Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Accurate crimping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

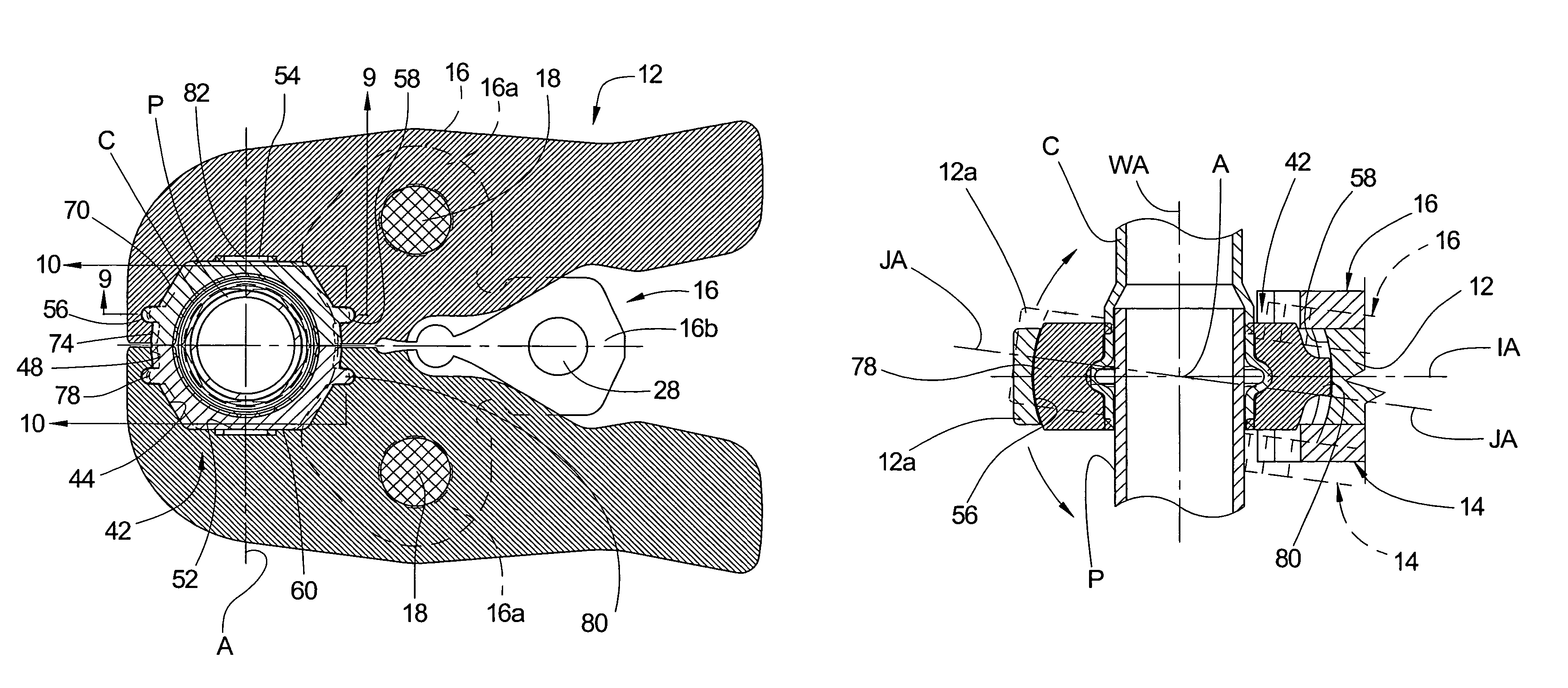

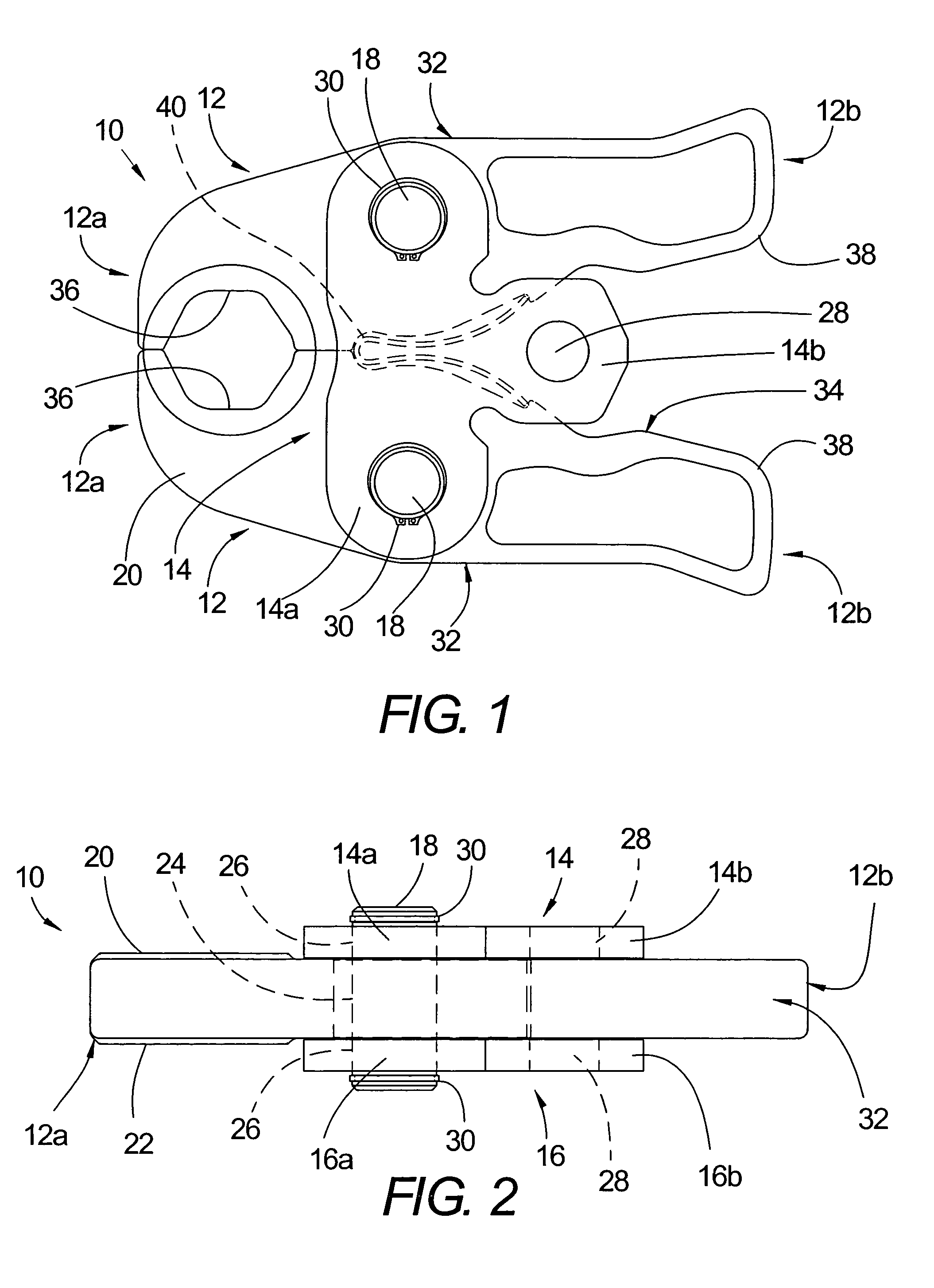

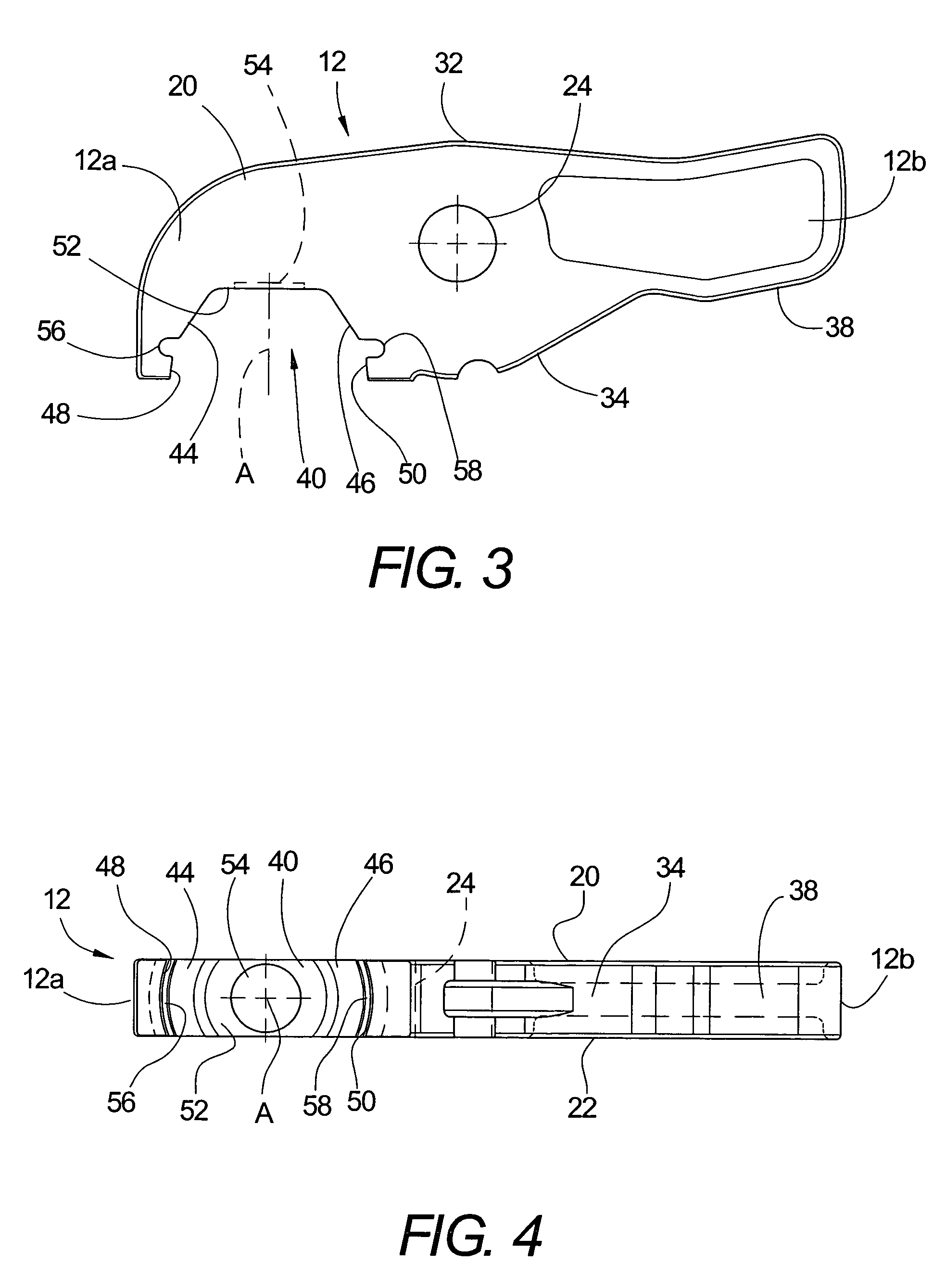

Mounting Stents On Stent Delivery Systems

InactiveUS20120010693A1Labor moreIncrease productionStentsBlood vesselsInsertion stentBalloon catheter

