Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Avoid downtime for maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

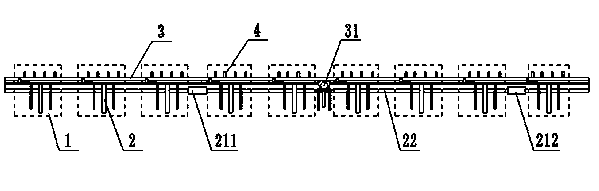

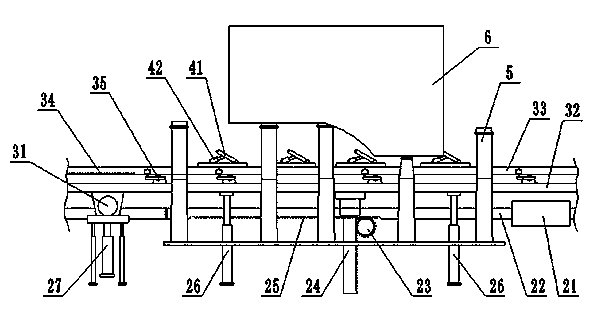

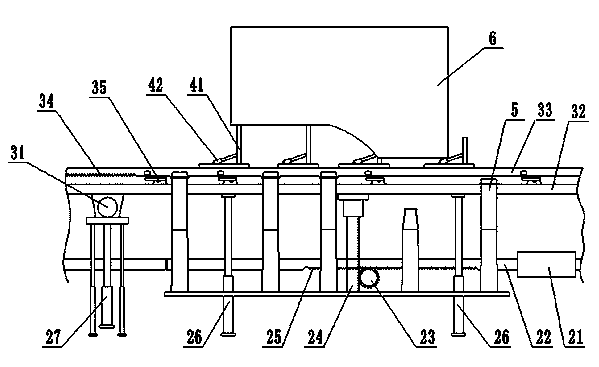

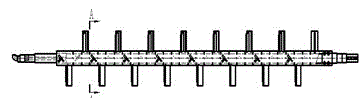

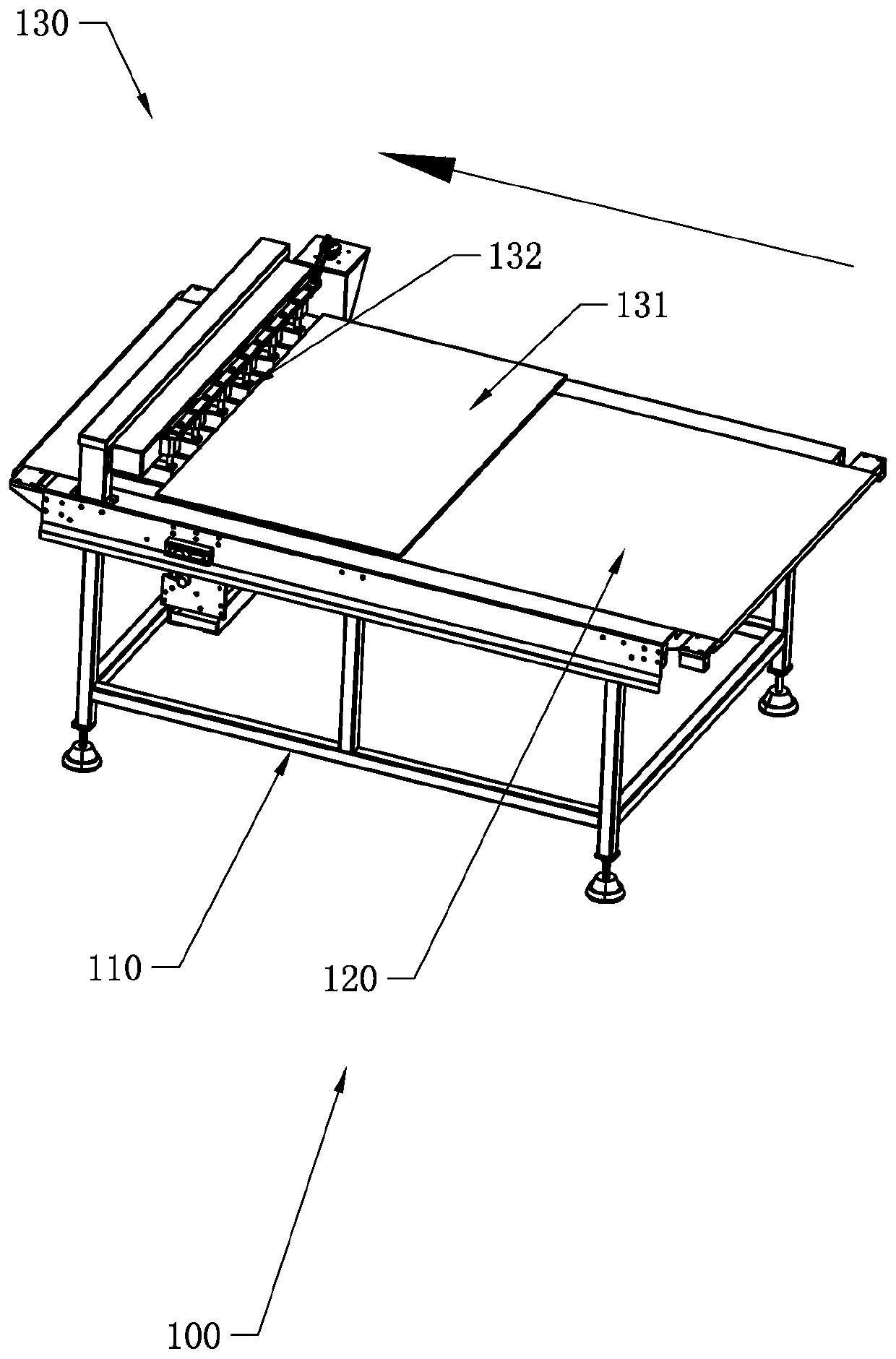

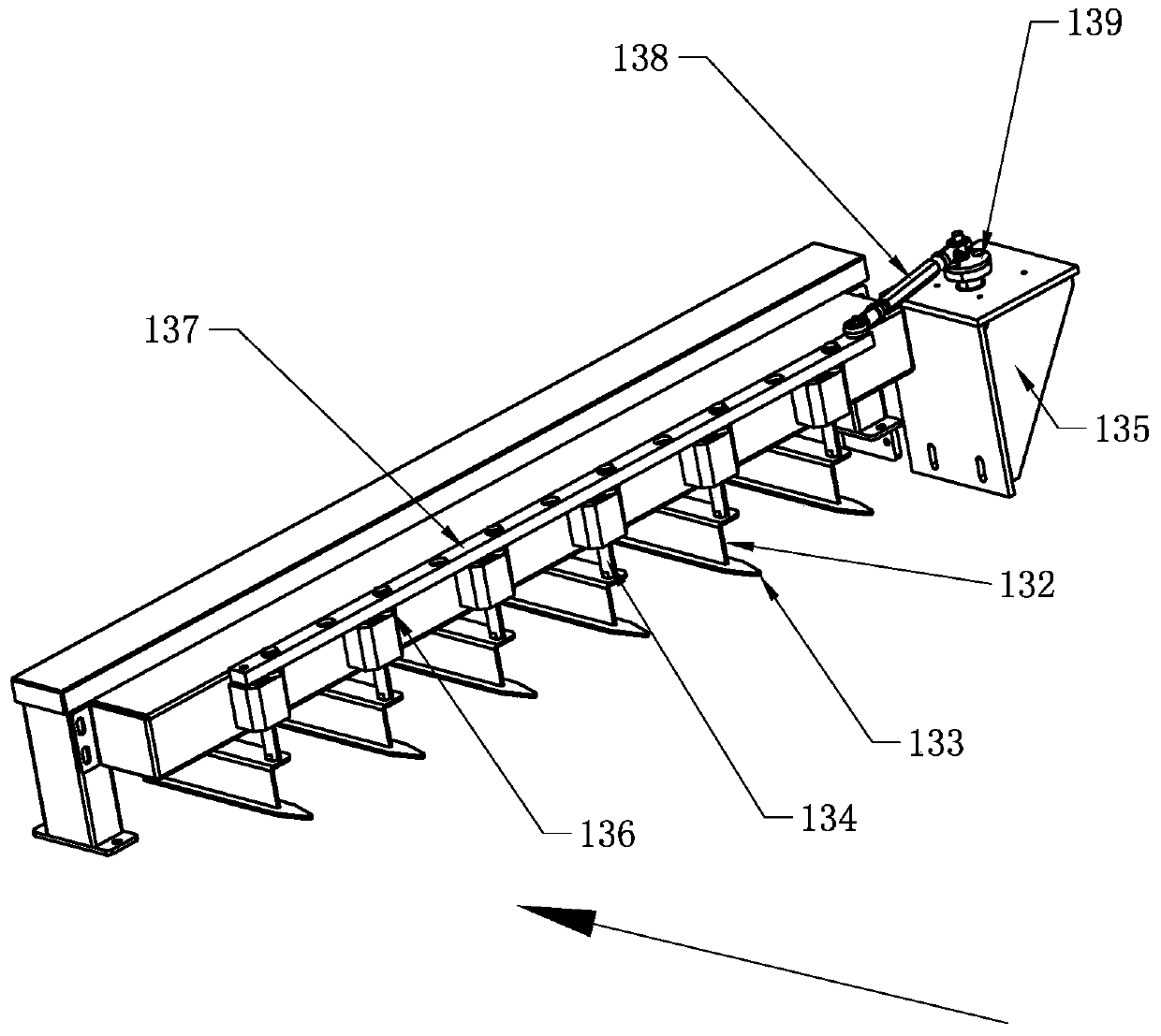

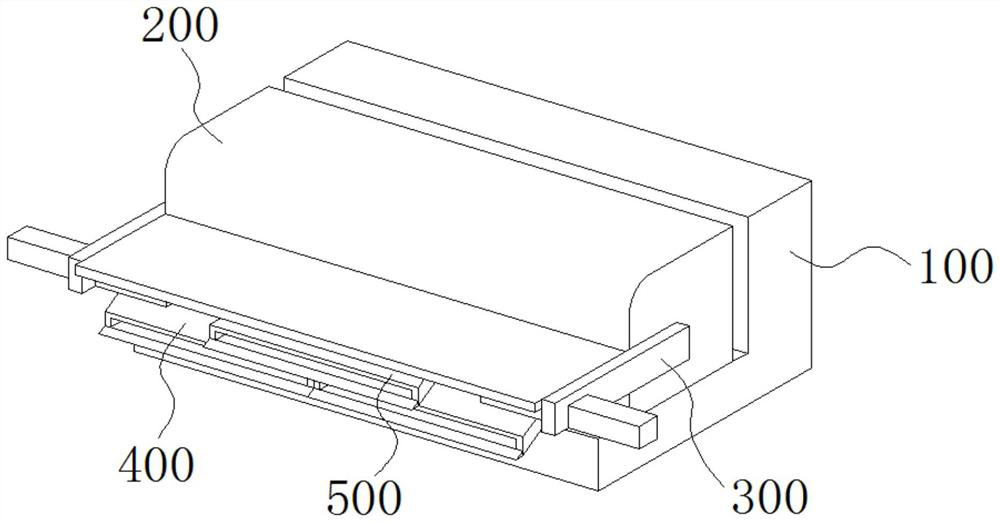

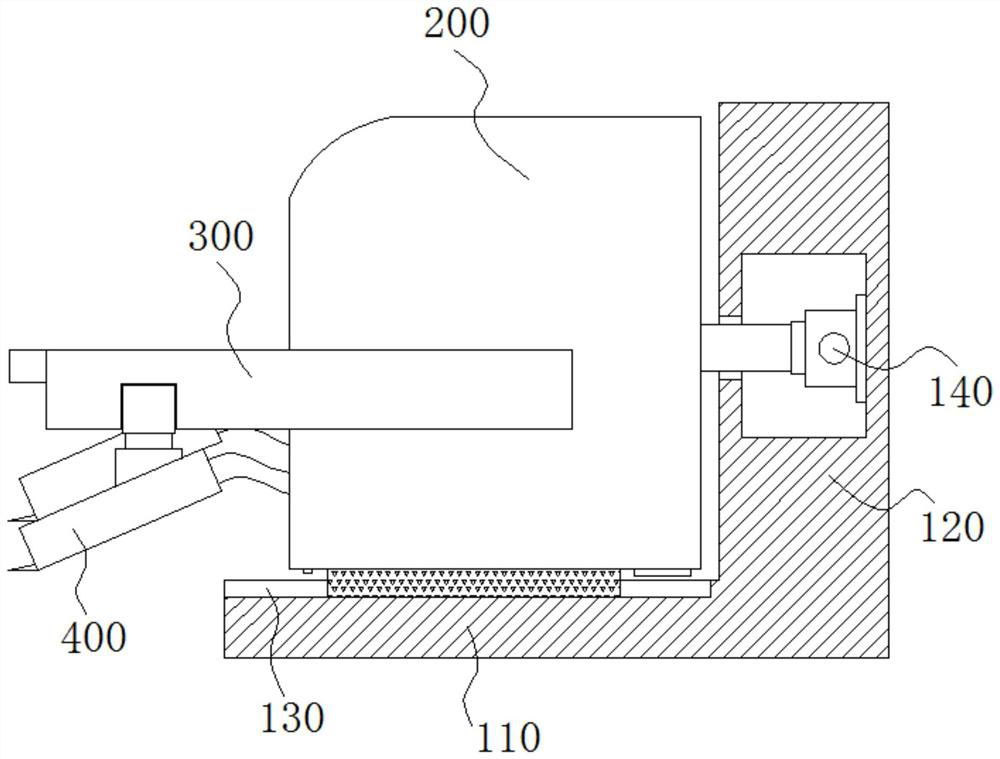

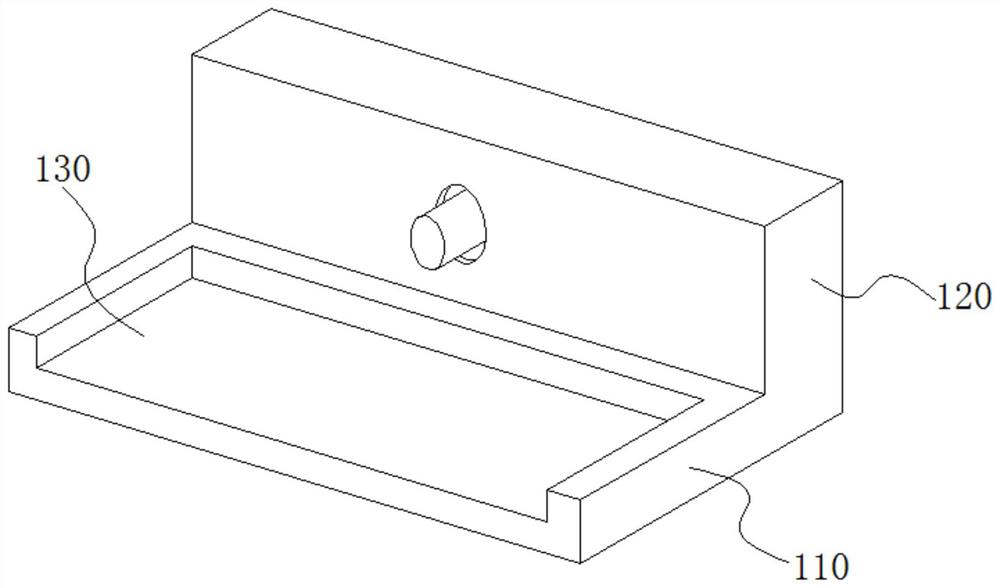

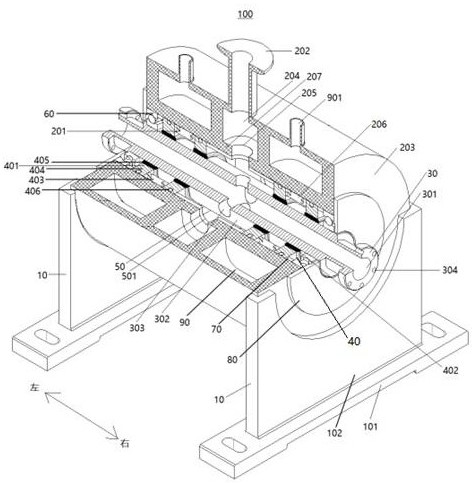

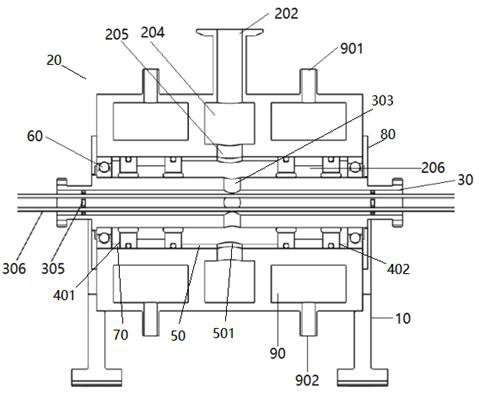

Car body welding lifting reciprocating transmission system

ActiveCN103754572ATransmission distance is easy to controlHigh precisionConveyorsProduction lineTransmission system

The invention discloses a car body welding lifting reciprocating transmission system which comprises a reciprocating transmission mechanism, a lifting mechanism and a car body supporting mechanism. The reciprocating transmission mechanism comprises a motor, a supporting beam, a walking beam, a gear rack and a rolling wheel component, the lifting mechanism is arranged at the bottom of the motor and the bottom of each work position supporting beam, and the supporting position and the height of the car body supporting mechanism can be adjusted. The car body welding lifting reciprocating transmission system has the advantages that the transmission distance is easy to control, precision is high, the operation is stable, efficiency is high, noise is low, the control is convenient and fast, the structure is compact, manufacturing cost is low, maintenance is convenient, and high safety performance is achieved, mixed routing manufacturing transmission of different car types can be achieved without shutdown, the application range of a production line is expanded, shutdown maintenance is avoided, production cost is saved, and good popularization and utilization value is achieved.

Owner:YIQI HONGTA YUNNAN AUTOMOBILE MFG

Waste plastic friction cleaning machine

InactiveCN103144218AFriction cleaning is effectiveSimple structureSievingScreeningWater dischargeWater flow

The invention provides a waste plastic friction cleaning machine, relating to the cleaning and recycling of waste plastic and applicable to the stage of further removing residual oil contamination and viscose of plastic bottles, sheets and films treated by a heat cleaning machine. The waste plastic friction cleaning machine mainly comprises a motor (16), a rotary joint (1), a screen (8), a spindle (6), a machine barrel (9), a rack (18) and the like. The waste plastic friction cleaning machine is simple in structure, and more excellent in friction cleaning effect on materials, and the problem that the screen is easily plugged can be solved. When the motor (16) drives the spindle (6) to rotate at high speed, materials entering the machine barrel (9) from a feeding inlet (5) are separated from dirt, the dirt is penetrated through the screen (8) under the double actions of strong centrifugal force and the high-pressure showering formed by a plurality of holes in the main spindle (6) and is discharged out through a water discharge outlet (20) along with water flow, while the materials are blocked in the screen (8) and spirally travels to a discharge outlet (14) under the driving of shifting plates distributed in a spiral line, so as to enter next cleaning stage.

