Seat belt retractor installation structure

A seat belt retractor and installation structure technology, applied in the direction of belt retractors, belt fixing devices, etc., can solve the problems of difficulty in ensuring the strength of the bracket plate, complicated structure in the car, and occupying space in the car, so as to improve the space Utilization rate, improvement of installation performance and tensile performance, and enhancement of installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

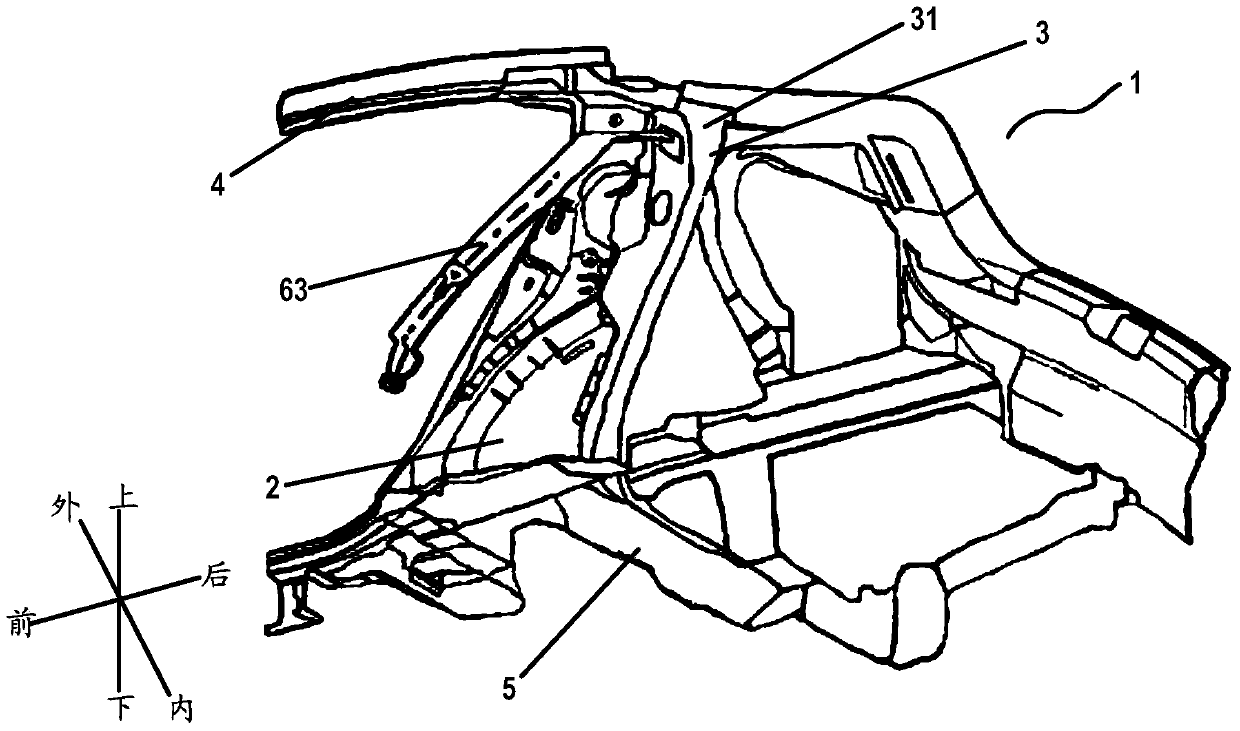

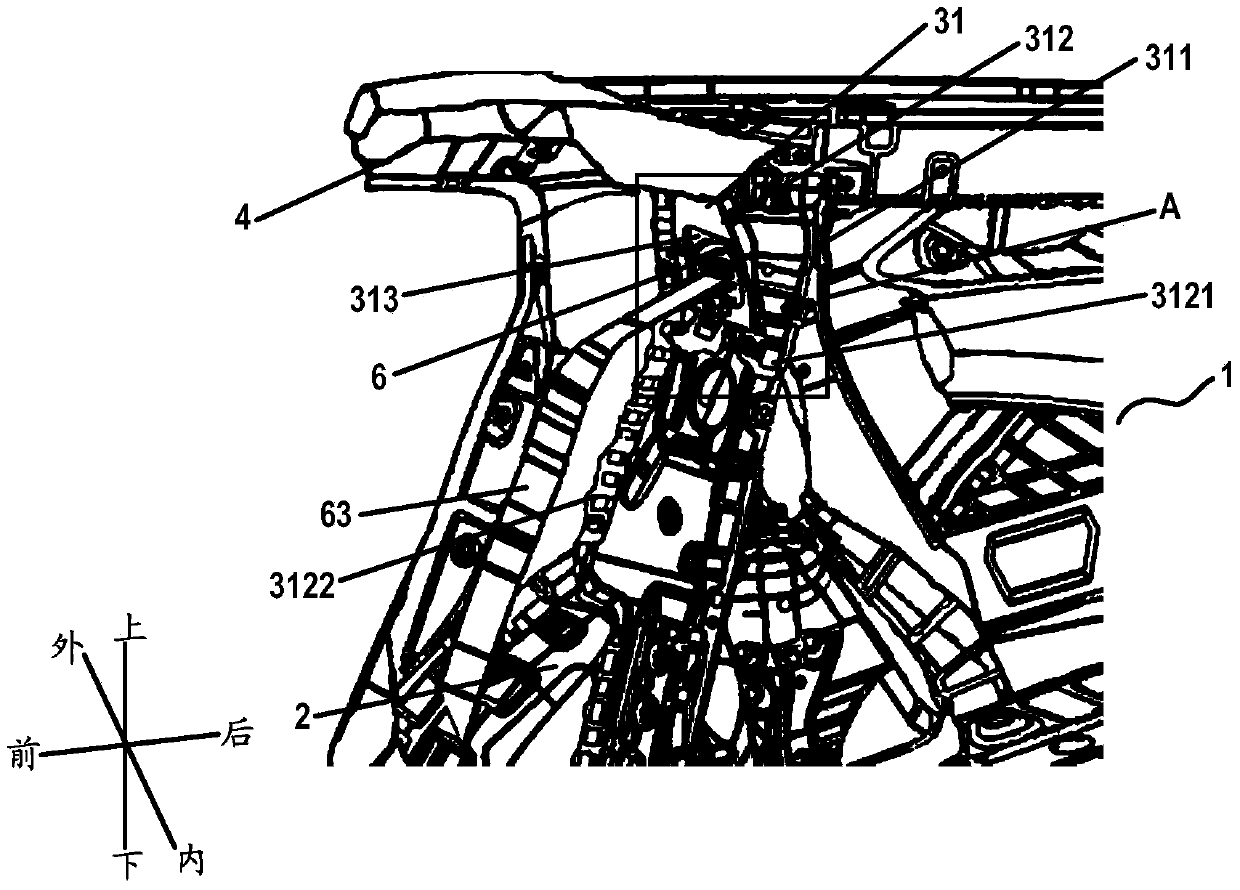

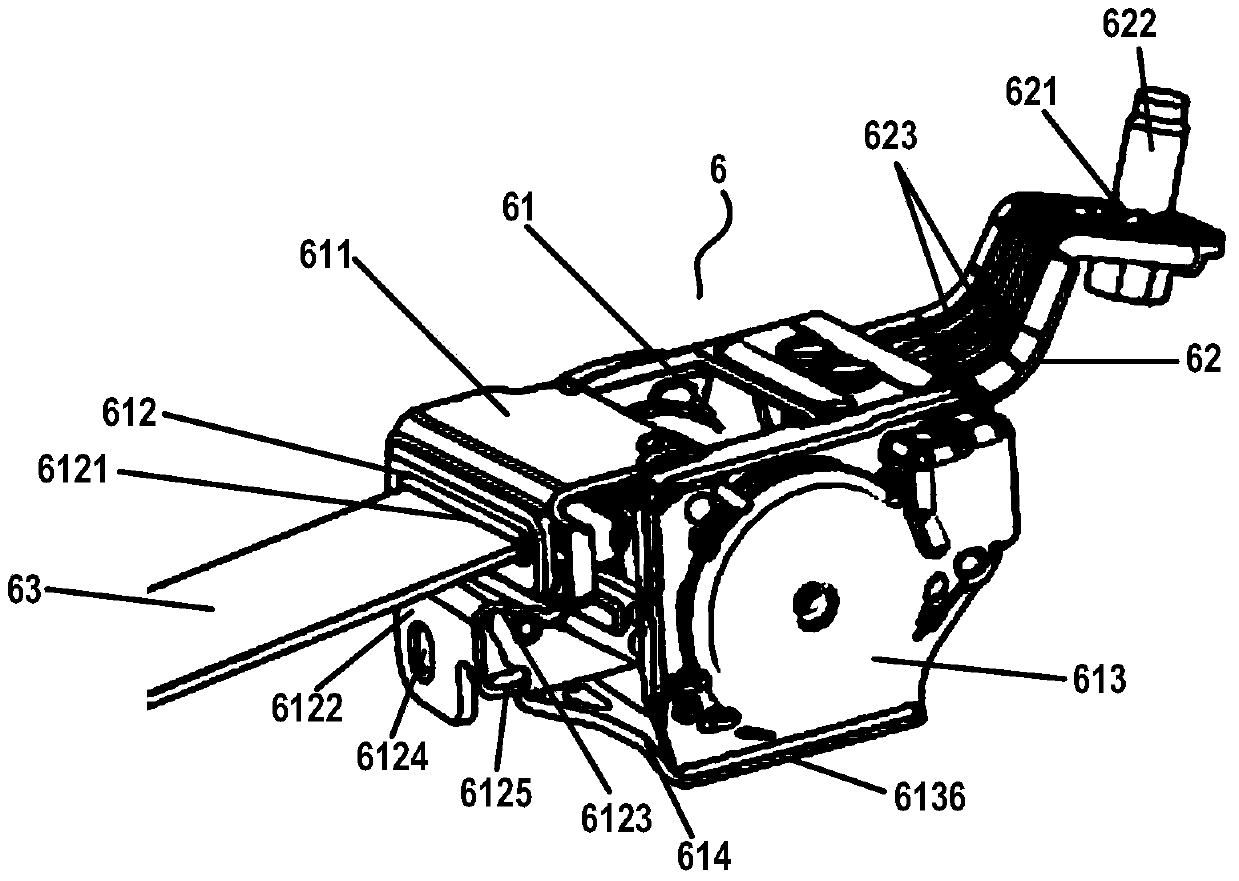

[0030] Hereinafter, preferred embodiments of the seatbelt retractor mounting structure for carrying out the present invention will be specifically described with reference to the drawings.

[0031] In the following description, with the driver and occupant sitting on the seat as the reference, the front and rear direction of the vehicle body is defined as front and rear, the vertical direction of the vehicle body is defined as up and down, the left and right sides in the vehicle width direction are defined as left and right, and the side close to the cabin is defined as the inside. The side away from the cabin is regarded as the outside. Here, the installation structure of the seat belt retractor can be formed on the left side of the vehicle body or on the right side of the vehicle body, but only the left side is used as an example for illustration in the description. In addition, for convenience of description, structural elements of the vehicle body that are not relevant to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com