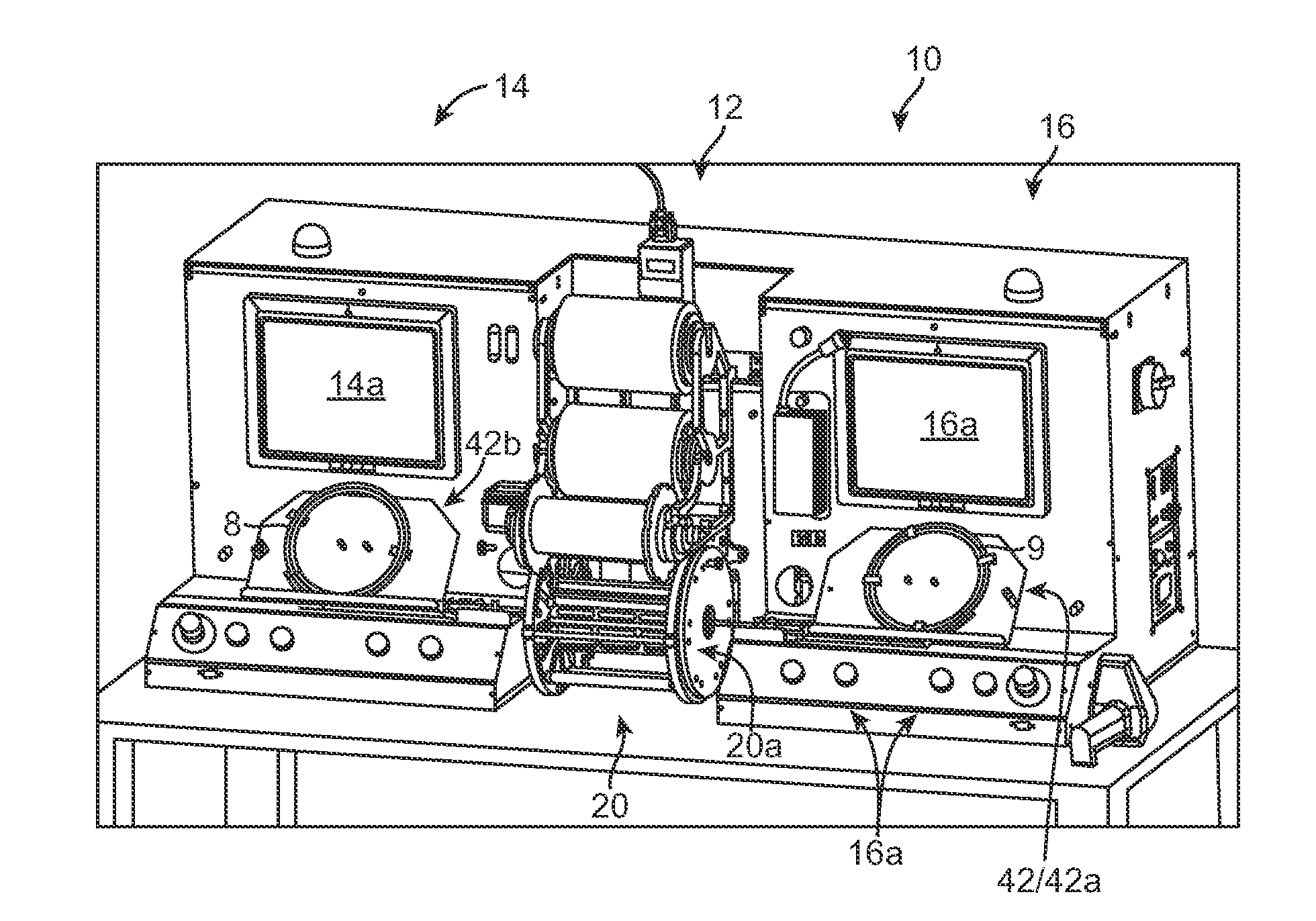

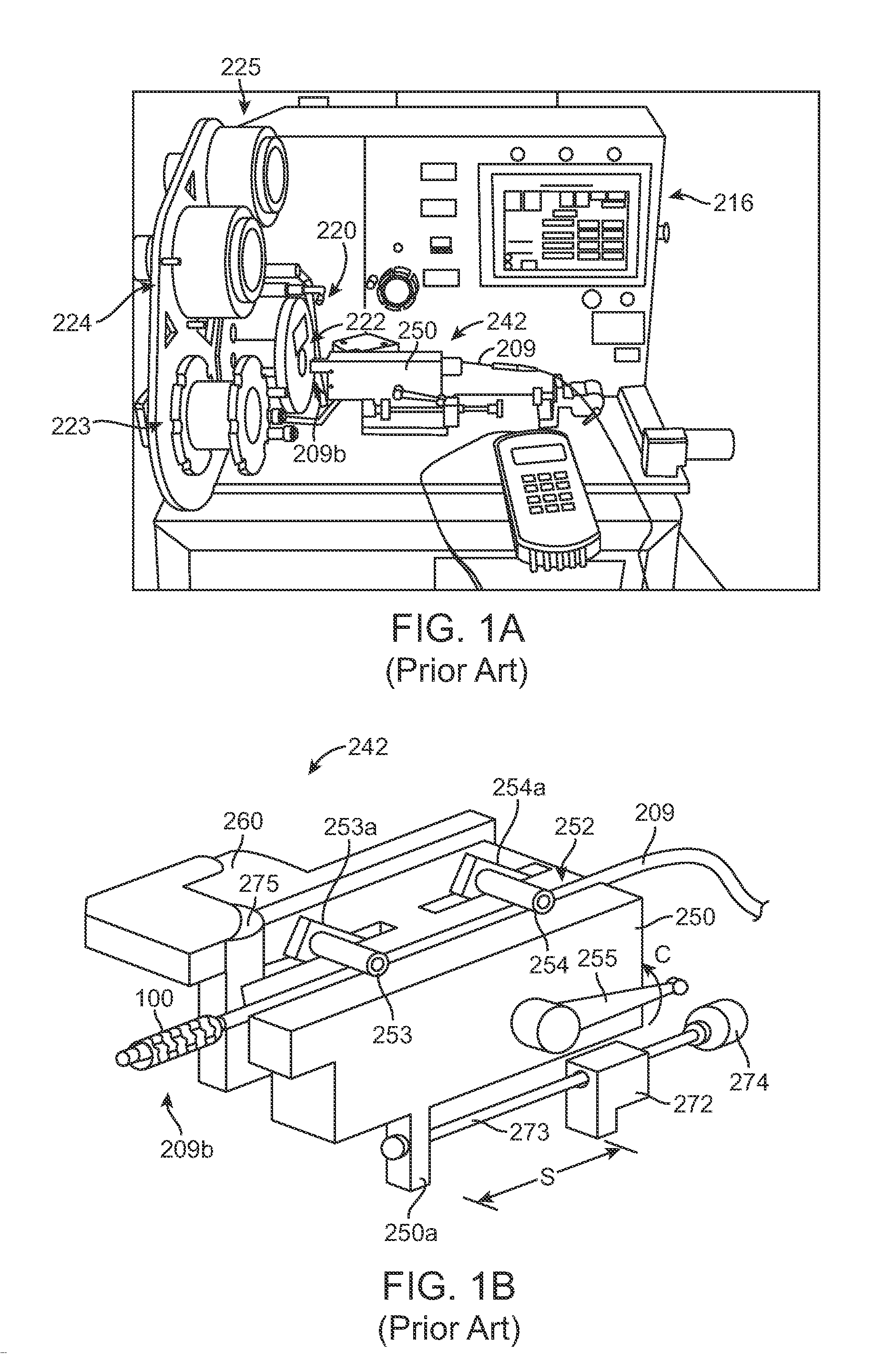

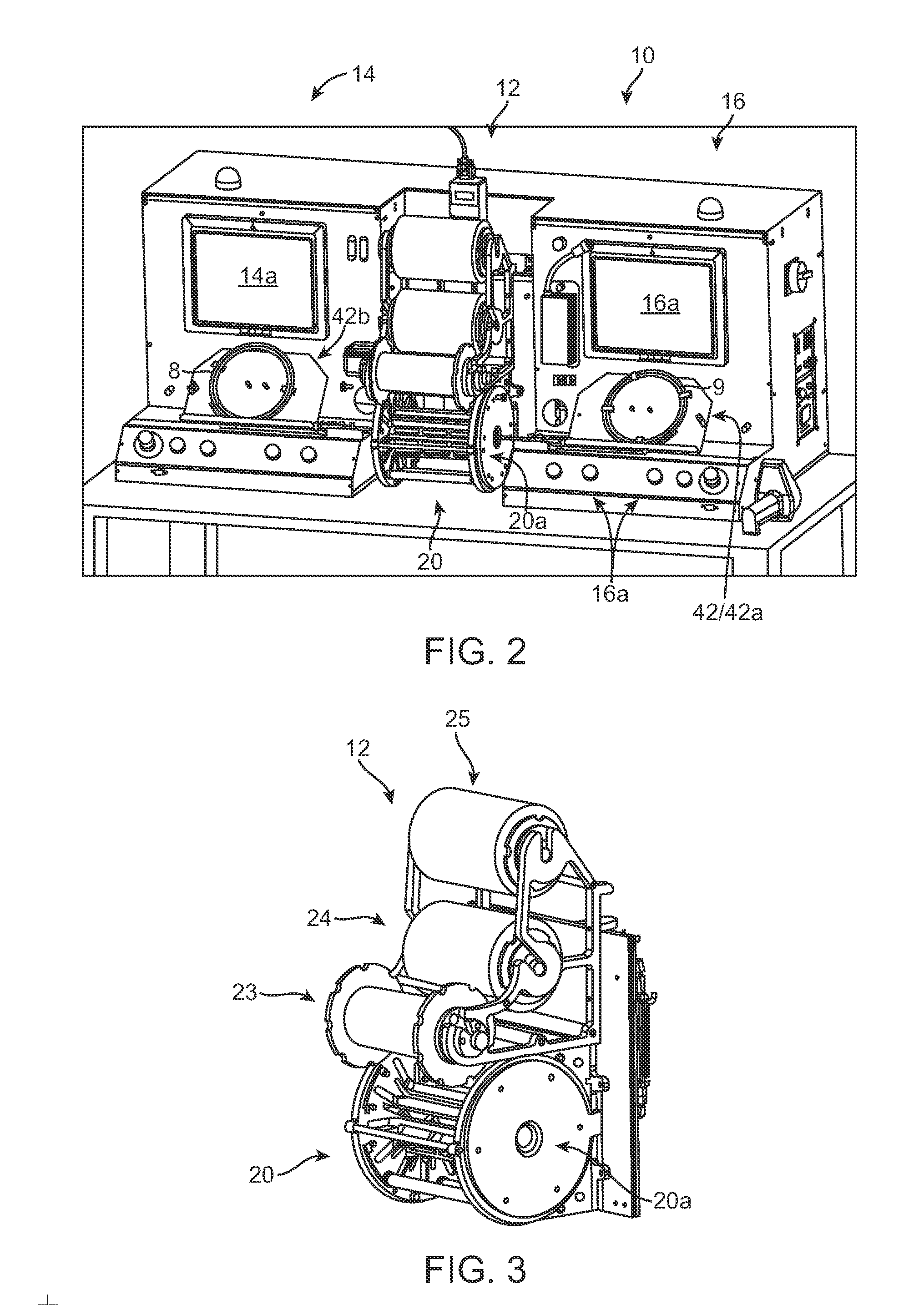

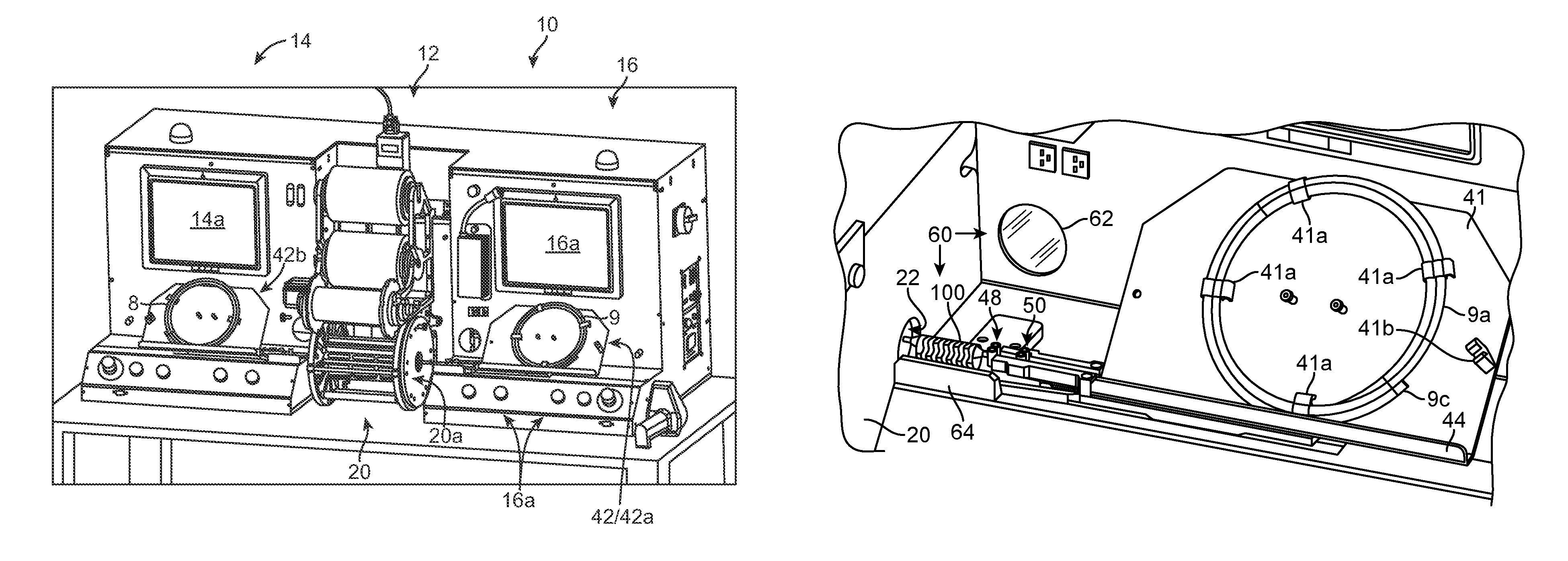

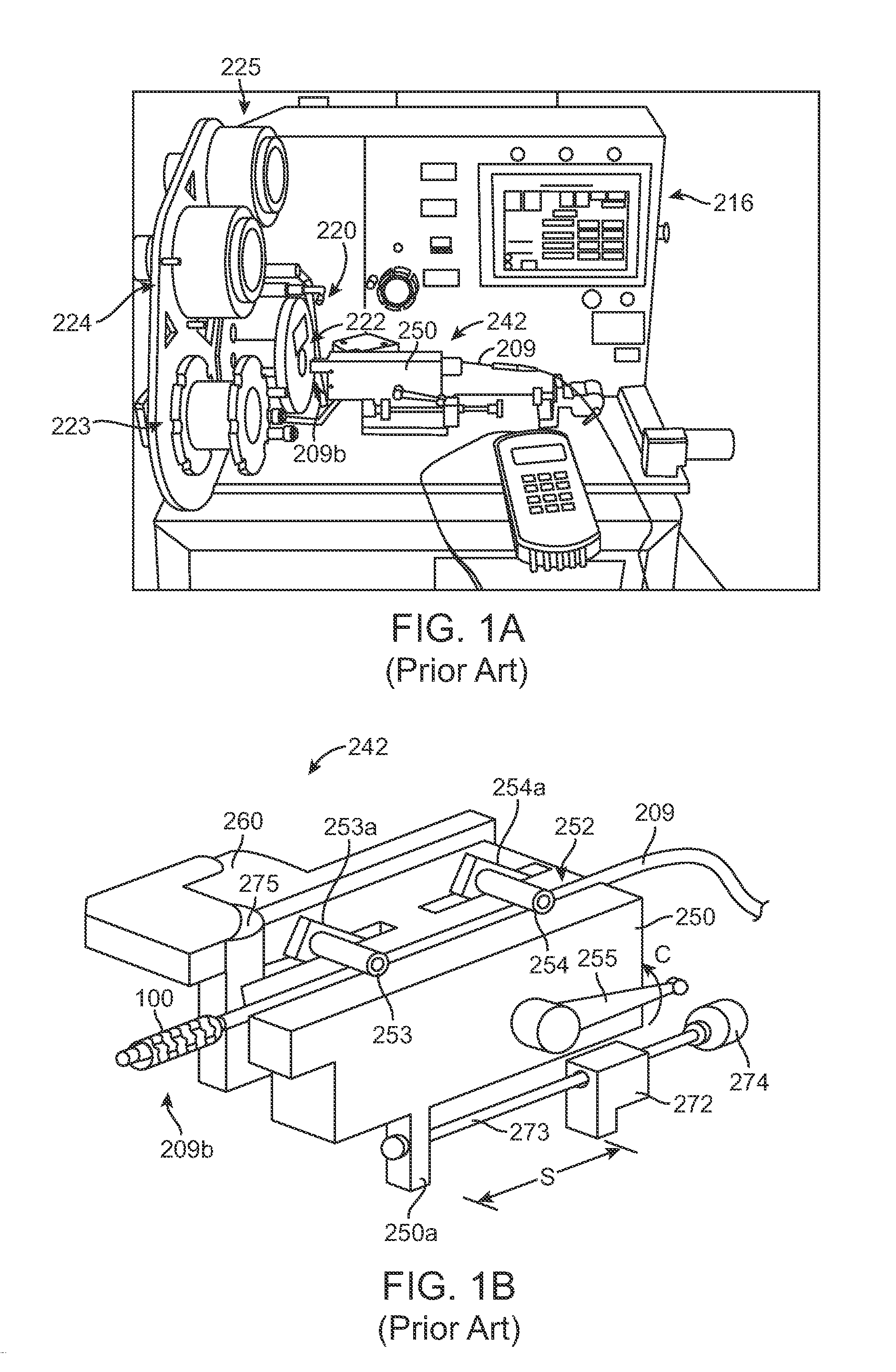

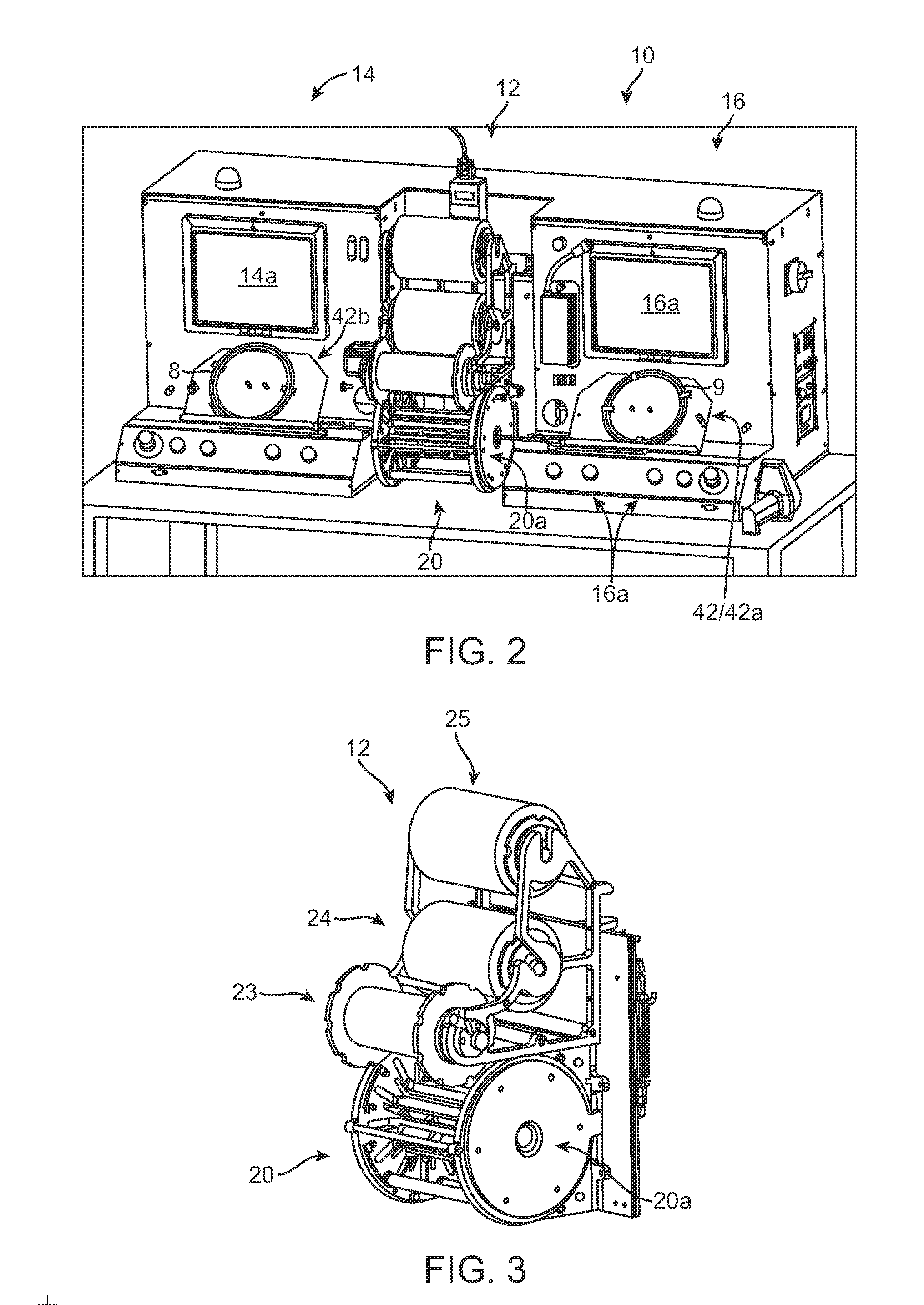

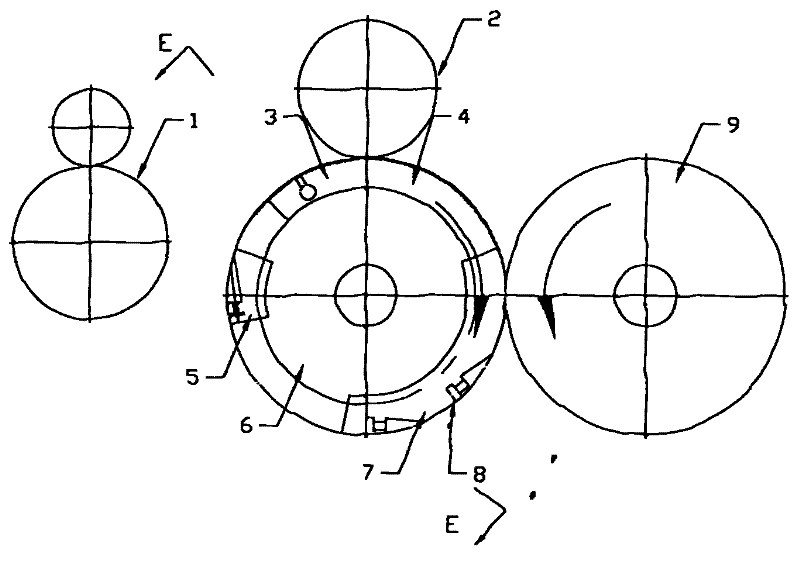

A system for mounting a stent on a balloon catheter includes two positioning and alignment stations, which are used to prepare a stent and catheter for crimping using the same crimping head. The system is configured for automated assembly of the stent and catheter prior to crimping. A catheter and stent are placed on a computer-controlled carriage that delivers the stent and catheter to the crimper head. Before placing the stent and catheter into the crimper head, an automated alignment system locates the stent between balloon markers.

Owner:ABBOTT CARDIOVASCULAR

Mounting stents on stent delivery systems

InactiveUS8752261B2Labor moreIncrease productionStentsForging hammersInsertion stentBalloon catheter

A system for mounting a stent on a balloon catheter includes two positioning and alignment stations, which are used to prepare a stent and catheter for crimping using the same crimping head. The system is configured for automated assembly of the stent and catheter prior to crimping. A catheter and stent are placed on a computer-controlled carriage that delivers the stent and catheter to the crimper head. Before placing the stent and catheter into the crimper head, an automated alignment system locates the stent between balloon markers.

