Electrostatic nozzle and controllable jet minimal quantity lubrication grinding system

a technology of lubrication grinding system and controllable jet, which is applied in the direction of liquid supply arrangement, induction-charge spraying, manufacturing tools, etc., can solve the problems of droplet diffusion, uncontrollable movement paths of droplets, polluting the environment, etc., to improve the oleophilic performance of the inner surface, improve the movement resistance of mql liquid, and reduce the disturbance of the jet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

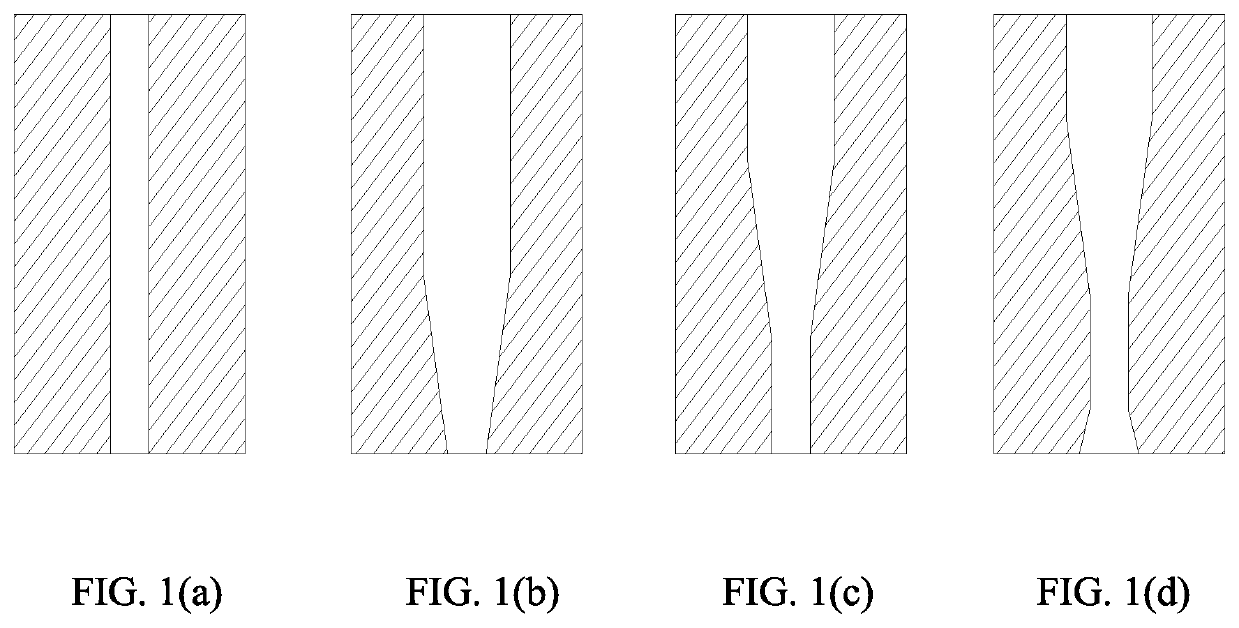

[0061]As shown in FIGS. 1(a)-1(d), a current injection nozzle structure has a cylindrical nozzle as shown in FIG. 1(a), a conical nozzle as shown in FIG. 1(b), a conical column-shaped nozzle as shown in FIG. 1(c) and a conical column diverging nozzle as shown in FIG. 1(d). The nozzle has relatively high requirements for velocity distribution and turbulence intensity of jet. The design of the nozzle requires that the jet velocity is relatively uniform, a velocity gradient is not easy to be too large, the turbulence intensity of the jet is low, the jet is not easy to have relatively large fluctuations, the concentration distribution of droplets at a nozzle outlet is uniform, and a concentration gradient of the jet is not easy to be too large. According to research experience of relevant workers, under the same inlet and outlet conditions, in velocity distribution, the velocity distribution at an outlet of the cylindrical nozzle is the most uneven, the central velocity distribution is ...