Owner:ZHANGJIAGANG BEIER MACHINERY

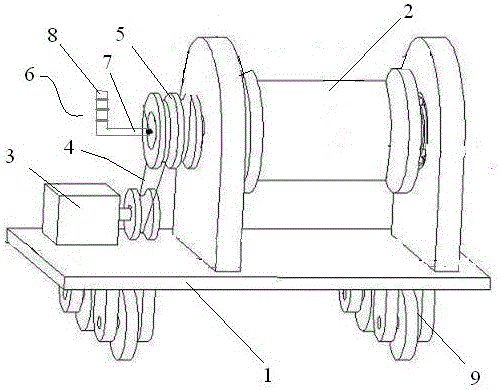

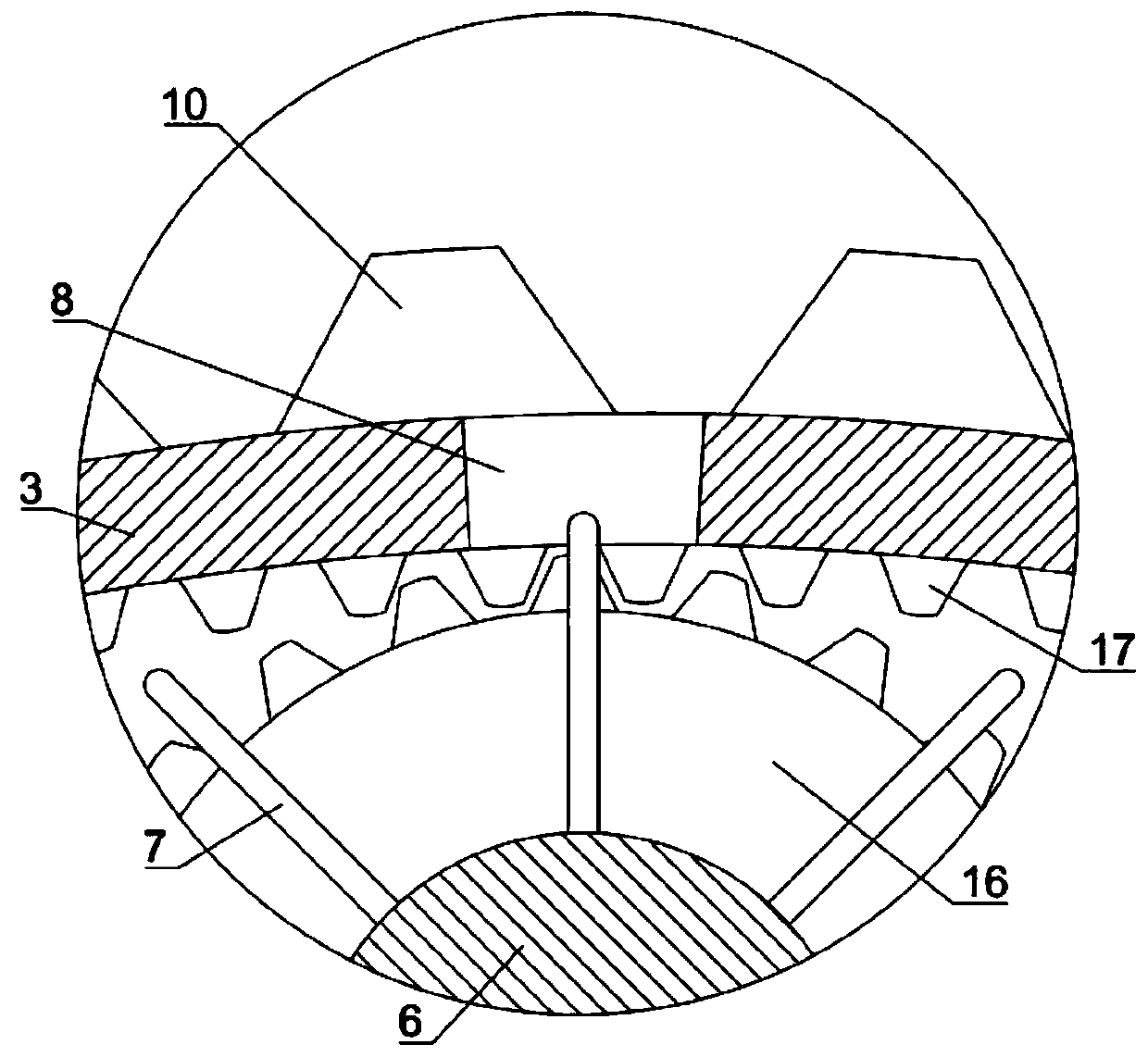

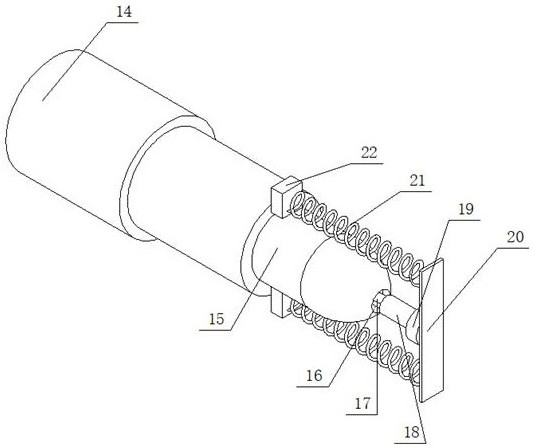

Multi-purpose cable winding machine

InactiveCN105836533AFlexible responseAvoid downtime for maintenanceFilament handlingWinding machineElectric machinery

The invention discloses a multi-purpose cable winding machine, comprising: a base, a winding disc installed on the base, and a plurality of driving mechanisms for driving the winding disc to rotate to wind cables, and a plurality of universal wheels are installed under the base. The beneficial point is that the cable winding machine of the present invention has multiple driving mechanisms. When the motor fails, the winding disk can also be manually driven to rotate, which can flexibly deal with production failures and avoid downtime for maintenance.

Owner:鲁宝霞

Method for removing contamination particles on electrostatic chuck in process chamber

ActiveCN102485356AAvoid downtime for maintenanceSave costsVacuum evaporation coatingSputtering coatingParticle adsorptionMedia layer

The invention provides a method for removing contamination particles on an electrostatic chuck in a process chamber. The method comprises the following steps of: providing a contamination particle adsorption wafer, wherein the contamination particle adsorption wafer comprises a substrate and an insulating medium layer growing on the substrate and the surface of the insulating medium layer is charged; placing the contamination particle adsorption wafer on the electrostatic chuck in the process chamber, wherein the insulating medium layer of the contamination particle adsorption wafer faces to the electrostatic chuck; adsorbing the contamination particles on the electrostatic chuck onto the insulating medium layer with the help of the charges carried by the insulating medium layer; and taking down the contamination particle adsorption wafer from the electrostatic chuck, and taking the contamination particle adsorption wafer out of the process chamber. By adopting the method provided by the invention, the contamination particles on the electrostatic chuck can be completely adsorbed once, the condition that when the process chamber implements the process, as the contamination particles exist on the electrostatic chuck, the machine is forced to stop for maintenance can be avoided, and the material cost and the time cost can be effectively saved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

