Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about "Vanadium halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

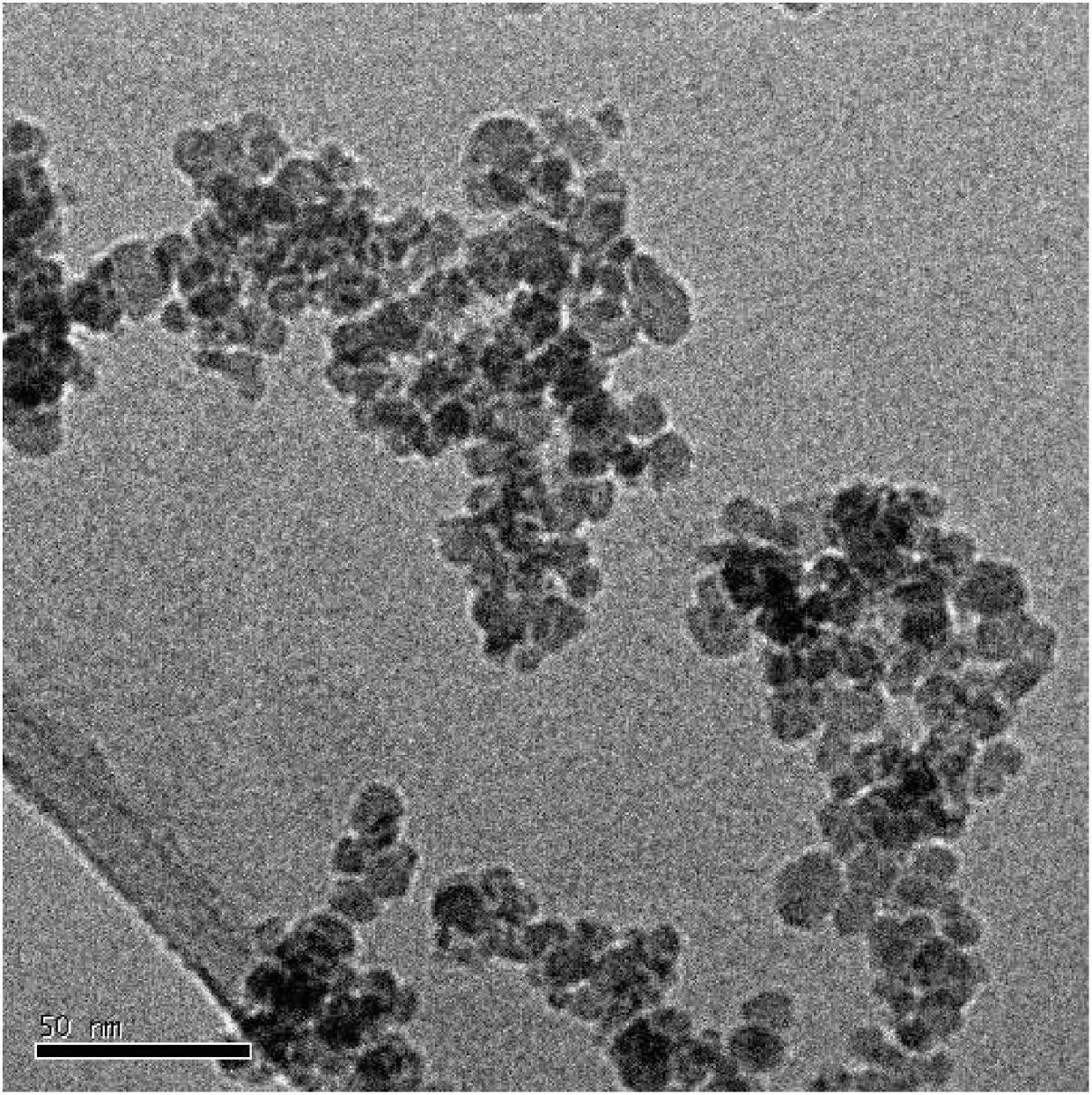

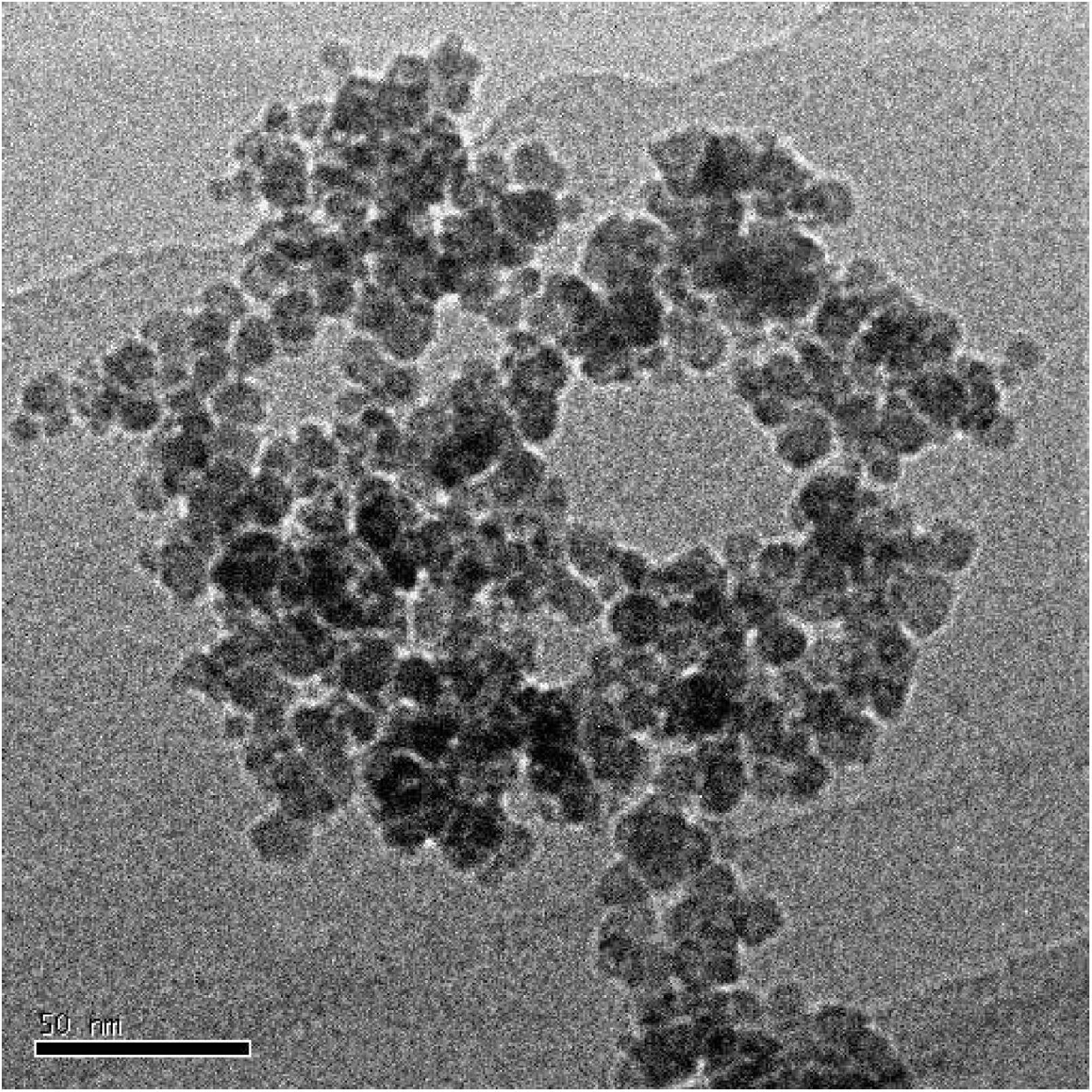

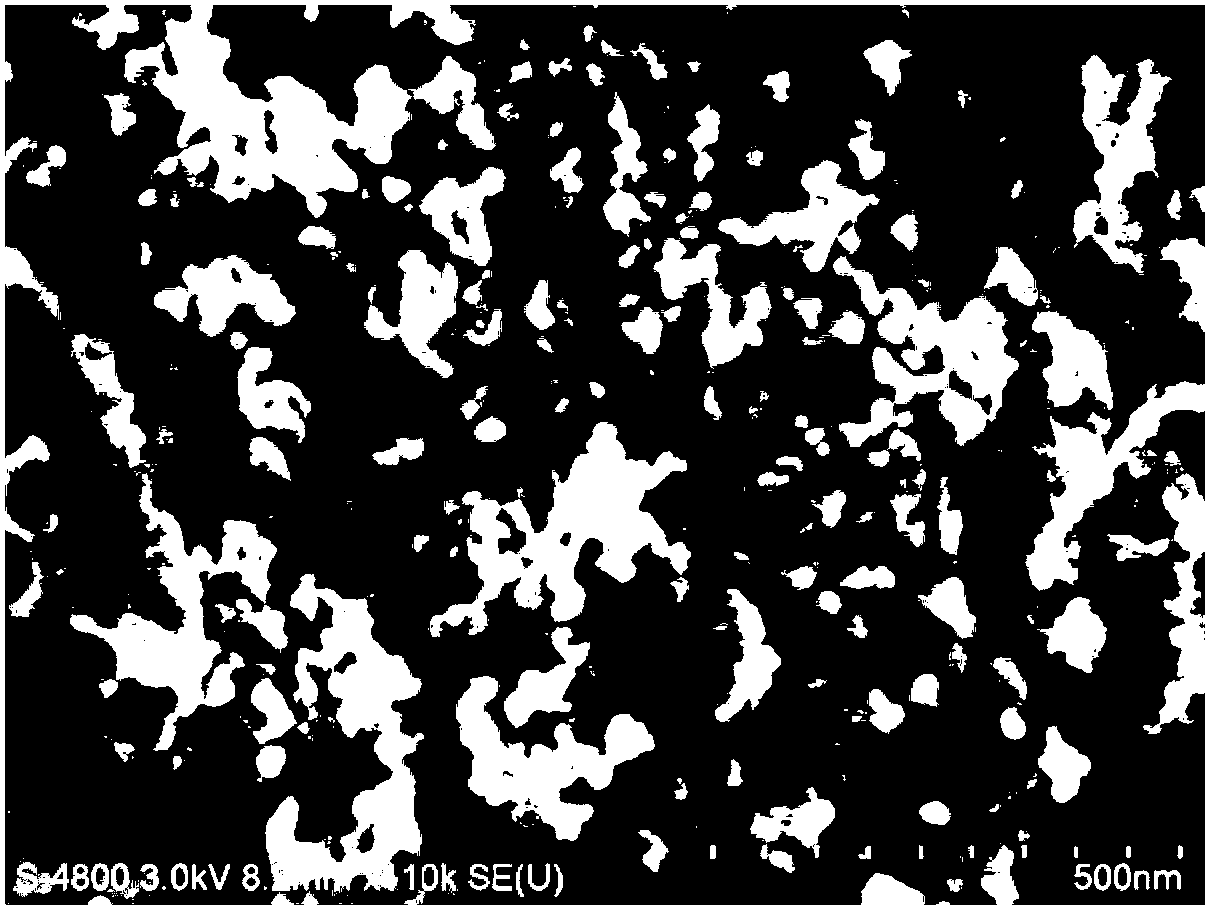

Chemical preparation method of magnetic graphene

InactiveCN102674476AUniform particle sizeAchieve controlled growthMaterial nanotechnologyInorganic material magnetismSolubilityChemical reaction

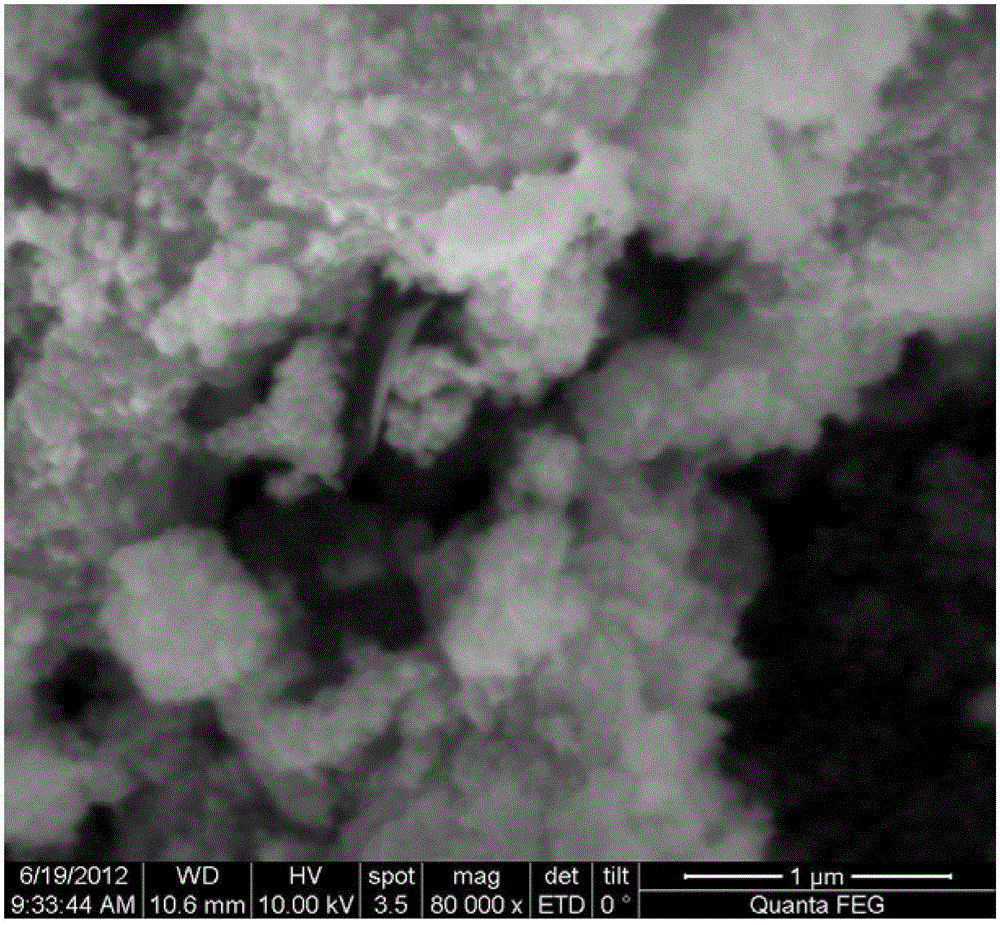

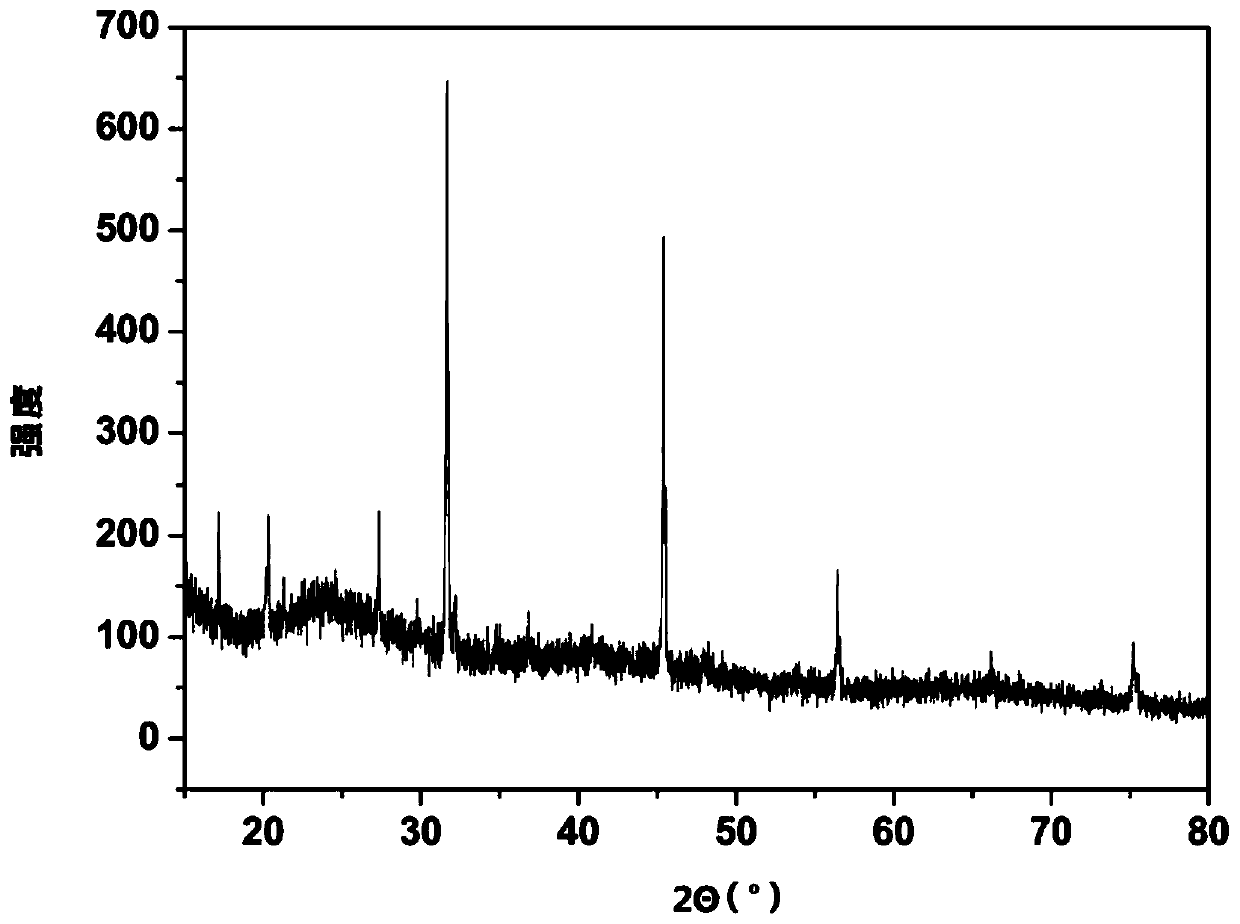

The invention relates to a preparation method of magnetic graphene, in particular to a chemical preparation method of magnetic graphene. The preparation method aims at solving the problems of the existing synthesis method that the reaction process is toxic and harmful to the environment, large-scale production cannot be realized, the morphology, size and magnetism of magnetic nanoparticles in the magnetic graphene are not controllable and the magnetic graphene cannot be dispersed in water. The chemical preparation method comprises the steps of: 1) preparing aminated Fe3O4 magnetic nanoparticles; 2) preparing graphene; and 3) preparing magnetic graphene through chemical reaction. The chemical preparation method of the magnetic graphene has the advantages that the high temperature and the high pressure are not required, the equipment is simple, the process cost is low, the environment is protected, no pollution is caused, the grain size of the synthesized magnetic nanoparticles is uniform, the controllable growth of the magnetic nanoparticles can be realized by changing reaction conditions, the solubility of the synthesized magnetic graphene is 0.8-1.2mg / ml, the magnetic graphene can be stably dispersed in water and sediment does not occur within 1-2 months. The graphene prepared by adopting the method can be used in biomedical, energy, electronic fields and the like.

