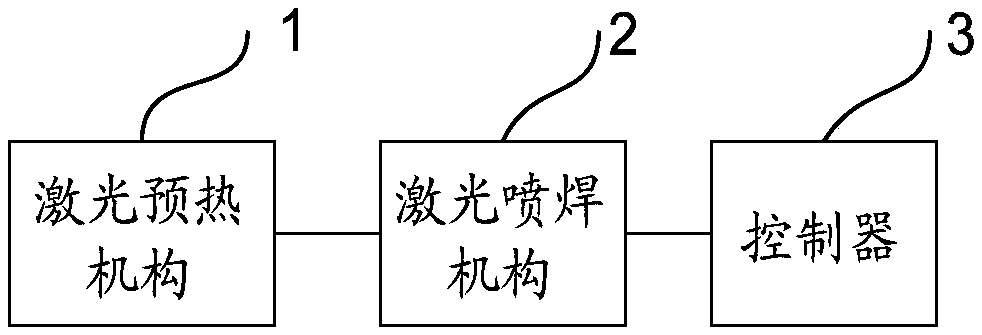

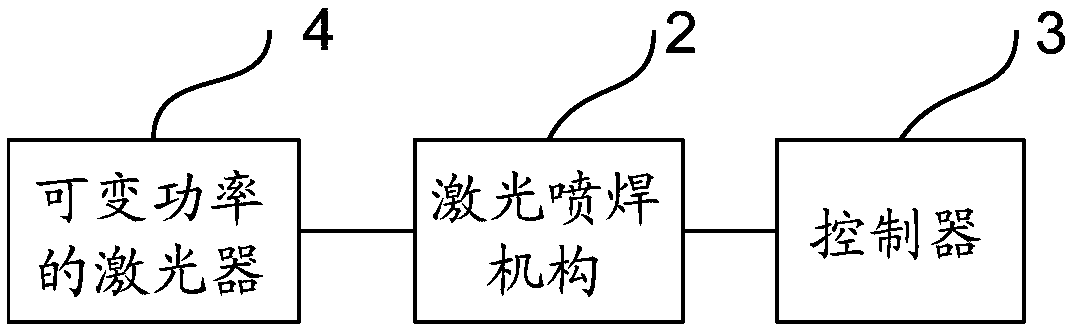

Motor reverser and voltage-sensitive resistor laser welding device and method

The invention discloses a motor reverser and voltage-sensitive resistor laser welding device and method, the laser welding method is suitable for the technical field of laser welding. The motor reverser and the voltage -sensitive resistor laser welding device comprise a laser preheating mechanism for heating the commutator terminal and a laser welding mechanism for jetting the welding ball to theterminal of the pre-heating commutator, and a controller for coordinating the working of the laser preheating mechanism and the laser welding mechanism. During use, the laser preheating mechanism is used for heating the terminals on the commutator with high heat conduction, and then injecting molten welding balls into the terminal and the voltage -sensitive resistor bonding pad, due to the fact that the terminal of the commutator is preheated, the temperature of the welding ball can be reduced, and the terminal can be soaked with the terminal, the voltage -sensitive resistor bonding pad cannotbe separated from the ceramic base, the welding process difficulty is lowered, meanwhile, due to the fact that the mass error of each ball is small, the welding spots are evenly distributed, so thatthe quality of each welding spot can be prevented from being unbalanced due to the fact that the quality of each welding spot is not uniform, and the service life is prolonged.

