Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

440results about "Wood stock bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

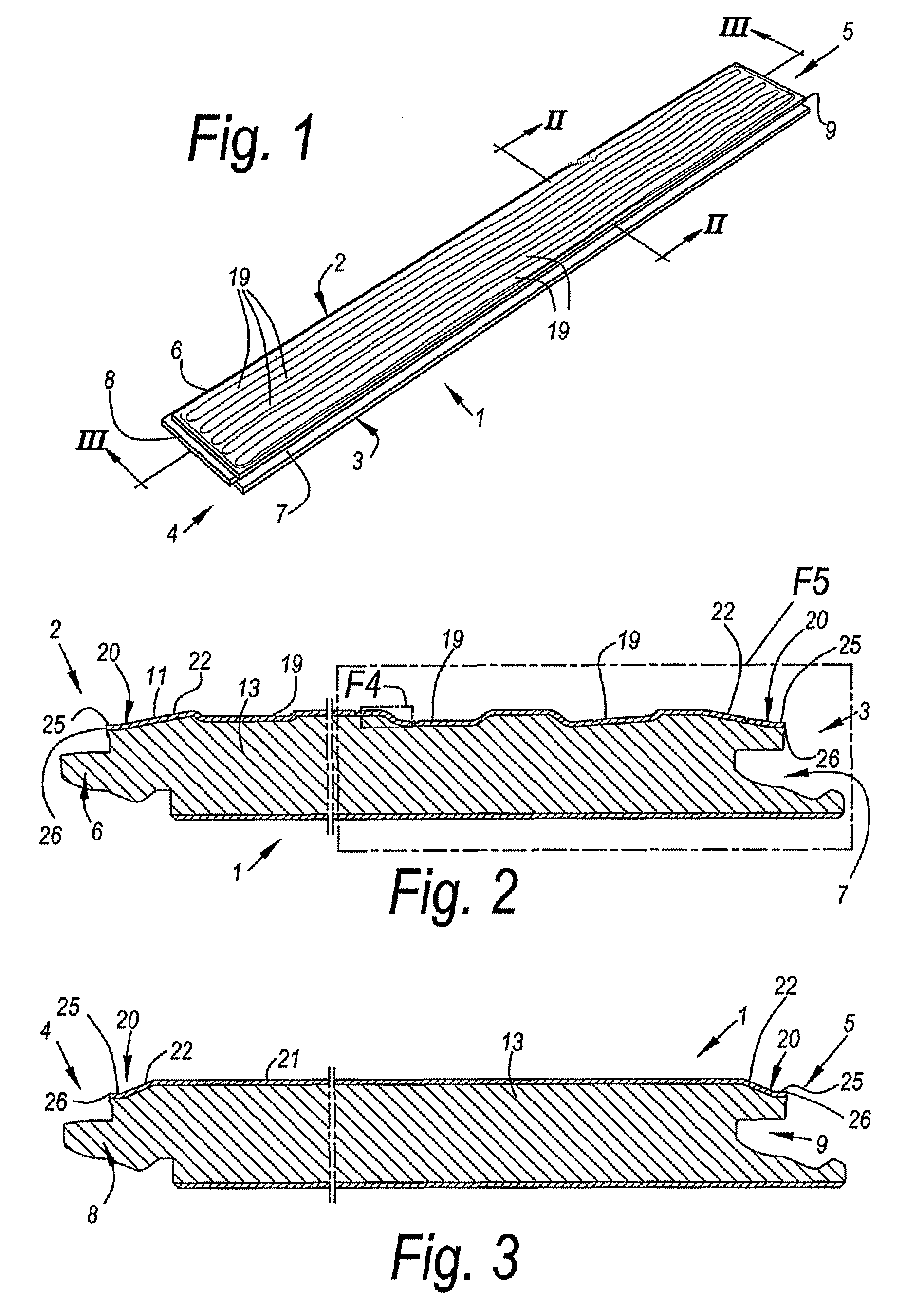

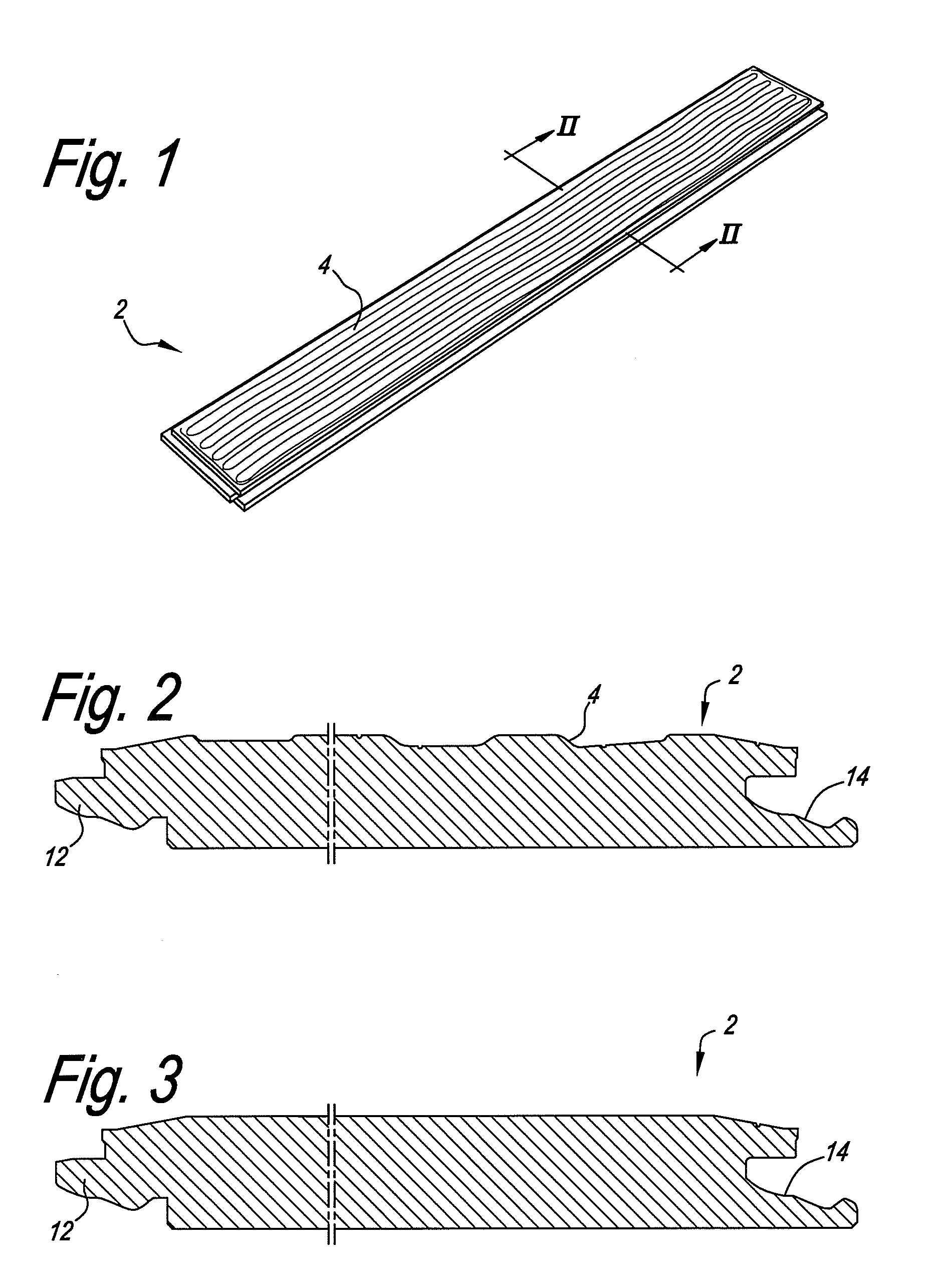

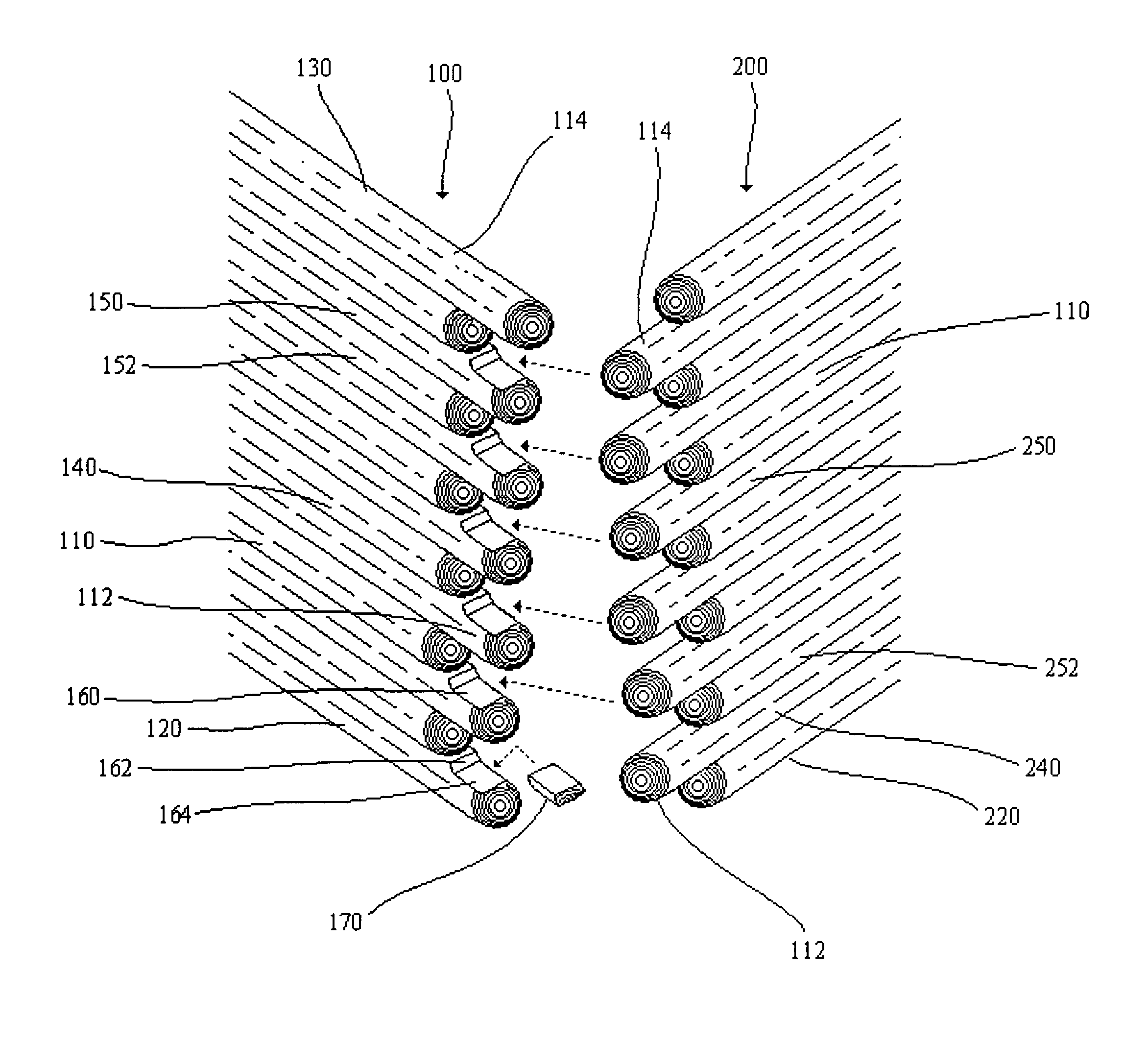

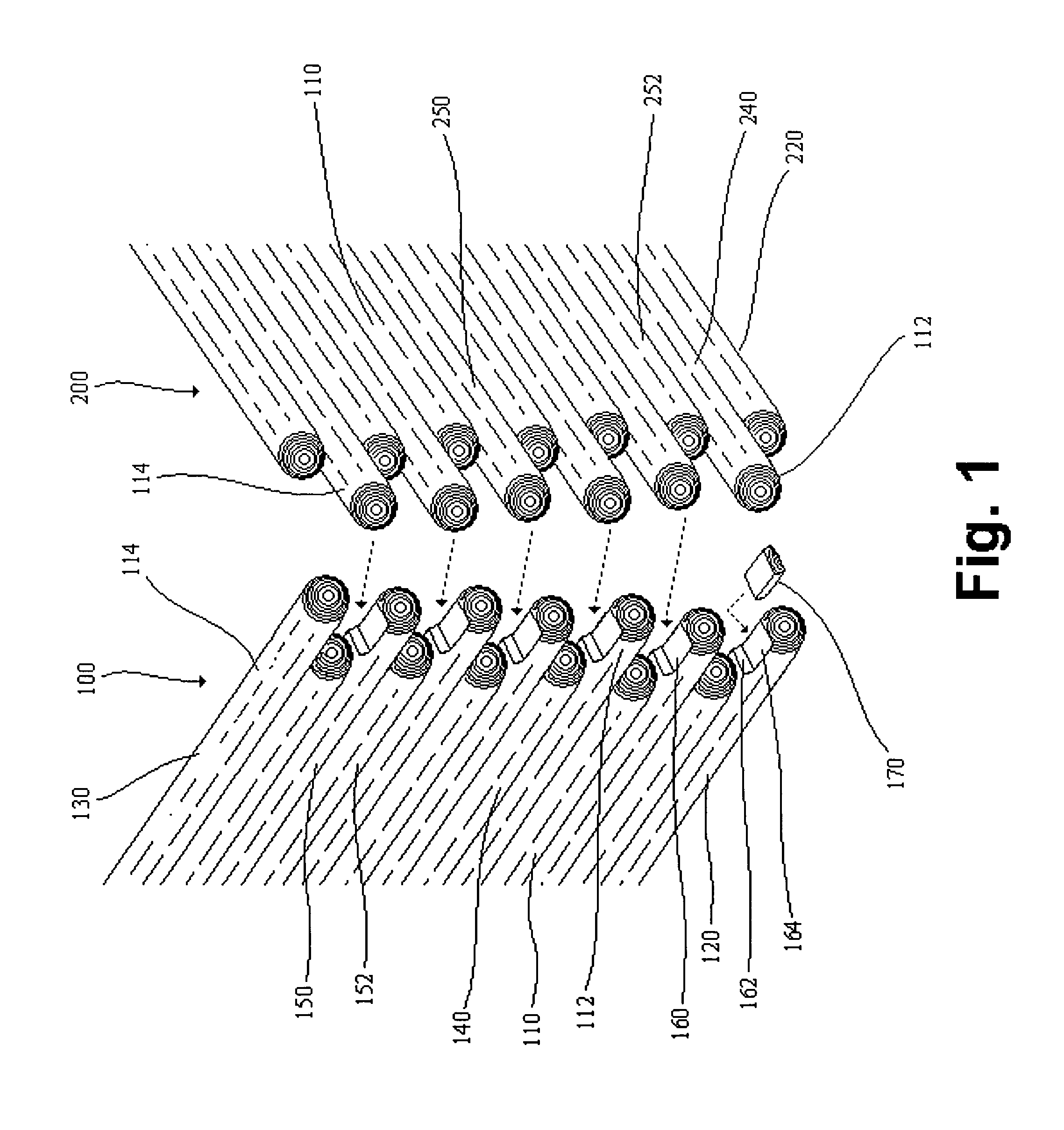

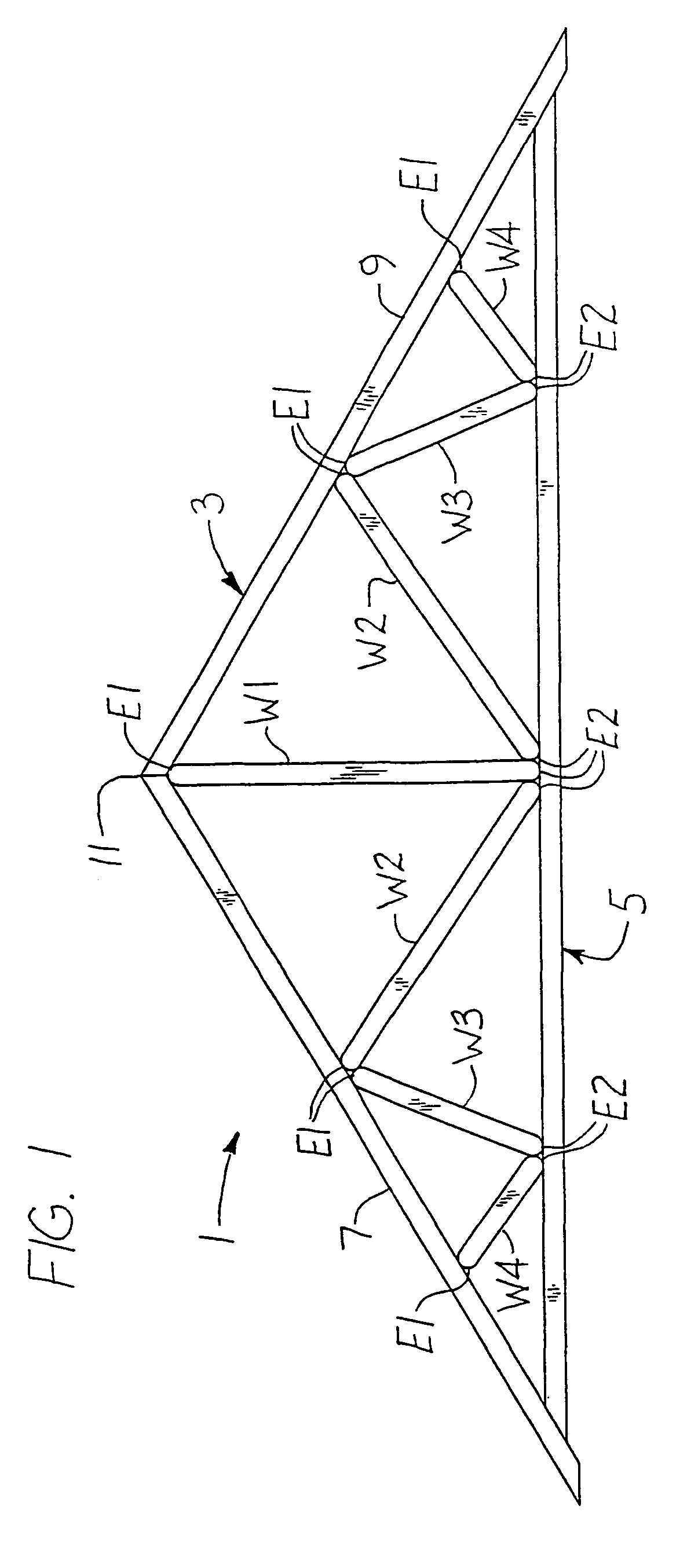

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

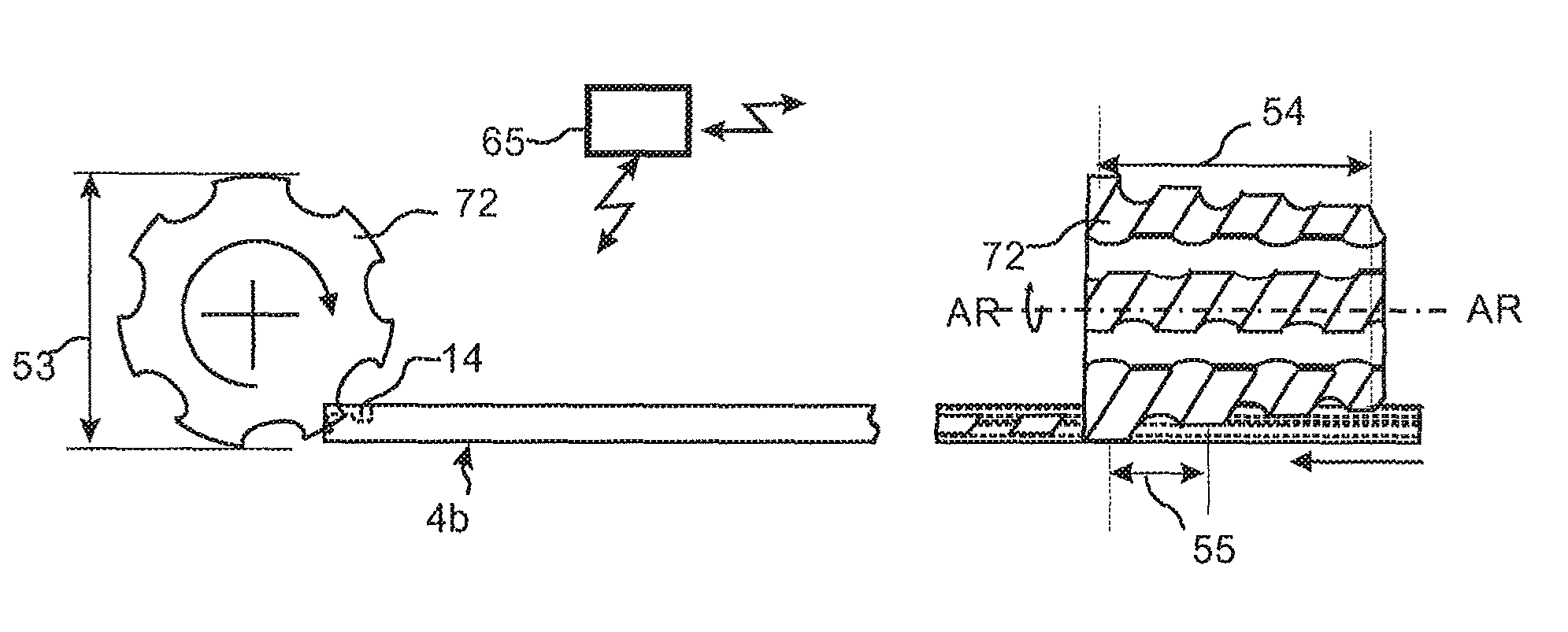

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

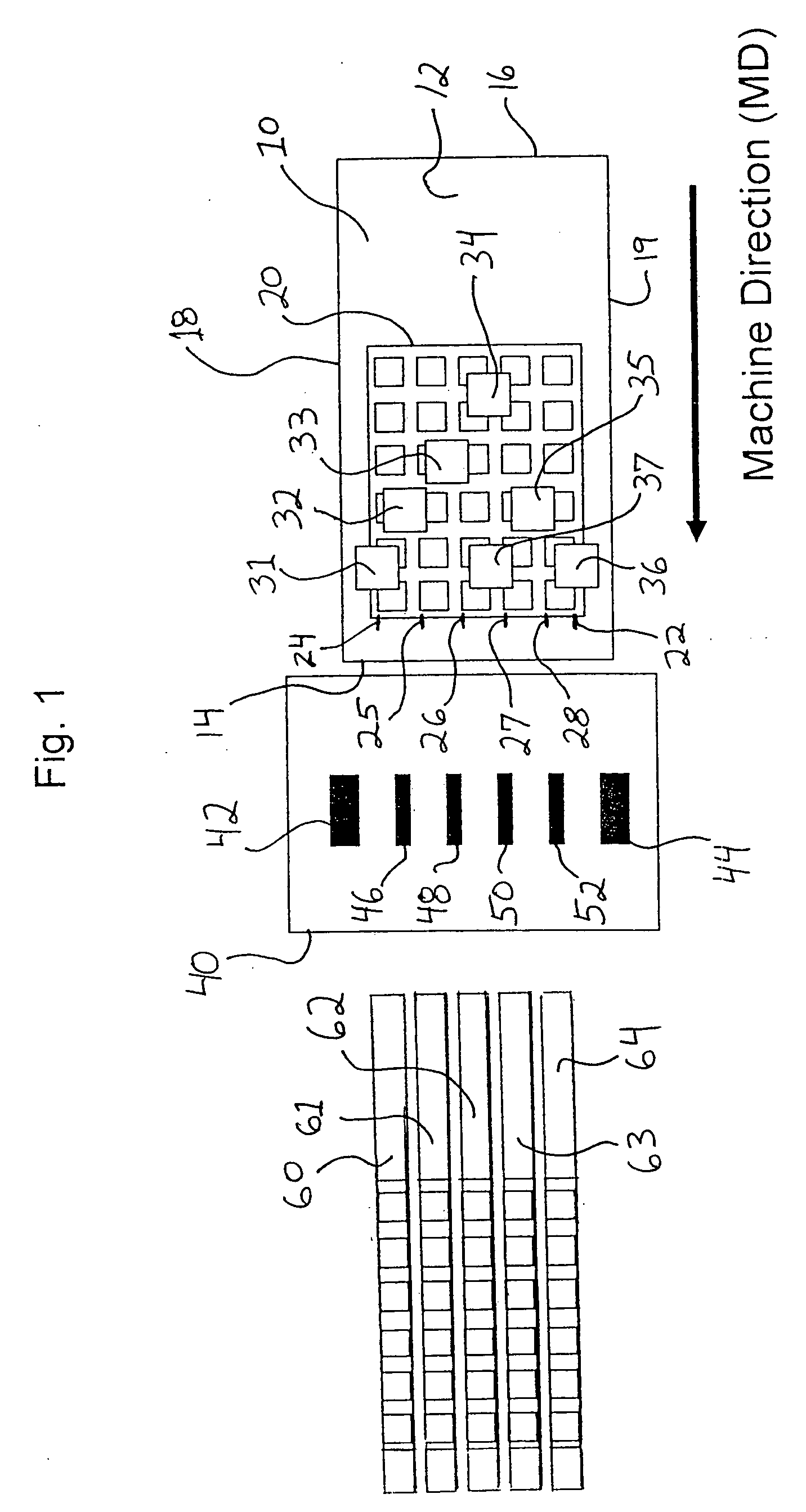

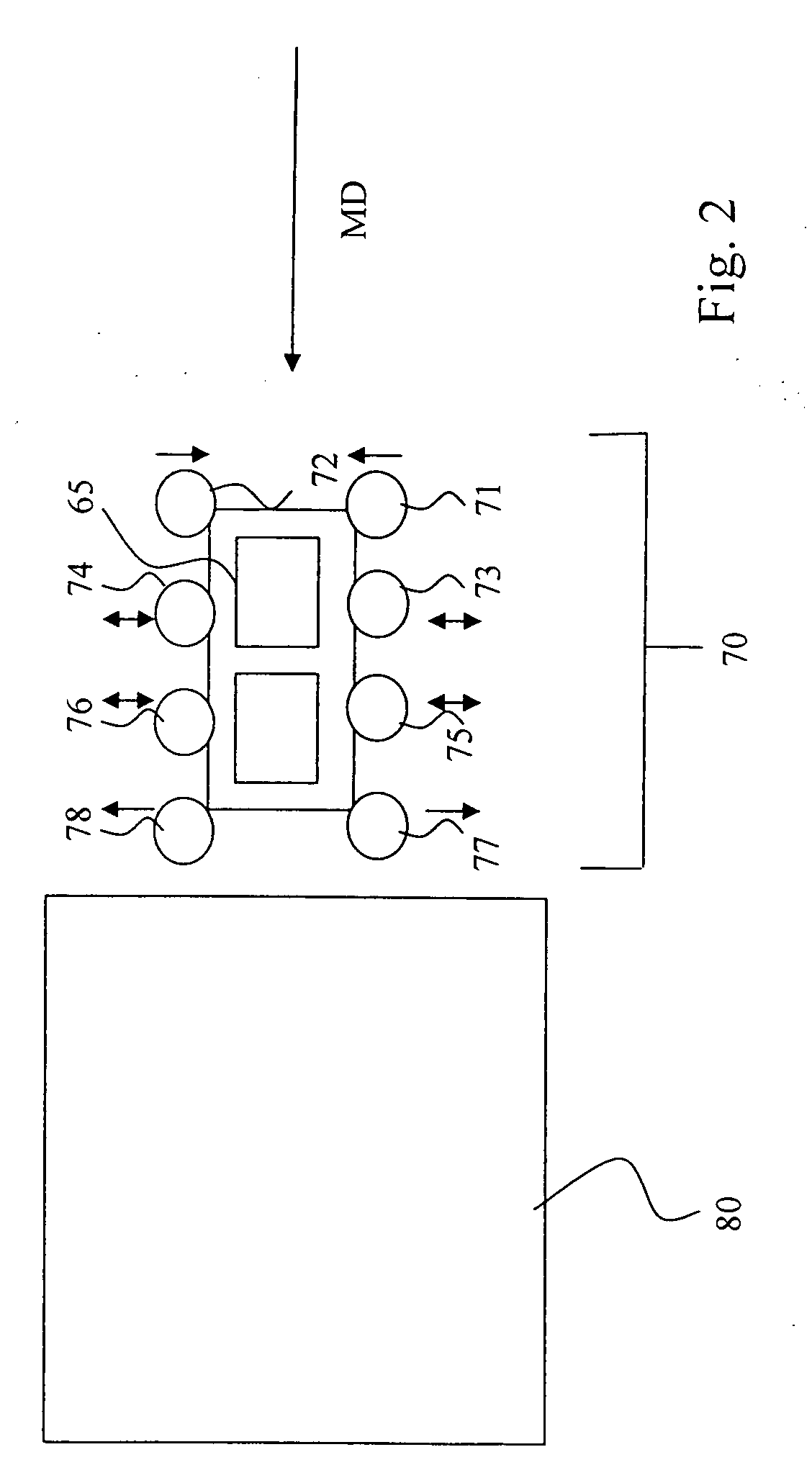

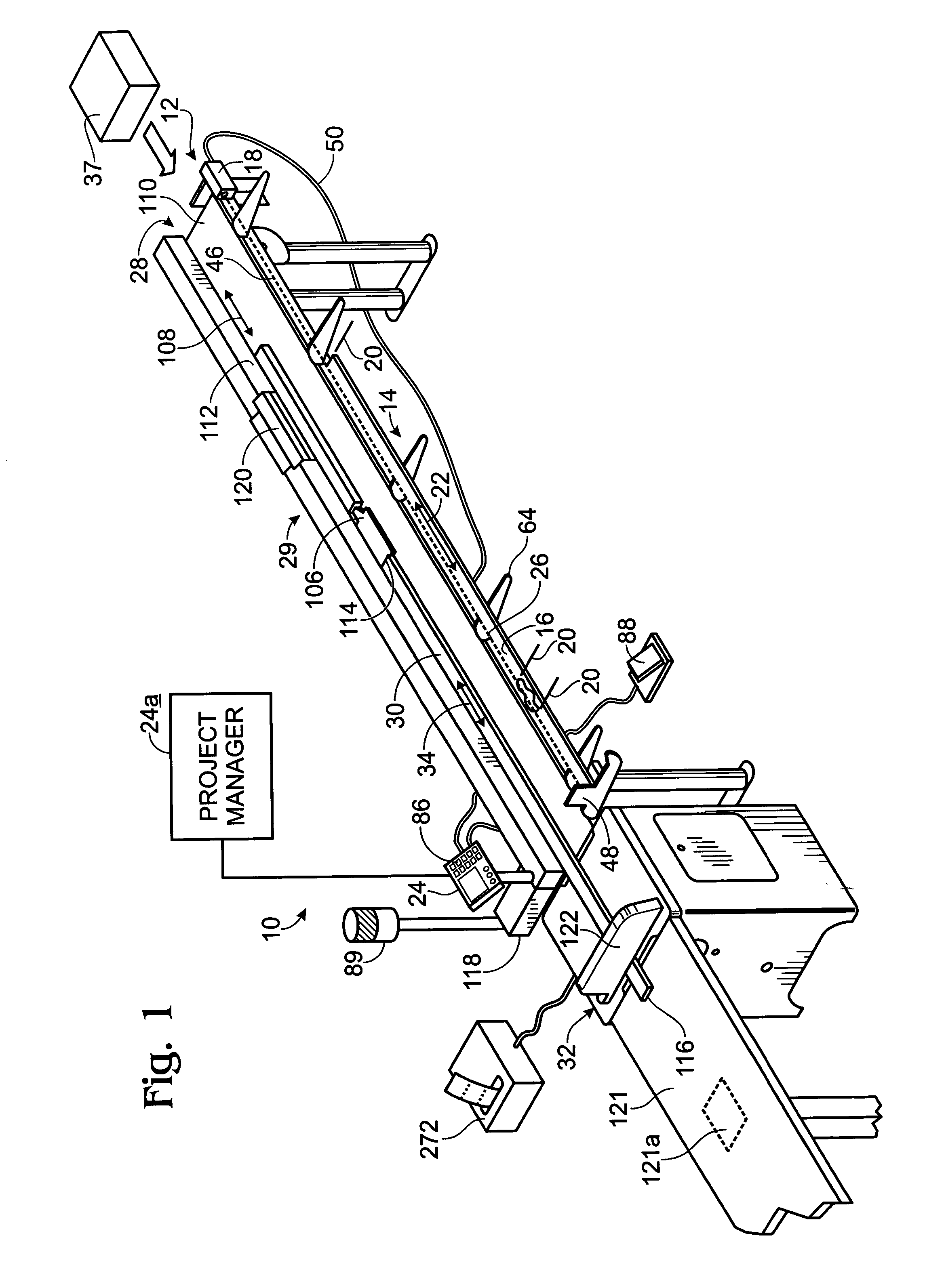

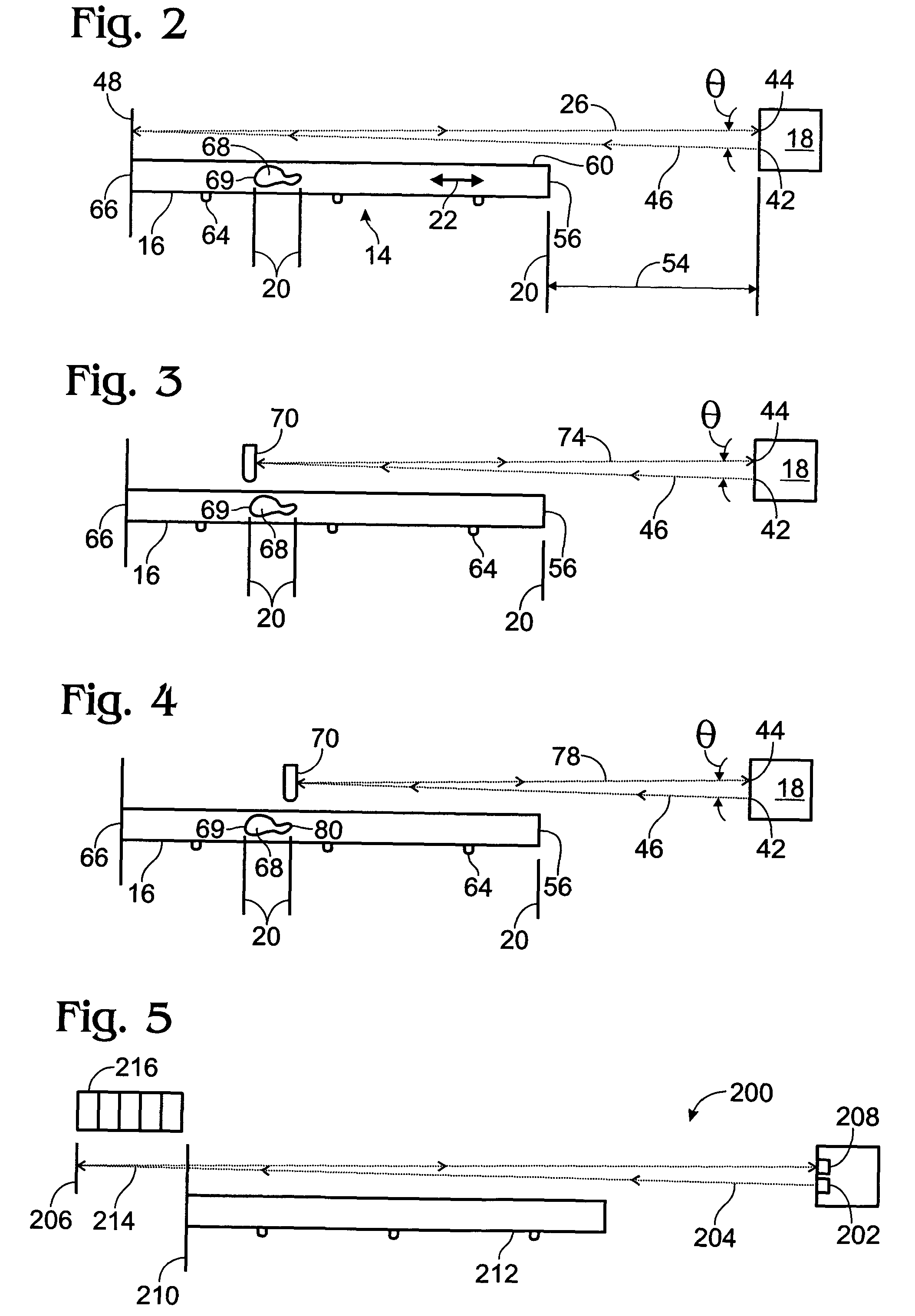

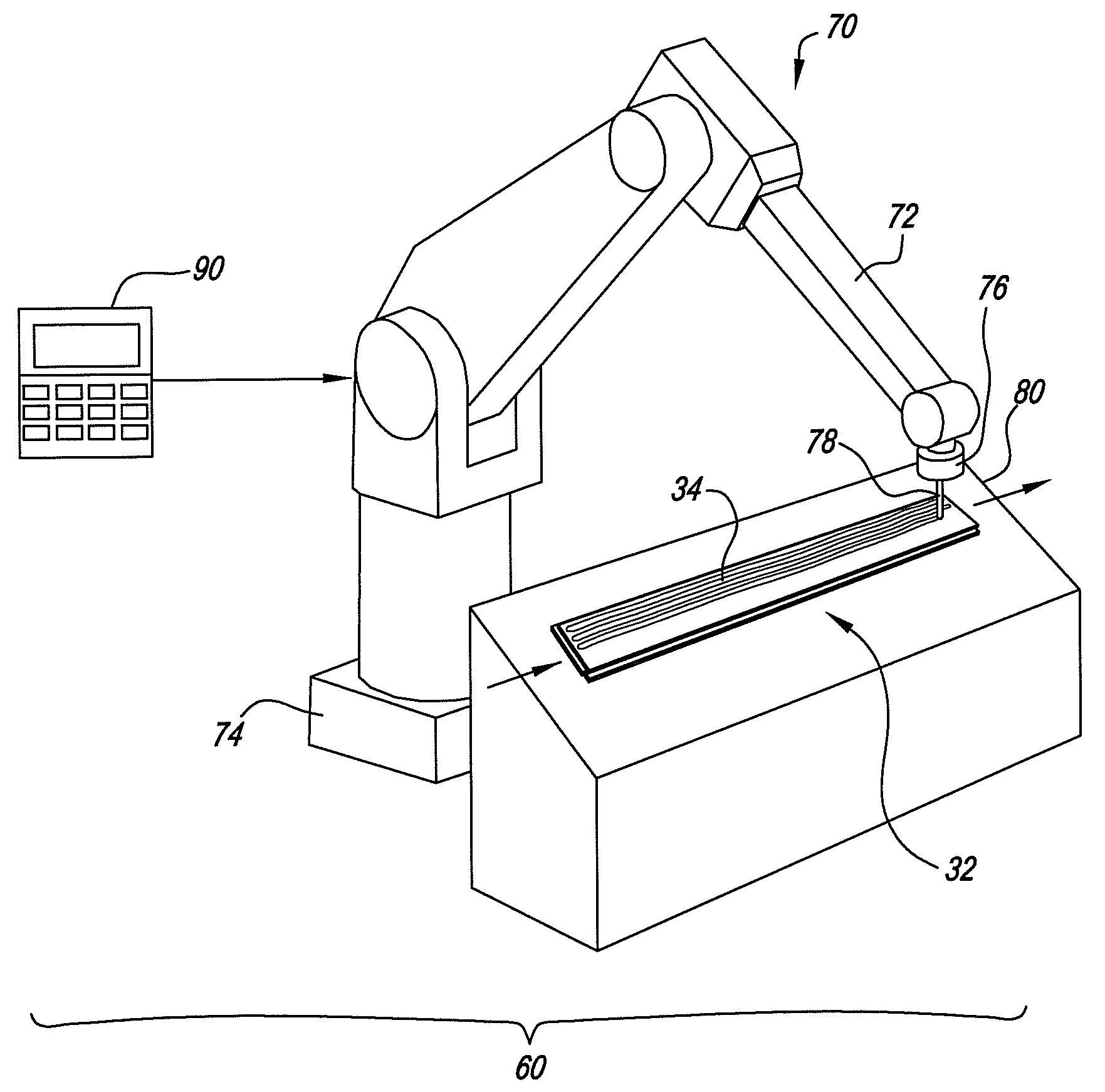