Owner:HARBIN INST OF TECH

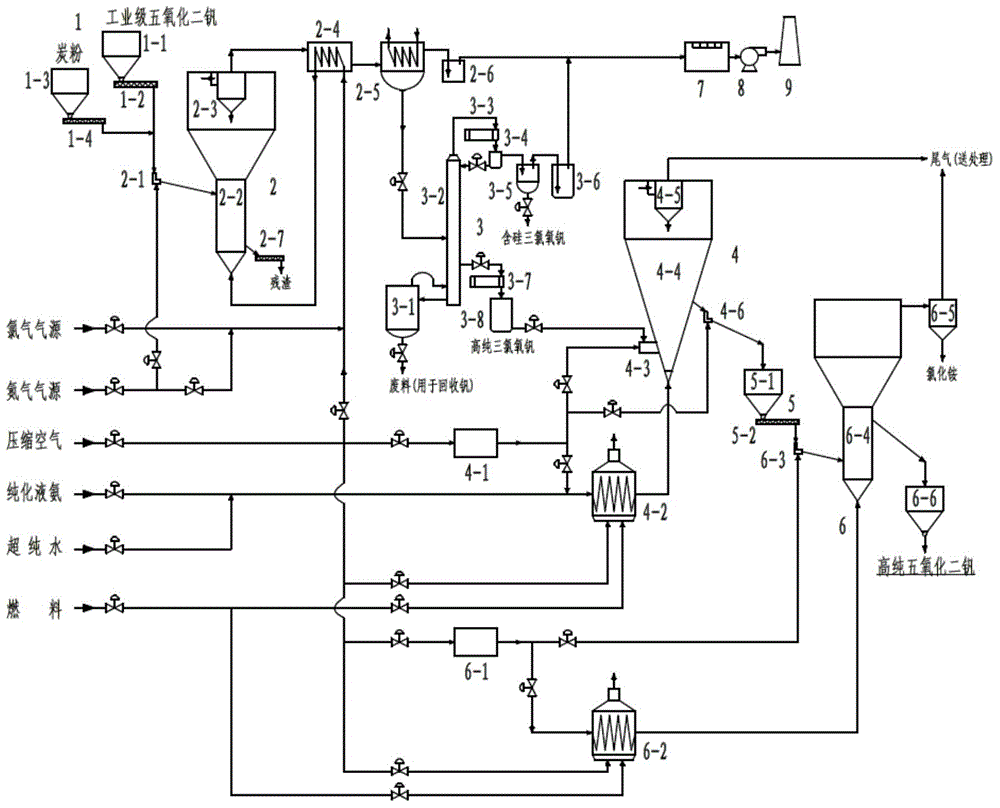

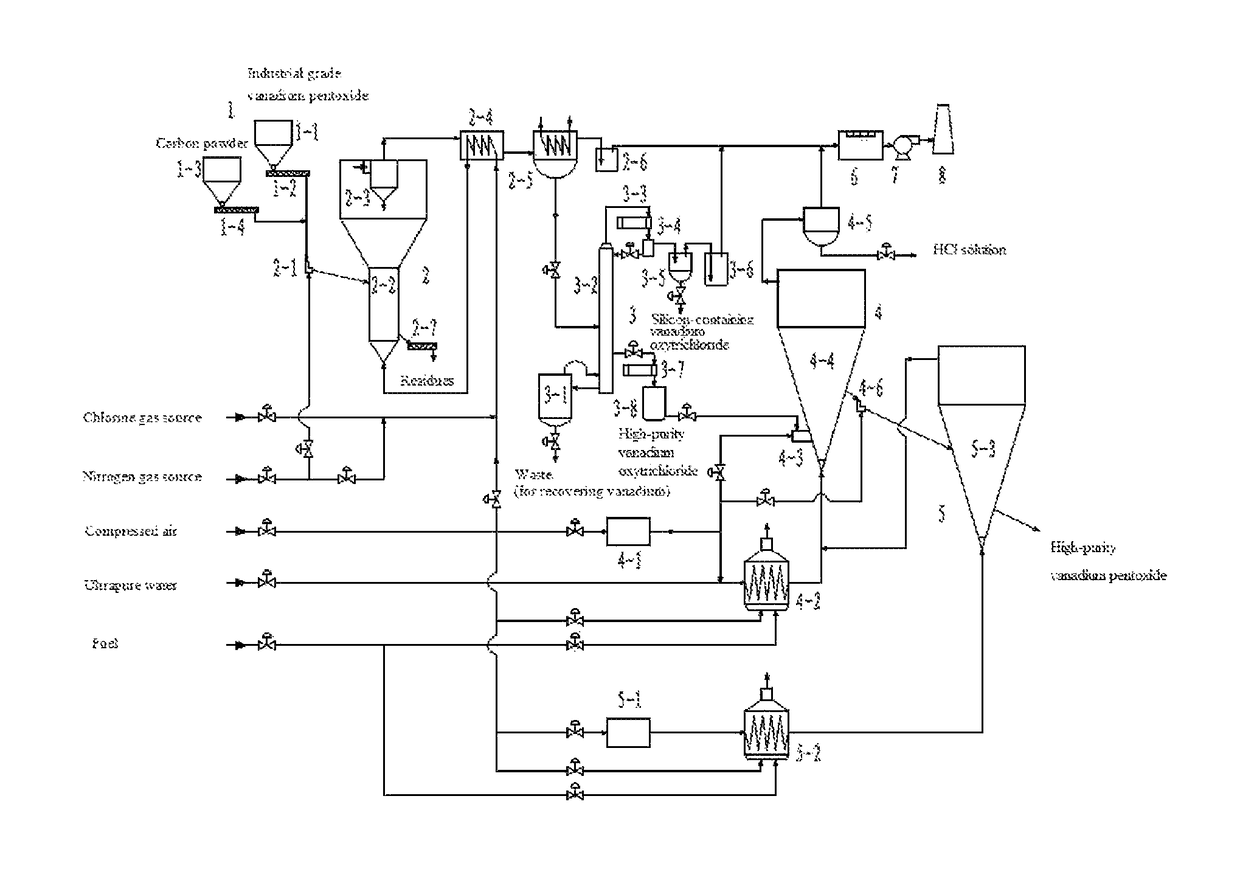

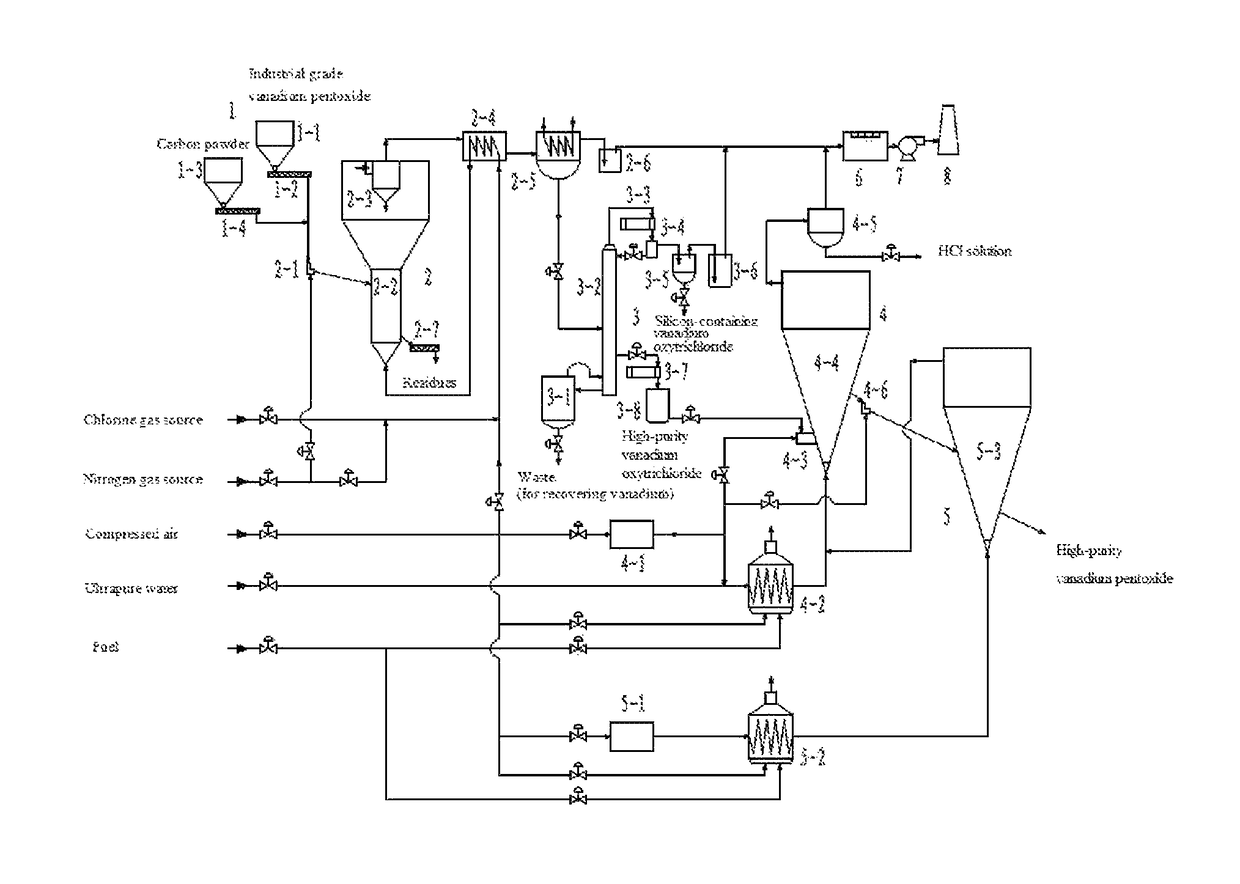

System and method for purifying and producing high-purity vanadium pentoxide powder

ActiveCN105984896AAchieve warm-upUniform temperature distributionNitrogen compoundsTransportation and packagingDistillationCalcination

The invention discloses a system and method for purifying and producing high-purity vanadium pentoxide powder, belonging to the fields of chemical engineering and materials. According to the invention, fluidizing low-temperature chlorination is used for converting industrial-grade vanadium pentoxide into vanadium oxytrichloride; through heat exchange between fluidization gas and chlorination flue gas, chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination, improving chlorination efficiency, and ensuring good selectivity of low-temperature chlorination; and the vanadium oxytrichloride is subjected to fluidized-vapor-phase ammoniation after distillation and purification and further to fluidized calcination to produce a high-purity vanadium pentoxide product. The system and method have the advantages that raw materials are good in adaptability, only a small amount of ammonia-nitrogen wastewater is discharged, low energy consumption in production and low cost in operation are realized, product quality is stable, etc.; and the system and method are applicable to large-scale industrial production of high-purity vanadium pentoxide having a purity of 4N or higher and have good economic benefits and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

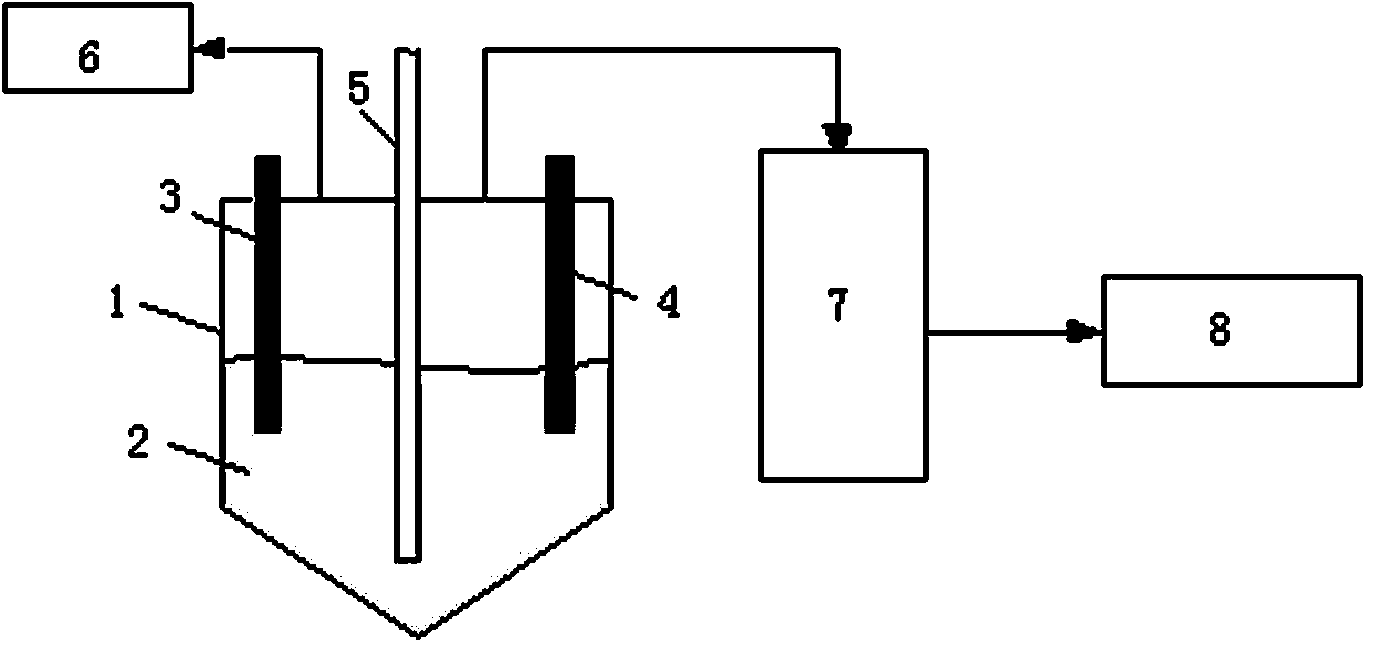

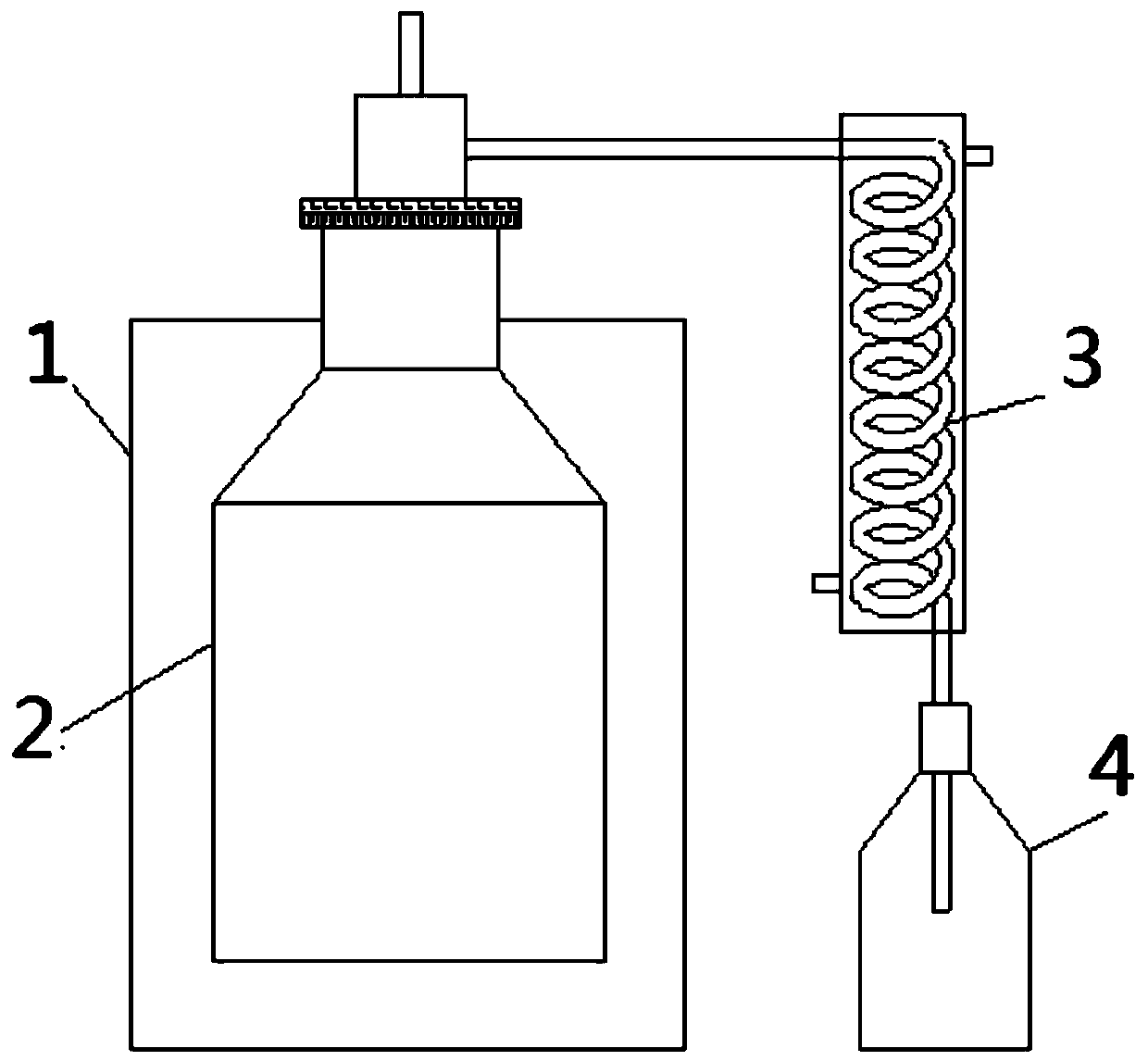

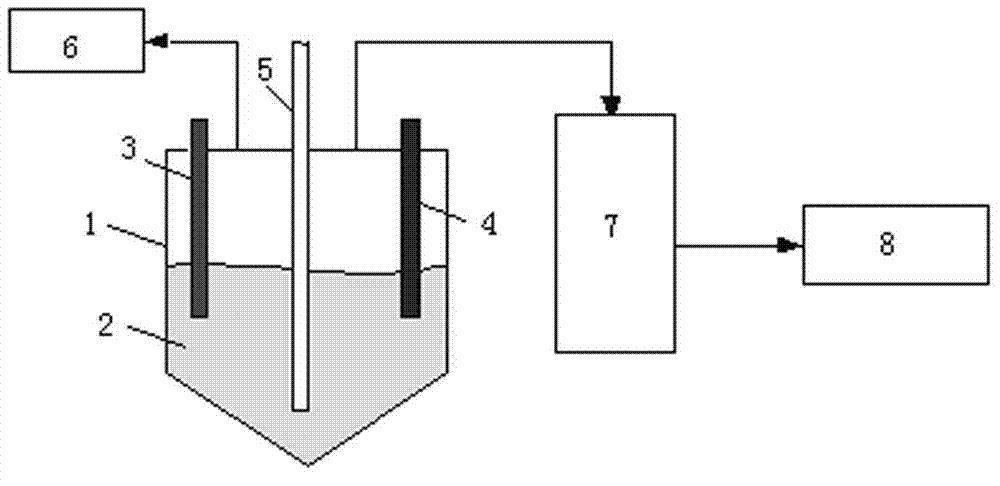

Method and system for recycling vanadium-containing mud generated in vanadium removal process of crude titanium tetrachloride

