Fan-shaped electrostatic induction atomizing nozzle with automatically adjustable electrode

An automatic adjustment, electrostatic induction technology, applied in the direction of induction discharge spray, electrostatic spray device, spray device, etc., can solve the problem that the best charging effect cannot be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

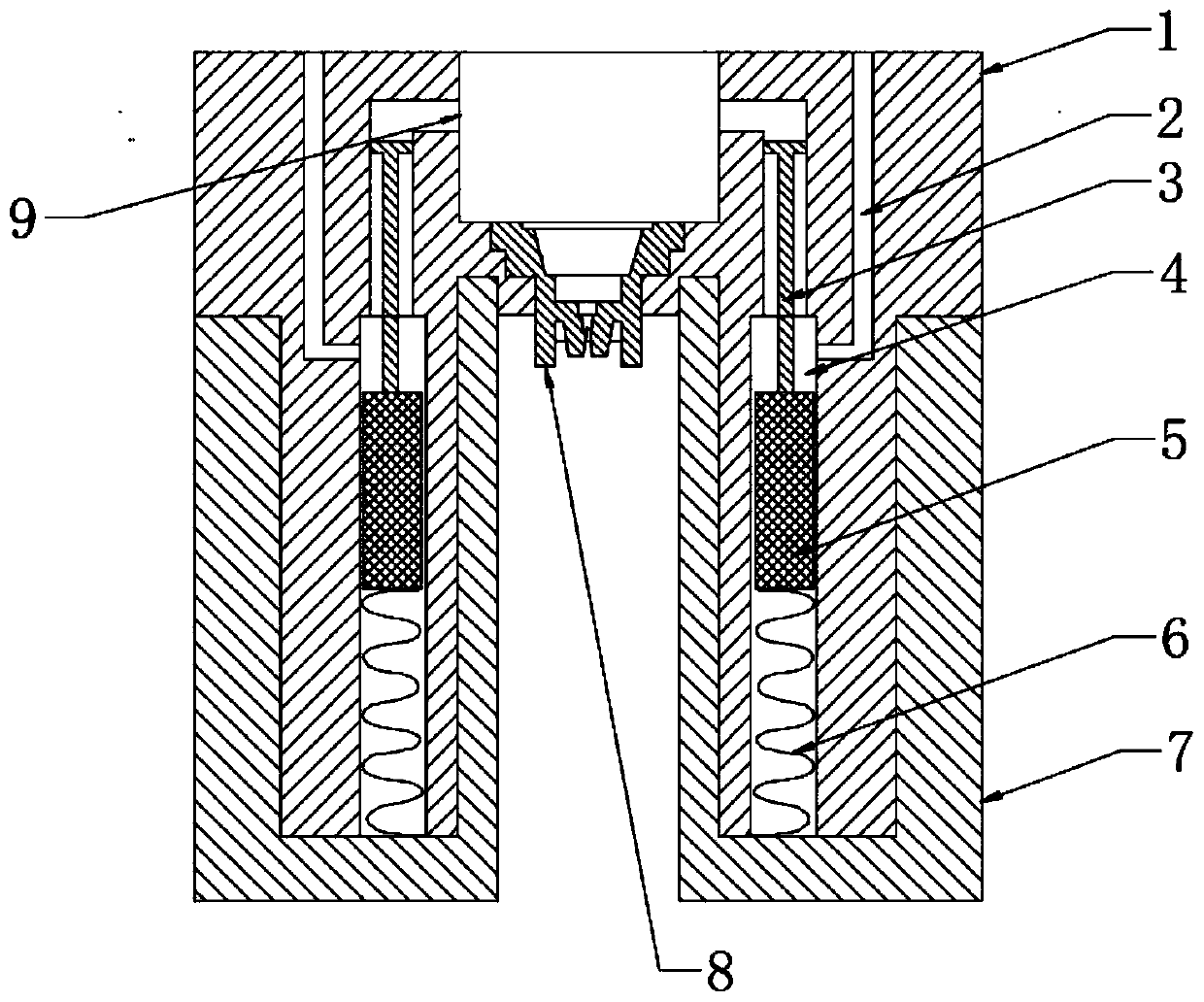

[0021] Embodiment 1, the electrode 5 is moved in the electrode groove 4 by loading the piston rod 3 through the actuator; according to the pressure of the nozzle, the loading force of the actuator is adjusted to control the moving distance of the electrode 5 in the electrode groove 4. The actuator can be an electric push rod or a straight line. According to the pressure of the nozzle, the controller controls the external force applied by the electric push rod or the straight line. The distance that the electrode 5 moves in the electrode groove 4 is proportional to the pressure of the nozzle.

Embodiment 2

[0022] Embodiment 2, the electrode tank 4 communicates with the liquid inlet chamber of the spray head 8 through the pressure hole 9, and the piston rod 3 is moved in the electrode tank 4 by hydraulic pressure; the other end of the electrode 5 is equipped with a spring 6 to The distance that the electrode 5 moves in the electrode groove 4 is proportional to the pressure of the shower head. When the liquid pressure is small, the spring 6 keeps the electrode 3 close to the nozzle outlet, and when the liquid pressure is high, the piston rod 3 will push the electrode 3 to overcome the elastic force of the spring 6, so that the electrode 3 moves down to far away from the nozzle outlet Location.

[0023] work process:

[0024] Install the nozzle required for spraying in the nozzle seat 1, and determine the electrode 5 and spring 6 according to the selected nozzle and the set spray pressure as a reference; extend the wire from the wire hole 2 into the electrode slot 4, and connect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com