Combined type supporting force guide piece for crossed support system

A technology of criss-crossing and supporting systems, which is applied in excavation, construction, infrastructure engineering, etc., can solve problems affecting the safety and stability of foundation pits, and the unbalanced force of the support system in foundation pits, etc., to achieve convenient construction and versatility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

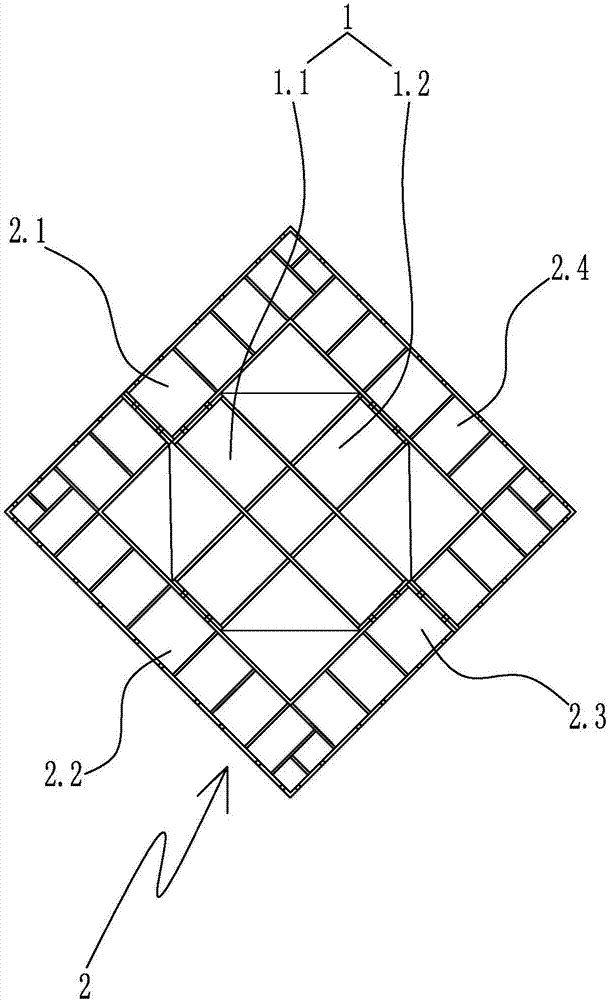

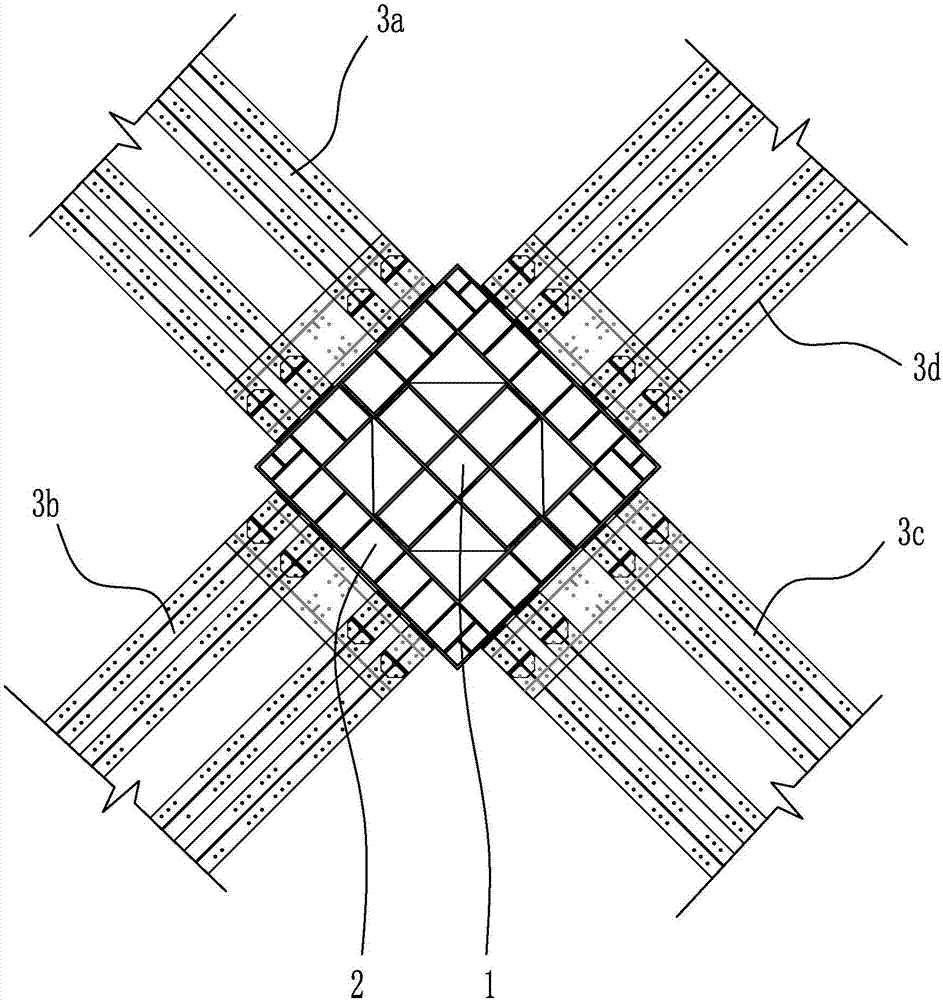

[0023] Example 1, such as figure 1 , figure 2 As shown, a combined support guide for a cross support system includes a guide support inner core 1 at least one layer of steel composite layers 2 distributed on the outer side of the guide support inner core in order from the inside out. In this embodiment The section steel combination layer is one layer.

[0024] The guiding support core includes first guiding supporting rods 1.1 and second guiding supporting rods 1.2 distributed in a crisscross pattern. The first guiding force supporting rod is perpendicular to the second guiding force supporting rod. Both the first guiding force support rod and the second guiding force support rod are made of H-shaped steel.

[0025] The section steel combination layer is a rectangular frame or a square frame, and the section steel combination layer of this embodiment is a square frame. The profiled steel composite layer and the guide support inner core together form a rectangular or square suppo...

Embodiment 2

[0031] Embodiment 2. For the rest of the structure of this embodiment, refer to Embodiment 1. The difference lies in:

[0032] The section steel composite layer in this embodiment is two layers. In the two adjacent profile steel composite layers: the first support profile on the outer side and the first support profile on the inner side are connected by bolts, the second support profile on the outer side and the second support profile on the inner side are connected by bolts. The third support section steel is connected with the third support section steel located on the inner side by bolts, and the fourth support section steel located on the outer side is connected with the fourth support section steel located on the inner side by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com