Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231results about "Fluid pressure measurement by acoustic means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact-based transducers for characterizing unsteady pressures in pipes

InactiveUS20050050956A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsTransducerEngineering

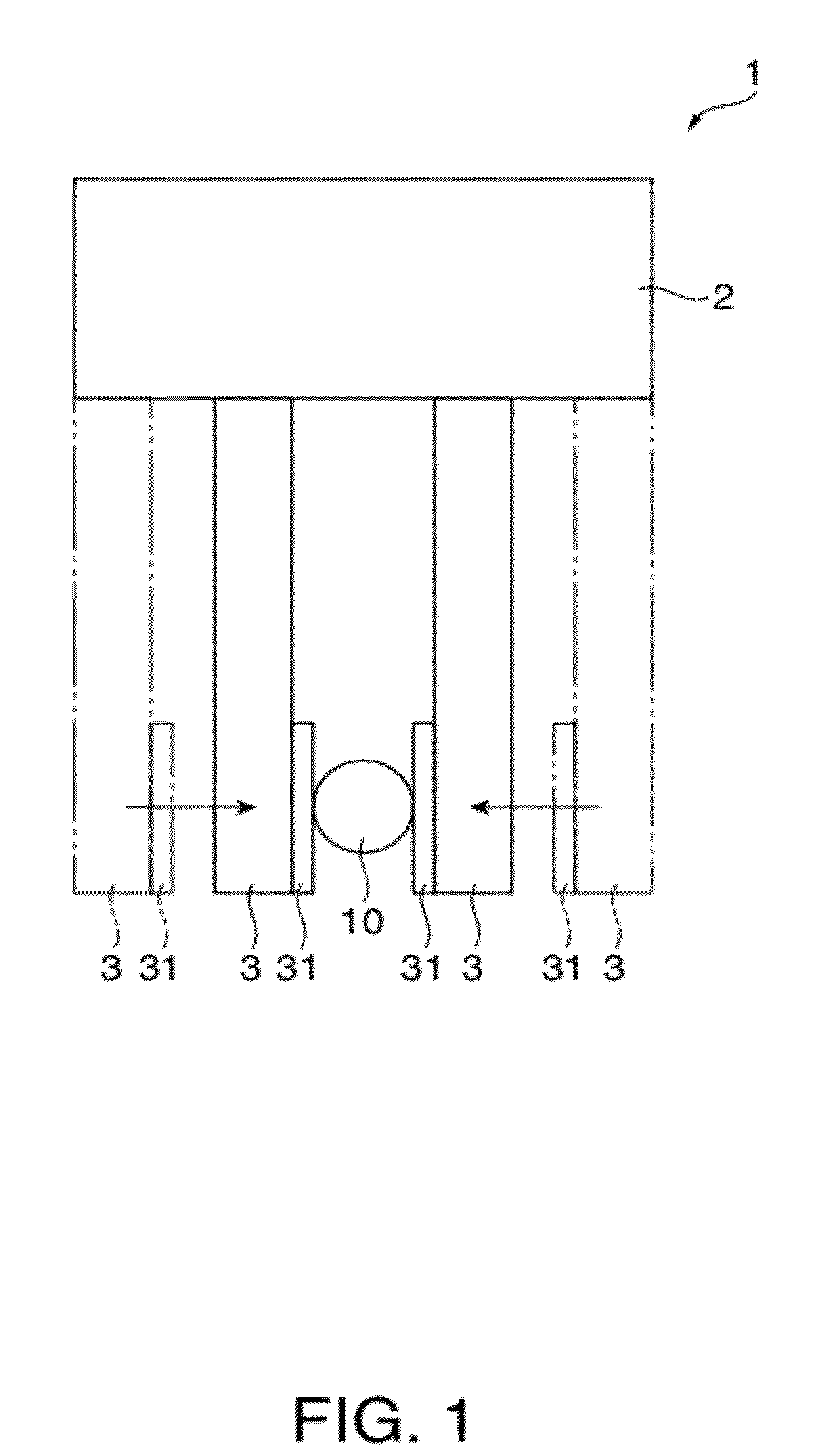

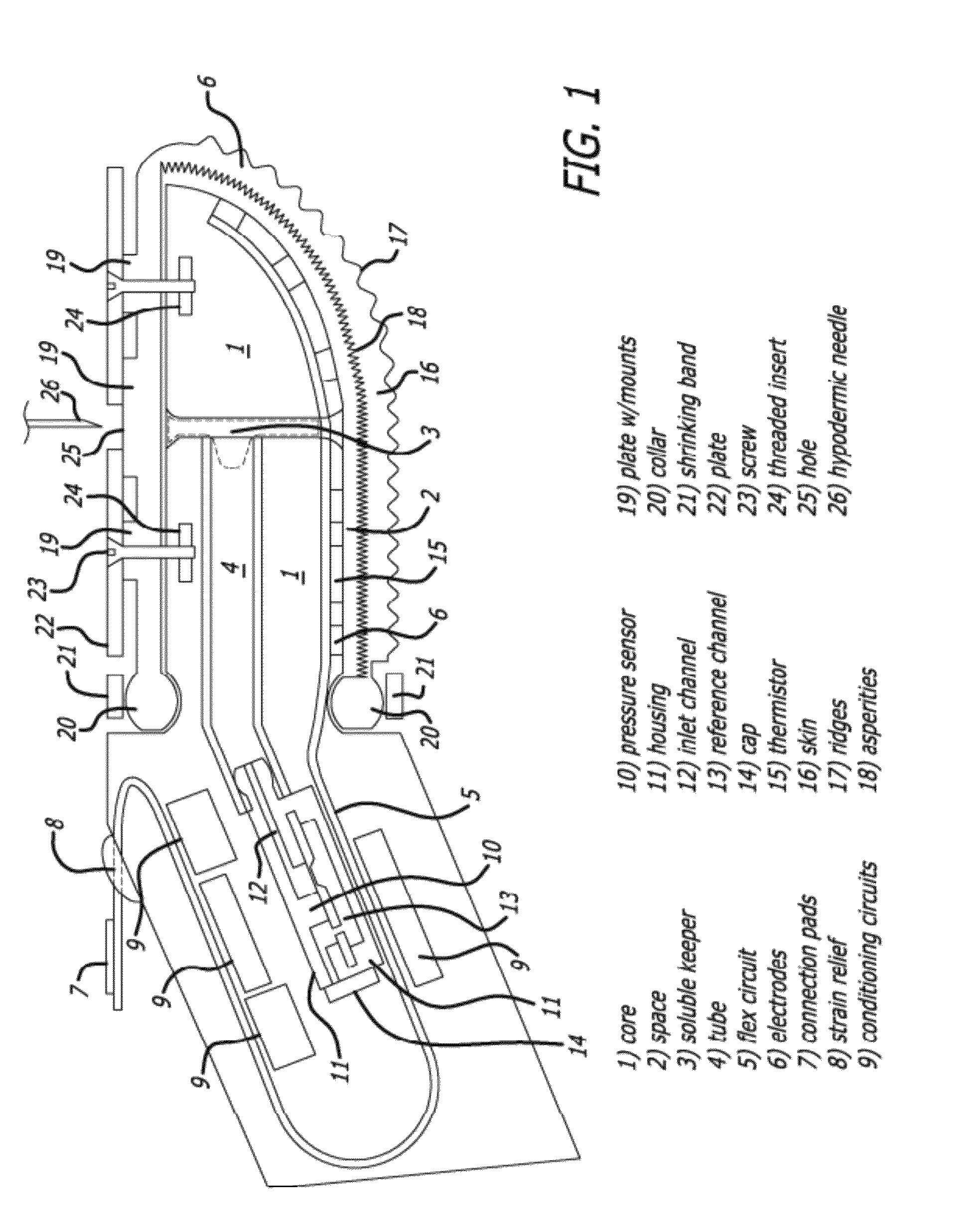

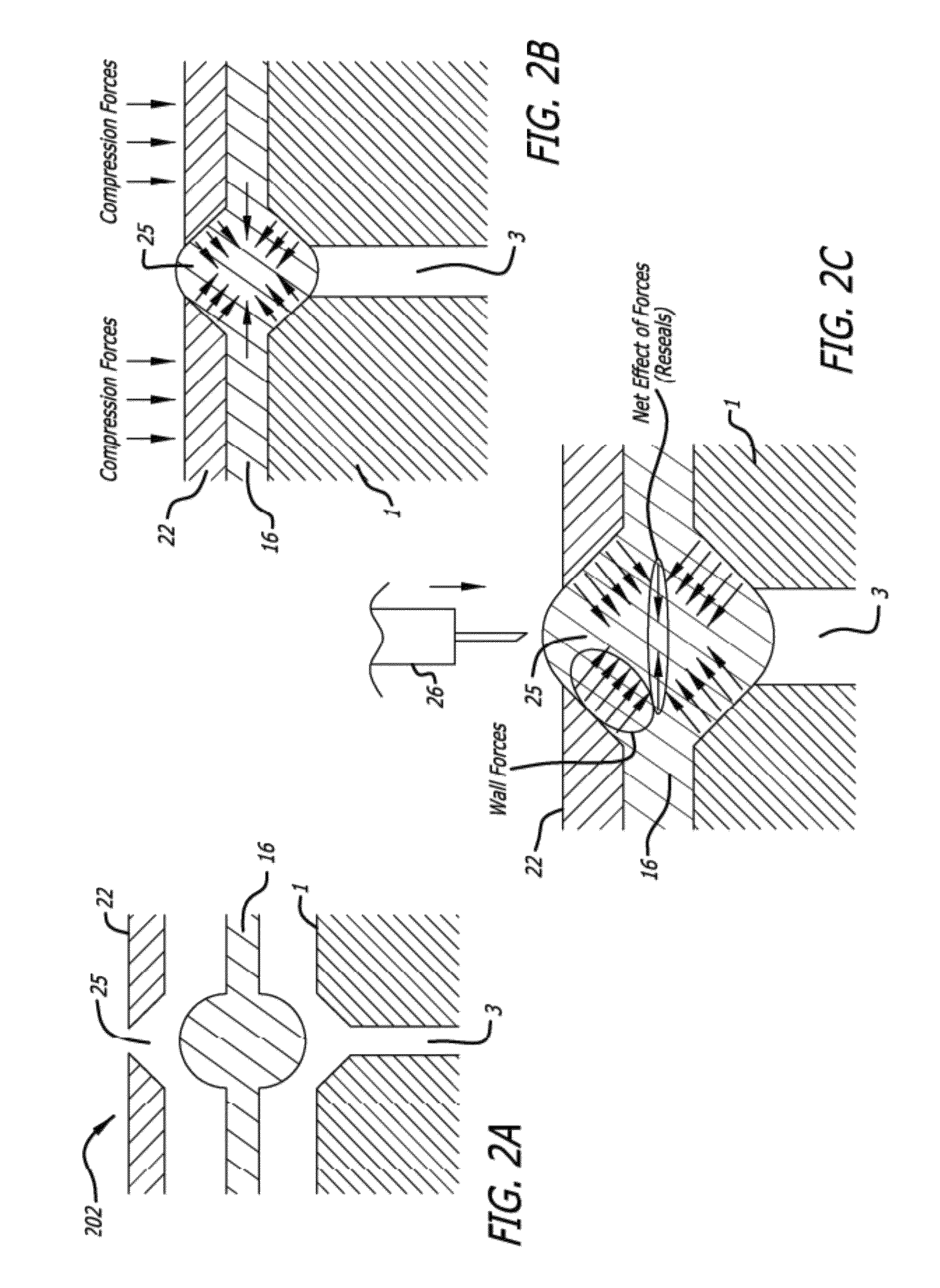

A sensor head characterizes unsteady pressures in a fluid flowing within a pipe, as may be caused by one or both of acoustic waves propagating through the fluid within the pipe and / or pressure disturbances that convect with the fluid flowing in the pipe. The sensor head comprises a rigid support structure and at least one transducer attached to the rigid support structure. The rigid support structure holds the transducer in contact with an outer surface of the pipe. The at least one transducer senses relative movement between the outer surface of the pipe and the support structure and provides a signal indicative of unsteady pressures within the fluid at a corresponding axial position of the pipe in response to the relative movement. The support structure may be attached to each transducer in an array of transducers, and may include a handle secured thereto for manipulating the sensor head into contact with the pipe. Output signals from the transducers are provided to a processing unit, which processes the output signals to provide a signal indicative of at least one parameter of the flow process.

