Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about "Induction-charging spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

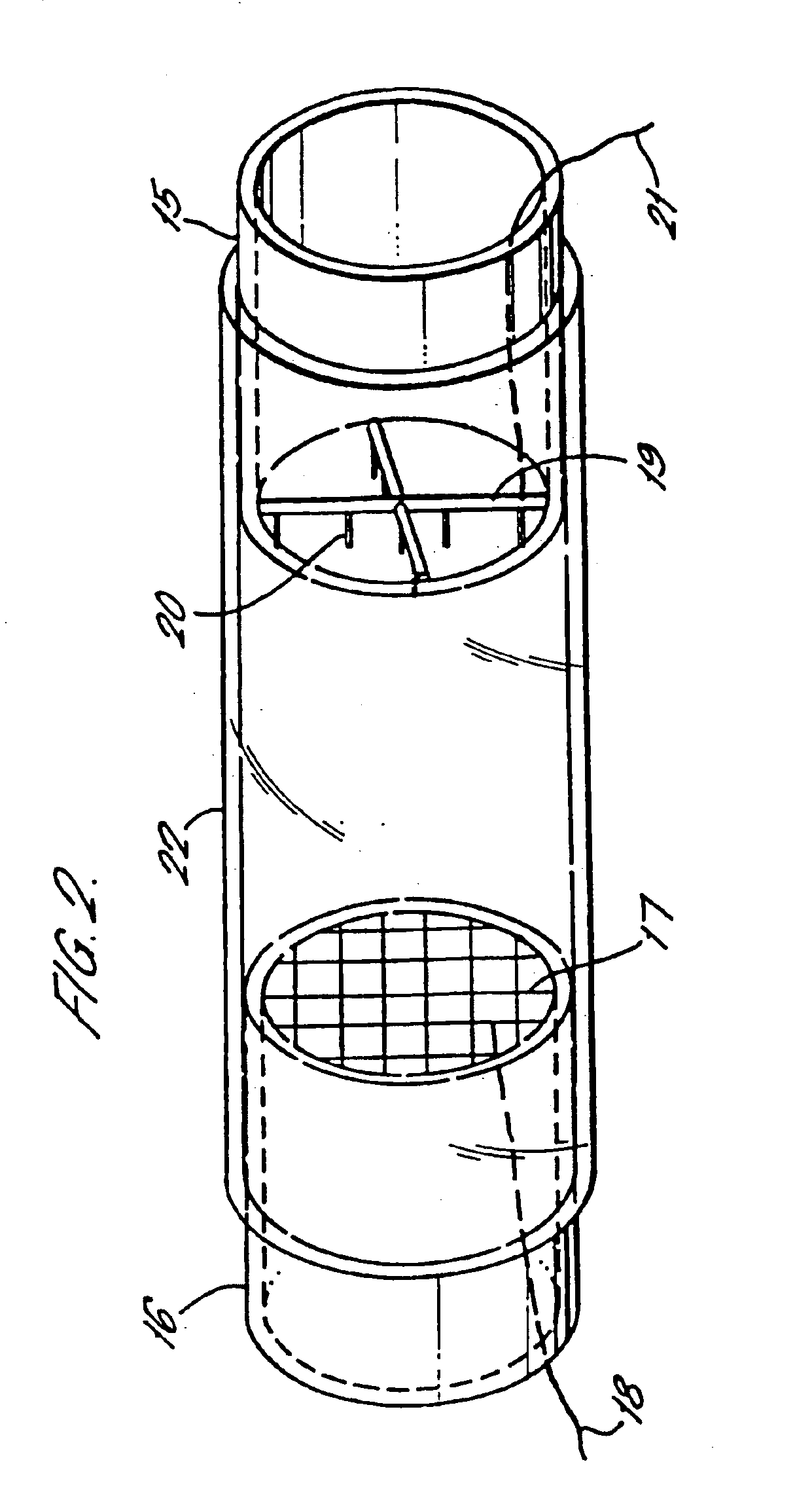

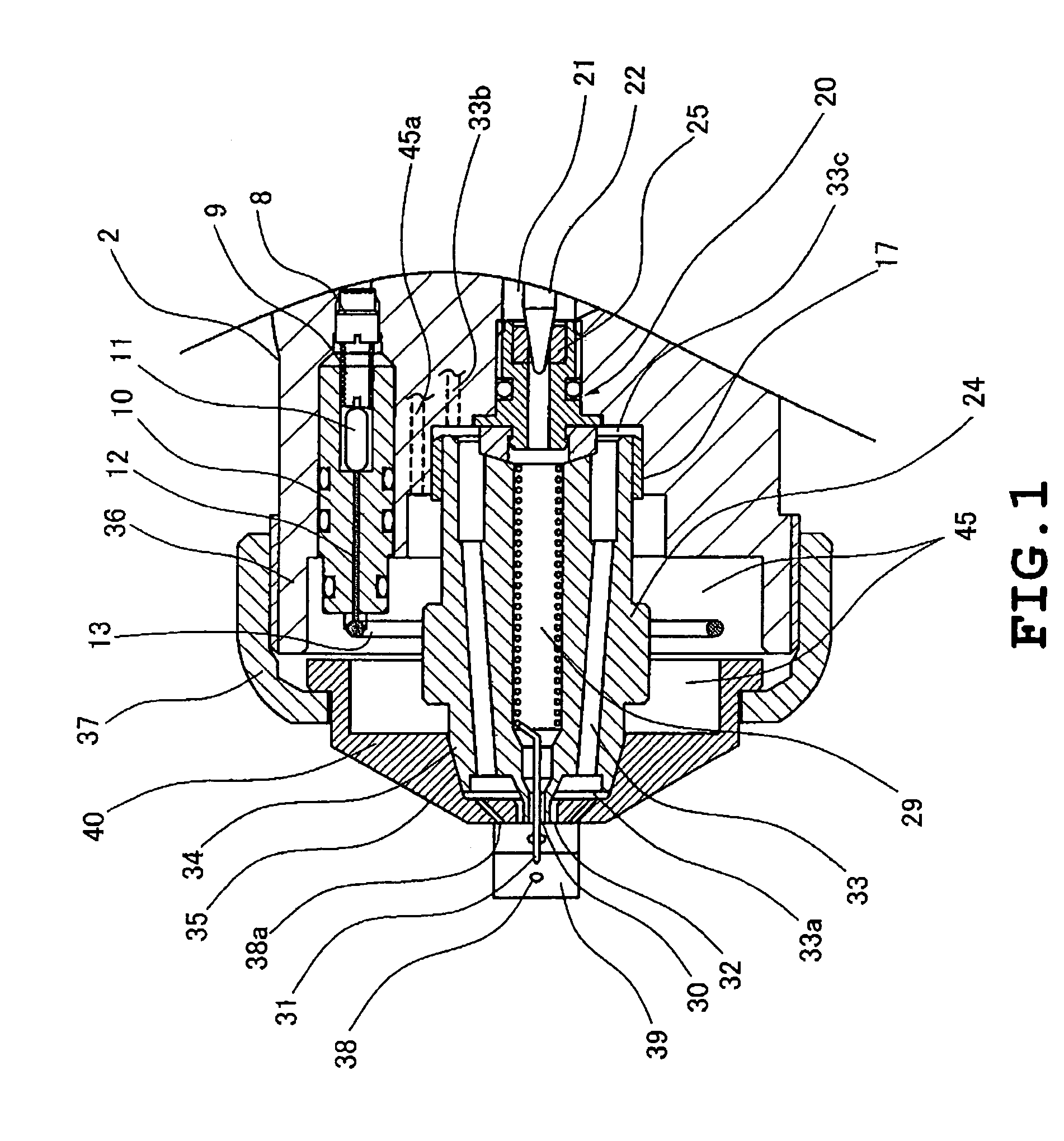

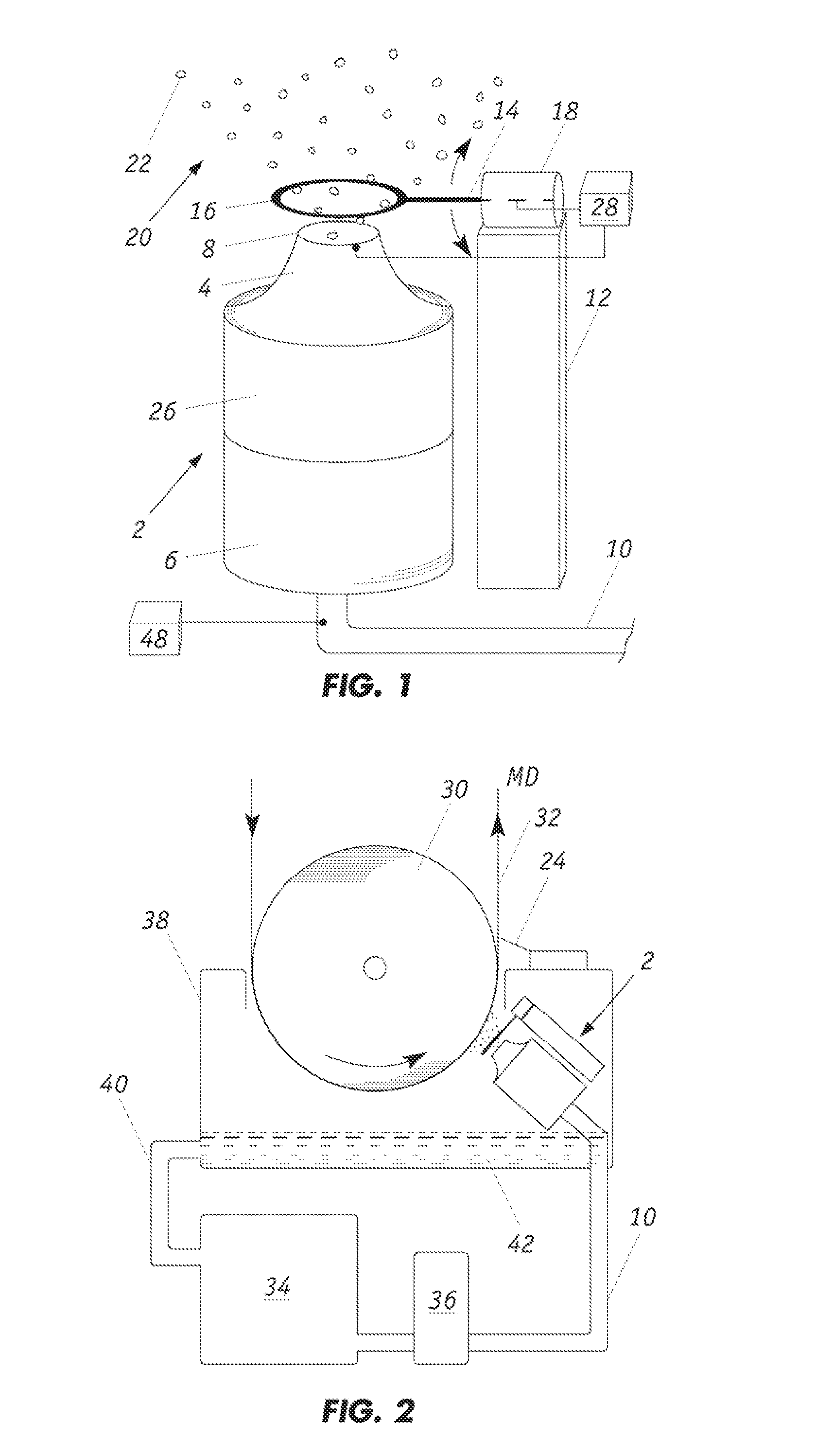

Dispensing device

An inhaler for enabling inhaled administration, has a housing having an outlet duct defining a passageway through which air can be drawn by inhalation on the part of a user. The housing contains a capillary nozzle; a container for containing a quantity of liquid to be supplied to the capillary nozzle; and an electric field controller for applying a voltage to the liquid prior to issue from the container via the capillary nozzle to expose the liquid to an electric field to cause comminution of the liquid emerging from the capillary nozzle to product a spray of electrically charged droplets such that upon inhalation by the user, electrically charged droplets for the deposition in the user's airways.

