Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about "Soap solutions manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

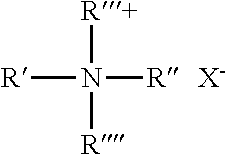

Controlled delivery system for fabric care products

InactiveUS7119060B2Improve impact performanceIncrease depositionCationic surface-active compoundsOrganic detergent compounding agentsControl releaseMedicine

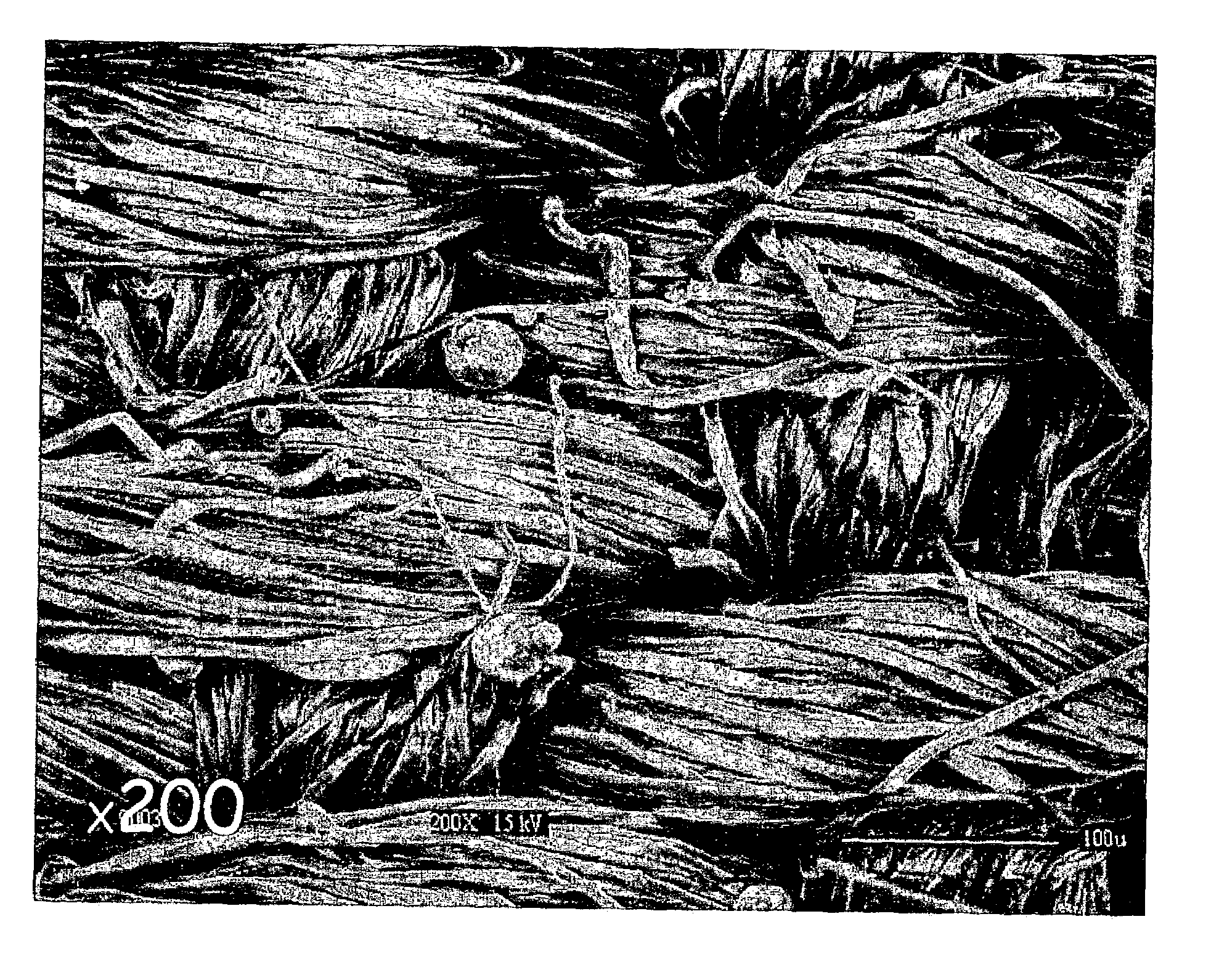

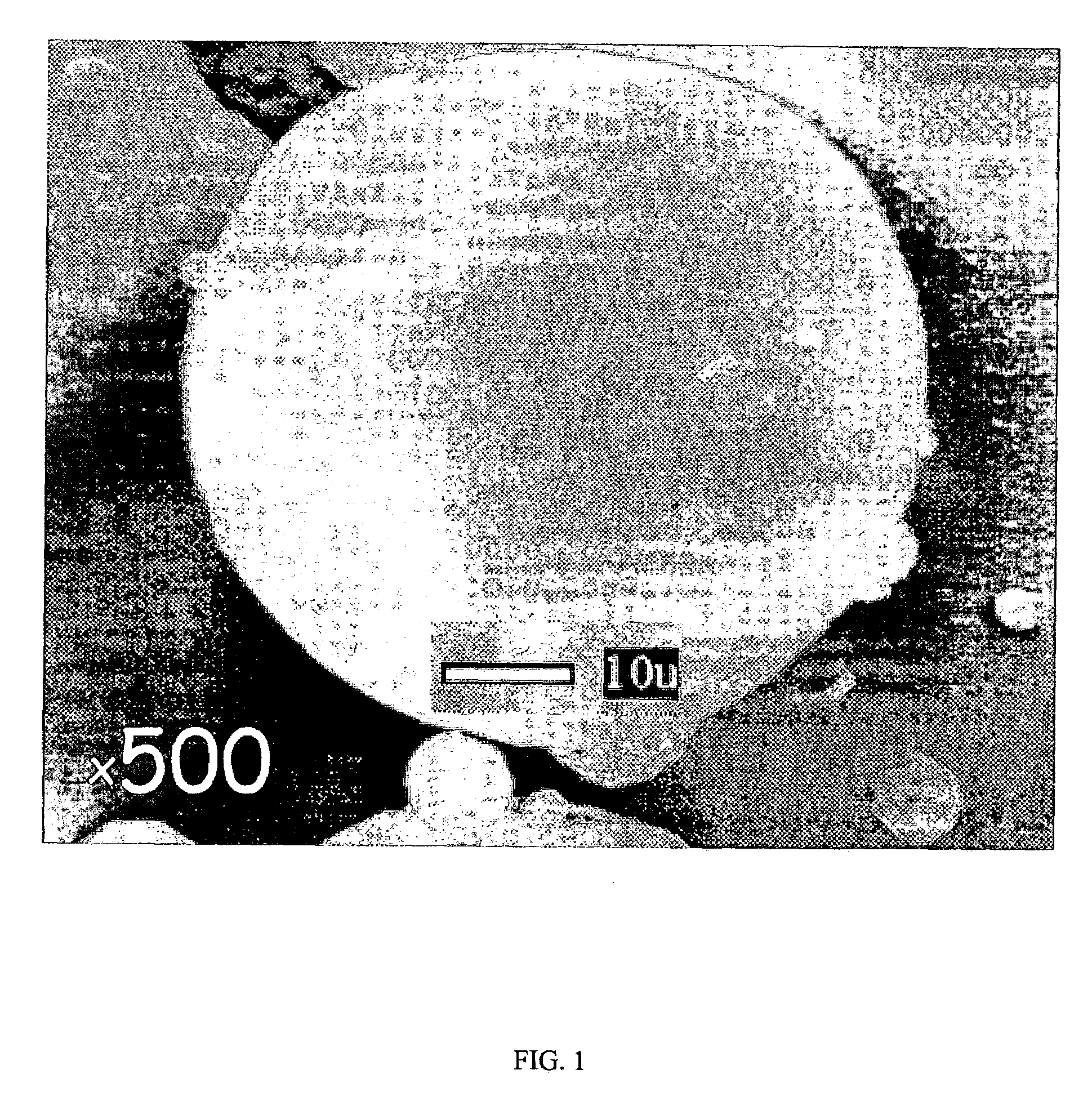

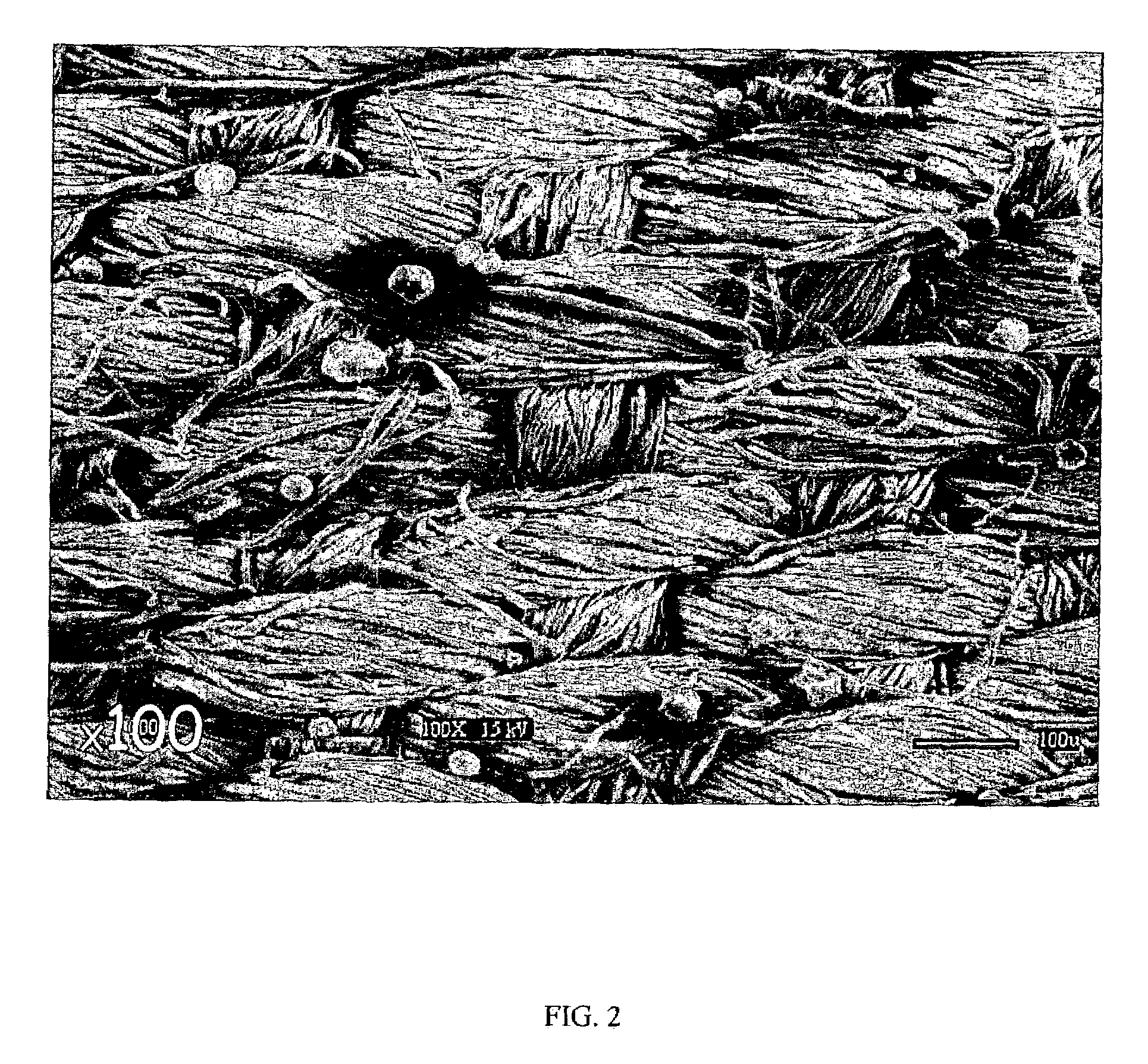

The present invention relates to a controlled delivery system that can be incorporated in liquid, as well as, dry granular, or powder, fabric care products, such as fabric softeners, laundry detergents, rinse added products, and other fabric care products, to enhance fragrance performance. The controlled delivery system of the present invention is a solid, substantially spherical particle comprising