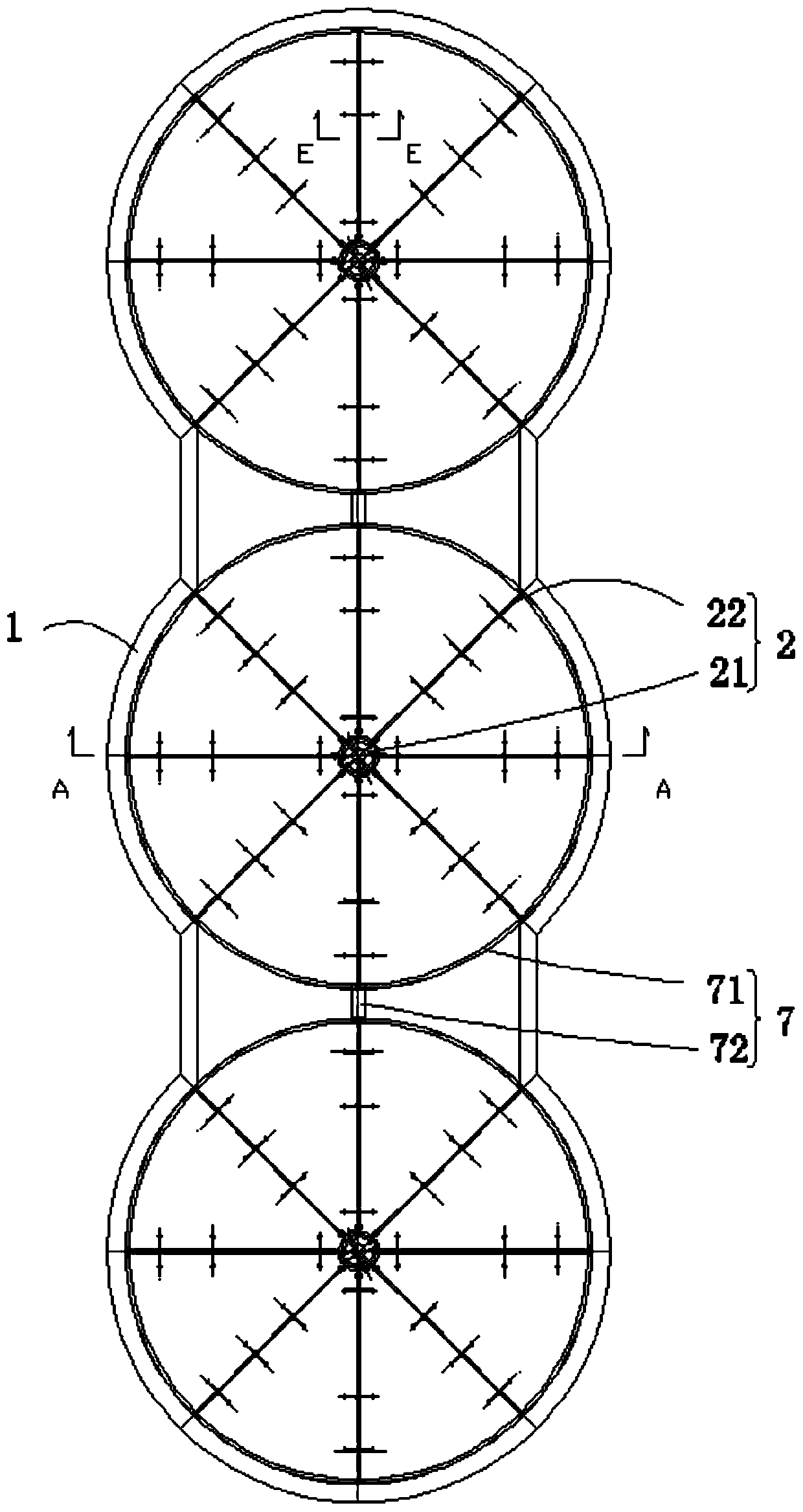

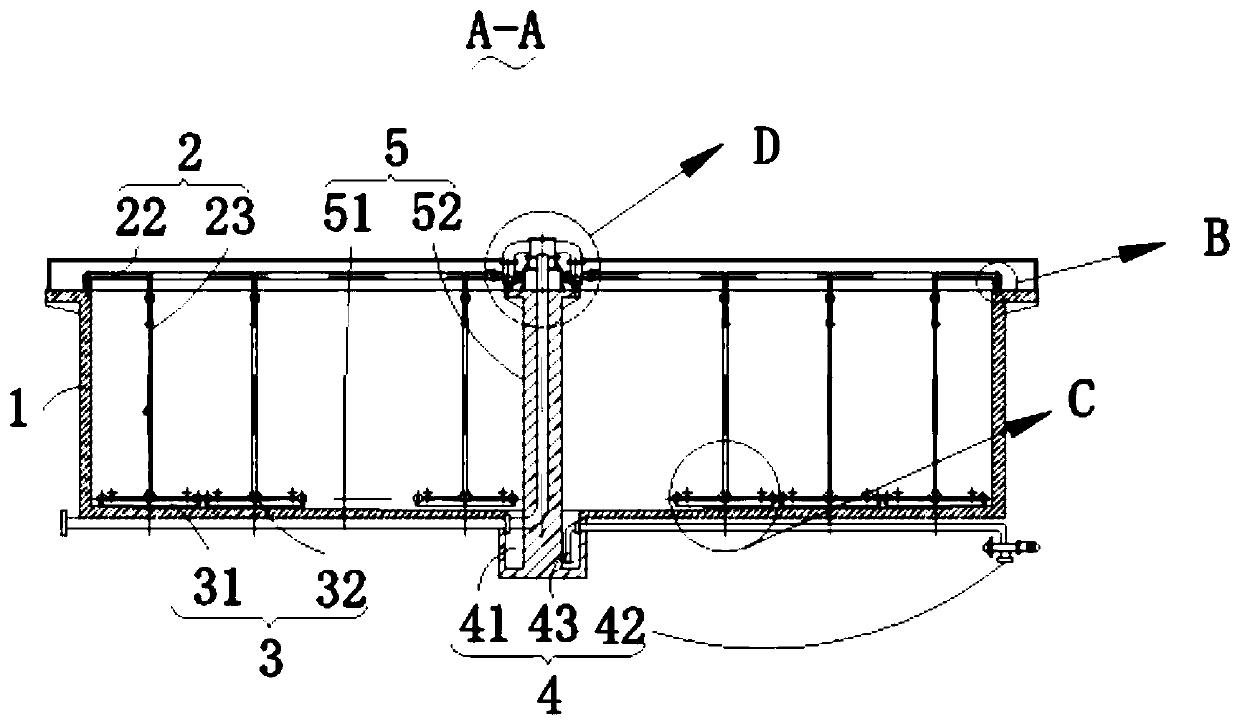

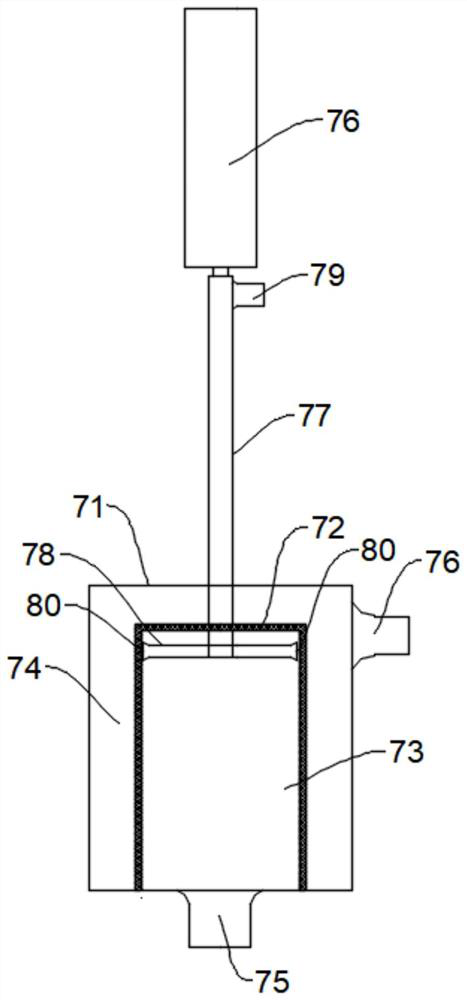

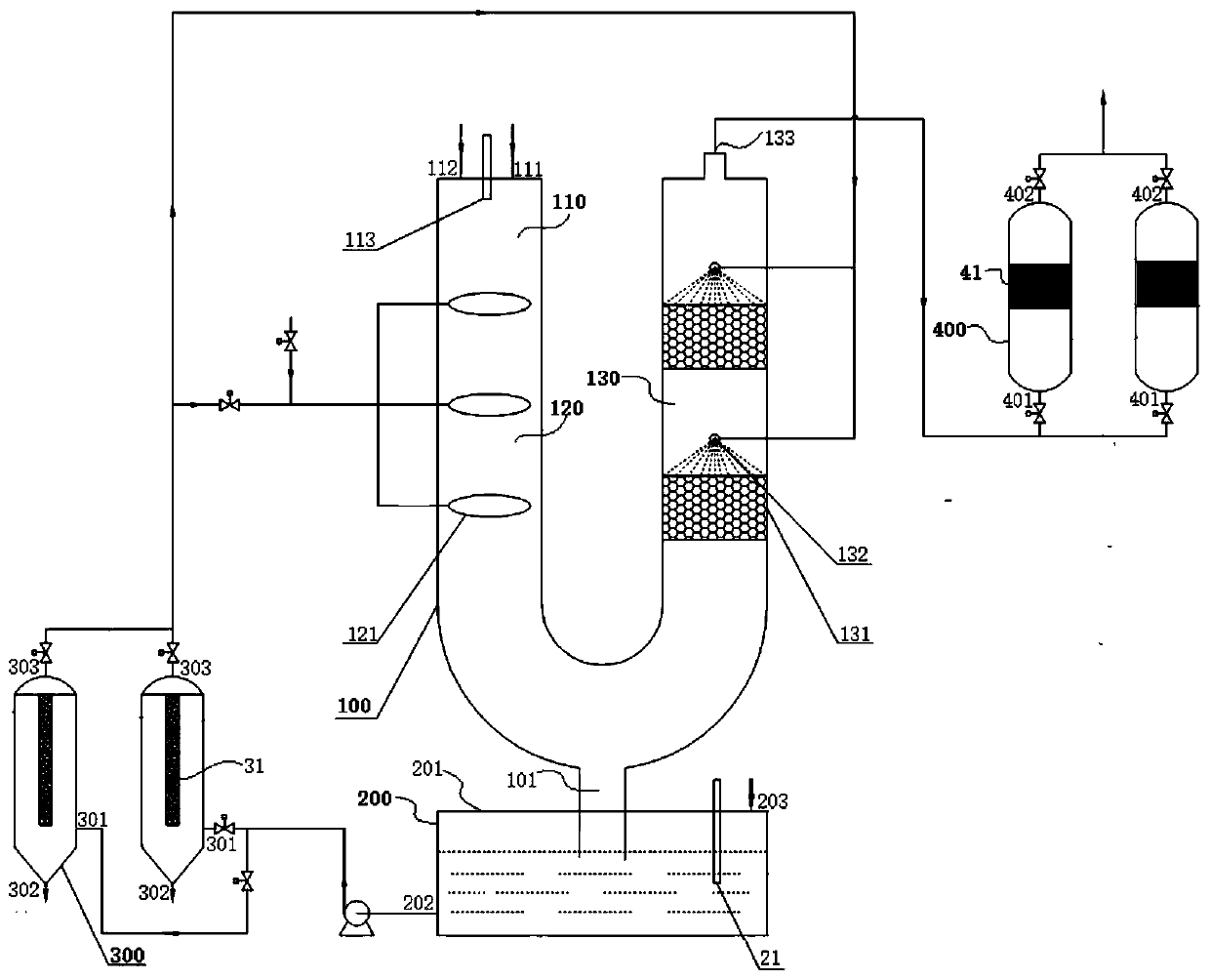

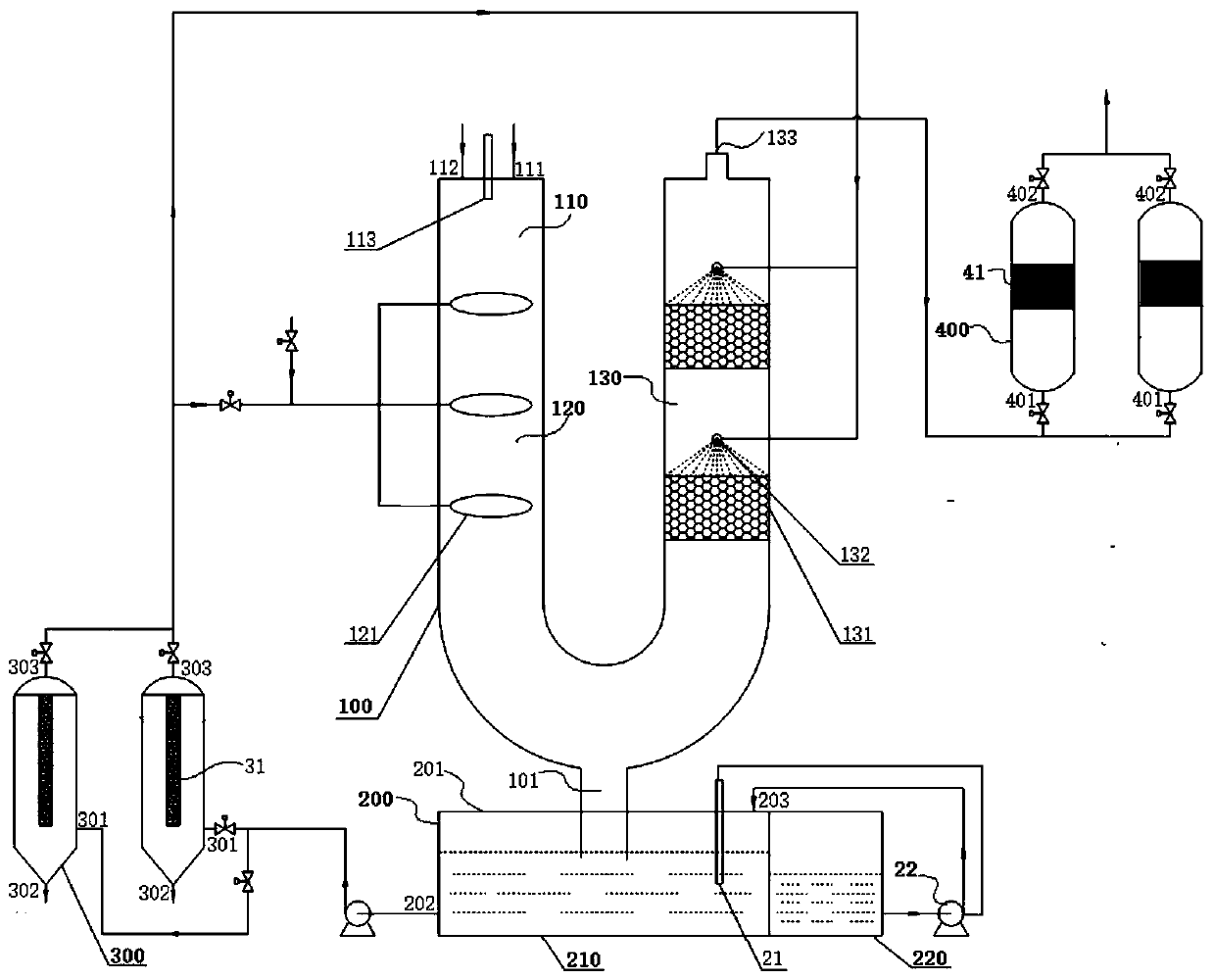

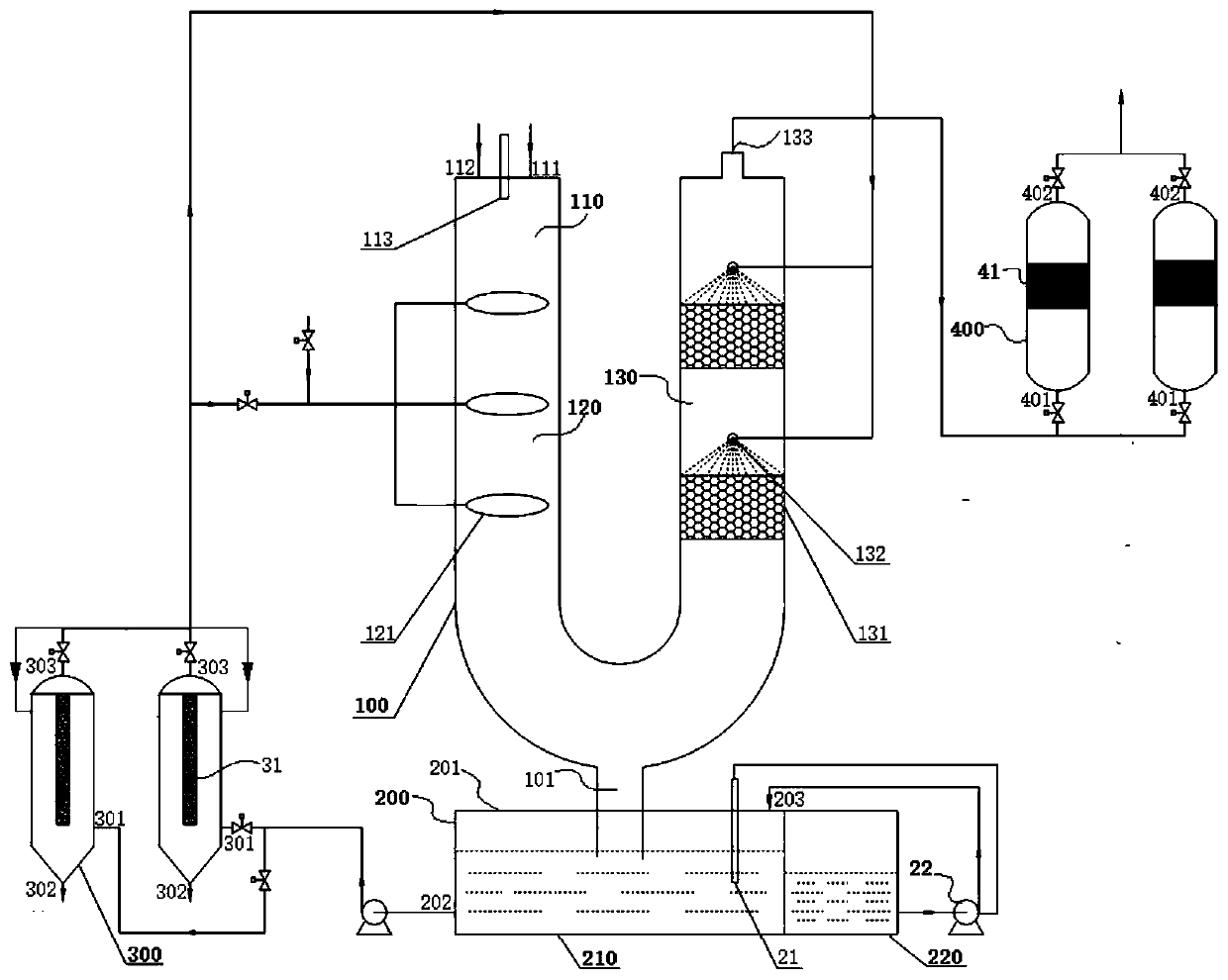

Novel rotary aeration device for sewage treatment

PendingCN111018146AWell mixedEvenly aeratedTreatment using aerobic processesSpecific water treatment objectivesTreatment pondWater treatment

The invention provides a novel rotary aeration device for sewage treatment. The novel rotary aeration device comprises a sewage treatment tank main body, a connecting mechanism mounted in the middle in the treatment tank main body and comprising an air inlet pipe and a supporting column; and an aeration mechanism comprising an air chamber mounted at the top of the supporting column, wherein the air chamber comprises an air chamber lower part (also serving as a rotary positioning center) fixed at the top of the supporting column and a rotary air chamber upper part, and the air chamber upper part is provided with bent pipes in four directions to be communicated with an annular pipe. A sealing mechanism sealed by graphite packing is arranged between an upper air chamber and a lower air chamber. The annular pipe is connected with eight transverse pipes arranged in a star shape, each transverse pipe is connected with three vertical pipes, each vertical pipe is connected with an aeration pipe, and an aeration disc is connected to the side face of the aeration pipe. The novel rotary aeration device provided by the invention pushes the whole device to rotate by utilizing the counter-actingforce of water when the aeration disc sprays air, and has the advantages of no aeration dead angle, convenience in maintenance, no need of a standby pool and the like.

Owner:ZHEJIANG CONSTR INVESTMENT ENVIRONMENTAL PROTECTION ENG CO LTD

Feeding device of egg tart cooking machine

PendingCN110447670ARealize continuous baking productionImprove production efficiencyCharging/discharging ovensEngineeringTransfer mechanism

The invention discloses a feeding device of an egg tart cooking machine, which includes a third frame body, the third frame body is provided with an intermittent transfer mechanism, and the intermittent transfer mechanism is used to make the egg tarts move in batches. The intermittent transfer mechanism includes a third conveyor belt and a fourth conveyor belt arranged along an egg tart conveyingdirection, the third conveyor belt is higher than a fourth conveyor belt, and the intermittent transfer mechanism further includes a transfer assembly for transferring the egg tarts from the third conveyor belt to the fourth conveyor belt. The transfer assembly is disposed between the third conveyor belt and the fourth conveyor belt. The transfer assembly includes a receiving cavity that receivesthe tart from up and down, a support plate that intermittently closes the bottom of the receiving cavity, a carrier board disposed below the support plate for placing egg tarts, a third power component for driving the carrier board to move up and down, and a side pushing plate for pushing the egg tarts from the carrier board to the fourth conveyor belt. The feeding device of the egg tart cooking machine of the present invention can output the egg tarts in a set quantity, is convenient for packaging, and does not affect the use of the egg tart cooking machine.

Owner:WUYI UNIV

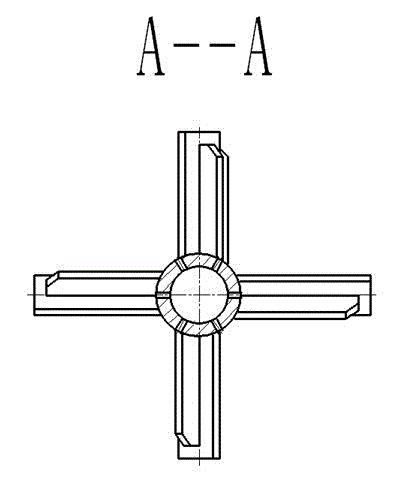

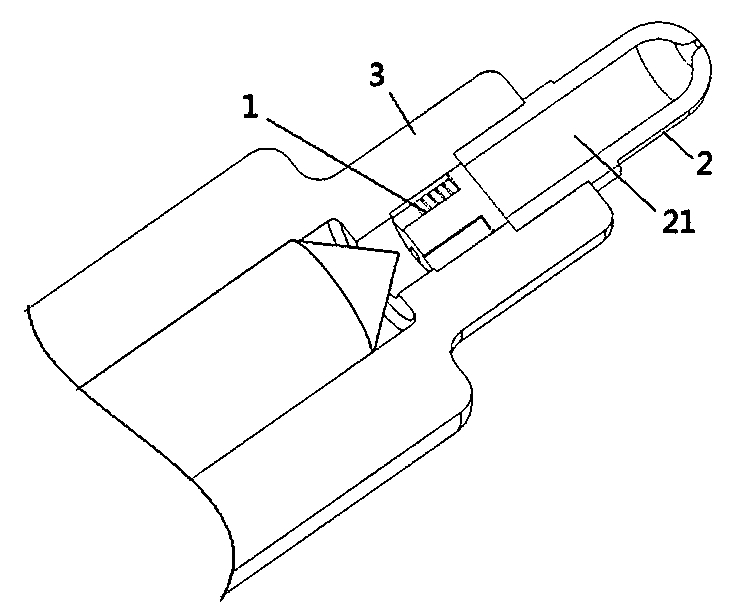

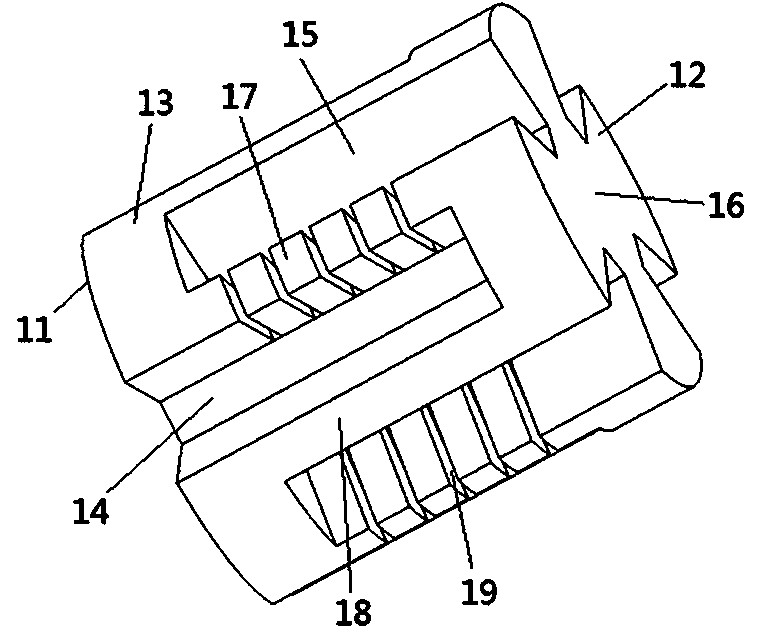

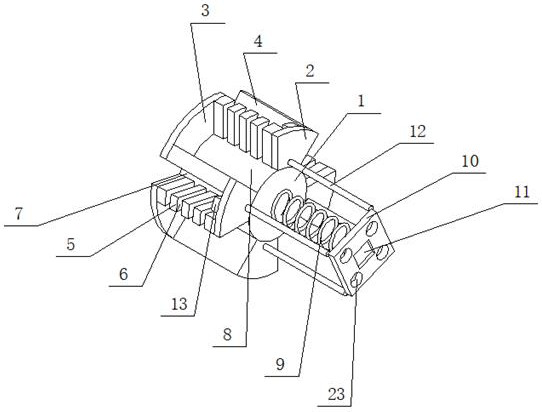

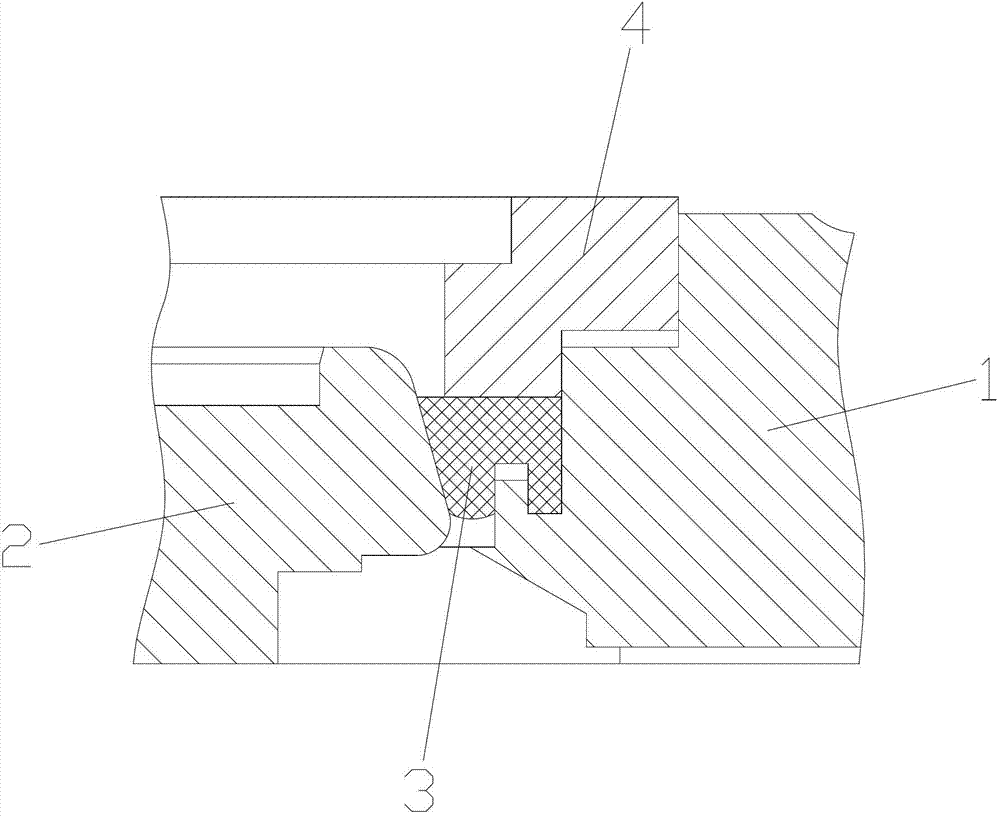

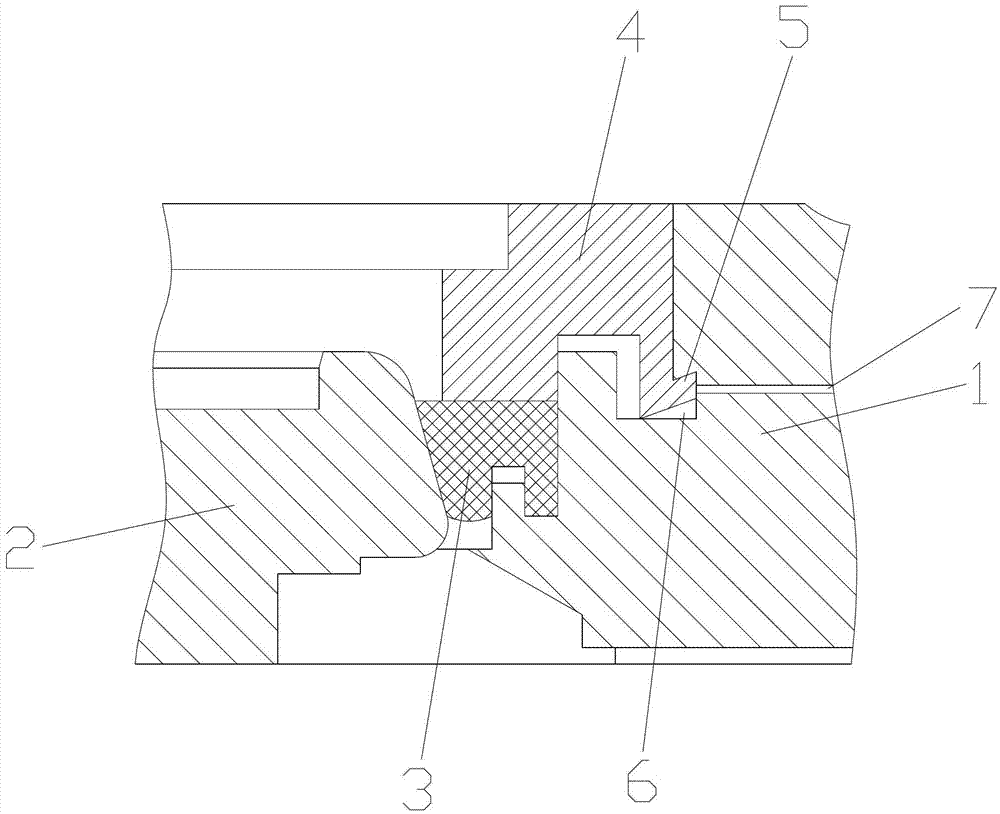

Anti-blocking device for injection molding machine nozzle and mould feed points

ActiveCN102765163BIncrease the circulation areaAvoid downtime for maintenanceInjection molding machineLarge size

The invention discloses an anti-blocking device for an injection molding machine nozzle and mould feed points. A filtering column is mounted at the rear end of a central hole of the injection molding machine nozzle or mounted on a portion, located in the rear of the injection molding machine nozzle, in an injection molding machine material tube, and is provided with feeding grooves, discharging grooves and filtering grooves, raw materials enter the filtering column from each feeding grooves of the filtering column and enter the discharging grooves after being filtered via the filtering grooves, and foreign materials in the raw materials are intercepted by the filtering grooves while the raw materials enter the injection molding machine nozzle and a mould from the discharging groove, therefore, halt and maintenance caused by blocking of the injection molding machine nozzle and the mould feed points are avoided. Feeding grooves and discharging grooves in large size can be cut on the filtering column, and a plurality of filtering grooves can be cut on shared groove walls among the feeding grooves and the discharging grooves, so that processing is facilitated, flow areas of the raw materials is increased greatly, and the anti-blocking device plays a role in intercepting and has small influences on injection flow and speed of the nozzle.