Owner:SHENZHEN ANEWBEST ELECTRONICS TECH

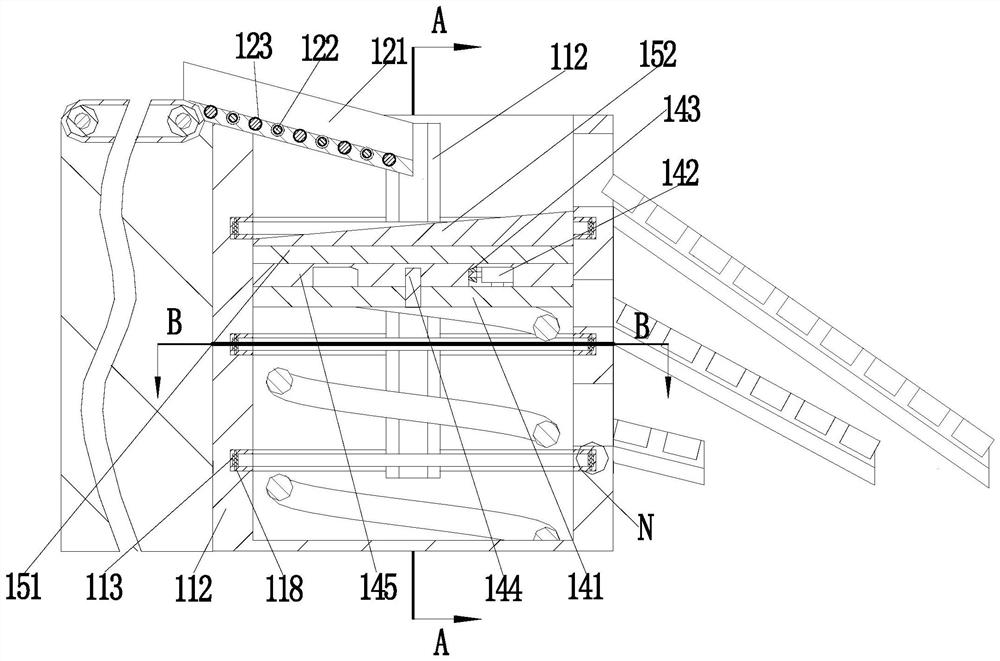

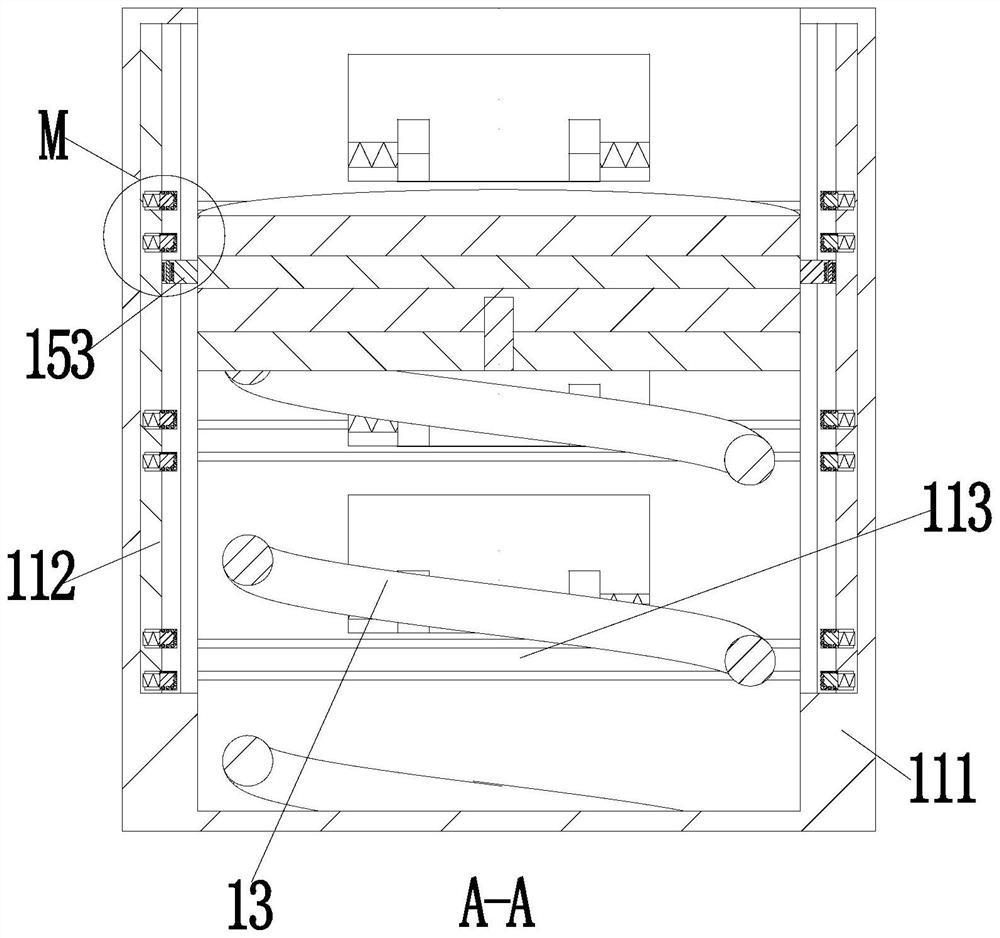

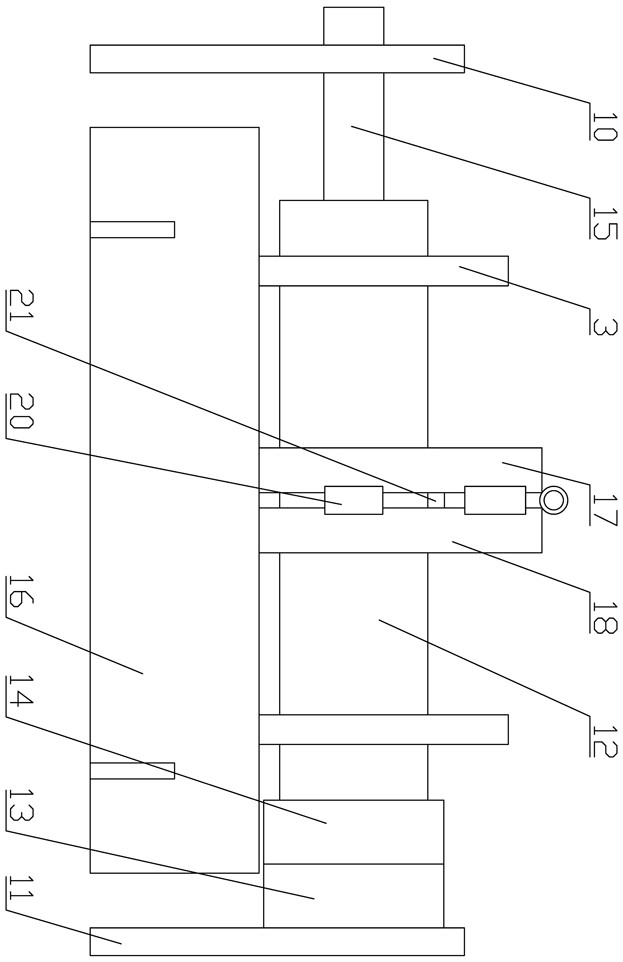

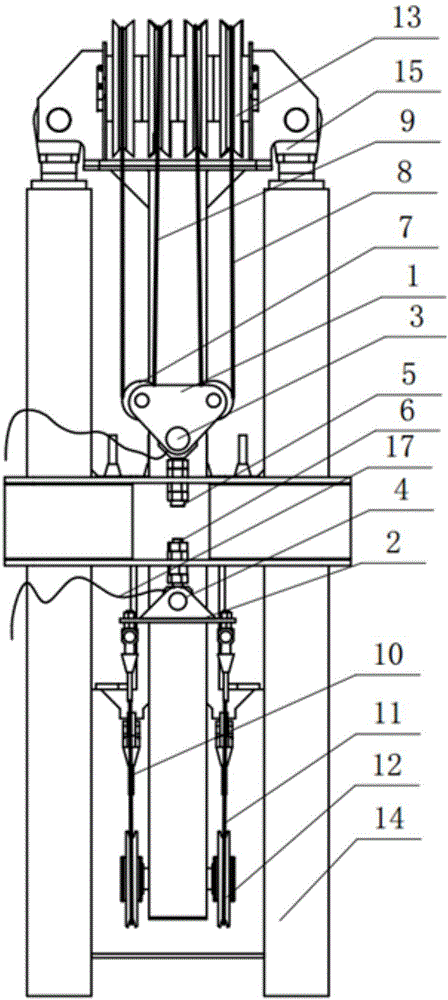

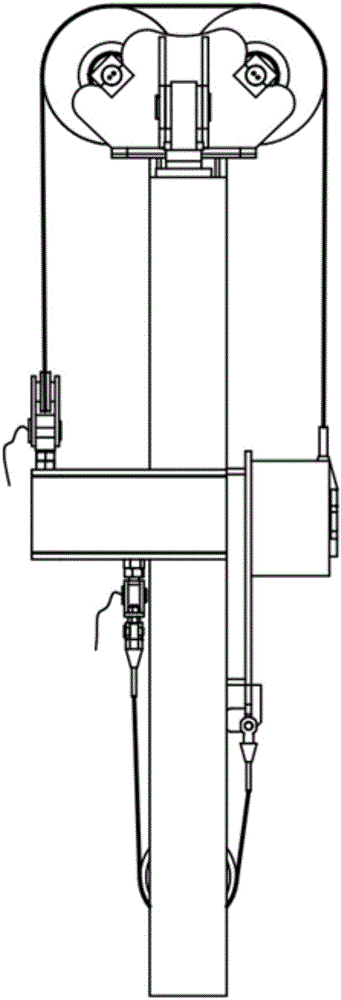

Self-balancing drilling and pulling-out mechanism with real-time bit pressure monitoring function

ActiveCN106194151AAvoid weight-on-bit distortionAvoid force imbalanceDrilling rodsConstructionsVertical motionEngineering

A self-balancing drilling and pulling-out mechanism with a real-time bit pressure monitoring function comprises a first-stage fixed machine body, a second-stage oil cylinder feeding machine body and a power head supporting plate. The second-stage oil cylinder feeding machine body is arranged on the first-stage fixed machine body through an oil cylinder in a telescopic mode. The second-stage oil cylinder feeding machine body comprises a machine body part located