Owner:ABBOTT CARDIOVASCULAR

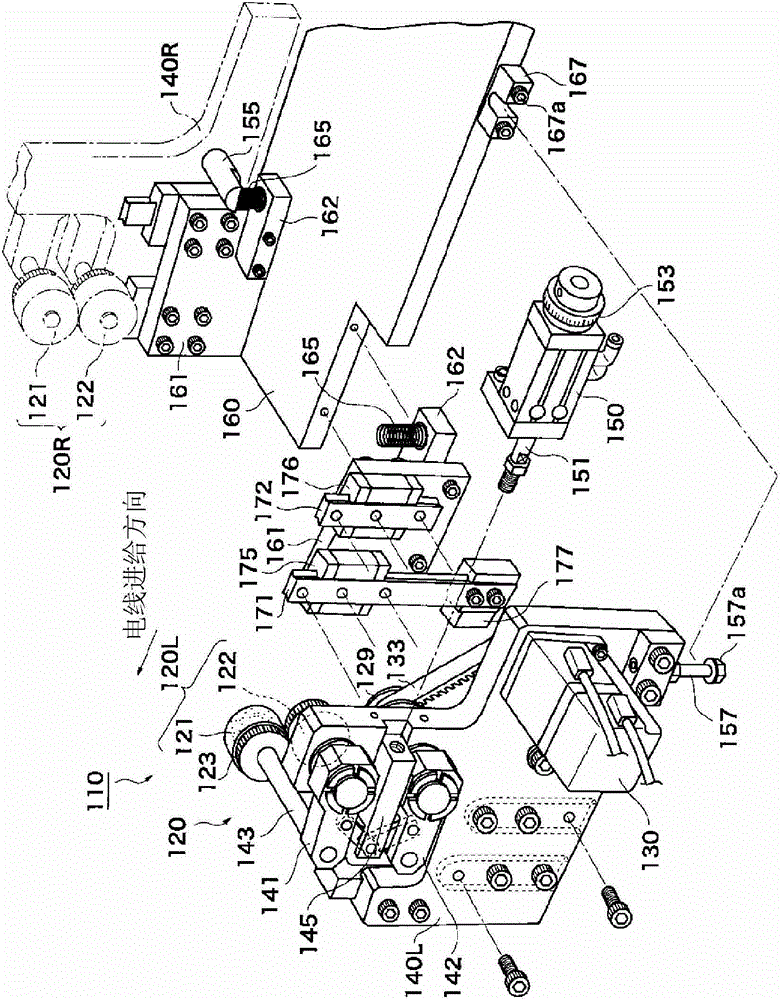

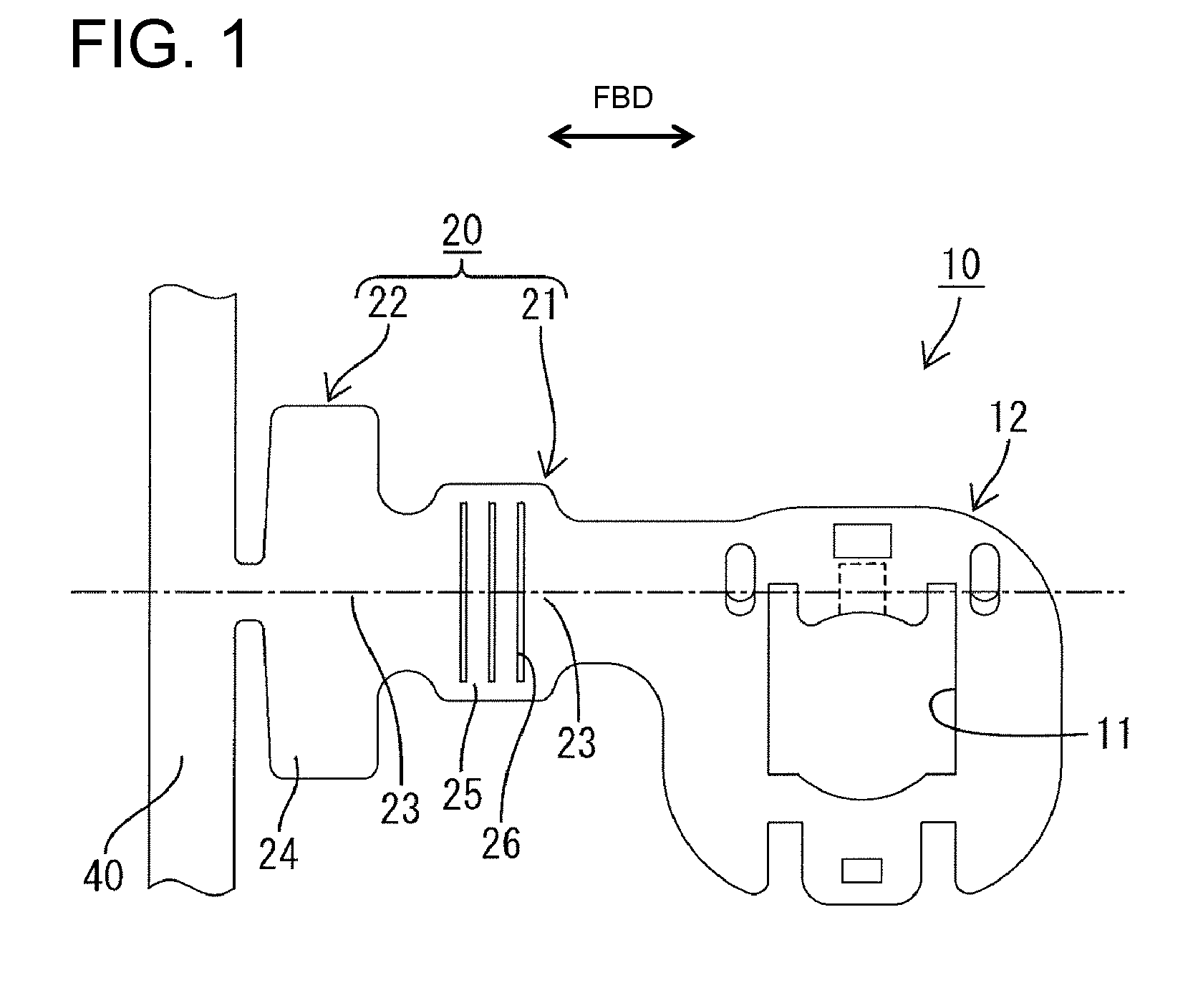

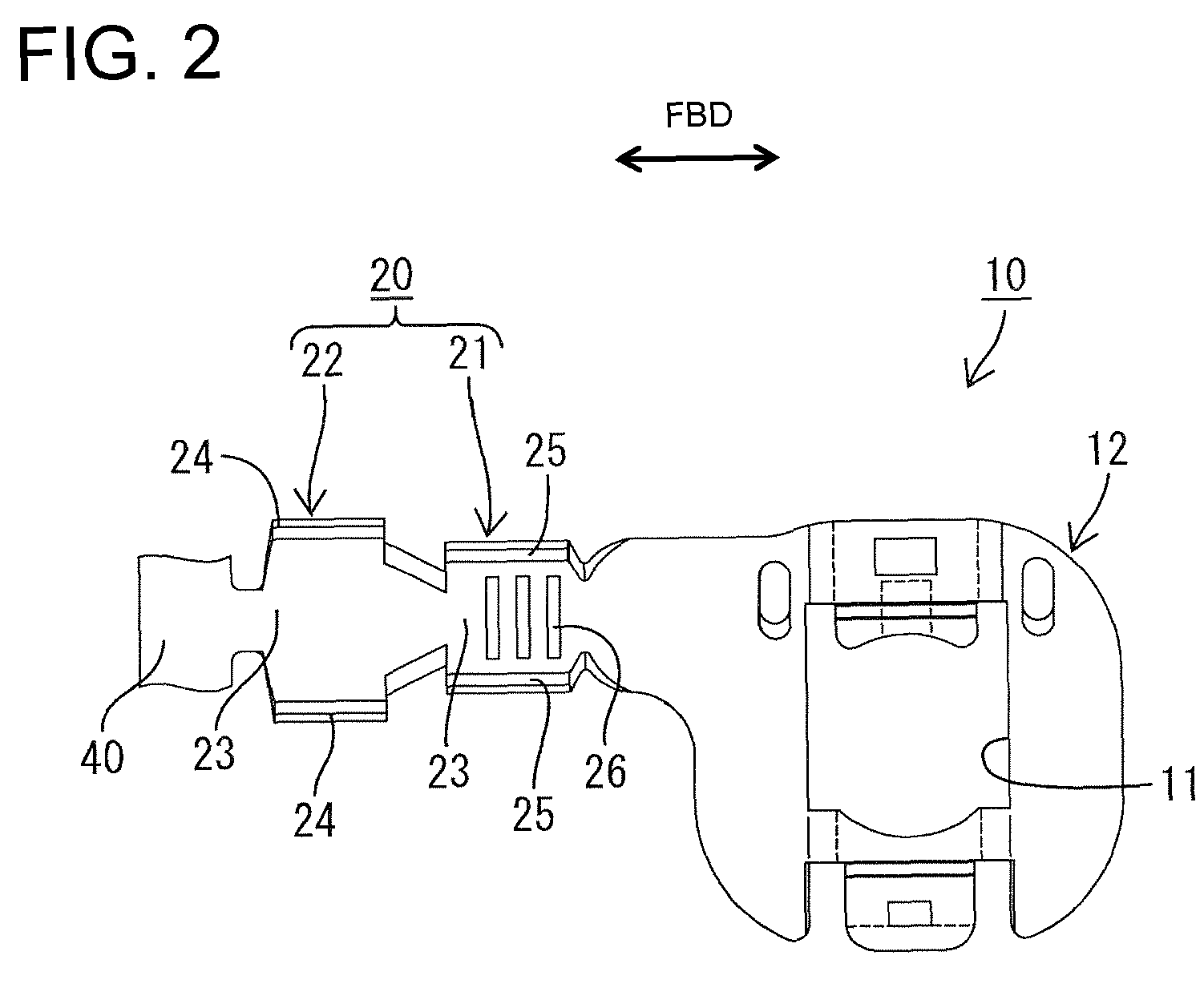

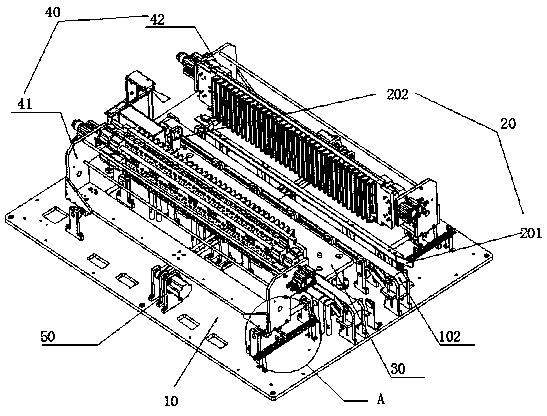

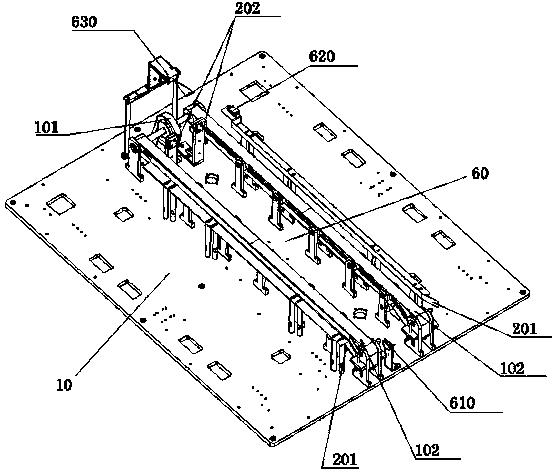

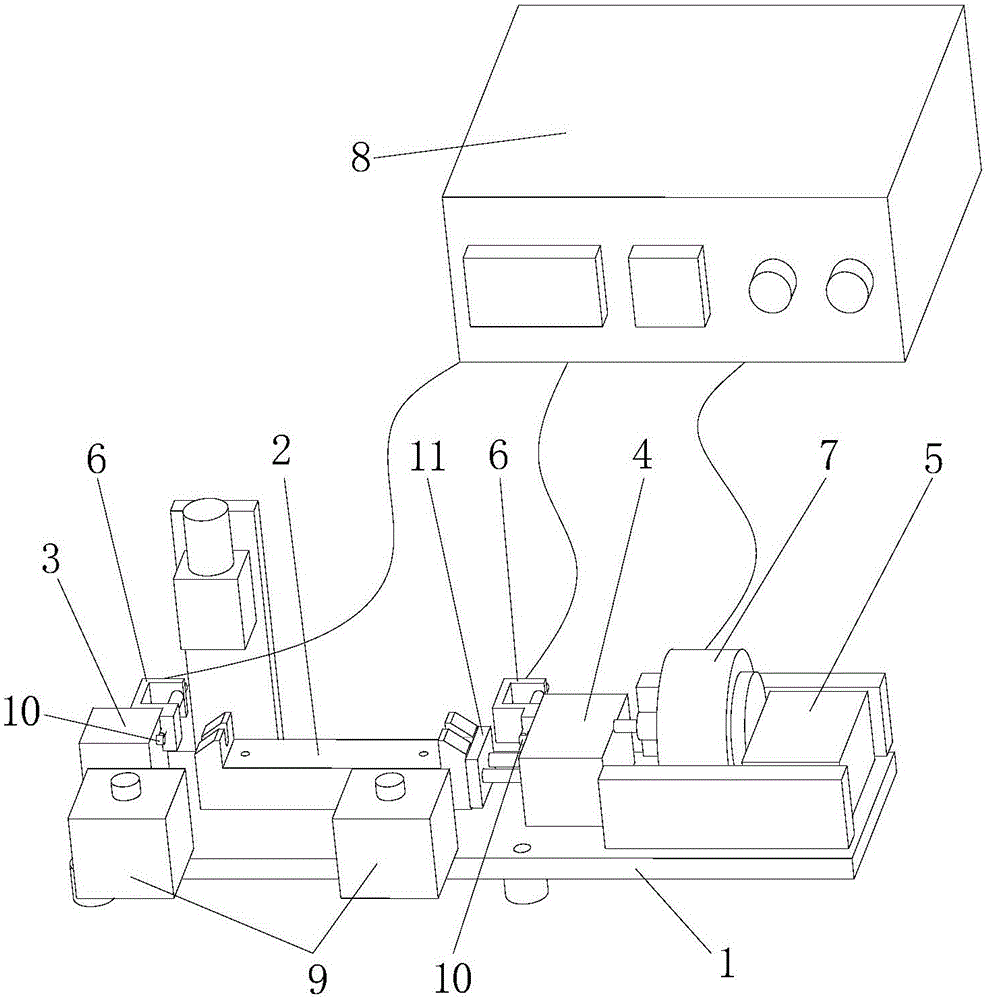

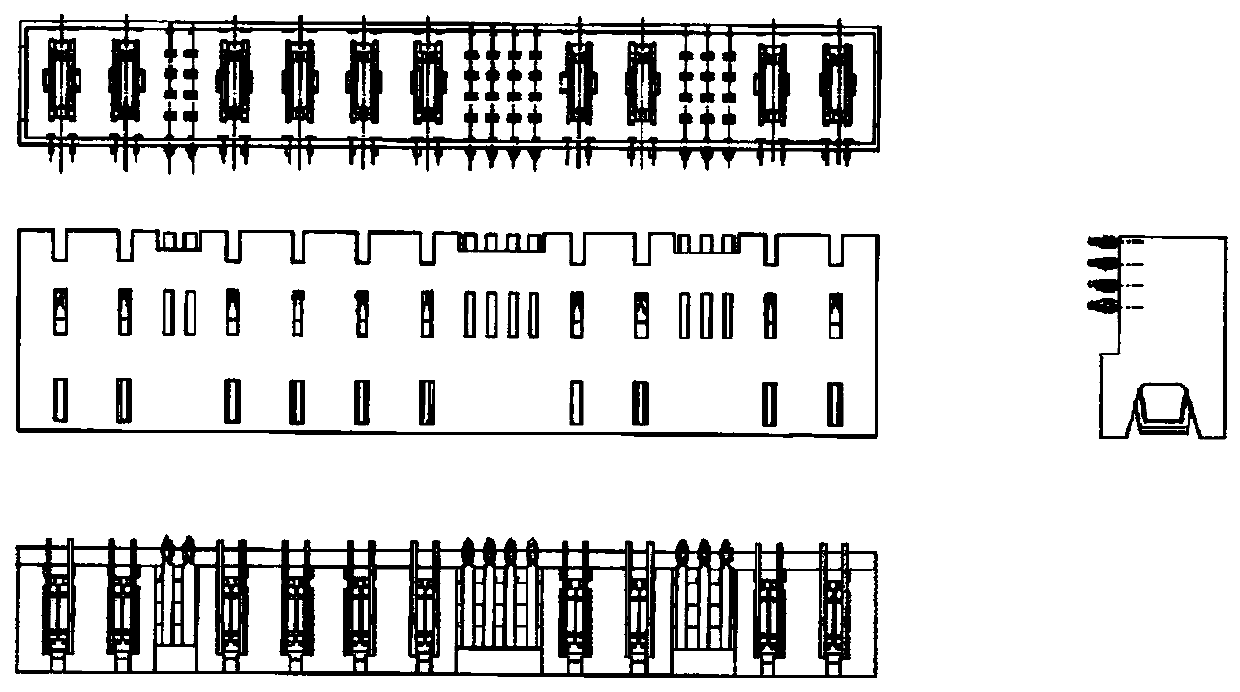

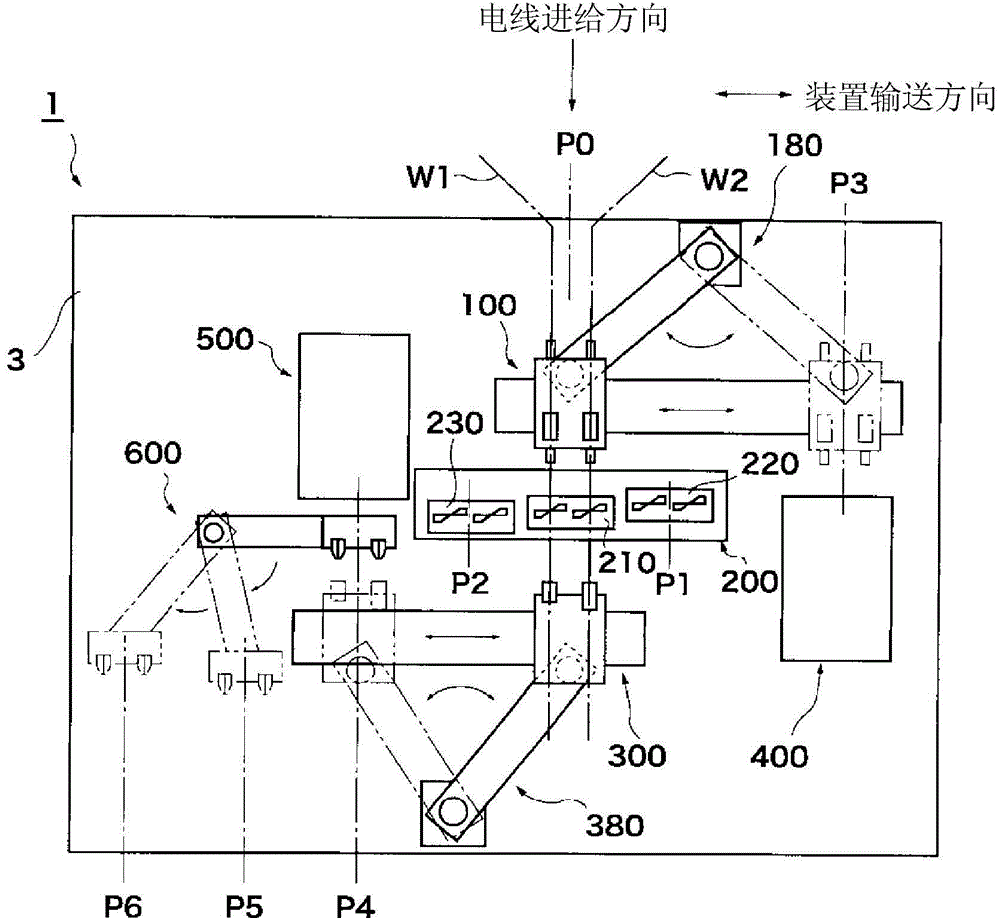

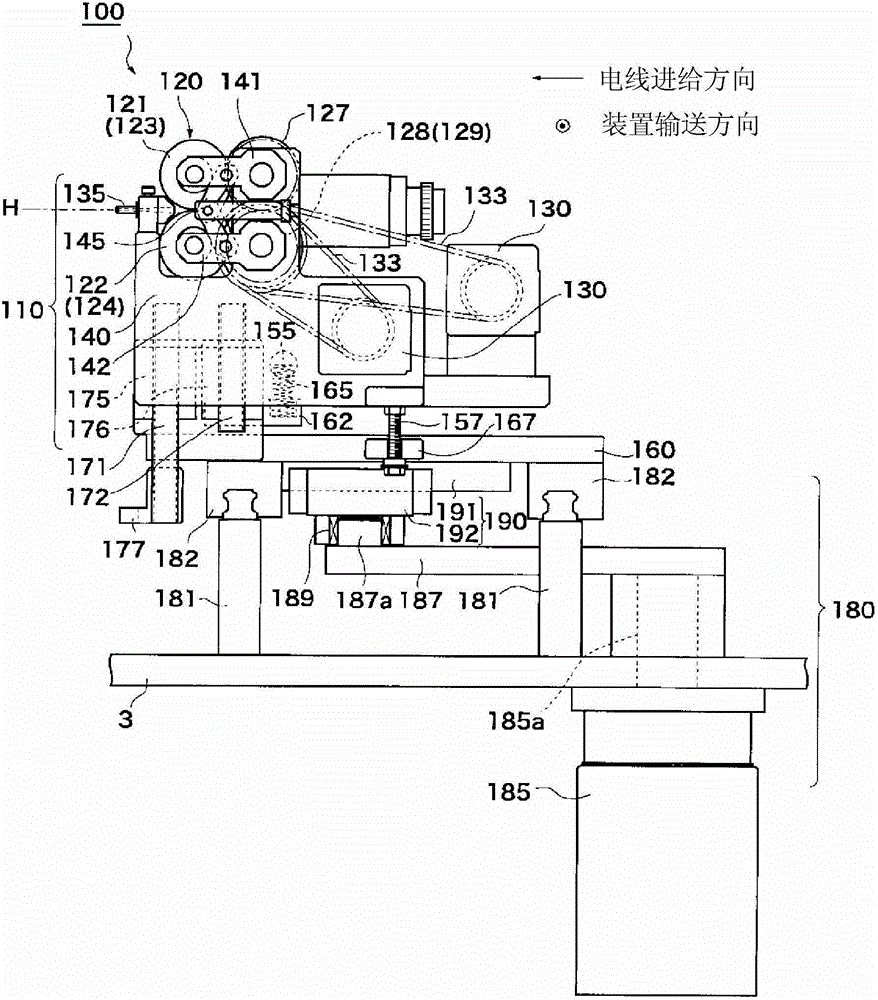

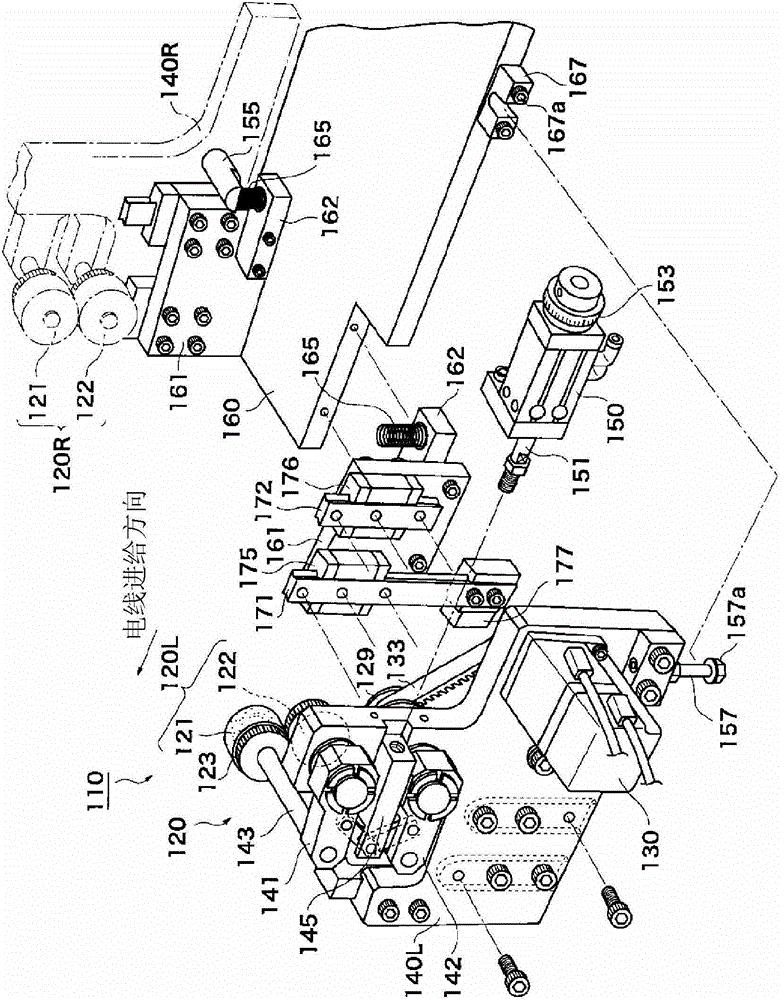

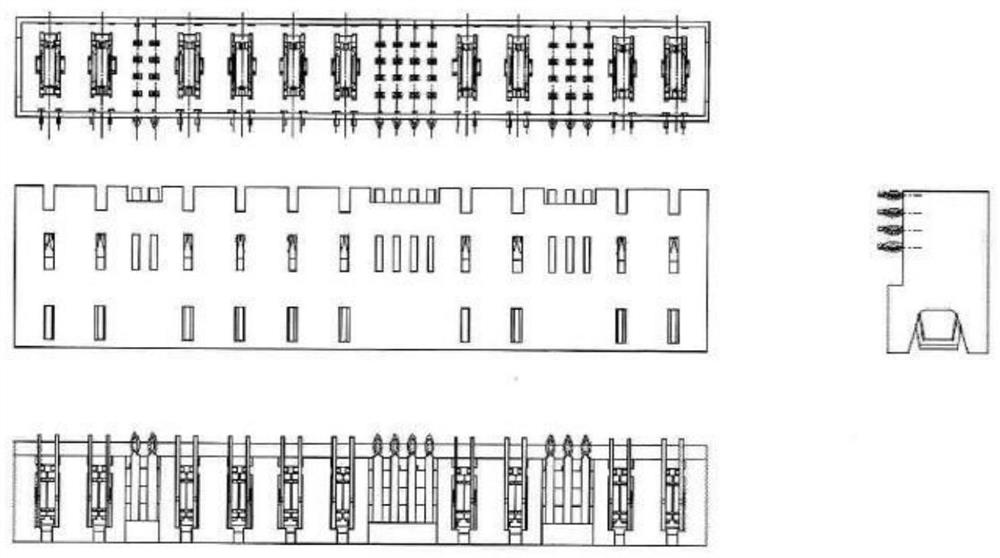

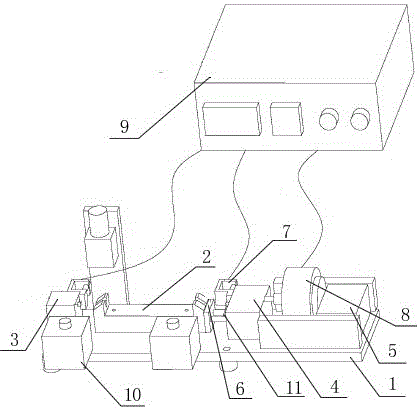

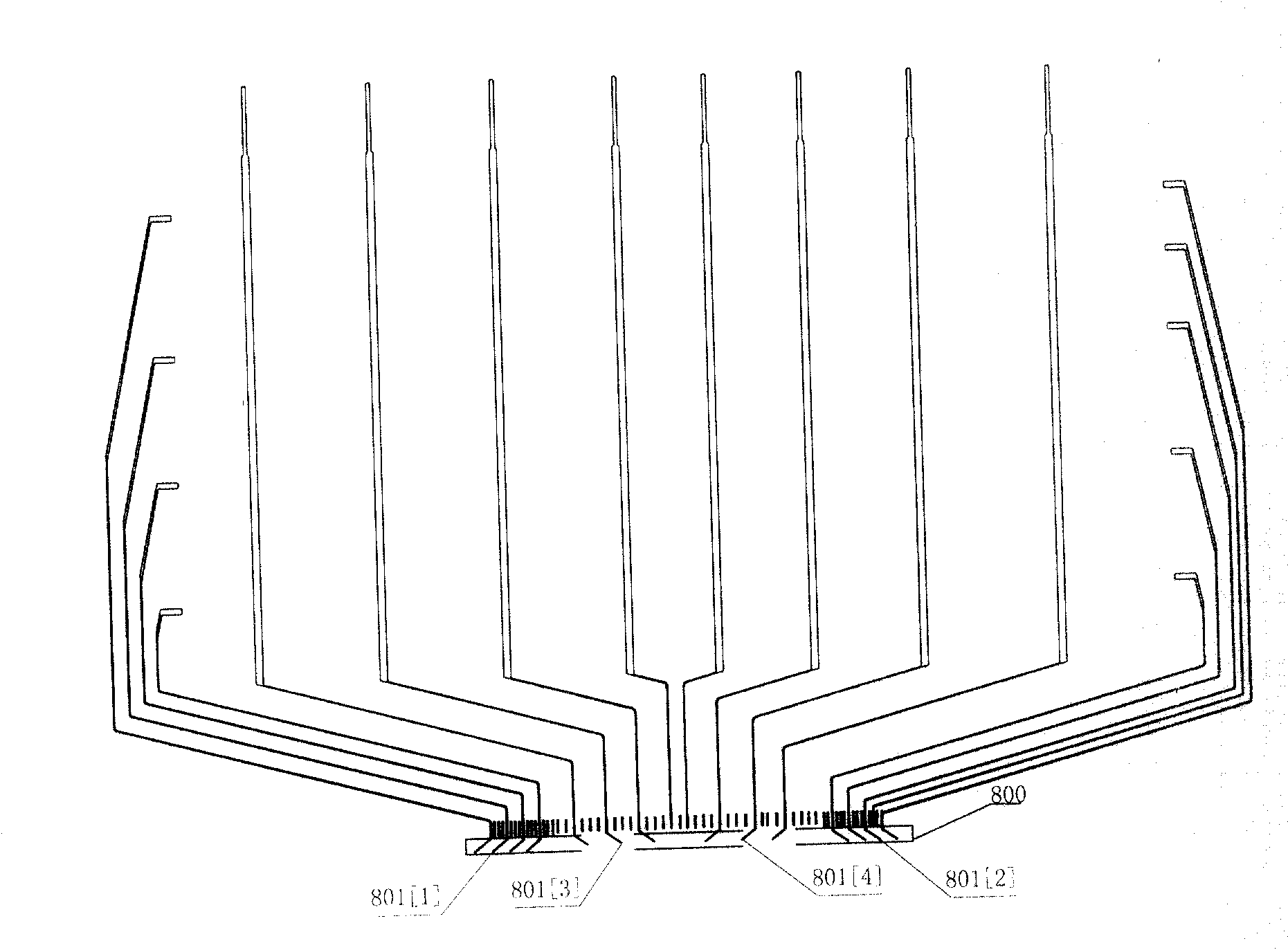

Multiple crimped wire manufacturing device, two terminal-crimped wire manufacturing method, multiple wire feeding device, terminal crimping method, and terminal crimping device

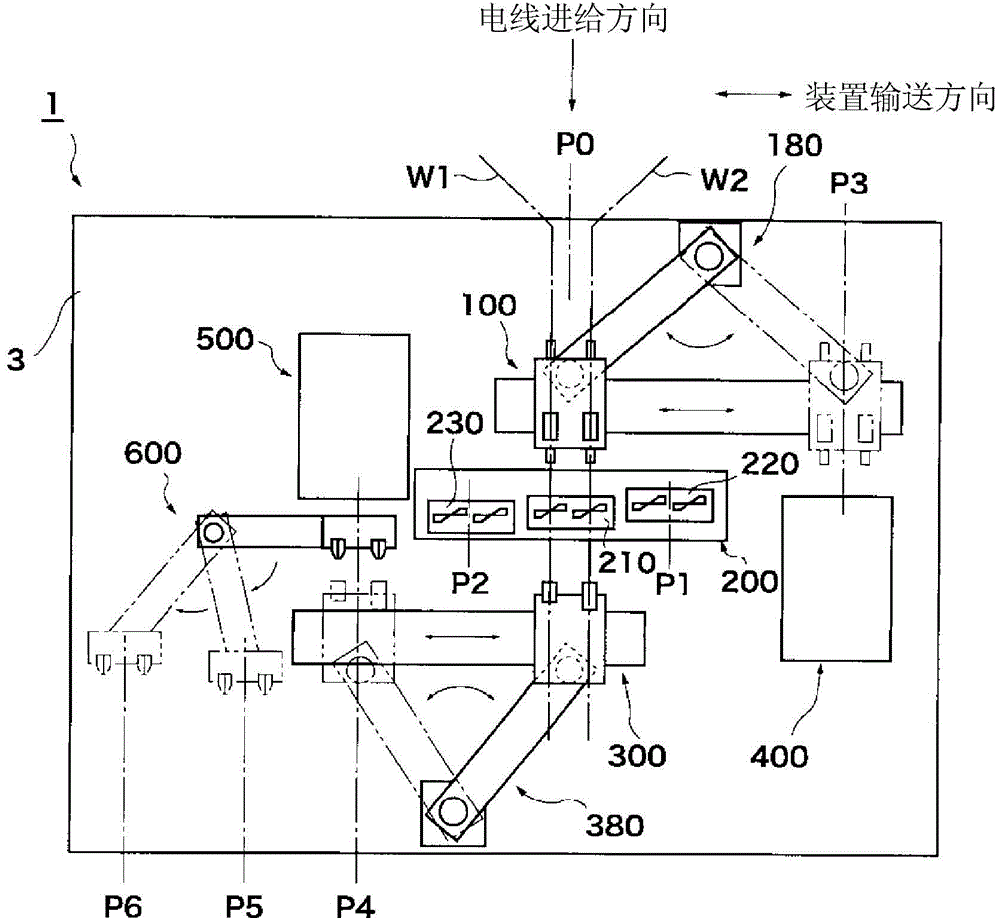

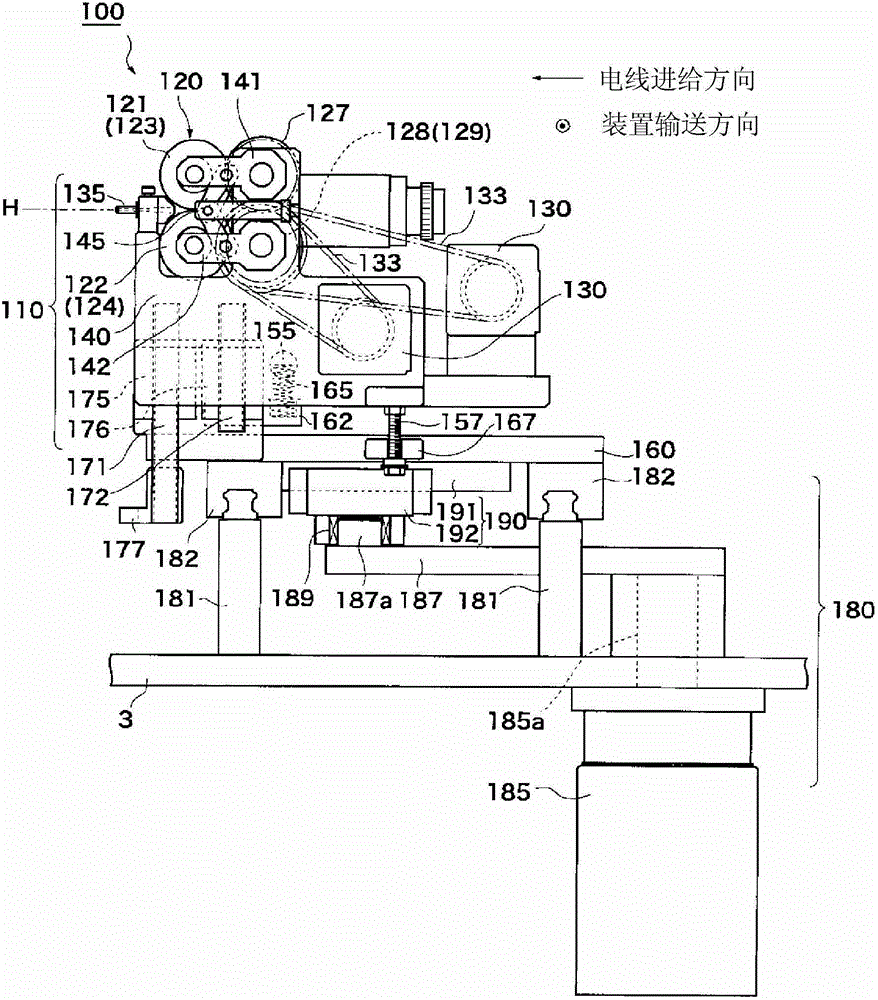

ActiveCN102948022AMiniaturizationSave spaceConnection formation by deformationEngineeringElectric motor

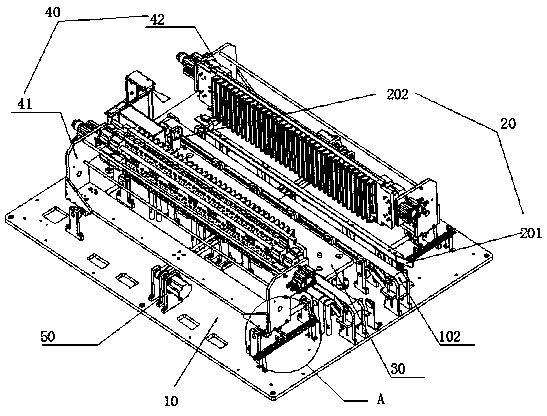

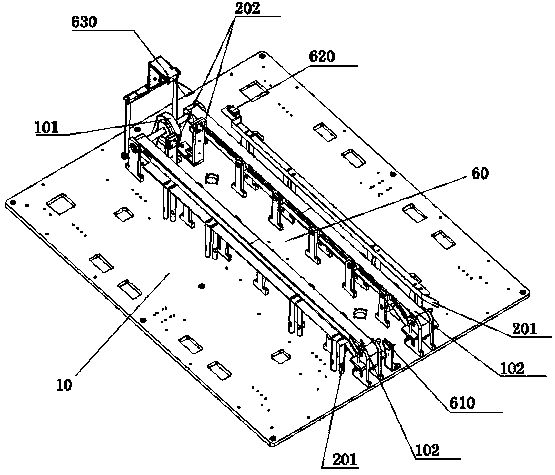

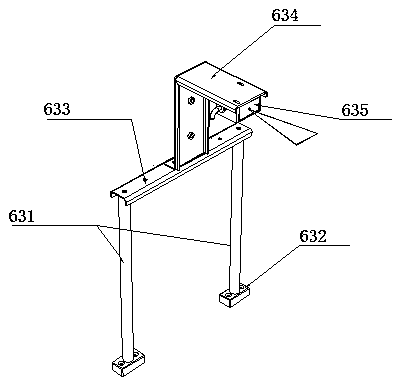

The invention provides a multiple crimped wire manufacturing device, a two terminal-crimped wire manufacturing method, a multiple wire feeding device, a terminal crimping method, and a terminal crimping device. The two terminal-crimped wire manufacturing device has an advantage of being able to accurately set the length of each wire and other advantages while suppressing the increase in size and weight of the whole device and the increase in price of the device as much as possible. The two terminal-crimped wire manufacturing device (1) includes a wire feeding device (100), a cutting and stripping device (200), a tail clamping device (300), crimping devices (400, 500), and a wire discharging device (600). The wire feeding device (100) has two sets of wire feeding rollers driven by different motors. Therefore, each wire can be fed only by a precise length. In addition, it is possible to discharge two wires having different lengths by changing the operation amount of each motor. Accordingly, it is also possible to provide, as a set, two terminal-crimped wires having different lengths and types of diameters and jackets.

