High-temperature butterfly valve

A technology of high-temperature butterfly valve and valve body, which is applied in the direction of lifting valve, valve details, valve device, etc., which can solve the problems affecting the operation stability of industrial oxygen generators, increasing the labor intensity of maintenance workers, and the sealing ring cannot be sealed, so as to prevent leakage , Reduce labor intensity, avoid the effect of downtime maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

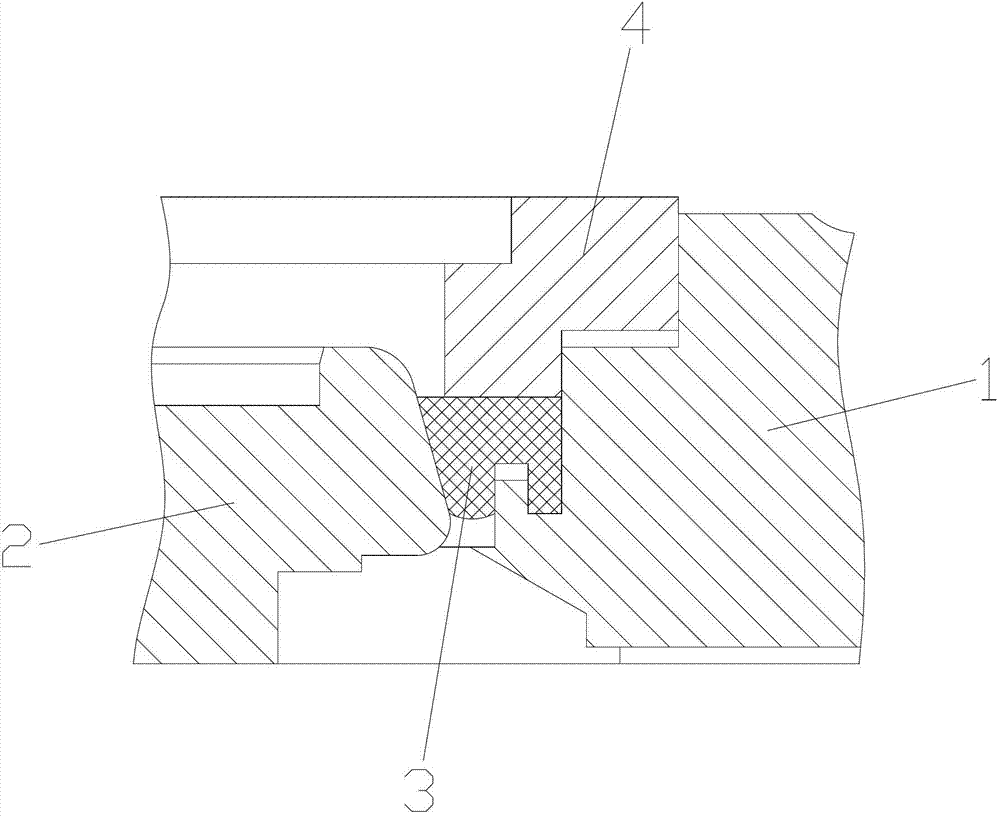

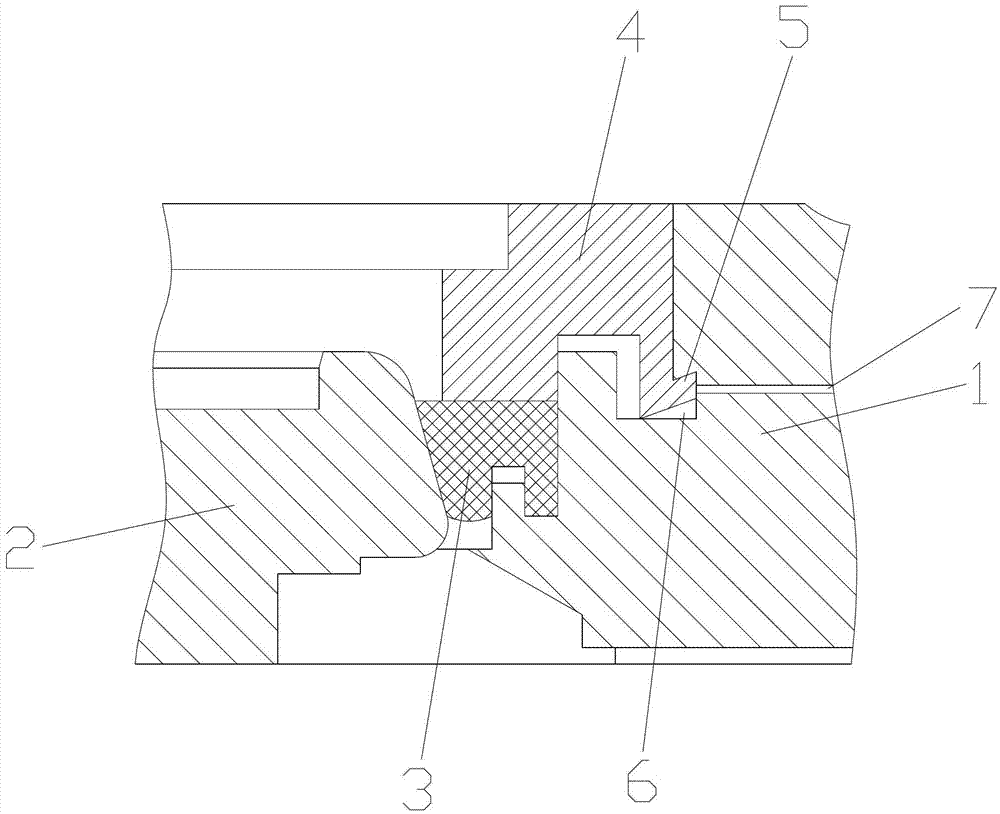

[0014] as attached figure 2 The shown high temperature butterfly valve of the present invention includes a valve body 1, a valve disc 2, a sealing ring 3 and a sealing ring gland 4, the valve disc 2 is arranged in the valve body 1, and the valve body 1 and A sealing ring 3 is provided between the valve flaps 2, and a sealing ring gland 4 for pressing the sealing ring 3 is also provided in the valve body 1, and a buckle 5 is provided at the lower end of the sealing ring gland 4; the valve body 1 is provided with a groove 6 that matches the buckle 5; the buckle 5 cooperates with the groove 6 to realize the fixing of the sealing ring gland 4; when the sealing ring gland 4 is fixed, the sealing ring gland 4 The upper end surface of the valve body is flush with the upper end surface of the valve body 1; the valve body 1 is provided with a straight hole 7 communicating with the groove 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com