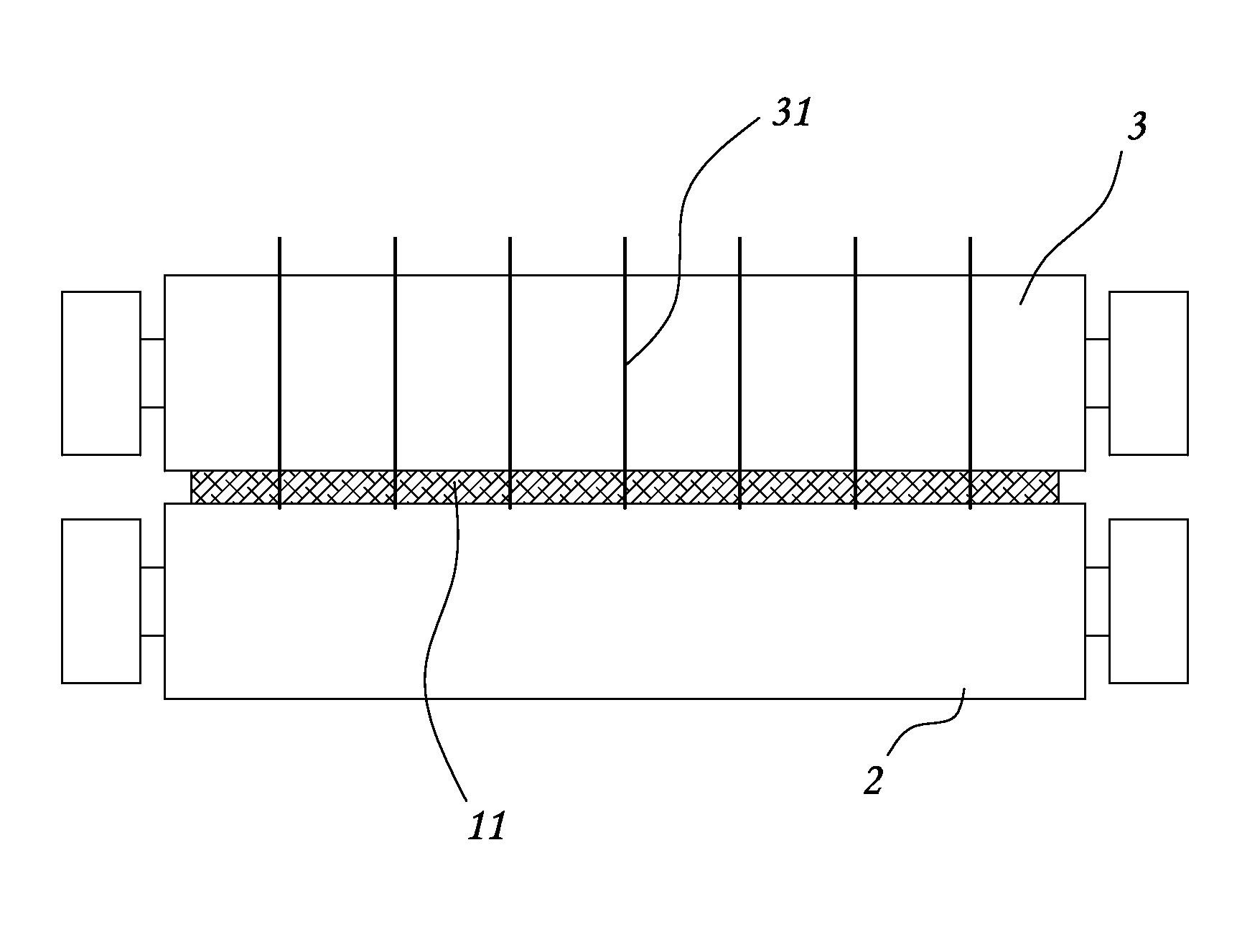

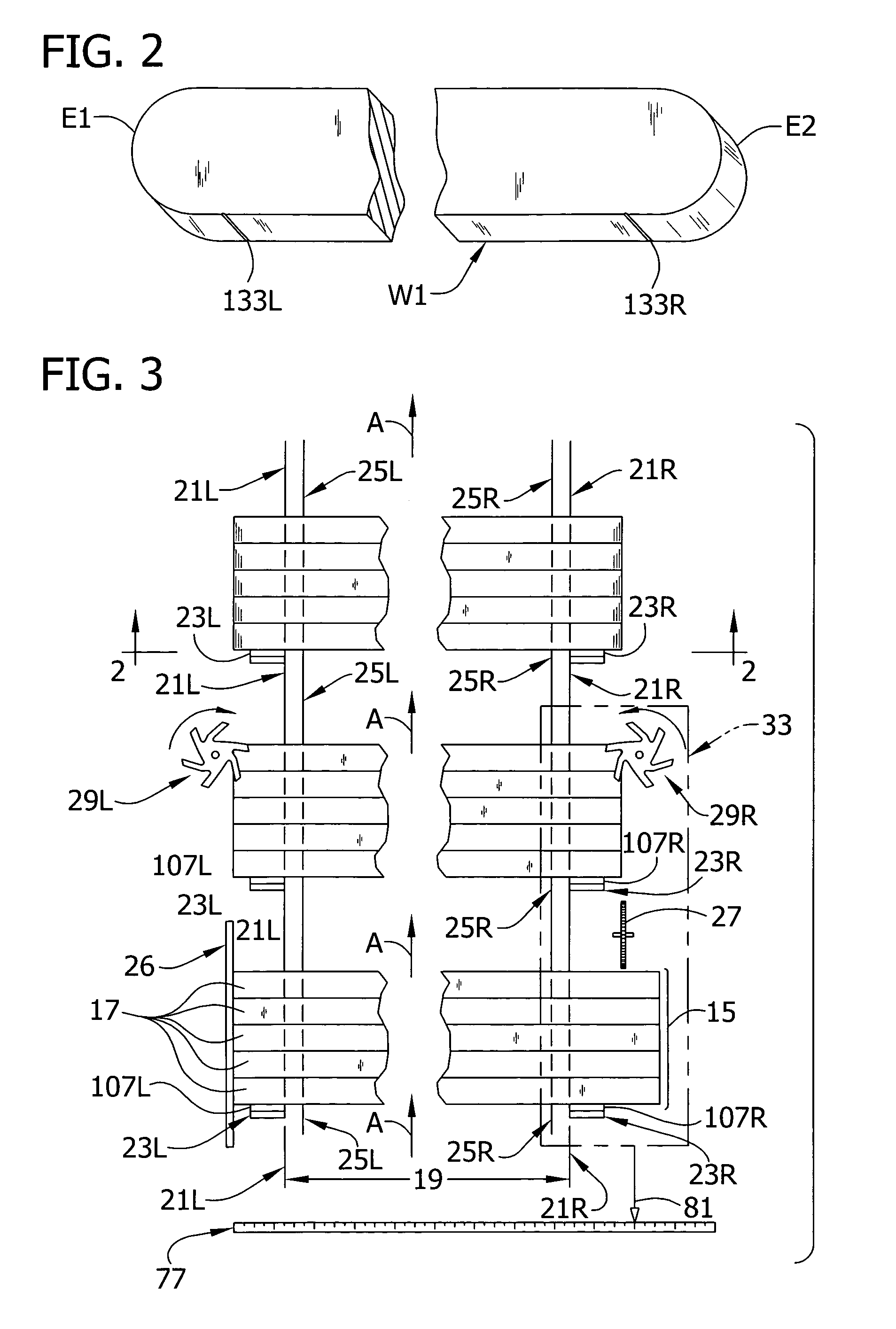

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

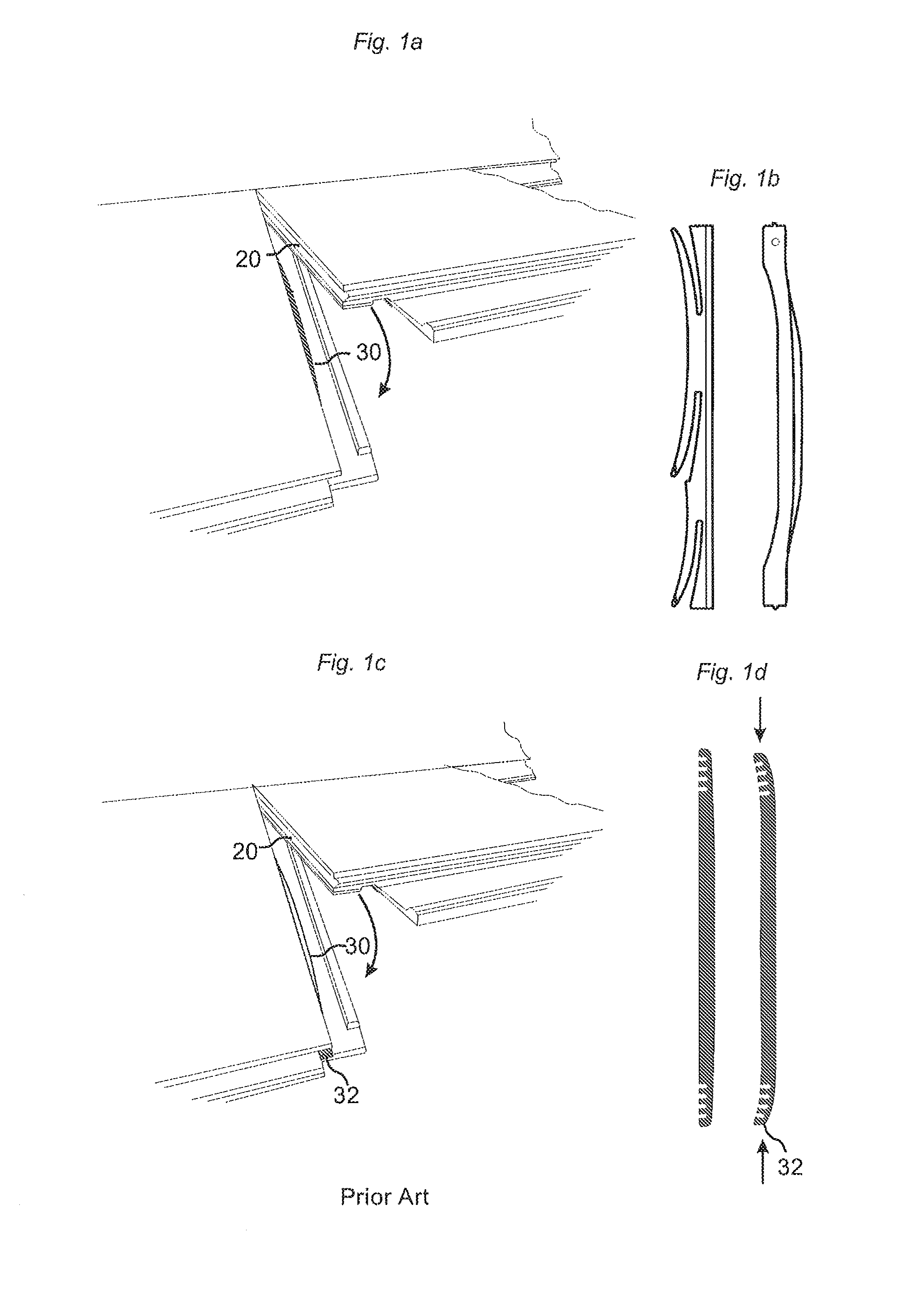

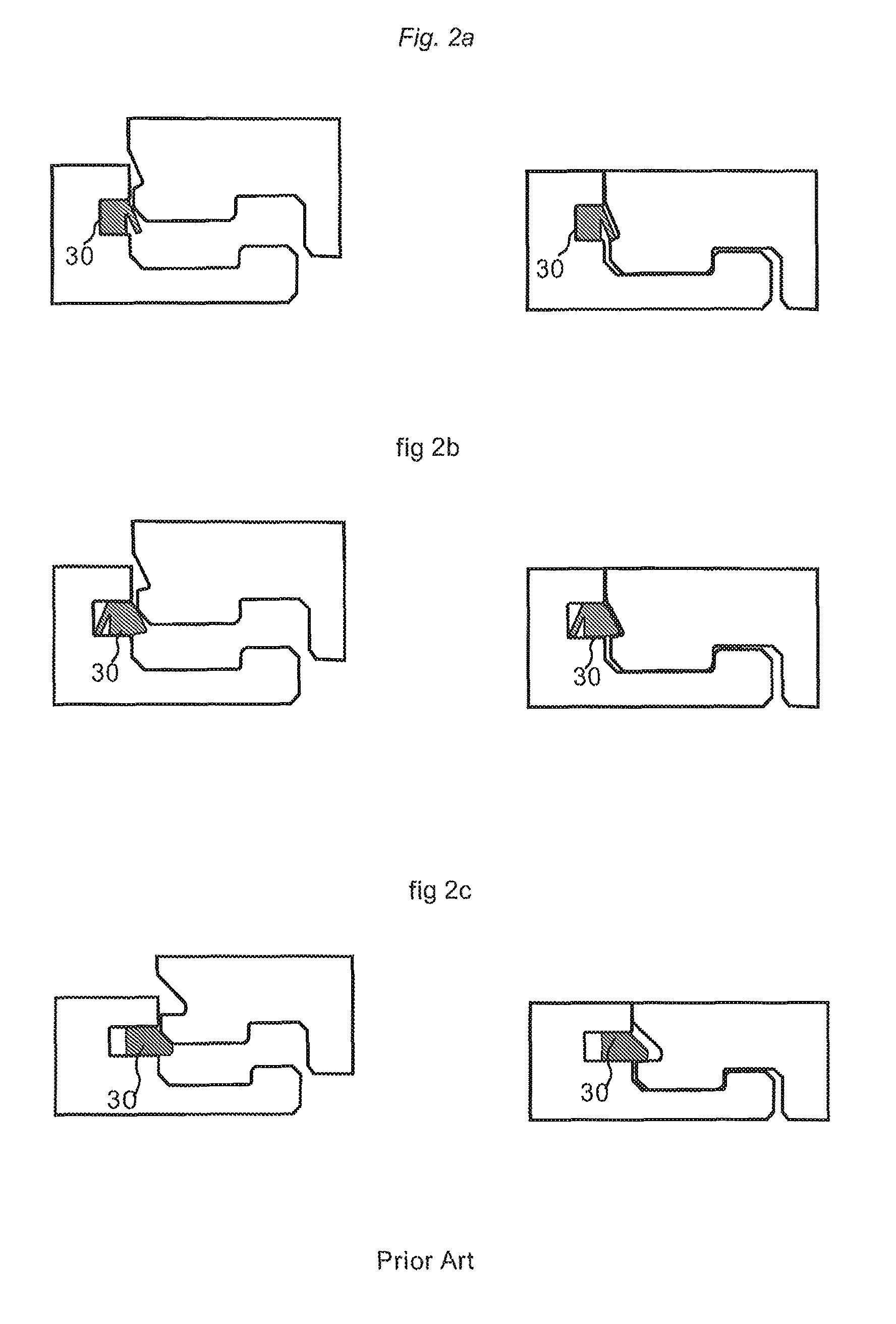

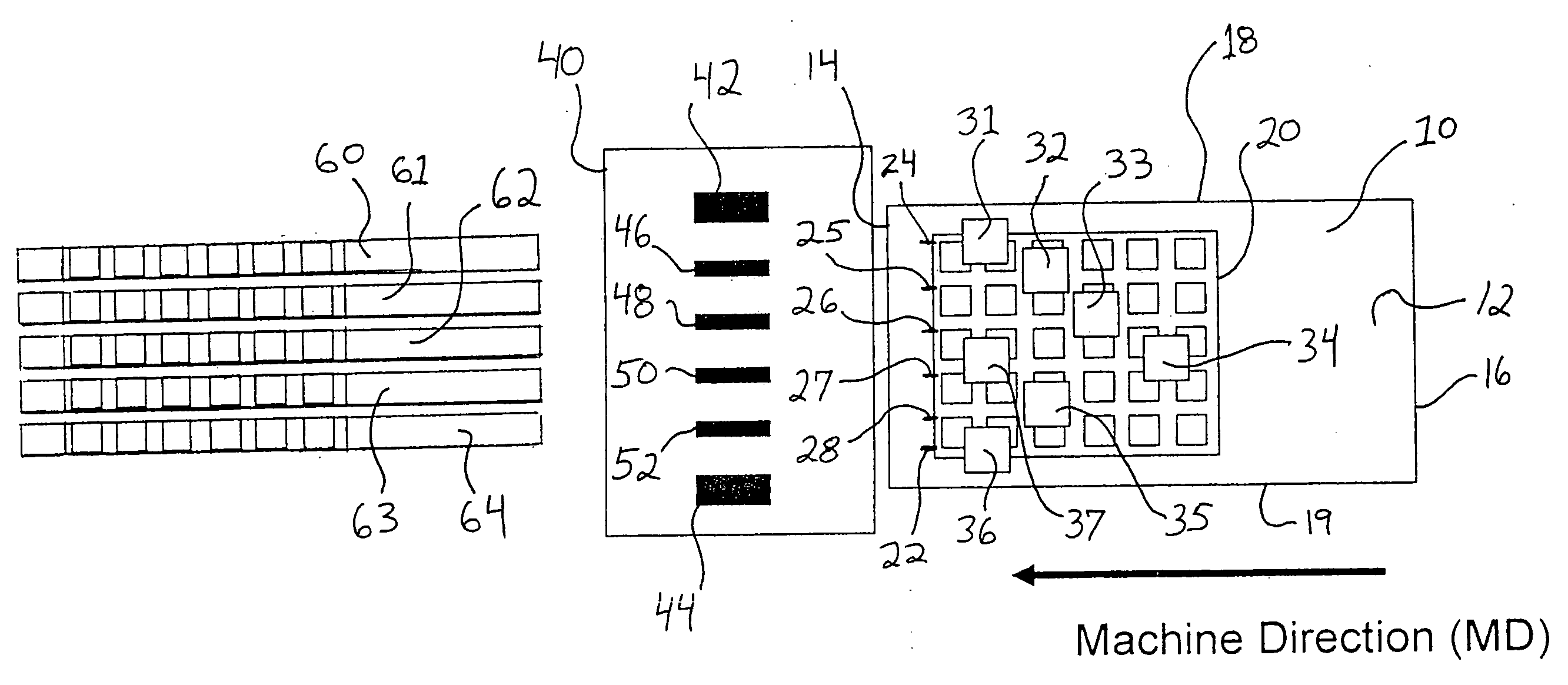

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

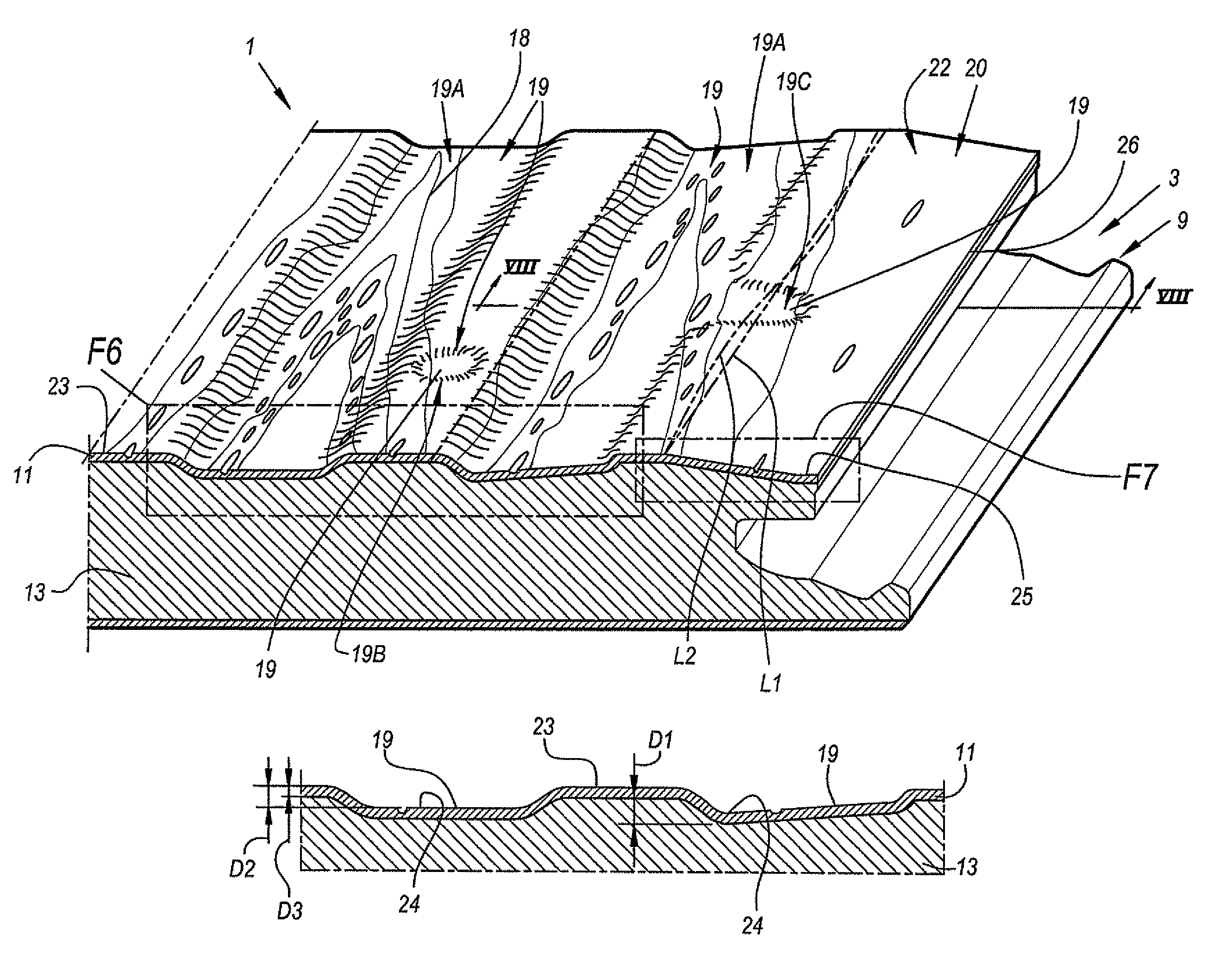

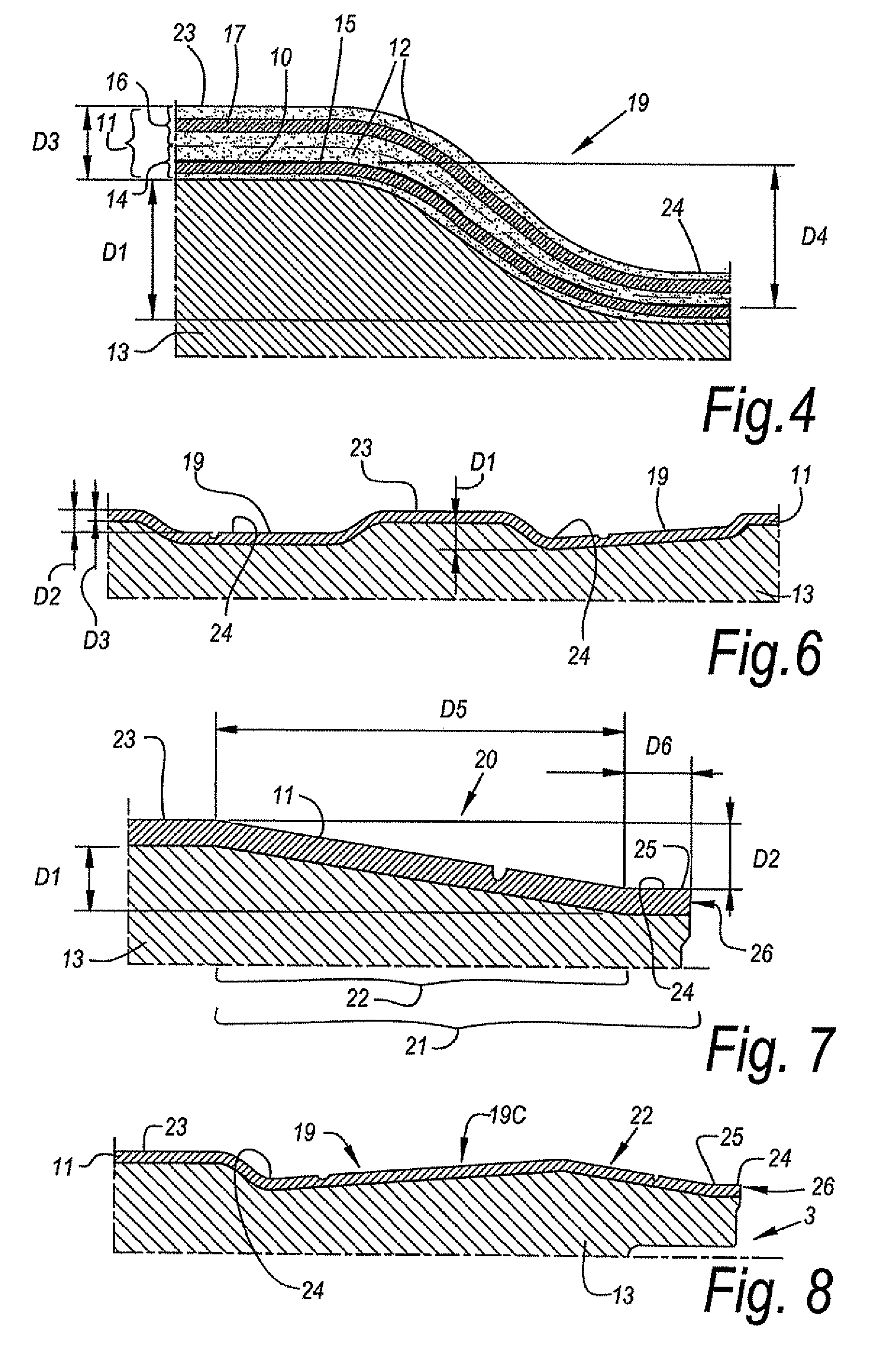

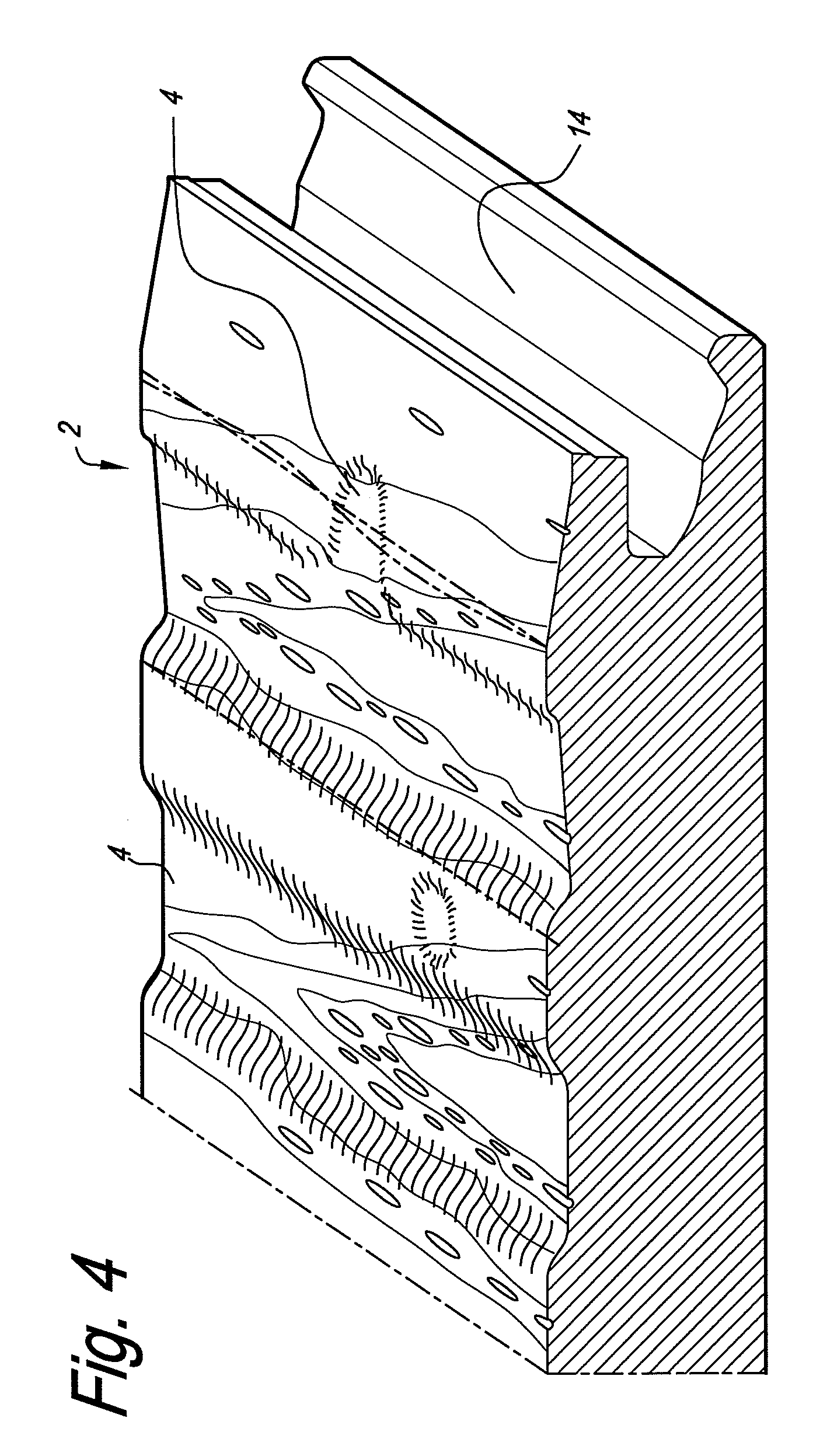

Floor panel, as well as method, device and accessories for manufacturing such floor panel

ActiveUS8272187B2Precise applicationRoof covering using tiles/slatesNatural patternsSynthetic materialsEngineering