hydrophobic cationic charge enhancing agents in conjunction with cationic fabric softening agents that assist in adhering the particles onto fabric. The particles can also include a fragrance. The particle can have an average particle diameter of from about 1 micron to about 500 microns. The controlled delivery system of the present invention can be utilized to deliver a broad range of fragrance ingredients onto fabric and prolong fragrance release from the dry laundered fabric over an extended period of time, or yield a high impact fragrance “burst” upon ironing the fabric. The invention also pertains to fabric care products comprising the controlled release system of the present invention.

Owner:SALVONA

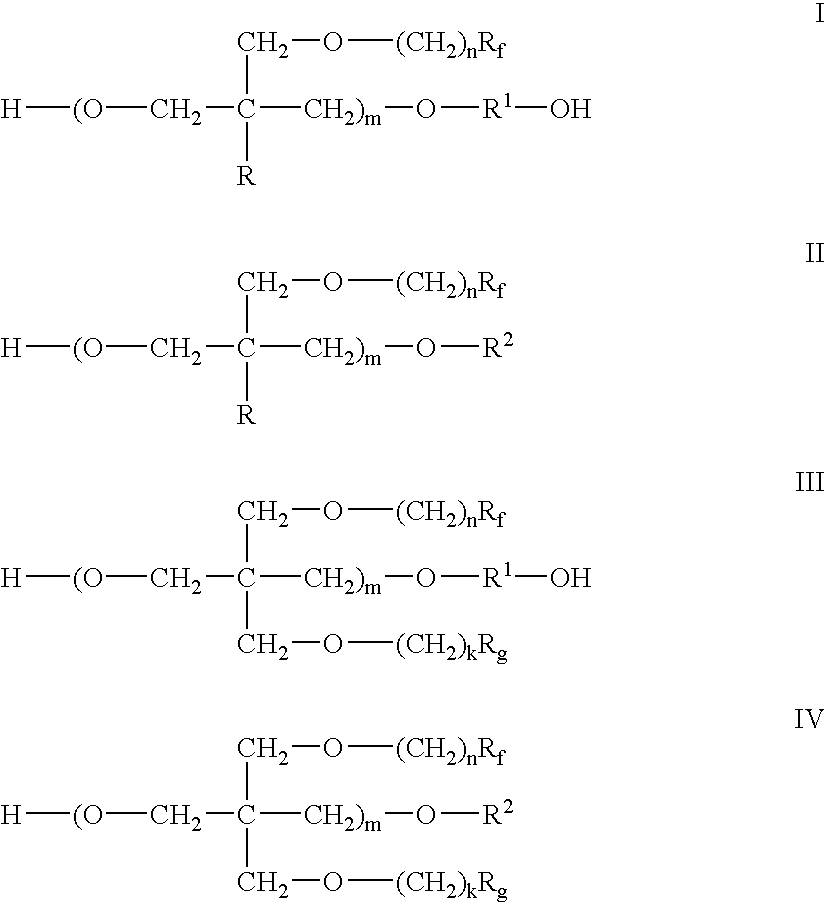

Chemical synthesis using solvent microdroplets

InactiveUS6419883B1Material nanotechnologySequential/parallel process reactionsChemical synthesisChemical species