Owner:镒生电线塑料(昆山)有限公司

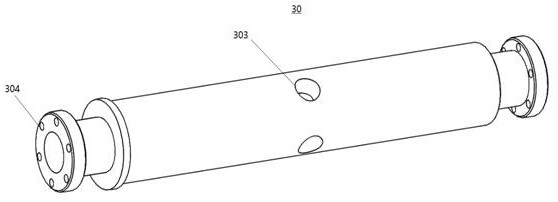

Shell heat exchanger of double-barrel casting

PendingCN109579563AExtend the production cycleShorten the production cycleHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerDesign cycle

The invention discloses a shell heat exchanger of a double-cylinder casting, comprising a double-cylinder shell, a base, casting end sockets, an end socket sealing ring, a heat exchange core, a rear sealing cover plate, a threaded plug, a fastening bolt, a cover plate sealing ring, an air inlet, an air outlet and a standby air inlet; the double-barrel shell comprises a first tube and a second tube, the openings of the first tube and the second tube are positioned at one side of the double-barrel shell, and the casting end sockets are arranged on the openings of the first tube and the second tube; the other side of the double-barrel shell is provided with the rear sealing cover plate; the top side of the double-barrel shell is provided with the air inlet, the air outlet and the standby airinlet. The shell heat exchanger provided by the invention has the characteristics of improving the passing rate of one-time test, improving the overall yield rate, shortening the production cycle of the heat exchanger, shortening the design cycle, reducing the outage maintenance loss and having strong capability.

Owner:API HEAT TRANSFER SUZHOU

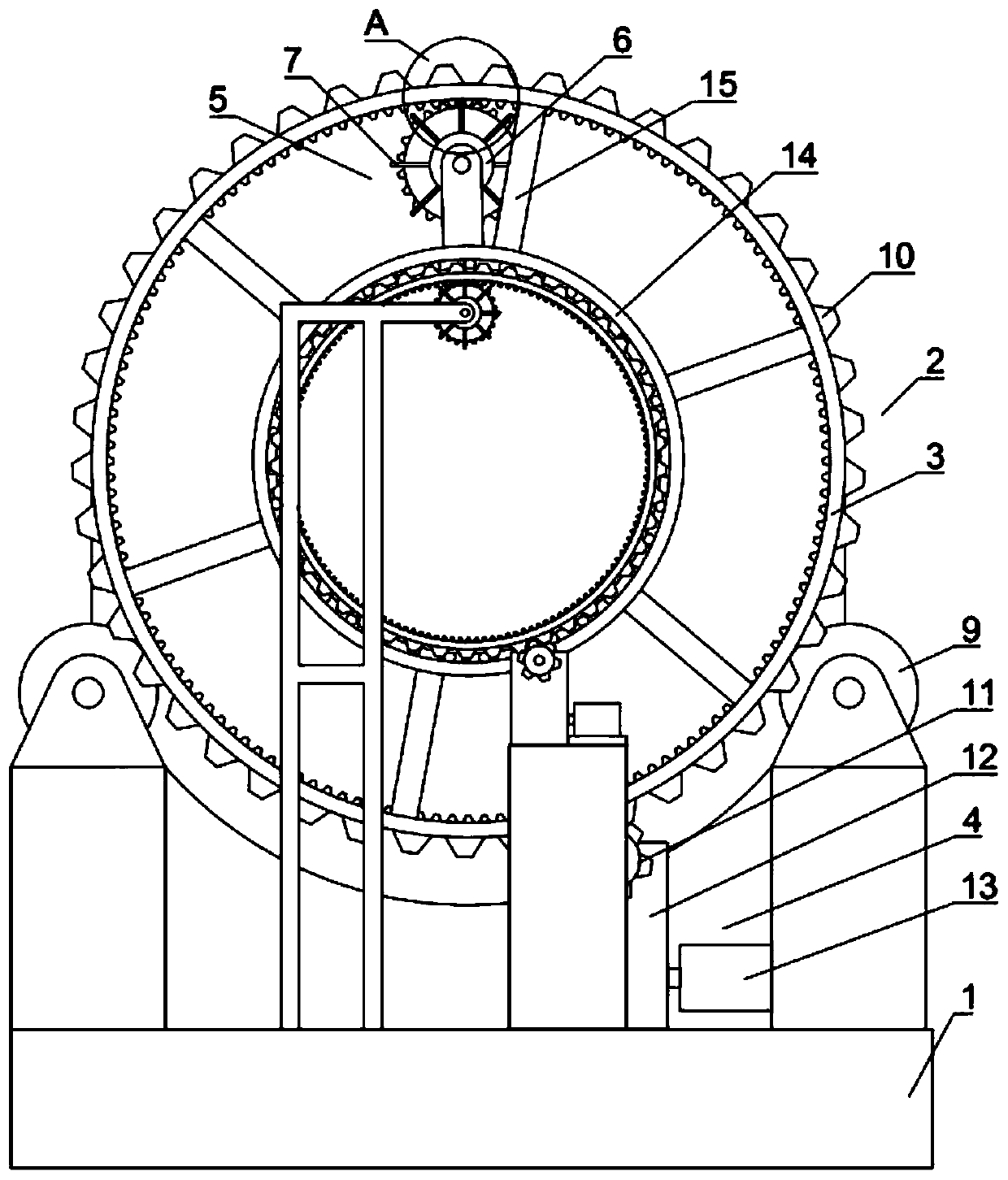

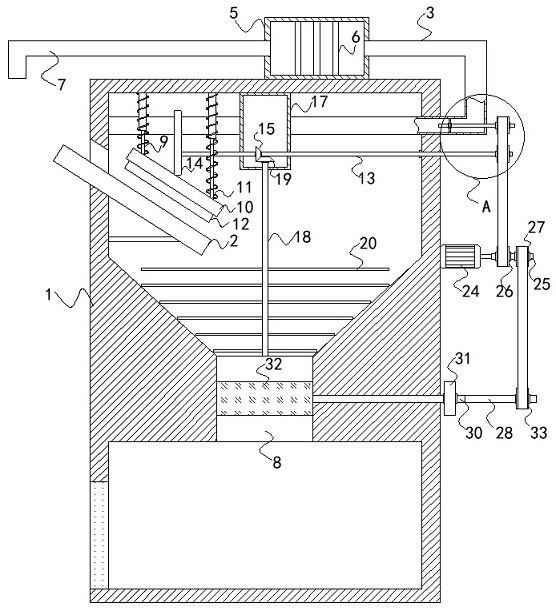

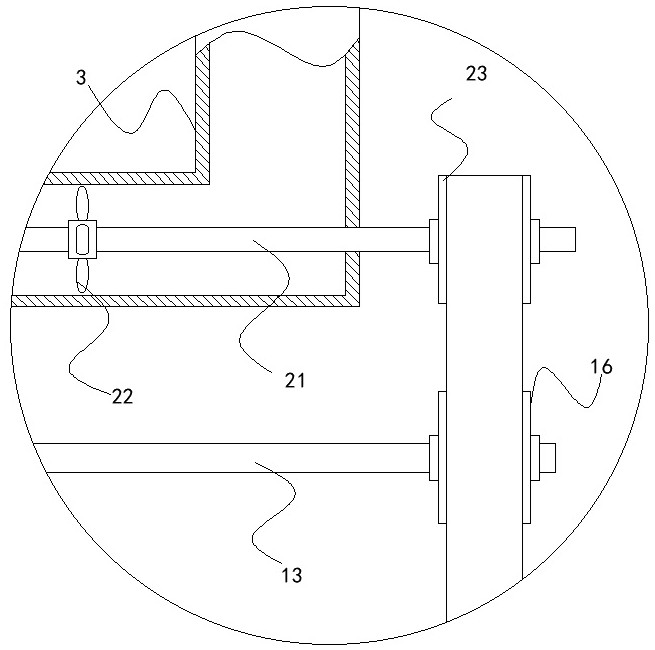

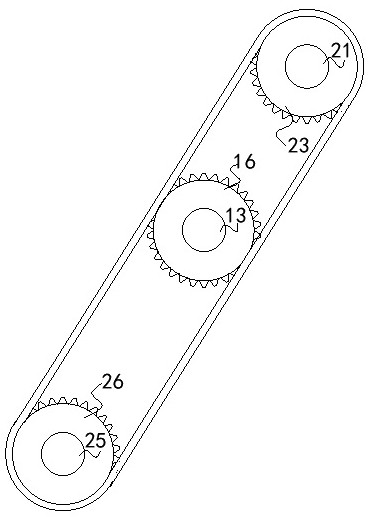

Mining multi-stage drum screen

InactiveCN110813699ASatisfy the requirement of rotation speedQuality assuranceSievingScreeningStructural engineeringMechanical engineering

The invention discloses a mining multi-stage drum screen. The mining multi-stage drum screen is characterized in that the mining multi-stage drum screen comprises a base and a plurality of screening mechanisms; each screening mechanism comprises a drum screen, a driving mechanism and an anti-blocking mechanism, the driving mechanisms drive the drum screens to rotate, the drum screens are sequentially and rotatably connected in a sleeved mode from inside to outside, and the outermost drum screen is rotatably mounted on the base; and the anti-blocking mechanism comprises an anti-blocking shaft and a plurality of anti-blocking rods, the anti-blocking shaft is rotatably mounted on the inner sides of the drum screens, and the anti-blocking rods are fixed to the outer circumferential surface ofthe anti-blocking shaft and used in cooperation with sieve meshes on the drum screens when the drum screens rotate. Compared with the prior art, the invention has the advantages that the rotating speeds of the drum screens can be adjusted separately to meet the requirements of minerals with different sizes for the rotating speeds of the drum screens, so that the mineral screening quality and efficiency are guaranteed, and the situation that the mining multi-stage drum screen has to be stopped for maintenance and sieve mesh cleaning due to blockage of the sieve meshes is avoided.

Owner:徐州铭创自动化科技有限公司

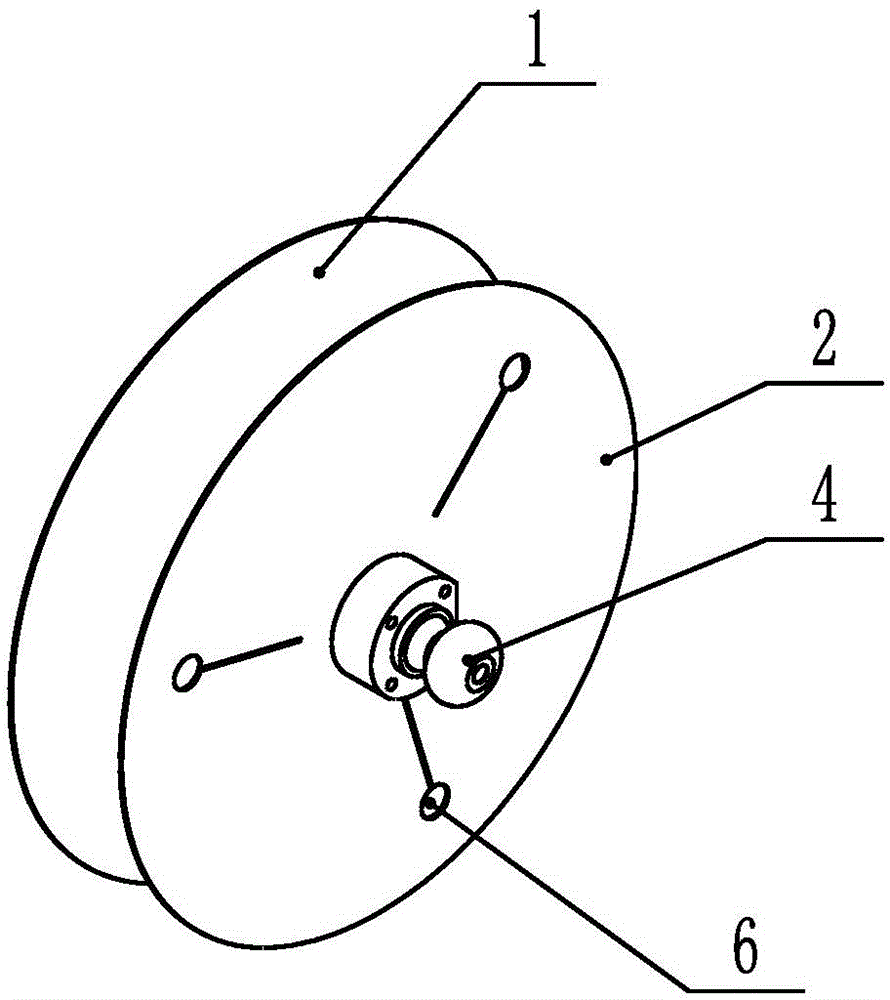

Waste collection disc of full-automatic stretching film packaging machine

InactiveCN104828652AAvoid downtime for maintenanceIncrease productivityWaste collectionWaste management

The invention discloses a waste collection disc of a full-automatic stretching film packaging machine. The waste collection disc comprises a waste collection disc body I, a waste collection disc body II, a waste collection disc fixed shaft, an assembling and disassembling handle and a clamping pin and is characterized in that the waste collection disc fixed shaft is arranged between the waste collection disc body I and the waste collection disc body II, and the assembling and disassembling handle is arranged on the right side of the waste collection disc body II; the assembling and disassembling handle penetrates the waste collection disc fixed shaft and the material receiving disc body I in sequence; the clamping pin is arranged on the left side of the material receiving disc body I, and the assembling and disassembling handle and the waste collection disc body I are connected and fixed through the clamping pin; and observation grooves are formed in the peripheries of the centers of the waste collection disc body I and the waste collection disc body II, and the top ends of the observation grooves are round. The waste collection disc has the beneficial effects that shutdown cleaning is not needed, an operator only needs to pull out the clamping pin, and can complete cleaning by drawing out the assembling and disassembling handle, shutdown maintenance caused by cleaning in the continuous production can be avoided, the production efficiency is improved, and the production cost is saved.

Owner:杨术本

Cleaning device for 3D printer platform

PendingCN113665119AImprove compatibilityThe adjustment method is simple and convenientAdditive manufacturing apparatus3D object support structuresComputer printing3d printer

Owner:深圳市金石三维打印科技有限公司

A method and system for short-cutting longitudinal distance changing of large ear pieces of diapers

ActiveCN106361500BEffective variable pitchMake sure the size specificationAbsorbent padsBaby linensManufactured materialStructural engineering

Owner:SONGJIA QUANZHOU MACHINERY

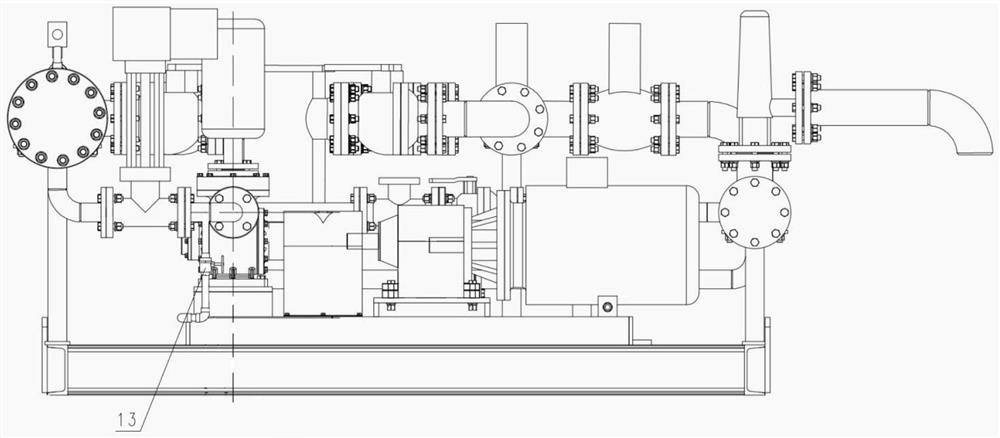

Oil-gas mixed transportation integrated device not prone to blockage

PendingCN114321718ANot easy to mix upShorten delivery timeDispersed particle filtrationTransportation and packagingLine tubingSafety valve

The invention relates to the field of oil-gas mixed transportation, in particular to an oil-gas mixed transportation integrated device not prone to blockage, which comprises a prying frame welding main body, an oil outlet and inlet pipeline and an oil outlet pipeline, the oil outlet and inlet pipeline and the oil outlet pipeline are mounted on the prying frame welding main body, and a first high-pressure electric valve is connected between the oil outlet pipeline and the oil inlet pipeline; the right end of the oil outlet pipeline is also connected with a first high-pressure electric valve and is sequentially connected with a safety valve and an output pipeline; the right end of the oil inlet pipeline is also connected with a first high-pressure electric valve, and is sequentially connected with a filter group and a shunt pipe; at least one oil-gas multiphase pump set is connected between the output pipeline and the flow dividing pipe, and the filtering set comprises a filtering structure and a cleaning structure. According to the invention, complicated pipelines are reduced, and meanwhile, the automatic cleaning mechanism is arranged, so that automatic cleaning can be realized under the non-stop condition, and therefore, blockage is not easy to occur.

Owner:CECEP TECH INVESTMENT +1

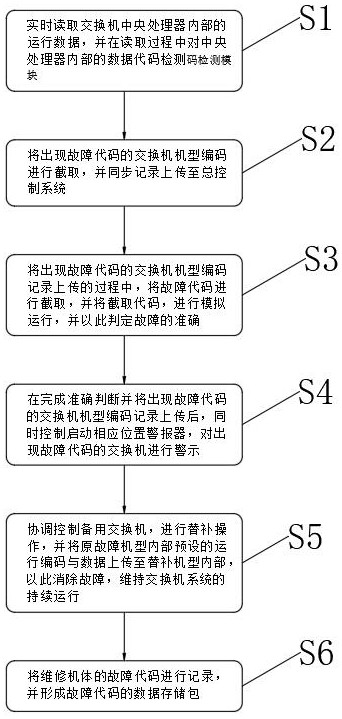

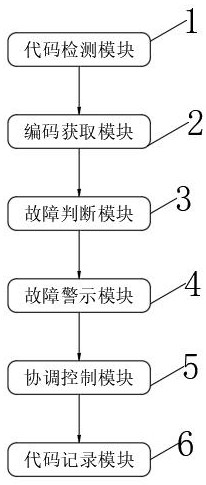

Low-cost high-efficiency switch fault processing device and method

PendingCN114048054AGuaranteed uptimeAvoid fault misjudgmentNon-redundant fault processingDowntimeProcessing

The invention relates to the technical field of switch equipment, and discloses a low-cost high-efficiency switch fault processing device. The device specifically comprises: a code detection module, which is used for reading operation data and control codes in each switch in real time and synchronously detecting the operation data and the codes; and a code acquisition module, which is used for intercepting and uploading the type number of the switch with the fault code when the fault code is detected. According to the invention, fault codes are substituted into a virtual model for simulation operation, so when the operation conditions of the switches are detected, the conditions of fault misjudgment and downtime maintenance caused by the vulnerabilities of a system are effectively avoided, and economic loss is effectively reduced accordingly; and meanwhile, a fault machine body is replaced by regulating and controlling a standby switch, so a fault is temporarily eliminated, the continuous operation of a switch system is maintained, and economic loss caused by long-time downtime maintenance is effectively reduced.