Owner:BATTELLE MEMORIAL INST

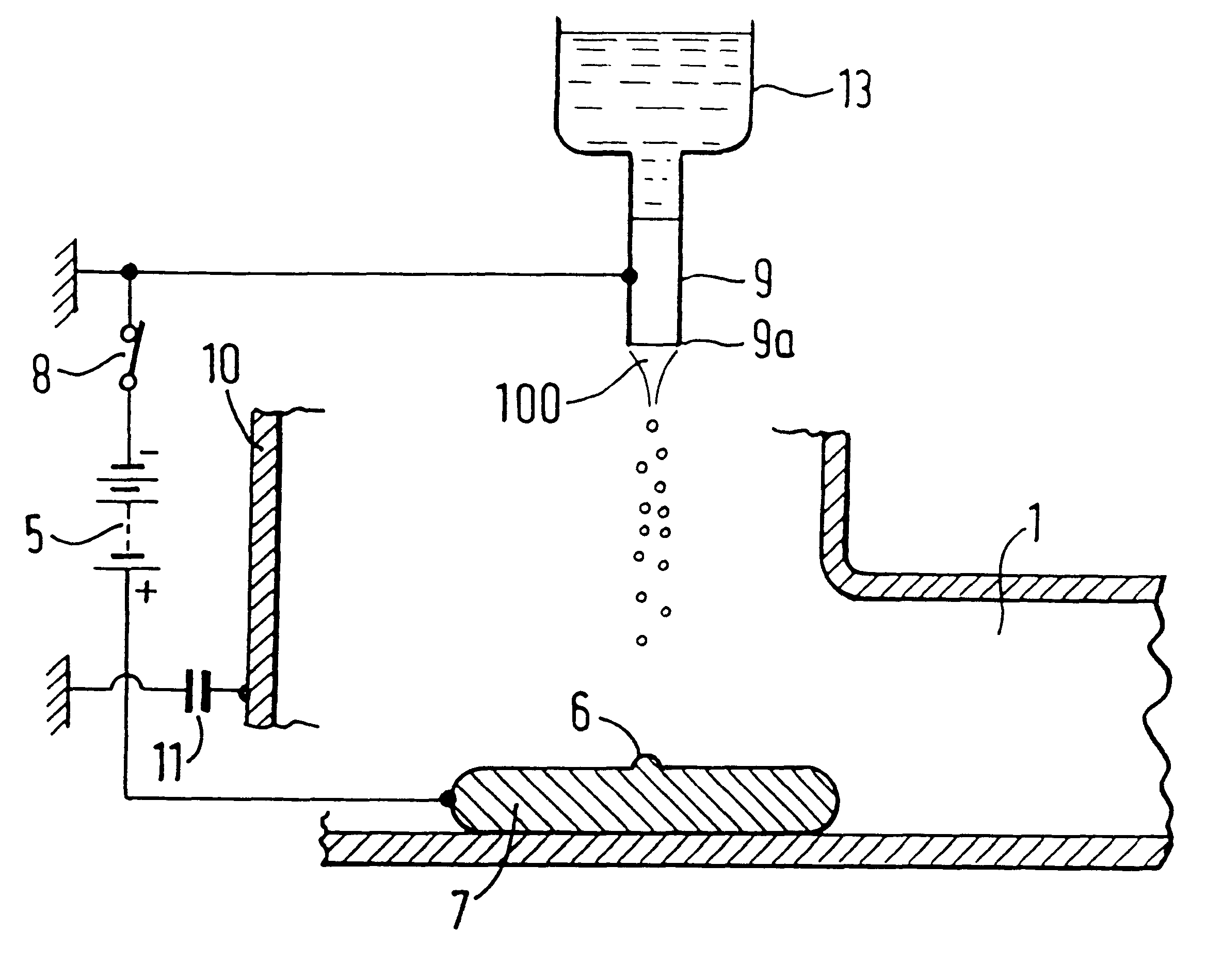

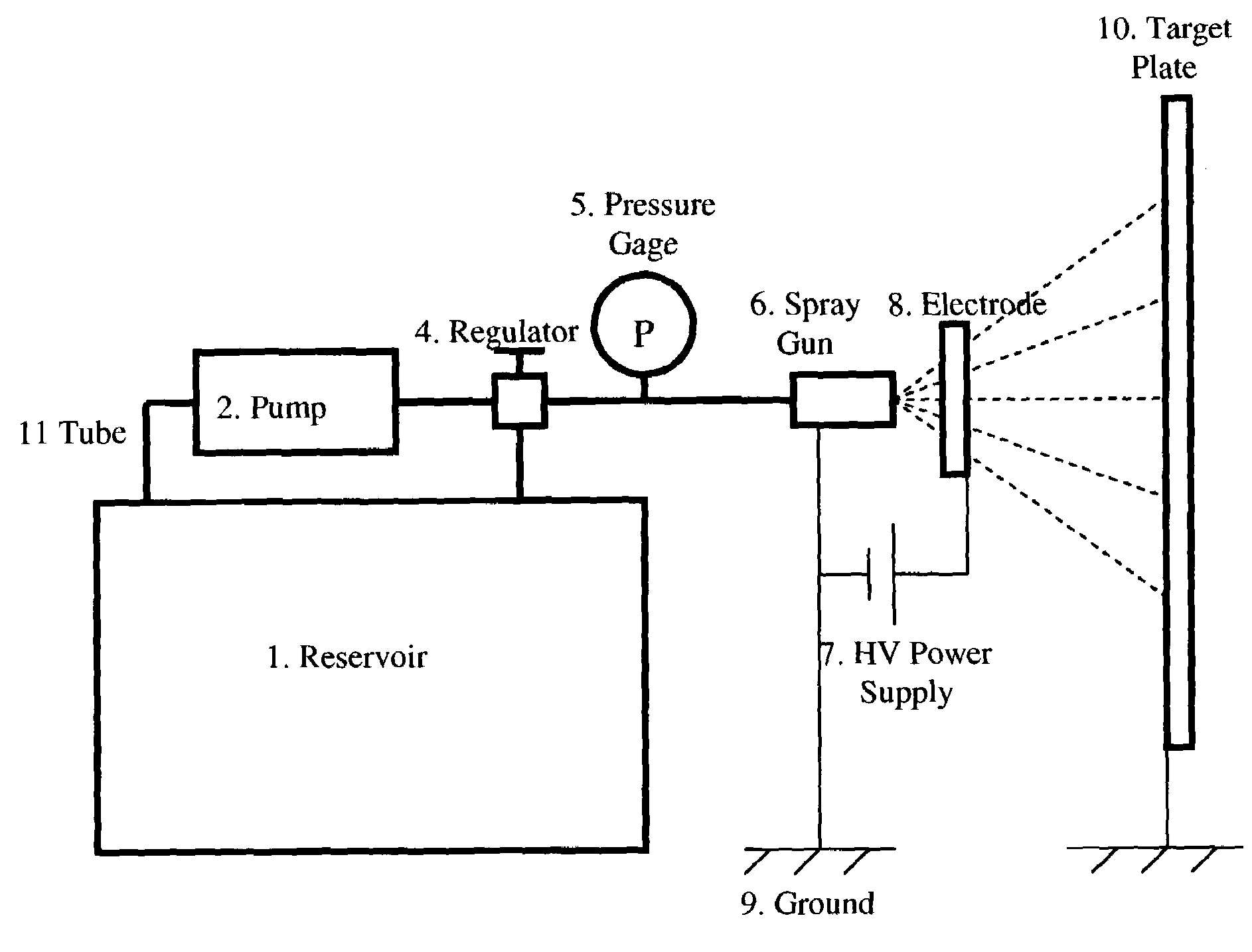

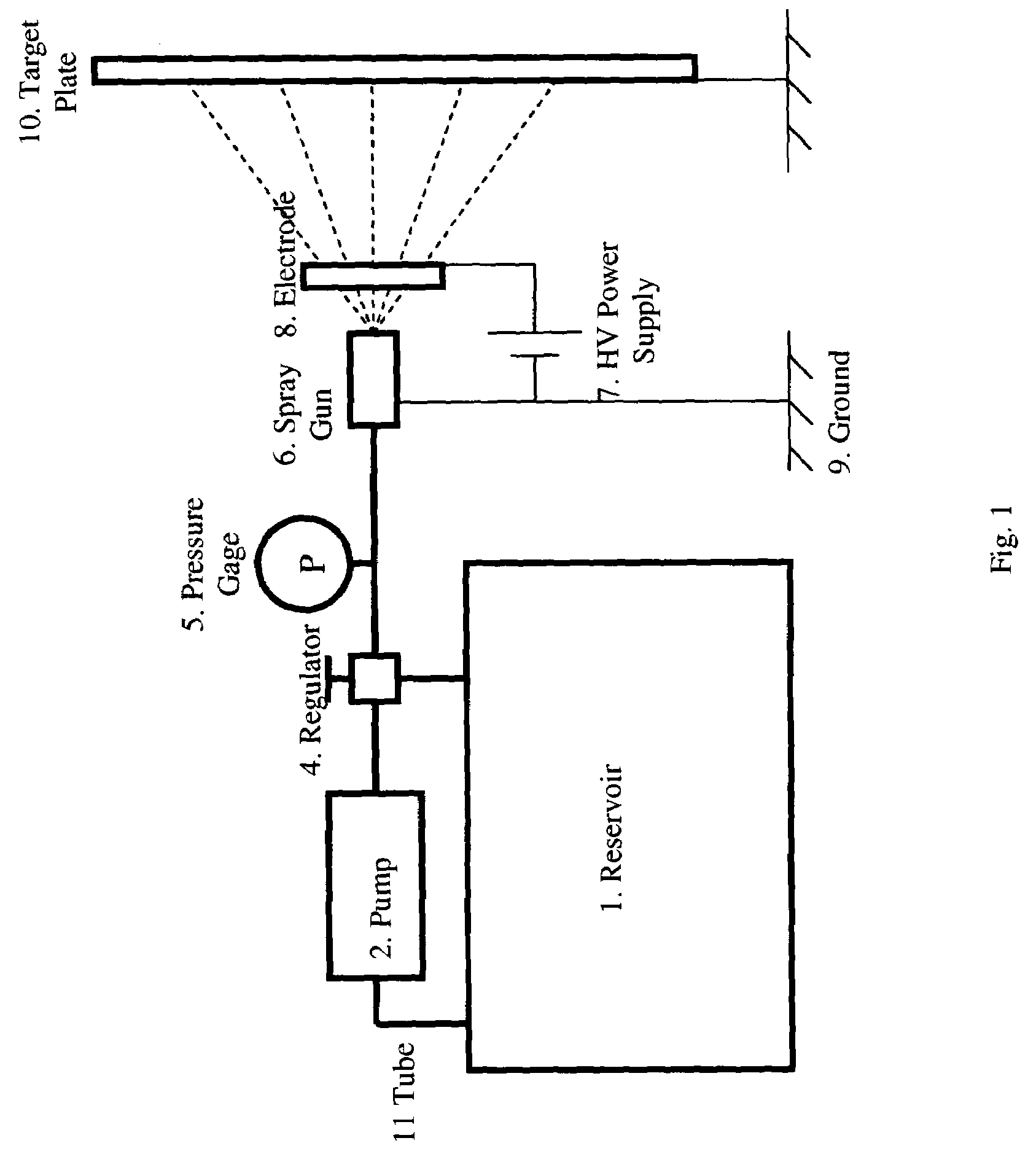

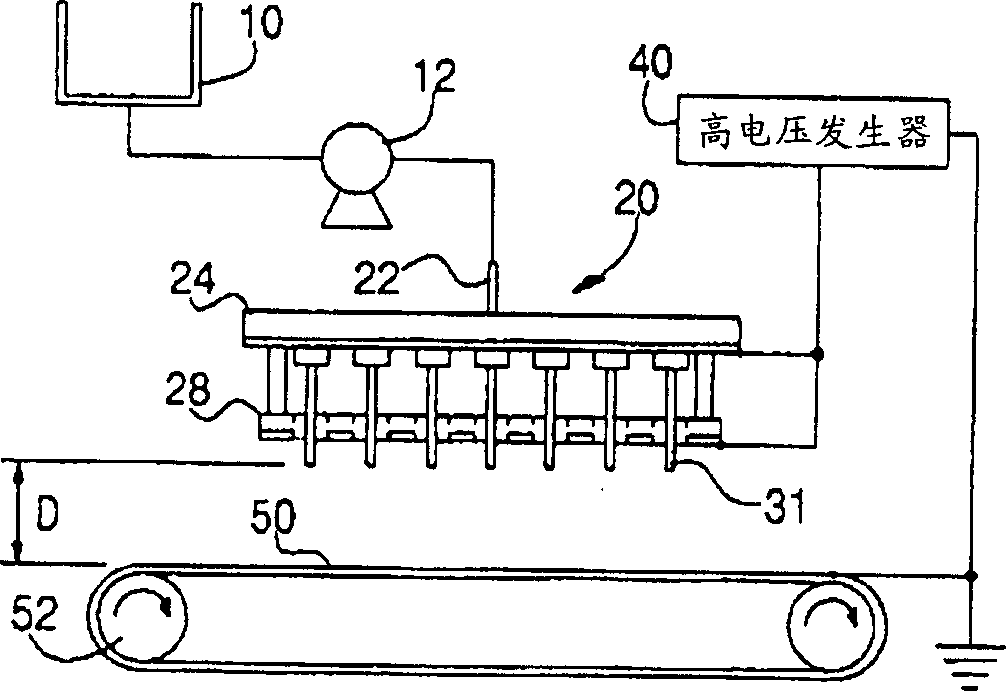

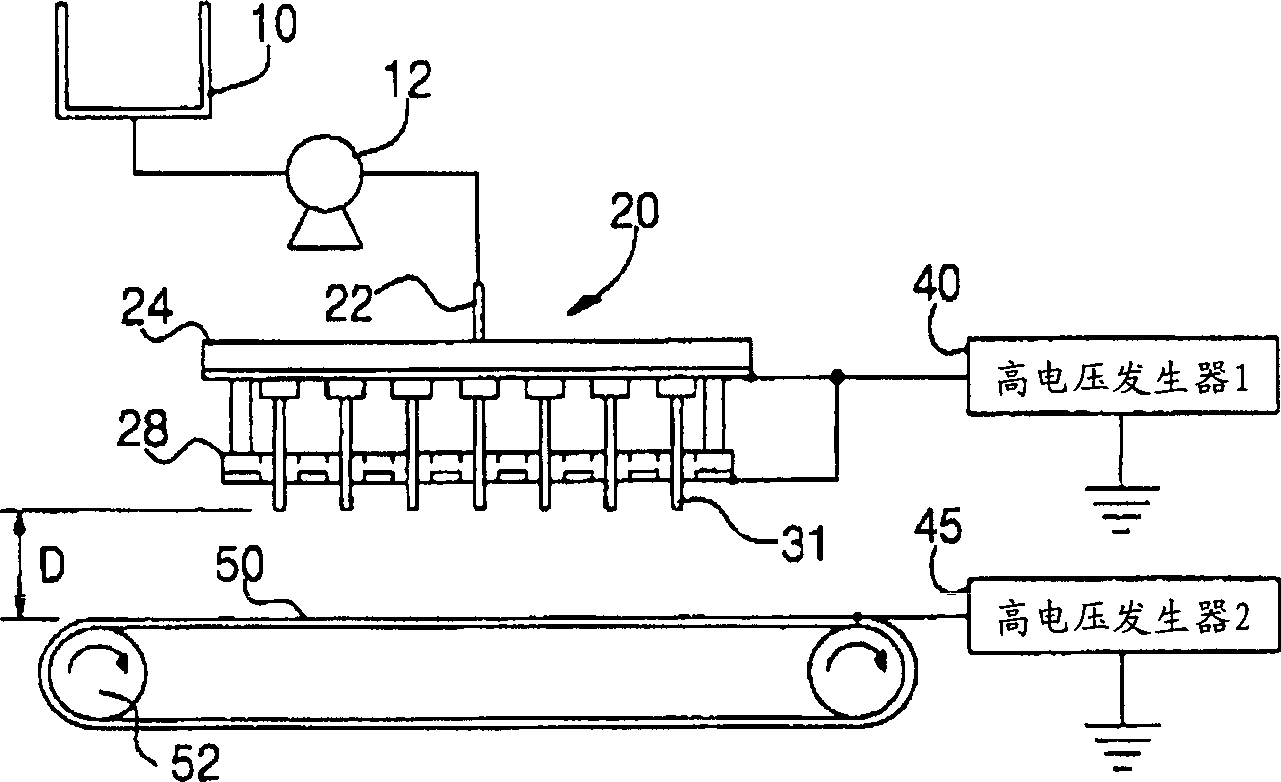

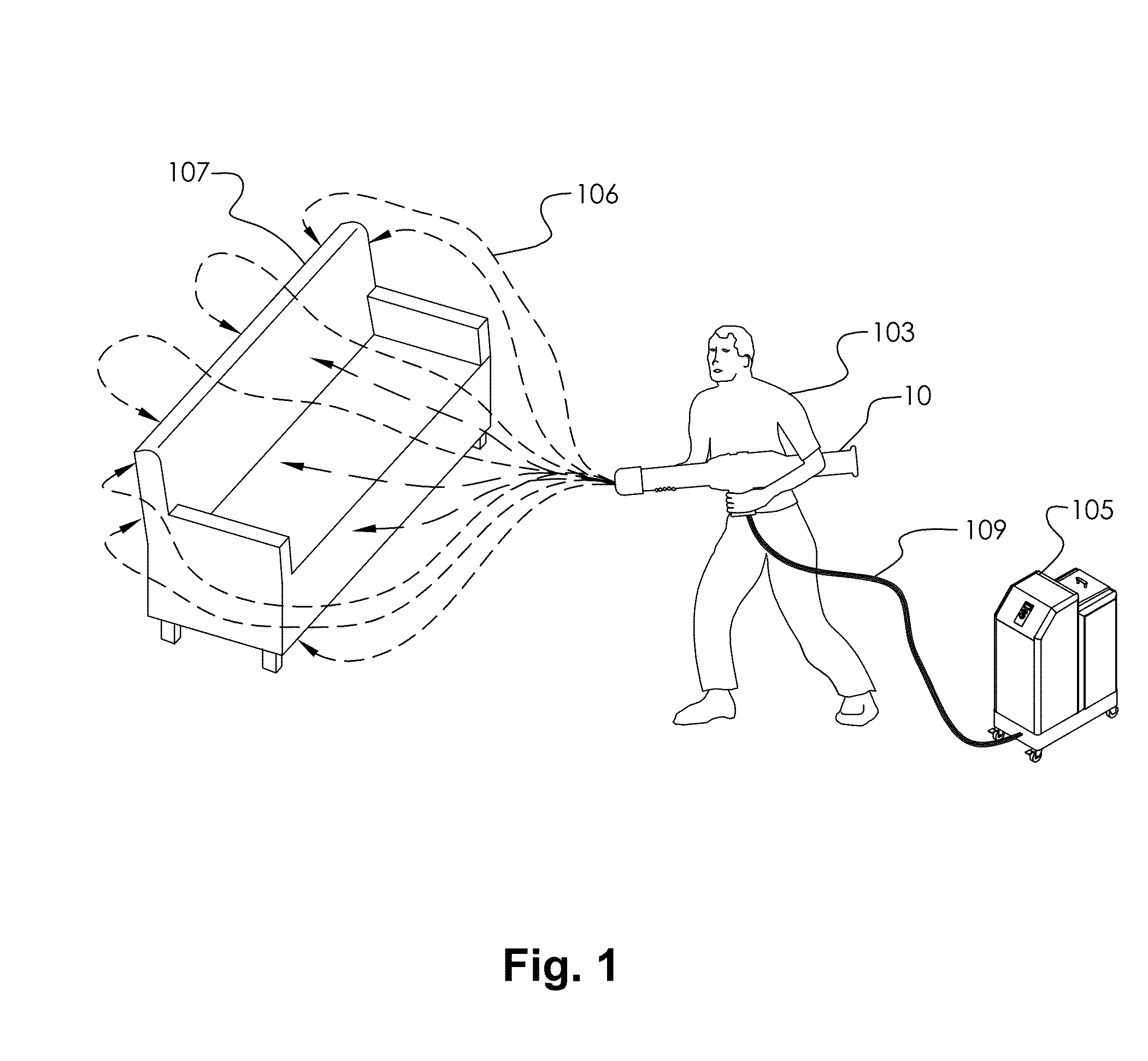

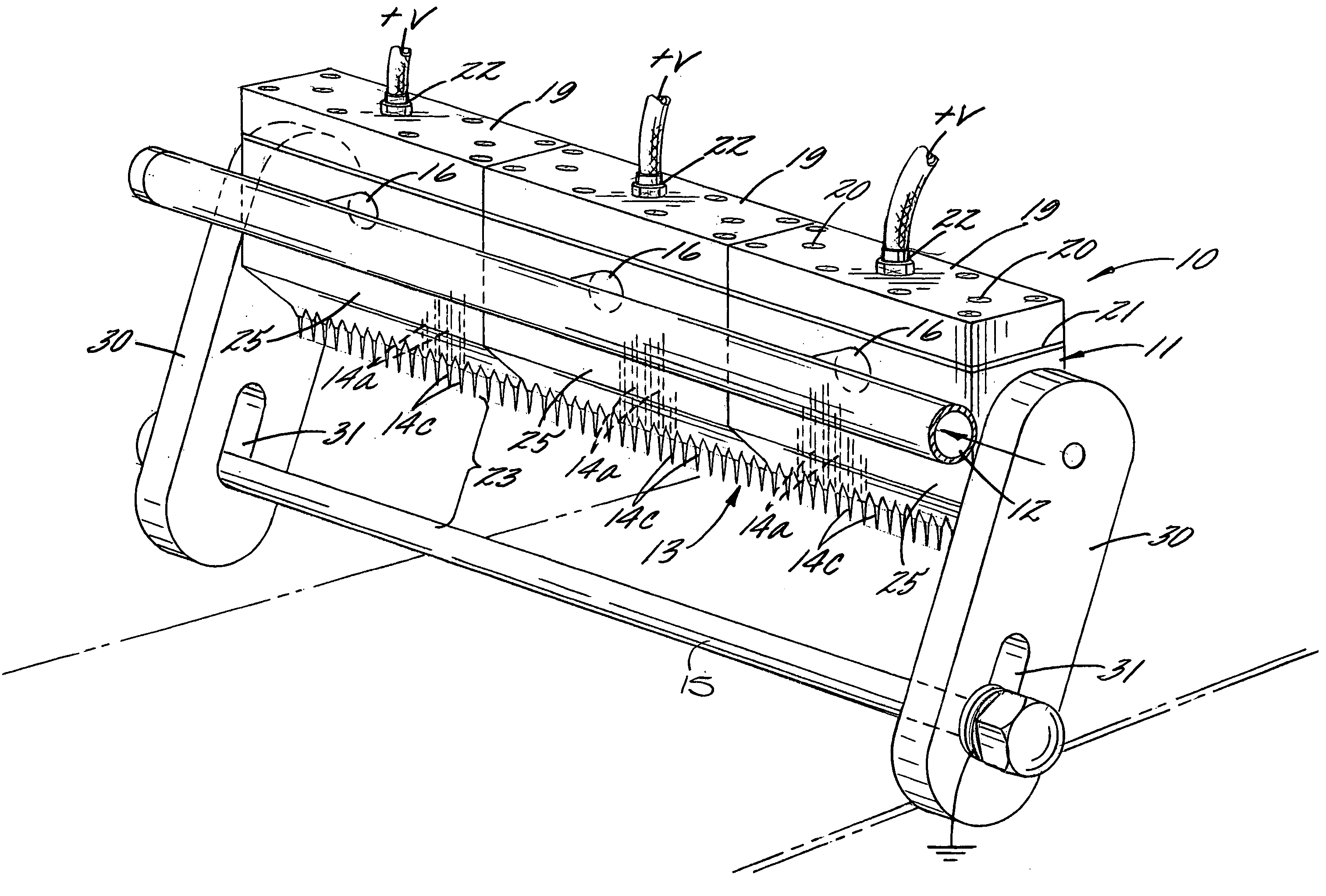

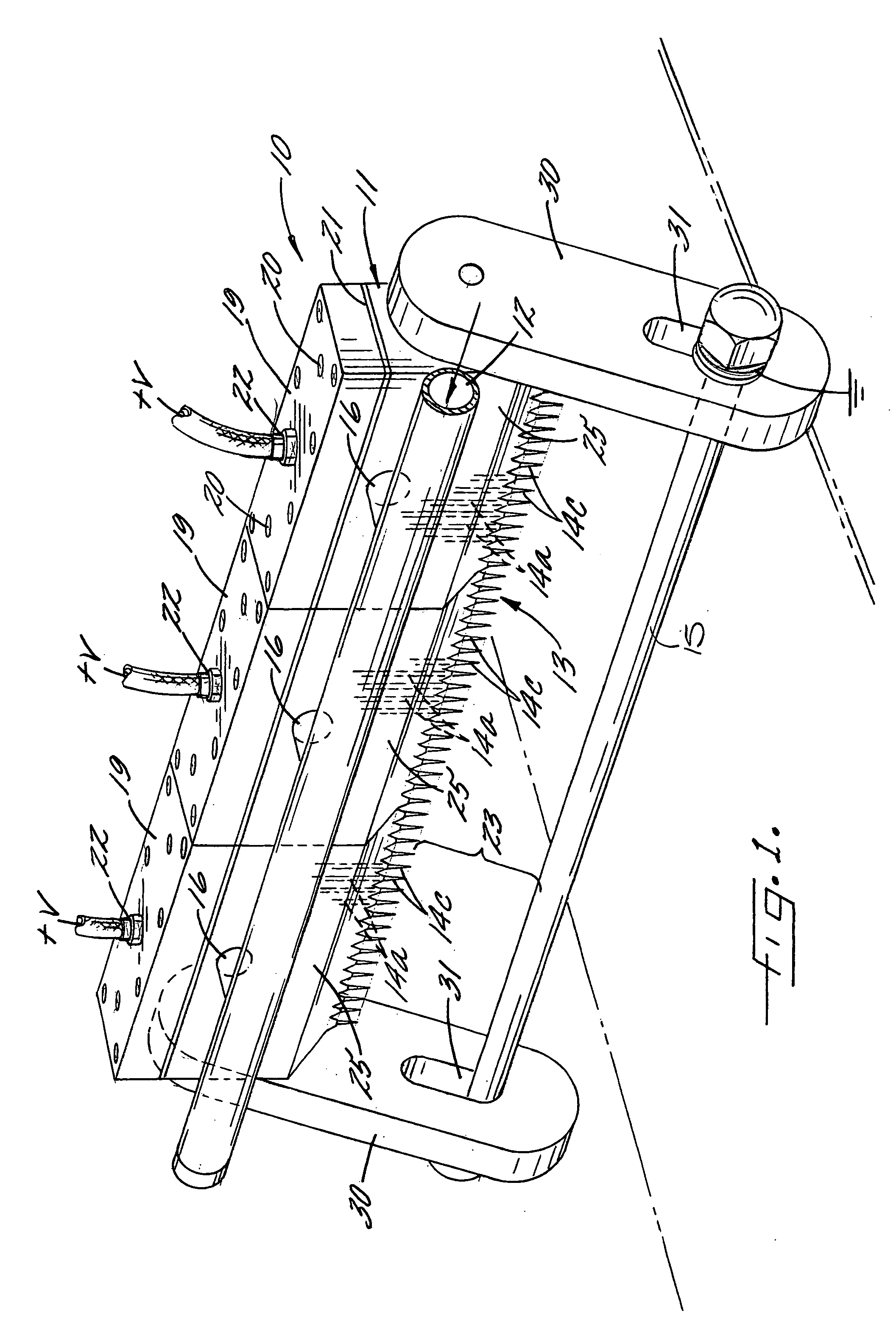

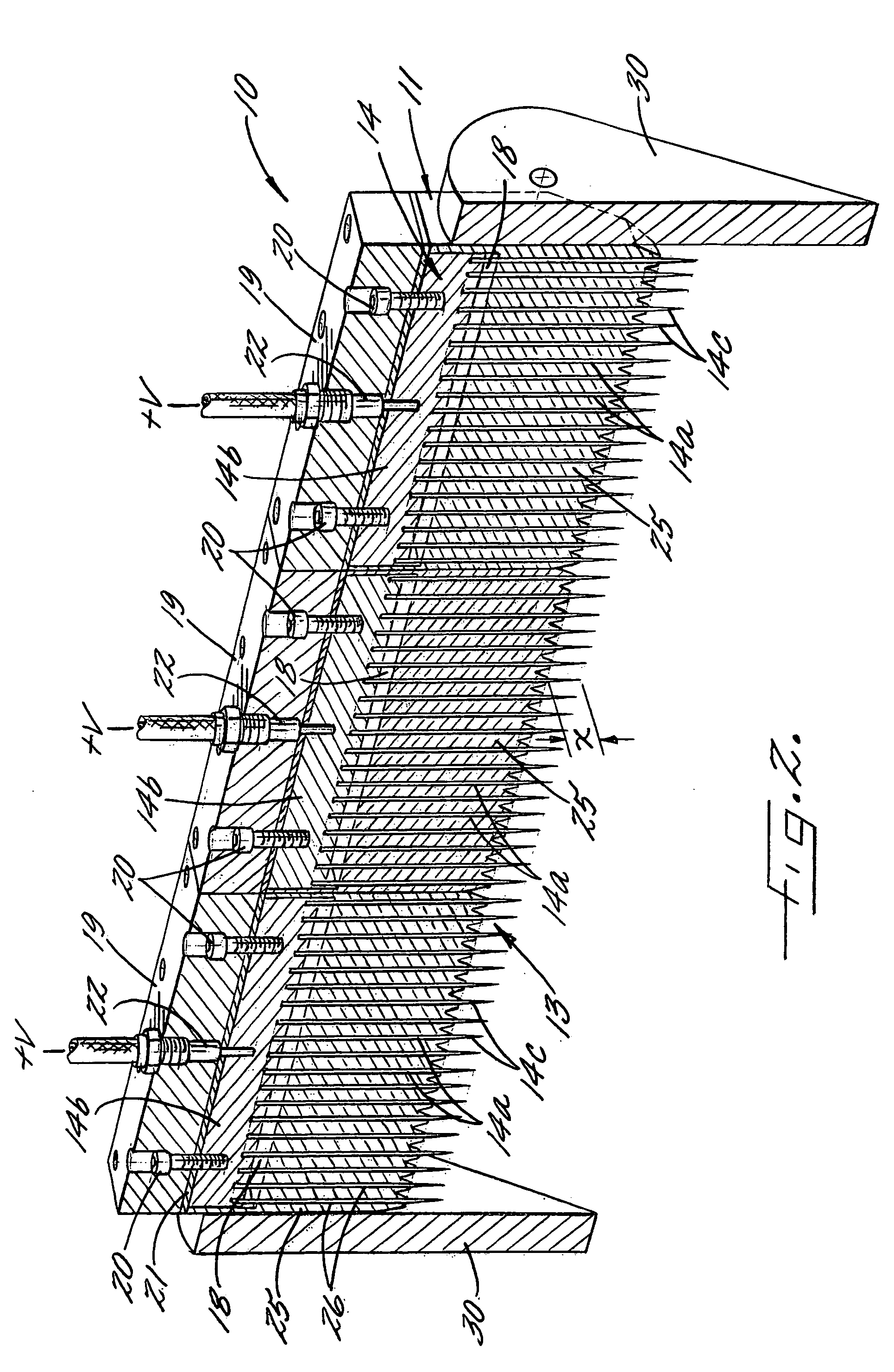

Method and apparatus for electrostatic spray

InactiveUS7150412B2High currentLeakage currentBurnersMovable spraying apparatusSpray nozzleEngineering

A method and apparatus to improve the atomization of liquid and the efficiency of depositing liquid particles onto target objects, or to coat the target object with a thin film of liquid, to reduce the risk of high-voltage electrical shock, and to reduce the weight of an electrostatic spray system has been developed by inducing electrostatic charges onto the atomized liquid particles sprayed from a grounded metal nozzle.

Owner:BIOMED PROTECT

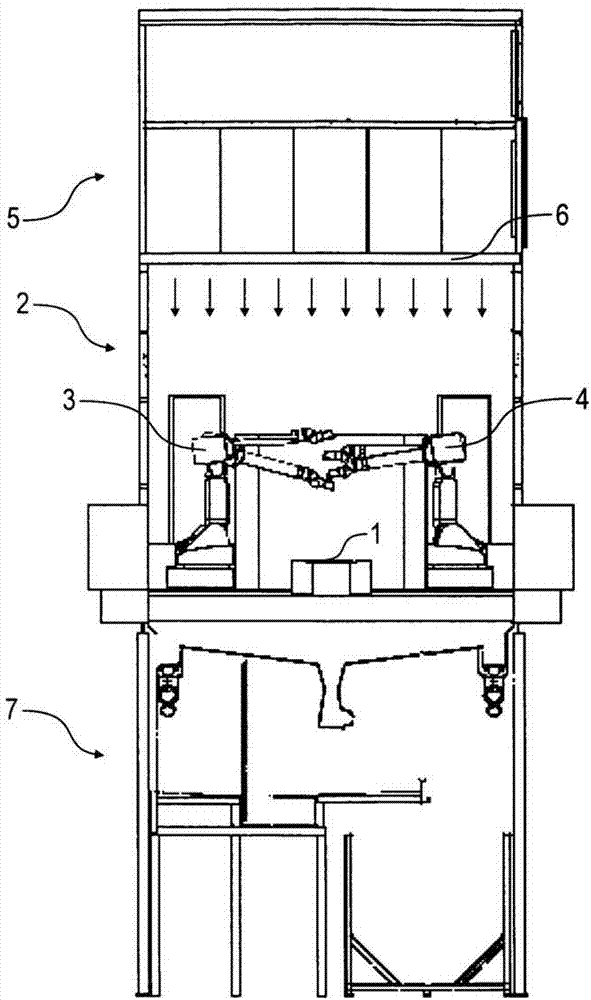

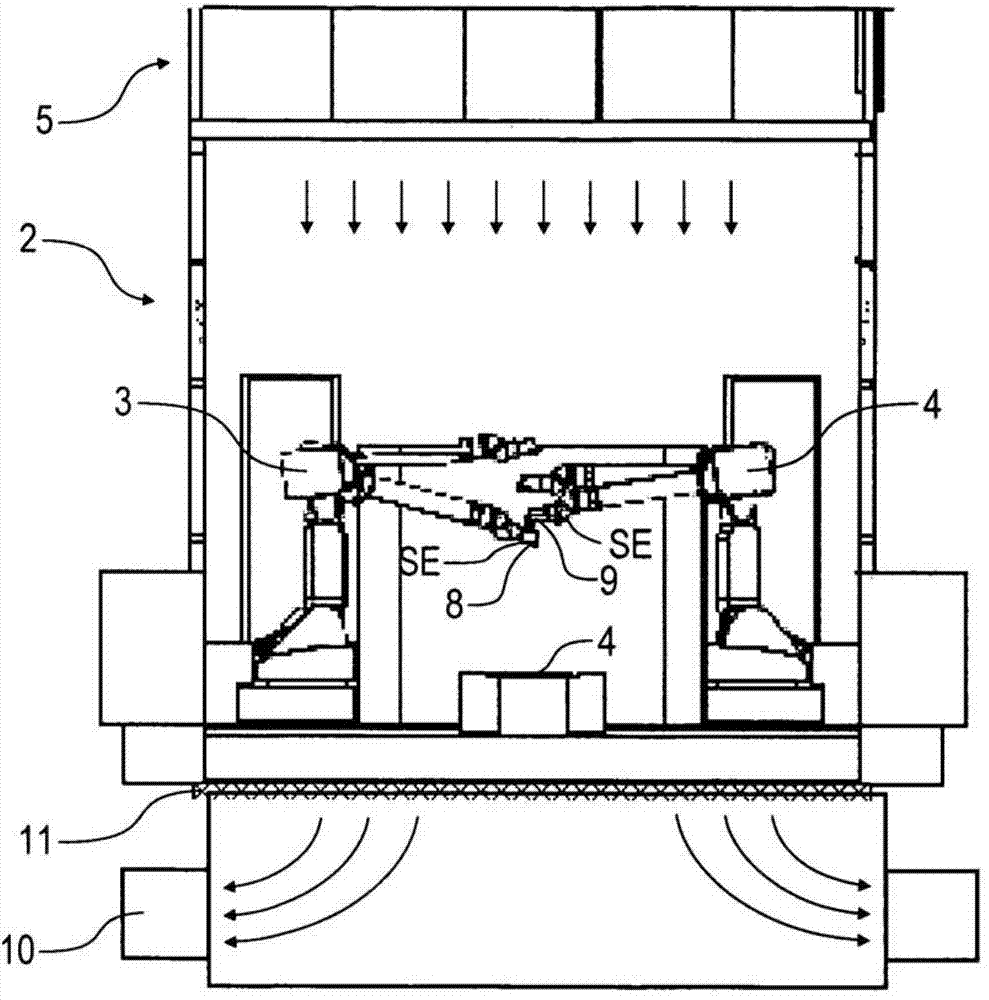

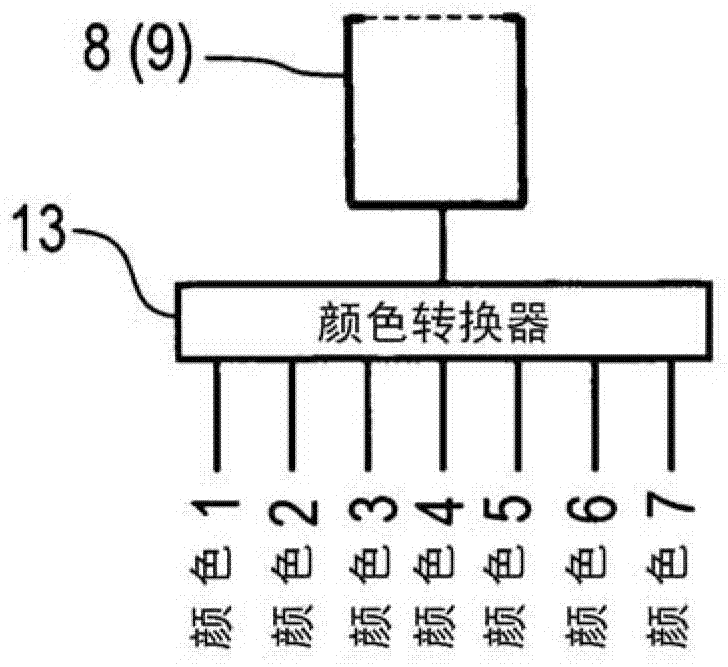

Coating device comprising a jet of coating medium which is broken down into drops

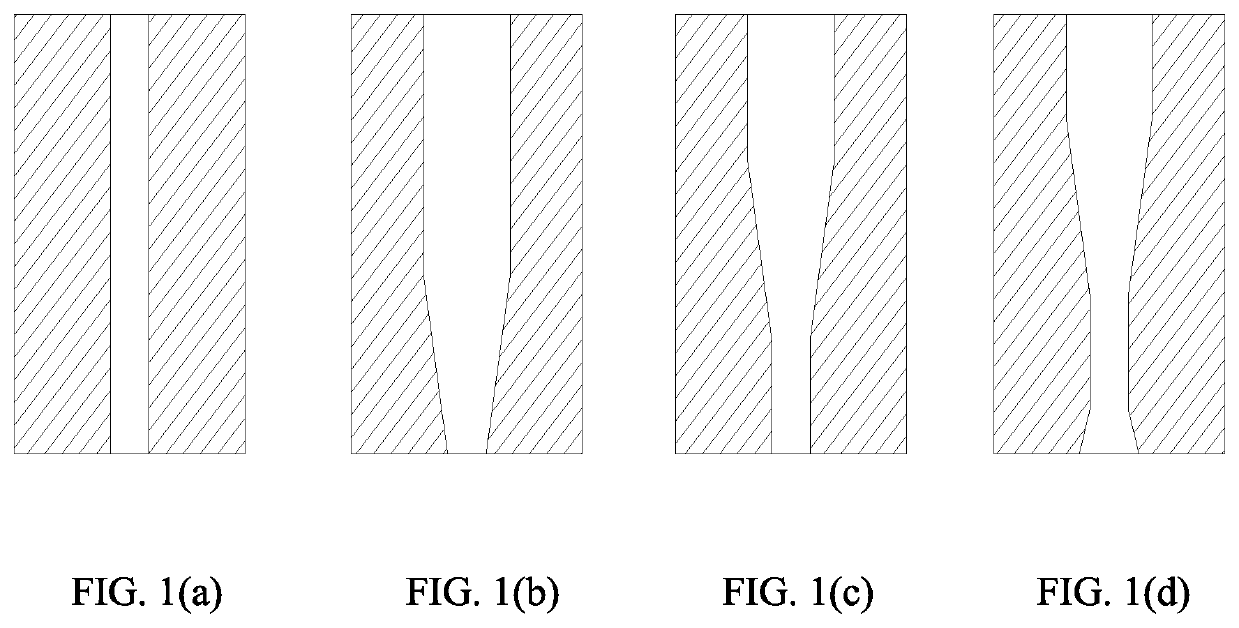

InactiveCN102971080AReduce volumeSave energyLiquid spraying plantsLiquid surface applicatorsInstabilityEngineering

The invention relates to a coating device and to an associated coating method for coating components with a coating medium, in particular for painting motor vehicle body components and / or motor vehicle accessories with a paint. The coating device comprises at least one applicator unit (8, 9) for expelling the coating medium from at least one coating medium nozzle. Furthermore a drop generator (TE; TE') can be provided in order to impose a vibration and / or an instability on the coating medium in order to generate coating agent drops (70) and / or to break down the coating medium into drops (70). The applicator unit (8, 9) is preferably provided in order to expel at least one coherent coating medium jet (70') which breaks down into drops (70).

Owner:DUERR SYST GMBH

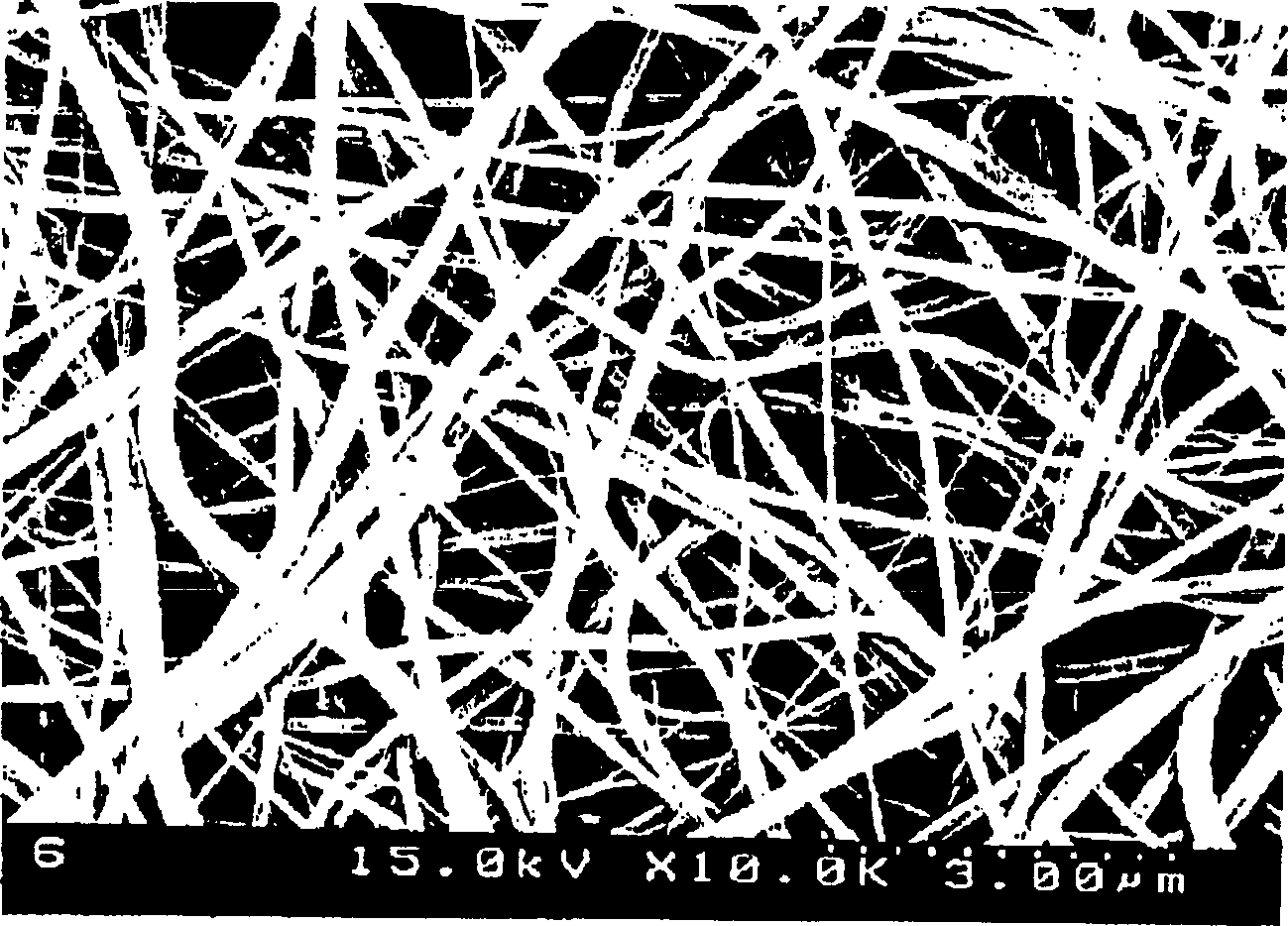

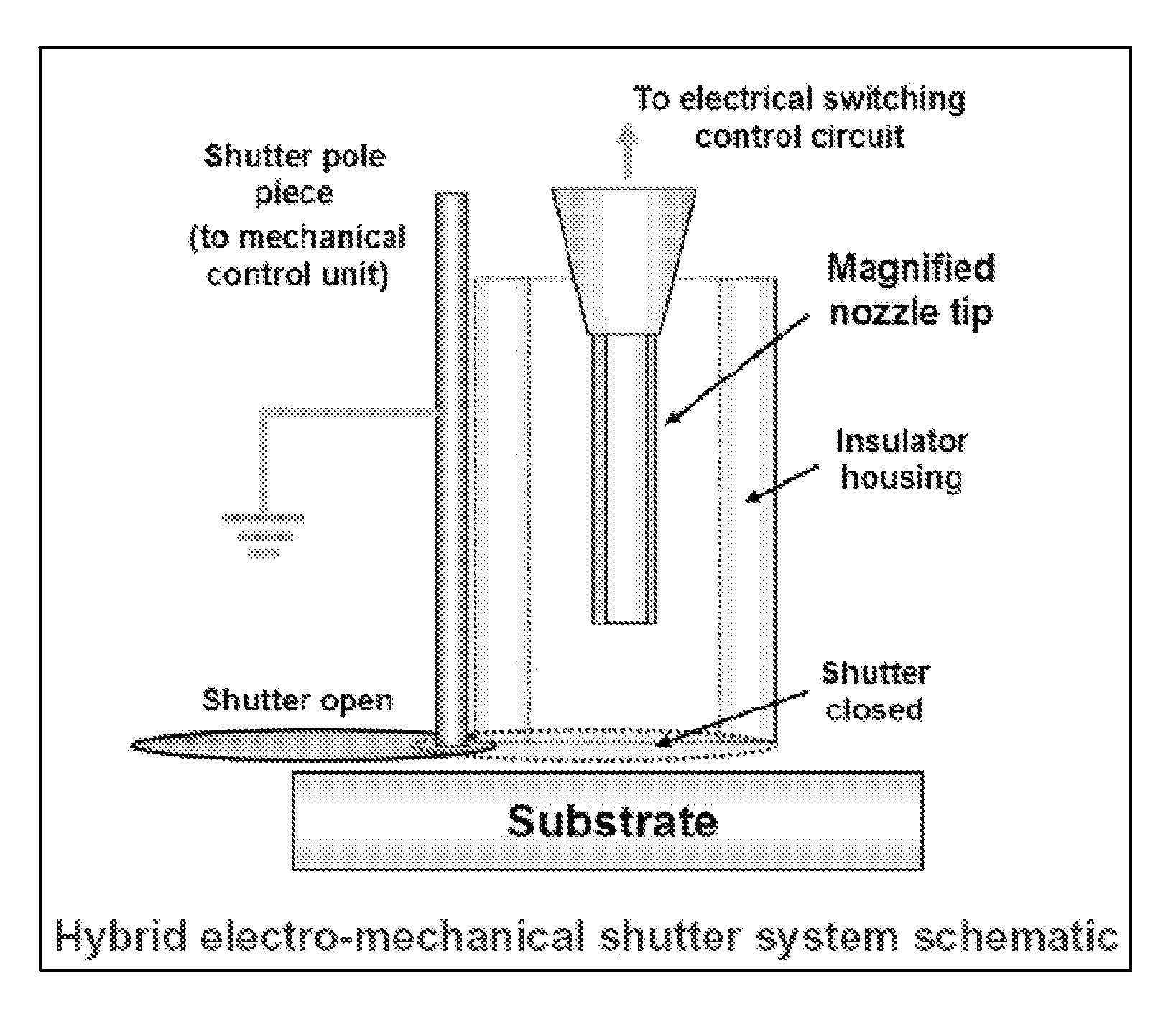

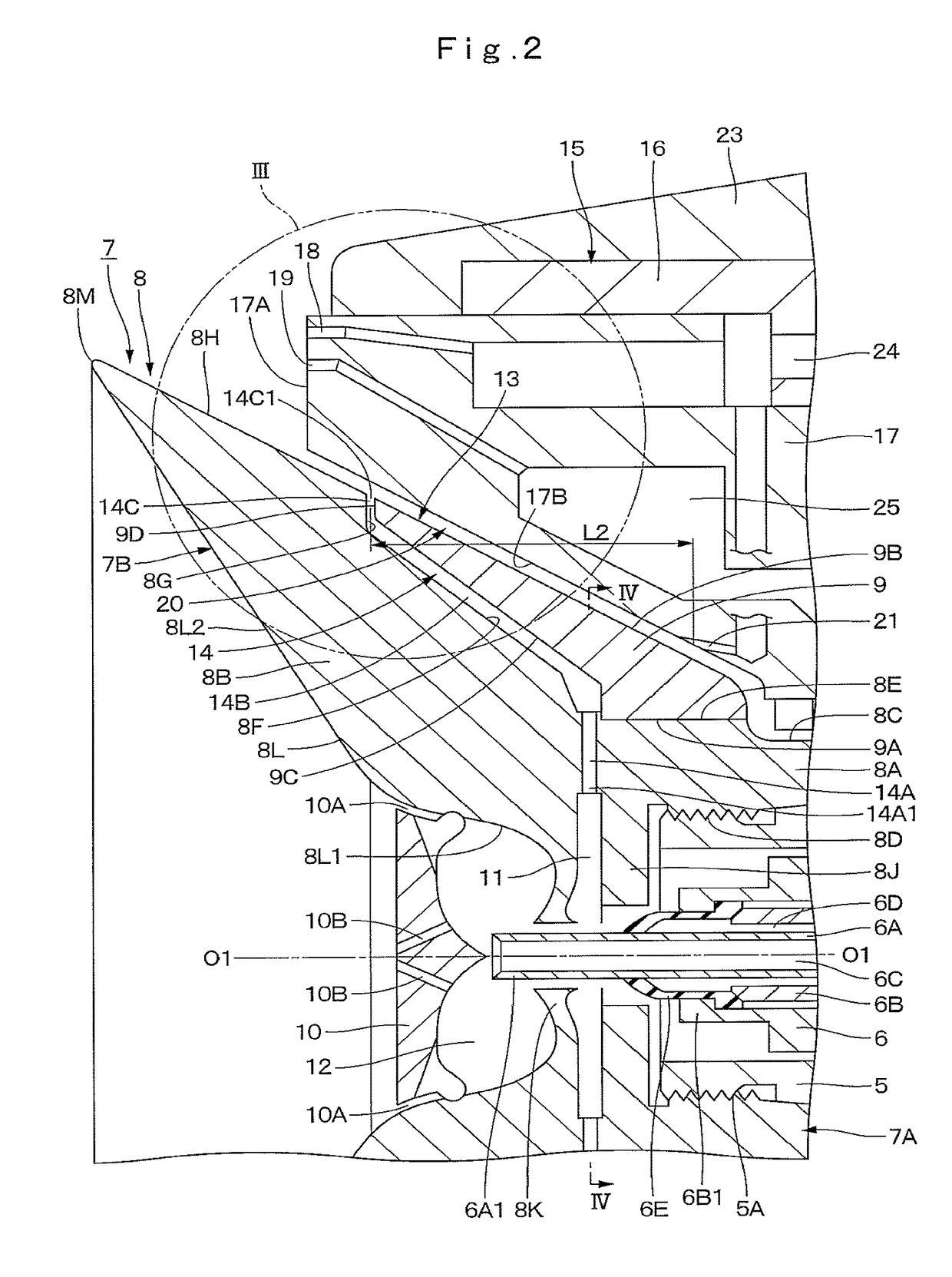

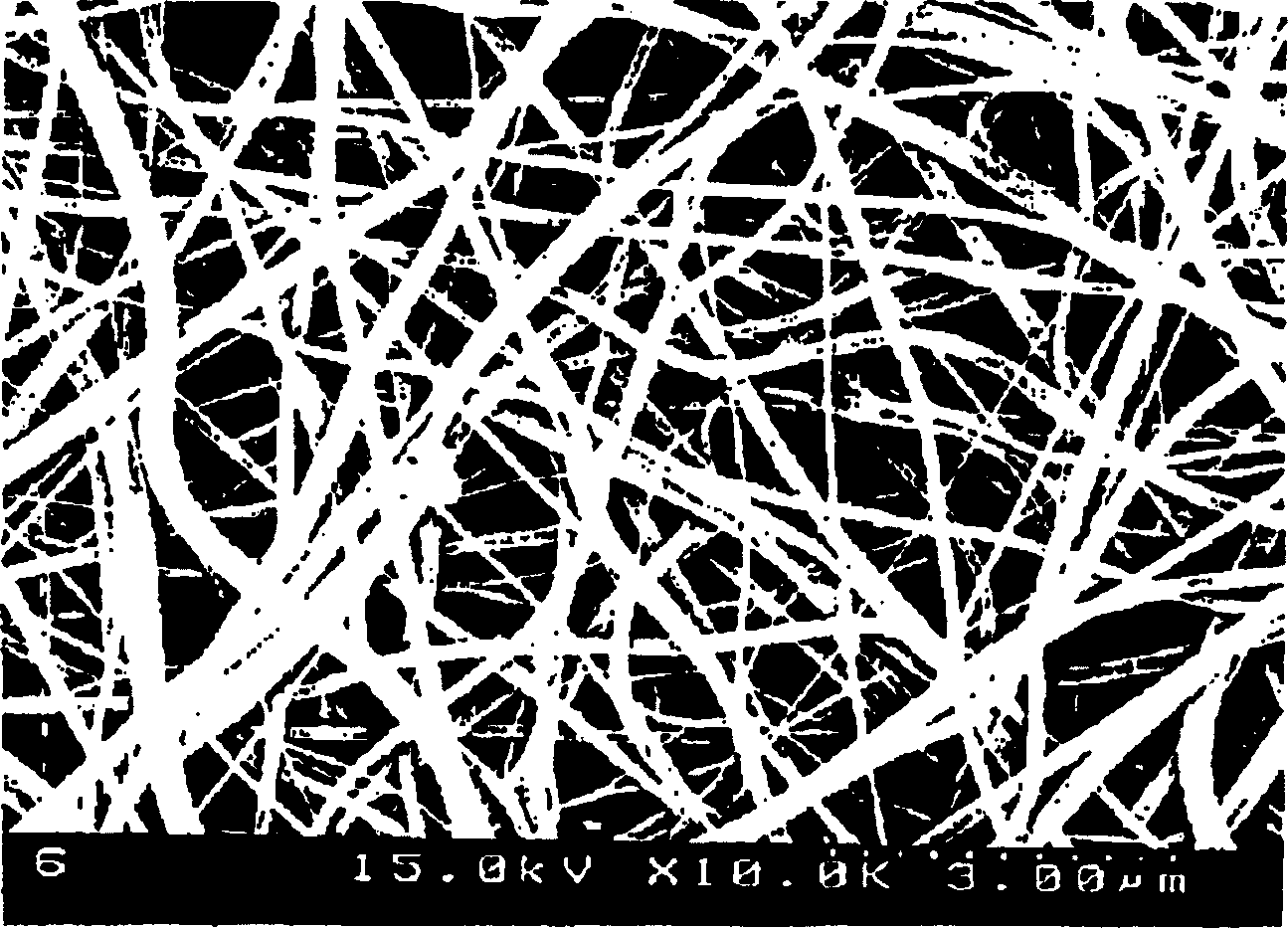

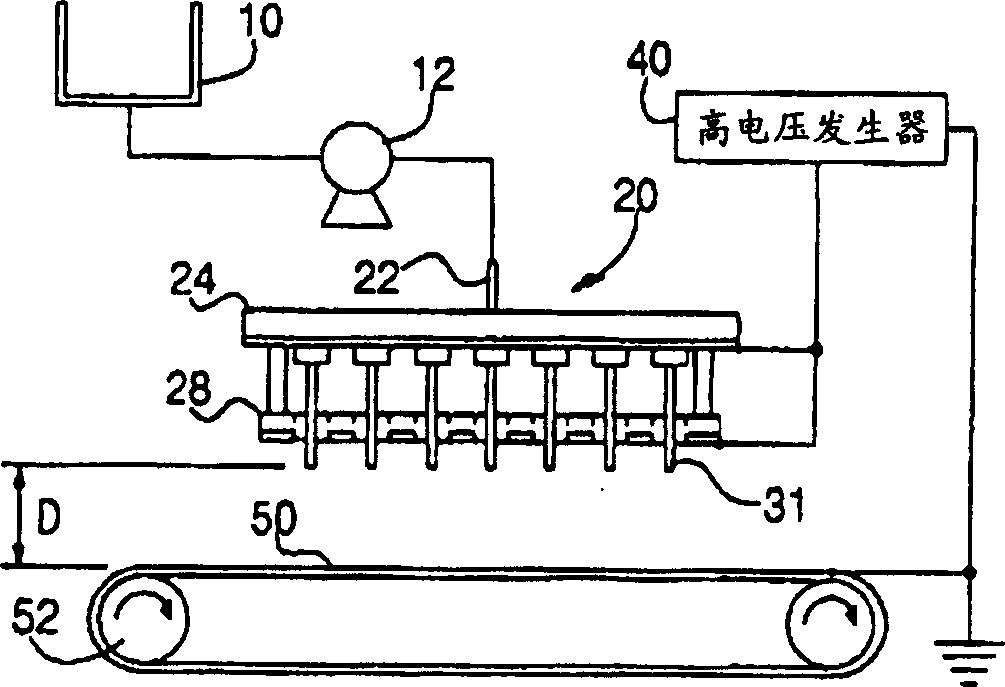

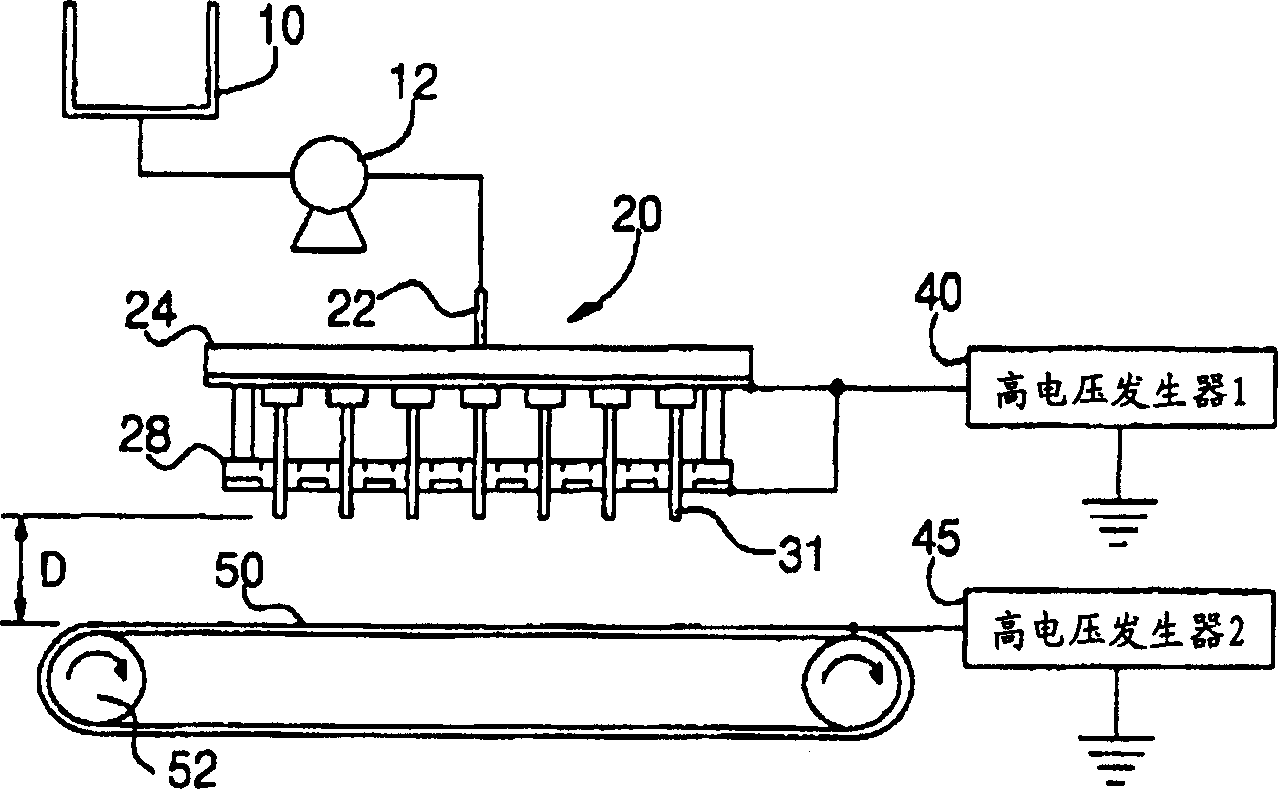

Polymer fibre web mfg. device and method

InactiveCN1435515AHigh porosityImprove productivityNew-spun product collectionWet spinning methodsFiberLiquid state

An apparatus and method for preparing high-molecular fibre net is disclosed. Said method includes preparing a liquid-state high-molecular substance, passing it through more than one electrically charged nozzles until it reaches the lower part of said nozzle while charging it by different electric polarity, and spraying it onto a moving collector.