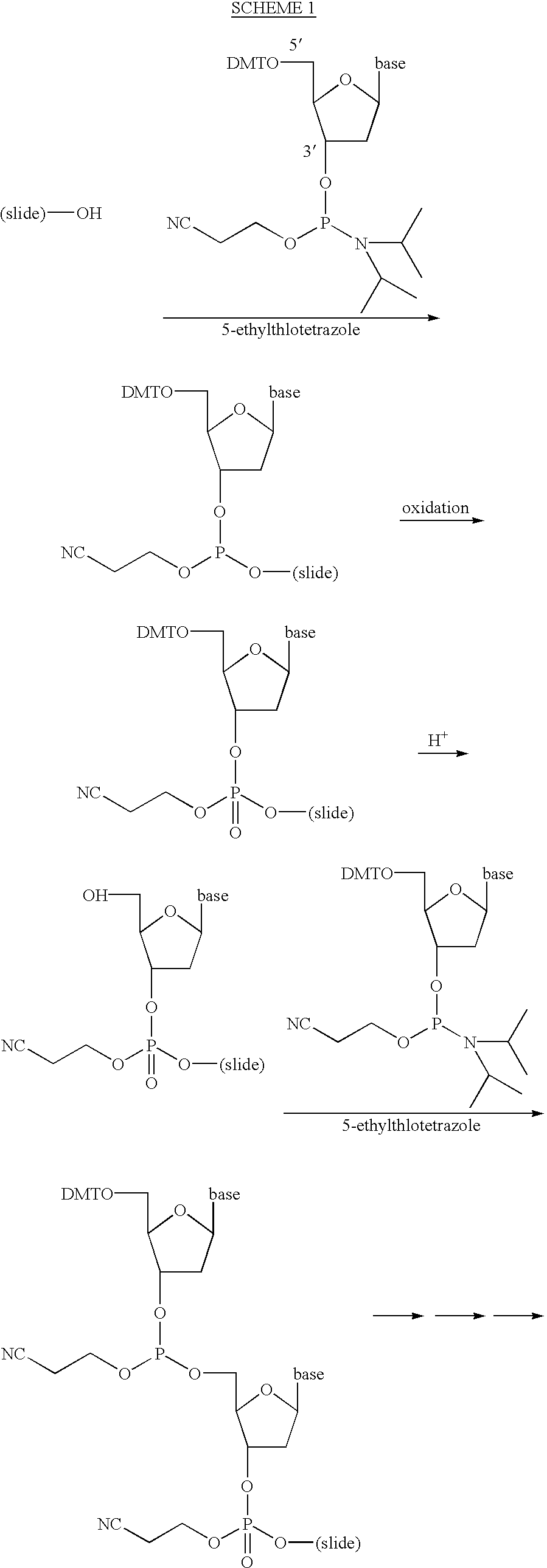

The present invention relates to microdroplets of a solution comprising a solvent having a boiling point of 150° C. or above, a surface tension of 30 dynes / cm or above, and a viscosity of 0.015 g / (cm)(sec). Such microdroplets are useful for the synthesis of chemical species, particularly biopolymers such as oligonucleotides and peptides, as well as arrays of chemical species. Preferably, the solvent has the formula (I):whereinA=O or S;X=O, S or N (C1-C4 alkyl)Y=O, S, N(C1-C4 alkyl) or CH2; andR=C1-C20 straight or branched chain alkyl.