between hollow square steel on the two sides. The upper end of the machine body part is connected to the free end of an oil cylinder telescopic rod in the first-stage fixed machine body through a cross beam. The power head supporting plate is located on the front side of the first-stage fixed machine body, and is connected to the first-stage fixed machine body after an upper self-balancing mechanism and a lower self-balancing mechanism wind around the upper end and the lower end of the second-stage oil cylinder feeding machine body correspondingly. Vertical motion of the power head supporting plate is achieved through vertical movement of the second-stage oil cylinder feeding machine body. Due to the facts that the self-balancing drilling and pulling-out mechanism is simple in structure, convenient to operate and capable of improving the pulling-out force and conducting real-time monitoring, the self-balancing drilling and pulling-out mechanism has practicability and applicability.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

An automatic milling machine

The invention relates to the field of notebook computer manufacturing, in particular to an automatic milling machine, which includes a table for placing the casing, a milling cutter device for milling waste materials, a control unit, and a suction cup device. The suction cup device includes a suction cup, a mounting plate for installing the suction cup, The power device controlled by the control unit and the vacuum device that provides negative pressure for the suction cup have a through groove on the mounting plate, and the suction cup slides and fits with the mounting plate through the through groove. Movement in the through groove of the plate. The invention can avoid the problem of unbalanced force on the shell when the shell is picked and placed due to the failure of the suction cup.

