Waste plastic friction cleaning machine

A friction cleaning machine, waste plastic technology, applied in the direction of plastic recycling, cleaning methods and utensils, filter screens, etc., can solve the problems of easy clogging of the screen, equipment shutdown and maintenance, etc., to solve the problem of screen clogging, effective friction cleaning, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

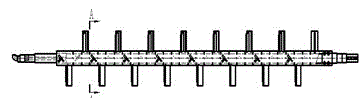

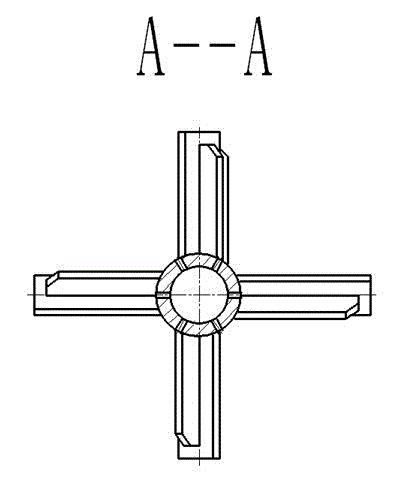

[0012] 1. Start without load, check whether the steering of the motor (16) is correct, connect the rotary joint (1) and drain water, and run idling for 3-5 minutes after starting up.

[0013] 2. Put the material into the feed port (5), and enter the barrel (9) through the main shaft (6) driven by the motor (16) for cleaning. Finally, the cleaned material enters the next machine through the discharge port (14). Processing in the cleaning phase.

[0014] 3. The present invention can be used alone or connected in series to the production line. It can be controlled automatically and individually when used in the production line.

[0015] 4. The present invention does not need to fully open the rotary joint (1) when in use, but to use intermittent water, open the water inlet ball valve after 2 hours of work, and flush the holes of the screen (8). After half an hour of flushing, the water inlet can be closed ball valve.

[0016] 5. Due to the high speed of the present invention, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com