Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Accurate hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

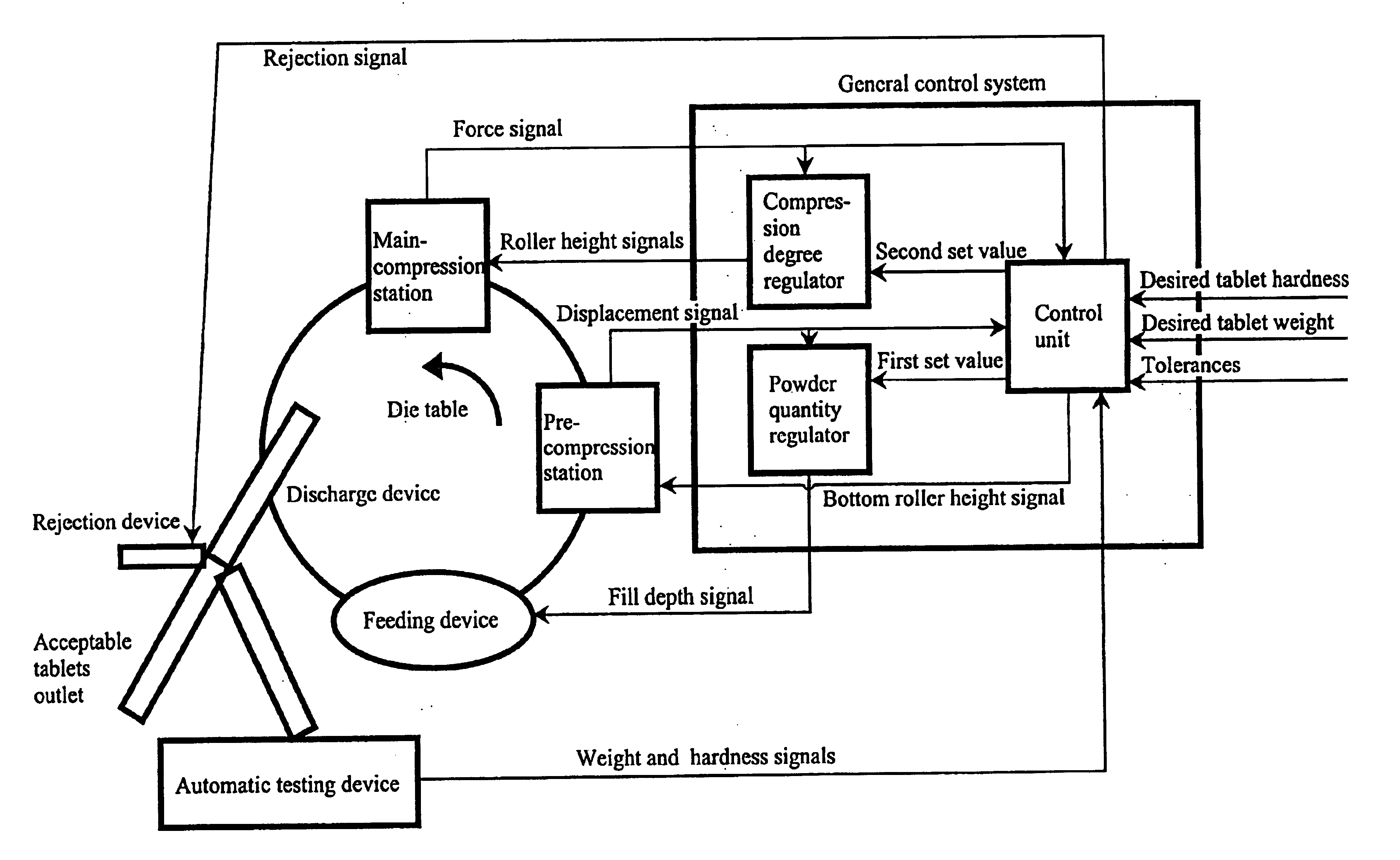

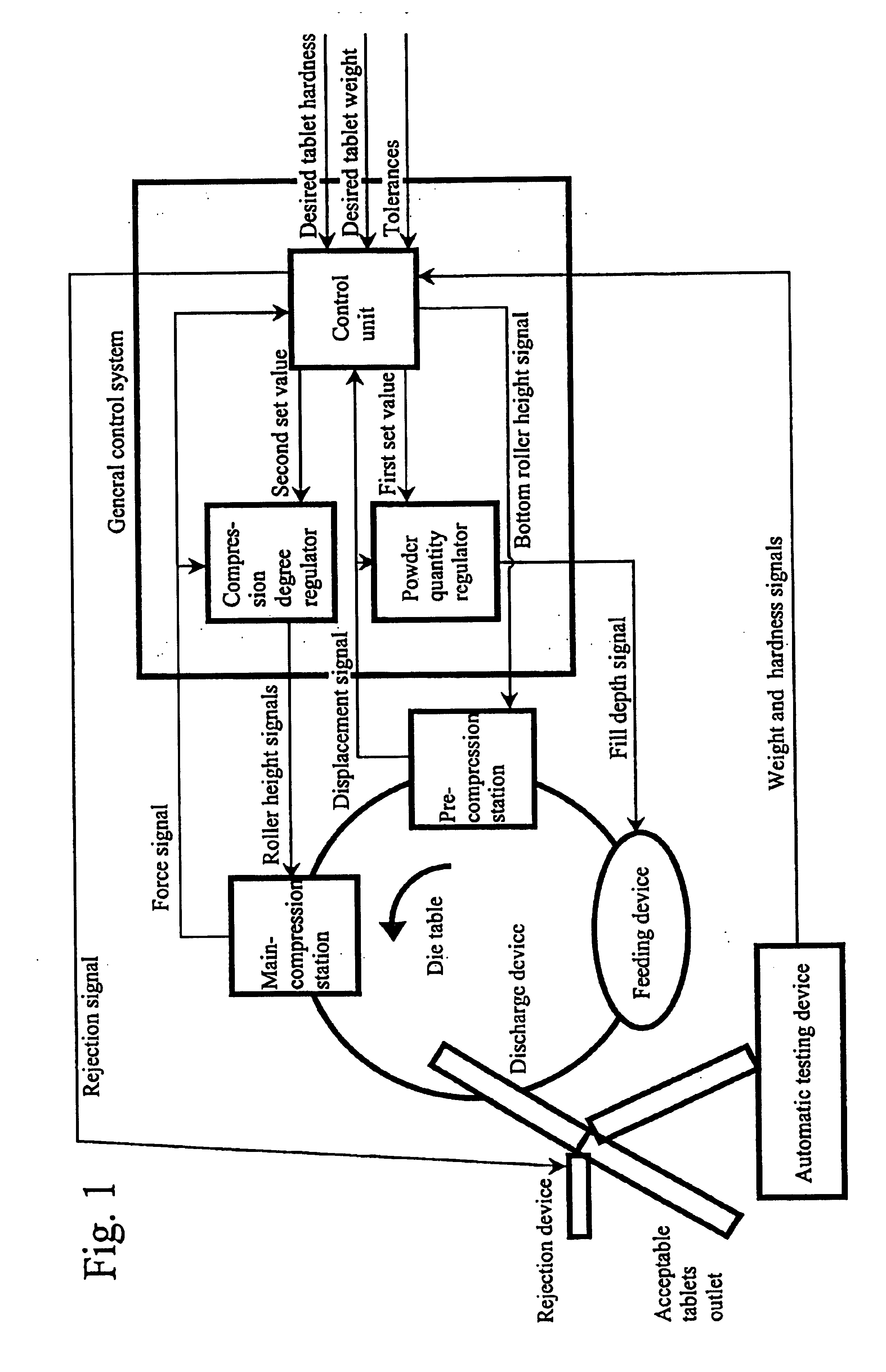

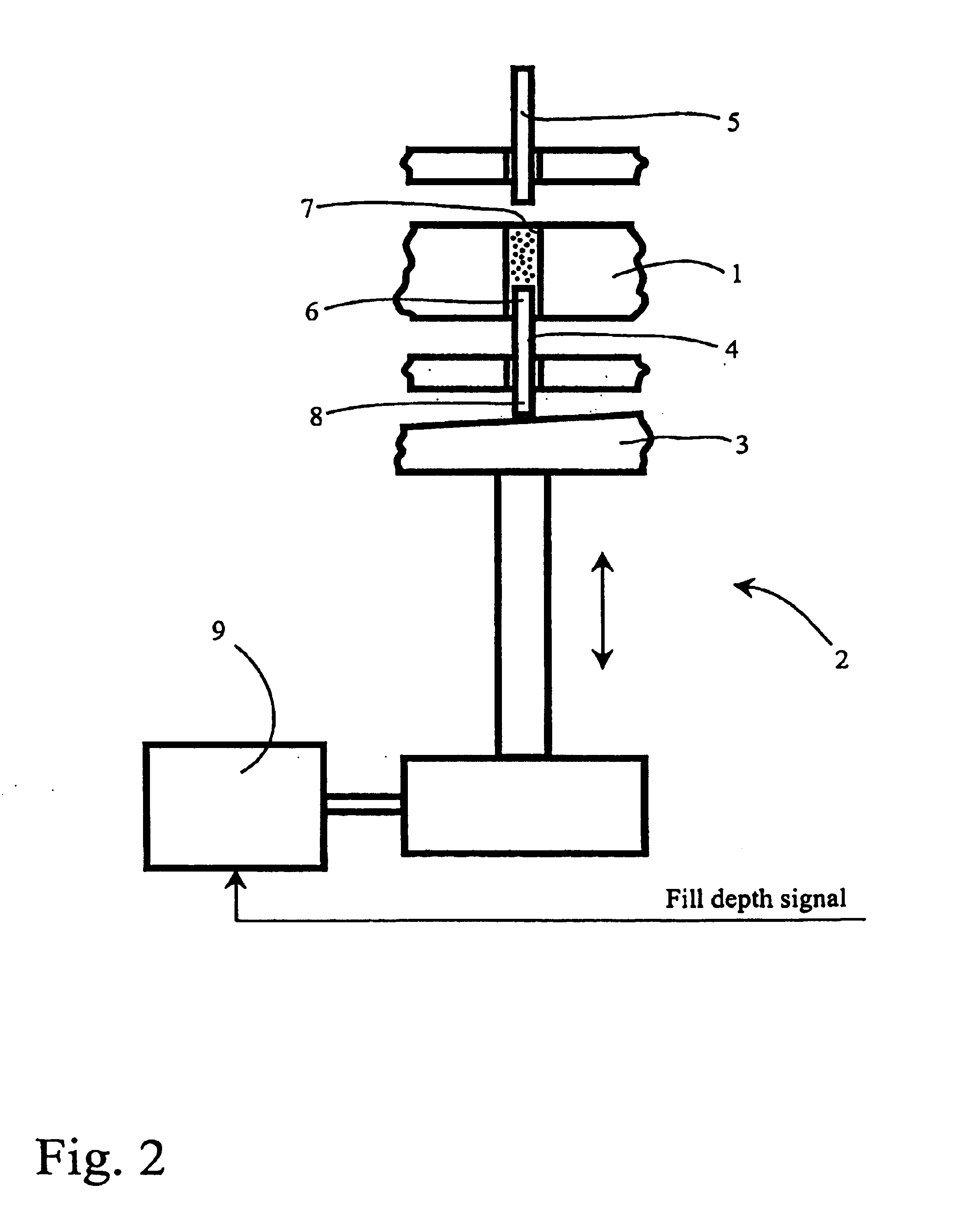

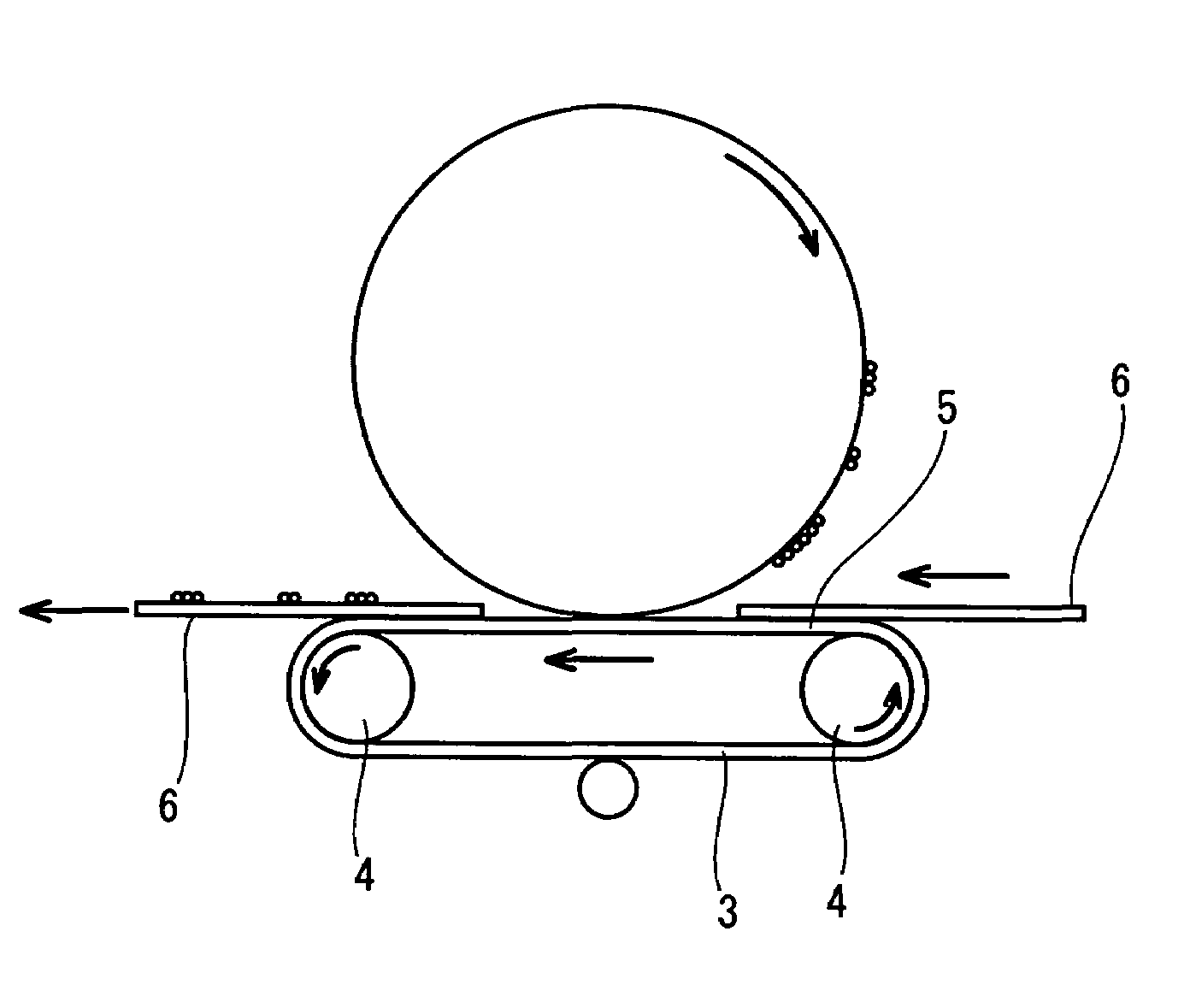

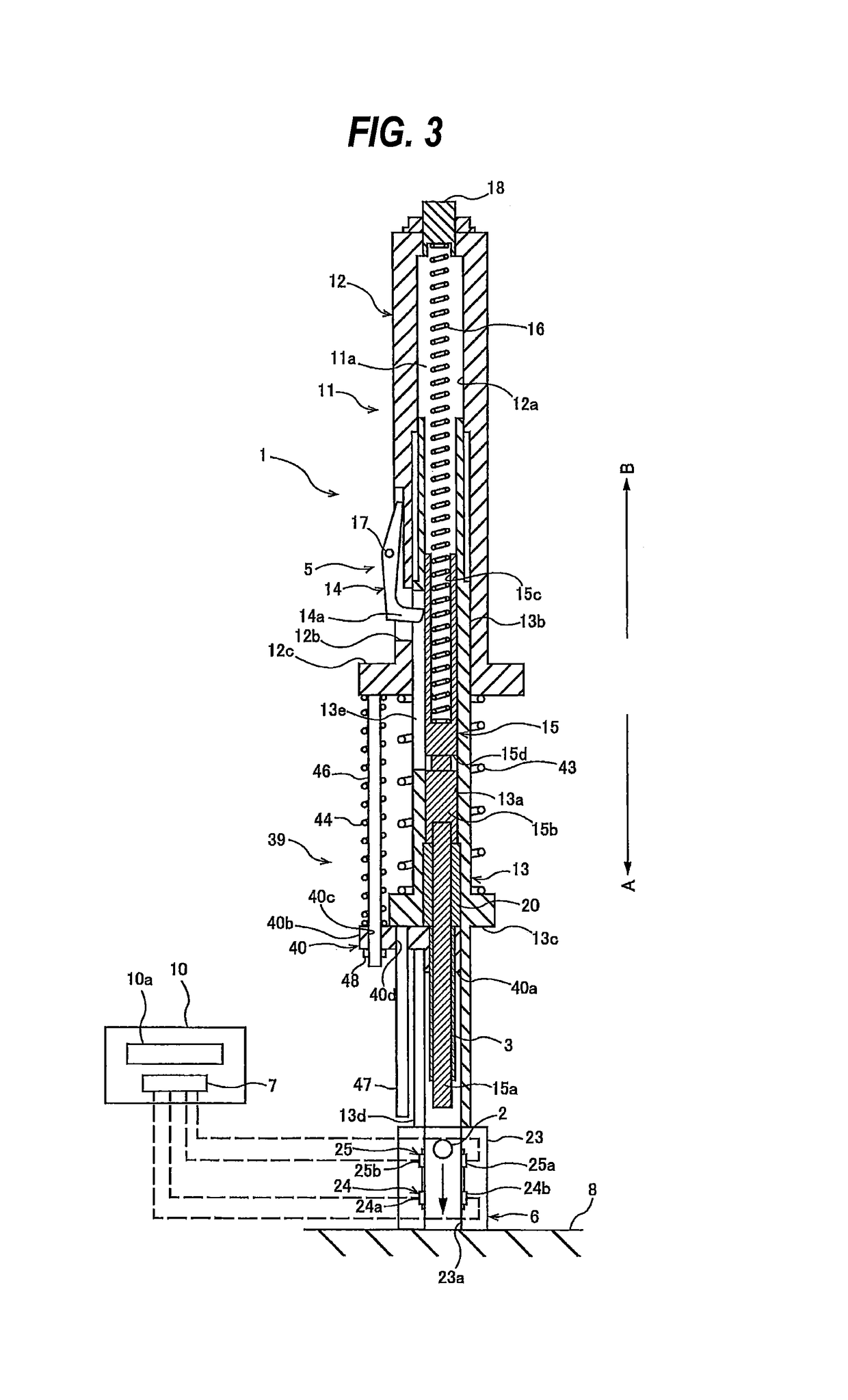

Method for controlling a rotary tablet press and such a press

InactiveUS20050200038A1Accurately controlAccurate hardnessConfectioneryWood working apparatusMachine pressProcess engineering

A method for controlling a rotary tablet press comprises the steps of consecutively supplying material into each die of a die table, subjecting the material to a pre-compression and a main-compression, measuring, during the pre-compression, a value representative of the weight of material compressed, and during the main-compression, a value representative of the hardness of the resulting tablet. The quantity of material supplied to each die is regulated on the basis of a deviation between a measured value representative of the weight and a first set value. The degree of compression during main-compression is regulated on the basis of a deviation between a measured value representative of the hardness and a second set value.

Owner:COURTOY

Scented candle and manufacturing method for same

InactiveUS6086644AExcellent perfume dispersionImprove stabilitySolid fuelsCapillary burnersCarbon numberFlavor