ActiveCN103936063AHigh yieldRealize one-time recyclingTitanium halidesVanadium halidesTitanium chlorideMolten salt

The invention provides a method and a system for recycling vanadium-containing mud generated in a vanadium removal process of crude titanium tetrachloride. The vanadium-containing mud contains titanium tetrachloride liquid and VOCl2 solid. The method comprises the steps of adding the vanadium-containing mud into a molten salt furnace, evaporating, and collecting titanium tetrachloride in the vanadium-containing mud; introducing chlorine into the vanadium-containing mud to ensure that chlorine is reacted with VOCl2 in the vanadium-containing mud, and obtaining mixed gas containing VOCl3 gas and chlorine; condensing the mixed gas to obtain VOCl3 liquid and chlorine, wherein molten salt is filled in the molten salt furnace, and the temperature of the molten salt furnace is kept at 600-750 DEG C. The recycling system is used for implementing the method, and comprises the molten salt furnace, an air supply pipe, a TiCl4 gas collecting unit and a condenser. The recycling method and recycling system, provided by the invention, are used for realizing one-time recovery of valuable elements namely titanium and vanadium in the vanadium-containing mud, and are high in yield of vanadium and titanium, and high in purity of obtained products.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

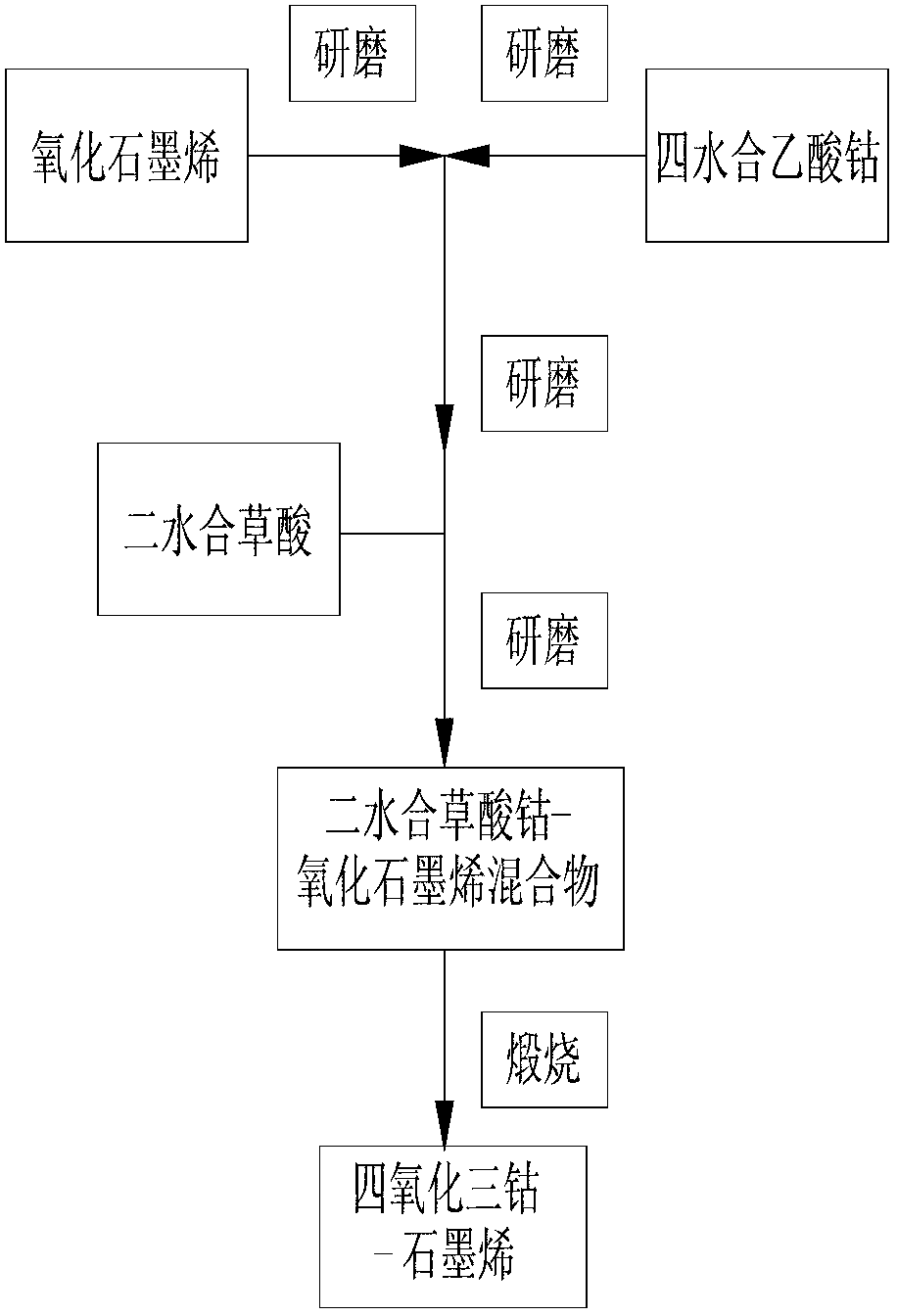

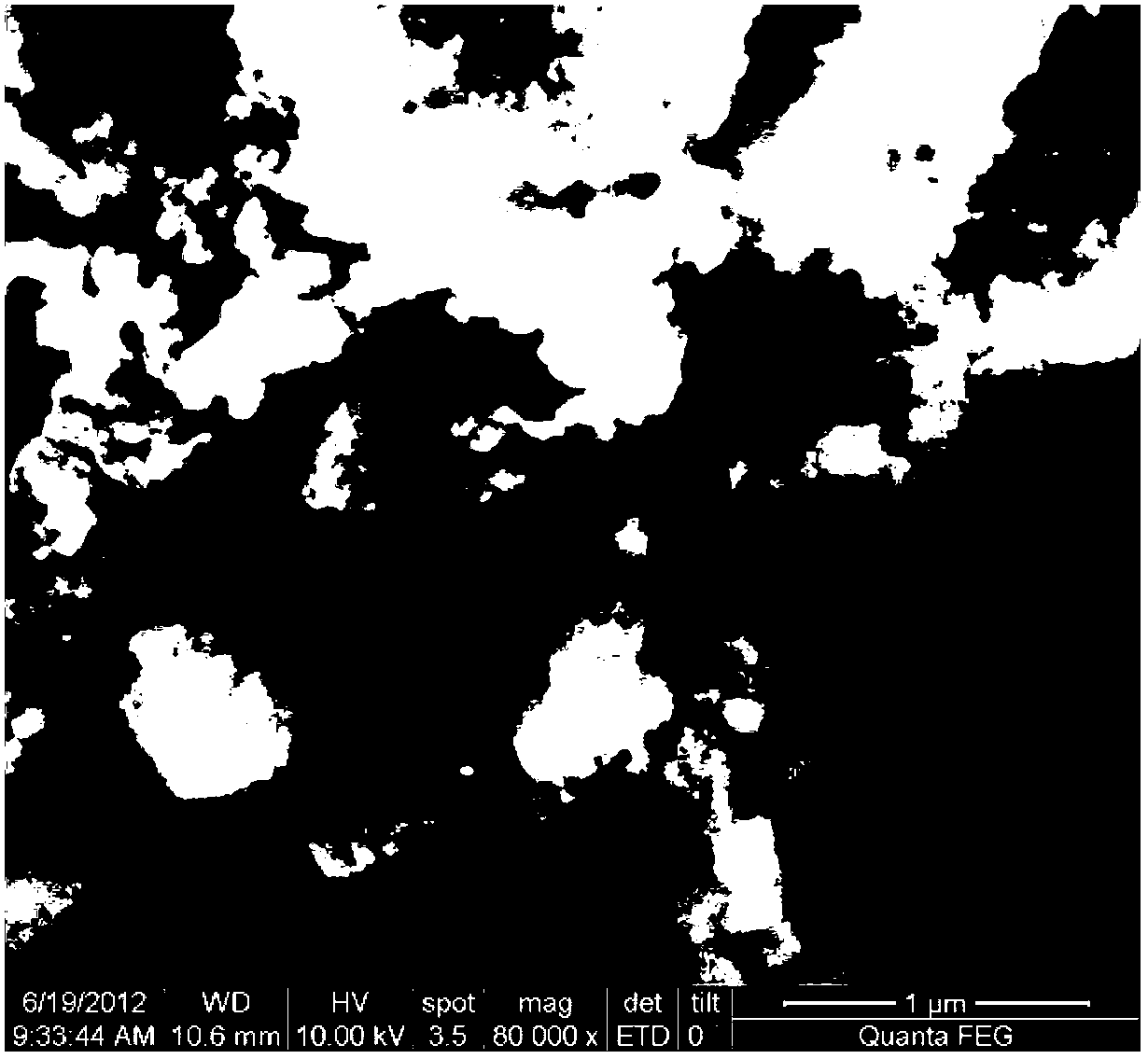

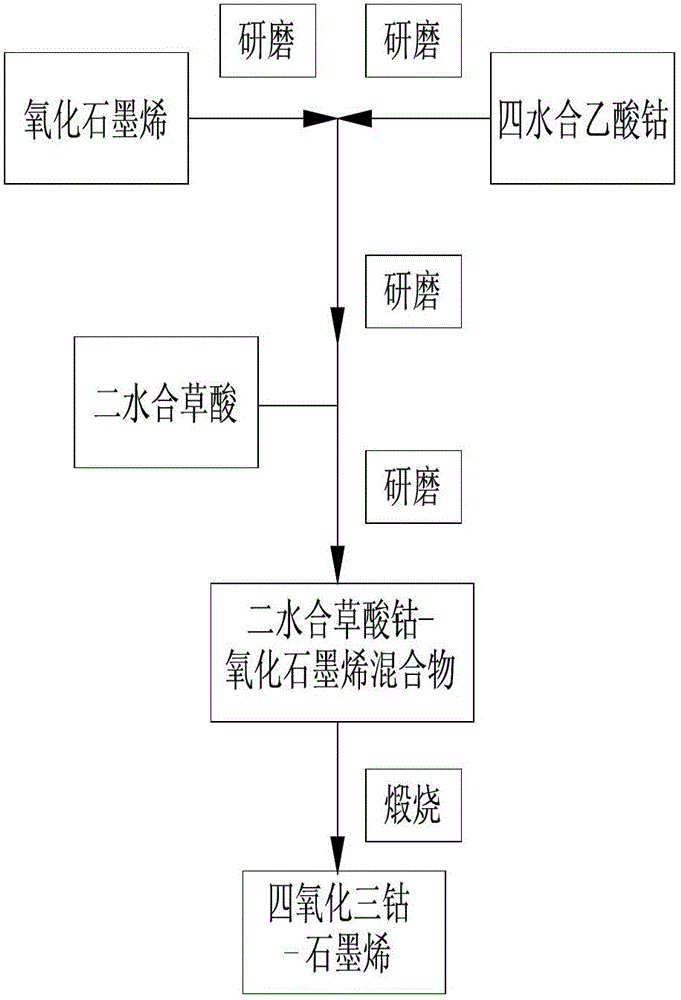

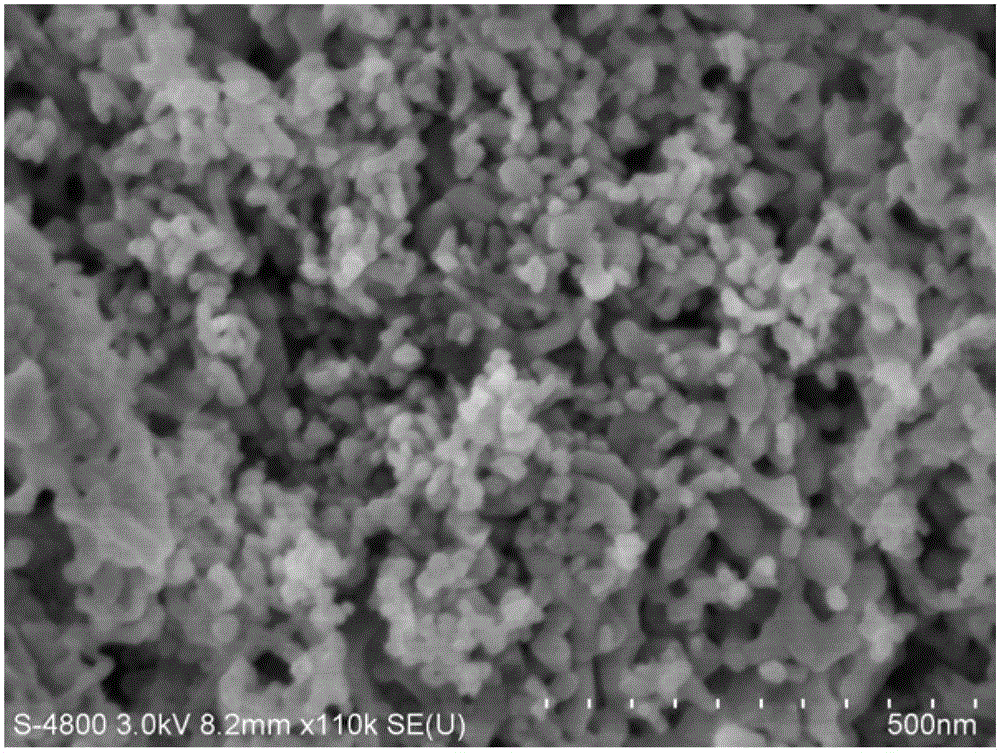

Preparation method based on solid-phase reaction for capacitor electrode material

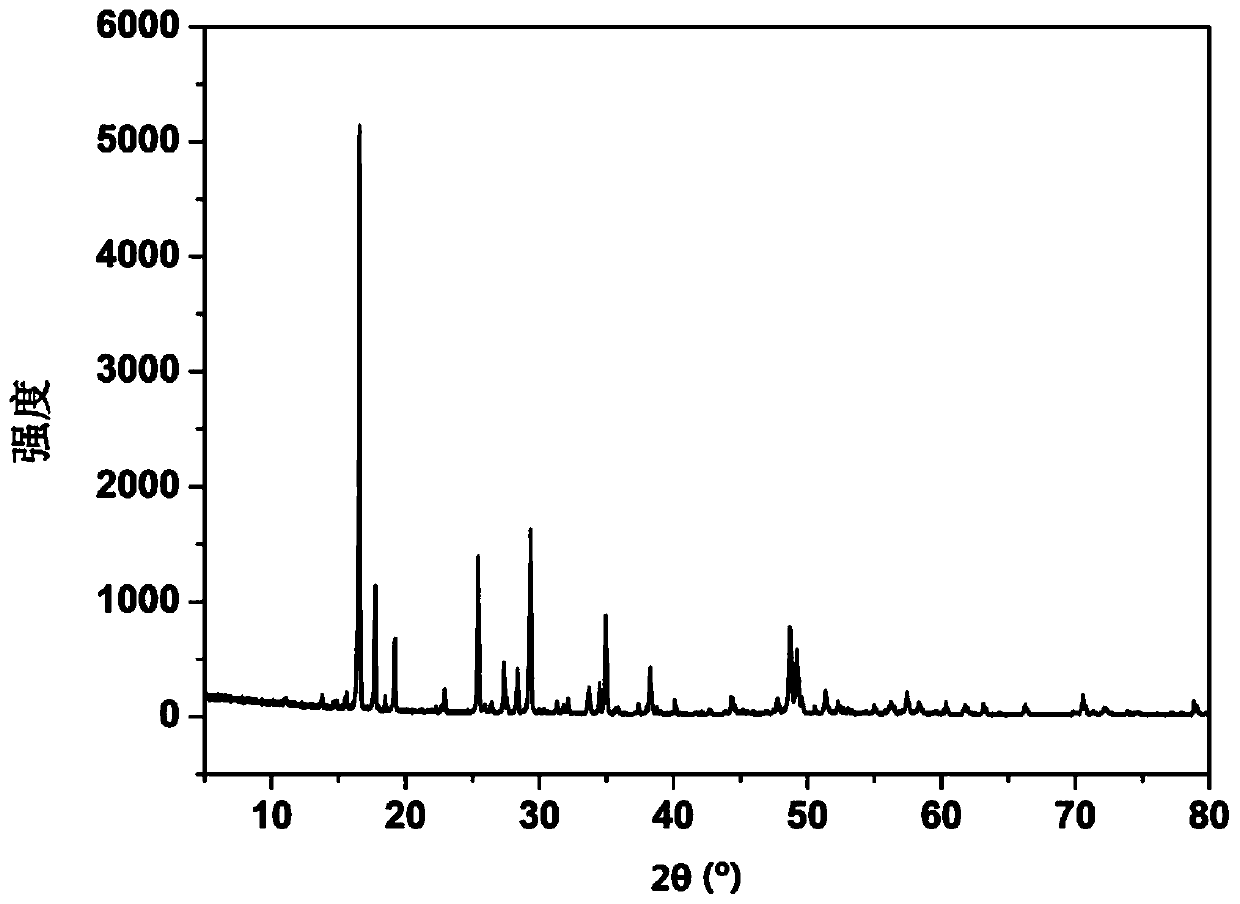

ActiveCN103274481AInhibit side effectsHigh yieldHybrid capacitor electrodesCobalt oxides/hydroxidesCapacitanceHexamethylenetetramine

The invention discloses a preparation method based on a solid-phase reaction for a capacitor electrode material. The preparation method comprises the following steps of: 1) adequately mixing and grinding cobalt acetate, oxalic acid and oxidized graphene to obtain an cobalt oxalate-oxidized graphene mixture; and 2) calcining the cobalt oxalate-oxidized graphene mixture aforementioned to obtain a cobaltosic oxide-graphene electrode material, wherein the dosage ratio by mole of cobalt acetate to oxalic acid is 1: 1, and the dosage of oxidized graphene is 5-30% of the mass of the finally obtained cobaltosic oxide; additionally, the selected ligand can also be citric acid and hexamethylenetetramine except oxalic acid; a solvent is not used in the solid-phase reaction of the preparation method disclosed by the invention, so that the side reactions generated in a water-phase reaction are avoided, the yield and the purity are increased, the reaction conditions are easy to control, and the operation is simple and practicable; and moreover, via the introduction of the graphene material, a novel way is provided for an oxide material with bad electrical conductivity, good energy storage property, and high theoretical specific capacitance in the field of capacitors, and the graphene material has important theoretical and practical application significance.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

