Induction electrostatic atomization nozzle

An electrostatic atomization and nozzle technology, applied in induction discharge spraying, electrostatic spraying device, spraying device, etc., can solve the problems of endangering operator safety, unstable charging effect of electrostatic spraying system, hidden danger of electrical safety, etc., to reduce the electric field. Intensity, the effect of avoiding the phenomenon of droplet adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

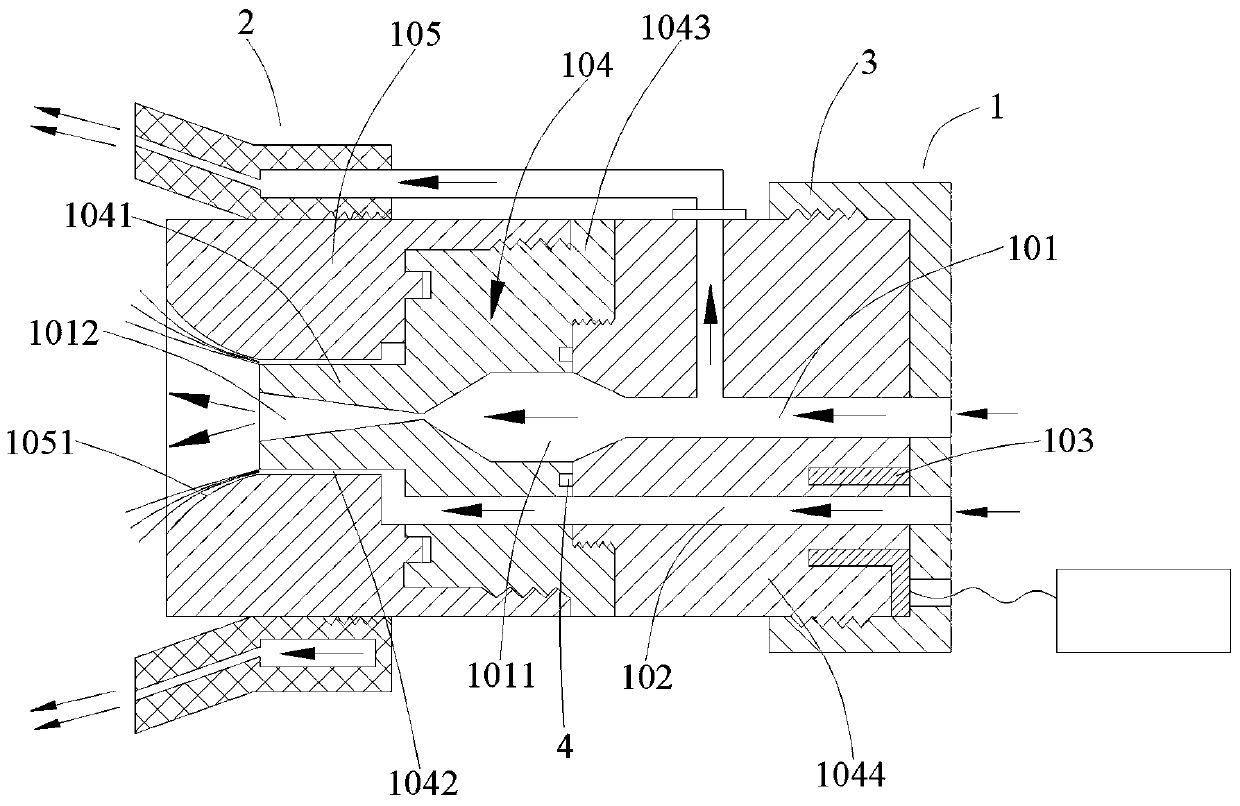

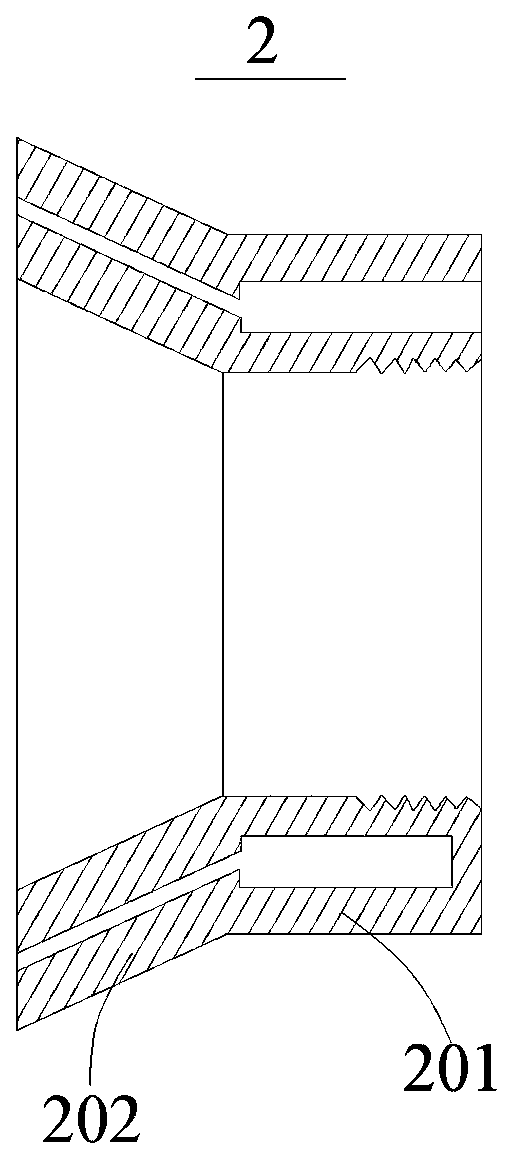

[0042] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0043] Such as Figure 1~3 As shown, an induction electrostatic