Owner:CIDRA

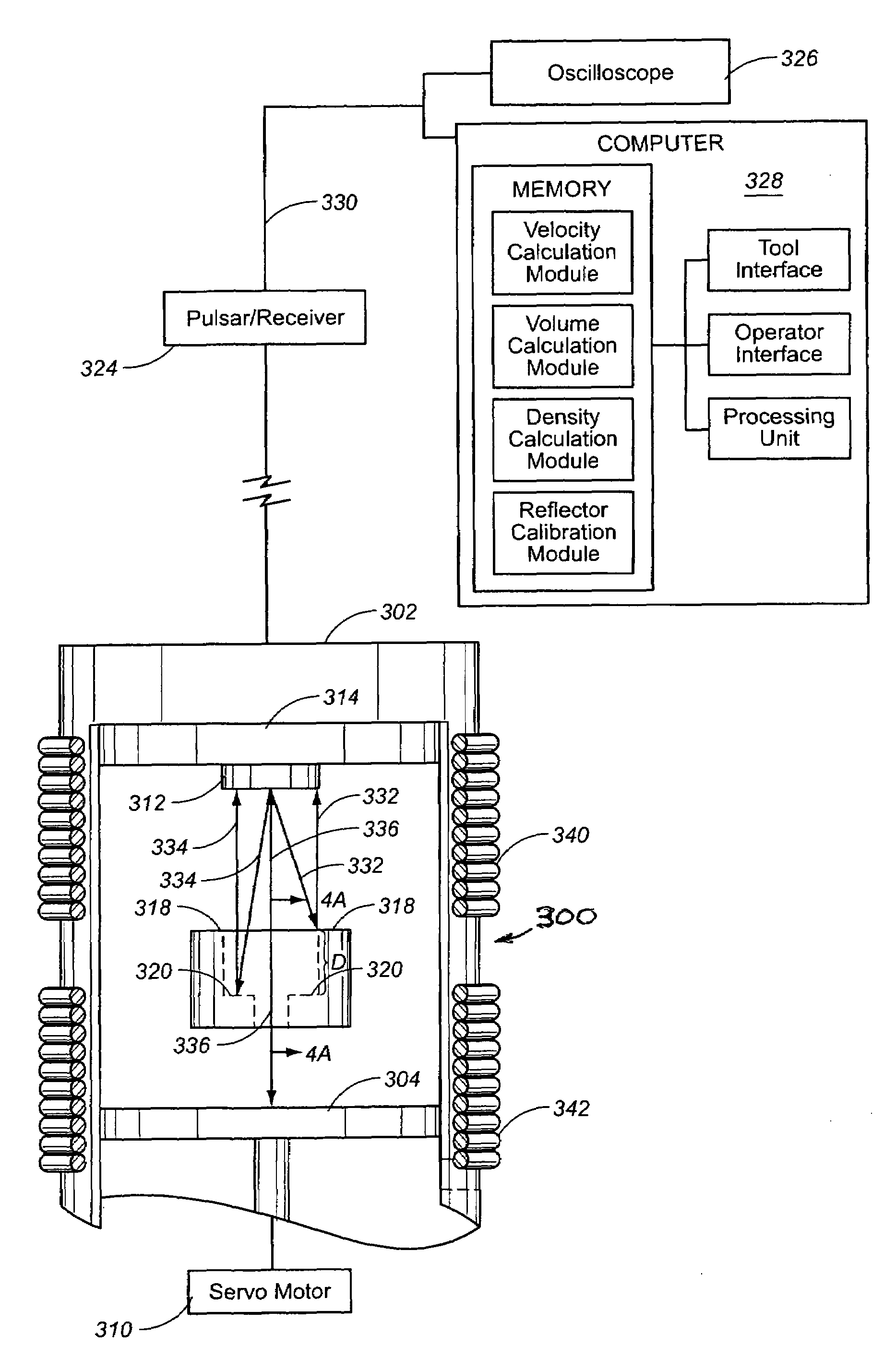

Apparatus and methods for acoustically determining fluid properties while sampling

ActiveUS20050223808A1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcoustic propertyTransmitter

An apparatus and methods for acoustically analyzing a fluid sample and determining one or more properties of the sample are disclosed by the present invention. The apparatus comprises a chamber, a transmitter positioned within the chamber for transmitting an acoustic signal through the fluid, a reflector movably positioned within the fluid inside the chamber for reflecting the acoustic signal, and a receiver positioned within the chamber for detecting reflections of the acoustic signal. The methods employ the use of a transmitter, a reflector movably positioned within the fluid inside the chamber, and a receiver to characterize the fluid sample based on one or more of its acoustic properties.