A scented candle includes a candle manufacturing material, a fragrance provider, and at least one of polypropylene glycol and polypropylene glycol monoalkyl ether with a general formula (I) H-(OC3H6)n-O-R(I)where n is an integer between 2 and 40 and R is H or an alkyl group with a carbon number between 1 and 10.

Owner:TAKASAGO INTERNATIONAL CORPORATION +1

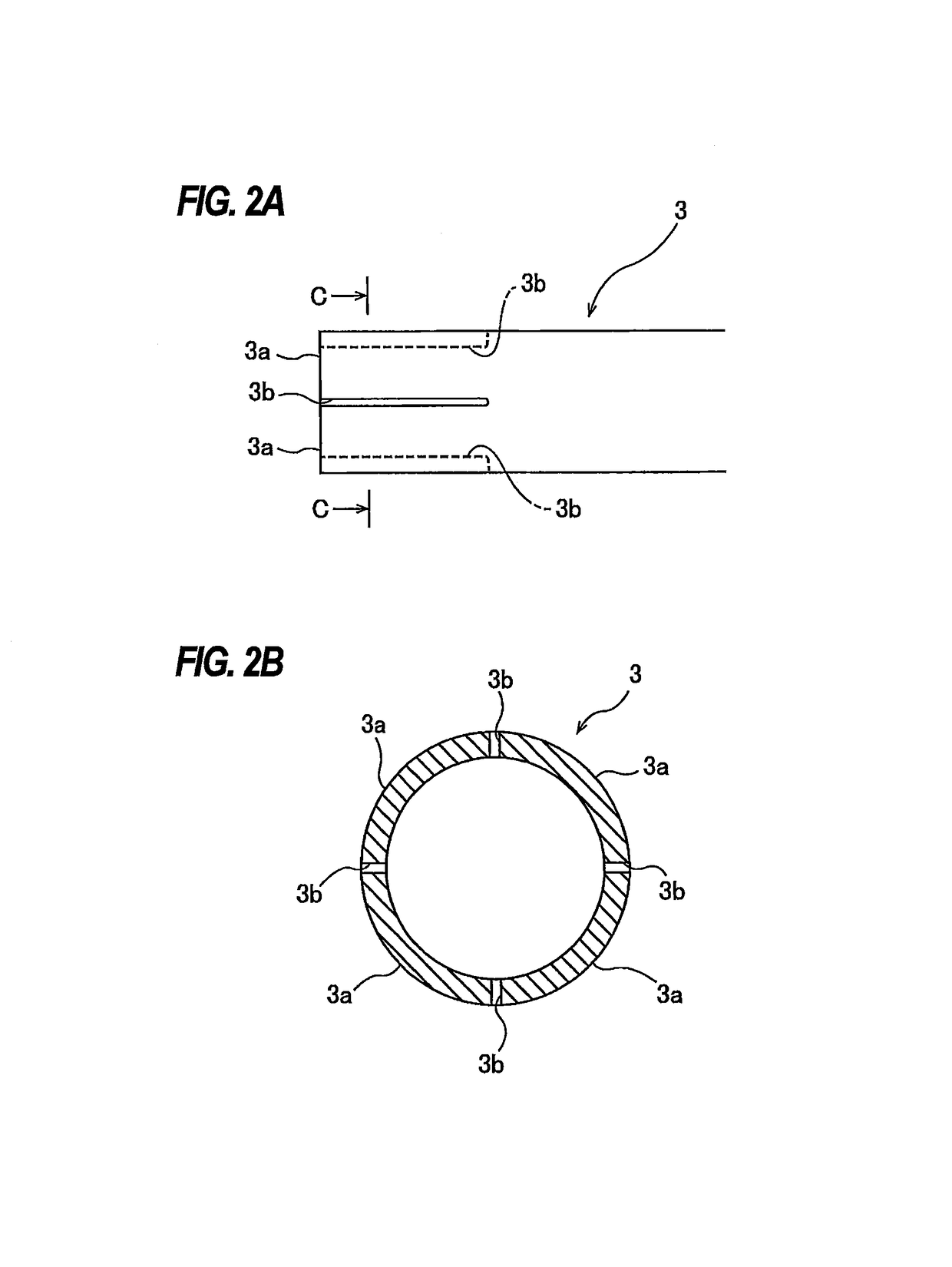

Conductive elastomer composition, conductive member using conductive elastomer composition, image-forming apparatus having conductive member

ActiveUS20060074162A1Lower the resistance valueAccurate hardnessConductive materialSpecial tyresThermoplasticElastomer

A conductive elastomer composition includes an ionic-conductive elastomer component, which contains an anion-containing salt having a fluoro group (F—) and a sulfonyl group (—SO2—). The conductive elastomer composition has a volume charge not more than 108.5 (Ω·cm) when the volume charge is measured at a voltage of 100V applied theretoin accordance with the method specified in JIS K6911. The conductive elastomer composition has a compression set not more than 30% when the compression set is measured at a temperature of 70° C. for 24 hours at a compressibility ratio of 25% in accordance with “the permanent set testing methods for rubber, vulcanized or thermoplastic” specified in JIS K6262.