Owner:UNIV OF WASHINGTON

Soaps produced from oil-bearing microbial biomass and oils

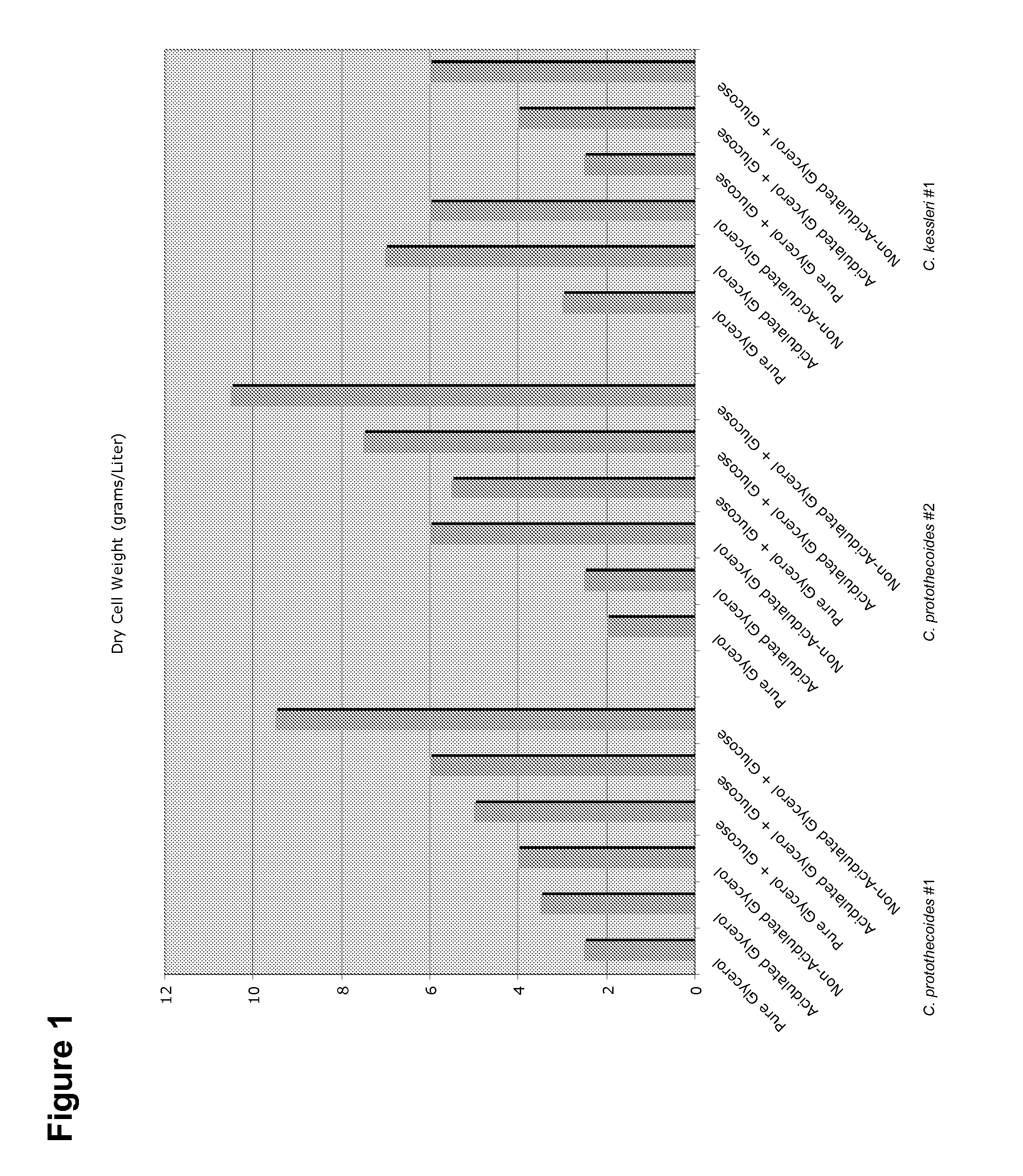

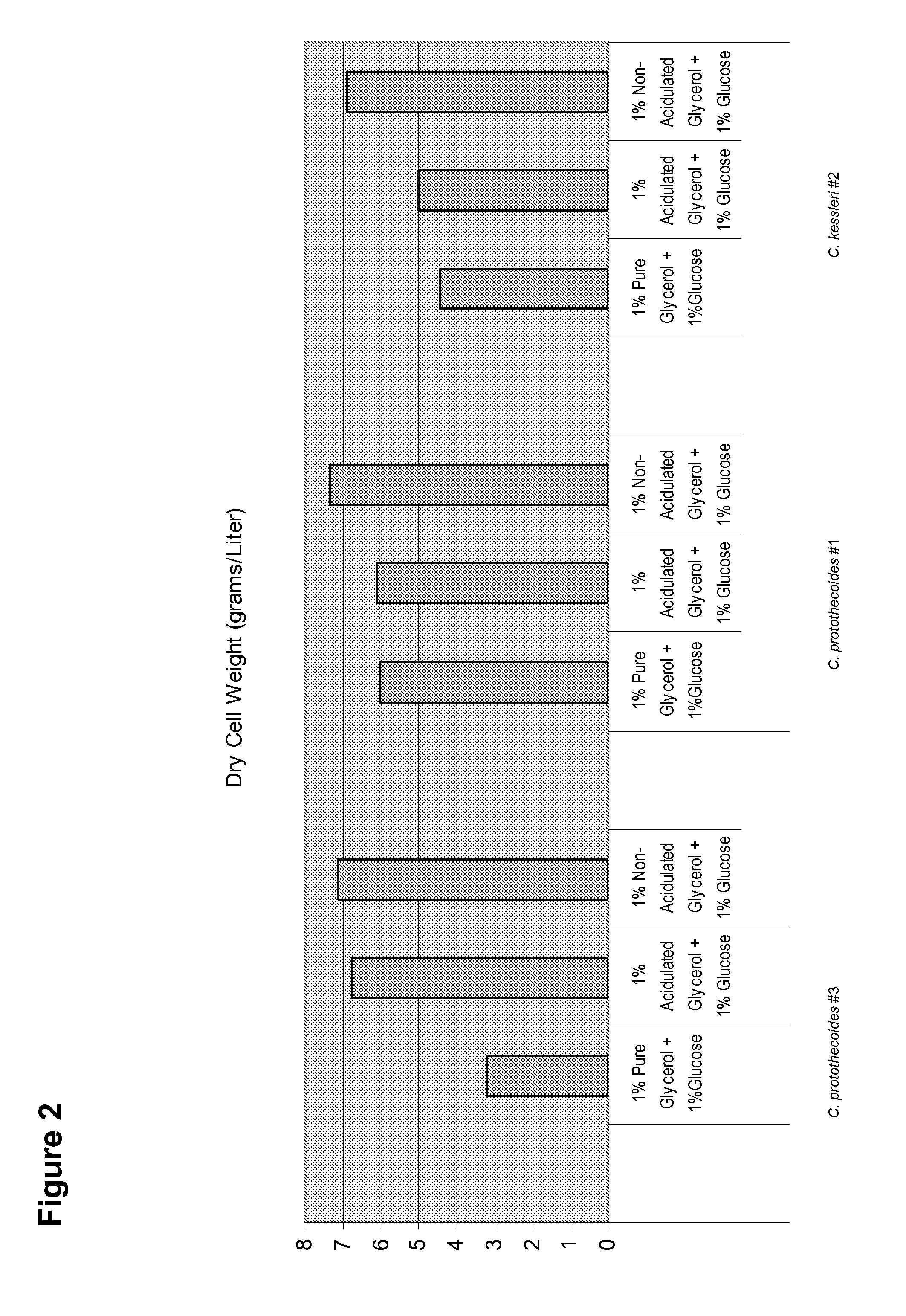

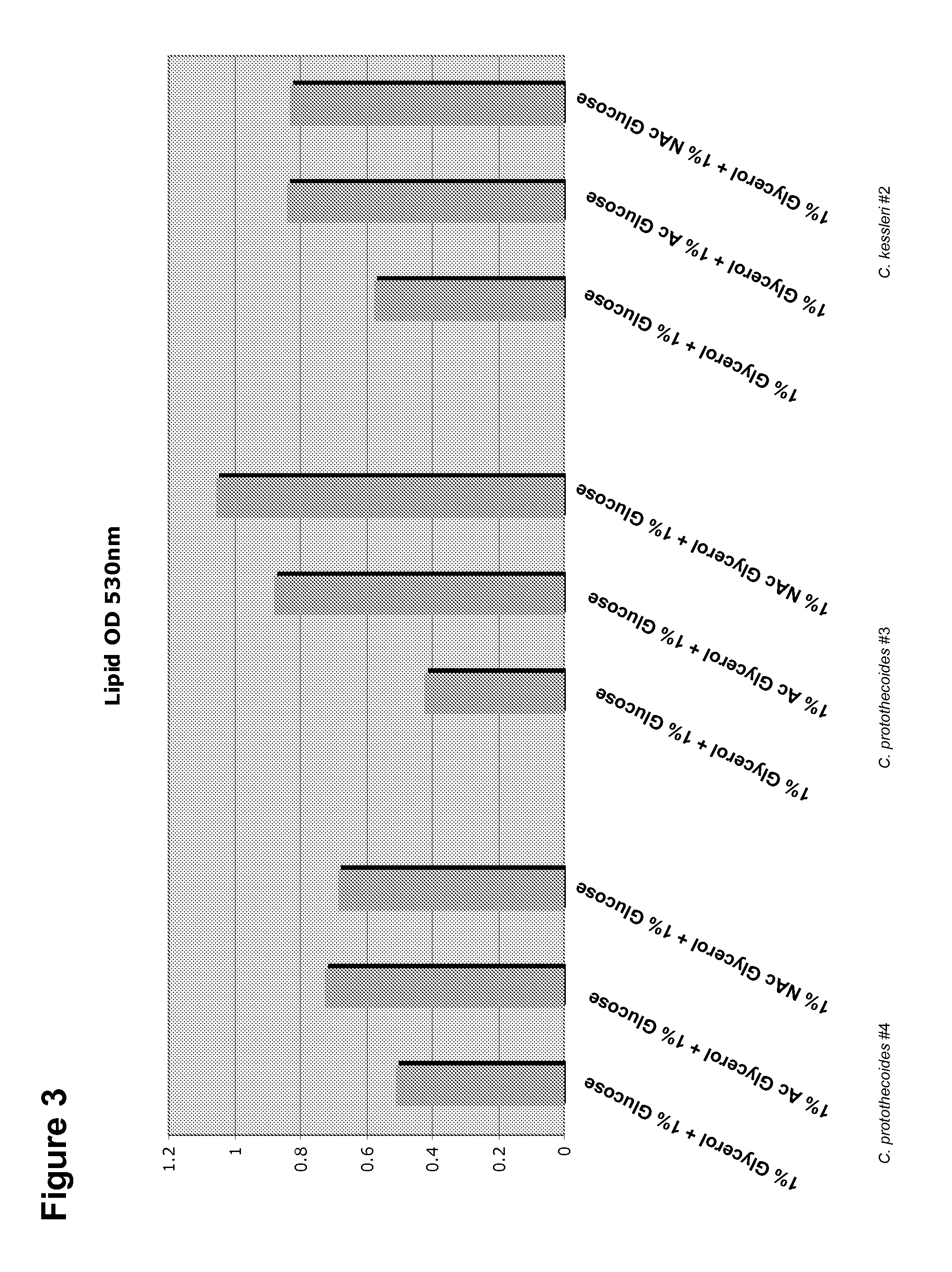

ActiveUS8119583B2Low costImprove efficiencySoap detergents with organic compounding agentsCosmetic preparationsMicrobial oilGlycerol