Owner:KOREA INST OF SCI & TECH

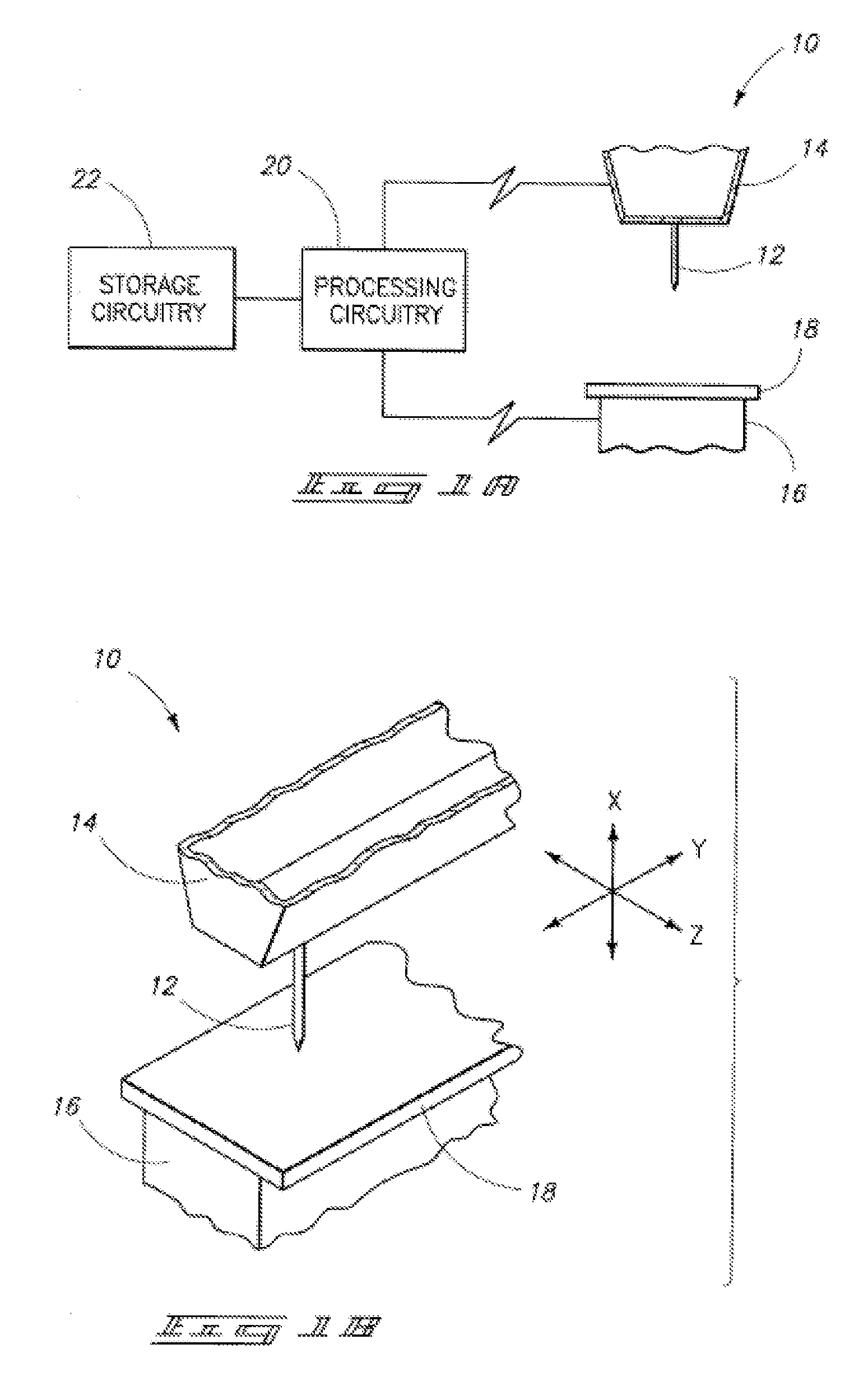

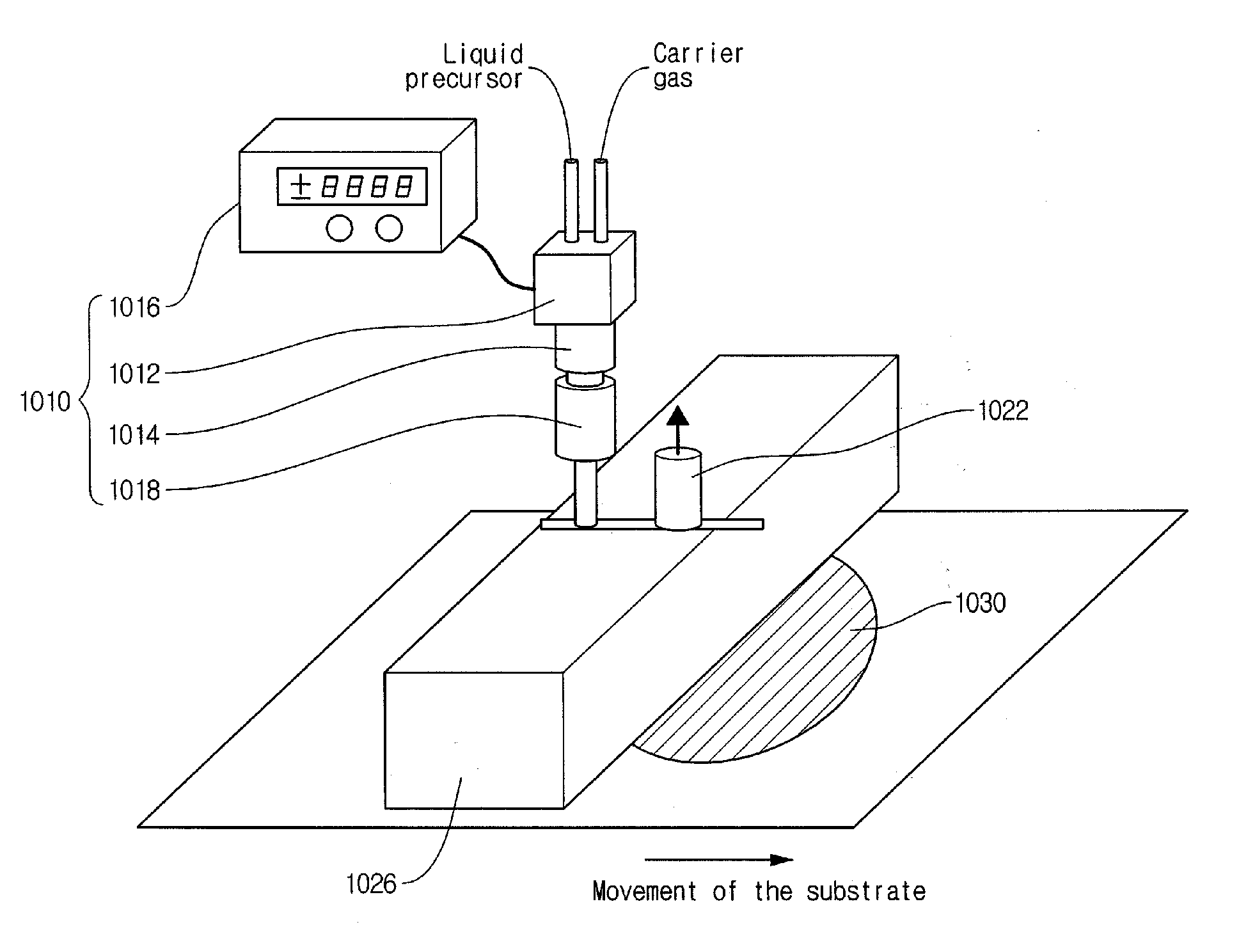

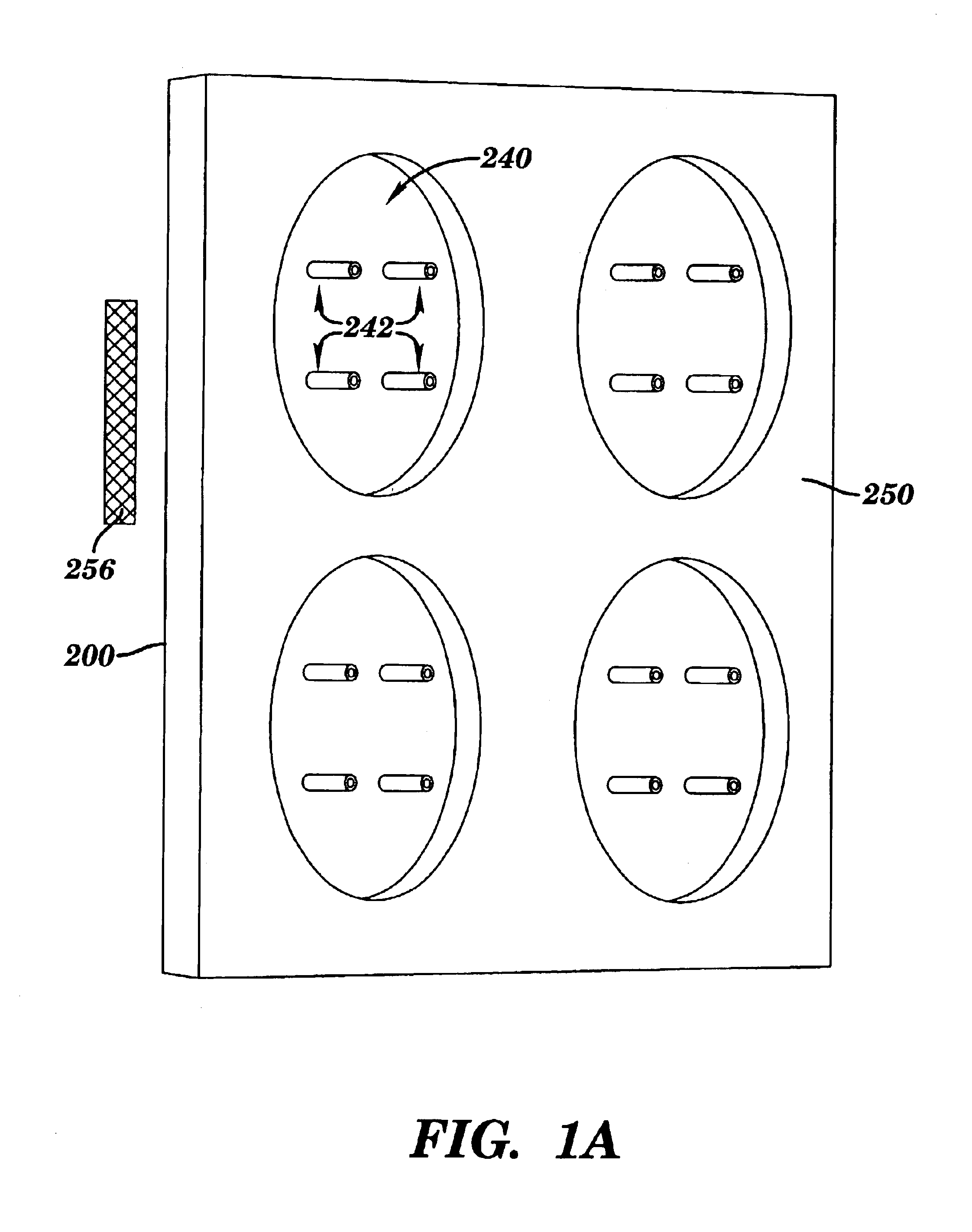

Apparatuses and methods for applying one or more materials on one or more substrates

A system that incorporates teachings of the present disclosure may include, for example, an apparatus having a tube with an ingress opening to receive a liquid, and an egress opening to release the liquid, a conductor positioned in a conduit of the tube, the conductor and the conduit having dimensions to cause a surface tension of the liquid to prevent a constant flow of the liquid from the egress opening, and a power supply coupled to the conductor to apply a charge to the liquid to overcome the surface tension and form at the egress opening a single jet stream of the liquid applicable on a substrate to create a pattern. The single jet stream can be controllable in part by a viscosity of the liquid. Additional embodiments are disclosed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

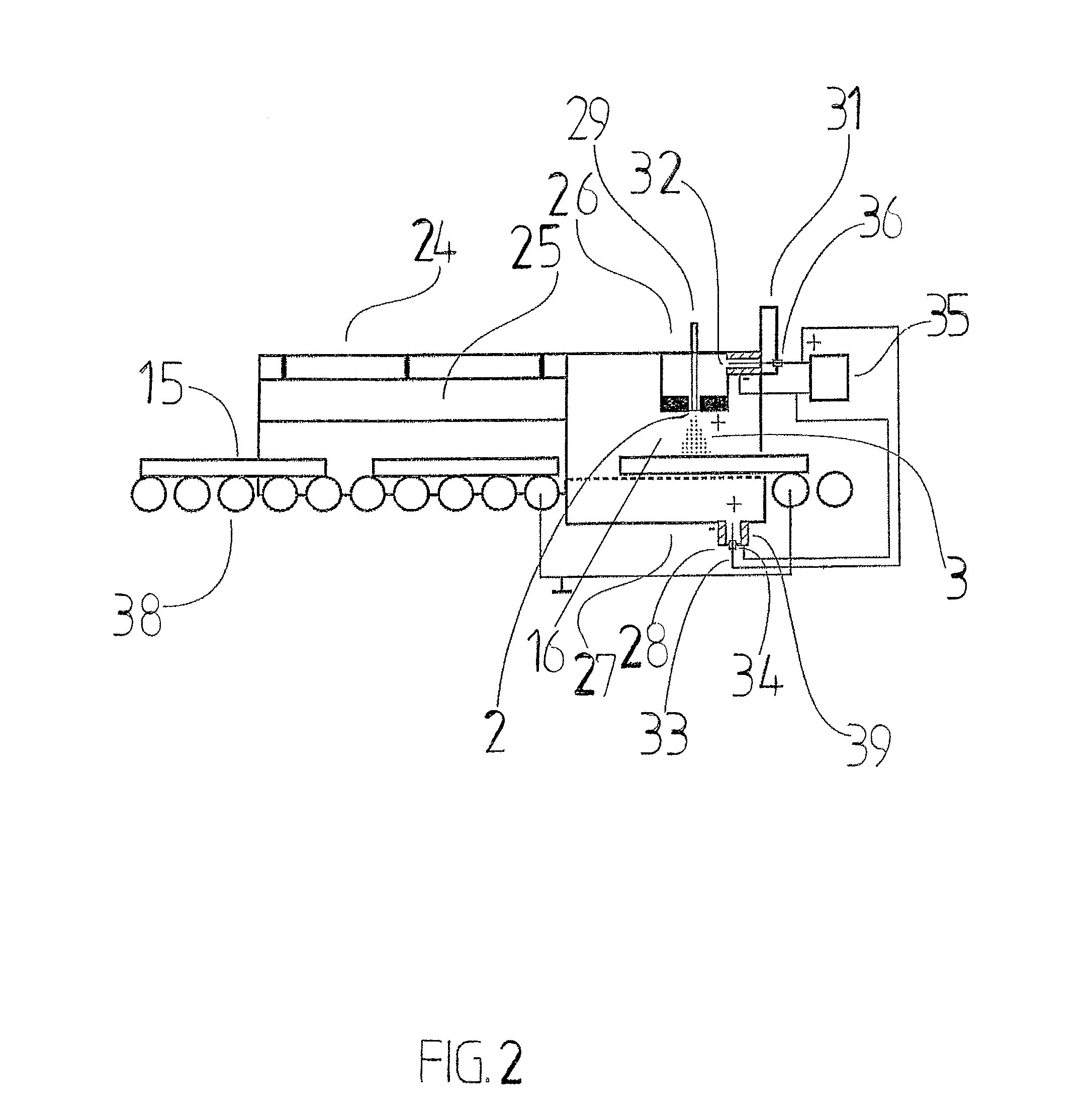

Gantry tower spraying system with cartridge/receptacle assembly

A gantry tower spraying system with a cartridge / receptacle assembly includes a gantry and a spray assembly coupled to the gantry to allow for translational movement of the spray assembly along the gantry. The spray assembly includes a receptacle for receiving a cartridge containing a cosmetic liquid for skin treatment, and a spray nozzle coupled to the receptacle for receiving the cosmetic liquid and dispensing the cosmetic liquid in a spray. The receptacle has an inner surface of a size and shape to generally conform to a size and shape of a portion of an outer surface of the cartridge. The spraying system can further be provided with an oscillation mechanism adapted to cause oscillation of the spray nozzle. The bottle can be provided with a keying mechanism for engaging a corresponding key structure of the receptacle.

Owner:SUNLESS

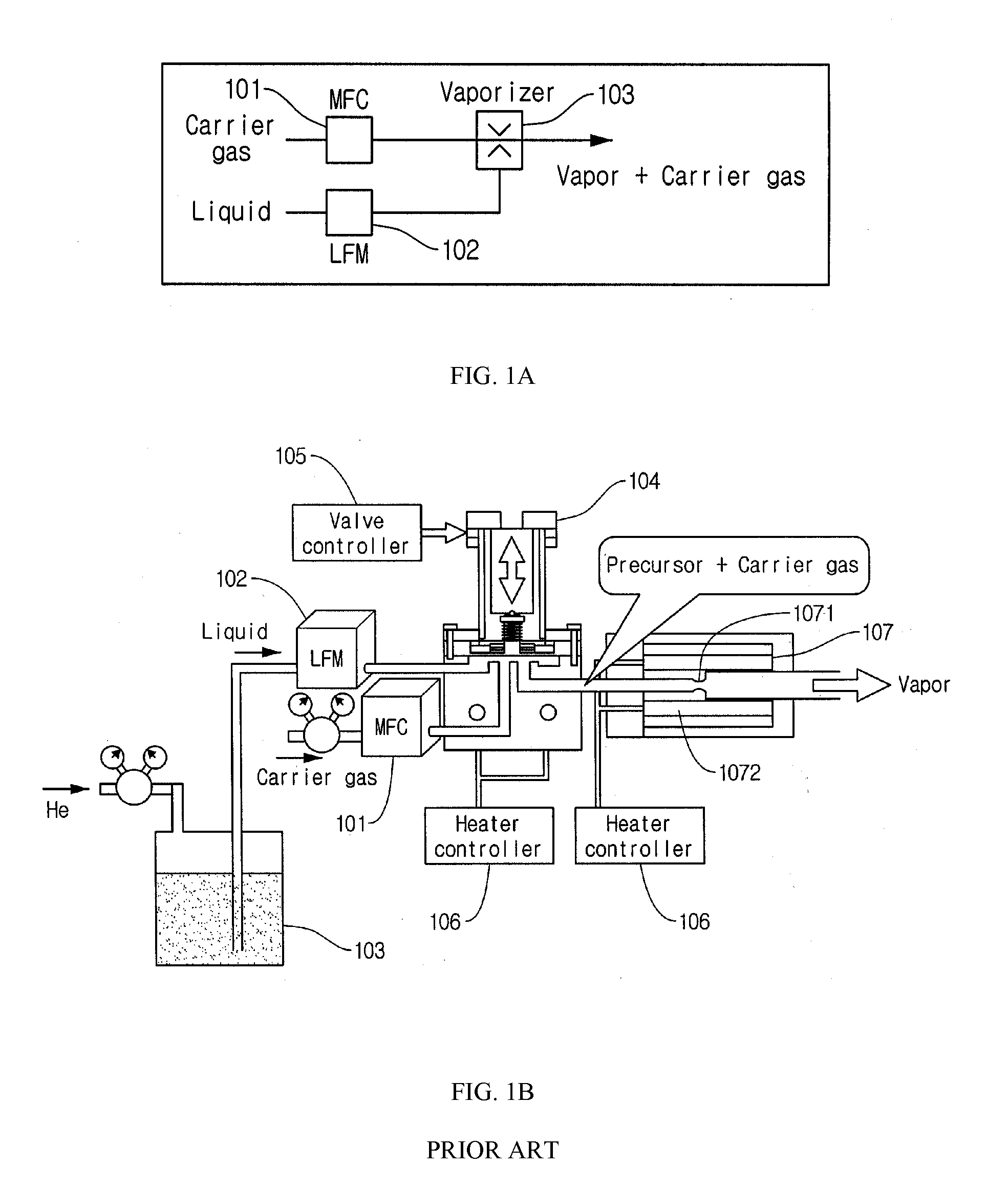

Vaporizing or atomizing of electrically charged droplets

InactiveUS20110262650A1Small sizeSemiconductor/solid-state device manufacturingPretreated surfacesGas phaseEngineering

A vaporizing apparatus includes a chamber, a nozzle for dispersing a liquid into droplets, an electrode electrically isolated from the nozzle, and a heater for generating a vapor by applying heat to the droplets. The voltage source applies charges to the droplets by applying a voltage between the nozzle and the electrode. The vaporizing apparatus may be used to devices that deposit organic or inorganic thin films by chemical vapor deposition and / or atomic layer deposition processes, devices for supplying precursor materials that are deposited to form a thin film in organic light emitting diodes, devices that supply organic or inorganic precursor materials for encapsulation, and devices for supplying organic or inorganic polymer.

Owner:VEECO ALD

Electrostatic liquid spray nozzle having an internal dielectric shroud

ActiveUS20140110492A1Reduce electric field strengthAvoid leakage currentBurnersLiquid spraying apparatusElectricityElectrical conductor

An electrostatic sprayer for spraying a liquid includes a nozzle formed from a a nozzle body that has an inlet for receiving a liquid and a liquid tip having an outlet for ejection of the liquid to form a liquid spray. The nozzle also includes an electrode disposed around the outlet of the liquid tip for charging the liquid and a dielectric shroud disposed around at least a portion of the liquid tip to prevent leakage currents from reducing a potential of the electric field between the liquid and the electrode, which would otherwise reduce the effectiveness of the sprayer. A conductor that couples the electrode to a power supply may pass through a hole extending through the shroud. The shroud may include one or more vents to permit air and liquid to pass through the dielectric shroud to reduce accumulation of liquid.

Owner:E S PROD DEV

Method and apparatus for dispersing a volatile composition

InactiveUS6877271B2Facilitate such dispersalLiquid surface applicatorsGaseous substancesInsect repellentOrganic chemistry

An apparatus and method for dispersing a volatile composition, which method comprises dispersing the volatile composition into an air steam; and generating an ion wind, thereby causing the molecules of the composition to become electrically charged. The composition can be an insect repellent, an insecticide, an anti-microbial, an anti-allergenic or a room-fragrancing composition

Owner:RECKITT BENCKISER (UK) LTD +1

Method of using a spray gun and material produced thereby

An apparatus for mixing a first material with a second material and then spraying the resultant material onto a surface. The second material is mixed with a gas before the being introduced to the first material. A static charge is created and deposited onto the resultant material to help align the resultant material particles.

Owner:ALPHAGEN MATERIALS TECH

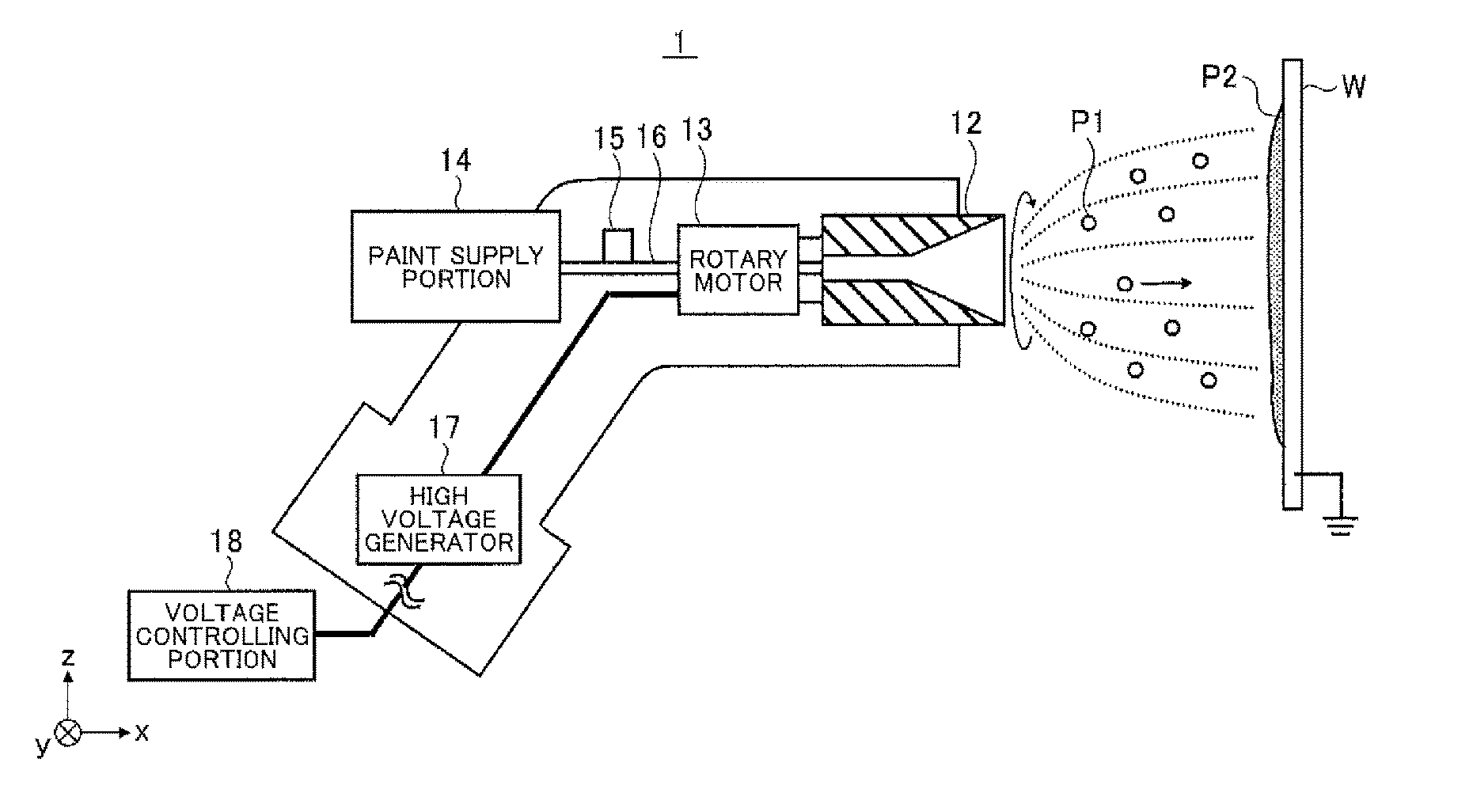

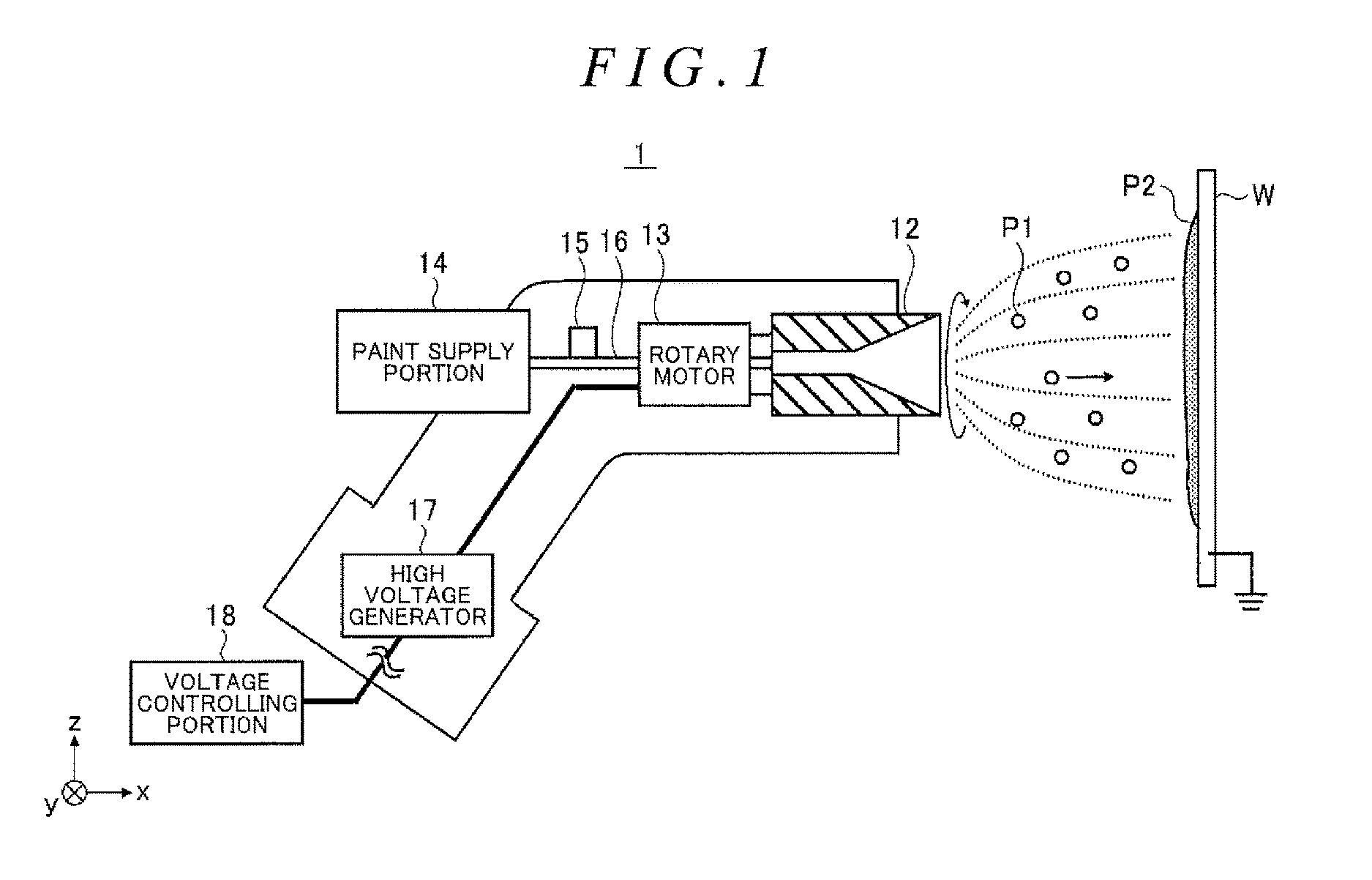

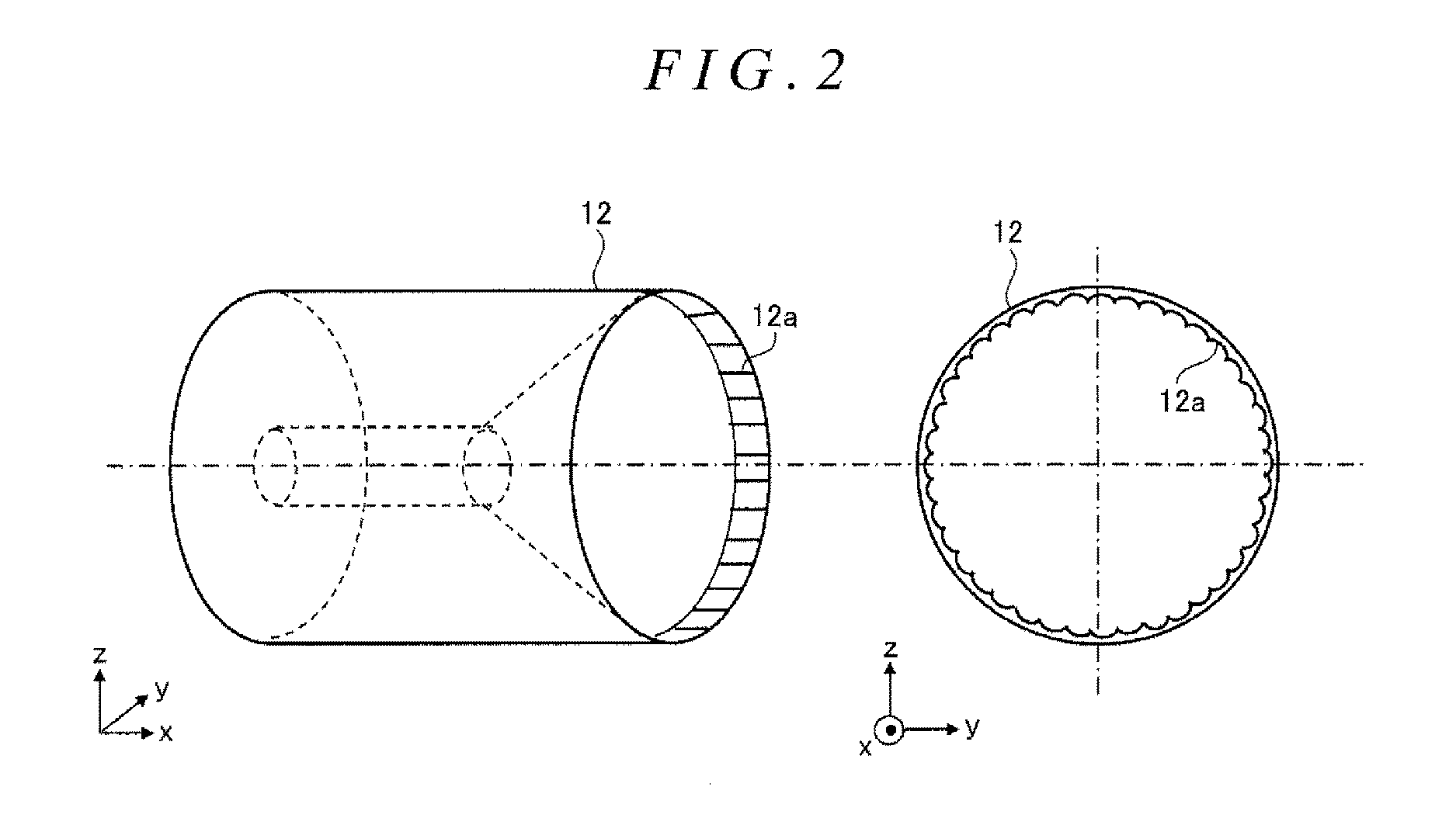

Electrostatic atomizing coating apparatus and coating method

ActiveUS20170056901A1Improve coating efficiencyEffective applicationLiquid surface applicatorsCoatingsUltimate tensile strengthVoltage

An electrostatic atomizing coating apparatus and method incorporate a rotary head having a base portion, an open end and a plurality of grooves formed radially on an inner peripheral surface of the open end, an inside diameter of the rotary head increasing from the base portion toward the open end, and a motor configured to rotate the rotary head to discharge a thread-shaped paint. A voltage is applied to the rotary head so as to form an electrostatic field between the open end of the rotary head and an earthed coating target and to electrostatically atomize the thread-shaped paint discharged from the open end. Voltage output from the generator is controlled so as to adjust an intensity of the electrostatic field and to control a particle diameter of the electrostatically atomized thread-shaped paint.

