Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Material is delayed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

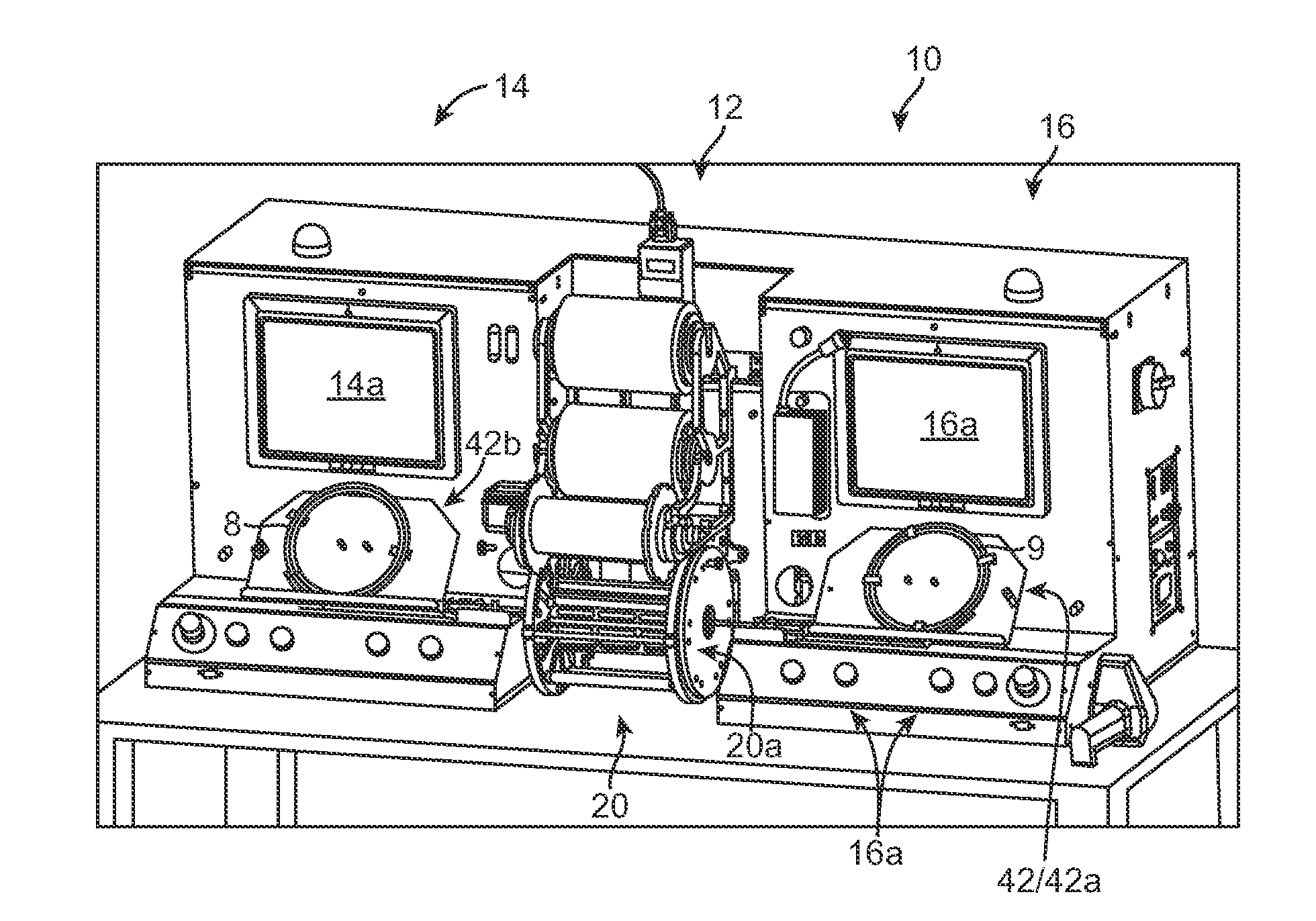

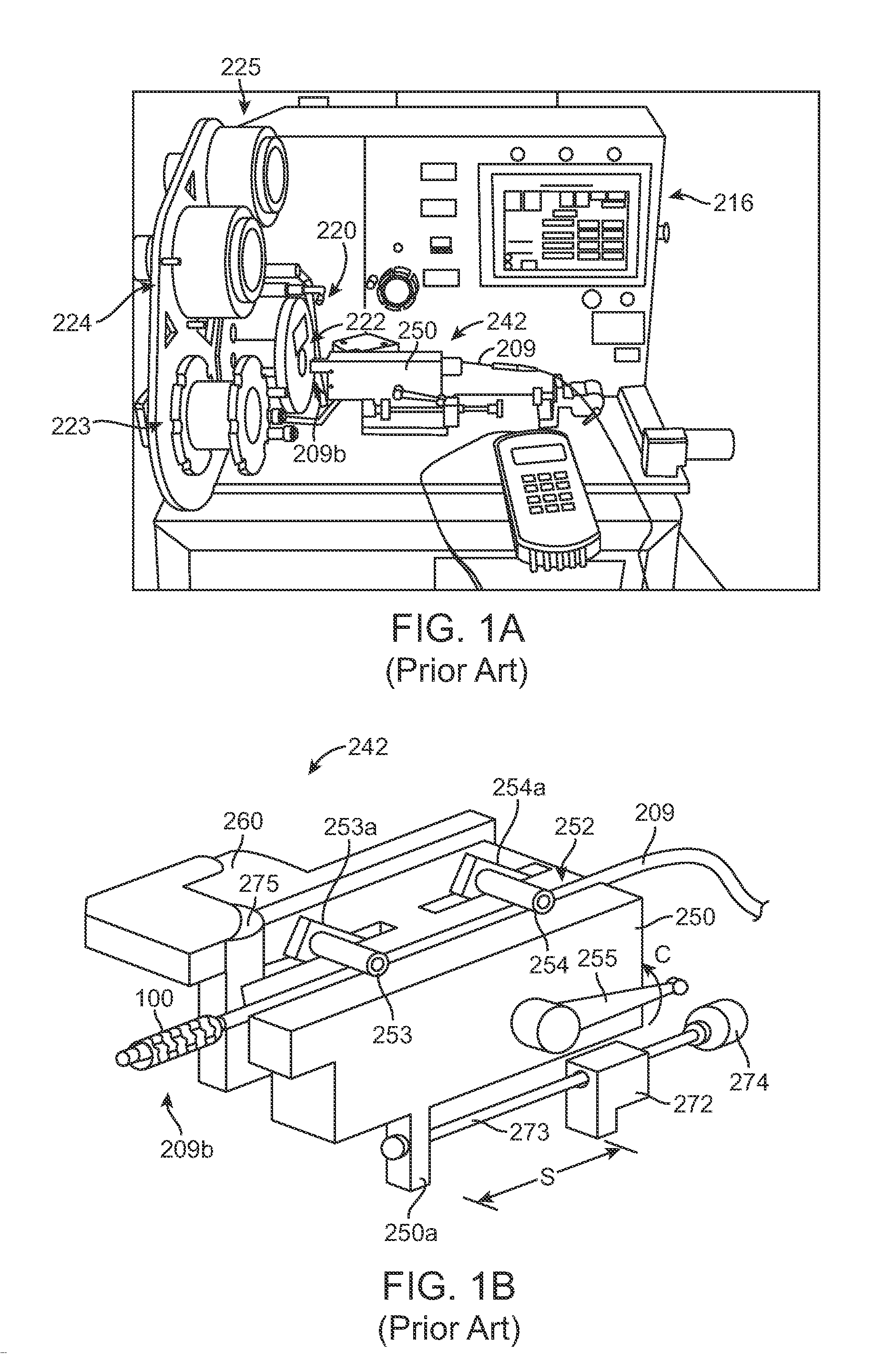

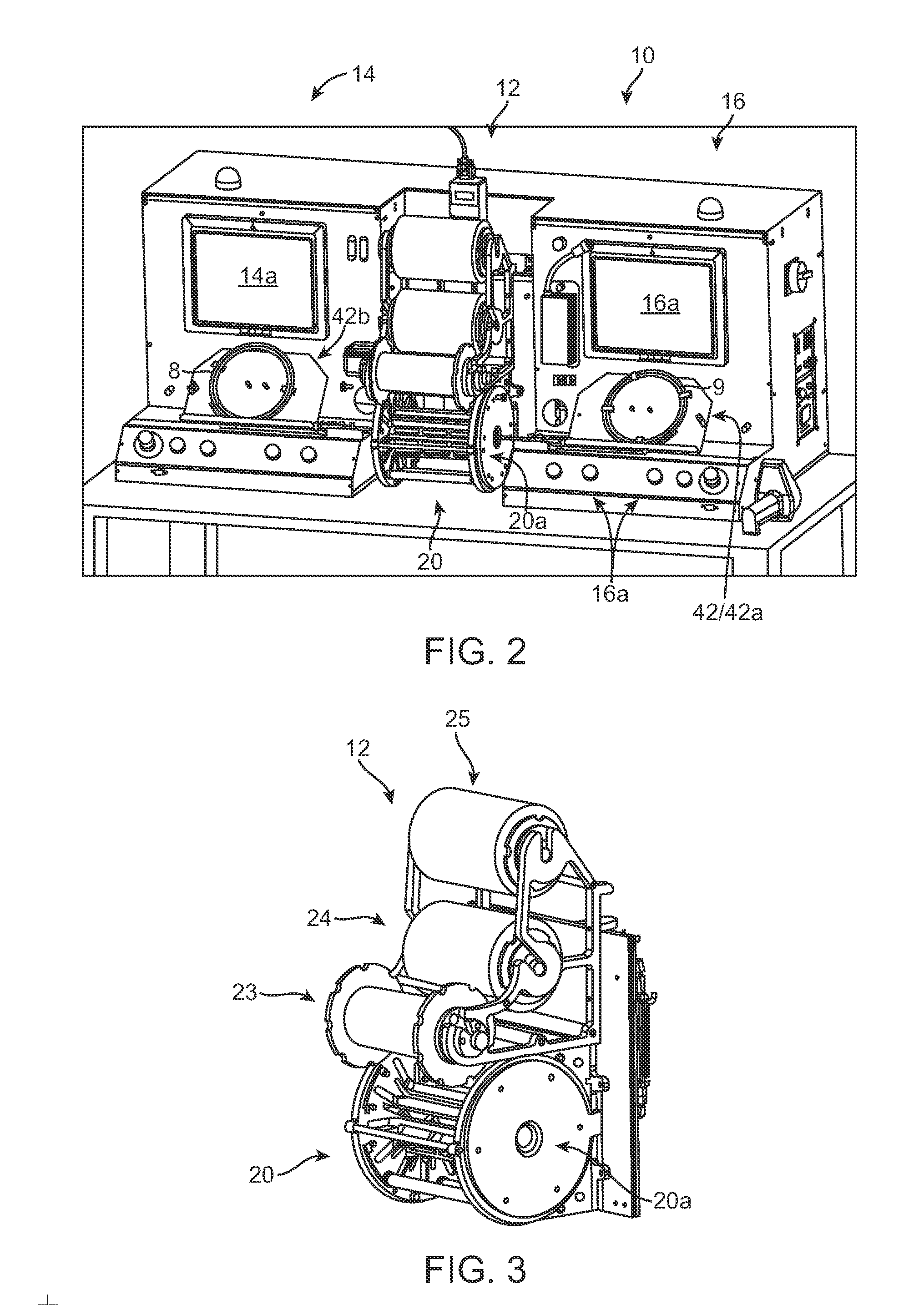

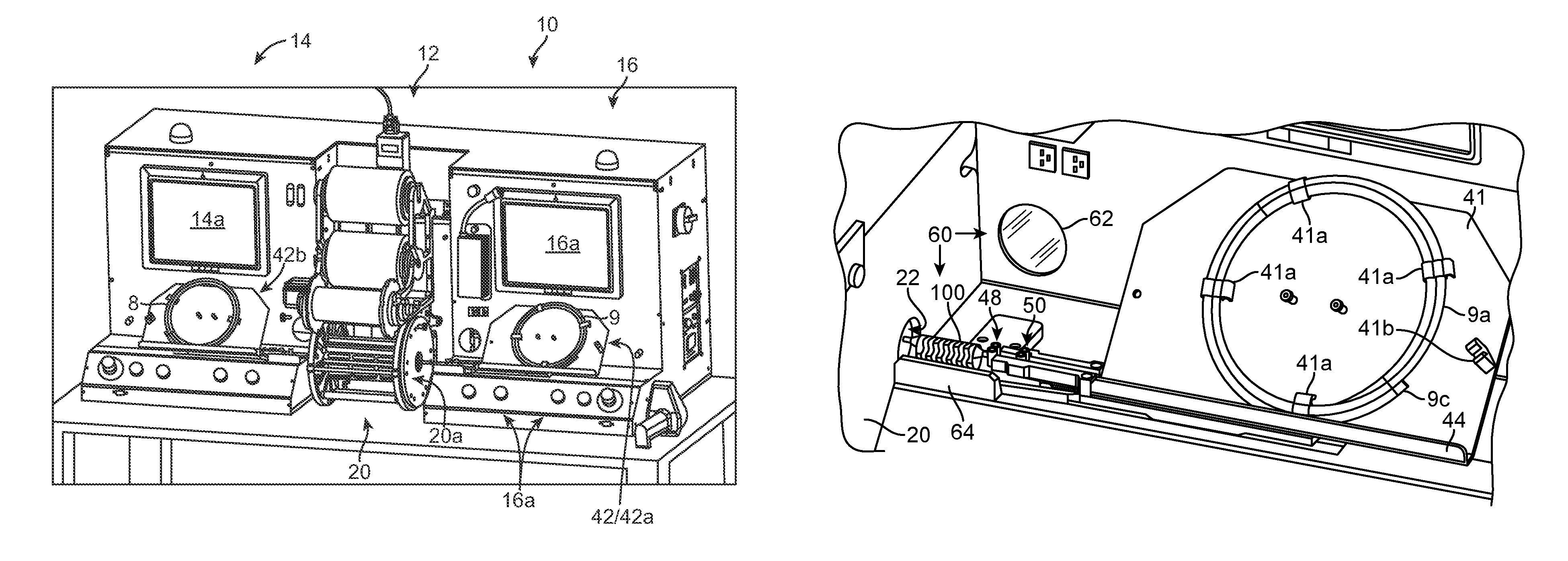

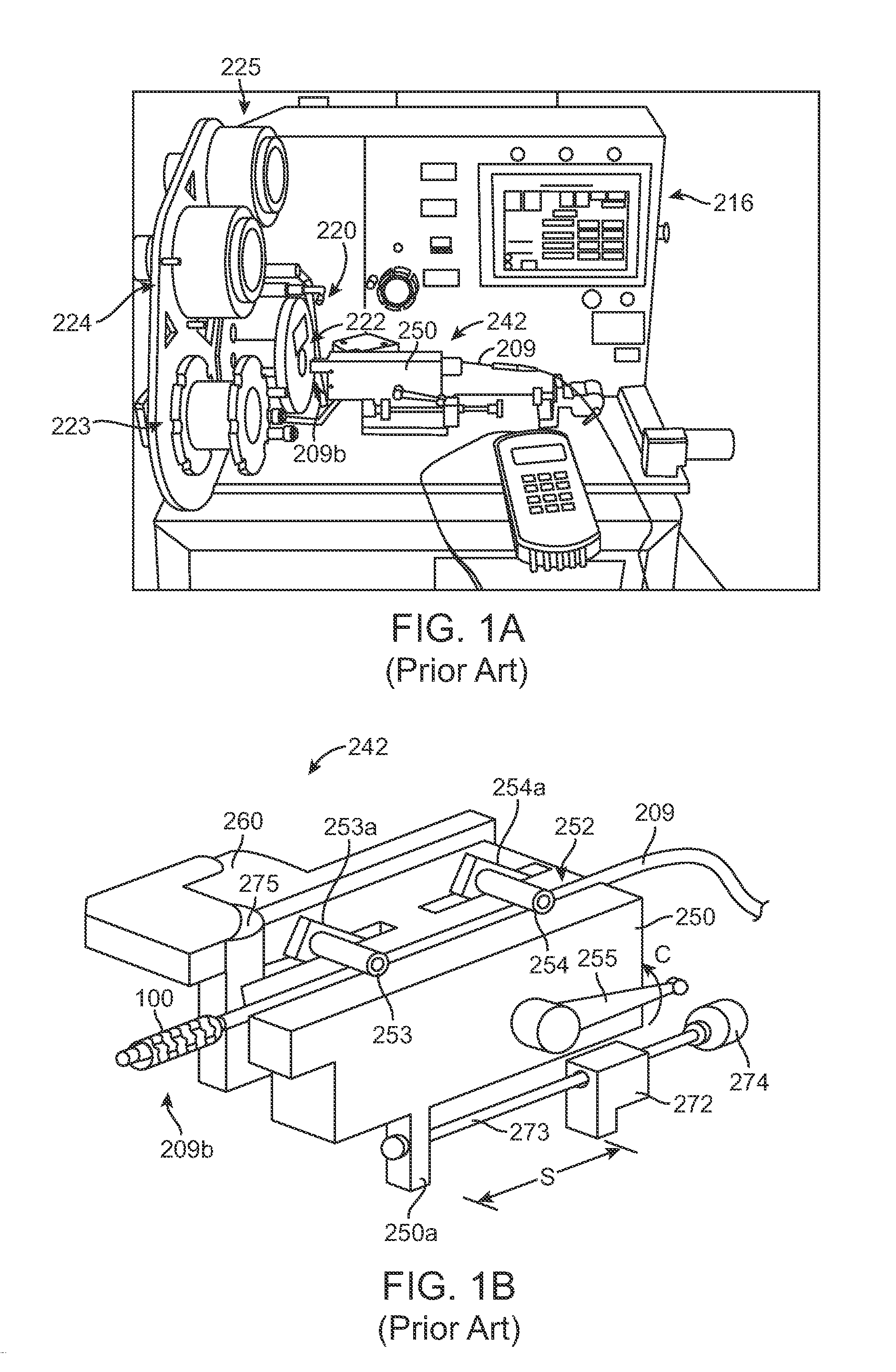

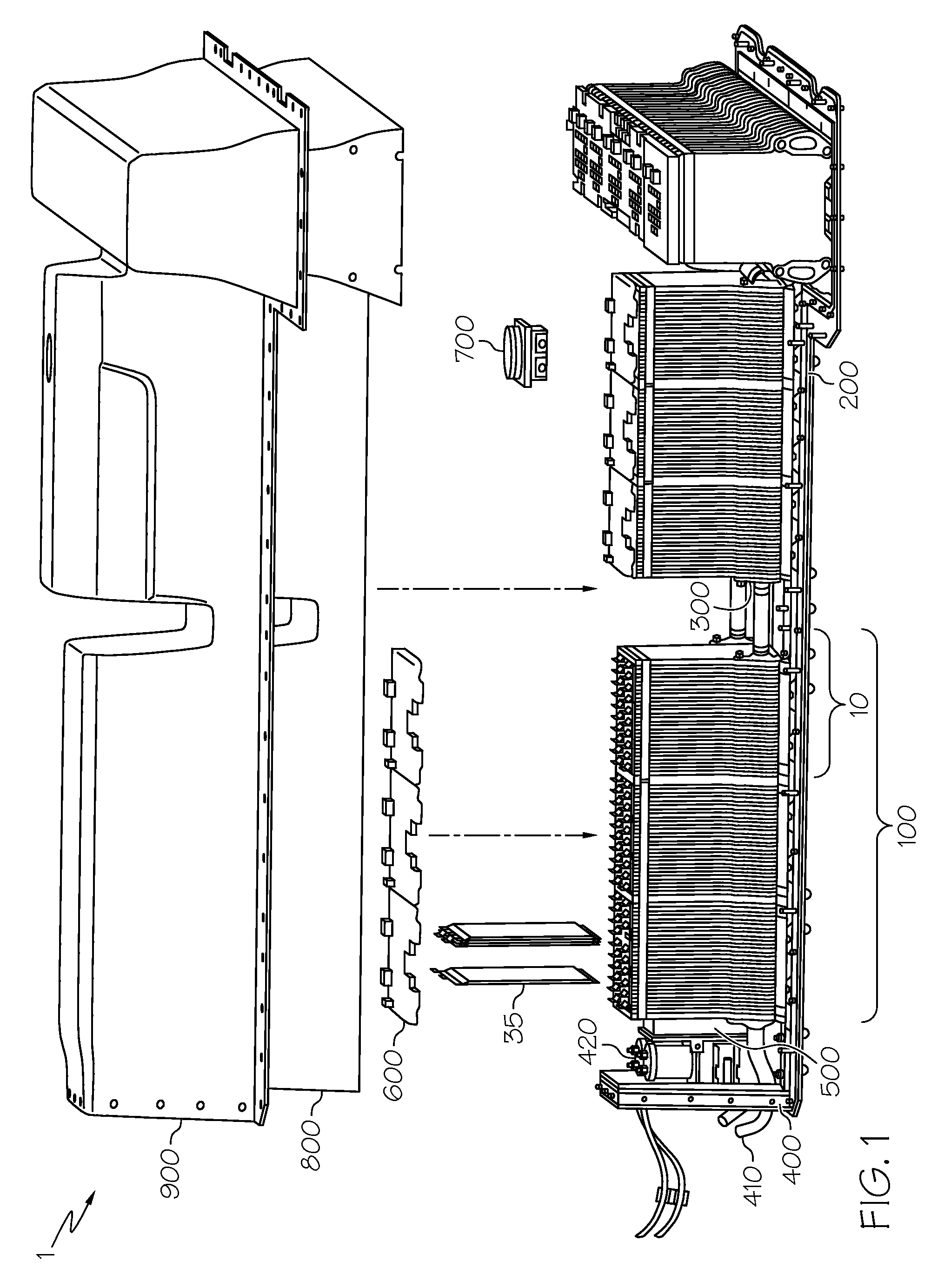

Mounting Stents On Stent Delivery Systems

InactiveUS20120010693A1Labor moreIncrease productionStentsBlood vesselsInsertion stentBalloon catheter

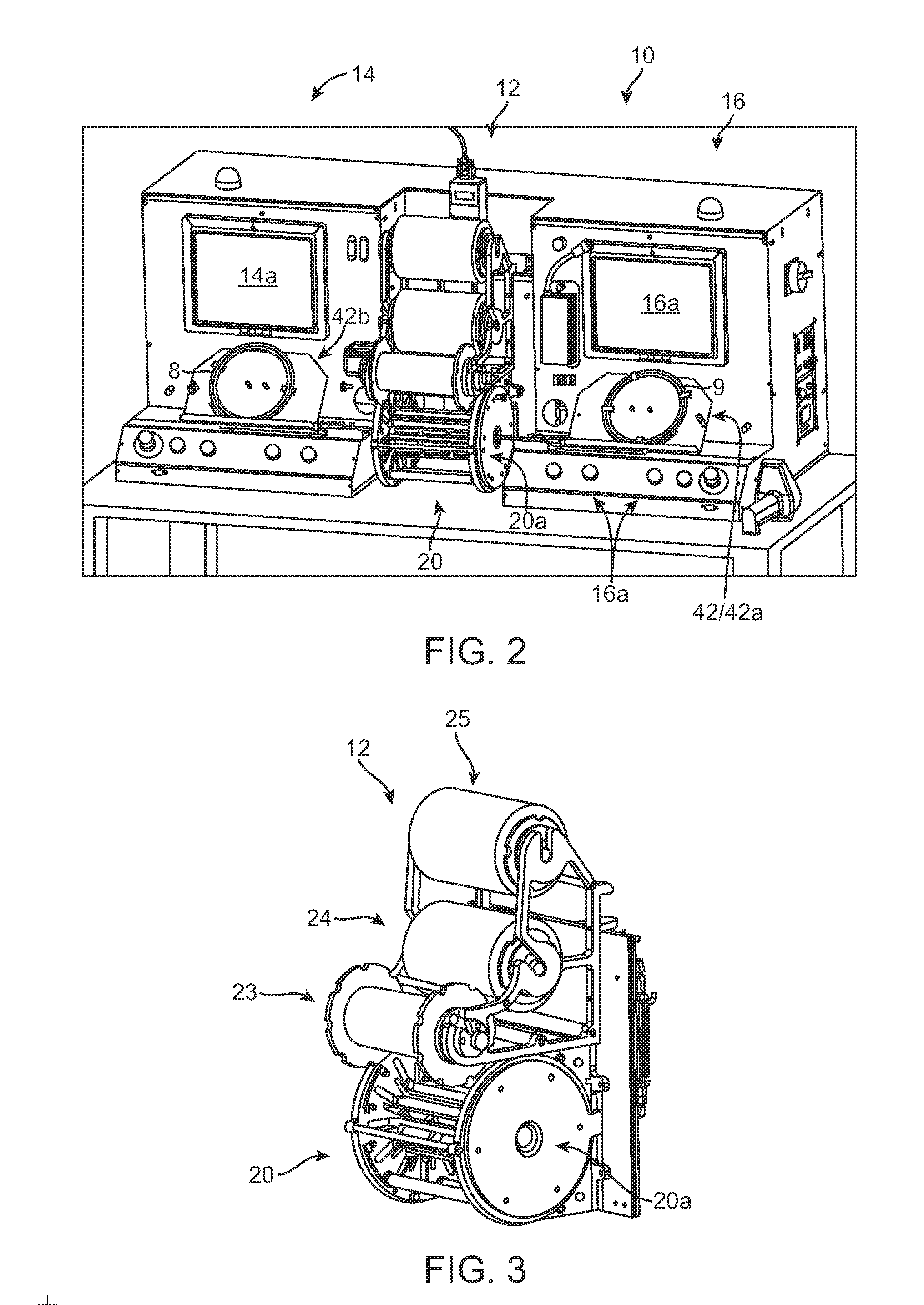

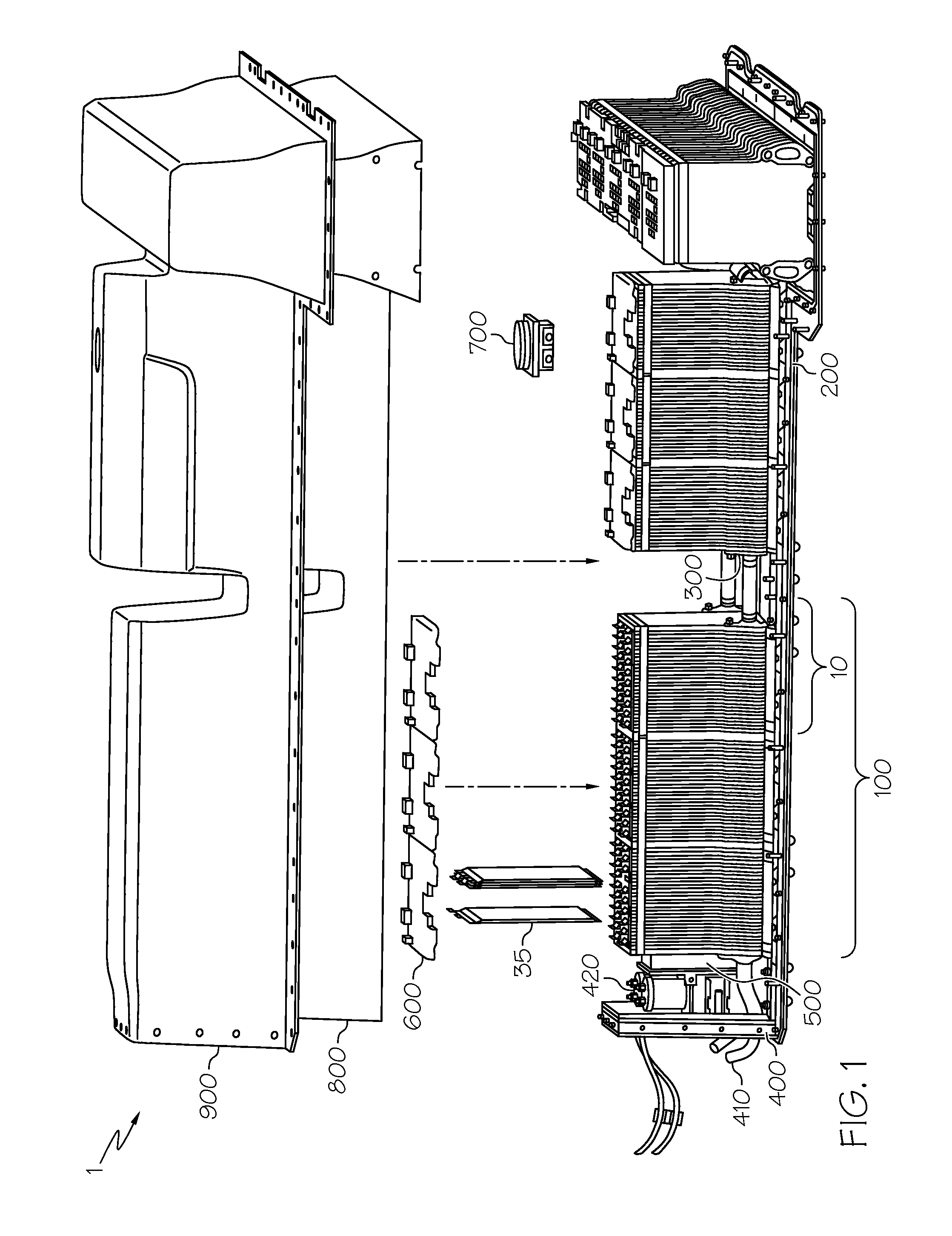

A system for mounting a stent on a balloon catheter includes two positioning and alignment stations, which are used to prepare a stent and catheter for crimping using the same crimping head. The system is configured for automated assembly of the stent and catheter prior to crimping. A catheter and stent are placed on a computer-controlled carriage that delivers the stent and catheter to the crimper head. Before placing the stent and catheter into the crimper head, an automated alignment system locates the stent between balloon markers.