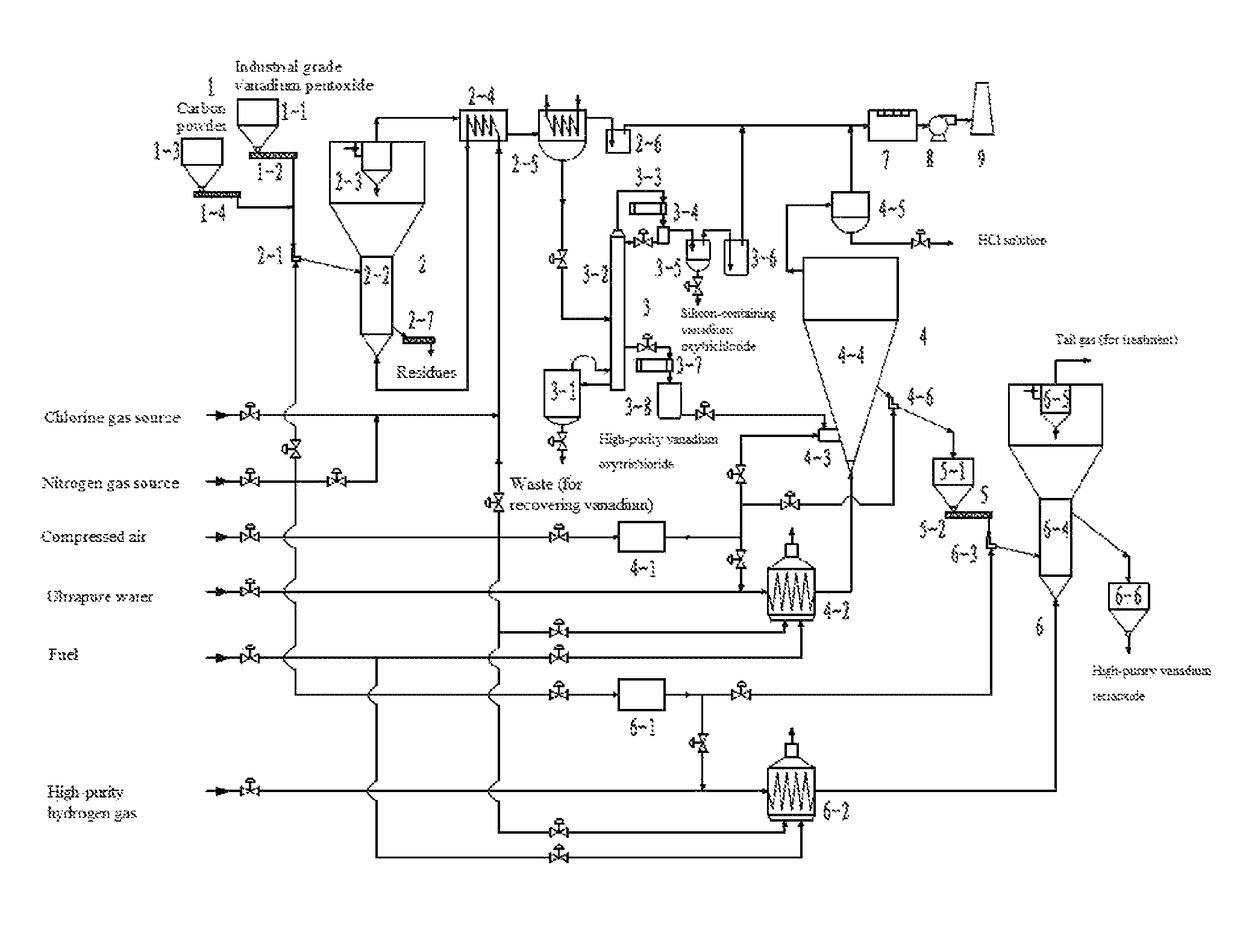

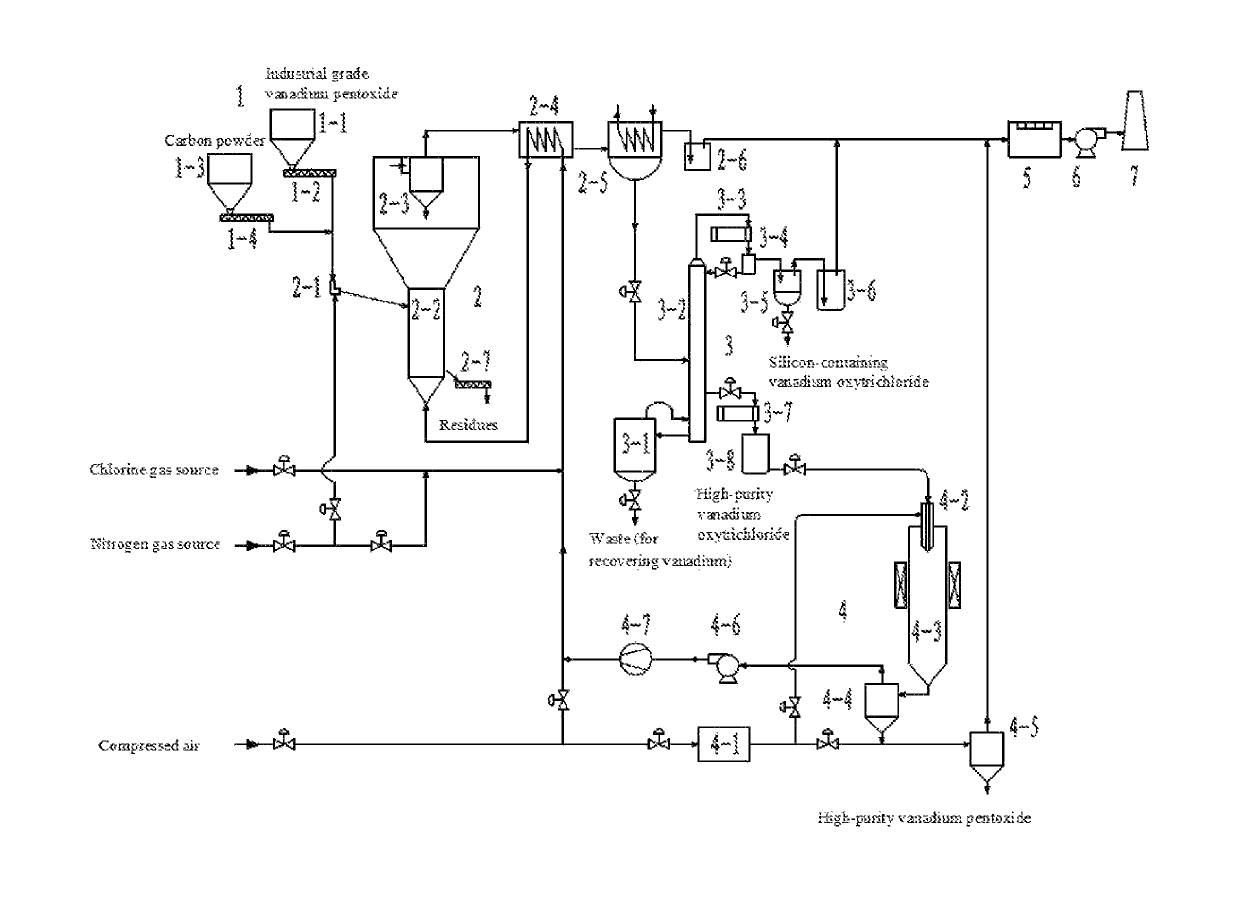

System and method for producing high-purity vanadium tetraoxide powder

ActiveUS20180009674A1Inhibit productionGood choiceChloride preparationEnergy inputGas phaseTechnical grade

The present invention provides a system and method for producing high-purity vanadium tetraoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to fluidized gas phase hydrolyzation, thereby producing a high-purity vanadium pentoxide product and a by-product solution of hydrochloric acid, and further obtaining a high-purity vanadium tetraoxide powder product through fluidized hydrogen reduction. The system and method have advantages of favorable adaptability to raw material, no discharge of contaminated wastewater, low energy consumption, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

System and Method for Purifying Vanadium Pentoxide

InactiveUS20180002190A1Improve inefficiencyUniform temperature distributionLiquid degasificationVanadium oxidesFlue gasWastewater

The present invention provides a system and method for purifying vanadium pentoxide. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to plasma oxidation, thereby obtaining a high-purity vanadium pentoxide product and chlorine gas. The chlorine gas is returned for low temperature chlorination. The system and method have advantages of favorable adaptability to raw material, no discharge of contaminated wastewater, low energy consumption and chlorine consumption in production, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

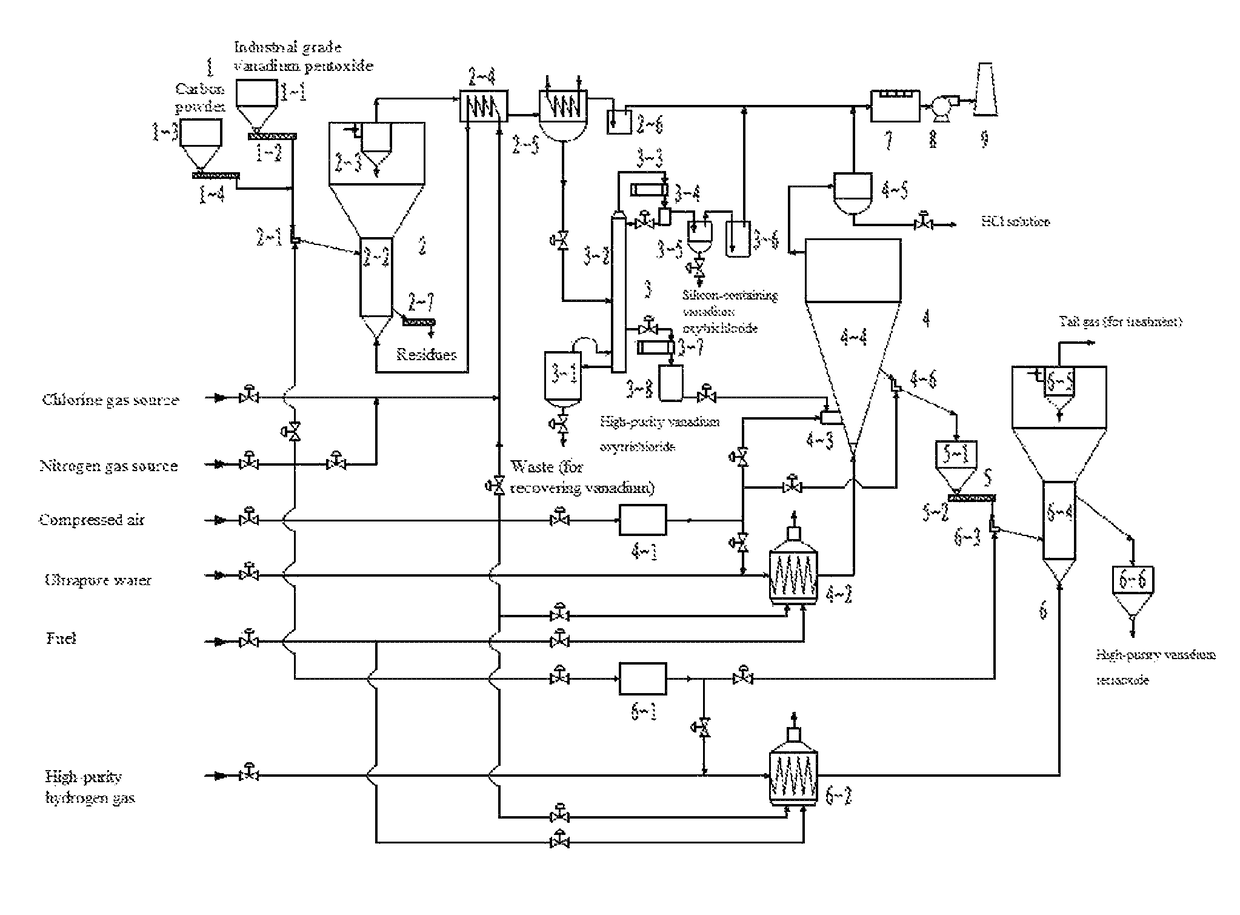

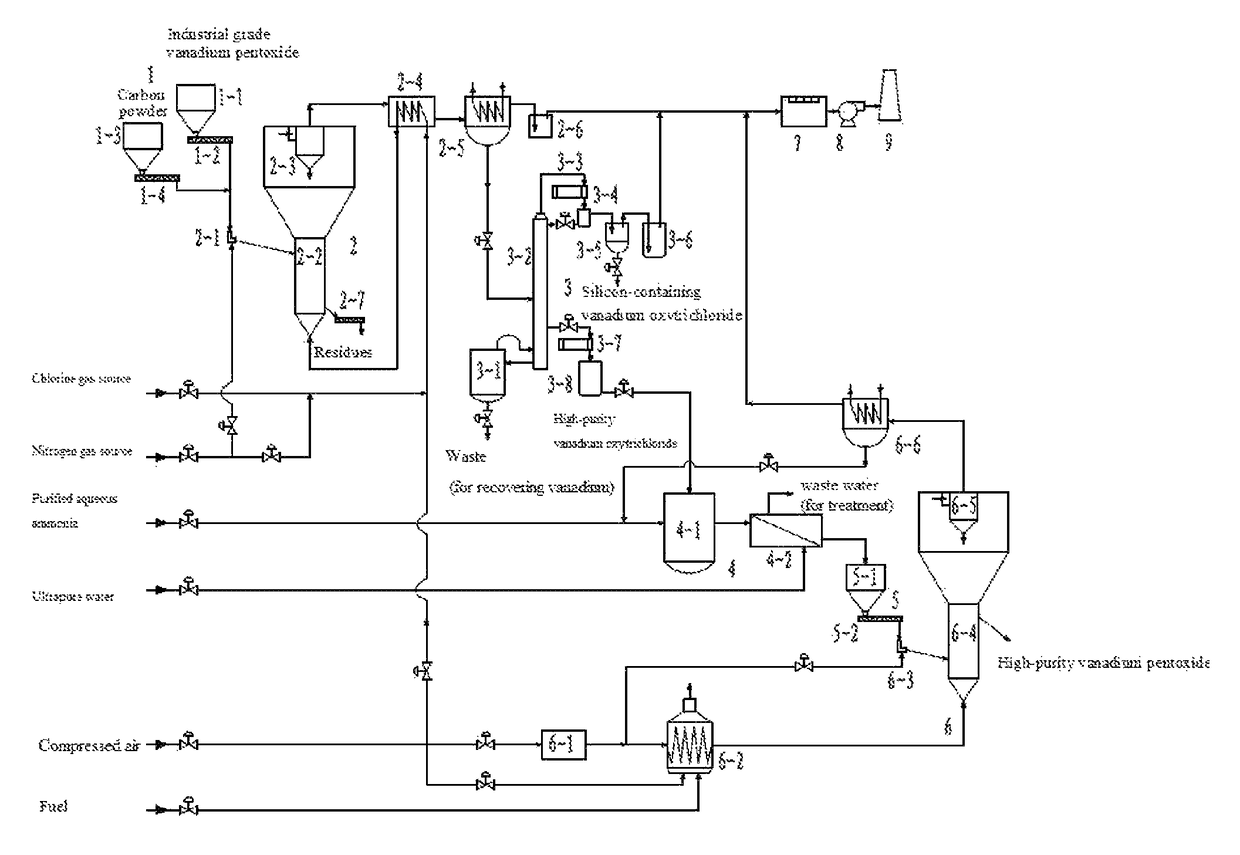

System and method for purifying and preparing high-purity vanadium pentoxide powder

ActiveUS20180009673A1Improve inefficiencyUniform temperature distributionTransportation and packagingNitrogen-metal/silicon/boron binary compoundsGas phaseAmmonium metavanadate

The present invention provides a system and method for purifying and preparing vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to fluidized gas phase ammonification, thereby obtaining ammonium metavanadate, and further obtaining a high-purity vanadium pentoxide powder product through fluidized calcination. The system and method have advantages of favorable adaptability to a raw material, no discharge of contaminated wastewater, low energy consumption and chlorine consumption in production, stable product quality and so on.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