Owner:重庆宇海精密制造股份有限公司

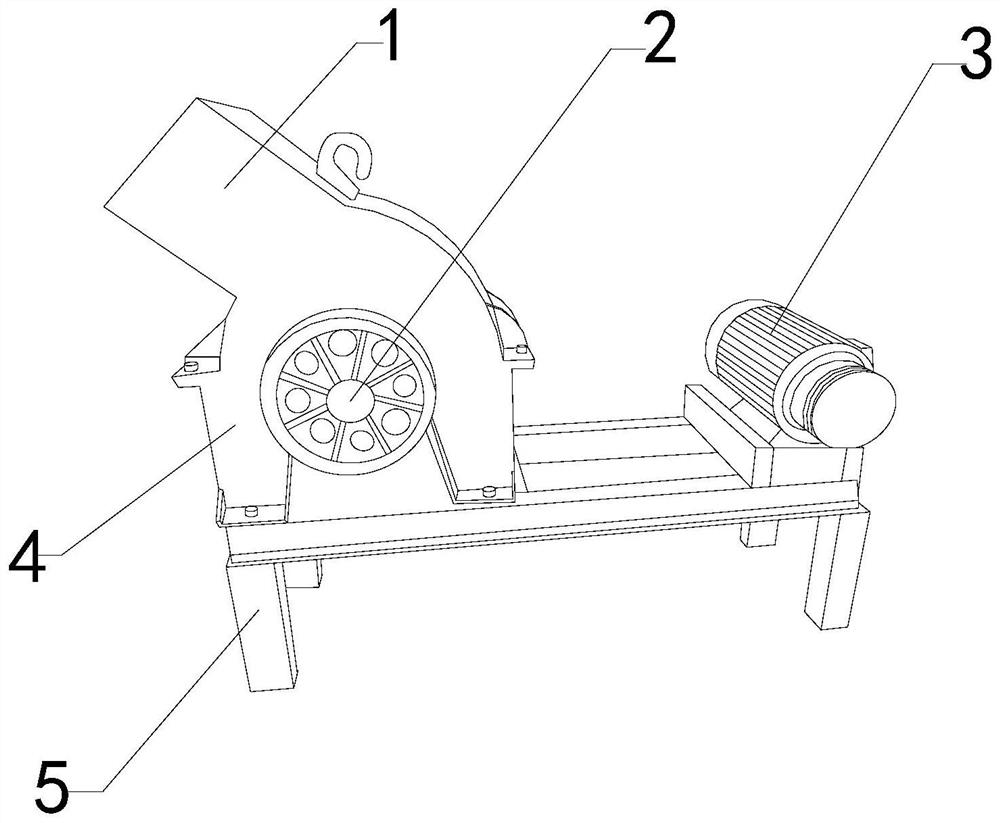

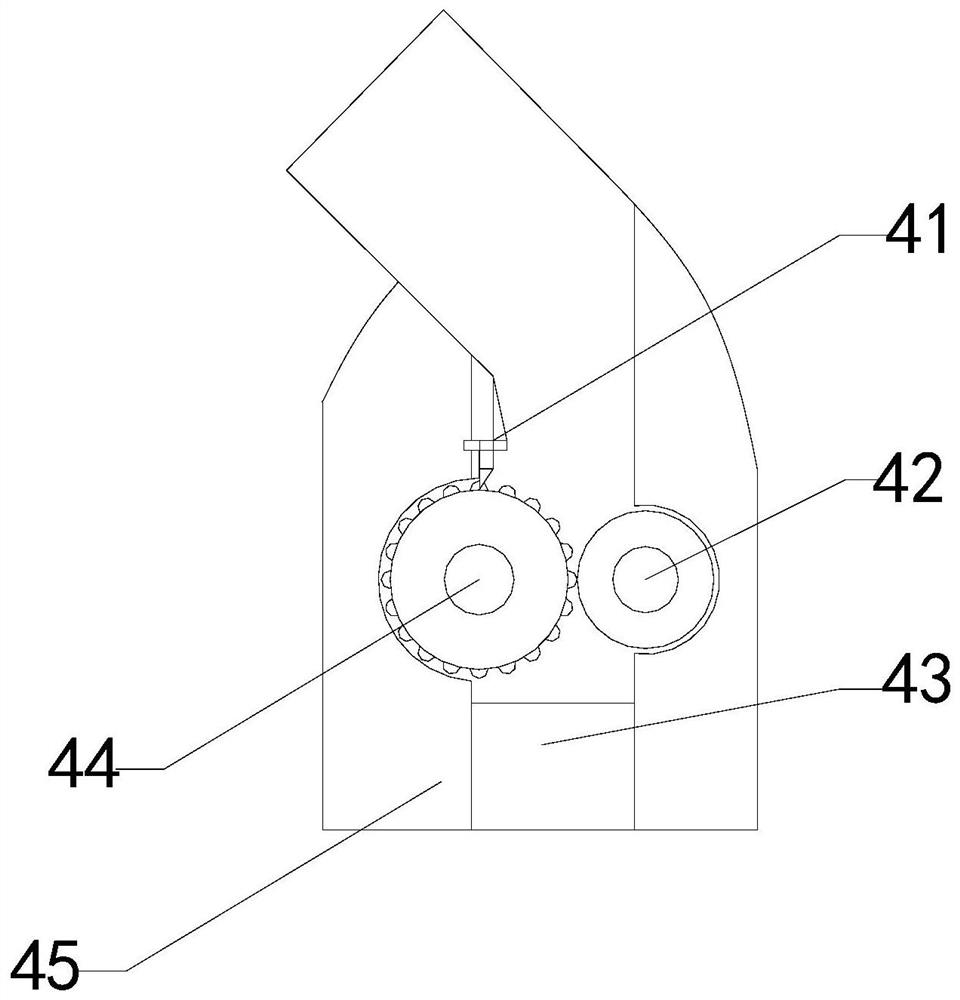

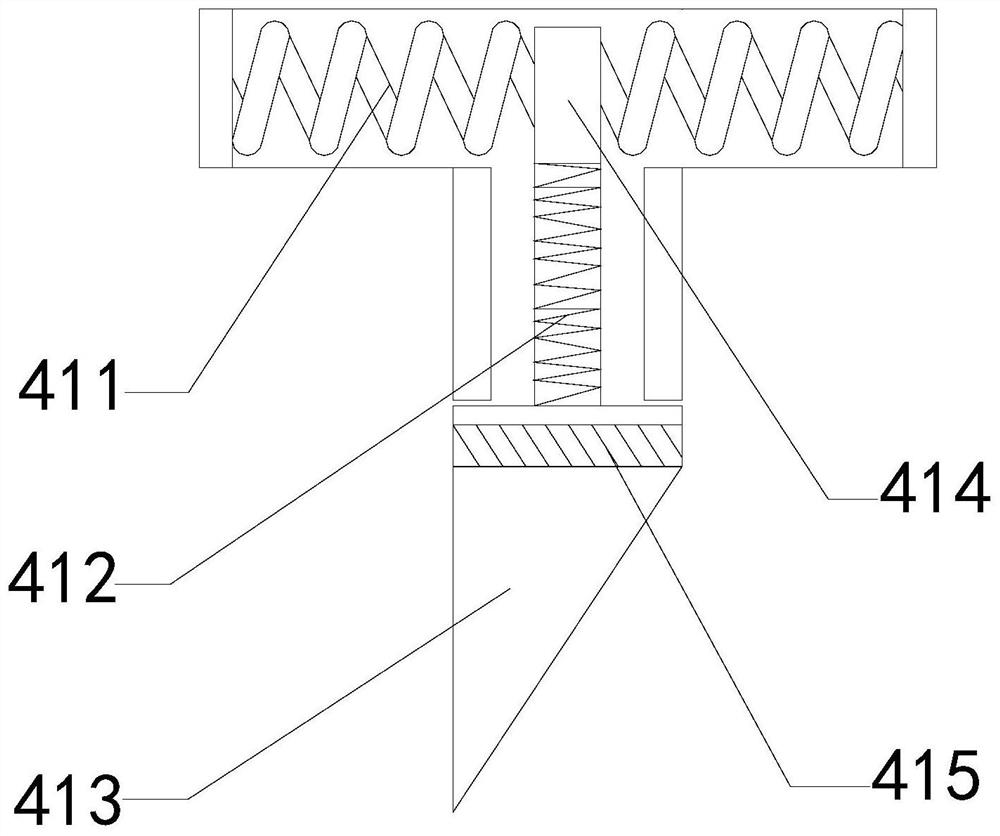

A polymer material crusher

ActiveCN111495494BAvoid pullingImprove broken rateGrain treatmentsMolecular materialsMaterials science

