Multiple crimped wire manufacturing device, two terminal-crimped wire manufacturing method, multiple wire feeding device, terminal crimping method, and terminal crimping device

A terminal crimping and manufacturing device technology, which is applied in the direction of connection and connection, circuit/collector parts, circuits, etc. by deformation, can solve the problem of not mentioning wire bending repair methods, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

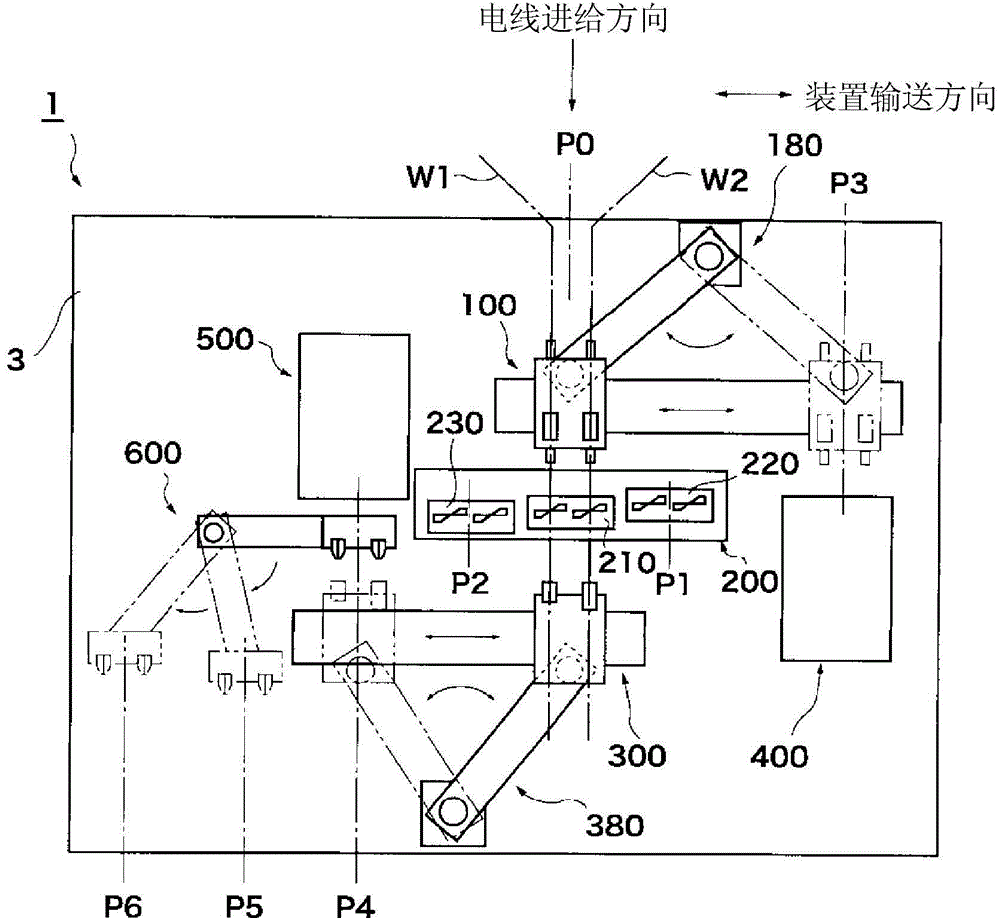

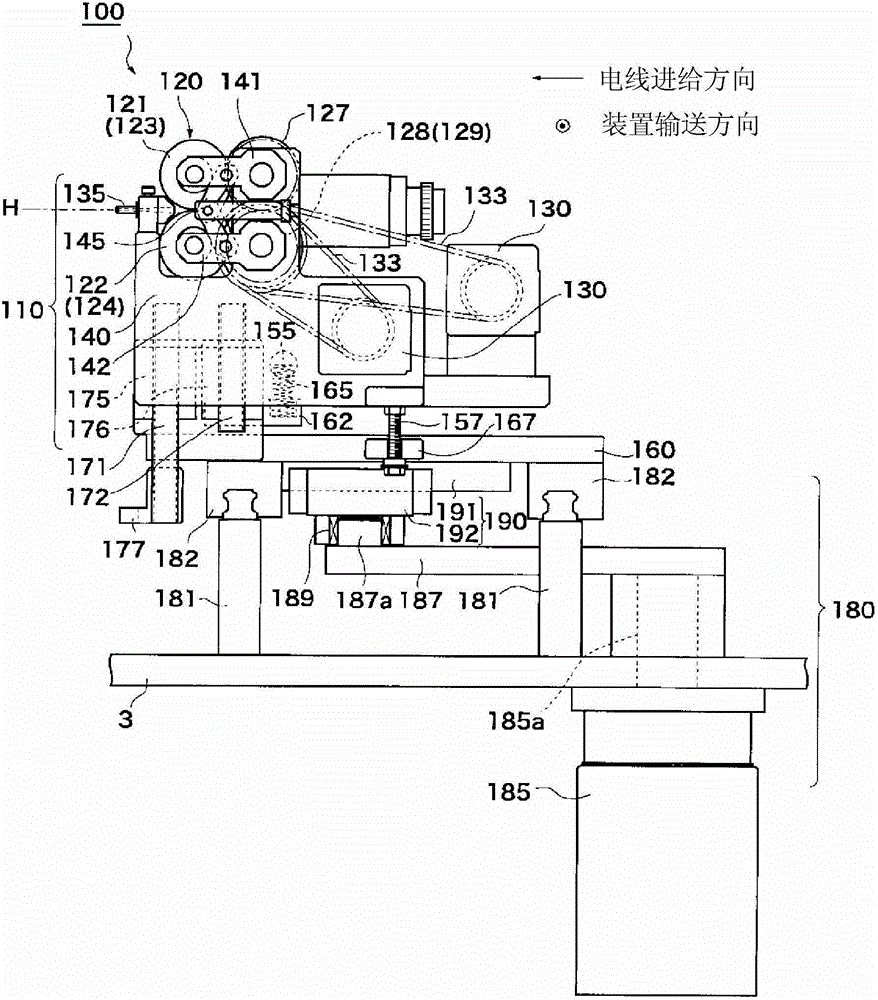

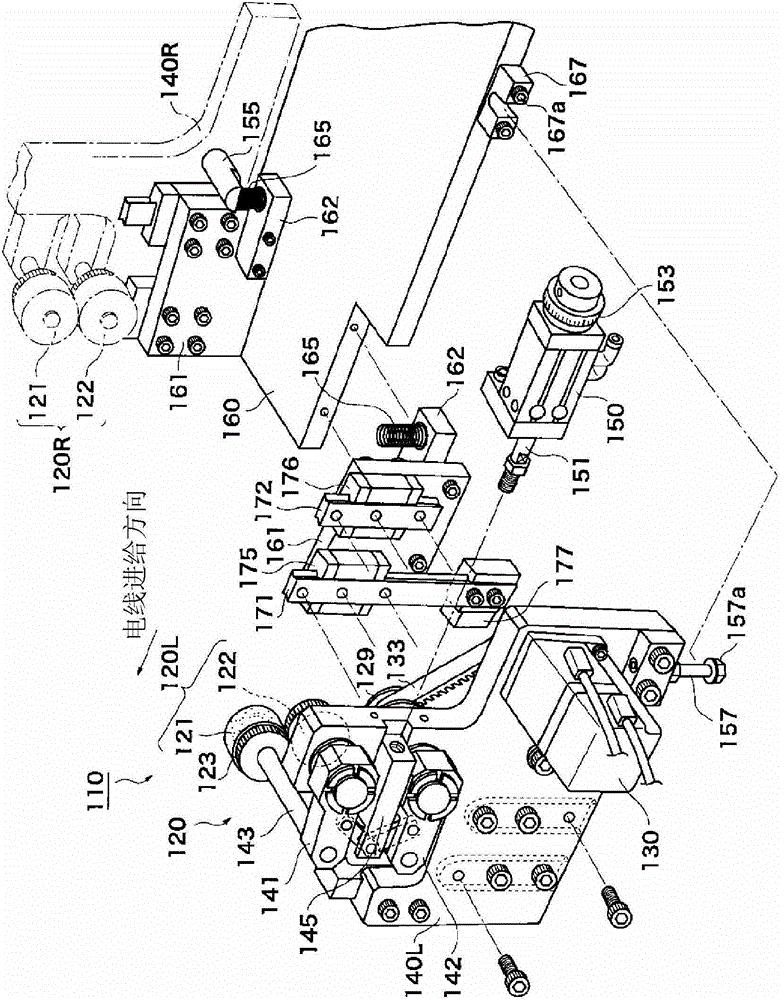

[0099] First, refer to figure 1 The overall structure of the multi-wire terminal crimping electric wire manufacturing apparatus of the present invention will be described. In this example, a two-wire type terminal crimping electric wire manufacturing apparatus that manufactures two terminal crimping electric wires will be described.

[0100] The two-wire type terminal crimping wire manufacturing apparatus 1 includes a wire feeding device 100 for feeding out (feeding out) wires from a wire bundle and clamping the wires, a cutting and stripping device 200 for cutting the wires and peeling off the sheath, The rear end clamping device (Japanese: テールルランプ) 300 for clamping the rear end of the cut electric wire, and the front end terminal crimping device for crimping the terminal at the front end of the electric wire clamped by the electric wire feeding device 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com