Owner:SUMITOMO RUBBER IND LTD

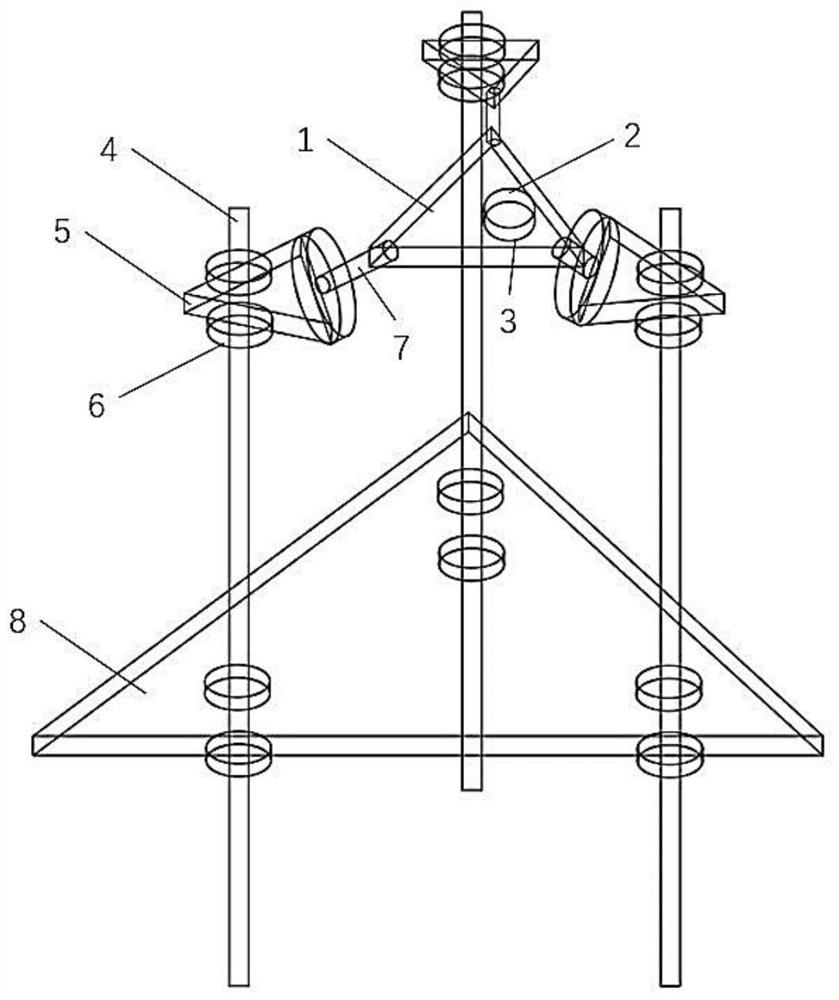

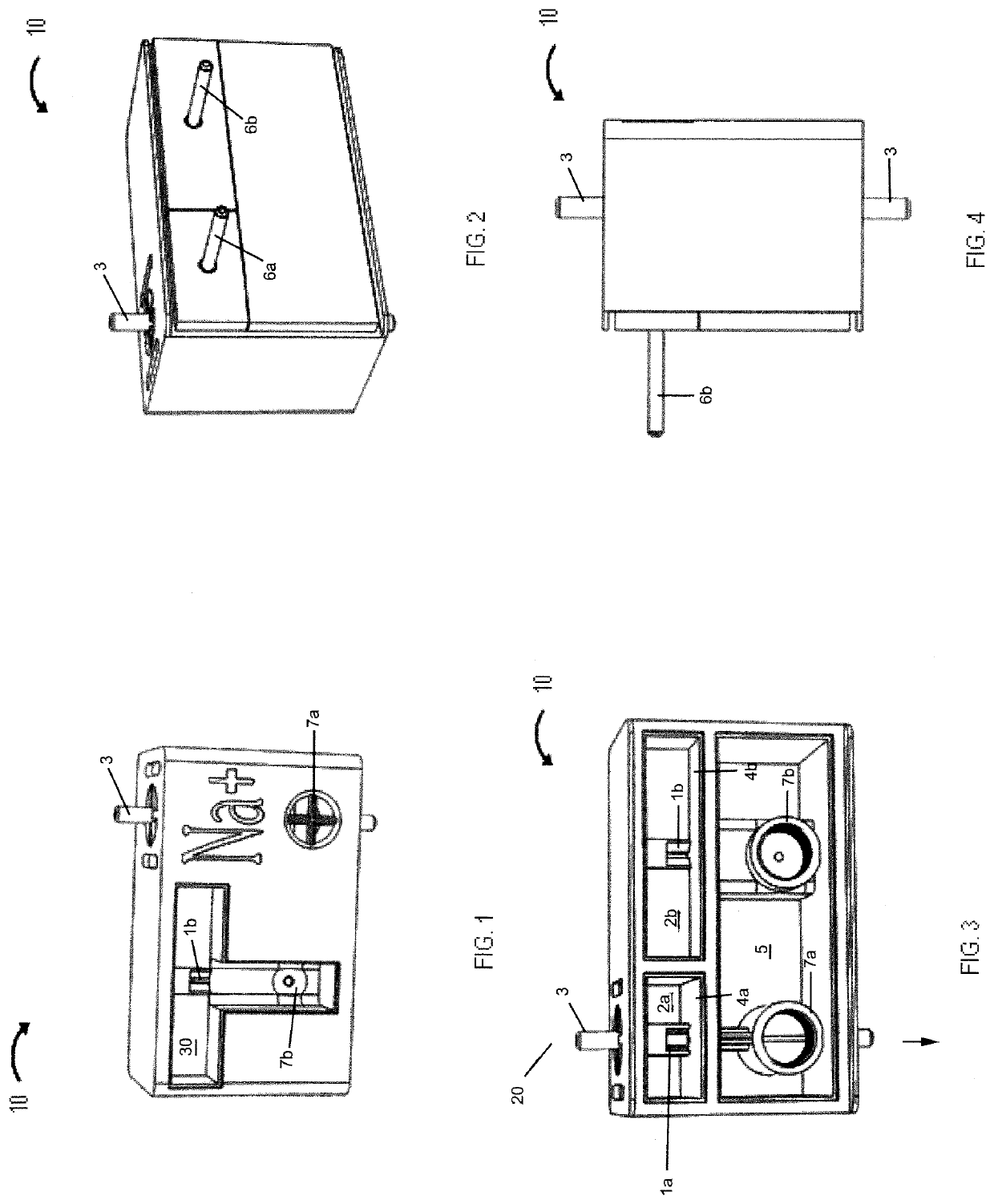

Automatic detector for textural properties of hardness and viscosity of cooked rice grains

InactiveCN101571468AAccurate hardnessReal hardnessFlow propertiesInvestigating material hardnessEngineeringHardness

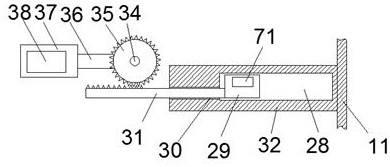

The invention relates to an automatic detector aiming at textural properties of hardness and viscosity of cooked rice grains. A structure of the automatic detector comprises: a motor is connected with a shaft which is connected with a cam; a guide rod is arranged below the cam; a spring is arranged on the guide rod, and the underside of the guide rod is provided with an upper measuring arm and a lower measuring arm which are connected to a box body; the upper measuring arm is provided with an upper moveable block; a fastening screw is arranged on the upper moveable block, and the underside of the upper moveable block is connected with a pressure head; the lower measuring arm is provided with a lower moveable block which is provided with a lower fastening screw, and the above of the lower moveable block is connected with a tray which aims at the pressure head on the above; and strain gauges are arranged on the upper measuring arm and the lower measuring arm to form a differential bridge to a PC machine. The automatic detector overcomes the defects that a texture analyzer has poor accuracy and cannot represent the change relation between two parameters, namely the stress and the deformation in the process that cooked rice is stressed. The automatic detector aims at the detection of the textural properties of the cooked rice grains, accurately and truly reflects the hardness and the viscosity of the cooked rice grains and performs quantification on the hardness and the viscosity.

Owner:YANGZHOU UNIV

Hardness tester

ActiveUS20050115310A1Accurate hardnessError minimizationInvestigating material hardnessDrive shaftEngineering

A hardness tester includes a supporting frame having a guiding channel, a driving axle slidably disposed in the supporting frame, and a penetrating pin, having a pin head, coaxially disposed in the guiding channel in a slidably movable manner to coaxially align with the driving axle for the pin head to penetrate on a testing surface of a tested object. A linear displacement device includes a transmission shaft movably disposed in the supporting frame at a position universally contacting between the driving axle and the penetrating pin, and a displacement sensor supported at the transmission shaft, wherein when the driving axle is driven for applying a penetrating force to the penetrating pin through the transmission shaft, the linear sensor detects a linear displacement of the transmission shaft with respect to the penetrating pin for measuring the hardness of the tested object.