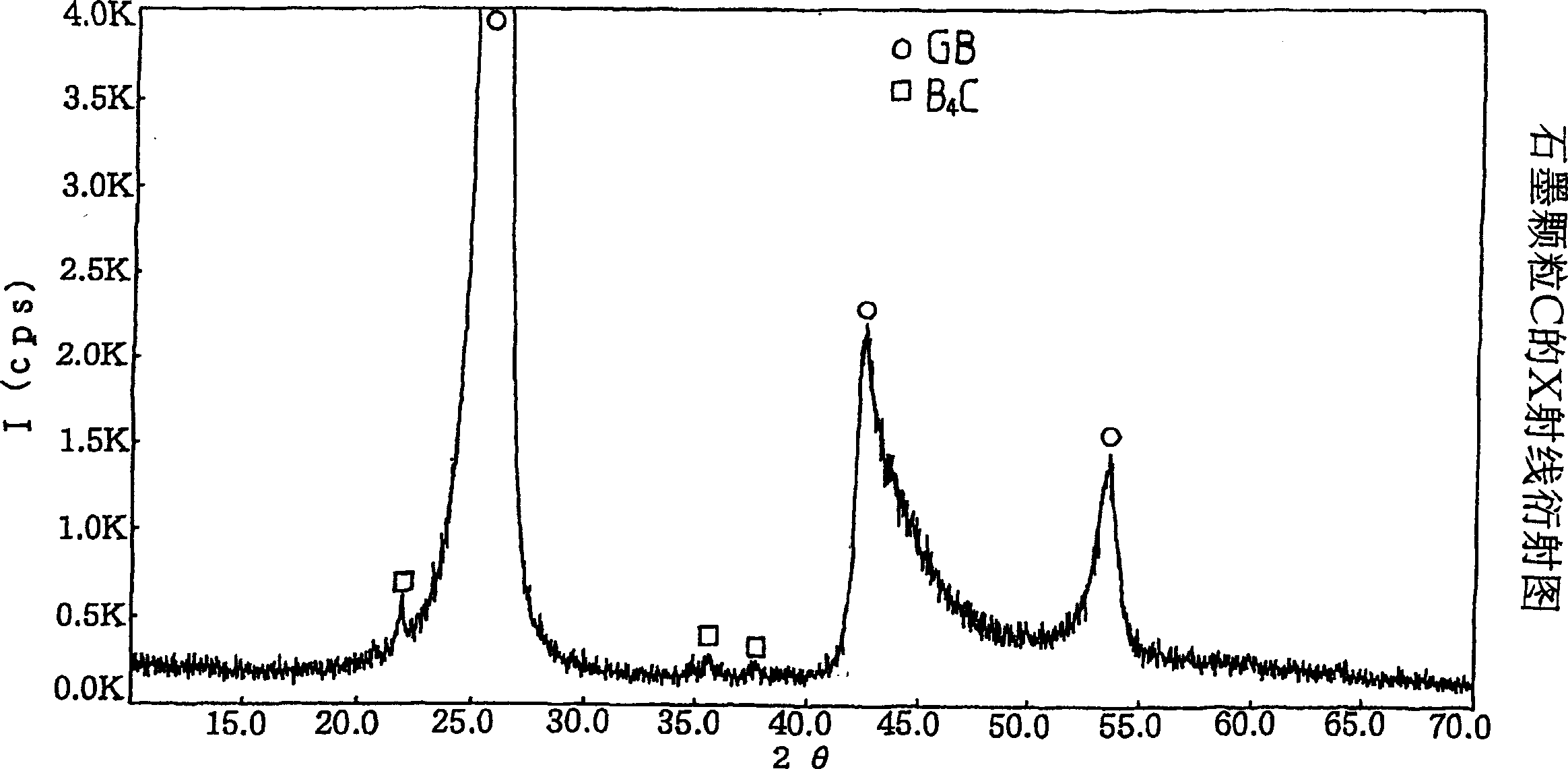

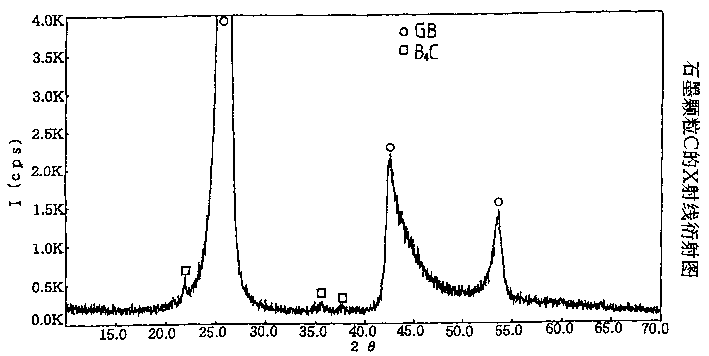

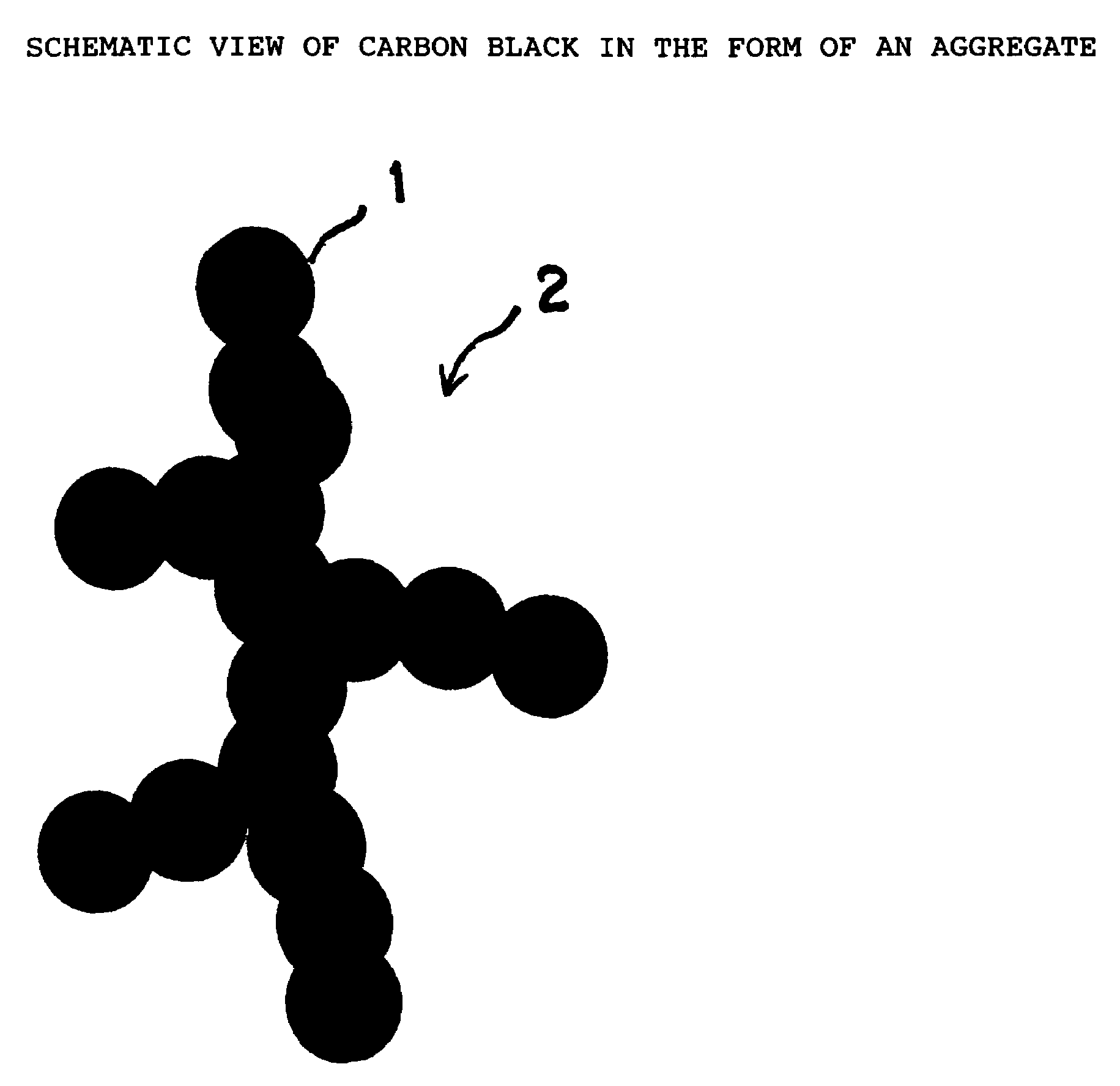

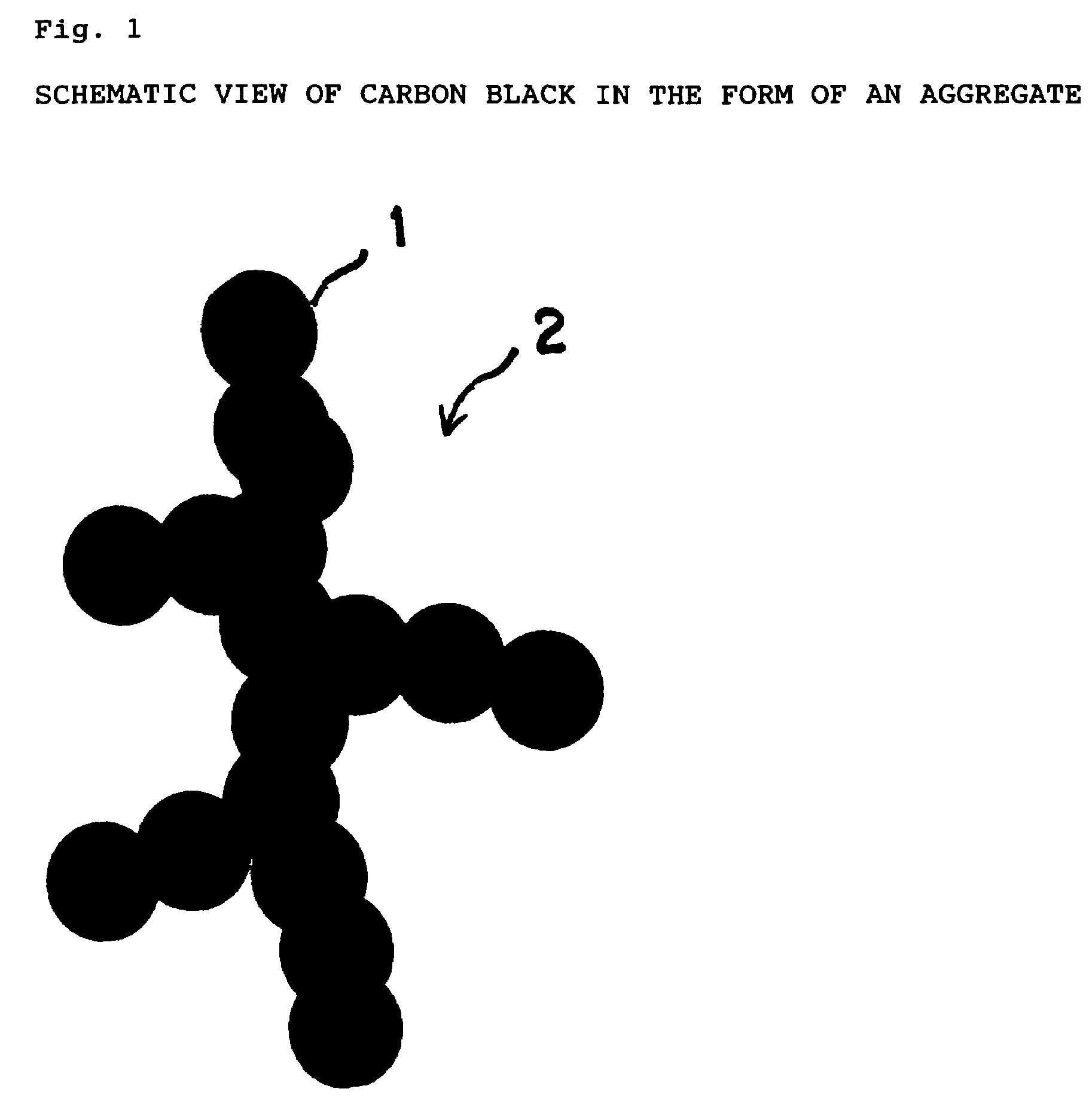

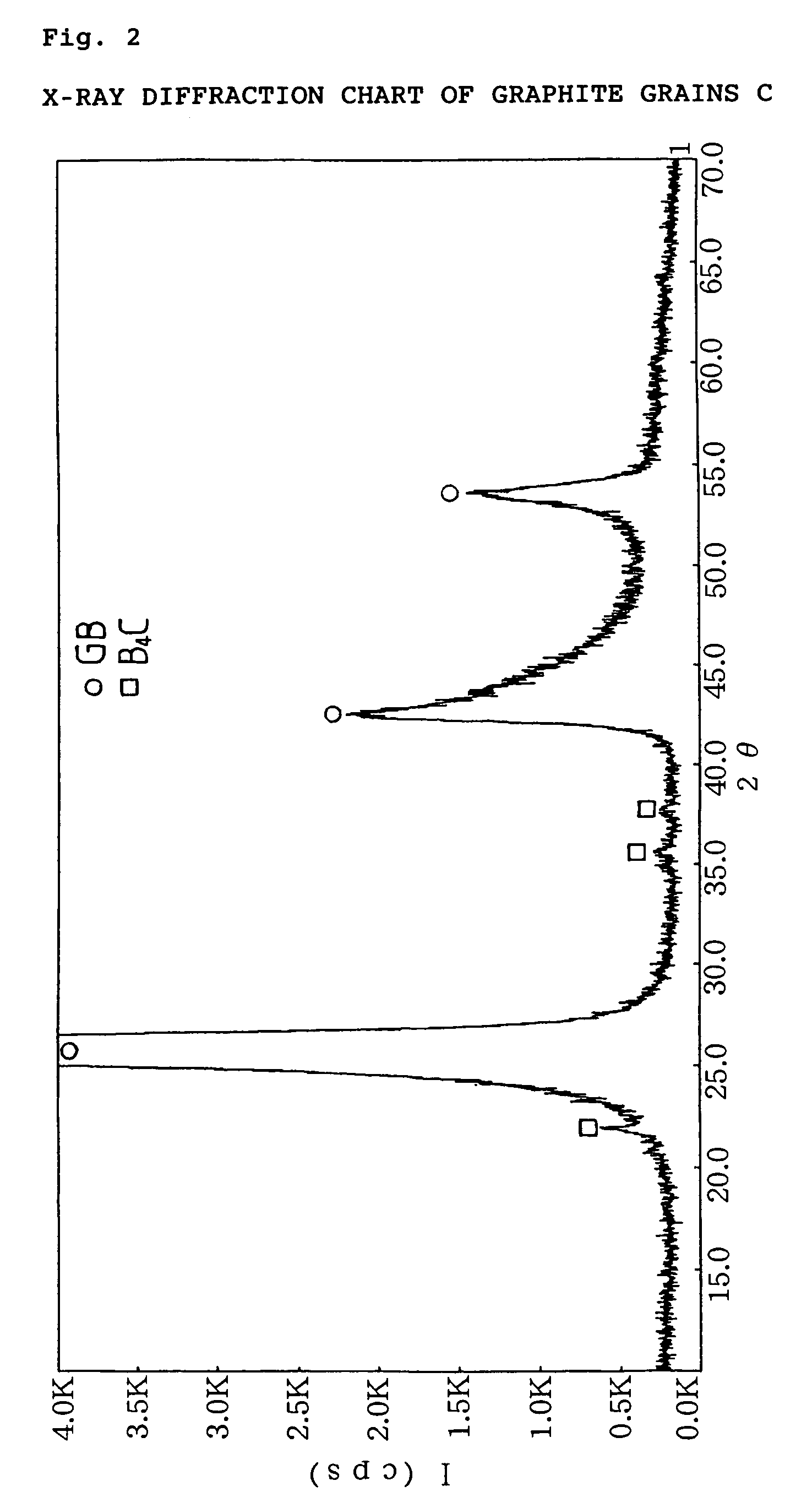

Refractory materials, method for production thereof and refraratory using the material

InactiveCN1461284AImprove thermal shock resistanceImprove oxidation resistanceMaterial nanotechnologyPigmenting treatmentRefractoryGraphite

Refractories obtained by molding a refractory raw material composition containing a refractory raw material including graphite grains having an average grain size of 500 nm or less or a refractory raw material including graphite grains obtained by graphitizing carbon black and a refractory filler, Or refractories containing carbonaceous grains (A) selected from carbon black or graphite grains obtained by graphitizing carbon black and having a DBP absorption (x) of 80 ml / 100 g or more, carbonaceous grains (B) selected from carbon black and graphite grains obtained by graphitizing carbon black and having a DBP absorption (x) of less than 80 ml / 100 g, and a refractory filler. Refractories excellent in corrosion resistance, oxidation resistance and thermal shock resistance, especially carbon-contained refractories having a low carbon content are thereby provided.

Owner:KROSAKI HARIMA CORP +1

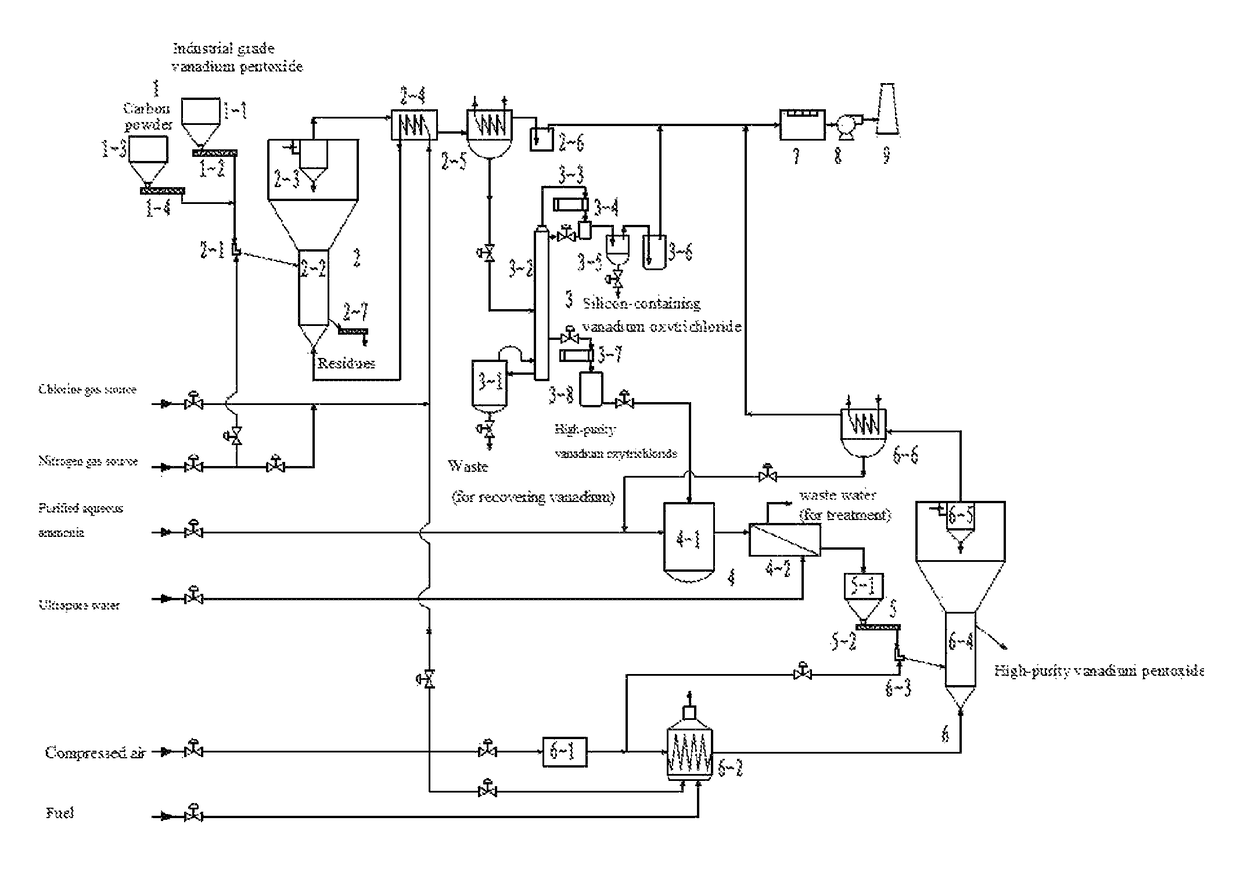

System and Method for Preparing High-Purity Vanadium Pentoxide Powder

ActiveUS20180022616A1Improve calcination decomposition efficiencyGood choiceDistillation in boilers/stillsChemical liquid solidificationTechnical gradeVanadium oxytrichloride

The present invention provides a system and method for preparing high-purity vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is subjected to purification by rectification, ammonium salt precipitation and fluidized calcination, thereby obtaining high-purity vanadium pentoxide, wherein the ammonia gas produced during calcination is condensed and then recycled for ammonium salt precipitation. The system and method have advantages of favorable adaptability to raw material, less pollution, low energy consumption in production, low operation cost, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Process for the extraction of specific transition metals with gaseous HCL

A process is disclosed for separation and recovery of vanadium, molybdenum, iron, tungsten, cobalt and nickel from alumina-based materials, mattes, ores, manufacturing by-products and waste. These elements are oxidized. The oxides are reacted with gaseous HCl to form volatile chloride-bearing compounds that subsequently sublimate. The volatile compounds are condensed in a downward-stepped thermal gradient that allows collection of moderate to high purity compounds of individual elements with exception of a nickel-cobalt co-condensate. Nickel is separated from cobalt by precipitation of nickel chloride from concentrated HCl pressurized with gaseous HCl.

Owner:METALS RECOVERY TECH

Refractory raw materials, method for production thereof and refractory using the material

InactiveUS7060642B2Reduce the amount requiredImprove corrosion resistanceMaterial nanotechnologyVanadium halidesShell moldingRefractory

Refractories obtained by molding a refractory raw material composition containing a refractory raw material including graphite grains having an average grain size of 500 nm or less or a refractory raw material including graphite grains obtained by graphitizing carbon black and a refractory filler. Or refractories containing carbonaceous grains (A) selected from carbon black or graphite grains obtained by graphitizing carbon black and having a DBP absorption (x) of 80 ml / 100 g or more, carbonaceous grains (B) selected from carbon black and graphite grains obtained by graphitizing carbon black and having a DBP absorption (x) of less than 80 ml / 100 g, and a refractory filler. Refractories excellent in corrosion resistance, oxidation resistance and thermal shock resistance, especially carbon-contained refractories having a low carbon content are thereby provided.

