Suction roll cross-folding creasing device of envelope (flat pouch) processor

A technology for making machines and flat bags, which is applied in the fields of envelope/bag manufacturing machinery, packaging, transportation and packaging, etc., and can solve the problem that it is difficult to make qualified envelopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

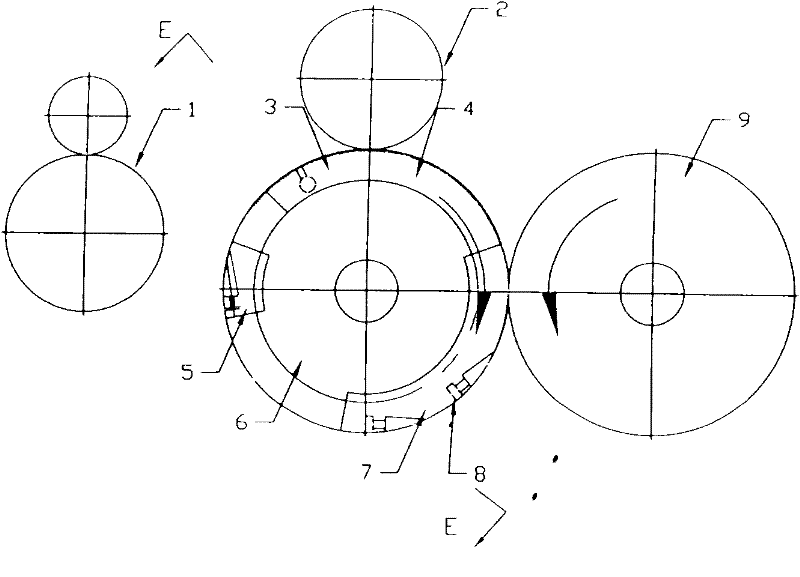

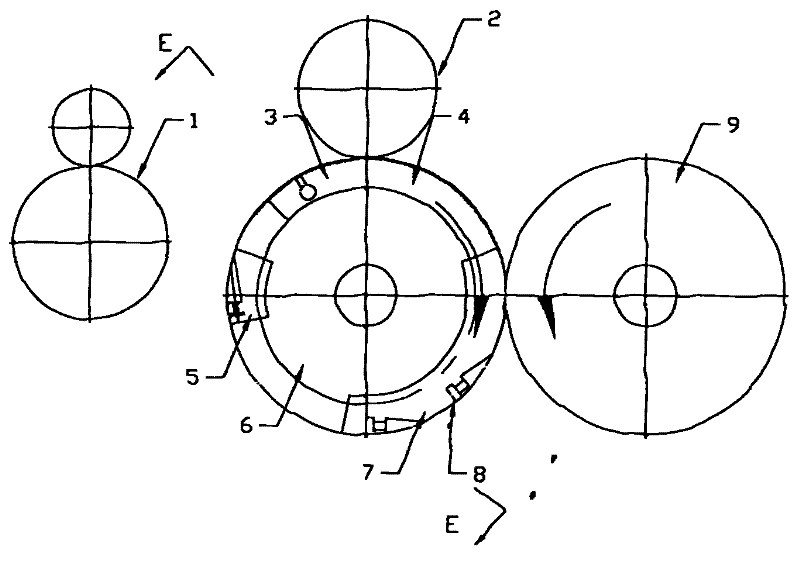

[0006] Such as figure 1 As shown, the paper is transferred from the front roller (1) to the suction arc plate (3), the paper head runs past point A by 10mm, adjust the ventilation of the air distribution sleeve (10), and the paper at the suction hole of the arc plate rotates and runs to point B for release. Air, the rear roller (9) absorbs the paper and transfers it to the lower functional area. The paper is running, and the two creasing knives (8) on the front and rear creasing knife seats press out two fold lines through the rubber roller (2). The distance between the folded lines is the width of the envelope (flat bag) made.

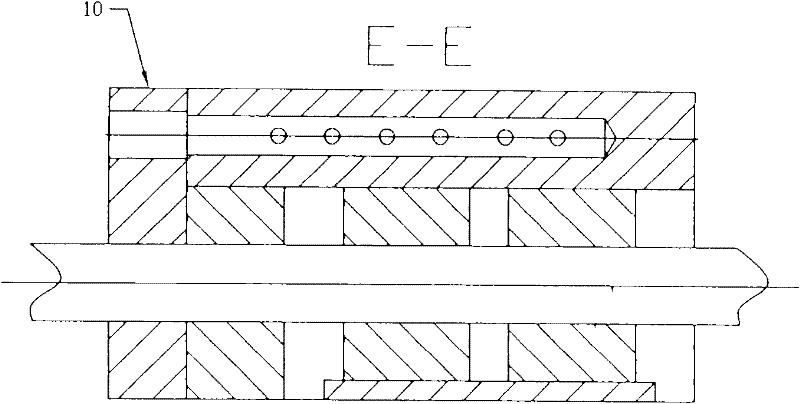

[0007] Such as figure 2 As shown, the suction arc plate (3) is fixed on the arc plate fixed plate (4), and the front and rear indentation tool holders are fixed on the knife seat fixed roller (6). Loosen the screws on the fixed plate (4) to adjust The position of the suction arc plate (3), the front creasing knife seat (5) equipped with the creasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com