Owner:JAPAN AUTOMATIC MACHINE

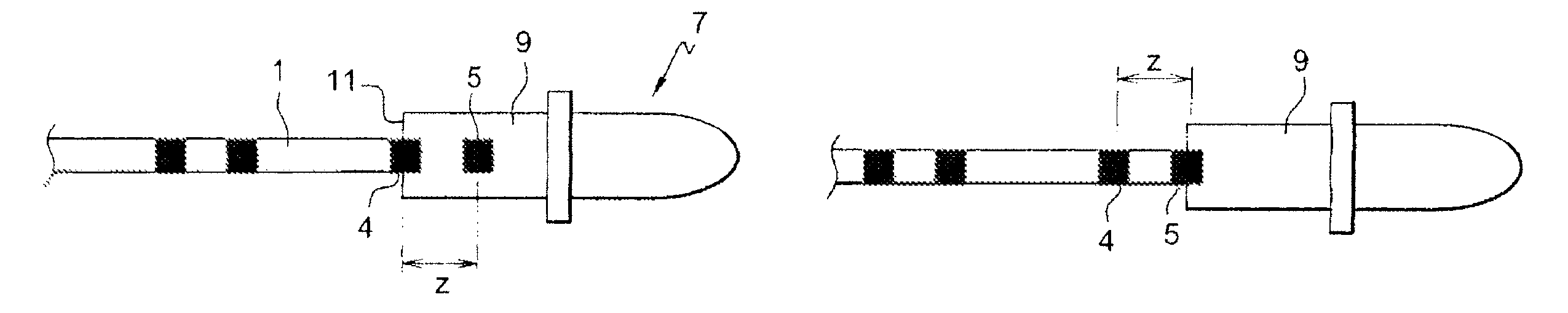

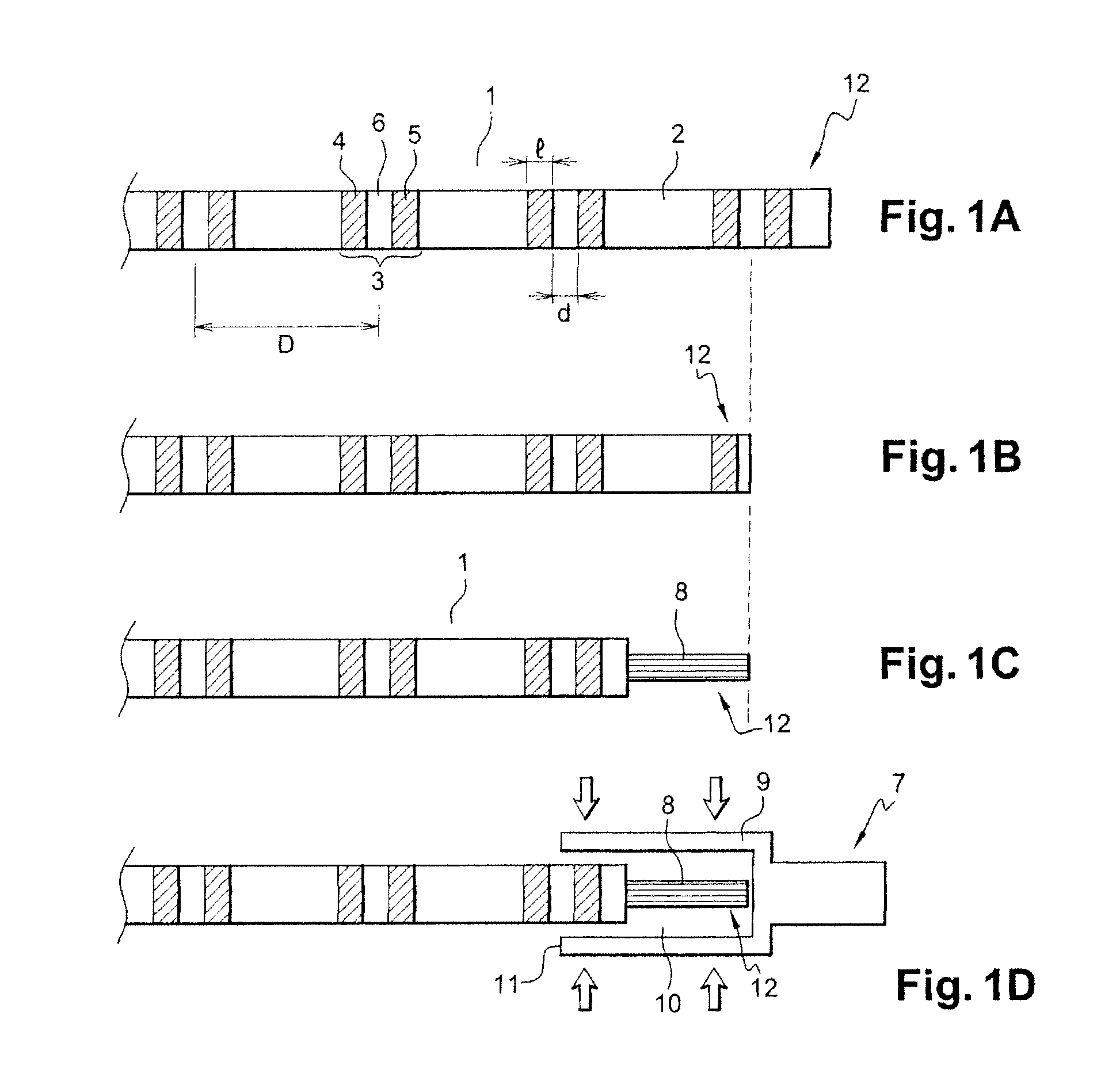

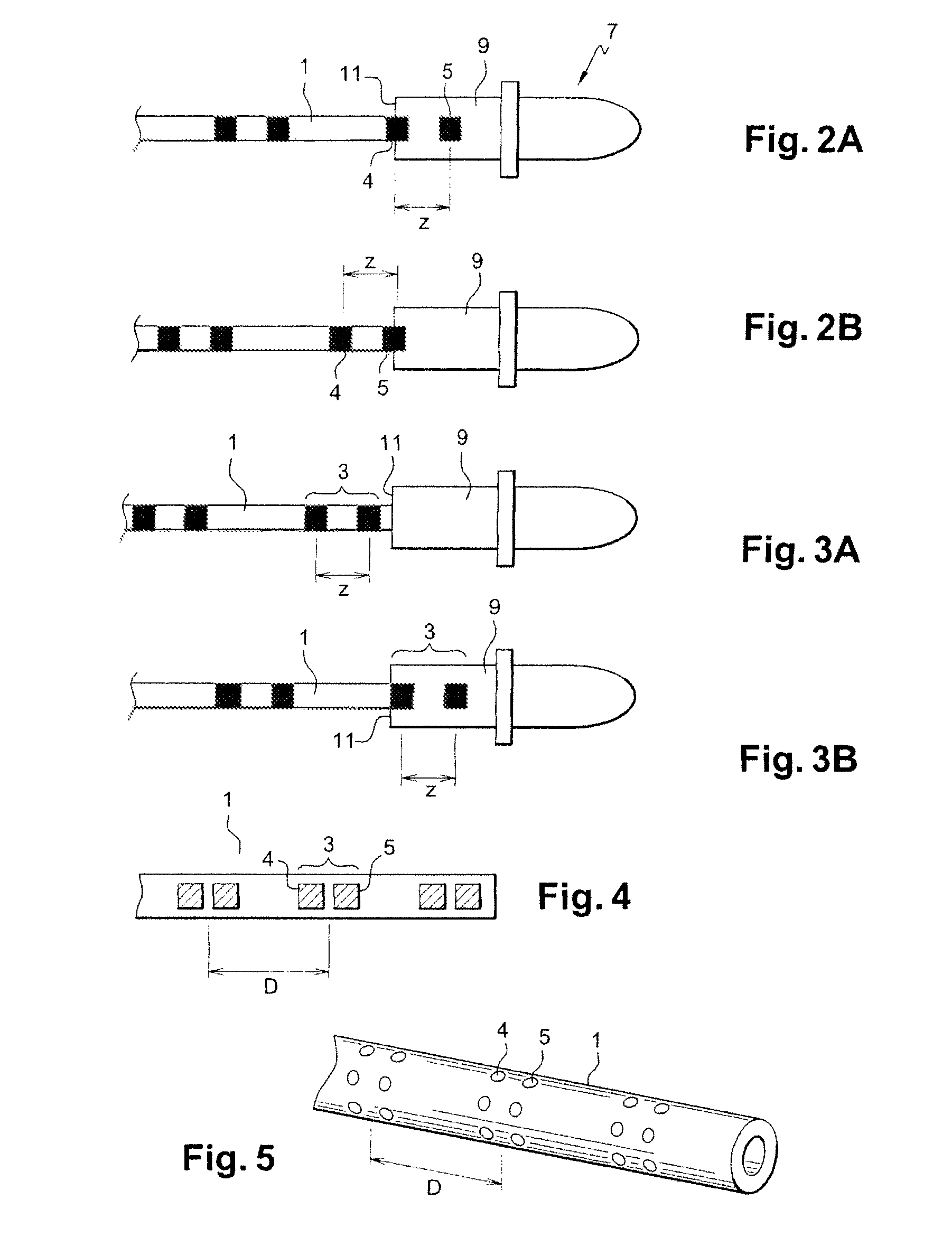

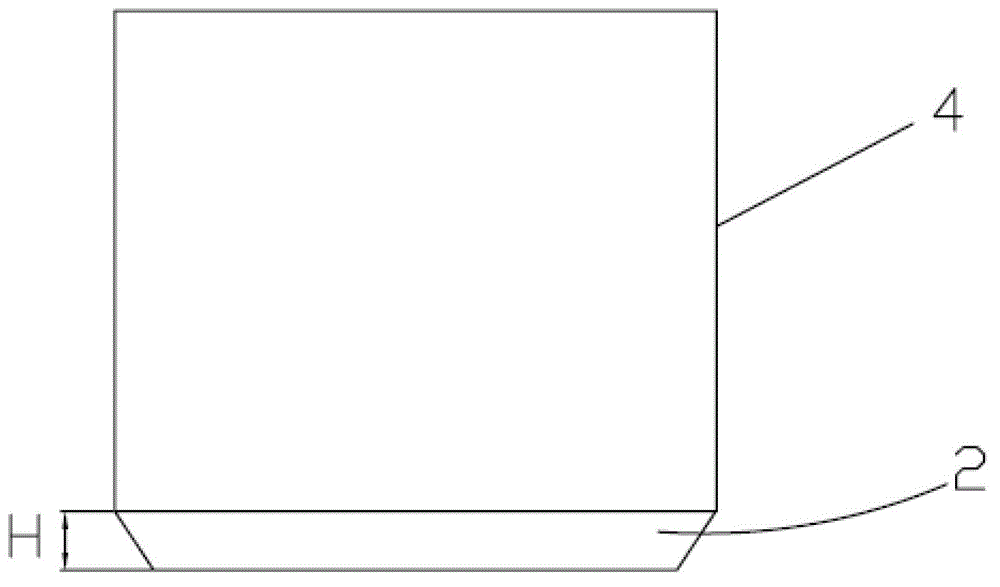

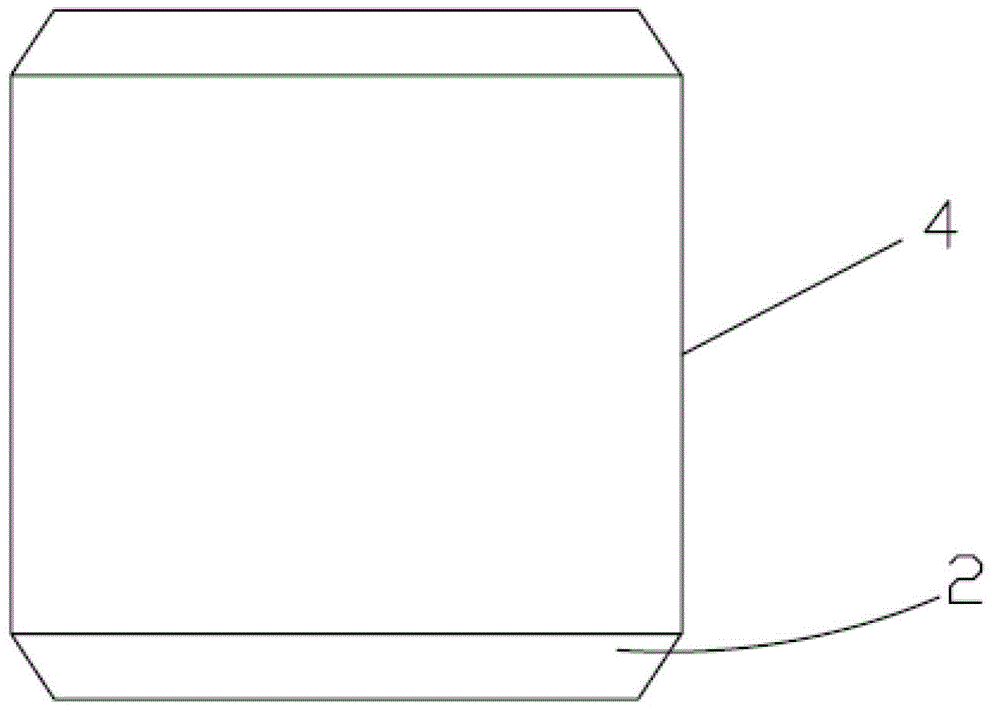

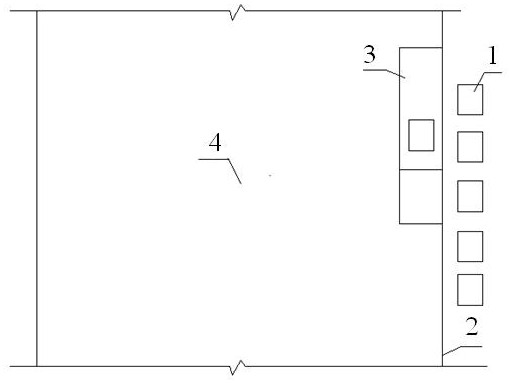

Electrical cable provided with external marking and method of crimping the barrel of a contact onto an electrical cable provided with external marking

ActiveUS8148639B2Precise positioningReliable checkPlastic/resin/waxes insulatorsInsulated cablesElectrical and Electronics engineeringClassical mechanics

An electrical cable (1) provided with a sheath (2) having external marking. The marking is formed from a block (3) of two patterns (4, 5), the two patterns being consecutive along a length of the cable, said block being repeated at least twice along the length of the cable starting from the free end (12) of the cable. The disclosed embodiments also relates to a method of crimping a contact (7) onto such a cable, the external marking of the cable making it possible to know the position of the cable in the barrel and thus guarantee that the crimping that takes place will be of good quality.

Owner:AIRBUS OPERATIONS (SAS)

Jaw arm for compression tools

InactiveUS7188508B2Easy alignmentAdd supportShaping toolsMetal working apparatusEngineeringMechanical engineering

A jaw arm for a compression tool has a jaw recess at one end and a jaw insert is supported in the recess for pivotal displacement relative thereto about an insert axis. A compression tool comprises a pair of parallel spaced apart side plates, and a pair of the jaw arms pivotally mounted between the plates. The pivotal inserts are self-aligning with respect to a pipe and coupling to be crimped together and provide for use of the compression tool in areas with limited accessibility.

Owner:EMERSON ELECTRIC CO

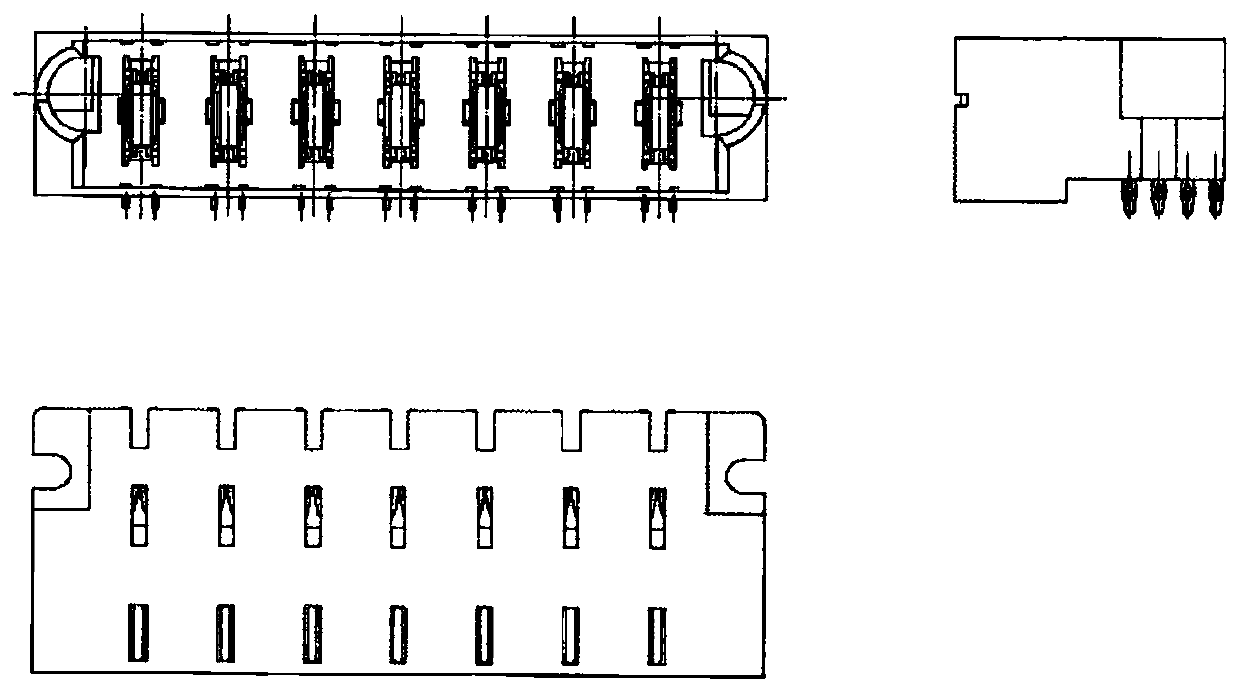

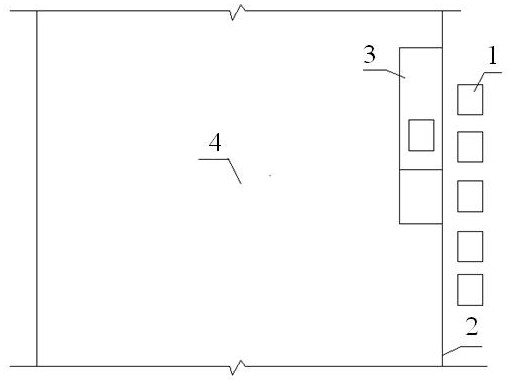

Rapid three-phase electronic type electric energy meter calibration crimp connection device and calibration method thereof

ActiveCN104569530AImprove test efficiencyImprove accuracyElectrical measurementsElectric machineryElectrical control

The invention belongs to the technical field of three-phase electronic type electric energy meter automation, and particularly relates to a rapid three-phase electronic type electric energy meter calibration crimp connection device and a calibration method thereof. Wheels are arranged at the bottom of the crimp connection device, a workbench is arranged on an electric control box supported through the wheels, a meter rack is vertically arranged on the workbench, multiple layers of meter hanging plates are arranged on the meter rack in an inclined mode, multiple unit meter plates are arranged on the surface of each meter hanging plate, left blocks and right blocks are arranged on the edges of the left side and the right side of each unit meter plate, and a control motor is arranged on the back face of each unit meter plate; a hollow plane groove is formed in the surface of each unit meter plate, a sliding floor is arranged in the hollow plane groove, and a three-phase electronic type electric energy meter is arranged on the surface of the sliding floor; left sliding grooves are formed between the sliding floor and the left blocks, right sliding grooves are formed between the sliding floor and the right blocks, a device meter bracket is arranged between the bottom edge of the unit meter plate and the bottom edge of the hollow plane groove, and crimp terminals are arranged on the device meter bracket.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU +1

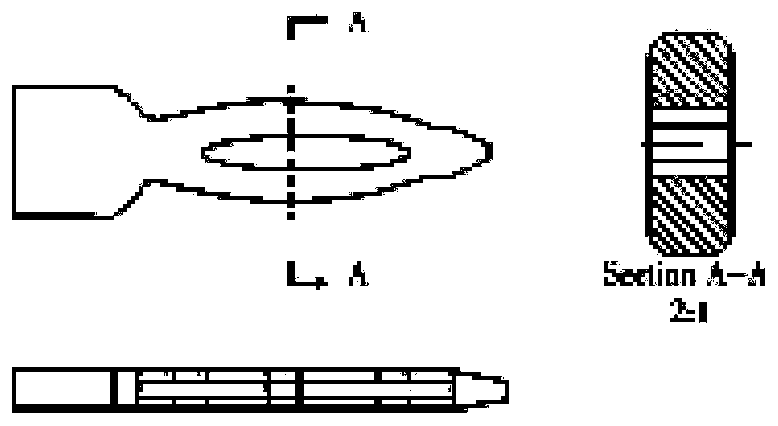

Crimping terminal fitting, method of forming it and wire with terminal fitting

InactiveUS8123575B2High strengthMaintain strengthContact member manufacturingConnections effected by permanent deformationEngineeringMechanical engineering

A crimping terminal fitting has a wire barrel (21) to be crimped and connected to core strands (31) of a wire (30). The wire barrel (21) has a base plate (23) continuously extending from a ground terminal (11) in a longitudinal direction. Two core crimping pieces (25) extend from the opposite sides of the base plate (23). A thinned portion (27) is formed at least at a leading end of each core crimping piece (25) and is thinner than the base plate (23).

Owner:SUMITOMO WIRING SYST LTD

Automatic testing mechanism for soft package lithium battery and equipment

The invention discloses an automatic testing mechanism for a soft package lithium battery and equipment. The testing mechanism comprises the components of an installing platform; a first fixing assembly and a second fixing assembly which are arranged on the installing platform; probe pressing modules which are arranged on the installing platform; and a driving mechanism which is arranged on the installing platform. Two sets of probe pressing modules are arranged. Furthermore each set of probe pressing module is provided with an anode tab holder and a cathode tab holder. The probe pressing module is connected with a preset movement track through a linear bearing. Furthermore the clamping cylinder in the two sets of probe pressing modules is controlled by one air inlet pipe, thereby controlling the two sets of probe pressing modules to test the soft package lithium battery simultaneously. The testing mechanism is compatible with a single-side outlet tab battery and a double-side outlet tab battery, thereby improving practicability of the testing mechanism. Furthermore simultaneous clamping of an anode probe holder and a cathode probe holder can be realized, thereby realizing higher clamping accuracy. Furthermore the probe pressing modules according to the invention can realize smooth motion and improves testing precision.

Owner:广东恒翼能科技股份有限公司

Error-proof tooling for bearing pressure welding

InactiveCN105127725AAccurate crimpingGuarantee product qualityMetal working apparatusEngineeringContact sensor

The invention relates to error-proof tooling for bearing pressure welding. The error-proof tooling is characterized by being mounted on a tooling base plate and comprising a product positioning base used for fixing a long shaft, a first bearing locating block and a second bearing locating block which are respectively positioned on the outer sides of the two end parts of the long shaft, wherein the first bearing locating block is fixedly connected onto the tooling base plate; the second bearing locating block is connected onto the tooling base plate in a sliding manner; an air cylinder used for pushing the second bearing locating block to slide is arranged on the tooling base plate; a contact sensor is arranged on each of the bearing locating surfaces of the first bearing locating block and the second bearing locating block; the air cylinder is connected with a pressure sensor; the contact sensors and the pressure sensor are in line connection with a control box; the control box is in line connection with a start switch. The invention has the following benefits: the tooling can achieve precise pressure welding of the product, and has a fool-proof function, the product quality is guaranteed, and waste caused by rework is reduced; the pressure sensor is assembled, so that the pressure of pressure welding can be induced, the error correction function is good, and the defective rate is decreased.

Owner:赛兹(常州)塑料传动器件有限公司

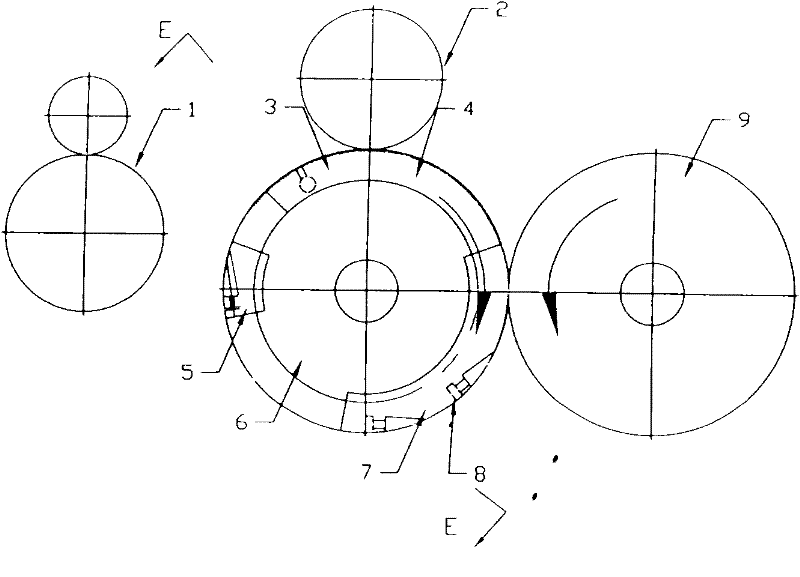

Suction roll cross-folding creasing device of envelope (flat pouch) processor

InactiveCN102529169AImprove qualityEasy to adjustEnvelopes/bags making machineryEngineeringPaper sheet

The invention relates to an envelope (flat pouch) processor, in particular relates to a suction roll cross-folding creasing device of a processor and belongs to the technical field of envelope (flat pouch) package. The device comprises a front roll, a rubber roll, an air suction arc board, an arc board fixing disc, a front creasing tool apron, a tool apron fixing roller, a rear creasing tool apron, a creasing tool, a rear roller and an air distribution sleeve. A paper sheet is delivered to the air suction arc board from the front roll, is sucked on the arc board so as to be rotated by virtue of air suction holes, and then is delivered to a lower functional zone through the rear roller, and the creasing tool fixed on the front creasing tool apron and the rear creasing tool apron and the rubber roll press the paper sheet into two folding lines so as to facilitate the folding of an envelope (flat pouch), and the width sizes of the folding lines are consistent, so that the production efficiency and the envelope (flat pouch) quality are improved.

Owner:镇江现代印刷机器厂

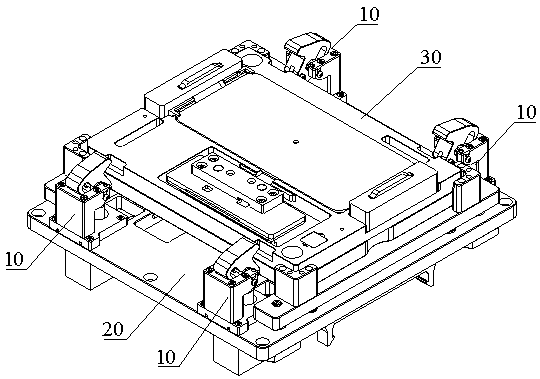

COF automatic aligning, press-jointing and lightening structure

PendingCN110126423ASave human effortShorten the timeLaminationLamination apparatusEngineeringPrinted circuit board

The invention relates to the technical field of aligning press-jointing equipment, and discloses a COF automatic aligning, press-jointing and lightening structure, which comprises a rack. A press-jointing assembly, an aligning assembly, and an automatic correcting assembly are arranged on the rack. The press-jointing assembly comprises a press head mechanism. A flexible printed circuit board is arranged on the press head mechanism. The aligning assembly is provided with a plurality of aligning cameras. The aligning cameras are opposite to the flexible printed circuit board and are used to shoot and position the datum points of the flexible printed circuit board. The automatic correcting assembly is arranged under the aligning assembly and the press-jointing assembly and is provided with amovable automatic correcting platform. A glass slice is placed on the automatic correcting platform. The aligning cameras shoot and position the datum points of the glass slice. The automatic correcting assembly will automatically adjust the position of the automatic correcting platform according to the positions of the datum points of the glass slice and the flexible printed circuit board obtained by the aligning cameras; the glass slice and the flexible printed circuit board are aligned, and then the press head mechanism is pressed down to laminate the glass slice and the flexible printed circuit board.

Owner:SHENZHEN SKING INTELLIGENT EQUIP

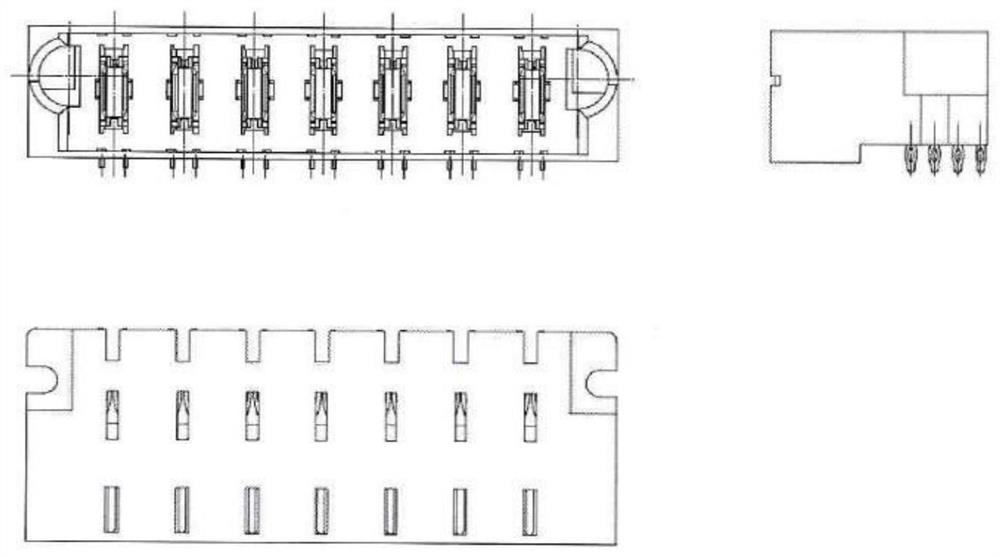

Crimping device and method for PCB connector

ActiveCN110366325AImprove reliabilityGuaranteed electrical and mechanical propertiesPrinted circuit assemblingPrinted circuit aspectsElectricityTwo degrees of freedom

The invention relates to a crimping device and method for a PCB connector, and relates to the technical field of machining. The invention solves the problem of pin crimping of a novel fisheye-shaped connector. Segmented crimping with a specified stroke is carried out by using a crimping machine during crimping. The crimping device has a limiting function, and the limiting design is carried out inthe length and width directions of a plastic shell based on a connector base, so that the crimping is more accurate after the limitation is carried out on two degrees of freedom, and the crimping device can be ensured not to pressure the pin. The structure and size of the crimping device are designed to ensure that the pin outlet rate after crimping reaches 100%, the phenomenon of pin shrinkage isavoided, the reliability is high through inspection and power-on test, and the required electrical property and mechanical property are ensured.