embodiment 2

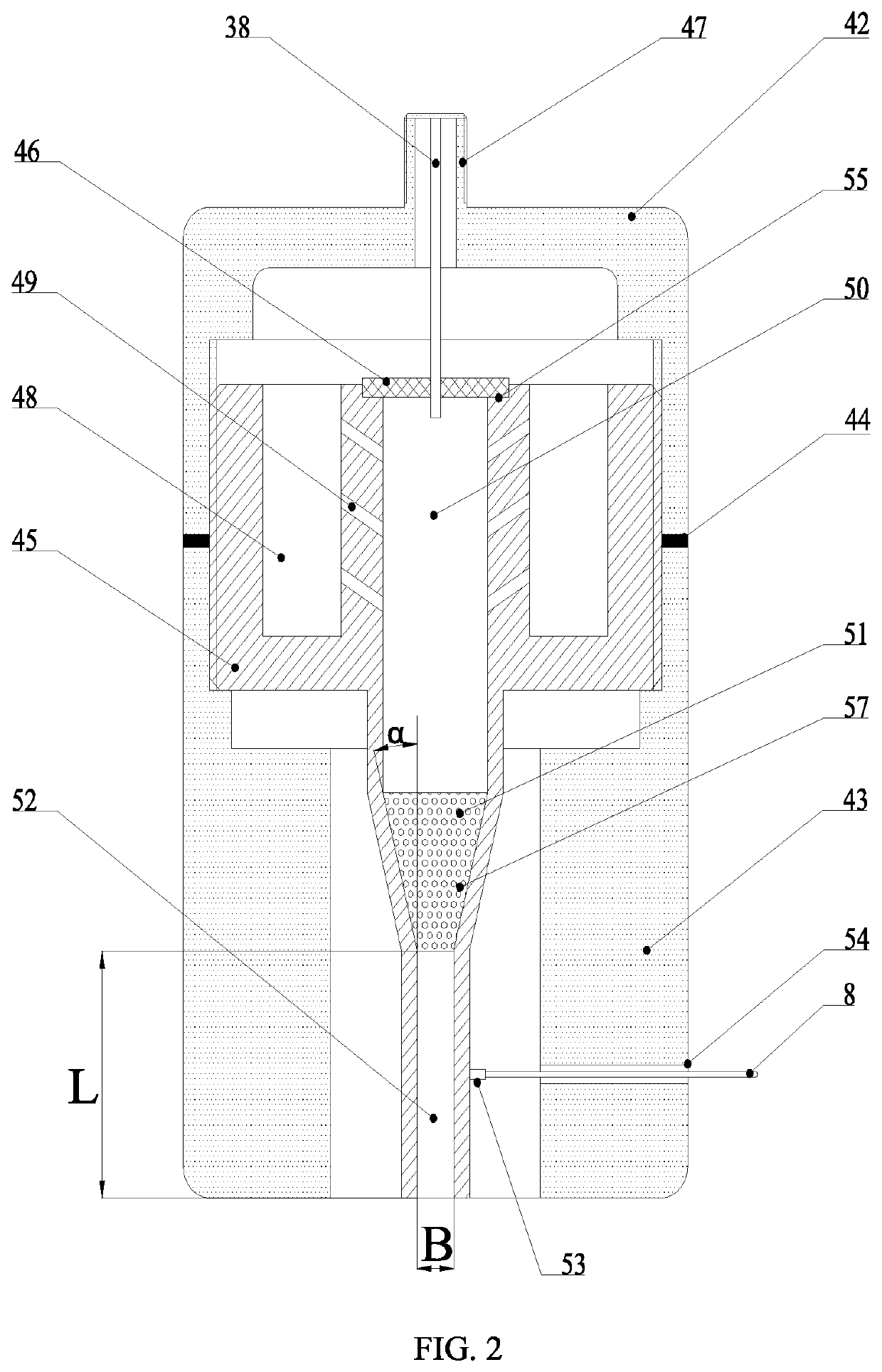

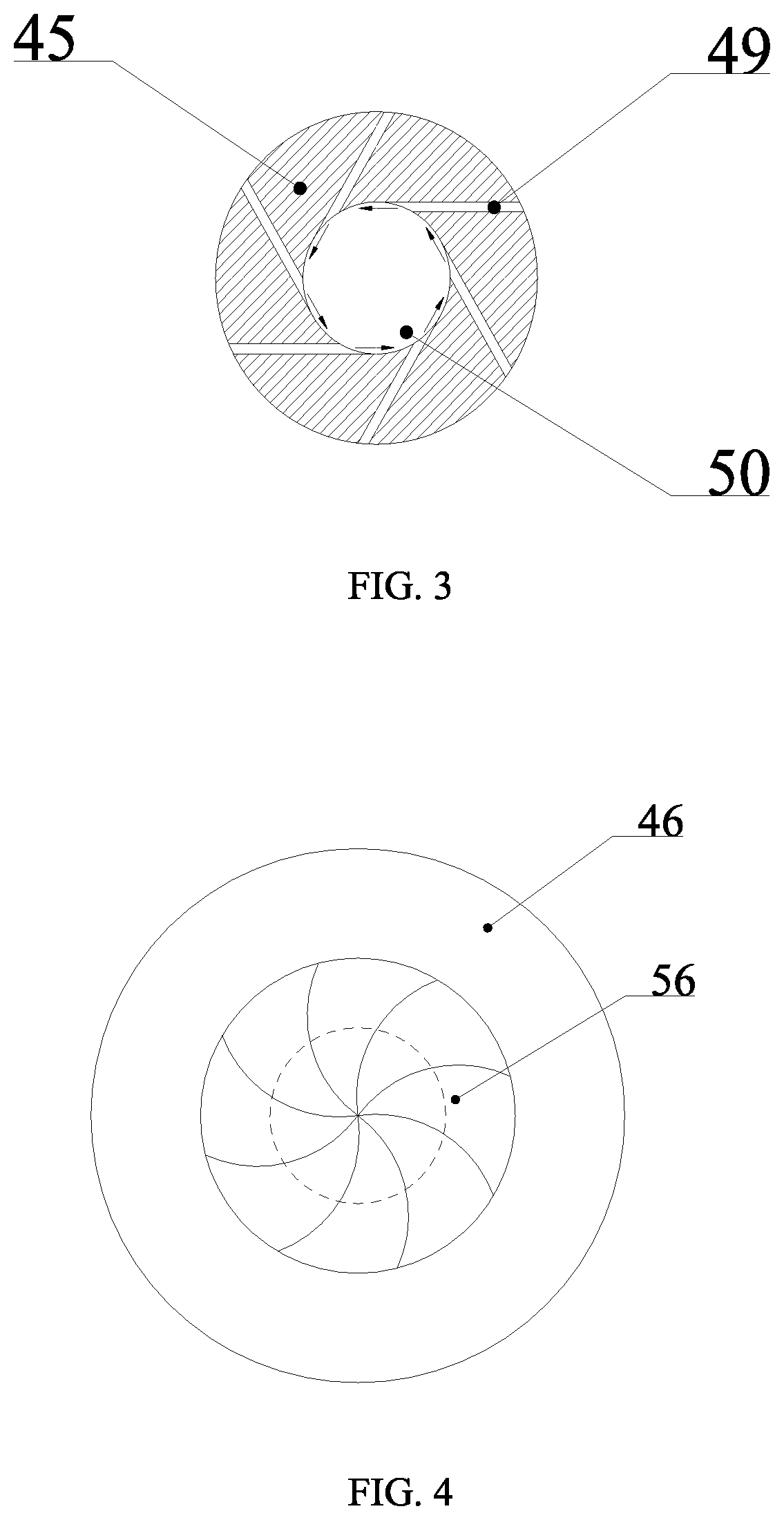

[0070]As shown in FIGS. 2-4, a two-stage composite micro-texture electrostatic nozzle according to the present embodiment comprises:

[0071]an upper nozzle body 42, a lower nozzle body 43, an insulation sealing ring 44, a nozzle core 45, an annular check ring 46, an MQL liquid conveying pipe interface 47, an air storage chamber 48, spiral air holes 49, a gas-liquid mixing chamber 50, an acceleration chamber 51, a nozzle outlet 52, a high-voltage wire interface 53, a high-voltage wire outlet through hole 54, a check ring placement groove 55, a V2O5 nanofiber sheet 56 and micro-bulges 57.

[0072]The upper nozzle body 42 is connected above the nozzle core through threads; the lower nozzle body 43 is connected below the nozzle core 45 through threads; and the insulation sealing ring 44 is arranged between the upper nozzle body 42 and the lower nozzle body 43 and can effectively prevent gas in the nozzle from leaking. The upper nozzle body 42 and the lower nozzle body 43 are made of insulati...

embodiment 3

[0077]As shown in FIGS. 2-4, a noise-reducing and resistance-increasing electrostatic nozzle according to the present embodiment specifically comprises an upper nozzle body 42, a lower nozzle body 43, an insulation sealing ring 44, a nozzle core 45, an annular check ring 46, an MQL liquid conveying pipe interface 47, an air storage chamber 48, spiral air holes 49, a gas-liquid mixing chamber 50, an acceleration chamber 51, a nozzle outlet 52, a high-voltage wire interface 53, a high-voltage wire outlet through hole 54, a check ring placement groove 55, a V2O5 nanofiber sheet 56 and micro-bulges 57.

[0078]The upper nozzle body 42 is connected above the nozzle core through threads; the lower nozzle body 43 is connected below the nozzle core 45 through threads; and the insulation sealing ring 44 is arranged between the upper nozzle body 42 and the lower nozzle body 43 and can effectively prevent gas in the nozzle from leaking. The upper nozzle body 42 and the lower nozzle body 43 are ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com