Waste collection disc of full-automatic stretching film packaging machine

A technology of stretching film and machine waste, which is applied in the field of collecting trays, can solve problems such as affecting production efficiency and increasing production costs, and achieve the effects of improving production efficiency, saving production costs, and solving shutdown maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

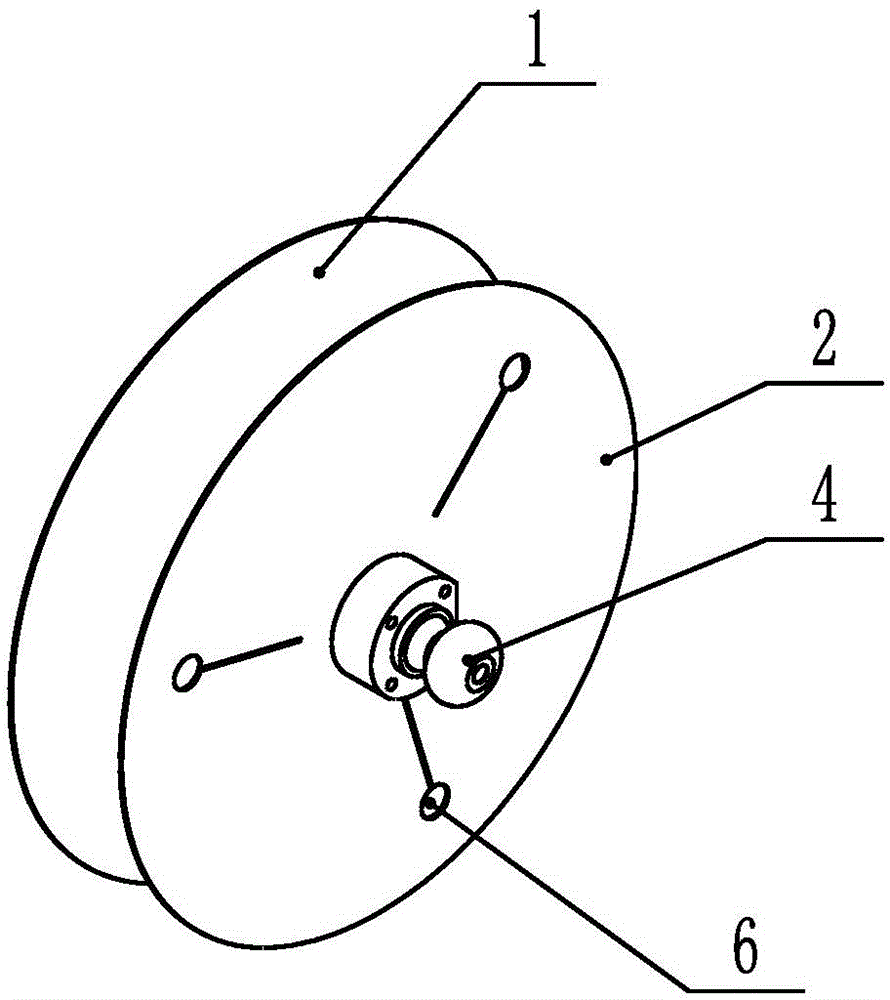

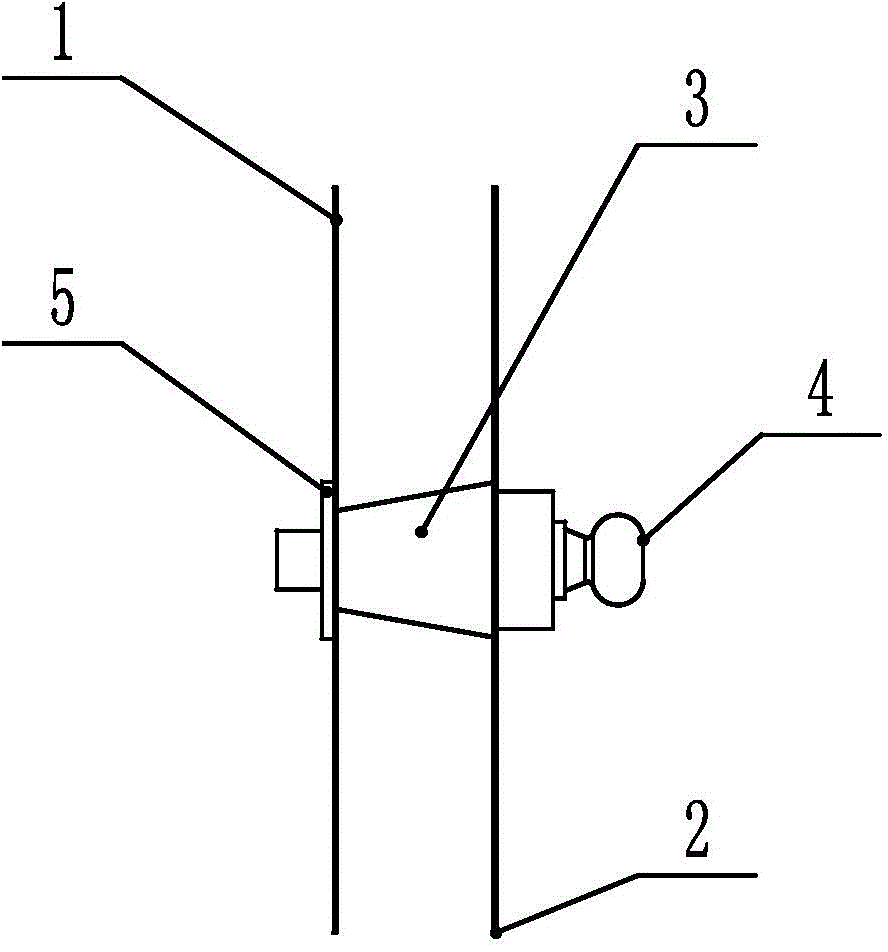

[0010] Such as figure 1 , 2 As shown, the present invention includes receiving tray I1, receiving tray II2, receiving tray fixed shaft 3, loading and unloading handle 4, bayonet pin 5, and is characterized in that a receiving tray I1 and receiving tray II2 are provided with a receiving tray. The fixed shaft 3 of the feeding tray, the right side of the receiving tray II2 is provided with a loading and unloading handle 4, and the loading and unloading handle 4 runs through the fixed shaft 3 of the receiving tray and the receiving tray I1 in turn, and the left side of the receiving tray I1 is provided with a card Pin 5, the bayonet pin 5 connects and fixes the loading and unloading handle 4 with the receiving tray I1, and the centers of the receiving tray I1 and the receiving tray II2 are provided with an observation slot 6, and the top of the observation slot 6 is circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com