Hydraulic pressure reel cart with clutch at transmission last level

A hydraulic winch and clutch technology, applied in the field of hydraulic winches, can solve problems such as difficult processing, unbalanced force on the power shaft, complex connection structure, etc., and achieve the effects of convenient processing, easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

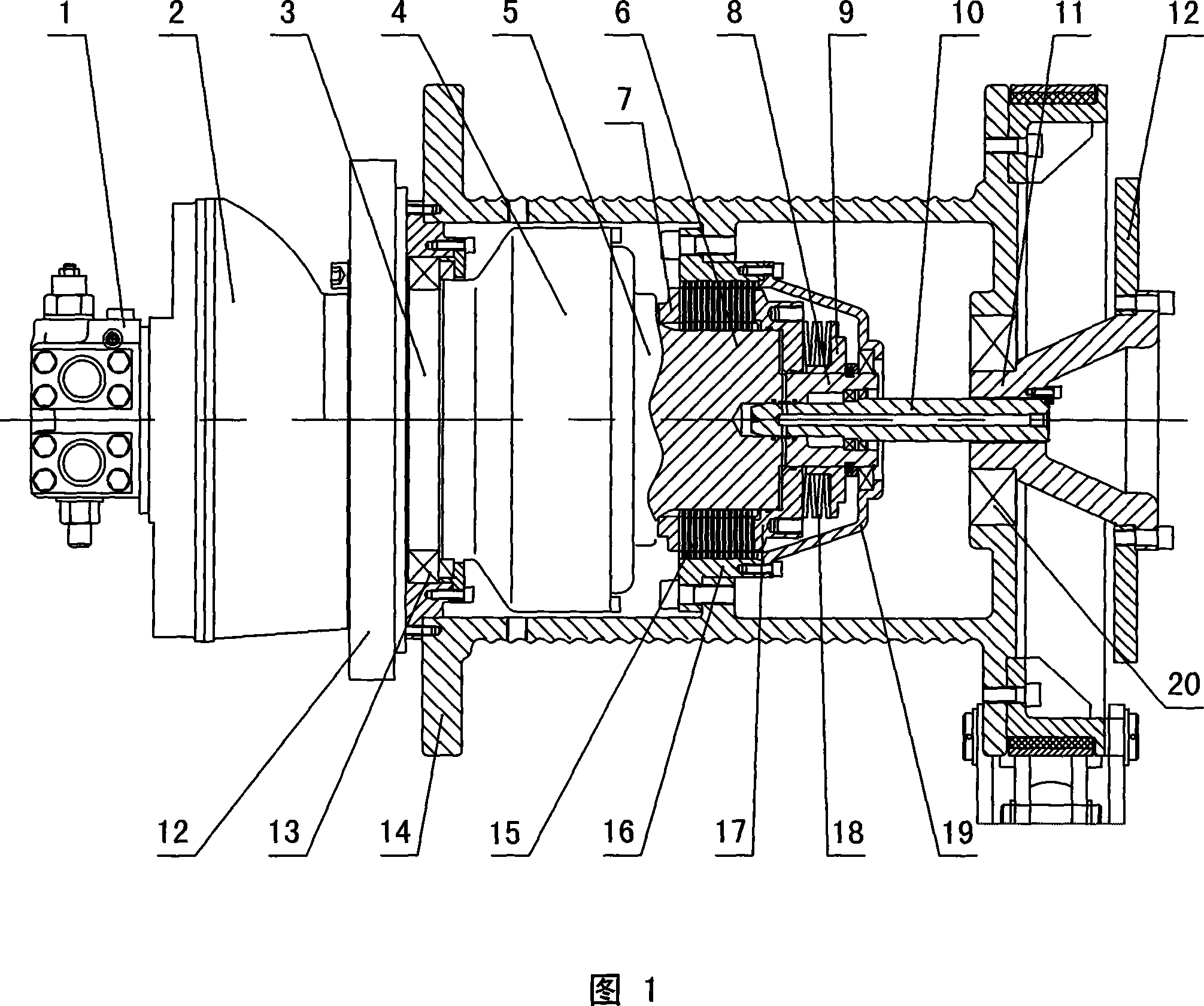

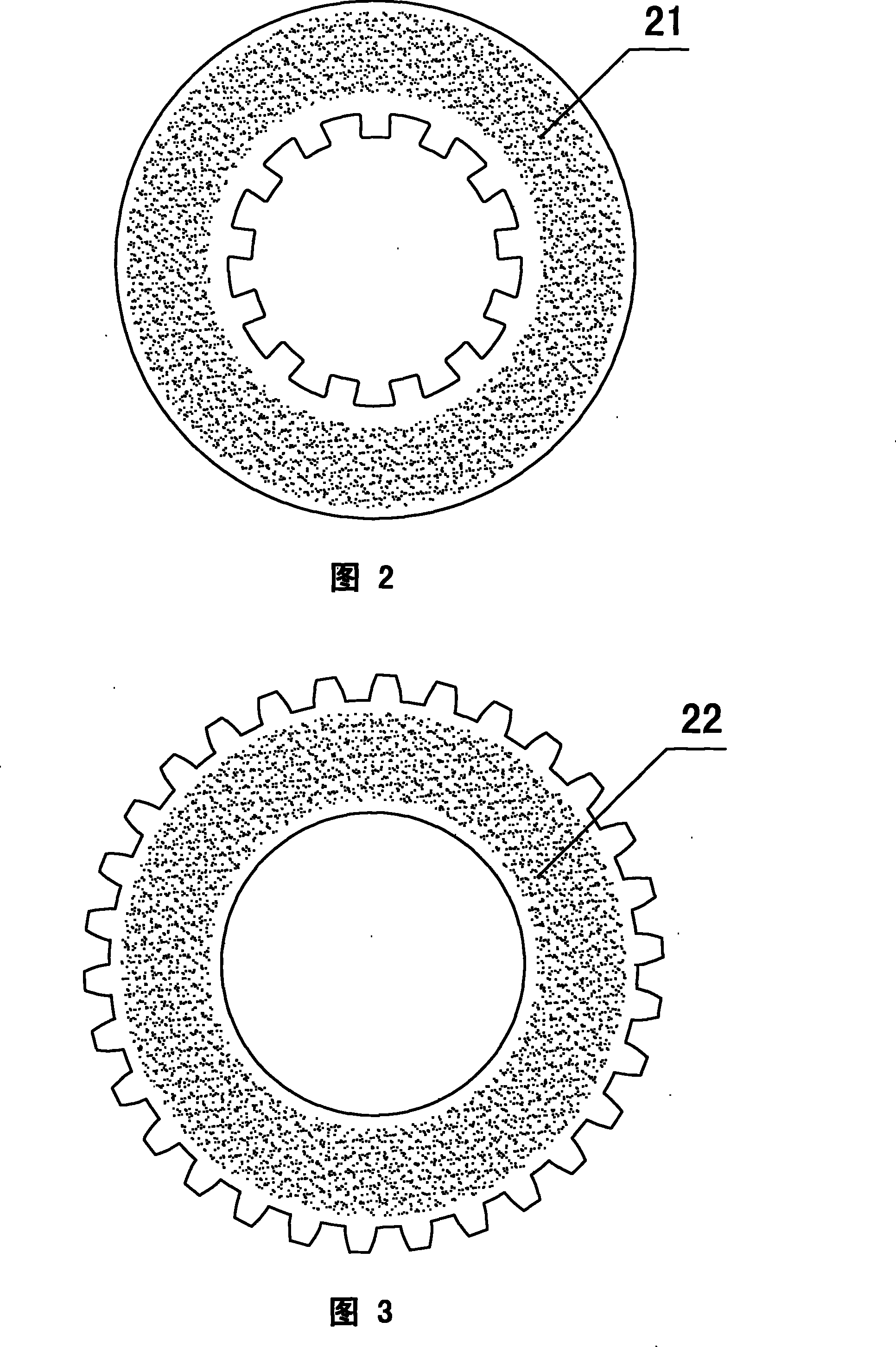

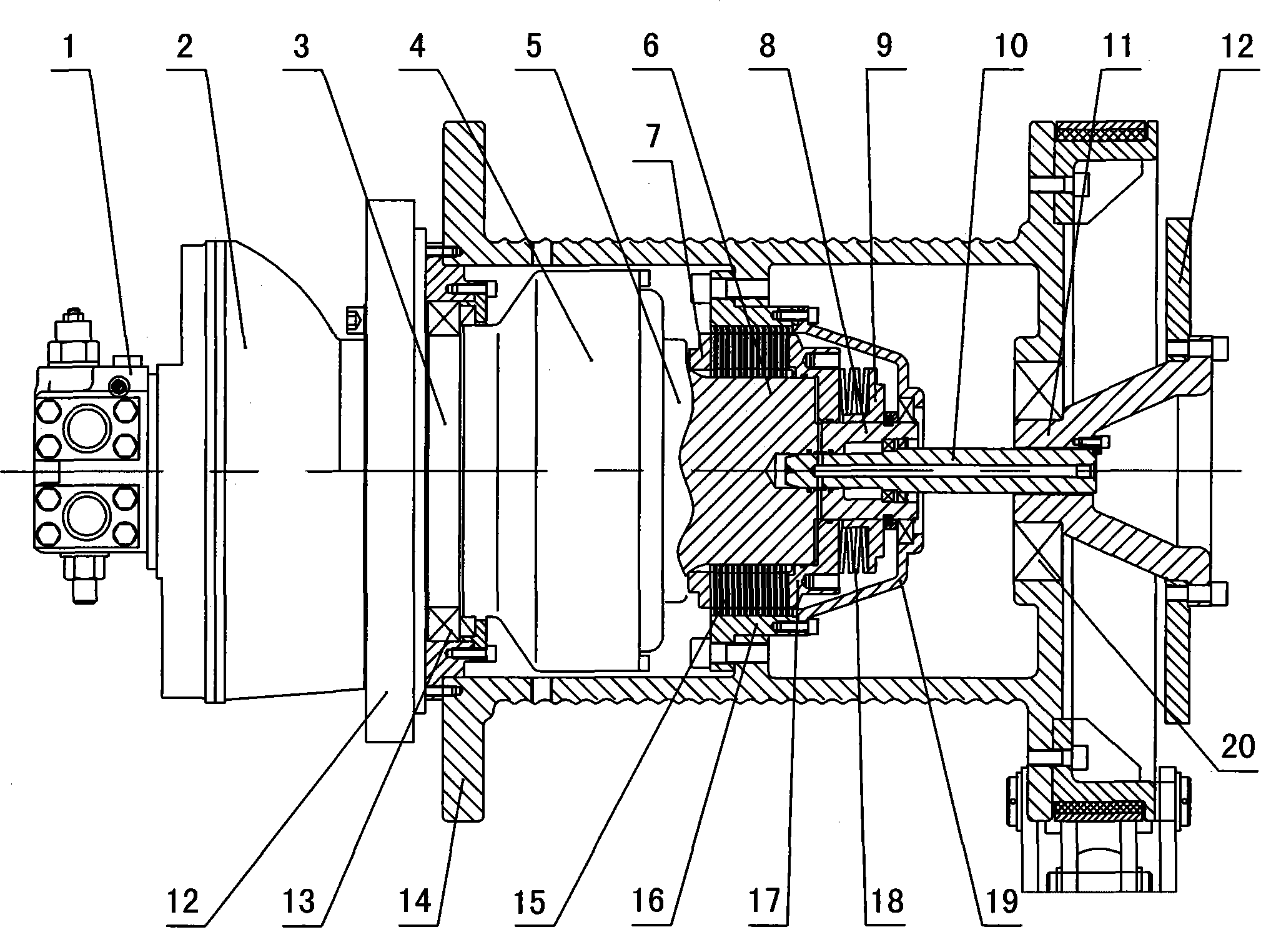

[0018] in such as figure 1 In the shown embodiment 1, the hydraulic winch with a clutch at the final stage of the transmission is composed of a hydraulic motor, a hydraulic brake, a planetary gear reducer, a hydraulic clutch, a reel and a hydraulic control circuit for controlling its work, and the hydraulic winch arranged in the reel 14 The hydraulic clutch is at the end of the transmission chain of the system, the planetary gear reducer 4 is set in the reel 14, and the right output end of the last stage planet carrier 5 is the spline shaft 6 connected to the multi-disc friction clutch, the spline shaft 6 The right end of the clutch is the piston 8 of the clutch control oil cylinder, and the spline shaft 6 is connected with the outer cylinder 16 of the internal gear structure through the friction plate 15. The friction plate is divided into a friction moving plate 21 and a friction fixed plate 22. The inner side of the friction moving plate 21 is provided with a gap suitable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com