Owner:武汉云新锐信息技术有限公司

A non-woven fabric return device

ActiveCN112121936BImprove crushing efficiencyImprove crushing effectDispersed particle filtrationTransportation and packagingStructural engineeringNonwoven fabric

The invention discloses a non-woven fabric returning device, which comprises a returning box. The returning box is provided with a first chamber and a second chamber from top to bottom. There is a blanking plate installed obliquely in the feeding port, a cutting mechanism is fixedly connected to the top surface of the first chamber, the cutting mechanism is located directly above the blanking plate, and a crushing mechanism is fixedly connected to the top surface of the first chamber. The end of the chamber away from the blanking plate rotates through a cam mechanism, the cam mechanism is connected with the crushing mechanism in transmission, the end of the cam mechanism located in the first chamber is in contact with the crushing mechanism, and the side wall of the first chamber is fixed and penetrated with a The absorption pipe is provided with a plurality of suction ports on the part of the absorption pipe located in the first chamber. The invention can effectively crush the recovered non-woven fabrics, which is convenient for subsequent processing. In addition, it can also collect and process the broken fluff floating in the air, which effectively improves the environmental protection of the recycling device. .

Owner:京环纺织品再利用邯郸有限公司

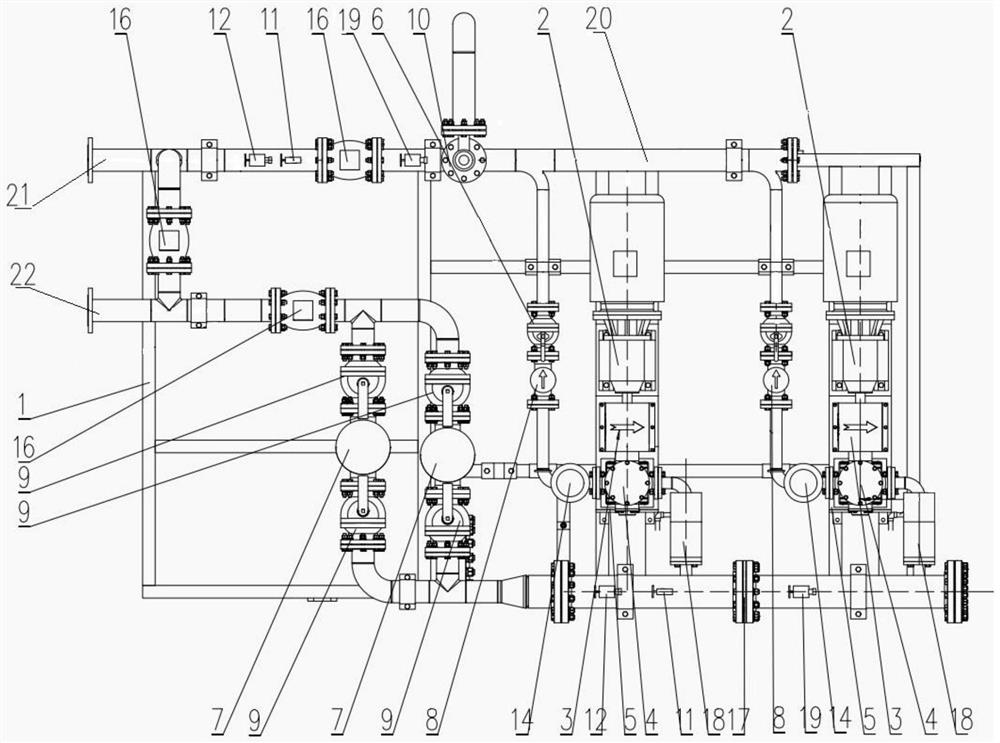

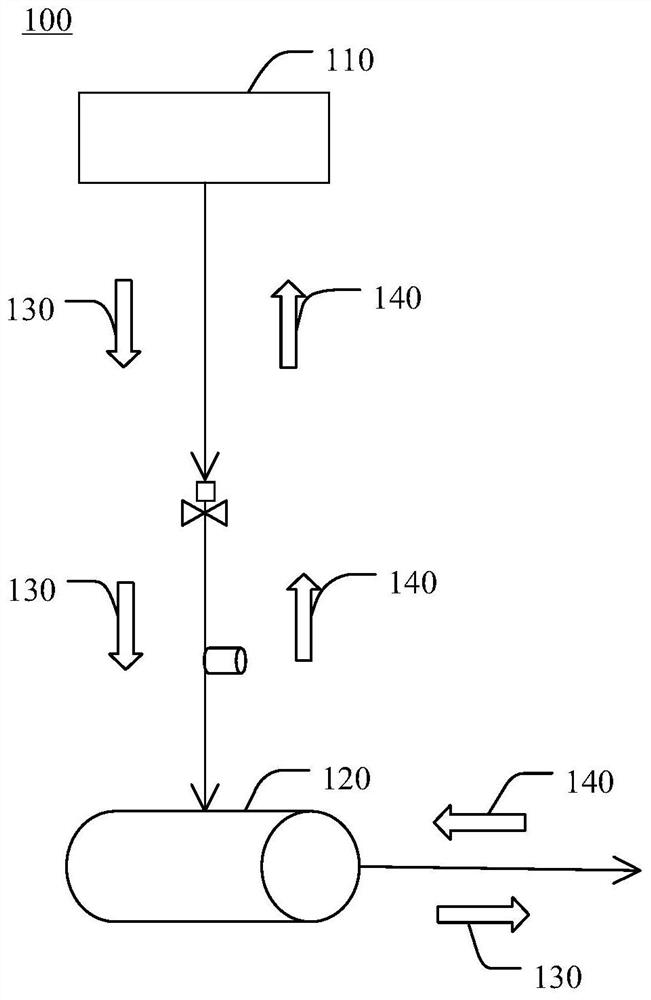

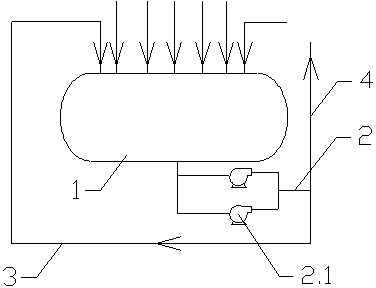

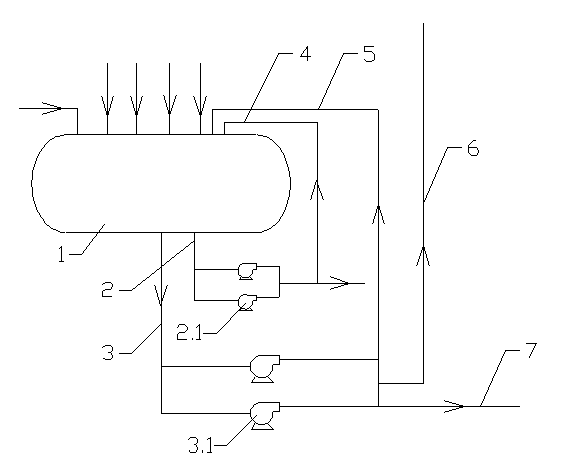

Pipeline system for heating medium feeding tank

InactiveCN104214514ALow failure rateAvoid downtime for maintenancePipeline systemsProduction lineProcess engineering

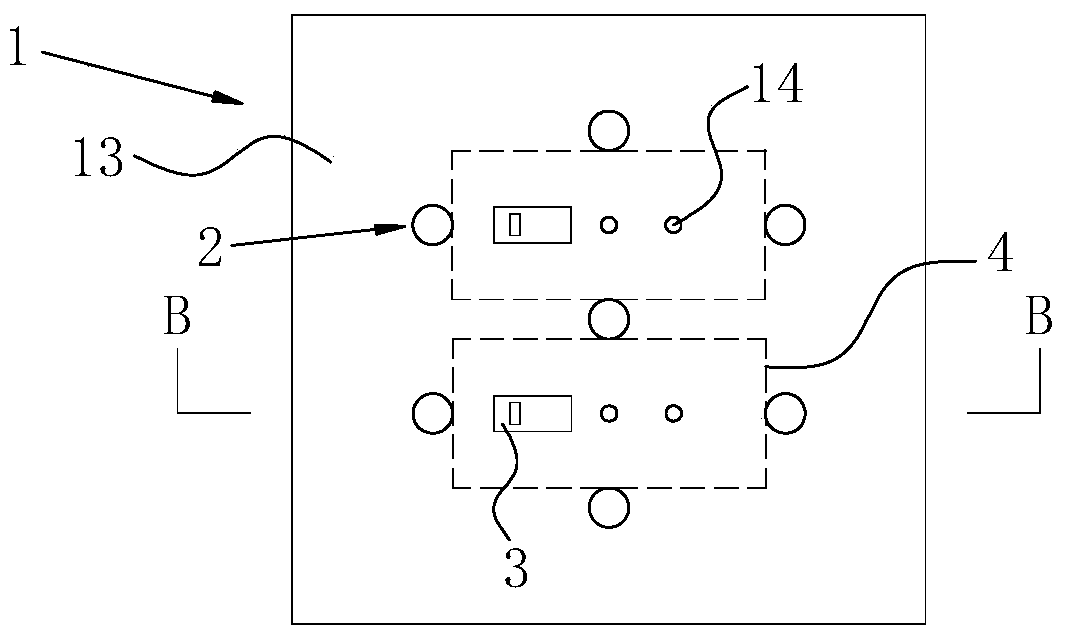

The invention relates to a pipeline system for a heating medium feeding tank. The pipeline system comprises the heating medium feeding tank (1) and is characterized in that the feed port of the heating medium feeding tank (1) is connected with a heating medium adding pipeline (2) and a condensation tank feeding pipeline (3), the discharge port of the heating medium feeding tank (1) is connected with a discharge pipeline (4), two output pumps (4.1) are arranged on the front section of the discharge pipeline (4) in parallel, a material return pipeline (5) is connected between the middle section of the discharge pipeline (4) and the material return opening of the heating medium feeding tank (1), the rear end of the discharge pipeline (4) is connected with a heating medium furnace (6), and the discharge port of the heating medium furnace (6) is connected with a flash tank (7) through a pipeline. The pipeline system for the heating medium feeding tank has the advantages of being low in fault rate and capable of effectively preventing production line halt and maintenance.