Owner:WUSOMING

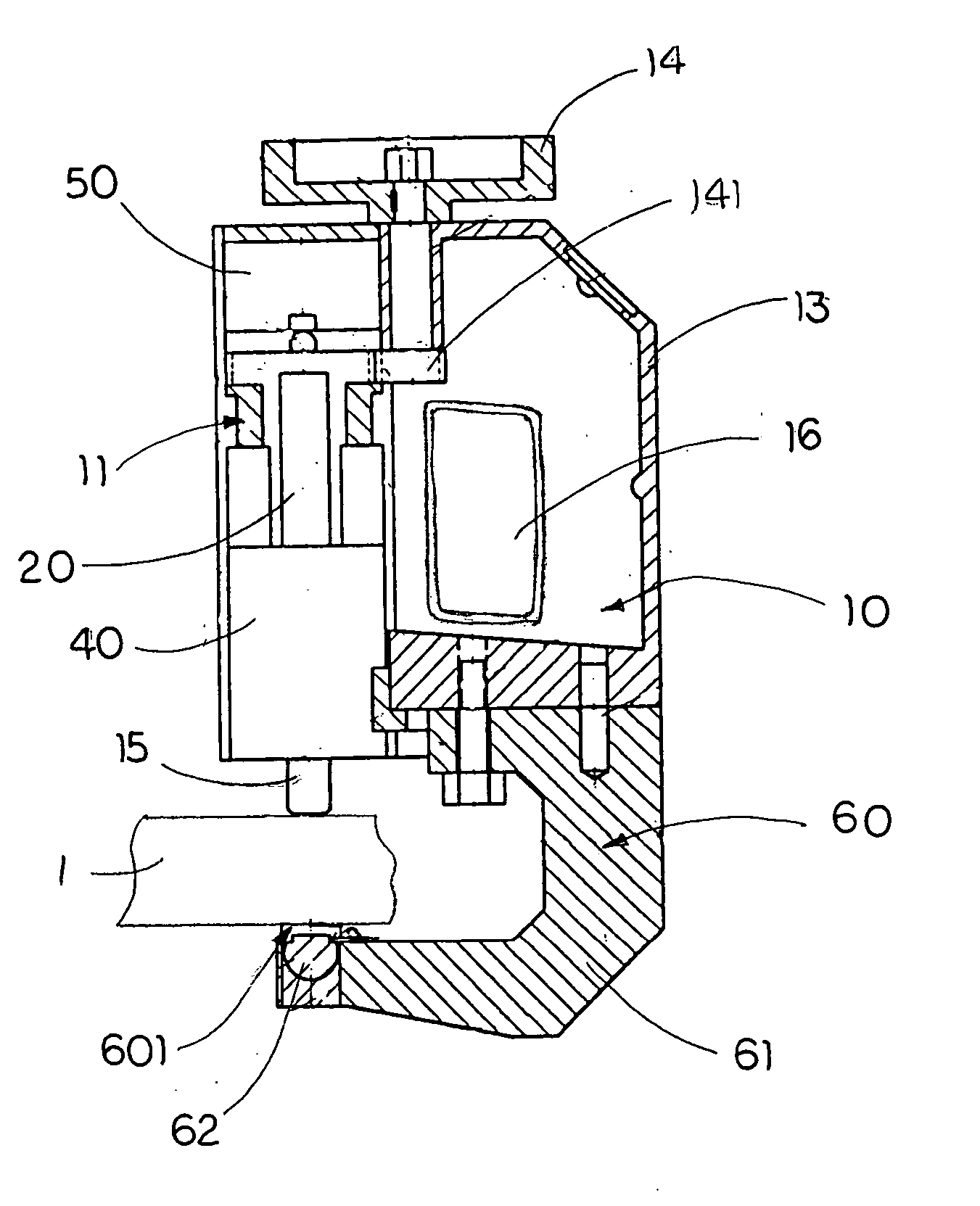

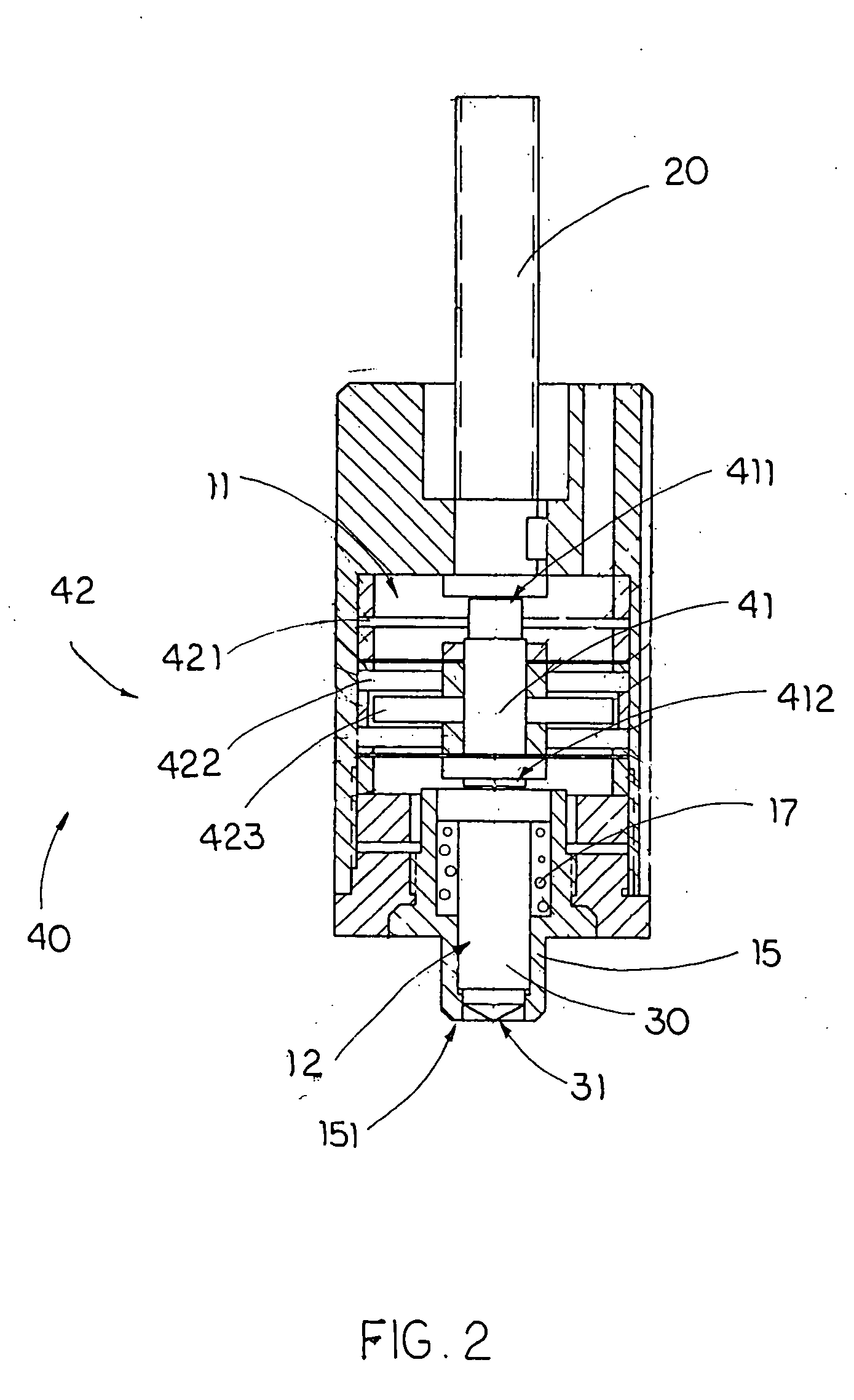

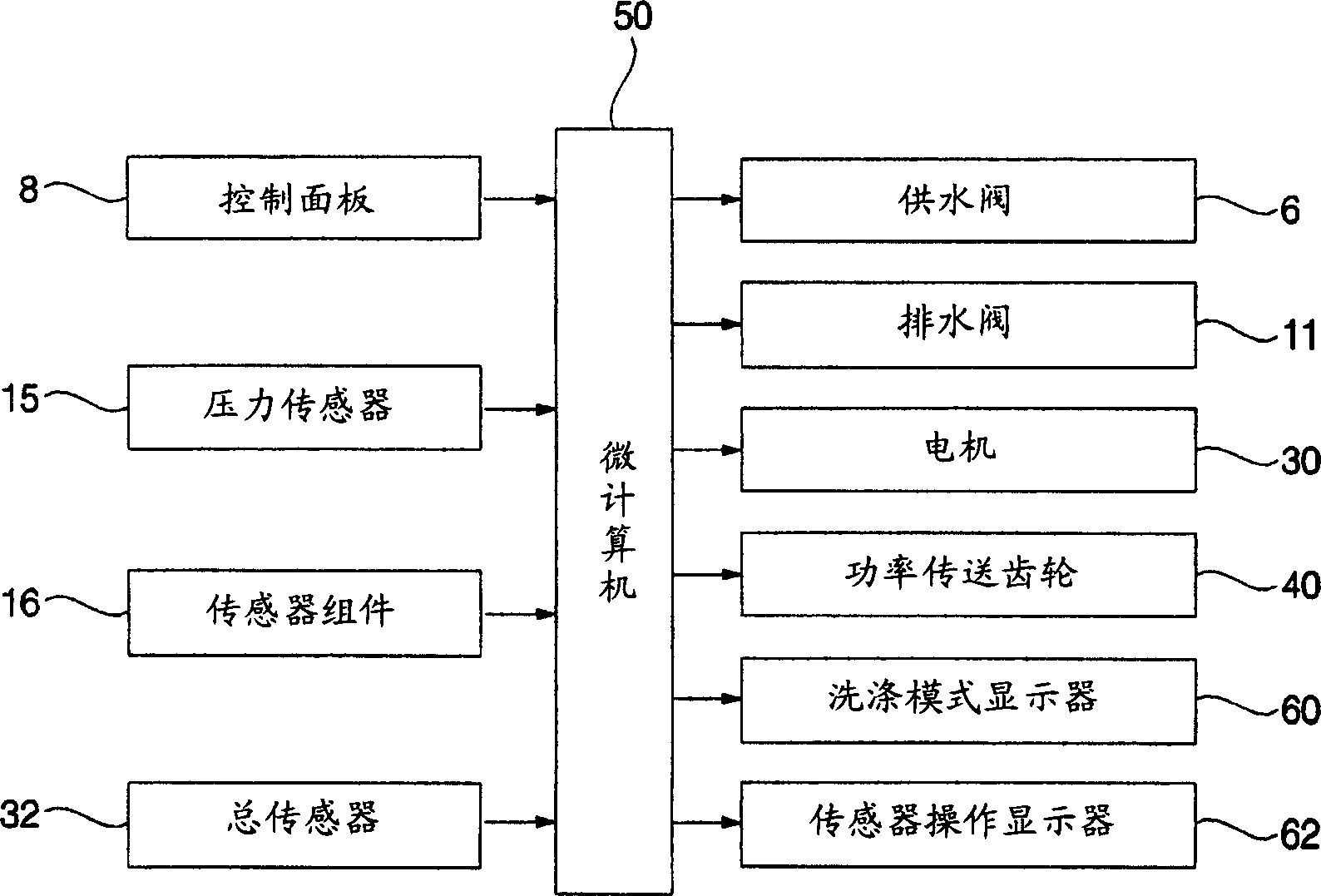

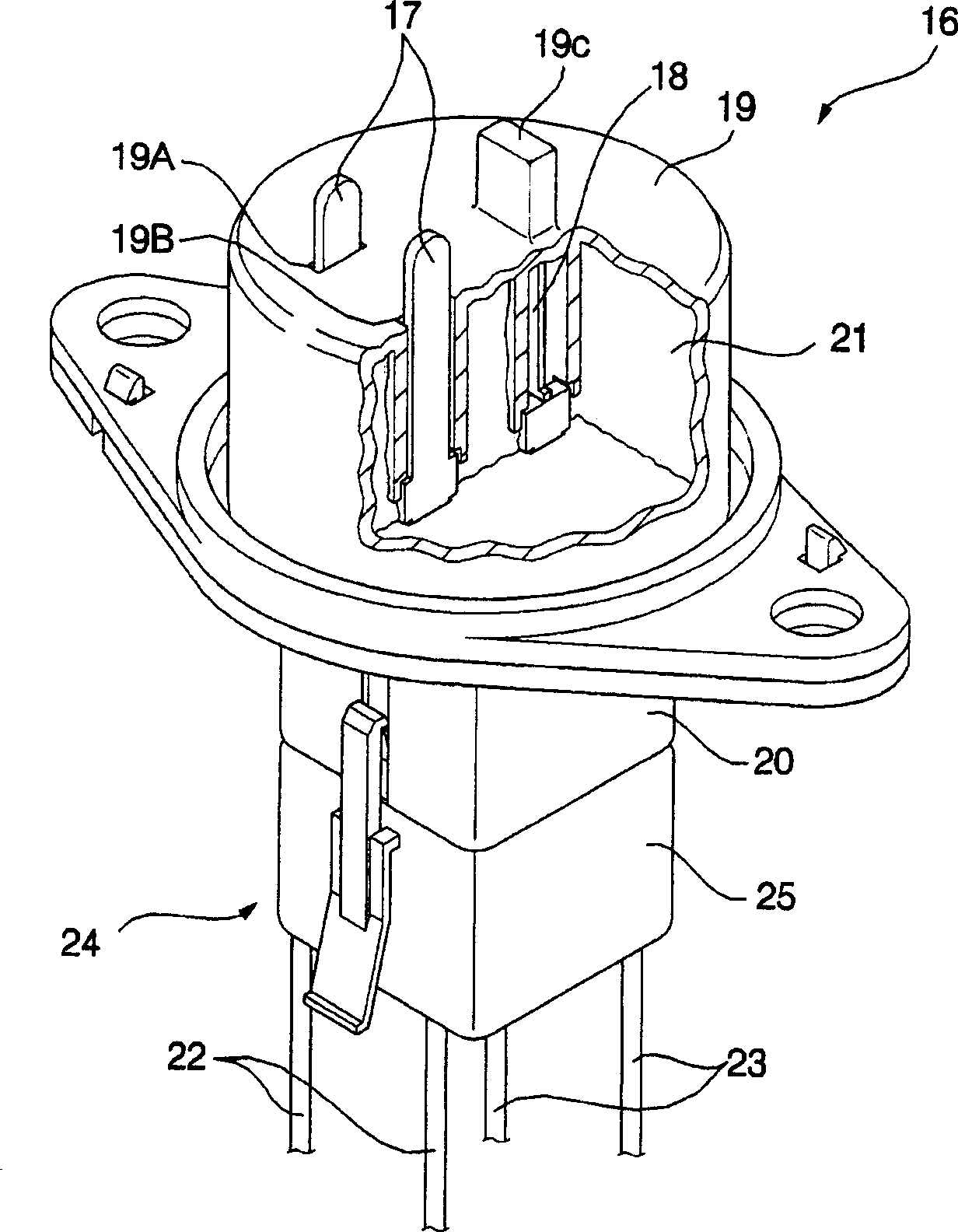

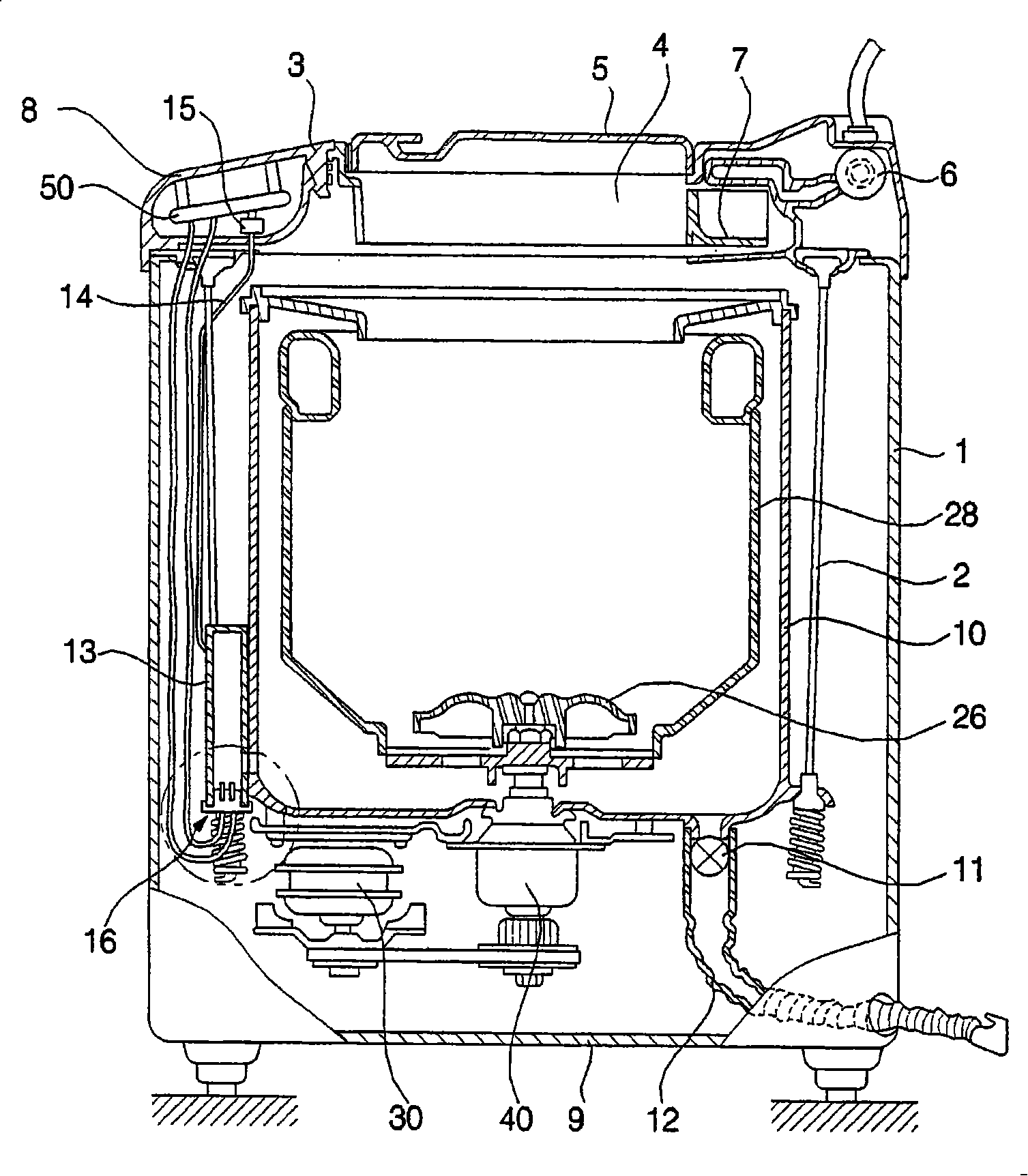

Control method of washing machine

InactiveCN1809660AShorten washing timeReduce hardness changesOther washing machinesControl devices for washing apparatusHardnessProcess engineering

Disclosed is a control method of a washing machine comprising the steps of (a) setting a washing pattern in the present operation of the washing machine in consideration of hardness of the water calculated in the previous operation of the washing machine, (b) operating the washing machine based on the set washing pattern, and (c) calculating and storing hardness of the water in the present operation of the washing machine to set a next washing pattern in the next operation of the washing machine, thereby having the optimum washing or rinsing capacity of the washing machine in consideration of different characteristics of water by regional groups.

