Cotton thread spinning-weaving device facilitating connection of broken threads

A cotton thread and thread breaking technology, which is applied in jointing devices, textiles and papermaking, spinning machines, etc., can solve problems such as long distances, inconvenient repairs, troublesome operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail through specific embodiments below.

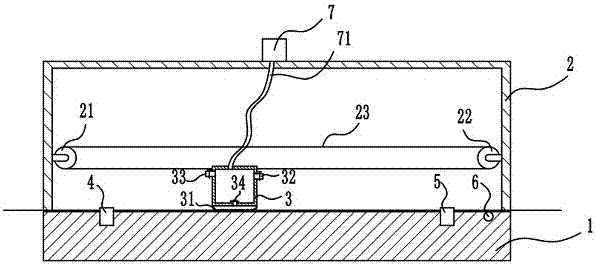

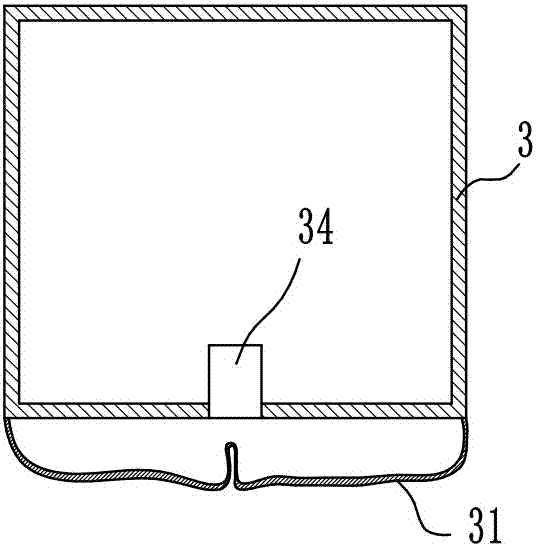

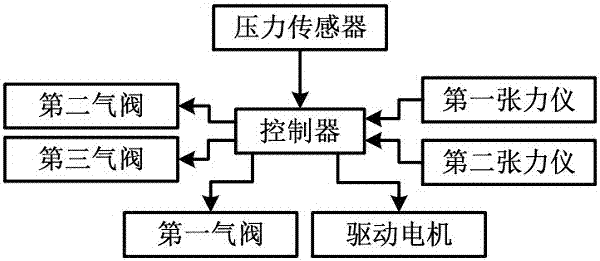

[0027] The reference signs in the accompanying drawings of the specification include: wire passing platform 1, bracket 2, gas storage box 3, first tensiometer 4, second tensiometer 5, pressure sensor 6, air pump 7, driving wheel 21, driven wheel 22, Conveyor belt 23, capsule cavity 31, right air outlet 32, left air outlet 33, lower air outlet 34, flexible pipe 71.

[0028] Such as figure 1 and figure 2 The shown cotton thread spinning device that is convenient for thread breaking includes a thread passing platform 1 for conveying spun yarn. Forward and reverse driving wheel 21, driven wheel 22 is set on the right side of support 2, driving wheel 21 and driven wheel 22 are all rotated and fitted on the connecting rod, and the two ends of the connecting rod are welded to the support 2 by welding pieces, driving The wheel 21 is driven by the driving motor to rotate forward a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com