Owner:TIANJIN JINHANG COMP TECH RES INST

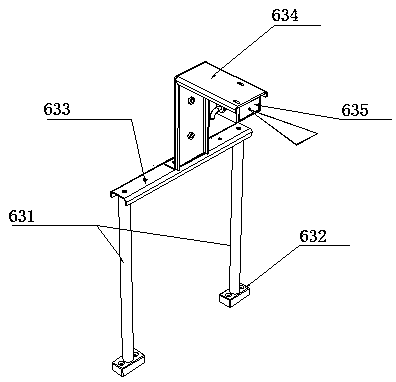

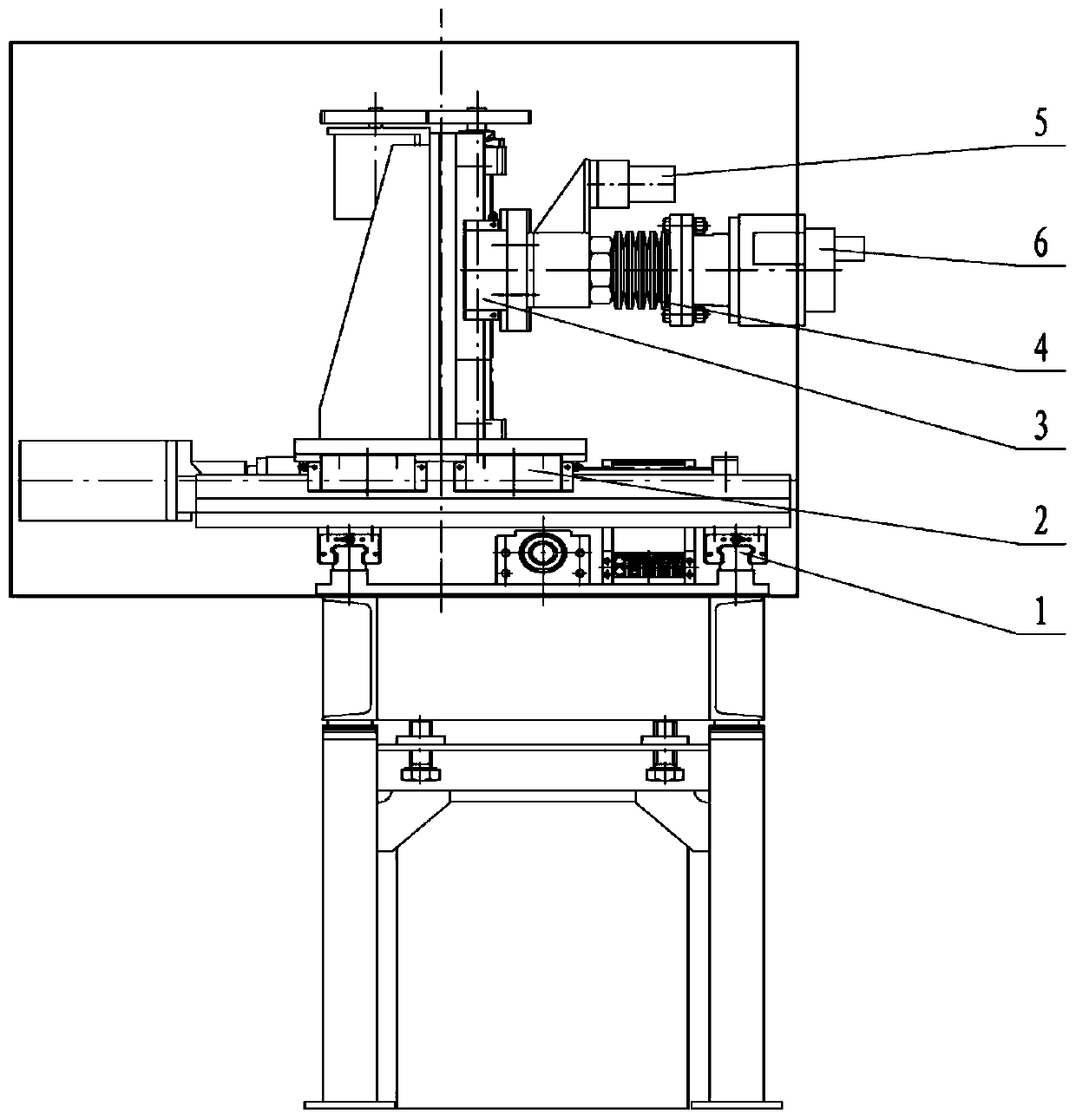

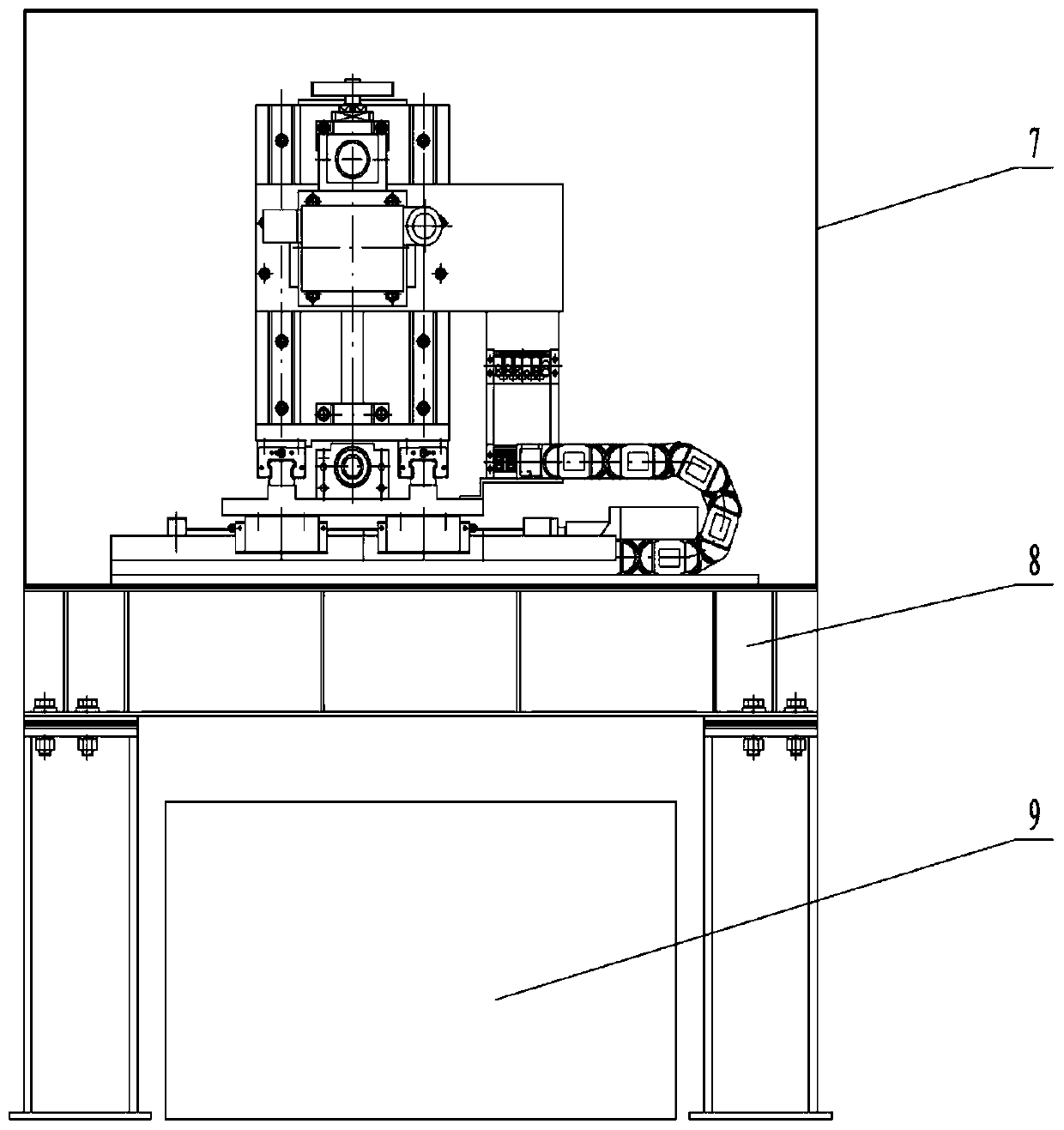

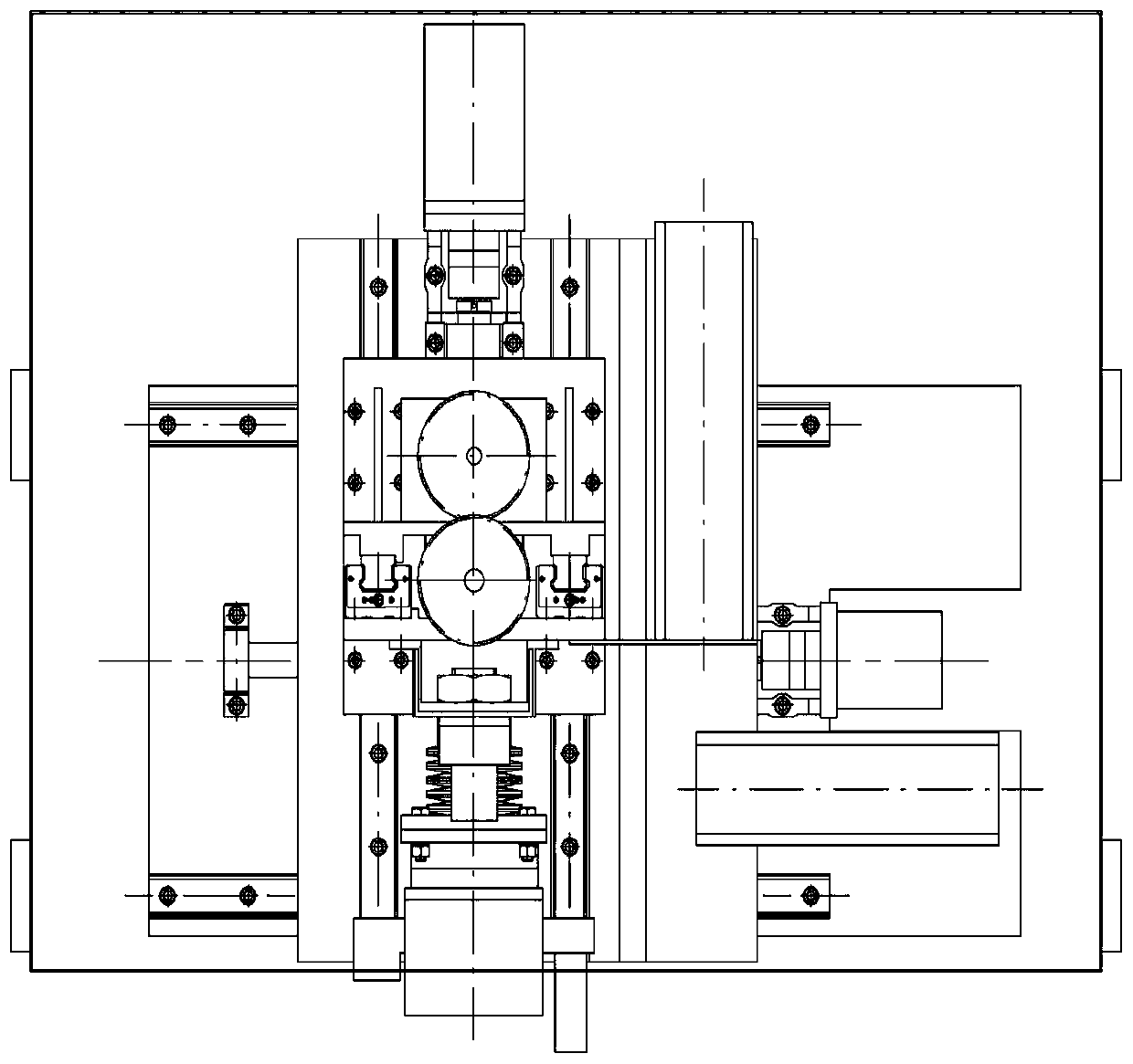

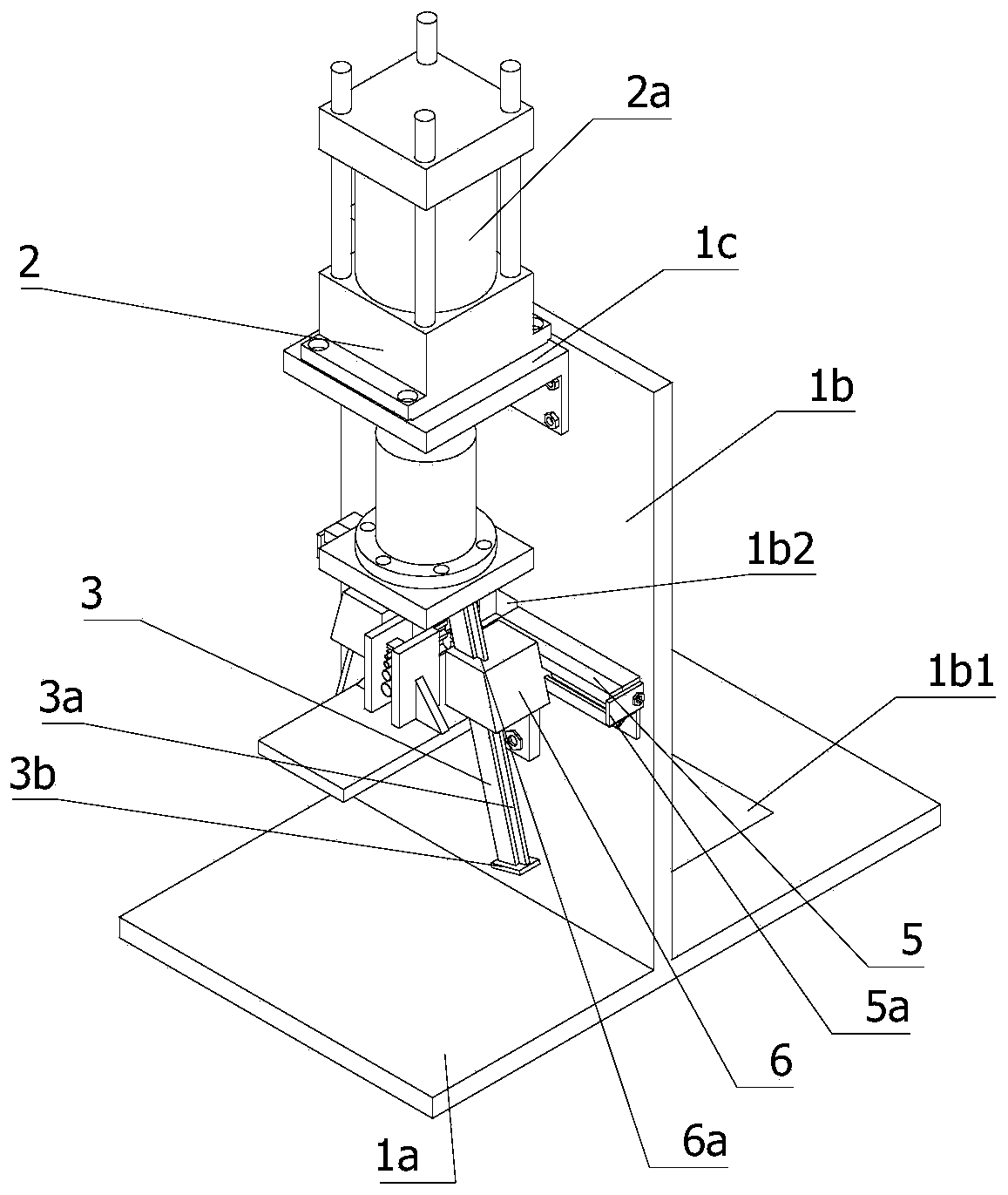

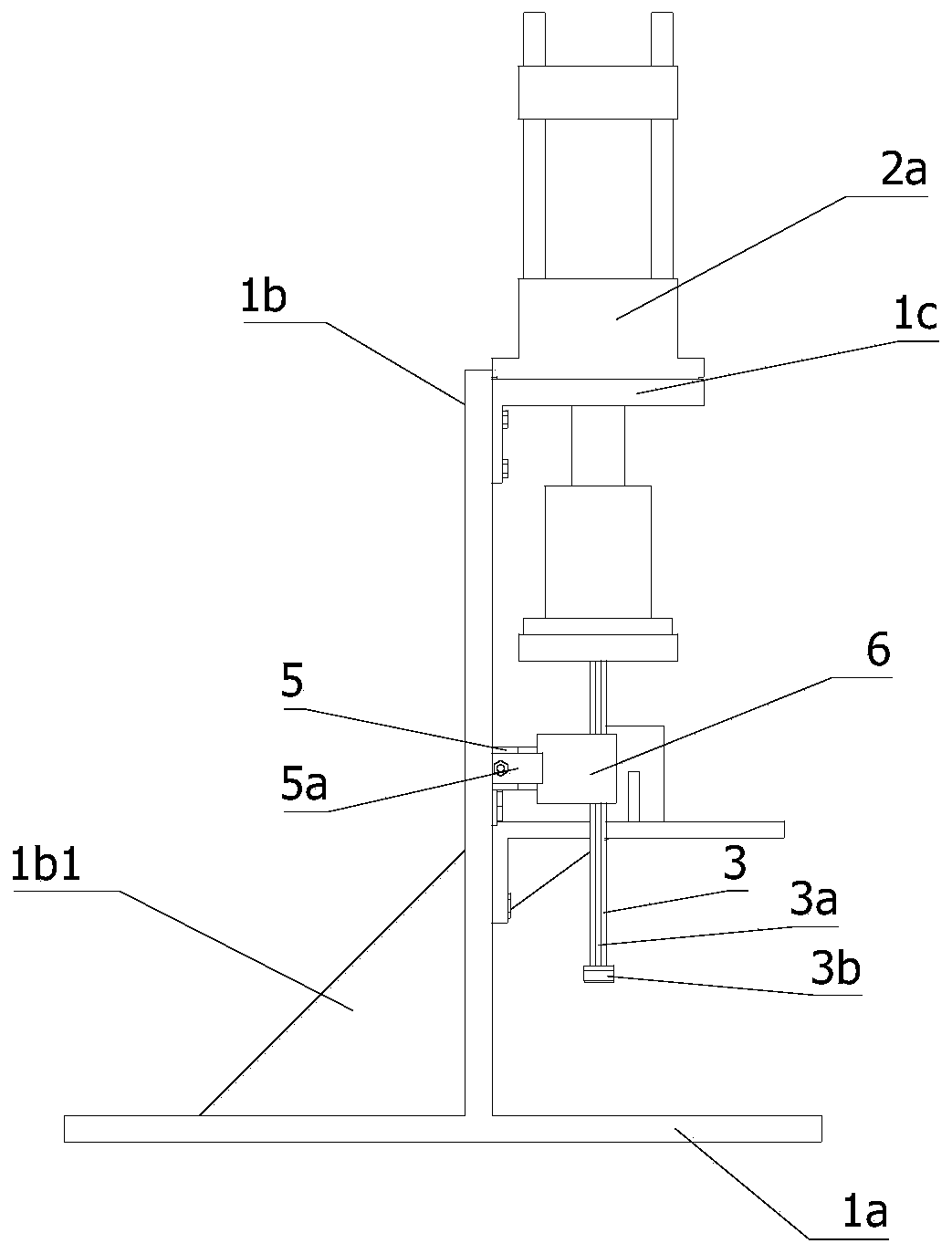

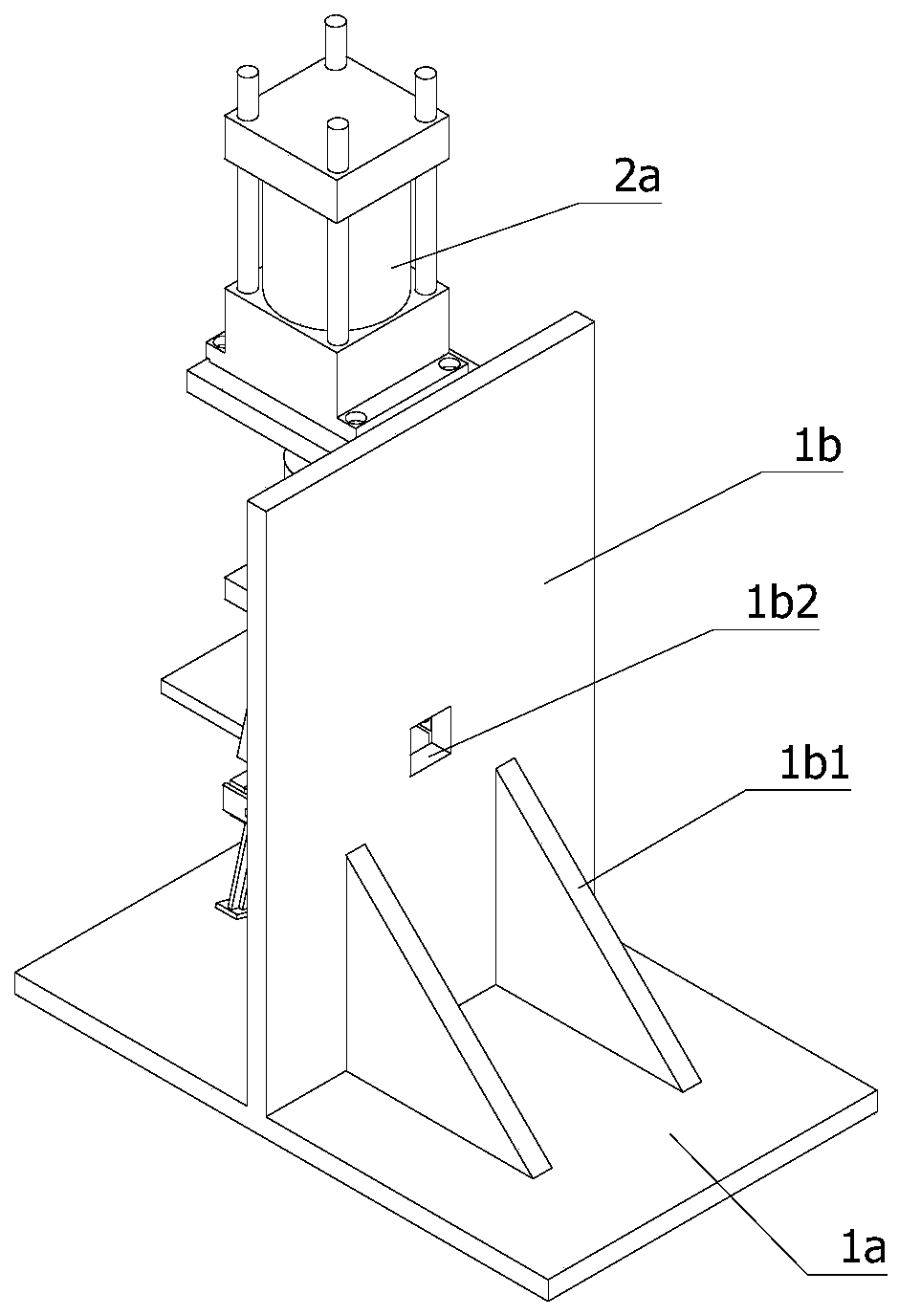

Automatic power-on device for torpedo car

ActiveCN111299564ASafe, stable and reliable power connectionIncrease the level of automationMelt-holding vesselsCoupling device detailsBall screwElectric machine

The invention discloses an automatic power-on device for a torpedo car. The device comprises a longitudinal moving mechanism, a transverse moving mechanism, a vertical lifting mechanism, an elastic compensation mechanism, a visual recognition module, a plug, a protective cover, an underframe and an electrical control module, wherein the longitudinal moving mechanism is mounted on the underframe, the transverse moving mechanism is mounted on a working table of the longitudinal moving mechanism, the vertical lifting mechanism is mounted on a working table of the transverse moving mechanism, theelastic compensation mechanism is mounted on a working table of the vertical lifting mechanism, a smart camera of the visual recognition module is mounted on a bracket of the elastic compensation mechanism, and the plug is mounted at the end part of the elastic compensation mechanism. A rectangular coordinate system mechanical structure is adopted, and servo / stepper motor drive and ball screw transmission are adopted. The longitudinal moving mechanism and the vertical lifting mechanism receive a control command of the electrical control module to perform long movement and vertical movement automatically, and the plug mounted at the end part of the elastic compensation mechanism is driven to reach the position corresponding to a socket of the torpedo car.

Owner:大连重工环保工程有限公司 +1

Special crimping pliers for high-voltage live working robot

ActiveCN112952513AExtended service lifeNot easy to damageTelevision system detailsLine/current collector detailsMotor driveElectric machinery

The invention discloses special crimping pliers for a high-voltage live working robot. The crimping pliers comprise a base, a working box and a crimping mechanism; a storage battery is fixedly installed at the bottom of the base, universal wheels are fixedly installed on the side face of the storage battery, a processing center is fixedly installed at the lower right corner in the working box, and a front camera is fixedly installed at the position, close to the bottom, of the right side of the working box; a lifting mechanism is fixedly installed at the lower left corner in the working box, a rotating mechanism is fixedly installed at the top of the lifting mechanism, a clamping mechanism is fixedly installed at the top of the processing center, and an overhead camera is fixedly installed in the middle of the top of the working box. According to the special crimping pliers for the high-voltage hot-line work robot, the motor drives the rotating column to rotate, so that the connecting pipe and the first magnet rotate for a circle, the first magnet and the second magnet are close to one side and attract each other, the pull rod is driven to move leftwards, the pull rod pulls the upper pressing die and extrudes the lower pressing die, and a high-voltage wire is crimped; the service life of the crimping pliers can be prolonged, and the operation robot is not prone to damage.