Owner:LG ELECTRONICS INC

Brake Disk Excellent in Temper Softening Resistance and Toughness

ActiveUS20090104068A1Improve the immunityPromote precipitationBraking elementsActuatorsAustenite grainToughness

A brake disk excellent in temper softening resistance and toughness comprising, by mass, 0.1% or less of C, 1.0% or less of Si, 2.0% or less of Mn, 10.5% to 15.0% of Cr, and 0.1% or less of N, the remainder being Fe and unavoidable impurities, such that the following inequalities are satisfied: 5Cr+10Si+15Mo+30Nb−9Ni—5Mn—3Cu−225N−270C<45 (1) and 0.03≦{C+N−(13 / 92)Nb}≦0.09 (2) wherein Cr, Si, Mo, Nb, Ni, Mn, Cu, N, and C each represent the content of the corresponding elements on a mass percent basis, and having a martensitic structure having prior-austenite grains with an average diameter of 8 to less than 15 μm.

Owner:JFE STEEL CORP

Conductive elastomer composition, conductive member using conductive elastomer composition, image-forming apparatus having conductive member

ActiveUS7098264B2Lower the resistance valueAccurate hardnessConductive materialSpecial tyresThermoplasticElastomer

A conductive elastomer composition includes an ionic-conductive elastomer component, which contains an anion-containing salt having a fluoro group (F—) and a sulfonyl group (—SO2—). The conductive elastomer composition has a volume charge not more than 108.5 (Ω·cm) when the volume charge is measured at a voltage of 100V applied thereto in accordance with the method specified in JIS K6911. The conductive elastomer composition has a compression set not more than 30% when the compression set is measured at a temperature of 70° C. for 24 hours at a compressibility ratio of 25% in accordance with “the permanent set testing methods for rubber, vulcanized or thermoplastic” specified in JIS K6262.

Owner:SUMITOMO RUBBER IND LTD

High-concentration polymer polyol and method for its production

If it is attempted to produce a polymer polyol at a high concentration, there will be a problem such that during polymerization of a monomer to form fine polymer particles, particles are likely to aggregate one another to form aggregates, and storage stability of the polymer polyol tends to deteriorate. A method for producing a polymer polyol is presented which comprises polymerizing at least one type of ethylenically unsaturated monomer together with a seed particle dispersion, in a polyol, wherein the seed particle dispersion is one obtained by polymerizing an ethylenically unsaturated monomer in the presence of an ethylenically unsaturated macromonomer, a solvent and a chain transfer agent, and the ethylenically unsaturated macromonomer is a reaction product of a specific polyol, an isocyanate compound and an ethylenically unsaturated monomer having a hydroxy group.

Owner:ASAHI GLASS CO LTD

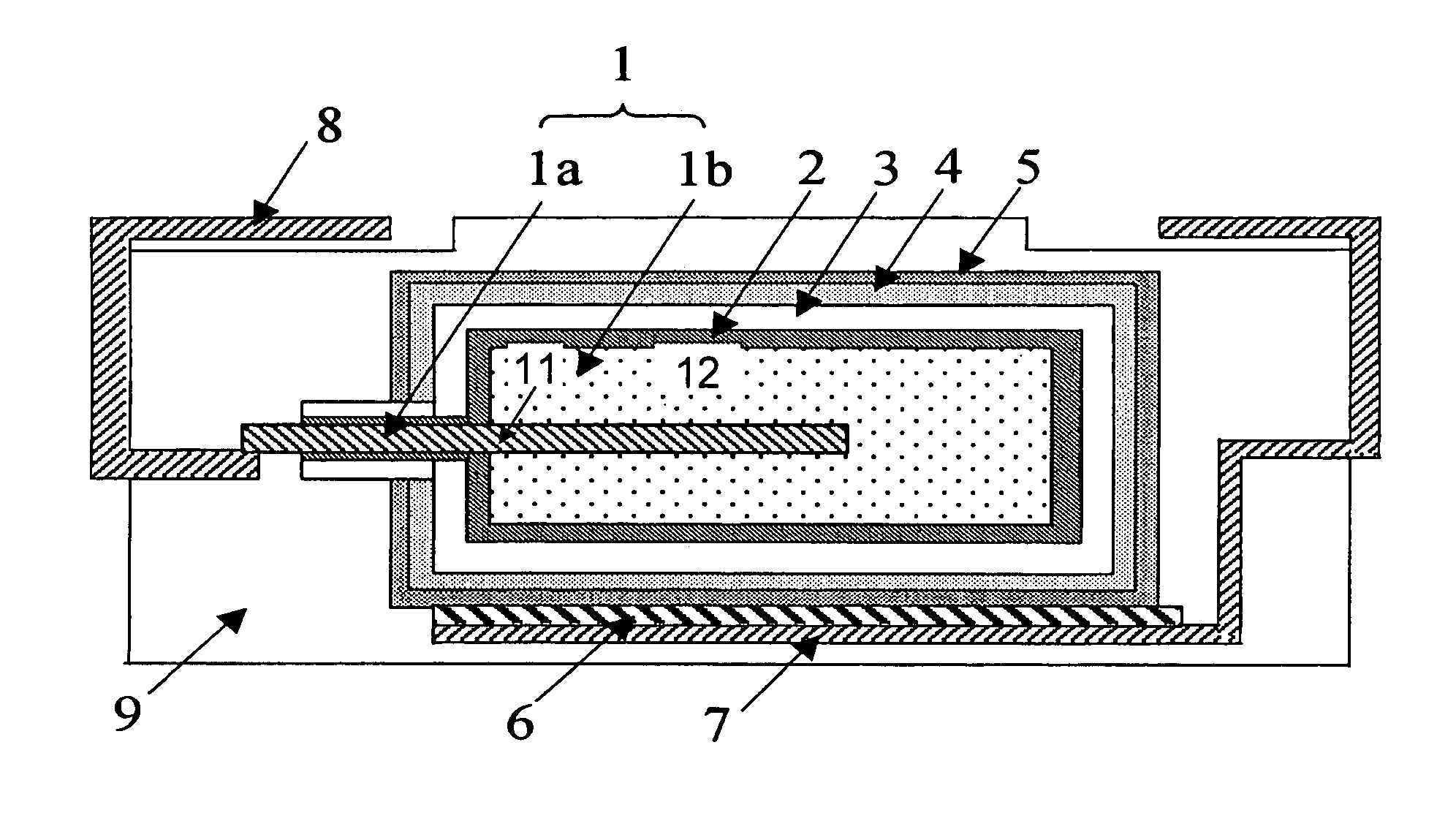

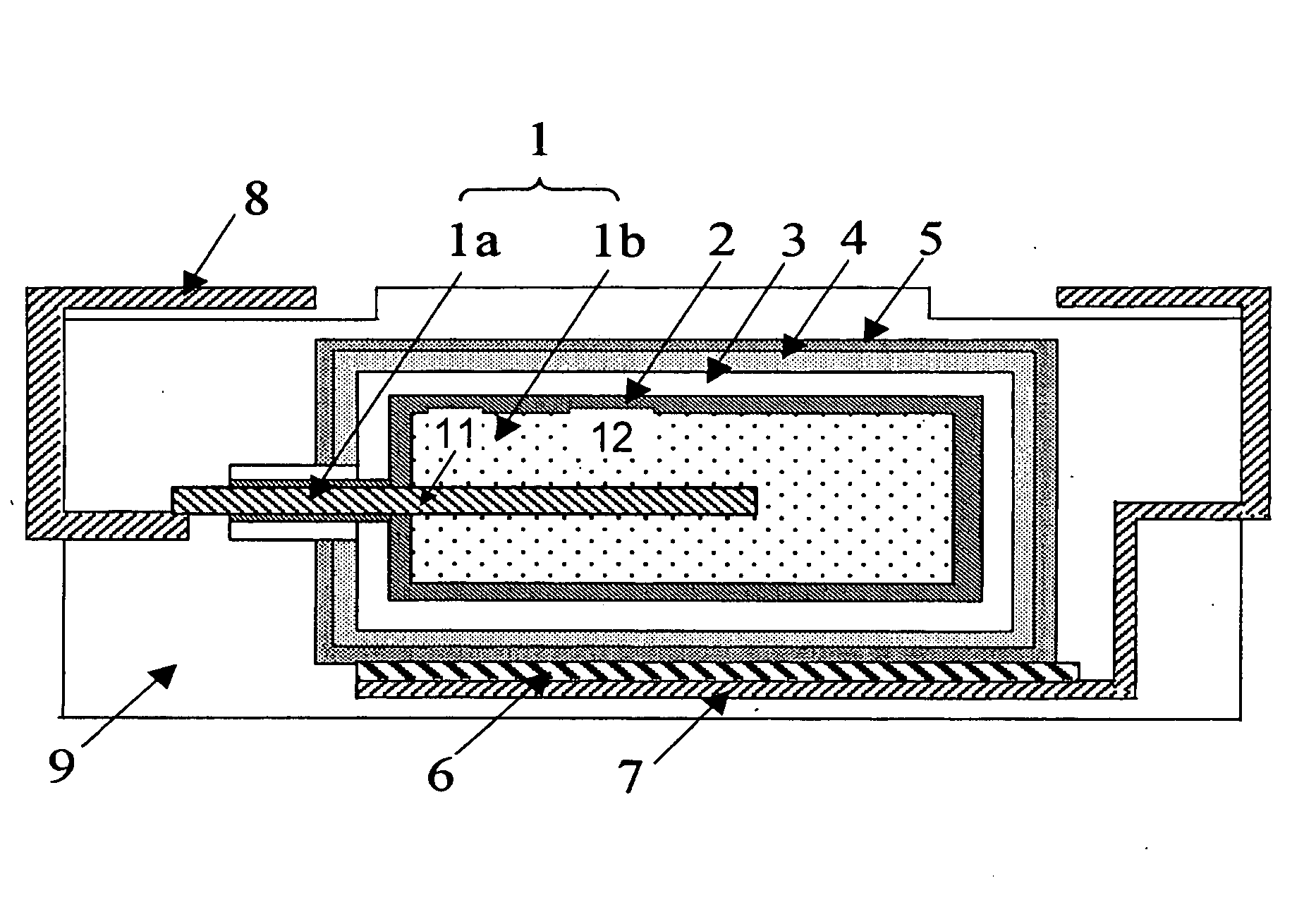

Solid electrolytic capacitor

InactiveUS7855869B2Stand stressImprove contact effectClosuresSolid electrolytic capacitorsElectrolysisHardness

An object of the present invention is to provide a solid electrolytic capacitor having a low defective fraction. A solid electrolytic capacitor of the present invention includes an anode structured by an anode lead formed by a valve metal, and porous body of valve metal connected to the anode, and a dielectric layer provided on a surface of the anode wherein a Vickers hardness of the anode lead, which is positioned at not more than 20 μm in depth from a surface of the anode lead is set 30 Hv-70 Hv.

Owner:SANYO ELECTRIC CO LTD

Hardness tester

ActiveUS7066013B2Accurate hardnessError minimizationMaterial strength using repeated/pulsating forcesInvestigating material hardnessDrive shaftHardness

A hardness tester includes a supporting frame having a guiding channel, a driving axle slidably disposed in the supporting frame, and a penetrating pin, having a pin head, coaxially disposed in the guiding channel in a slidably movable manner to coaxially align with the driving axle for the pin head to penetrate on a testing surface of a tested object. A linear displacement device includes a transmission shaft movably disposed in the supporting frame at a position universally contacting between the driving axle and the penetrating pin, and a displacement sensor supported at the transmission shaft, wherein when the driving axle is driven for applying a penetrating force to the penetrating pin through the transmission shaft, the linear sensor detects a linear displacement of the transmission shaft with respect to the penetrating pin for measuring the hardness of the tested object.

Owner:WUSOMING

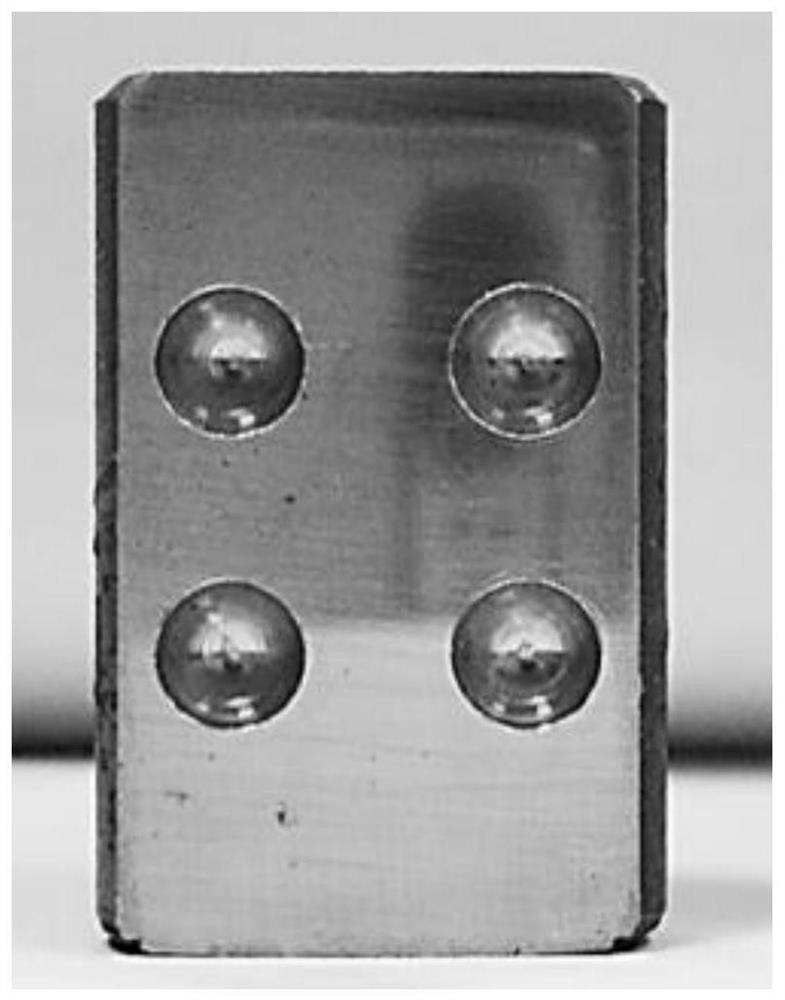

Apparatus for measuring coefficient of restitution and hardness tester

ActiveUS20170131193A1Reduce mass effectCorrection coefficientOptical detectionDevices using time traversedCoefficient of restitutionEngineering

An apparatus for measuring for measuring coefficient of restitution which is capable of reducing a mass effect and performing tests in free directions, is disclosed. The apparatus for measuring coefficient of restitution includes a holder for holding a spherical indenter, an ejection mechanism configured to eject the indenter held by the holder from the holder to a specimen, a speed measuring unit configured to measure an impact speed that is a speed of the indenter before the indenter impacts against the specimen, and a rebound speed that is a speed of the indenter after the indenter is rebounded from the specimen; and an arithmetic unit configured to calculate a coefficient of restitution that is a ratio of the rebound speed to the impact speed.