Owner:JIANGYIN BOLUN CHEM FIBER

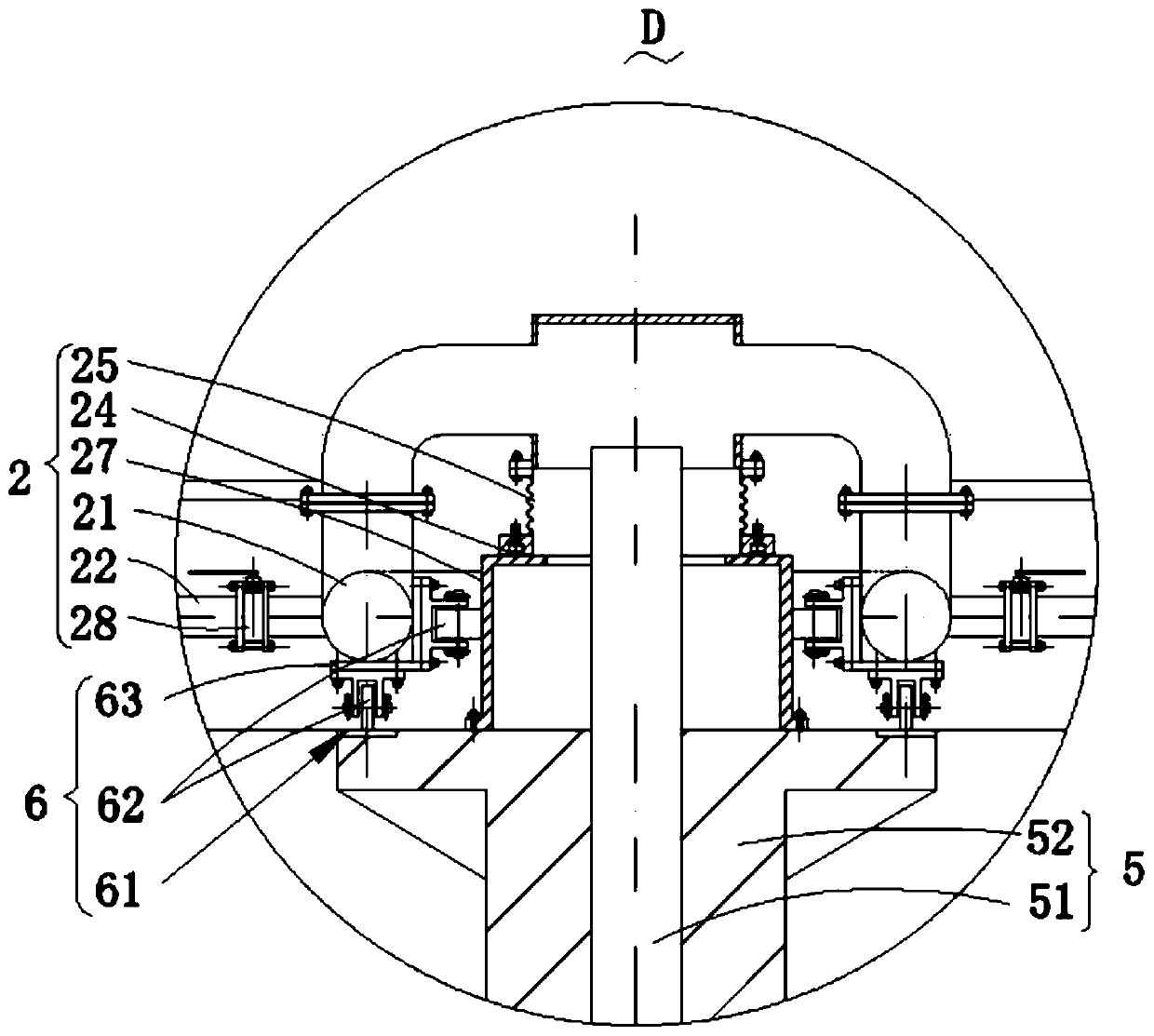

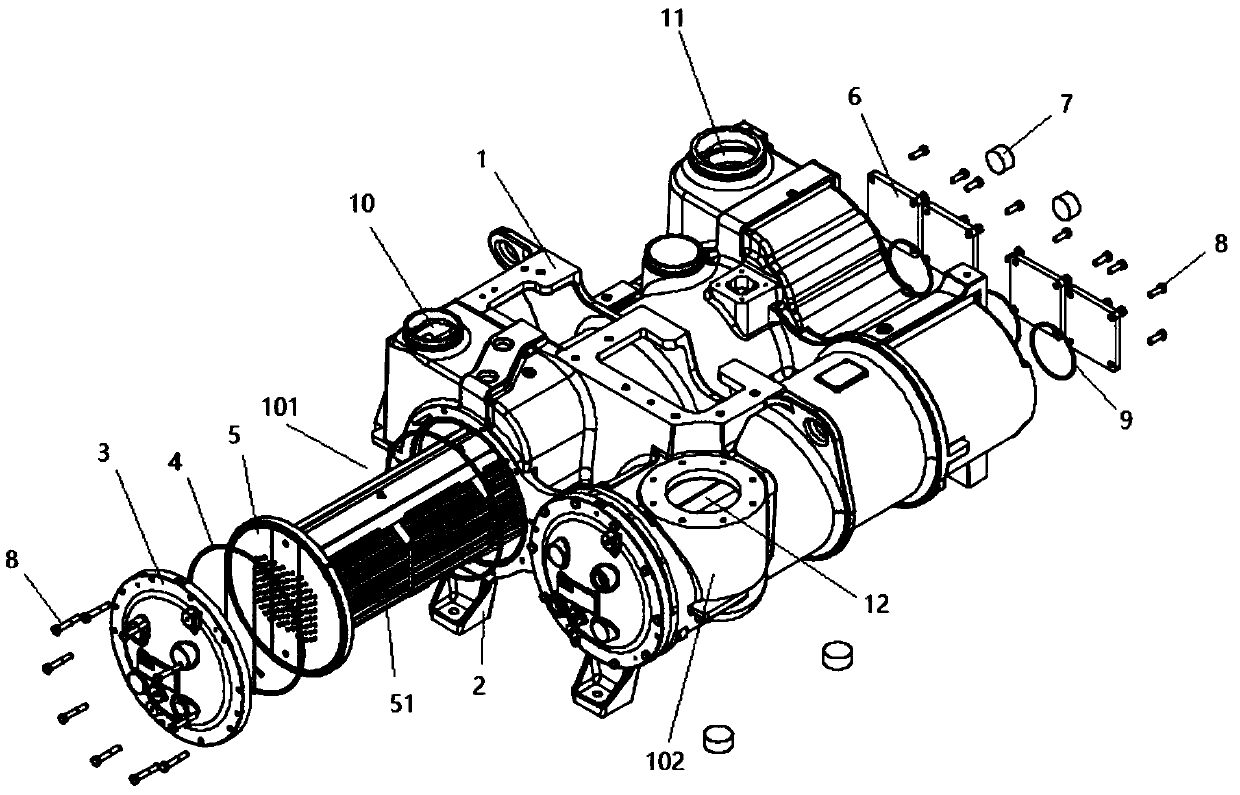

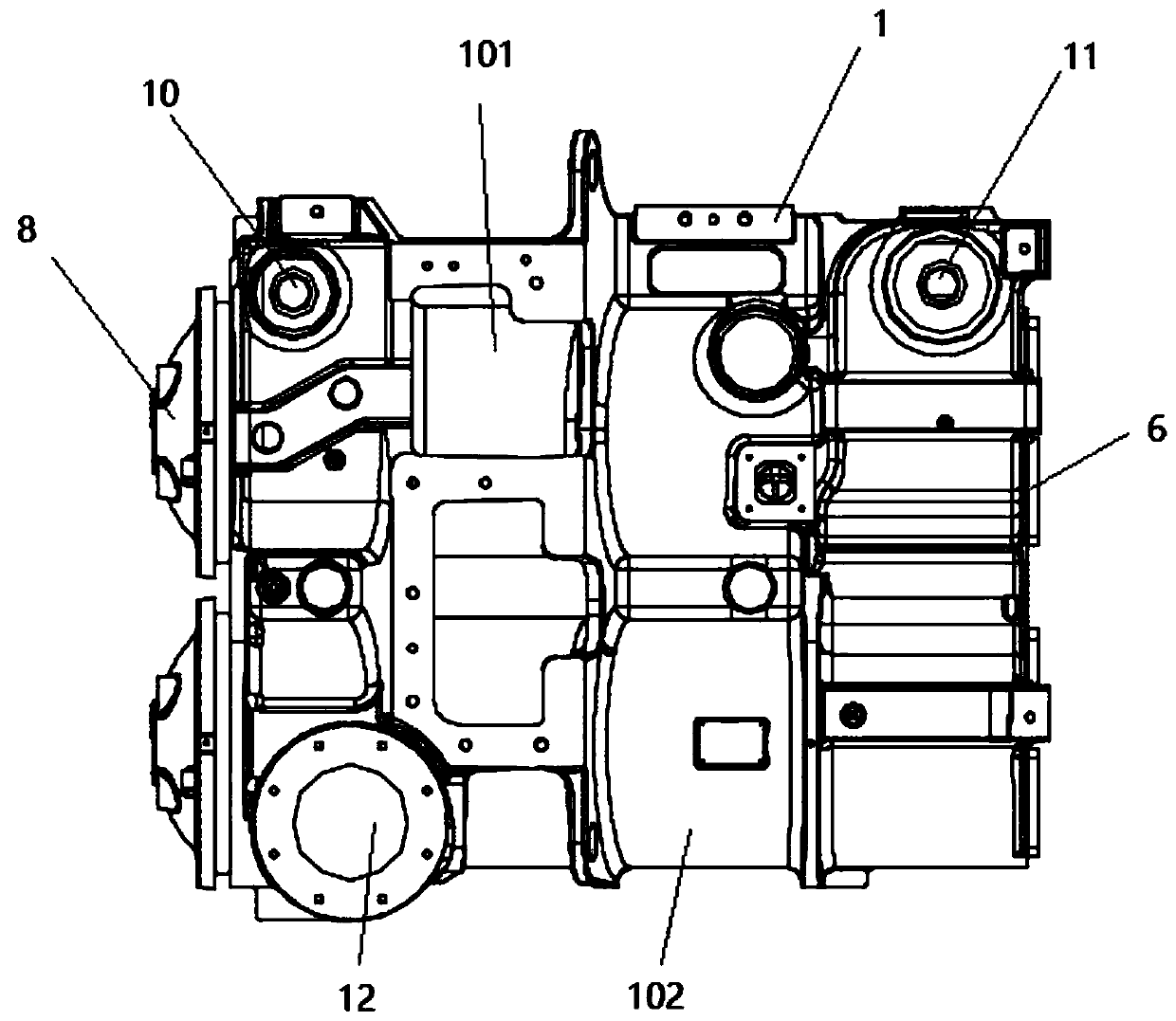

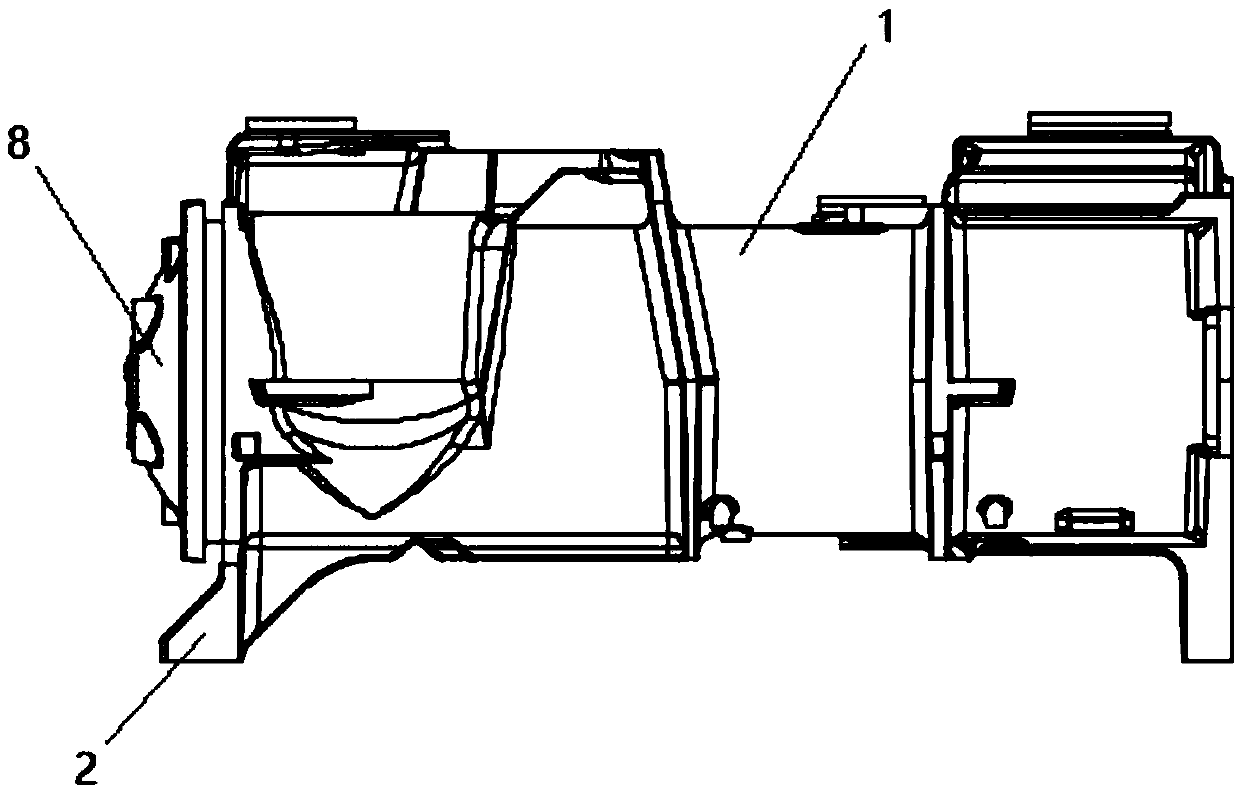

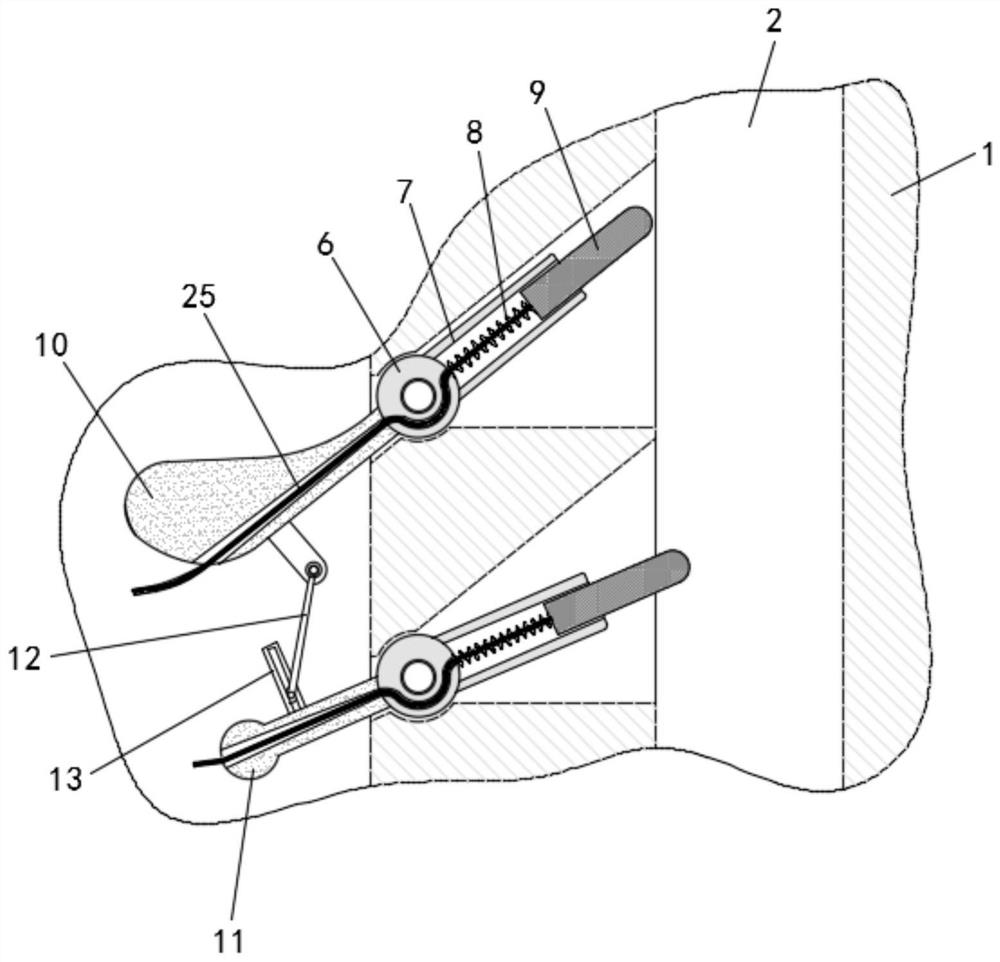

Attachment structure of motor rotor with low temperature winding

ActiveCN111740527BAvoid downtime for maintenanceAvoid checkingMagnetic circuit rotating partsSupports/enclosures/casingsElectric machineryEngineering

The invention discloses a motor rotor accessory structure with a low-temperature winding. The motor rotor accessory structure comprises: a supporting seat; a rack arranged on the supporting seat and defining a mounting space; a hollow rotating shaft arranged in the mounting space and capable of rotating relative to the rack; a sealing assembly arranged between the hollow rotating shaft and the rack; and a gas sucking opening formed in the rack and communicated with the hollow rotating shaft cavity of the hollow rotating shaft. According to the invention, by matching the rack, the hollow rotating shaft and the gas sucking opening, two ends of the hollow rotating shaft are respectively communicated with the motor rotor vacuum cavity, and the motor rotor in rotary work can continuously discharge gas through the gas sucking opening, so that the situation that the air pressure of the vacuum cavity of the motor rotor rises due to tiny leakage or partial material deflation in the vacuum cavity of the motor rotor can be prevented, and shutdown maintenance and inspection of the motor due to leakage of the vacuum cavity of the motor rotor are avoided.

Owner:TSINGHUA UNIV

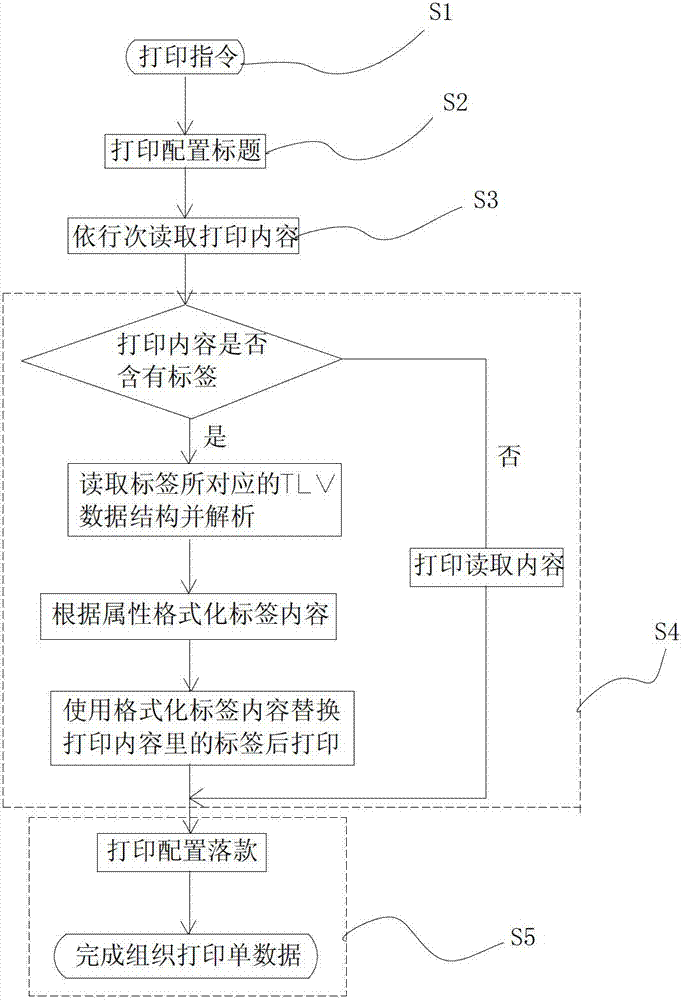

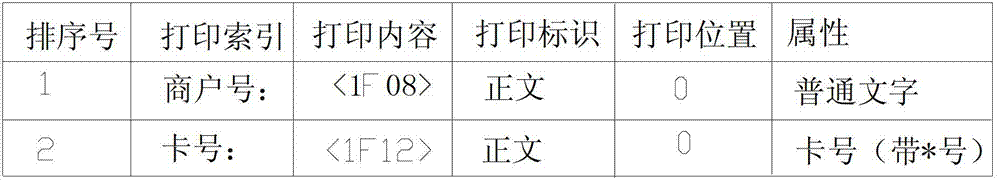

Printing method for point-of-sale (POS) machine trading center based on threshold limit value (TLV) format data

InactiveCN102982624BFlexible Configuration PrintingAvoid downtime for maintenanceCash registersLimit valueComputer science

Owner:SHENZHEN XINGUODU TECH

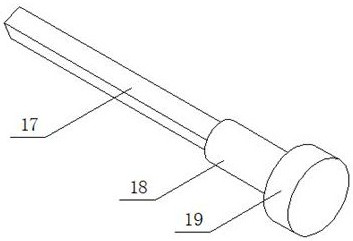

Injection molding machine nozzle and mold entry point anti-blocking device for plastic pipe fittings production

The invention relates to the technical field of plastic pipes, in particular to an injection molding machine nozzle and a mold entry point anti-blocking device for the production of plastic pipe fittings. The technical problem to be solved by the present invention is that the filter tank of the comparison case is easy to cause impurities to accumulate after being used for a period of time. In order to solve the above-mentioned technical problems, the present invention provides an injection molding machine nozzle and mold entry point anti-blocking device for the production of plastic pipe fittings. The outer side of the left side of the main column is fixedly connected with a bottom plate at equal intervals, a blocking column is fixedly connected between the top plate and the bottom plate, a filter column is fixedly connected between the top plate and the bottom plate, and filter columns are arranged at equal intervals in the middle of the filter column. The outer side of the main column is equally spaced with feeding grooves, the outer side of the main column is equally spaced with discharge grooves, the right side of the main column is fixedly connected with a filter spring, and the right side of the filter spring The fixed connection has a pressure plate.

Owner:芜湖新磊塑胶科技有限公司

A method for removing contamination particles on an electrostatic chuck in a process chamber

ActiveCN102485356BAvoid downtime for maintenanceSave time and costVacuum evaporation coatingSputtering coatingParticle adsorptionTime cost

The invention provides a method for removing contamination particles on an electrostatic chuck in a process chamber. The method comprises the following steps of: providing a contamination particle adsorption wafer, wherein the contamination particle adsorption wafer comprises a substrate and an insulating medium layer growing on the substrate and the surface of the insulating medium layer is charged; placing the contamination particle adsorption wafer on the electrostatic chuck in the process chamber, wherein the insulating medium layer of the contamination particle adsorption wafer faces to the electrostatic chuck; adsorbing the contamination particles on the electrostatic chuck onto the insulating medium layer with the help of the charges carried by the insulating medium layer; and taking down the contamination particle adsorption wafer from the electrostatic chuck, and taking the contamination particle adsorption wafer out of the process chamber. By adopting the method provided by the invention, the contamination particles on the electrostatic chuck can be completely adsorbed once, the condition that when the process chamber implements the process, as the contamination particles exist on the electrostatic chuck, the machine is forced to stop for maintenance can be avoided, and the material cost and the time cost can be effectively saved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

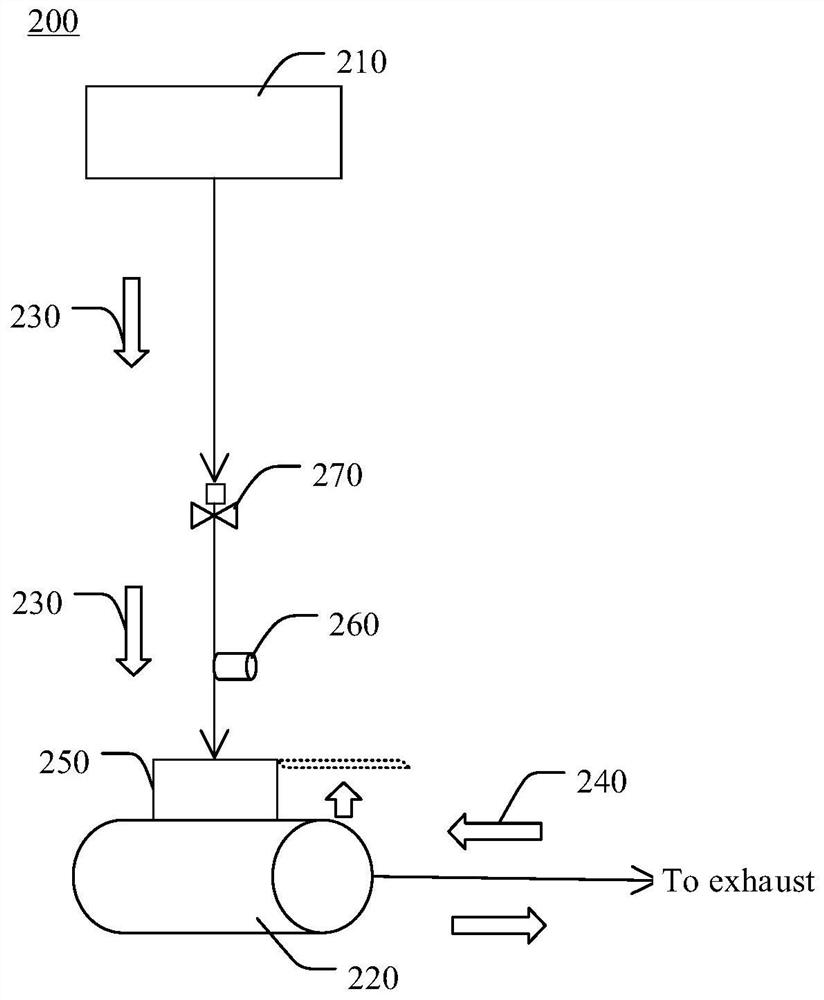

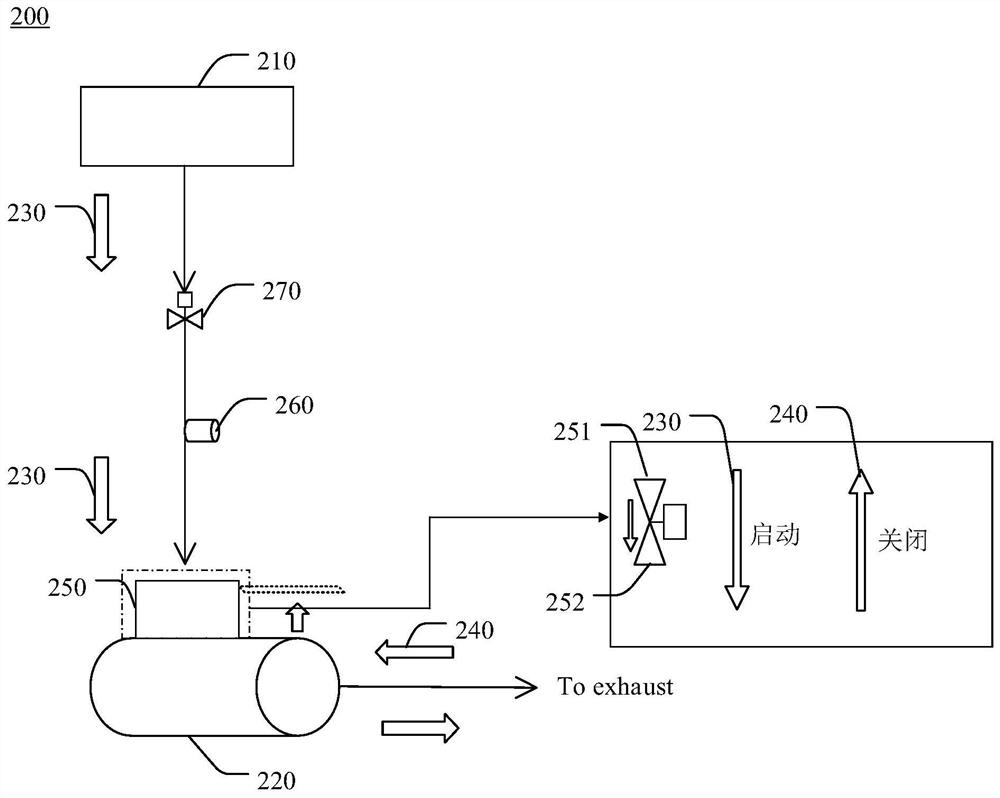

Vacuum system of etching equipment and anti-backflushing method

PendingCN114156151AGuaranteed vacuumAvoid downtime for maintenanceElectric discharge tubesForeign matterEngineering

The invention discloses a vacuum system of etching equipment and an anti-backflushing method. The vacuum system comprises a vacuum chamber; the pump is communicated with the vacuum chamber and is used for vacuumizing the vacuum chamber; the anti-backflushing device is connected between the vacuum chamber and the pump and is used for preventing a medium in the pump from flowing to the vacuum chamber; the vacuum valve is connected between the vacuum chamber and the pump and used for adjusting the size of medium flow in the vacuumizing process and controlling starting and stopping of the vacuumizing process. According to the vacuum system of the etching equipment provided by the invention, the anti-back-flushing device is additionally arranged between the vacuum chamber and the pump, and when the pump jumps and stops working, the anti-back-flushing device prevents foreign matters in the pump from being recharged into the vacuum chamber, so that the vacuum degree in the vacuum chamber is ensured, the product scrapping of the vacuum chamber is prevented, and the production efficiency is improved. And meanwhile, the vacuum chamber is not influenced, so that the shutdown maintenance of the vacuum chamber is avoided, and the normal operation time of equipment is ensured.