Owner:KROSAKI HARIMA CORP +1

Method for preparing vanadic fluoride

InactiveCN102502831AImprove conversion rateEasy to operateVanadium halidesVanadium pentafluorideFluoride

The invention discloses a method for preparing vanadic fluoride. The method comprises the following steps: (i) the pretreatment is performed to a reactor, vanadium is put in the reactor, and is preheated to 100 to 200 DEG C, and the reactor is evacuated to 0.1 below zero to 0.08 below zero MPa; (ii), the synthetic reaction is carried out, fluorine gas is fed into the reactor slowly, and fluorine gas and vanadium are in synthetic reaction in the reactor to generate vanadium tetrafluoride; (iii), the dismutation reaction is carried out, and vanadium tetrafluoride is in dismutation reaction in the reactor to obtain crude products of vanadic fluoride; (iv) impurities in the crude products of vanadic fluoride are removed; and (v) vanadic fluoride is purified. The invention has the advantages that equipment is simple, the operation is convenient, the content of impurities is low, the rate of conversion of intermediate by-products can be improved effectively, and the product purity can reach more than 95 percent.

Owner:HUAHE NEW TECH DEV COMPANY RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

System and method for producing high-purity vanadium tetraoxide powder

The present invention provides a system and method for producing high-purity vanadium tetraoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to fluidized gas phase hydrolyzation, thereby producing a high-purity vanadium pentoxide product and a by-product solution of hydrochloric acid, and further obtaining a high-purity vanadium tetraoxide powder product through fluidized hydrogen reduction. The system and method have advantages of favorable adaptability to raw material, no discharge of contaminated wastewater, low energy consumption, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Preparation method of vanadium pentafluoride

InactiveCN102502830AImprove conversion rateEasy to operateVanadium halidesVanadium pentafluorideDistillation

The invention discloses a preparation method of vanadium pentafluoride. The method comprises the following steps of: (i) pretreating a reactor, putting vanadium into the reactor, preheating the reactor, and pumping out; (ii) undergoing a synthetic reaction: contacting fluorine gas with metal vanadium in the reactor for undergoing a synthetic reaction to generate vanadium pentafluoride; (iii) removing impurities from crude vanadium pentafluoride in a distillation tower; and (iv) purifying the vanadium pentafluoride in the distillation tower. The method has the advantages of simple equipment, convenience for operating and low impurity content, the transformation rate of an intermediate byproduct can be increased effectively, and product purity can be over 95 percent.

Owner:HUAHE NEW TECH DEV COMPANY RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

System and method for producing high-purity vanadium pentoxide powder

ActiveUS10099939B2Inhibit productionGood choiceTransportation and packagingGas washing apparatusGas phaseCalcination

The present invention provides a system and method for producing high-purity vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to fluidized gas phase hydrolyzation and fluidized calcination, thereby producing a high-purity vanadium pentoxide product and a by-product of hydrochloric acid solution. The system and method have advantages of favorable adaptability to raw material, no discharge of contaminated wastewater, low energy consumption in production, low operation cost, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

System and method for purifying vanadium pentoxide

InactiveUS10294118B2Inhibit productionGood choiceLiquid degasificationVanadium oxidesFlue gasWastewater

The present invention provides a system and method for purifying vanadium pentoxide. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is purified by rectification, and then subjected to plasma oxidation, thereby obtaining a high-purity vanadium pentoxide product and chlorine gas. The chlorine gas is returned for low temperature chlorination. The system and method have advantages of favorable adaptability to raw material, no discharge of contaminated wastewater, low energy consumption and chlorine consumption in production, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

System and method for preparing high-purity vanadium pentoxide powder

ActiveUS10053371B2Improve calcination decomposition efficiencyGood choiceDistillation in boilers/stillsEnergy inputVanadium oxytrichloridePollution

The present invention provides a system and method for preparing high-purity vanadium pentoxide powder. Industrial grade vanadium pentoxide is converted to vanadium oxytrichloride by low temperature fluidizing chlorination, wherein chlorinating gas is preheated via heat exchange between fluidizing gas and chlorination flue gas, and an appropriate amount of air is added to enable a part of carbon powder to combust so as to achieve a balanced heat supply during the chlorination, thereby increasing the efficiency of chlorination and ensuring good selectivity in low temperature chlorination. The vanadium oxytrichloride is subjected to purification by rectification, ammonium salt precipitation and fluidized calcination, thereby obtaining high-purity vanadium pentoxide, wherein the ammonia gas produced during calcination is condensed and then recycled for ammonium salt precipitation. The system and method have advantages of favorable adaptability to raw material, less pollution, low energy consumption in production, low operation cost, stable product quality, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

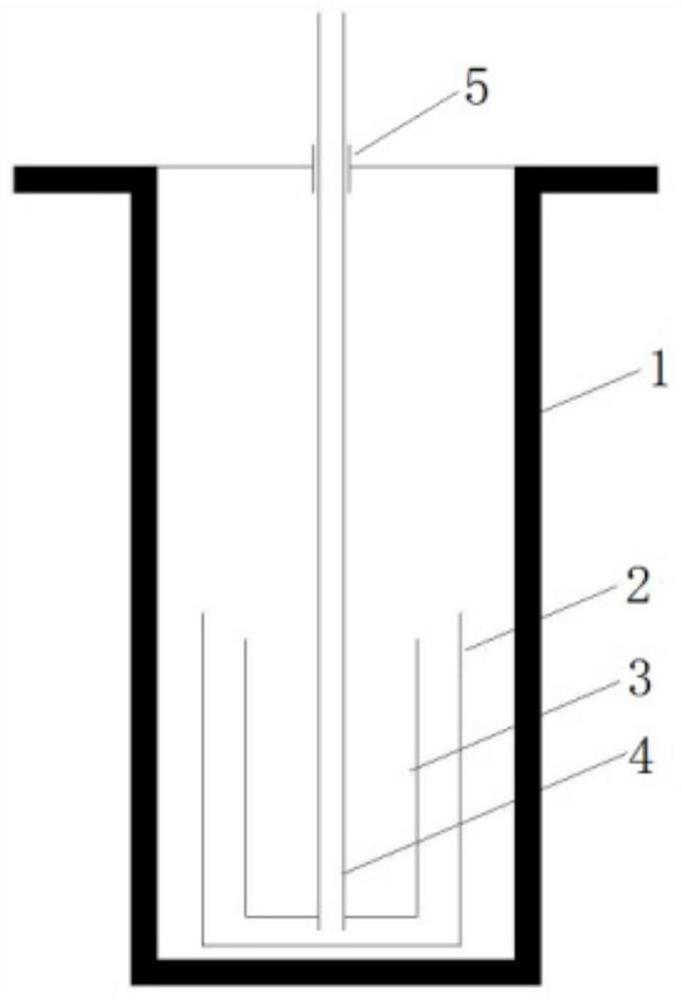

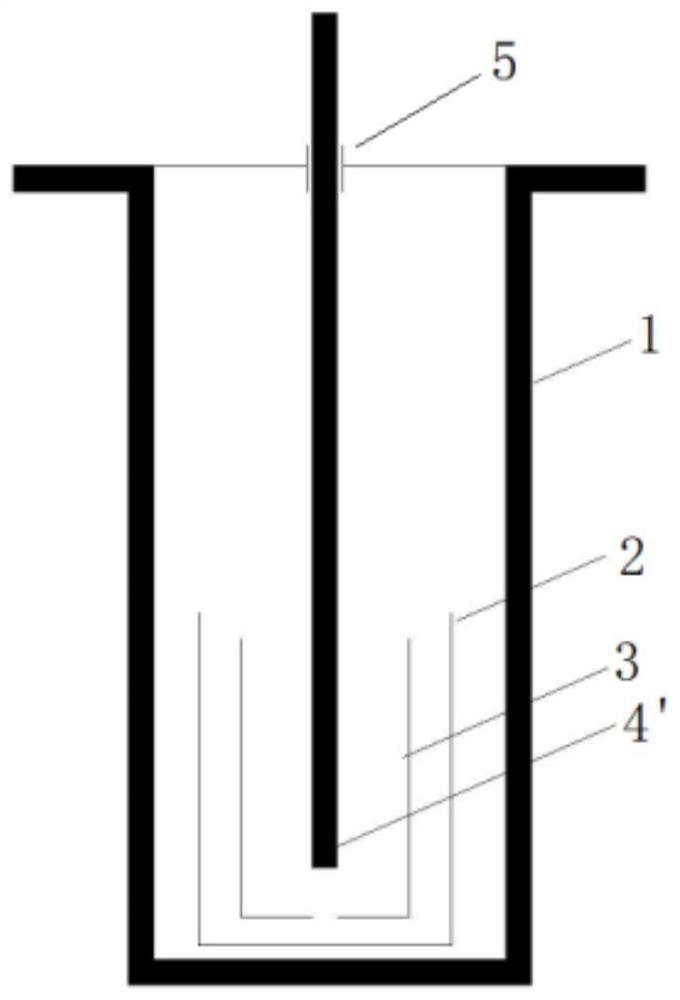

Device and method for preparing metal vanadium from vanadium alloy

PendingCN114525552AIncrease the chlorination rateIncrease contentProcess efficiency improvementVanadium halidesWater chlorinationNon-ferrous extractive metallurgy

The invention relates to the field of non-ferrous metal metallurgy, in particular to a device and method for preparing vanadium metal from vanadium alloy, in the process of preparing vanadium from the vanadium alloy, a gap between a second reactor and a first reactor is used for containing the vanadium alloy and molten chloride; the alundum tube penetrates through the furnace cover and the second reactor through the first through hole and the second through hole, and chlorine is introduced into a material between the second reactor and the first reactor through the alundum tube, so that the material between the two reaction tanks can be kept in a fluidized state in the reaction process; therefore, the chlorination rate of the vanadium alloy and the content of the prepared vanadium chloride are obviously improved. In the electrolysis process of the second reactor, the first reactor can be prevented from making direct contact with the cathode bar, namely the cathode and the anode, electrolysis failure is avoided, the effect of protecting the cathode bar is achieved, only electrolytic ions are allowed to migrate to the cathode through the second through hole to deposit products, other impurities making contact with the cathode are reduced, and the content of cathode impurities is remarkably reduced.

Owner:承德钒钛新材料有限公司 +2

Method for producing fluorine-containing lithium compound

InactiveCN1304279CSolve routine problemsAntimony halidesLithium hexafluorophosphateLithium compoundFluoride

A method for simply producing an LiMFx which is free from impurities such as HF and other by-products that adversely affect battery performance is disclosed. The method for producing a fluorine-containing lithium compound which can be represented by a certain general formula is characterized in that LiF is brought into contact with an element M (M is an element selected from the group consisting of B, P, As, Sb, Bi, V, Nb, and Ta) and / or a fluoride of the element M in the presence of fluorine gas.

Owner:SANTOKU CORP

Preparation method based on solid-phase reaction for capacitor electrode material

ActiveCN103274481BInhibit side effectsHigh yieldHybrid capacitor electrodesCobalt oxides/hydroxidesCapacitanceHexamethylenetetramine

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for preparing vanadium tetrachloride from ferrovanadium fine powder

The invention relates to the technical field of chemical metallurgy, and discloses a method for preparing vanadium tetrachloride from ferrovanadium fine powder. The method comprises the following steps: (1) paving ferrovanadium fine powder and petroleum coke in a crucible, wherein the mass ratio of the ferrovanadium fine powder to the petroleum coke is 1: (4-10); (2) putting the corundum crucible into a quartz reactor, then putting the quartz reactor into a heating furnace, introducing chlorine and nitrogen to perform chlorination reaction, and condensing and centrifugally separating a gas product to obtain crude vanadium tetrachloride; (3) putting the crude vanadium tetrachloride product into a polytetrafluoroethylene distillation-condensation device, adding distilled water, and stirring for reaction; and (4) primary distillation is carried out at 130-140 DEG C, secondary distillation is carried out at 150-160 DEG C when the mass of a condensation product is 5-10% of the mass of the crude vanadium tetrachloride product, and the condensation product is the vanadium tetrachloride product when the mass of the condensation product is 50-75% of the mass of the crude vanadium tetrachloride product. The method is simple, the impurity removal efficiency is high, and the product purity is high.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