Owner:TOYOTA JIDOSHA KK

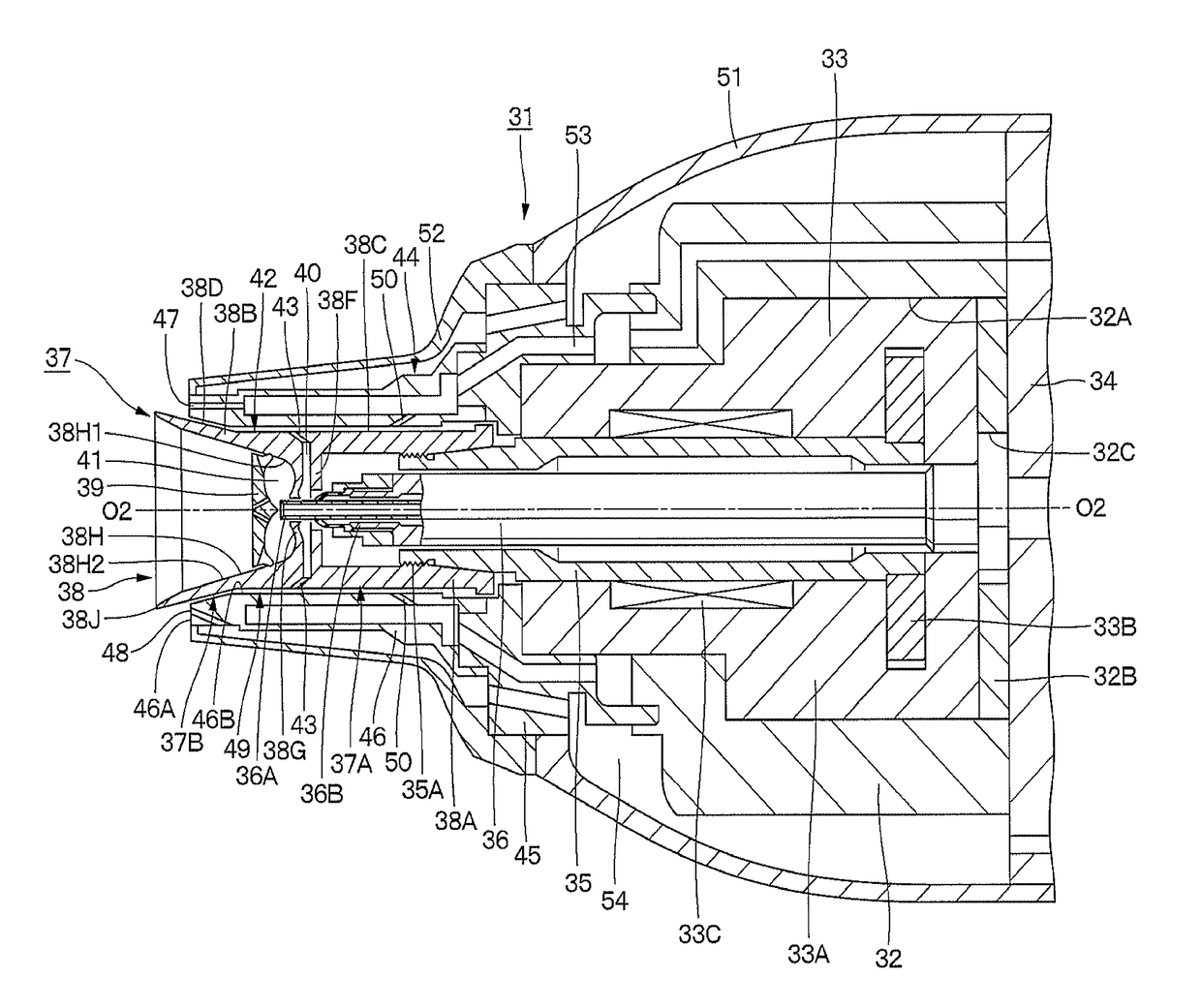

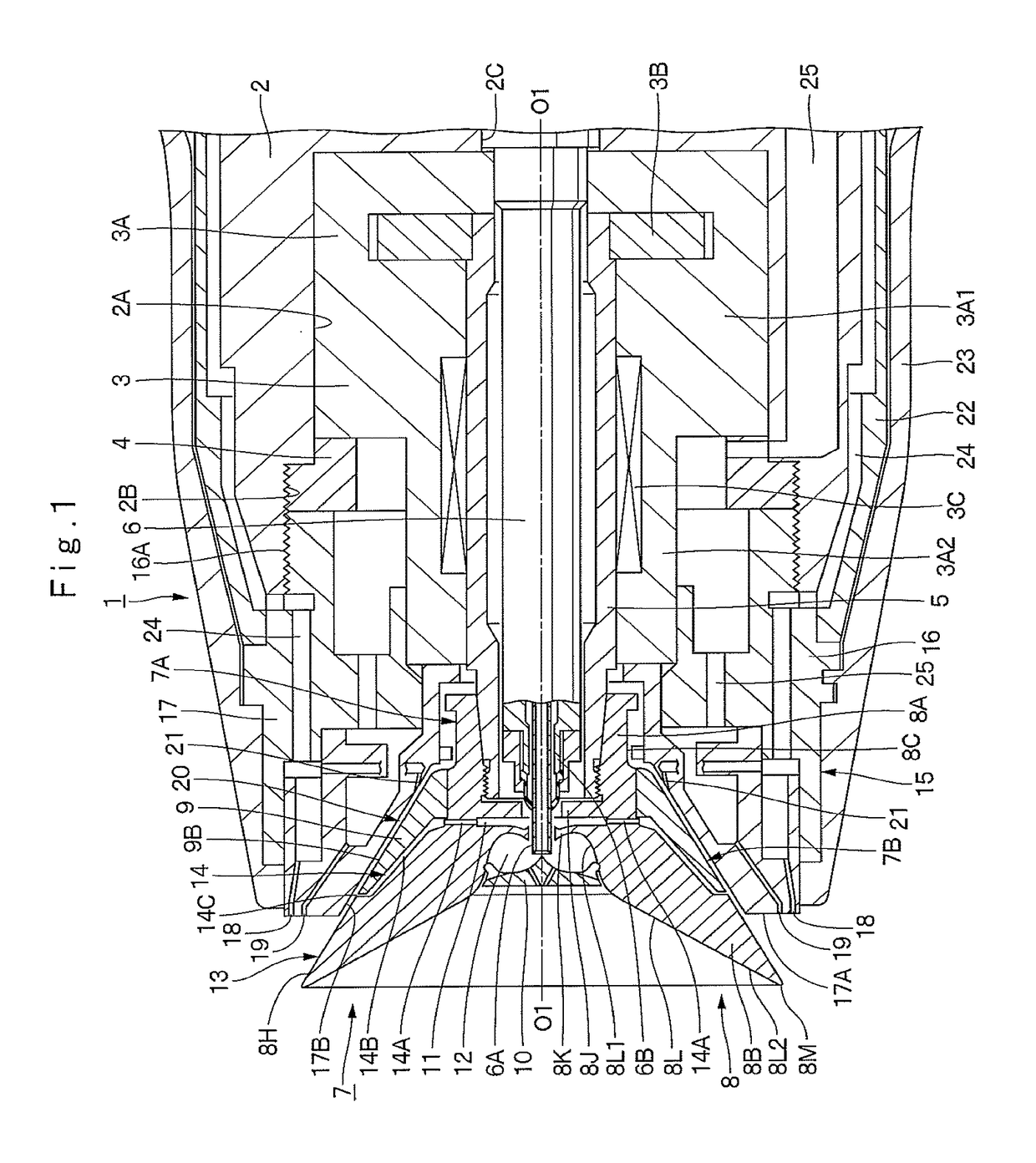

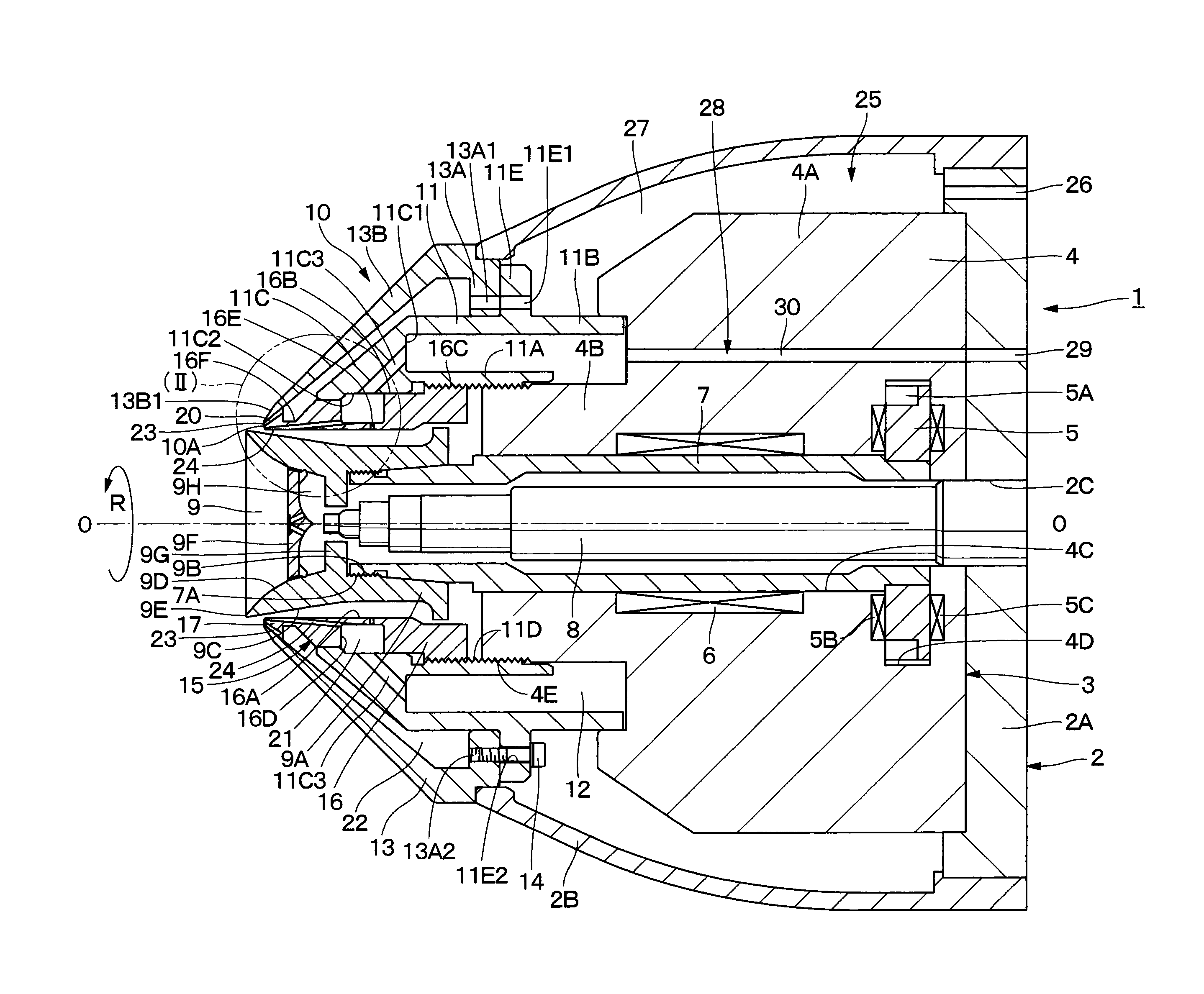

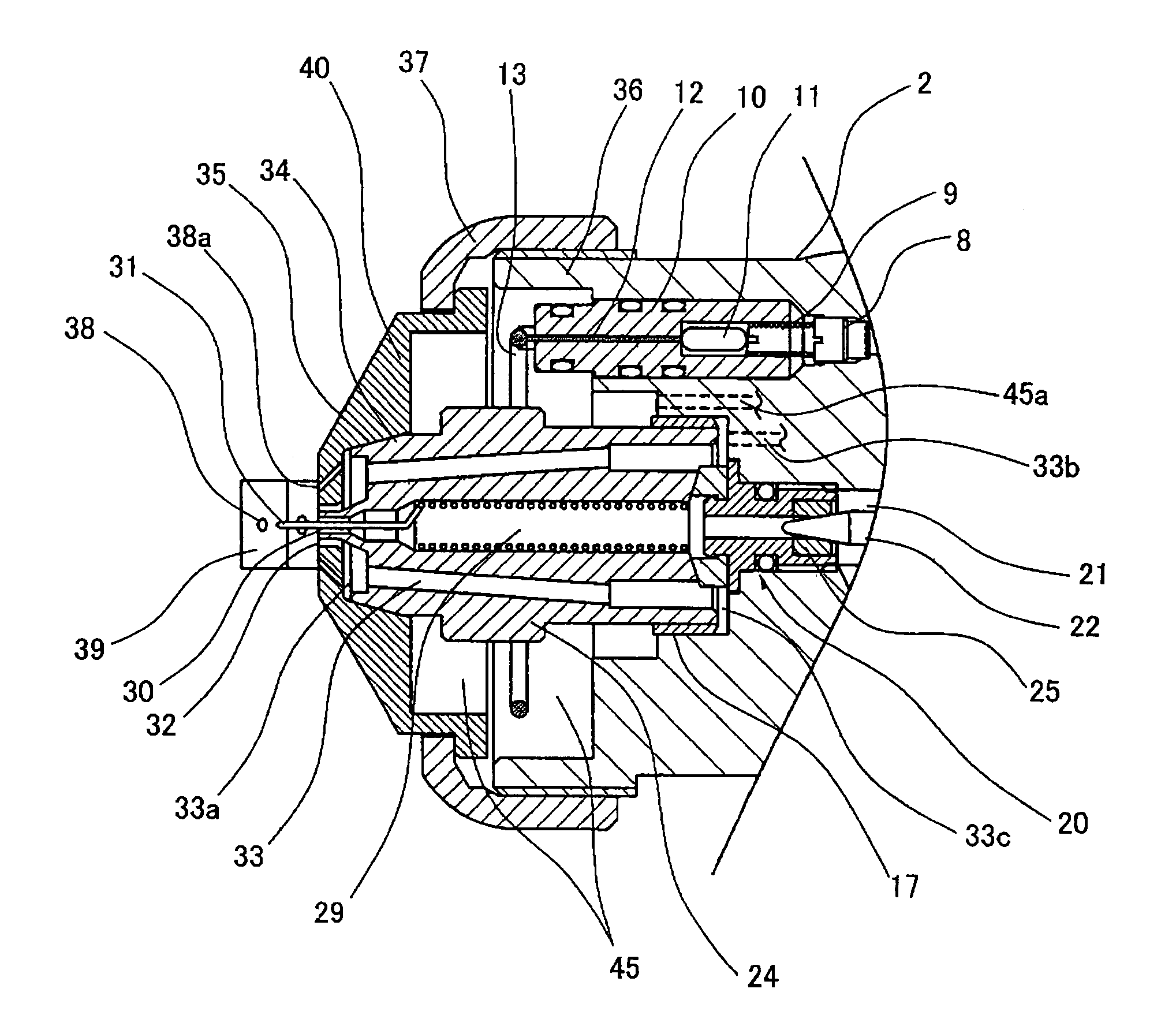

Rotary atomizing head type coating machine

ActiveUS20170128969A1Increase productivityImprove workabilityLiquid spraying plantsMovable spraying apparatusAcute angleEngineering

A rotary atomizing head (7) is provided with an outer peripheral surface washing passage (14) open onto anatomizing head outer peripheral surface (13) for causing wash fluid supplied from a feed tube (6) to flow out into an annular clearance (20) between the rotary atomizing head (7) and a shaping air ring (15). An outflow opening (14C1) of an outflow passage (14C) constituting the outer peripheral surface washing passage (14) is provided in a position closer to the backside into the annular clearance (20) by a length dimension (L1) than a front end surface (17A) of a front ring section (17) constituting the shaping air ring (15). Further, the outflow opening (14C1) opens to the annular clearance (20) in an angle (α1) that is an acute angle to the atomizing head outer peripheral surface (13).

Owner:ABB (SCHWEIZ) AG

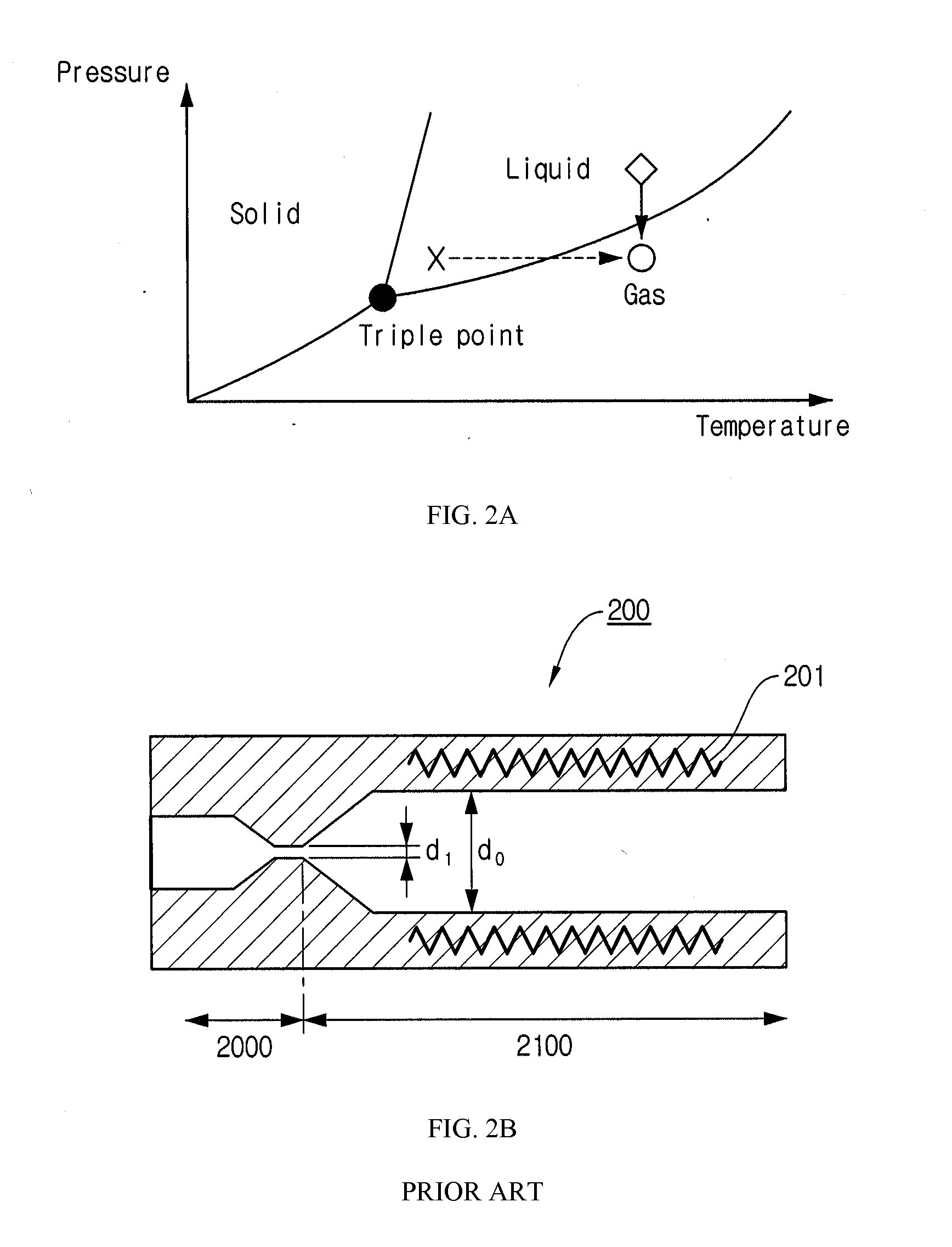

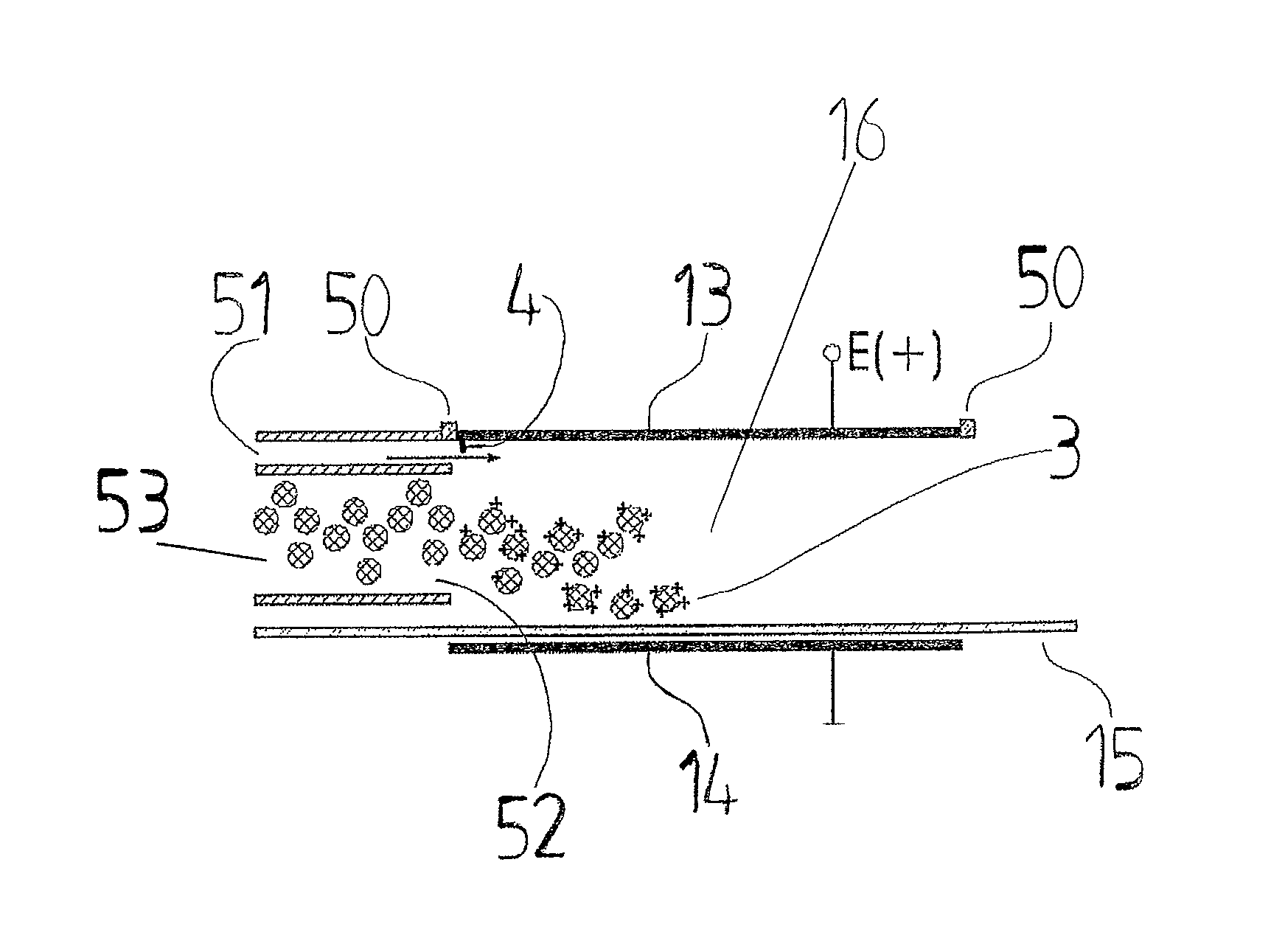

Apparatus and method for coating glass substrate

InactiveUS20130164452A1Increase probabilitySimple processElectric shock equipmentsChemical vapor deposition coatingMaterials scienceDeposition chamber

A method and apparatus for coating a substrate using one or more liquid starting materials. The substrate is coated by atomizing one or more liquid starting materials into droplets and vaporizing the droplets in a deposition chamber for before the starting materials react on the surface of the substrate. The droplets are guided towards the substrate with electrical forces before the droplets are vaporized.

Owner:BENEQ OY

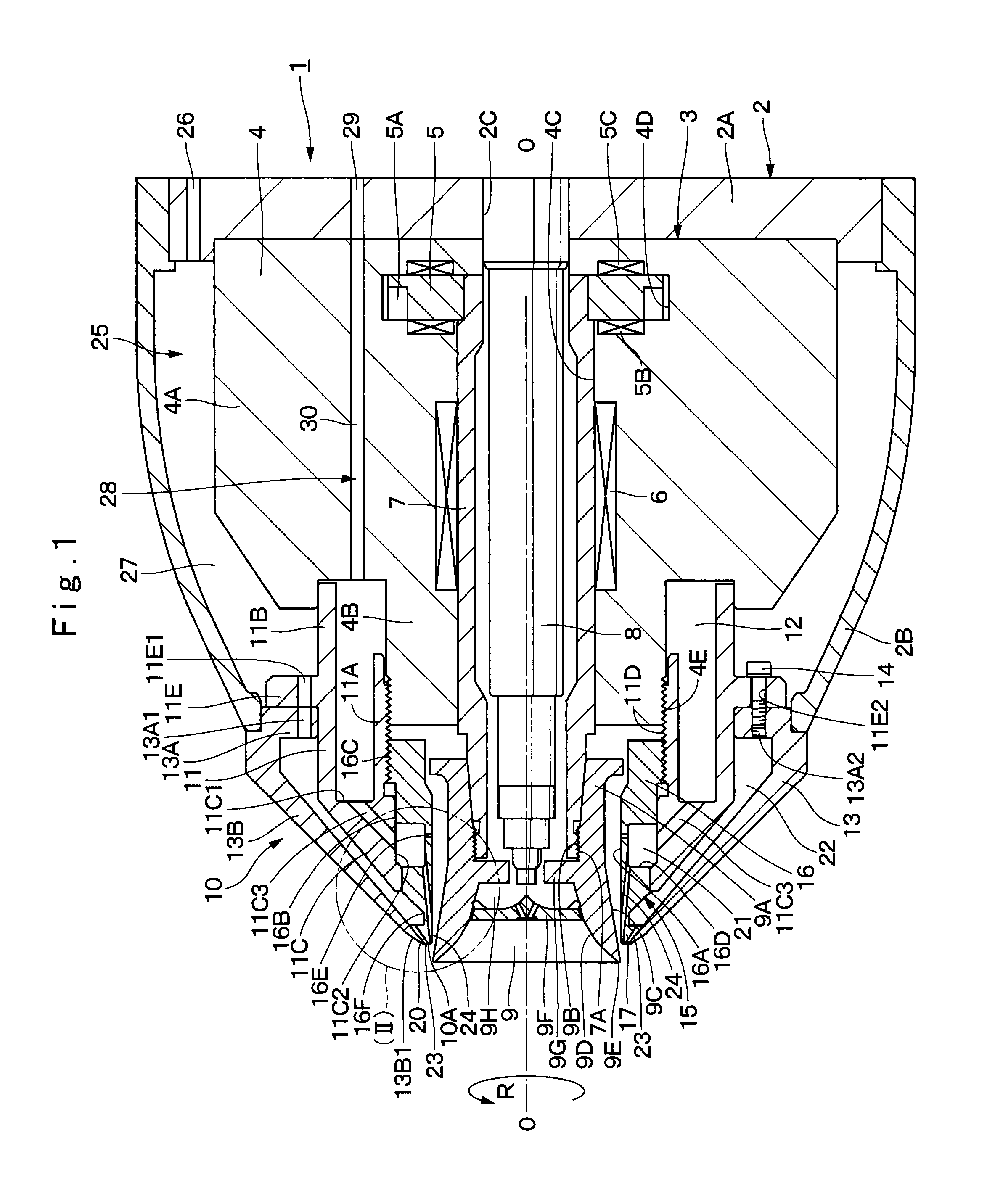

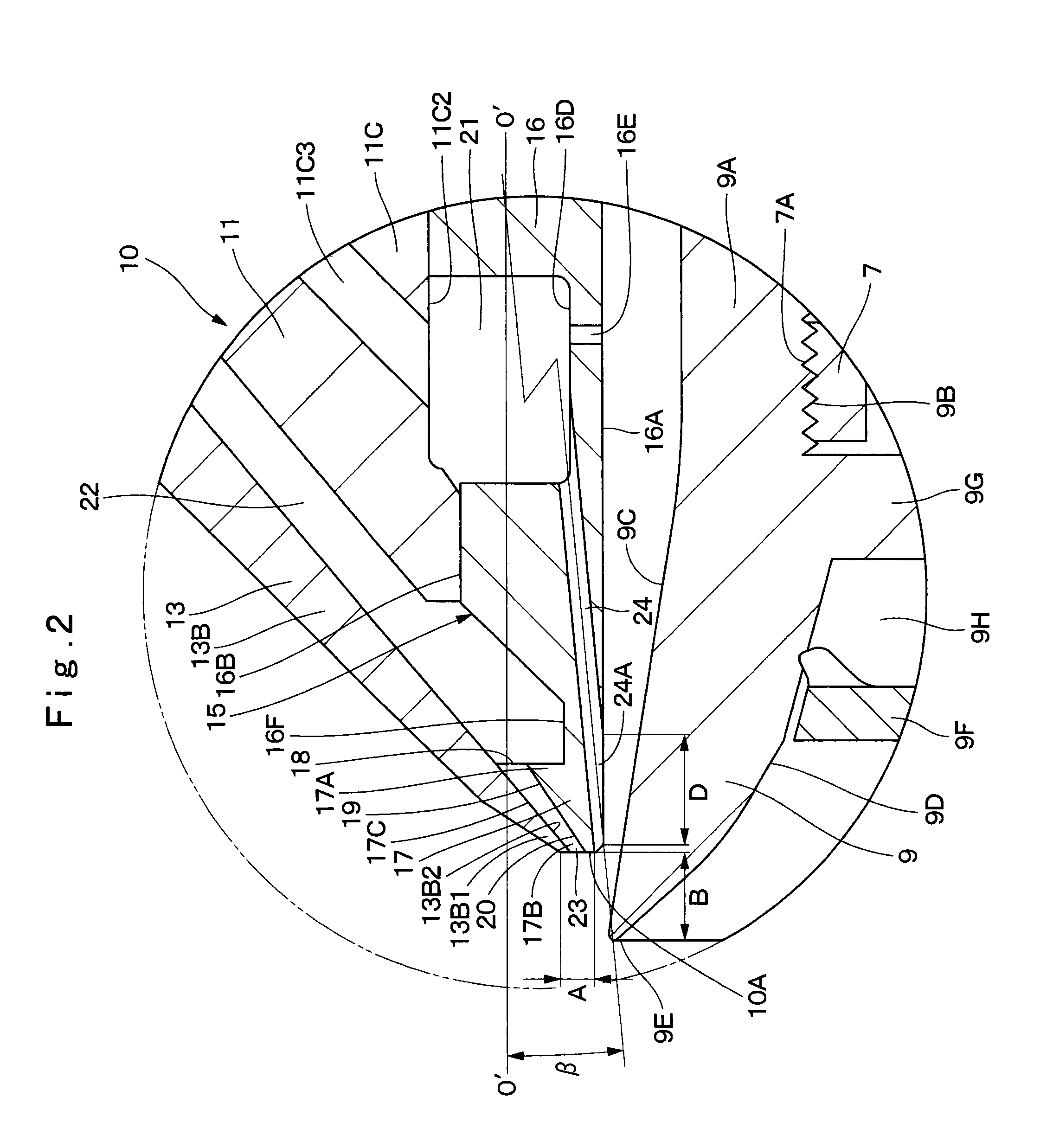

Rotary atomizing head type coating machine

ActiveUS20160059248A1Easy to cleanDifficult to attachMovable spraying apparatusSpray nozzlesEngineeringSpray forming

A shaping air ring (10) is configured of a body (11), a cover (13) and a nozzle (15). A tapered conical protrusion (17) is provided in a front end of the nozzle (15) to abut on the cover (13) in contact therewith without a clearance therebetween. Numerous inclined recessed grooves (20) are provided on a forward tapered surfaces (17C) of the conical protrusion (17) over the entire periphery. Further, a first shaping air ejecting hole (23) is formed between each of the inclined recessed grooves (20) and an inner peripheral surface (13B2) of the cover (13) to eject shaping air toward a releasing edge (9E) of a rotary atomizing head (9). Second shaping air ejecting holes (24) are provided on an inner peripheral surface (16A) of the nozzle (15) to eject shaping air along an outer peripheral surface (9C) of the rotary atomizing head (9).

Owner:ABB (SCHWEIZ) AG

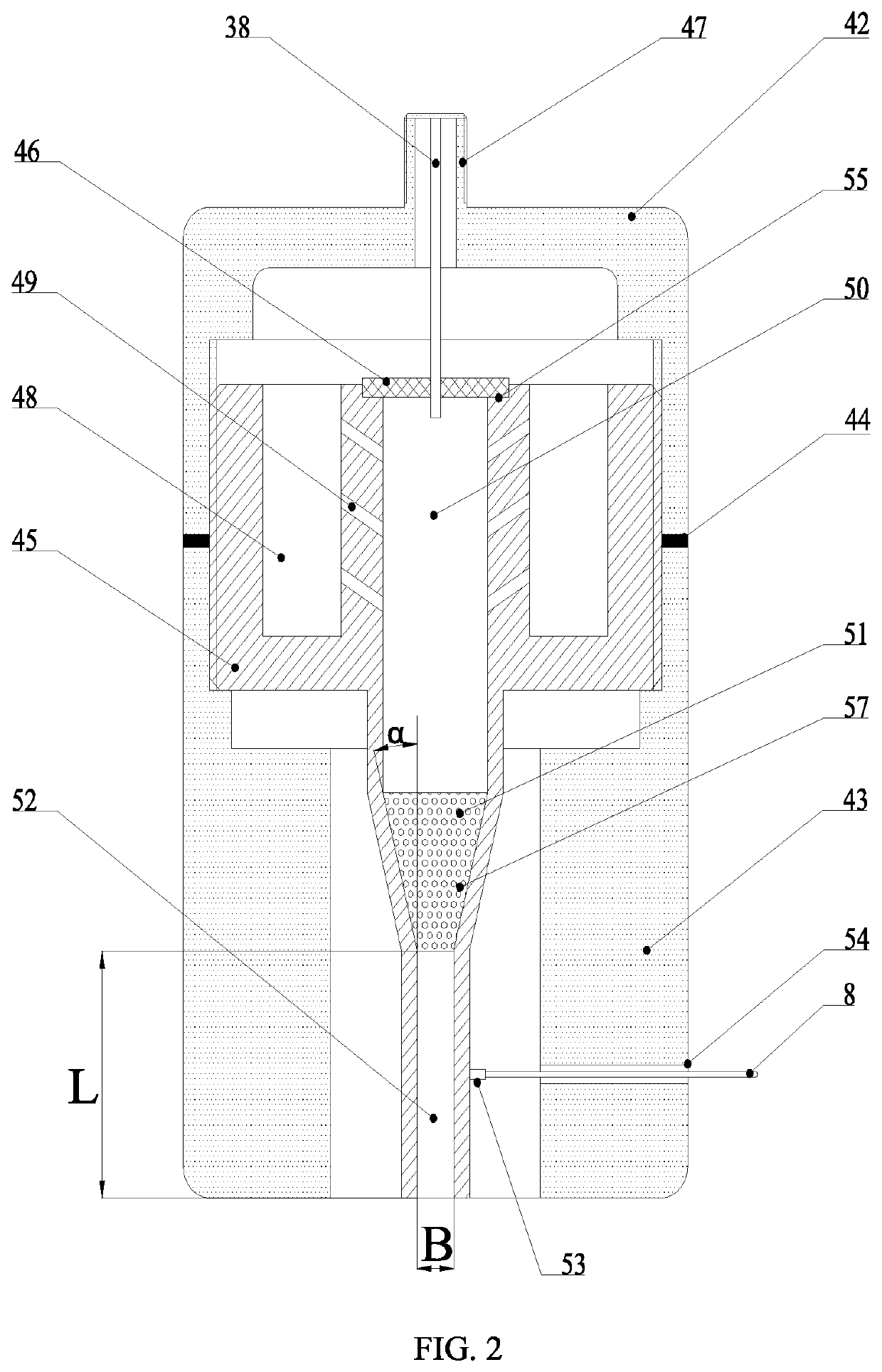

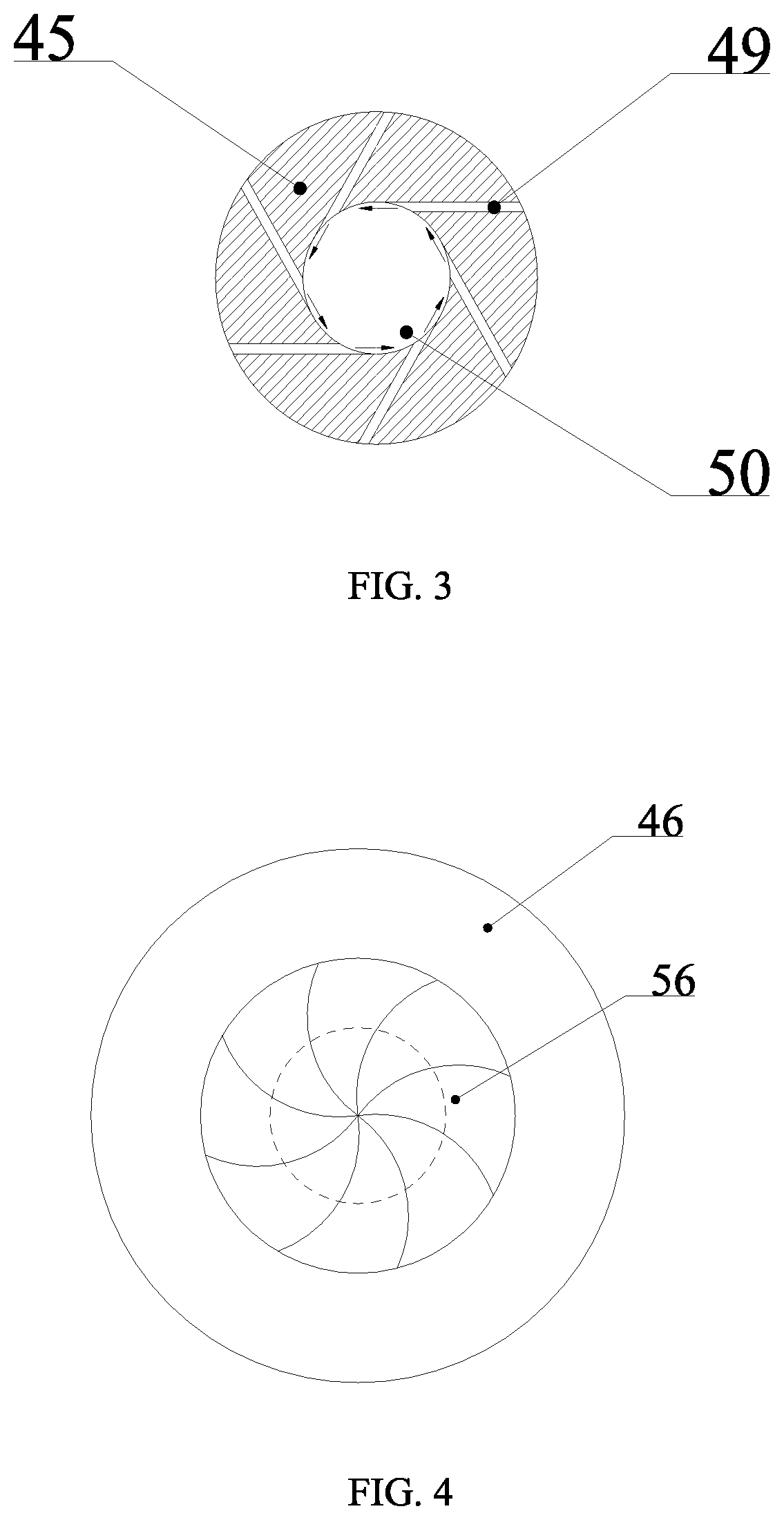

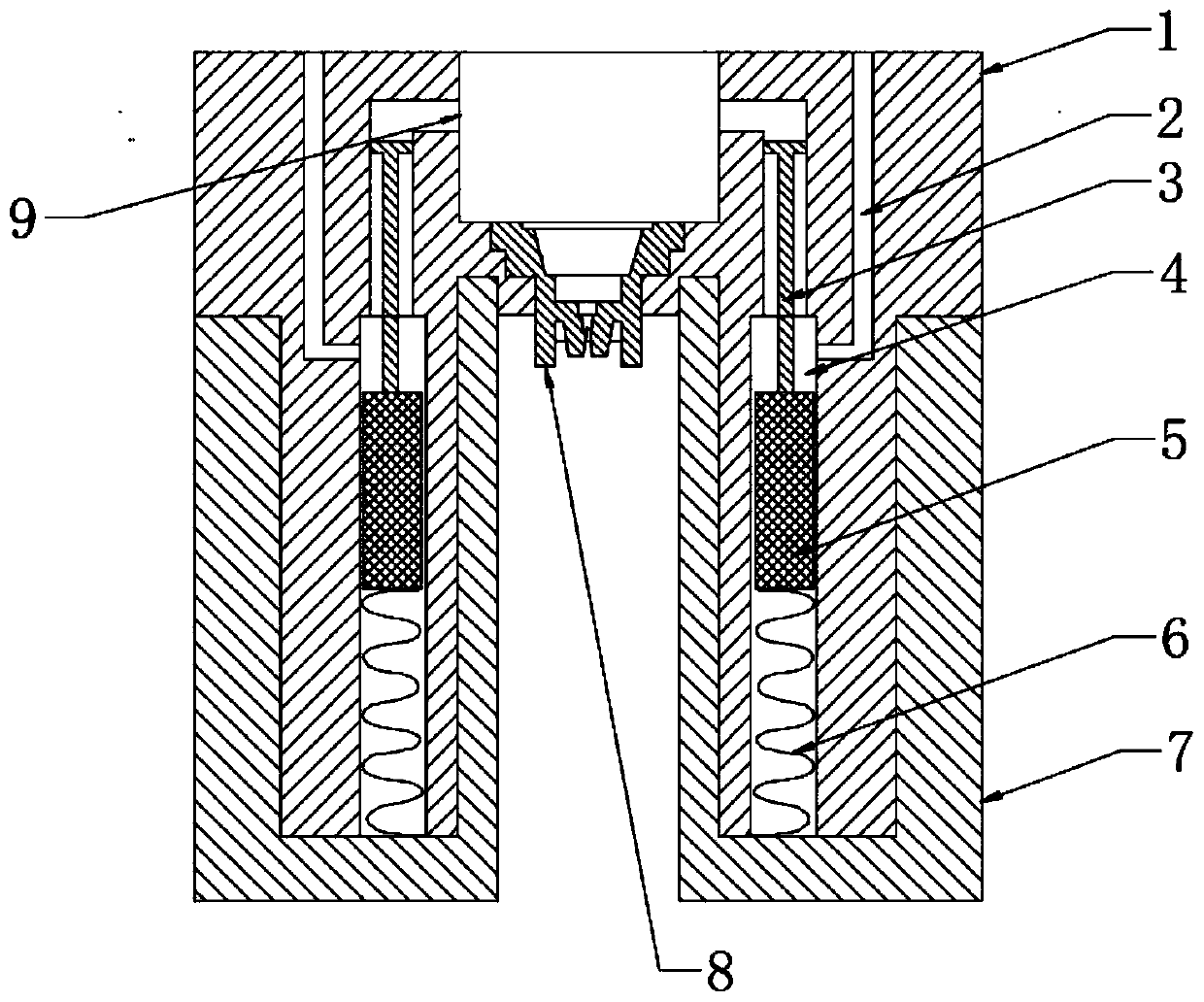

Electrostatic nozzle and controllable jet minimal quantity lubrication grinding system