Owner:ABBOTT CARDIOVASCULAR

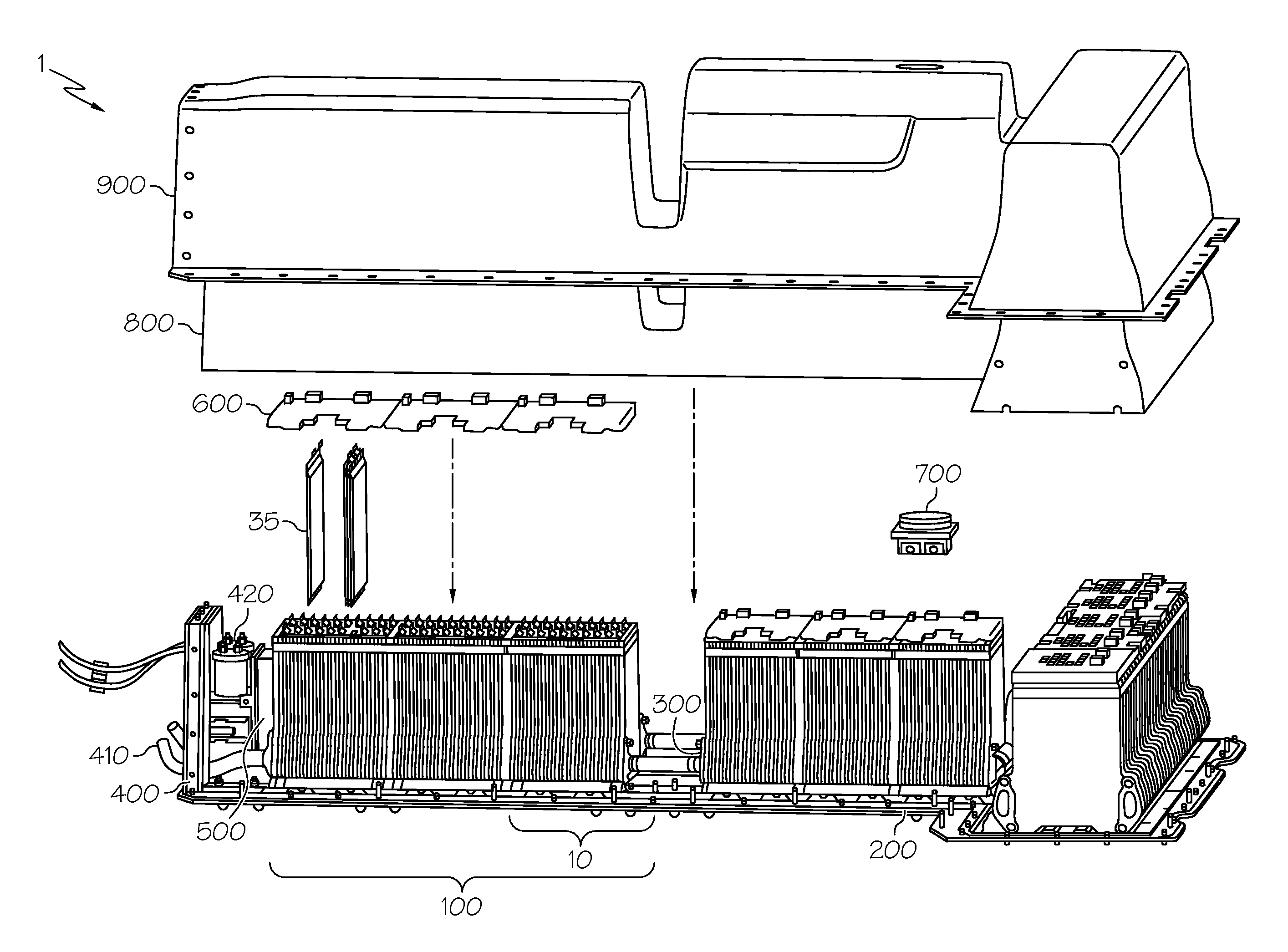

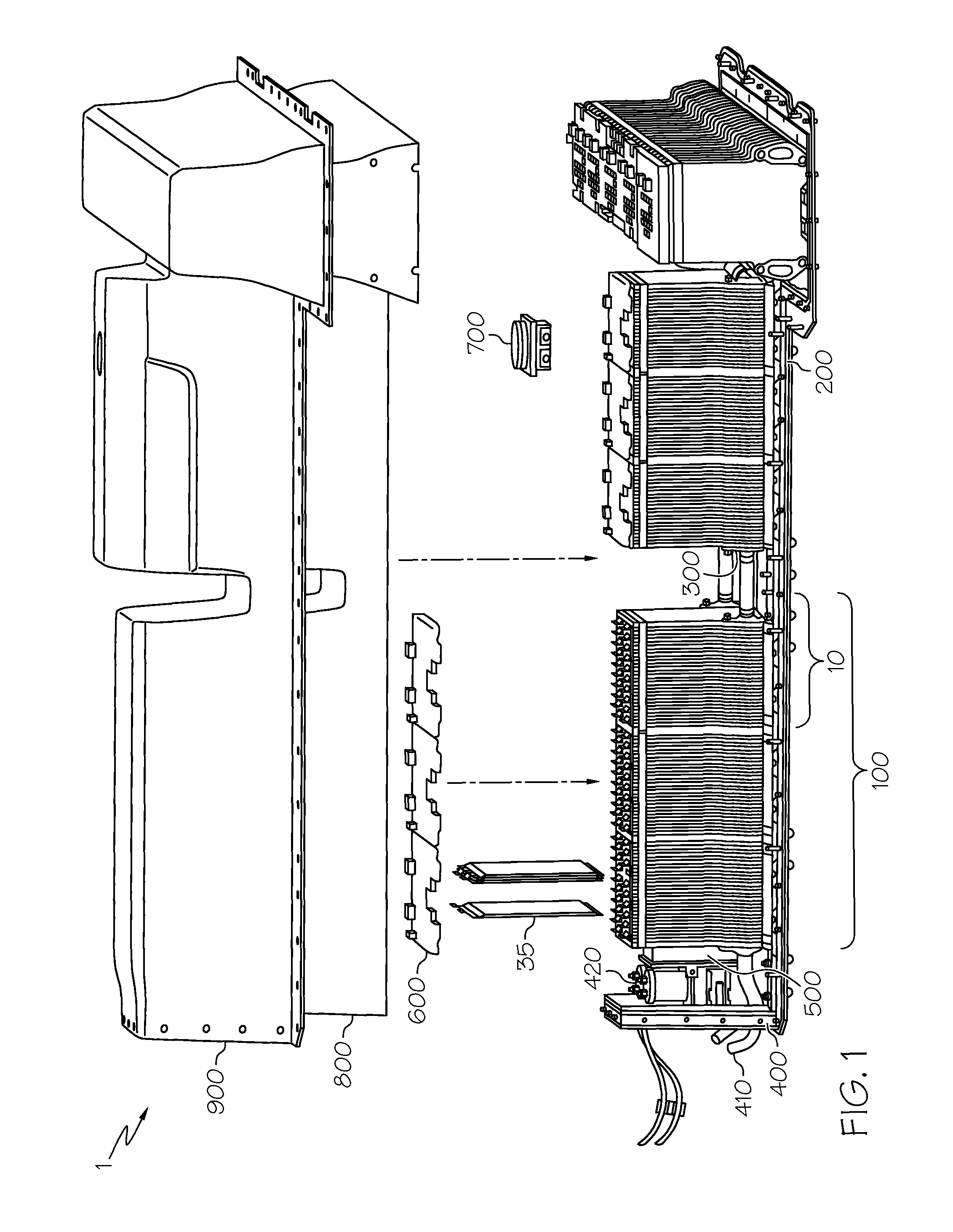

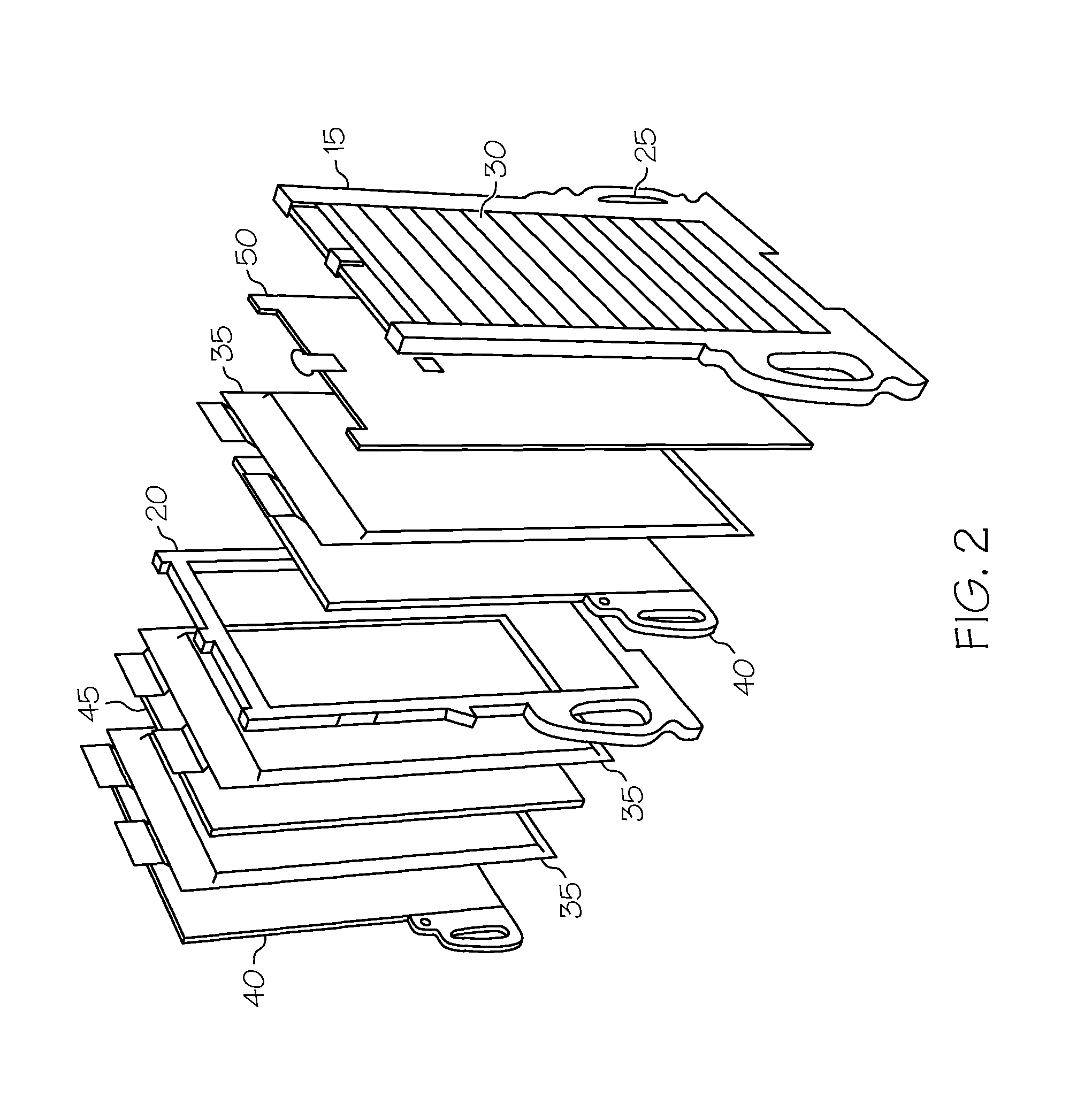

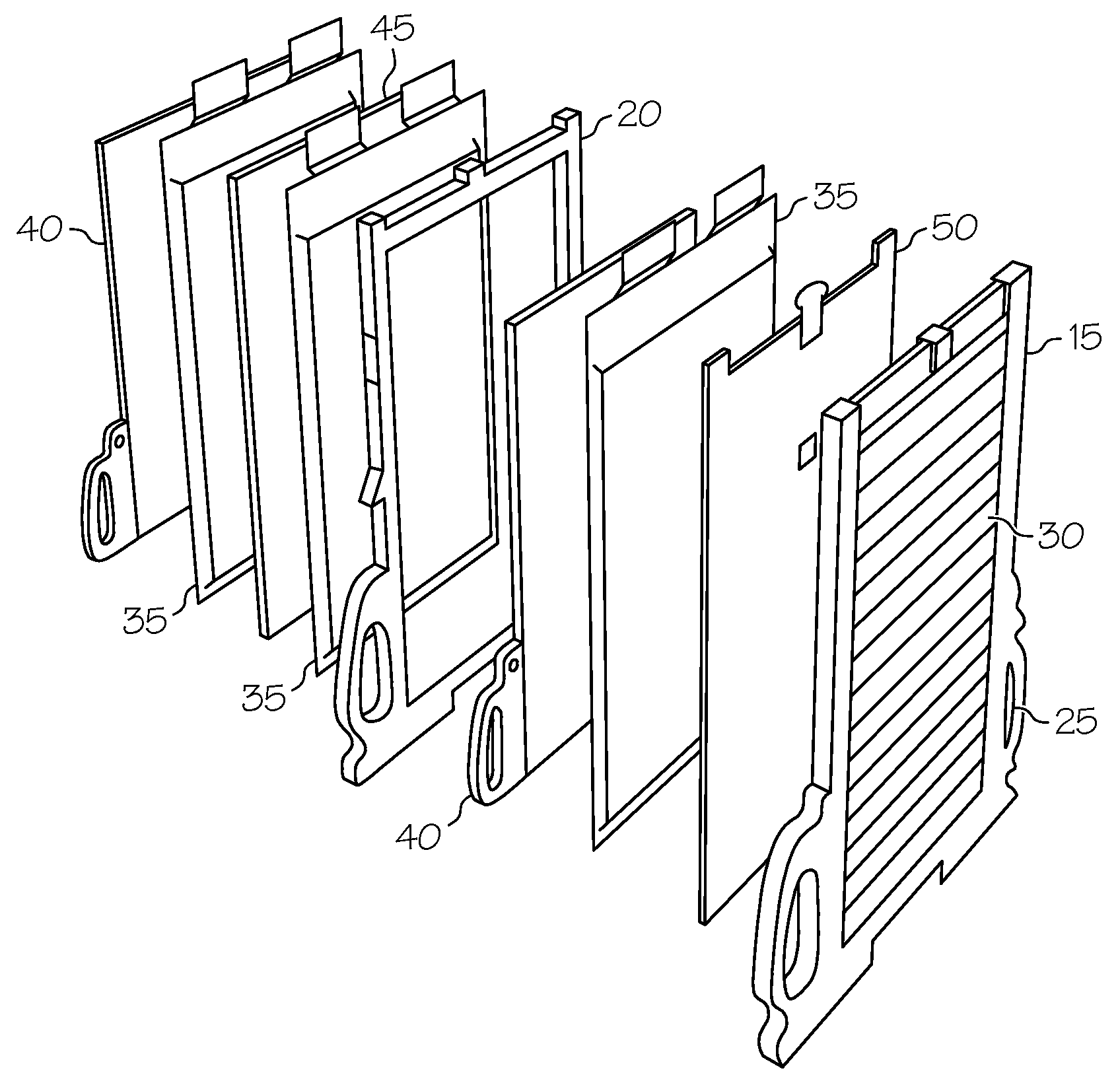

Battery thermal interfaces with microencapsulated phase change materials for enhanced heat exchange properties

InactiveUS20120258337A1Improve temperature uniformityReduce heatElectric devicesCell temperature controlEngineeringThermal management system

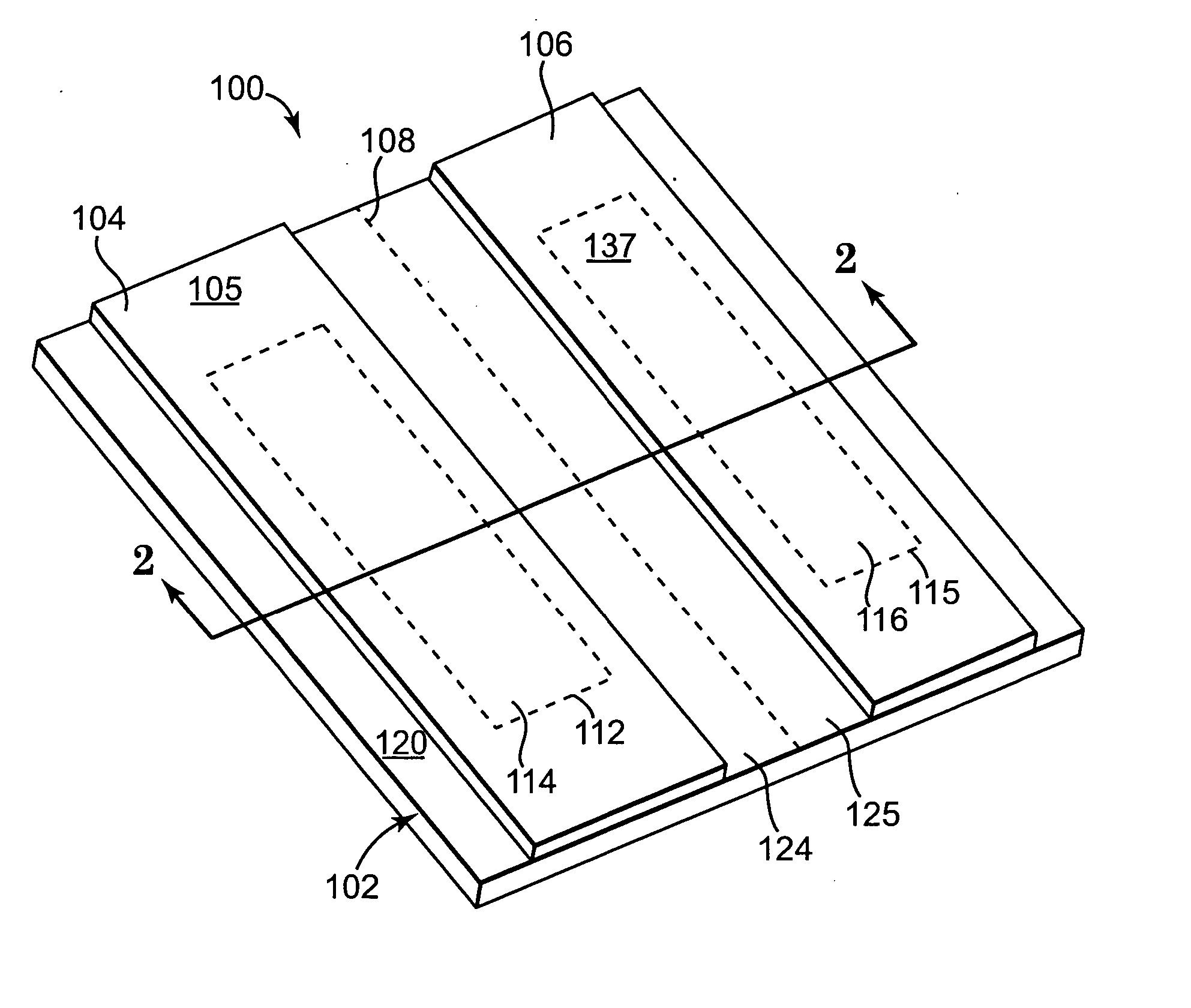

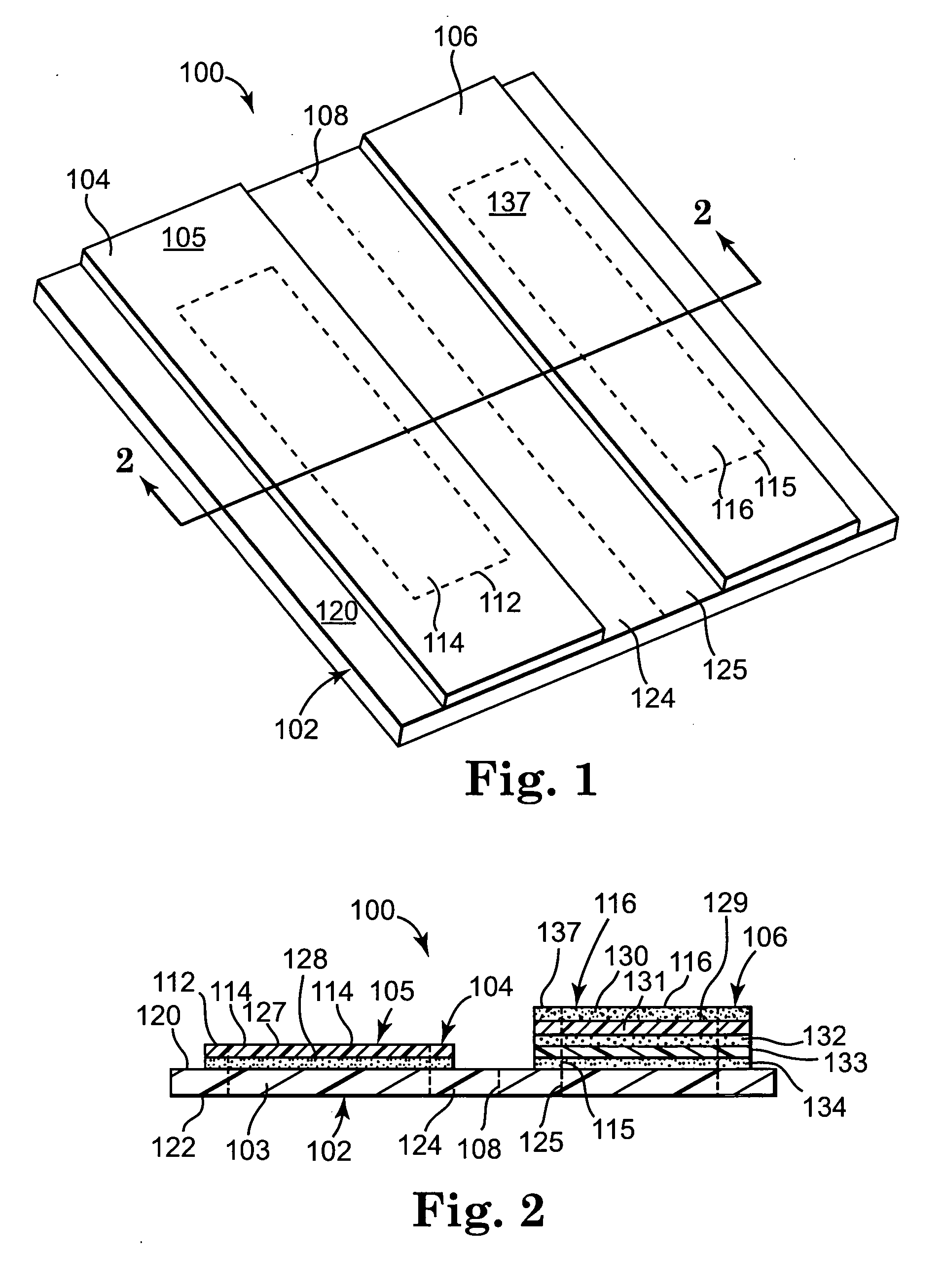

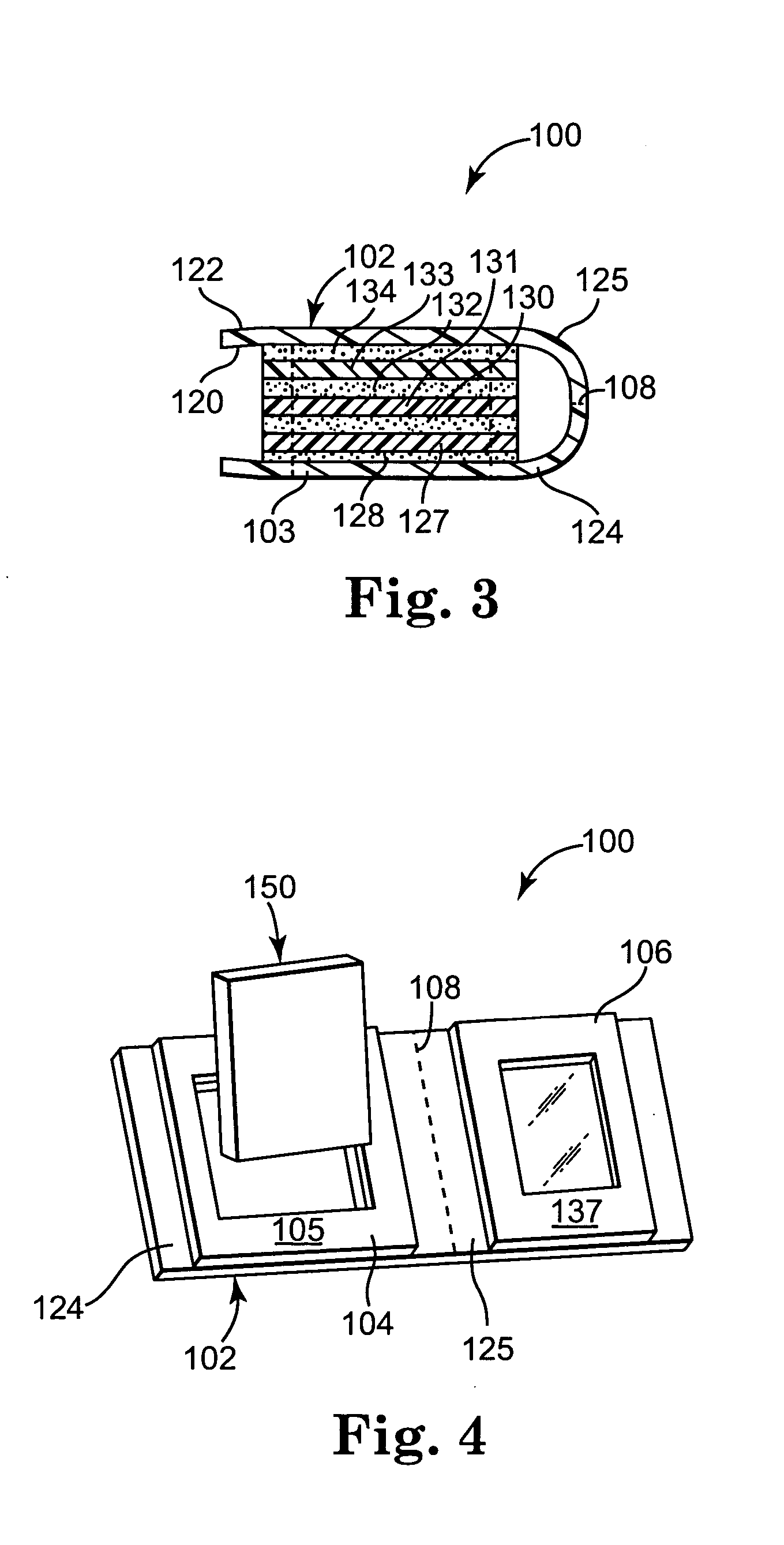

A battery module with microencapsulated phase change materials as an automotive thermal management system. In one form, the microencapsulated phase change material is in the form of a foam made of a core encased in a generally polymer-based shell. In a more particular form, the foamed material may be tailored to go through isothermal phase change at more than one temperature, such as a relatively cold temperature and a relatively high temperature. A thermal management system based on the use of such microencapsulated phase change material includes heating and cooling capabilities for conditions expected to be encountered under both high-temperature and low-temperature vehicular operating conditions. Methods of controlling the temperature in battery modules are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

