A polymer material crusher

A polymer material and crusher technology, applied in the direction of grain processing, etc., can solve the problems of destroying the balance of natural rubber, stopping natural rubber, and reducing the crushing rate of natural rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

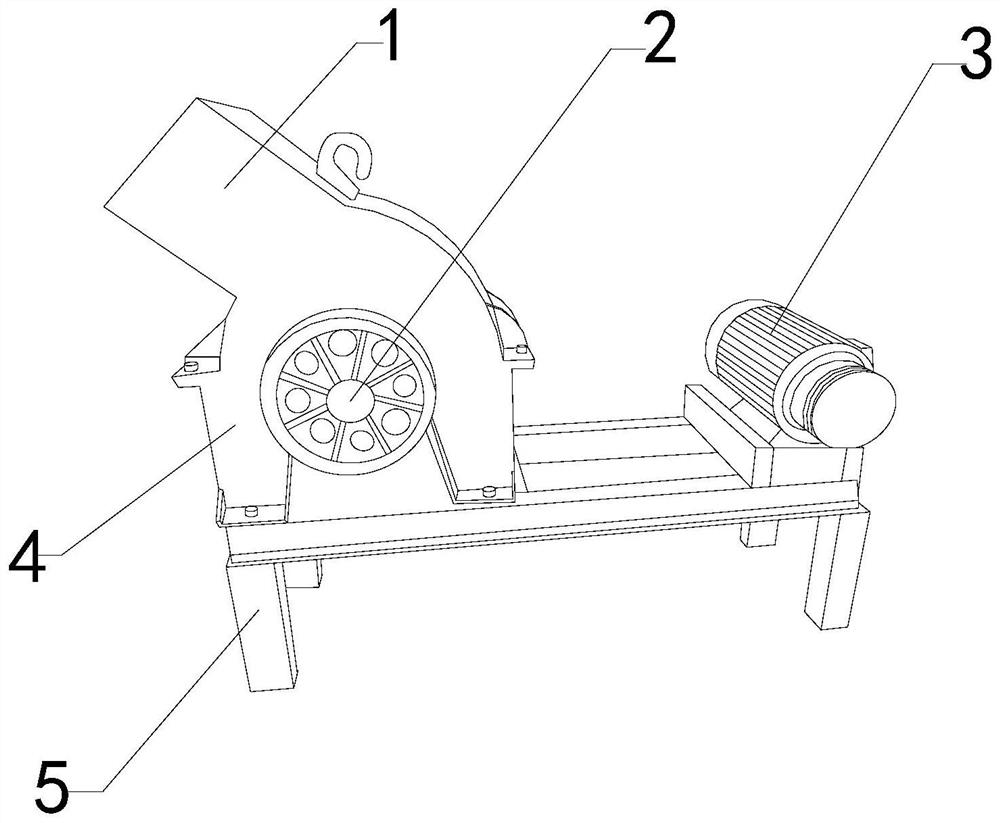

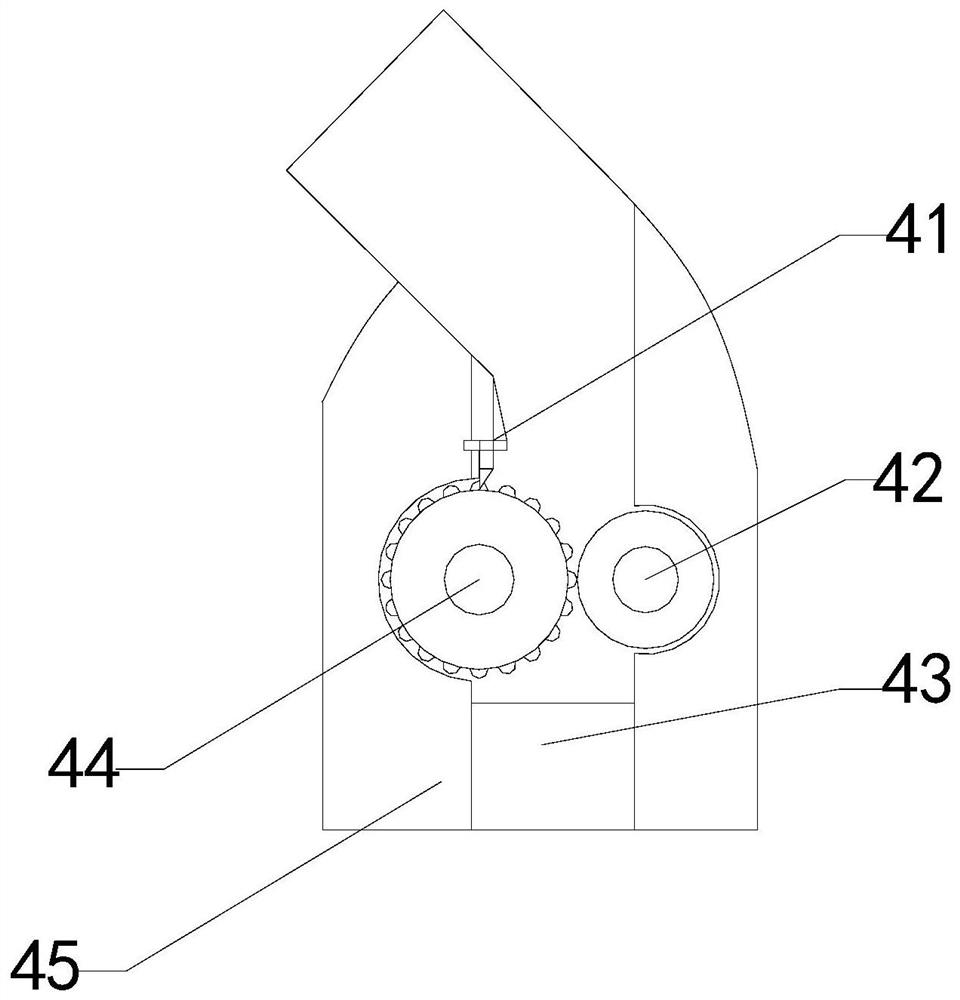

[0023] Such as Figure 1-Figure 5 Shown:

[0024] The present invention is a kind of polymer material breaker, and its structure comprises material inlet 1, rotating disk 2, rotating machine 3, crushing device 4, support frame 5, and described material inlet 1 and crushing device 4 are integrated structure, so The rotating disc 2 is embedded in the outer end of the crushing device 4, the rotating machine 3 is installed on the right side of the crushing device 4, the crushing device 4 is installed on the upper end of the support frame 5, and the crushing device 4 is provided with a cleaning mechanism 41. Movable rod 42, discharge port 43, crushing rod 44, mounting plate 45, the cleaning mechanism 41 is installed on the upper end of the crushing rod 44, the movable rod 42 is mounted on the right side of the crushing rod 44, and the discharge The opening 43 is embedded in the lower right end of the crushing rod 44, the cleaning mechanism 41 is embedded in the left side of the mo...