Owner:YAMAMOTO SCI TOOL LAB CO LTD +1

Solid electrolytic capacitor

InactiveUS20080148541A1Reduce defective rateAccurate hardnessClosuresSolid electrolytic capacitorsElectrolysisHardness

An object of the present invention is to provide a solid electrolytic capacitor having a low defective fraction. A solid electrolytic capacitor of the present invention includes an anode structured by an anode lead formed by a valve metal, and porous body of valve metal connected to the anode, and a dielectric layer provided on a surface of the anode wherein a Vickers hardness of the dielectric layer, which is positioned not more than 20 μm in depth from a surface of the anode lead is set 30 Hv-70 Hv.

Owner:SANYO ELECTRIC CO LTD

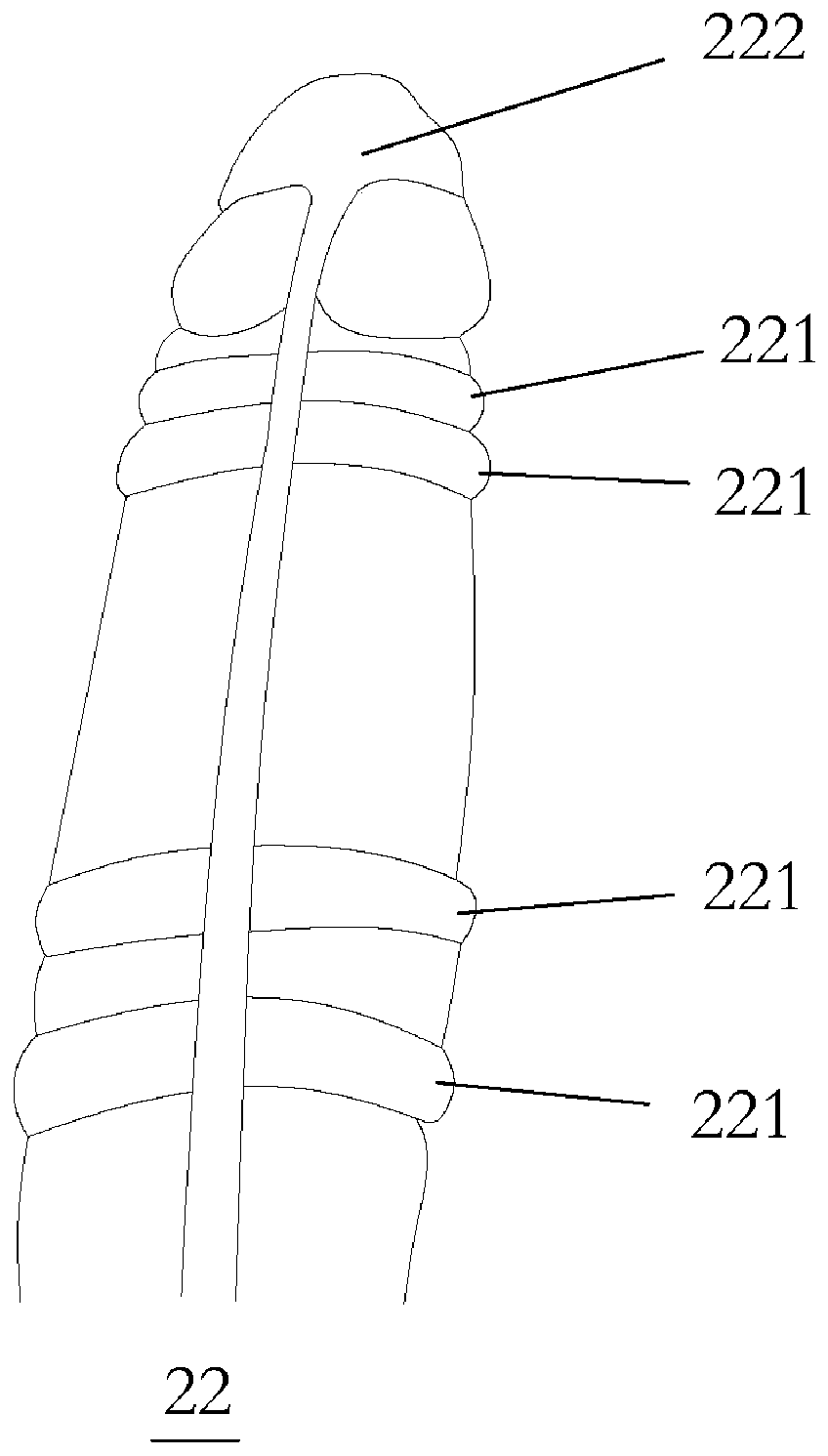

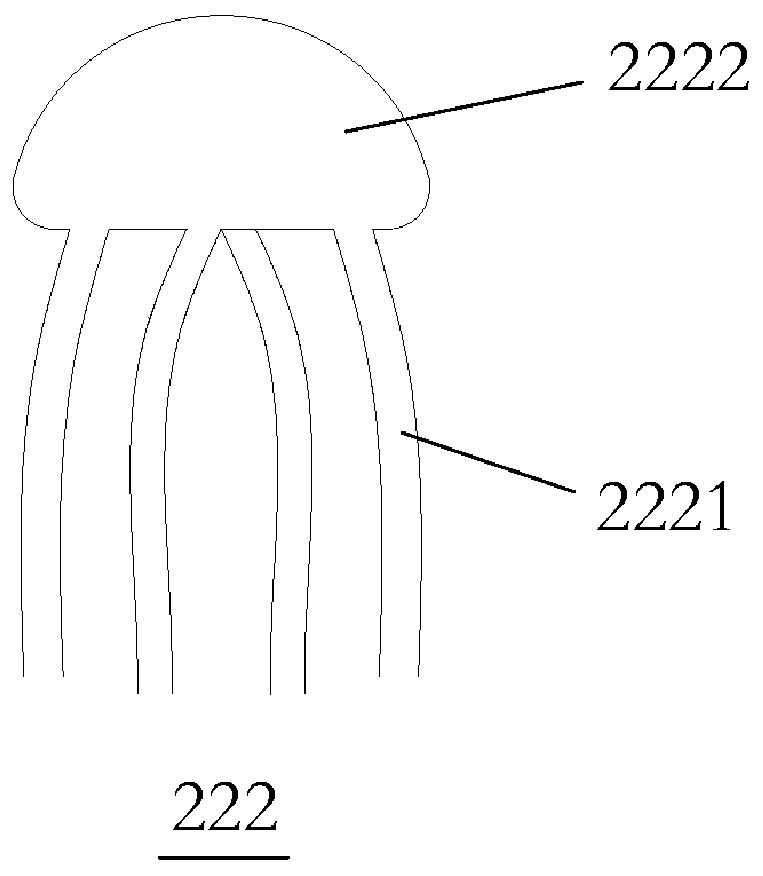

Penile erection multi-parameter evaluation system based on flexible sensor and evaluation method

PendingCN111543951AAccurate hardnessAvoid repeated stimulationDiagnostic signal processingSensorsPenisMedicine

The invention provides a penile erection multi-parameter evaluation system based on a flexible sensor and an evaluation method. The penile erection multi-parameter evaluation system comprises a circumference measuring device, a hardness measuring device and a data processing device. The circumference measuring device comprises a circumference change sensor which is a flexible tensile strain sensor; the hardness measuring device comprises a radial hardness sensor and an axial hardness sensor which are used for measuring the corresponding deformation of the penis along with the change of the hardness of the penis in an erection process, and the radial hardness sensor and the axial hardness sensor are both flexible stretchable pressure sensors; and the data processing device is used for receiving data acquired by the circumference change sensor and the radial hardness sensor and processing the data. On one hand, the radial pressure change of the penis can be measured, on the other hand, the axial pressure change of the penis can be measured, then the radial hardness and the axial hardness of the penis are determined, and meanwhile the peripheral diameter change of erection of the penis and the penis blood flow and temperature are recorded.

Owner:THE THIRD AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

Apparatus for measuring water hardness using ion selective electrode

ActiveUS20190302087A1Minimize liquid junction potentialAccurate hardnessWater treatment parameter controlSpecific water treatment objectivesIon exchangeSoftened water

An apparatus for determining total hardness in a fluid stream utilizing an ion exchange column in a monovalent cationic form having an inlet and an outlet, where one or more monovalent ion selective electrodes are positioned either at an inlet, outlet, or at both locations simultaneously. The monovalent cation selective electrodes are in electrical communication with one another, and in fluid communication with one or more valves incorporated within a fluid path in order to introduce feed water / softened water to the monovalent cation selective electrodes. Additionally, one blending valve may be incorporated in the ion exchange column to allow a fraction of the feed (hard) water to mix with a fraction of the softened water. In this manner, the blending valve may be utilized to adjust the hardness of the water at the output.

Owner:ECOWATER SYST

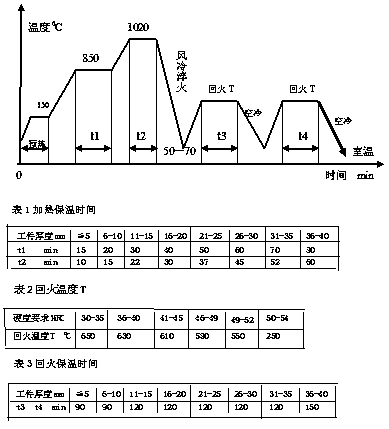

Precise heat treatment and quenching technology of precision part of high-purity hot-work die steel