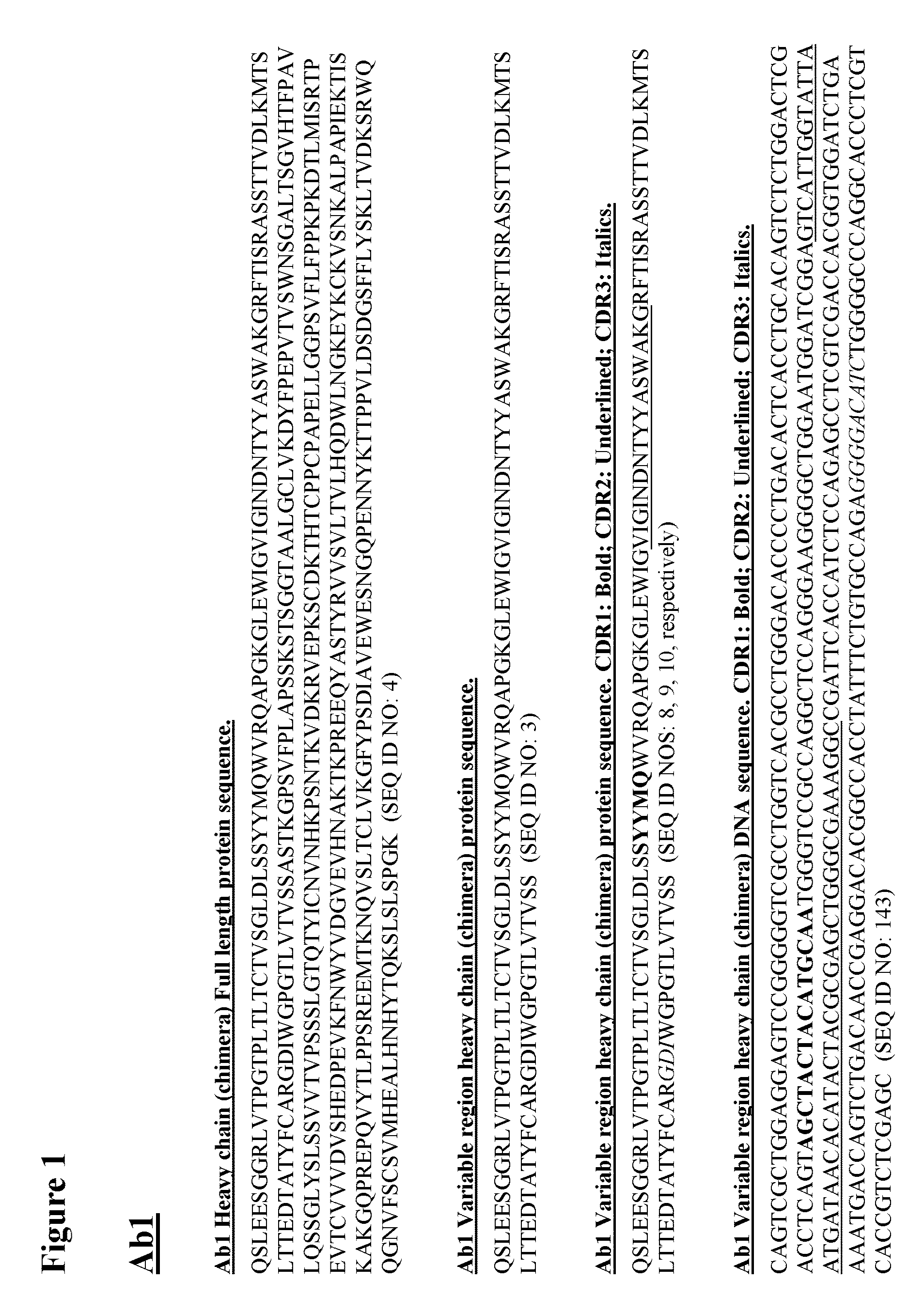

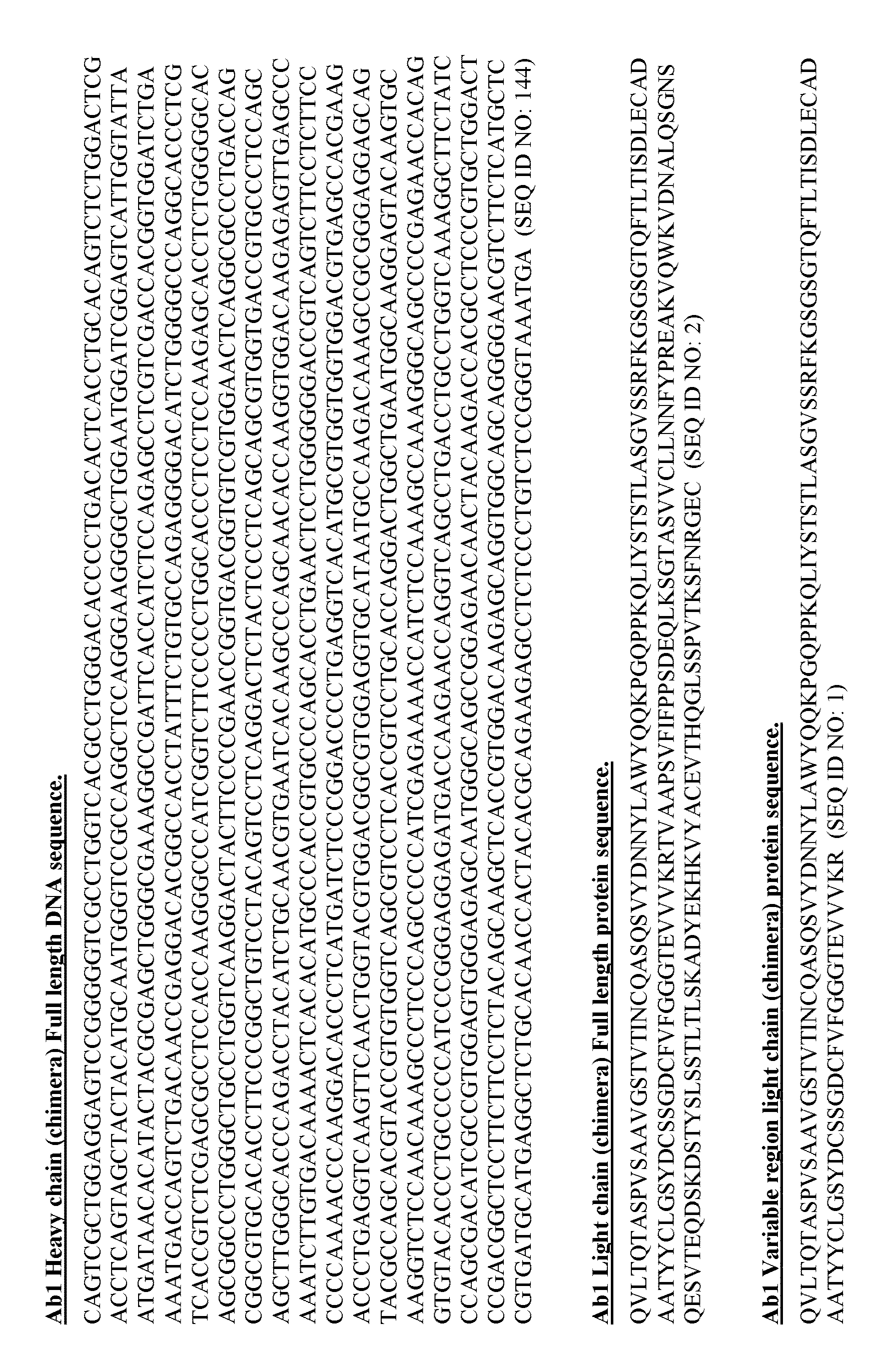

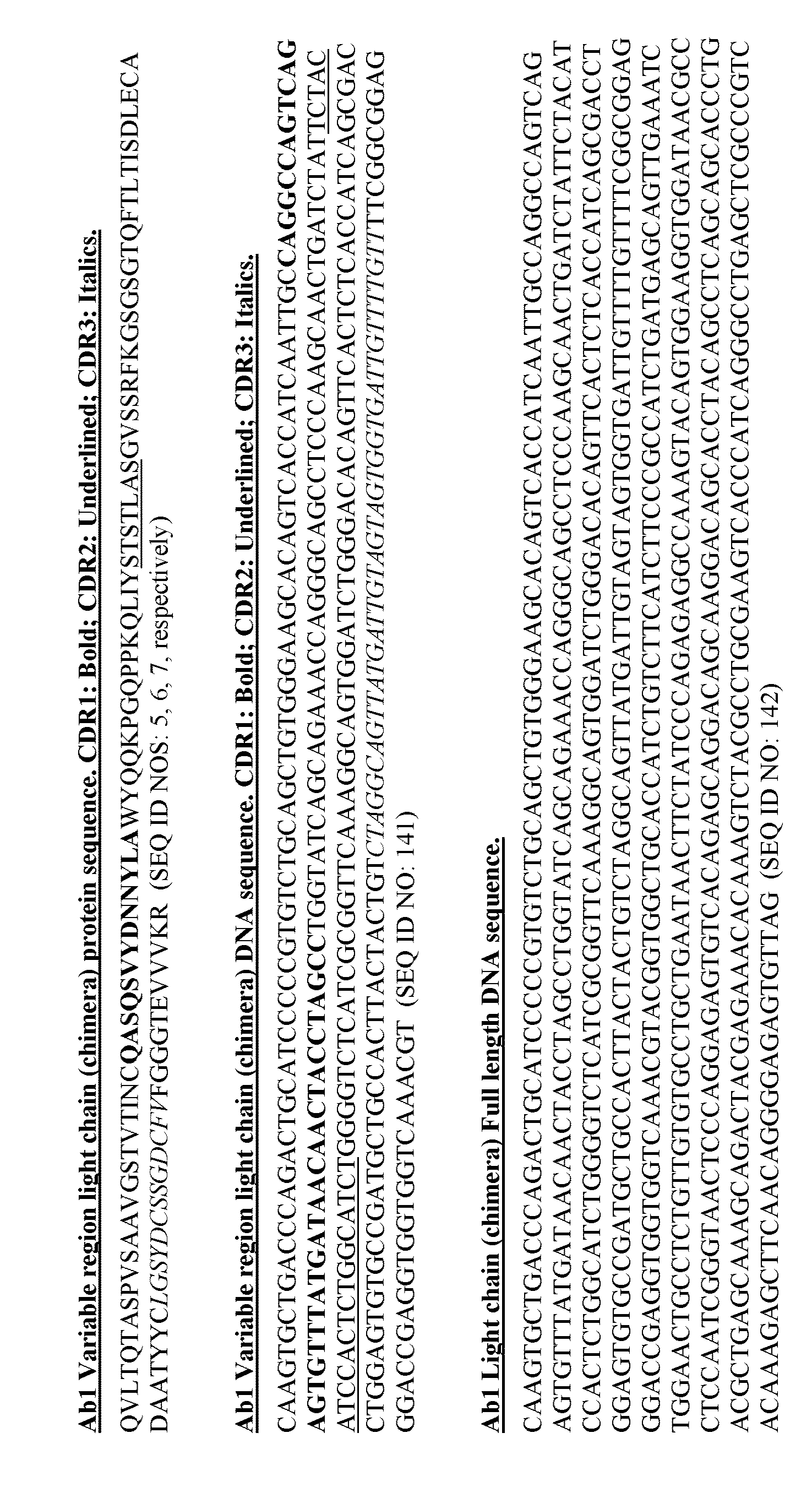

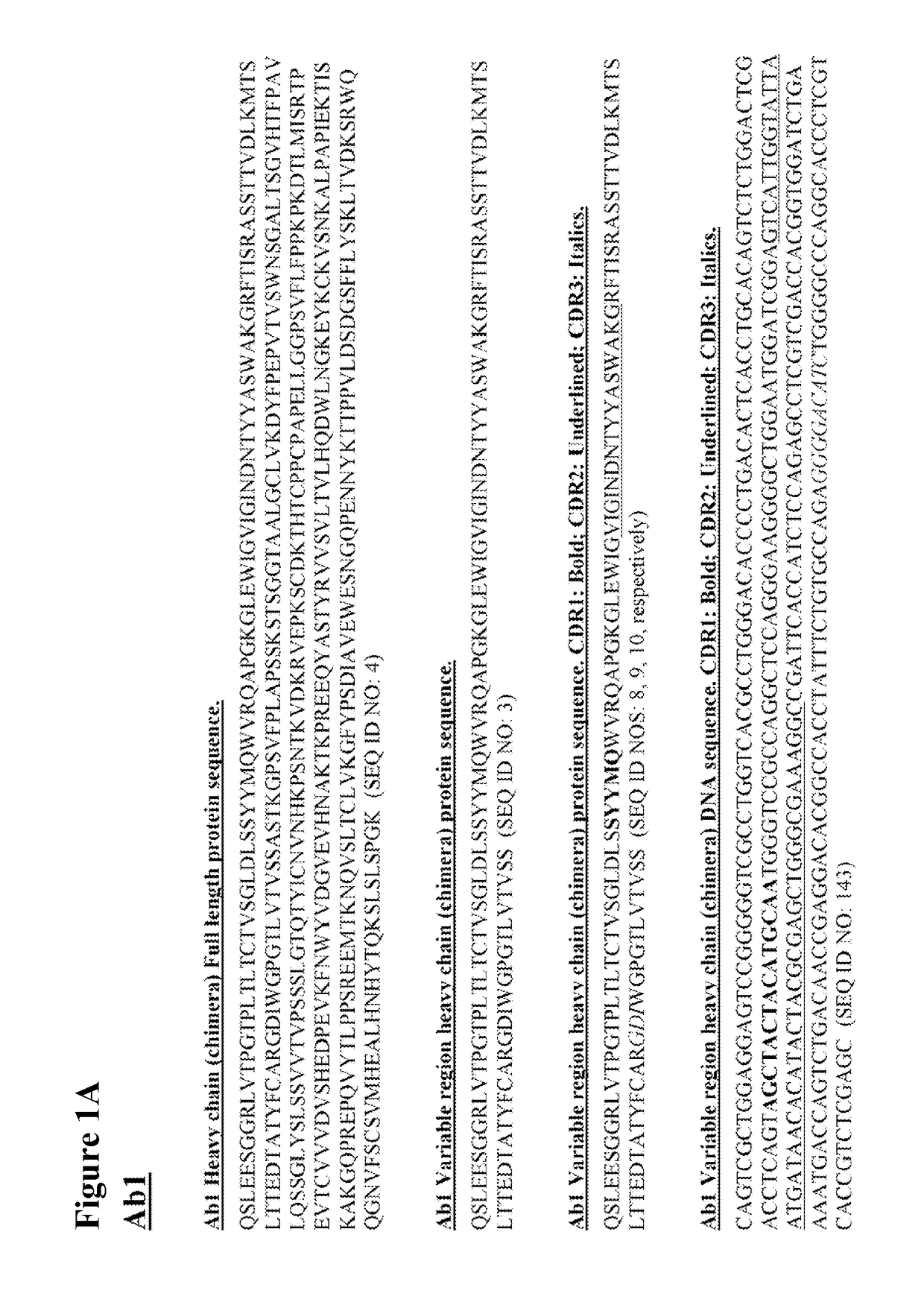

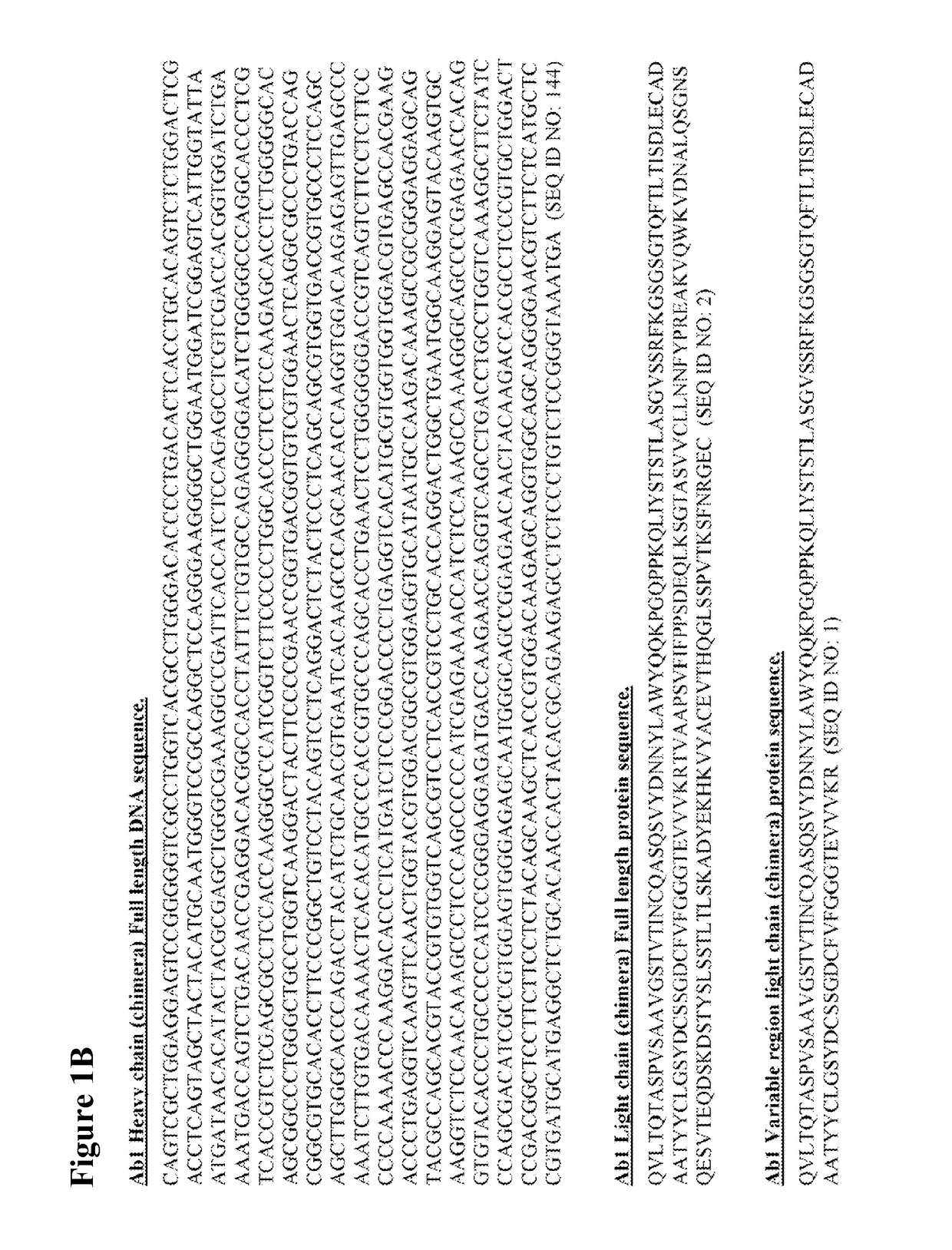

Use of Anti-cgrp antibodies and antibody fragments to treat diarrhea in subjects with diseases or treatments that result in elevated cgrp levels

ActiveUS20120294822A1Prevent goodConvenient treatmentAntibacterial agentsPeptide/protein ingredientsDiseaseTreatment results

The present invention is directed to methods for treating diarrhea, both chronic or acute forms, by the administration of a therapeutically or prophylactically effective amount of antibodies and fragments thereof having binding specificity for CGRP. In particular the methods prevent or reduce diarrhea in conditions or treatments resulting in elevated CGRP levels, e.g., in the GI tract (colon) that are associated with diarrhea and / or improper electrolyte and fluid excretion from the bowel or urinary system. More specifically, this invention relates to treatments using the anti-CGRP antibodies and fragments described herein, and binding fragments thereof.

Owner:UNIV OF IOWA RES FOUND +1

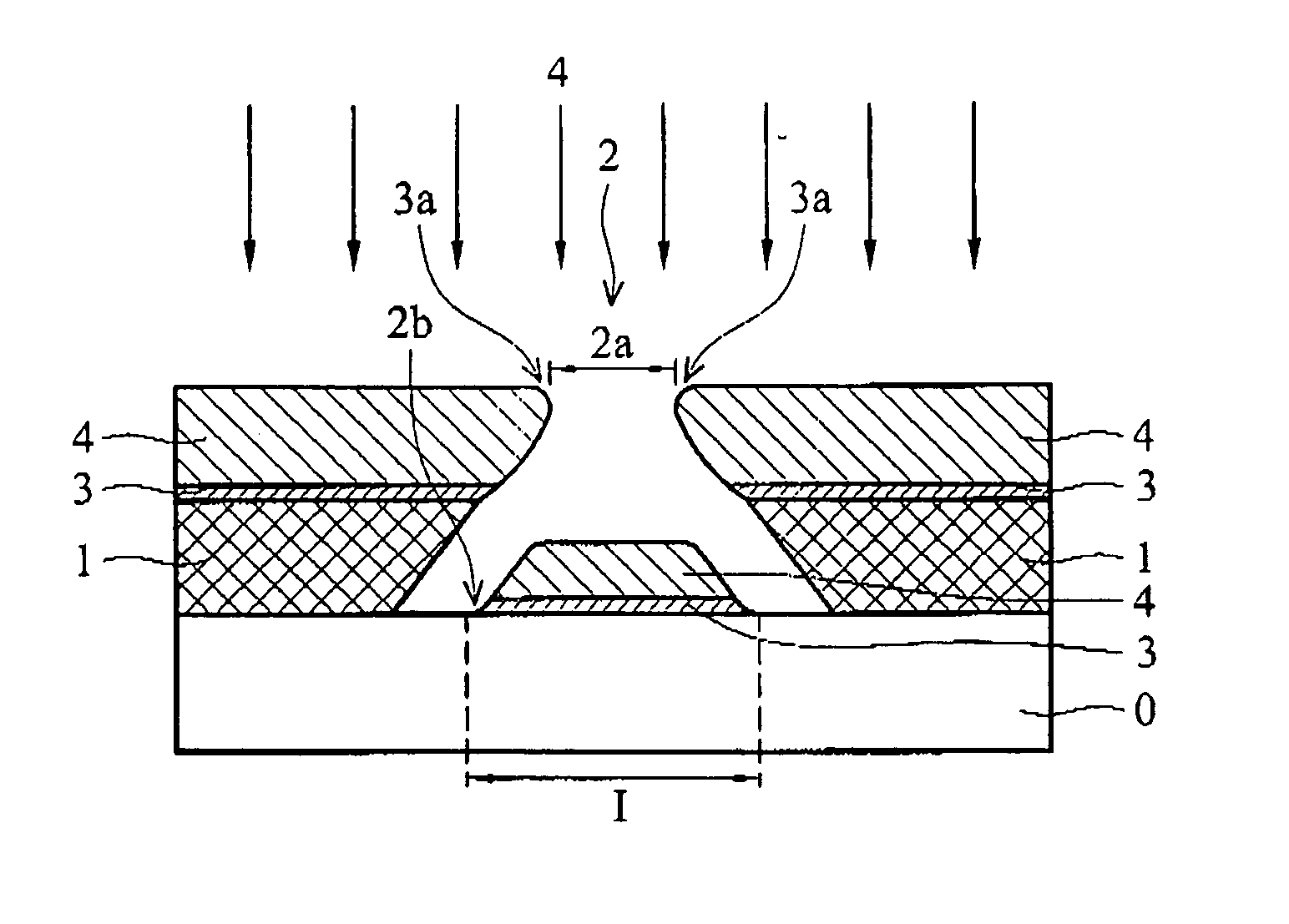

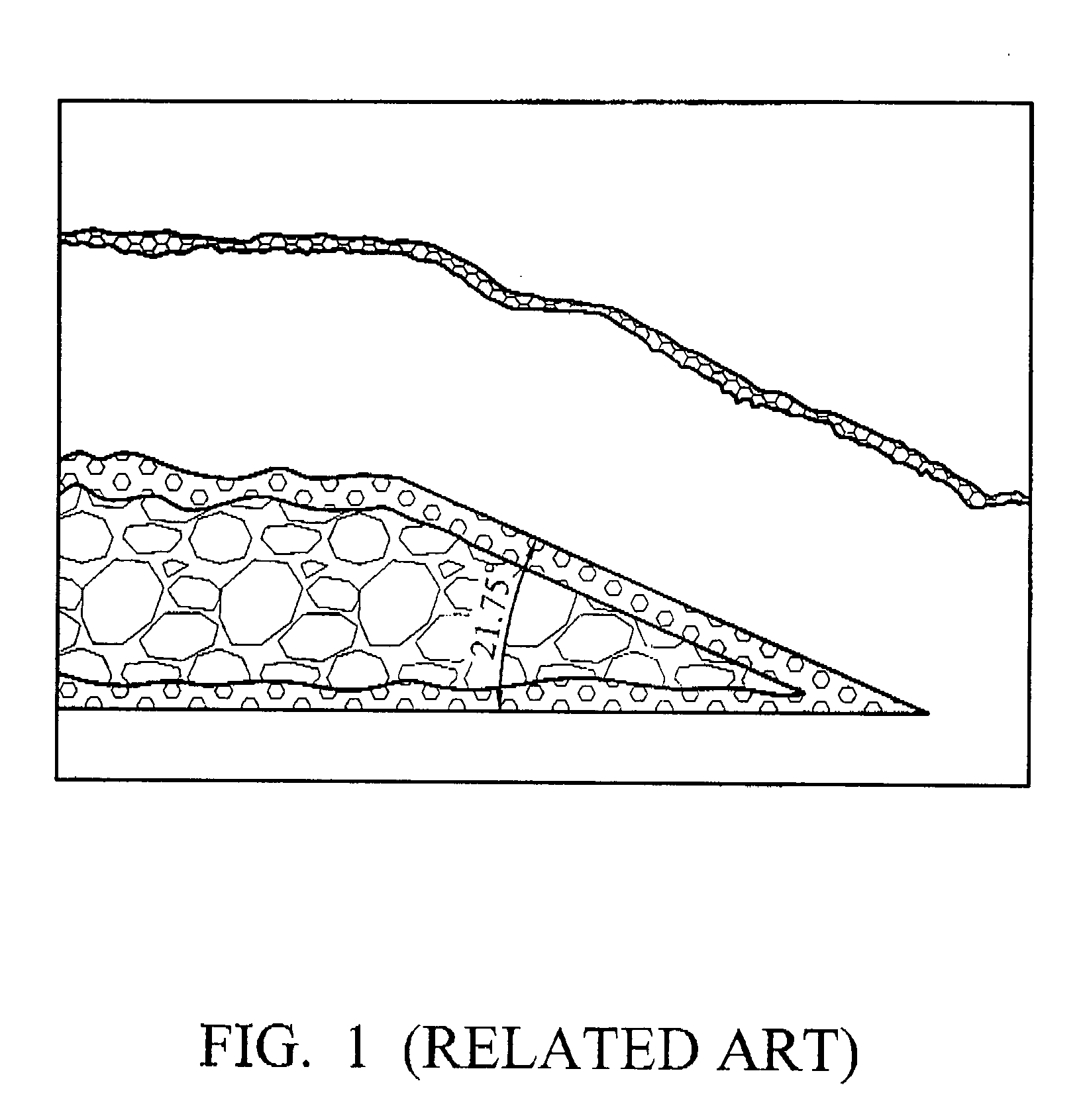

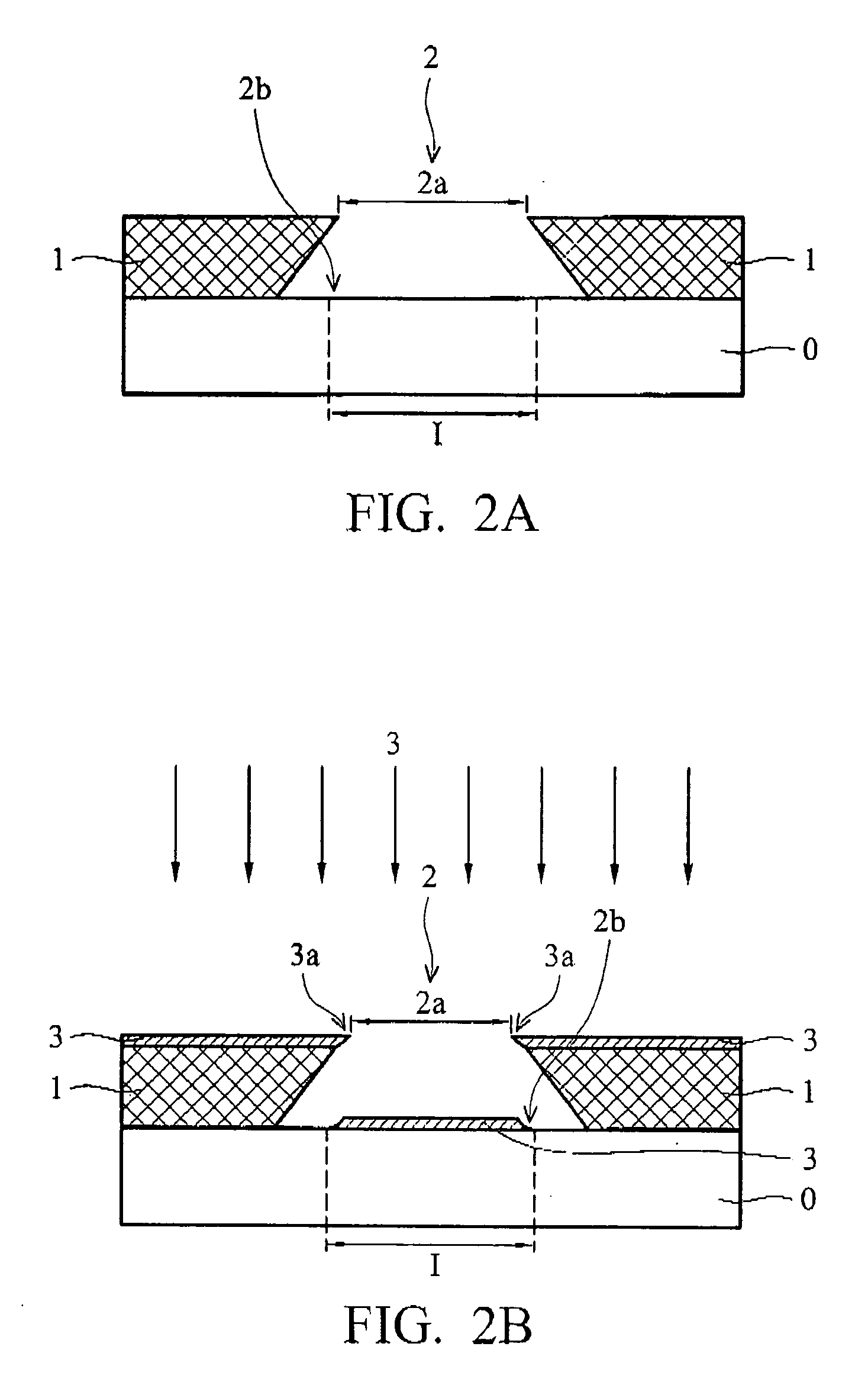

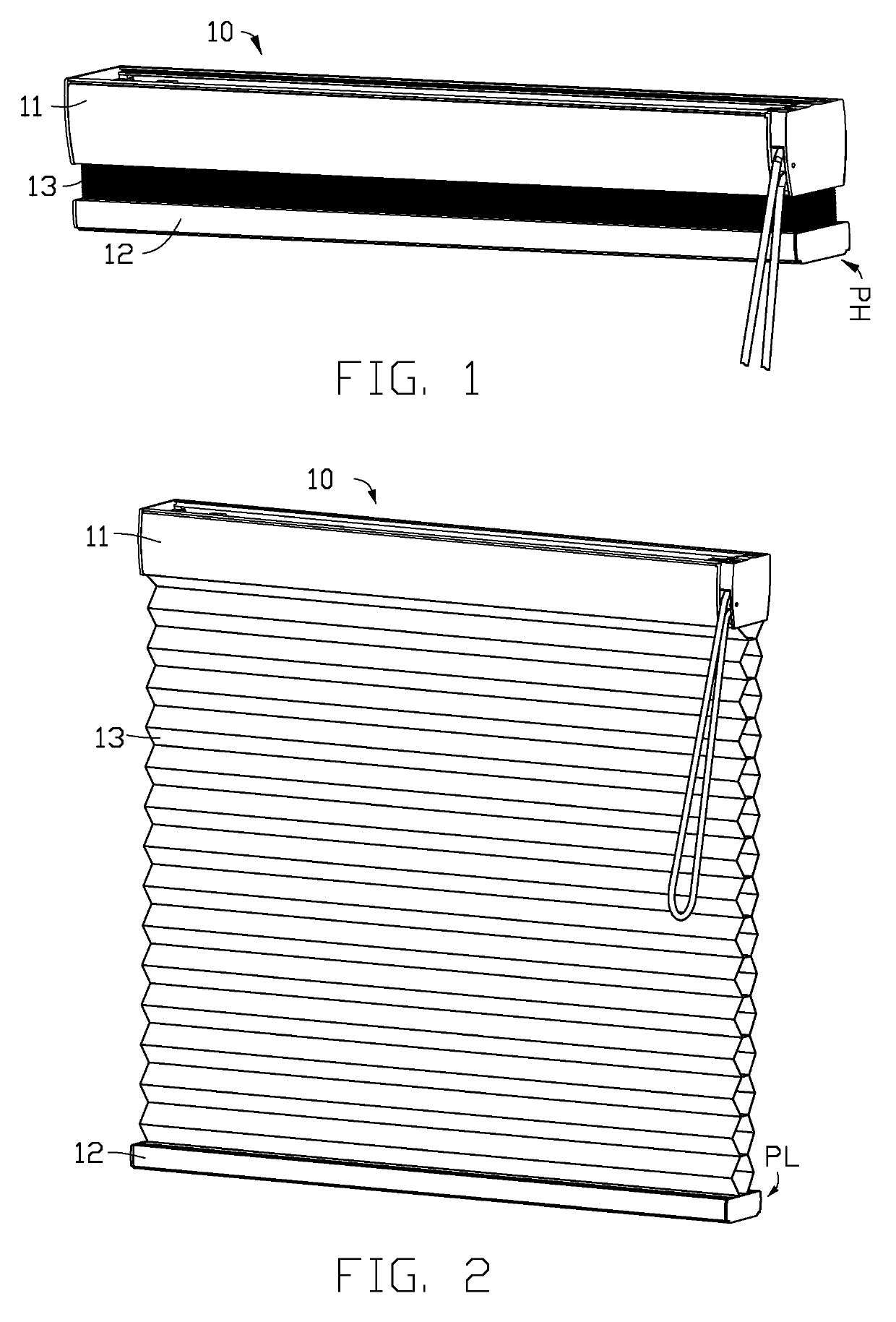

Fabrication method for liquid crystal display

ActiveUS20050158900A1Reducing R/C time delayImprove display qualitySemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

A method of fabricating a liquid crystal display panel is provided, which comprises the steps of providing a substrate; forming a mask layer over the substrate, wherein the mask layer has a reverse-tapered opening exposing a predetermined conductive line area; depositing a metal layer on the substrate within the predetermined conductive line area to form a conductive line with a tapered sidewall by performing an anisotropic deposition process; and removing the mask.

Owner:HANNSTAR DISPLAY CORPORATION

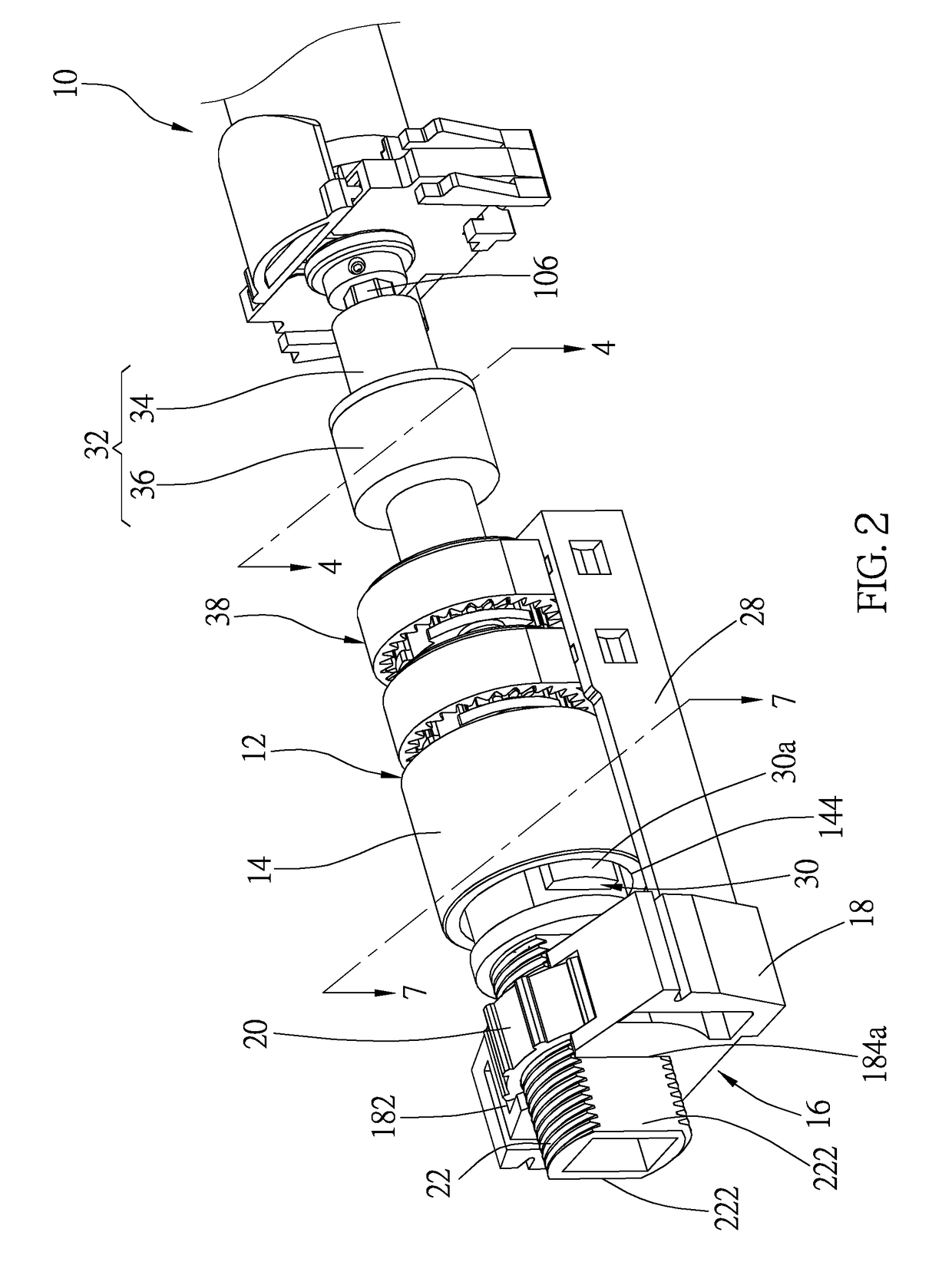

Mounting stents on stent delivery systems

InactiveUS8752261B2Labor moreIncrease productionStentsForging hammersInsertion stentBalloon catheter

A system for mounting a stent on a balloon catheter includes two positioning and alignment stations, which are used to prepare a stent and catheter for crimping using the same crimping head. The system is configured for automated assembly of the stent and catheter prior to crimping. A catheter and stent are placed on a computer-controlled carriage that delivers the stent and catheter to the crimper head. Before placing the stent and catheter into the crimper head, an automated alignment system locates the stent between balloon markers.