InactiveUS20200282411A1Improve lipophilicityLiquid supply arrangementsSpray nozzlesEngineeringLubrication

The present disclosure provides an electrostatic nozzle and a controllable jet minimal quantity lubrication (MQL) grinding system. The electrostatic nozzle comprises a nozzle core; an upper nozzle body is connected above the nozzle core; a free space is formed between the upper nozzle body and the nozzle core for storing compressed air and reducing pressure; a lower nozzle body is connected below the nozzle core; a gas-liquid mixing chamber, an acceleration chamber and a nozzle outlet are sequentially arranged inside the nozzle core from top to bottom; and micro-bulges are uniformly distributed on an inner wall of the acceleration chamber.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

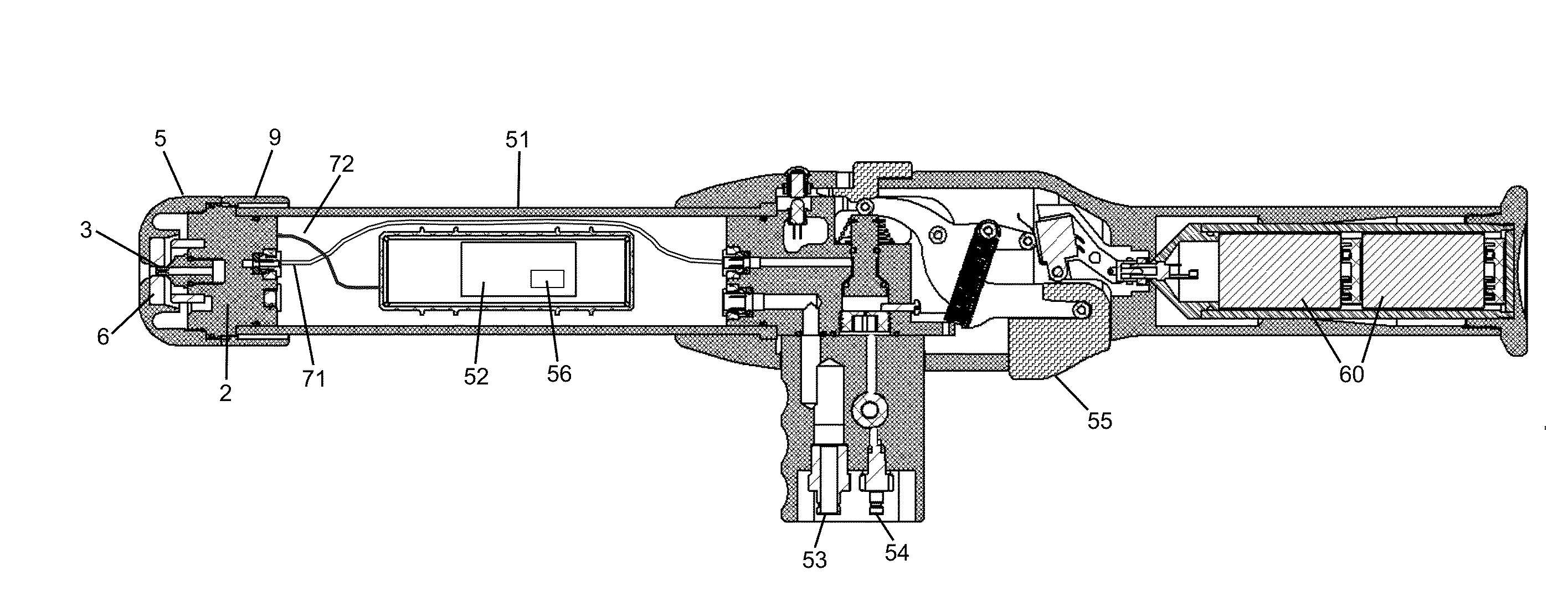

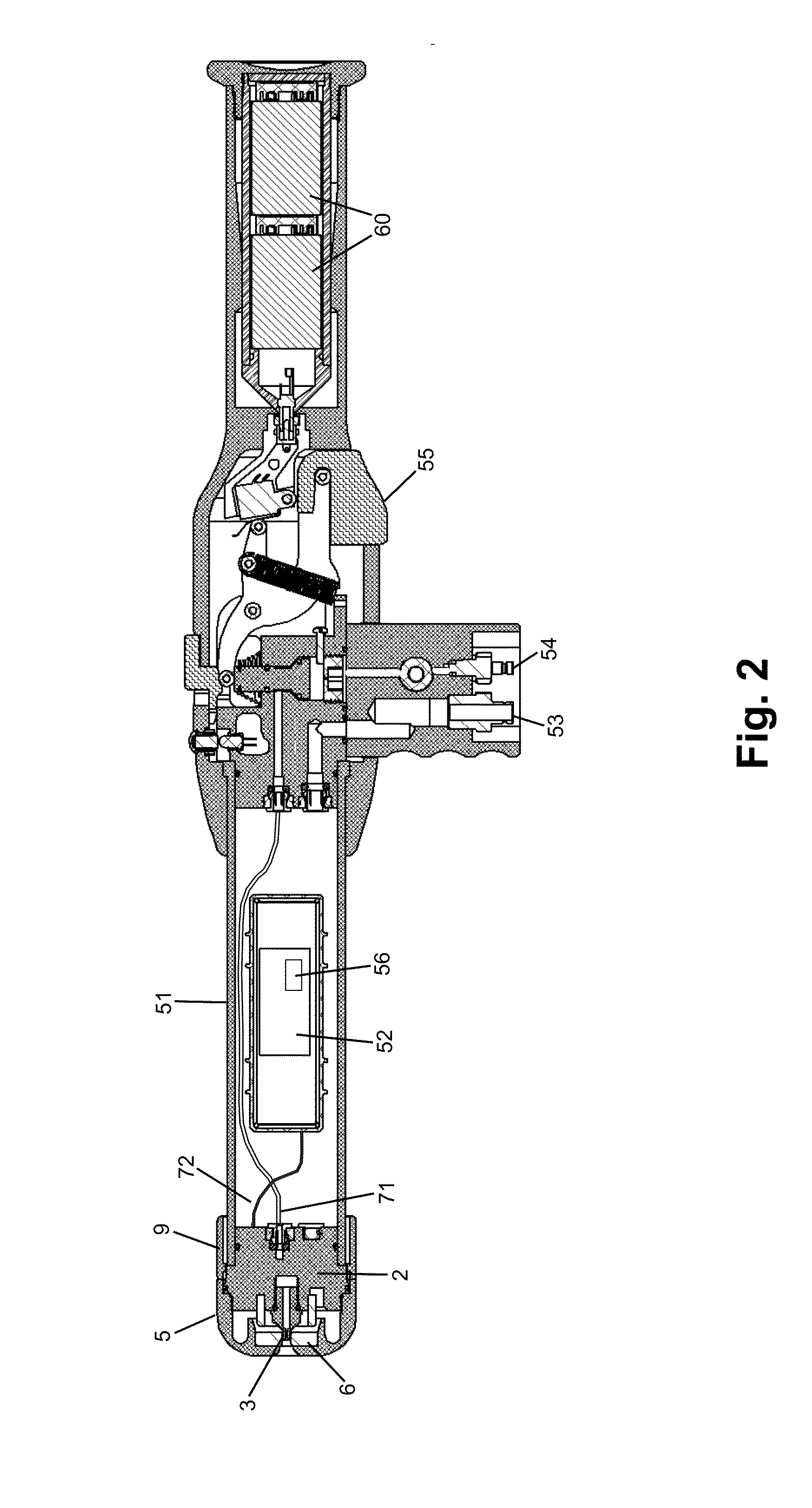

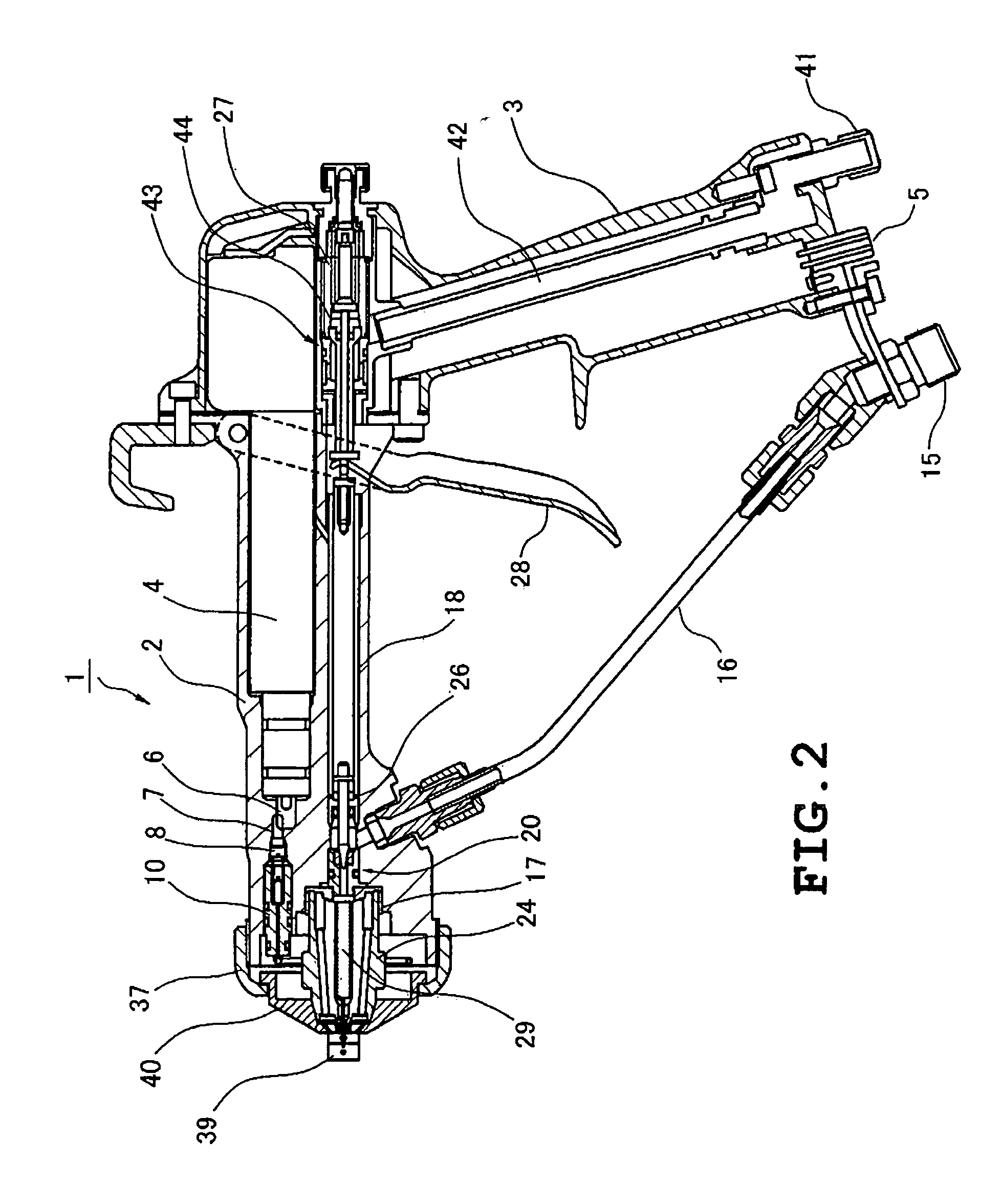

Electrostatic coating spray gun

InactiveUS7748651B2Compact structureReduce the amount requiredBurnersLiquid surface applicatorsElectrical resistance and conductanceElectrostatic coating

A spray gun suitable for electrostatic coating, using a coating material whose electric resistance is relatively low. A coating material nozzle is attached to the front middle region of a barrel having a forwardly projecting cylindrical section on the front outer peripheral edge, and an air cap which covers their front surfaces is installed. A pattern air flow channel is formed between the air cap, coating material nozzle outer peripheral surface and the cylindrical section inner peripheral surface, and an annular electrode is attached to the inside of the flow channel. The air cap is centrally provided with an atomization air spout hole, and a coating material delivery port at the front end of the coating material nozzle is inserted therein. A pin electrode is projected forward through the coating material delivery port. Two pairs of projections project forward from two sets of opposed locations for the air cap, each with a pattern air spout hole. The pin electrode is grounded and a high dc voltage is applied to the annular electrode.

Owner:ASAHI SANAC KK

Method for carrying out outer anticorrosion on DN3600 buried steel tube by adopting molten epoxy powder

InactiveCN101602043AGuaranteed coating environmentGuaranteed coating effectPretreated surfacesCoatingsEpoxyMetallurgy

The invention relates to a method for carrying out outer anticorrosion on a DN3600 buried steel tube by adopting molten epoxy powder, and belongs to the field of anticorrosion of tube materials. A coating process comprises material loading, preheating of the outer surface of the steel tube, deep shot blasting and derusting, superlarge power medium-frequency heating, powder spraying and coating and water cooling. Aiming at the characteristics of large diameter and extremely-small rate of the wall thickness to the diameter of a large-diameter buried steel tube with DN3600 millimeter and more than DN3600 millimeter, the method optimizes the whole machining process, controls the velocity of temperature rising, heating and cooling through the control of a moving speed of the steel tube, ensures the coating environment and the coating effect of the steel tube and the adhesion effect of a coating layer and ensures that the quality of an outer anticorrosive coating layer of the large-diameter buried steel tube meets the relevant quality acceptance standards of the state.

Owner:SHANGHAI JIANZHIZHEN ANTI CORROSION TECH DEV

Method Of Using a Spray Gun and Material Produced Thereby

An apparatus for mixing a first material with a second material and then spraying the resultant material onto a surface. The second material is mixed with a gas before the being introduced to the first material. A static charge is created and deposited onto the resultant material to help align the resultant material particles.

Owner:ALPHAGEN MATERIALS TECH

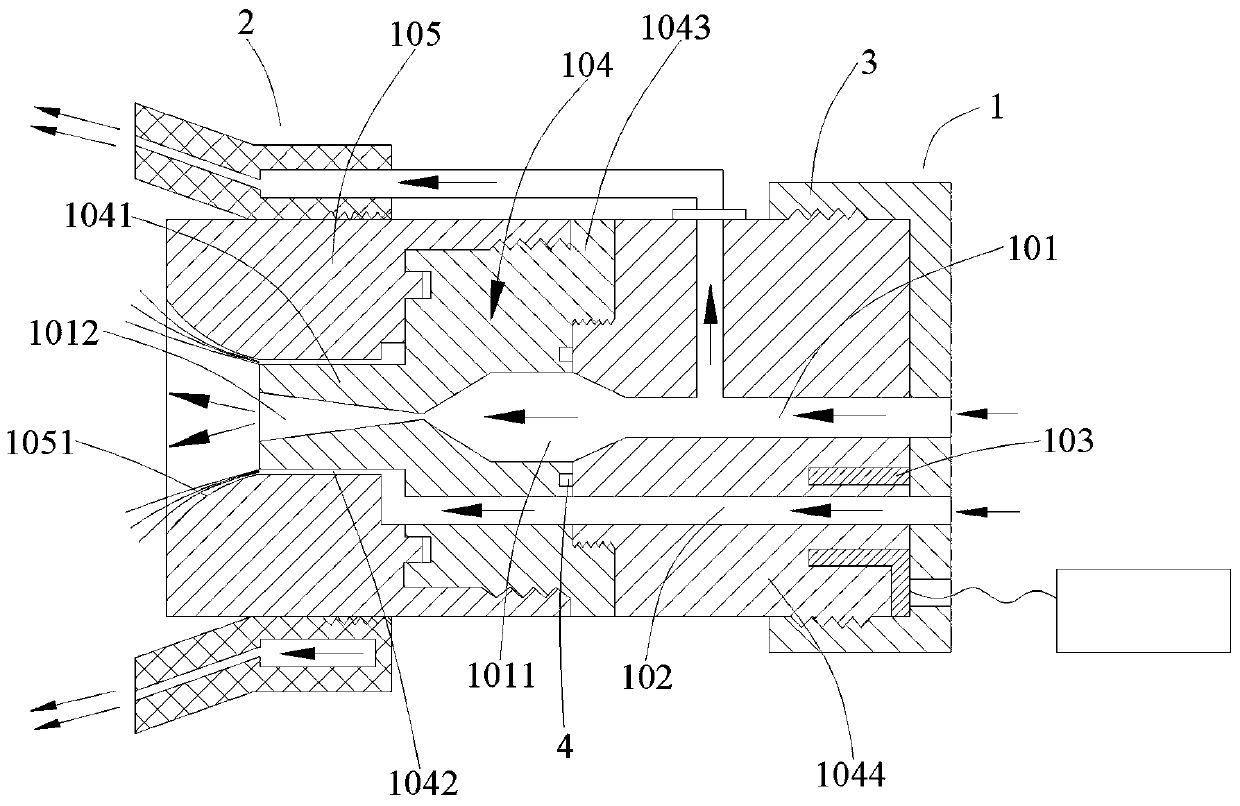

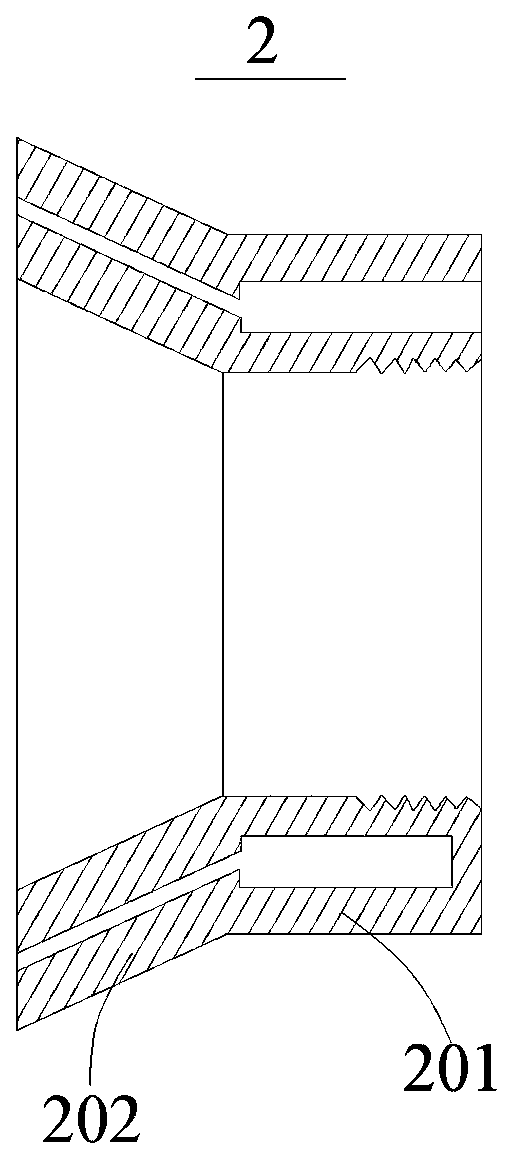

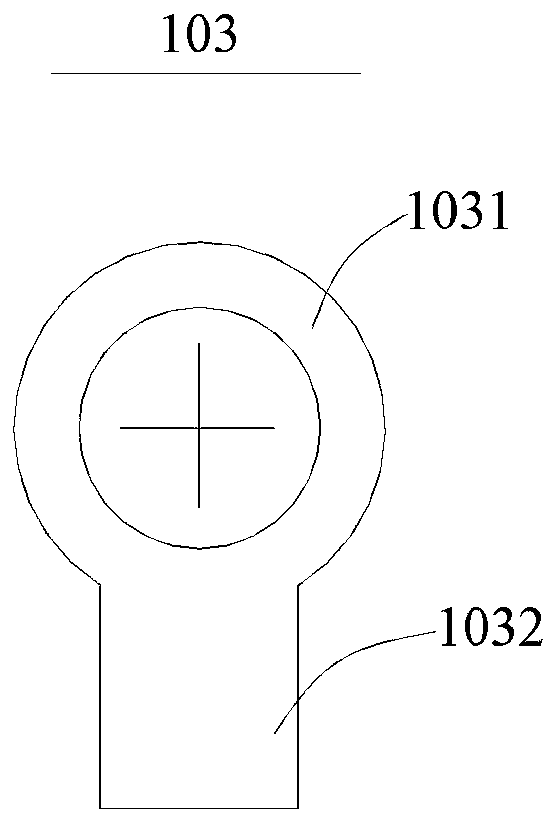

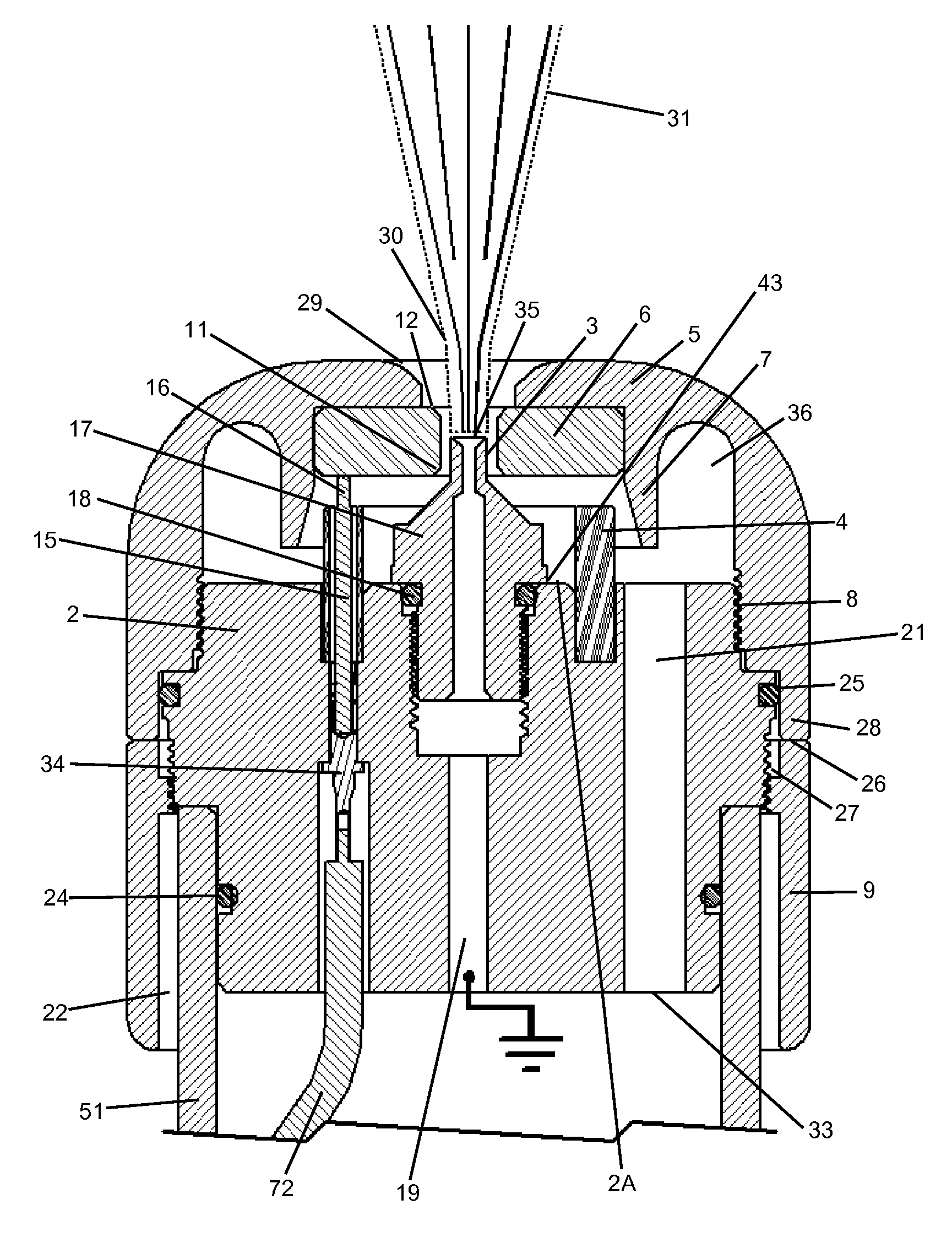

Induction electrostatic atomization nozzle

ActiveCN110180693AAvoid adsorptionReduce electric field strengthSpraying power supplySpray nozzlesEngineeringElectric field

The invention relates to an induction electrostatic atomization nozzle. The induction electrostatic atomization nozzle comprises a nozzle body, wherein the nozzle body is provided with an internal gasflow channel, the liquid flow channel is located at the inlet of a liquid flow channel, and the liquid flow channel is provided with an electrode ring. According to the induction electrostatic atomization nozzle, the electrode ring is arranged at the inlet end of the liquid flow passage, the position of the electrode ring far away from the induction electrostatic atomization nozzle is guaranteed,and thus the electric field intensity at the position of an induction electrostatic atomization spray head is reduced, and the fog drop adsorption phenomenon is avoided to a certain extent.