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

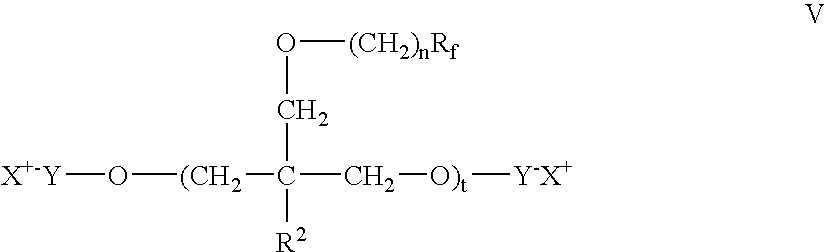

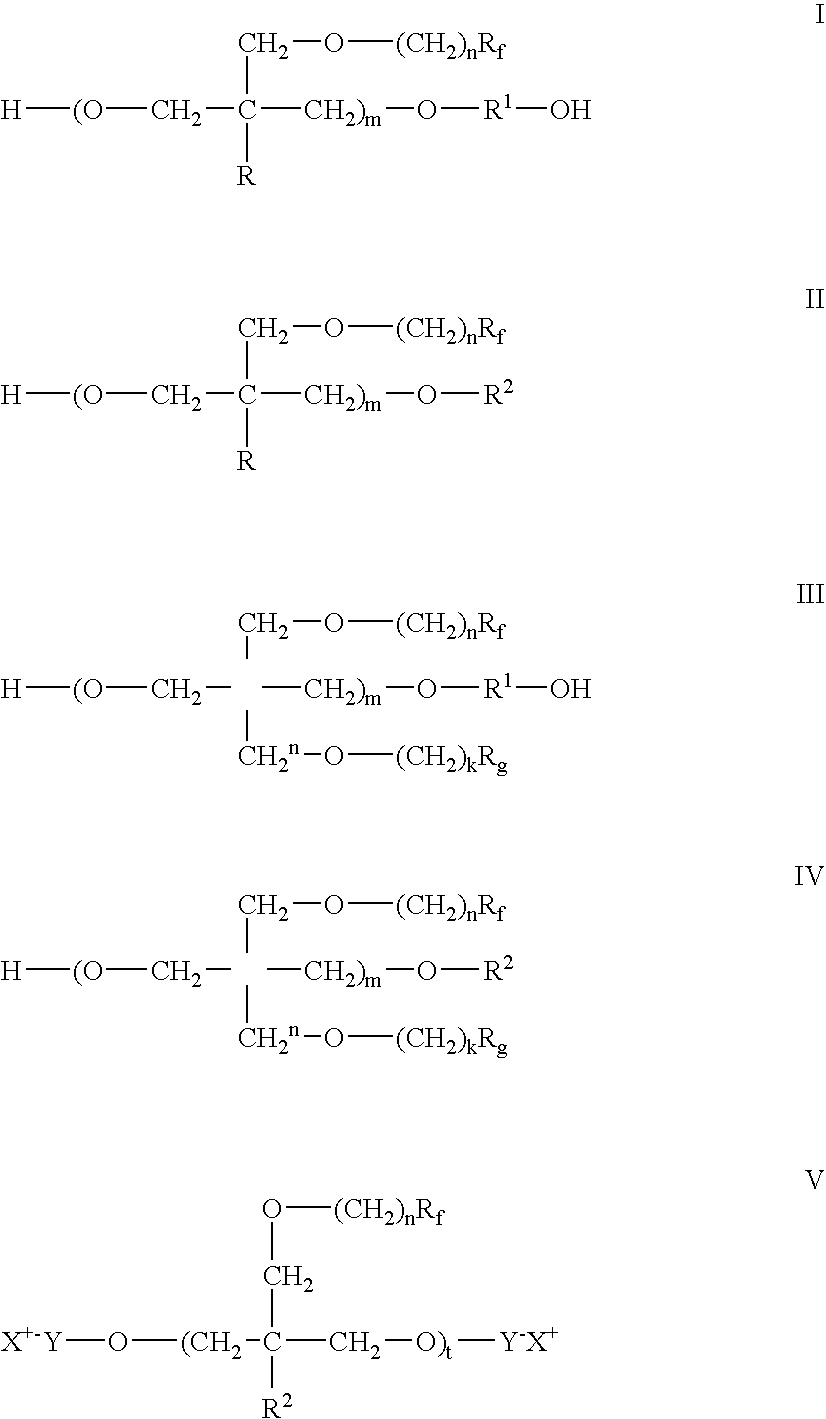

Polymer-fluorosurfactant associative complexes

ActiveUS7288514B2Improve protectionIncrease resistanceSoap detergents with organic compounding agentsOrganic detergent compounding agentsWater dispersibleWater soluble

The present invention relates to associative complexes of water soluble and / or water dispersible polymers and polymeric fluorosurfactants, compositions and methods for modifying substrates to provide treated articles with surface protective properties including easier cleaning, increased stain and / or soil repellency, and increased resistance to bio-fouling and environmental contamination.

Owner:THE CLOROX CO

Water soluble abrasive composition containing borax pentahydrate

InactiveUS6037316ASuitable for processingFine granularityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsHard-surface cleanerWater soluble

The invention provides an improved surface safe, aqueous, liquid hard surface cleaner which contains a nonionic surfactant, or combination of nonionic and anionic surfactants, a water soluble abrasive, namely, borax pentahydrate, in an amount which takes at least a portion of the abrasive out of solution, and water.

