Refractory materials, method for production thereof and refraratory using the material

A technology of refractory materials and manufacturing methods, applied in the field of refractory material raw materials and refractory material composition, can solve problems such as no enlightenment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

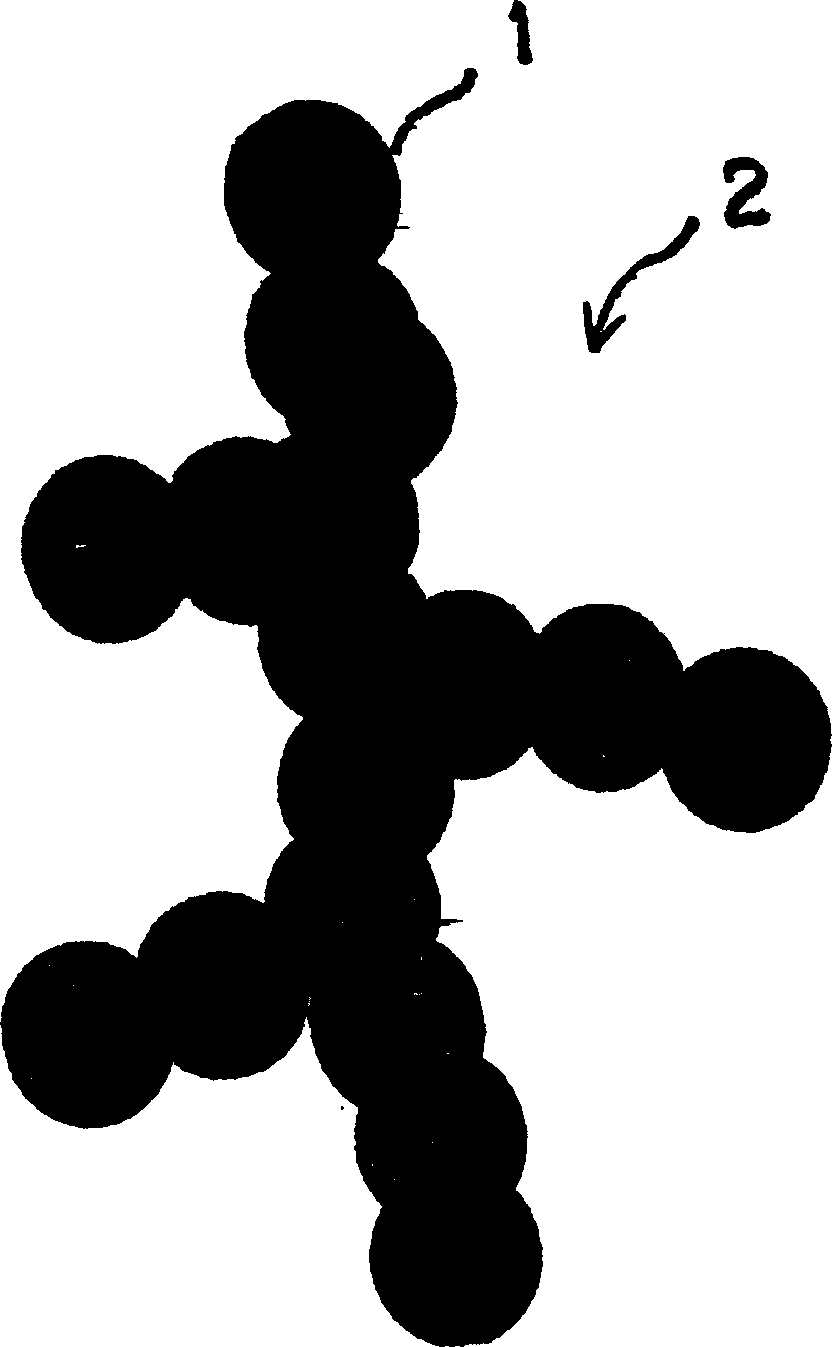

[0123] Synthesis of graphite particle A (carbon particle b)

[0124] As a carbon black raw material, "Nitron #10 modification" manufactured by Nichika Carbon Co., Ltd. was used. This carbon black is a kind of carbon black belonging to Fa-st · Extor-Ding furnace black (FEF), and its average primary particle diameter is 41nm, and DBP absorption (x) is 126ml / 100g, and the DBP absorption of compressed sample ( y) is 89ml / 100g, which is the carbon particle a used in this example. It was heat-treated at 2100° C. for 3 hours in a carbon furnace (manufactured by Fuji Denpa Industries, Ltd., FVS-200 / 200 / 200, FRET-50) under an argon gas atmosphere to make it graphitized to obtain graphite particles A ( carbon particles b). The obtained particles were subjected to X-ray diffraction measurement, a peak derived from the graphite structure was observed, and it was judged that graphite particles were generated. The lattice spacing calculated from the diffraction lines corresponding to the...

Synthetic example 2

[0126] Synthesis of graphite particle B (carbon particle e)

[0127] Graphite particle B (carbon particle e) was synthesized as in Synthesis Example 1 except that the raw material carbon black used was changed. As the raw material carbon black, "HTC#20" manufactured by Nichika Carbon Co., Ltd. was used as the carbon black raw material. The carbon black is a so-called thermal black (FT) carbon black, its average primary particle size is 82nm, the DBP absorption (x) is 29ml / 100g, and the DBP absorption (y) of the compressed sample is 30ml / 100g , is the carbon particle d used in this example. The obtained particles were subjected to X-ray diffraction measurement, a peak derived from the graphite structure was observed, and it was judged that graphite particles were generated. The lattice spacing calculated from the diffraction lines corresponding to the 002 plane spacing of graphite was 3.42 Å. The particles had an average primary particle diameter of 70 nm, a DBP absorption (...