Owner:JIANGSU UNIV

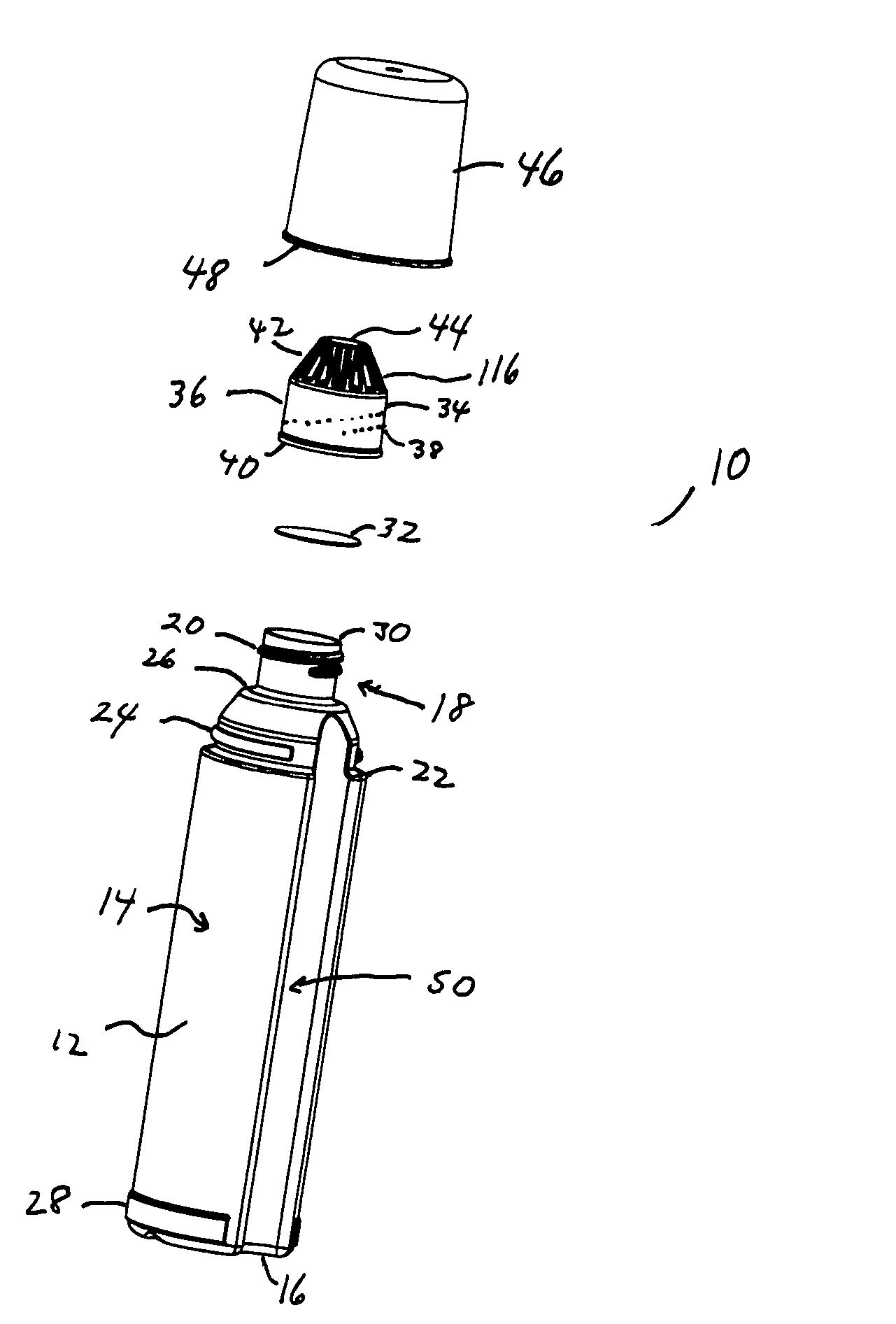

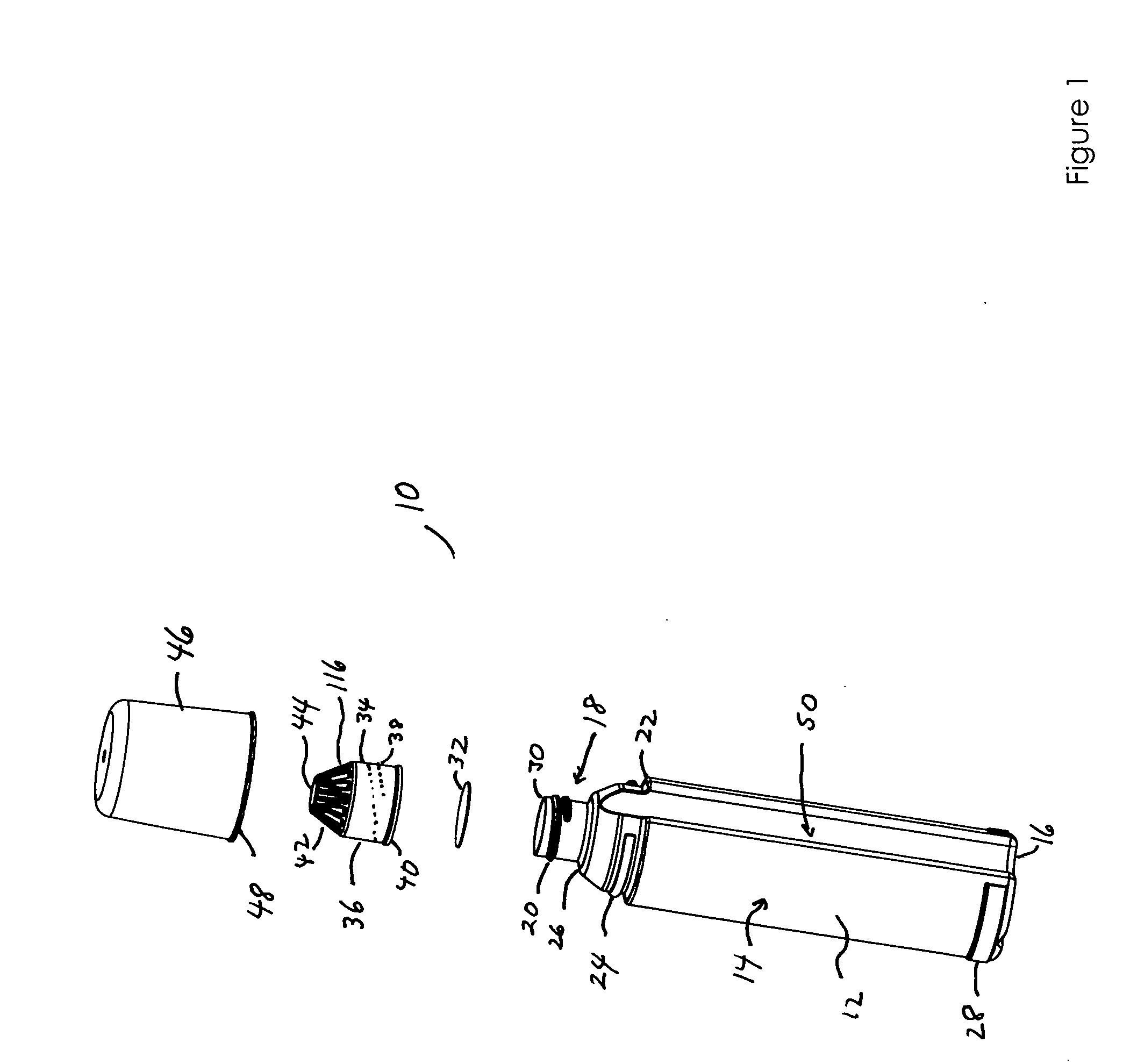

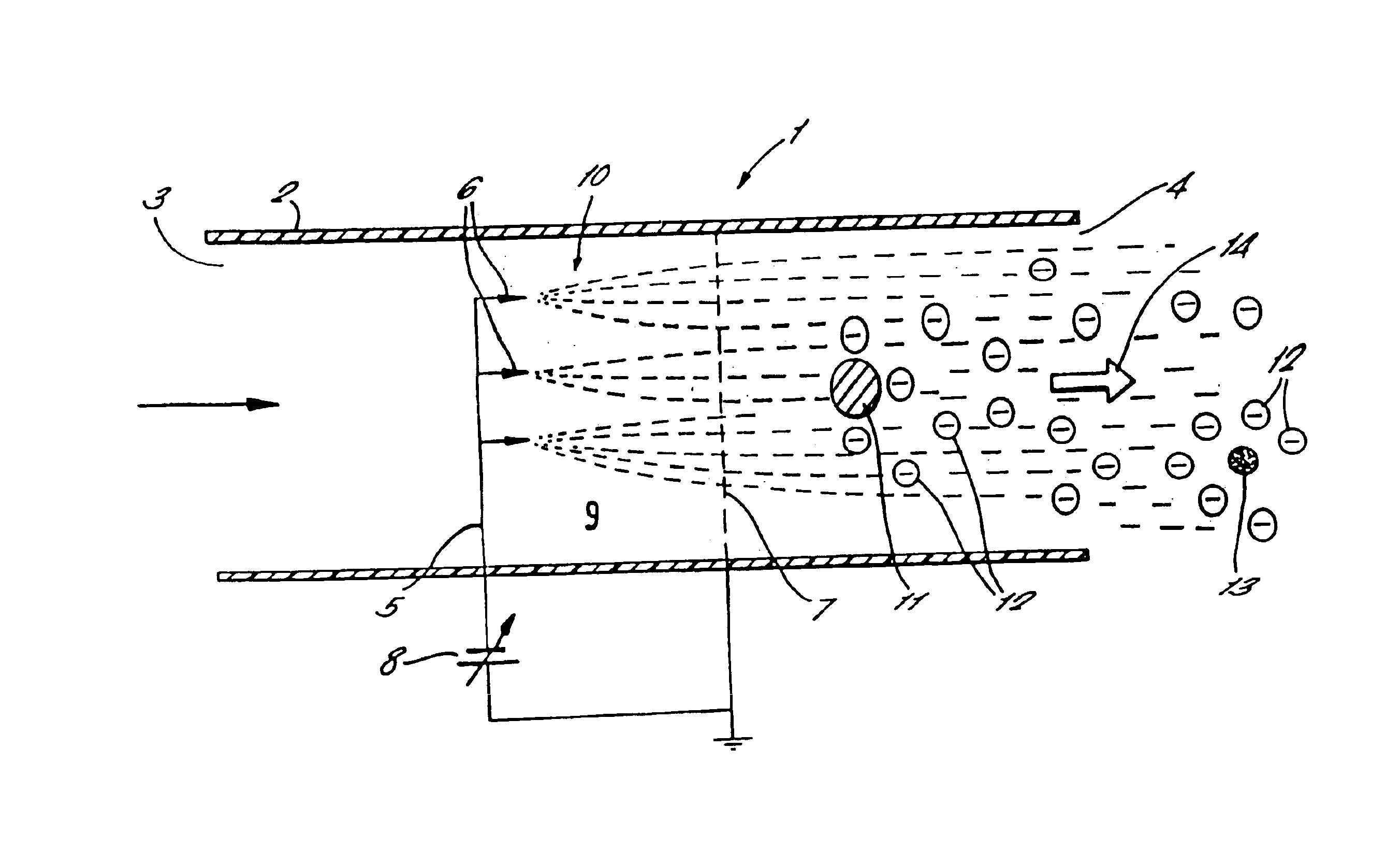

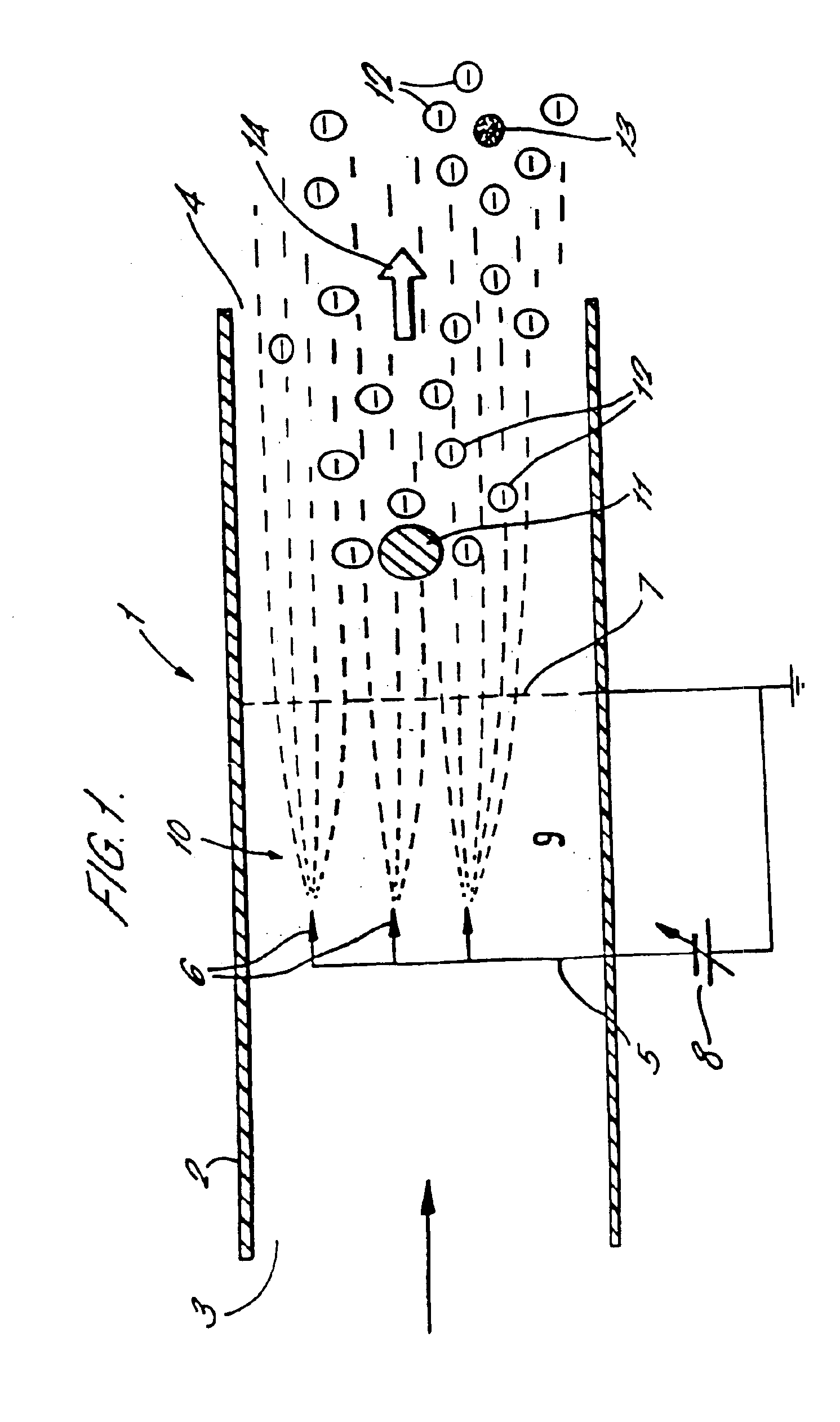

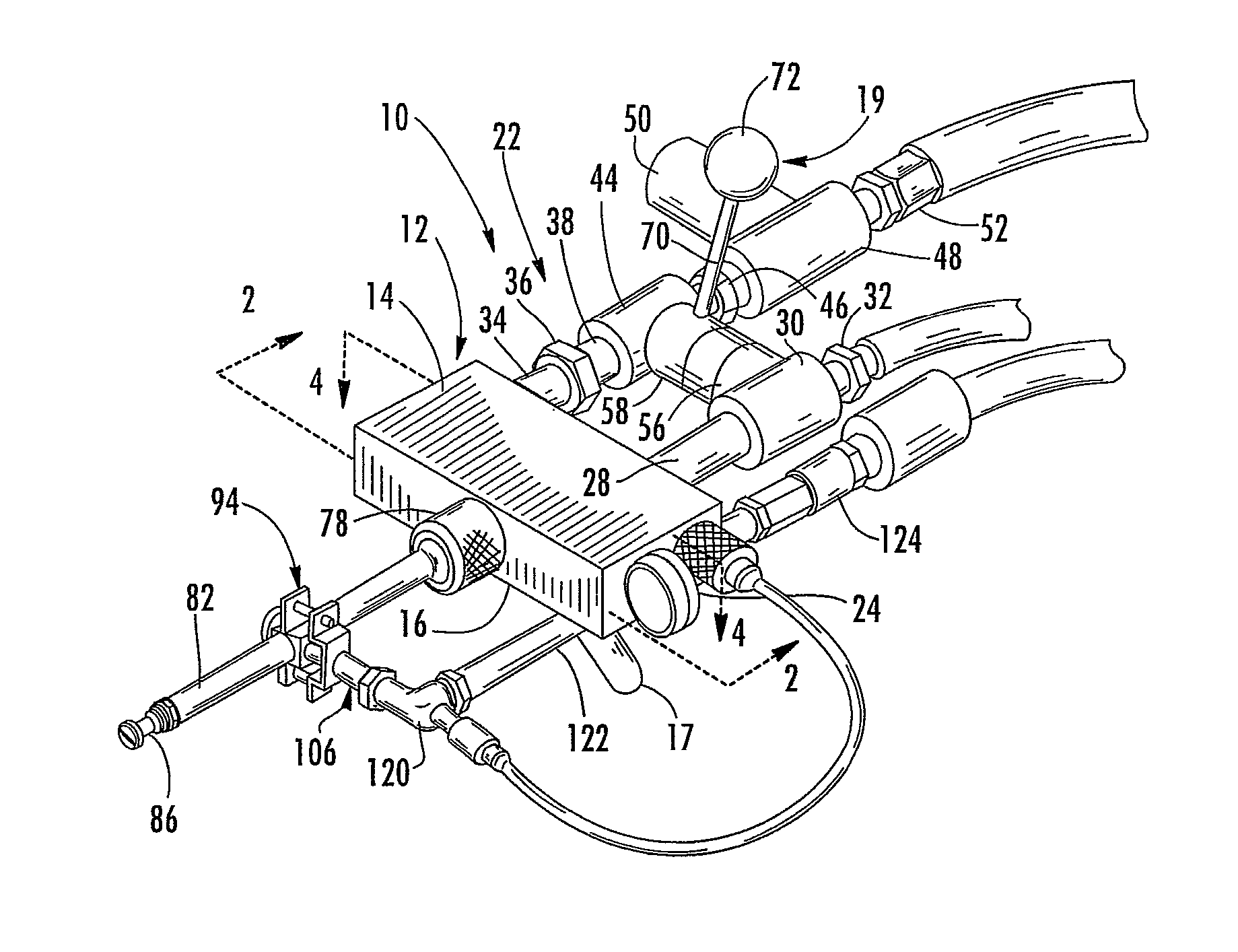

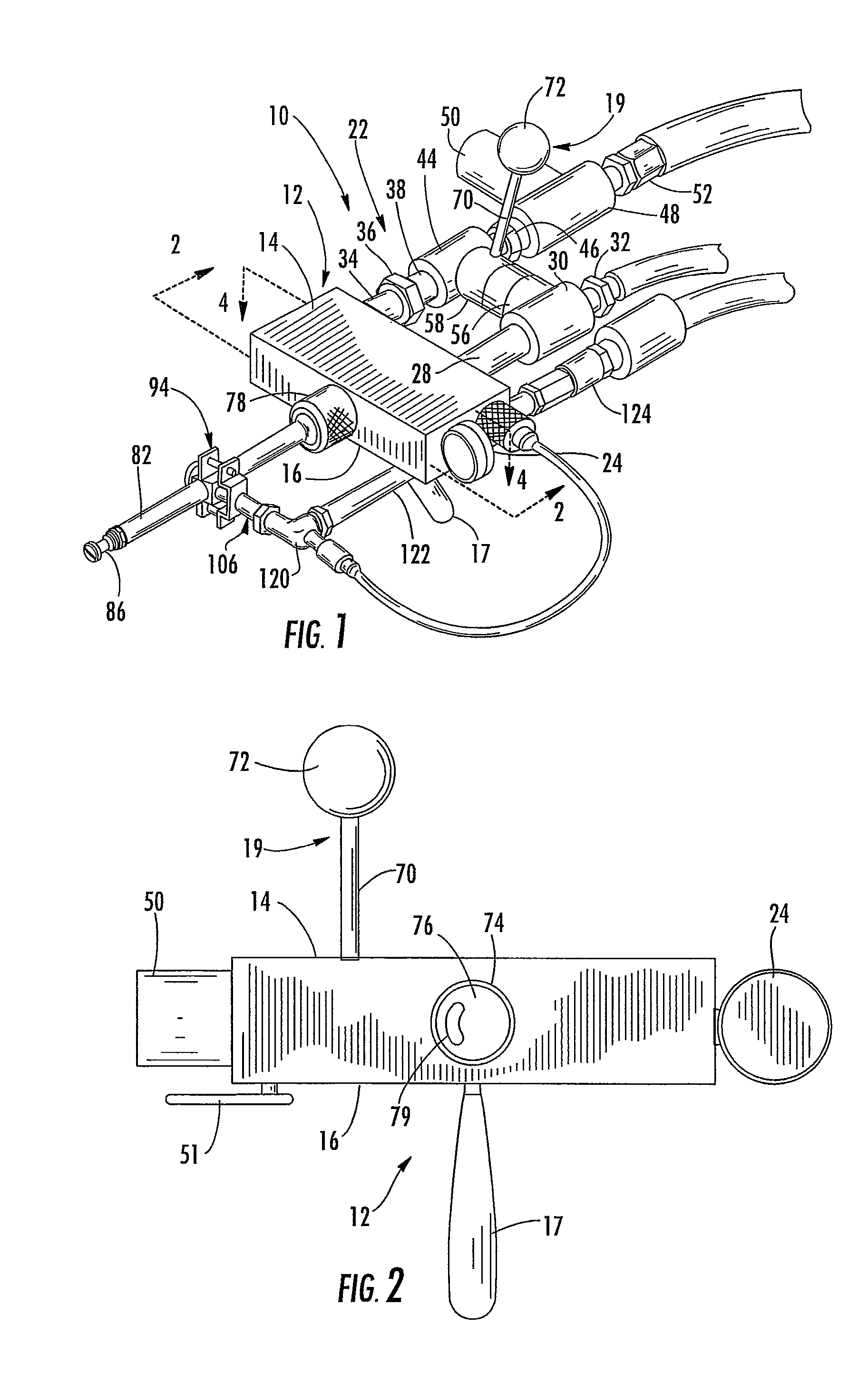

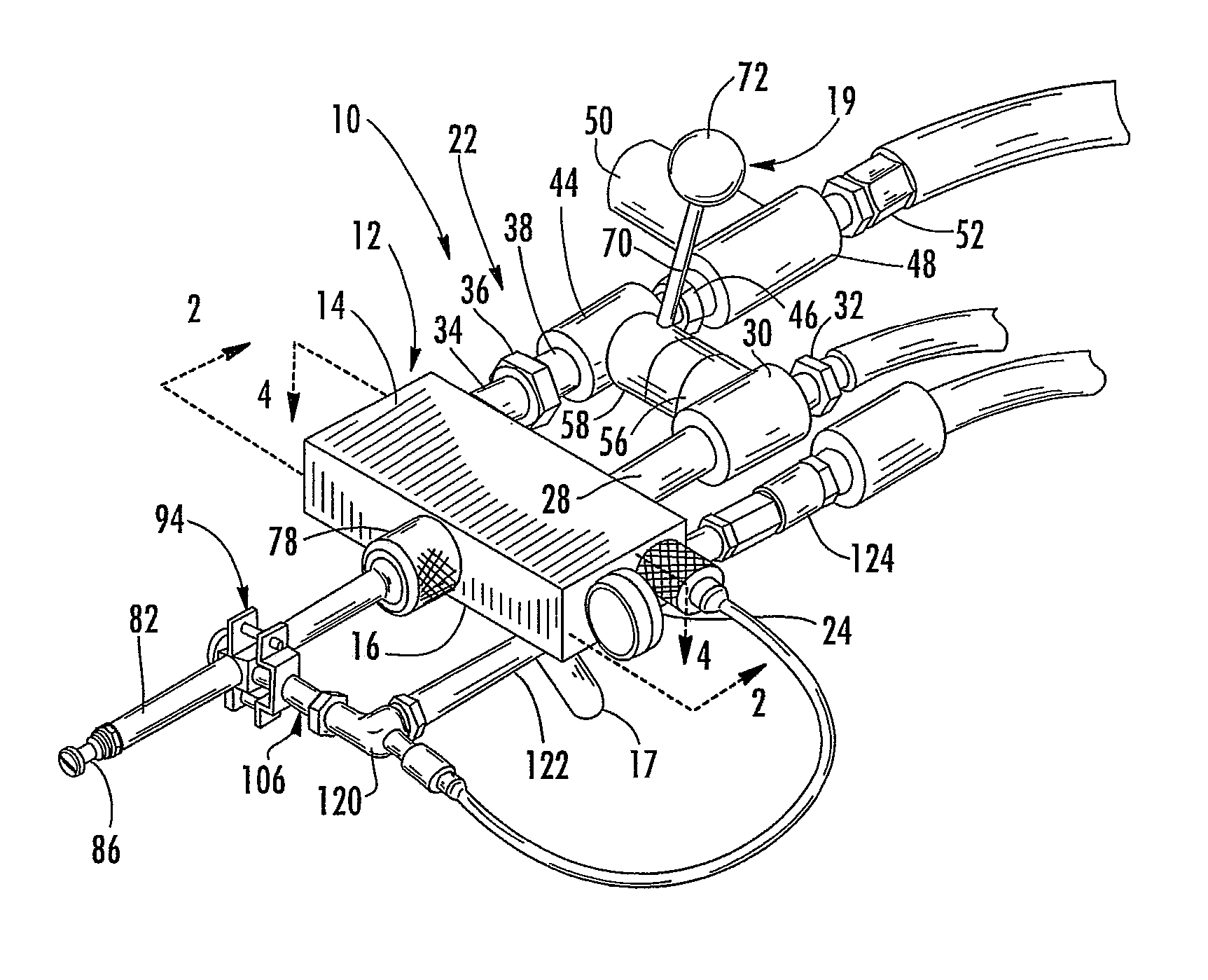

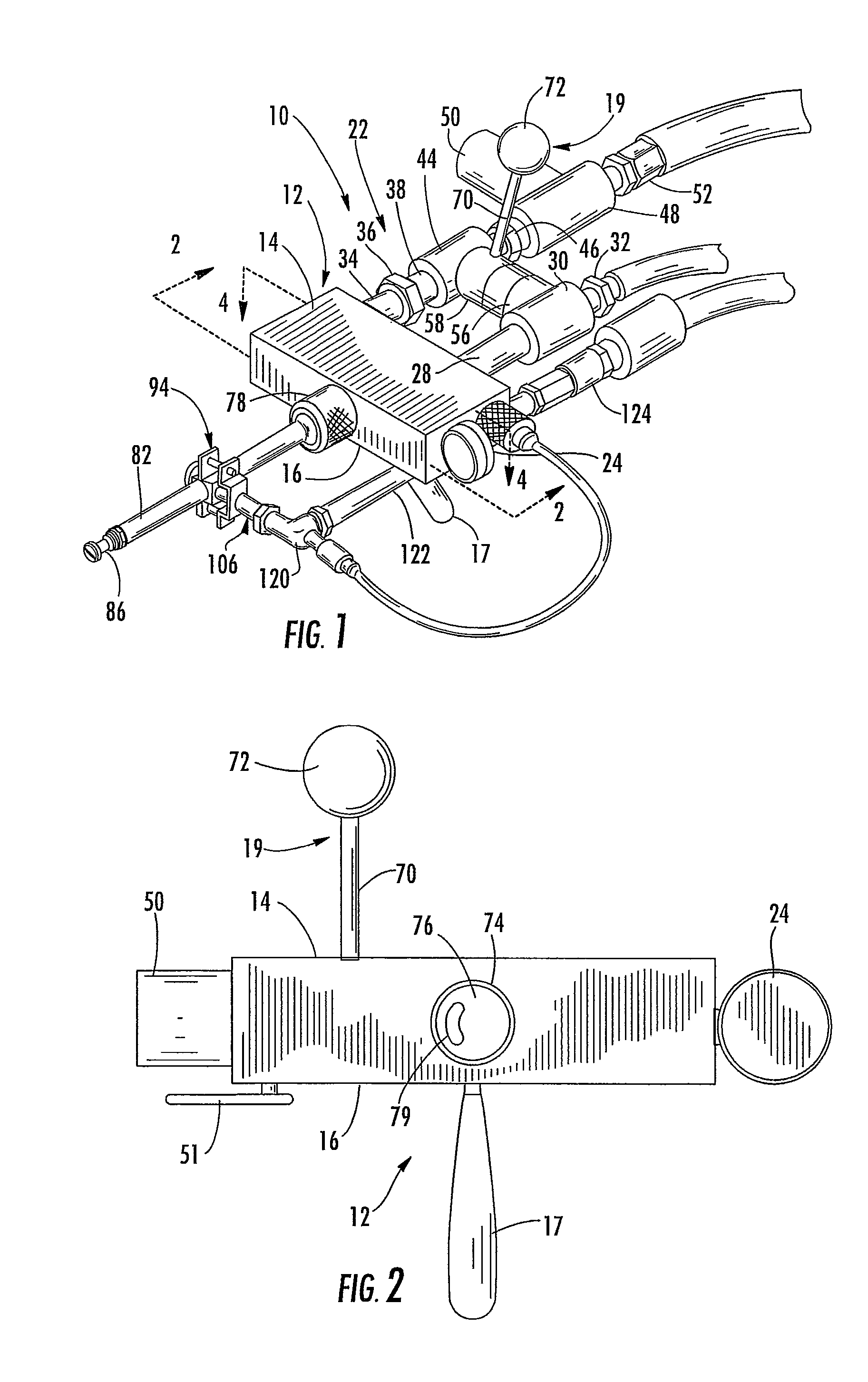

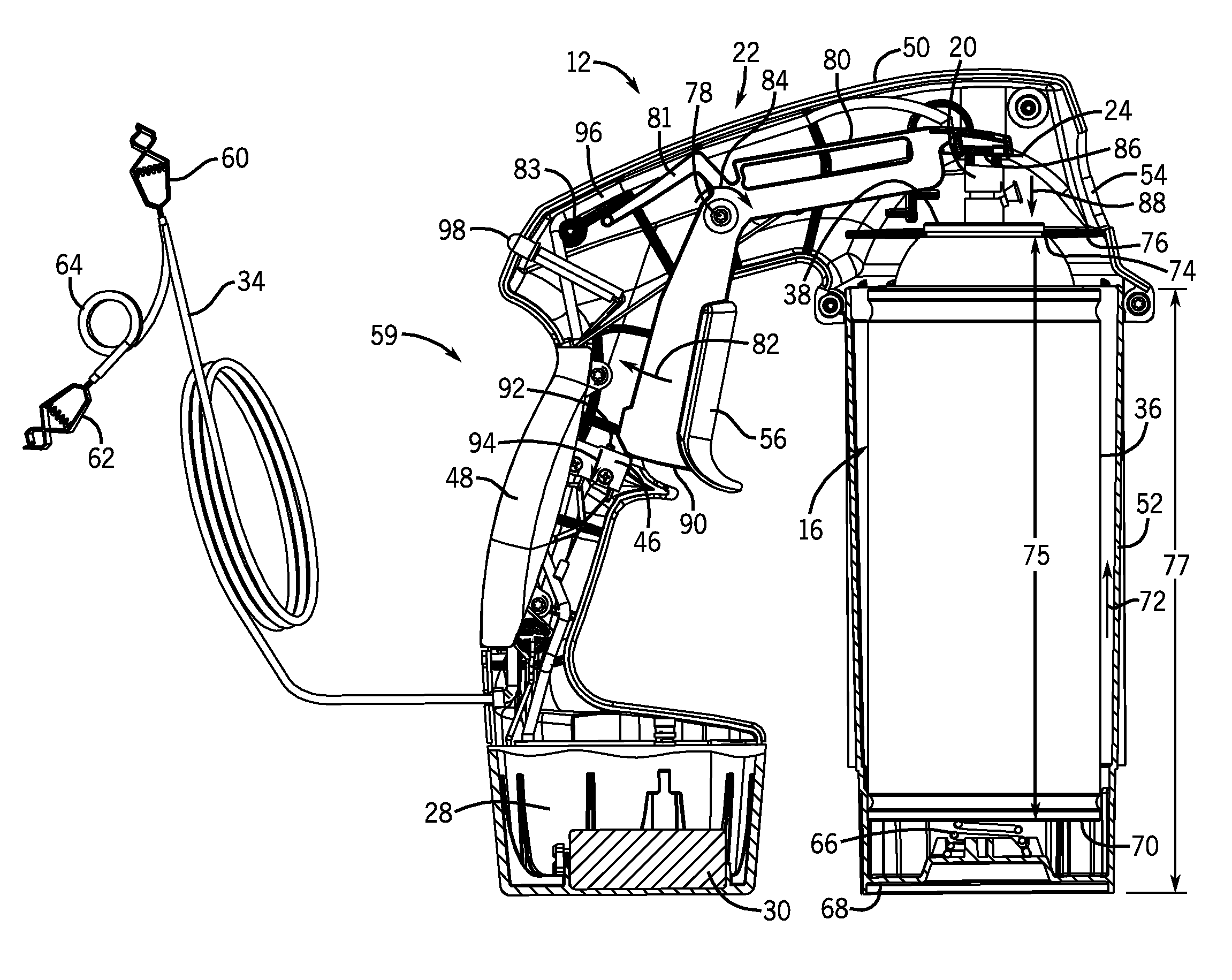

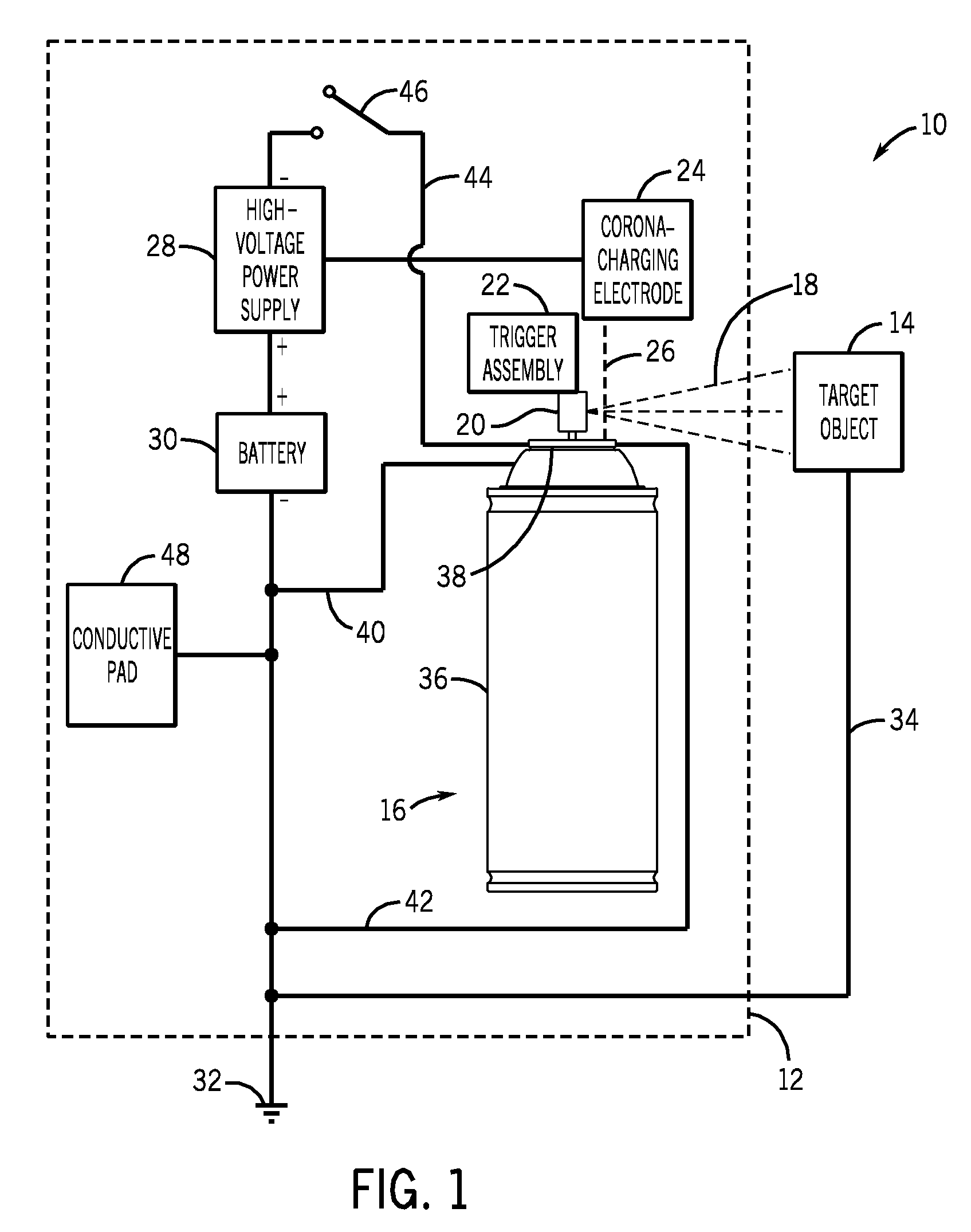

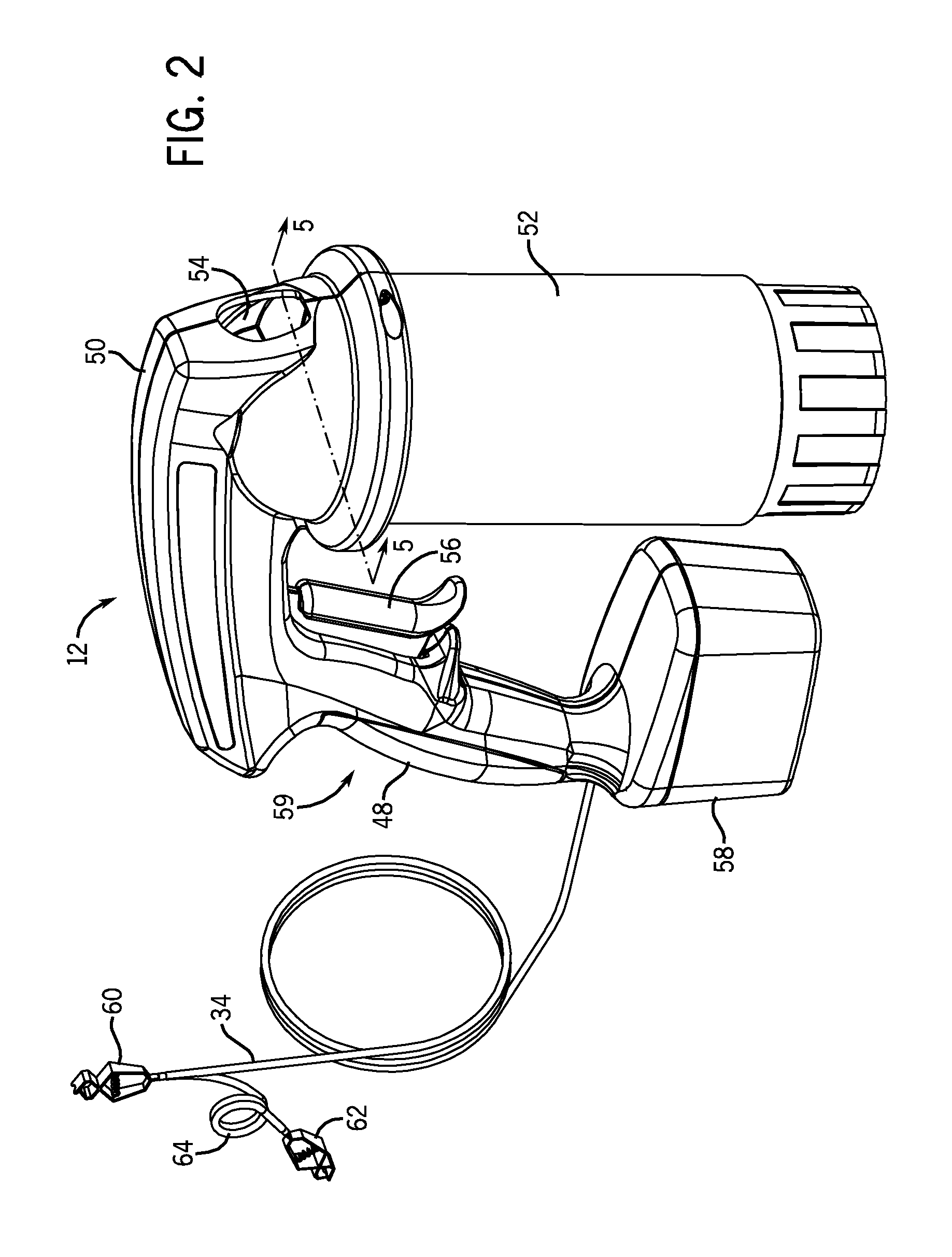

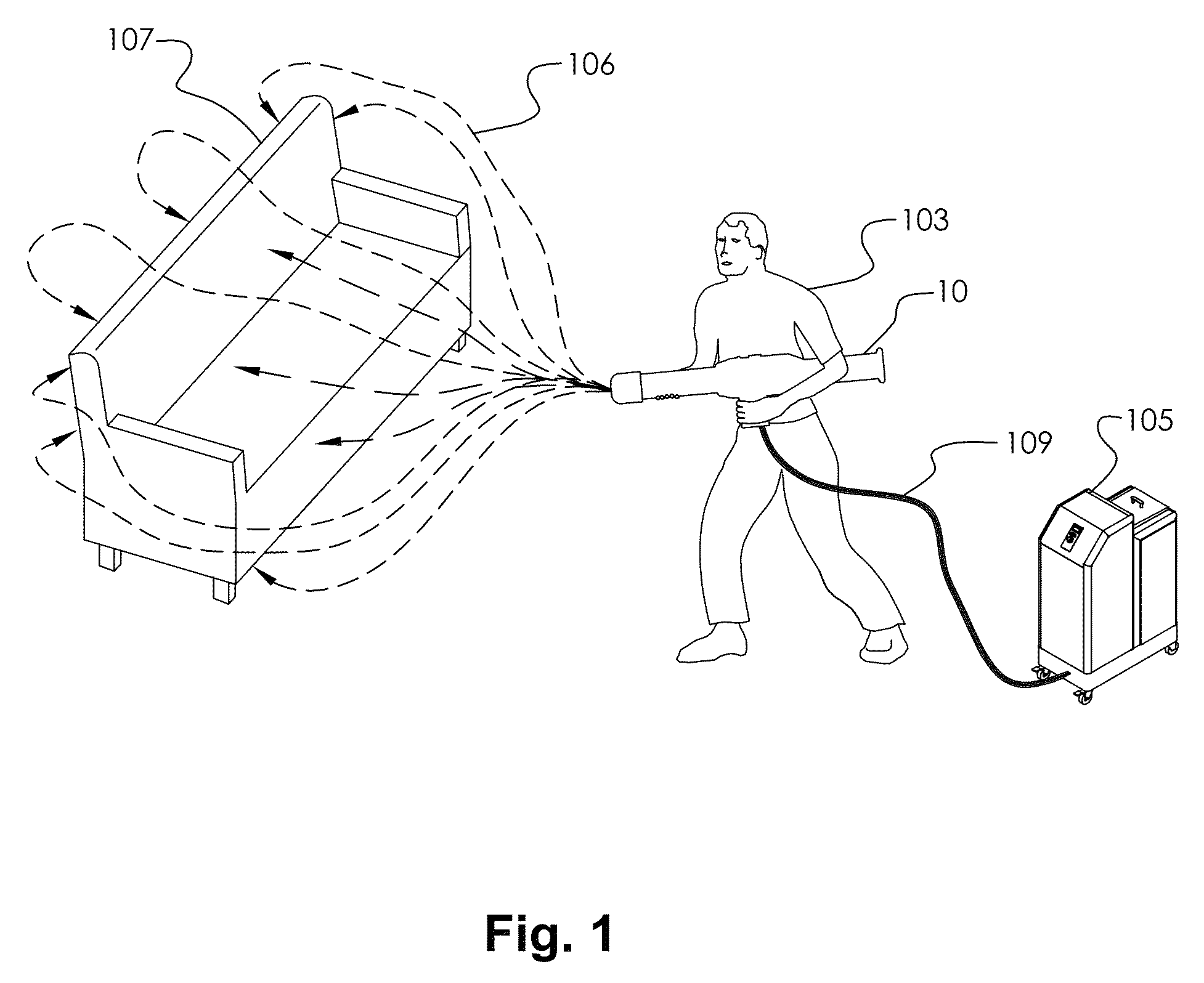

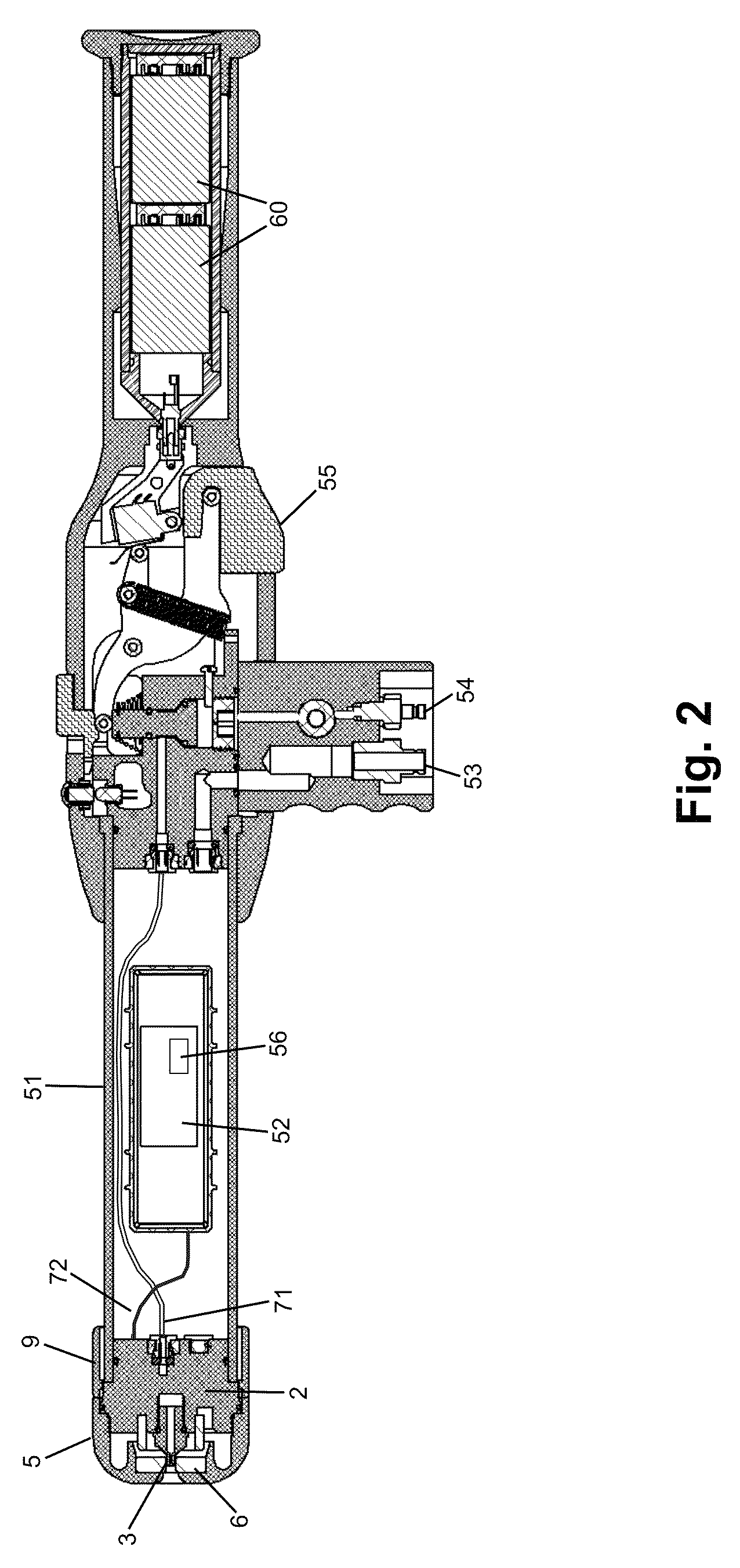

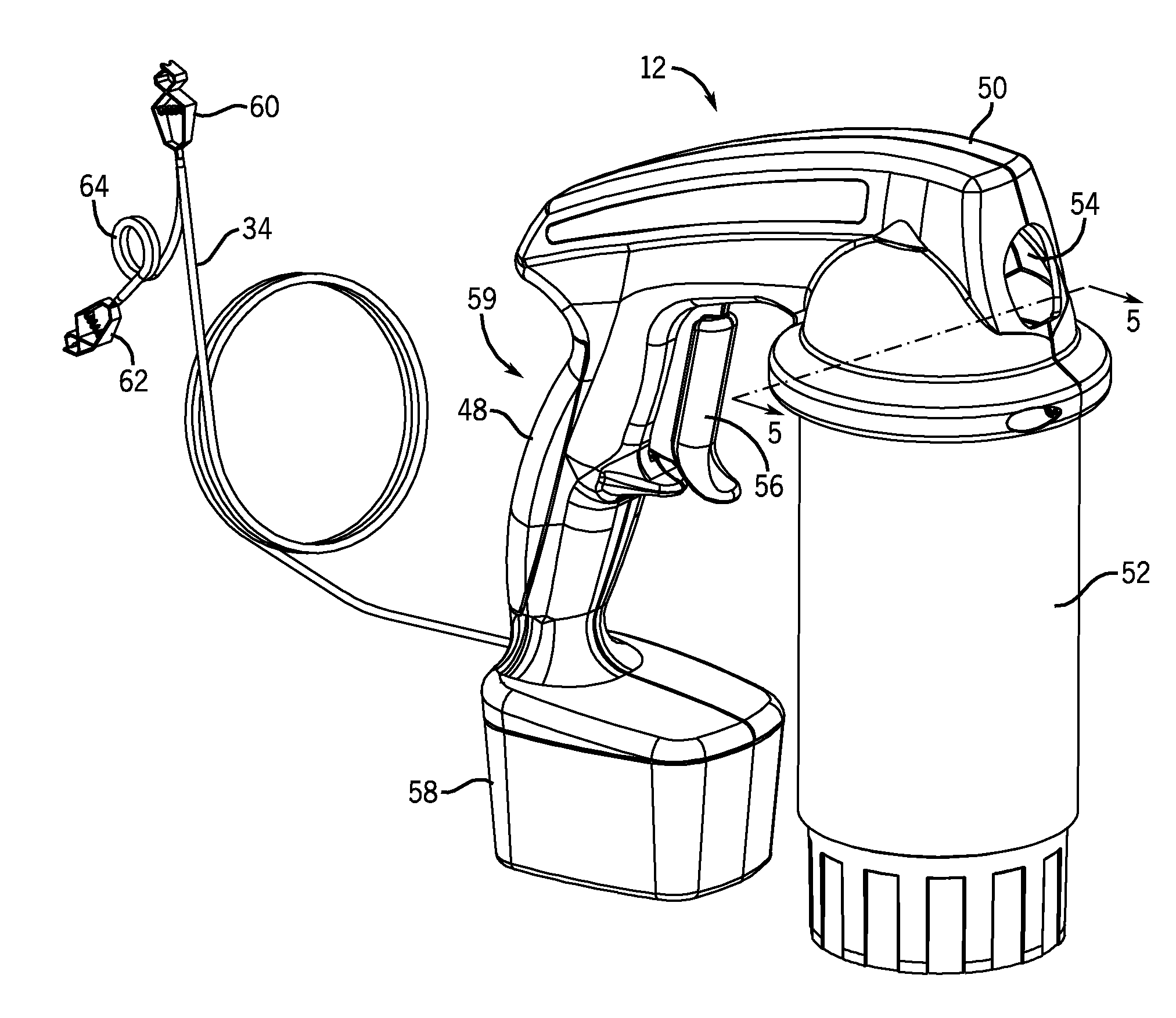

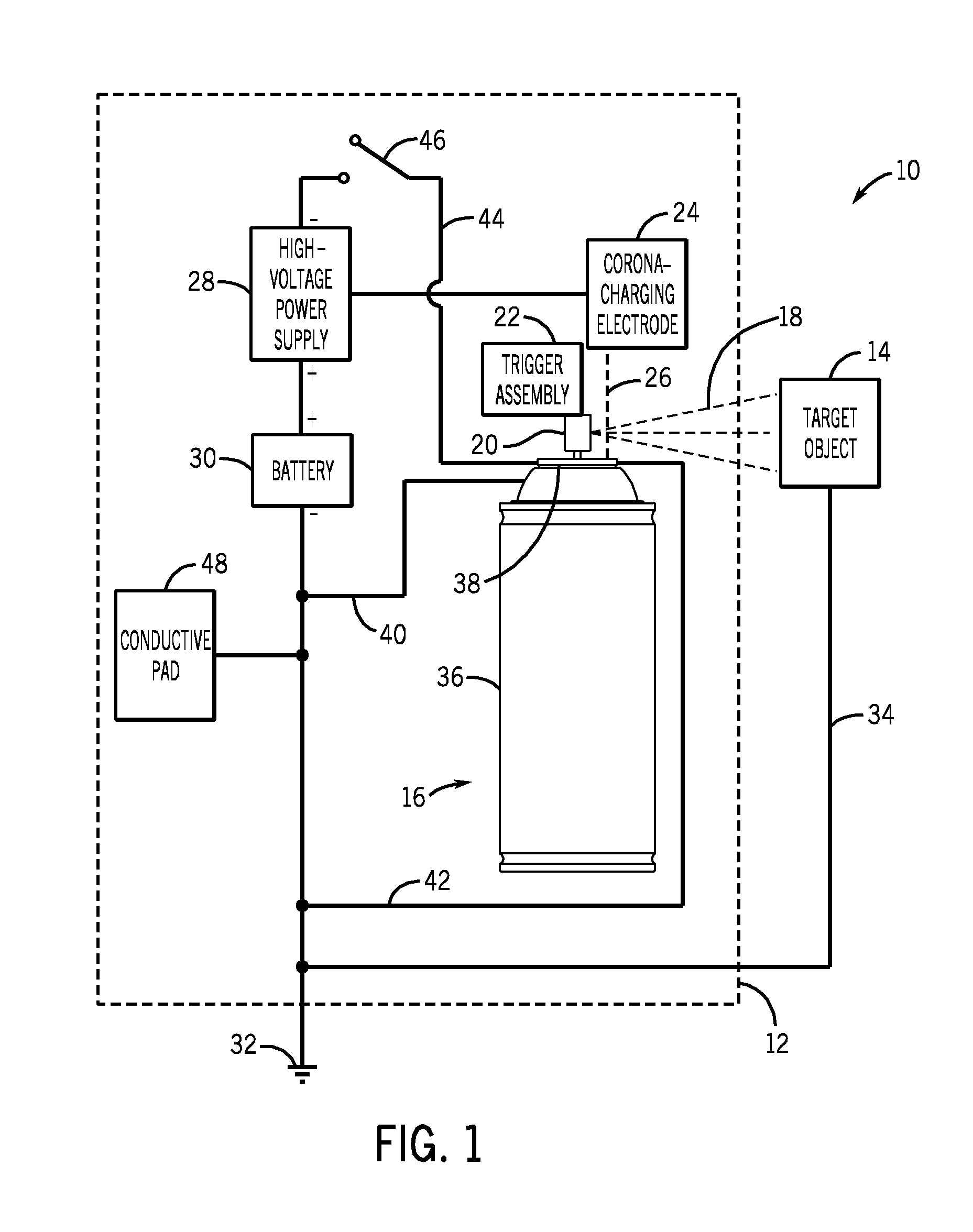

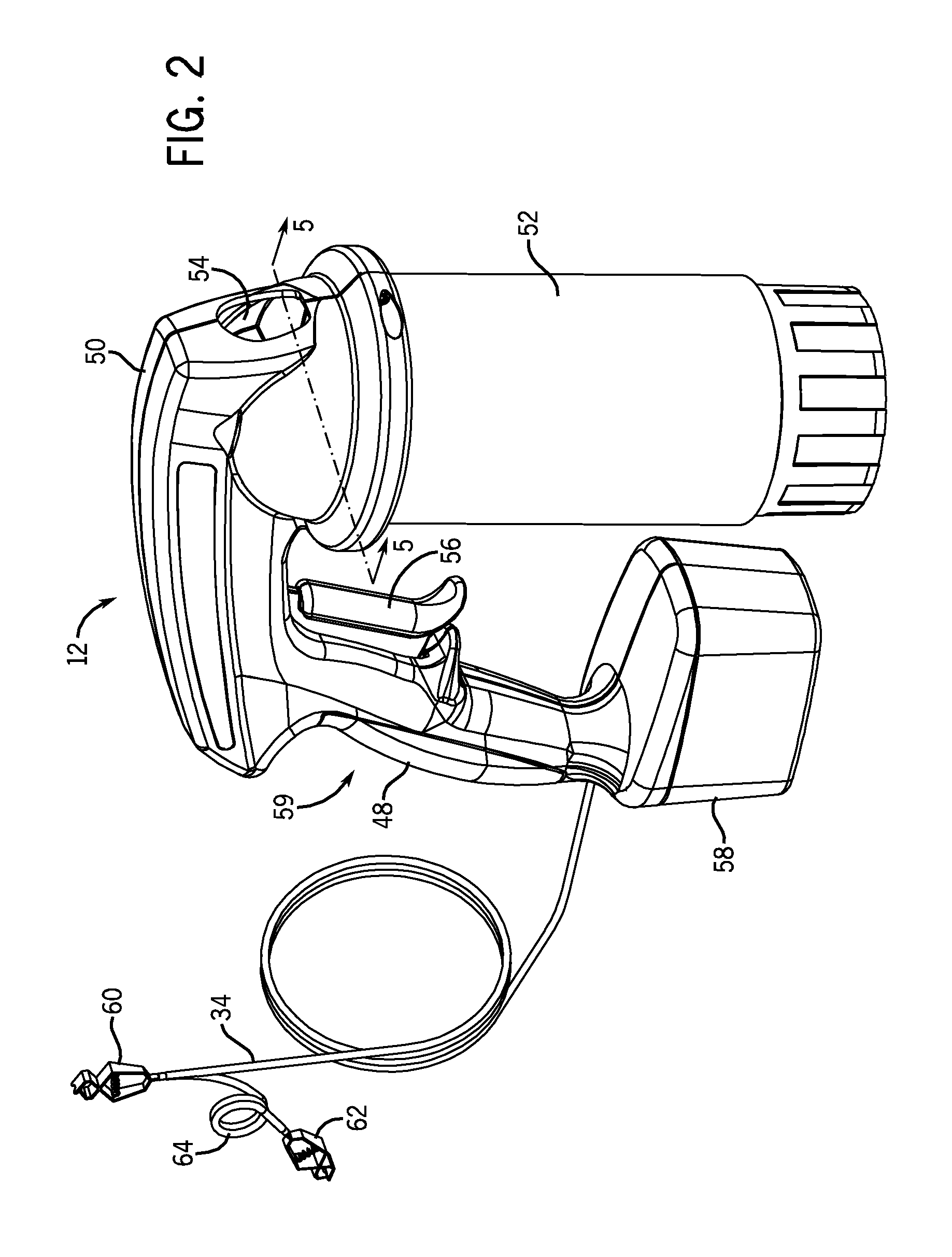

Electrostatic spray system

A system, in certain embodiments, includes a spray device including a frame having a receptacle configured to receive a self-contained spray can. The spray device further includes a first conductive element configured to contact the self-contained spray can, and a first electrical conductor extending between the first conductive element and an earth ground such that a first electrical potential of the self-contained spray can is substantially equal to a second electrical potential of the earth ground while the self-contained spray can is in contact with the first conductive element. The spray device also includes a corona-charging electrode positioned adjacent to a spray nozzle of the self-contained spray can. The corona-charging electrode is configured to emit a stream of ions toward the self-contained spray can such that a spray of fluid from the spray nozzle passes through the stream of ions and becomes electrostatically charged.

Owner:CARLISLE FLUID TECH INC