Owner:GUIZHOU POWER GRID CO LTD

Multiple crimped wire manufacturing device, two terminal-crimped wire manufacturing method, multiple wire feeding device, terminal crimping method, and terminal crimping device

ActiveCN102948022BChange output lengthAccurate outputConnection formation by deformationEngineeringMechanical engineering

Owner:JAPAN AUTOMATIC MACHINE

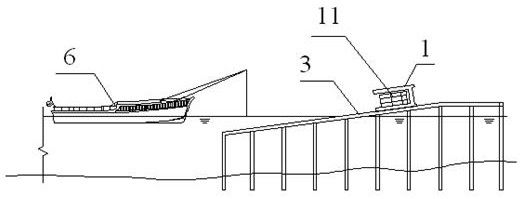

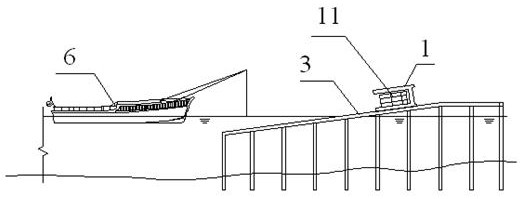

Dry-dock-free underwater shallow-buried open-cut large channel basic structure unit and construction method

ActiveCN112982476AReduce the difficulty of site selectionAvoid influenceArtificial islandsUnderwater structuresAir volumeMarine engineering

The invention relates to a dry-dock-free underwater shallow-buried open-cut large channel basic structure unit and a construction method. The basic structure unit used in the method has the following characteristics that the length of each basic structure unit is 20-25m, a sealing door is arranged at one end of each basic structure unit, the other end of each basic structure unit is of an open structure, and a drainage pressure relief valve is arranged at the lower end of each sealing door; a rubber water stop belt is arranged at the end of each basic structure unit in a surrounding mode, and a floating and ballasting cabin capable of adjusting the water inlet and drainage capacity is fixed in each basic structure unit; and at least four axis positioning foot stands are arranged at the bottom of each basic structure unit. The channel basic structure unit can be directly prefabricated on the flat ground, a large temporary dry dock does not need to be built, the temporary engineering investment is reduced, the manufacturing cost of an underwater channel is reduced, and the construction period of the underwater channel is shortened; and the basic structure unit can slide into a water area from a land area through a slideway, the basic structure unit is kept in a suspended state in water by adjusting the air volume in the floating and ballasting cabin, the basic structure unit is pulled and sunk by a floating crane ship, the construction efficiency is improved, and the water construction difficulty is reduced.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

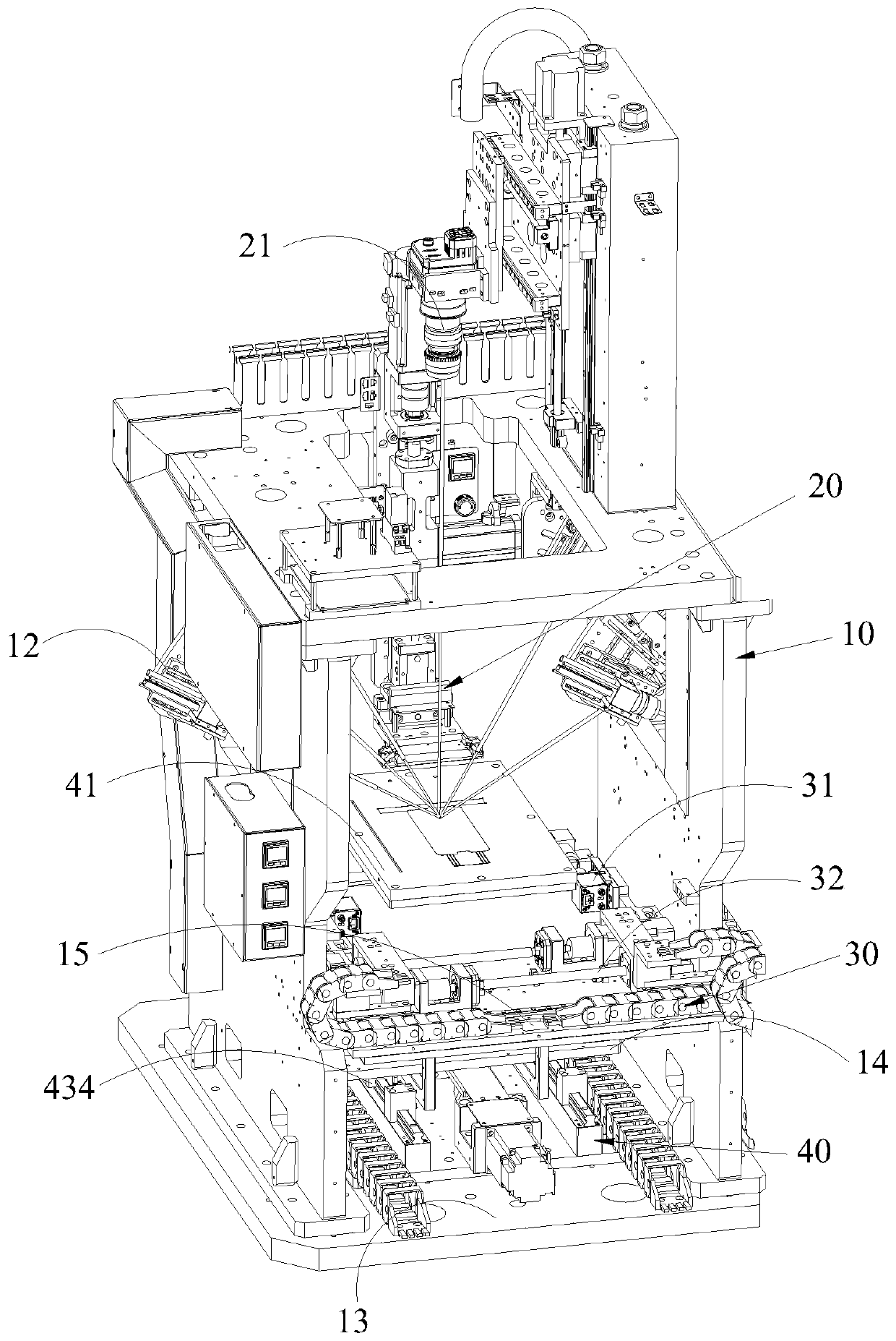

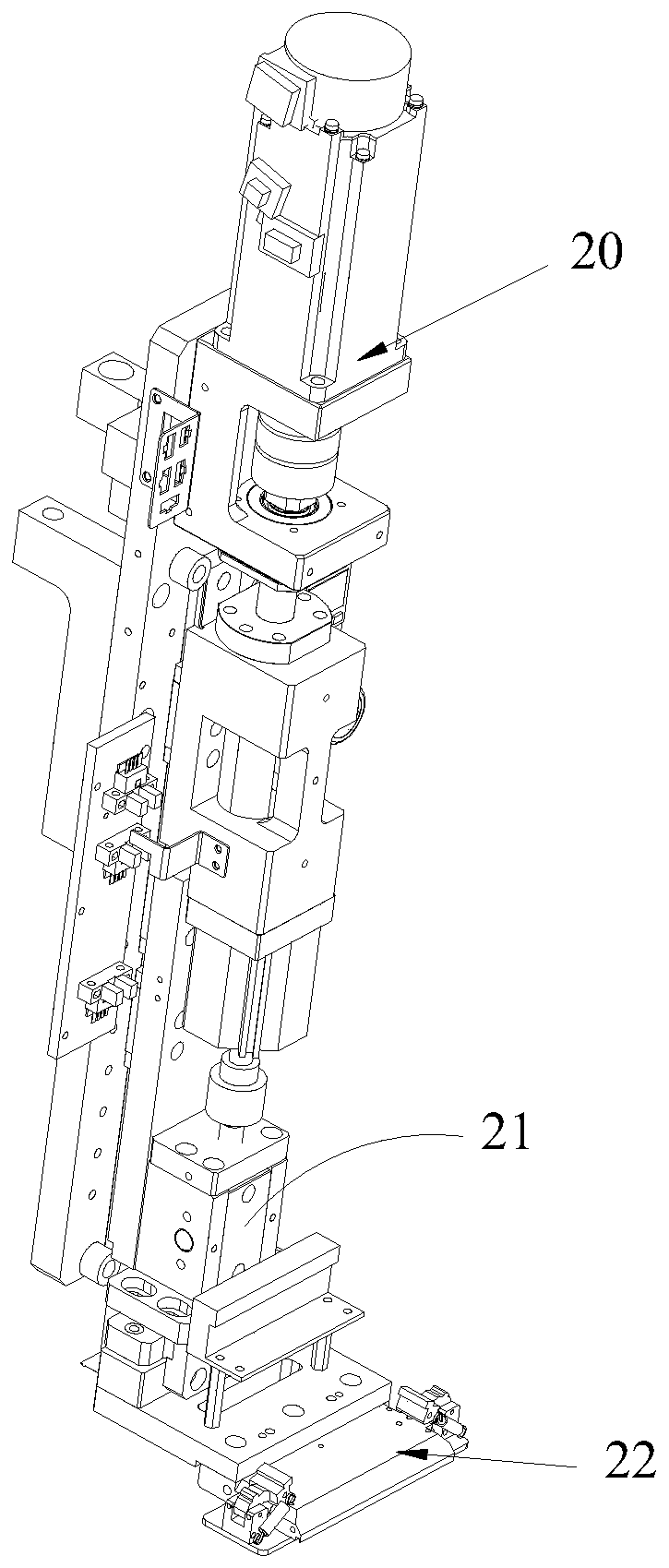

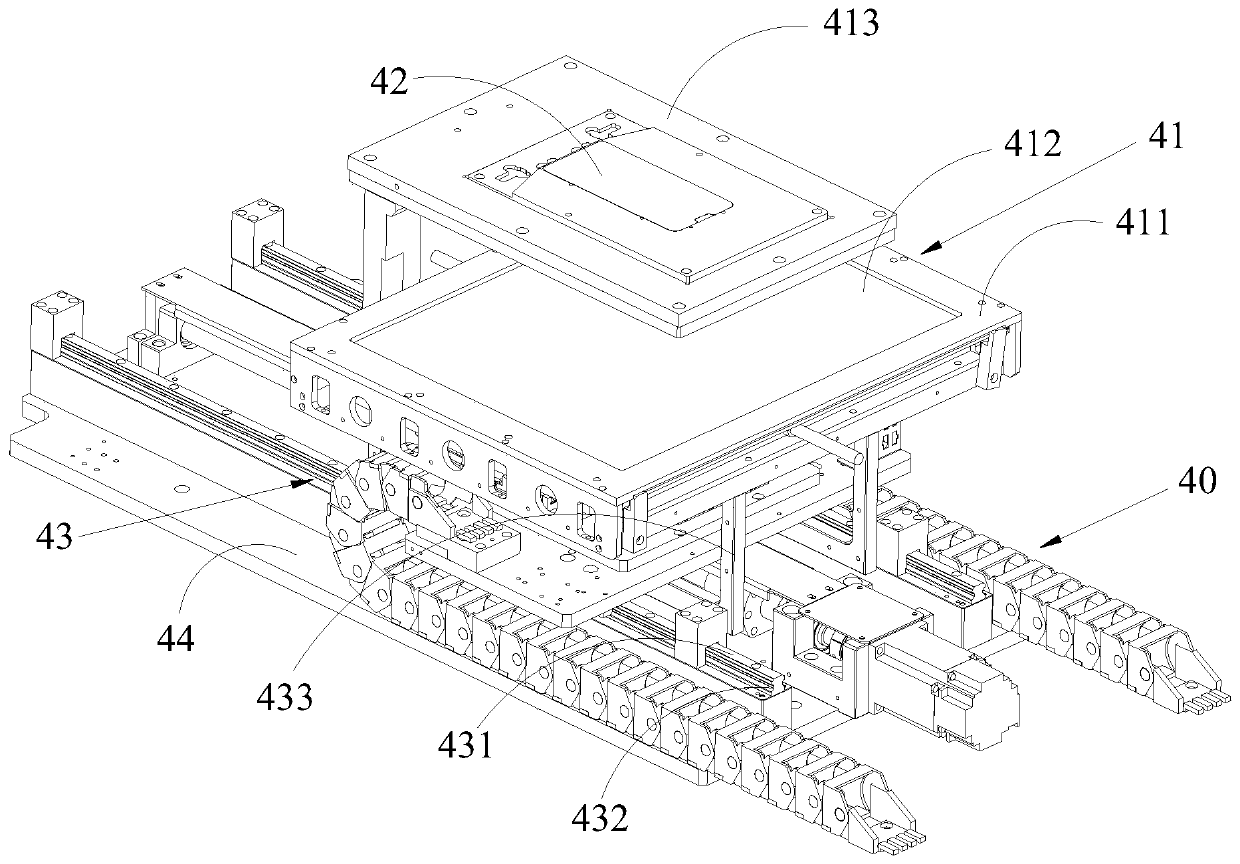

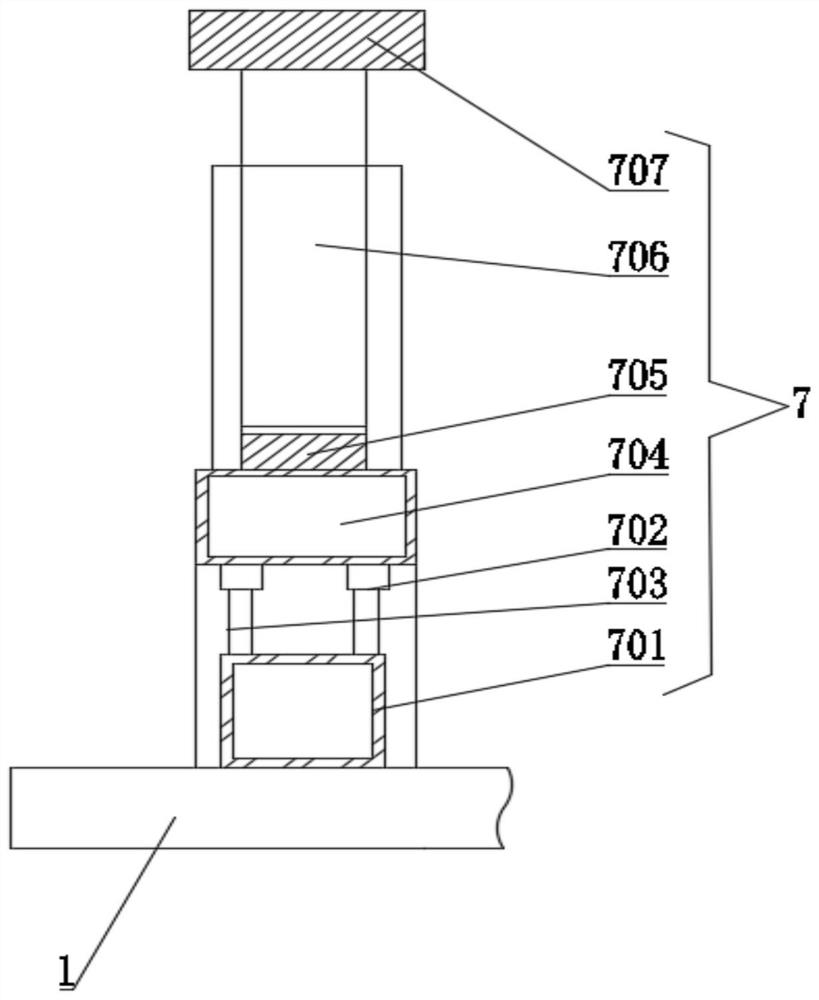

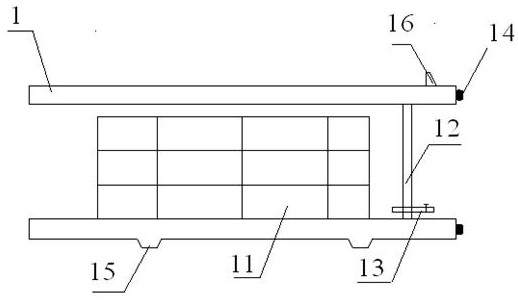

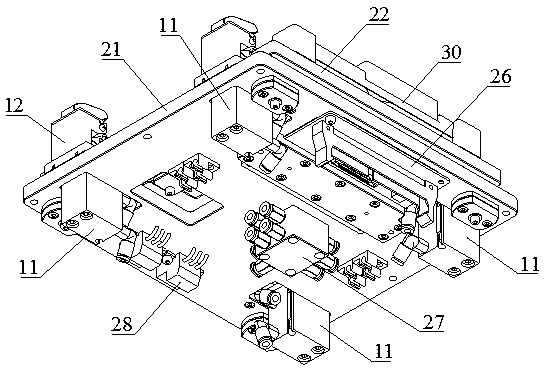

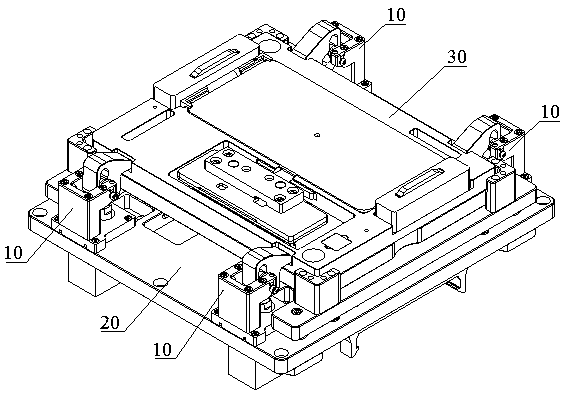

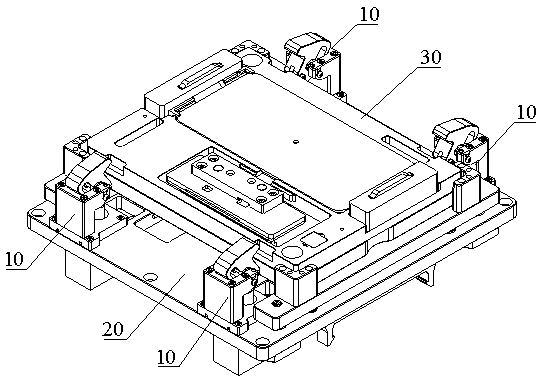

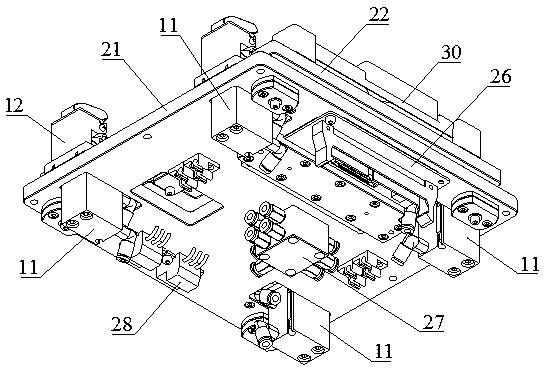

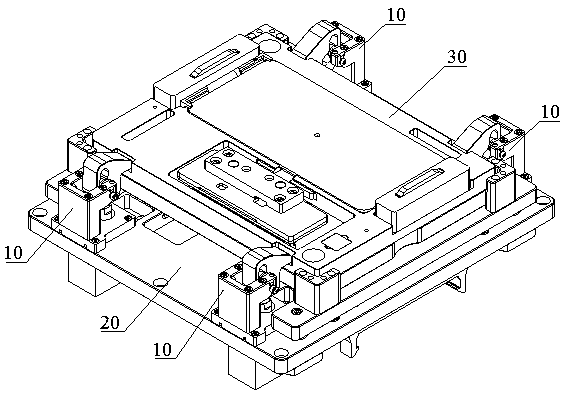

Product carrier automatic crimping mechanism and point screen test equipment

ActiveCN110780095BIncrease success rateAccurate crimpingMeasurement instrument housingProcess engineeringMechanical engineering

The invention discloses an automatic crimping mechanism of a product carrier and a screen clicking test device. The automatic crimping mechanism comprises a product carrier, an automatic crimping module and a crimping table; the crimping table comprises a fixed bottom plate, a floating plate for bearing the product carrier, an electrical plug and a switching PCB; and the floating plate is arrangedon the fixed bottom plate in a floating manner, the electrical plug matches a plugging point on the product carrier and is in signal communication with the switching PCB, and the automatic crimping module is driven by a power to apply a downward pressure to the floating plate to realize crimping connection between the electrical plug and the plugging point on the product carrier. According to theautomatic crimping mechanism of the product carrier and the screen clicking test device suitable for an automatic line body, the automatic crimping module is adopted to automatically crimp the product carrier with a to-be-tested product on the crimping table, a pressing block of the automatic crimping module is pressed into a pressing groove in the product carrier, so that crimping is more accurate, crimping force is increased, crimping accuracy is guaranteed, and the success rate of screen clicking is increased.

Owner:武汉精毅通电子技术有限公司

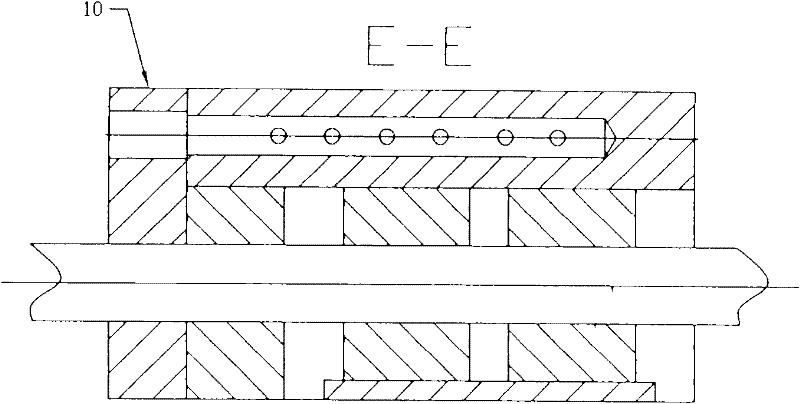

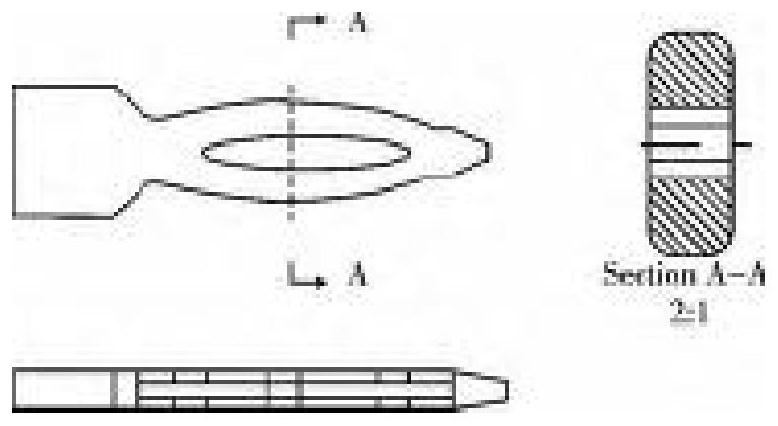

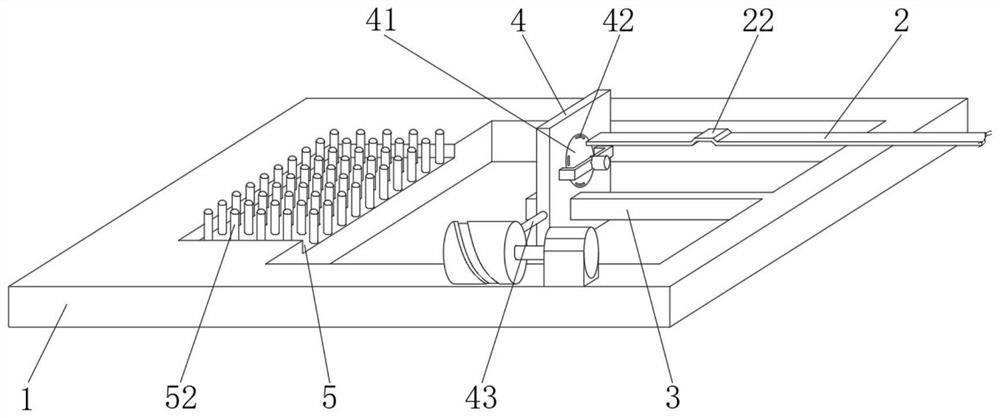

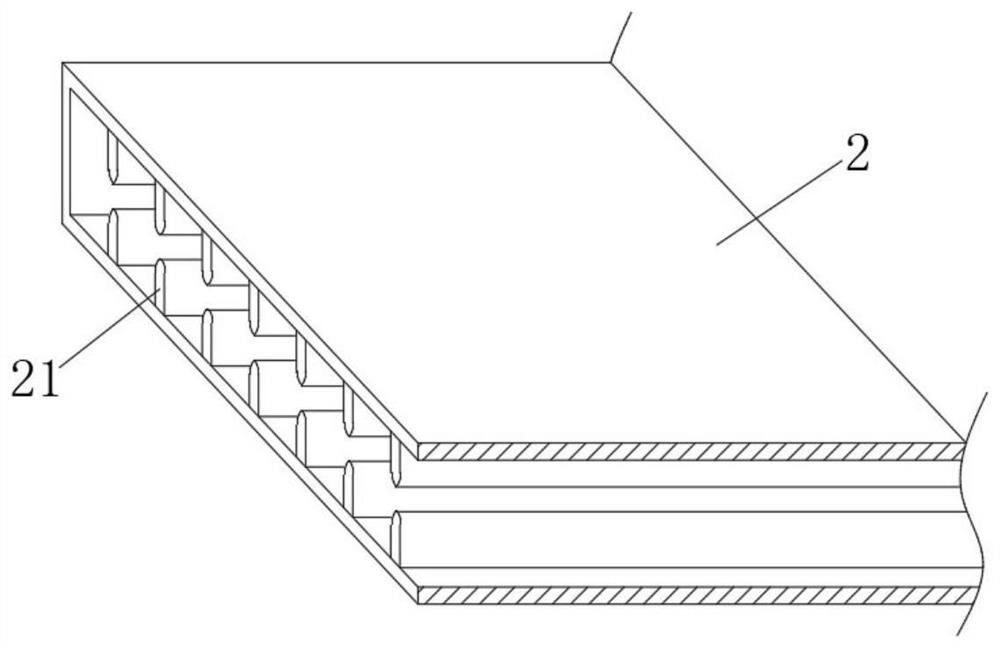

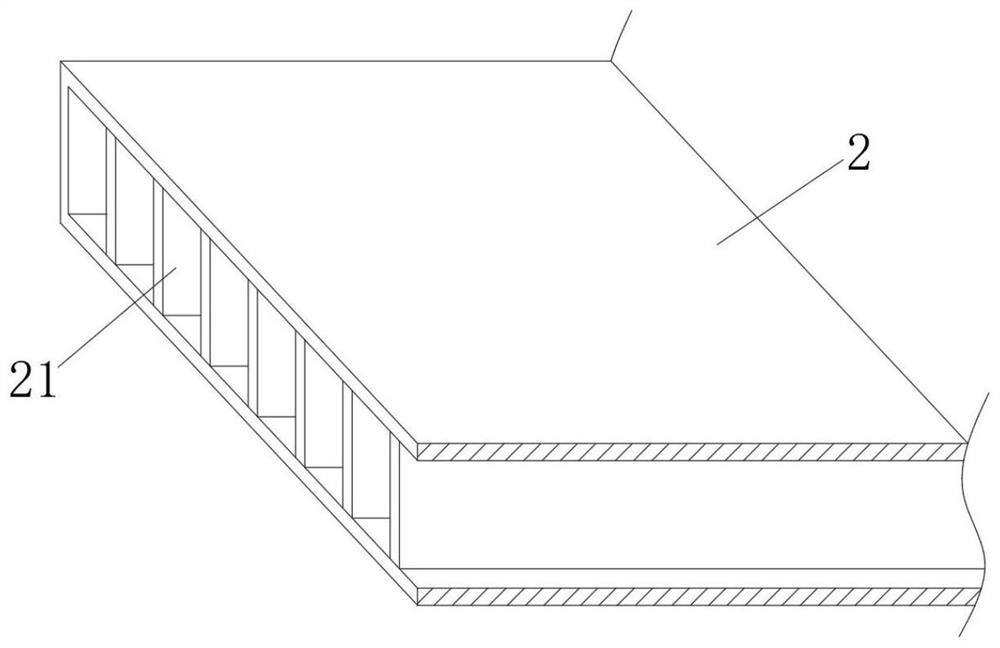

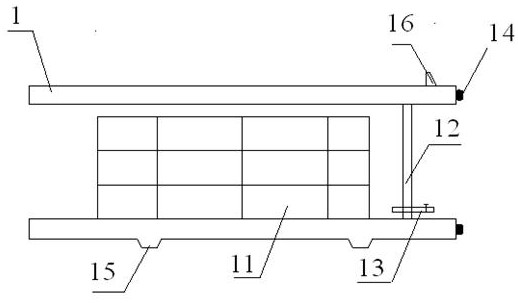

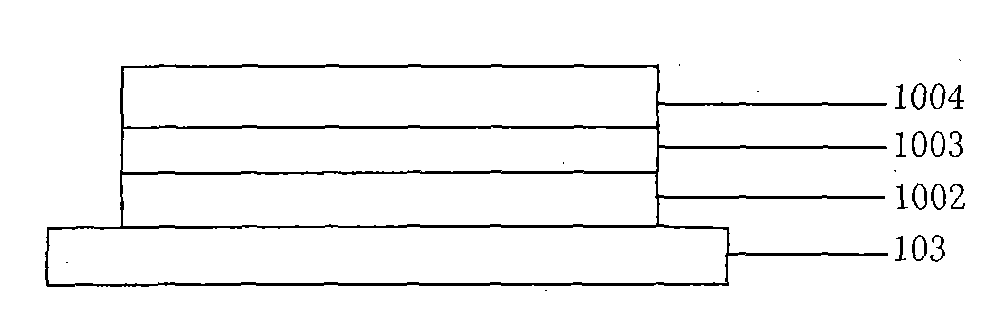

Heat conduction metal core and PCB (Printed Circuit Board) board using same

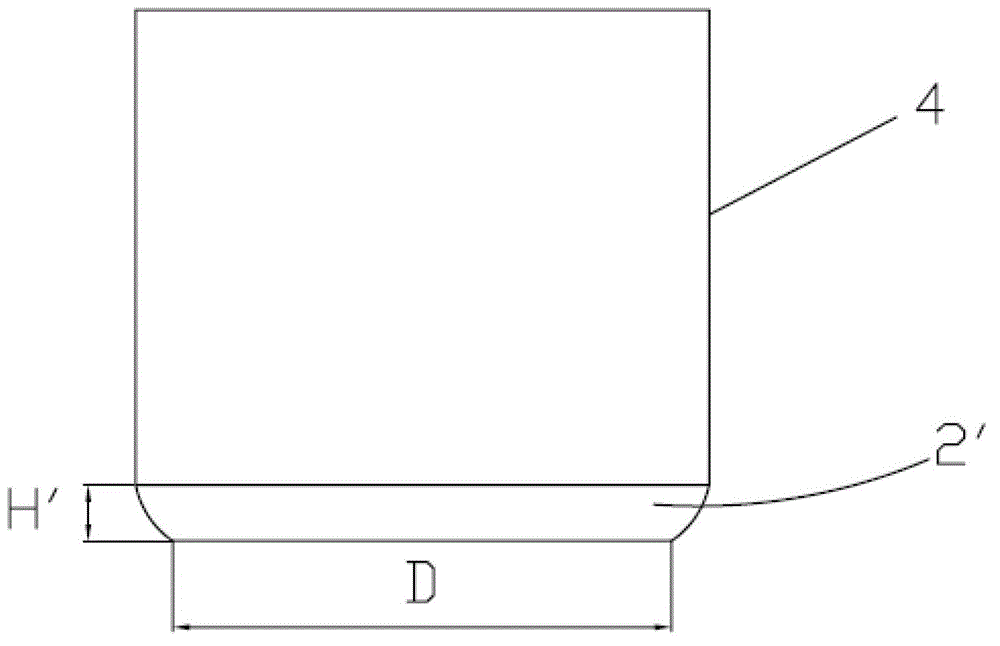

InactiveCN102917535AAccurate crimpingCrimp flatPrinted circuit detailsCooling/ventilation/heating modificationsNuclear engineeringPrinted circuit board

