Shell heat exchanger of double-barrel casting

A heat exchanger and shell technology, which is applied in the field of double-cylinder casting shell heat exchangers, can solve the problems of long procurement cycle, high inspection and maintenance cost of single-cylinder heat exchangers, long design and development cycle, etc., so as to reduce downtime. The effect of maintenance loss, improving the one-time test pass rate, and reducing the leakage rate of the client

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The purpose of the present invention can be achieved through the following technical solutions:

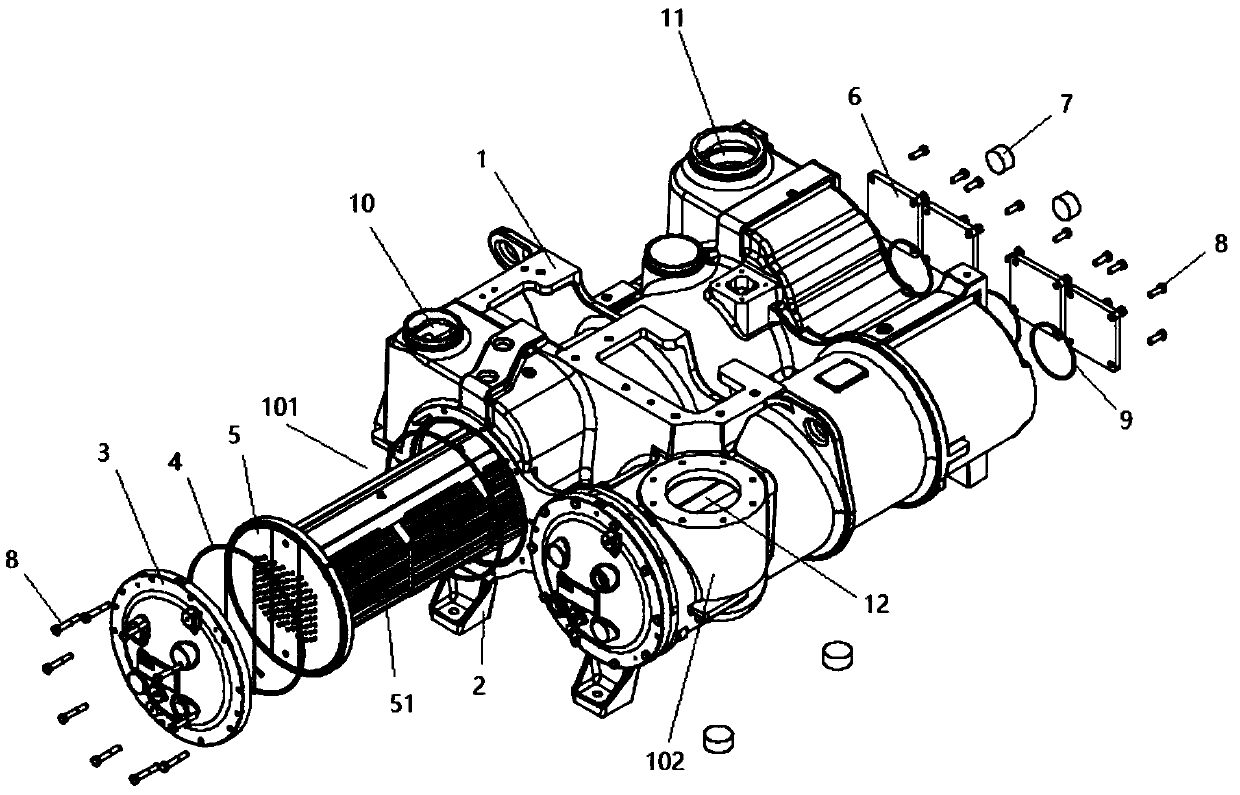

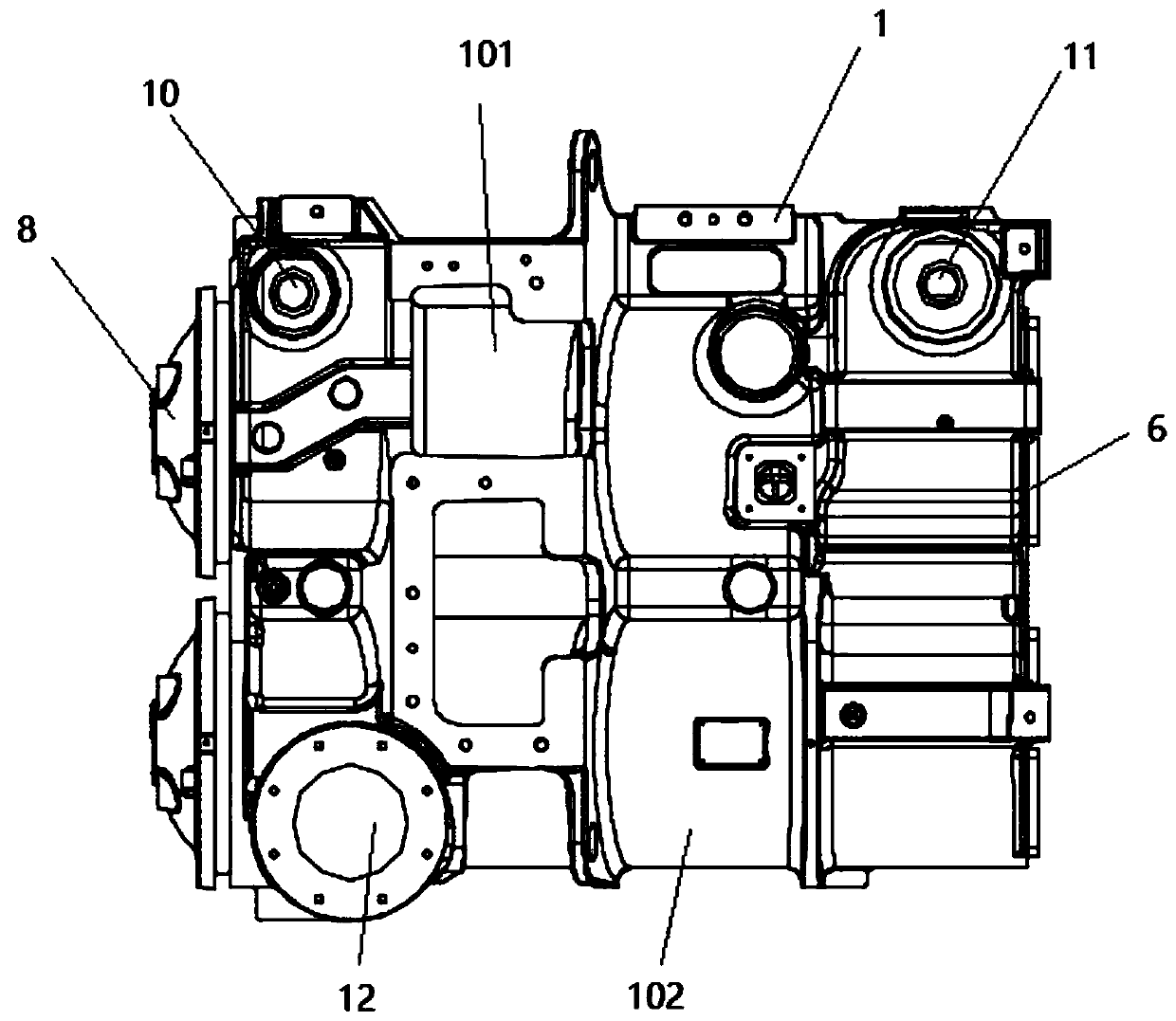

[0026] A double-tube casting shell heat exchanger, see Figure 1-4 , including double cylinder shell 1, base 2, casting head 3, head sealing ring 4, heat exchange core 5, rear cover plate 6, threaded plug 7, fastening bolt 8, cover plate sealing ring 9 , air inlet 10, air outlet 11, spare air inlet 12;