Owner:ABBOTT CARDIOVASCULAR

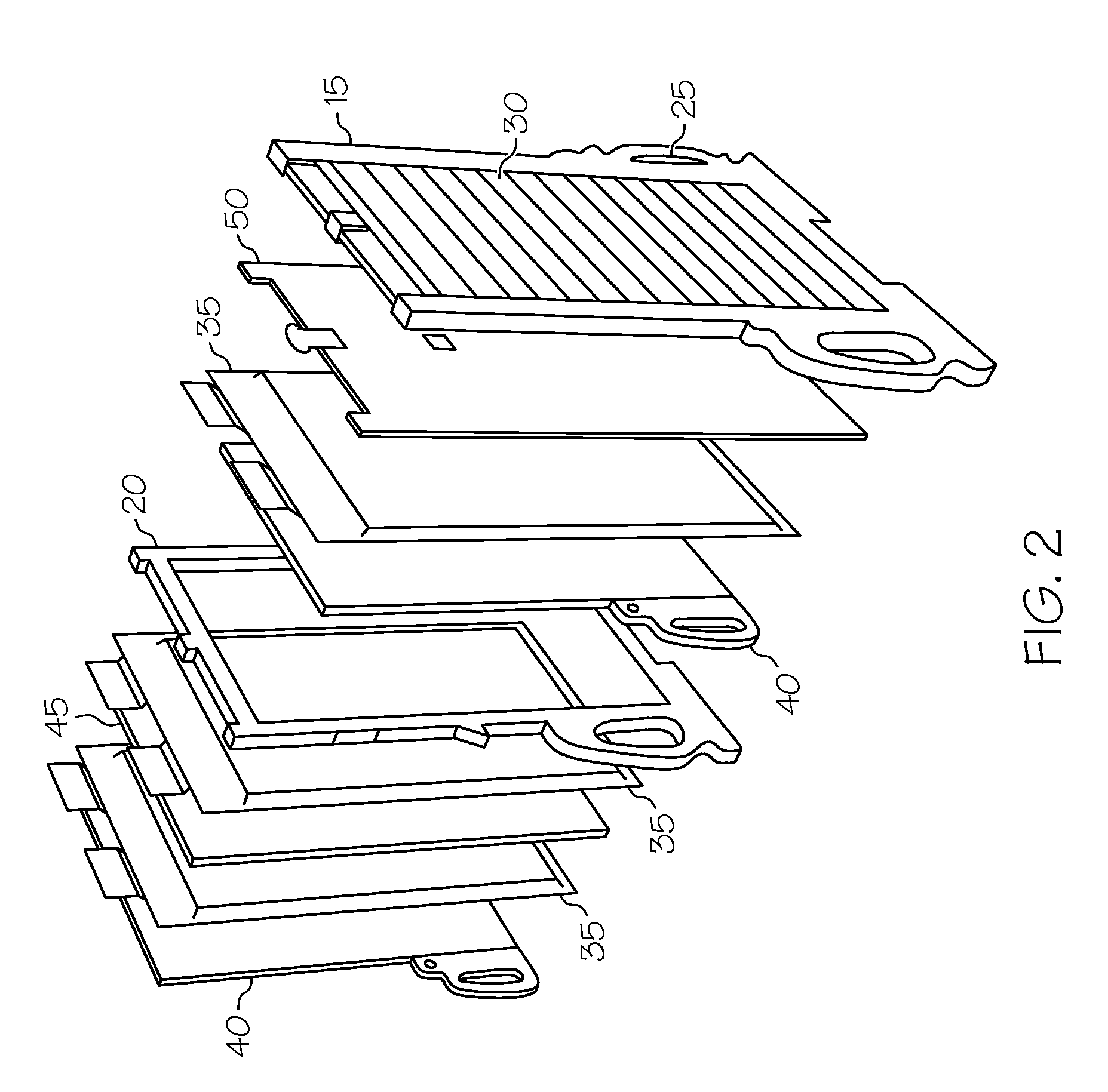

Printable intermediate construction incorporating registrably positioned laminate components that can be imaged and then easily formed into a laminated card or decal on demand

Owner:PROCESS LABEL SYST

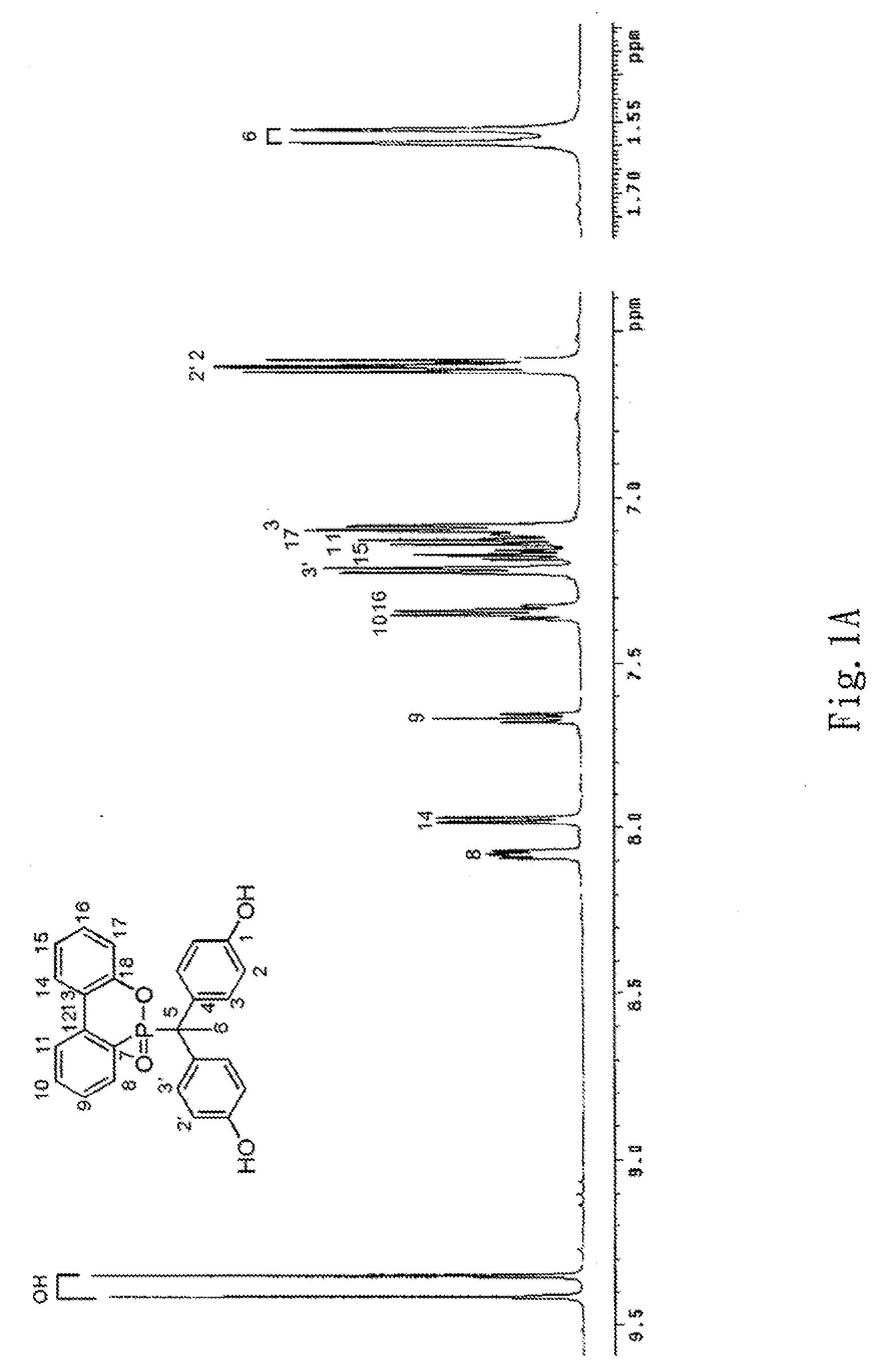

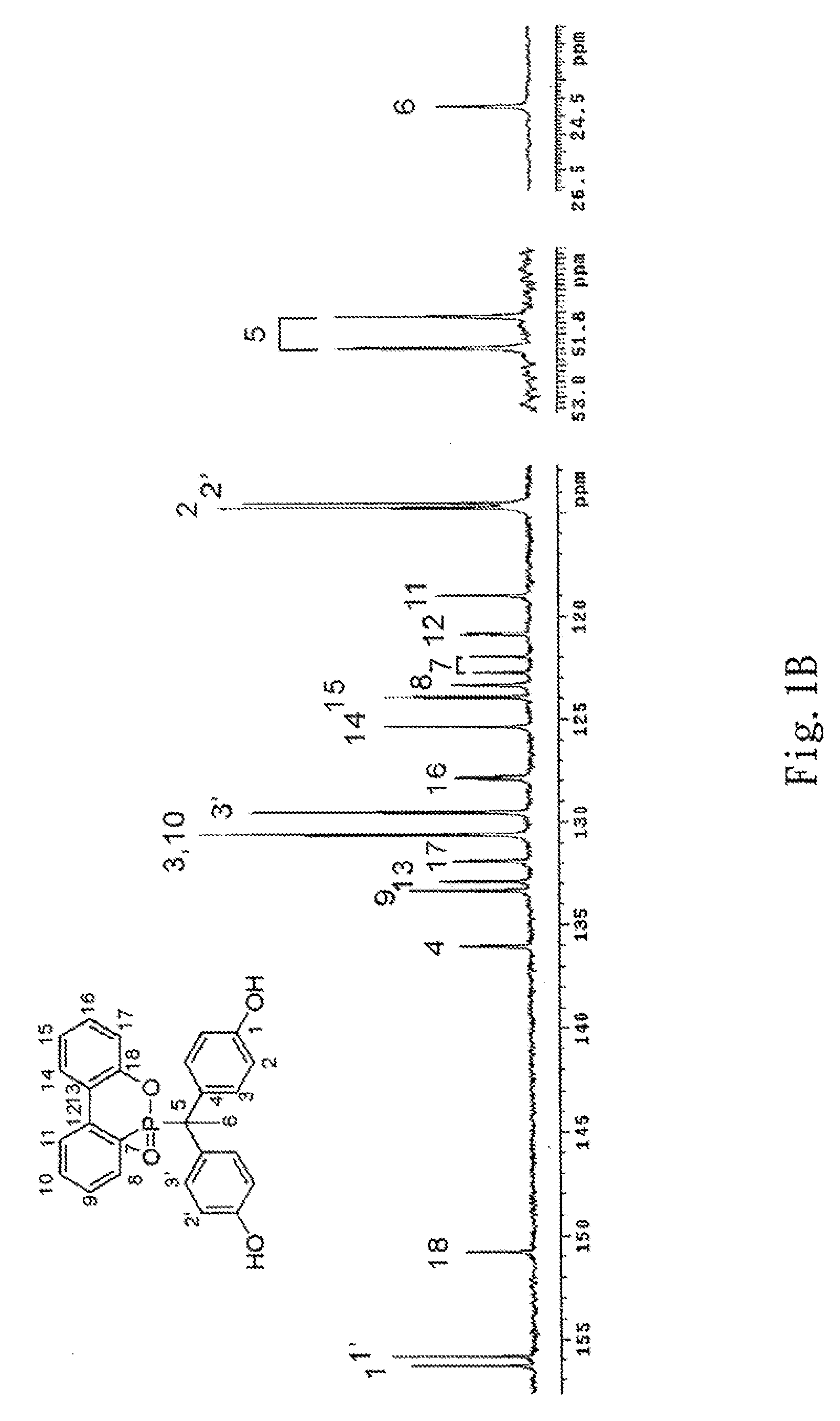

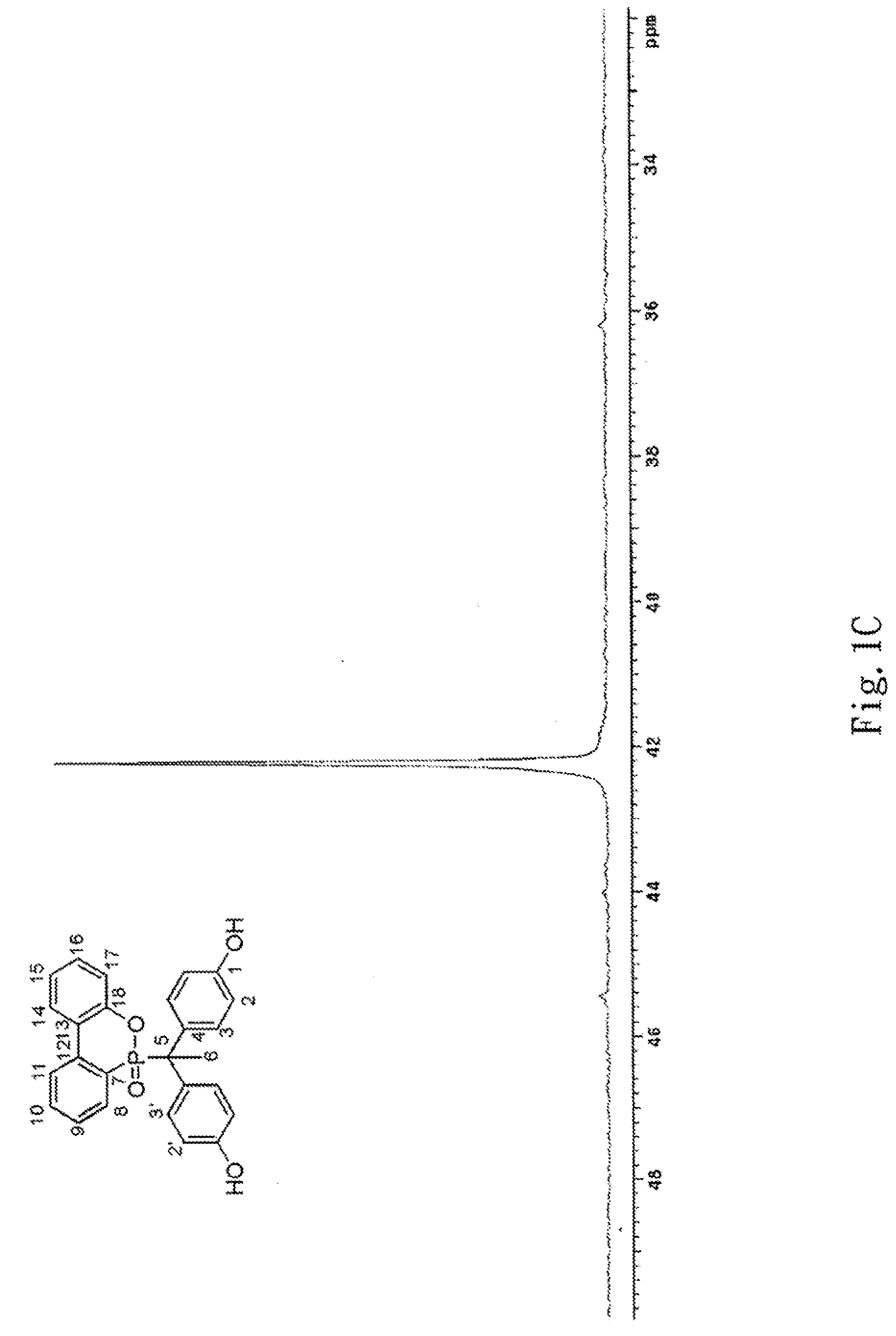

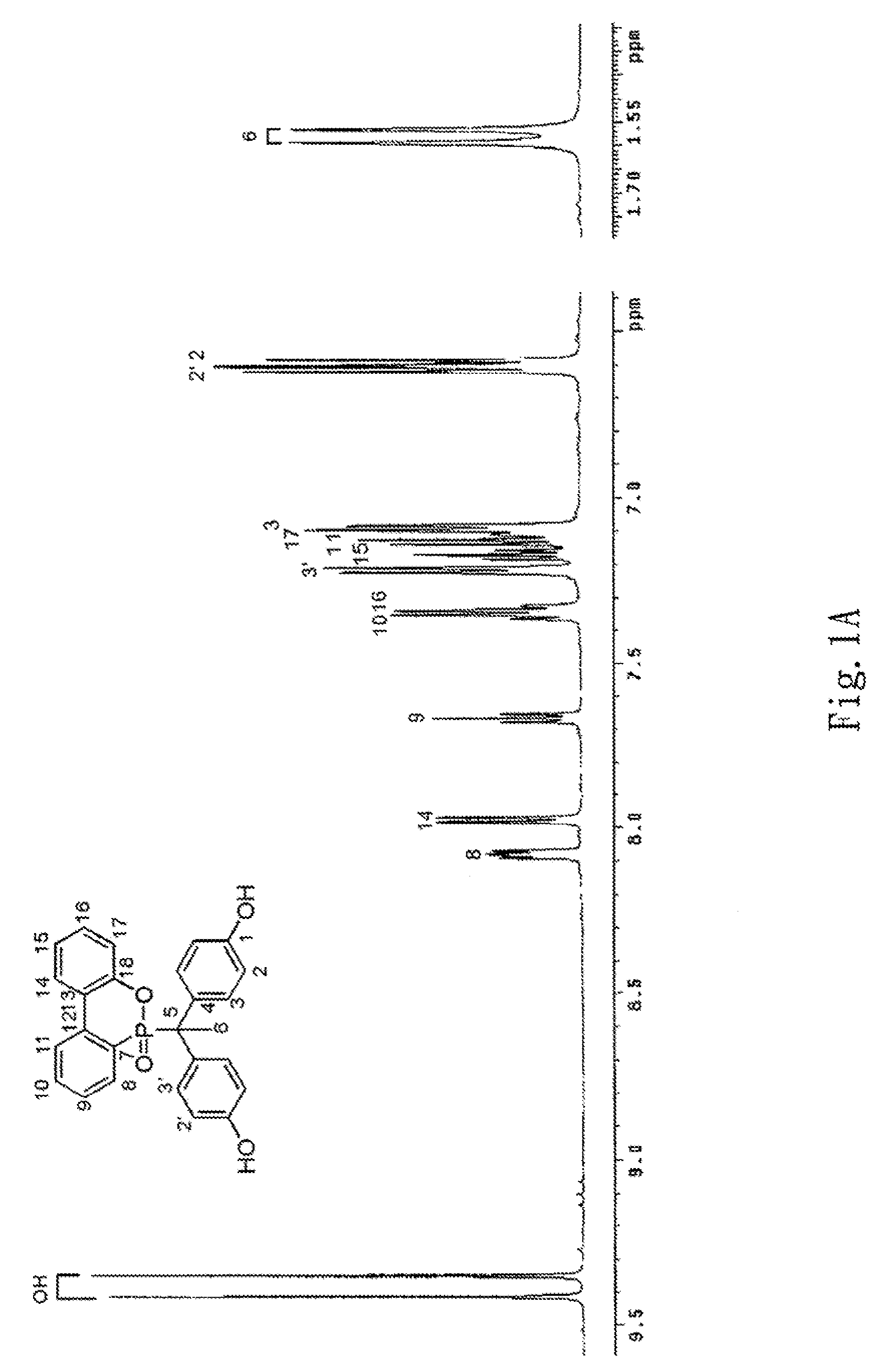

Phosphorus-containing bisphenols and preparing method thereof

ActiveUS20100016585A1Material is delayedImprove heat resistancePhosphorus organic compoundsGroup 5/15 element organic compoundsCombinatorial chemistryAcid catalyzed

The Phosphorus-containing bisphenols and preparing method thereof are disclosed. A method for producing the phosphorus-containing bisphenol of the general formula (1) includes reacting compounds respectively defined by a general formula (a), (b), (c) and an acid catalyst to yield compounds of phosphorus-containing bisphenol.

Owner:CHANG CHUN PLASTICS

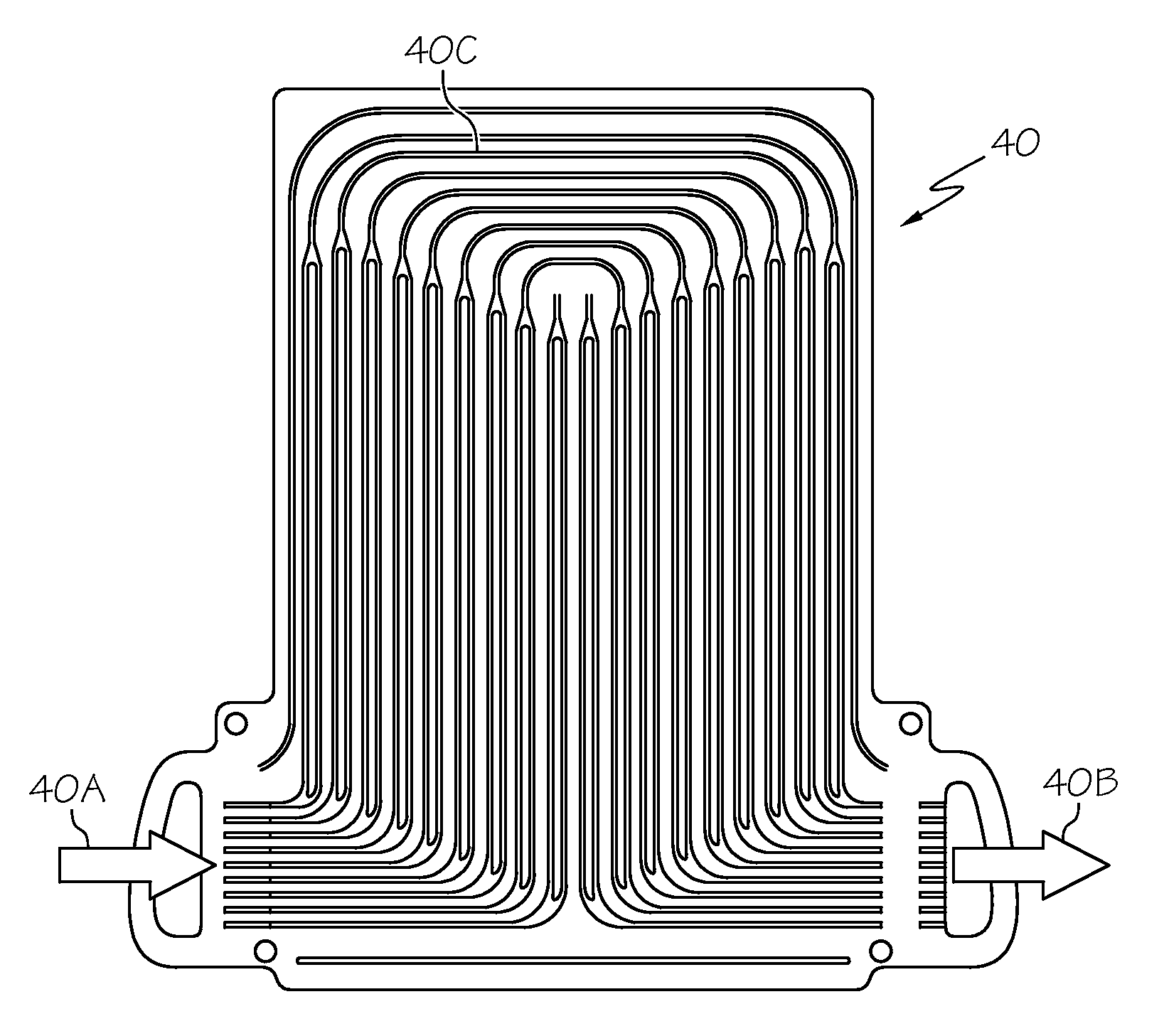

Liquid coolant with microencapsulated phase change materials for automotive batteries

InactiveUS20130004806A1Improve heat exchange capacityReduce the required powerCell temperature controlElectric propulsion mountingAutomotive batteryCombined use

A microencapsulated phase change material used in conjunction with a cooling fluid as part of a thermal management system for an automotive battery pack assembly. The microencapsulated phase change material is made to have enhanced latent heat transfer properties at lower (colder) temperatures and higher (elevated) temperatures such that a vehicle employing such an automotive battery pack assembly is more resistant to environments where freezing and overheating might otherwise be prevalent.