Embodiment 2

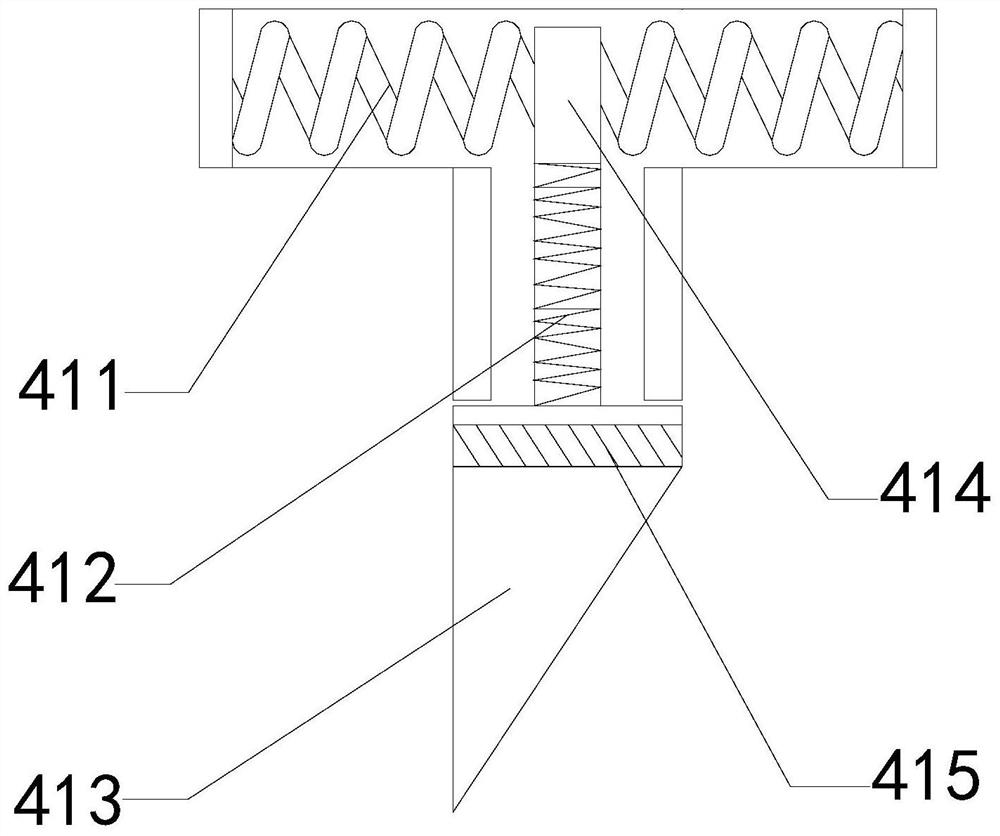

[0031] Such as Figure 6-Figure 7 Shown:

[0032] Wherein, the crushing rod 44 is provided with a connecting rod 441, a smooth plate 442, and a bending mechanism 443, the smooth plate 442 is installed at both ends of the bending mechanism 443, the connecting rod 441 is connected with the rotating disk 2, and the connecting rod 441 and the smooth plate 442 are located on the same central axis, and the surface of the smooth plate 442 is a curved structure, which surrounds the outside of the connecting rod 441, preventing the sand from causing the natural rubber to stop, and avoiding the unbalanced force when the natural rubber is broken. Avoid affecting the uniformity of natural rubber crushing.

[0033] Wherein, the bending mechanism 443 is provided with a bending block b1, a bending bar b2, and a connecting block b3. The bending block b1 is installed on the upper end of the bending bar b2, and the bending bar b2 is embedded in the connecting block b3. The block b3 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com