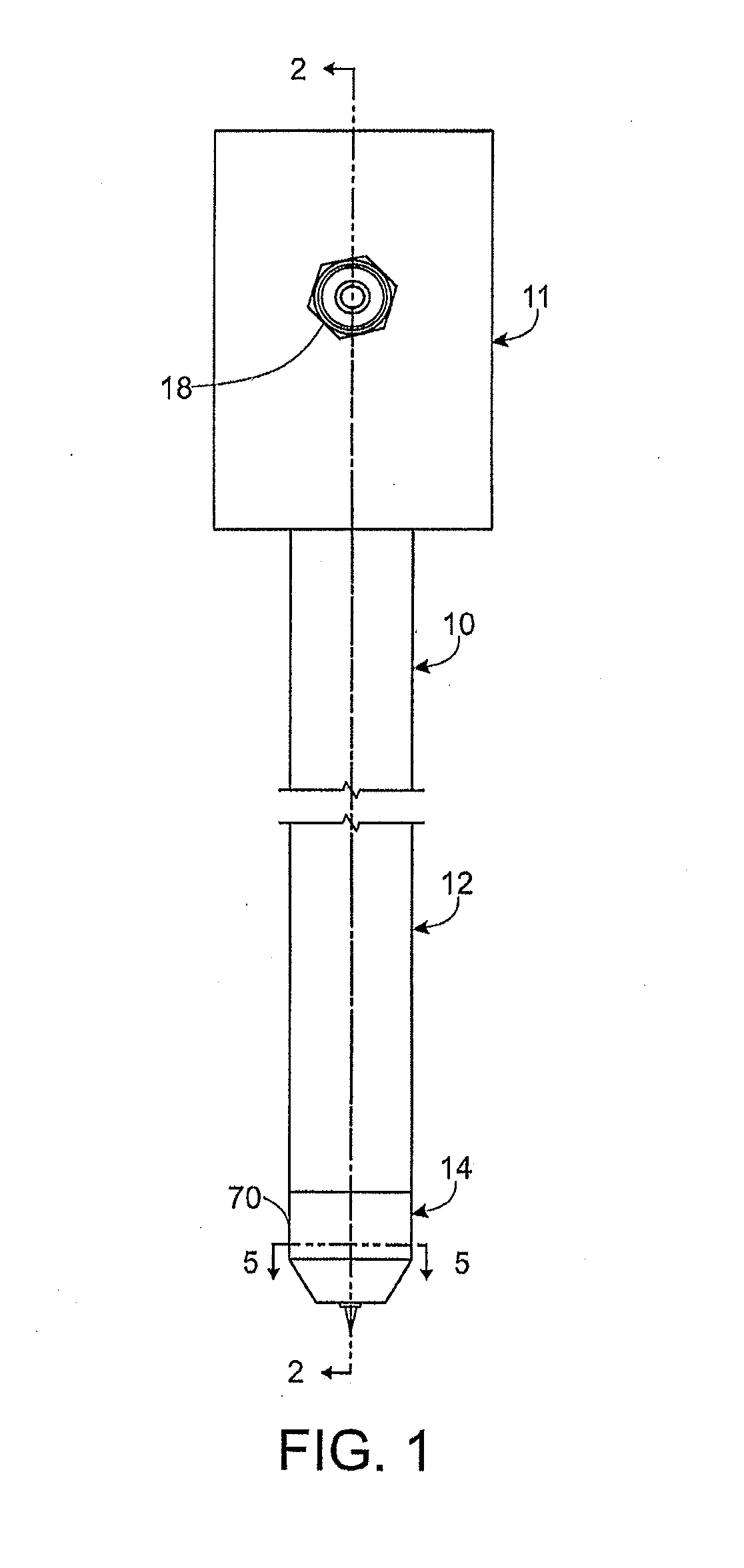

Separation media, multiple electrospray nozzle system and method

InactiveUS6956207B2Increase flow rateExtending useful fluid flow rate rangeComponent separationSamples introduction/extractionChromatographic separationMicro column

A microfabricated silicon chip with a separation material, such as in situ prepared porous polymer monoliths in its microchannels is disclosed. The polymer monoliths are liquid-permeable and serve as microcolumns for liquid chromatography, which are prepared by in situ radical polymerization of a mixture containing vinyl monomers and solvents (porogen) in the microchannels. A method and system are disclosed to generate one or more electrospray plumes from one or more nozzles that provide an ion intensity as measured by a mass spectrometer that is approximately proportional to the number of electrospray plumes formed for analyses contained within the fluid. A plurality of electrospray devices can be used in the form of an array of miniaturized separate electrospray devices for the purpose of generating multiple electrospray plumes from multiple nozzles for the same fluid for analysis. This invention dramatically increases the sensitivity of microchip electrospray devices compared to prior disclosed systems and methods. The silicon chip having the packed microchannels disclosed herein finds application in coupling with mass spectrometry for sample analysis. Also disclosed is a separation block having multiple through-substrate channels filled with a separation material such as polymer monolith which can be stacked in multiple blocks for sequential two-dimensional chromatographic separation and integrated with the electrospray device.