Owner:GM GLOBAL TECH OPERATIONS LLC

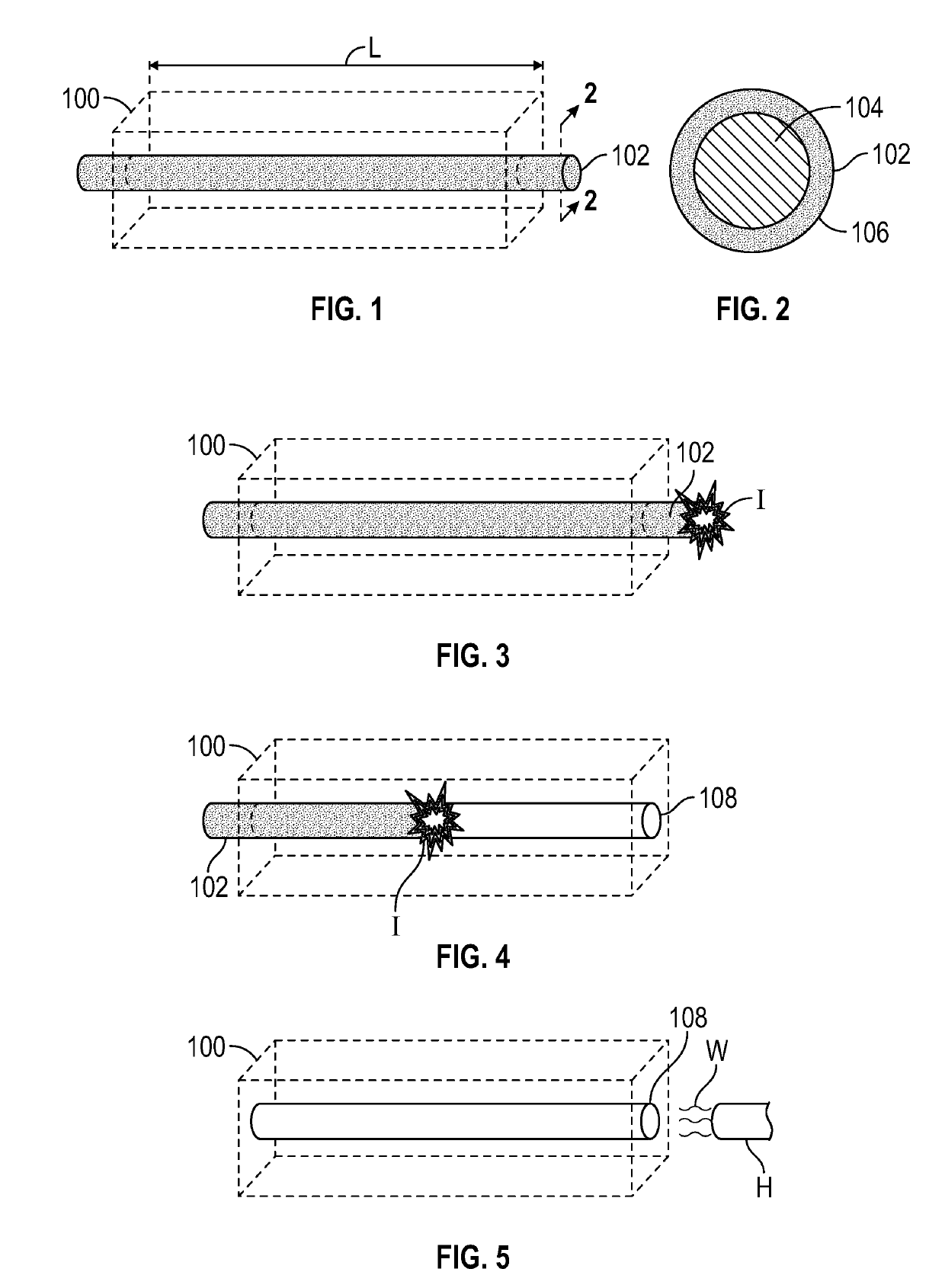

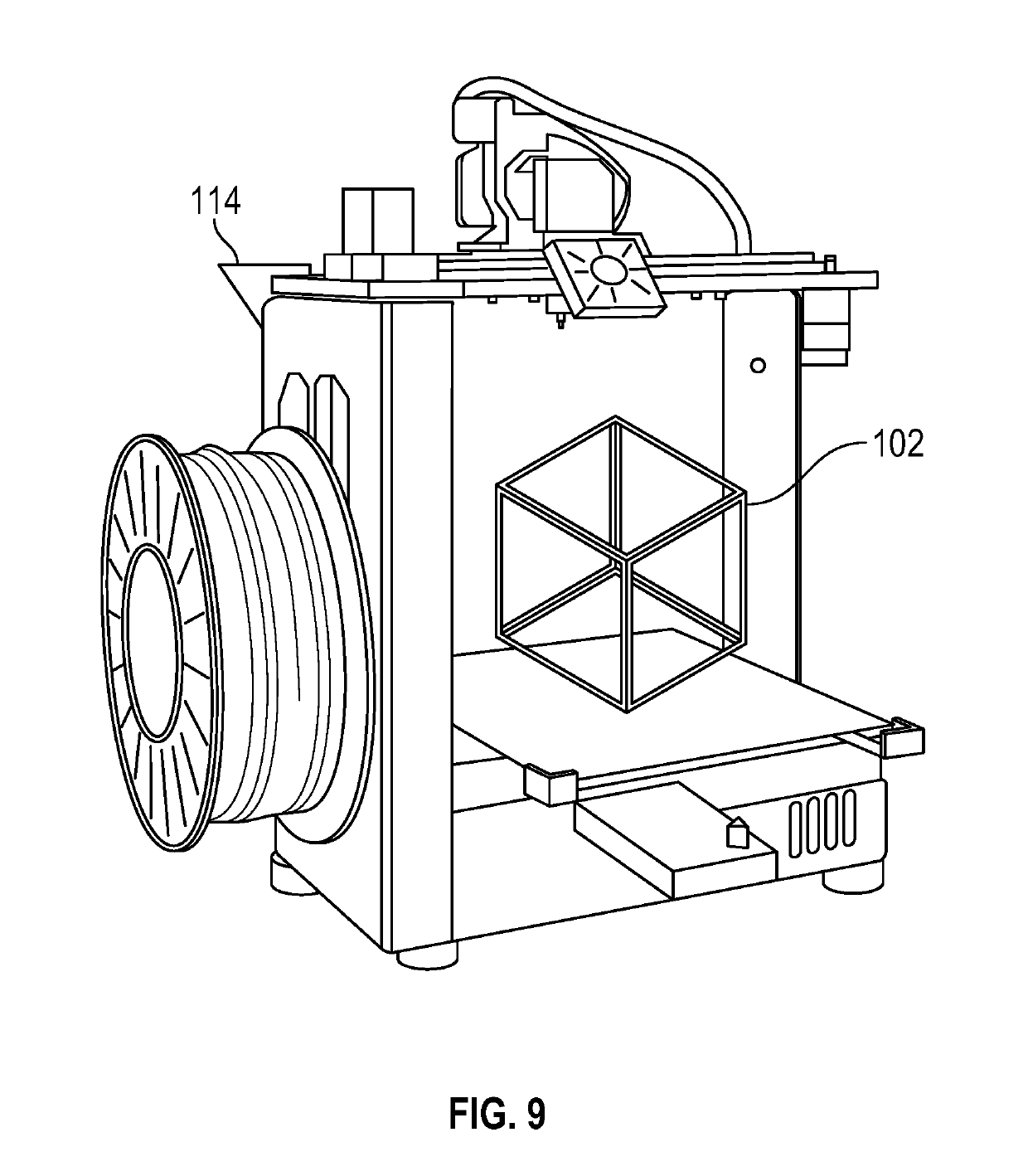

Vascular channel manufacture by deflagration

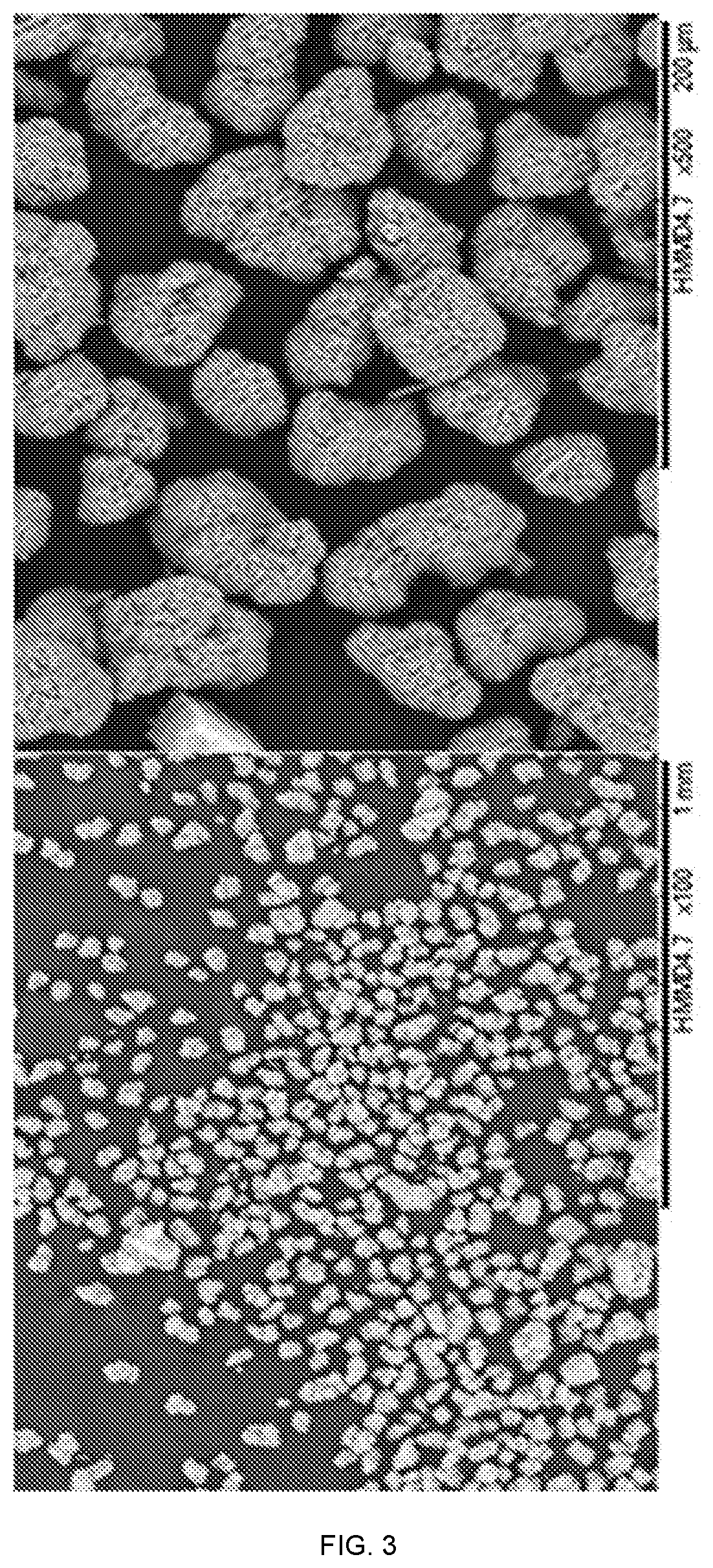

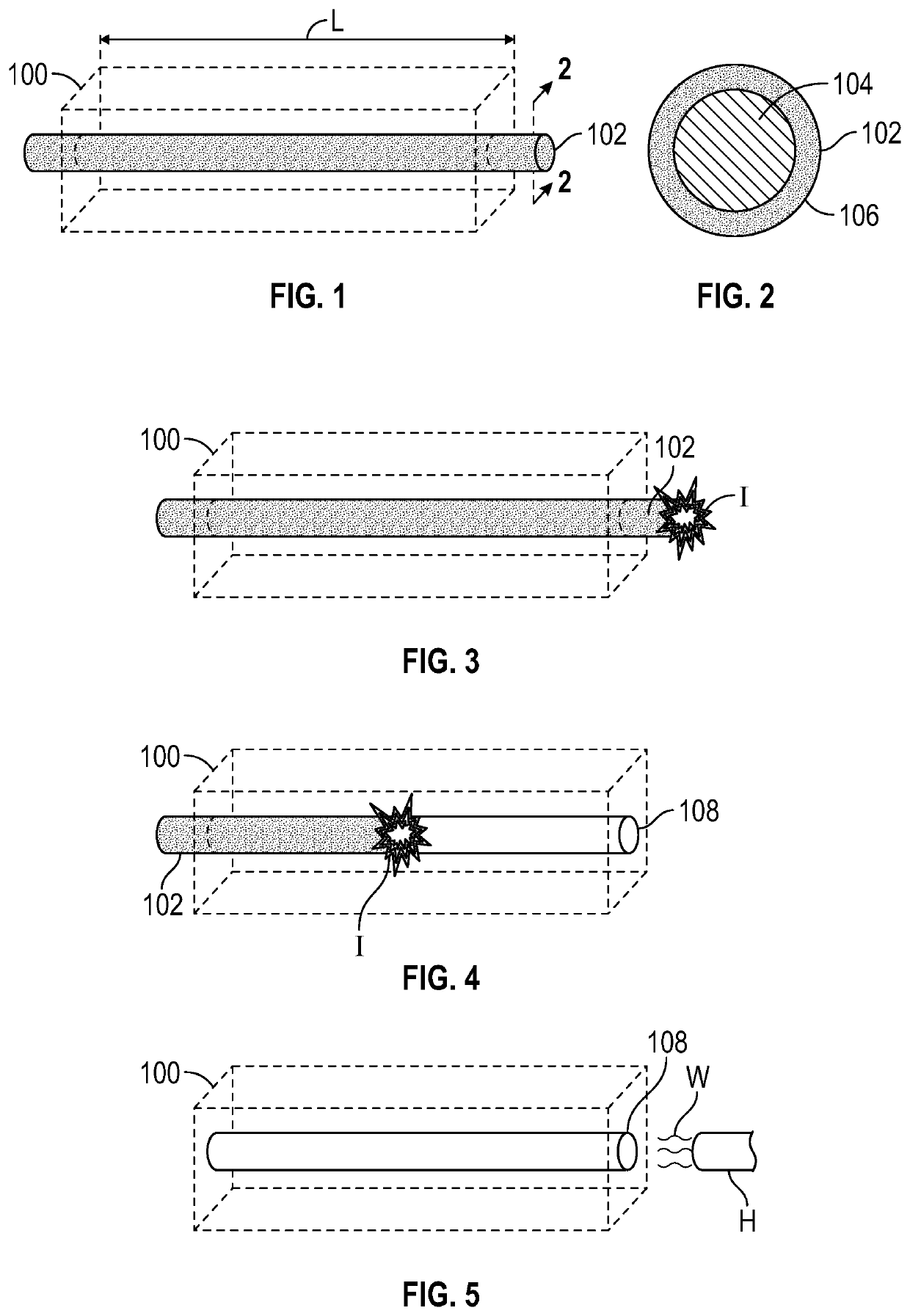

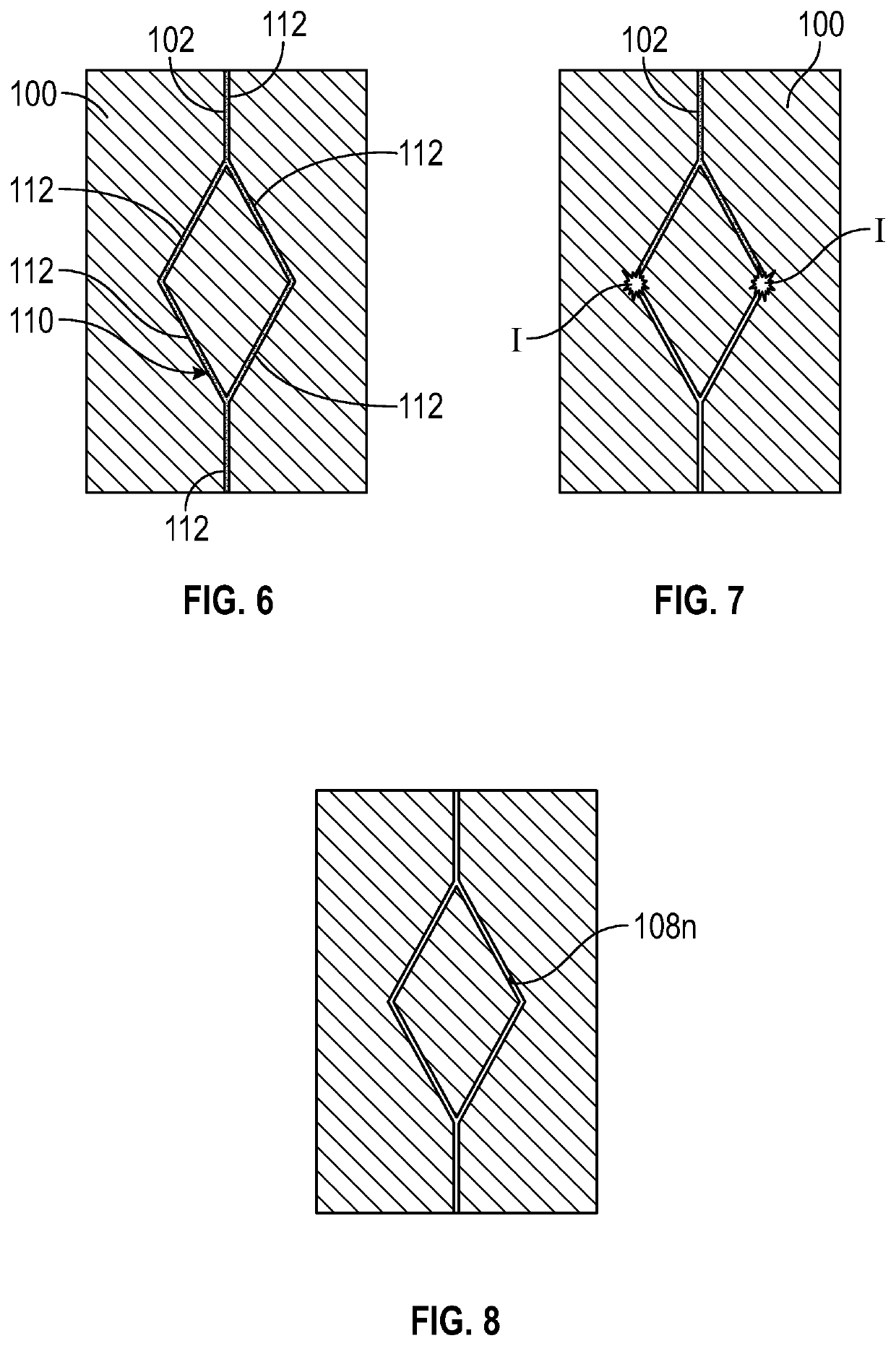

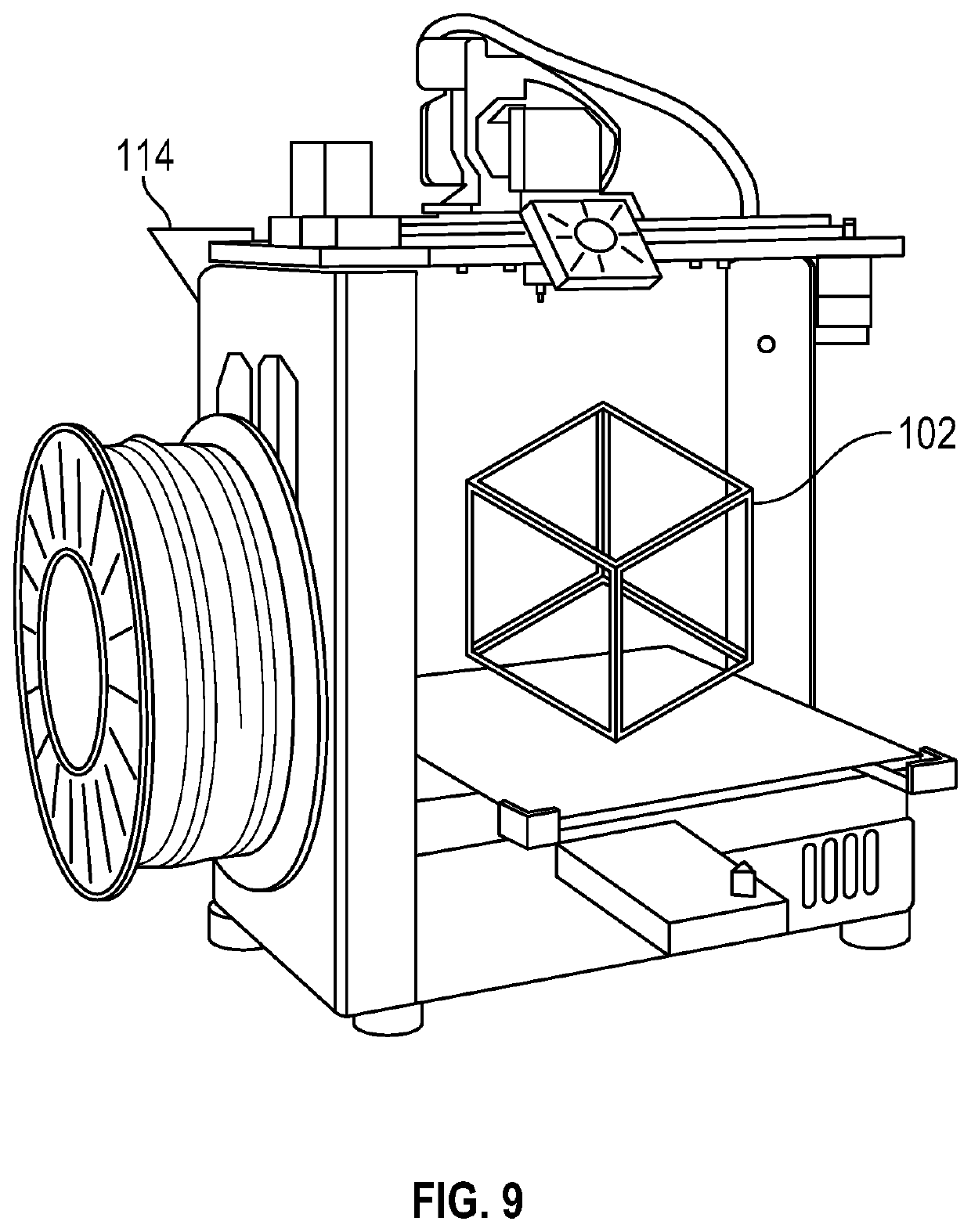

ActiveUS20190168473A1Minimize thermal effectMaterial removalAdditive manufacturing apparatusDomestic articlesDeflagrationEngineering

A method of forming channels within a substrate includes: (a) molding a sacrificial component directly into the substrate; (b) igniting the sacrificial component to cause a deflagration of the sacrificial component, thereby forming a channel in the substrate; and (c) cleaning the channel in the substrate to remove byproducts of the deflagration of the sacrificial component. The sacrificial component includes a combustible material with a protective shell, and the substrate includes a polymeric material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Use of anti-CGRP antibodies and antibody fragments to treat diarrhea in subjects with diseases or treatments that result in elevated CGRP levels

ActiveUS9855332B2Material is delayedIncrease opportunitiesAntibacterial agentsPeptide/protein ingredientsDiseaseTreatment results

The present invention is directed to methods for treating diarrhea, both chronic or acute forms, by the administration of a therapeutically or prophylactically effective amount of antibodies and fragments thereof having binding specificity for CGRP. In particular the methods prevent or reduce diarrhea in conditions or treatments resulting in elevated CGRP levels, e.g., in the GI tract (colon) that are associated with diarrhea and / or improper electrolyte and fluid excretion from the bowel or urinary system. More specifically, this invention relates to treatments using the anti-CGRP antibodies and fragments described herein, and binding fragments thereof.

Owner:UNIV OF IOWA RES FOUND +1

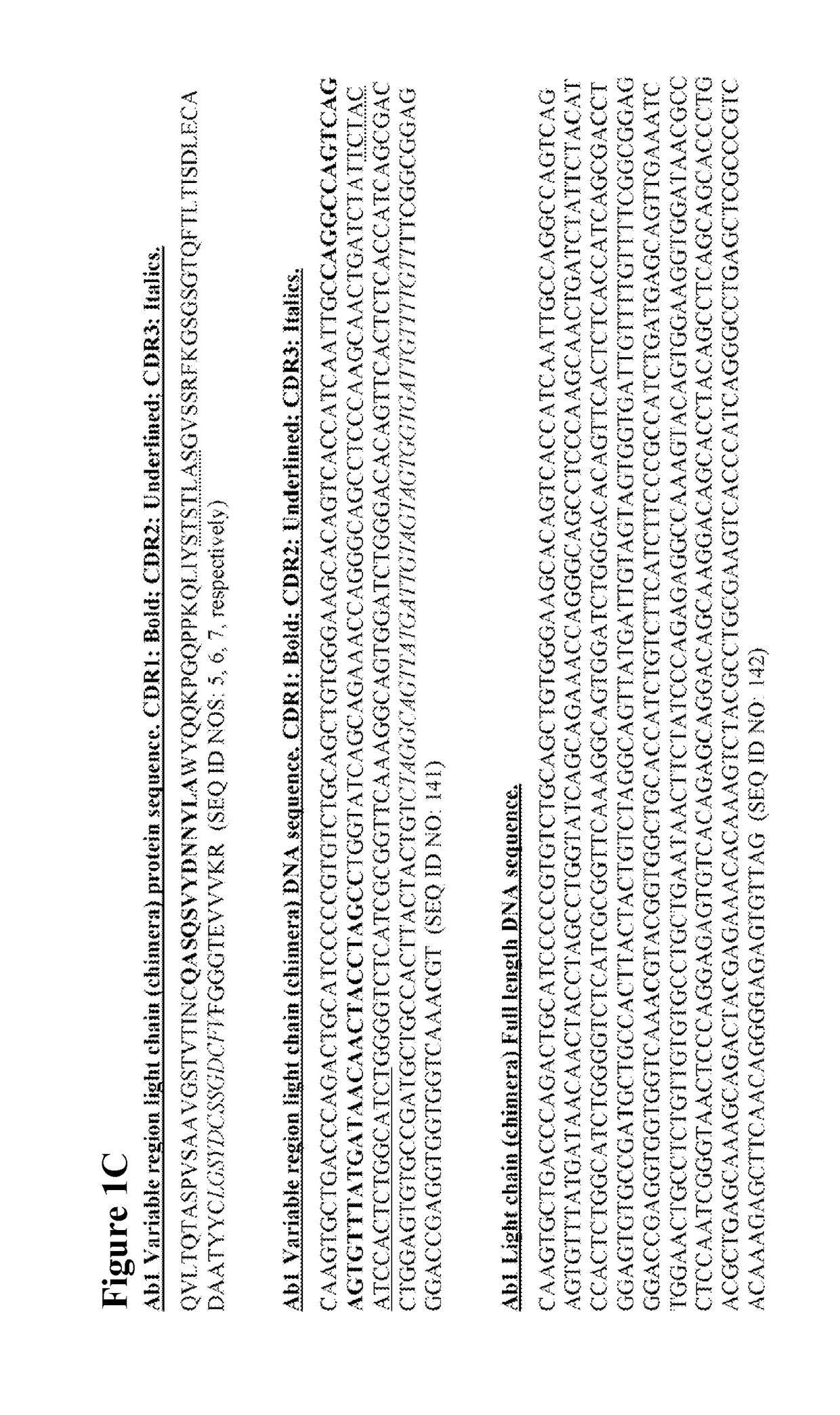

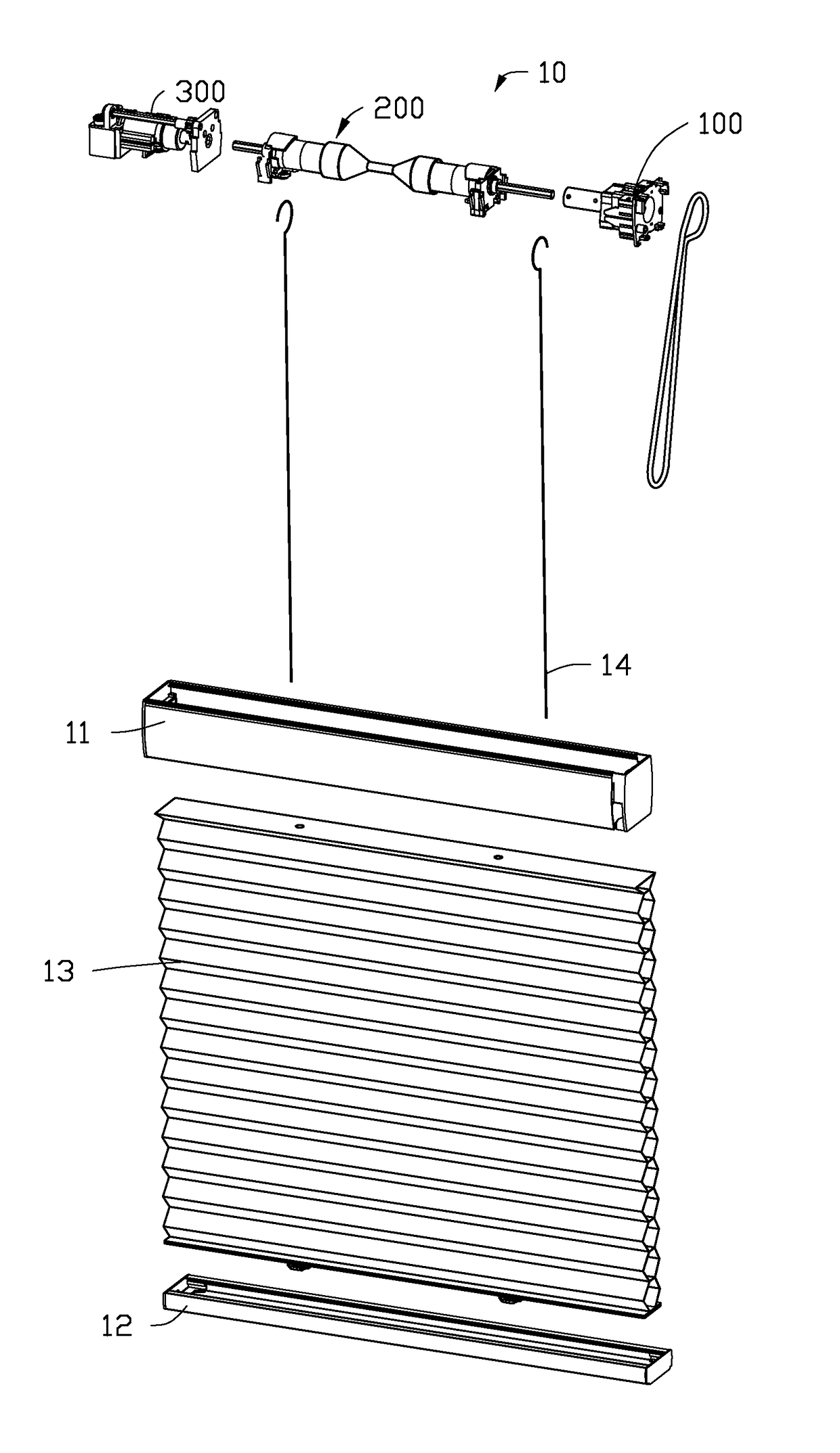

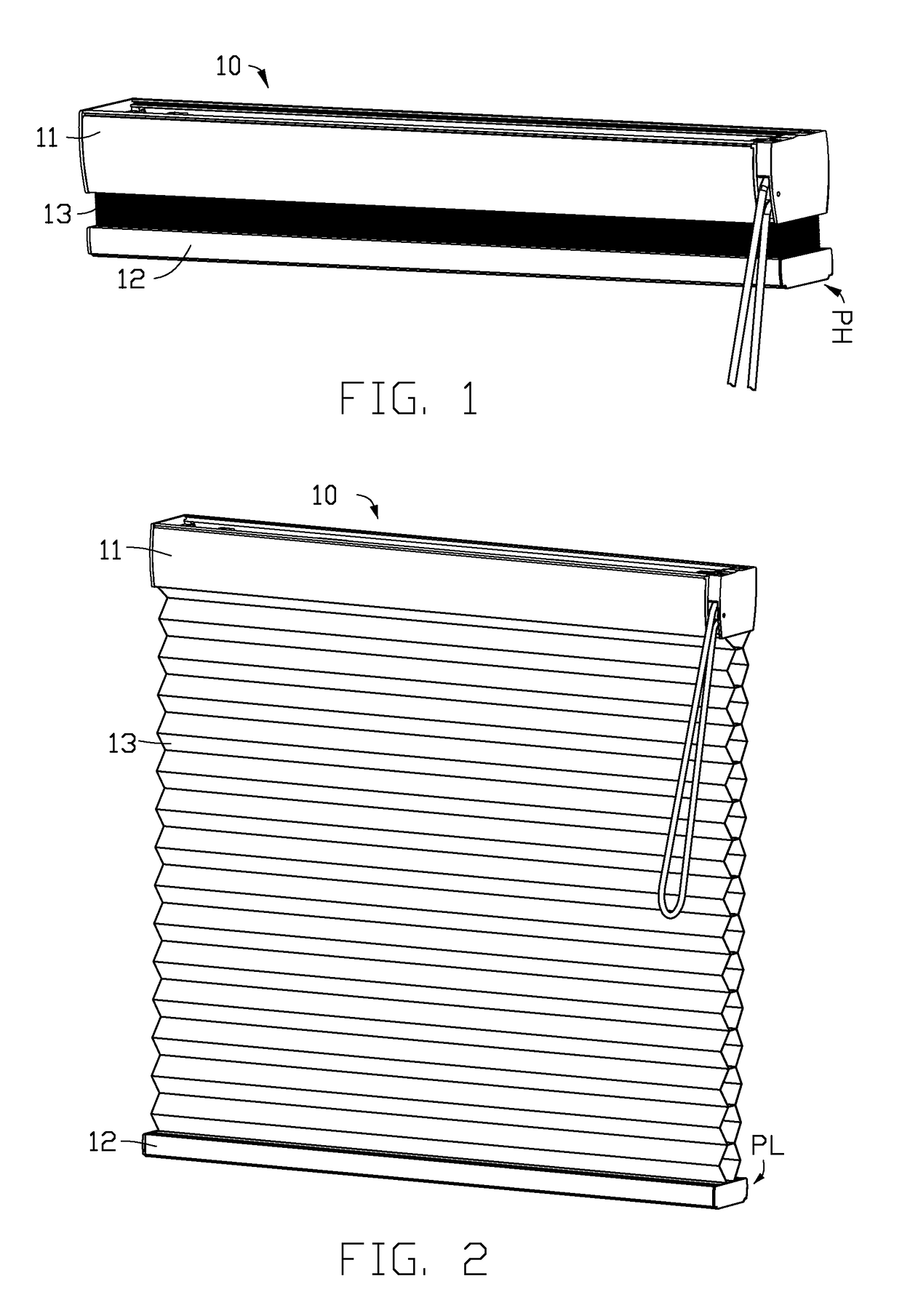

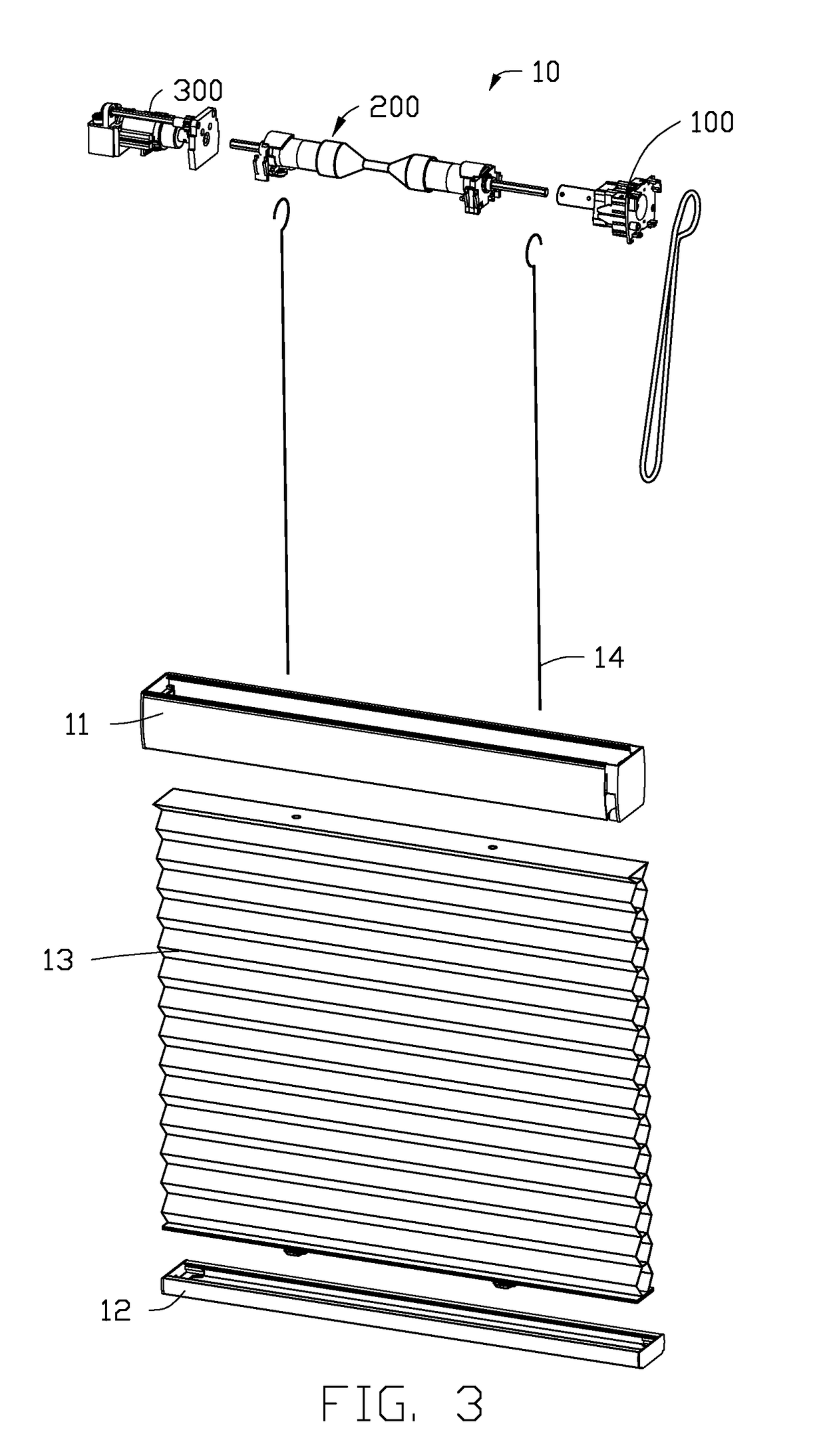

System and device for window covering system

ActiveUS10451145B2Improve securityReduce wearRotating vibration suppressionDoor/window protective devicesCovering systemRelative motion

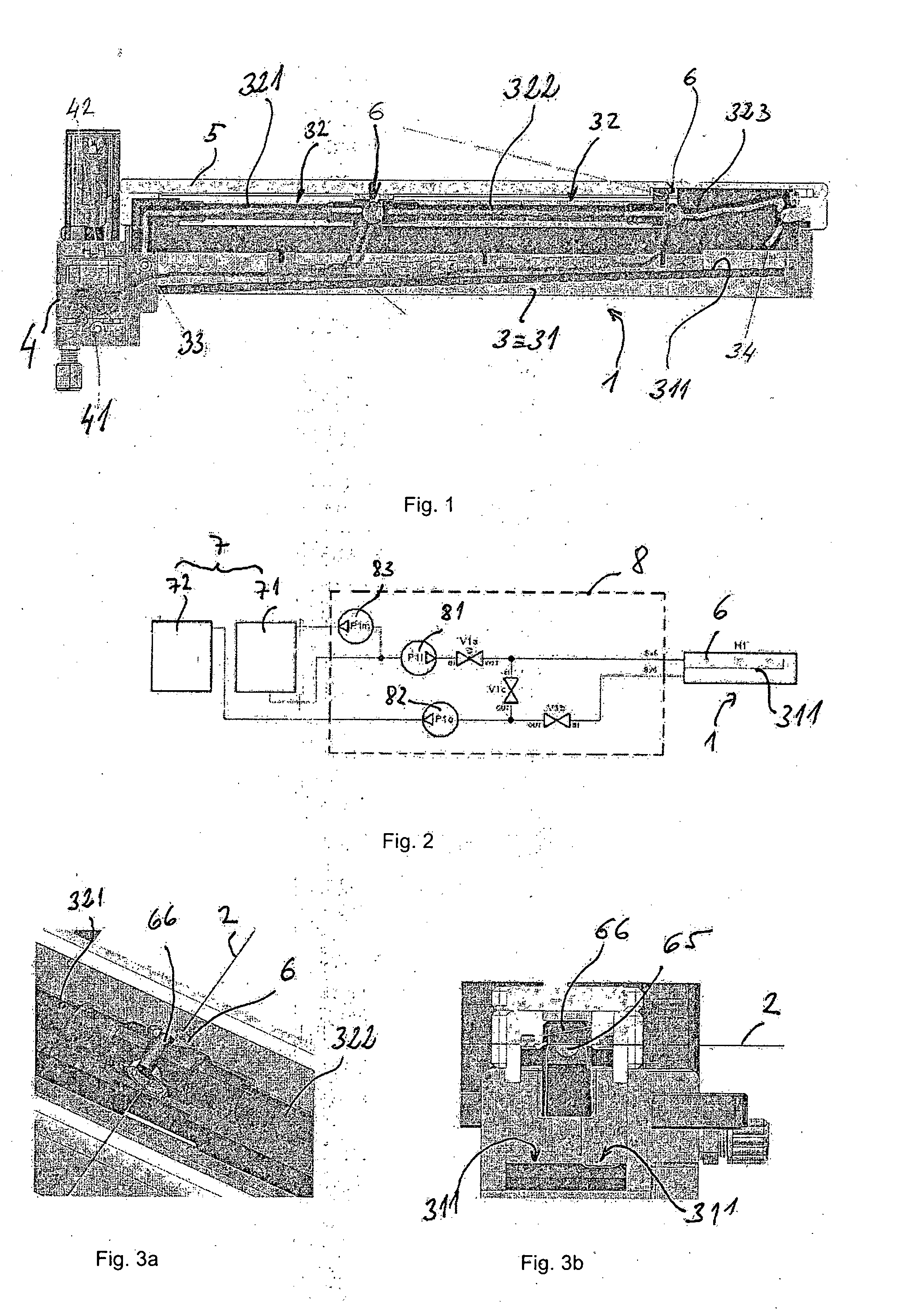

A damping adjustment device for adjusting a damping force to a window covering system while the window covering system is expanding, wherein the damping adjustment device comprises a damping module comprising first and second damping units. The damping force is outputted by the damping module to the window covering system when the first and second damping units generate an interaction force in between by a relative motion therebetween. An adjusting module is connected to the damping module for operating with the damping module simultaneously, wherein the damping force from the damping module is adjusted by the adjusting module altering a relative position of the first damping unit and the second damping unit when the relative motion occurs therebetween. A window covering system comprises the damping adjustment device, wherein expansion speed of a covering material of the window covering system can be effectively controlled and adjusted by the damping adjustment device.