Owner:SHELL OIL CO

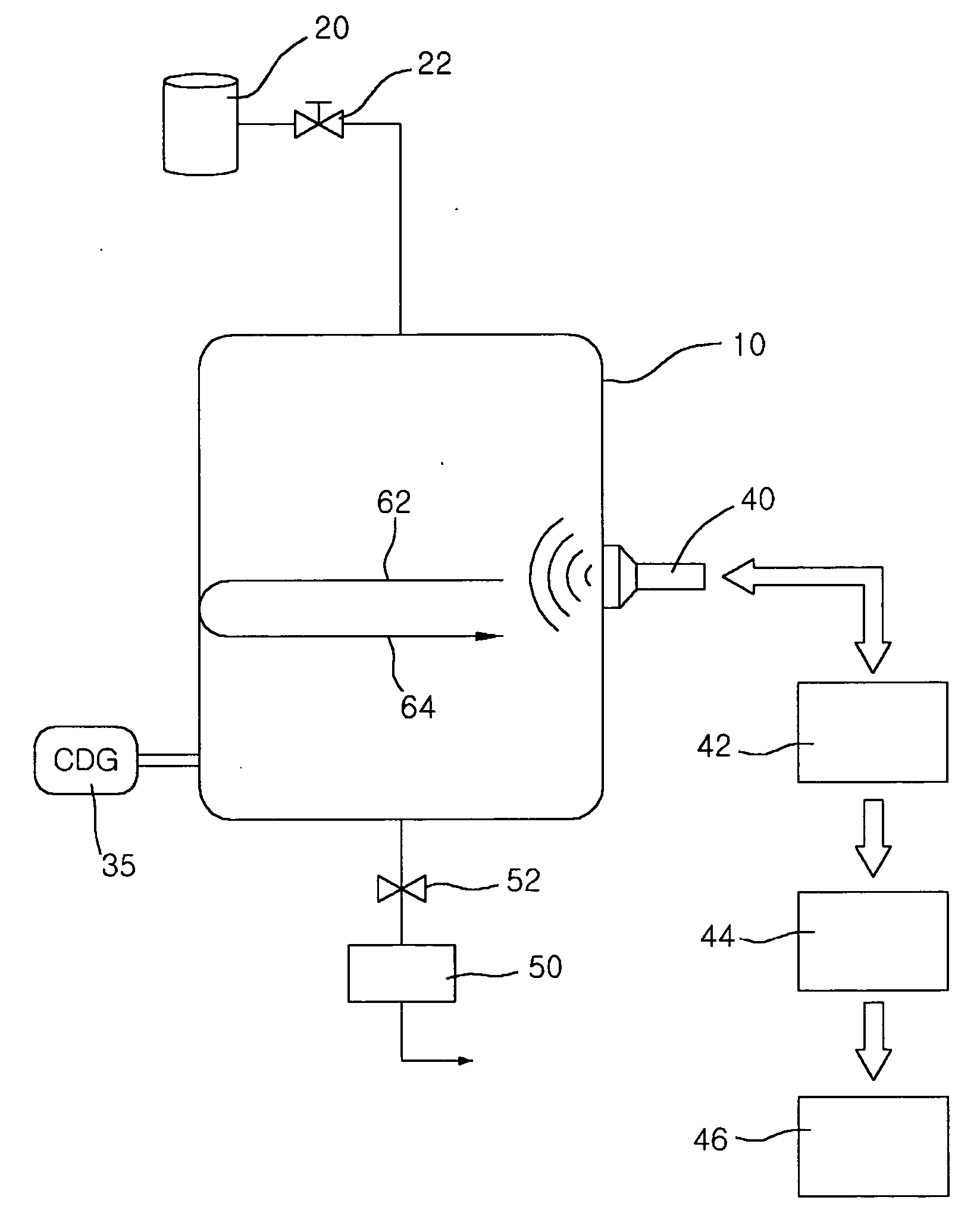

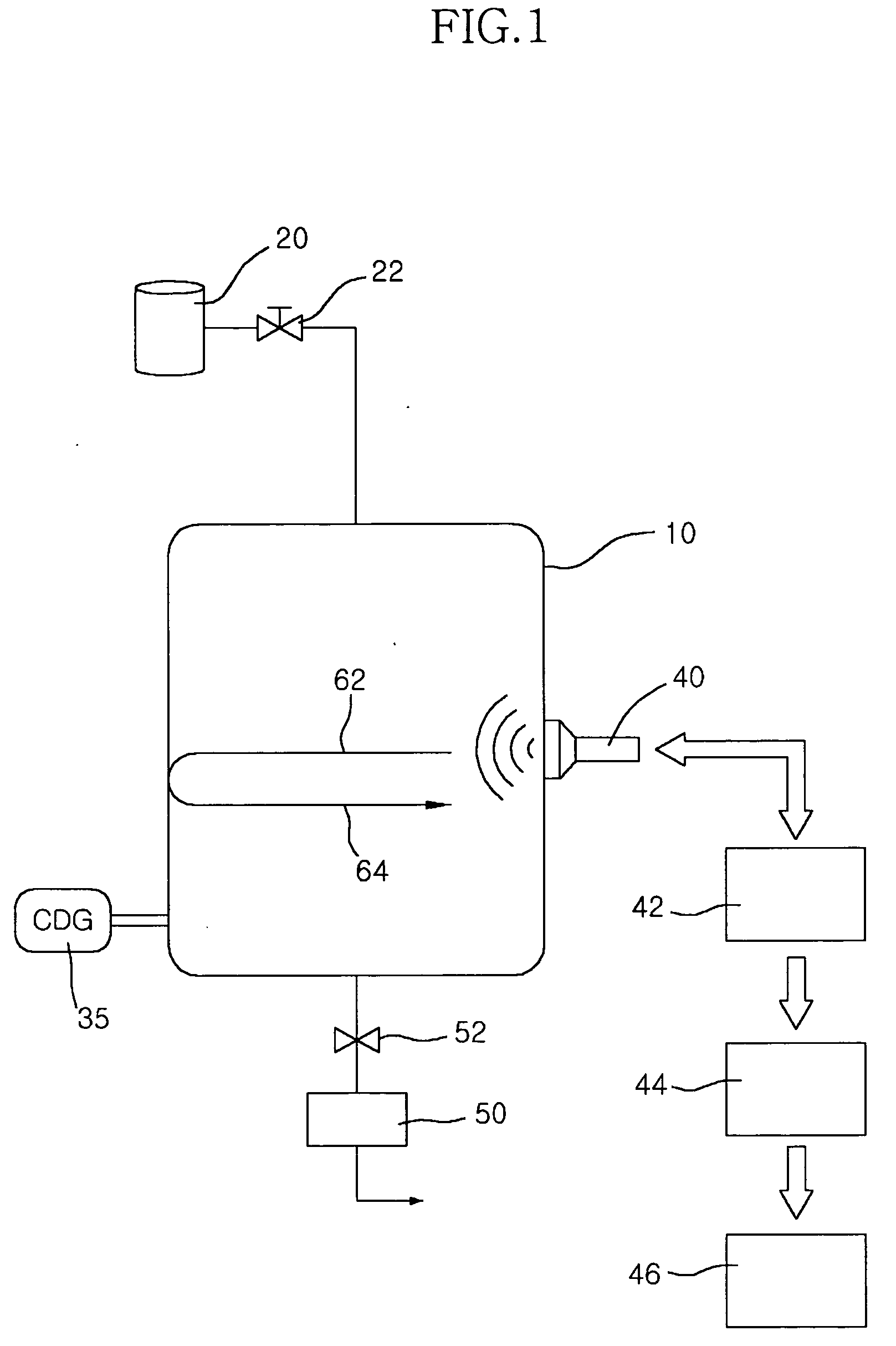

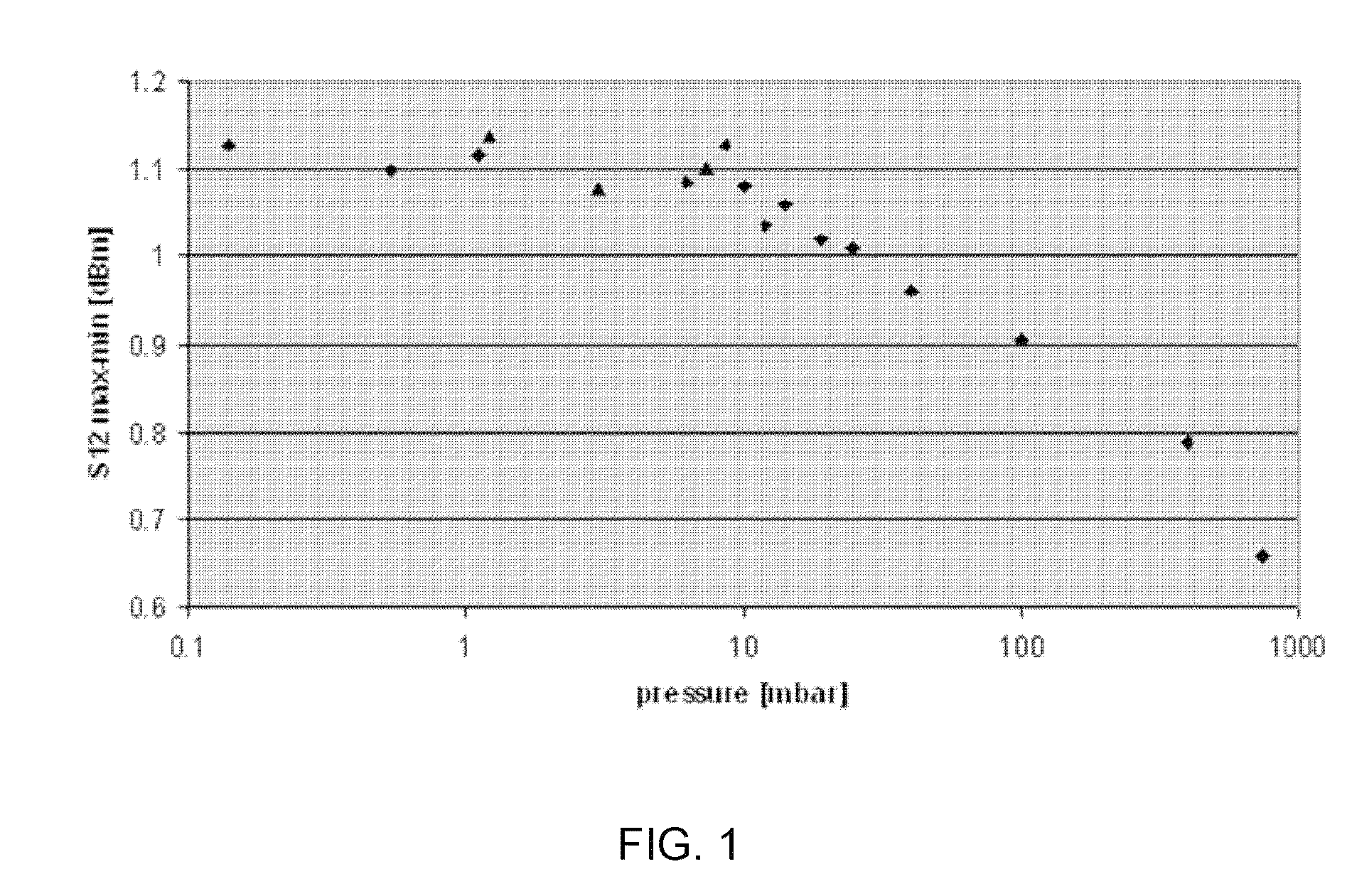

Pressure measuring system for vacuum chamber using ultrasonic wave

InactiveUS20070068260A1Reduce vacuumEasy to measureVacuum gaugesPressure difference measurement between multiple valvesReflected wavesVacuum chamber

Disclosed is a pressure measuring system for a vacuum chamber, in particular, a pressure measuring system for a vacuum chamber using ultrasonic wave. In this regard, there is provided a pressure measuring system for a vacuum chamber using ultrasonic wave, comprising a vacuum chamber 10 formed with desired vacuum at the inside thereof; ultrasonic wave-emitting means mounted close to an outer peripheral surface of the vacuum chamber 10 for emitting an ultrasonic wave 62 to the inside of the vacuum chamber 10; ultrasonic wave-receiving means for receiving a reflection wave 64 reflected after the striking of the ultrasonic wave 62 emitted from the ultrasonic wave-emitting means to the vacuum chamber; reflection wave-detecting means for detecting the reflection wave 64 from the ultrasonic wave-receiving means; and amplitude-analyzing means for analyzing the amplitude of the reflection wave 64 detected by the reflection wave-detecting means.