atomization nozzle of the present invention includes a nozzle body 1, the nozzle body 1 has an internal gas flow channel 101, and a liquid flow channel 102 surrounding the internal gas flow channel 101;

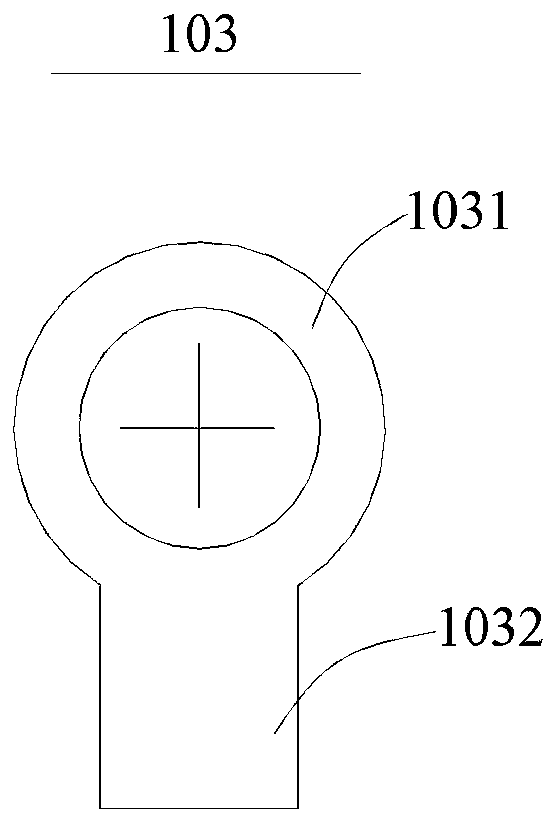

[0044] An electrode ring 103 is disposed around the liquid flow channel 102 at the inlet of the liquid flow channel 102 .

[0045] This kind of induction electrostatic atomization nozzle, by placing the electrode ring 103 at the inlet end of the liquid flow channel 102, ensures that the electrode ring 103 is far away from the position of the induction electrostatic atomization nozzle, thereby re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com