Owner:NIEN MADE ENTERPRISE CO LTD

Fabrication method for liquid crystal display

ActiveUS7169653B2Improve operationQuality improvementSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

A method of fabricating a liquid crystal display panel is provided, which comprises the steps of providing a substrate; forming a mask layer over the substrate, wherein the mask layer has a reverse-tapered opening exposing a predetermined conductive line area; depositing a metal layer on the substrate within the predetermined conductive line area to form a conductive line with a tapered sidewall by performing an anisotropic deposition process; and removing the mask.

Owner:HANNSTAR DISPLAY CORPORATION

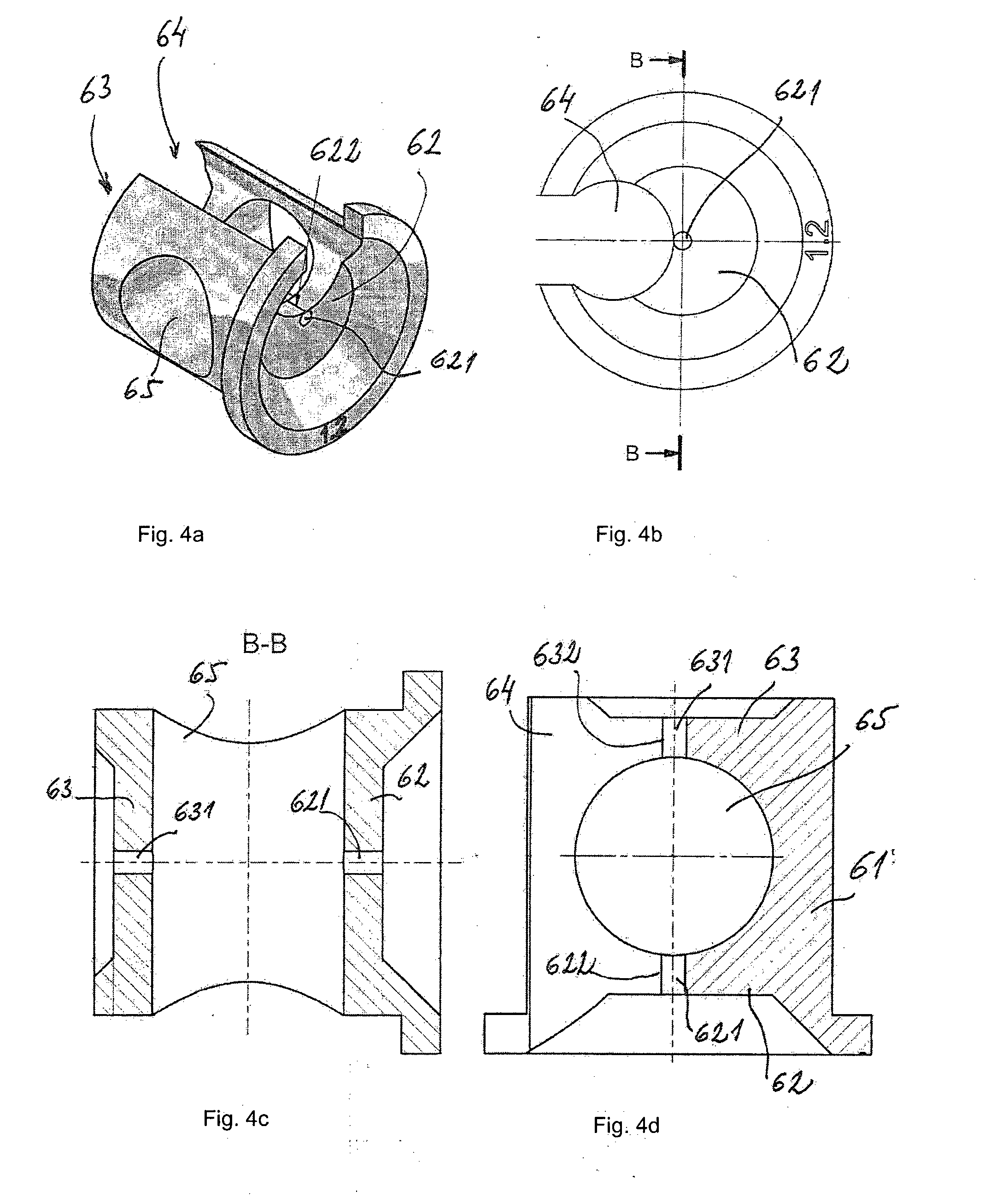

Damping device of window covering

ActiveUS20170211657A1Material is delayedRotating vibration suppressionDoor/window protective devicesMagnetic polesEngineering

A damping device of a window covering is provided, including a headrail, a covering material, and a driving device, wherein the driving device is located in the headrail to raise and extend the covering material. The damping device is provided in the headrail, and includes a metal member and a magnetic member, wherein at least a magnetic pole of the magnetic member faces the metal member. The metal member is located within a magnetic field of the magnetic member. Either one or both the metal member and the magnetic member is drivable by the driving device to make the metal member and the magnetic member move relative to each other. Whereby, the damping device is able to provide a desired damping effect at different temperature or after a long period use, such that the rotation of the metal member and the movement of the covering material are slowed down.

Owner:NIEN MADE ENTERPRISE CO LTD

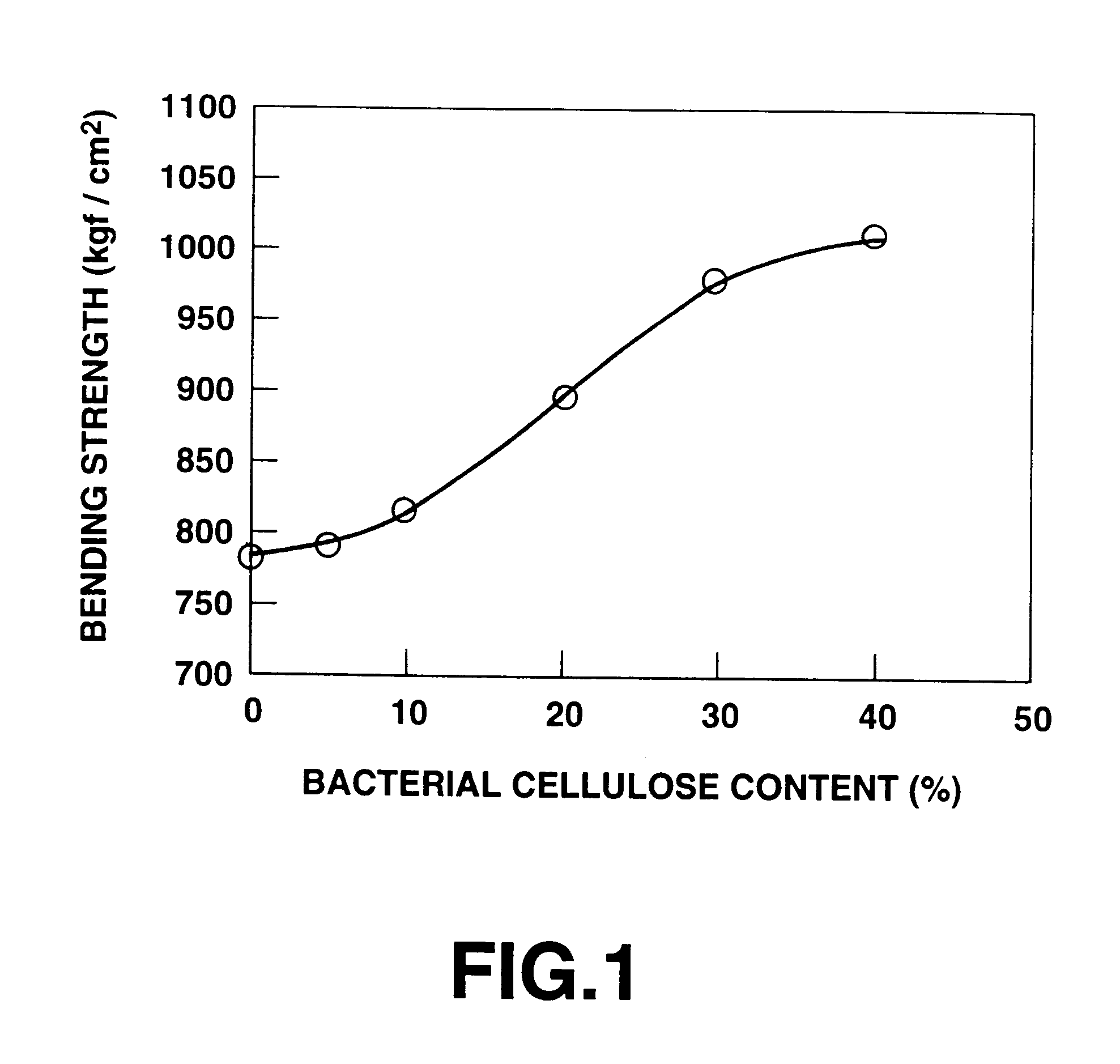

Polymeric composite material and method of manufacturing the same

InactiveUS6410618B2Improve various physical propertyMaterial is delayedCosmetic preparationsSugar derivativesPolymer scienceFibril

A polymeric composite material contains a biodegradable polymeric material that can be biologically decomposed in soil. More specifically, it contains bacterial cellulose including ribbon-shaped micro-fibrils that can be biologically decomposed by microbes in addition to the biodegradable polymeric material and shows improved physical properties including tensile strength.Such a polymeric composite material can be prepared by a method including causing predetermined microbes cultured in a liquid culture medium to produce bacterial cellulose, collecting and drying the produced bacterial cellulose into a powdery state and mixing the powdery bacterial cellulose and a biodegradable polymeric material to produce a composite material.

Owner:SONY CORP

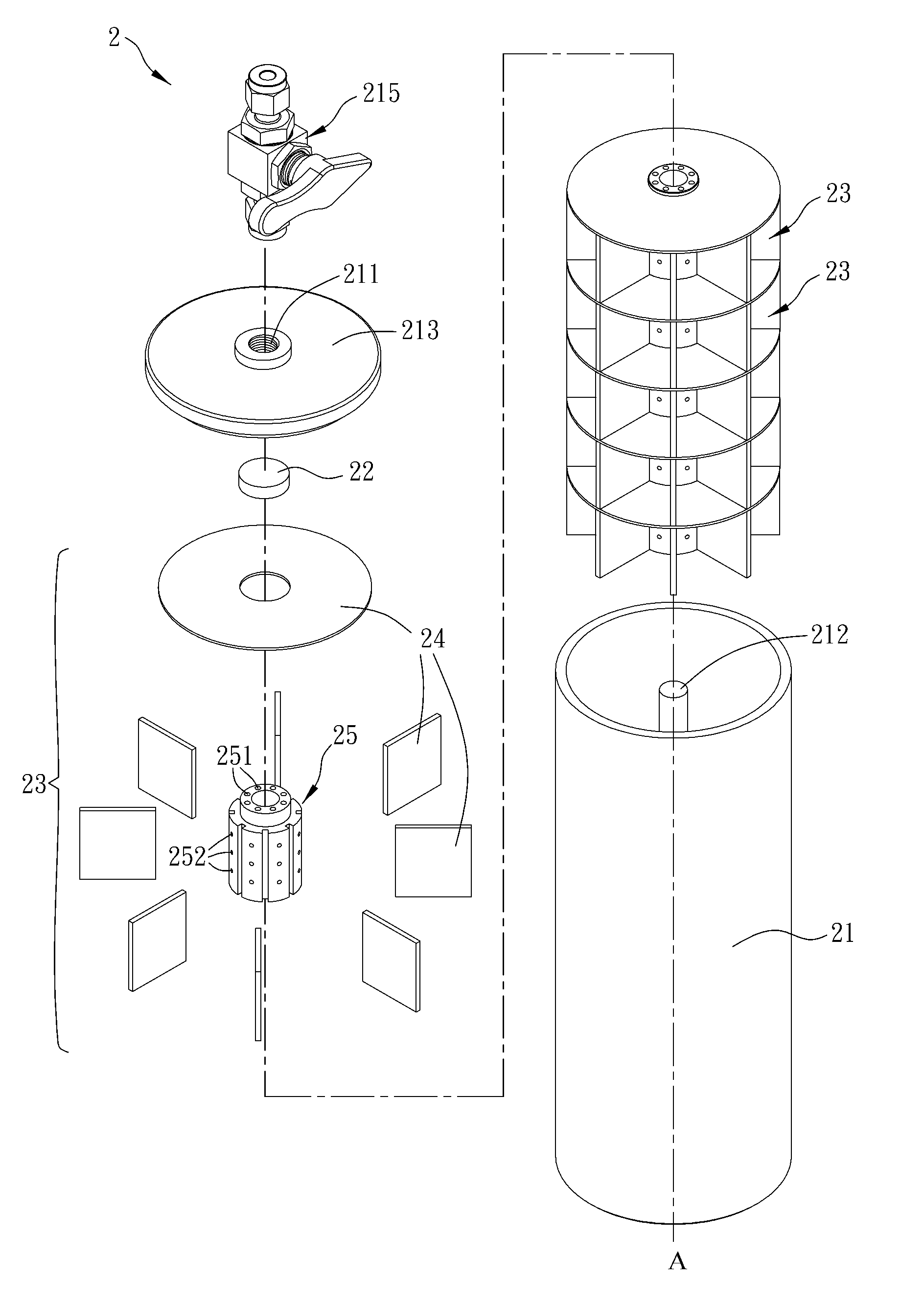

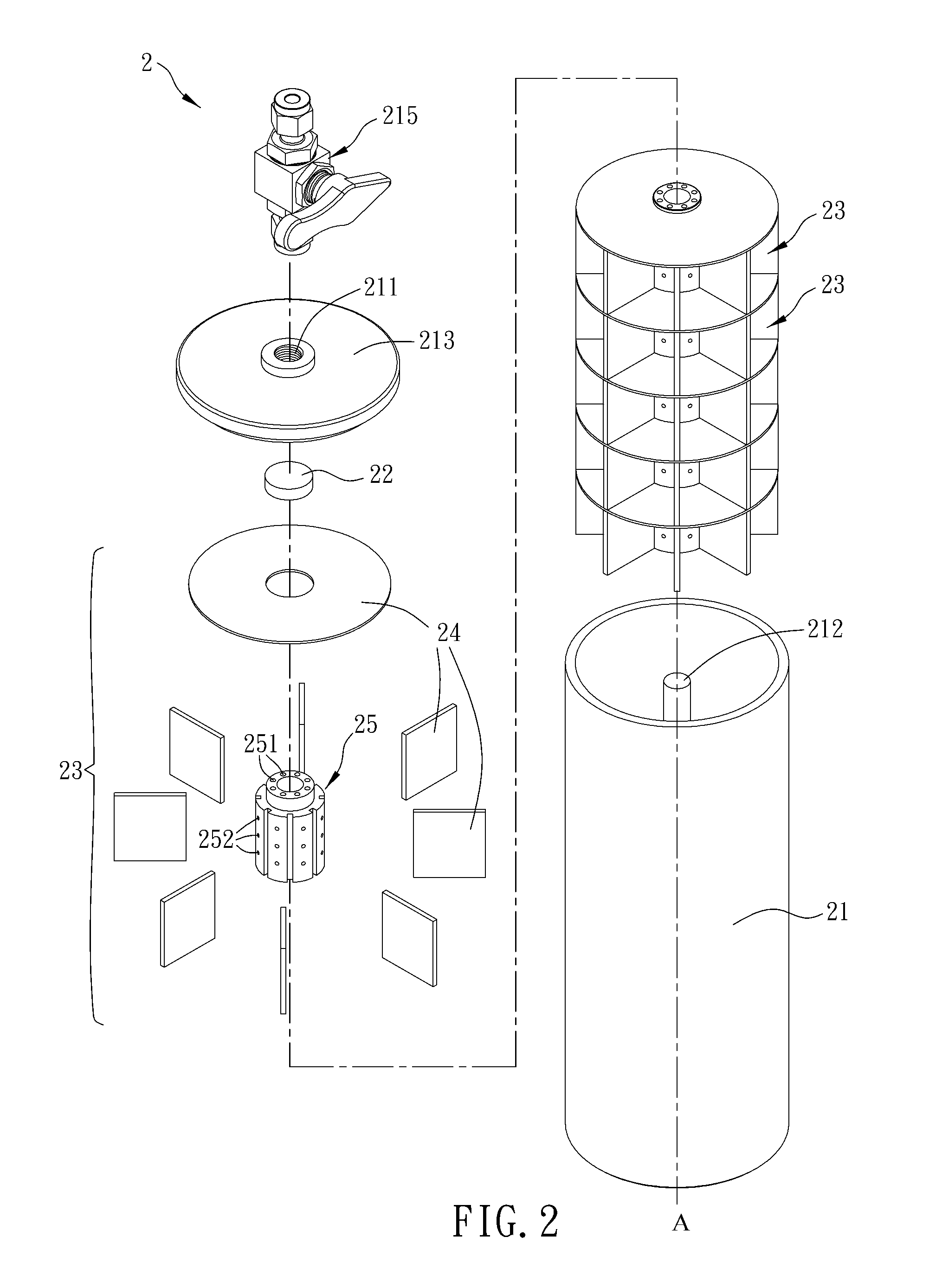

Hydrogen storage apparatus

InactiveUS20120211376A1Material be accumulate be easeEase phenomenonFixed capacity gas holdersLiquid materialEngineeringMechanical engineering

A hydrogen storage apparatus includes a canister, a first filter element and at least one hydrogen storage unit. The canister has an opening and a rod. The first filter element is disposed in the opening. The hydrogen storage unit is accommodated in the canister. The hydrogen storage unit includes a compartment structure and a hydrogen channel element. The compartment structure divides a space inside the canister, and the hydrogen channel element is pierced by the rod and connected with the compartment structure. The hydrogen channel element includes a plurality of axial channels and a plurality of radial channels. The axial channels are connected with the opening and the radial channels. The radial channels are connected with the space inside the canister.

Owner:NAT CENT UNIV

Liquid coolant with microencapsulated phase change materials for automotive batteries

InactiveUS8623538B2Prolong lifeImprove temperature uniformityAir-treating devicesCell temperature controlAutomotive batteryThermal management system

A microencapsulated phase change material used in conjunction with a cooling fluid as part of a thermal management system for an automotive battery pack assembly. The microencapsulated phase change material is made to have enhanced latent heat transfer properties at lower (colder) temperatures and higher (elevated) temperatures such that a vehicle employing such an automotive battery pack assembly is more resistant to environments where freezing and overheating might otherwise be prevalent.

Owner:GM GLOBAL TECH OPERATIONS LLC

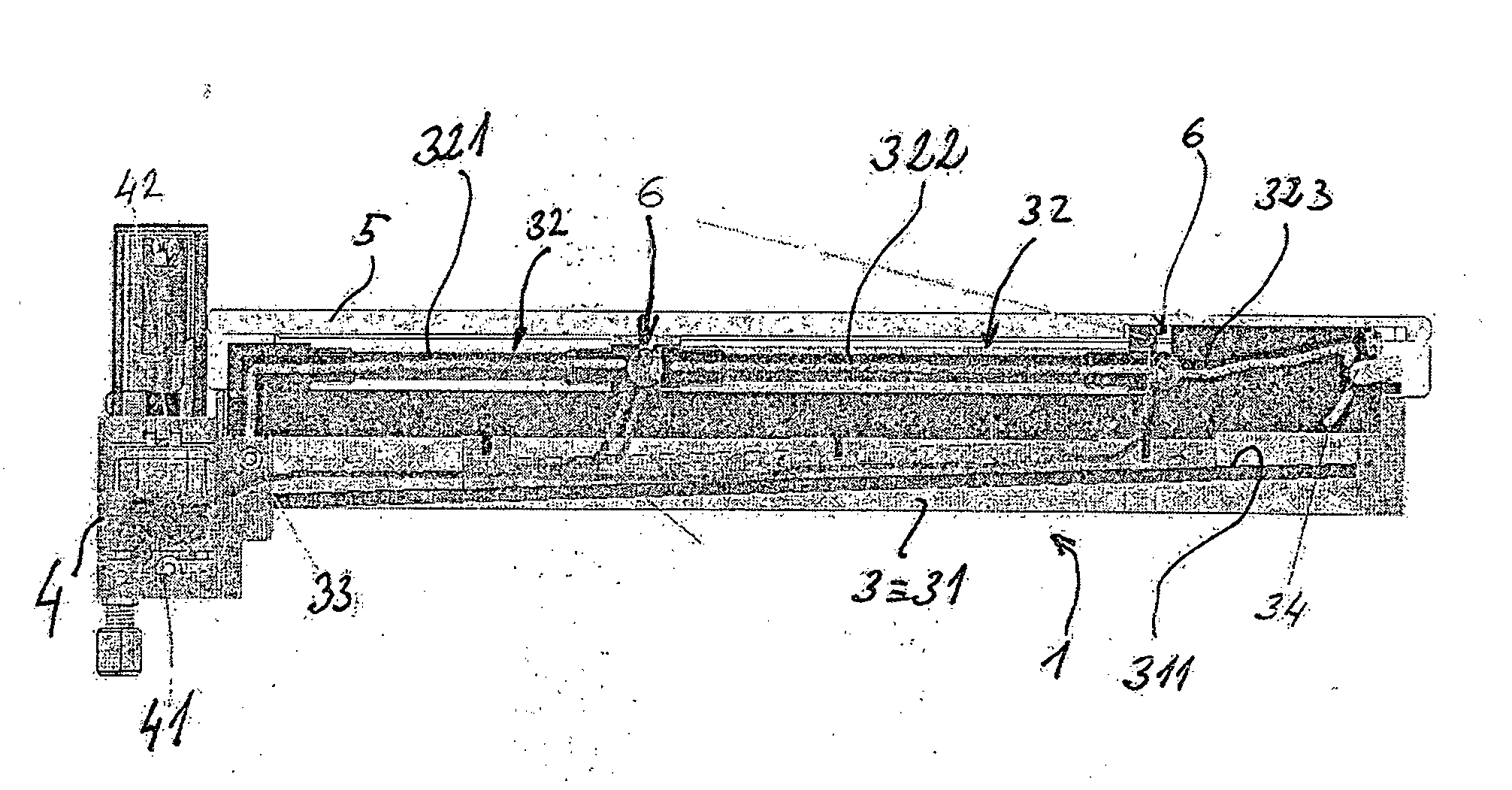

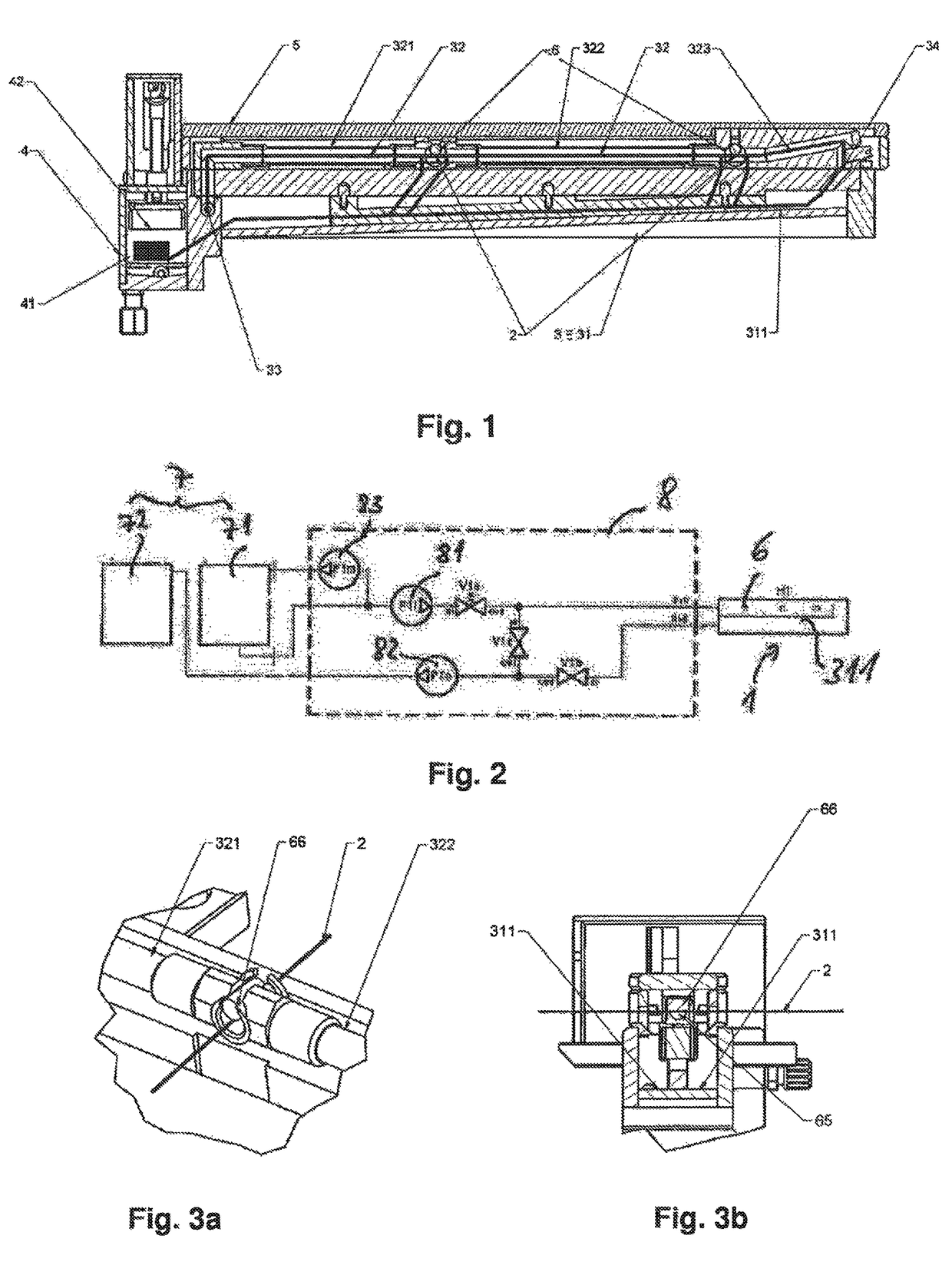

Method and device for application of liquid polymeric material onto spinning cords

ActiveUS20140061959A1Improve uniformityMaterial is delayedElectro-spinningAuxillary shaping apparatusElectrospinningLiquid state

The present disclosure relates to a method and a device for application of liquid polymeric material onto the active spinning zone of the cord of the spinning member of the spinning electrode, where the application means moving reversibly along the active spinning zone of the cord in the device for production of nanofibres through electrostatic spinning of liquid material in electrostatic field of high intensity between at least one spinning electrode and against it arranged collecting electrode. The liquid polymeric material is applied onto the cord around its whole circumference without any contact with gaseous environment in the spinning space, where the application means reversibly moves, whereas while the cord is leaving the application means the thickness of the layer of the liquid polymeric material is being reduced and immediately after leaving the application means the process of electrostatic spinning of the liquid polymeric material applied on the cord is started.

Owner:ELMARCO SRO

Battery thermal interfaces with microencapsulated phase change materials for enhanced heat exchange properties

InactiveUS8927131B2Prolong lifeImprove temperature uniformityElectric devicesCell temperature controlComputer moduleEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

System and device for window covering system

ActiveUS20170211320A1Improve securityReduce wearRotating vibration suppressionDoor/window protective devicesCovering systemRelative motion

A damping adjustment device for adjusting a damping force to a window covering system while the window covering system is expanding, wherein the damping adjustment device comprises a damping module comprising first and second damping units. The damping force is outputted by the damping module to the window covering system when the first and second damping units generate an interaction force in between by a relative motion therebetween. An adjusting module is connected to the damping module for operating with the damping module simultaneously, wherein the damping force from the damping module is adjusted by the adjusting module altering a relative position of the first damping unit and the second damping unit when the relative motion occurs therebetween. A window covering system comprises the damping adjustment device, wherein expansion speed of a covering material of the window covering system can be effectively controlled and adjusted by the damping adjustment device.