Floor panel, more particularly a laminate floor panel, wherein this floor panel comprises a decor, a top layer on the basis of synthetic material, and an underlying substrate (13), whether or not composed of several layers or parts, wherein the floor panel (1), in the surface over which the decor (10) extends, is provided with embossed portions.

Owner:FLOORING IND LTD

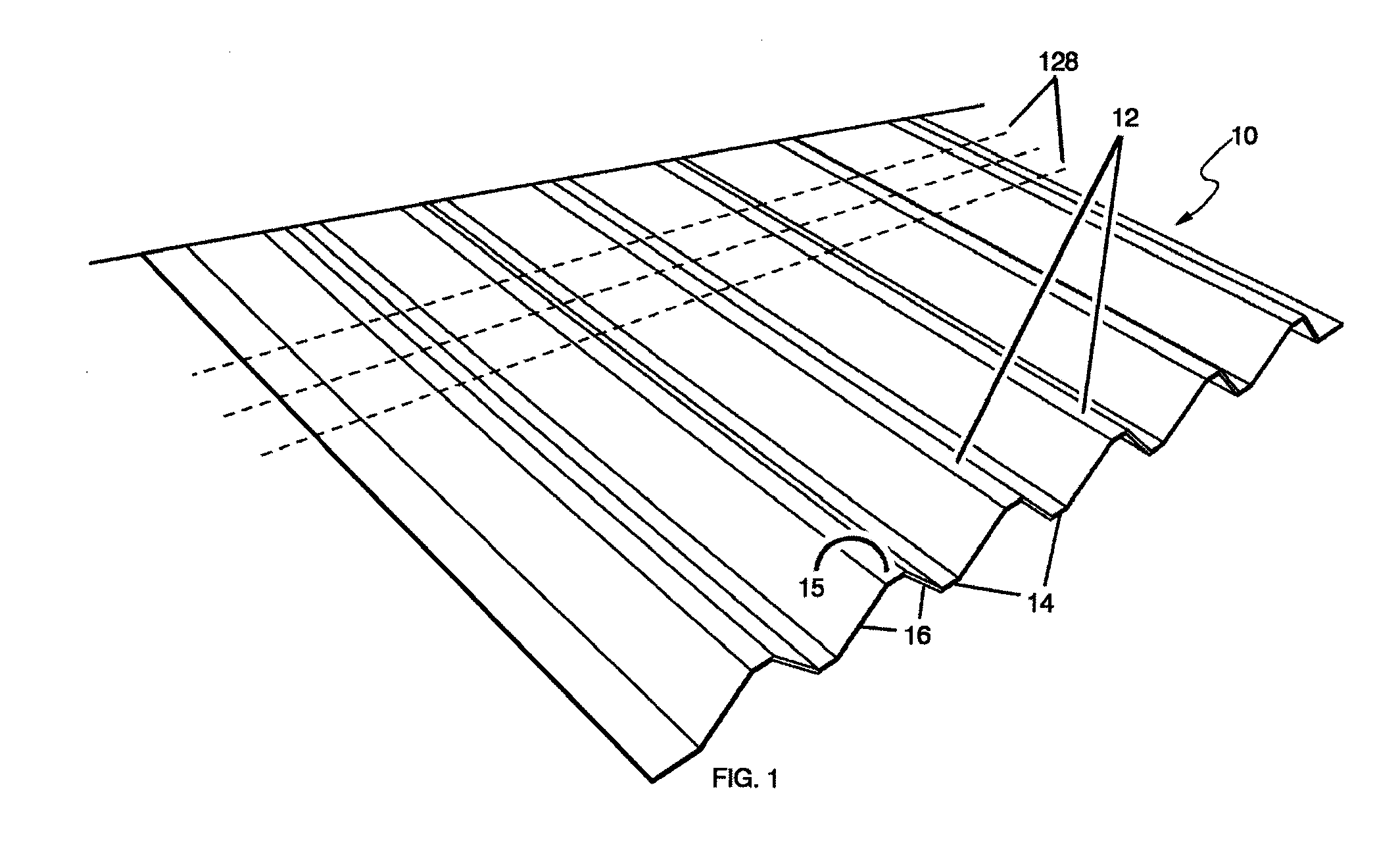

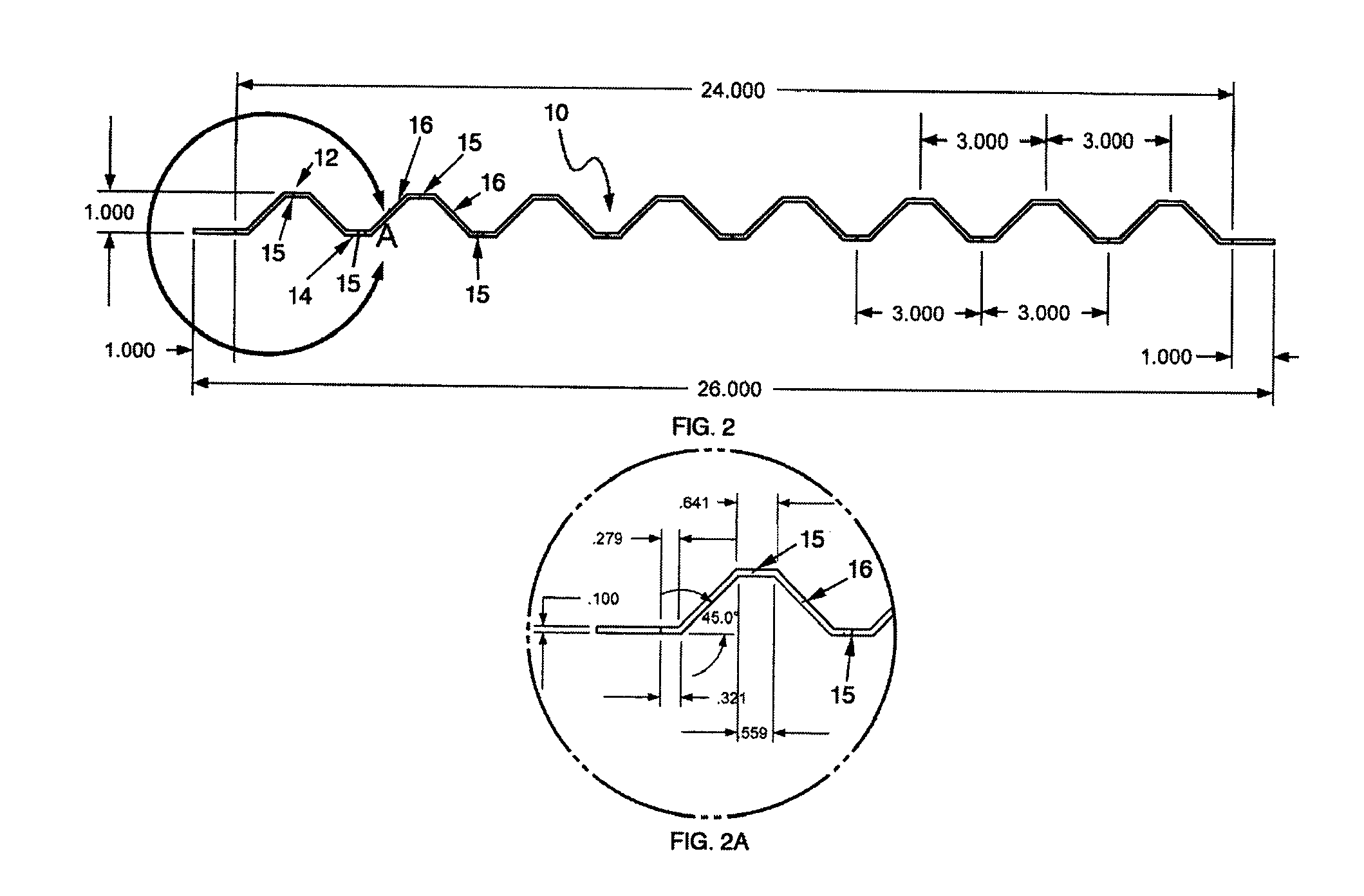

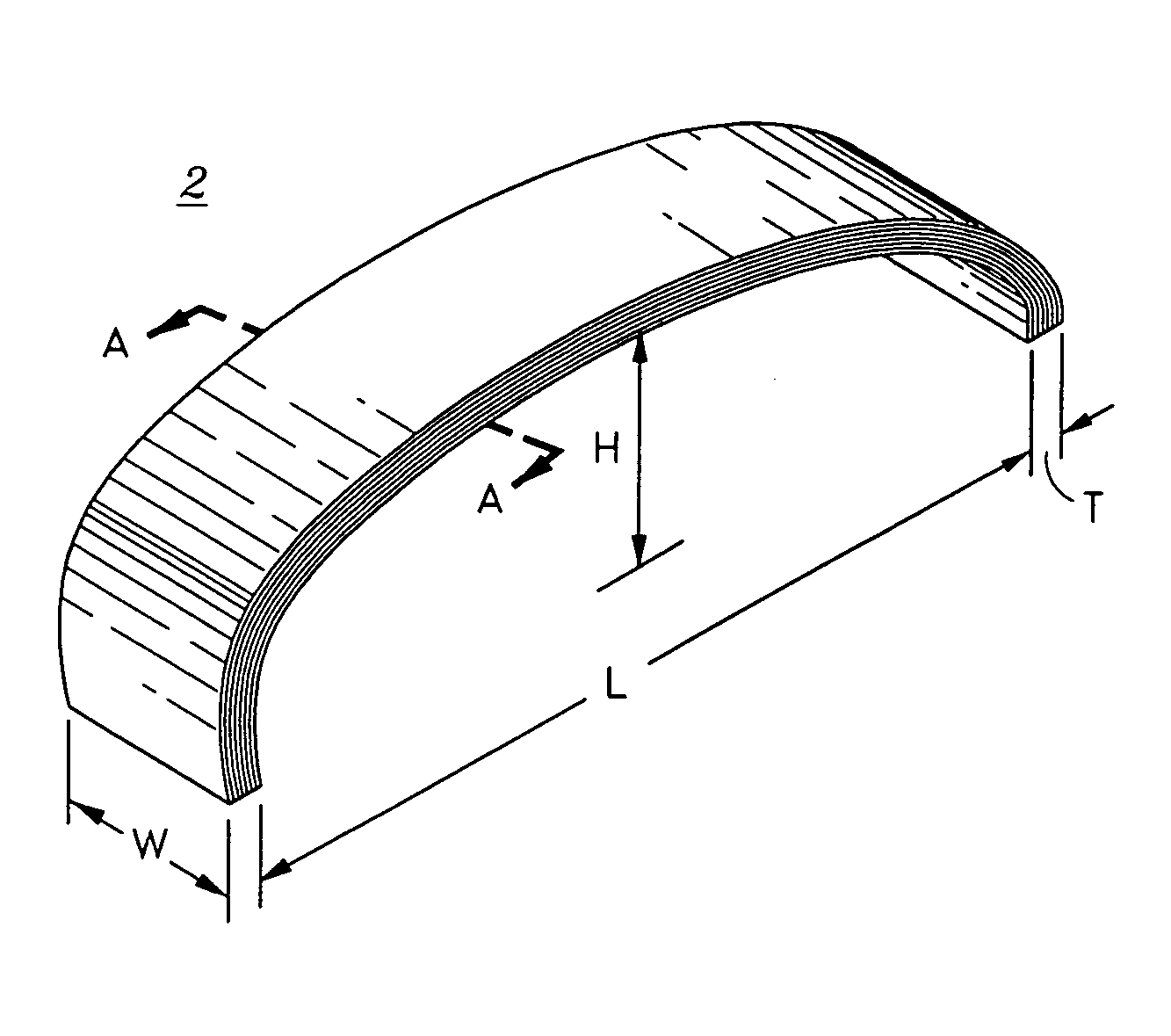

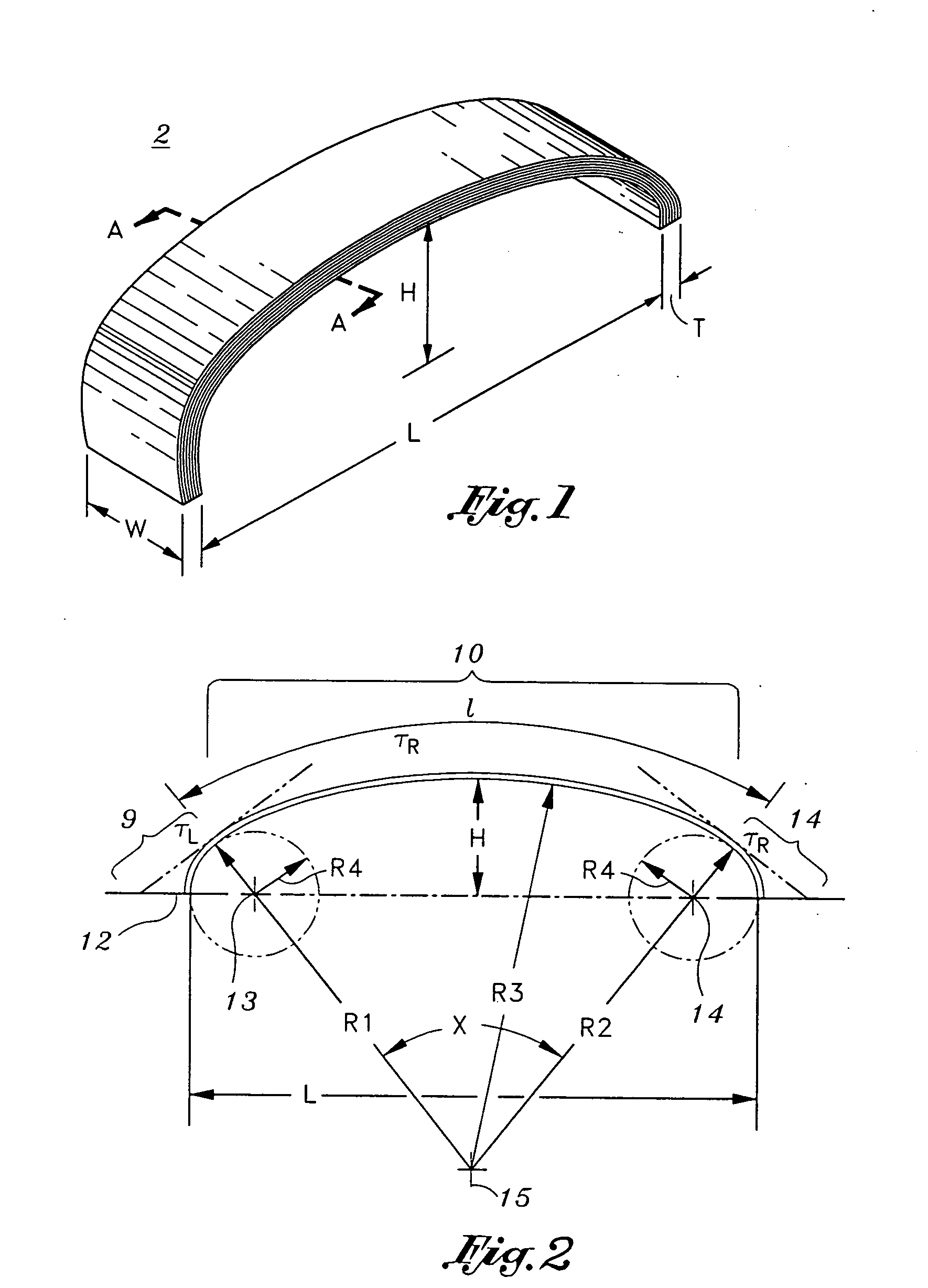

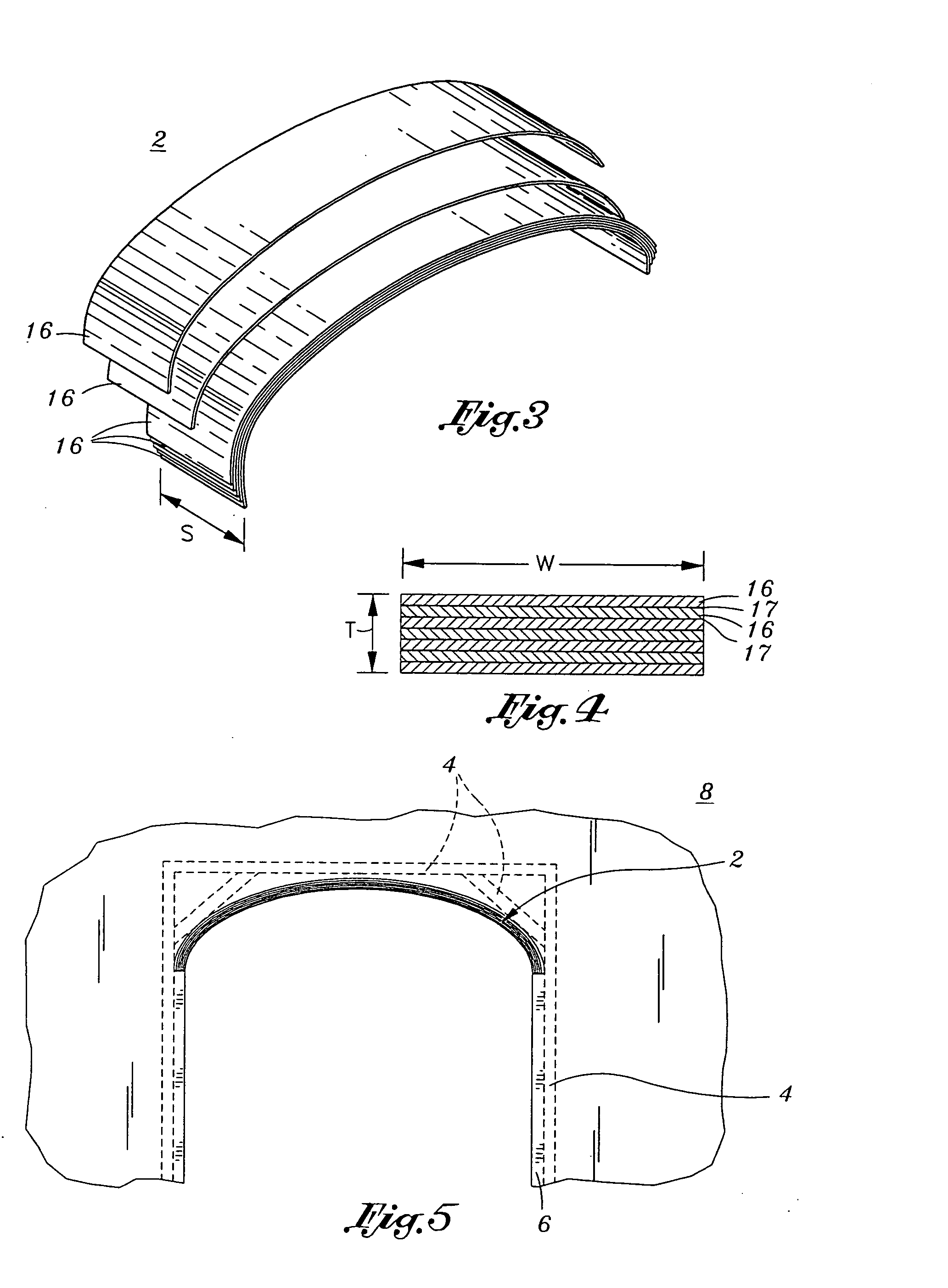

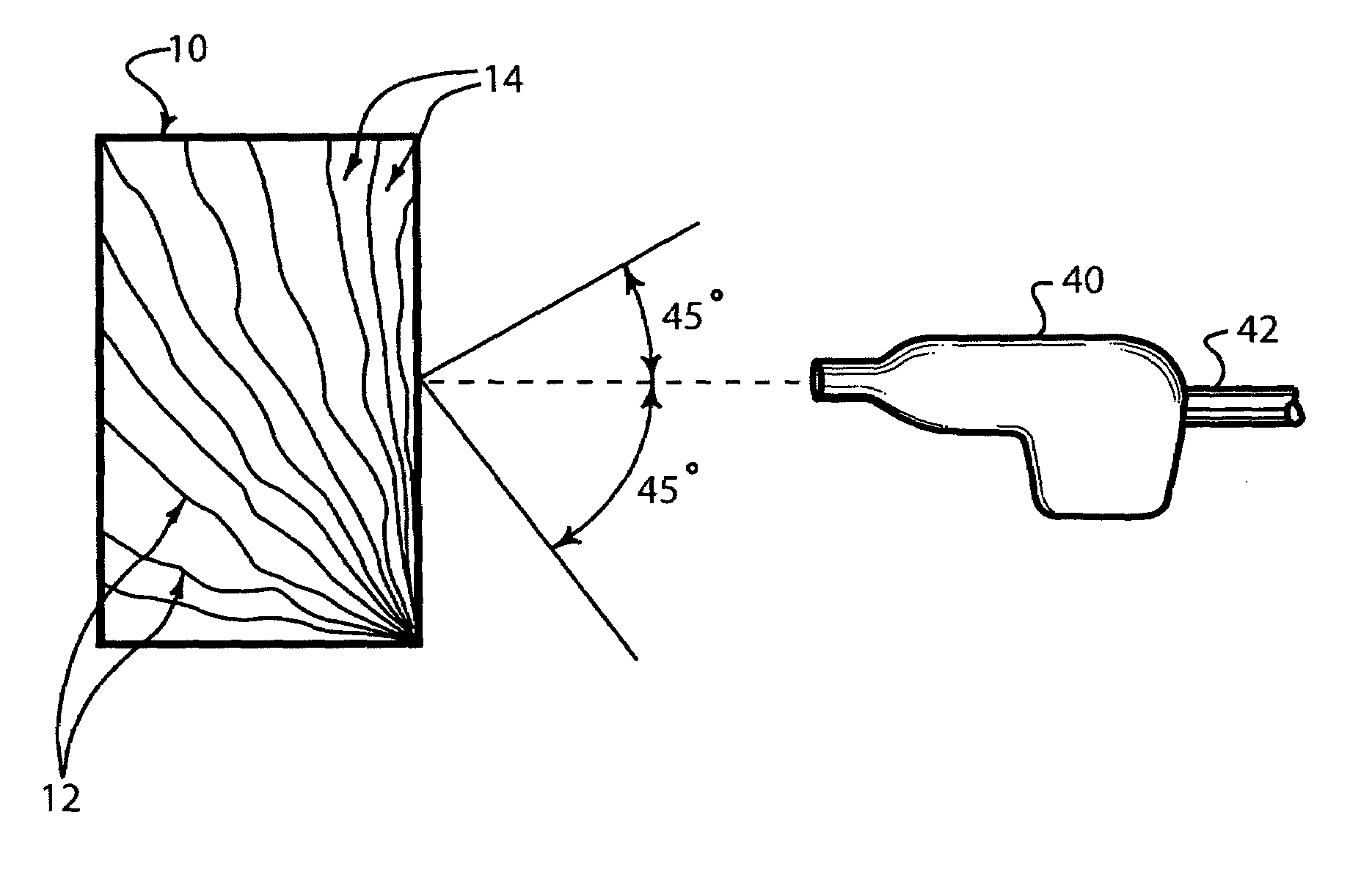

Engineered Molded Fiberboard Panels. Methods of Making the Panels, and Products Fabricated From the Panels

