Connecting structure for screw shaft

A technology of connection structure and screw shaft, which is applied in the direction of couplings, couplings with safety disconnection joints, mechanical equipment, etc., can solve problems such as infirmity, improve productivity, facilitate operation, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

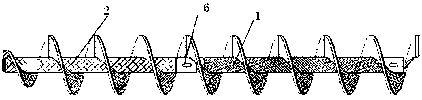

[0017] Refer to attached Figure 1-3 , a connection structure of a screw shaft, comprising a screw shaft segment A1 and a screw shaft segment B2, a connecting device is arranged between the screw shaft segment A and the screw shaft segment B, and the connecting device includes a The inner hexagonal coupling 4 and the outer hexagonal coupling 5 at the end of the spiral shaft section B, the inner hexagonal coupling and the outer hexagonal coupling match, inside the inner hexagonal coupling or outside the outer hexagonal coupling There is a positioning sliding key, and correspondingly, a positioning chute is provided outside the outer hexagonal coupling or inside the inner hexagonal coupling. The positioning sliding key matches the positioning chute. The outer hexagonal coupling and the inner hexagonal coupling A radial through hole 6 is arranged at the joint of the shaft device, a connecting pin is arranged in the through hole, and a fixing device is arranged on the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com