Owner:KOREA RES INST OF STANDARDS & SCI

Perceptual weighting device and method for efficient coding of wideband signals

InactiveUS20050108007A1Quality improvementReduce the differenceDigital technique networkCode conversionEngineeringPerceptual weighting

A perceptual weighting device for producing a perceptually weighted signal in response to a wideband signal comprises a signal pre-emphasis filter, a synthesis filter calculator, and a perceptual weighting filter. The signal pre-emphasis filter enhances the high frequency content of the wideband signal to thereby produce a pre-emphasized signal. The signal pre-emphasis filter has a transfer function of the form: P(z)=1−μz−1, wherein μ is a pre-emphasis factor having a value located between 0 and 1. The synthesis filter calculator is responsive to the pre-emphasized signal for producing synthesis filter coefficients. Finally, the perceptual weighting filter processes the pre-emphasized signal in relation to the synthesis filter coefficients to produce the perceptually weighted signal. The perceptual weighting filter has a transfer function, with fixed denominator, of the form: W(z)=A(z / γ1) / (1−γ2z−1) where 0<γ2<γ1≦1.

Owner:SAINT LAWRENCE COMM

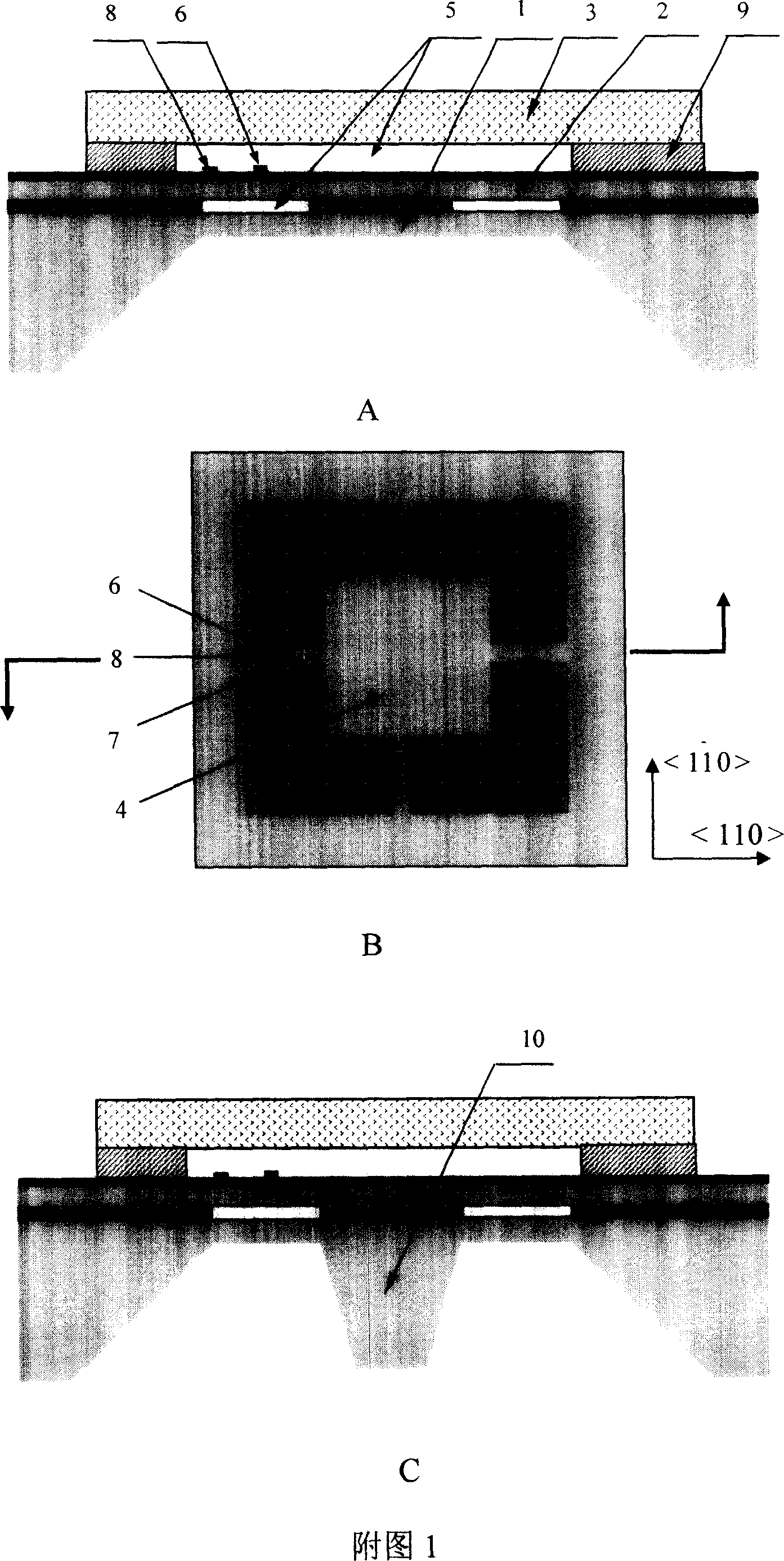

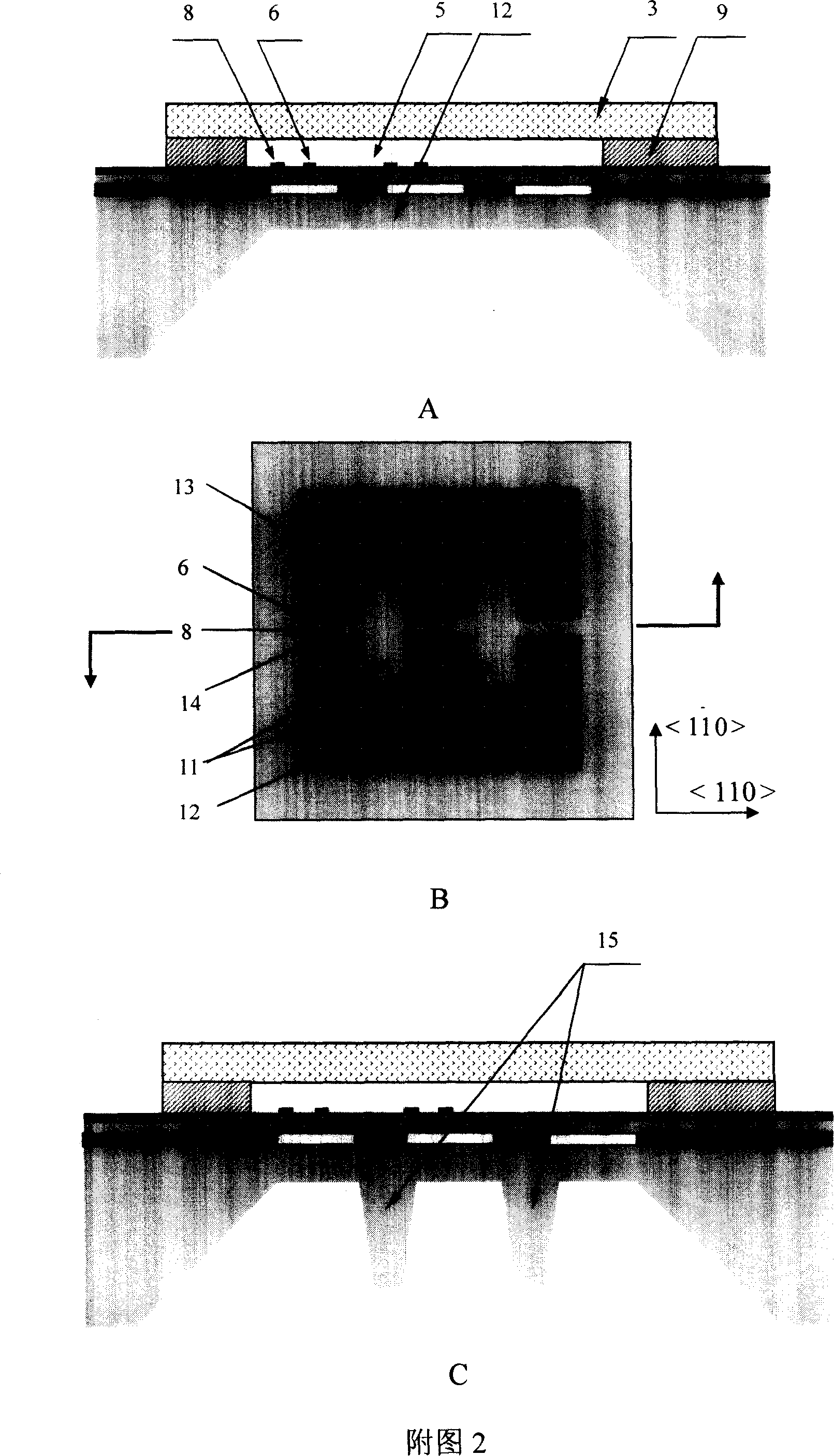

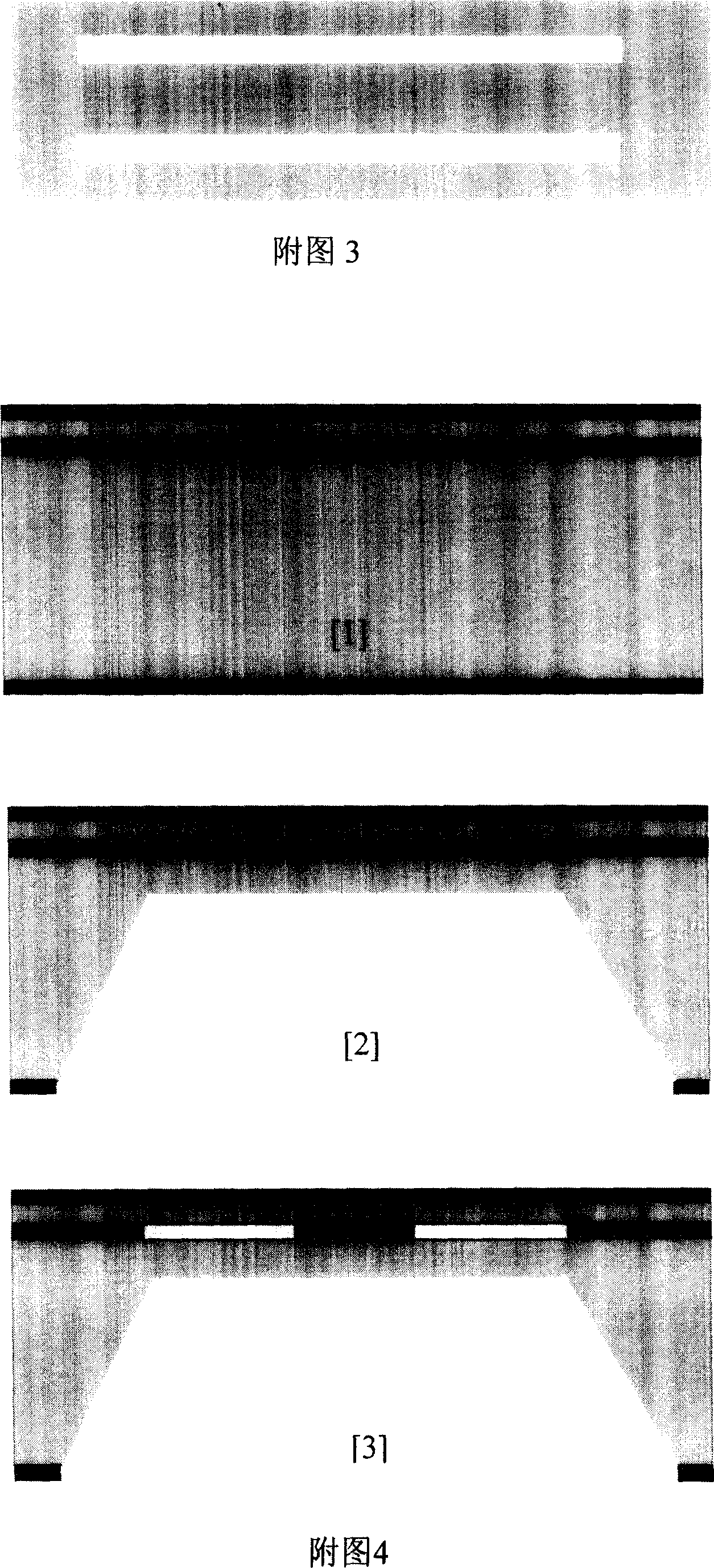

Structure of silicon micromachine resonant micro-pressure sensor chip and its manufacturing method

InactiveCN101153825AImprove signal-to-noise ratioHigh resolutionForce measurement by measuring frquency variationsFluid pressure measurement using elastically-deformable gaugesSignal-to-noise ratio (imaging)Rigid core