Owner:THE CLOROX CO

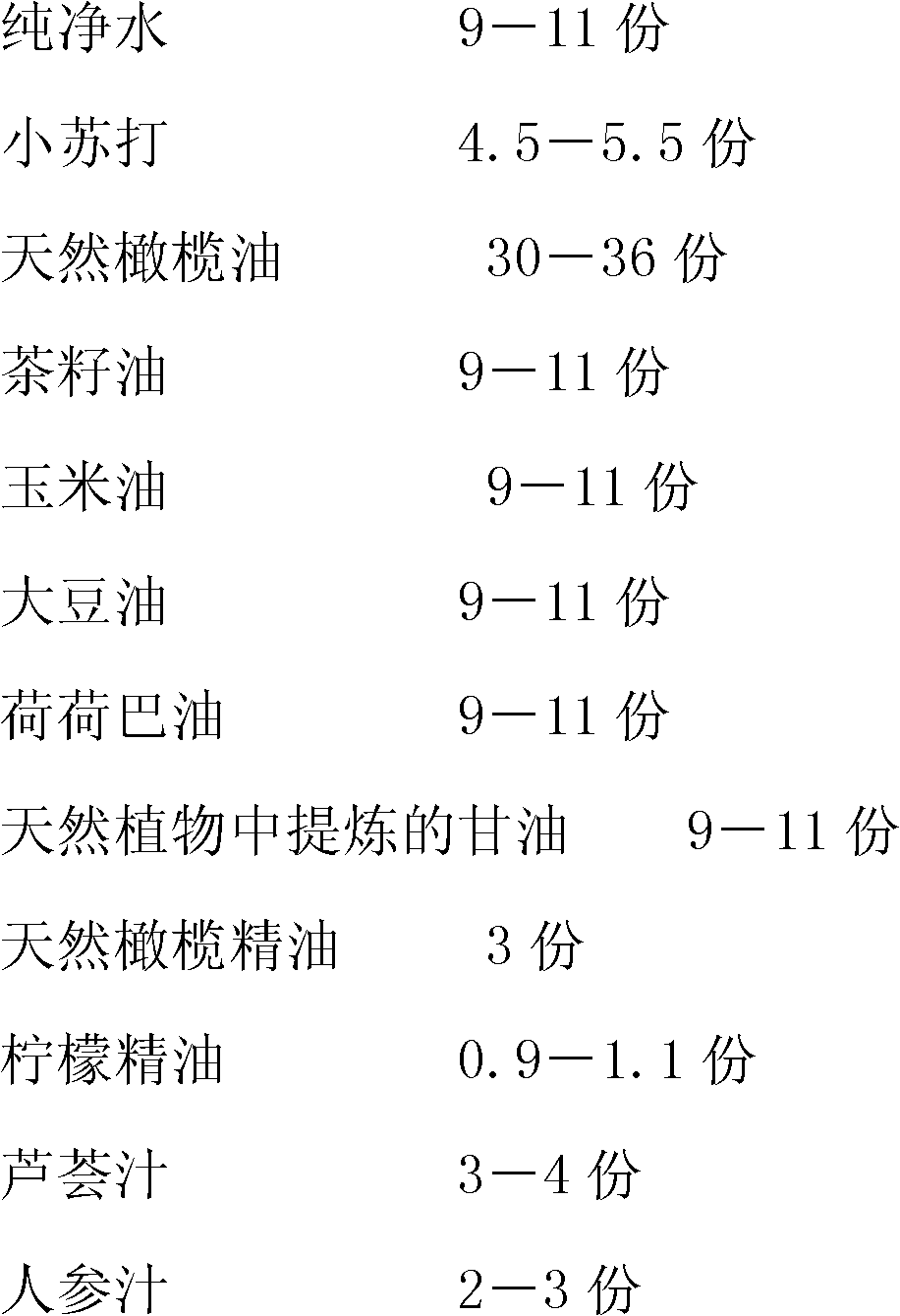

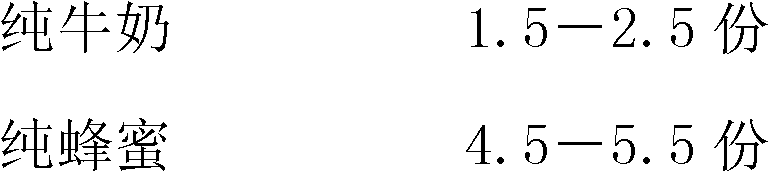

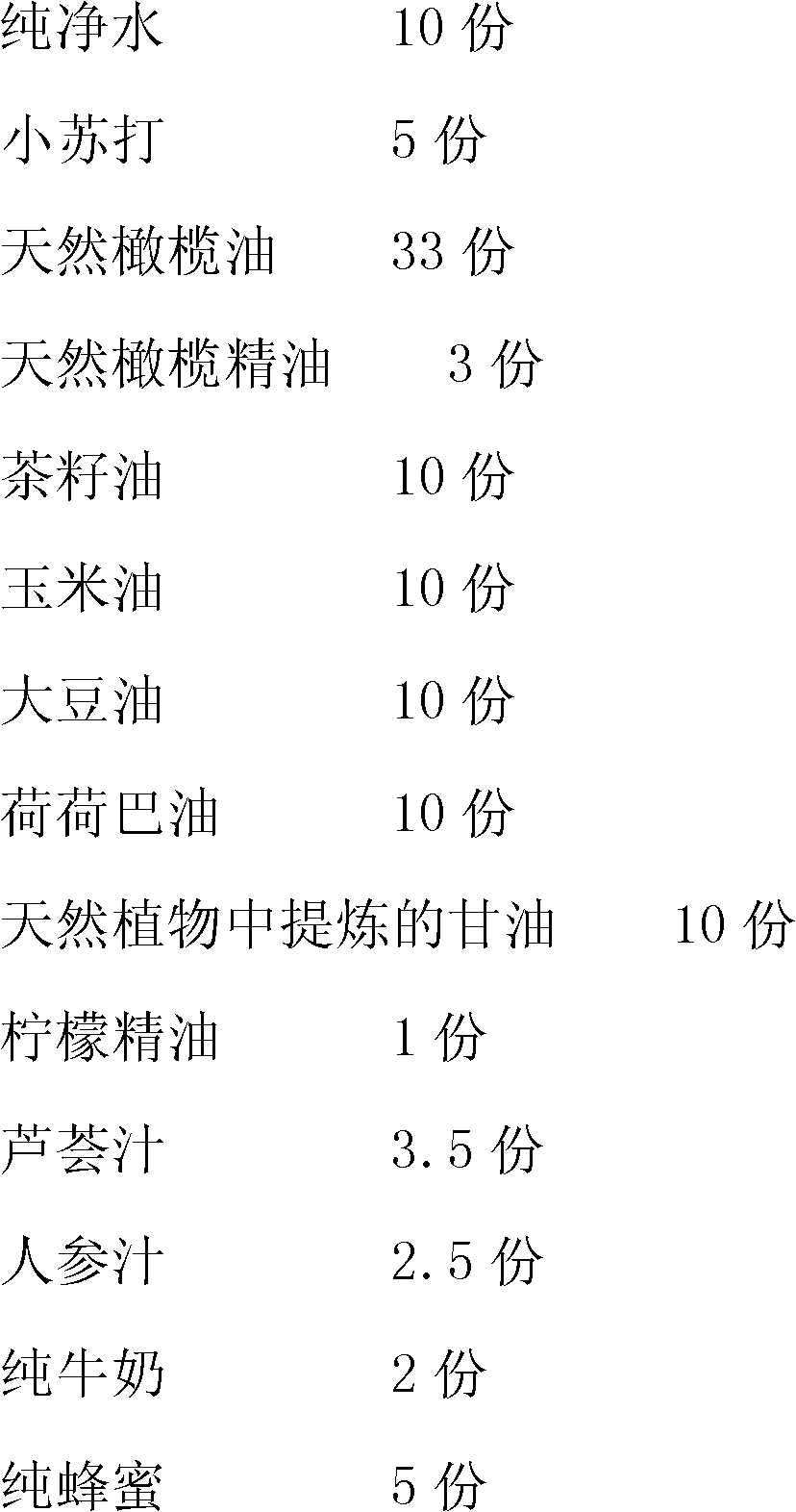

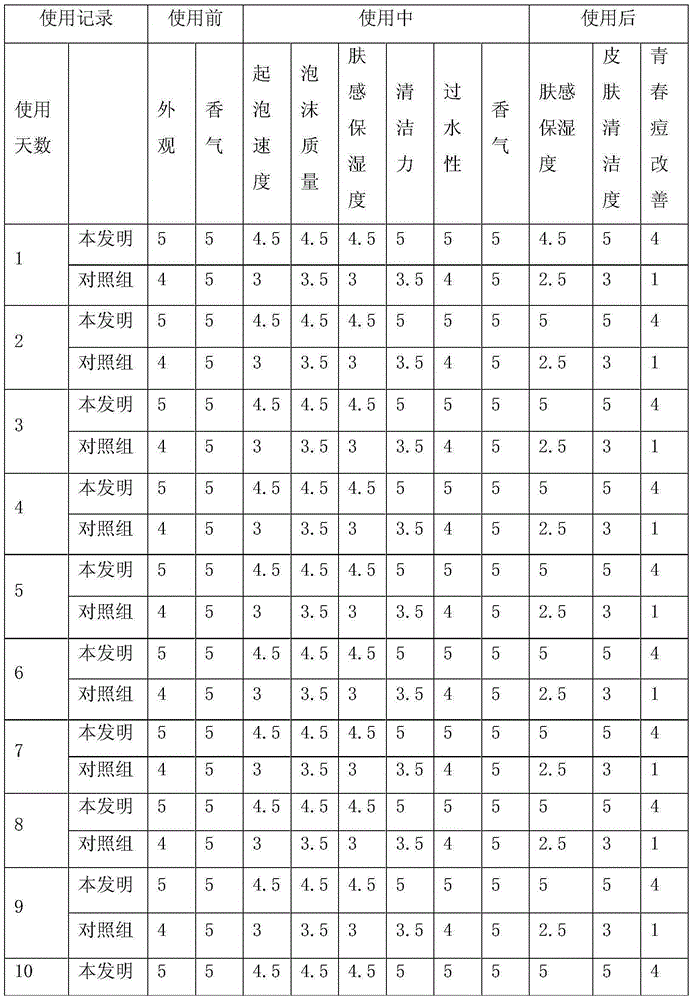

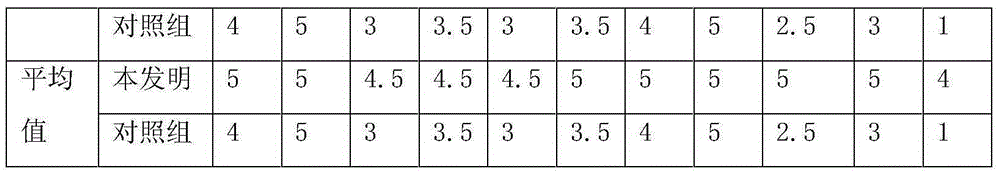

Pure natural plant perfumed soap and preparation method thereof

InactiveCN102329702ATo promote metabolismFormed earlySoap detergents with organic compounding agentsAlkali/ammonium soap compositionsPremature agingWrinkle skin

The invention relates to pure natural plant perfumed soap. The pure natural plant perfumed soap is prepared from the following raw materials in parts by mass: 9-11 parts of purified water, 4.5-5.5 parts of baking soda, 30-36 parts of natural olive oil, 9-11 parts of tea seed oil, 9-11 parts of corn oil, 9-11 parts of soybean oil, 3 parts of Jojo natural olive essential oil, 9-11 parts of Jojoba oil, 9-11 parts of glycerin extracted from natural plants, 0.9-1.1 parts of lemon essential oil, 3-4 parts of aloe juice, 2-3 parts of ginseng juice, 1.5-2.5 parts of pure milk and 4.5-5.5 parts of pure honey. The pure natural plant perfumed soap provided by the invention has the beneficial effects that the pure natural plant perfumed soap has certain bacteriostatic action, and can significantly improve whelk and dermatitis; multiple natural nutriments in camellia oil and Jojoba oil can provide sufficient nutrients and water for skin, thus skin is moisturized and has luster and good elasticity;and after bath, perfume is maintained on skin, skin metabolism can be accelerated, the formation of wrinkle and cell premature aging can be effectively prevented and stoped, and youth and luster can be restored, thereby achieving the effects of nourishing and whitening skin.

Owner:HANGZHOU NORMAL UNIVERSITY

Natural Cleaning Compositions

ActiveUS20090023620A1Non-ionic surface-active compoundsOrganic detergent compounding agentsColloidal silicaGlycerol

A cleaning composition with a limited number of natural ingredients contains alkyl polyglucoside, solvent and colloidal silica. The cleaning composition optionally has an additional amount of glycerol. The cleaning composition optionally has a small amount of fragrance. The cleaning composition can be used to clean hard surfaces and cleans as well or better than commercial compositions containing synthetically derived cleaning agents.

Owner:THE CLOROX CO

Stable hydroalcoholic compositions

Disclosed is a composition including a lower alcohol and water in a weight ratio of about 35:65 to 100:0, between at least 0.5% and 8.0% by weight thickener system comprised of at least two emulsifiers, each emulsifier present in at least 0.05% by weight wherein the composition free of auxiliary thickeners has a viscosity of at least 4,000 centipoise at 23 degrees C. and wherein each emulsifier is comprised of at least one hydrophobic group and at least one hydrophilic group. The composition is useful as a presurgical scrub replacement, a lotion or other hand preparation.