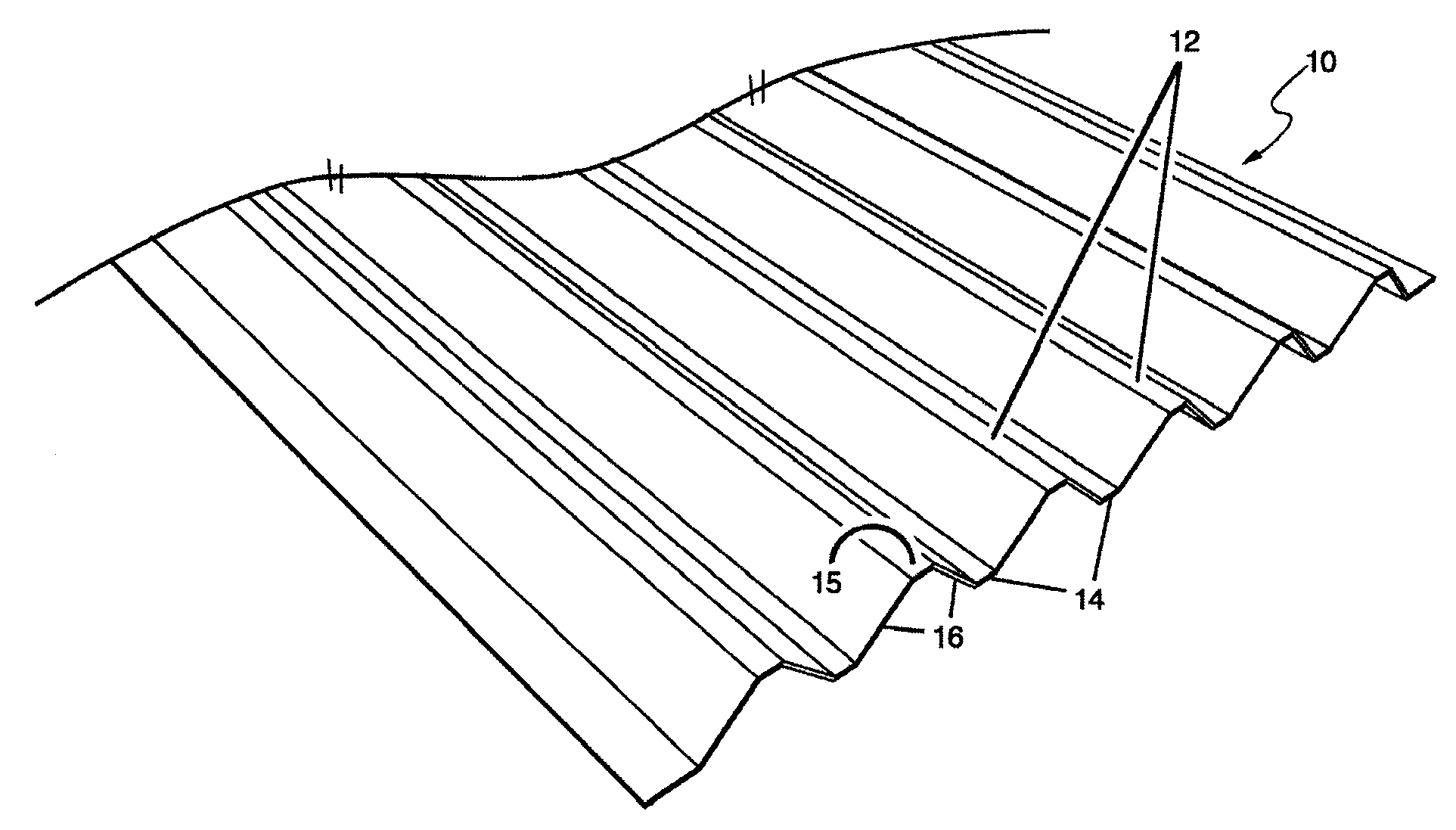

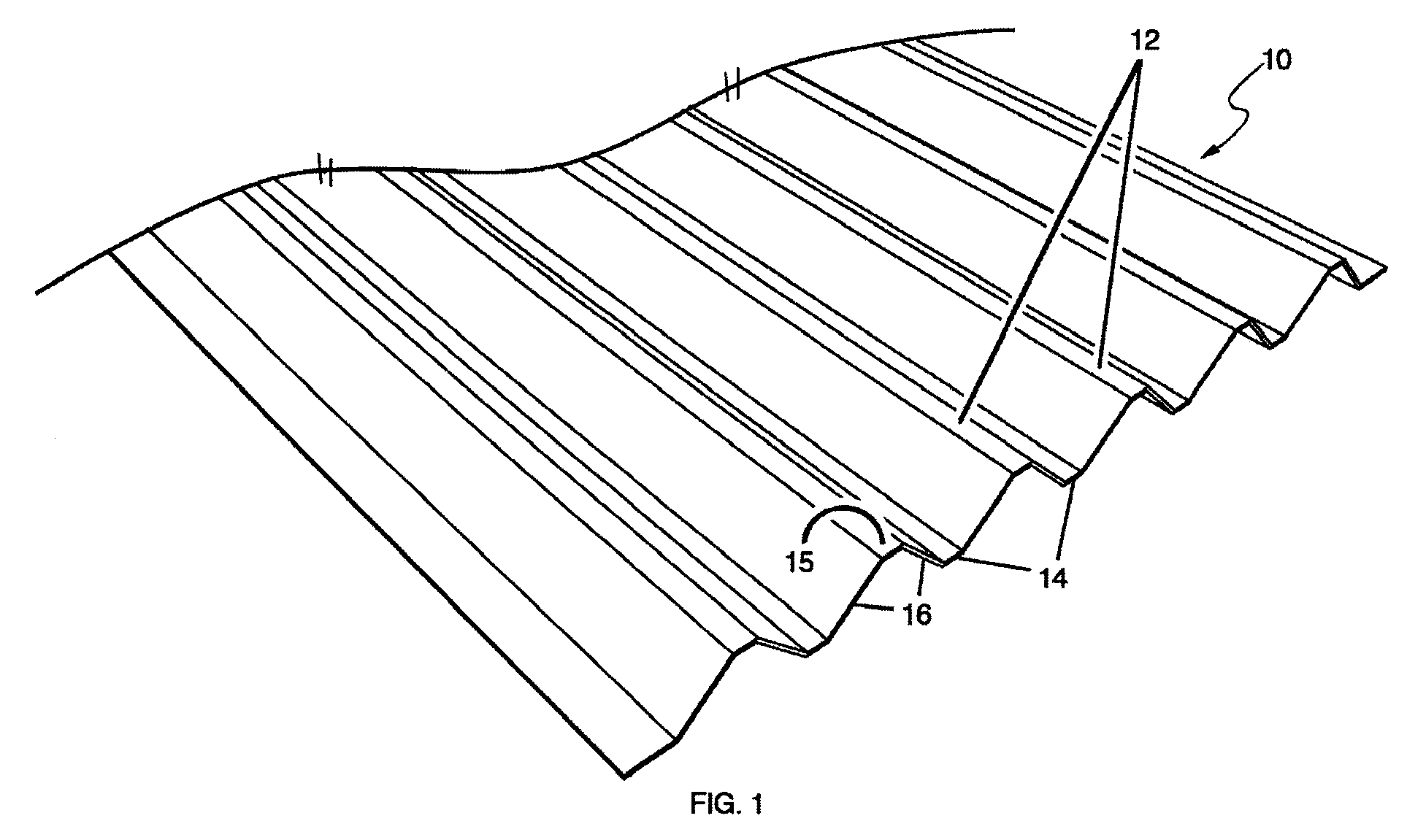

A honeycomb-shaped panel is formed from a plurality of generally sinusoidally shaped strips of molded fiberboard material each having spaced, oppositely directed flat peaks, the peaks of adjacent strips being secured together to form a plurality of hexagonally shaped cells extending perpendicular to the surfaces of the sheet. The strips may be cut from a single sheet of corrugated fiberboard sheet material and then secured together to form the honeycomb panel, or a plurality of such panels may be secured together face to face with their ribs aligned to form a stack, and selected cuts may be made through the secured, stacked panels to form a plurality of honeycomb panels of desired surface shape and height dimensions. The strips forming the cells are substantially rigid and resistant to collapse of the cells, and form a substantially rigid core when assembled between two flexible fiberboard skins, while the panel is bendable to adopt a desired panel curvature.

Owner:US SEC AGRI +1

Engineered Molded Fiberboard Panels and Methods of Making and Using the Same

A fiberboard panel is formed from at least one corrugated sheet of molded cellulose fiber material having alternating ribs and grooves. Spaced slits are cut through the ribs on one face of the sheet and terminate short of the opposite face so as to form at least one slotted portion of more flexibility which may be bent to form a curve. The corrugated sheet is sandwiched between two flat sheets of the same material to form a composite panel. The corrugated sheet or panel is formed by a wet processing method including successive cold and hot press steps in which a wet mat is pressed between an opposing perforated platen and non-perforated, elastomeric material platen of cross-sectional shape substantially matching the desired panel shape and dimensions.

Owner:NOBLE ENVIRONMENTAL TECH CORP +1

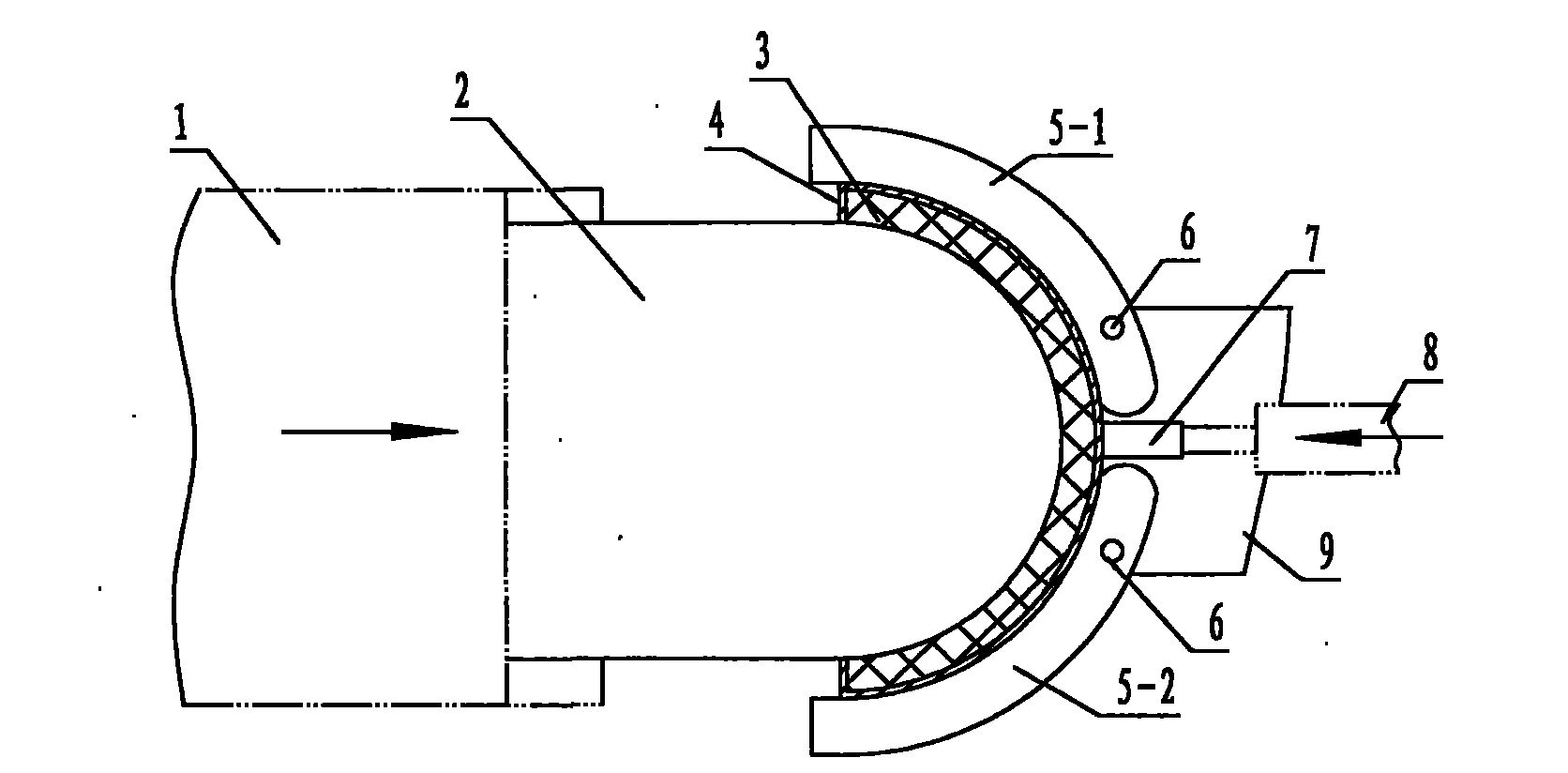

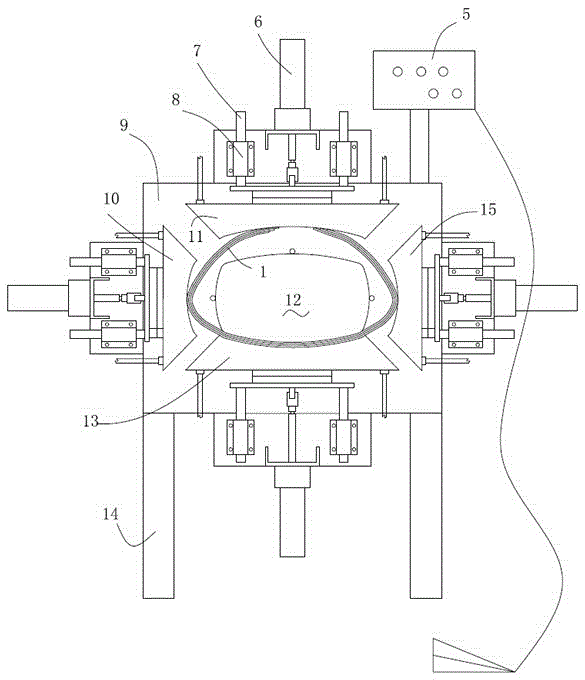

Bending molding process for wooden product solid wood

InactiveCN101774194AEliminates parallel grain compression processSimple structureWood treatment detailsWood stock bendingSolid woodSteel belt

The invention relates to a bending molding process for wooden product solid wood, which is used for solving the bending problems of solid wood, and comprises the following steps: a. blank softening; b. bending molding, in which a protective steel band is attached to one side of the softened solid blank to be placed between an arc molding head of an internal mold and an arc molding surface of an external mold, and the arc molding surface consists of two split modules, the internal mold moves towards the solid wood blank and exerts force on the solid wood blank, and simultaneously back pressure is exerted at the other side of the solid wood blank by a jacking block; the two split modules bend and deform along the solid wood blank and take the hinge point as the center of a circle to rotate naturally so as to gradually clutch the solid wood blank until the solid wood blank is bent and molded; and c. stripping drying. The invention eliminates the solid wood longitudinal compression process, and has simple process and low production cost; the solid wood does not need to be softened by a chemical softener before bending, and the production processes are environmentally friendly; the structures of the solid wood bending internal mold and external mold are simple, the design is reasonable, the molding is rapid, the force exerting is balanced, and the quality of products is stable and reliable.

Owner:石家庄开发区纪元电气有限公司

Solid wood bending technological method for curve-shaped structural member of redwood furniture

ActiveCN104802247AImprove the level of production technologyHigh strengthWood compressionWood treatment detailsSolid woodColor effect

The invention discloses a solid wood bending technological method for a curve-shaped structural member of redwood furniture. The solid wood bending technological method comprises the following steps: (1) wood type selection and lumber processing; (2) boiling or steaming for thermal treatment for softening; (3) longitudinal compression; (4) die bending forming; (5) drying sizing; (6) aging for life nourishing; (7) later processing and bending to manufacture the curve-shaped structural member of the redwood furniture. The solid wood bending technological method has the advantages that the generally conventional lineation sawing processing method can be replaced; a redwood type solid wood lumber can be directly bent into a curve-shaped part; the production technological level for the curve-shaped part of the redwood furniture can be increased, and the production technological steps can be simplified; the utilization rate of redwood type woods can be increased, the intensity of the curve-shaped part is enhanced, and the texture and color effect and the paint decoration quality on the surface of a product are guaranteed.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

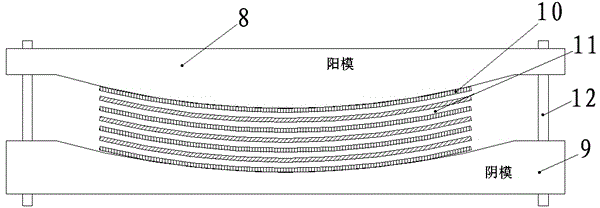

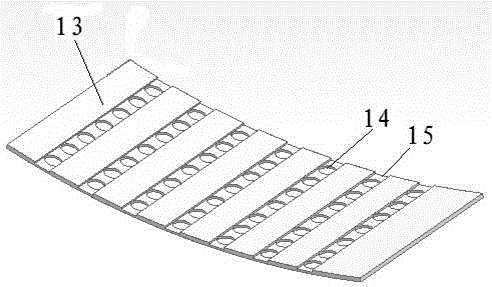

Manufacturing method of bent bamboo furniture and bent bamboo rod pieces

The invention provides a manufacturing method of bent bamboo furniture and bent bamboo rod pieces. The manufacturing method involves manufacturing of the bent bamboo rod pieces and bent bamboo plate pieces. According to the method, bamboo is divided into long-strip-shaped bamboo filaments or bamboo splits after bamboo skin and bamboo pith which can affect the bonding performance are removed; adhesives are arranged on the surfaces of the bamboo filaments or the bamboo splits after the bamboo filaments or the bamboo splits are dried; plate blank is formed in a planar cold press in a cold pressing mode; the plate blank is arranged in a bending forming die in an overlaying mode, pressing is conducted to enable the plate blank to form bent-plate-shaped bent bamboo rod plates, the bent bamboo rod plates and the die are sent into a heating chamber to be heated and cured, after the die is disassembled, according to the requirements of bent bamboo rods, the plates are cut into bent bamboo rods in a sawing mode in the bending direction of the bamboo filaments, and the bent bamboo rod pieces are formed after the surfaces are smoothed; meanwhile, the bamboo is sawed off at fixed length and divided into rectangular bamboo strips, assembly is conducted according to the requirements of the plate blank, the plate blank is arranged in a drying and shaping die to be compressed, and drying, heating and shaping are conducted to form bent bamboo plate piece panels; the surfaces of the panels are coated with adhesives, the panels are laid in a heat curing die, and pressing, heating and curing are conducted to obtain the bent bamboo plate pieces.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

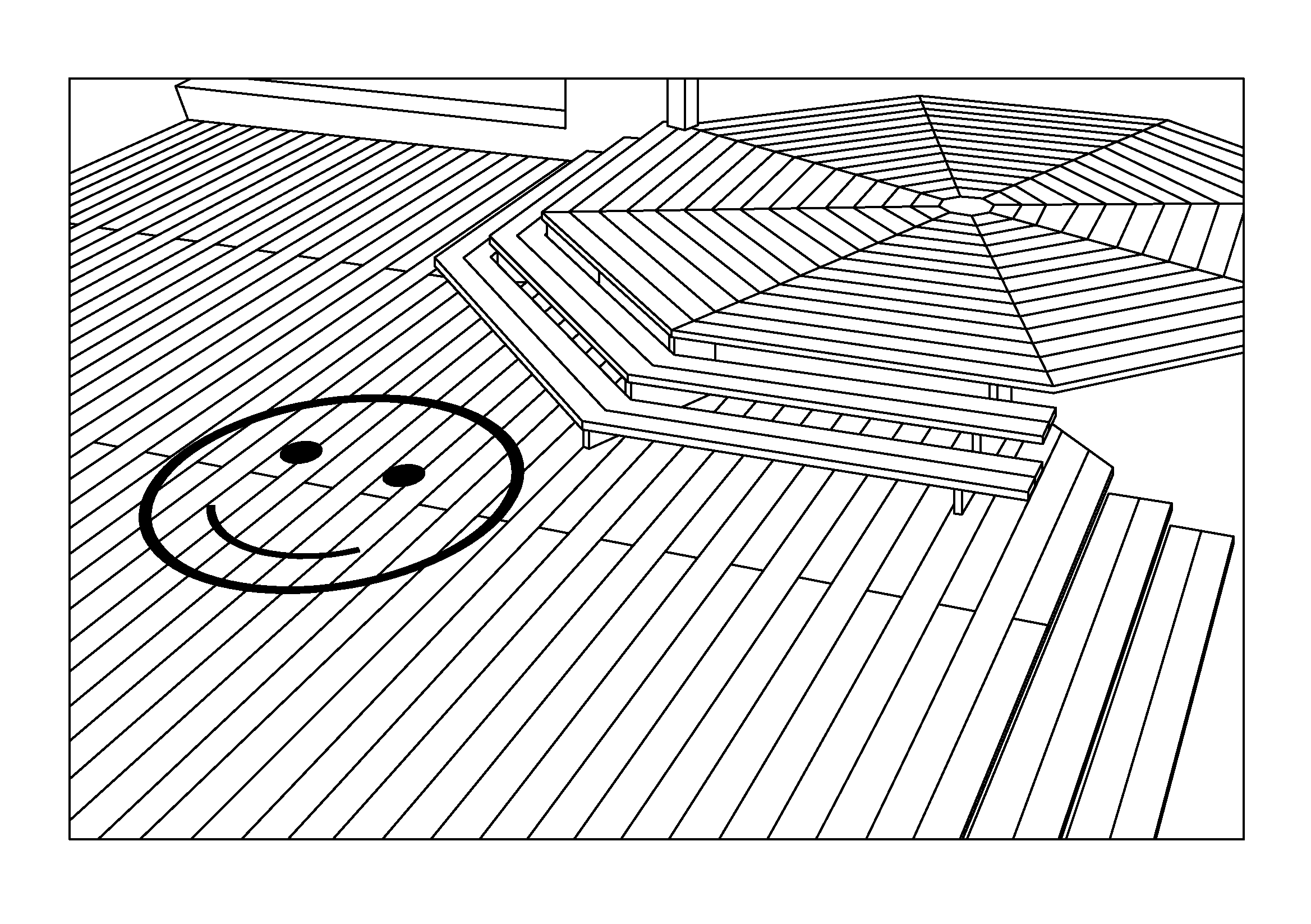

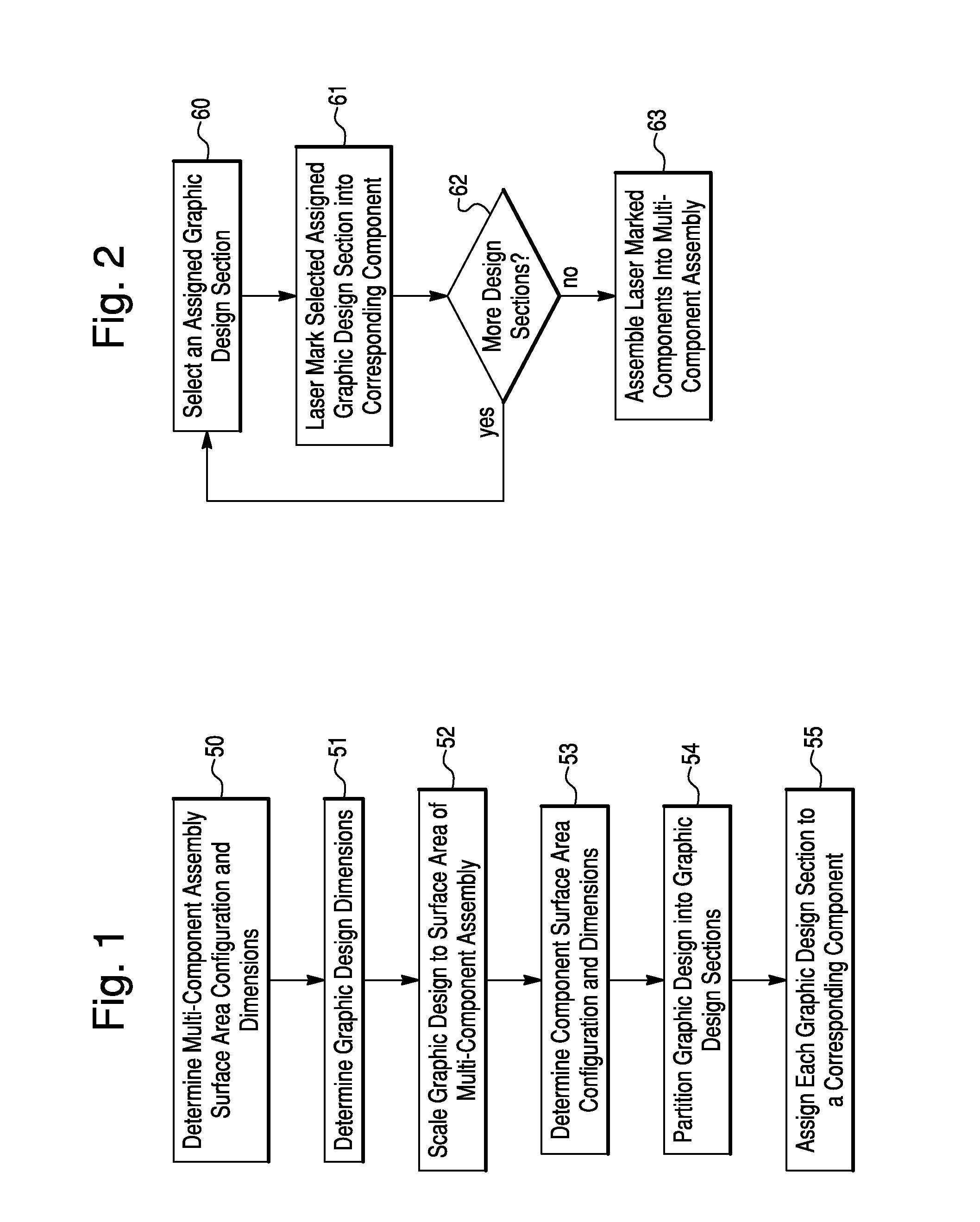

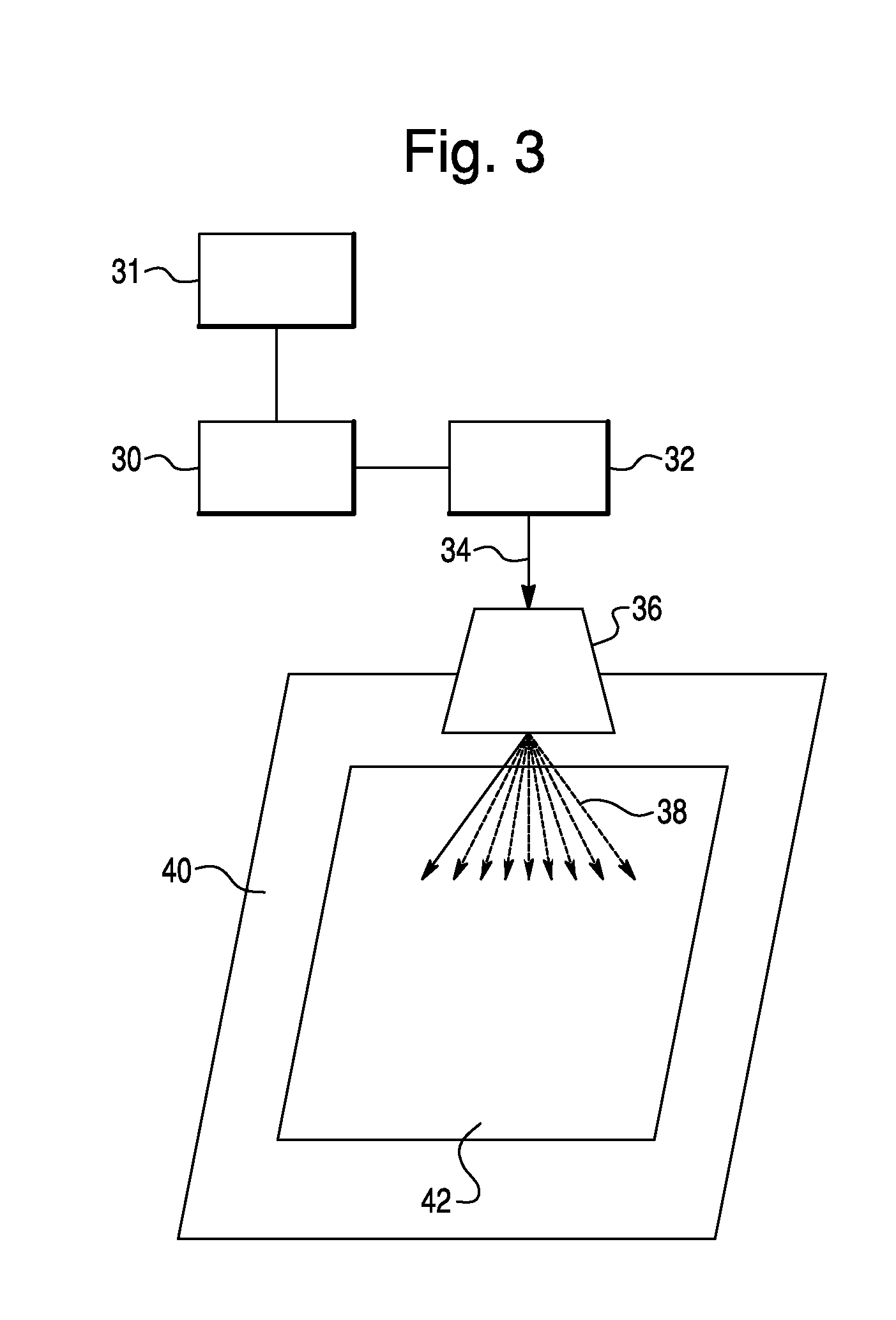

Laser-marked multi-component assemblies, kits, and related methods

Owner:MASONITE CORP

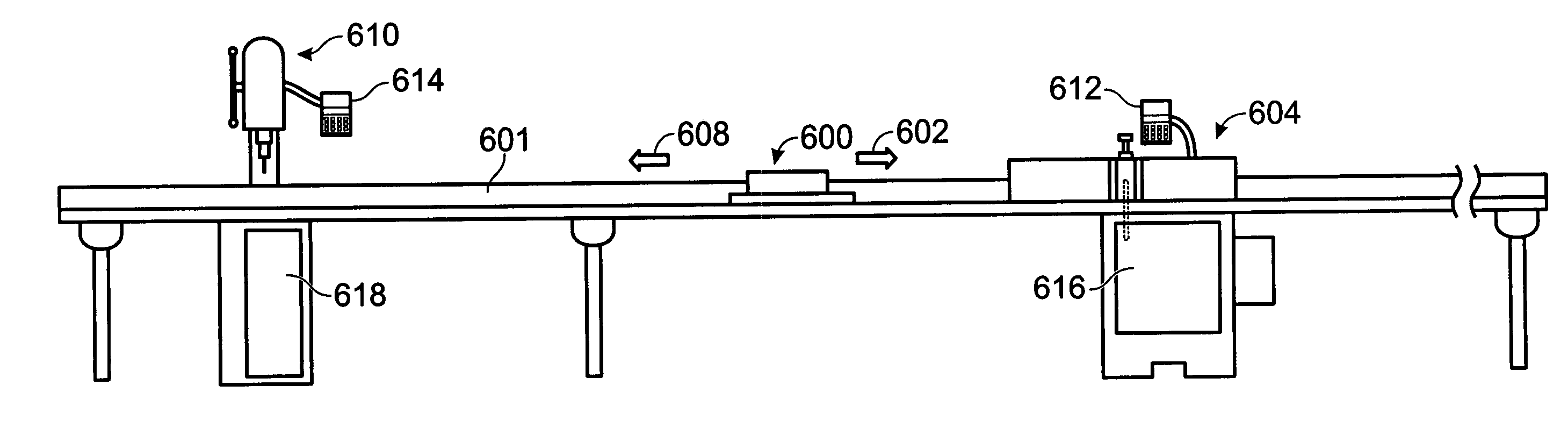

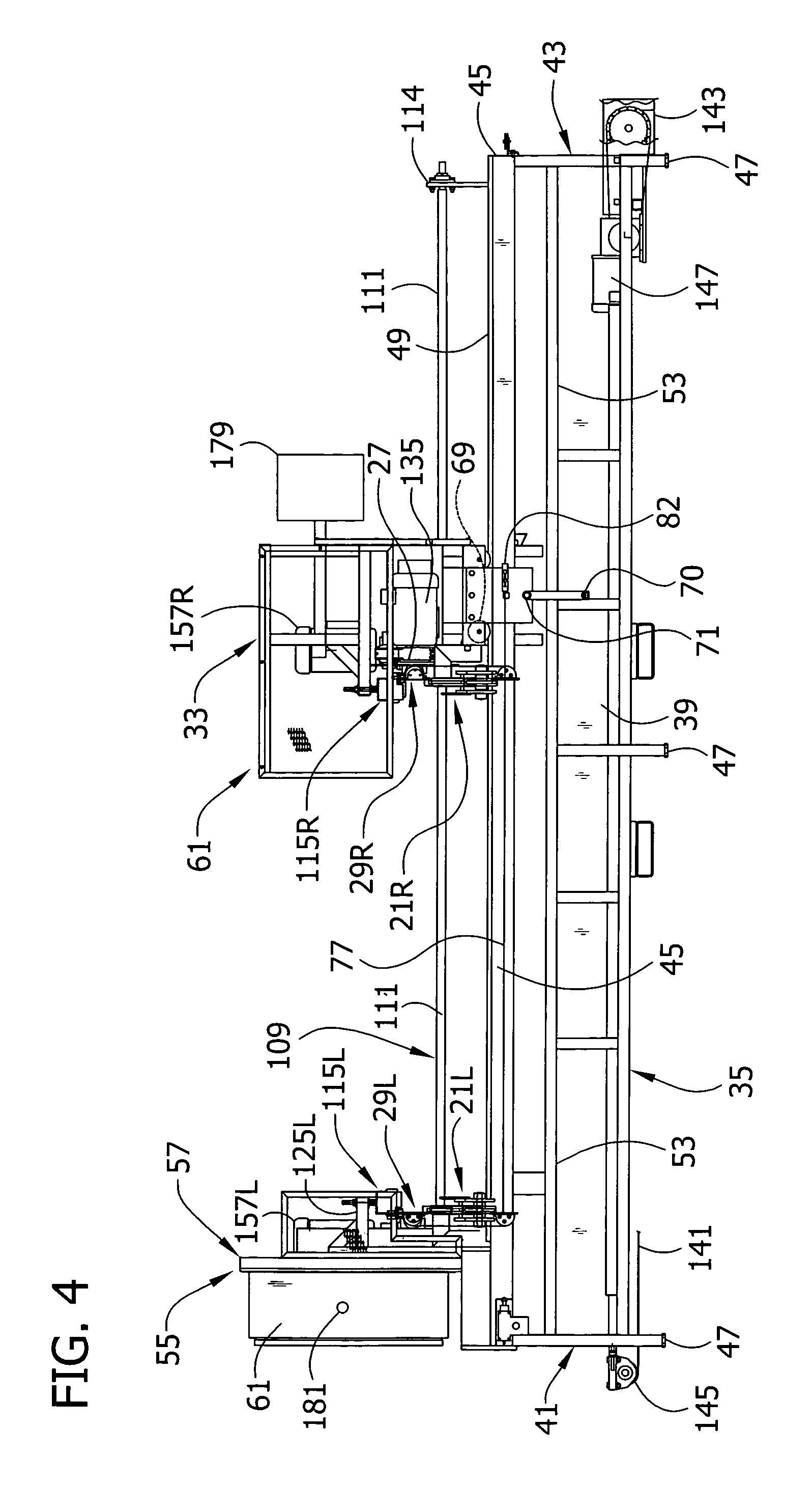

Apparatus and methods for double ended processing

System, including apparatus and method, involves processing materials in opposite directions between two machines along a processing path.