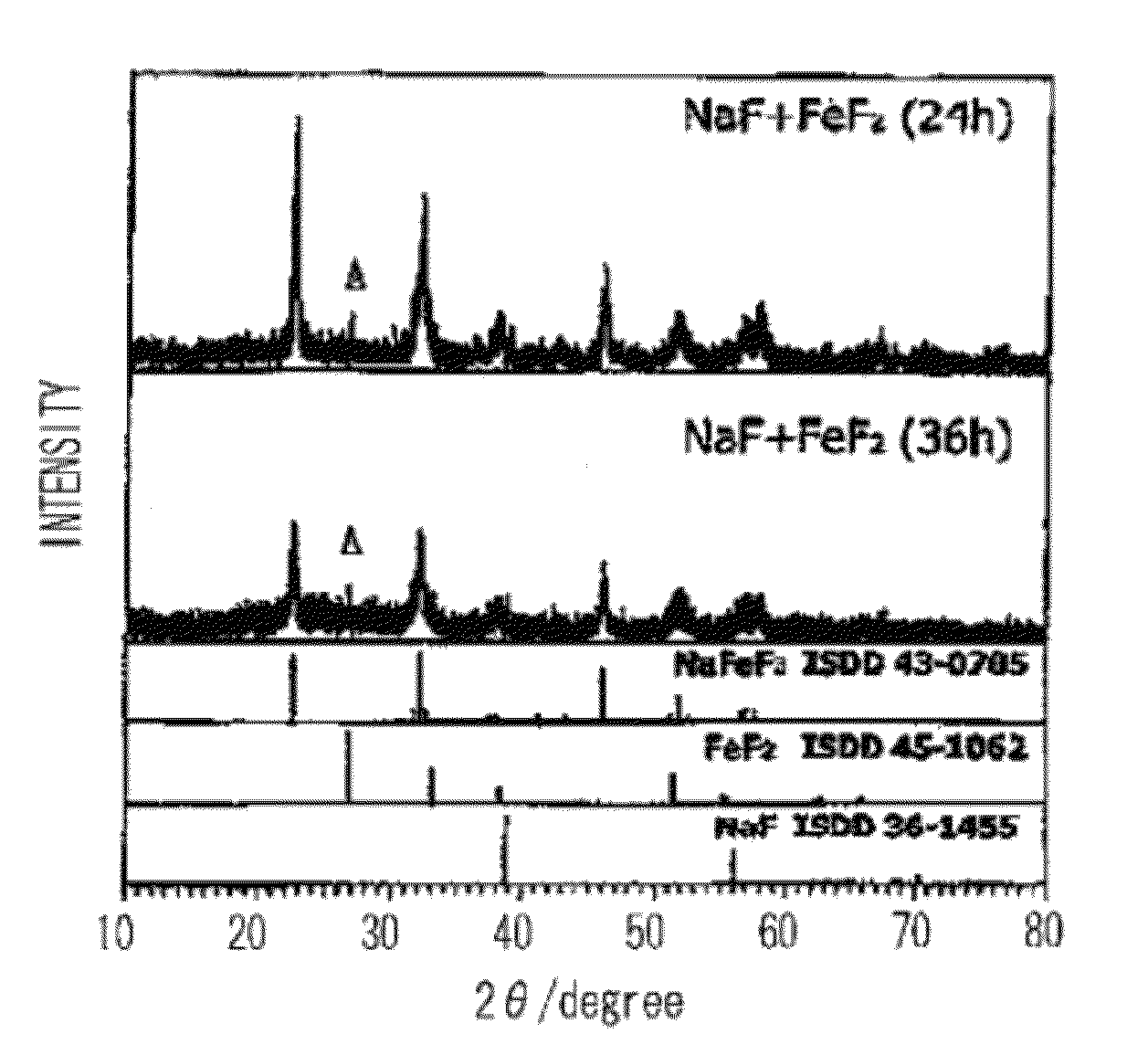

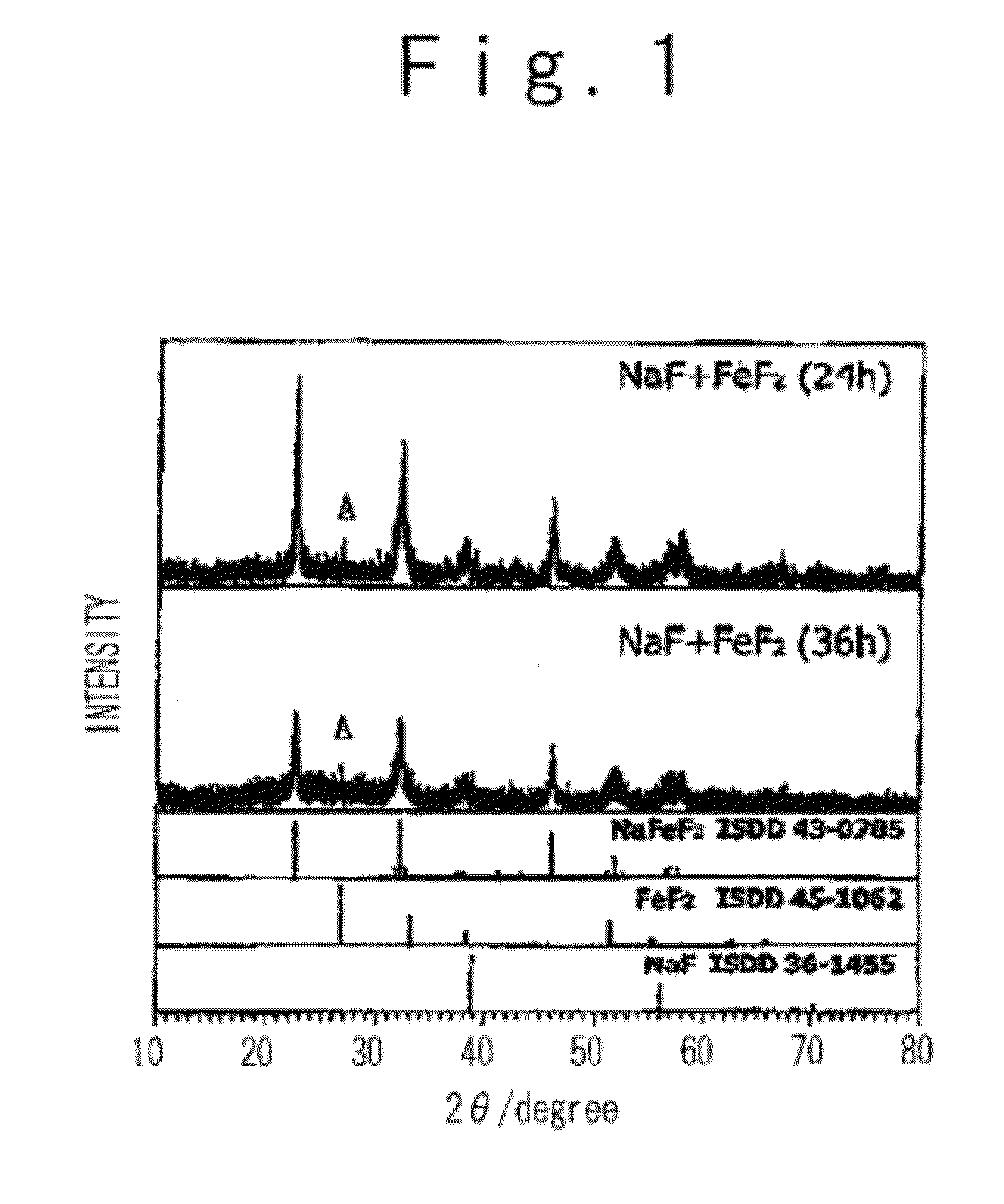

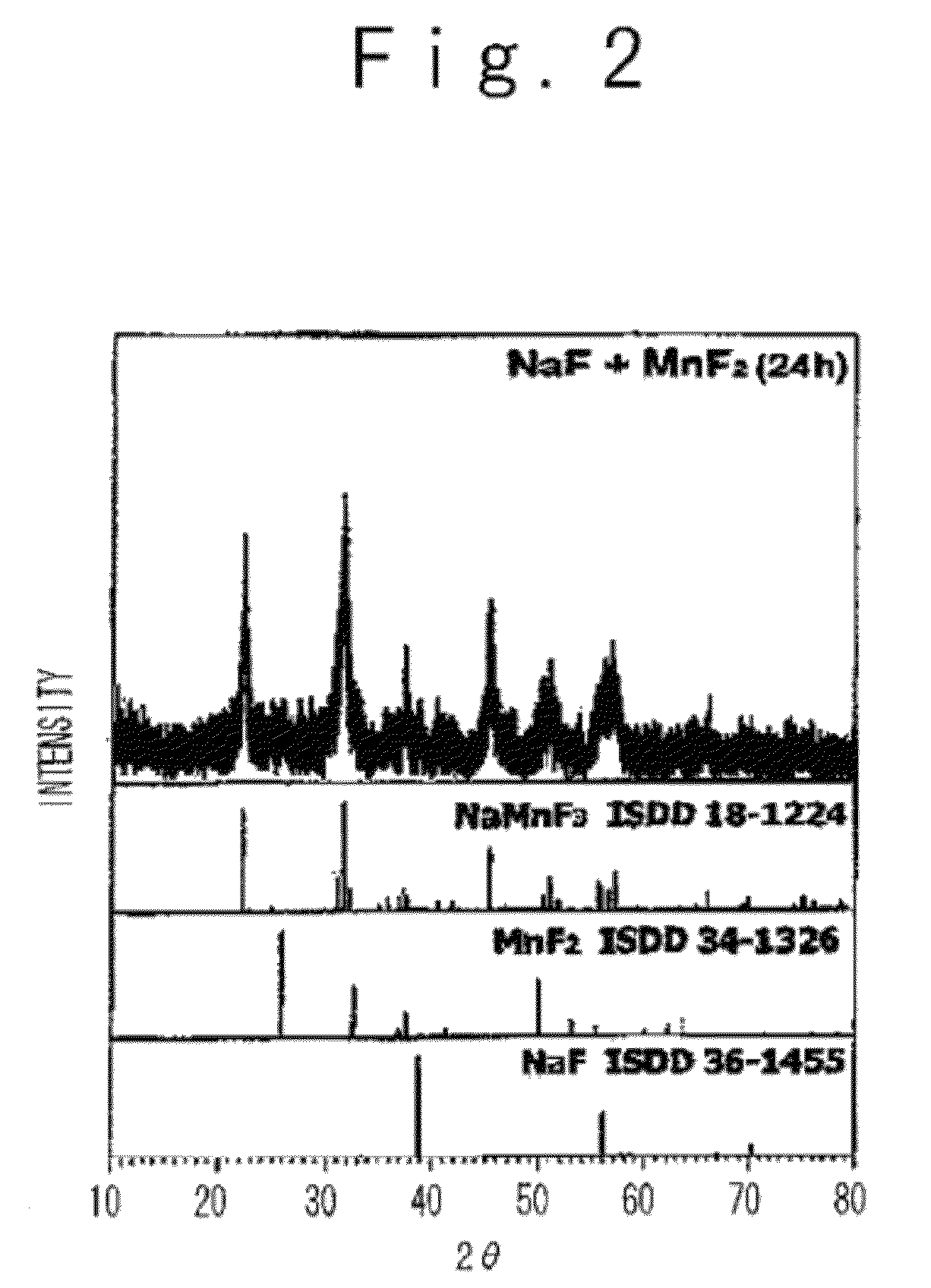

Production method and production device of metal halide

ActiveCN111186818AProduction method steps scienceThe production method steps are reasonableZinc halidesAlkali metal halidesHalogenHazardous substance

The invention provides a production method and a production device of a metal halide. The production method of the metal halide comprises the following steps: 1, mixing a halogen source and a metal element source; 2, putting the mixture into a reactor, and introducing protective gas into the reactor for 1-5 hours; 3, under the protection of a protective atmosphere, heating the mixture to 100-400 DEG C, and carrying out heat preservation for 0.5-10 hours; and 4, under the protection of a protective atmosphere, continuously heating to 500-1000 DEG C, and carrying out heat preservation for 1-50 hours to obtain the metal element halide. The production method of the metal halide is simple in step and easy to implement, no toxic or harmful substances are generated, and harm of high-corrosivity and high-toxicity halogen to human beings and the environment is avoided or reduced.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

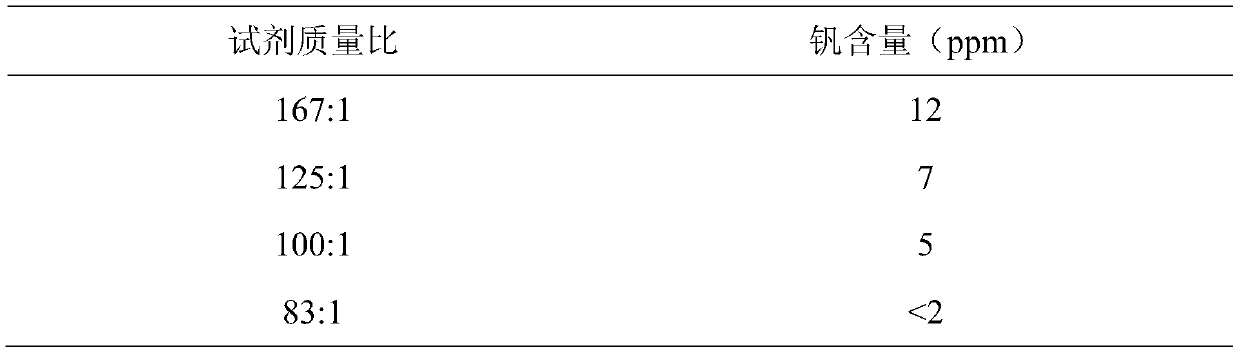

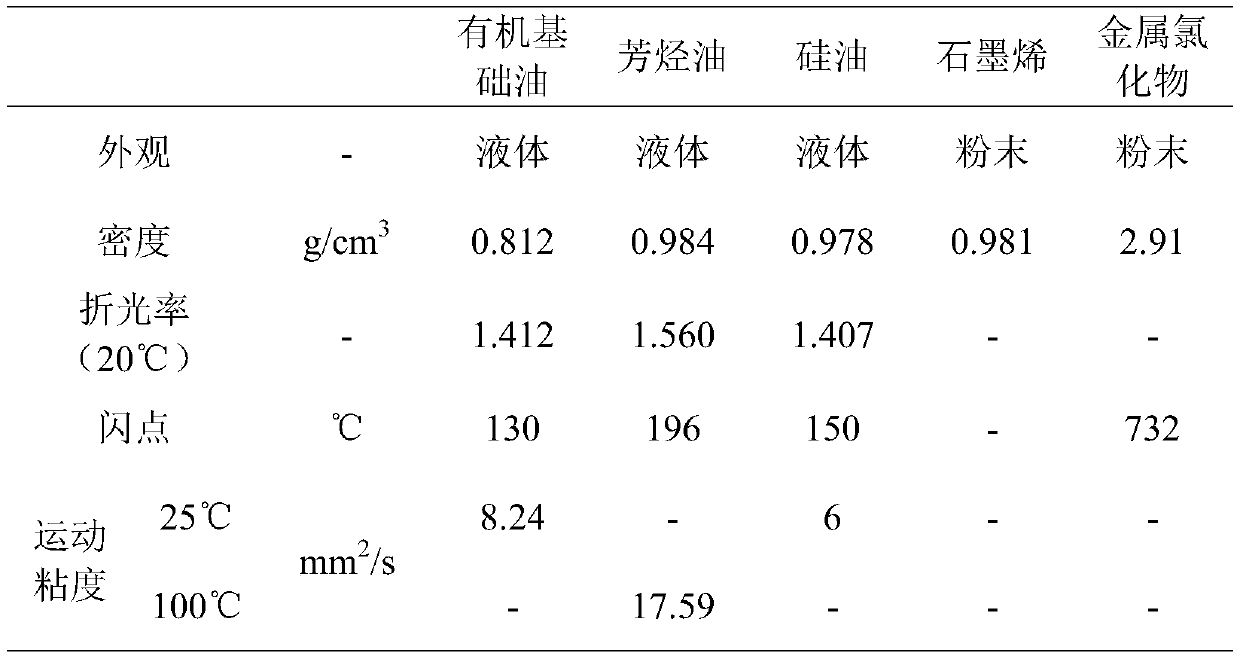

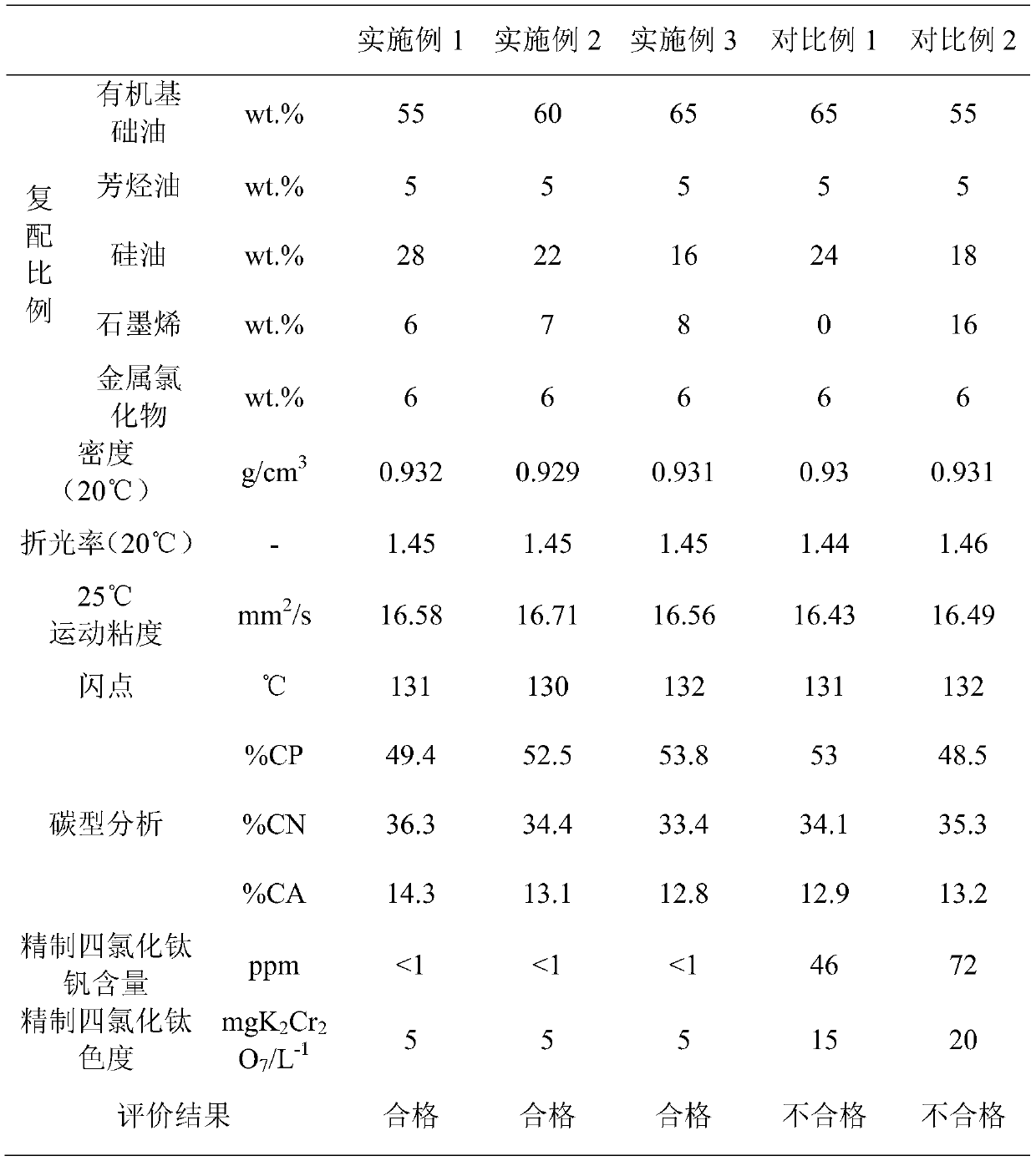

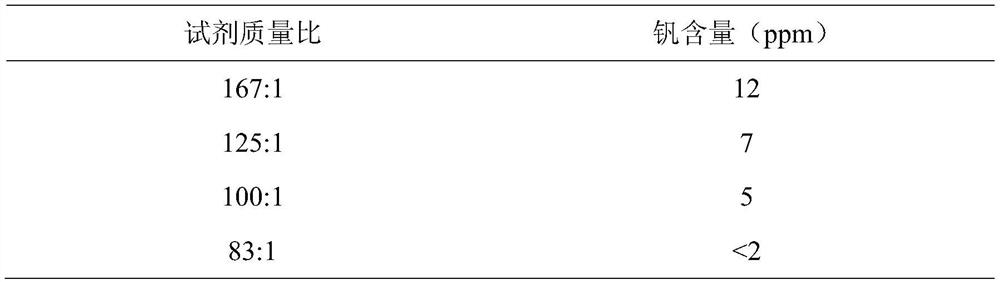

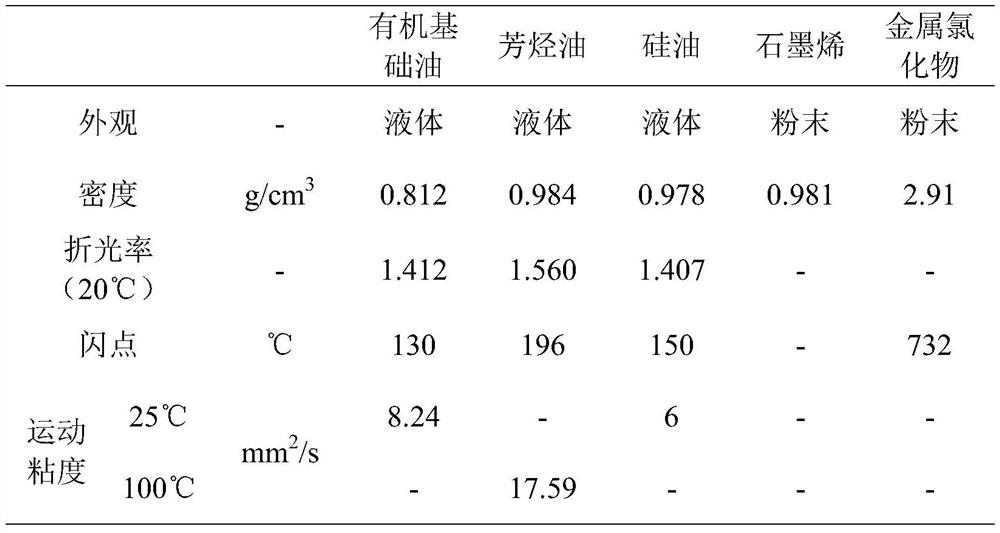

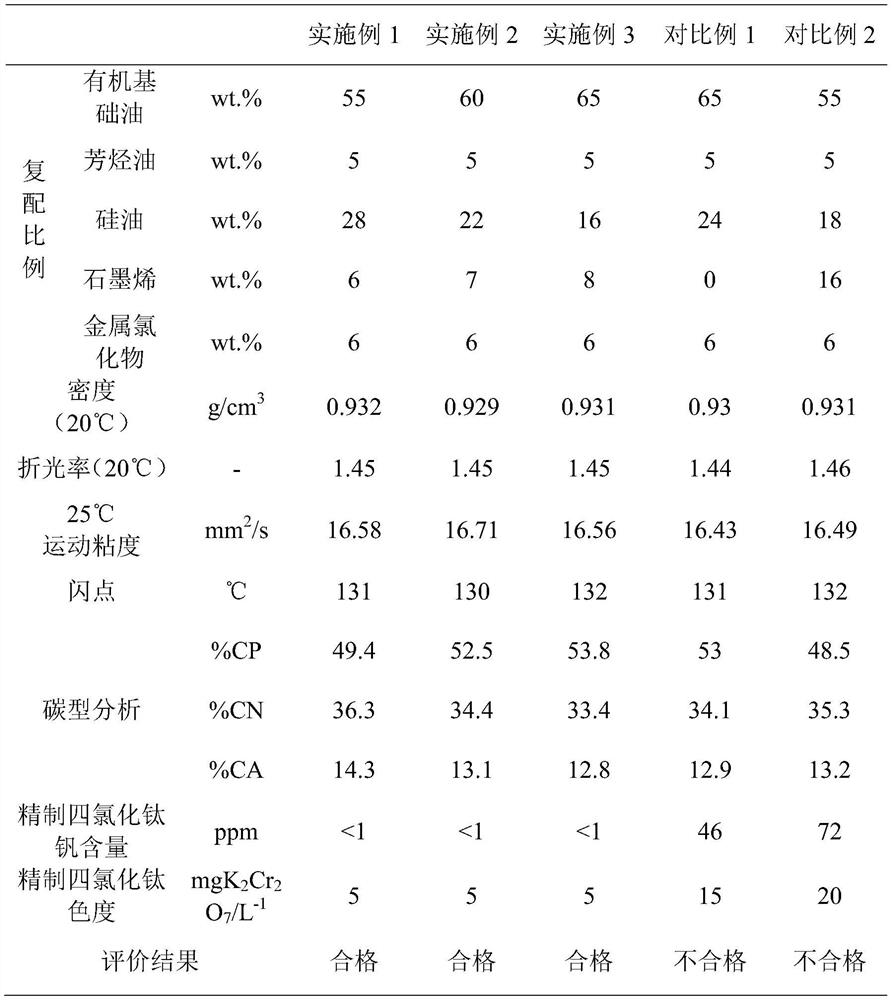

Compound organic substance for efficiently removing vanadium from crude titanium tetrachloride and preparation method of the compound organic substance

ActiveCN109956498AEfficient removal of vanadiumLess quantityVanadium halidesCompound organicDimethylaniline N-oxide

The invention belongs to the field of purifying titanium tetrachloride with organic substances, and particularly relates to a compound organic substance for efficiently removing vanadium from crude titanium tetrachloride. The organic substance comprises: organic base oil, aromatic hydrocarbon oil, silicone oil, graphene and metal chloride, wherein the mass ratio of the components is (40-70):(2-10):(10-30):(5-10):(2-10), successively. The organic base oil is mixed white oil; the aromatic hydrocarbon oil is dimethylaniline; the silicone oil is dimethyl silicone oil; the graphene is copper-loadedgraphene oxide; the metal chloride is zinc chloride. The organic substance is easy to catalyze and crack, the vanadium removal efficiency is high, and the vanadium removal dosage is low.