The invention discloses a macromolecule material crusher, the structure of which comprises a material inlet, a rotating disc, a rotating machine, a crushing device, and a support frame. The crushing device is provided with a cleaning mechanism, a movable rod, a discharge port, a crushing rod, and a mounting plate. , when the crusher is running, the natural rubber bond on the surface of the crushing rod is scraped off by the cleaning mechanism, and the force of scraping is buffered by the rubber block and the spring, and the cleaning block is scraped off by the scraping block. Clean up the knots to prevent clogging, avoid the stickiness on the surface of the broken rod to pull the natural rubber, improve the crushing rate of the natural rubber when it is crushed, prevent the sand from causing the natural rubber to stop, and avoid the unbalanced force when the natural rubber is crushed , to avoid the impact on the uniformity of natural rubber crushing, and the characteristics of bending through the bending rod after scraping, prevent the cleaning mechanism from being damaged by excessive force after scraping, and also avoid the cleaning mechanism after scraping off the adhesive Cannot pass through a curved smooth board.

Owner:义乌市义心科技有限责任公司

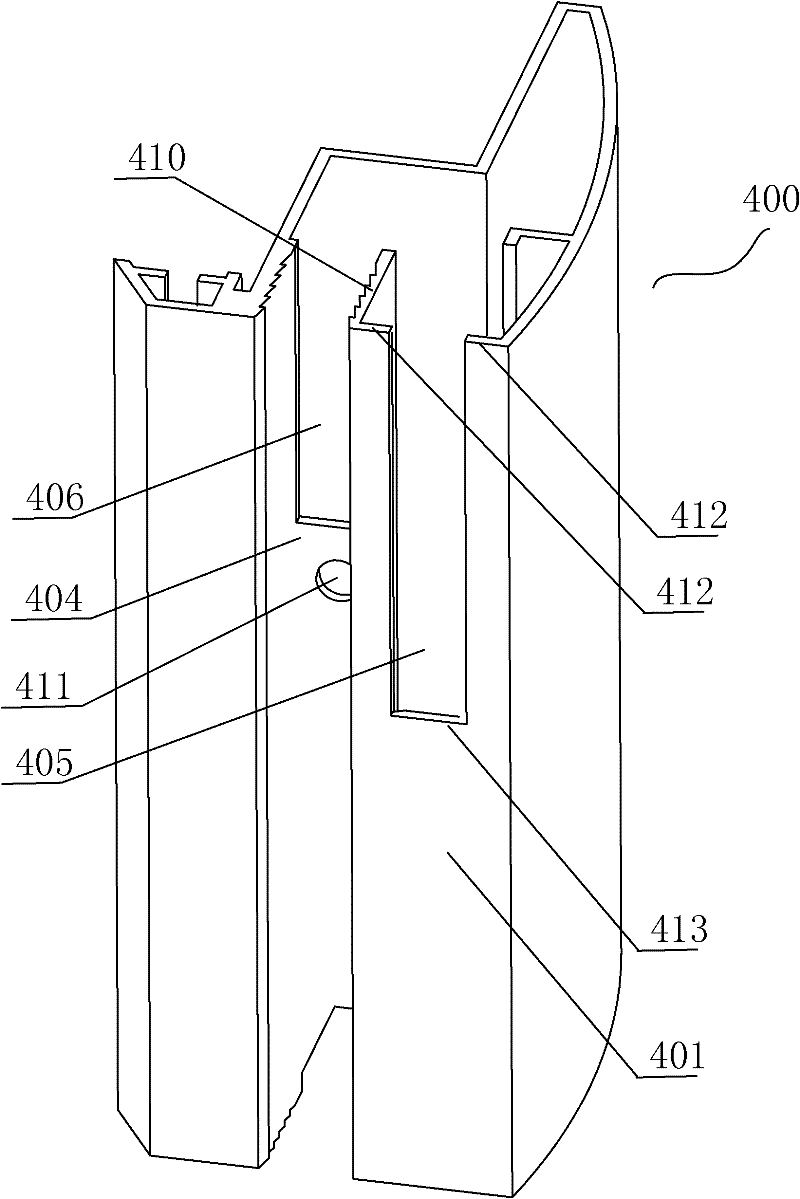

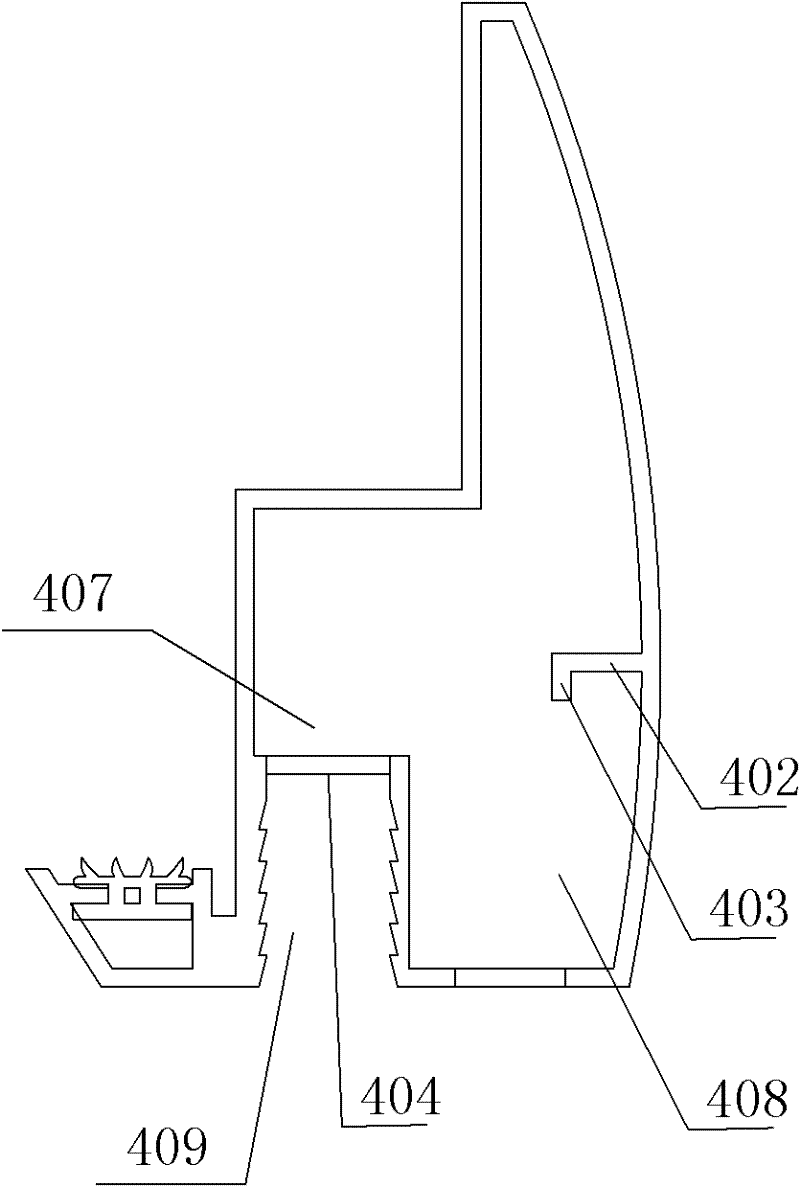

Section bar connector, section bar and section bar connecting structure

ActiveCN102022011BImprove mechanical performanceImprove aestheticsDoors/windowsBathsEngineeringMechanical engineering

In order to overcome the defects of beauty and stress performance of the traditional section bar connecting structure, the invention relates to a section bar connecting structure as well as a section bar constituting the section bar connecting structure and a section bar connector matched with the section bar. The section bar connector comprises a connector main body (1), a connector main body (2) and a locking part preventing the connector from separating, the section bar comprises a first section bar matched with the connector main body (1) and a second section bar matched with the connector main body (2), a first chute and a slipway which are arranged on the connector main body (1) are respectively matched with a second U-shaped opening and a first U-shaped opening which are arranged on the first section bar, the connector main body (1) can be wrapped by the first section bar, an embedded protrusion arranged on the connector main body (2) is matched with an embedded cavity of the second section bar and embedded in the embedded cavity of the second section bar, the connector main body (2) is also provided with a first sliding rail matched with the first chute and a second sliding rail matched with the slipway, and the connector main body (1) and the connector main body (2) are locked and connected through the locking part.

Owner:安徽克琳黛尔智能家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com