Owner:PRECISION AUTOMATION

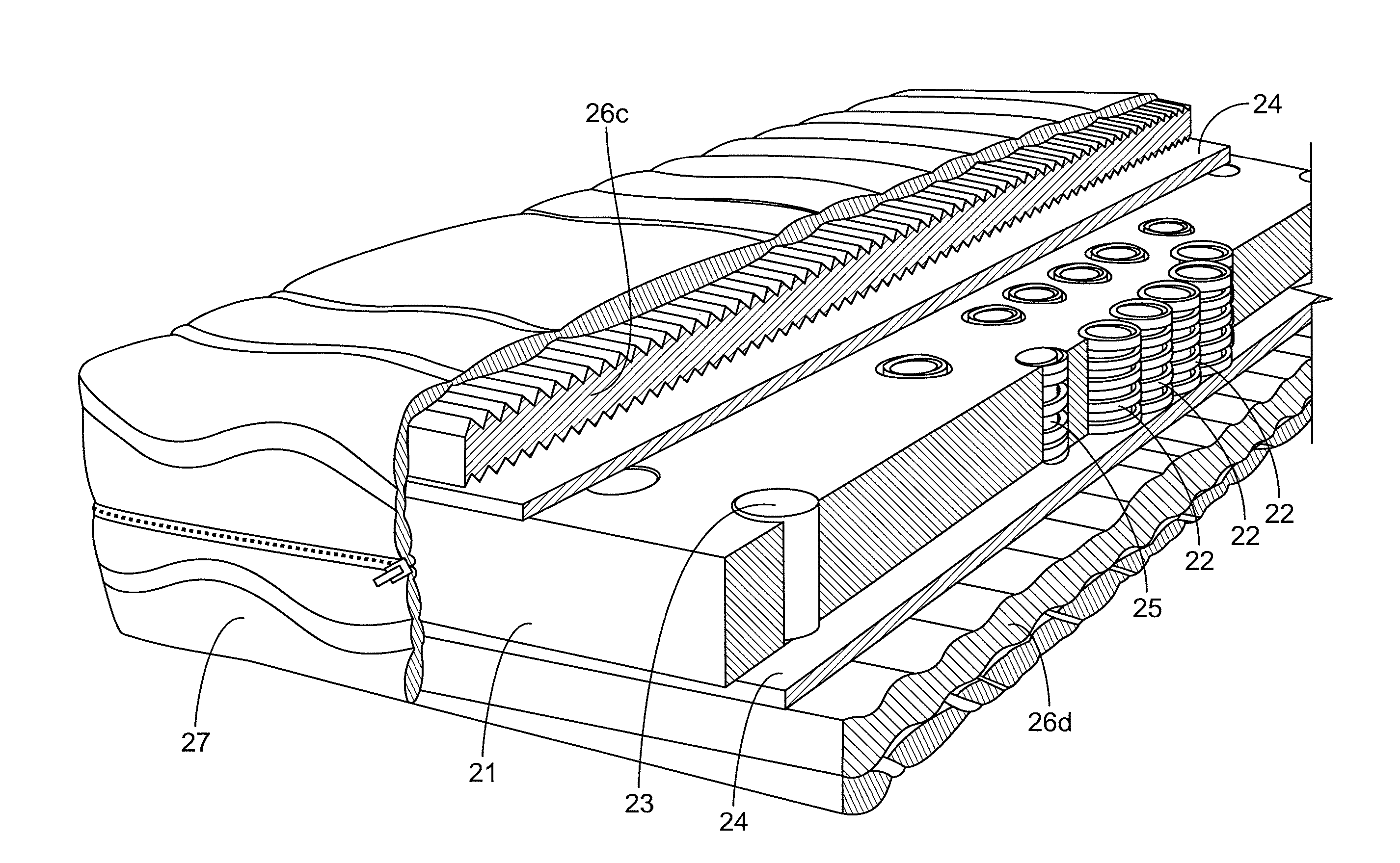

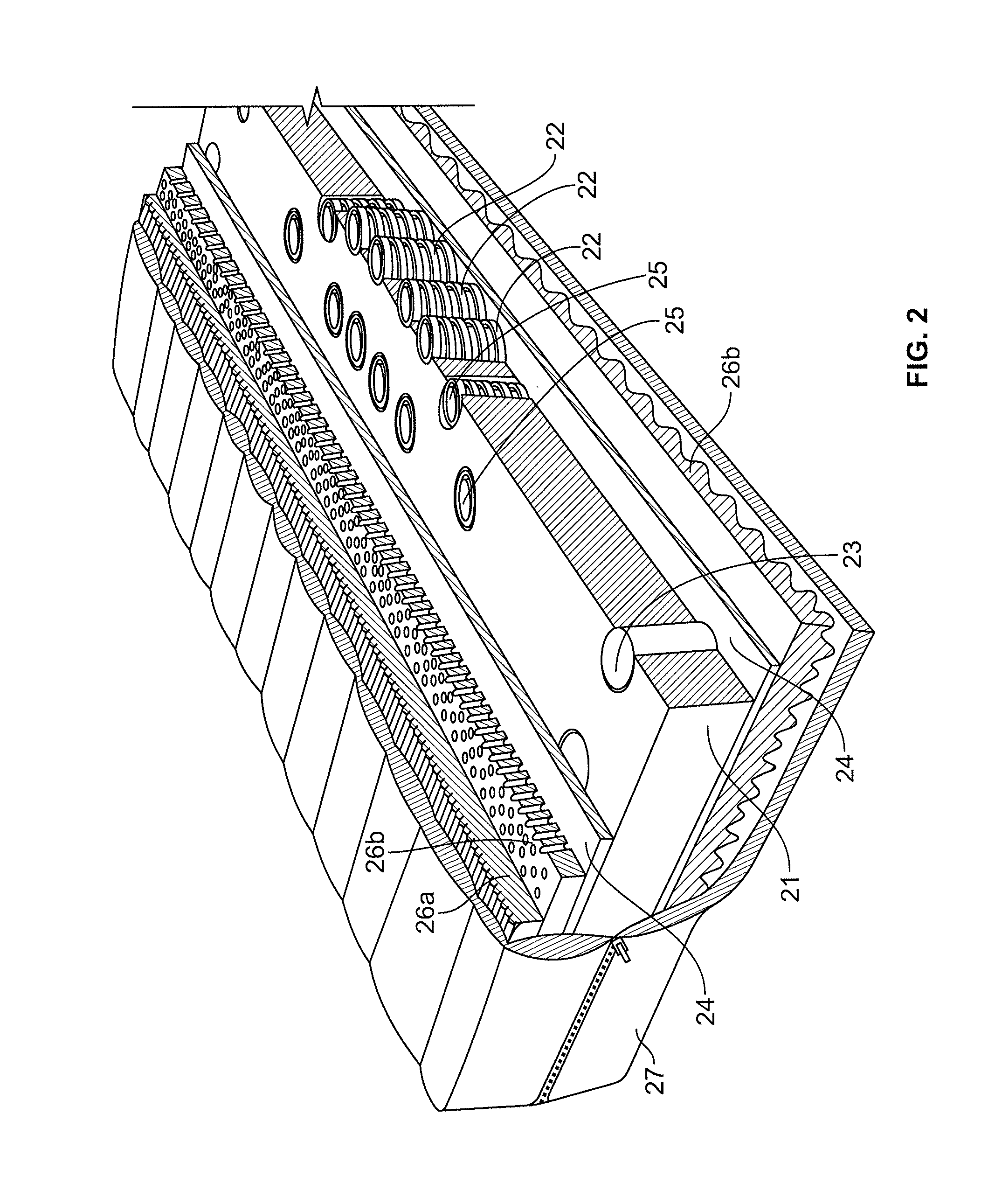

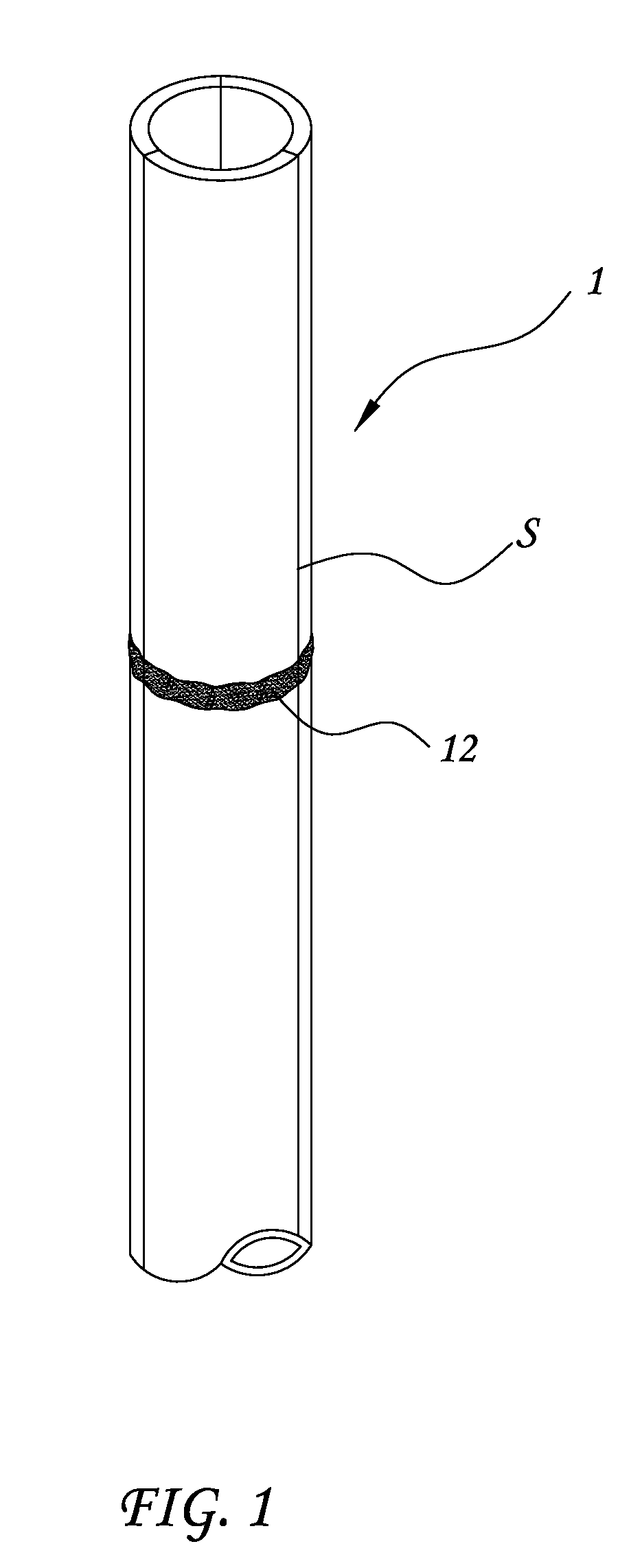

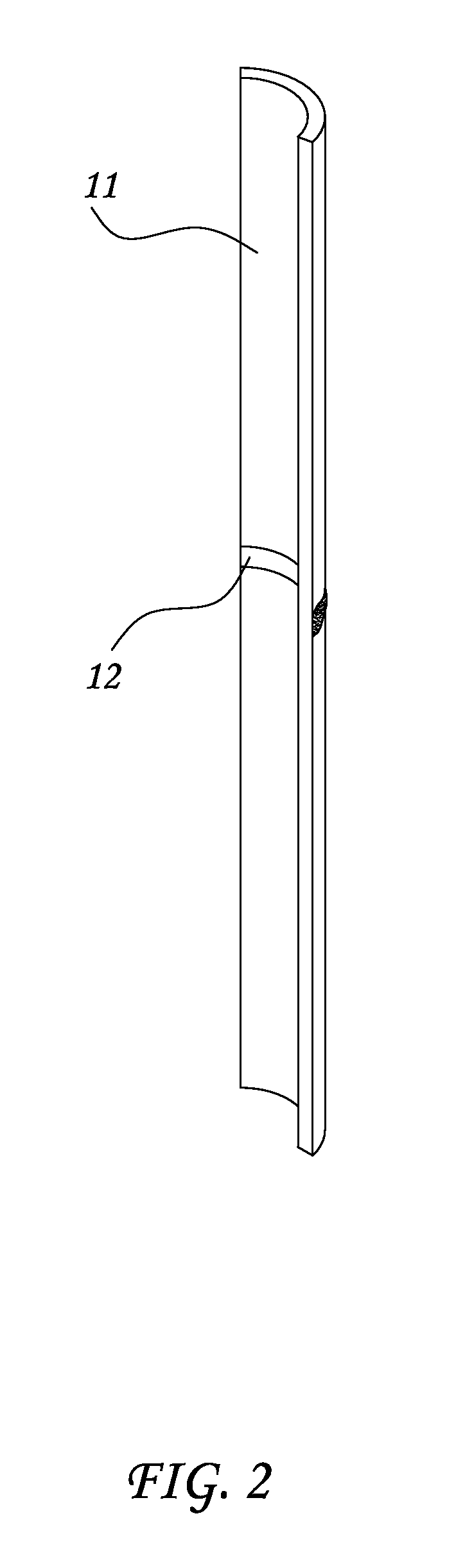

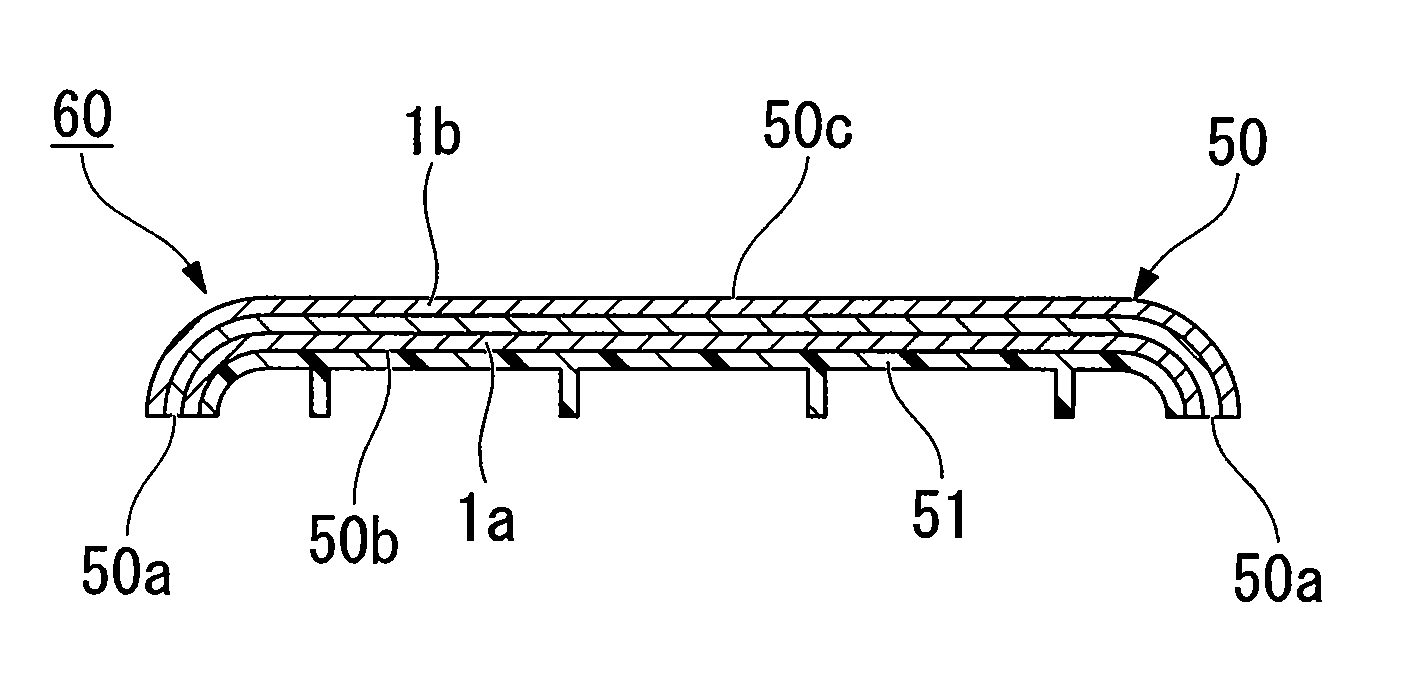

Wooden spring and mattress manufactured with wooden springs

Described are wooden coil springs, including those made of non-compressed wood, and mattresses with such coil springs. Also described is a method of producing a coil spring made of non-compressed wood, which includes winding a slat on reel, steaming and drying to produce the wooden coil spring. Such a coil spring may have a cylindrical shape, a cone shape or a truncated cone shape, and may have a substantially perpendicular end turn with respect to the longitudinal axis of the coil spring.

Owner:VOROS GABOR

Automated floor board texturing cell and method

Owner:ALADDIN MFG CORP

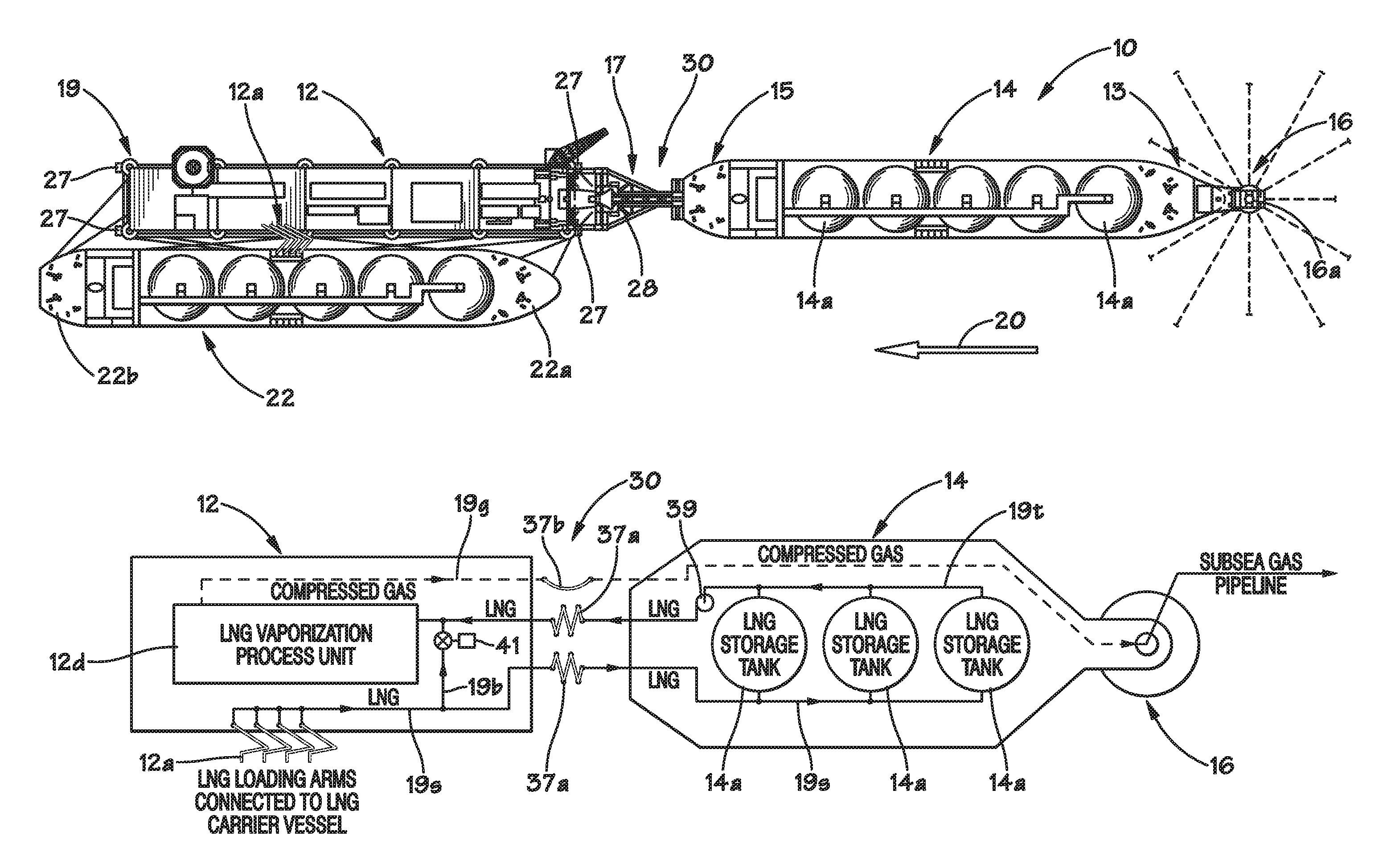

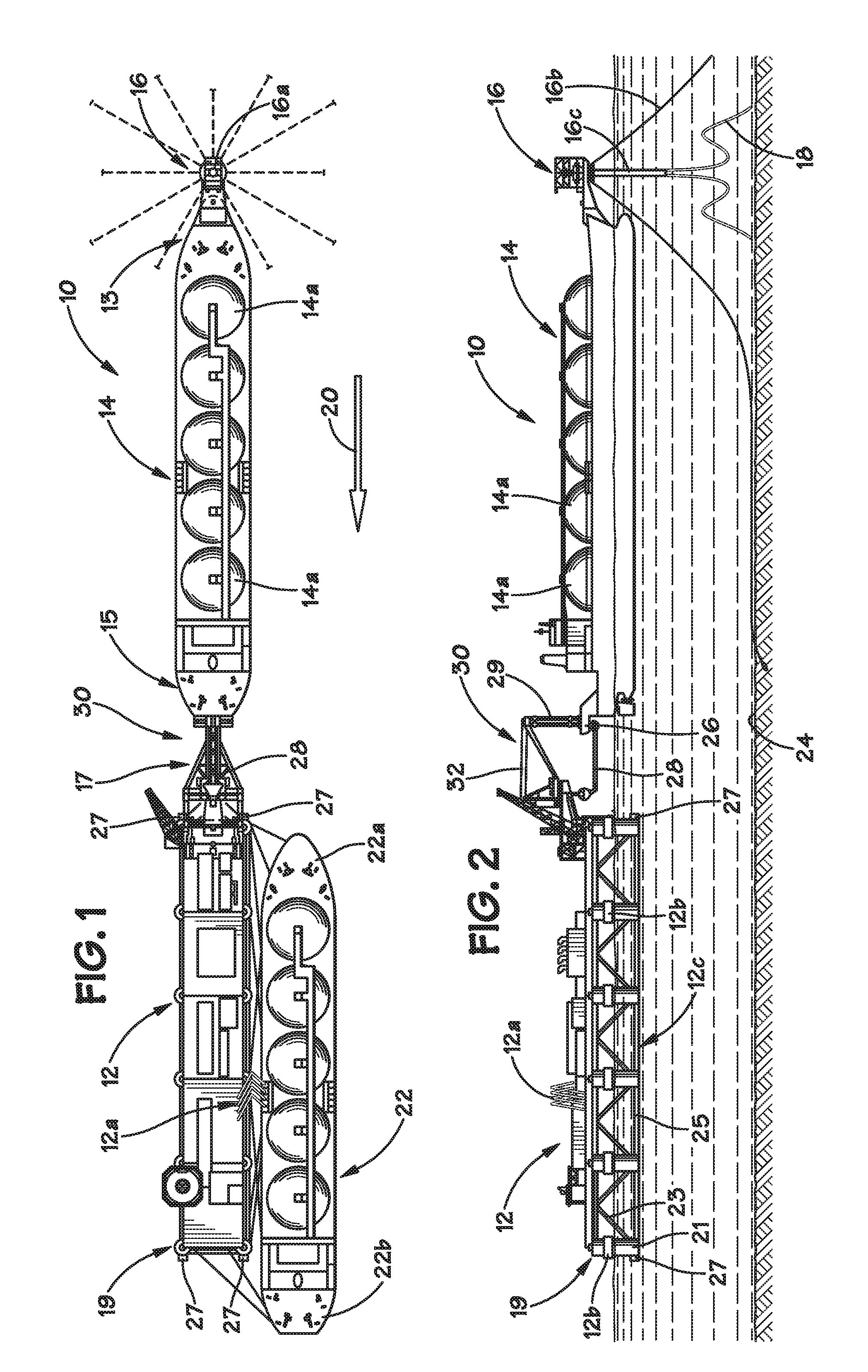

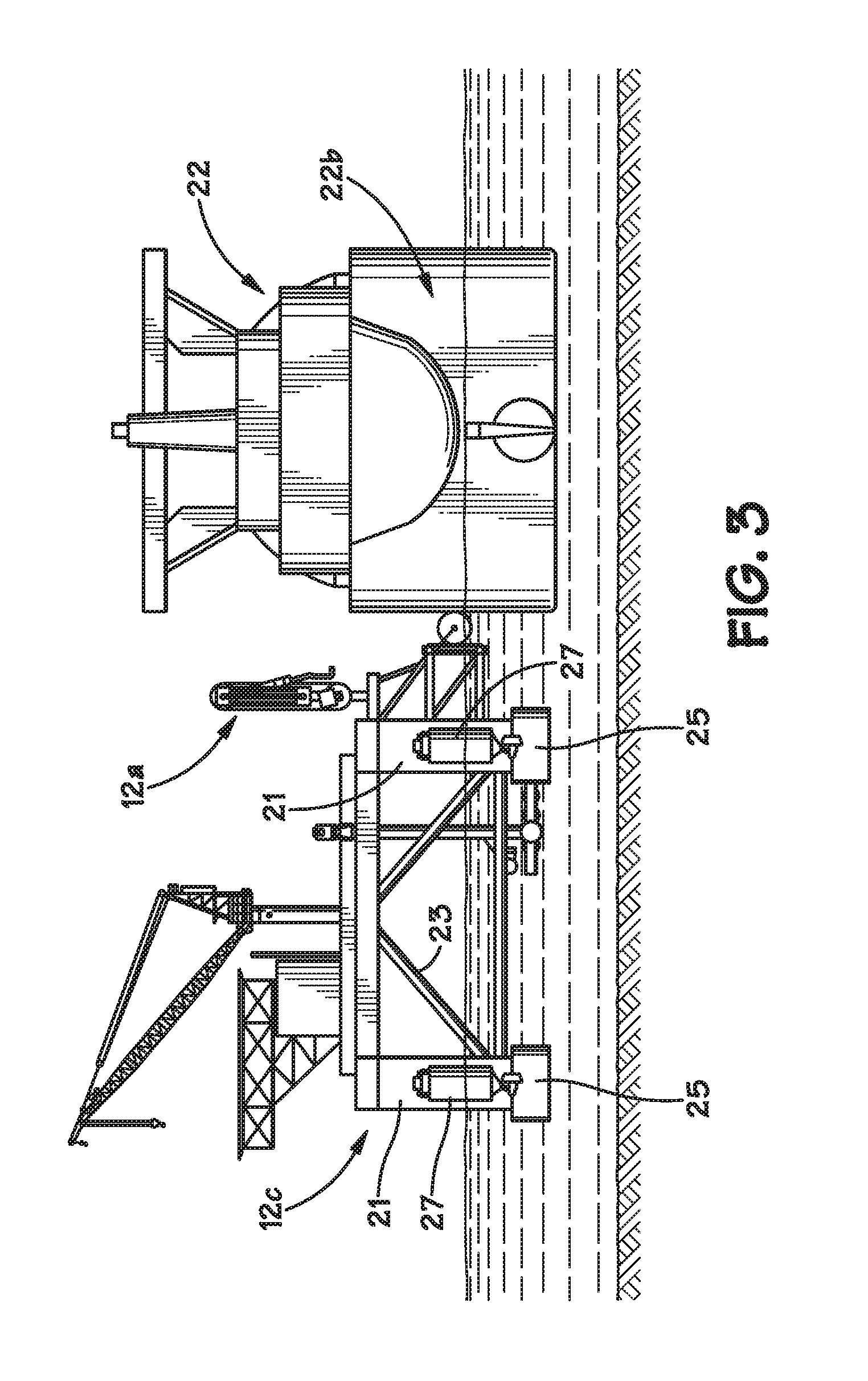

Floating LNG regasification facility with LNG storage vessel

InactiveUS8186170B2Container filling methodsGas handling applicationsMarine engineeringSubmarine pipeline

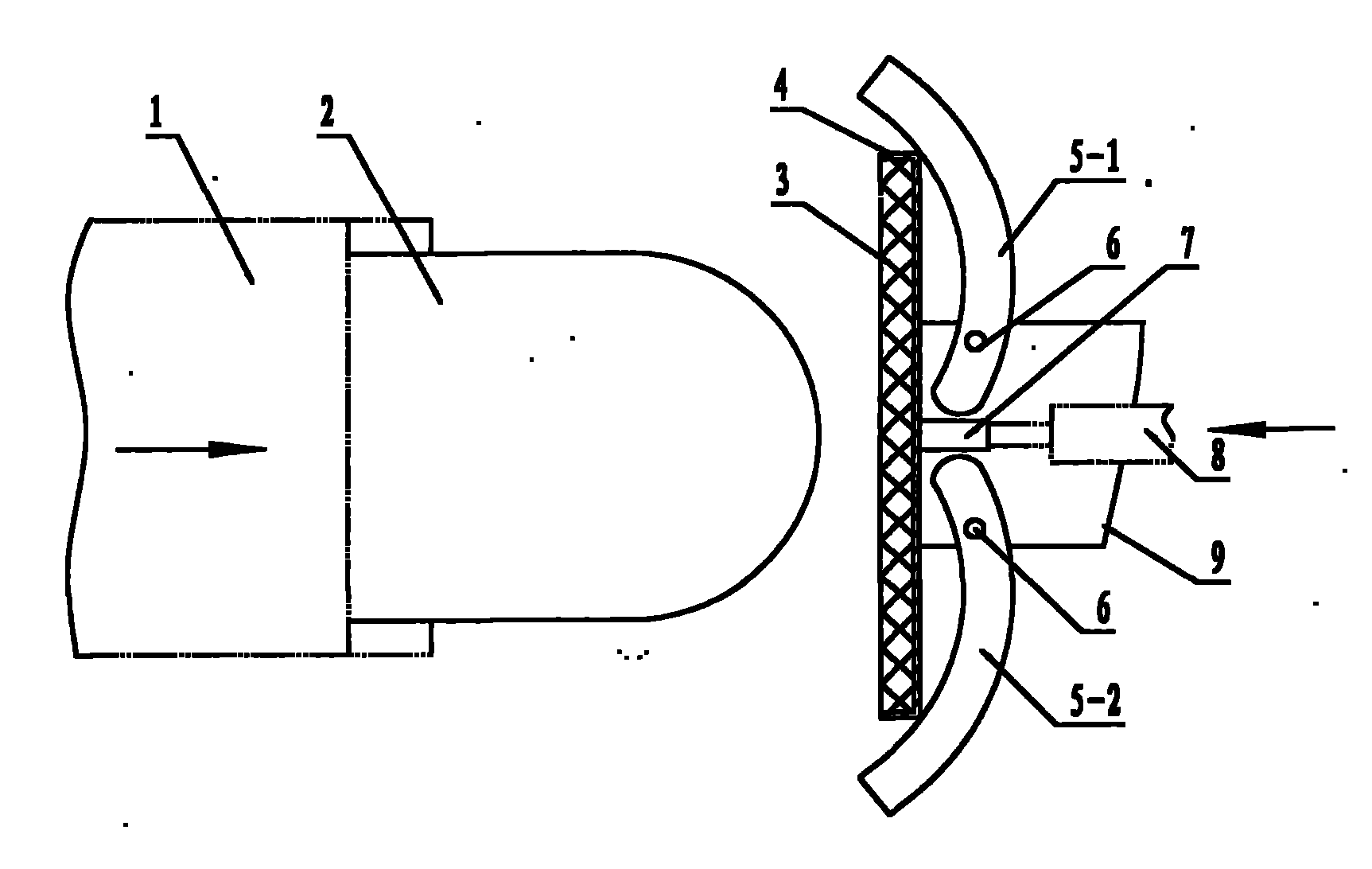

An LNG terminal is disclosed which includes an offshore mooring turret, an LNG storage vessel operatively coupled to the mooring turret, the LNG storage vessel including at least one LNG storage tank for the storage of liquid natural gas and a regasification vessel operatively coupled to the LNG storage vessel. A method of operating an offshore LNG terminal is also disclosed which includes obtaining liquefied natural gas from at least one LNG storage tank on an LNG storage vessel that is operatively coupled to a mooring turret, regasifying the liquefied natural gas from the LNG storage vessel using a regasification vessel operatively coupled to the LNG storage vessel, and supplying the regasified gas to at least one subsea pipeline via the mooring turret.