Owner:YANGTZE MEMORY TECH CO LTD

High-temperature butterfly valve

InactiveCN103398184ANot easy to misplacePrevent leakageLift valveValve housingsEngineeringOperational stability

The invention discloses a high-temperature butterfly valve comprising a valve body, a valve clack, a seal ring, and seal ring cover. The valve clack is arranged in the valve body. The seal ring is arranged between the valve body and the valve clack. The valve body is further provided with the seal ring cover used for press the seal ring. A fastener is arranged on the lower portion of the seal ring cover. A groove matched with the fastener is formed in the valve body. The fastener and the groove are matched to have the seal ring cover fixed. By the arrangement, the well-ground seal ring is less prone to dislocation along the circumferential direction during mounting, so that good sealing effect can be achieved between the well-ground seal ring and the valve clack to prevent valve leakage and unnecessary maintenance downtime of an industrial oxygen generator, operational stability of the industrial oxygen generator is guaranteed, and meanwhile, labor intensity of maintenance workers is reduced.

Owner:顾林男

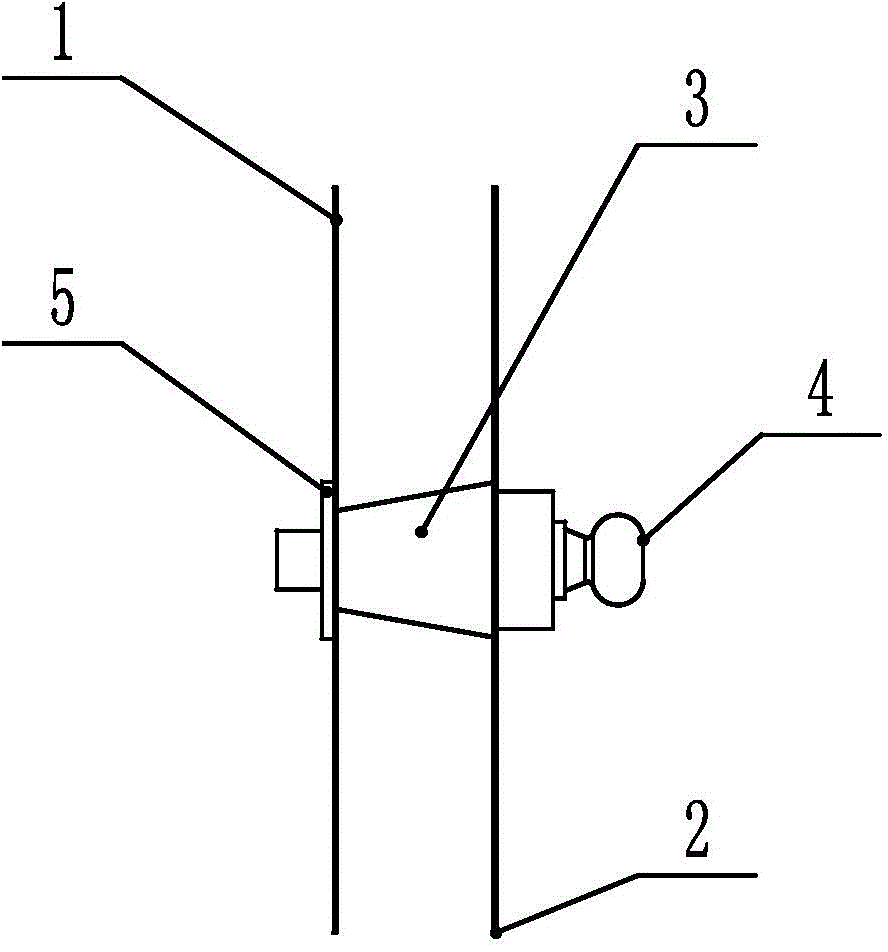

Pipeline system of second condensation tank

InactiveCN104208895ALow failure rateAvoid downtime for maintenanceVapor condensationFailure rateProduction line

The invention relates to a pipeline system of a second condensation tank. The pipeline system contains a second condensation tank (1) and is characterized in that the lower part of the second condensation tank (1) is provided with a discharge pipeline (2); a return pipeline (3) is connected between the posterior section of the discharge pipeline (2) and a return port of the second condensation tank (1); the posterior section of the discharge pipeline (2) is also connected with a first condensation tank feeding pipeline (4); and two export pumps (2.1) are connected in parallel at the anterior section of the discharge pipeline (2). The pipeline system of the second condensation tank has advantages as follows: failure rate is low; and shut-down and maintenance of a production line are avoided effectively.

Owner:JIANGYIN BOLUN CHEM FIBER

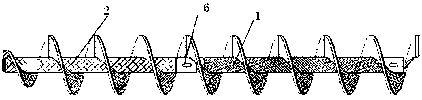

Connecting structure for screw shaft

InactiveCN108019438AHigh strengthExtended service lifeCouplings with disconnecting safety membersCouplingPhysics

A connecting structure for a screw shaft comprises a screw shaft section A and a screw shaft section B; a connecting device is arranged between the screw shaft section A and the screw shaft section Band comprises an inner hexagonal coupling arranged at one end of the screw shaft section A and an outer hexagonal coupling arranged at one end of the screw shaft section B; the inner hexagonal coupling is matched with the outer hexagonal coupling; a positioning sliding key is arranged inside the inner hexagonal coupling or outside the outer hexagonal coupling; a positioning sliding groove is correspondingly formed outside the outer hexagonal coupling or inside the inner hexagonal coupling; the positioning sliding key is matched with the positioning sliding groove; radial through holes are formed in positions where the outer hexagonal coupling and the inner hexagonal coupling are matched; a connecting pin is arranged in the through holes; and a fixing device is arranged on the connecting pin. The connecting structure has the beneficial effects as follows: 1, the new connecting manner is high in strength, shutdown for maintenance due to breakage of the joint of the screw shaft is avoided, the service life of the screw shaft is prolonged, the maintenance time is saved, and the productivity is increased; 2, by the aid of the new connecting manner, when the conveying torque is overloaded, the inner hexagonal coupling and the outer hexagonal coupling are broken firstly, the screw shaft is protected, and meanwhile, the fault of sticking of an original driving piece is avoided.

Owner:辽宁三三工业有限公司

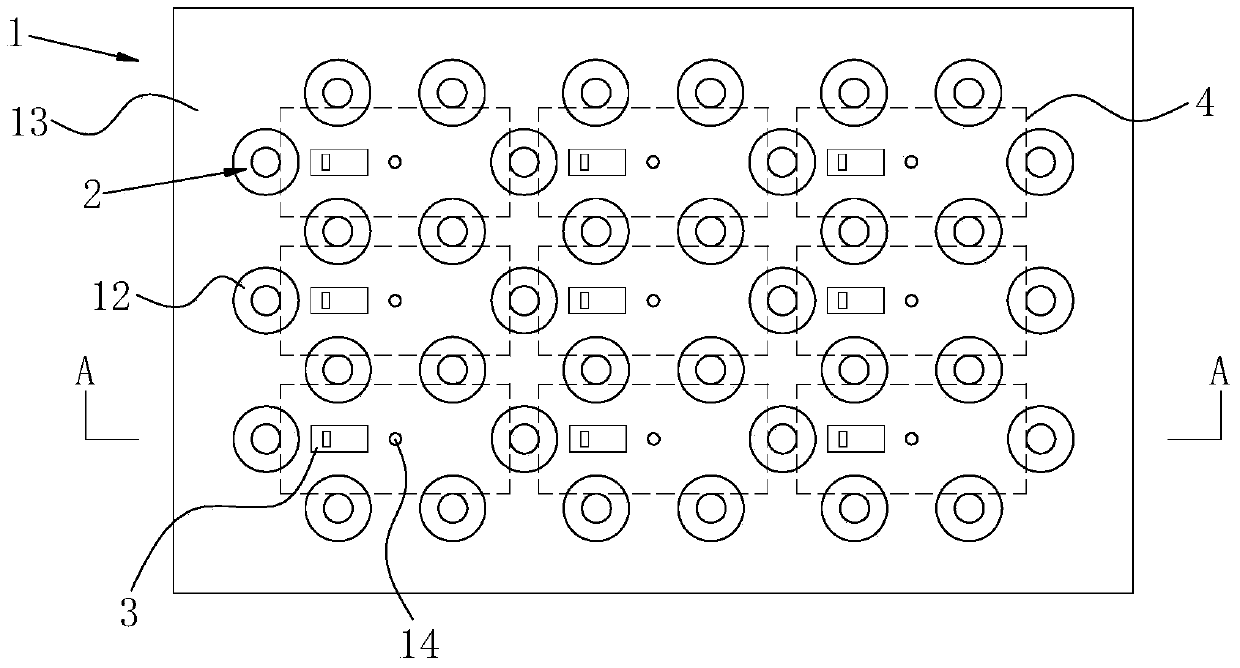

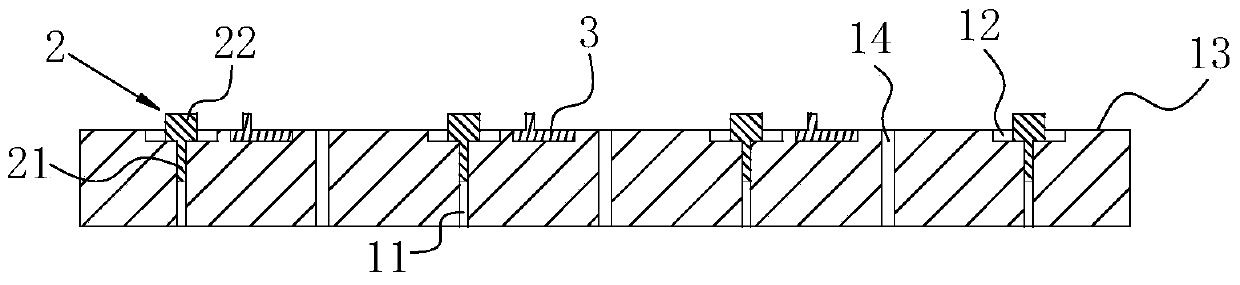

A glass screen screen printing jig, screen printing equipment and screen printing method

ActiveCN105711236BMeet processing positioning requirementsReduce labor intensityScreen printersScreen printingEngineering

The invention relates to the technical field of screen printing of glass screens of mobile phones and particularly discloses a screen printing fixture for glass screens. The fixture comprises a screen printing base, wherein a plurality of glass screen accommodating areas are arranged on the screen printing base, a plurality of limiting columns are inserted in the screen printing base and located on edges of each glass screen accommodating area, and the limiting columns are detachably connected with the screen printing base. The screen printing fixture for the glass screens can perform screen printing processing on multiple glass screens at a time, can meet processing positioning requirements of the glass screens of different specifications, can shorten adjustment time during switching of processing objects, can be quickly repaired and avoid long-time shutdown for maintenance, can effectively improve the working efficiency and guarantee the processing precision, can also effectively reduce the maintenance cost and is beneficial to maximization of the enterprise benefit. The invention further provides screen printing equipment and method for the glass screens. Screen printing can be performed on the whole plate of glass screens on the screen printing fixture for the glass screens at a time, so that the production efficiency is effectively improved, and the labor intensity of workers is reduced.

Owner:东莞市奇声电子实业有限公司

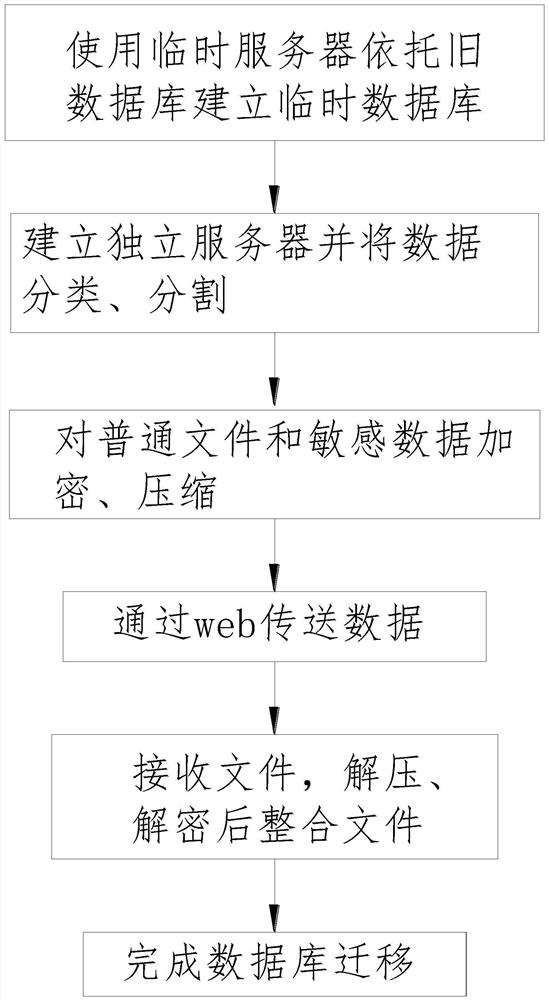

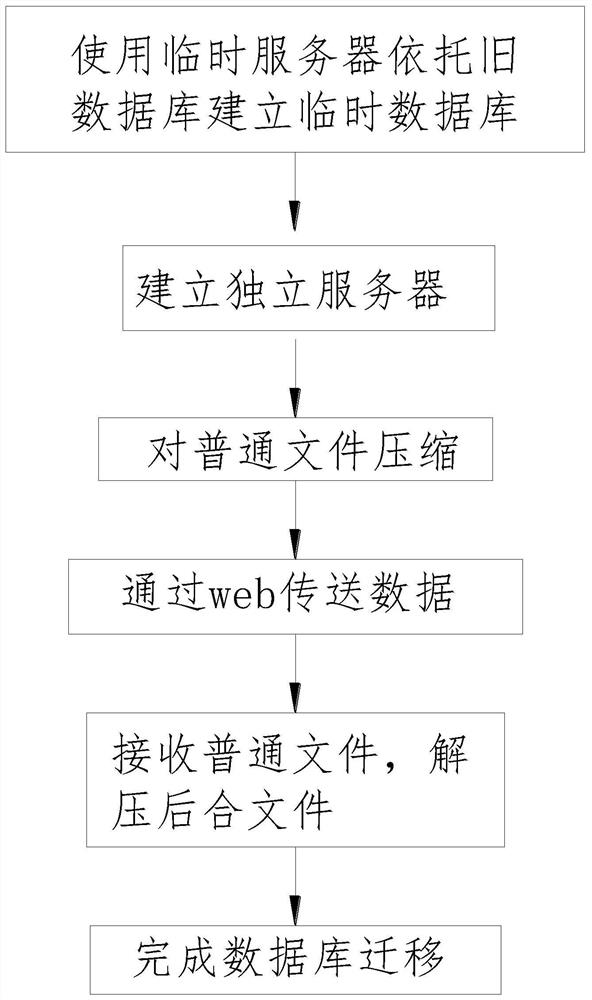

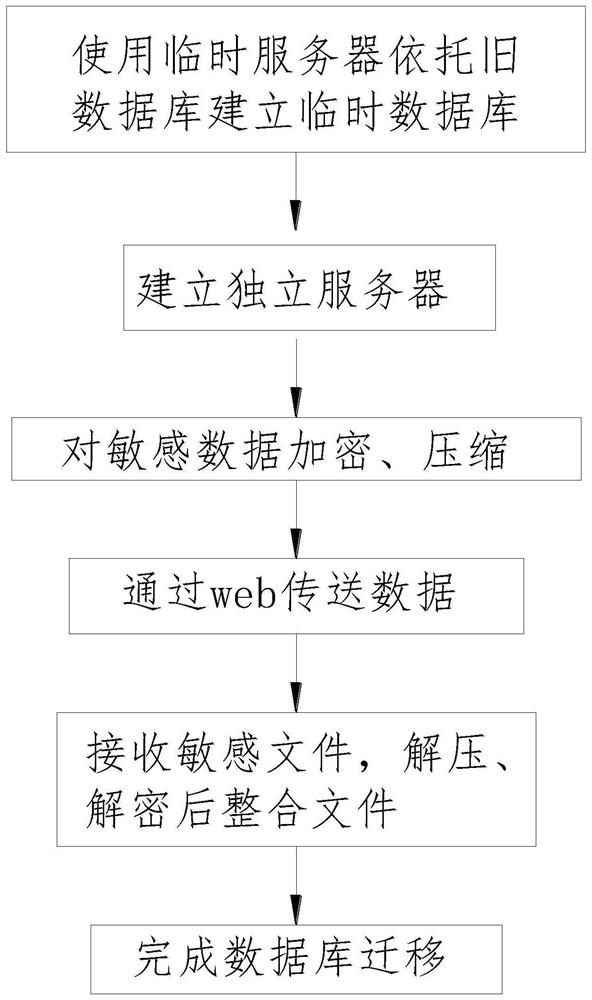

Data migration method for encrypted database

PendingCN113901027APrevent leakageAvoid downtime for maintenanceRelational databasesDigital data protectionData packFile transmission

The invention discloses a data migration method for an encrypted database. The storage method for vehicle data without being tampered comprises the following steps: establishing a temporary database by using a temporary server on the basis of an old database; establishing an independent server, and classifying and segmenting data; encrypting and compressing the common file and the sensitive data file; transmitting data through a web; receiving the file, decompressing, decrypting and integrating the file; comparing and feeding back; and completing database migration. The encryption module is used for encrypting the sensitive data packets respectively, leakage of data information is avoided, safety is high, the temporary database is established by using the temporary server and relying on the old database, the old server is switched to the temporary server for operation, server shutdown maintenance is avoided, user loss is reduced, inconvenience brought to users is avoided, waste of transmission time caused by interruption in the file transmission process is reduced, and the data migration speed is increased due to the fact that the independent server is arranged.