Owner:3M INNOVATIVE PROPERTIES CO

Bleach-containing washing or cleaning agents

InactiveUS20050239681A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphateBleach

A particulate washing or cleaning composition containing (A) a phosphate-free water-soluble builder component and (B) alkali metal percarbonate particles having a coating containing alkali metal silicate.

Owner:HENKEL KGAA

Technology for ultrasonically producing cold soap

InactiveCN102994280AShort reaction timeLow production costSoap detergents with other compounding agentsAlkali/ammonium soap compositionsEngineeringSOAP

Owner:吴妙娴 +1

Essential oil soap and preparation method thereof

InactiveCN102002450AAvoid harmSoap solutions manufacturingSoap detergent compositionsNatural productPulp and paper industry

The invention belongs to the field of washing products, and in particular relates to a soap and a preparation method thereof. The soap has the main technical characteristic that: the soap is prepared from the following main raw materials by weight: 250g of grease, 50g of water, 30g of NaOH and 10g of essential oil. The preparation method comprises the following steps of: 1) stirring the water and the NaOH until the NaOH is completely dissolved, and cooling to the temperature of between 40 and 50 DEG C; 2) slowly adding the grease into the NaOH solution until the grease is completely mixed with the NaOH solution; 3) adding the essential oil and uniformly stirring; 4) pouring into a die and standing for 24 to 48 hours; and 5) demoulding after soap liquid is cured, putting in a shady and ventilated place for 4 to 8 weeks. The essential oil soap prepared by the method can have different effects according to the type of the added essential oil, and is beneficial to the skin and body of a human; and the soap is a purely natural product, so the soap is harmless to the human body.

Owner:韩萍萍

Red wine soap and preparation method thereof

InactiveCN102433228AAnti agingHas deep antioxidantSoap solutions manufacturingSoap detergent compositionsGrape seedPotassium

The invention discloses a red wine soap, which is mainly prepared from the following raw materials in part by mass: 40 to 60 parts of red wine, 230 to 270 parts of edible oil, 40 to 60 parts of vegetable nursing oil, 80 to 120 parts of purified water, 40 to 60 parts of honey, 800 to 1,200 parts of transparent soap base, and 0.05 to 0.15 part of grape seed essential oil. The red wine soap is rich in grape polyphenol, has the effects on deep oxidation resistance, whitening and moisturizing, achieves the effect of delaying skin aging at the same time of cleaning the skin, and is a good natural skin-care cosmetic; and the dry red wine contains multiple vitamins such as VE, VB, VB2 and the like and multiple mineral matters such as calcium, magnesium, iron, potassium, sodium and the like, wherein the combined effect of the mineral matters and multiple trace elements is superior to that of the best mineral water.

Owner:北京华建德旺物资中心

Handmade soap composition, handmade soap and preparation method thereof

InactiveCN103045419AThe effect is dryNo tightnessDetergent materialsSkin careVegetable oilAdditive ingredient

Owner:CANTON DAMEKISS DAILY CHEM FACTORY LIMITED

Natural cleaning compositions

ActiveUS7521413B2Inorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsColloidal silicaGlycerol

A cleaning composition with a limited number of natural ingredients contains alkyl polyglucoside, solvent and colloidal silica. The cleaning composition optionally has an additional amount of glycerol. The cleaning composition optionally has a small amount of fragrance. The cleaning composition can be used to clean hard surfaces and cleans as well or better than commercial compositions containing synthetically derived cleaning agents.

Owner:THE CLOROX CO

Stable hydroalcoholic compositions

Disclosed is a composition including a lower alcohol and water in a weight ratio of about 35:65 to 100:0, between at least 0.5% and 8.0% by weight thickener system comprised of at least two emulsifiers, each emulsifier present in at least 0.05% by weight and wherein each emulsifier is comprised of at least one hydrophobic group and at least one hydrophilic group. The composition is useful as a presurgical scrub replacement, a lotion or other hand preparation.

Owner:3M INNOVATIVE PROPERTIES CO

Tea-seed-oil acne-removing facial soap

ActiveCN105316135AReduce stimulationDamage suppressionAntipyreticAnalgesicsPeppermintsScutellariae radix

The invention provides a tea-seed-oil acne-removing facial soap. The tea-seed-oil acne-removing facial soap comprises the following ingredients in parts by weight: 1.5-3 parts of tea seed oil, 2-5 parts of a camellia seed extract, 19-21 parts of stearic acid, 7-10 parts of lauric acid, 3-5 parts of sodium hydroxide, 4-6 parts of allantoin, 0.1-0.4 part of borneol, 0.8-1.1 parts of a peppermint aqueous extract and 1-4 parts of a scutellaria root aqueous extract. The tea-seed-oil acne-removing facial soap is rich in various essence ingredients, such as tea saponin, squalene, vitamin E and other antioxidant ingredients, is strong in saponification, and has the strong effects of moistening skin, diminishing inflammation, relieving itching, cleaning and removing acne.

Owner:CHONGQING HUPO TEA OIL CO LTD +1

Natural cleaning compositions

ActiveUS7465700B1Non-ionic surface-active compoundsOrganic detergent compounding agentsColloidal silicaGlycerol

A cleaning composition with a limited number of natural ingredients contains alkyl polyglucoside, ethanol and colloidal silica. The cleaning composition optionally has a small amount of glycerol. The cleaning composition optionally has a small amount of fragrance. The cleaning composition can be used to clean hard surfaces and cleans as well or better than commercial compositions containing synthetically derived cleaning agents.

Owner:THE CLOROX CO

Method for cleaning hard surfaces using a composition comprising a colloidal silica sol

InactiveUS7745383B2Avoid Excessive CondensationEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsColloidal silicaColloid

Owner:HENKEL KGAA

Antimicrobial nano-silver transparent soap and preparation method thereof

InactiveCN102978034APure textureMild in natureSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsCelluloseGlycerol

The invention relates to a skin-care and washing product, and specifically relates to an antimicrobial nano-silver transparent soap and a preparation method thereof. The antimicrobial nano-silver transparent soap comprises a modified nano-silver solution, a surfactant and a cellulose thickening amendment and is prepared according to the following weight parts: 5-15 parts of glycerol, 5-10 parts of propylene glycol, 10-25 parts of sodium palmitoleate, 8-12 parts of sodium cocoate, 5-12 parts of sodium stearate, 10-20 parts of sodium myristate, 8-15 parts of stearic acid, 2-6 parts of EDTA-4Na, 10.5-26.5 parts of a mixed soluble surfactant, 4-12 parts of the modified nano-silver solution, 6-18 parts of the cellulose thickening amendment and 1-5 parts of essence. The soap has pure quality, mild property, rich and meticulous foam and strong decontamination capability, has the function of antisepsis and anti-inflammation, and has very good moistening and protecting effects for human skins.

Owner:YANCHENG CITY HUZHENG NANO MATERIAL SCI & TECH

Liquid soap and preparation method thereof

InactiveCN102994279ADo not cause harmSoap detergents with other compounding agentsAlkali/ammonium soap compositionsOrganic chemistryBiomedical engineering

The invention relates to a liquid soap and a preparation method thereof. The liquid soap disclosed by the invention is completely made from natural constituents, does not irritate skin, has no toxic and side effects, and is obvious in skin-cleaning and skin-protecting effects.

Owner:吴妙娴 +1

Lithospermum soap and making method thereof

InactiveCN102002448ASignificant acneSignificant anti-inflammatory effectSoap solutions manufacturingSoap detergent compositionsMedicineLithospermum

The invention relates to soap for washing and a making method thereof, in particular to a functional soap and a making method thereof. The invention adopts the technical scheme that the lithospermum soap is prepared from the following components in percentage by weight: 60-70 percent of grease, 8-10 percent of NaOH, 20-30 percent of water and 10-16 percent of lithospermum roots. The lithospermum soap without any additive does not irritate the skin and is particularly suitable for acne patients and patients with sensitive skin to use because the lithospermum has the remarkable effects of removing acne and diminishing inflammation. The making method of the invention has the most prominent advantage of flexibility, not only is suitable for industrial production, but also can be made at home.