Owner:SOFEC

Manufacturing method of solid wood furniture bent parts

InactiveCN105599096ASolve the technical problems of large amount of sewage and long softening cycleImprove bending qualityRadiation/waves wood treatmentWood treatment detailsSolid woodProcess engineering

The invention provides a manufacturing method of solid wood furniture bent parts. The method includes the following steps that firstly, material varieties are selected, and raw materials are machined; secondly, microwave heating softening treatment is performed; thirdly, bending and forming are performed; fourthly, drying and shaping are performed; fifthly, cooling is performed. The manufacturing method can replace a common cooking softening technology and a kiln drying shaping technology, production technology time is shortened, and production efficiency is improved; the springback rate of bend wood is reduced through a microwave heating softening method, and the bending quality of manufactured products is improved; no waste liquid is generated in the production process, and environmental friendliness is facilitated in the production process; the production period is short, production cost is low, and economic benefits can be increased easily.

Owner:中山市大涌镇生产力促进中心

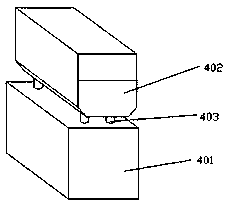

Multi-deflection bending shaping device and bending shaping method for furniture wood processing

InactiveCN110271069AImprove accuracyAvoid deformationPressure wood treatmentWood treatment detailsClamp connectionDrive shaft

The invention discloses a multi-deflection bending shaping device for furniture wood processing. The device is composed of a material inlet platform, a soaking tank, a fumigation box, a heat-preservation levelling platform, a bending shaping box and a material outlet platform, the material inlet platform is provided with a first conveyer belt, a second conveyer belt is obliquely arranged in the soaking tank, a third conveyor belt and a steam spray pipe are arranged in the fumigation box, and the heat-preservation levelling platform is composed of a base seat, lifting rods and a lifting platform; the interior of the bending shaping box is connected with each first hot pressing roller through one corresponding first hydraulic rod and is connected with each second hot pressing roller through one corresponding second hydraulic rod, driven gears of the second hot pressing rollers are connected with a driving gear chain of a driving shaft, and the bending shaping box communicates with a hot air fan; and a slide groove of a bottom plate in the material outlet platform is in clamp connection with a T-shaped supporting foot of a motor, and the motor is connected with a horizontal push rod. The device provided by the invention realizes a bending shaping method of soaking, steam fumigation, low-pressure levelling, repeated hot roll bending and repeated hot roll shaping, is suitable for wood with different deflection, and has high bending and shaping efficiency, and high accuracy, and the shaped wood is not easy to deform.

Owner:利辛县爱侣家俱加工有限公司

Material and process for its production

Owner:LINDHE CURT +1

Flat bamboo element fabrication method

InactiveUS20090250141A1Eliminate useReduce energy consumptionCane mechanical workingPlant material mechanical workingEngineeringKnife blades

A flat bamboo element fabrication method for making flat bamboo elements by trimming prepared bamboo cane and cutting the trimmed bamboo cane into a number of bamboo bars of equal length and width and then delivering each bamboo bar through the gap in between the bottom ramming roller and upper ramming roller of a ramming machine for ramming into a flat bamboo element that has a crack pattern therein. In an alternate form, the upper ramming roller has parallel circular cutter blades for cutting each rammed flat bamboo bar into multiple flat bamboo elements.

Owner:WANG WEN TSAN

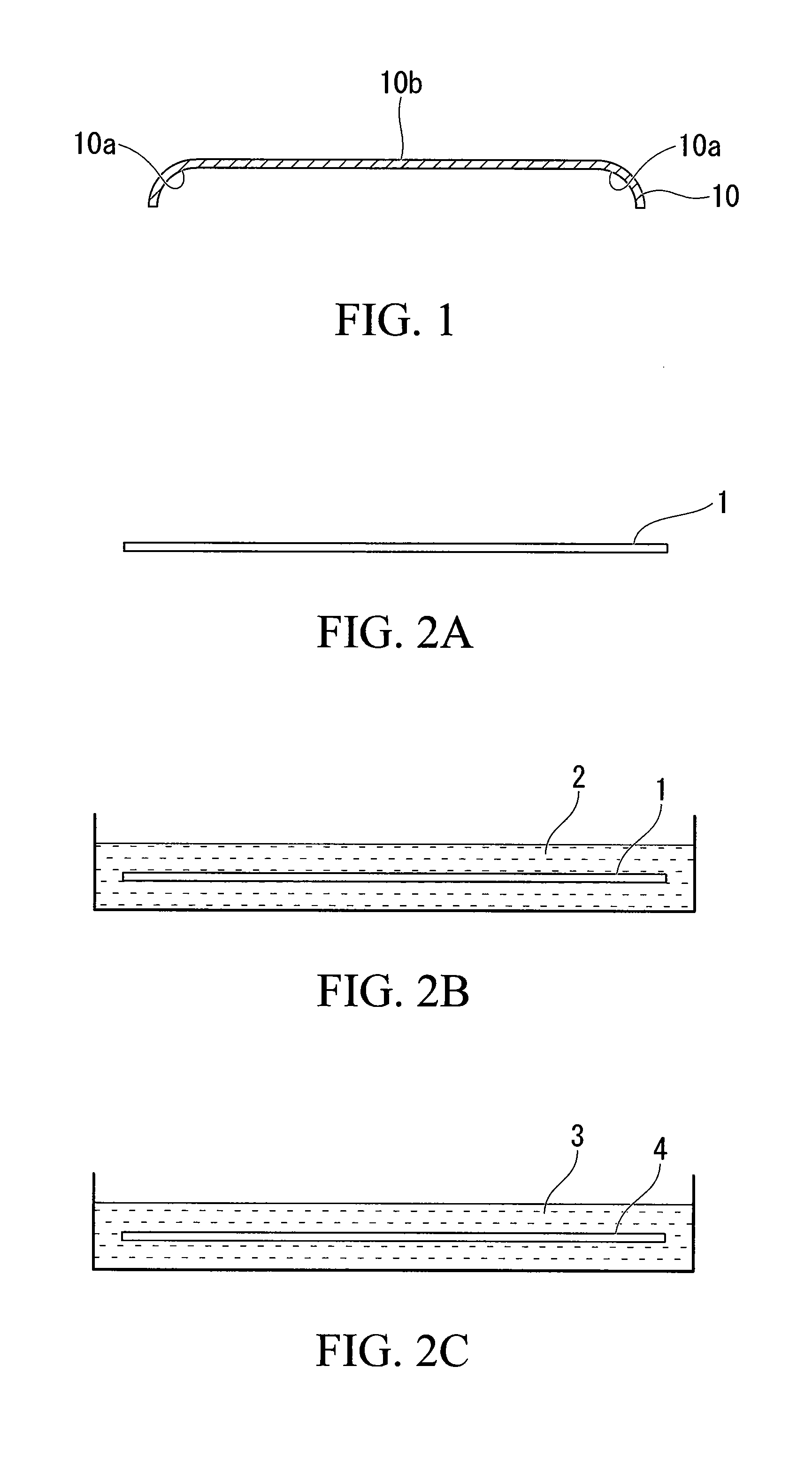

Method of forming a wooden mold as well as wooden structure, vehicle interior material, and acoustic structure processed by the method

InactiveUS20080020222A1Increase volumeReduce thicknessWood compressionWood veneer joiningAcrylic resinWater soluble

A method of forming a wooden mold may include, but is not limited to, the following processes. A resin solution may be impregnated into at least one wood board thereby forming at least one resin-impregnated wood board. The resin solution may include a resin component. The resin component may include at least one water-soluble bifunctional acrylic resin and at least one trifunctional or higher-functional acrylic resin. The at least one resin-impregnated wood board may be deformed. The resin component in the at least one resin-impregnated wood board may be cured at the same time or after the at least one resin-impregnated wood board may be deformed.

Owner:YAMAHA CORP

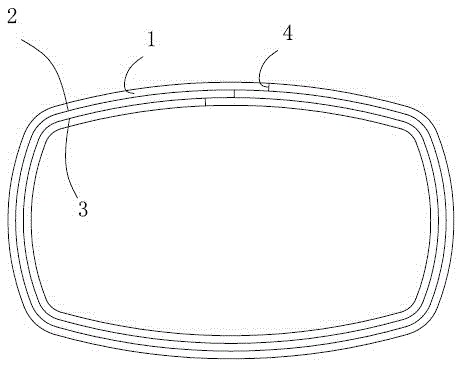

Bamboo frame forming process

ActiveCN105522634AWon't burnConvenient heating controlCane mechanical workingWood stock bendingEngineeringSoftening

The invention relates to a bamboo frame forming process which solves the defects that current bamboo frame marking-taping adopts an artificial mode, bamboo wood is required to be cut into relatively thin flat bamboo strips, processing is inconvenient, and working efficiency is low. The bamboo frame forming process comprises the following steps: firstly heating a fixed mould and a movable mould assembly to a proper temperature; preparing bamboo strips; arranging the bamboo strips; placing the bamboo strips and closing a mould; sizing; and de-molding. The bamboo frame forming process is used for heating the fixed mould and the movable mould assembly, and clamping the bamboo strips after heating, so that a heat source is not directly acted to the bamboo strips; the heating temperature of the bamboo strips can be controlled by controlling the heating temperature of the fixed mould and the movable mould assembly, so that the bamboo strips are ensured to be not burned in roasting or baking during softening, and the heating control of the fixed mould and the movable mould assembly is relatively convenient; the movable mould assembly and the fixed mould are closed for clamping the bamboo strips, so that bounce force generated by the bamboo strips can be overcome, and therefore, the thickness of the bamboo strips can be increased, the bamboo frame can be formed by making-taping with less bamboo strips, the processing efficiency is high, and all bamboo strips of the bamboo frame can be simultaneously bent and sized once.

Owner:ZHEJIANG SANJIAN IND & TRADE

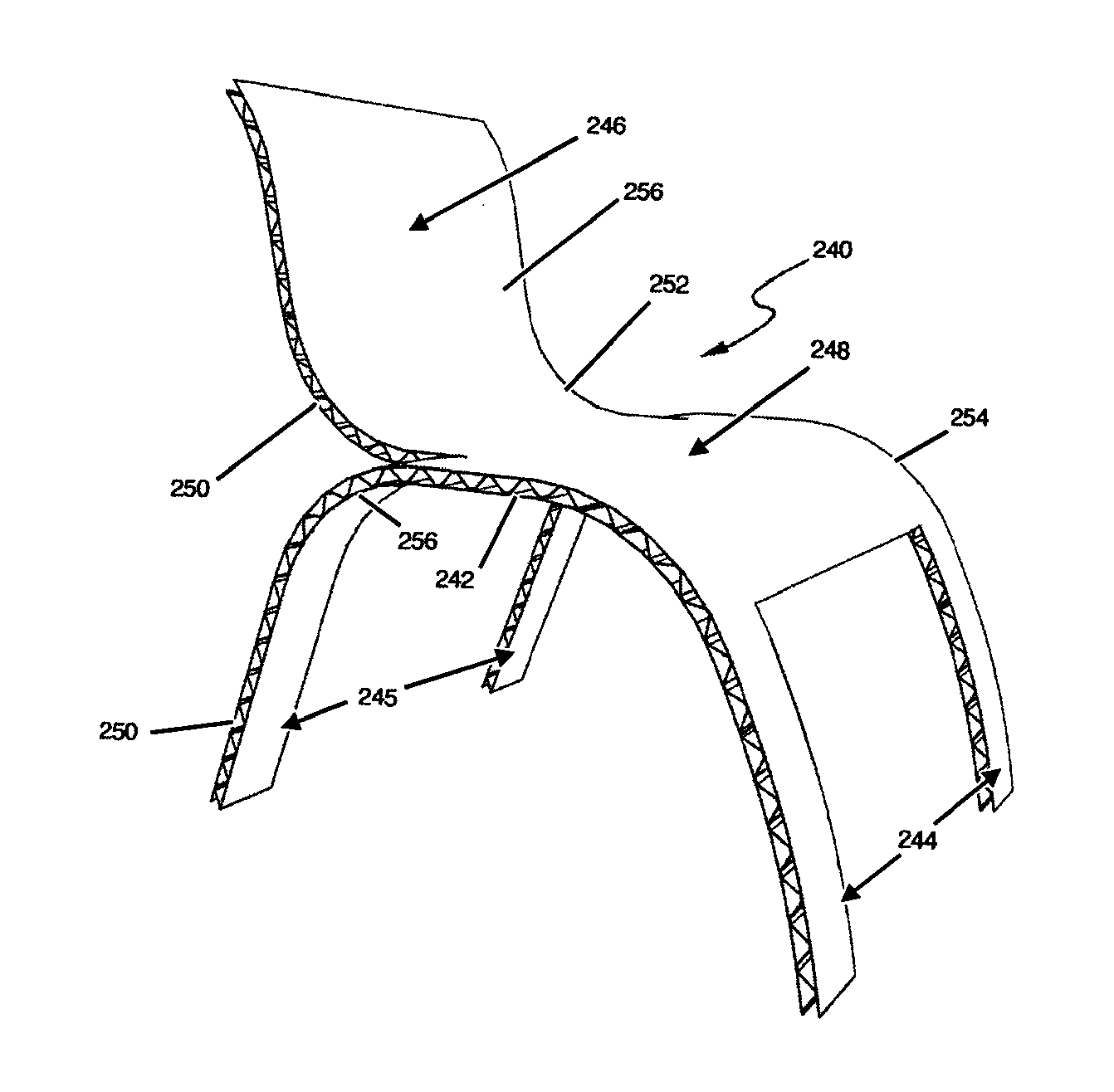

Apparatus and method for forming a dual radius arch mounting structure

InactiveUS20050183347A1Avoid deformationPrevent bucklingArched structuresVaulted structuresEngineeringVertical orientation

An apparatus and method is provided for forming a dual radius arch frame structure. The apparatus includes a longitudinal member having a centerline and centerpoint. A laterally adjustable support is further included which has one end attached to the centerpoint of the longitudinal member in a perpendicular orientation and a vertical support attached to a distal end of the laterally adjustable support. A left outer form is provided which has a generally semi-circular shaped arch centered and oriented about a left pivot axis located on the centerline a predetermined distance from the centerpoint. A right outer form is also provided which has a generally semi-circular shaped arch centered and oriented about a right pivot axis located on the centerline a predetermined distance from the centerpoint. Additionally, an arched shaped center cord is adapted to be connected to a receiving edge of the left outer form and of the right outer form in a tangentially continuous manner. Also, at least one adjustable left strut assembly interconnects the left outer form to the vertical support and at least one adjustable right strut assembly interconnects the right outer form to the vertical support.

Owner:BARRY MICHAEL A +1

Process for treating wood with a mixture of garnet particles and glass beads

Owner:LOVELAND SCREW MACHINE

Log structure and method for constructing same

InactiveUS20070137122A1Easy constructionImprove usabilityWallsBuilding repairsStructural engineeringEngineering

An improved structure, whereby the log structure is comprised of at least two adjacent walls mated to form a corner, with each wall constructed of logs laid horizontally upon each other, the logs alternating between protruding and nonprotruding logs, such that the ends of the protruding logs of the walls are interleaved, with the ends of the protruding logs of the first wall having notches cut from them to facilitate the mating of the first and second walls, and further comprising plugs to be inserted into the notches upon completion of assembly of the log structure, and a method for constructing same.

Owner:PEACO LAWRENCE

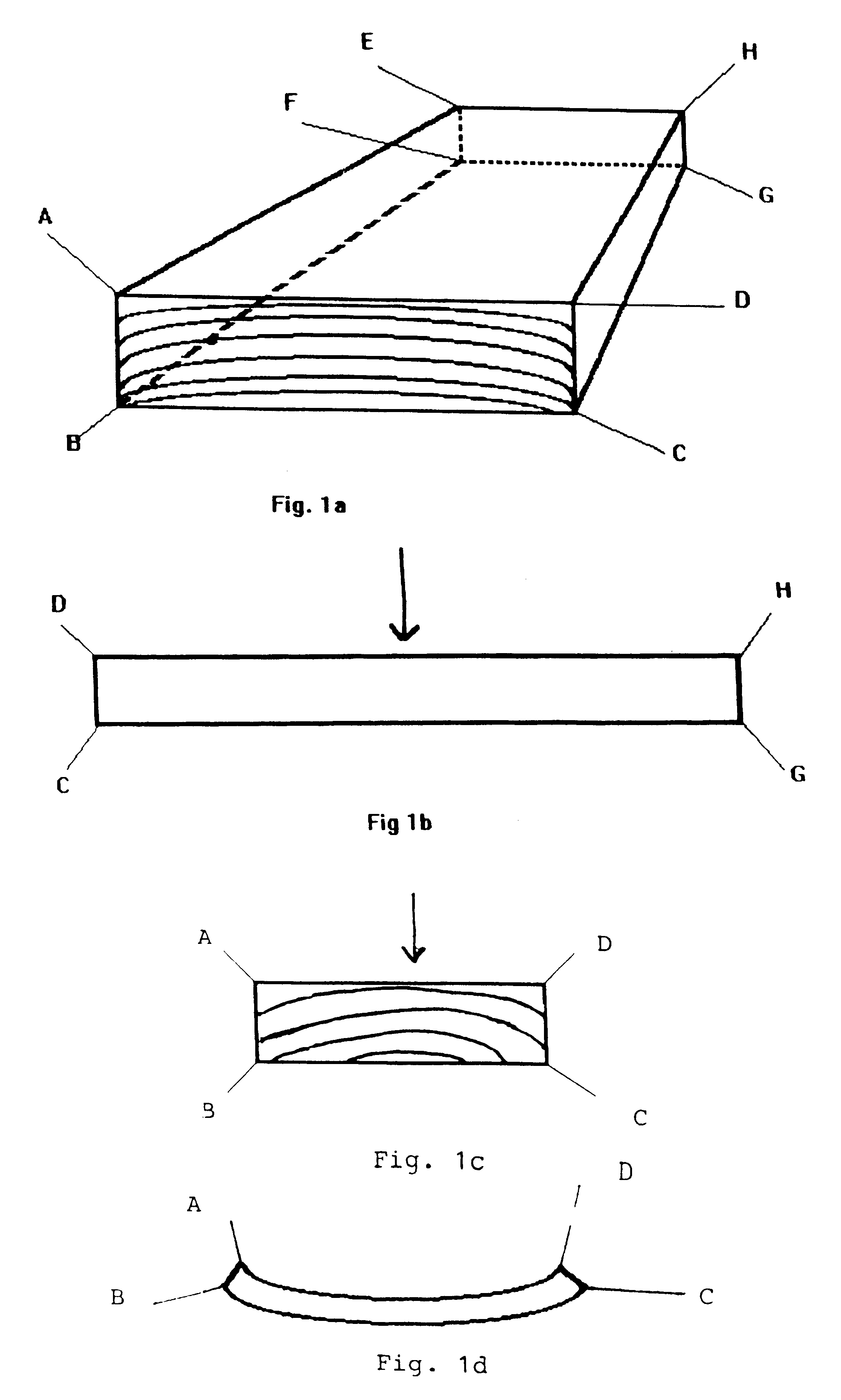

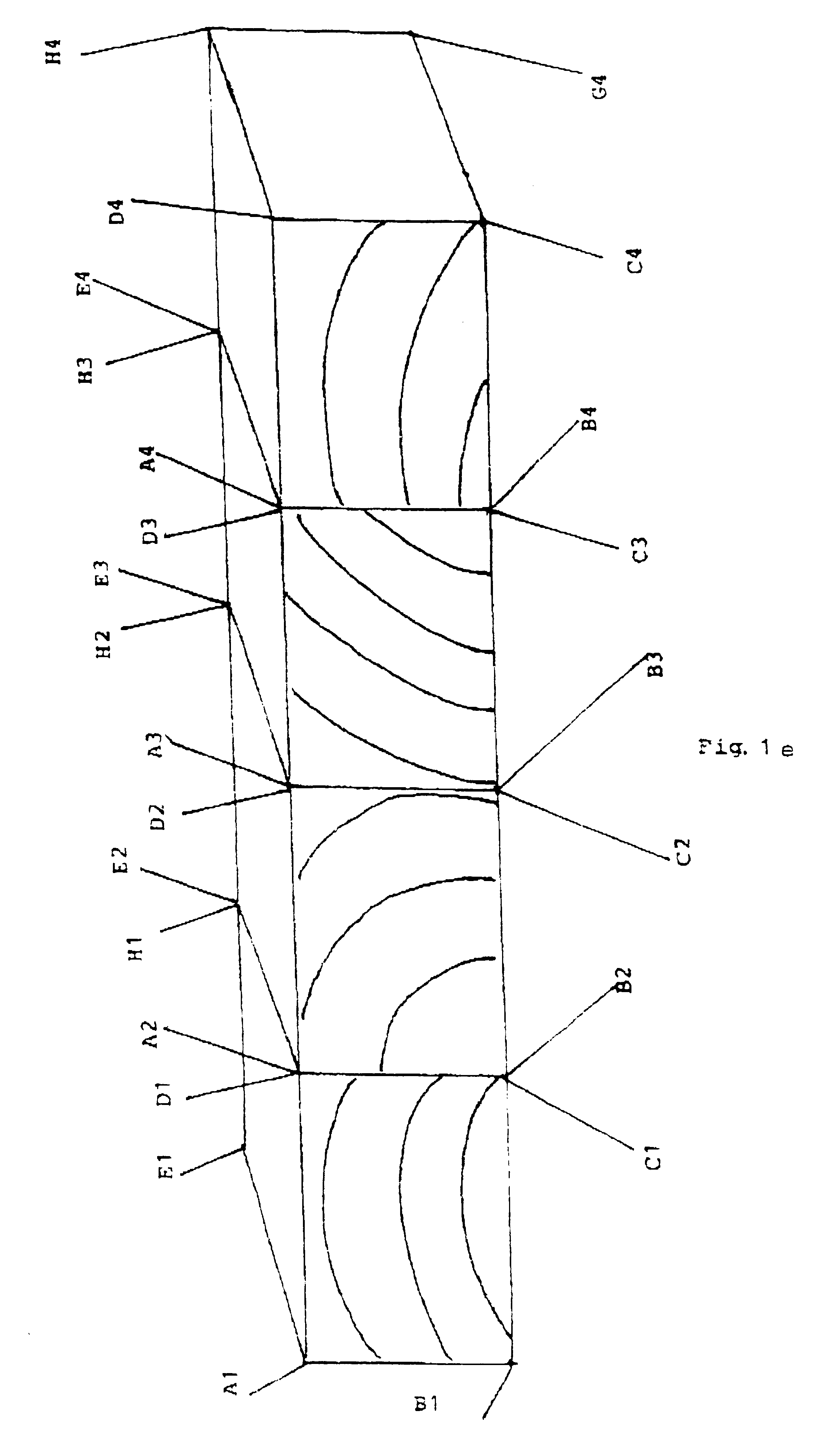

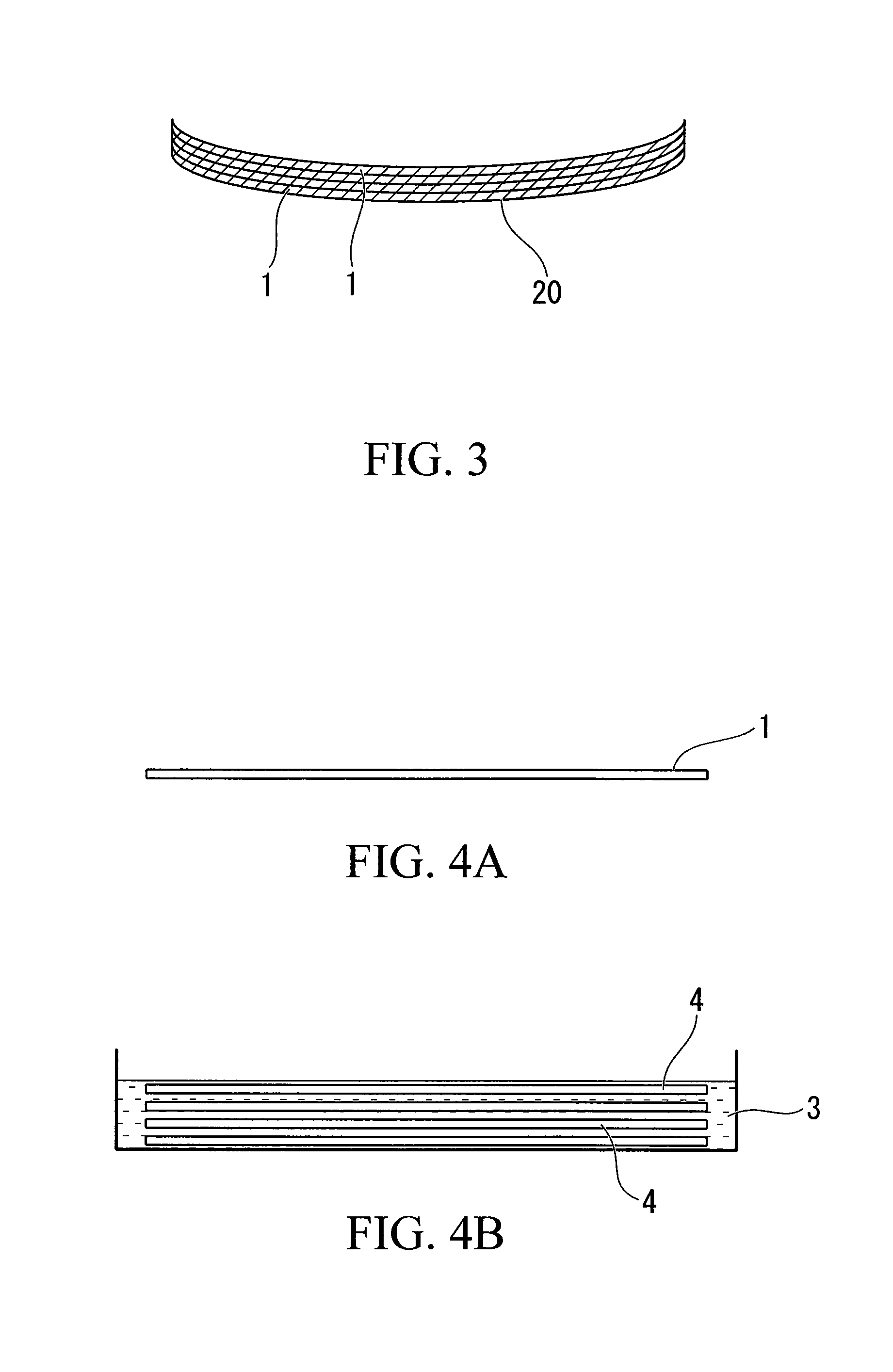

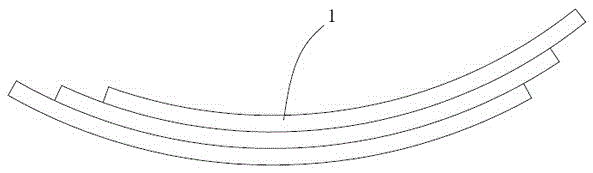

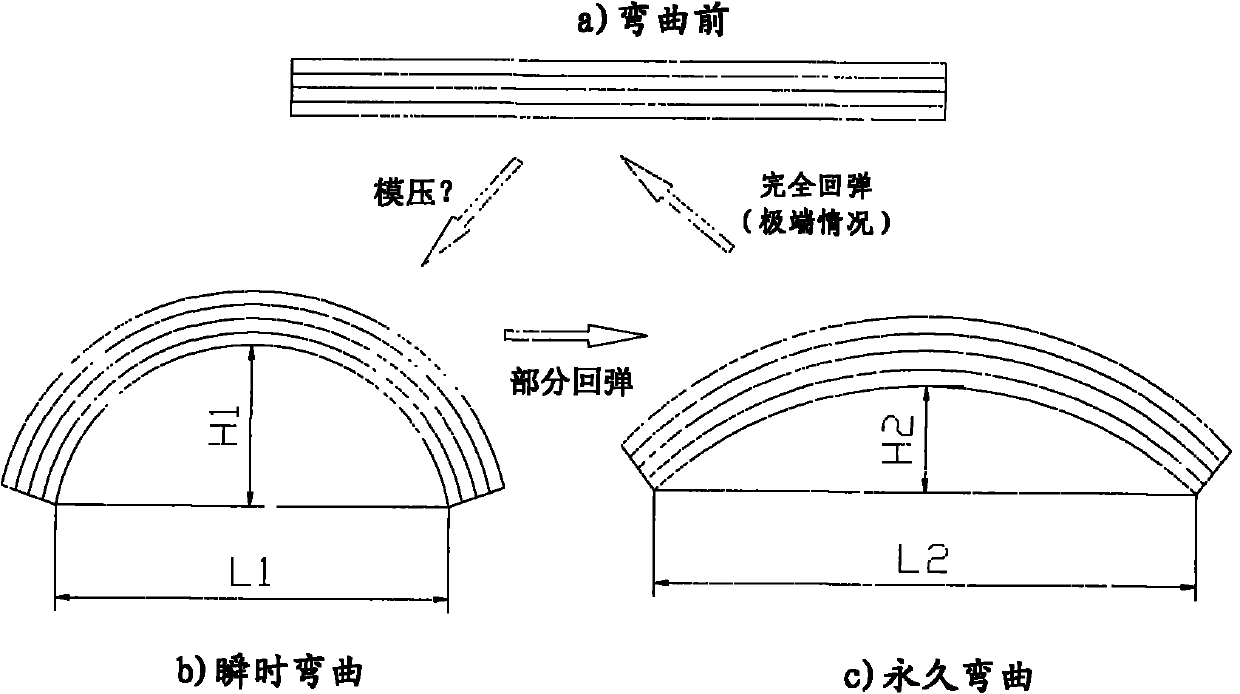

Method for manufacturing curved laminated veneer lumber

InactiveCN102001114AReduce manufacturing costShorten the production cycleWood veneer joiningWood stock bendingFiber saturation pointEngineering

The invention belongs to the field of wood processing and discloses a method for manufacturing curved laminated veneer lumber. By the method, a plurality of layers of veneers are parallelly assembled, glued and hot pressed along the grains according to the following conditions: a, each veneer has the same breadth size and the moisture content of lower than a fiber saturation point; b, loose sides and tension sides or front sides and back sides of all veneers are kept in the same direction during parallely assembling; and c, one or more parameters of the veneers, such as the moisture content, thickness and density are increased or reduced layer by layer. In the method, the conventional plane hot press can be directly used without a die, so the production cost is saved, and the production cycle is shortened. As the bending of a product is determined by the nature of the laminated veneer lumber and is not influenced by the action of external force, the problem of serious resilience is solved, and sustained bending of the laminated veneer lumber can be realized.