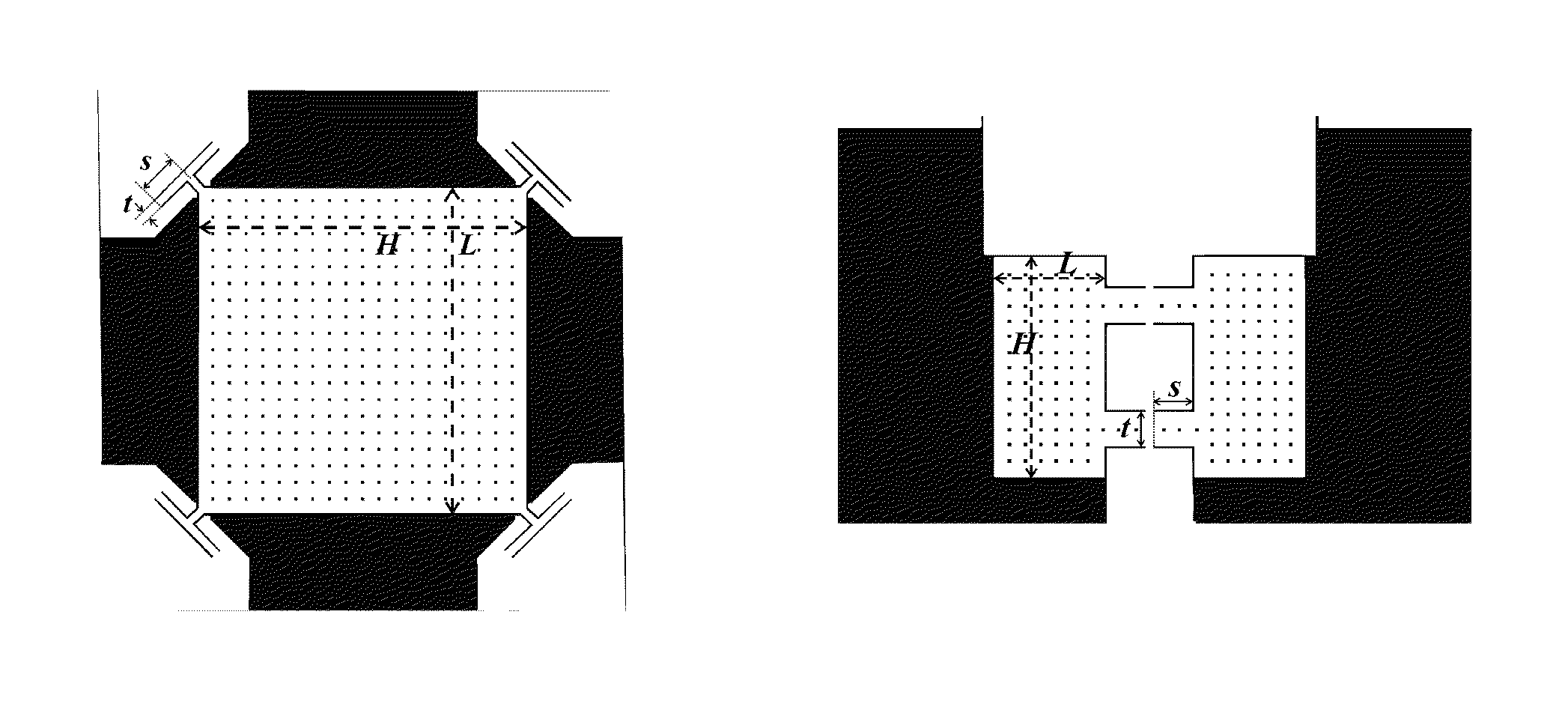

The invention discloses a structure of two resonant micro pressure sensor chips and a method of manufacturing the same. The structure of two resonant micro pressure sensor chips comprises a pressure inductive diaphragm with one or two rigid cores, a double-end clamped support beam and a cover plate 3. Under the function of fluid pressure, the diaphragm with rigid cores deforms to exert the double-end clamped support beams on the surface of the diaphragm to change resonant frequency upon the function of axial stress. Fluid pressure can be reflected by measuring the change in the resonant frequency of the double-end clamped support beam. The silicon resonant micro pressure sensor of the invention has higher signal-to-noise ratio, resolution, sensitivity and measurement precision and the output of the invention is the frequency signal.

Owner:CHINA JILIANG UNIV

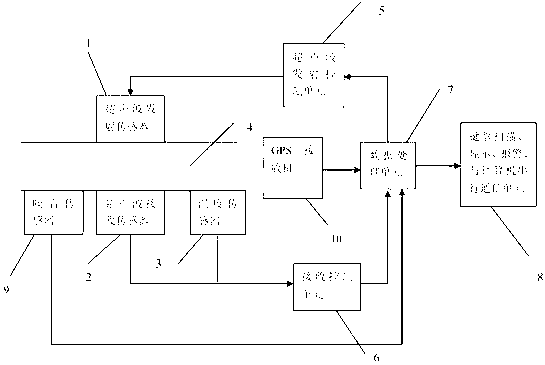

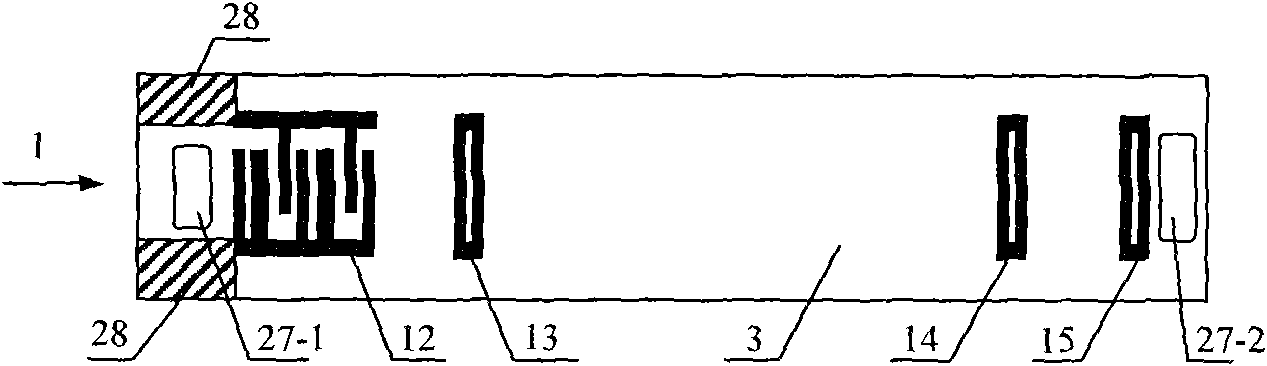

Non-intrusive pipeline real-time monitoring, prewarning and fault locating system

InactiveCN103245454AReflect real-timeEasy to usePipeline systemsFluid pressure measurement by acoustic meansEngineeringTemperature monitoring

The invention discloses a non-intrusive pipeline real-time monitoring, prewarning and fault locating system, and belongs to the technical field of pipeline system temperature and pressure monitoring, and pipeline system fault diagnosis. The method adopted by the invention comprises the following three aspects: temperature and pressure real-time monitoring, prewarning, and fault locating; the pressure monitoring and the temperature monitoring adopt non-intrusive measuring methods, the pressure is monitored by adopting an ultrasonic non-invasive measuring method, the temperature is monitored by adopting a traditional temperature sensor non-invasive measuring method, and sensors for pressure monitoring and temperature monitoring are mounted on the outer wall of a pipeline; a design database is used for prewarning a fault signal; and a negative-pressure wave leak detection method is adopted for locating a fault in a pipeline system.