Owner:ADVION

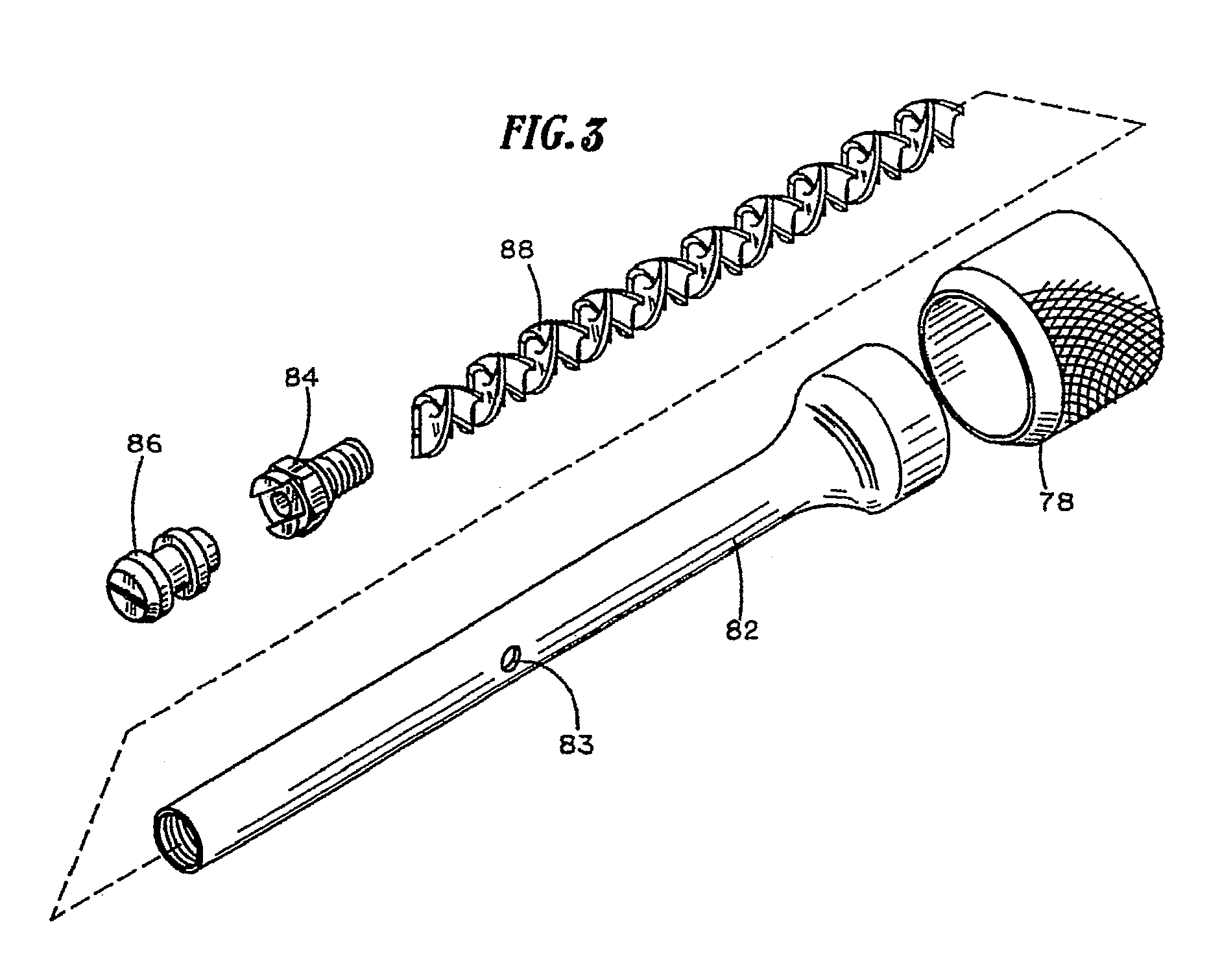

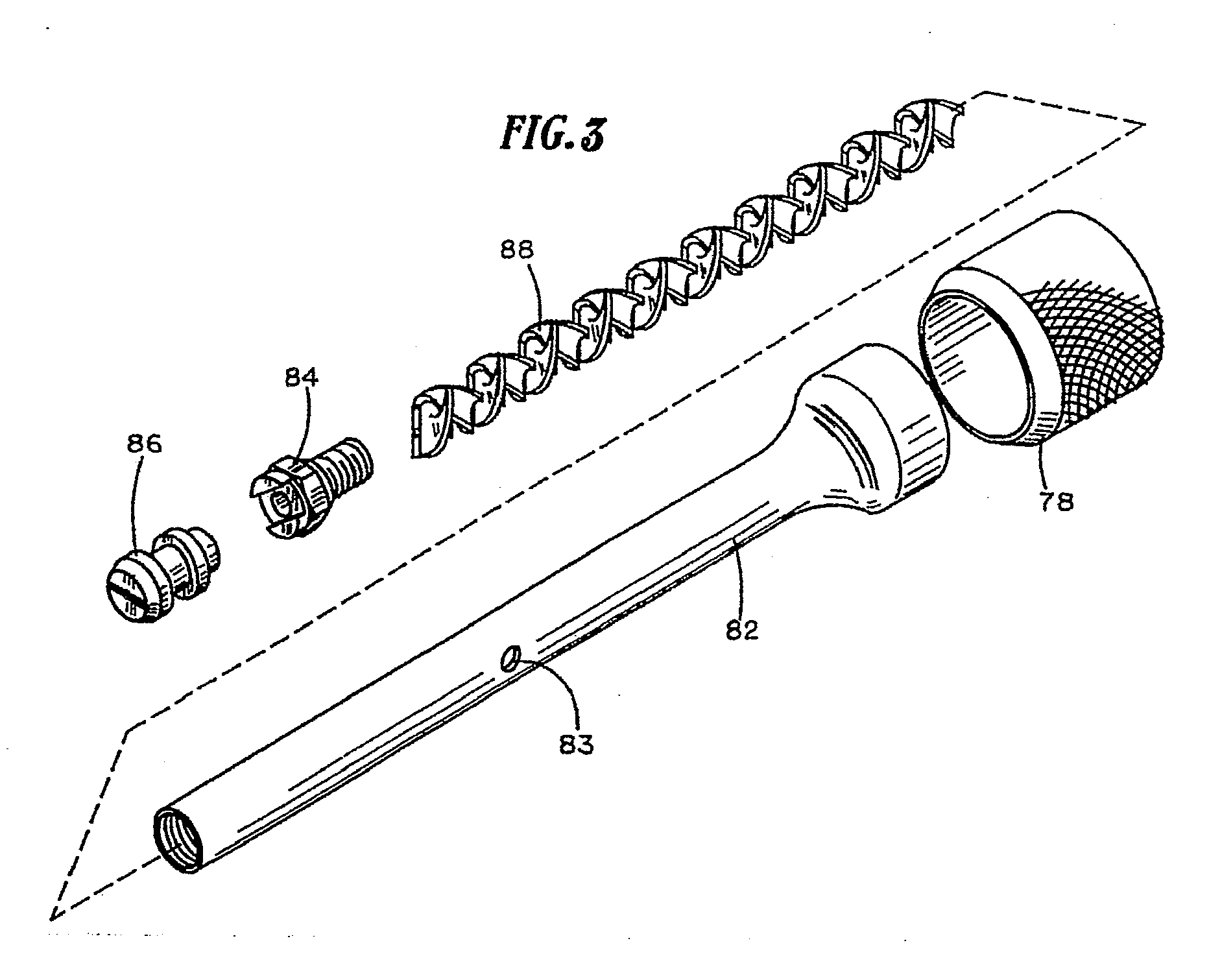

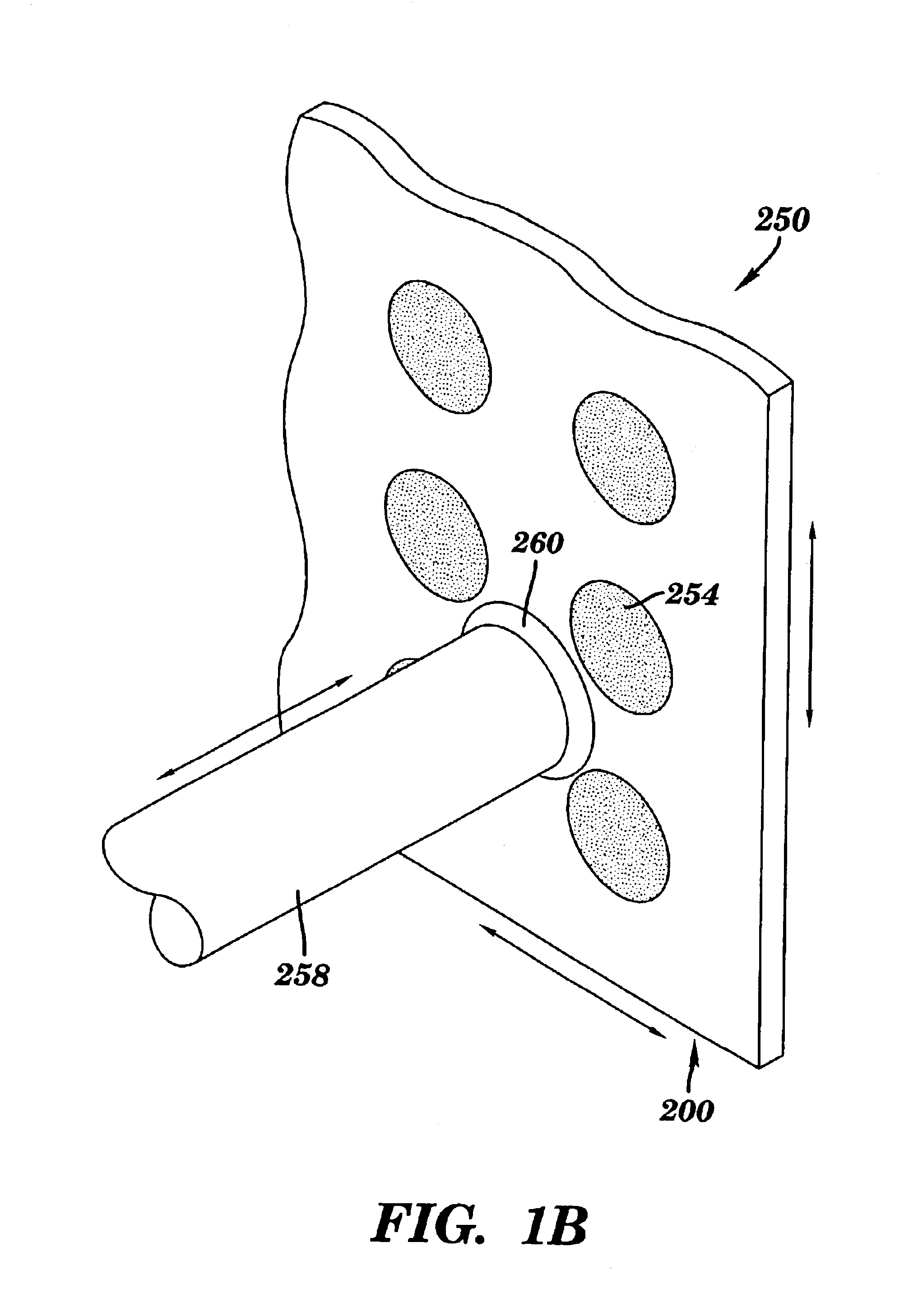

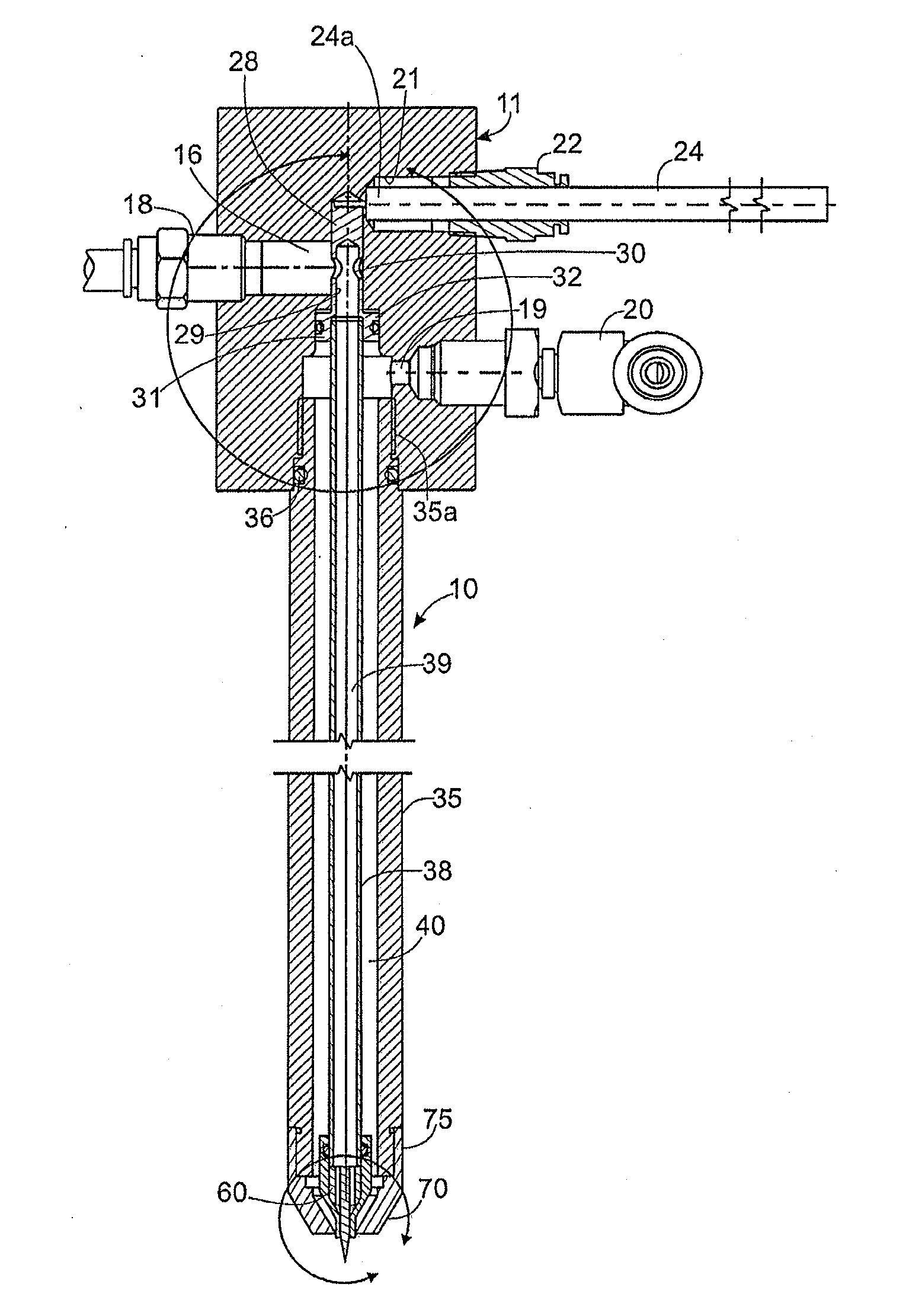

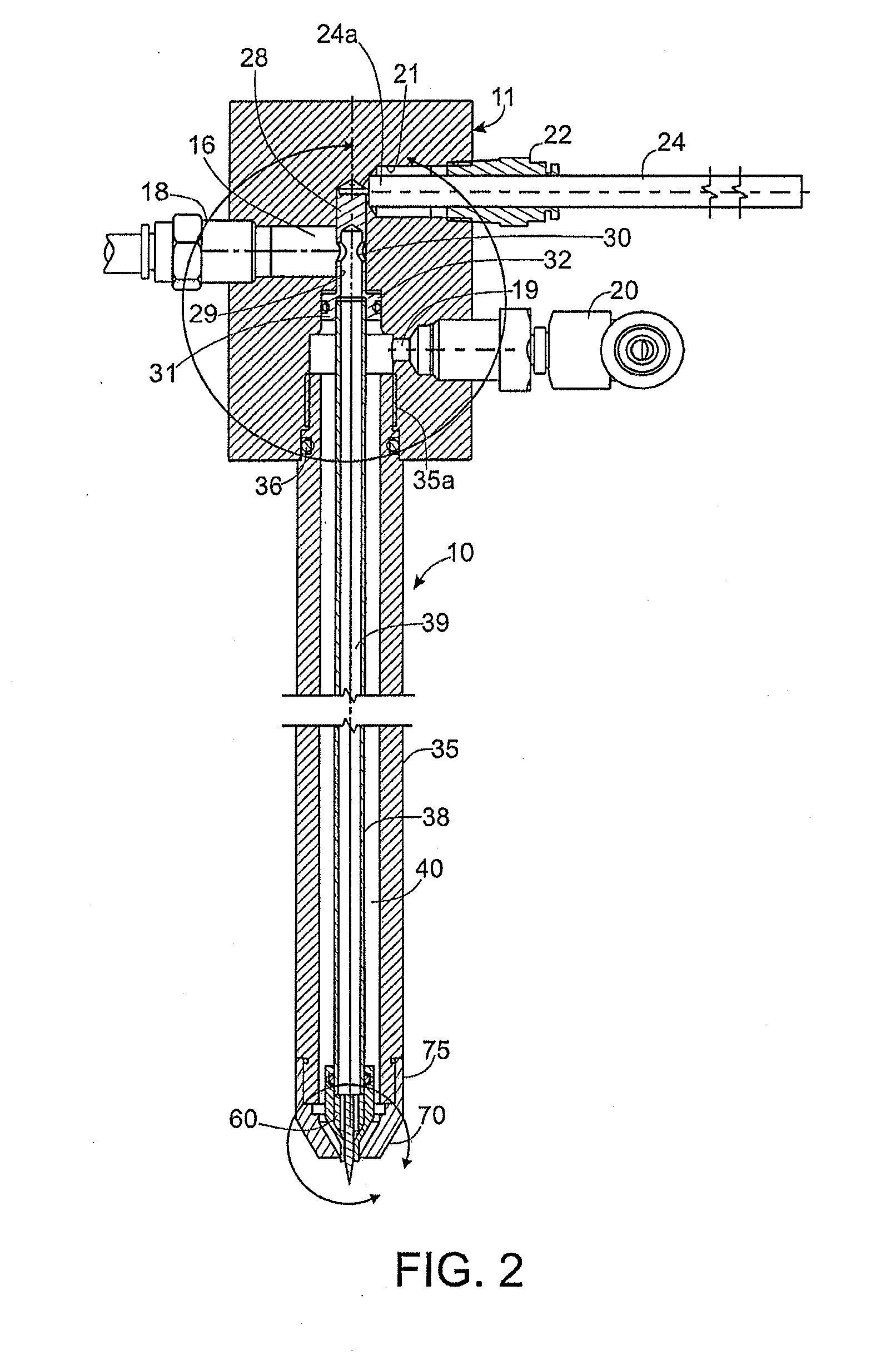

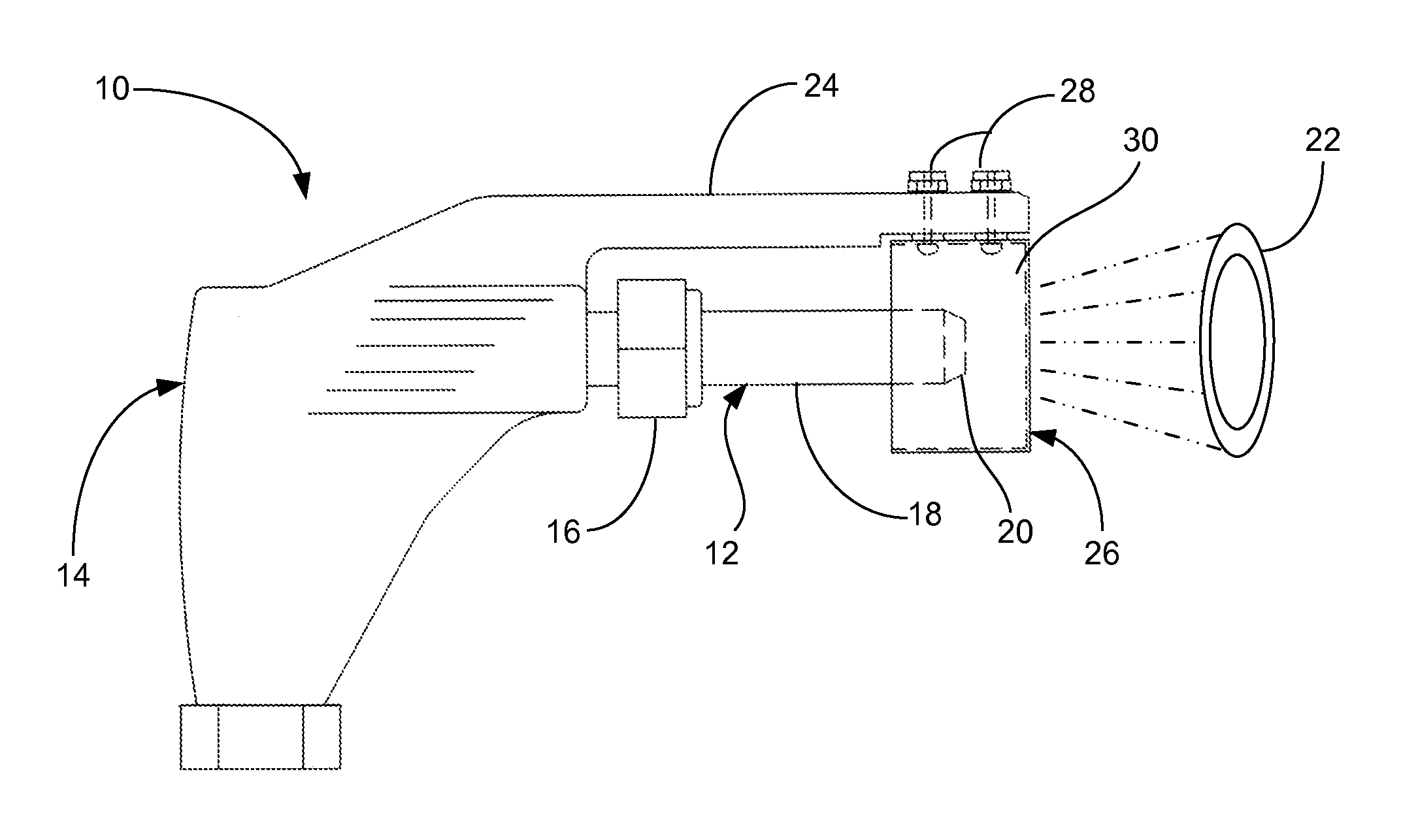

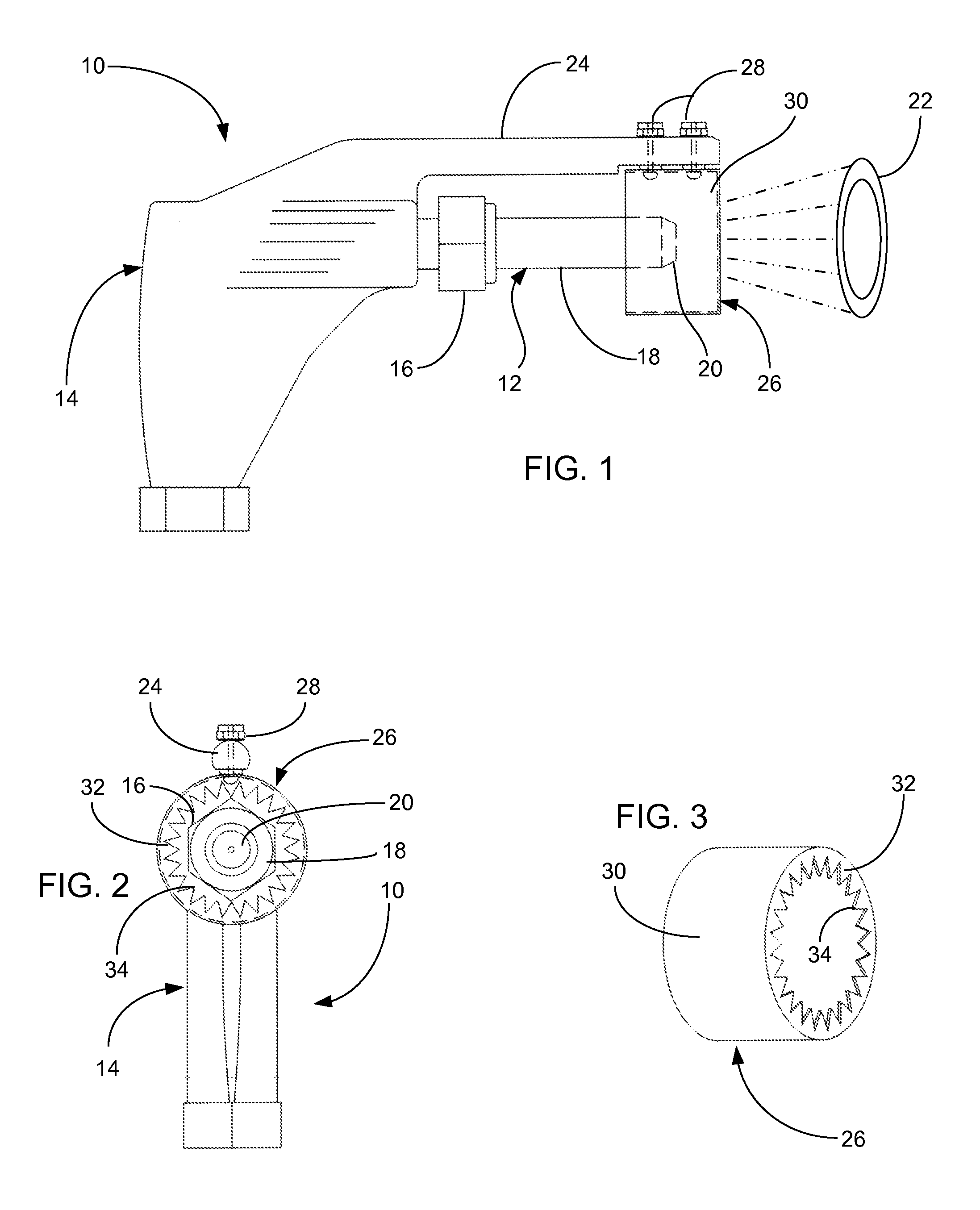

Electrostatic spray nozzle assembly

ActiveUS20160228892A1Guaranteed uptimeEasy to assembleLiquid supply arrangementsLiquid spraying apparatusAnimal stingEngineering

An air assisted electrostatic liquid spray nozzle assembly having a relatively long elongated nozzle body with a spray tip and surrounding air cap disposed at a downstream end of the nozzle body. The spray nozzle assembly includes an upstream electrode for connection to a high voltage electric source, an elongated feed tube, an electrically enhancing stinger, and the spray tip which are secured and retained by the air cap in electrically conductive relation to each other such that liquid passing through liquid passages of the electrode, feed tube, stinger, and spray tip is discharged in an electrostatically charged pattern of liquid particles. The air cap is removable to permit easy removal and replacement of the spray tip, stinger, and liquid feed tube.

Owner:SPRAYING SYST

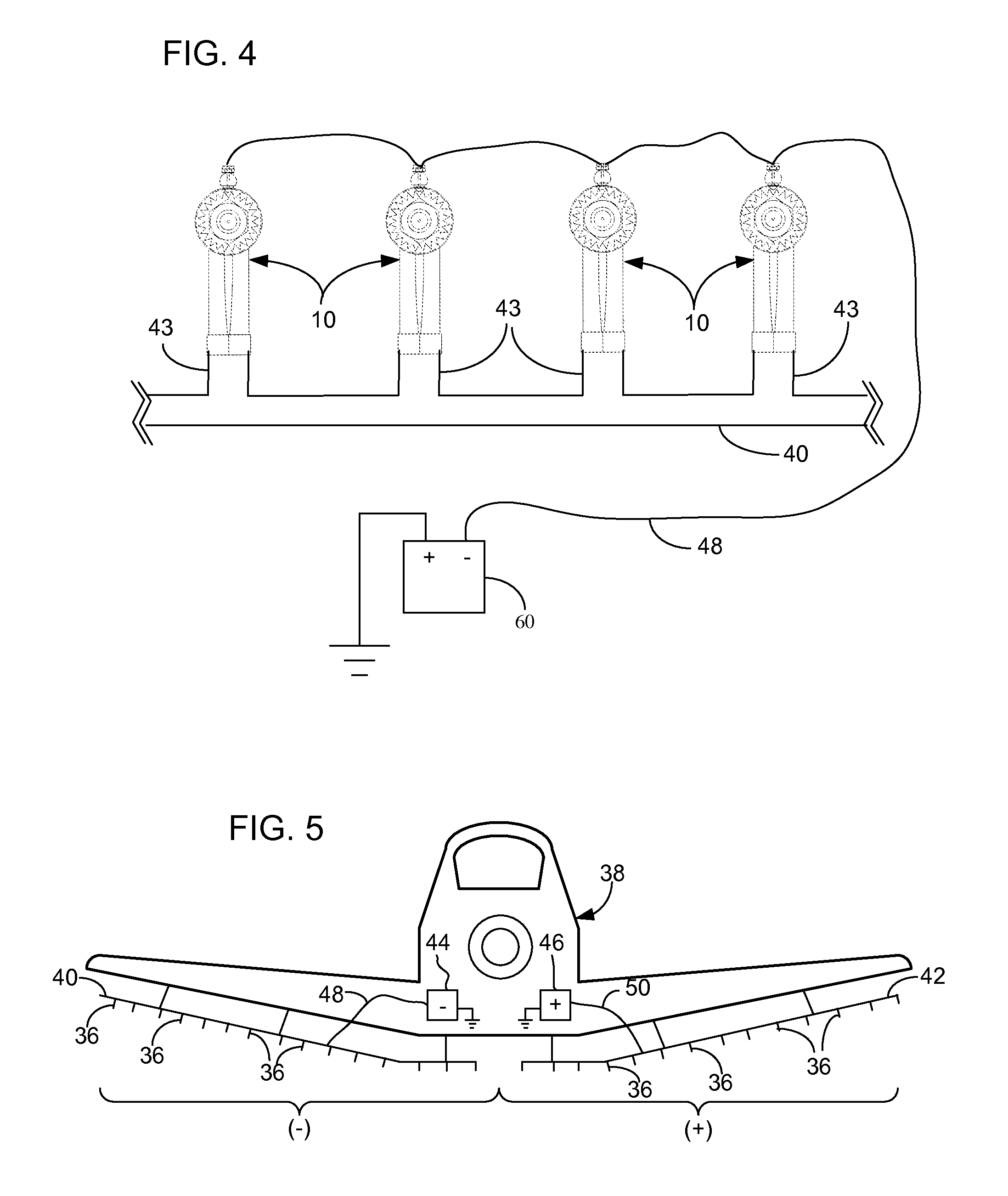

Aerial spraying apparatus

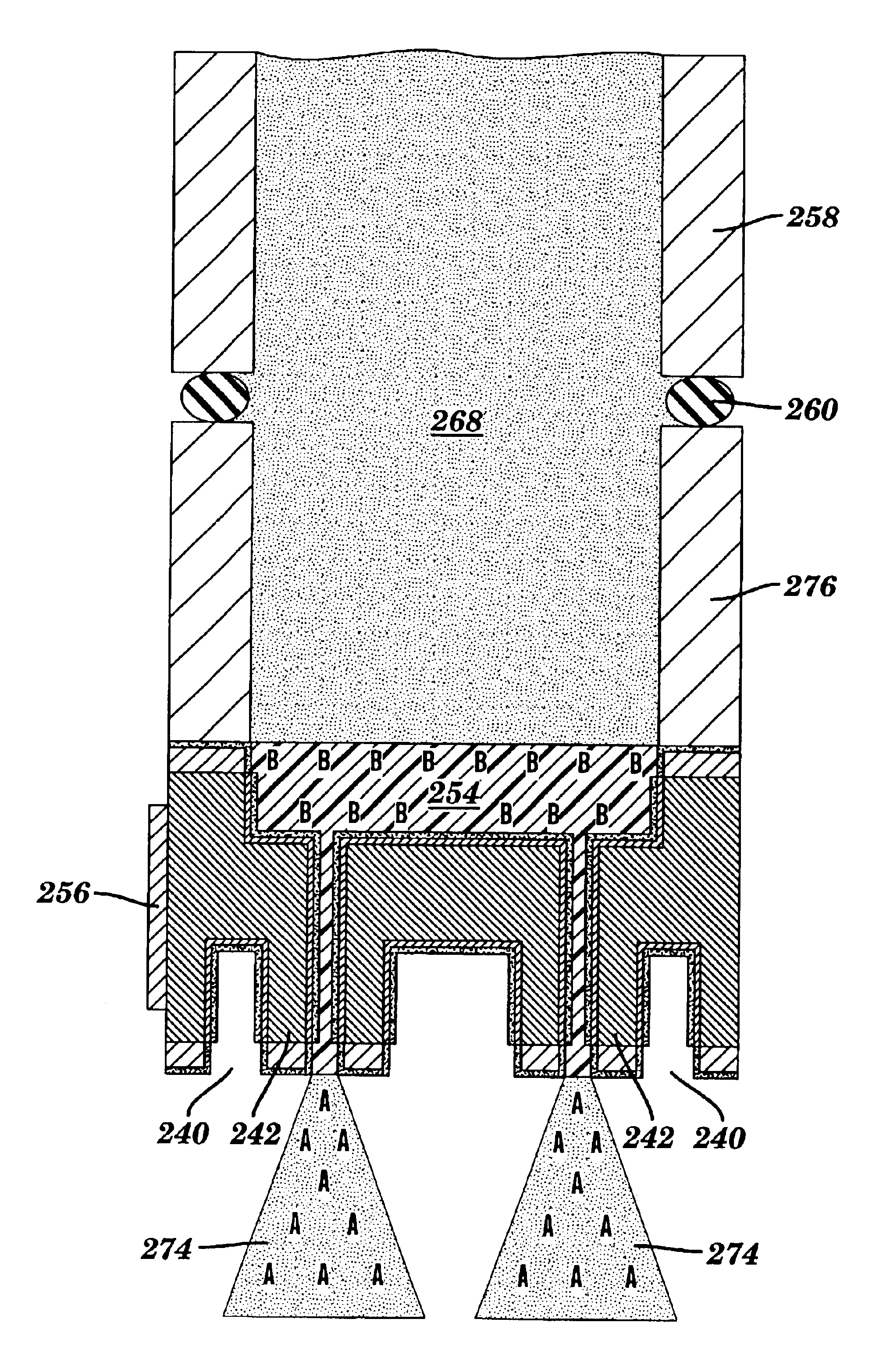

An apparatus for spraying and inducing an electrostatic charge upon a liquid in excess of 0.8 millicoloumb / kilogram is connectable to a boom fitted to a vehicle, such as an aircraft, having a dc power supply. The apparatus comprises a nozzle constructed from a substantially non-conductive material and includes a spray tip designed to provide a hollow conical spray pattern. A support member extends from the nozzle and supports a charging electrode for inducing an electrostatic charge upon the liquid sprayed through the nozzle. The charging electrode attaches to the support member and is electrically connectable to the dc power supply. The charging electrode includes a cylindrical portion and a plurality of corona discharge members extending inwardly from a distal end of the cylindrical portion adjacent to the spray tip. The charging electrode is positioned to permit the hollow conical spray pattern to pass unhindered therethrough.

Owner:JOHNSON AIRSPRAY

Polymer fibre web manufacturing device and method

InactiveCN1284888CHigh porosityImprove productivityNew-spun product collectionWet spinning methodsFiberLiquid state

The present invention provides a device and a method for manufacturing porous polymer fiber net by using charge induction spinning method. The manufacturing method includes: at least a step of forming at least one polymer substance in a liquid state; while passing the above-mentioned liquid state polymer substance through more than one charged nozzle, it is located at the lower part of the above-mentioned nozzle; The step in which charges of opposite polarity are then ejected on a collector moving at a certain speed.

Owner:KOREA INST OF SCI & TECH

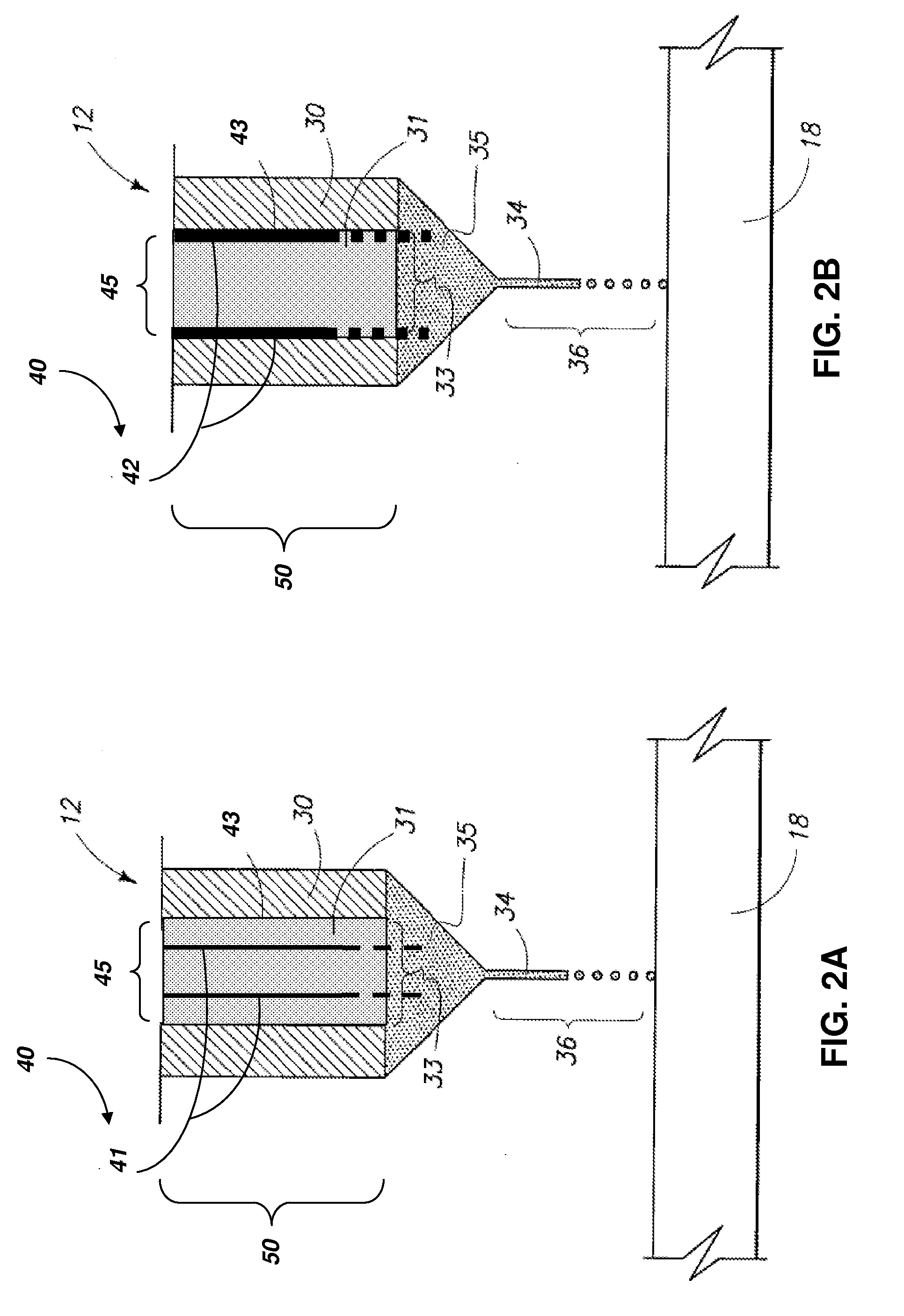

Electrostatic liquid spray nozzle having an internal dielectric shroud

ActiveUS9138760B2Reduce electric field strengthAvoid leakage currentLiquid spraying plantsLiquid spraying apparatusElectricityElectrical conductor

An electrostatic sprayer for spraying a liquid includes a nozzle formed from a a nozzle body that has an inlet for receiving a liquid and a liquid tip having an outlet for ejection of the liquid to form a liquid spray. The nozzle also includes an electrode disposed around the outlet of the liquid tip for charging the liquid and a dielectric shroud disposed around at least a portion of the liquid tip to prevent leakage currents from reducing a potential of the electric field between the liquid and the electrode, which would otherwise reduce the effectiveness of the sprayer. A conductor that couples the electrode to a power supply may pass through a hole extending through the shroud. The shroud may include one or more vents to permit air and liquid to pass through the dielectric shroud to reduce accumulation of liquid.

Owner:E S PROD DEV

Method for applying a powder coating

A method for the application of at least two different powder coating layers to a substrate comprising the steps of application of a first powder coating layer followed by the application of a second powder coating layer, without any substantial curing of the first powder coating layer prior to the application of the second powder coating layer, followed by the simultaneous curing of the first powder coating layer and the second powder coating layer, wherein the first powder coating layer is applied to the substrate using a corona charging system and the second powder coating layer is applied to the substrate using a tribo charging system, or the first powder coating layer is applied to the substrate using a tribo charging system and the second powder coating layer is applied to the substrate using a corona charging system and the first powder coating layer and second powder coating layer have an opposite electrostatic polarity.

Owner:AKZO NOBEL COATINGS INT BV

Electrostatic spray system

A system, in certain embodiments, includes a spray device including a frame having a receptacle configured to receive a self-contained spray can. The spray device further includes a first conductive element configured to contact the self-contained spray can, and a first electrical conductor extending between the first conductive element and an earth ground such that a first electrical potential of the self-contained spray can is substantially equal to a second electrical potential of the earth ground while the self-contained spray can is in contact with the first conductive element. The spray device also includes a corona-charging electrode positioned adjacent to a spray nozzle of the self-contained spray can. The corona-charging electrode is configured to emit a stream of ions toward the self-contained spray can such that a spray of fluid from the spray nozzle passes through the stream of ions and becomes electrostatically charged.

Owner:CARLISLE FLUID TECH INC

Electrostatic spray system

ActiveUS20050194476A1Efficient and reliable sprayingMade preciselyBurnersSpraying power supplyVoltage sourceElectrical and Electronics engineering

An electrostatic spraying assembly is provided. The spraying assembly includes a housing having a fluid inlet passage that is connectable to a fluid source and communicates with a plurality of discharge passageways each of which extends through the housing to a downstream end at a discharge end of the housing. The housing has a one piece construction and is made of an electrically insulative material. The spraying assembly also includes an electrode assembly. The electrode assembly includes a plurality of elongate electrode elements each of which is disposed in a respective one of the discharge passageways in the housing and an electrode header. The electrode header is electrically connectable to a voltage source and each of the electrode elements is electrically connectable to the electrode header.

Owner:SPRAYING SYST

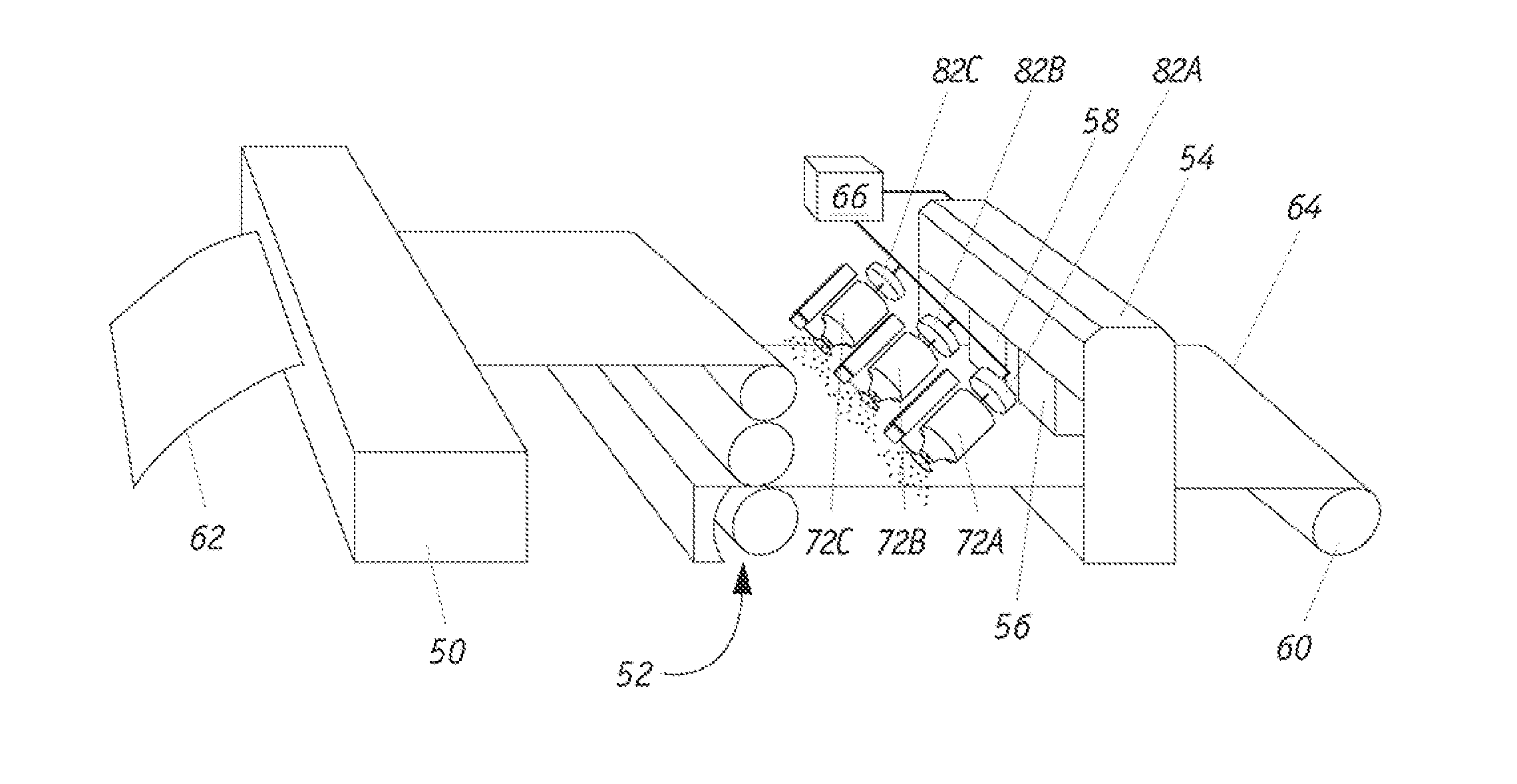

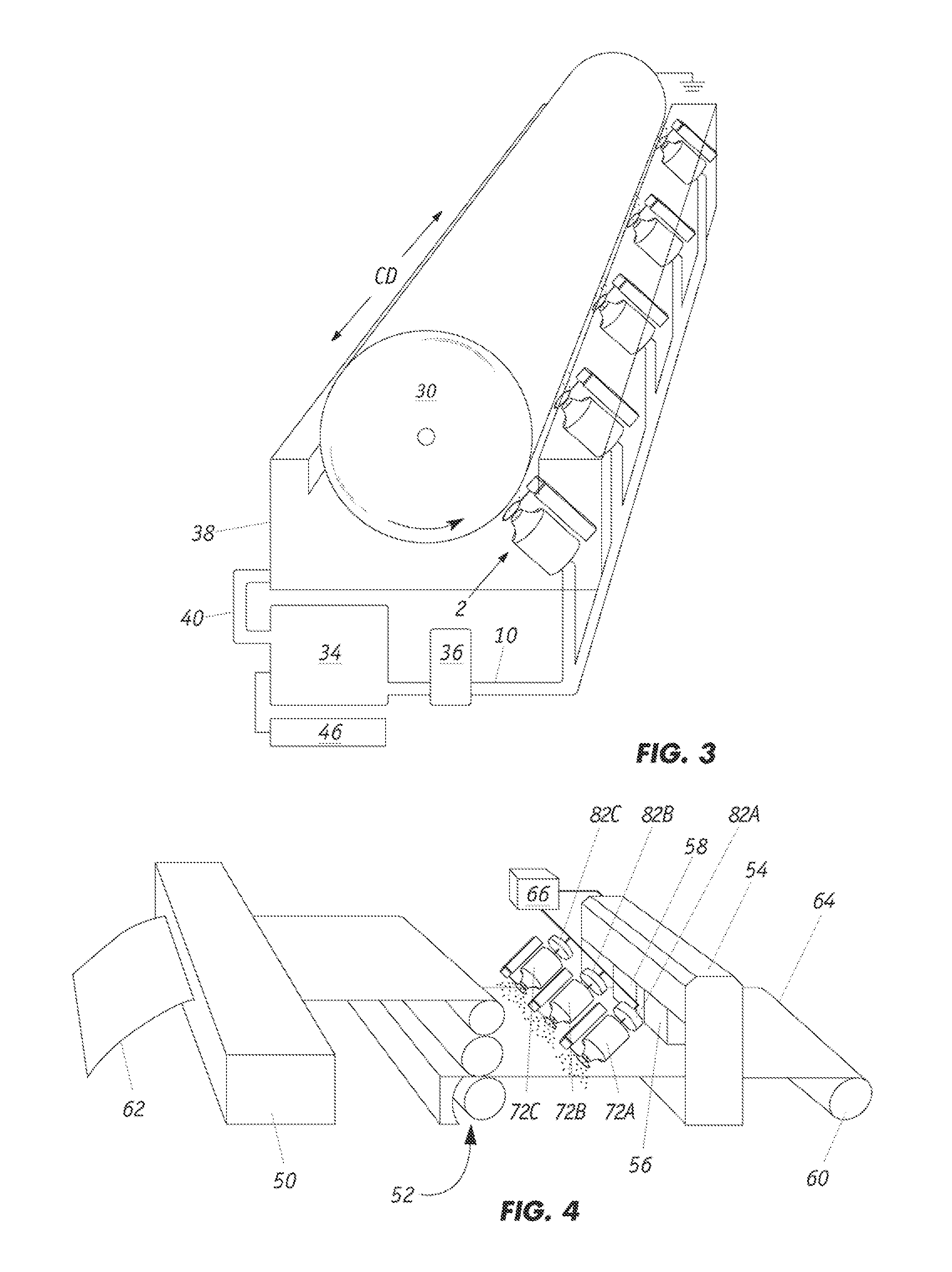

Method to Create Uniform Distribution, Minimize Applied Solution Volume and Control Droplet Size of Water and/or Coating Applications for Web Applications

ActiveUS20130156970A1Quantity minimizationPromotes even distributionBurnersLiquid spraying plantsWeb applicationSpray nozzle

A coating apparatus produces a spray of charged droplets and controls the spray angle of travel of the spray toward the object to be coated. Electrically charging droplets minimizes the amount of coating material required to uniformly coat a surface as compared to conventional web coating techniques such as blade coating. An inductive ring guides the spray charged droplets as they exit the nozzle of a spray device. The electrostatic repulsion between the charged droplets insures that a uniform coating of liquid formulation can be applied to a web surface.

Owner:HONEYWELL ASCA INC

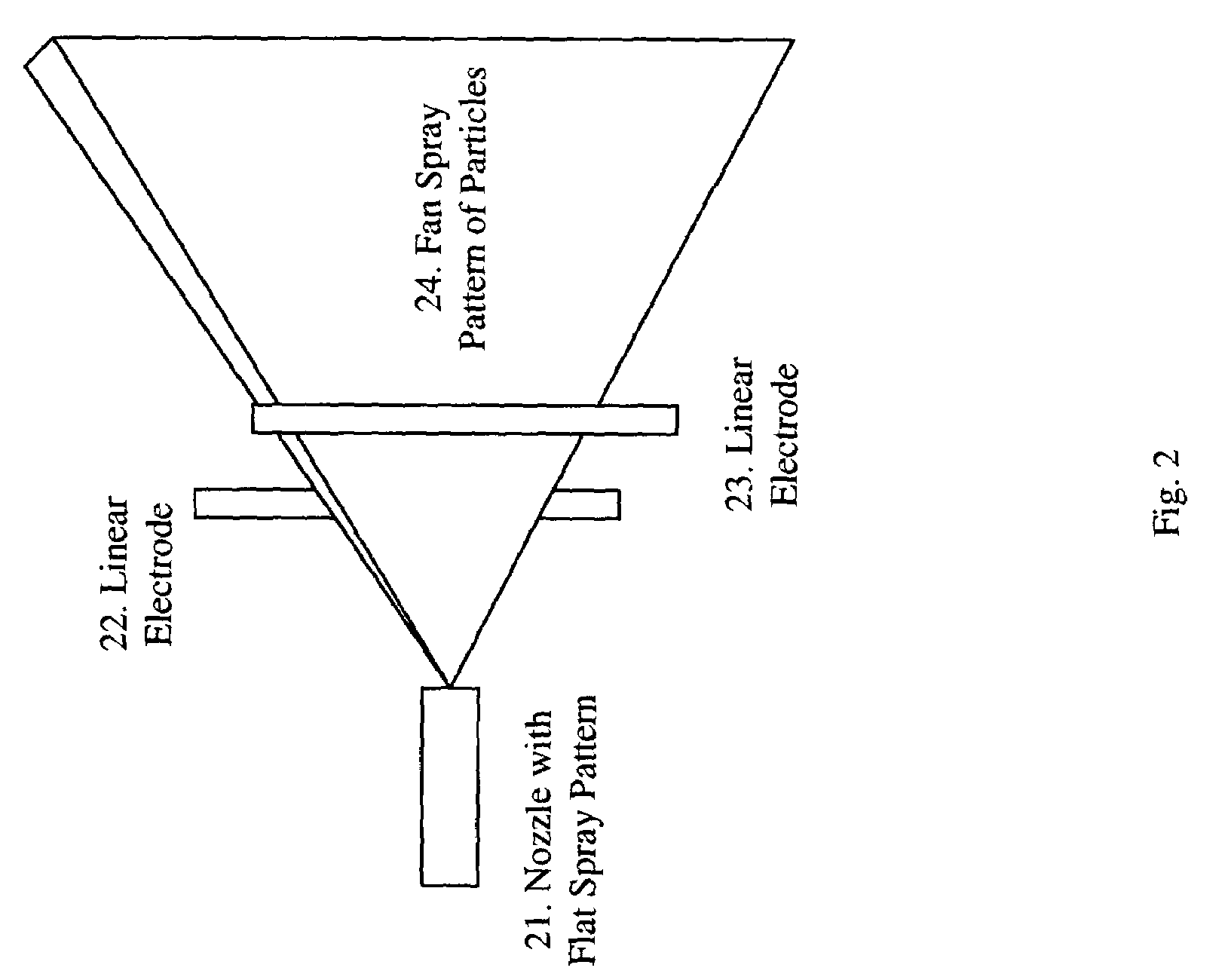

Fan-shaped electrostatic induction atomizing nozzle with automatically adjustable electrode

ActiveCN111054530ARealize automatic adjustmentSpraying power supplySpray nozzlesSprayerStructural engineering

The invention provides a fan-shaped electrostatic induction atomizing spray head with an automatically adjustable electrode, which comprises a spray head and a spray head seat, the spray head is arranged on the spray head seat, and electrode devices capable of moving along the spraying direction of a nozzle are uniformly distributed in the spray head seat near the spray head and are used for enabling spray droplets to inductively charge. The electrode device comprises an electrode and a piston rod; a plurality of electrode grooves are evenly distributed near the sprayer seat with the sprayer as the center, an electrode is placed in any electrode groove, one end of the electrode is connected with a piston rod, and the piston rod is loaded through external force to enable the electrode to move in the electrode groove. According to the invention, the position of the electrode can be automatically adjusted under the condition that the spray pressure is changed.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com