Owner:NANJING FORESTRY UNIV

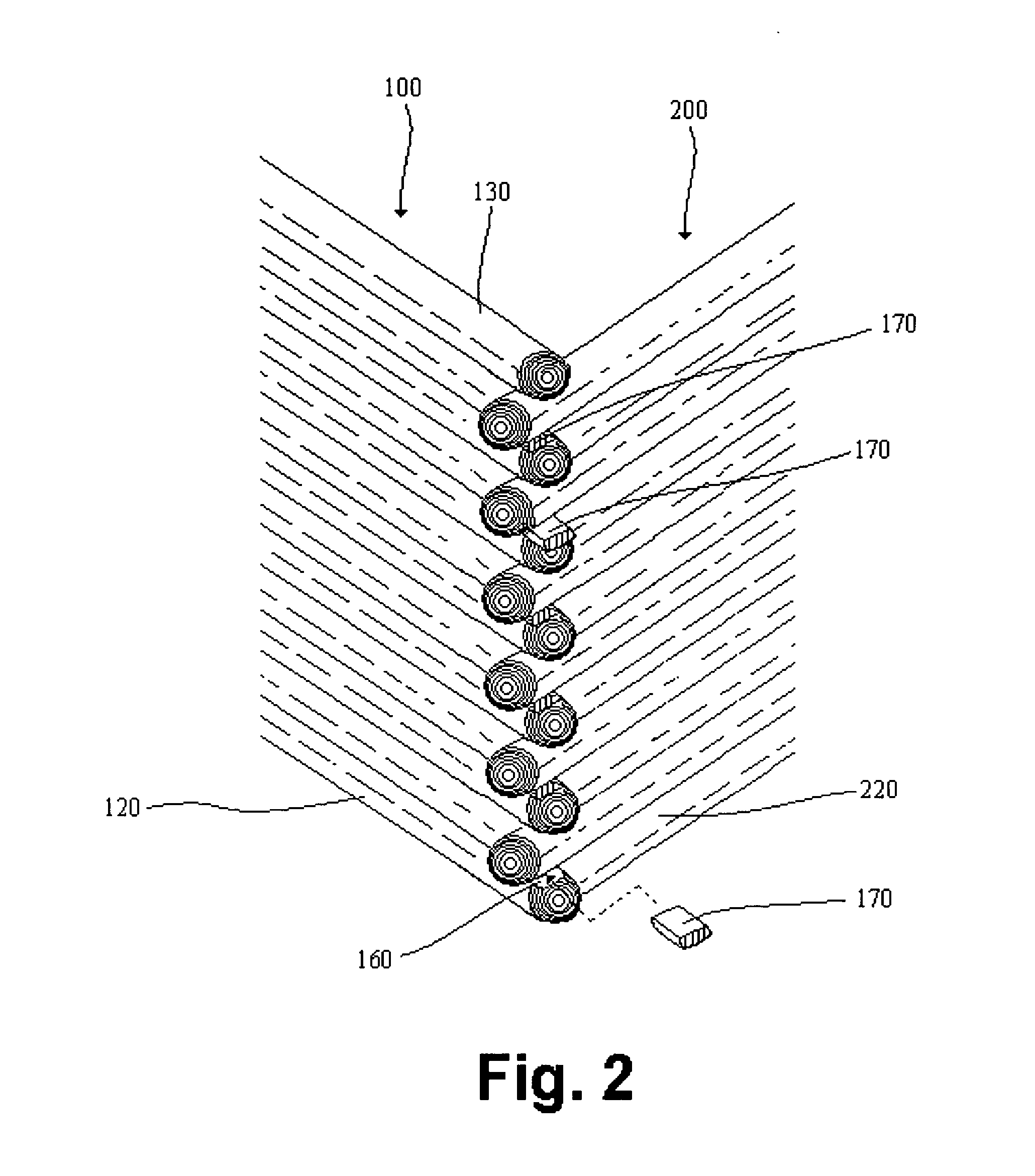

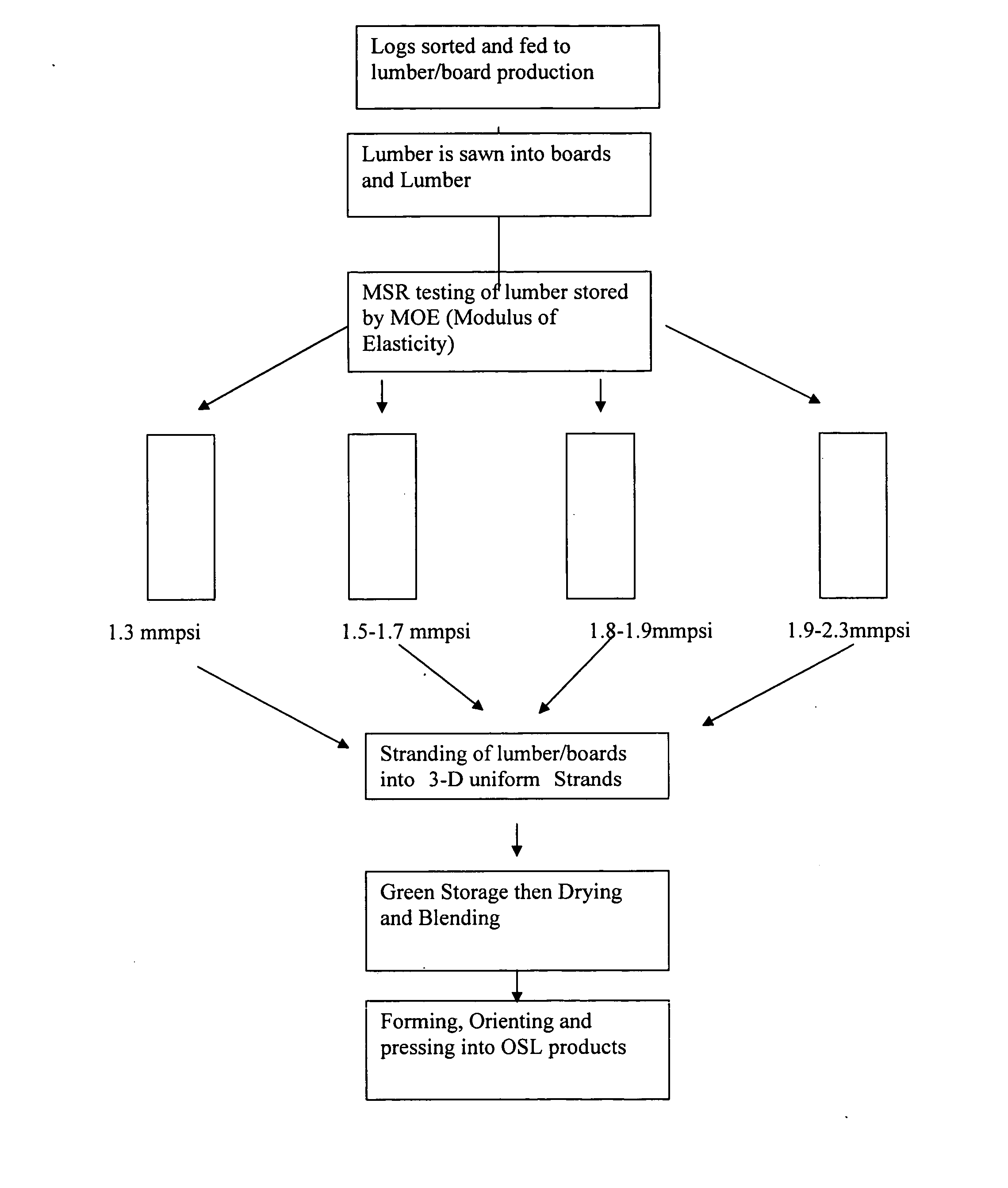

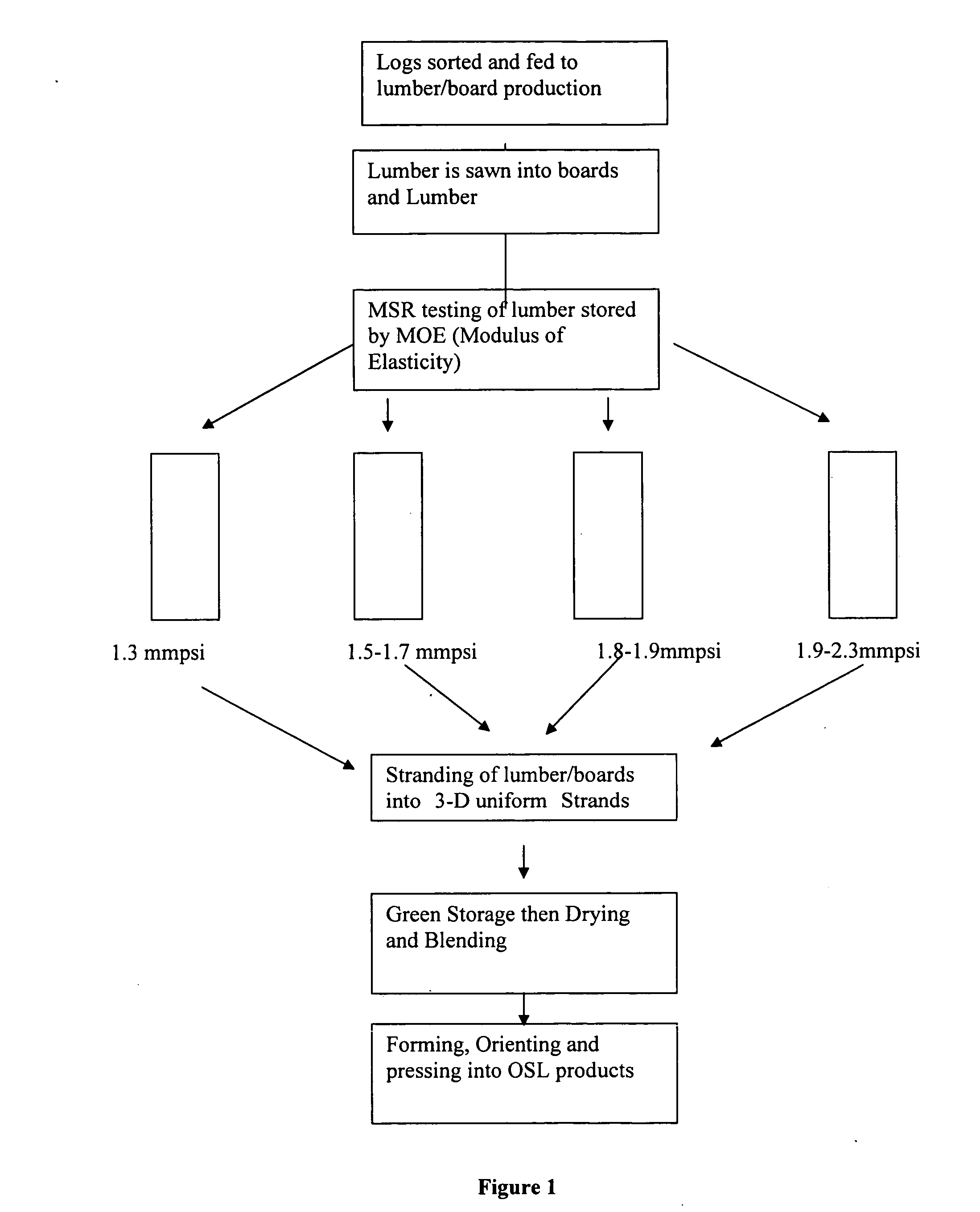

Methods for making improved strand wood products and products made thereby

An overall method of making engineered strand wood products in relation to a number of different possible criteria is provided. Such a method may involve any combination of different screening procedures to determine the best wood sources from which individual strands may be prepared. Such screening procedures may include initial determinations of certain physical characteristics of individual logs, further or initial determinations of certain physical characteristics of portions of sawn logs, further or initial determinations of certain physical characteristics of individual strands, and any combinations thereof. Additionally, after the initial physical characteristic sorting is completed, optionally the wood may be cut into uniformly sized and shaped strands for incorporation within a target strand product. Still further, such strands, in substantially uniform size and shape, as well as substantially uniform physical characteristics, may then be incorporated into a target strand product in specific predetermined configurations. Such various possible combinations of screening procedures and / or selective stranding processes results in strand products (boards, lumber, and the like) of improved properties over previously made strand products. Thus, encompassed within this invention are processes involving each of these procedures either individually or in combination with other sequential processes for the production of desired strand products.

Owner:HUBER ENGINEERED WOODS

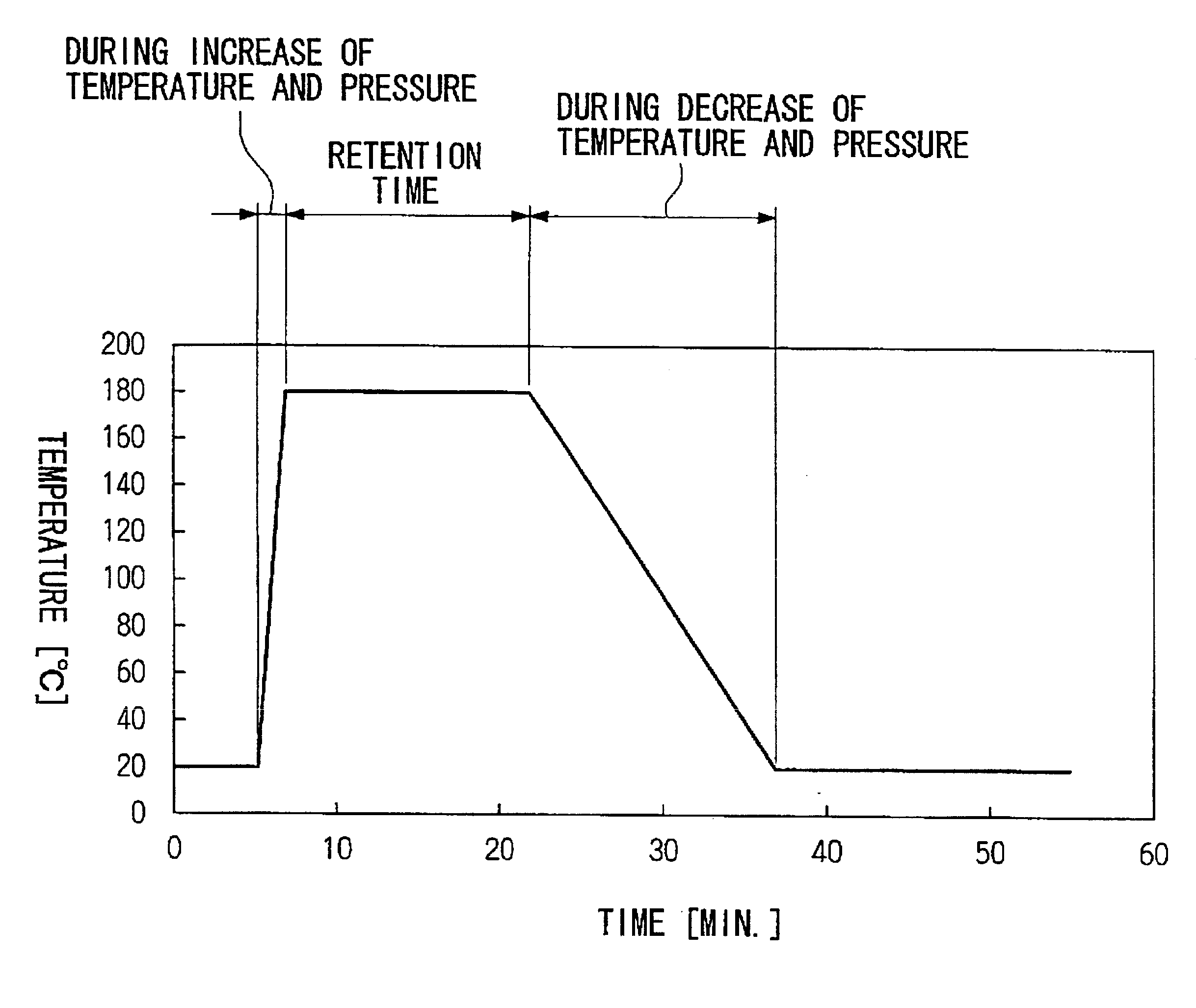

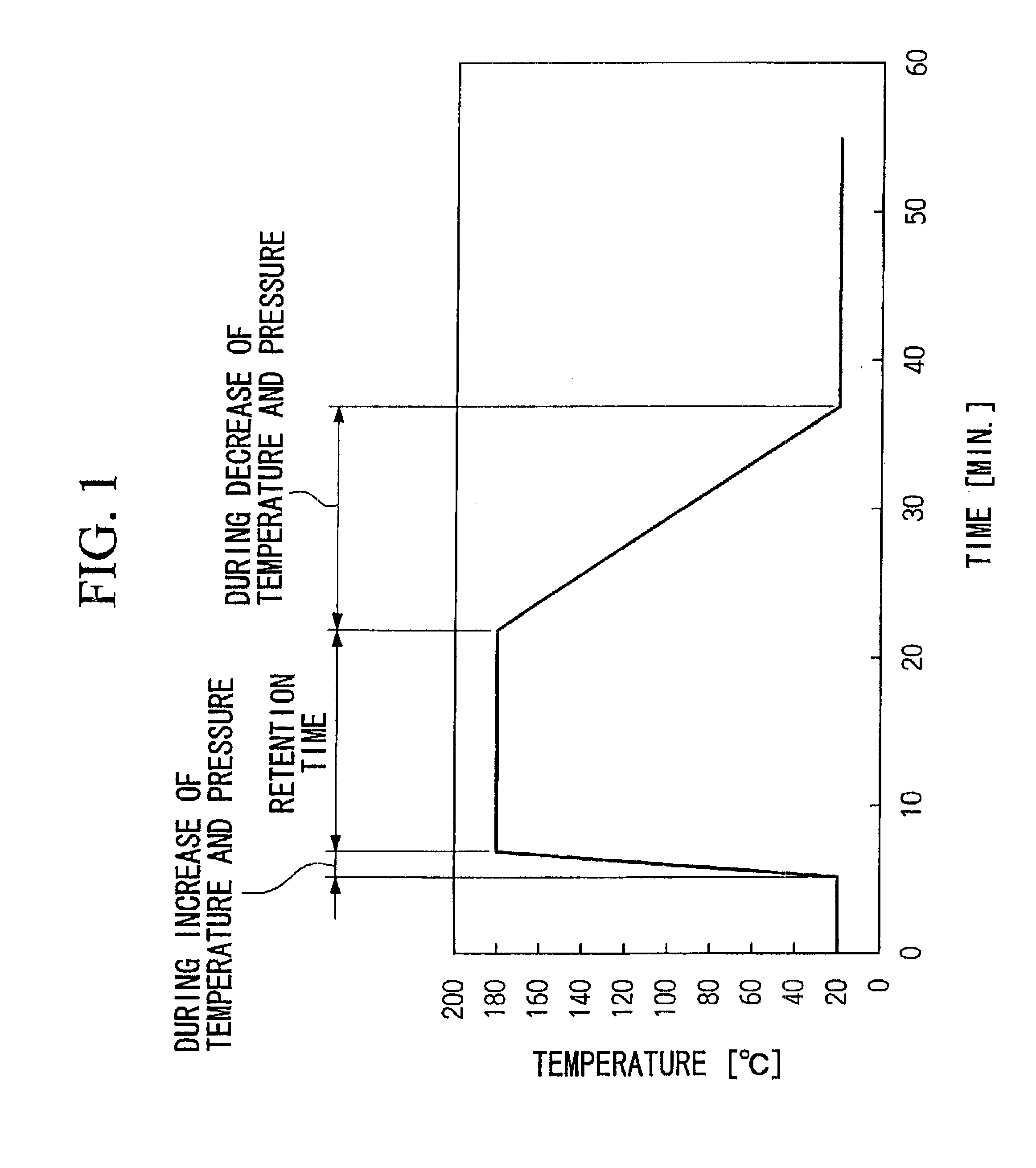

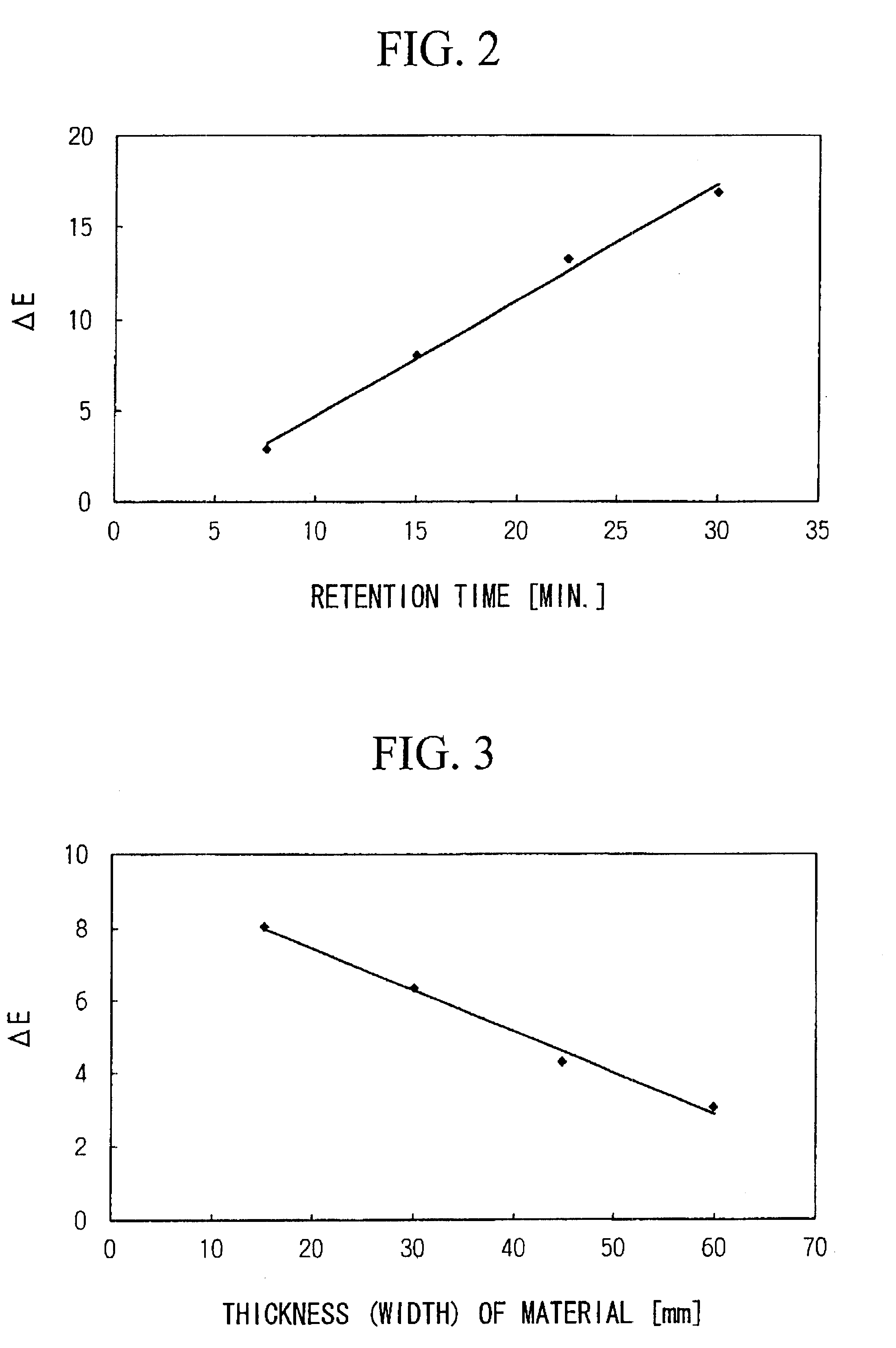

Method for manufacturing modified wood

InactiveUS6667429B2Simplified processing stepsShort timeElectrophonic musical instrumentsDrying using combination processesChemical treatmentHornbeam

Wood such as spruce, maple, and hornbeam are retained in high pressure steam of pressure 0.2 to 1.6 MPa at 120 to 200° C. for 1 to 60 minutes, and subsequently, cooled and dried to obtain a modified wood having superior acoustic properties and old wood-like appearance due to a change to a deep color tone. Since the conventional modification methods by chemical treatment using chemicals such as resorcin and formaldehyde are not used, the treatment steps are simple and a modified wood used as a material for musical instruments is obtained at low cost.

Owner:YAMAHA CORP

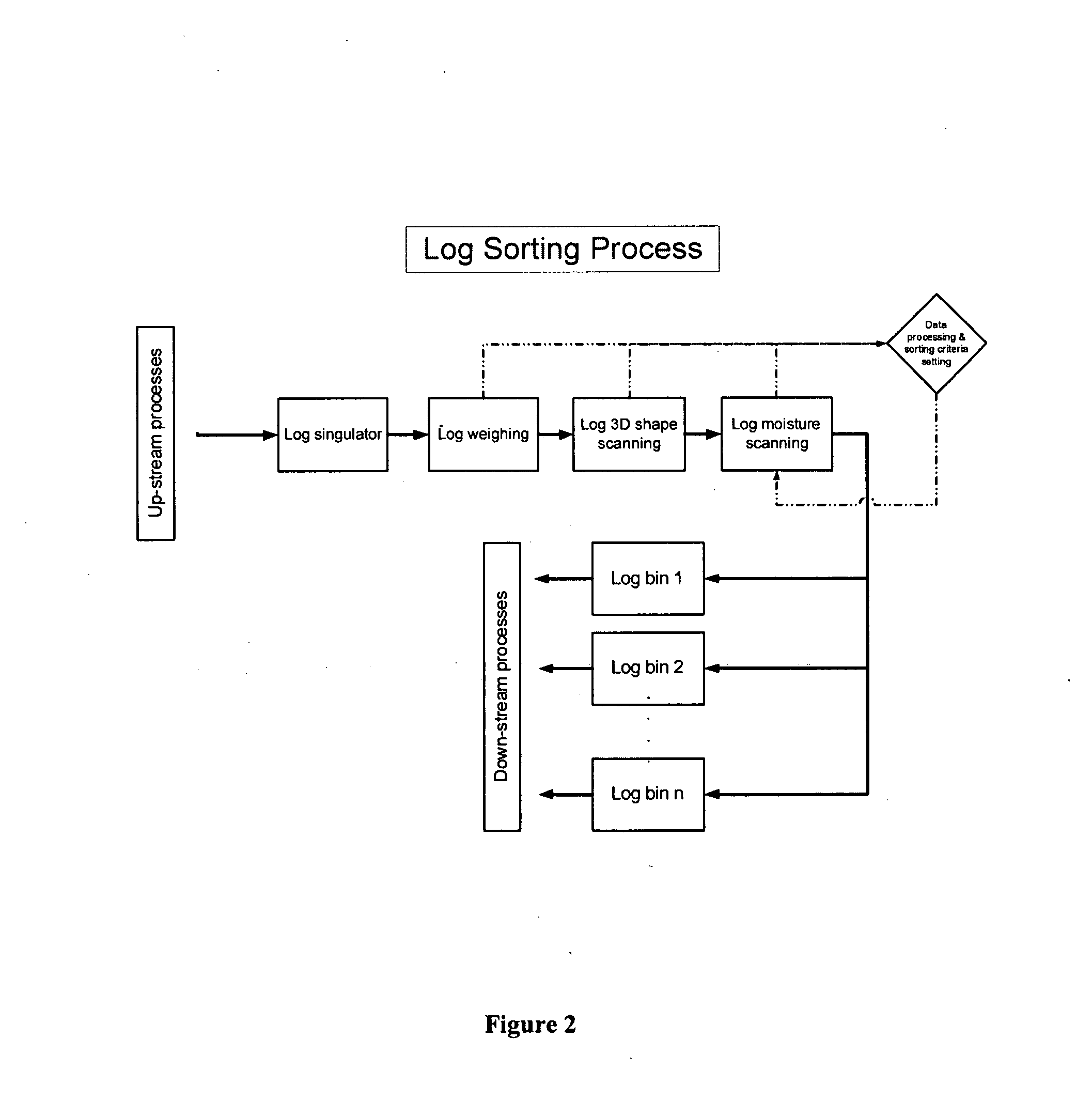

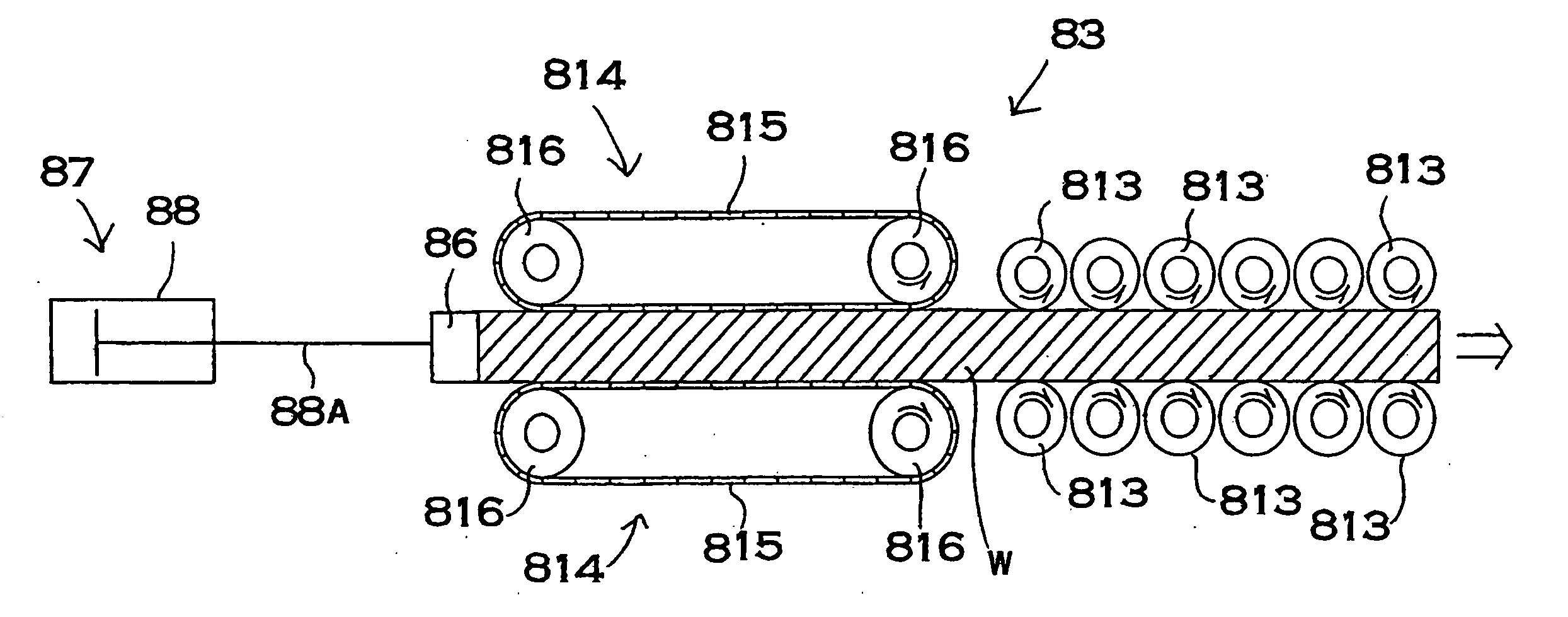

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS20030029519A1Reduce stepsMinimize travelAdjusting equipmentFeeding apparatusFiberEngineering

A log handling and cutting system which cuts logs into lengths, and allows for maximum use of fiber. The system includes equipment for singulating the logs, optimally removing the bark from the logs, scanning the true log image, cutting the logs to length, and sorting the cut logs arranged in a sequence of coupled operations. The logs are singulated using a dual quadrant singulation system to provide maximum singulation reliability, thereby allowing a single operator to attend to this process. Once singulated, the logs are fed automatically into a debarker where the diameter and volume are scanned and debarker-operating parameters are set for optimum bark removal. The log is then scanned, tree length, using a unique scanning system, which determines the true image of the log. This enables the determination by computer of the optimum bucking solution of the log as well as a proper sorting of the optimum random lengths. The saws are adjusted in response to the computer solution and the log is positioned by a positioner according to a computer generated reference datum. This results in the log being positioned for cutting to the optimum random lengths. A command signal is sent from the computer to the log sorting system, which tracks the position of the random lengths and allows them to be sorted to the appropriate sort storage bin.