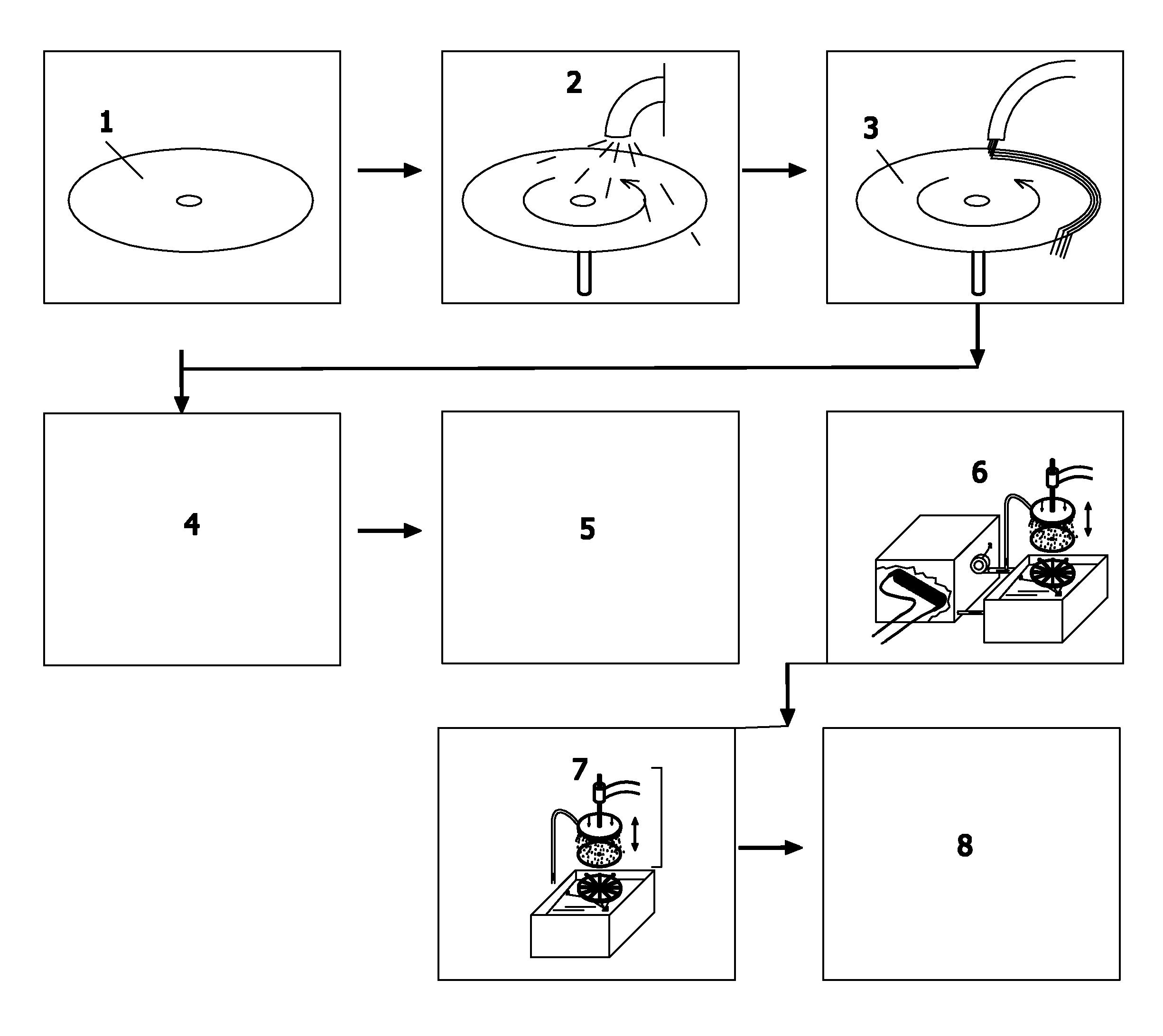

The invention discloses a precise heat treatment and quenching technology of a precision part of high-purity hot-work die steel, and belongs to the field of special steel heat treatment. The high-purity hot-work die steel ASSAB 8407 material imported from Sweden is aimed, wherein the material mainly comprises the following components of 0.39% of C, 5.2% of Cr, 0.1% of Si, 1.4% of Mo, 0.9% of V, and the precise heat treatment and quenching technology is provided. In the heat treatment process, different tempering temperatures are adopted to obtain accurate hardness; different heat treatment time is adopted for workpieces with different thicknesses, so that crystal grain changes inside the material can be accurately controlled, grain refinement can be kept, the structure is uniform, the workpiece of a die can obtain high impact toughness and high wear resistance; according to the technical scheme, the method comprises the following steps that (1) the workpiece with the thickness difference smaller than 5 mm is placed into a quenching furnace, and the workpiece is preheated to 150 DEG C in a heating rate of less than 75 DEG C per hour; (2) two level heating is carried out in the quenching furnace to the quenching temperature of 1020 DEG C and the temperature is kept according to heating preservation time t2; (3) the workpiece is discharged out of the furnace and is air-cooled andquenched; and (4), the workpiece is put into a tempering furnace two times for tempering, and tempering temperature T DEG C is carried out according to tempering heat preservation time t3 and t4 (FIG.1).

Owner:黄石高校智源技术咨询服务有限公司

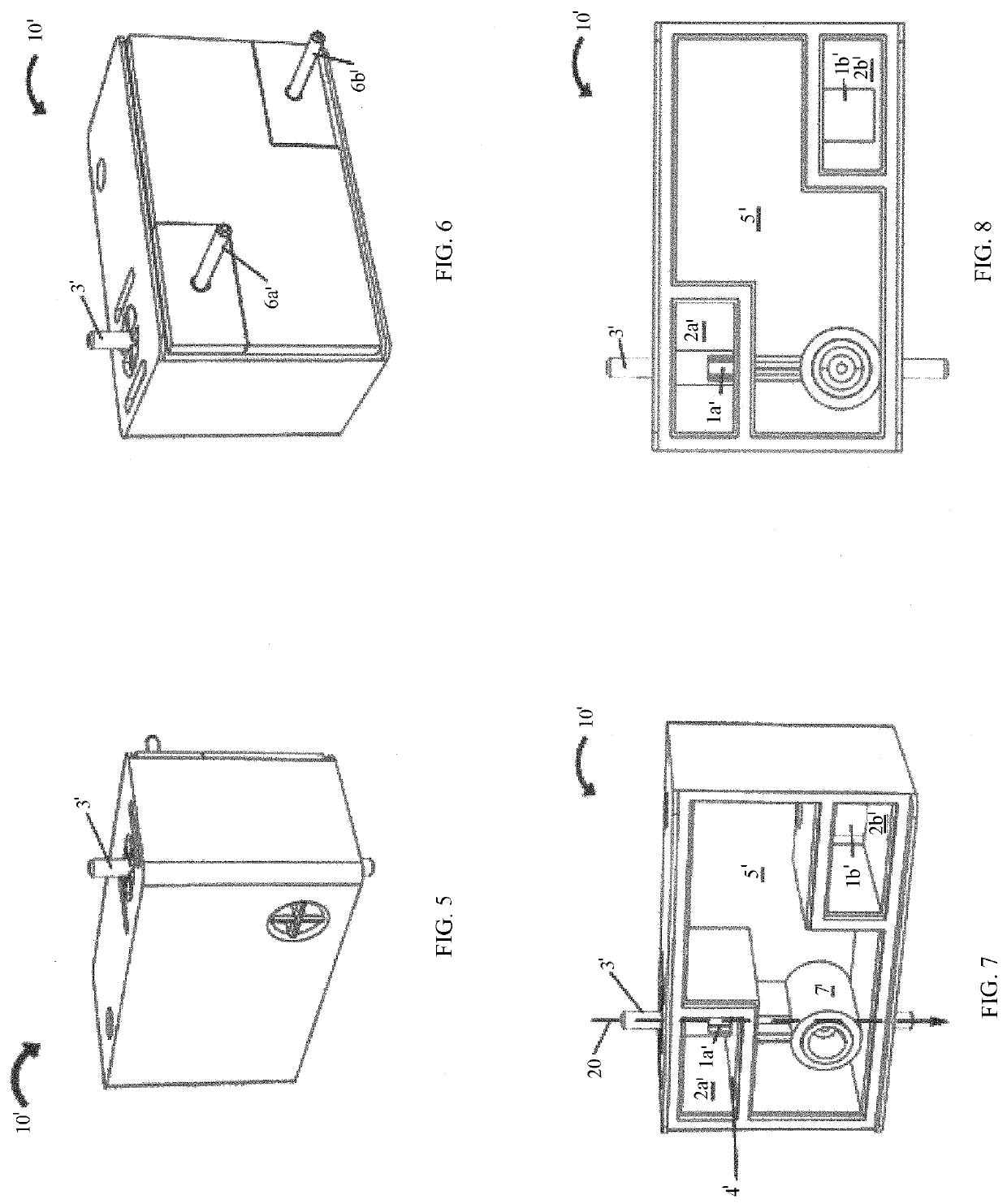

Voice-control intelligent mattress with hardness capable of being adjusted in multiple stages

ActiveUS20210112991A1Easy to adjustSimple operation modeStuffed mattressesSpring mattressesEngineeringStructural engineering

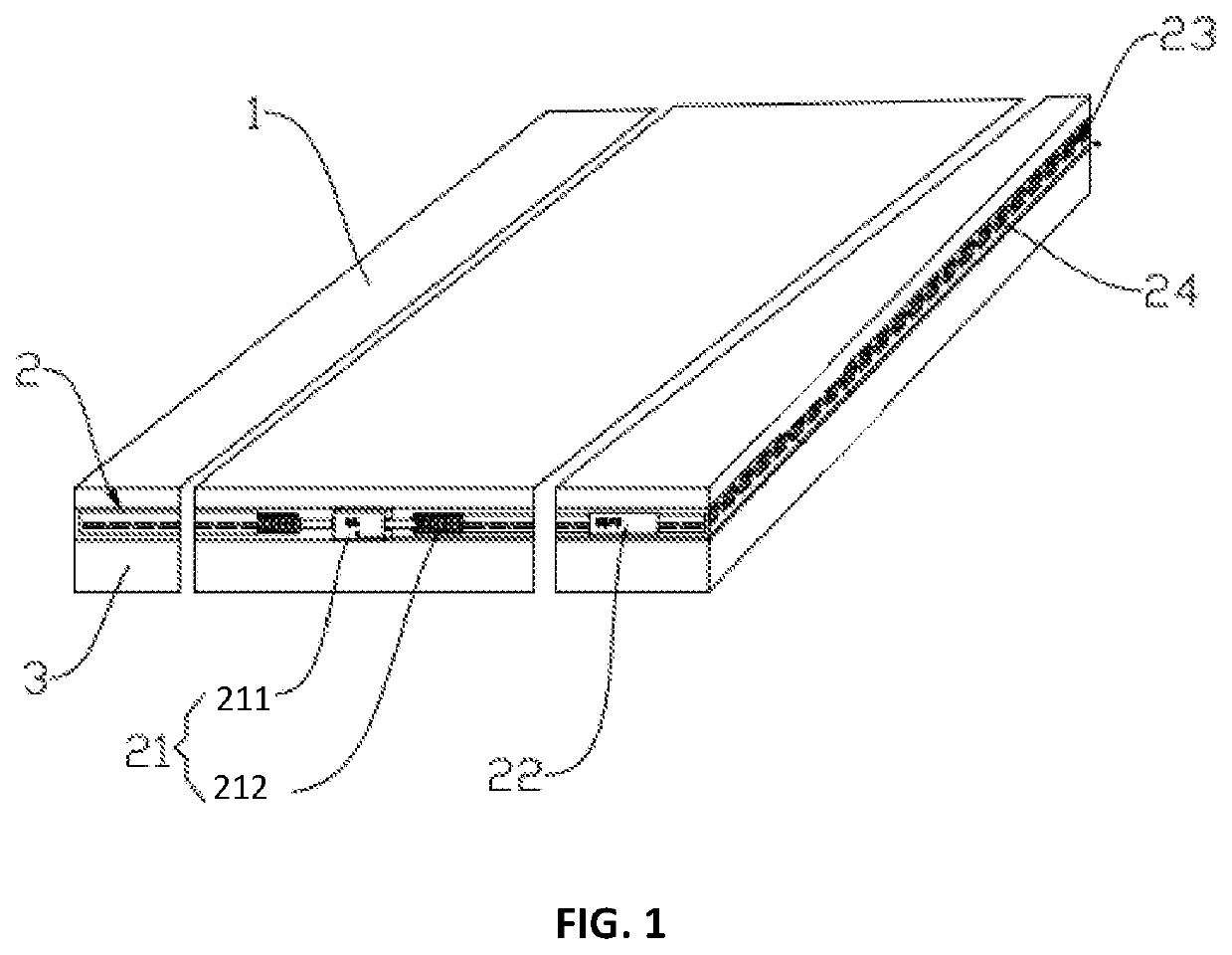

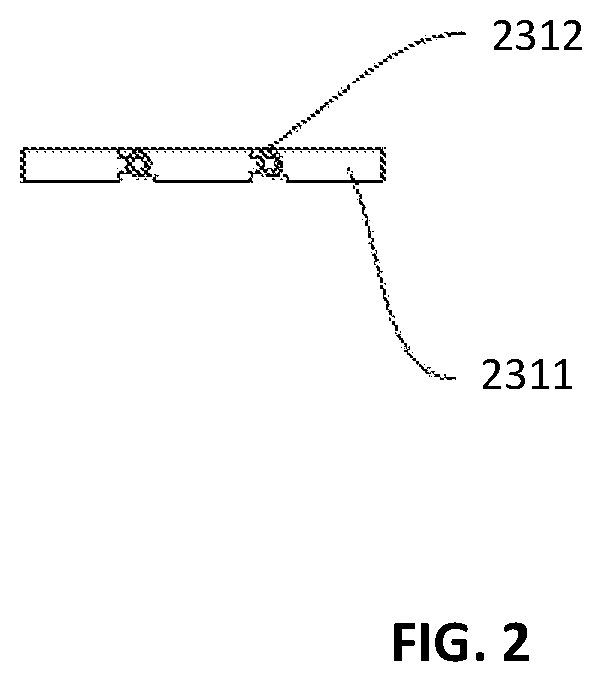

A voice-control intelligent mattress with hardness capable of being adjusted in multiple stages comprises an upper-layer soft pad, a hardness-adjusting device and a lower layer or a multi-layered hard pad that are sequentially arranged from top to bottom; the hardness-adjusting device comprises two adjusting units symmetrically arranged with the transverse center line of the present invention, and a voice-control module connected with the adjusting unit through a wire for controlling the starting and stopping of the adjusting unit; two adjusting frames connected with the adjusting unit are symmetrically arranged on the two sides of the adjusting unit; an elastic mesh belt installed on the adjusting frames is tightened or loosened along the expansion or contraction of the adjusting frames; the hardness of the mattress can be precisely adjusted so that the various demands of users can be satisfied.

Owner:CHEN RUIXI

Seat, method of manufacturing the same, and method of treatment for recovery from permanent set in fatigue of the seat

InactiveUS7996970B2Improve ventilationGood dispersionUpholstery manufactureStuffed mattressesFiberHardness

To provide a seat having a three-dimensional complex undulated cushion body securing hardness in a stress direction and excelling in dispersibility of the stress and durability, and a method of manufacturing the same.A seat 1 includes frames (15, 25), cushion bodies (11, 21) obtained by forming a plurality of sheet-like fibrous structures 4a to 4d integrally, and covers (13, 23), wherein a sheet-like fibrous structure 4 is formed by performing cotton blending of thermally adhesive composite short fibers to inelastic crimped short fibers and thermally adhering crossing points, and the sheet-like fibrous structure 4 satisfies a relationship of A≧3B / 2 when the number of short fibers arranged along a thickness direction is represented as A and the number of short fibers arranged along a direction perpendicular to the thickness direction is represented as B, and the cushion bodies 11, 21 are obtained by disposing in a state in which the sheet-like fibrous structures 4a to 4d are stacked and compressed in a mold 40, and forming the sheet-like fibrous structures 4a to 4d integrally by performing high pressure steam molding, and provided on the frames 15, 25 such that a thickness direction extends along a direction in which a load is applied.