The invention provides a heat conduction metal core and a PCB board using same. The heat conduction metal core comprises a core body and a leading-in structure which is extended from the end part of the core body, wherein the leading-in structure is a cone which is gradually tapered towards the end far from the core body. With the leading-in structure, the heat conduction metal core can be easily pressed to an open slot of the PCB board; moreover, the leading-in structure can be pre-positioned at the top of the open slot of the PCB board without dropping and inclining, so that the heat conduction metal core can be accurately and flatly pressed to the open slot of the PCB board; and besides, the heat conduction metal core is firmly combined with the PCB board without dropping. The heat conduction metal core is pressed on the heat conduction metal core PCB board, simple in the heat conduction structure and good in radiating effects.

Owner:DONGGUAN SHENGYI ELECTRONICS

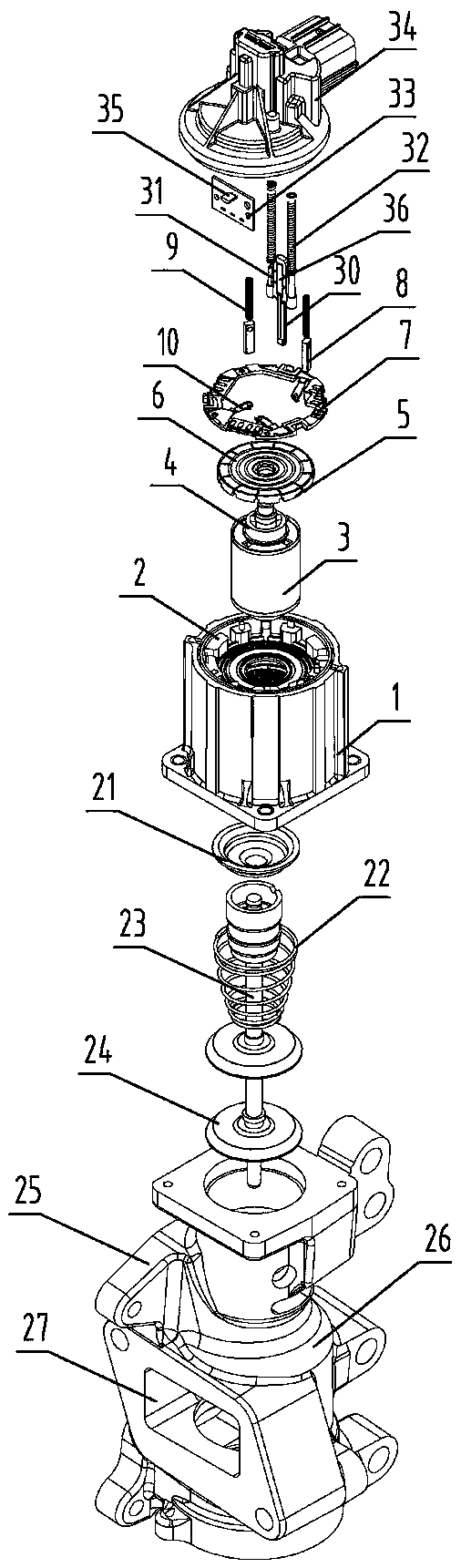

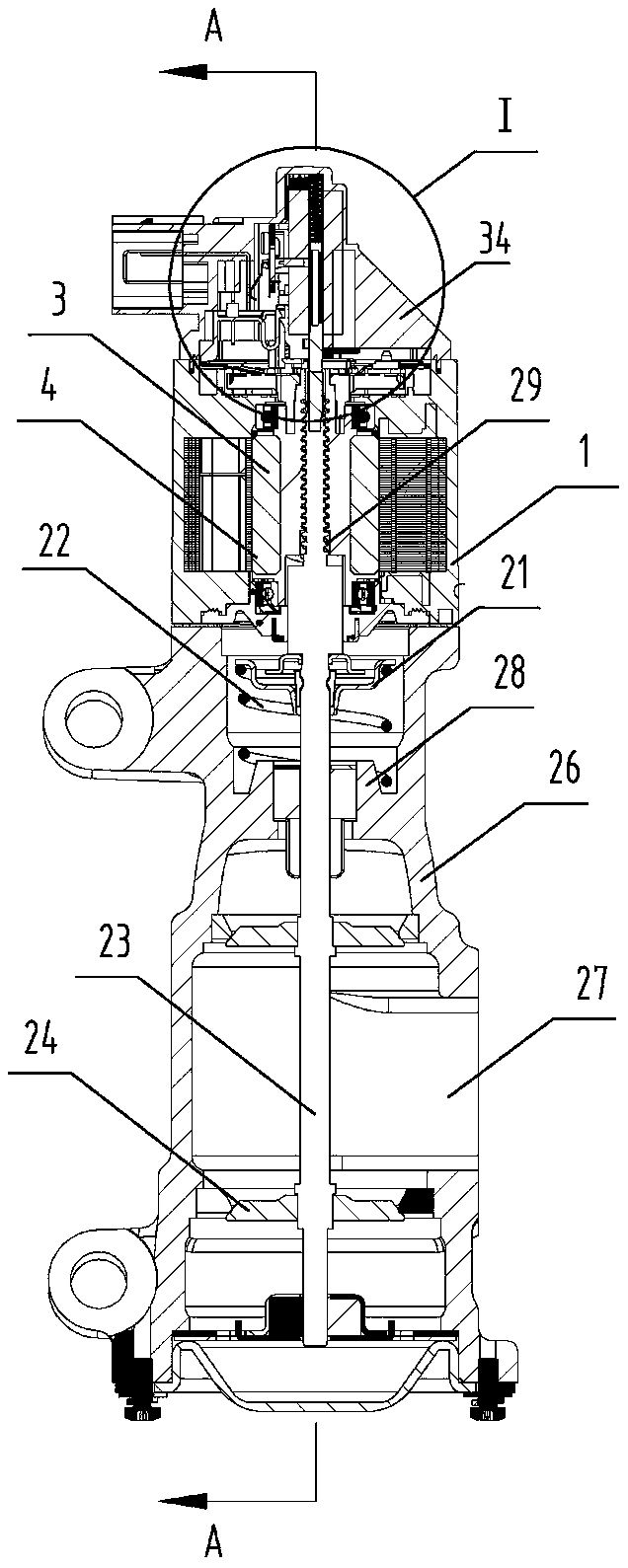

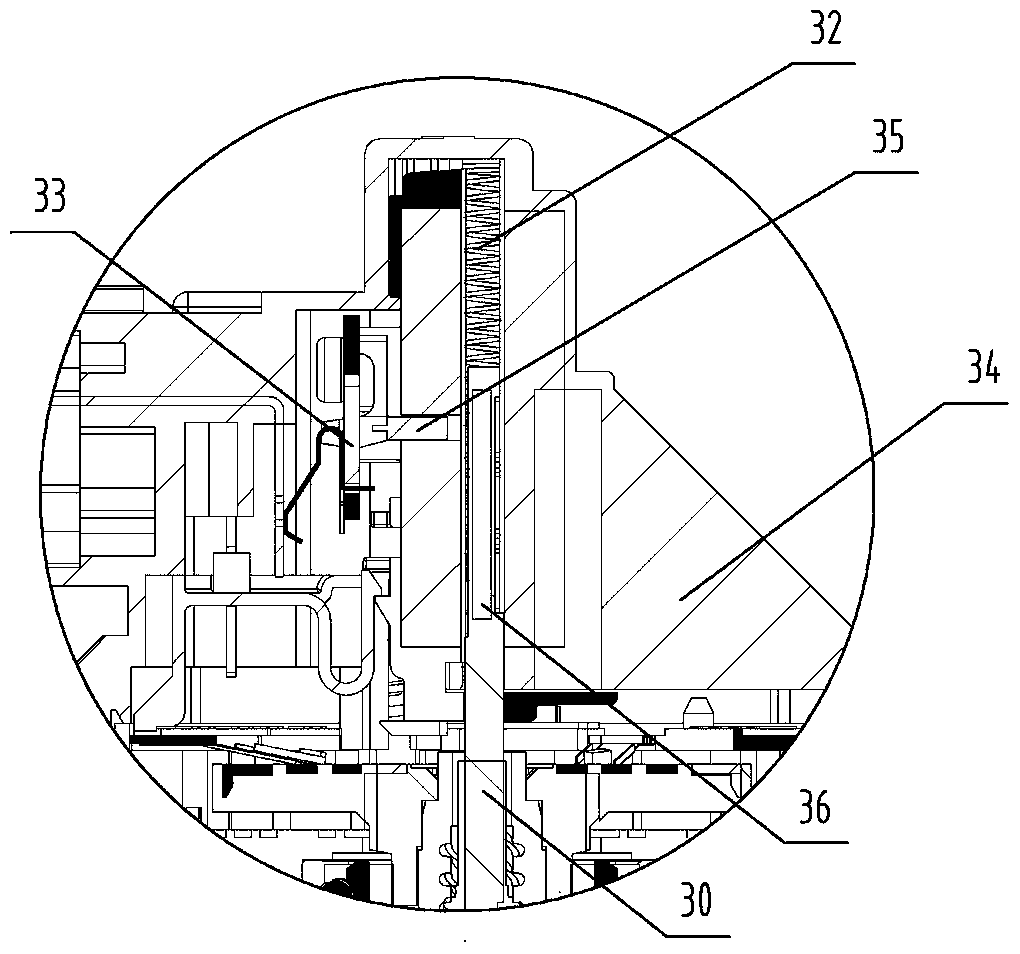

Fast EGR valve capable of being controlled precisely

PendingCN108757229AQuick responseEnables automatic physical connection reversingExhaust gas recirculationMachines/enginesControl signalHigh power density

The invention discloses a fast EGR valve capable of being controlled precisely and belongs to the technical field of supply of combustible mixtures of engines. The fast EGR valve comprises a shell which is provided with a gas inlet and a gas outlet. A motor is installed in the shell. A pushing rod is installed in a rotor of the motor. A piston is installed on the pushing rod. The piston controls opening and closing of the gas inlet and the gas outlet. The fast EGR valve is characterized in that the motor comprises a stator of a brushless motor and a rotor of the brushless motor, a power supplyelectric brush is fixed to the shell, each phase winding of the stator is connected with one power taking electric brush in a one-to-one manner, a reversing device is fixed to the rotor, a magnet isinstalled on the pushing rod, a Hall sensor is fixed in the shell, the Hall sensor inducts a magnetic field of the magnet and transmits signals to a circuit board to serve as control signals of starting and stopping of the motor. According to the valve, automatic physical connecting and reversing of the stator windings can be achieved fast and directly, the valve has the advantage of high power density of the brushless motor and has the advantage of achieving automatic reversing fast, the moving response speed of a valve rod can be increased, the position of the valve rod can be detected precisely, and then the purpose of precise control is achieved.

Owner:ZIBO TAIZHAN MECHANICAL & ELECTRICAL

A kind of crimping device and method for pcb board connector

ActiveCN110366325BOvercoming Crimp ProblemsAccurate crimpingPrinted circuit assemblingPrinted circuit aspectsEngineeringCrimp

The invention relates to a crimping device and method for a PCB board connector, and relates to the technical field of mechanical processing. The invention solves the crimping problem of a new type of fish-eye connector pin. During crimping, a crimping machine is used to carry out segmental crimping with a specified stroke. The length and width of the plastic shell are limited in two directions, and the crimping is more accurate after the two degrees of freedom are limited, which can ensure that the crimping device will not press the pin. The structure and size design of the crimping device can ensure 100% needle exit rate after crimping, no needle shrinkage phenomenon, high reliability after inspection and power-on test, and ensure the required electrical and mechanical properties.

Owner:TIANJIN JINHANG COMP TECH RES INST

Automatic crimping mechanism of product carrier and screen clicking test device

ActiveCN110780095AIncrease success rateAccurate crimpingMeasurement instrument housingProcess engineeringMechanical engineering

The invention discloses an automatic crimping mechanism of a product carrier and a screen clicking test device. The automatic crimping mechanism comprises a product carrier, an automatic crimping module and a crimping table; the crimping table comprises a fixed bottom plate, a floating plate for bearing the product carrier, an electrical plug and a switching PCB; and the floating plate is arrangedon the fixed bottom plate in a floating manner, the electrical plug matches a plugging point on the product carrier and is in signal communication with the switching PCB, and the automatic crimping module is driven by a power to apply a downward pressure to the floating plate to realize crimping connection between the electrical plug and the plugging point on the product carrier. According to theautomatic crimping mechanism of the product carrier and the screen clicking test device suitable for an automatic line body, the automatic crimping module is adopted to automatically crimp the product carrier with a to-be-tested product on the crimping table, a pressing block of the automatic crimping module is pressed into a pressing groove in the product carrier, so that crimping is more accurate, crimping force is increased, crimping accuracy is guaranteed, and the success rate of screen clicking is increased.

Owner:武汉精毅通电子技术有限公司

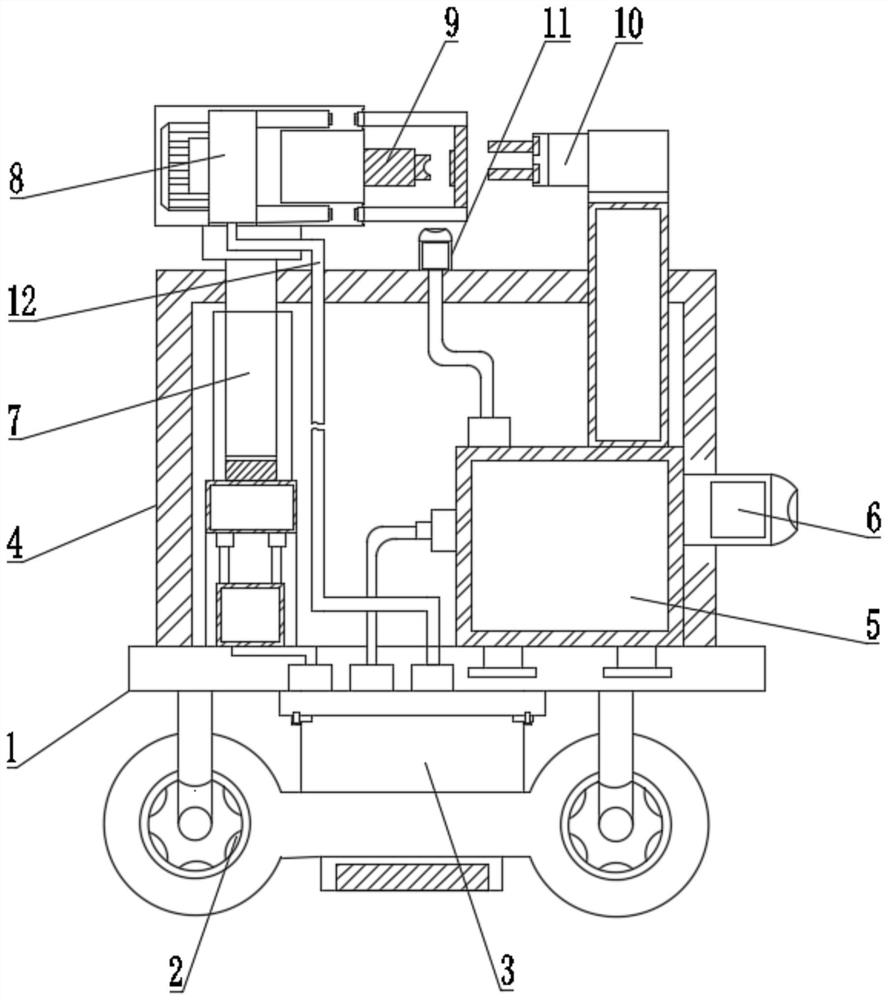

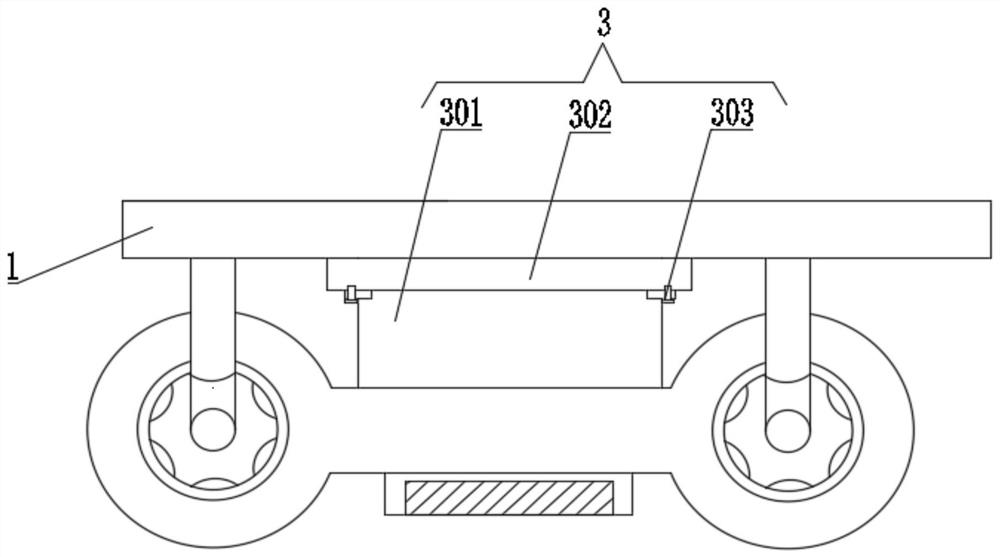

A fast three-phase electronic electric energy meter verification crimping device and verification method thereof

ActiveCN104569530BImprove test efficiencyImprove accuracyElectrical measurementsSurface mountingElectric machine

The invention belongs to the technical field of automation of three-phase electronic electric energy meters, and in particular relates to a rapid three-phase electronic electric energy meter verification crimping device and a verification method thereof. The bottom end of the crimping device is provided with wheels, and an electric control box supported by the wheels There is a workbench on the top, and a watch frame is installed vertically on the workbench. Several layers of hanging watch boards are installed obliquely on the workbench. Several unit watch boards are installed on the surface of the hanging watch board. There are left stoppers, right stoppers and control motors installed on the back of the left and right sides. There are also recessed plane grooves on the surface of the unit panel. A sliding bottom plate is arranged in the concave plane groove. The upper surface of the sliding bottom plate A three-phase electronic watt-hour meter is installed, a left chute and a right chute are arranged between the sliding bottom plate and the left block and the right block, and a device is also provided between the lower edge of the unit meter plate and the lower edge of the depressed plane groove. A table holder, the device is provided with crimping terminals on the table holder.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU +1

Flexible flat cable crimping device and crimping method based on Internet of Things

The invention discloses a flexible flat cable crimping device and crimping method based on Internet of Things, and relates to the related technical field of flat cable crimping device.The flexible flat cable crimping device comprises a butt joint platform, the side surface of the butt joint platform is provided with a wire transmission groove used for wire transmission, the interior of the butt joint platform is slidably connected with a sliding plate through the sliding rod, and the top surface of the butt joint platform is provided with a fixing groove; a movable hole is formed in the inner wall of the fixing groove, a movable rod is inserted into the movable hole, and a rotating disc is rotatably mounted on the side surface of a sliding plate; a motor for providing power for the rotating disc is arranged on the side surface of the sliding plate, a wire hole is formed in the side surface of the rotating disc, a rotating rod is rotatably installed on the side surface of the sliding plate, and the end, away from the sliding plate, of the rotating rod extends into the spiral groove in the outer wall of the turbine worm; and a servo motor for providing power for the turbine worm is arranged on the top surface of the butt joint platform, and the servo motor and the motor are connected with a logic controller through wires. Through cooperative use of the devices, the crimping of the flexible flat cable can be smoother, meanwhile, the investment of a labor force can be reduced, and the production efficiency and the yield are improved.

Owner:南京秉昱科技有限公司

Bearing mounting tool

InactiveCN106041490ANovel structureReasonable designMetal working apparatusEngineeringPressure sensor

The invention discloses a bearing installation tool. The tool is installed on a bottom plate and includes a product positioning base, a first bearing positioning block, and a second bearing positioning block. The first bearing positioning block is fixedly arranged on the bottom plate, and the second bearing The positioning block is slidingly connected to the base plate, and the base plate is also provided with a cylinder. The side of the product positioning base is fixedly provided with a crimping positioning baffle, and the bearing positioning surfaces of the first bearing positioning block and the second bearing positioning block are provided with contact sensors. The cylinder is connected with a pressure sensor, the contact sensor and the pressure sensor circuit are connected with a control box, and the control box circuit is connected with a start switch. The invention has a novel structure and a reasonable design. The installation tooling set in this structure can realize accurate crimping of products, avoid over-tight or too loose installation, ensure product quality, reduce the number of reworks, and use the pressure sensor provided to induce crimping The pressure is convenient and fast for crimping and installation, reducing the defective rate and improving work efficiency.