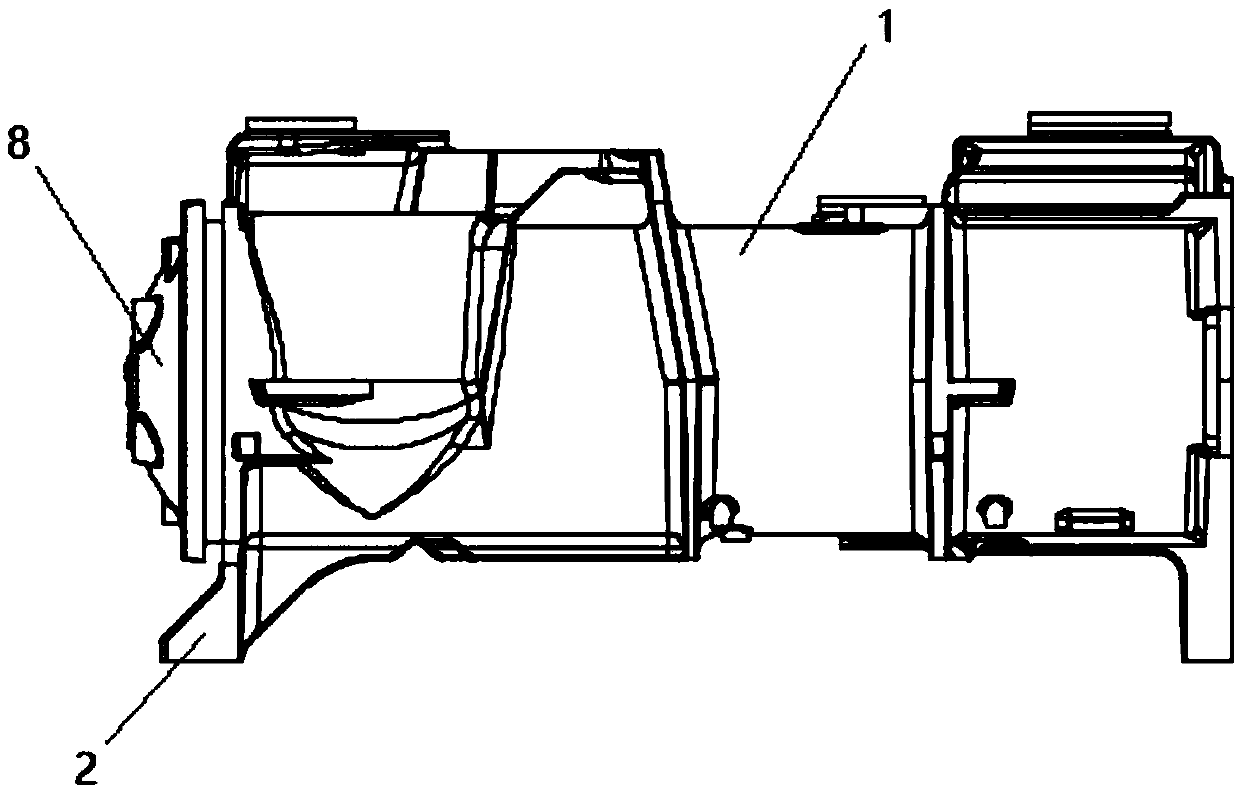

[0027] The double-tube housing 1 includes a first tube 101 and a second tube 102, the openings of the first tube 101 and the second tube 102 are located on one side of the double-tube shell 1, the first tube 101, the second The opening of the two tubes 102 is provided with a casting head 3; the other side of the double tube shell 1 is provided with a rear cover plate 6;

[0028] The top side of the double cylinder housing 1 is provided with an air inlet 10, an air outlet 11, and a spare air inlet 12;

[0029] The bottom of the double cylinder shell 1 is provided with a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com