Error-proof tooling for bearing pressure welding

A bearing and tooling technology, applied in the field of bearing crimping and error-proof tooling, can solve problems such as affecting work efficiency, over-tightening and over-loosening, and reverse installation of bearings, so as to reduce waste of rework, ensure product quality, and reduce defective rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

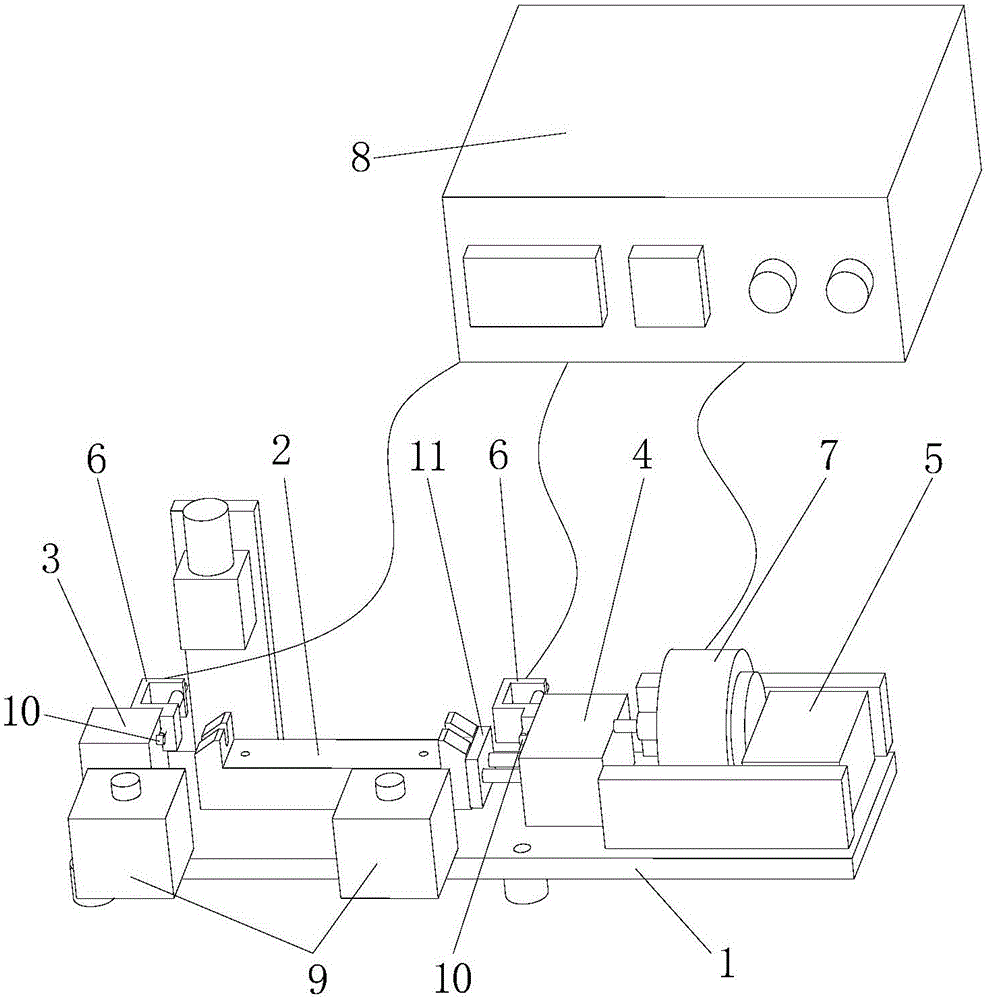

[0013] Such as figure 1 The shown one kind of bearing crimping error-proof tooling is installed on the tooling base plate 1, and is used for the crimping installation of the long shaft and the bearings at both ends of the long shaft, including the product positioning base 2 for fixing the long shaft, which are respectively located on the long shaft The first bearing locating block 3 and the second bearing locating block 4 on the outside of both ends are used for positioning the bearing, the first bearing locating block 3 is fixedly connected to the tooling base plate 1, and the second bearing locating block 4 is slidably connected to the tooling base plate 1 On the bottom plate 1 of the tooling, there is a cylinder 5 that pushes the second bearing position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com