Owner:XINCHANG YIYUAN PRECISION MACHINERY

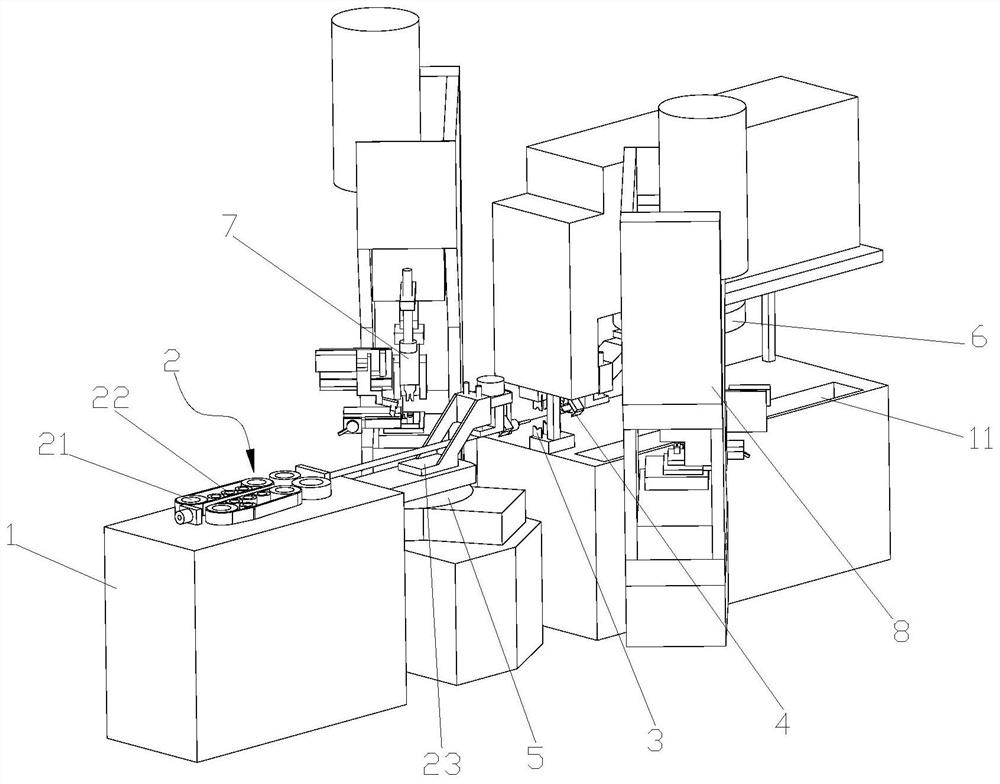

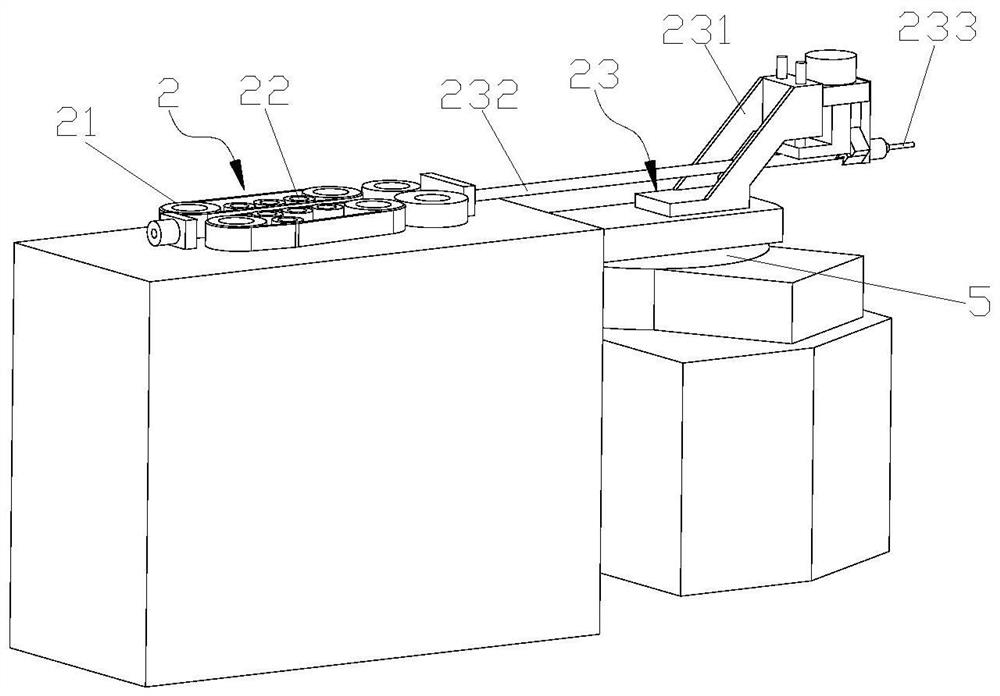

A double-head crimping terminal machine for wire harness

ActiveCN113381261BImprove crimping process efficiencyAccurate crimping positionLine/current collector detailsEngineeringTransfer line

The disclosure relates to a double-head crimping terminal machine for wire harnesses, including a frame and a wire harness feeding module, a cutting module, a clamping module, a first swinging module, a second swinging module, a first crimping terminal module, The second pressing terminal module and control module; the wiring harness module is used to transport the wiring harness; the cutting module is set in the middle of the wiring harness delivery path; the clamping module is set in the rear section of the wiring harness delivery path; the first pressing terminal module is set beside the wiring harness seat side; the first swinging module is linked with the harness seat; the second crimping terminal module is arranged on the side of the clamping module; the second swinging module is linked with the clamping module; the control module is respectively connected with the wire harness module, the cutting module, the clamping module, The first swing module, the second swing module, the first press terminal module, and the second press terminal module are connected for signals. The present disclosure can quickly complete the processing of crimping terminals at both ends of the wire harness, can effectively improve the efficiency of terminal crimping processing, simplify manual operations, and improve the degree of automation of equipment.

Owner:广州新李汽车零部件有限公司

A soft package lithium battery automatic testing mechanism and equipment

ActiveCN109444754BImprove practicalityImprove test accuracyElectrical testingComputer moduleEngineering

The invention discloses an automatic testing mechanism for a soft package lithium battery and equipment. The testing mechanism comprises the components of an installing platform; a first fixing assembly and a second fixing assembly which are arranged on the installing platform; probe pressing modules which are arranged on the installing platform; and a driving mechanism which is arranged on the installing platform. Two sets of probe pressing modules are arranged. Furthermore each set of probe pressing module is provided with an anode tab holder and a cathode tab holder. The probe pressing module is connected with a preset movement track through a linear bearing. Furthermore the clamping cylinder in the two sets of probe pressing modules is controlled by one air inlet pipe, thereby controlling the two sets of probe pressing modules to test the soft package lithium battery simultaneously. The testing mechanism is compatible with a single-side outlet tab battery and a double-side outlet tab battery, thereby improving practicability of the testing mechanism. Furthermore simultaneous clamping of an anode probe holder and a cathode probe holder can be realized, thereby realizing higher clamping accuracy. Furthermore the probe pressing modules according to the invention can realize smooth motion and improves testing precision.

Owner:GUANGDONG HYNN TECH CO LTD

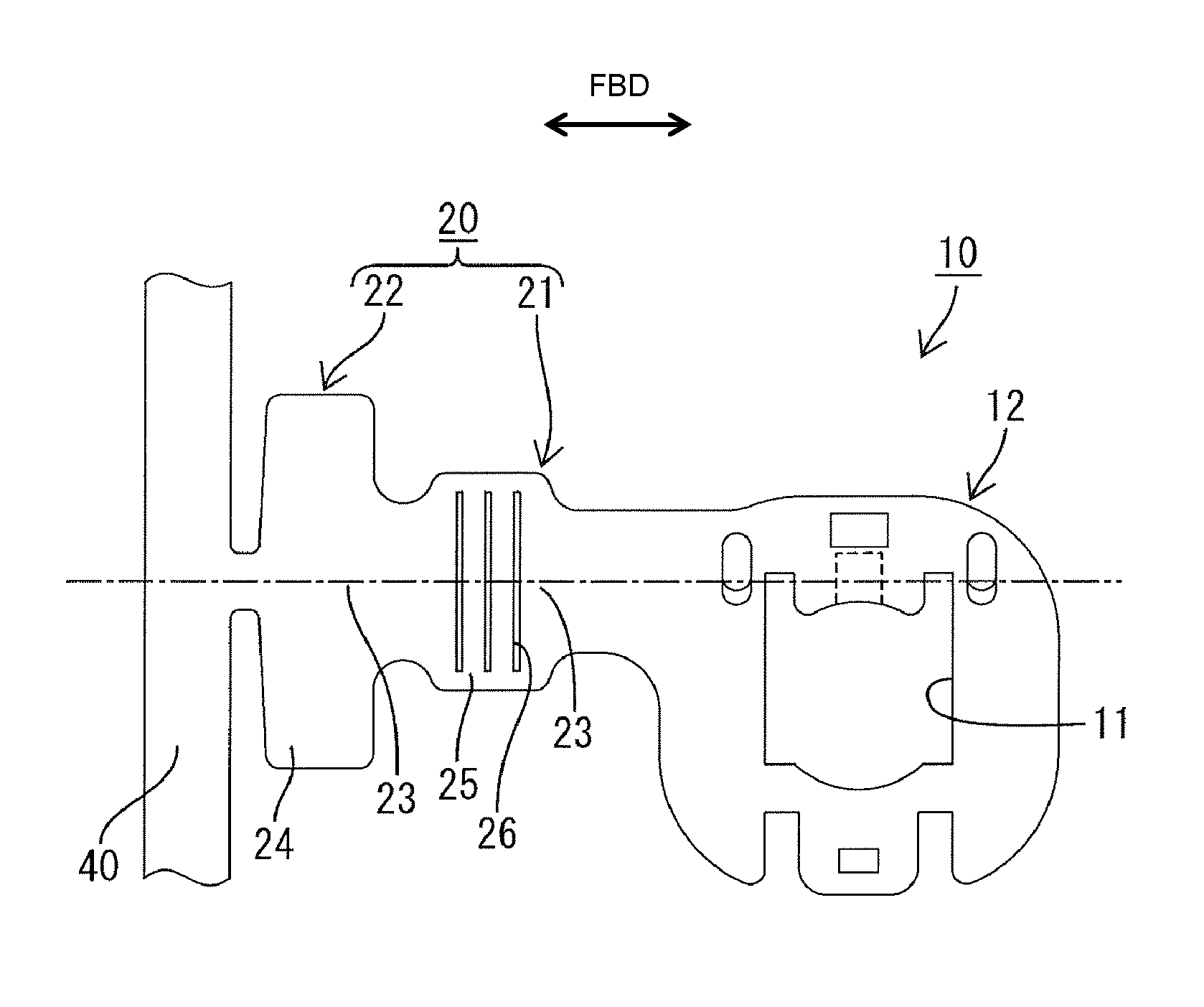

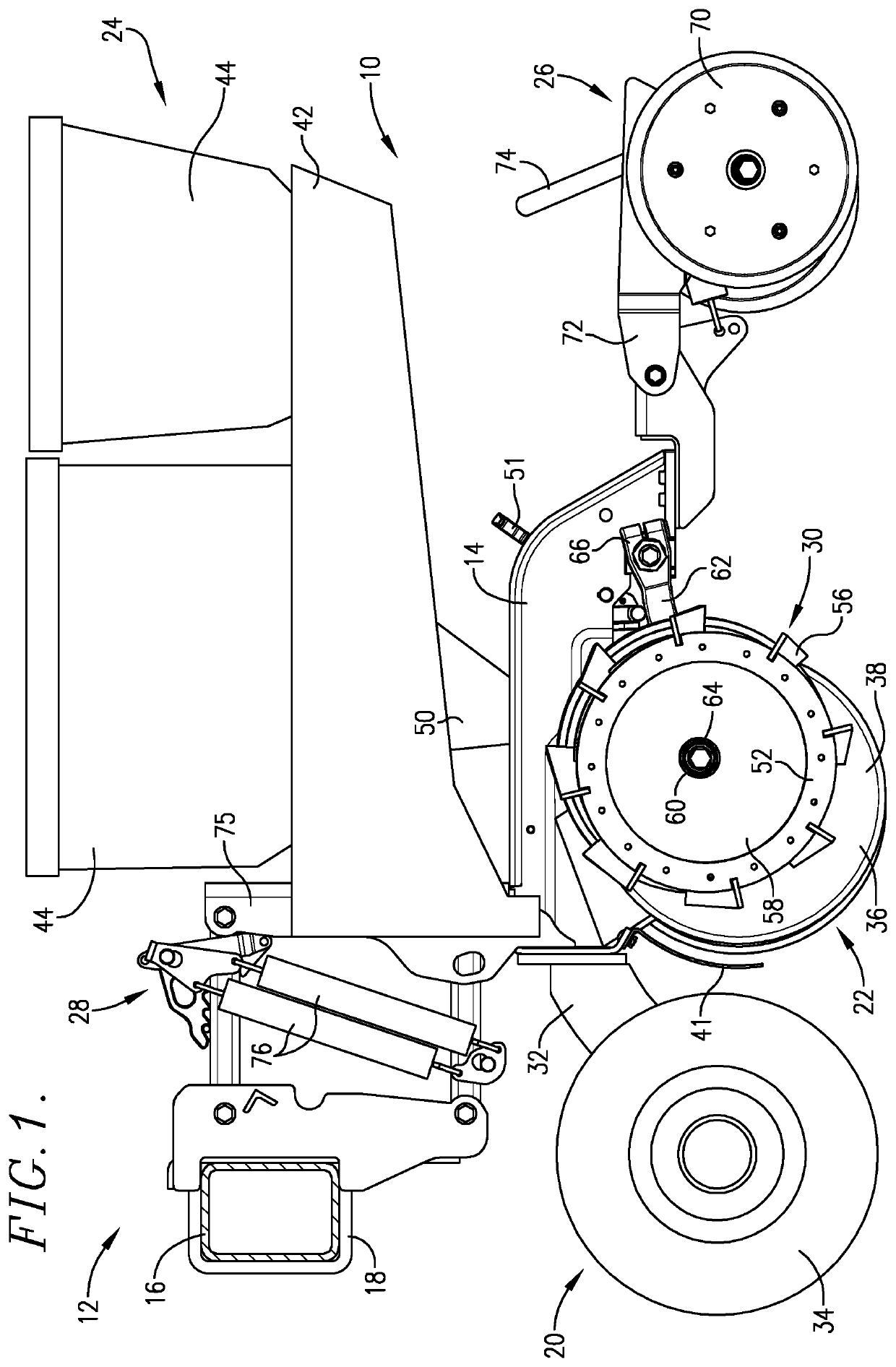

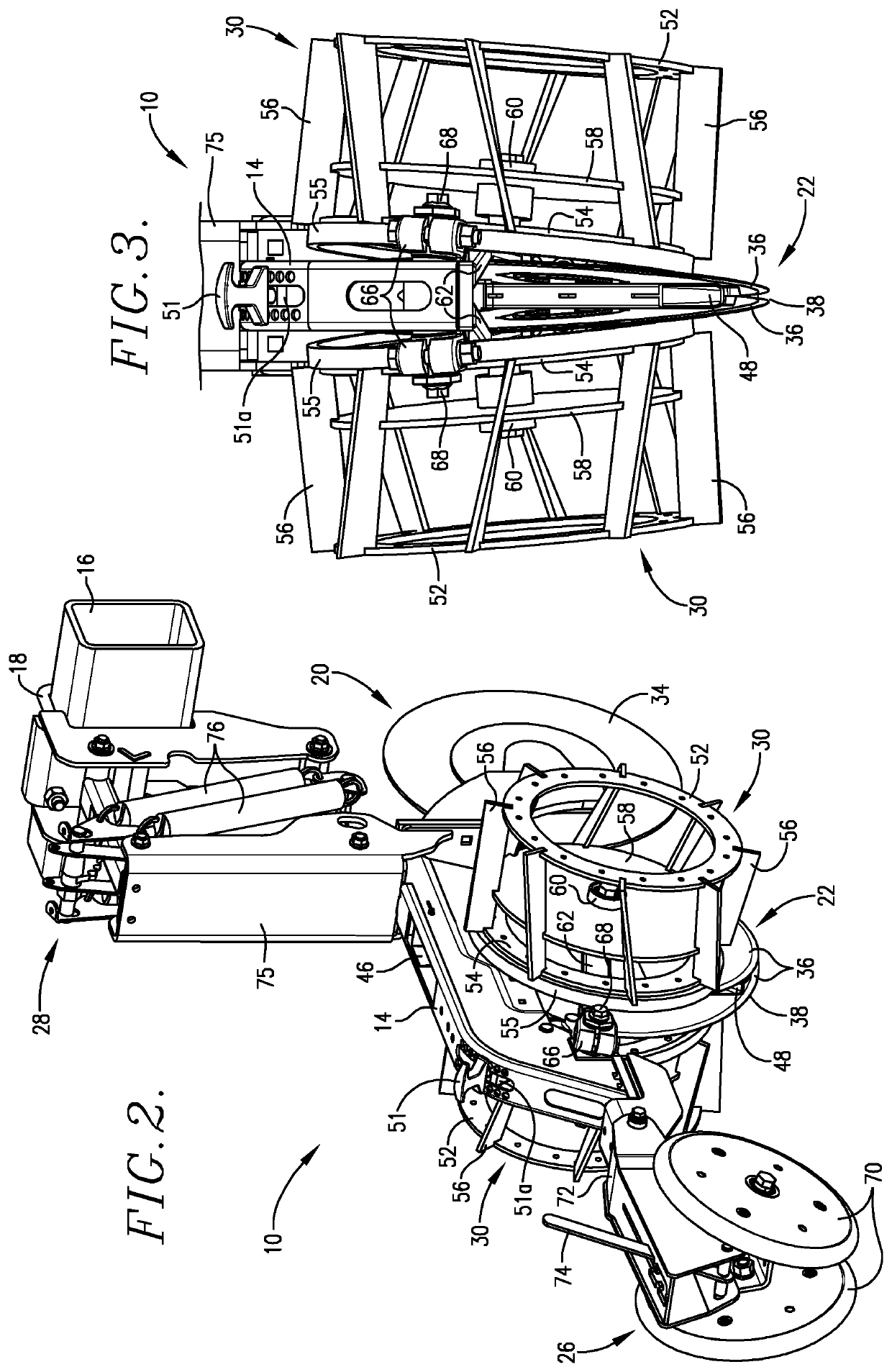

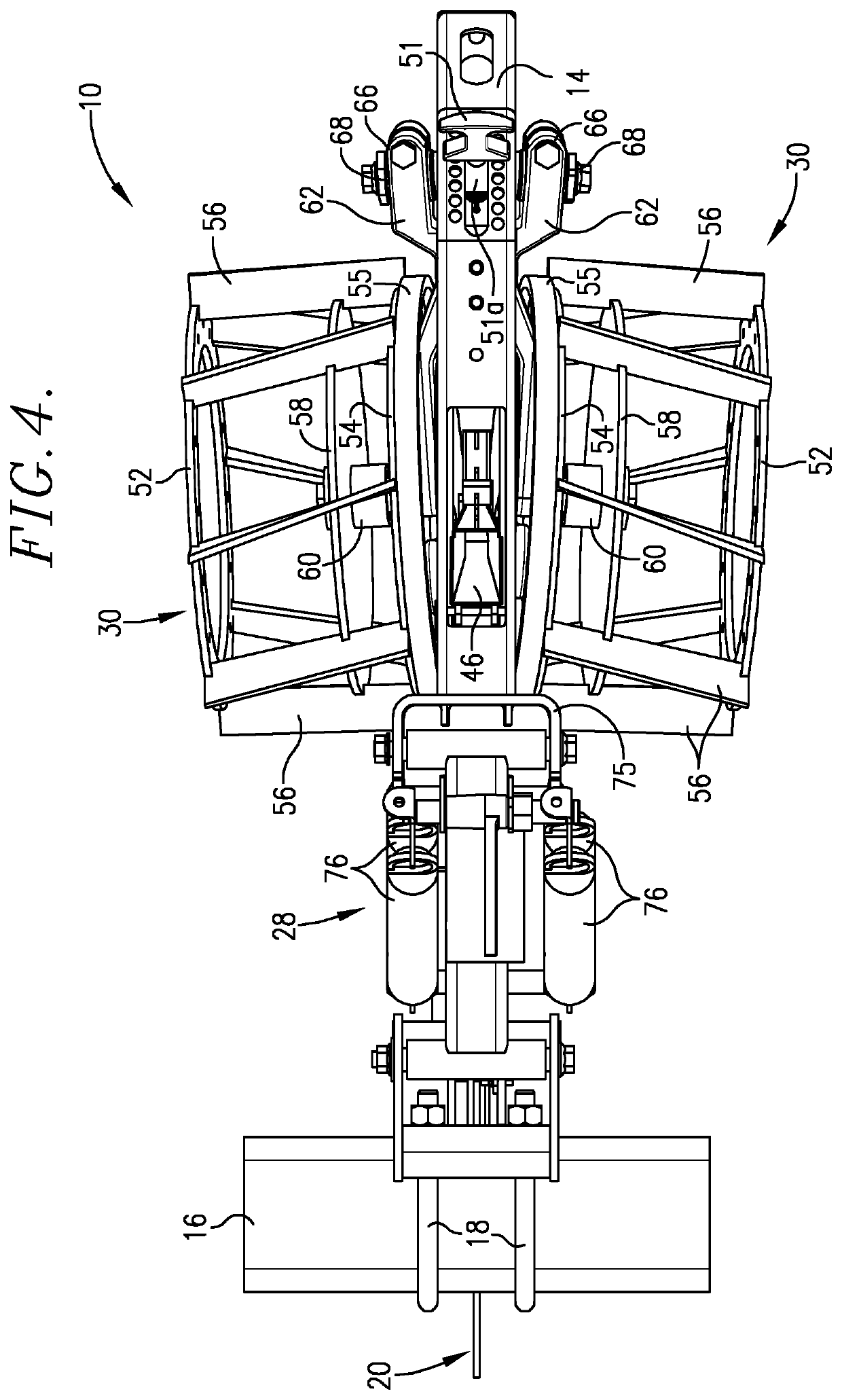

Gauge wheel cover crop crimper

InactiveUS20210227741A1Eliminating separate crimpingEliminating seeding operationSpadesTill seedingSeederAgricultural science

A planter implement (12) includes one or more row units (10) equipped with a furrowing assembly (22), a seed / fertilizer assembly (24), and a furrow-closing assembly (26). The unit (10) is equipped with a pair of right- and left-hand crimper wheels (30) respectively mounted on opposite sides of the furrowing assembly (22). Each crimper wheel (30) has a pair of support rims (52, 54) with a series of elongated bar elements (56) extending between and secured to the rims (52, 54). The bar elements (56) extend beyond the outer periphery of the rims (52, 54) in order to crimp surface crops as the row units (10) pass over a field; the bar elements (56) are oriented to direct material outwardly from each wheel (30) in order to prevent clogging thereof. The crimper wheels (30) are adjustably mounted on the row units (10) and serve as gauge wheels for the units (10).

Owner:HEINEN RODNEY R

Rapid Construction Method of Underwater Shallow Buried Open Cut Large Channel without Dry Dock

ActiveCN112982476BReduce the difficulty of site selectionReduce investmentArtificial islandsUnderwater structuresAir volumeUnderwater channel

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

High-voltage crimping machine for automobile wire harness

InactiveCN110729613AAccurate crimpingRealize crimpingLine/current collector detailsVehicle connectorsDrive by wireMachine

The invention belongs to the technical field of automobile machining and relates to a high-voltage crimping machine for automobile wire harnesses. The high-voltage crimping machine comprises a supporting frame, a linear driver, two inclined guide rails, two pressing heads, two transverse guide rails and two sliding blocks; the two inclined guide rails are symmetrically arranged in the middle of the supporting frame and located below the linear driver; the two inclined guide rails gradually extend downwards and deviate from each other from top to bottom; the tops of the inclined guide rails arefixedly connected with the output end of the linear driver the two sliding blocks are slidably connected with the two sliding rails correspondingly; the two inclined guide rails penetrate through thetwo sliding blocks correspondingly and are slidably connected with the sliding blocks; and the two pressing heads are vertically and fixedly arranged on the opposite surfaces of the two sliding blocks correspondingly. The hydraulic linear driver of the high-voltage crimping machine of the invention can more accurately crimp the automobile wire harnesses; a procedure for manually adjusting anglesis omitted; production is more convenient, faster and more efficient; with different semi-hexagonal grooves adopted, the equipment can be adaptive to various types of automobile wire harnesses, and the practicability of the equipment is improved.

Owner:苏州经纬通电子科技有限公司

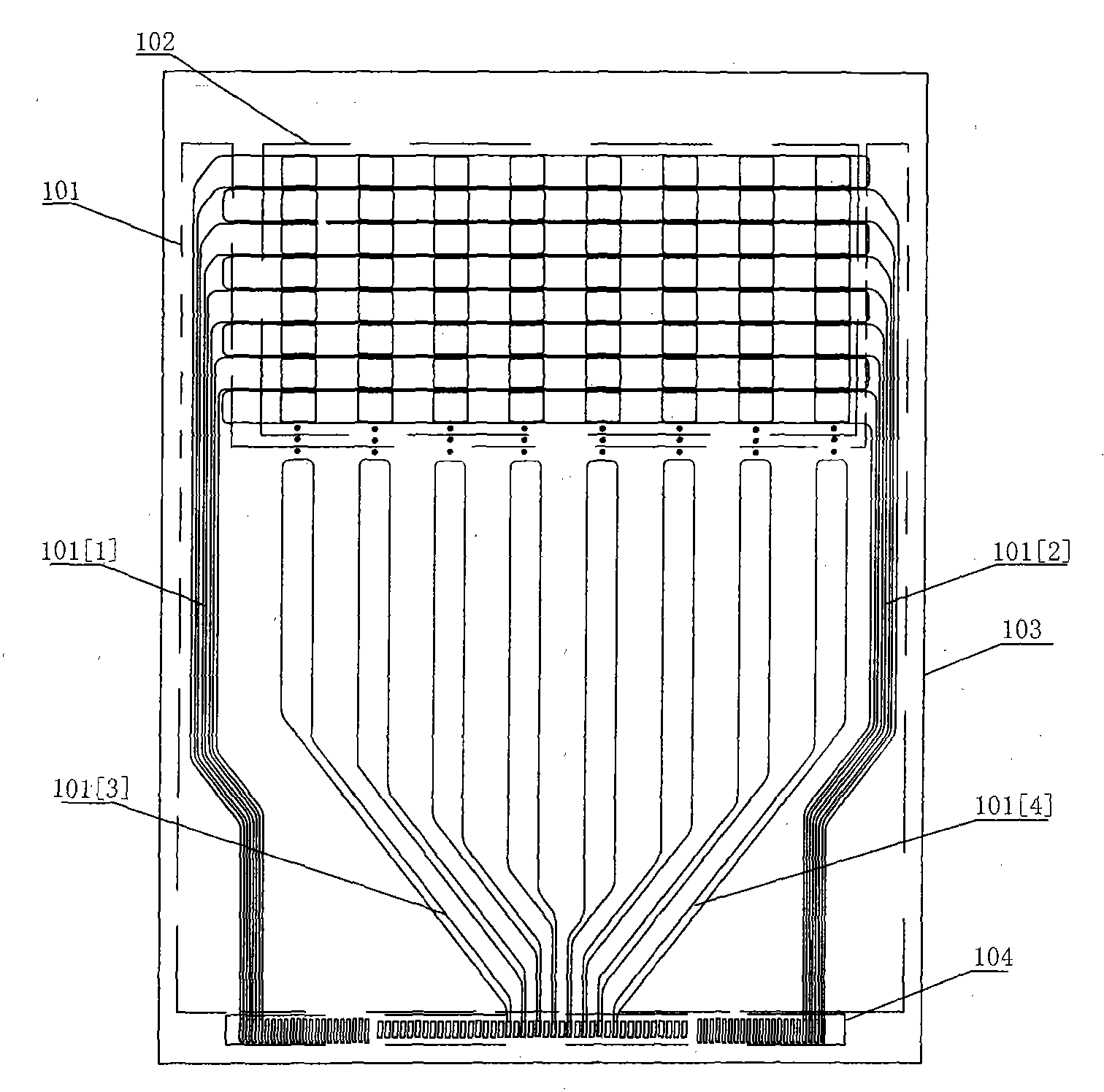

Organic electroluminescence device

ActiveCN101800238BAvoid short circuitIncrease the extension lengthSemiconductor/solid-state device detailsSolid-state devicesTest phaseOrganic electroluminescence

The invention discloses an organic electroluminescence device and a test method thereof. The organic electroluminescence device comprises a luminescent area, a lead wire area and a bonding area. The luminescent area comprises an anode, a organic functional layer and a cathode; the lead wire area consists of a lead wire connecting the anode and the cathode with a driving chip or a circuit board; the bonding area is an area in which the lead wire is connected with the driving chip or the circuit board, wherein a lead wire elongation area is comprised, the end of the lead wire is located in the lead wire elongation area, and the lead wire in the lead wire elongation area and the lead wire in the lead wire area are in parallel or form a certain angel. The invention changes the lead wire arrangement of the OLED. Therefore the conductive adhesive tape can be more easily and accurately in compression connection with the lead wire, and simultaneously prevent the procession lead wire from short circuit during the test phase of the screen body.

Owner:SUZHOU QUINGYUE OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com