Synthetic example 3

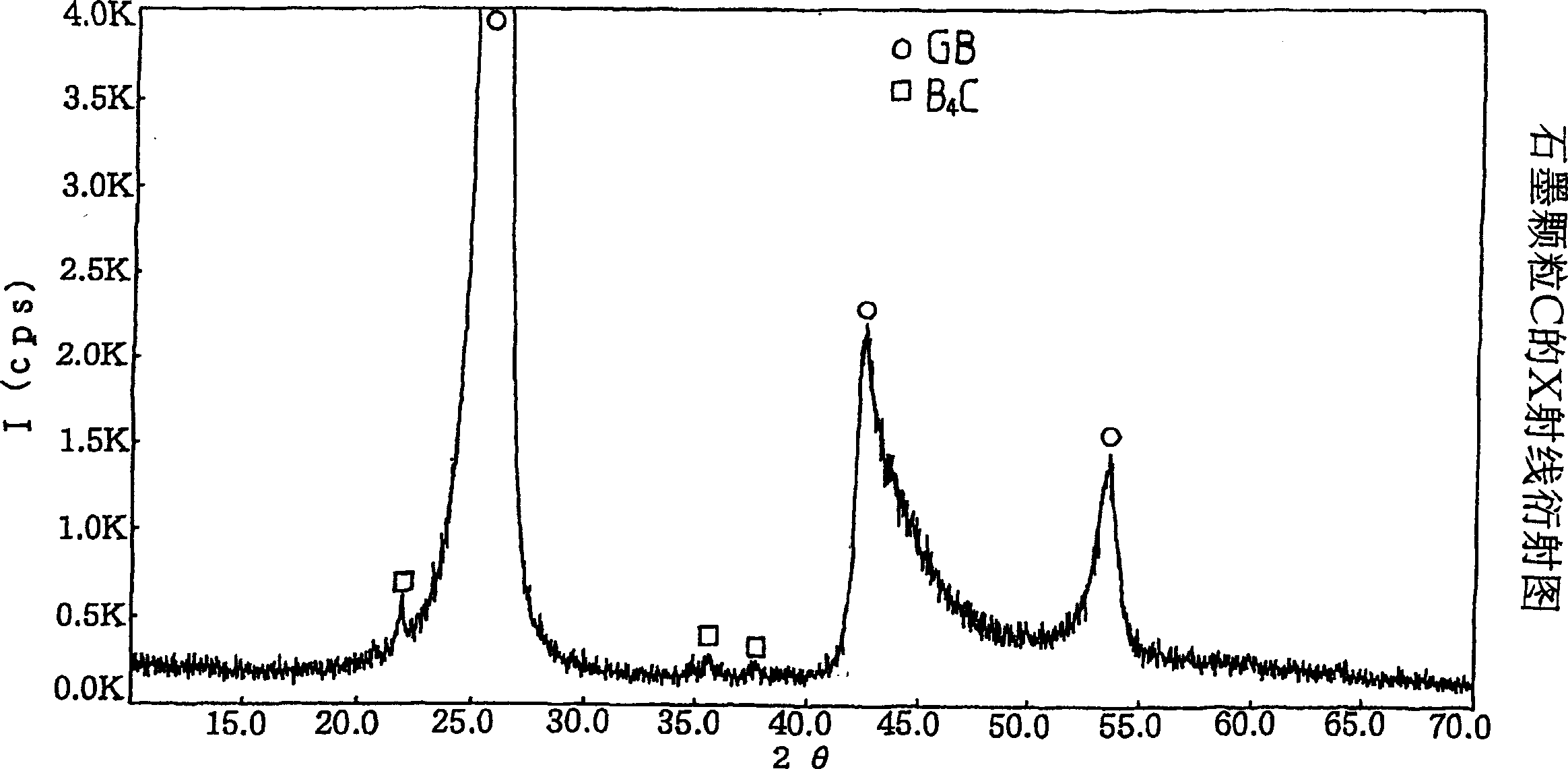

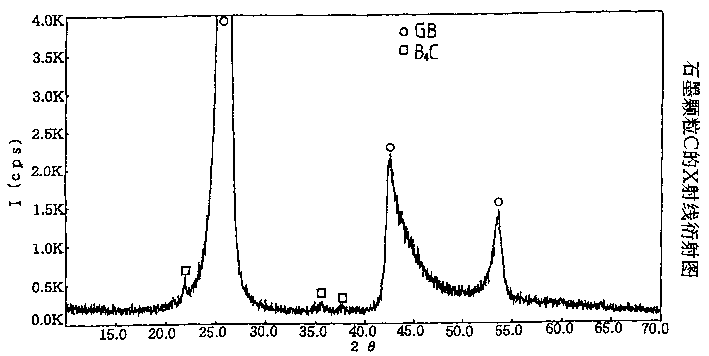

[0129] Synthesis of graphite particles C (carbon particles c)

[0130] Mix carbon black "Nitelon #10 modified" and boron powder, so that the molar ratio of carbon and boron is 10:4, put into a crucible made of silicon dioxide, put a graphite film on the crucible, and its two ends are connected to electrodes. The electrode is energized to generate heat from the graphite film, and the above-mentioned mixture is ignited, and graphite particles C (carbon particles c) are obtained by self-combustion synthesis using the reaction heat when carbides are formed. The obtained particles were subjected to X-ray diffraction measurement, a peak derived from the graphite structure was observed, and it was judged that graphite particles were generated. The lattice spacing calculated from the diffraction lines corresponding to the 002 plane spacing of graphite was 3.38 Å. Acknowledgment from B 4 The 2θ=37.8° peak of the 021 diffraction line of C. The X-ray diffraction pattern is shown in f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com