Owner:TS TECH CO LTD +1

Enteric medicinal composition for oral use

InactiveUS7678817B2Accurate hardnessAccurate viscosityBiocideDispersion deliveryAdditive ingredientAlginic acid

Owner:MEDRX CO LTD

Apparatus for measuring coefficient of restitution and hardness tester

ActiveUS10161839B2Reduce mass effectCorrection coefficientOptical detectionDevices using time traversedCoefficient of restitutionHardness

An apparatus for measuring for measuring coefficient of restitution which is capable of reducing a mass effect and performing tests in free directions, is disclosed. The apparatus for measuring coefficient of restitution includes a holder for holding a spherical indenter, an ejection mechanism configured to eject the indenter held by the holder from the holder to a specimen, a speed measuring unit configured to measure an impact speed that is a speed of the indenter before the indenter impacts against the specimen, and a rebound speed that is a speed of the indenter after the indenter is rebounded from the specimen; and an arithmetic unit configured to calculate a coefficient of restitution that is a ratio of the rebound speed to the impact speed.

Owner:YAMAMOTO SCI TOOL LAB CO LTD +1

Metal Coating Method

InactiveUS20140326367A1Stay in shapeAccurate hardnessPretreated surfacesMetallic material coating processesMetal coatingWear resistant

This invention discloses a metal coating method whereby an abrasion resistant and wear resistant coating is first applied to the metal object, the coated metal object is then fused onto the metal object and the resulting coated metal object is more abrasion resistant and wear resistant while retaining the metal object's original shape.

Owner:AGRISOLUTIONS WEAR TECH CORP

Material of storage device, storage device and a bag thereof

ActiveUS9808057B2Easy to useProtection from damageSynthetic resin layered productsBagsEngineeringHardness

The present invention discloses a material of storage device, a storage device and a bag of the same. The material of storage device comprise a composite layer composed of polyurethane layer, polyurethane-polyurea copolymer layer, ethylene-vinyl acetate copolymer layer materials. The storage device is formed by the above material, which can be folded in vertical direction and / or horizontal direction; the storage device has a plurality of cavity-shaped storage chamber. A bag formed by the storage device is disclosed. The material and structure of the present invention has the features of waterproof, light weight, proper hardness, capability to fold, high wearing feature, scratch resistant. The storing spatial pattern of the said storage device could be adjusted when needed; it could effectively protect the stored items. The provided bag could be opened partially, allowing quickly and conveniently access to the stored items, the storage space in the bag is designed for a better protection of stored items.

Owner:MICHAEL L JEAN RAYMOND BOURGEOIS

Voice-control intelligent mattress with hardness capable of being adjusted in multiple stages

ActiveUS11253080B2Easy to transportAccurate hardnessStuffed mattressesSpring mattressesStructural engineeringMechanical engineering

A voice-control intelligent mattress with hardness capable of being adjusted in multiple stages comprises an upper-layer soft pad, a hardness-adjusting device and a lower layer or a multi-layered hard pad that are sequentially arranged from top to bottom; the hardness-adjusting device comprises two adjusting units symmetrically arranged with the transverse center line of the present invention, and a voice-control module connected with the adjusting unit through a wire for controlling the starting and stopping of the adjusting unit; two adjusting frames connected with the adjusting unit are symmetrically arranged on the two sides of the adjusting unit; an elastic mesh belt installed on the adjusting frames is tightened or loosened along the expansion or contraction of the adjusting frames; the hardness of the mattress can be precisely adjusted so that the various demands of users can be satisfied.

Owner:CHEN RUIXI

A metal characteristic analysis device

ActiveCN111579002BAccurate hardnessIncrease impact forceMeasurement devicesFrictional coefficientEngineering

The invention discloses a metal characteristic analysis device, comprising a frame, a cavity is arranged in the frame, a rotating shaft is arranged in the cavity for rotation, and a connecting rod is fixedly connected to the lower end of the rotating shaft, and the One end of the connecting rod away from the rotating shaft is fixedly connected with a cylindrical block, and a rotating block is arranged in the cylindrical block. The rotating block is provided with a centrifugal cavity that runs through up and down, and two centrifugal chambers are fixedly connected in the centrifugal cavity. A convex block symmetrical about the rotation center of the rotation block, the present invention analyzes and tests the gravity and hardness of the metal block, and the metal block clamped by the clamping block is multiplied by the friction coefficient of the clamping block by the indication of the pressure gauge The gravity of the metal block is obtained, and the impact force is gradually increased during the hardness test to test the maximum impact force of the metal block, so that the hardness of the tested metal block is more accurate.

Owner:淄博华岳环保设备有限公司

Material strain-hardness relation detection method

ActiveCN113218796ASolving Hardness Measurement ProblemsExact strain-hardness relationshipInvestigating material hardnessHardnessDigital image

The invention relates to a material strain-hardness relation detection method, which comprises the following steps: carrying out paint spraying treatment on an axial side plane with a spherical pit of a semi-tubular sample by utilizing a to-be-detected sample capable of obtaining large strain, vertically placing the semi-tubular sample subjected to paint spraying at the centers of an upper die and a lower die, and performing extruding from top to bottom to generate compression deformation, acquiring strain in-situ measurement data by acquiring a deformation image during deformation; cutting the compressed and deformed semi-tubular sample, embedding the cut semi-tubular sample into phenolic resin for hardness testing, and correcting and fitting hardness data to obtain a strain-hardness relationship. The strain distribution of the sample is measured in real time by combining a digital image technology, the surface hardness distribution of the deformed sample is directly measured, and the strain-hardness relationship of the material is determined on the basis of the measured strain and hardness data.

Owner:SHANGHAI JIAO TONG UNIV +1

Control method of washing machine

InactiveCN1809660BReduce consumptionImprove convenienceOther washing machinesControl devices for washing apparatusHardnessProcess engineering

Disclosed is a control method of a washing machine comprising the steps of (a) setting a washing pattern in the present operation of the washing machine in consideration of hardness of the water calculated in the previous operation of the washing machine, (b) operating the washing machine based on the set washing pattern, and (c) calculating and storing hardness of the water in the present operation of the washing machine to set a next washing pattern in the next operation of the washing machine, thereby having the optimum washing or rinsing capacity of the washing machine in consideration ofdifferent characteristics of water by regional groups.

Owner:LG ELECTRONICS INC

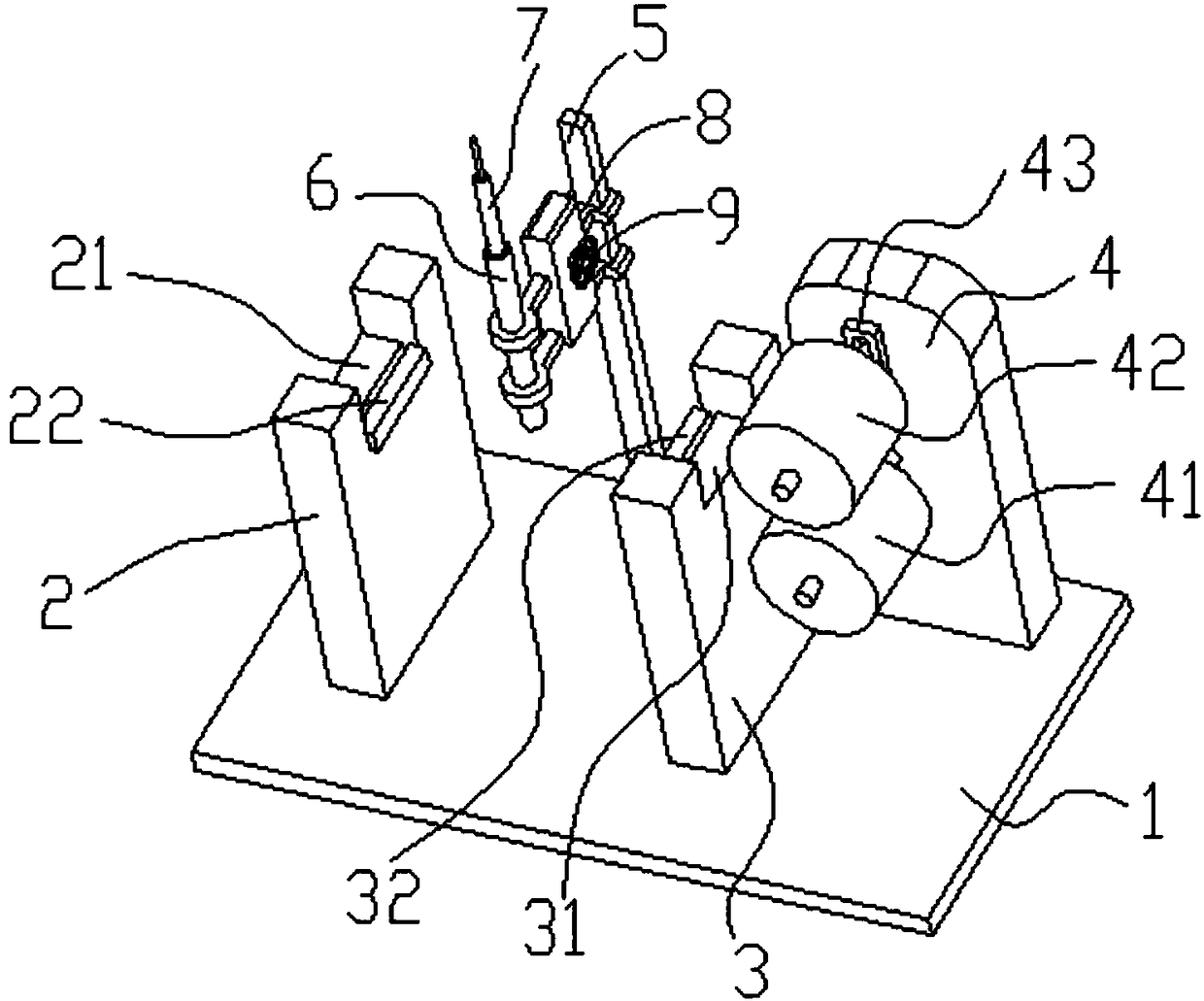

An automatic testing device for the stiffness of synthetic fabrics for rubberized shoe uppers

ActiveCN106198273BQuality improvementAccurate hardnessMaterial strength using steady bending forcesInvestigating material hardnessAdhesive cementEngineering

The invention discloses hardness (stiffness) automatic detecting equipment for rubber shoe upper synthetic cloth. The equipment comprises a base, and is characterized in that an inlet support and an outlet support are arranged on the base in parallel in a spaced mode, an infrared emitter is arranged on the inlet support, and an infrared receiver is correspondingly arranged on the outlet support; a force applying sleeve is arranged in the middle of the position above the connecting line of the inlet support and the outlet support, and a movable force applying rod is mounted in the force applying sleeve; traction equipment is mounted on the outer side of the outlet support. According to the hardness (stiffness) automatic detecting equipment for the rubber shoe upper synthetic cloth, the uniformity of adhesive cement at each point of the cross section of the whole synthetic cloth can be continuously detected, a data-driven and standard detecting result is formed, therefore, the stiffness of the synthetic cloth can be controlled within an optimal range, and high-quality rubber shoes can be conveniently produced.

Owner:JIHUA 3517 RUBBER PROD

Preparation method of low-sugar whole potato flour energy bar

PendingUS20220295803A1High hardnessGreat tasteDough treatmentFood ingredient functionsBiotechnologyStarch gelatinization

The present disclosure belongs to the technical field of food processing. Use of sucrose and maltose as binders in the existing energy bars leads to high hardness and adhering tooth in energy bars. Aiming at the problem, the present disclosure provides a preparation method of a low-sugar whole potato flour energy bar. Using starch gel and sugar alcohol as binders, whole potato flour and dried honey powder are added to prepare the energy bar; the starch is gelatinized, the sugar alcohol is dissolved, and gelatinized starch and a sugar alcohol solution are mixed in a mass ratio of 2:1 to 1:1 to prepare the binder; the binder is mixed with stir-fried whole potato flour and the dried honey powder, stirred evenly, and subjected to mold pressing or cool forming to obtain the energy bar.

Owner:QINGDAO AGRI UNIV

Automatic detector for textural properties of hardness and viscosity of cooked rice grains

InactiveCN101571468BAccurate hardnessReal hardnessFlow propertiesInvestigating material hardnessHardnessEngineering

Owner:YANGZHOU UNIV

Apparatus for measuring water hardness using ion selective electrode

ActiveUS11016074B2Accurate hardnessMinimize liquid junctionWater treatment parameter controlSpecific water treatment objectivesChemical physicsSoftened water

An apparatus for determining total hardness in a fluid stream utilizing an ion exchange column in a monovalent cationic form having an inlet and an outlet, where one or more monovalent ion selective electrodes are positioned either at an inlet, outlet, or at both locations simultaneously. The monovalent cation selective electrodes are in electrical communication with one another, and in fluid communication with one or more valves incorporated within a fluid path in order to introduce feed water / softened water to the monovalent cation selective electrodes. Additionally, one blending valve may be incorporated in the ion exchange column to allow a fraction of the feed (hard) water to mix with a fraction of the softened water. In this manner, the blending valve may be utilized to adjust the hardness of the water at the output.

Owner:ECOWATER SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com