A zero-degree installation angle calibration method for fan blades

A technology for wind turbine blades and a calibration method, which is applied to wind turbines, wind turbine monitoring, engines, etc., can solve problems such as late installation time and a large number of zero-position installation angles of wind turbine blades have not been calibrated, so as to avoid force imbalance. , Reduce the loss of power generation, the effect of obvious technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

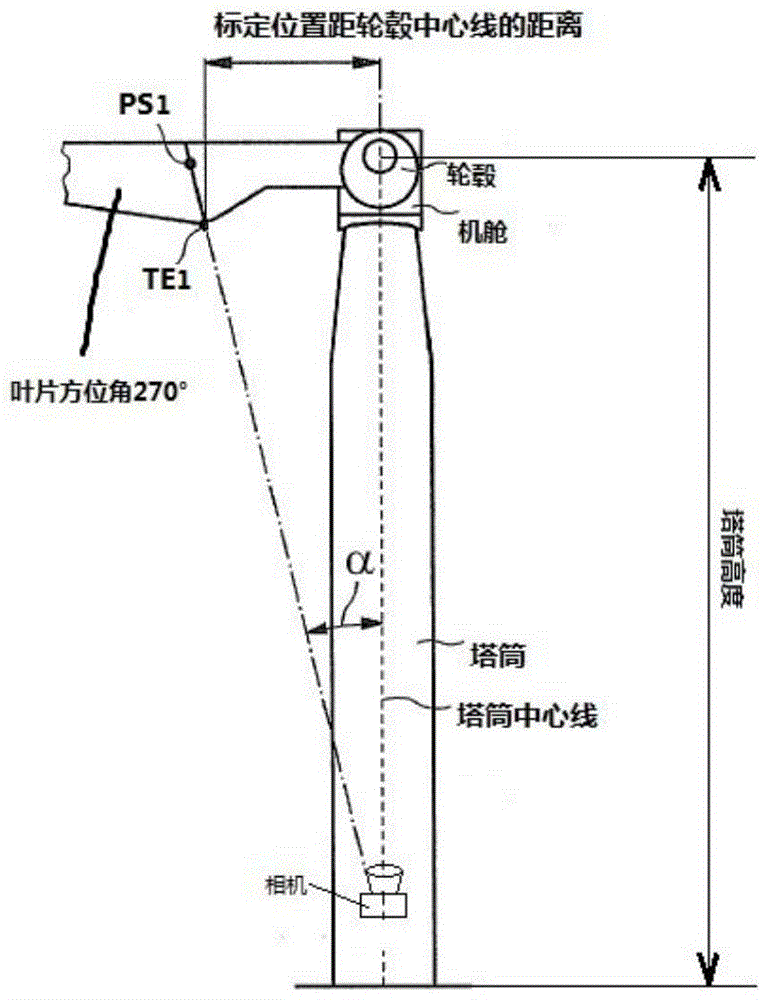

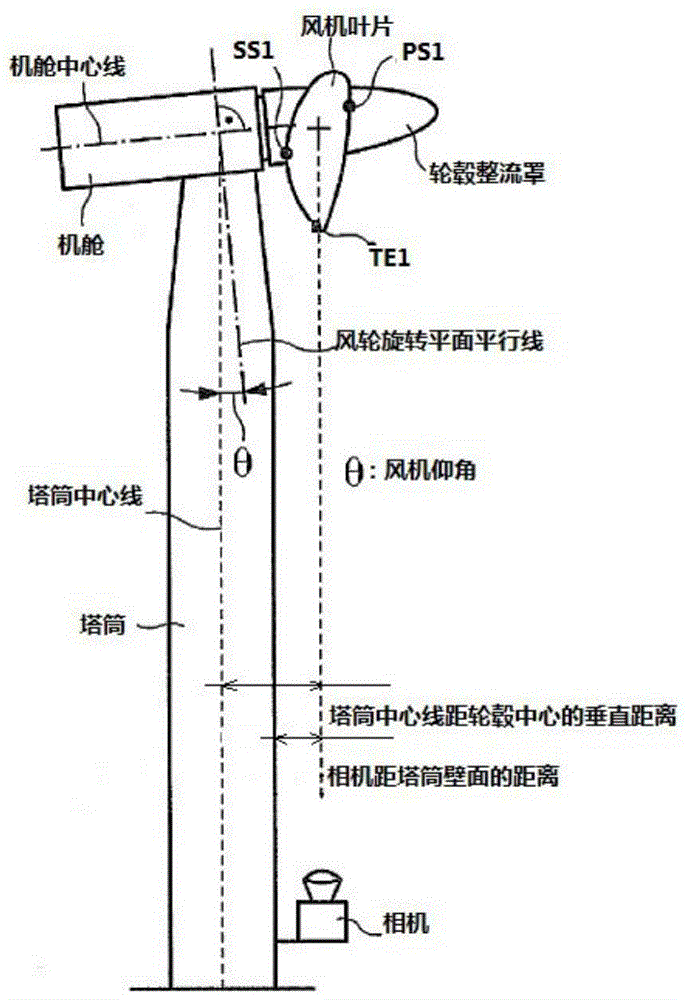

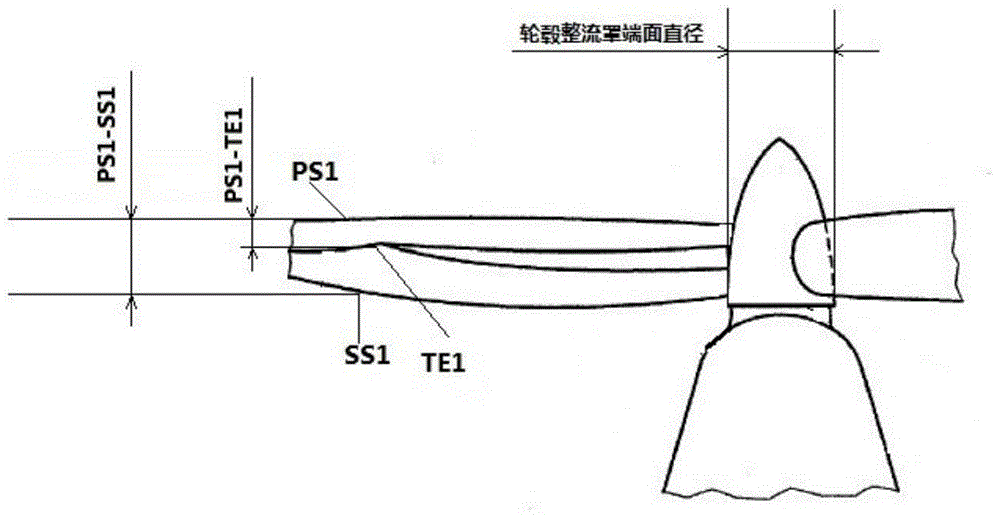

[0025] The invention discloses a method for calibrating the zero-degree installation angle of fan blades. By taking pictures of the installation positions of the actual fan blades at the installation angle of 0°, the photographed pictures are processed, and are compared with the position of the fan blades to be calibrated at the installation angle of 0°. The three-dimensional model is compared, and the positional relationship between the highest point PS of the pressure surface, the trailing edge point TE of the suction surface and the lowest point SS of the suction surface at the specific airfoil section of the calibration blade is calculated, that is, the ratio: λ=(PS- TE) / (PS-SS), determine whether the 0° installation angle of the actual fan blade is correct, adjust the installation angle of the fan blade positively or negatively according to the calibration result, and complete the installation angle calibration process of the three blades in turn.

[0026] Specifically inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com