Owner:NIEN MADE ENTERPRISE CO LTD

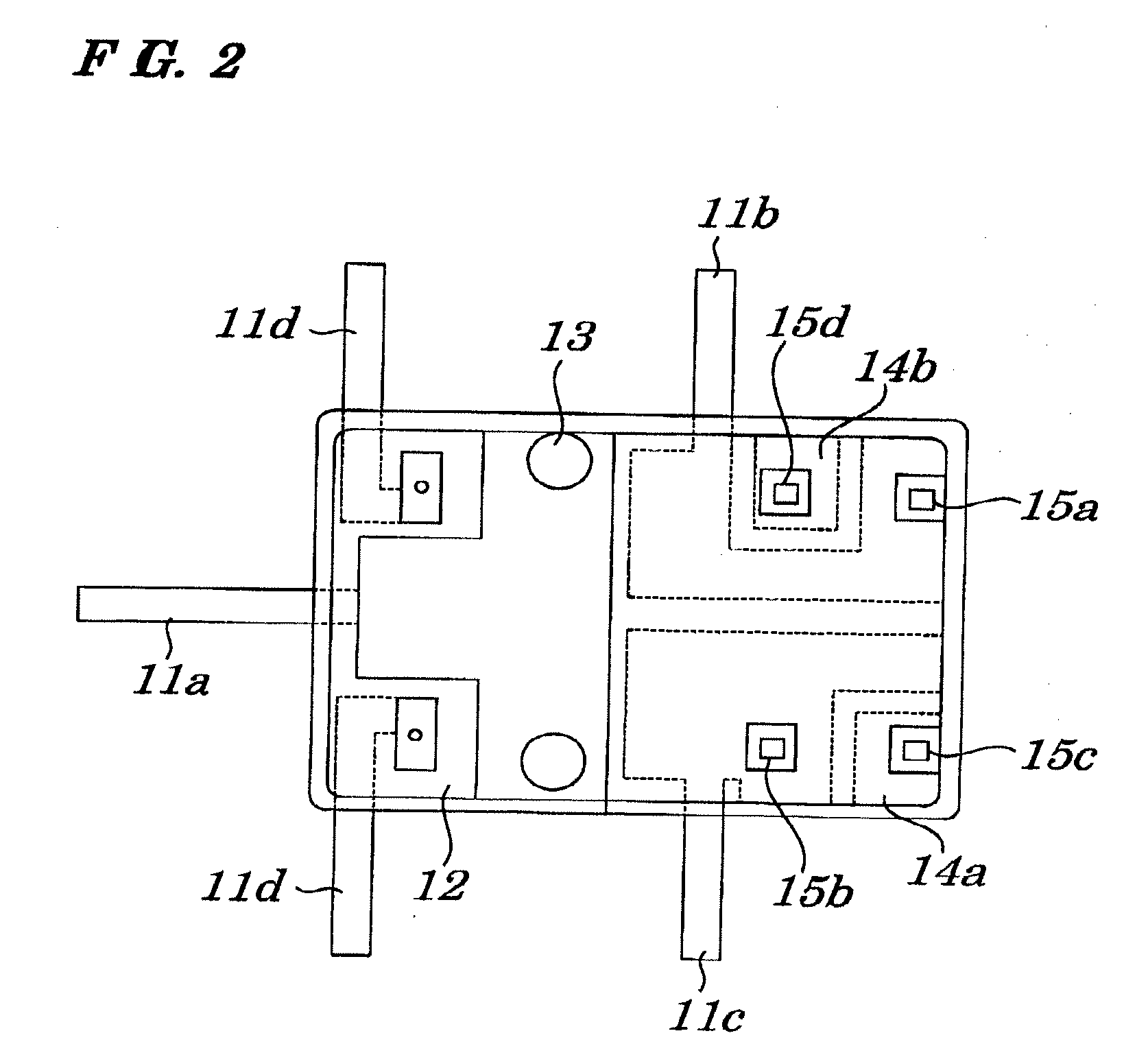

Electromagnetic relay

ActiveUS20070087585A1Material is delayedIncrease contact areaCoupling device connectionsElectromagnetic relay detailsExternal connectionEngineering

An electromagnetic relay is provided which allows free design of arrangements of each external connecting terminal and is capable of effectively dissipating heat from a base and suppressing a rise in temperatures within the electromagnetic relay. The electro-magnetic relay includes a core, a coil, a yoke, an armature, an electromagnetic block made up of a movable spring having a movable contact mechanically coupled to the armature, a pair of fixed contacts made up of an ordinarily closed fixed contact and an ordinarily opened fixed contact both being contacted with the movable contact, a group of external connecting terminals, a base, and an armored cover, wherein the movable spring and the yoke make up part of a current-carrying path, and a yoke extended portion is in direct mechanical contact with the movable contact external connecting terminal and the ordinarily closed fixed contact is mechanically coupled to an ordinarily closed fixed contact external connecting terminal.

Owner:EM DEVICES CORP

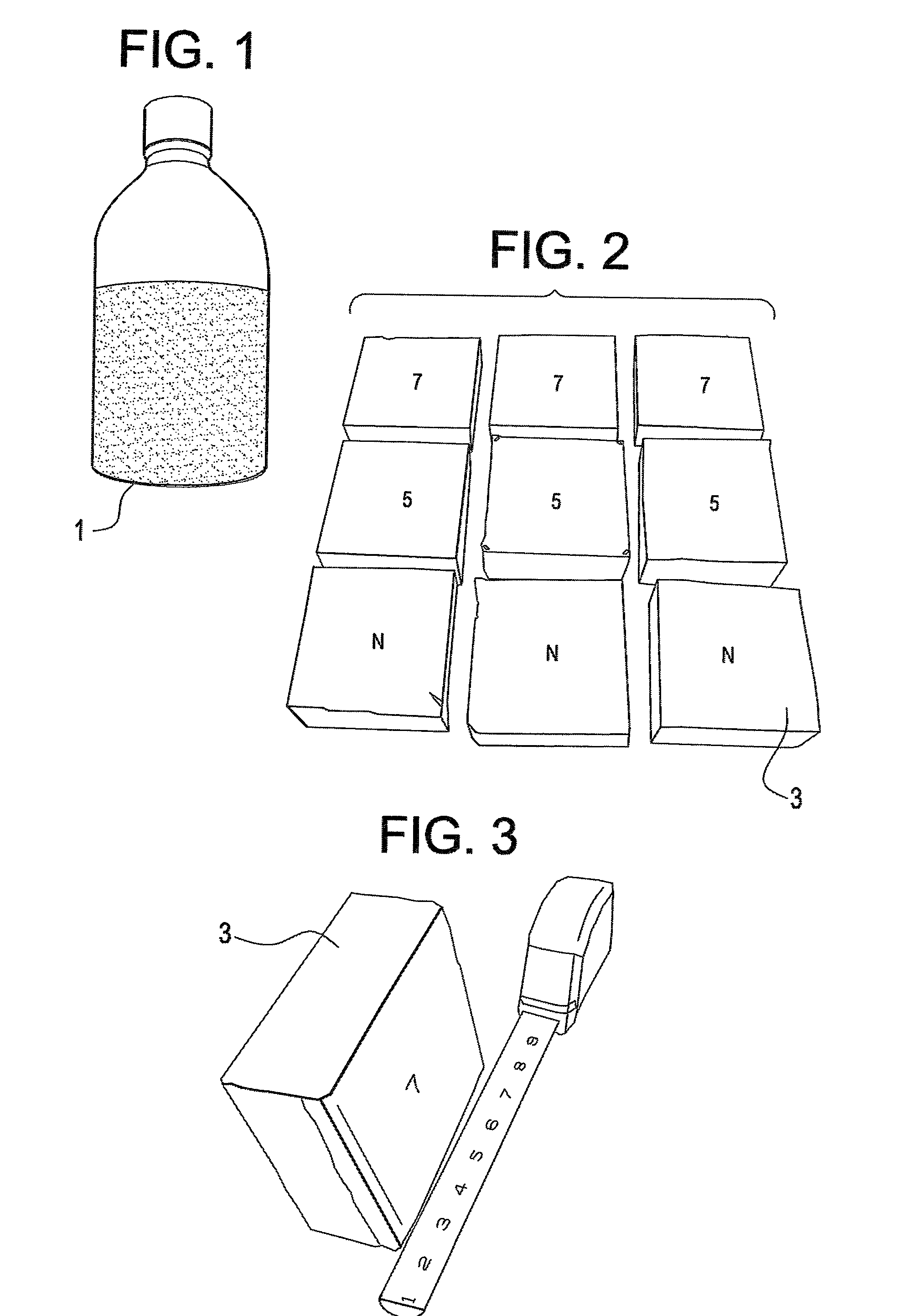

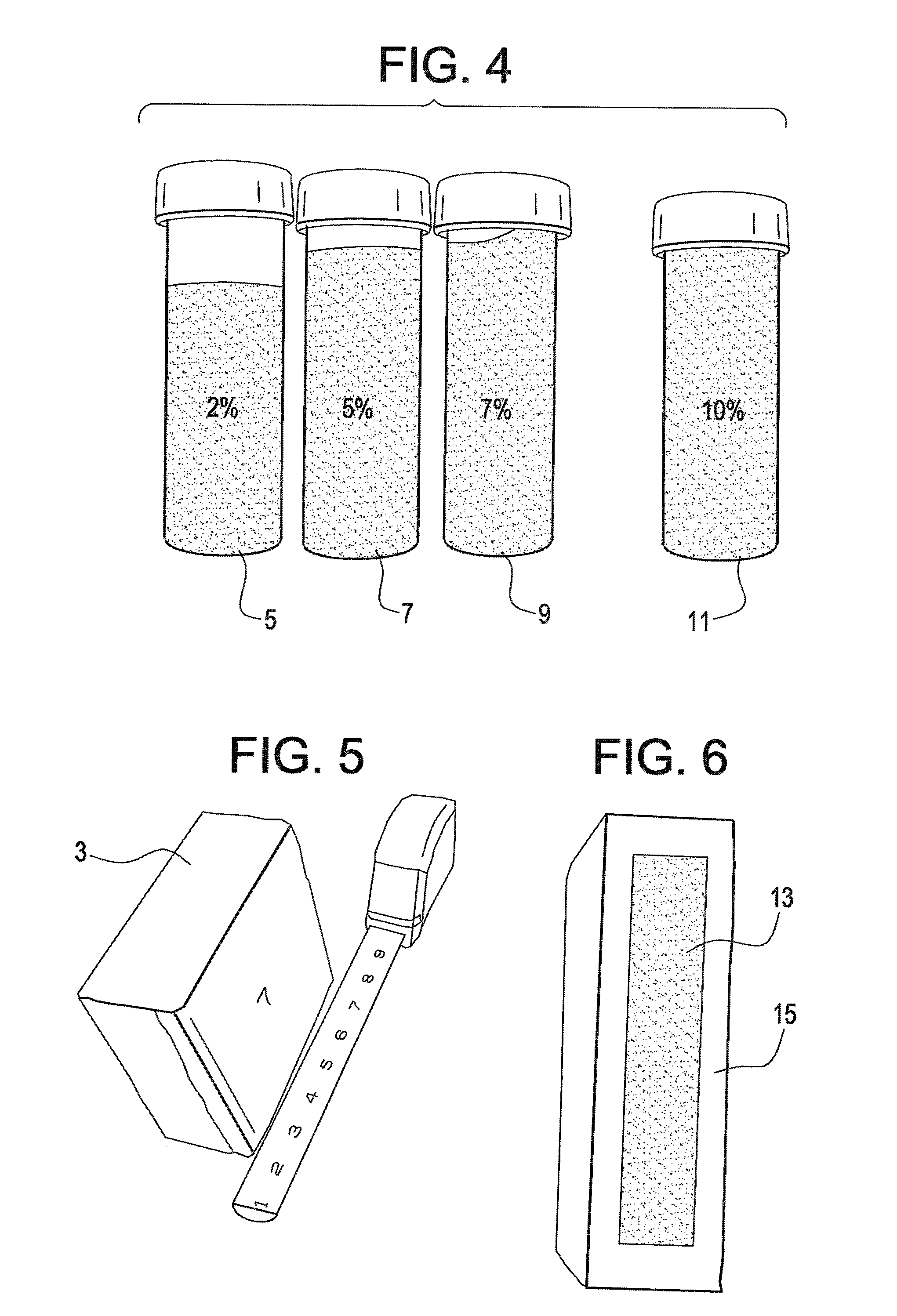

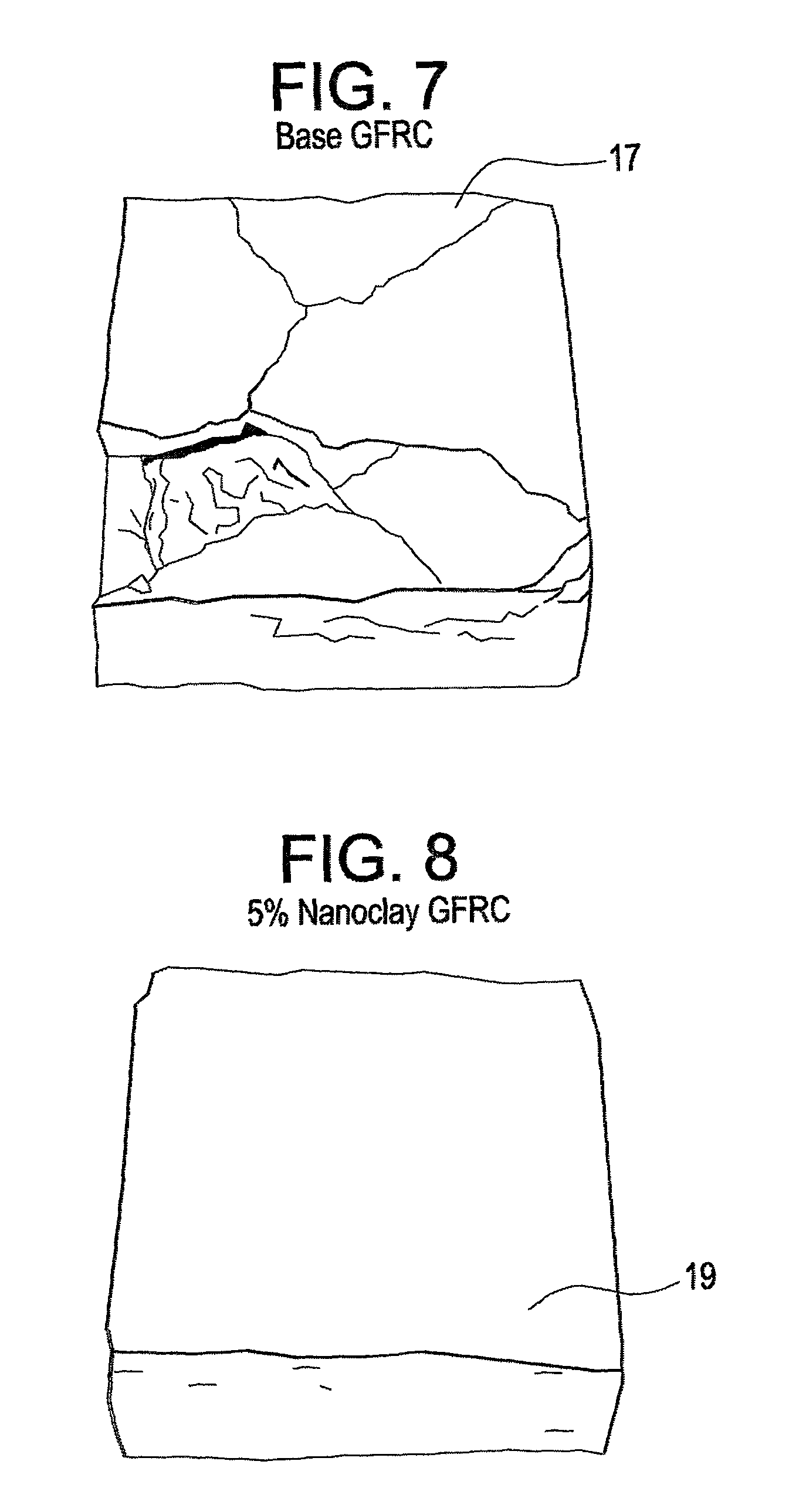

Highly flame retardant foam concrete

ActiveUS8399089B1Improve flame retardant performanceEmission reductionNatural mineral layered productsThin material handlingFiberFoam concrete

A nanomaterial based admixture improves the fire retardancy of foam-based GFRC material to a minimum of 3 hours, creating Nano GFRC. A dispersion of nanoclay in water is prepared by heating water to 80-90 ° C., adding the desired amount of nanoclay and stirring with a magnetic stirrer for 30-45 minutes, producing a stable and uniform dispersion. Concrete is made by mixing sand, acryl, water, nanoclay solution, and cement in a bucket, adding enough water reducer to thin the mixture enough to stir, adding fibers, and mixing the composite using a rotor for about 10 minutes. Polystyrene foam is sandwiched with the prepared mixture on all sides to make the concrete. This resulting concrete is lightweight and strong, reduces CO and CO2 emissions by a factor of three compared to standard GFRC, and shows dramatic improvement in fire retardant properties.

Owner:OCEANIT LAB

Method and device for application of liquid polymeric material onto spinning cords

The present disclosure relates to a method and a device for application of liquid polymeric material onto the active spinning zone of the cord of the spinning member of the spinning electrode, where the application means moving reversibly along the active spinning zone of the cord in the device for production of nanofibres through electrostatic spinning of liquid material in electrostatic field of high intensity between at least one spinning electrode and against it arranged collecting electrode. The liquid polymeric material is applied onto the cord around its whole circumference without any contact with gaseous environment in the spinning space, where the application means reversibly moves, whereas while the cord is leaving the application means the thickness of the layer of the liquid polymeric material is being reduced and immediately after leaving the application means the process of electrostatic spinning of the liquid polymeric material applied on the cord is started.

Owner:ELMARCO SRO

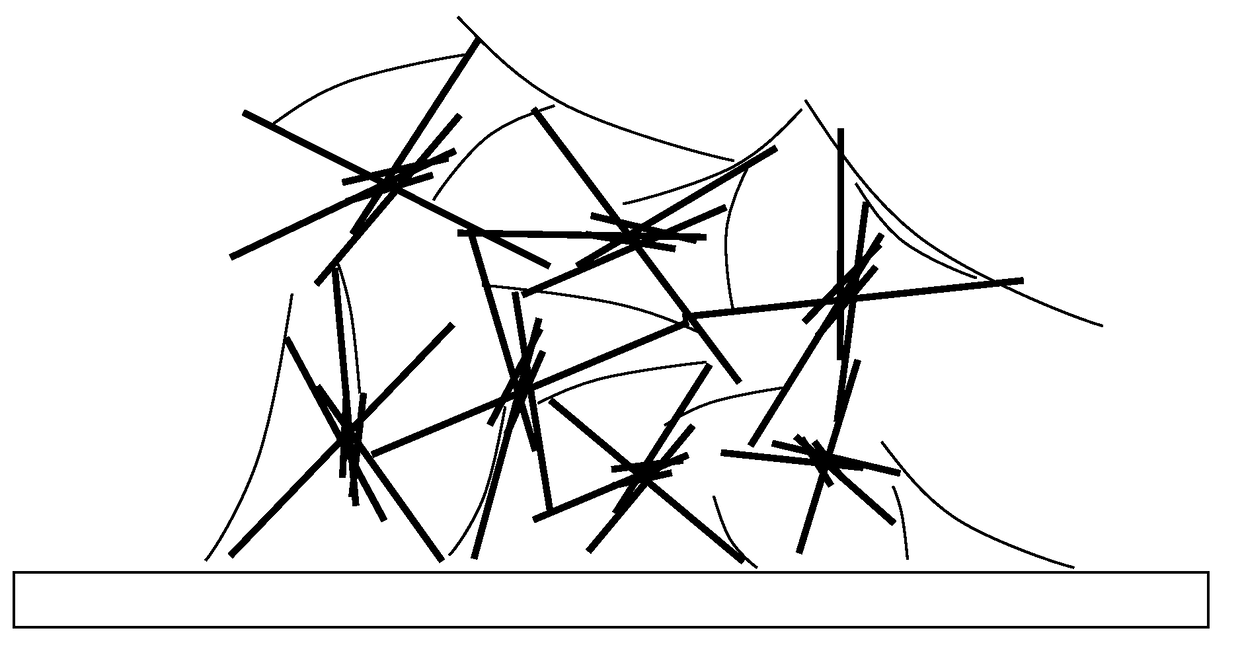

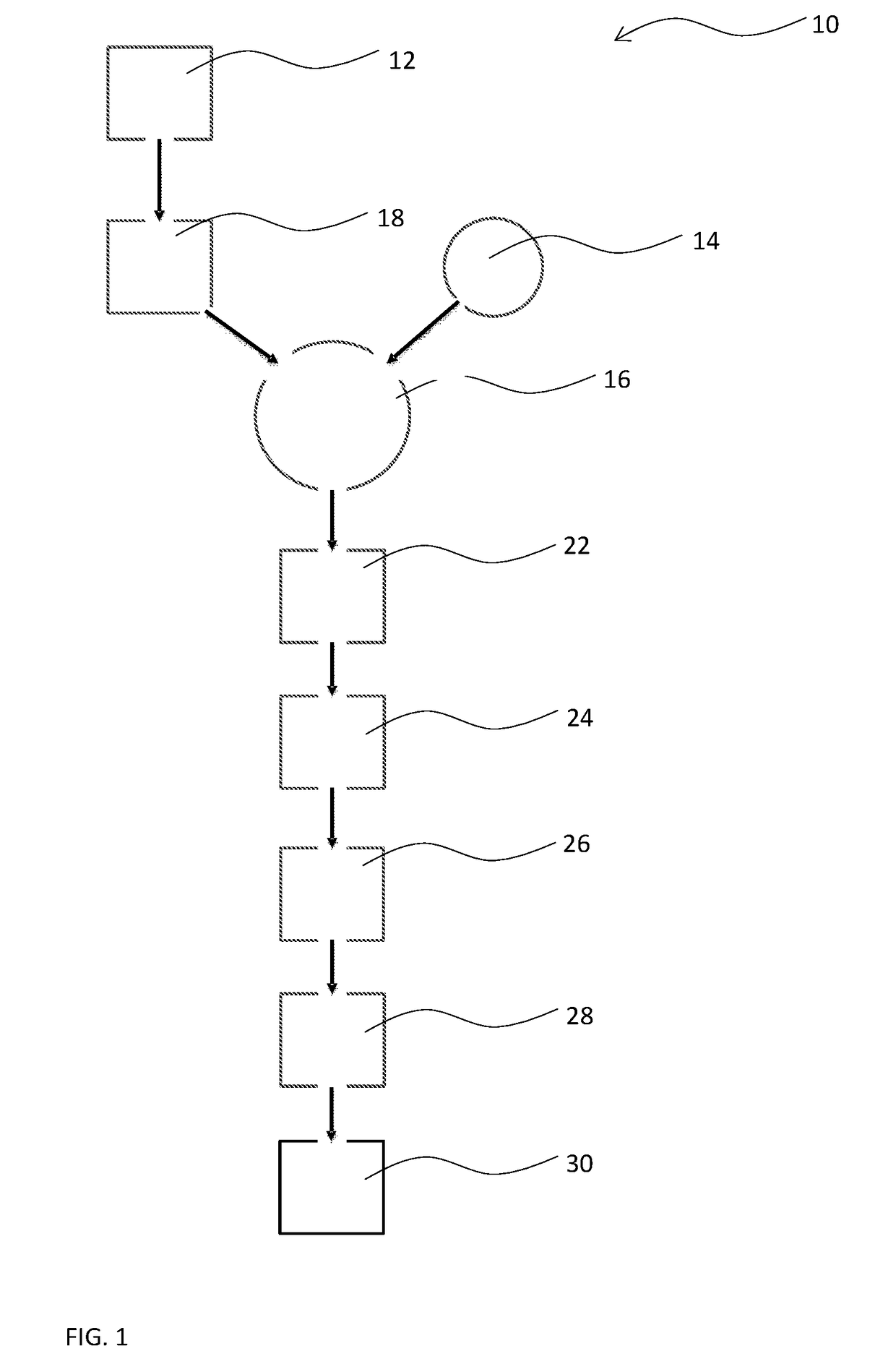

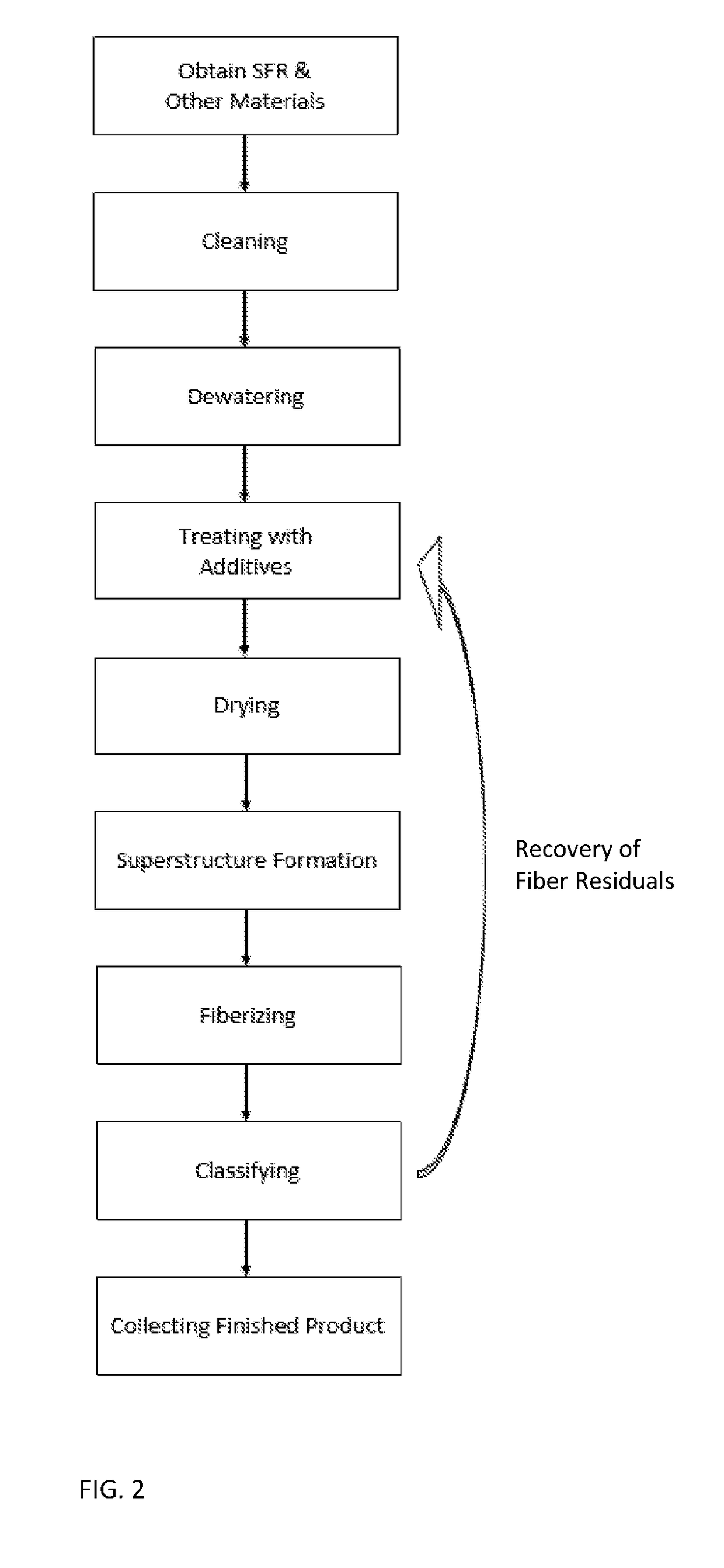

Cellulose-based insulation and methods of making the same

PendingUS20180320367A1Adequate and sustainable supplyLow costConstruction materialFibre treatmentFiberCellulose

A cellulose-based fire resistant insulation and related method for making the same. The insulation includes a plurality of superstructures that establish voids in the insulation. The insulation may be blown in place while the superstructures maintain the void portion of the insulation. The insulation is made with fiber residuals, either alone or in combination with other cellulosic materials. The method of making the insulation includes the steps of treating the cellulosic materials with a fire retardancy chemical or chemicals and creating bonds between the fibers to form the superstructures.

Owner:CLEANFIBER INC

Phosphorus-containing bisphenols and preparing method thereof

ActiveUS8134021B2Material is delayedImprove propertiesPhosphorus organic compoundsMedicinal chemistryBisphenol

The Phosphorus-containing bisphenols and preparing method thereof are disclosed. A method for producing the phosphorus-containing bisphenol of the formula (1) includes reacting compounds respectively defined by a formula (a), (b), (c) and an acid catalyst to yield compounds of phosphorus-containing bisphenol.

