Fast EGR valve capable of being controlled precisely

An EGR valve, precise control technology, applied in engine components, exhaust gas recirculation, machine/engine, etc., can solve the problems of complex stepper motor control technology, lag in exhaust gas flow adjustment response, slow response speed of valve stem movement, etc. Avoid contamination and corrosion, fast automatic reversal, and the effect of increasing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

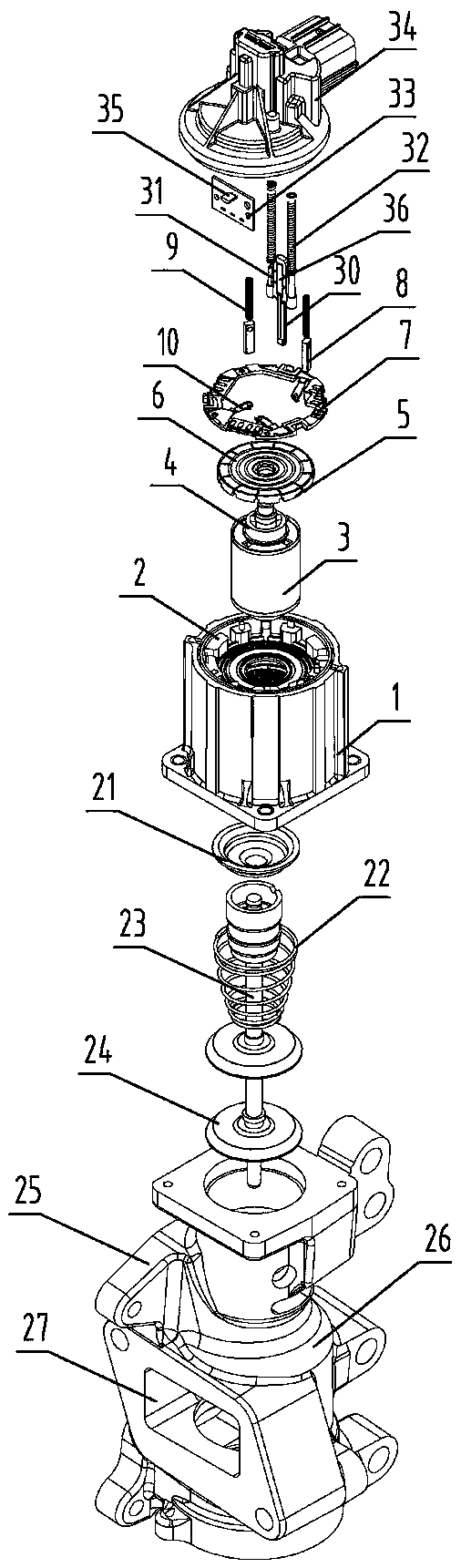

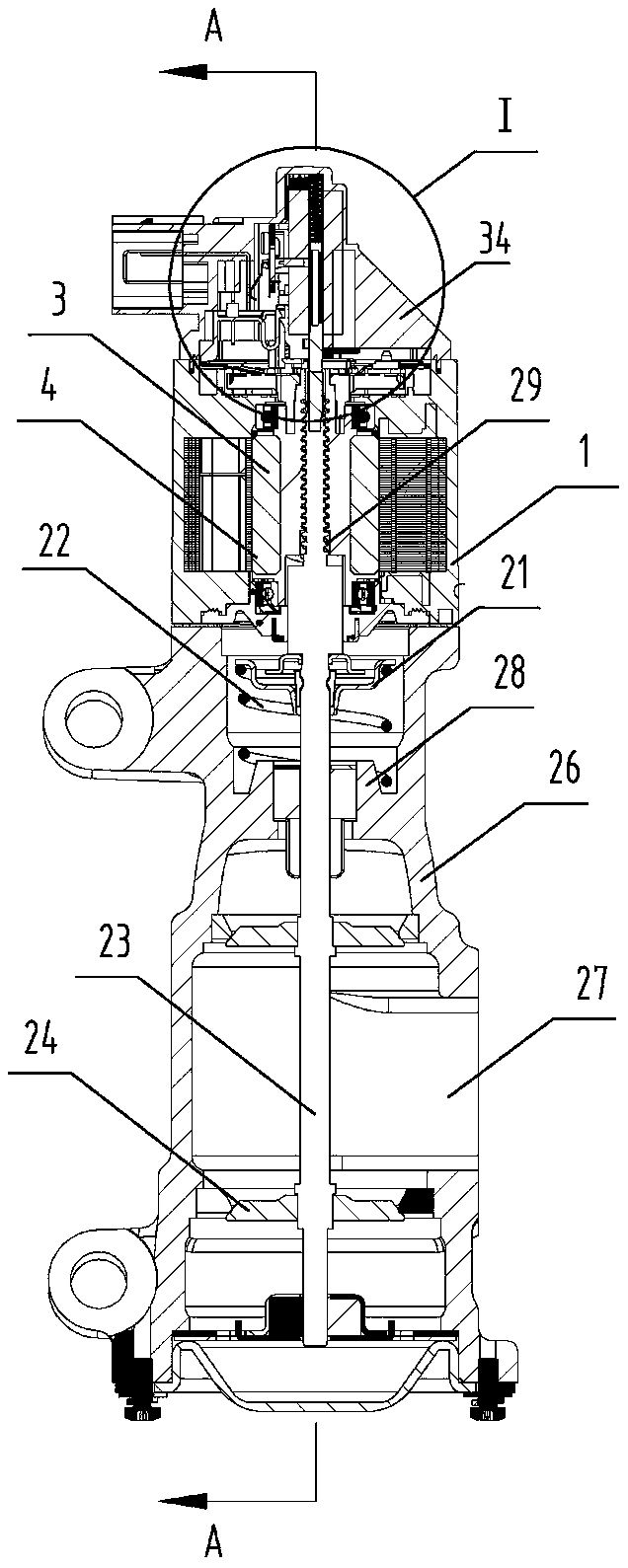

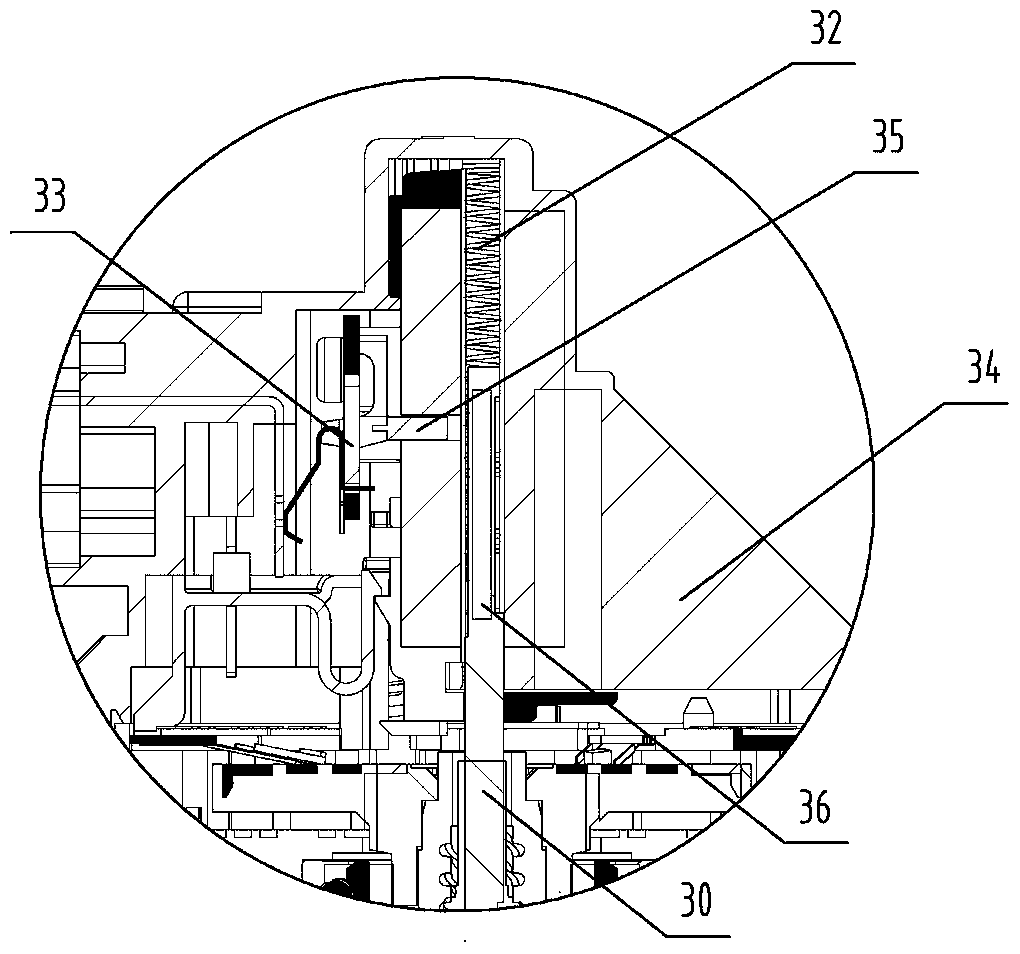

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] The present invention according to figure 1 The upper and lower positions corresponding to the placement state are defined as upper end (top) and lower end.

[0039] Such as figure 1 and figure 2 As shown, the present invention divides the housing of the whole valve into three parts: the motor casing 1, the end cover 34 and the valve seat 26. The end cover 34 is installed on the upper port of the motor casing 1, and the valve seat 26 is installed on the motor casing. 1 on the lower port. An air inlet 27 and an air outlet 25 are provided on the valve seat 26 . The stator 2 of the brushless motor and the rotor of the brushless motor are installed in the motor housing 1. The rotor adopts the structure that the magnetic ring 3 is placed outside the iron core 4. The trapezoidal internal thread 29 is processed in the iron core 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com