Owner:BEIJING UXSINO SOFTWARE

System for treating dust-containing tail gas

The invention discloses a system for treating dust-containing tail gas; the system comprises a combustion-dust removal-dust collection device, which comprises a combustion section, which is provided with a dust-containing tail gas inlet, a combustion support gas inlet, and a heat source; a dust removal section, which is connected with the combustion section and provided with an annular pipe, wherein a plurality of holes facing the inner wall of the dust removal section are evenly distributed in the circumferential direction of the annular pipe; a dust collection section, which is connected with the dust removal section and provided with filler, a liquid atomizer and a dust-collected gas outlet, wherein the liquid atomizer is located above the filler, and the dust-collected gas outlet is located above the liquid atomizer; a slurry outlet which is connected with the dust removal section and the dust collection section; a pH regulating device, which is provided with a slurry inlet, a slurry outlet after slurry mixing, a pH regulator inlet and a pH detector, and the slurry outlet extends below the liquid level of the pH regulating device; a liquid-solid separation device, which is provided with a filter element, a mixed slurry inlet, a slag slurry outlet and a filtered liquid outlet, and the filtered liquid outlet is connected with the ring pipe and the liquid atomizer; and a gaspurification device, which is provided with an adsorption layer, a dust-collected gas inlet and a purified gas outlet.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

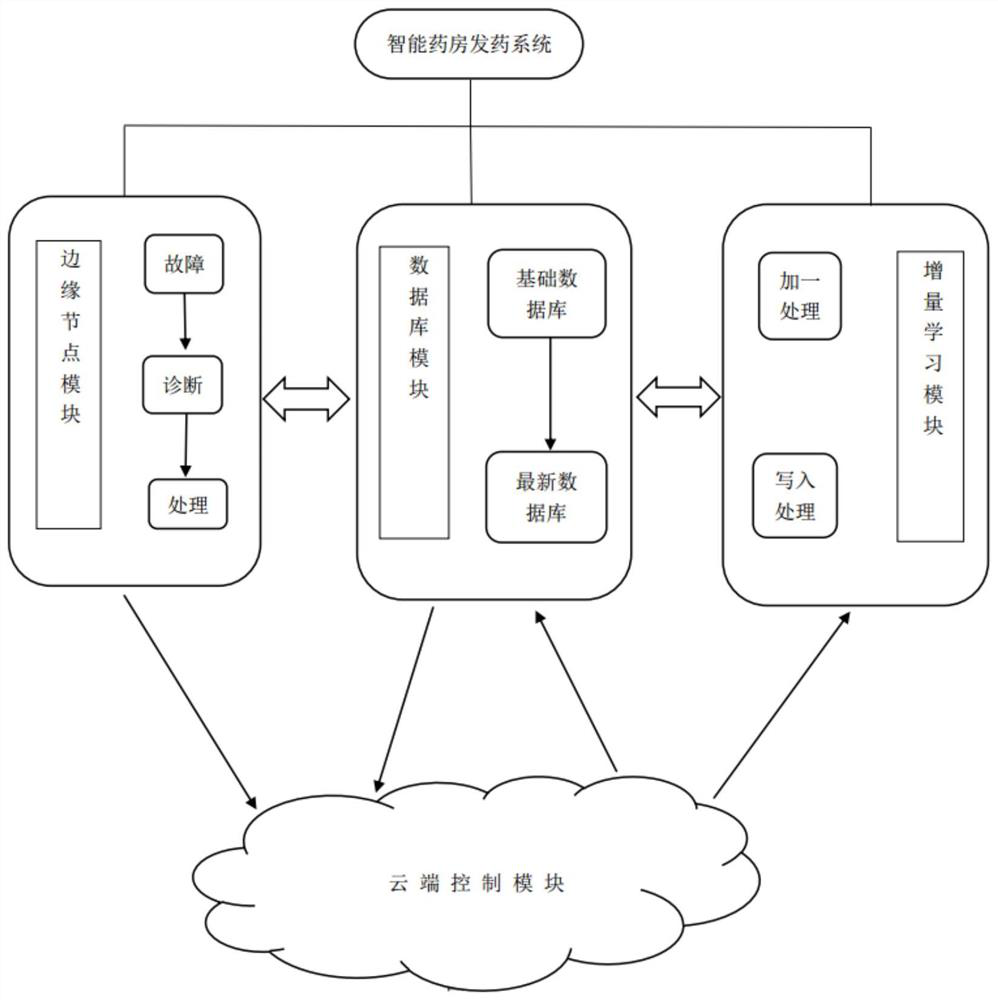

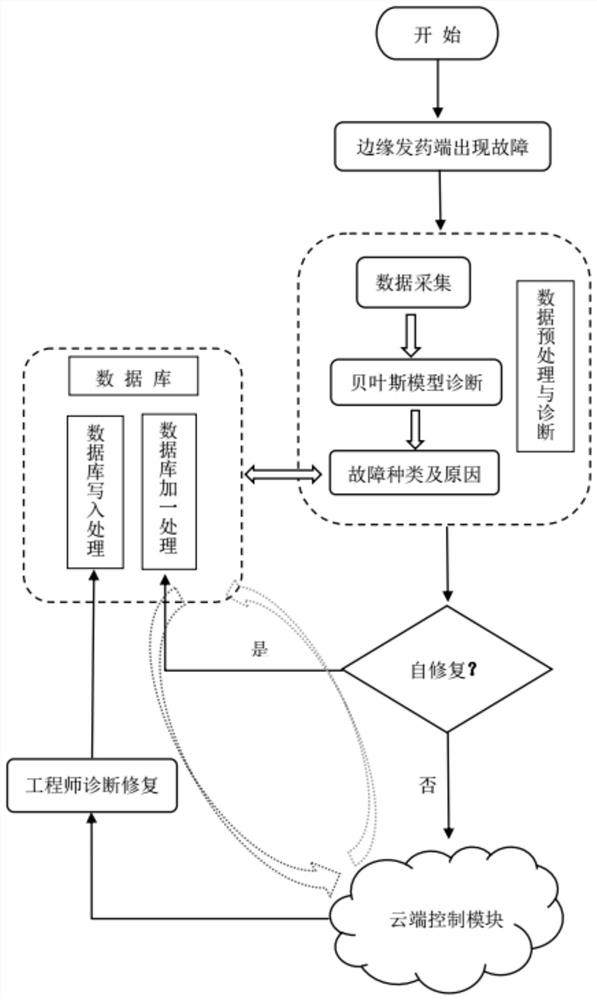

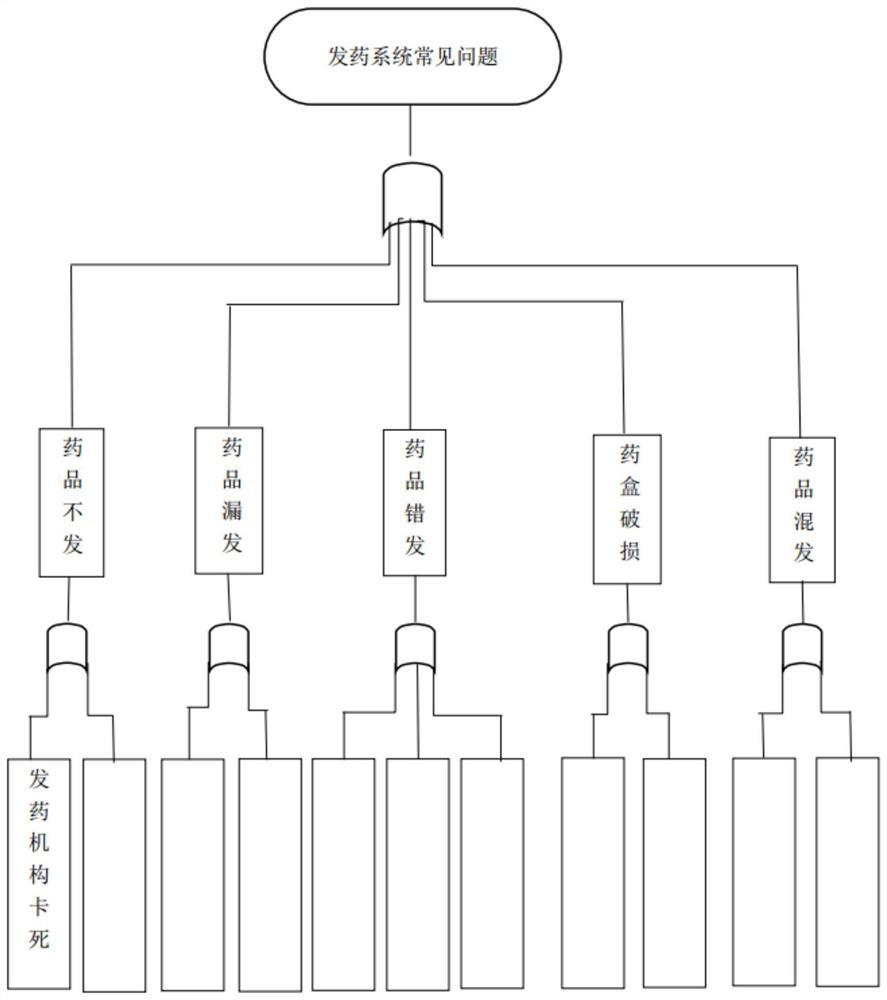

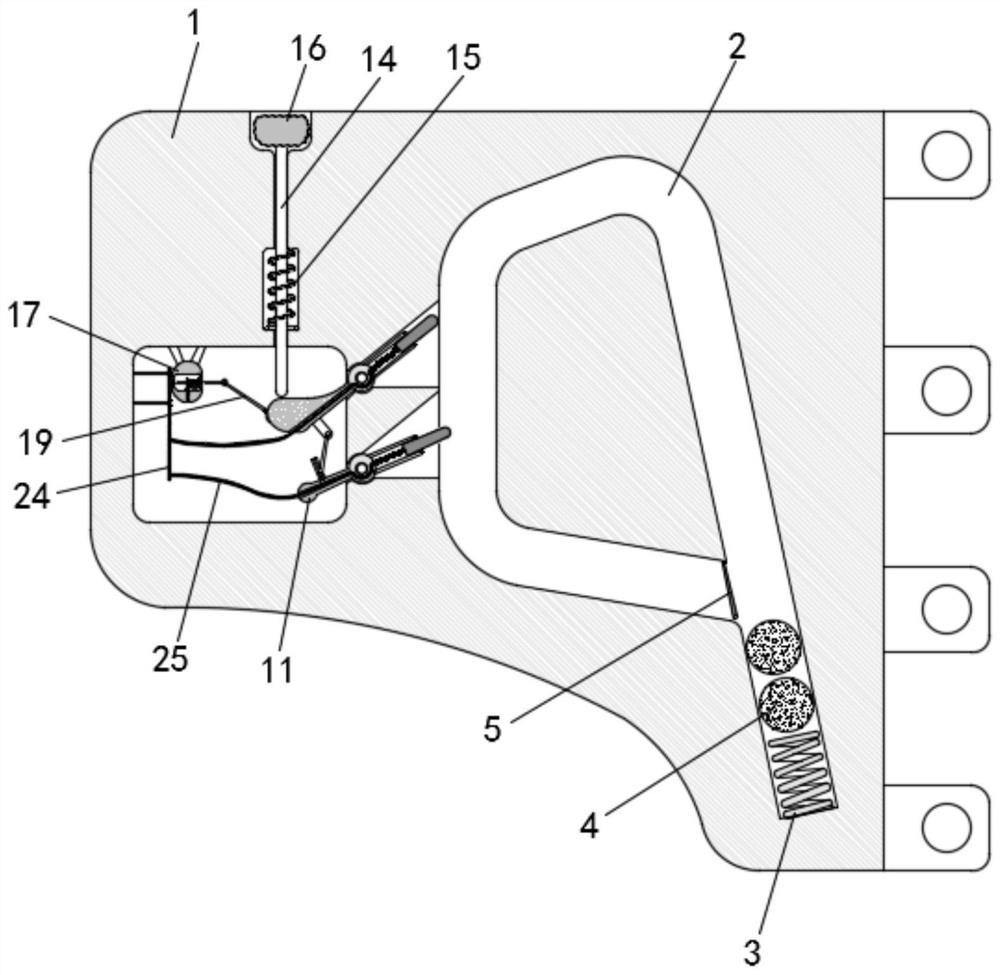

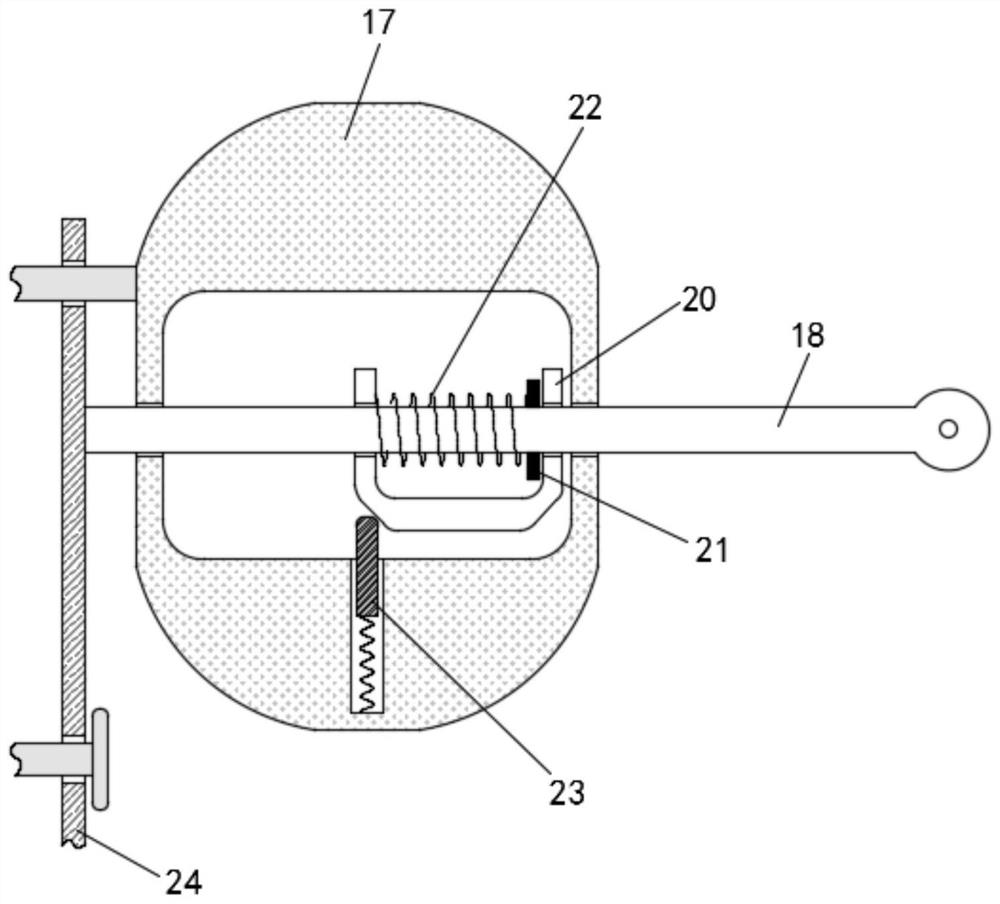

Intelligent pharmacy self-diagnosis and self-repairing system and method based on cloud-edge collaboration

PendingCN113284599AAvoid downtime for maintenanceImprove the efficiency of drug deliveryMedical equipmentPharmacyInformation transmission

The invention provides an intelligent pharmacy self-diagnosis and self-repairing system and method based on cloud-edge collaboration, and the system comprises: an edge node module which takes each dispensing machine in an intelligent pharmacy as an edge node; a plurality of database modules, wherein the database modules are in one-to-one correspondence with the dispensing machines, and the database modules are used for storing fault information of the dispensing machines; a plurality of incremental learning modules, wherein the incremental learning modules are in one-to-one correspondence with the database modules and are used for updating the database modules; and a cloud control module, wherein the edge node module interacts with the cloud control module cooperatively, wherein the edge node module can perform fault data acquisition and can perform self-diagnosis and self-repairing on most faults. The cooperative interaction mode comprises the steps that the edge node module transmits fault information which cannot be subjected to self-diagnosis and self-repairing to the cloud control module, and the cloud control module performs early warning on the faults and and transmits the position mark number of the early warning node and the fault reason to an engineer.

Owner:JIANGSU UNIV

Energy-saving and environment-friendly vibration amplitude detection device for mold workshop detection

ActiveCN112710378ATimely repair and maintenanceRealize the function of automatic resetVibration measurement in solidsVibration amplitudeSlide plate

The invention provides an energy-saving and environment-friendly vibration amplitude detection device for mold workshop detection. Two rolling balls are placed at the top end of a P-shaped groove elastic piece formed in a detection seat body, an outer support plate and an inner support plate are fixedly connected to the right side of a rotary drum, and a limiting rod group corresponding to a connecting rod is fixedly connected to the top of a counterweight bottom plate; a notice board is fixedly connected to the top of the lifting rod, a baffle ring is fixedly sleeved with the outer side of the inserting rod and located in the U-shaped base, and the left side of the inner support plate is connected with the sliding plate through a pull rope. When a machine tool vibrates greatly, the elastic piece jacks up the rolling balls, the first rolling ball is blocked by the inner support plate on the lower side, the counterweight bottom plate drives the counterweight swing plate to deflect, the second rolling ball is blocked by the inner support plate on the upper side, the counterweight swing plate ejects the lifting rod and the notice board upwards, and a worker observes the notice board, and therefore, large-amplitude vibration of the machine tool can be judged, and maintenance and repair can be carried out in time.

Owner:广东天佳誉模具科技有限公司

Pipeline system of first condensation jar

InactiveCN104215088ALow failure rateAvoid downtime for maintenanceSteam/vapor condensersProduction lineEngineering

The invention relates to a pipeline system of a first condensation jar. The pipeline system comprises the first condensation jar (1) and is characterized in that the lower portion of the first condensation jar (1) is provided with a first discharging pipeline (2) and a second discharging pipeline (3), a first material return pipeline (4) is connected between the rear section of the first discharging pipeline (2) and a material return port of the first condensation jar (1), the front section of the first discharging pipeline (2) is provided with two first output pumps (2.1) in a parallel connection mode, a second material return pipeline (5) is connected between the rear section of the second discharging pipeline (3) and the material return port of the first condensation jar (1), the rear section of the second discharging pipeline (3) is further connected with a heating medium supplying tank material return pipeline (6) and a condensation jar feeding pipeline (7), and the front section of the second discharging pipeline (3) is provided with two second output pumps (3.1) in a parallel connection mode. The pipeline system of the first condensation jar has the advantages of being low in fault rate and effectively preventing a production line from stopping and being maintained.

Owner:JIANGYIN BOLUN CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com