Owner:BOHAI UNIV

Cathode active material for non-aqueous electrolyte secondary battery and manufacturing method of the same

Owner:MITSUBISHI HEAVY IND LTD +1

Method and system for recycling vanadium-containing mud generated in vanadium removal process of crude titanium tetrachloride

ActiveCN103936063BHigh yieldRealize one-time recyclingTitanium halidesVanadium halidesTitanium chlorideMolten salt

The invention provides a method and a system for recycling vanadium-containing mud generated in a vanadium removal process of crude titanium tetrachloride. The vanadium-containing mud contains titanium tetrachloride liquid and VOCl2 solid. The method comprises the steps of adding the vanadium-containing mud into a molten salt furnace, evaporating, and collecting titanium tetrachloride in the vanadium-containing mud; introducing chlorine into the vanadium-containing mud to ensure that chlorine is reacted with VOCl2 in the vanadium-containing mud, and obtaining mixed gas containing VOCl3 gas and chlorine; condensing the mixed gas to obtain VOCl3 liquid and chlorine, wherein molten salt is filled in the molten salt furnace, and the temperature of the molten salt furnace is kept at 600-750 DEG C. The recycling system is used for implementing the method, and comprises the molten salt furnace, an air supply pipe, a TiCl4 gas collecting unit and a condenser. The recycling method and recycling system, provided by the invention, are used for realizing one-time recovery of valuable elements namely titanium and vanadium in the vanadium-containing mud, and are high in yield of vanadium and titanium, and high in purity of obtained products.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

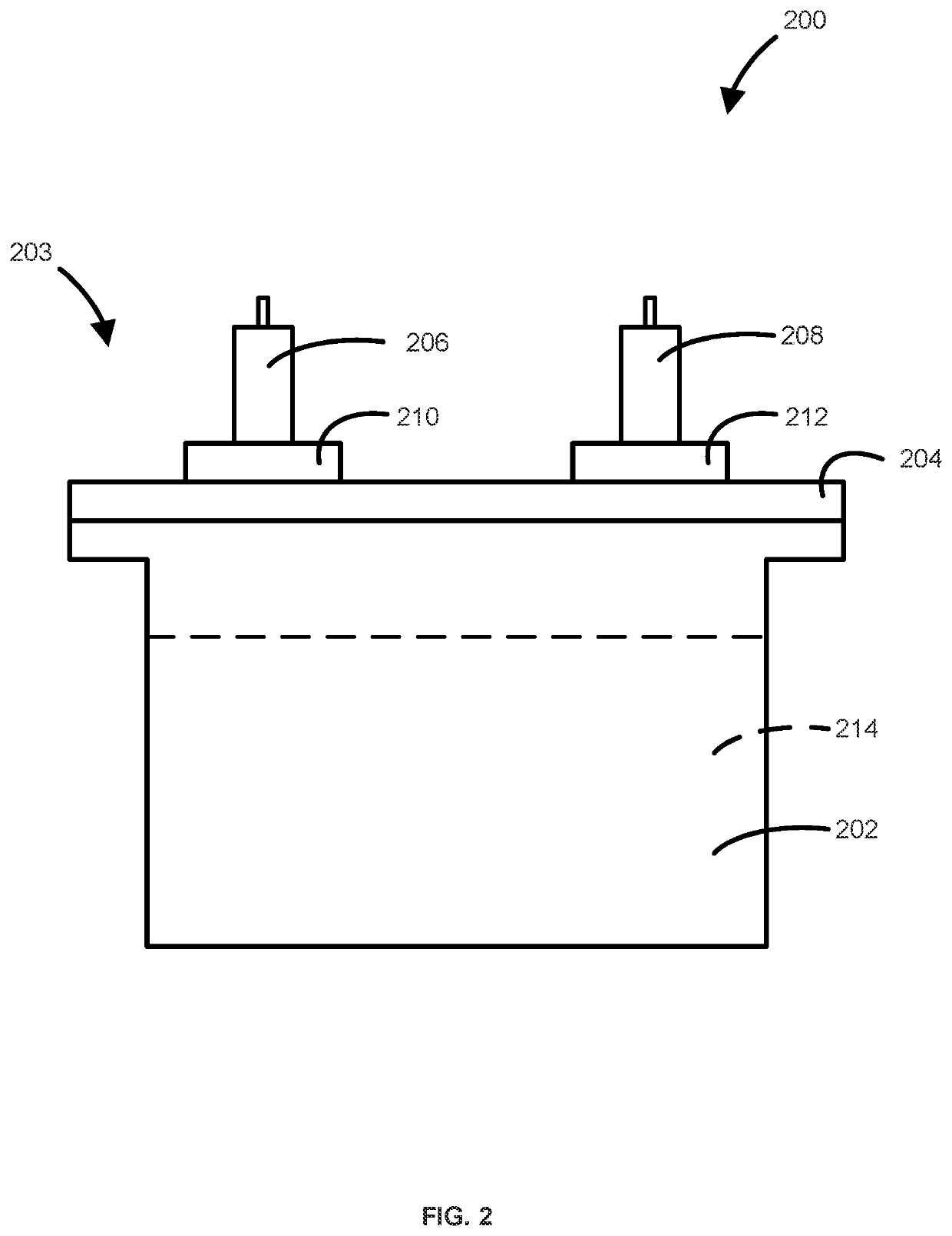

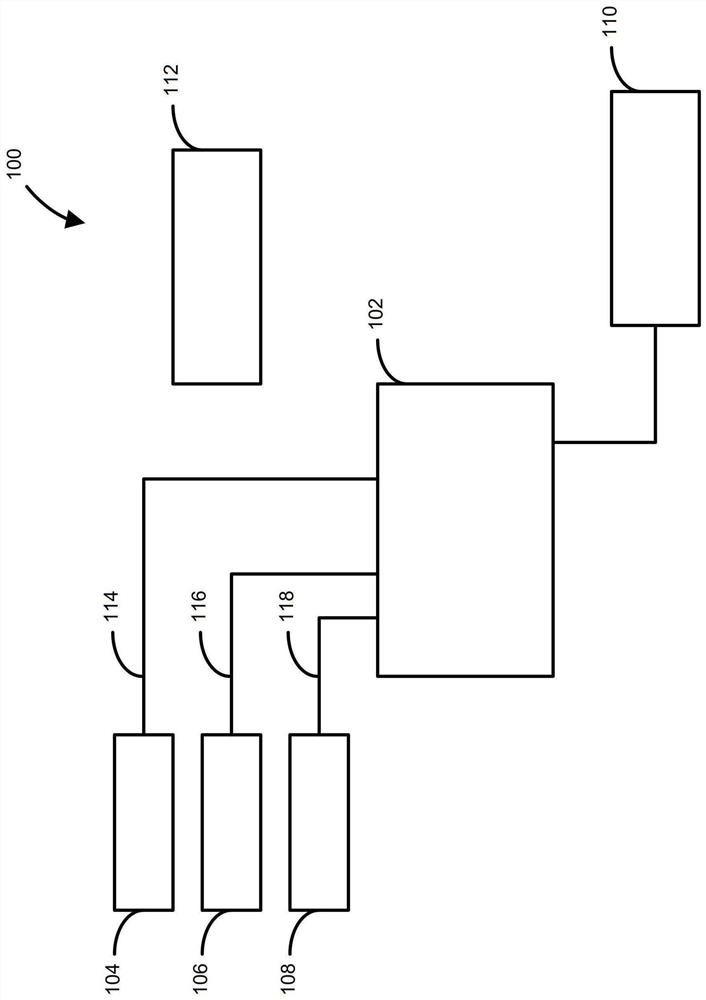

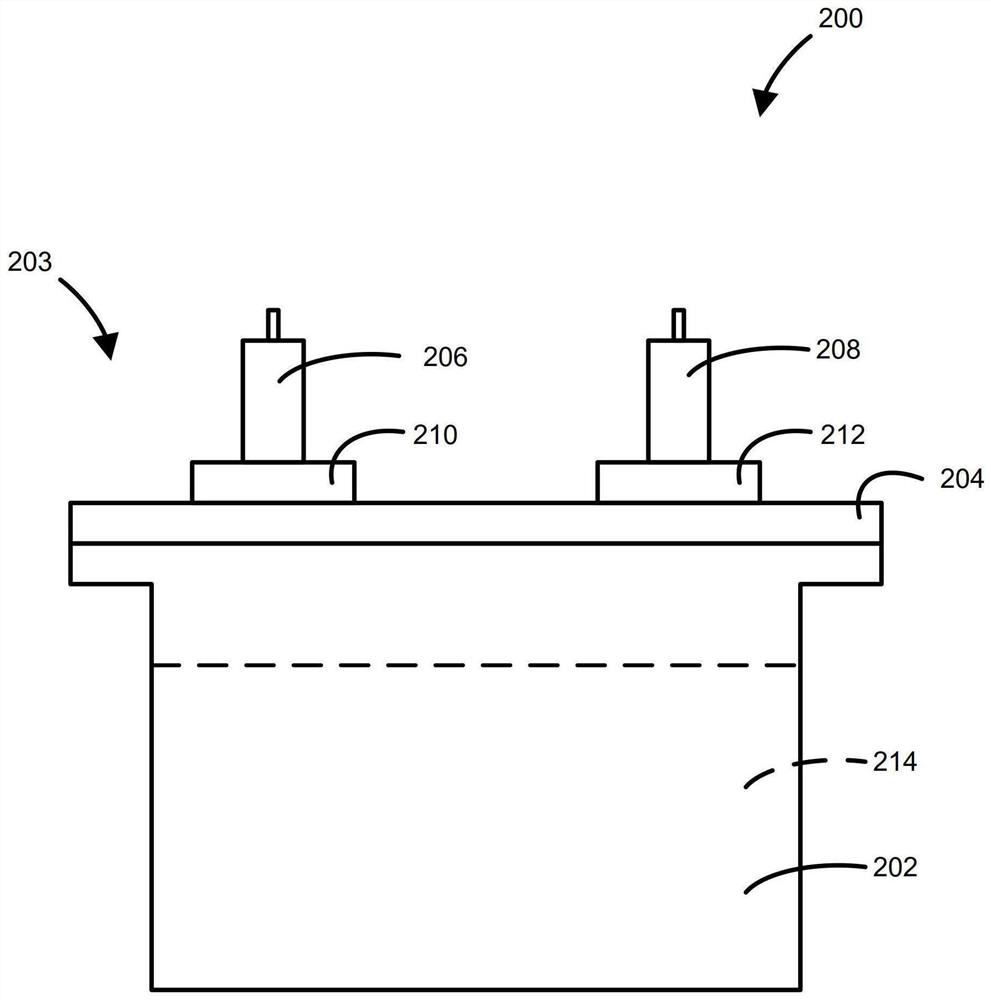

Methods and apparatus for stabilizing vanadium compounds

PendingUS20210331935A1Vacuum evaporation coatingSputtering coatingVanadium CompoundsCombinatorial chemistry

Methods of stabilizing a vanadium compound in a solution, compositions including a vanadium compound and a stabilizing agent, apparatus including the composition, systems that use the composition, and methods of using the compositions, apparatus, and systems are disclosed. Use of the stabilizing agent allows for use of desired precursors, while mitigating unwanted decomposition of the precursors.

Owner:ASM IP HLDG BV

Methods and apparatus for stabilizing vanadium compounds

PendingCN113549893AVacuum evaporation coatingSputtering coatingVanadium CompoundsCombinatorial chemistry

Methods of stabilizing a vanadium compound in a solution, compositions including a vanadium compound and a stabilizing agent, apparatus including the composition, systems that use the composition, and methods of using the compositions, apparatus, and systems are disclosed. Use of the stabilizing agent allows for use of desired precursors, while mitigating unwanted decomposition of the precursors.

Owner:エーエスエムアイピーホールディングベーフェー

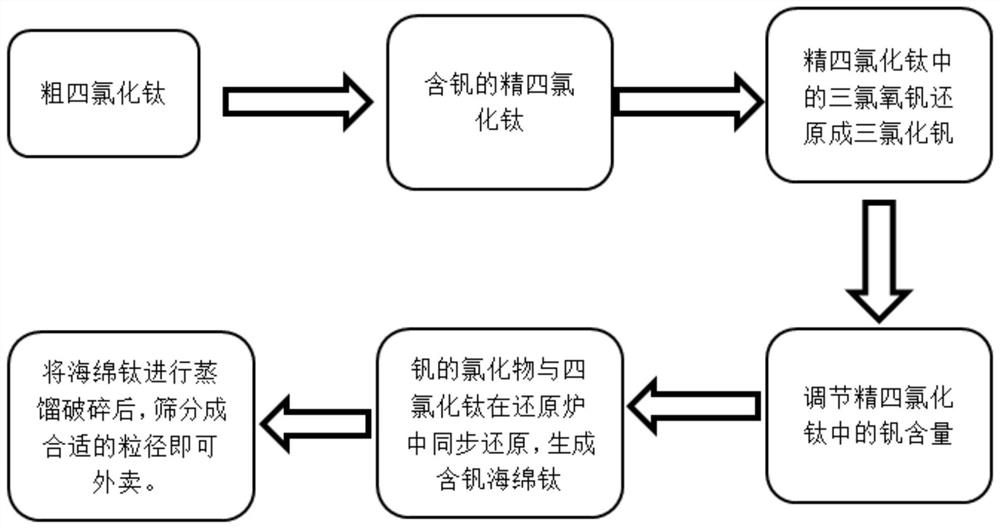

Method for recycling vanadium resources

PendingCN113737024AAchieve recyclingPrevent hardeningTitanium tetrachlorideProcess efficiency improvementRefining (metallurgy)Engineering

The invention discloses a method for recycling vanadium resources, and belongs to the technical field of metallurgy. The problems of long flow, high energy consumption and serious pollution in the traditional technology are solved. The method comprises the following steps that A, in the refining process of crude titanium tetrachloride, refined titanium tetrachloride is obtained without adding a vanadium removal agent; B, a reducing agent is added into the vanadium-containing refined titanium tetrachloride in the step A, so that vanadium oxytrichloride in the titanium tetrachloride is reduced into vanadium trichloride; C, the vanadium-containing solution obtained in the step B is subjected to sedimentation and solid-liquid separation; and D, the vanadium-containing solution obtained after solid-liquid separation in the step C is distilled, the concentration of titanium tetrachloride in the solution is adjusted according to production requirements, finally, a finished product is obtained, vanadium recycling is achieved, the recycling process is simplified, and energy consumption and pollution are reduced.

Owner:云南国钛金属股份有限公司

A kind of compound organic compound for high-efficiency vanadium removal of crude titanium tetrachloride and preparation method thereof

ActiveCN109956498BReduce initial additionLow cost of industrializationVanadium halidesCompound organicMetal chloride

The invention belongs to the field of refining titanium tetrachloride from organic matter, and specifically relates to a compound organic matter for the efficient removal of vanadium from crude titanium tetrachloride, including organic base oil, aromatic oil, silicone oil, graphene and metal chloride; the organic base oil , aromatic oil, silicone oil, graphene and metal chlorides in the following order: 40~70:2~10:10~30:5~10:2~10; the organic base oil is mixed white oil; The aromatic hydrocarbon oil is dimethylaniline; the silicone oil is dimethyl silicone oil; the graphene is copper-loaded graphene oxide; the metal chloride is zinc chloride; the present invention is easily cracked by catalysis, except The efficiency of vanadium is high, and the amount of organic matter used for vanadium removal is small.

Owner:BOHAI UNIV

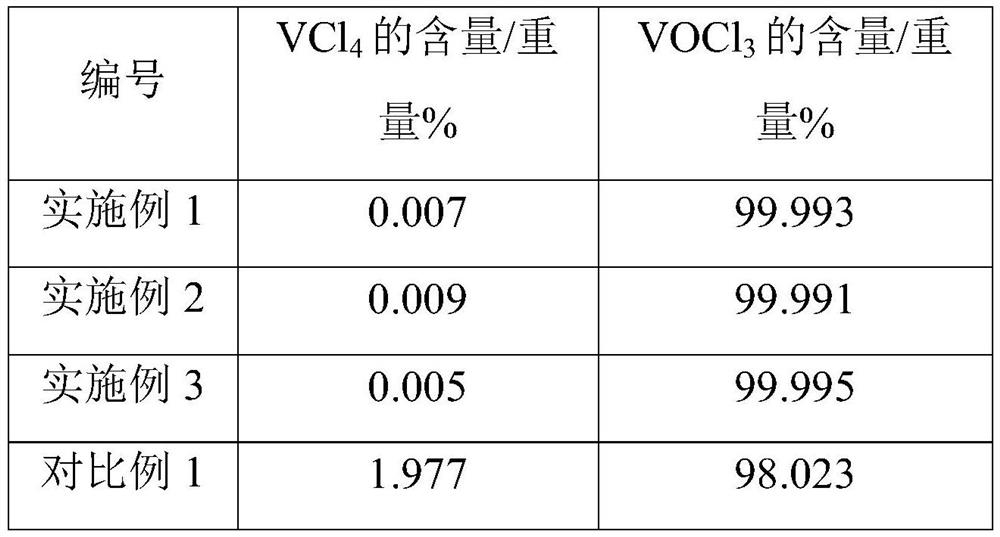

Method for purifying crude vanadium oxytrichloride

PendingCN114380332AAchieve purificationSimple and fast operationVanadium halidesVanadium atomVanadium oxytrichloride

The invention relates to the field of chemical metallurgy, and discloses a method for purifying crude vanadium oxytrichloride. The method comprises the following steps: (1) under the condition of reflux condensation, crude vanadium oxytrichloride is contacted with oxygen for reaction, the reaction temperature is 100-180 DEG C, the reaction time is 2-5 hours, and the temperature of a condensing medium for reflux condensation is-5 to-20 DEG C; and (2) distilling the material obtained in the step (1), and collecting a liquid product obtained by condensation. The method has the advantages that the effect of removing VCl4 from the crude vanadium oxytrichloride is good, the effect of purifying the crude vanadium oxytrichloride is good, the operation is simple and convenient, the process conditions are mild, and the purity of the obtained vanadium oxytrichloride product is high.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com