Heat conduction metal core and PCB (Printed Circuit Board) board using same

A heat-conducting metal and PCB board technology, applied in the direction of cooling/ventilation/heating transformation, printed circuit components, etc., can solve the problems of non-grounded heat sink, low production efficiency, complex process, etc., to achieve tight integration, good heat dissipation effect, The effect of simple heat conduction structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

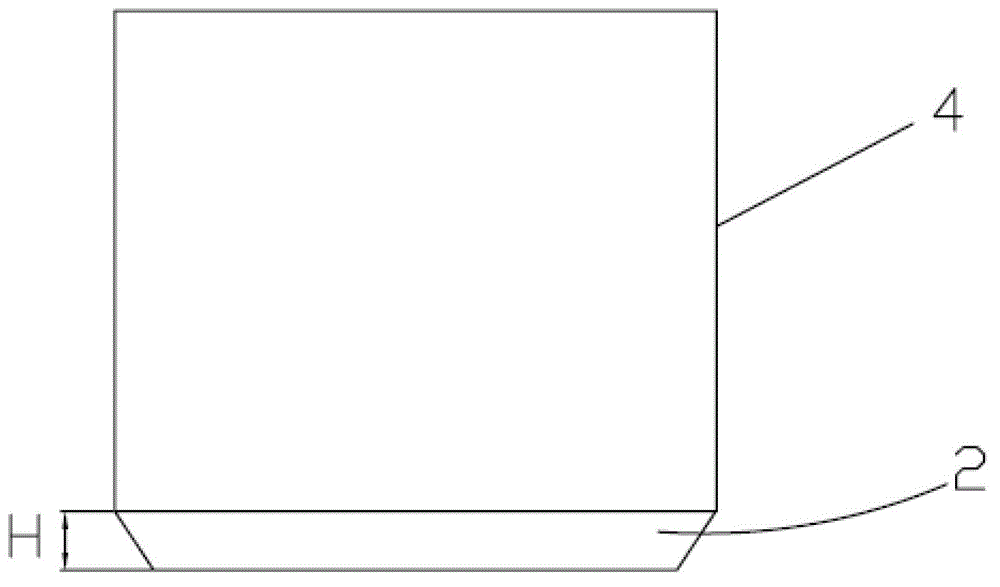

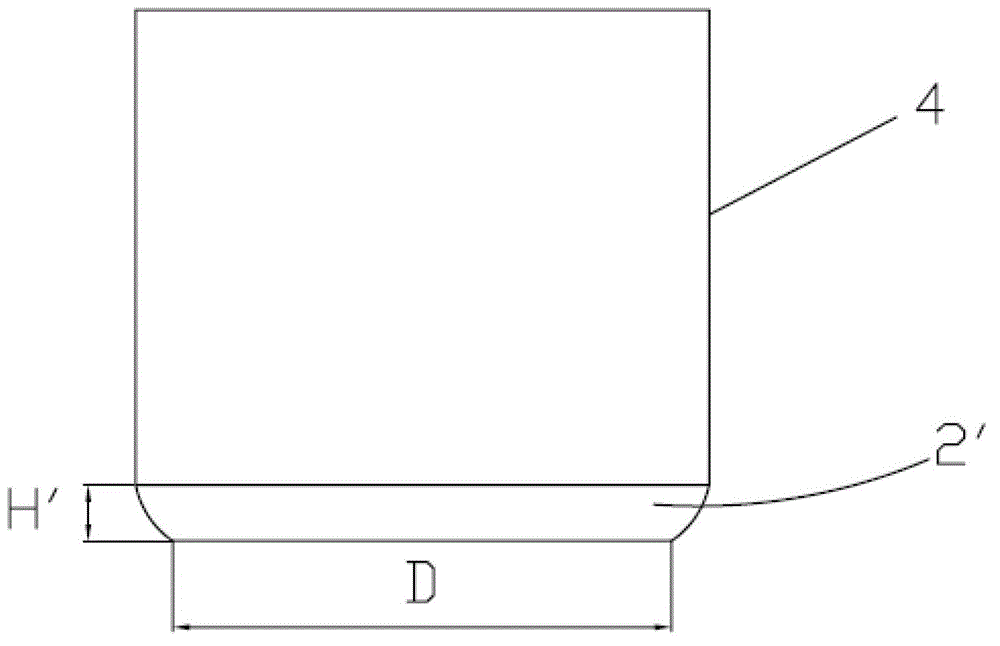

[0027] see figure 1 , the present invention provides a heat-conducting metal core, including a core body 4, and an introduction structure 2 axially extended from the end of the core body 4. .

[0028] Wherein, the introduction structure 2 can be arranged at one end or both ends of the core body 4 , and in this embodiment, the introduction structure 2 is only arranged at one end of the core body 4 .

[0029] The longitudinal section of the introduction structure 2 is trapezoidal, that is, the longitudinal section passing through the axis of the core 4 is trapezoidal. The height H of the trapezoid is between 0.2mm and 0.5mm.

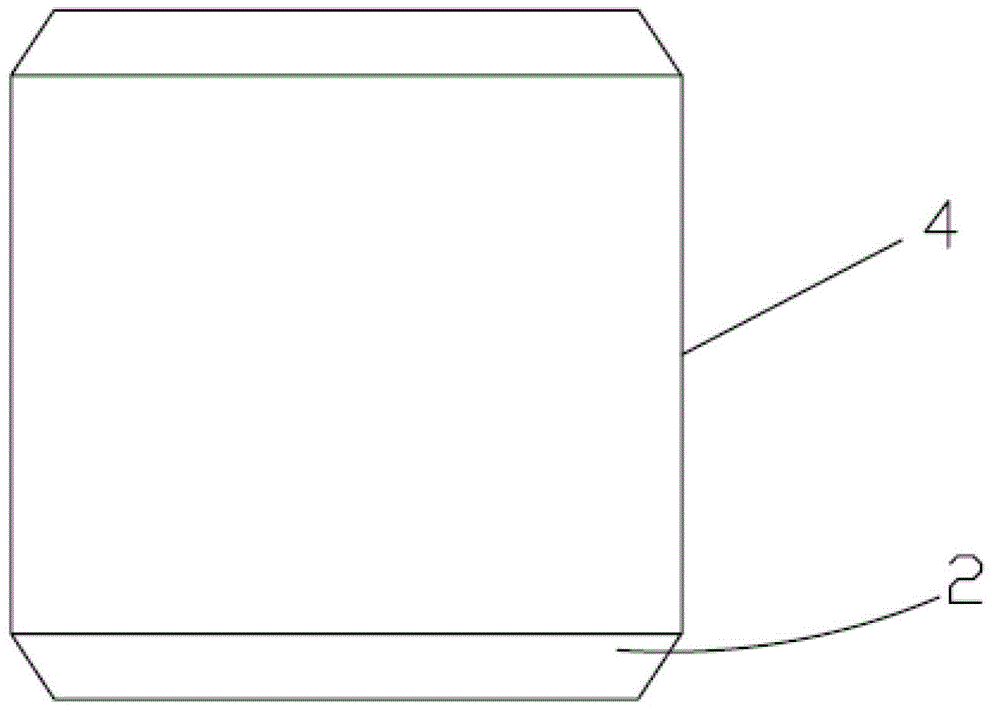

[0030] see figure 2 , is a schematic structural diagram of the second embodiment of the heat-conducting metal core of the present invention. In this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com