Owner:CHANG CHUN PLASTICS CO LTD

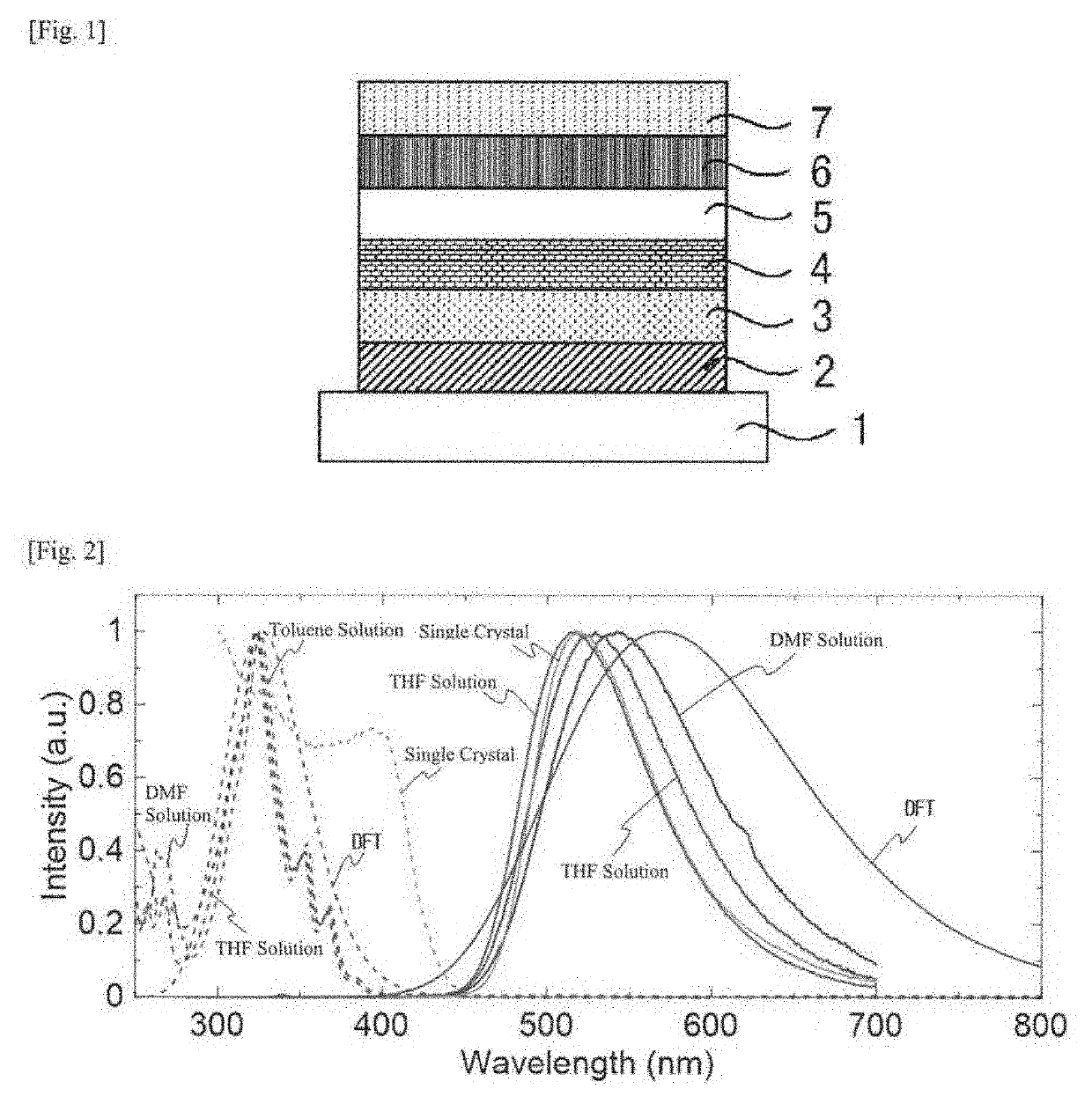

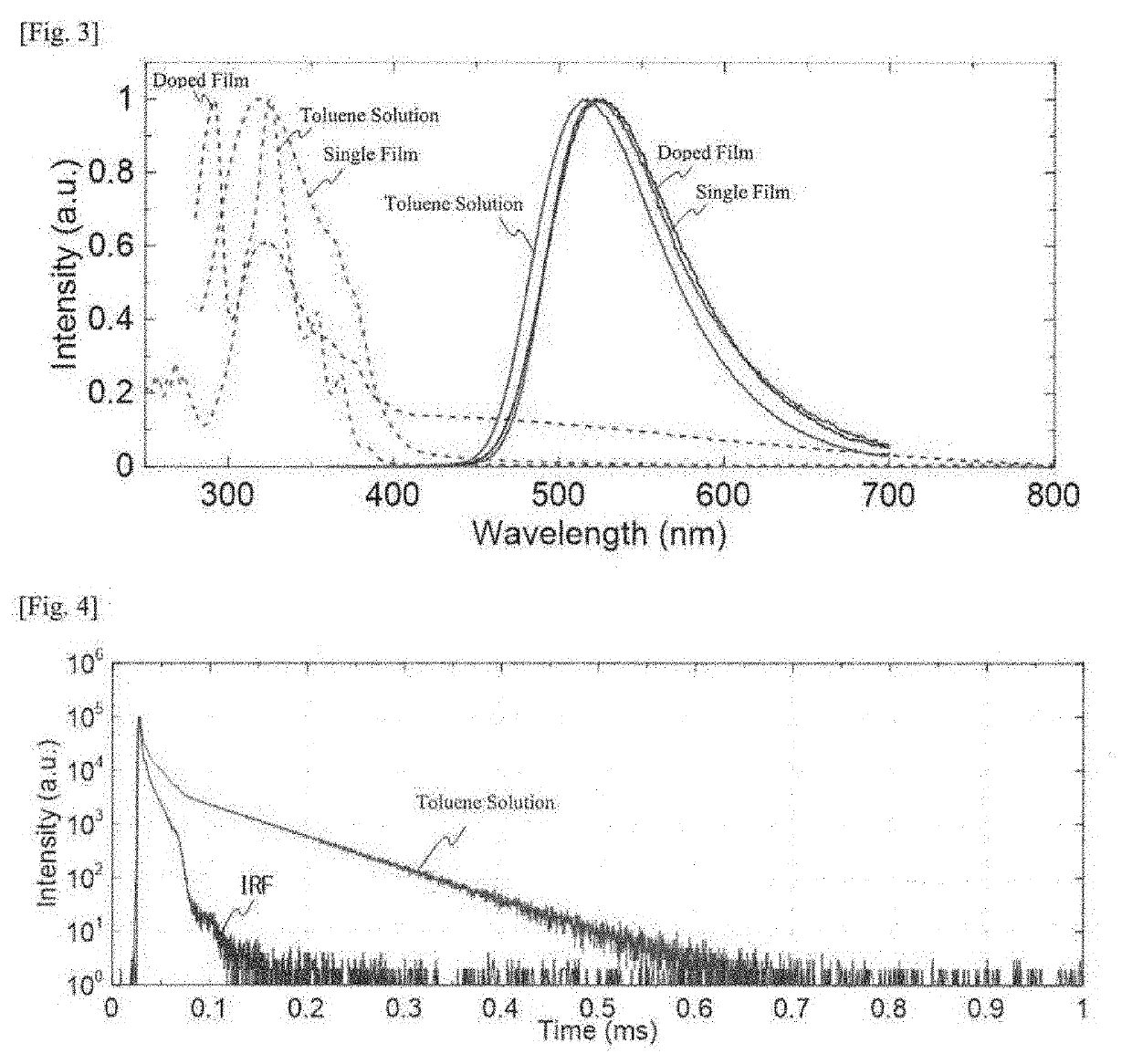

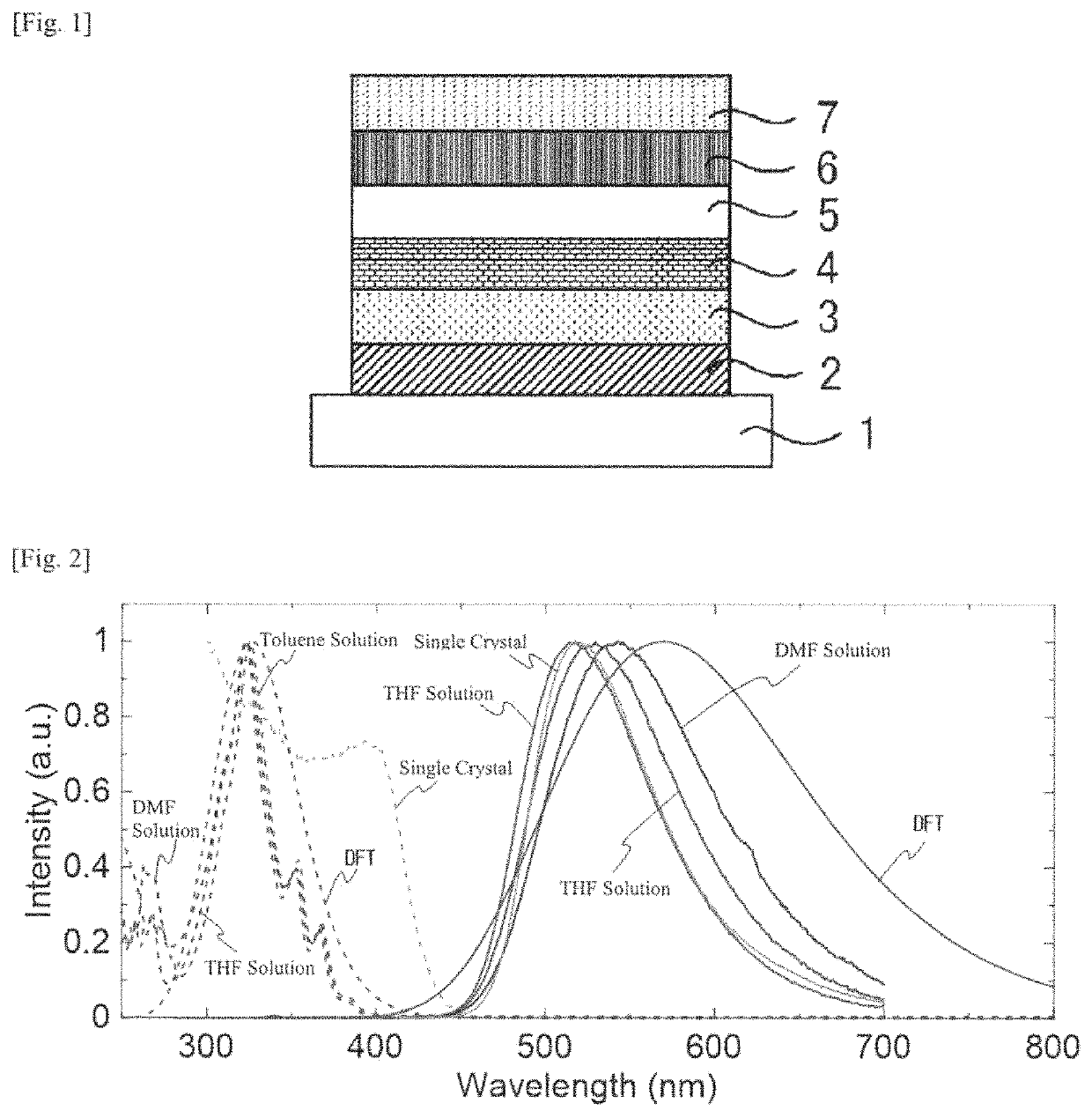

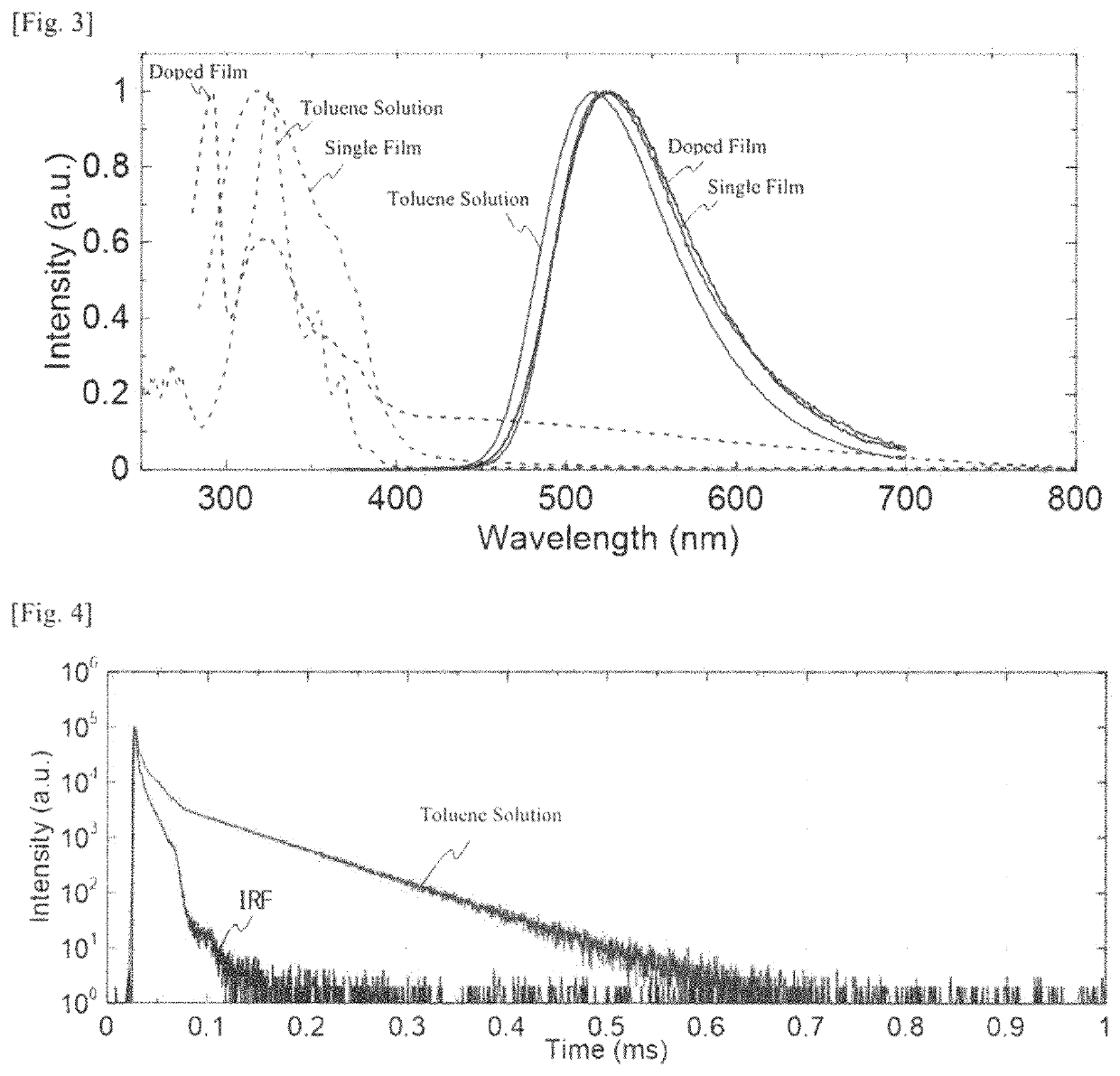

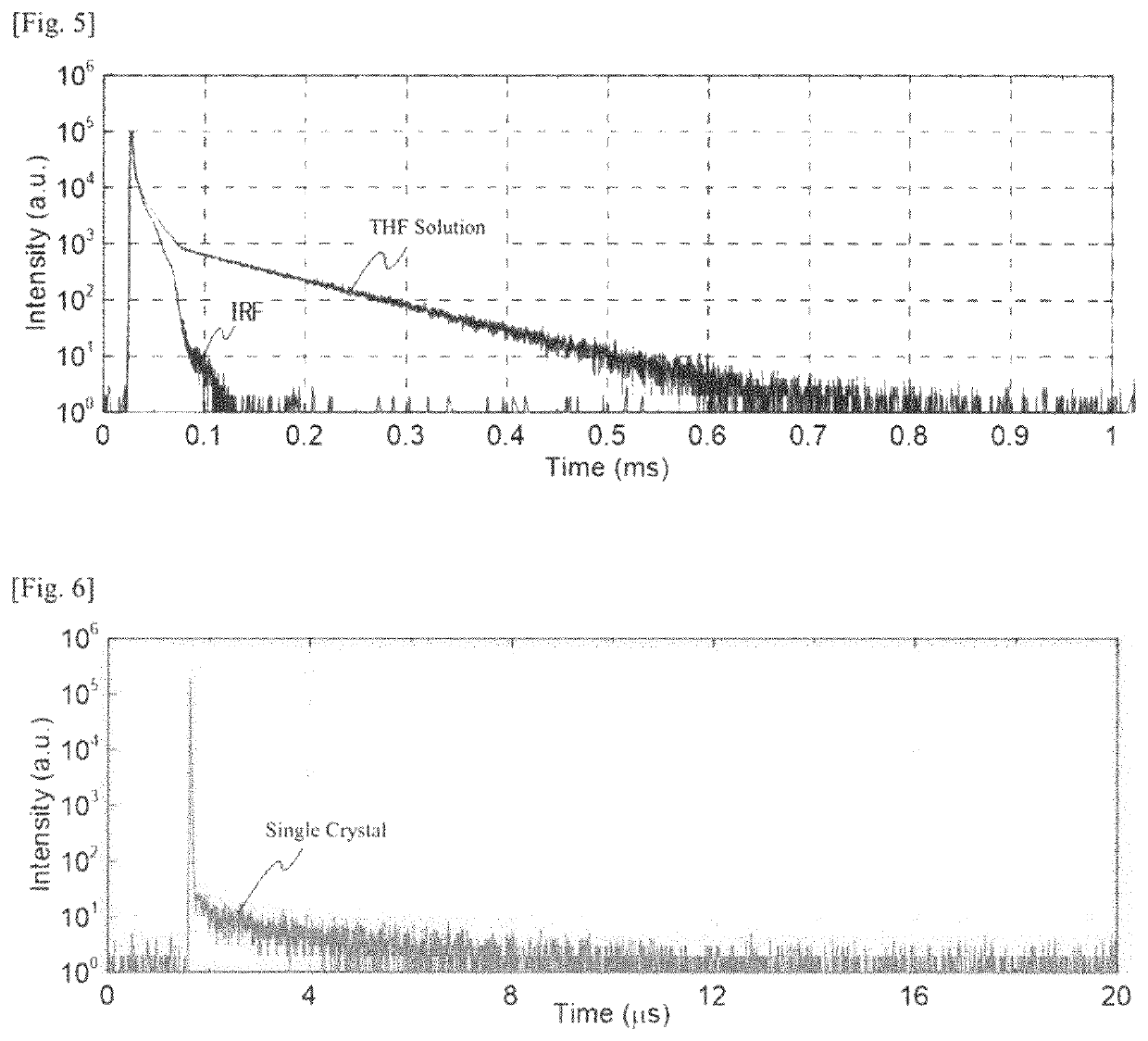

Organic light-emitting element, and light-emitting material and fluorescent body used in same

ActiveUS20190348617A1High quantum yieldImprove stabilityOrganic chemistrySolid-state devicesOrganic light emitting deviceFluorescence

Disclosed is an organic light-emitting device using a compound capable of emitting delayed fluorescence and capable of undergoing intramolecular hydron transfer. The compound includes, for example, a compound represented by the general formula. X1 to X3 each represent O or S; R1 to R6 each represent nH or a substituent; n, n1 to n3 each represent an integer of 1 to 3.

Owner:KYUSHU UNIV +1

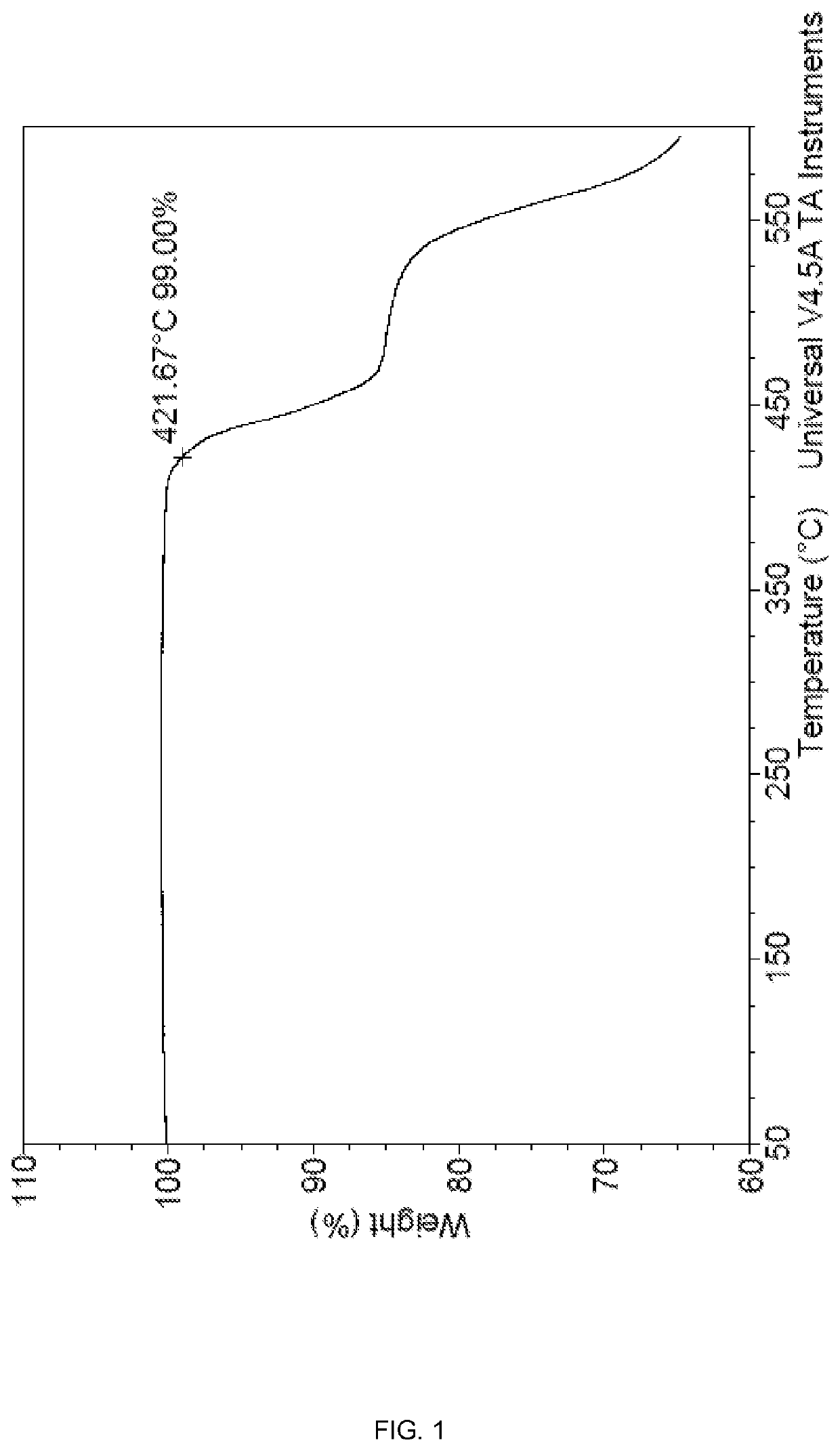

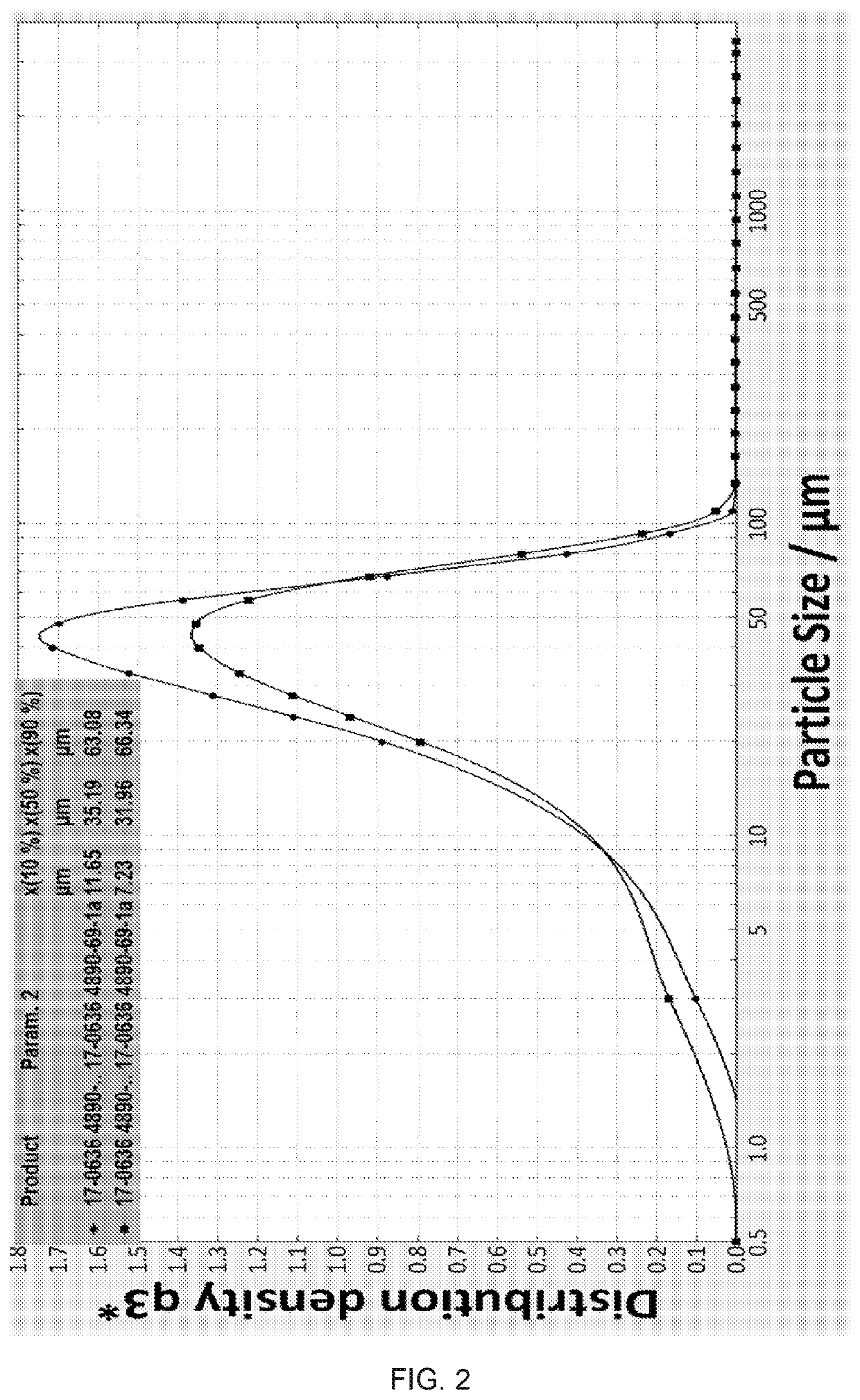

Method For Preparing Readily Processable, Thermally-Stable, Phosphorus-Containing Flame Retardant Material

PendingUS20220081536A1Improve processingSpeed up the processGroup 5/15 element organic compoundsPhosphorus halideMiscibility

The present disclosure provides for the production of non-halogenated phosphorus containing, thermally stable flame retardant materials directly in the form of a powder or small particles. The process generally includes heating one or more phosphonic acid salts in a high boiling, water miscible, acid stable solvent to dehydration reaction temperatures of 200° C. or higher.

Owner:LANXESS CORP

Vascular channel manufacture by deflagration

ActiveUS10744682B2Minimize thermal effectMaterial is delayedAdditive manufacturing apparatusDomestic articlesEngineeringMechanical engineering

A method of forming channels within a substrate includes: (a) molding a sacrificial component directly into the substrate; (b) igniting the sacrificial component to cause a deflagration of the sacrificial component, thereby forming a channel in the substrate; and (c) cleaning the channel in the substrate to remove byproducts of the deflagration of the sacrificial component. The sacrificial component includes a combustible material with a protective shell, and the substrate includes a polymeric material.

Owner:GM GLOBAL TECH OPERATIONS LLC

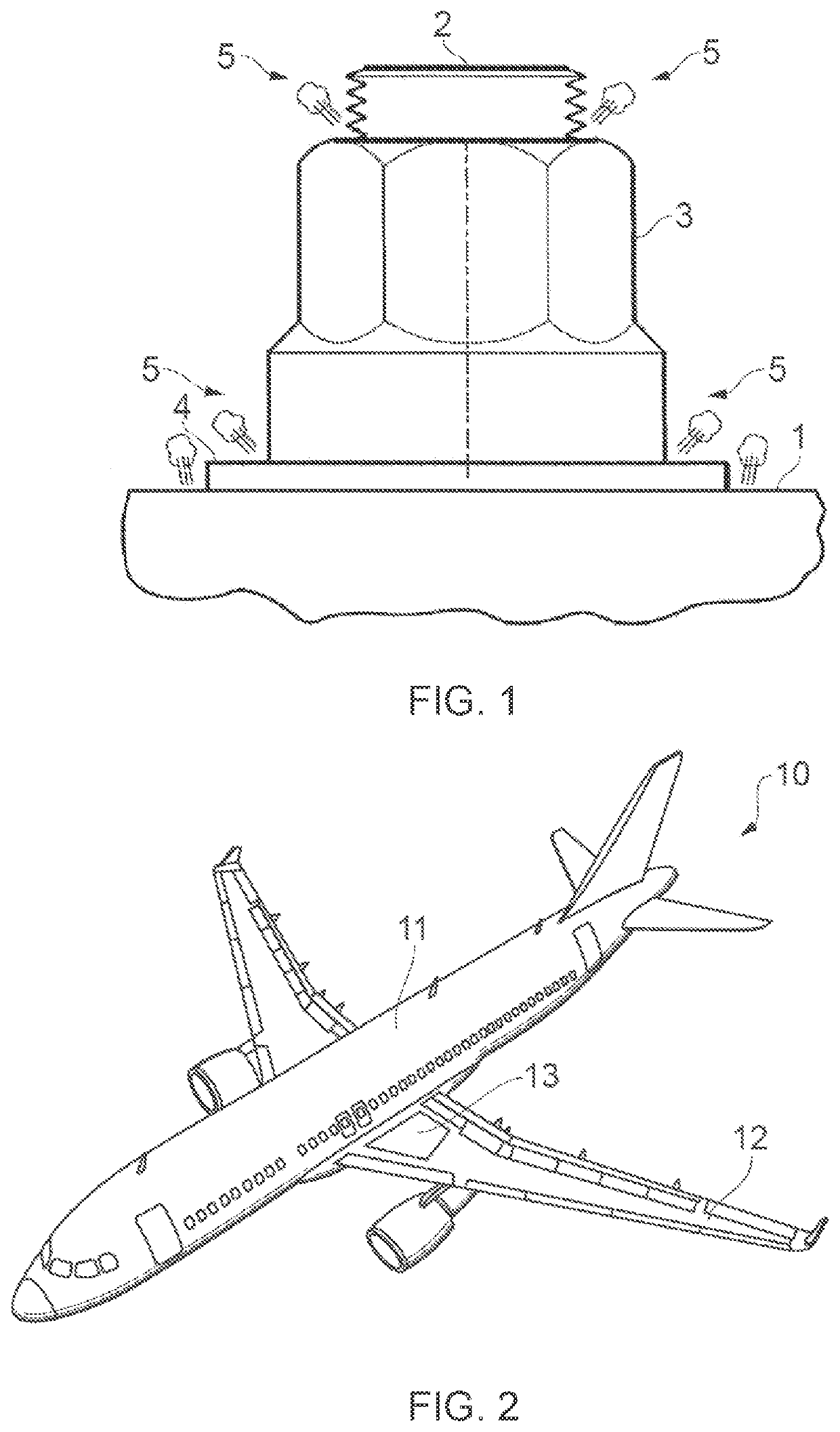

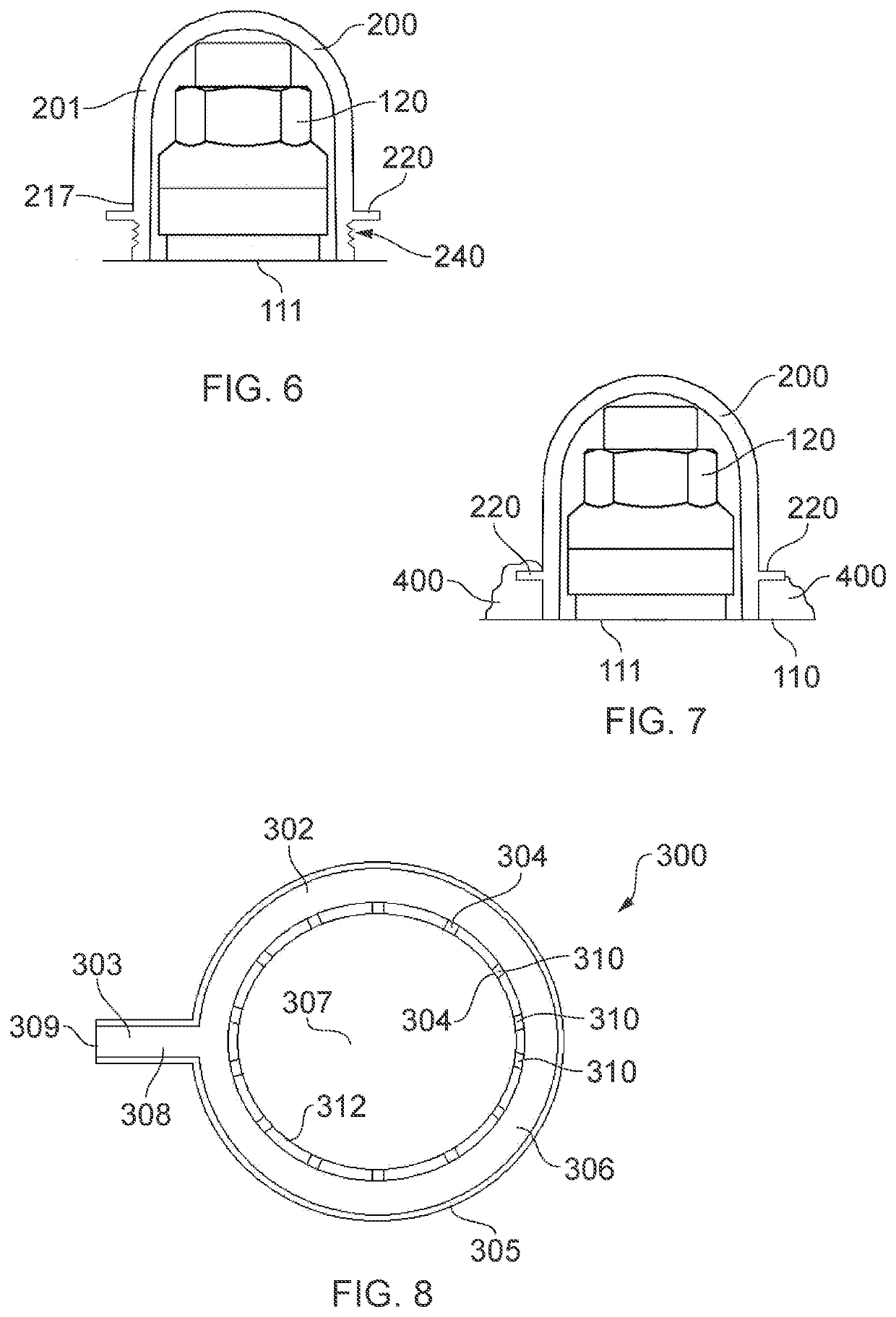

Spark containment cap

PendingUS20200165006A1Speed up the flowMaximize contact areaLiquid surface applicatorsAircraft lighting protectorsEngineeringSealant

A spark prevention cap is disclosed. The cap forms a sealed cavity around an end of a fastener protruding from a surface of a structure, for example, an aircraft structure. The cap has a cap body with an annular base terminating at a rim. The rim surrounds an opening into a central cavity for receiving the end of the fastener. The annular base has an external circumferential surface extending from the base rim, and a mating feature on the external circumferential surface configured to contact a sealant material applied externally to the cap.

Owner:AIRBUS OPERATIONS LTD

Organic light-emitting element, and light-emitting material and fluorescent body used in same

ActiveUS11322693B2High quantum yieldHigh light emitting efficiencyOrganic chemistrySolid-state devicesOrganic light emitting deviceFluorescence

Disclosed is an organic light-emitting device using a compound capable of emitting delayed fluorescence and capable of undergoing intramolecular hydron transfer. The compound includes, for example, a compound represented by the general formula. X1 to X3 each represent O or S; R1 to R6 each represent nH or a substituent; n, n1 to n3 each represent an integer of 1 to 3.

Owner:KYUSHU UNIV +1

Packet for a spreadable condiment

A packet for a spreadable condiment. The housing defines an interior cavity to contain the condiment. An upper layer oppositely disposed of a lower layer to form the interior cavity. The upper layer is secured to the lower layer by an adhesive. The housing has a tab which can be removed to make an opening for the condiment to be passed through. Furthermore, the housing has an indicia to indicate the contents of the housing. Additionally, the housing has a peelable layer to provide additional access to the housing.

Owner:HEBERT DAMON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com