Owner:WEYERHAEUSER CO

Method of and apparatus for forming timbers with rounded ends

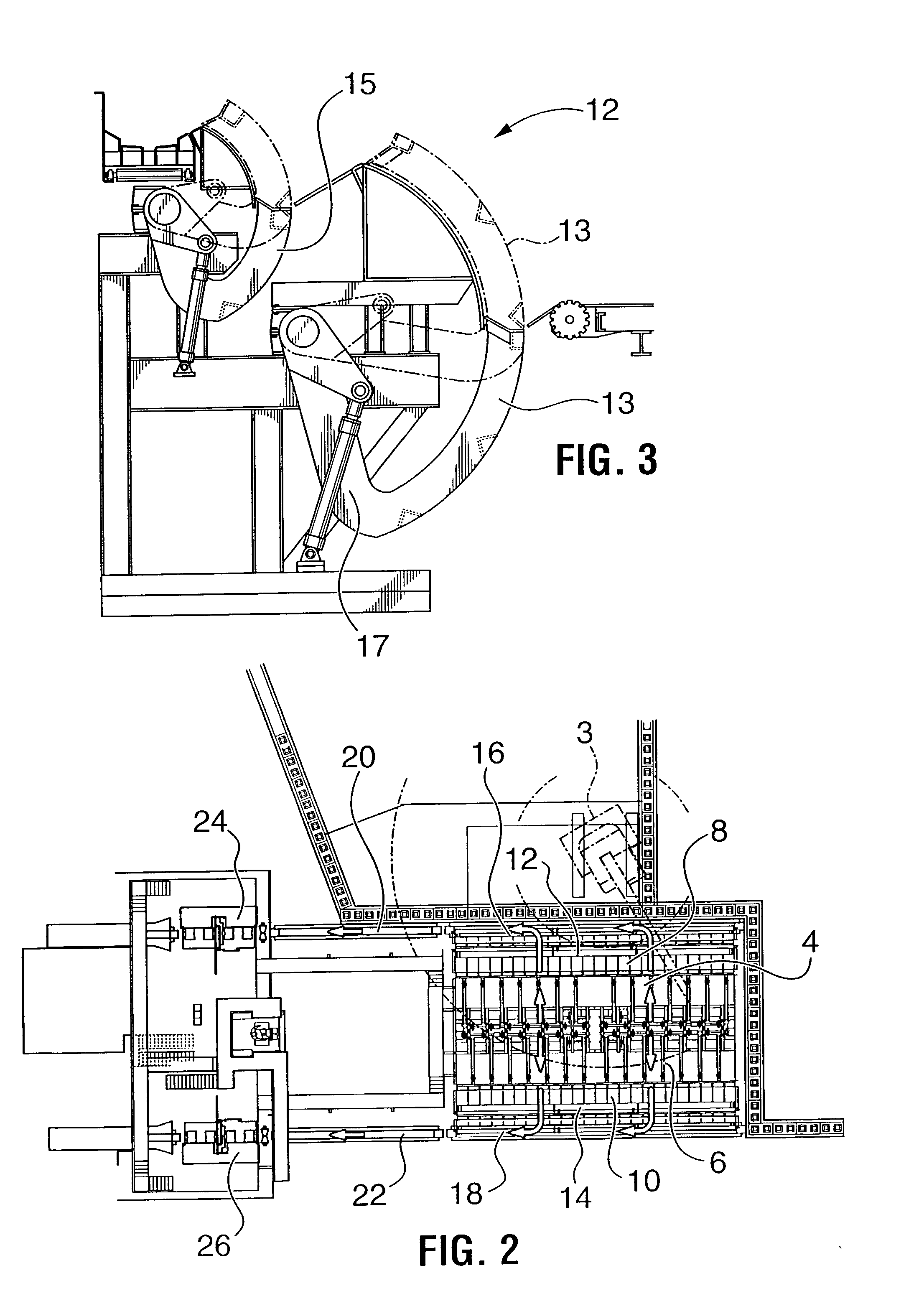

InactiveUS7093628B2Improve productivityReduce labor costsMulti-purpose machinesWood mortising machinesTimber roof trussEngineering

The method of forming timbers especially for use as webs in timber roof trusses comprising feeding timbers in a predetermined path with the timbers extending transversely to the direction of feed and, as the timbers are so fed, shaping the ends thereof to rounded form, and apparatus for carrying out said method comprising conveyors for feeding the work, a saw for cutting the timbers to length, and cutters for the end shaping.

Owner:MITEK HLDG INC

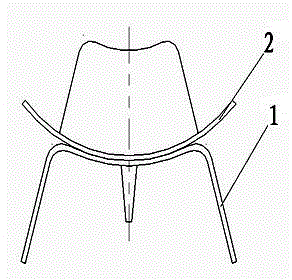

Curving method of bamboo joint component of wood substance seat

A binding method of wood seat bamboo joint module is provided, which is characterized in that: the invention comprises a steaming and boiling softening, module fixing, drying and forming technics. Put the processed wood module into a sealing temperature keeping container, the module is soften by the steaming effect in the container; the softened module is put into a bend module to fix; the prepared binding module into a drying furnace to dry. The invention solves the problem that the cutting method and the sticking method wastes wood material and has low quality when producing binding wood seat, which is suitable for precede binding to the module during the production process of the wood furniture.

Owner:常克顺

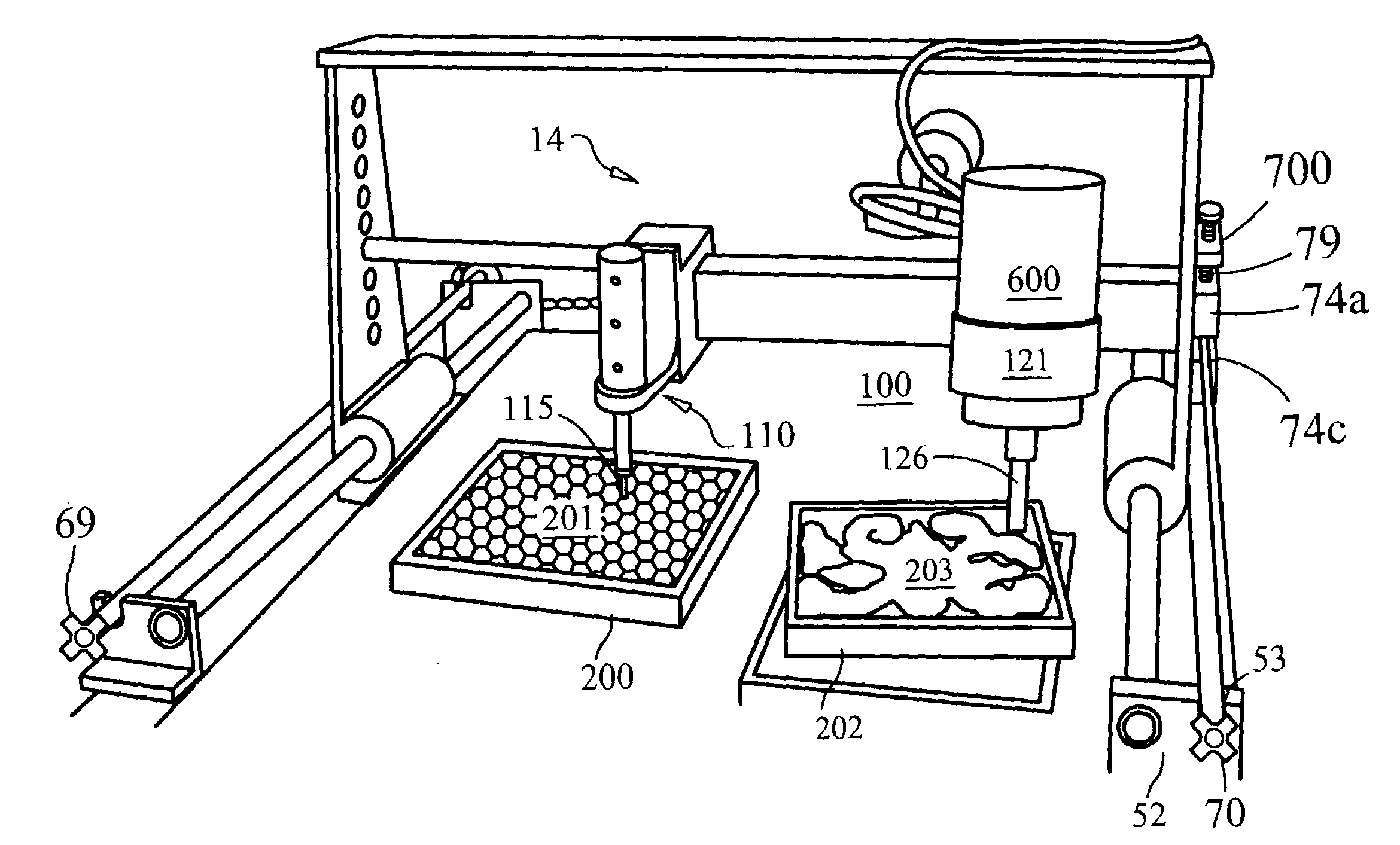

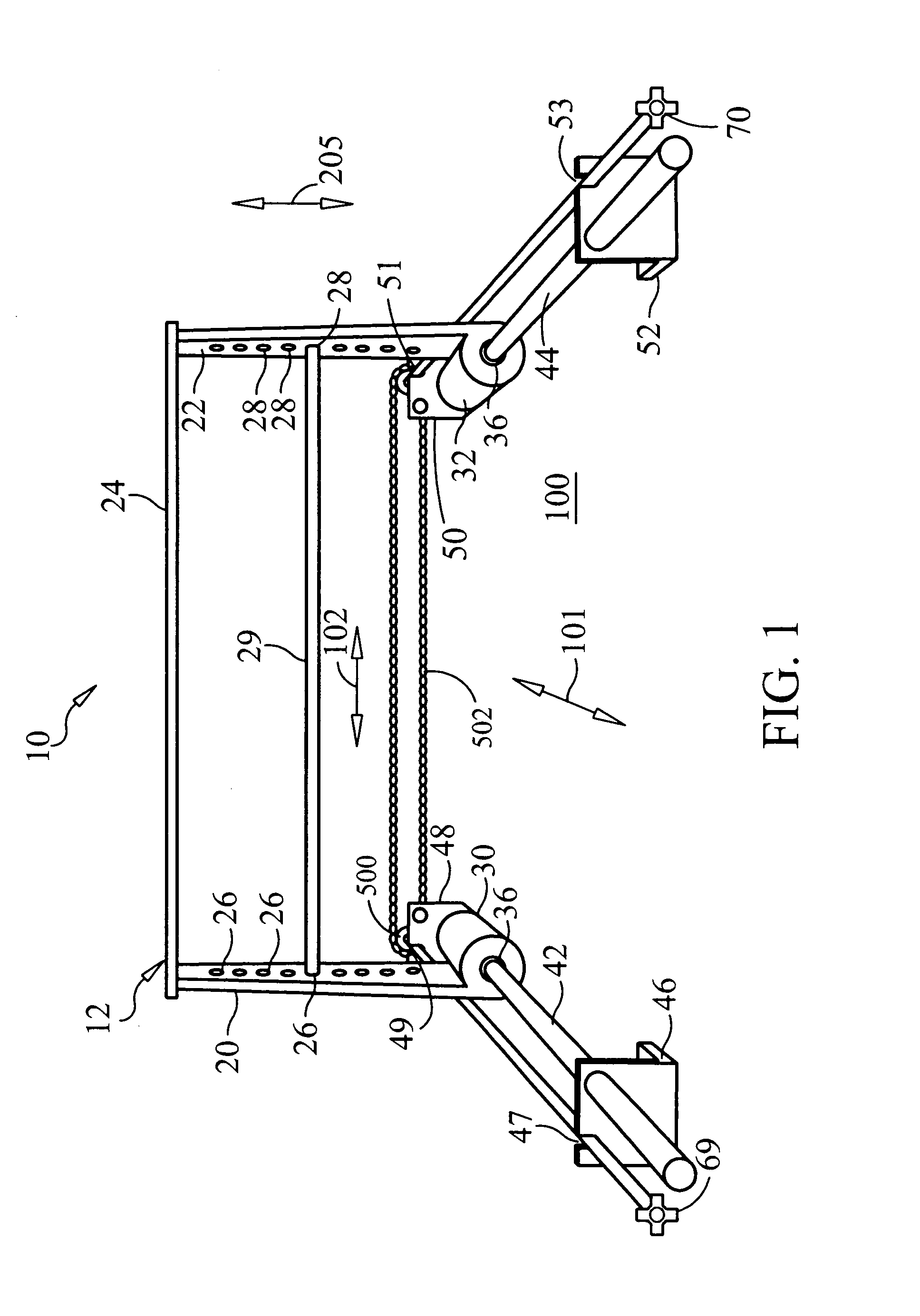

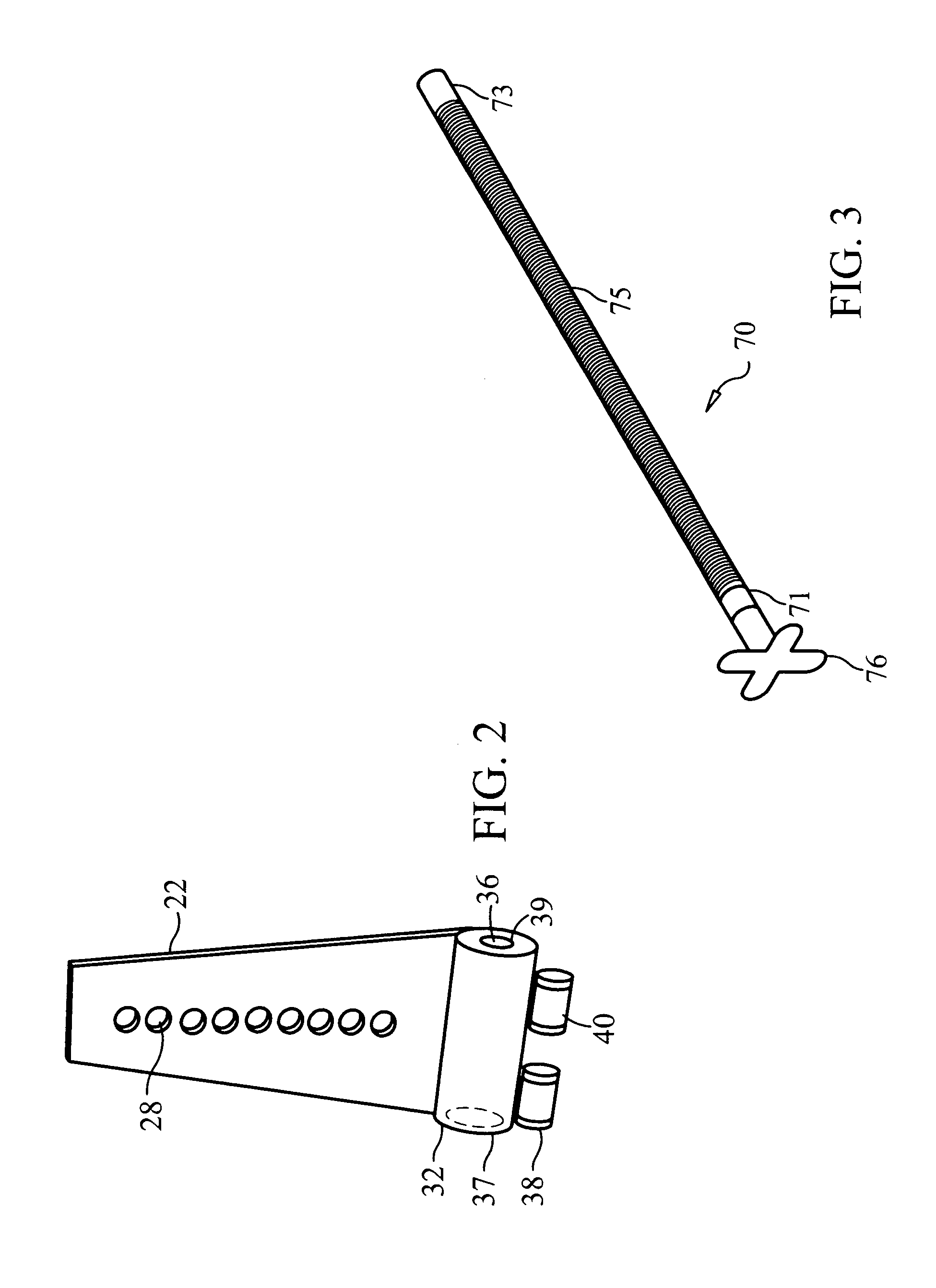

Wood carving assembly and a method for making the same

InactiveUS7281552B1Overcome disadvantagesExact copyMulti-purpose machinesProfiling/shaping machinesEngineeringTool holder

A carving assembly 10 for use in duplicating a blank or form. The carving assembly 10 includes stylus 112 and a tool holder 120 which are coupled together using a slidable carriage 14 to allow any movement of the stylus to cause a cutting tool 121 mounted in the tool holder 120 to move in the exact same manner. Carriage 14 is mounted upon a frame, assembly which permits sliding motion in two orthogonal directions 101, 102.

Owner:COLEMAN HARRISON L +1

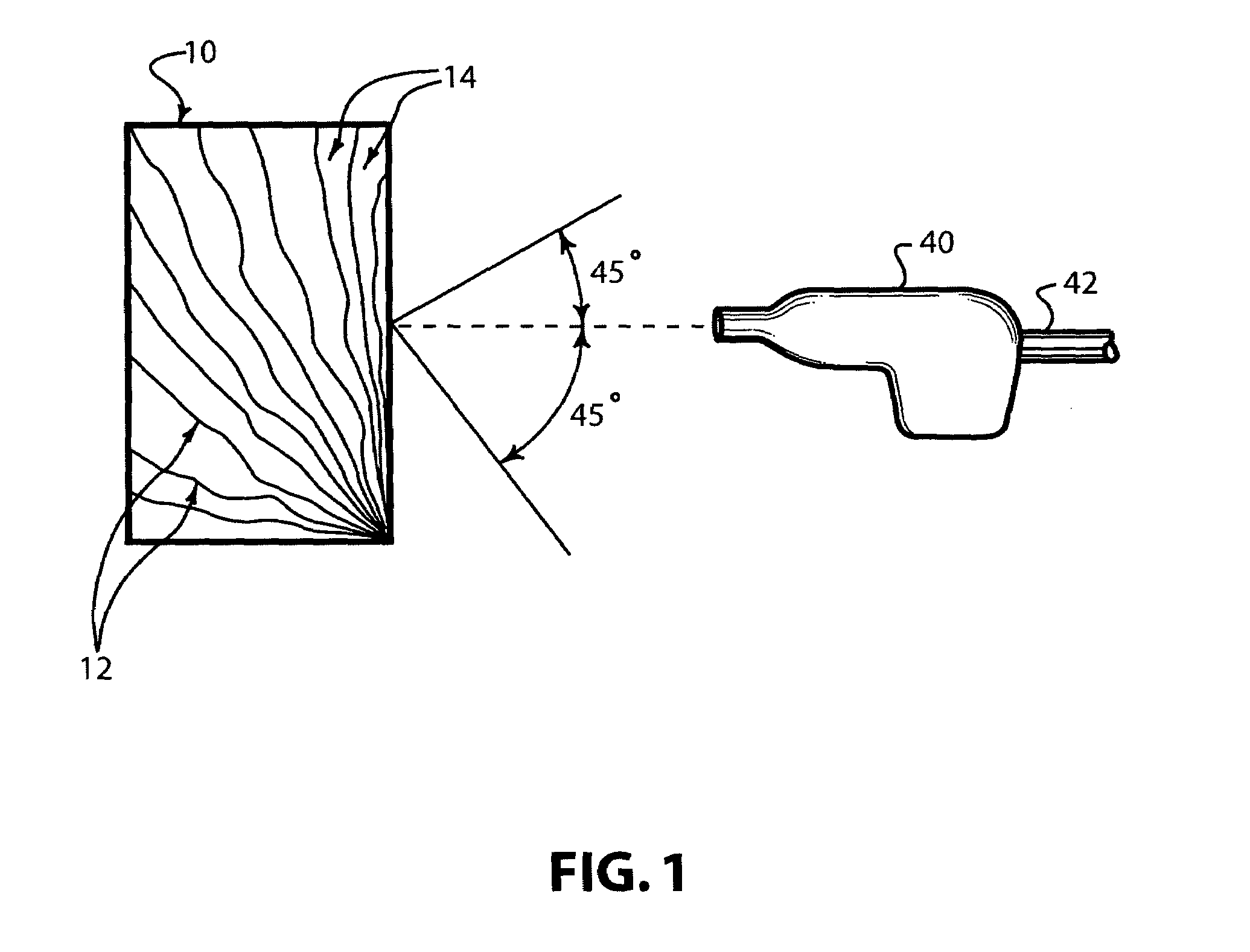

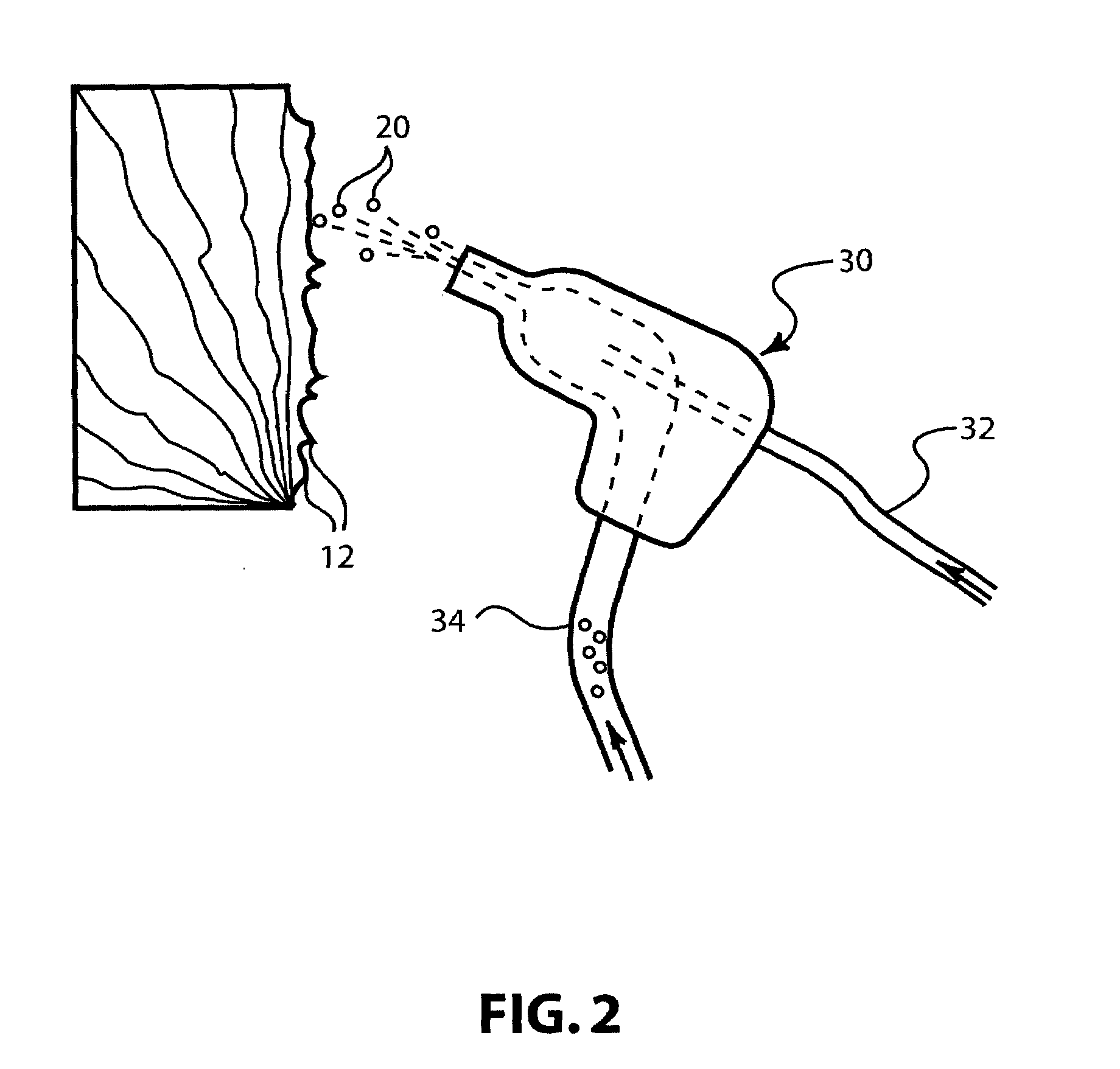

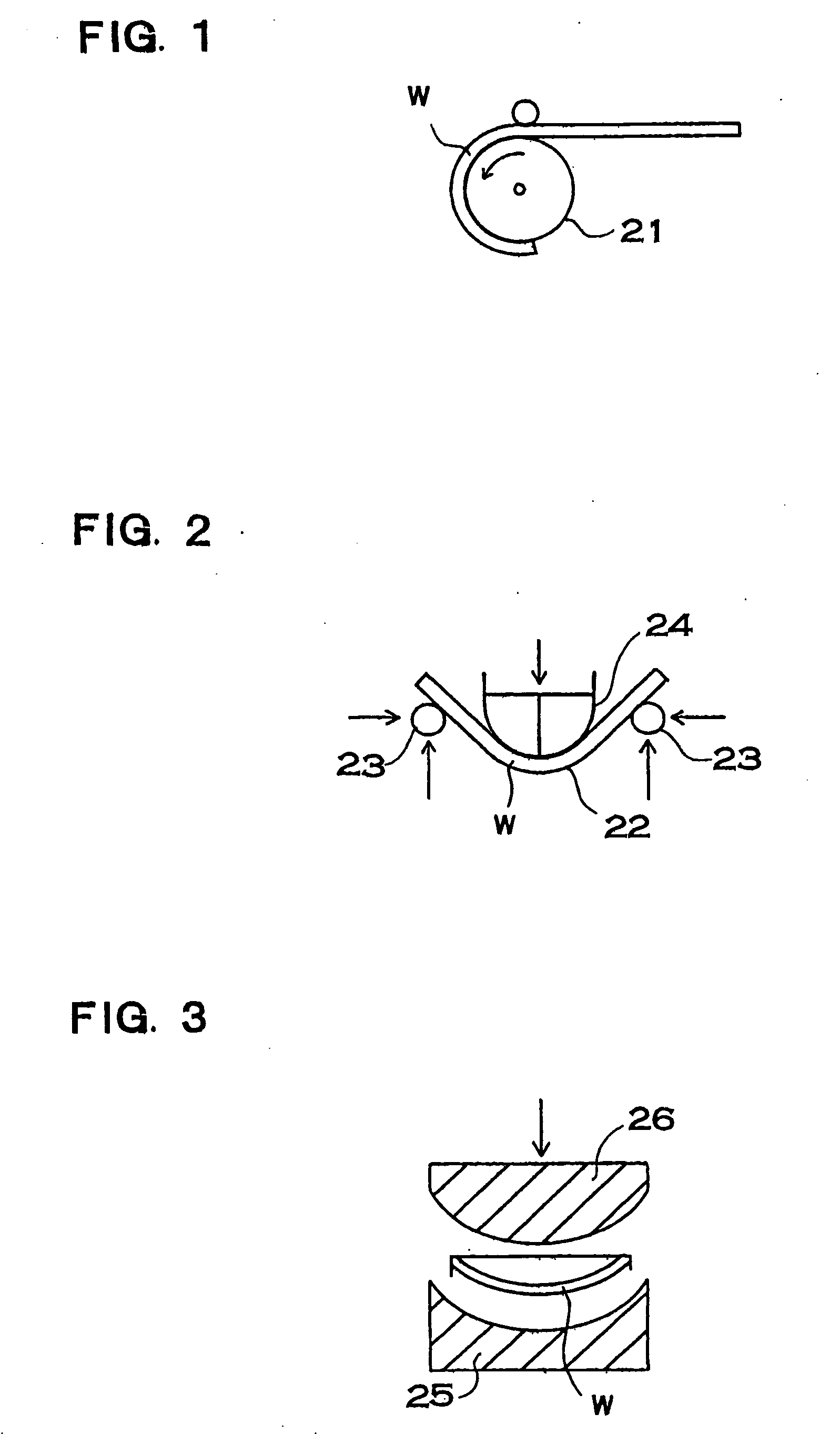

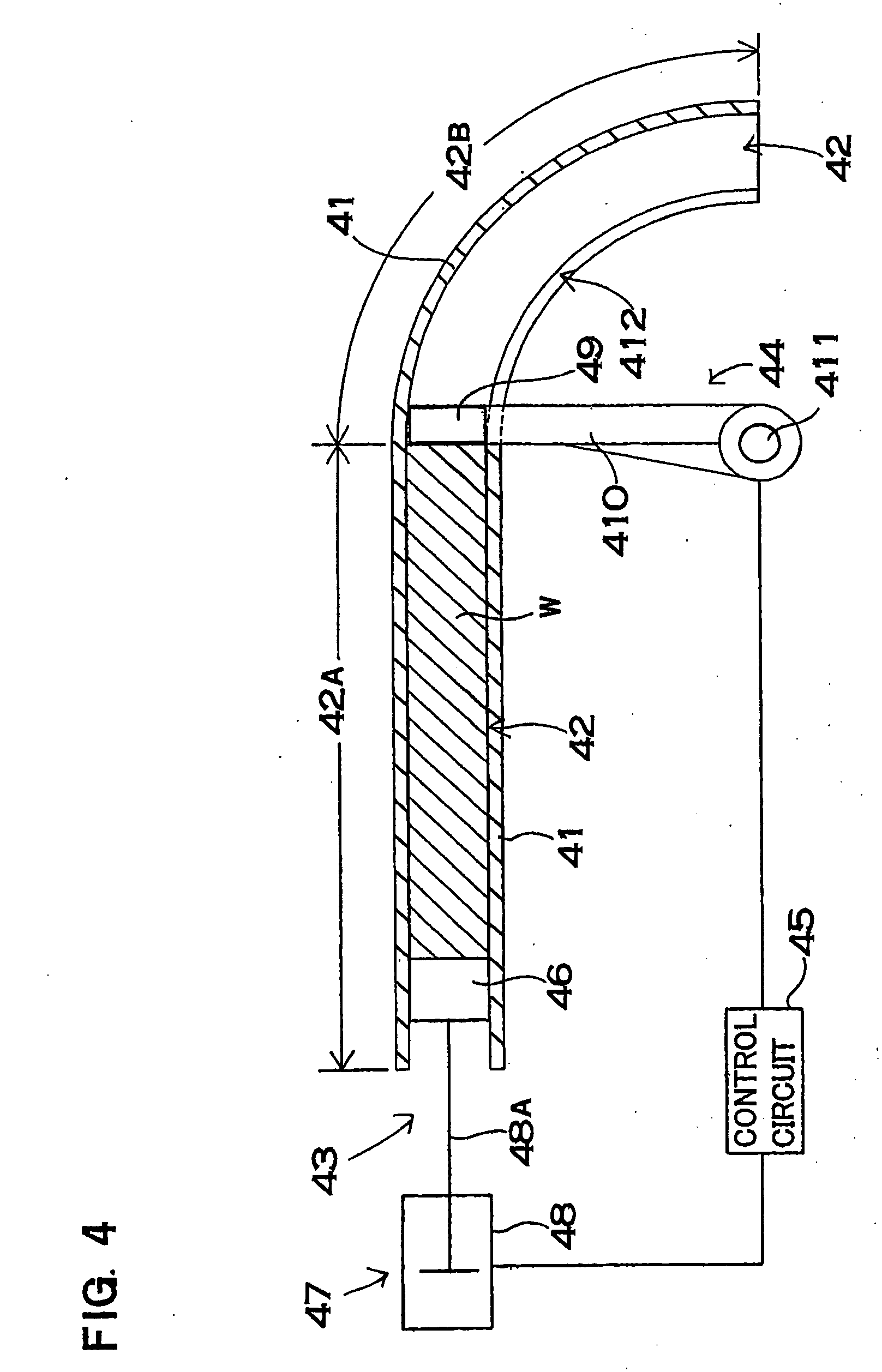

Method of bending wood materials and an apparatus for bending wood materials

InactiveUS20050150573A1Limit wood material movementPrevent tension fractureWood compressionWood stock bendingPulp and paper industry

Owner:YAMAMOTO TETSUKOSHO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com