Owner:郭欣然

Multiuse, solid cleaning device and composition

InactiveUS20050130868A1Reduce and eliminate direct transferReduce solubilityInorganic/elemental detergent compounding agentsFlow mixersAlkalinitySolubility

A multiuse laundry cleaning device in a solid state containing a homogeneous quantity of cleaning agent configured to dissolve and release a substantially consistent quantity of cleaning agent over a plurality of laundry wash and rinse cycles. The cleaning agent includes a gas-releasing component, potassium silicate as a solubility control component to limit the solubility of the cleaning agent, an alkalinity agent as a pH regulator, and a water softener to solvate metal ions in a solution of water. Controlled dissolution of the cleaning agent composition releases a desired quantity of cleaning agent in each cleaning cycle over a plurality of cycles. A porous covering or bag may be disposed around the solid cleaning agent.

Owner:ECO SAFE TECH L L C

Method for fast and continuously saponifying grease

ActiveCN104017678AGuaranteed Saponification RateIncrease productivitySoap solutions manufacturingProcess engineeringSpray dried

The invention relates to the technical field of soap making, and particularly relates to a method for fast and continuously saponifying grease. The method sequentially comprises the following steps: A, blending, namely uniformly mixing the grease and fatty acid in proportion to obtain mixed liquor; B, saponification, namely respectively heating the mixed liquor and liquid caustic soda, mixing the heated mixed liquor and the heated liquid caustic soda to carry out saponification reaction, and adding to a brine solution with an additive so as to obtain a soap base after the saponification reaction is completed; C, soap pellet forming, namely carrying out vacuum spray drying, extrusion, homogenization, refining and pellet cutting on the soap base to obtain a soap pellet, wherein 60-80 parts by weight of the grease and 20-40 parts by weight of the fatty acid are fed. The saponification method disclosed by the invention has the advantages of continuity, stability, fast reaction rate, short reaction time, high production efficiency, less energy consumption, low production cost and large-scale industrial production.

Owner:YIHAI DONGGUAN OIL & CHEM IND

Preparation method of anti-microbial Chinese herbal medicine toilet soap

InactiveCN103409251AAnti-bacterialFormulation ScienceSkin careAlkali/ammonium soap compositionsCoconut oilTraditional medicine

The invention relates to a preparation method of anti-microbial Chinese herbal medicine toilet soap. The formula is as follows: the toilet soap comprises the following components in parts by weight: 170-200 parts of coconut oil, 170-200 parts of sunflower seed oil, 100-200 parts of palm oil, 75-150 parts of sodium hydroxide, 10-15 parts of a Chinese herbal medicine antibacterial agent, 190-220 parts of water and 1-3 parts of essential oil. The toilet soap provided by the invention has the characteristics of scientific and reasonable formula, mildness to skin and virus prevention and sterilization.

Owner:严积芳

Low-temperature instant soap powder and preparation method thereof

InactiveCN102604760AImprove solubilityLower Clough PointSoap detergents with organic compounding agentsDetergent powders/flakes/sheetsSolubilityActive agent

The invention discloses low-temperature instant soap powder and a preparation method thereof. The low-temperature instant soap powder comprises the following raw material components in percentages by weight: 10-85% of acid component; 1-40% of alkali component; 0-40% of assistant; and 1-50% of surfactant. The preparation method of the low-temperature instant soap powder, provided by the invention, comprises a step of reacting a precursor of soap (including the acid component and the alkali component) with the assistant and the surfactant so as to form microscopic combination or linkage with the soap, the other assistant and the surfactant, thereby improving the solubility of the soap powder greatly and reducing a Kraft point of the soap powder; and the low-temperature instant soap powder has the low-temperature instant effect.

Owner:GUANGZHOU LIBY

Transparent soap

ActiveCN104629951AHigh content of active substancesIncreased durabilitySoap detergents with organic compounding agentsAlkali/ammonium soap compositionsSucrosePEG 400

The invention discloses a transparent soap which is prepared by a conventional method from the following raw materials in parts by mass: 80-90 parts of soap grains, 1-5 parts of fatty acid, 1-5 parts of glycerin, 1-5 parts of sorbitol, 2-8 parts of sucrose, 1-3 parts of polyethylene glycol 400, 0-0.12 part of a chelating agent, 0-0.10 part of an antioxidant, 0-1 part of essential oil and 0-3 parts of essence. According to the transparent soap disclosed by the invention, common soap grains are adopted, and the application range of the raw materials is relatively wide; the adopted additives are of a medical grade or edible grade, thereby being safe and environment-friendly; the content of effective active substances in the product is high, and the product durability is perfect; and the production process is a common soap production process, and the requirements on the process and equipment are not high.

Owner:SHANGHAI SOAP FACTORY

Amino acid composite soap and preparation method thereof

ActiveCN102329704AUnique mildnessImprove hard water resistanceSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsAntioxidantTitanium

The invention relates to amino acid composite soap and a preparation method thereof. The amino acid composite soap consists of the following raw materials in proportion by weight: 0.1-20.0% of amino acid surface active agent, 0.01-2.0% of titanium white, 0.05-0.5% of metal ionic chelating agent, 0.01-0.5% of antioxidant, 0.5-2.5% of compound perfume and fatty acid soap as a rest component. Due to the unique tenderness, the favorable hard water resistance and the stronger skin moistening effect of the amino acid surface active agent, the cheerful use feeling can be brought to a consumer; further, after the consumer uses the amino acid composite soap, the surface of the skin is lenitive, comfortable and refreshing without a tense, dry and astringent feeling; and the amino acid composite soap is a medium-grade and high-grade skin cleaning article nowadays.

Owner:广东柏亚化妆品有限公司

Plastics compatible detergent composition and method of cleaning plastics

InactiveUS6838422B2Inorganic/elemental detergent compounding agentsCationic surface-active compoundsAlcoholEnd-group

A plastics compatible detergent composition is provided by the invention. The plastics compatible detergent composition includes about 0.01 wt. % to about 10 wt. % anionic surfactant; about 0.01 wt. % to about 10 wt. % cationic surfactant; about 0.01 wt. % to about 10 wt. % of at least one of reverse polyoxyalkylene block copolymer surfactant, alcohol alkoxylate surfactant having polyoxypropylene and / or polyoxybutylene end groups, and mixtures thereof; about 0.01 wt. % to about 10 wt. % alkylpolyglycoside surfactant; and about 0.01 wt. % to about 20 wt. % silicone surfactant. A method for washing an article having a plastic surface is provided by the invention. The method includes a step of applying the detergent composition to the plastic surface, and rinsing the detergent composition from the article.

Owner:ECOLAB USA INC

Detergent made use of fermentation technology and production method thereof

InactiveUS20070190625A1Prevent proliferationSuppression problemInorganic/elemental detergent compounding agentsCosmetic preparationsBiological bodyYeast

Regarding a detergent made using fermentation technology and its production method, in a production process of soap, effective microorganisms (EM) and EM-X ceramic powder are added to enhance a saponification degree of fat, strengthen a cleaning power as well, and also to realize a detergent capable of proliferating effective microorganisms in sewage water after washing and cleaning the sewage water, and exhibit an effect as a water purification material after washing. On selecting microorganisms, as a living organism playing a starter role in an environmental purification process, in particular, effective microorganisms (EM) consisting mainly of facultative anaerobic lactic acid bacteria, yeast and photosynthetic bacteria and EM-X ceramic powder are introduced in a production process of soap, thereby, a treated material obtained according to the present invention exhibits an environmental purification effect as a substrate of benign microorganisms or a microorganism material.

Owner:EM RES ORG

Antibacterial and cold-resistant soap

InactiveCN103805378ANatural materialsEasy to makeSkin careAlkali/ammonium soap compositionsBiotechnologyJojoba oil

The invention relates to an antibacterial and cold-resistant soap which is prepared through the following steps: with fresh onion juice and ginger juice as main materials, adding a concentrated solution of traditional Chinese medicines such as folium artemisiae argyi, honeysuckle, folium isatidis, dandelion, gallnuts and the like; mixing sodium hydroxide, jojoba oil and water according to a certain ratio; stirring, solidifying and demolding. The antibacterial and cold-resistant soap is natural in raw material, simple in preparation, free of side effects and capable of effectively inhibiting the formation of bacteria on the surface of skin and achieving the effects of preventing cold and resisting to cold so as to be particularly suitable for use in autumn and winter.

Owner:苏亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com