Owner:SOUTHWEST PETROLEUM UNIV

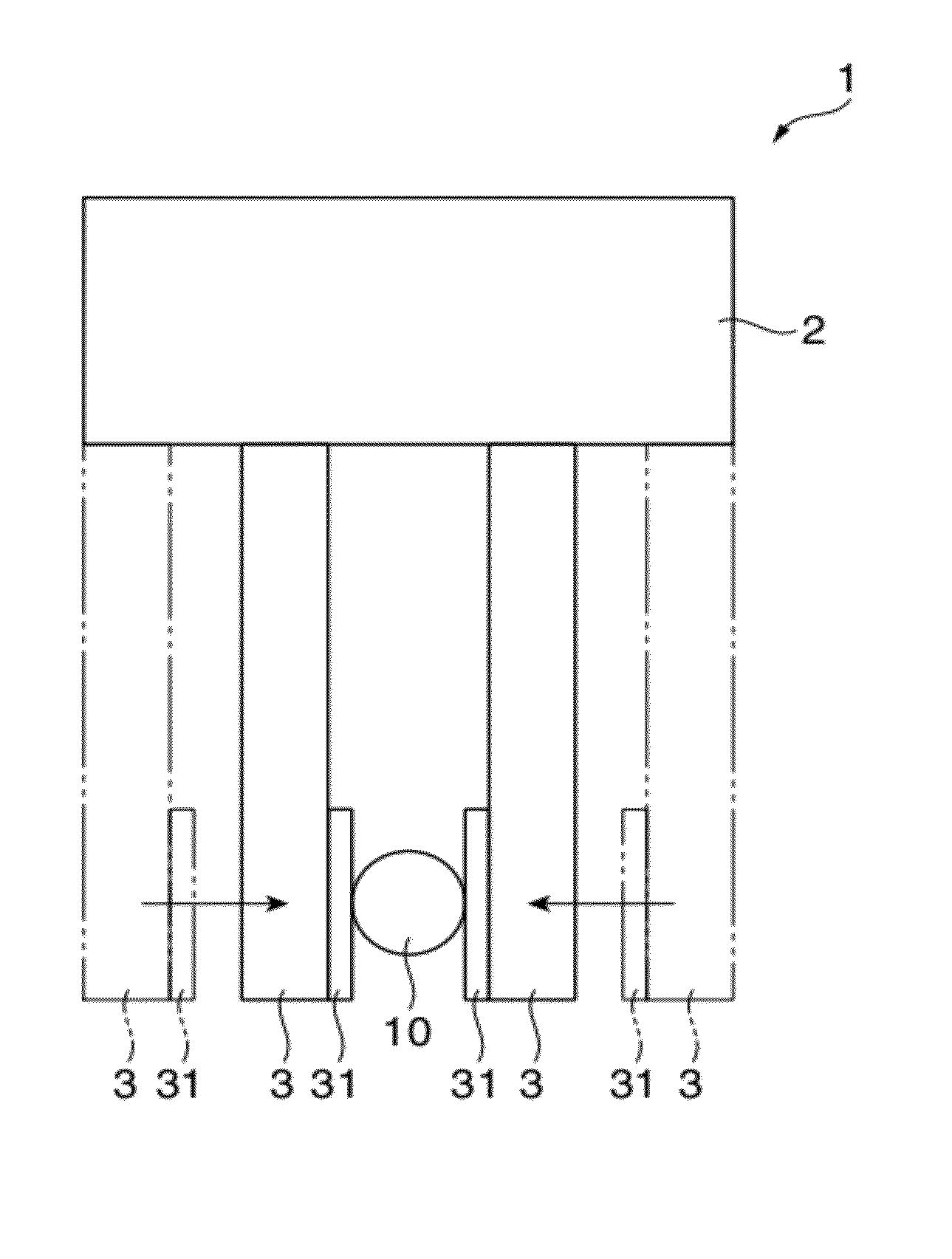

Pressure sensor, sensor array, method for manufacturing sensor array, and grasping apparatus

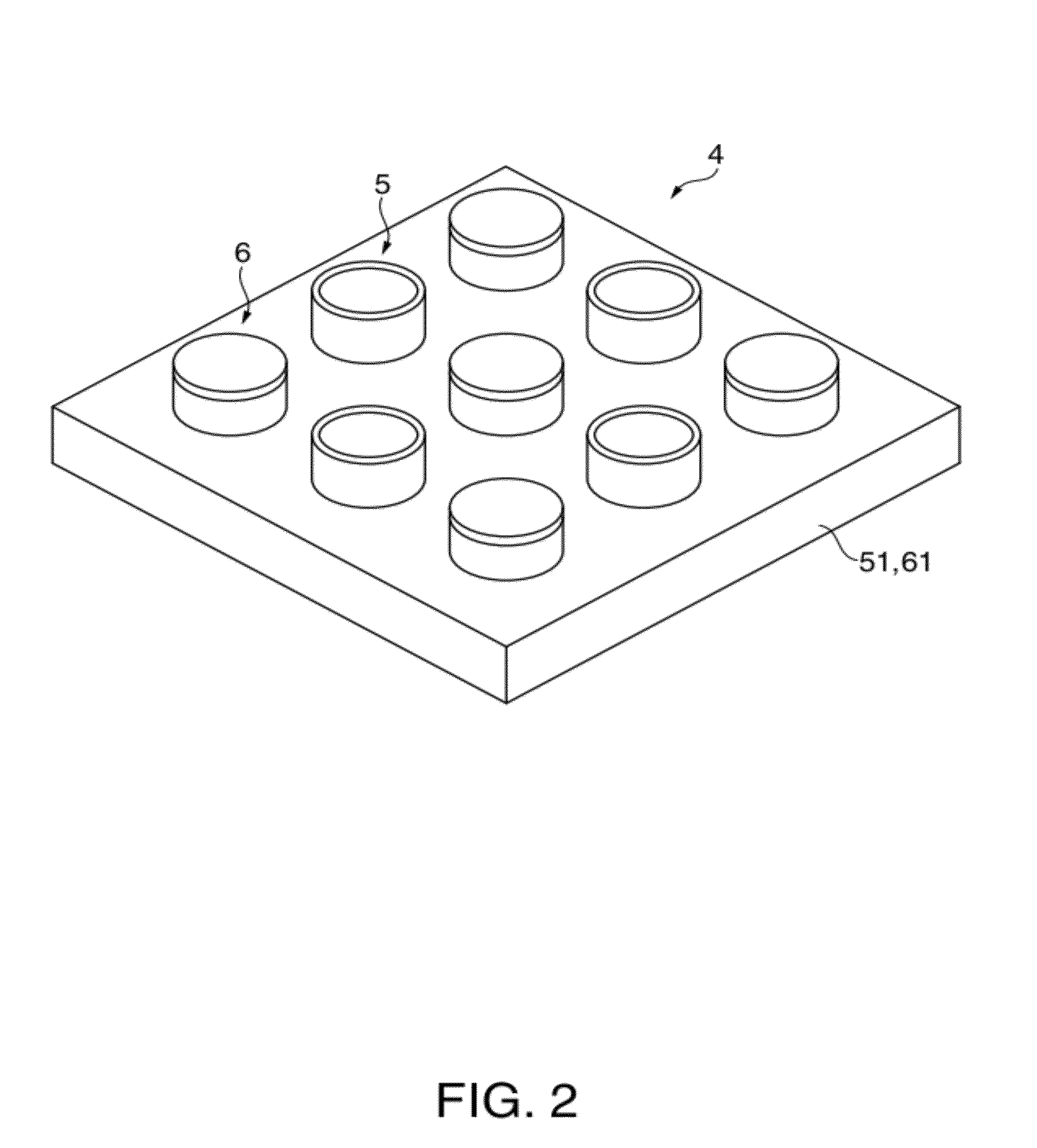

ActiveUS20120247217A1Increase driving speedPrecise grasping pressureFluid pressure measurement using piezo-electric devicesPiezoelectric/electrostrictive device manufacture/assemblySensor arraySilicone oil

A pressure sensor includes: a supporting body which has an opening; a pressure detecting portion which includes a supporting film provided on the supporting body and having a diaphragm portion closing the opening, and a piezoelectric body provided on the diaphragm portion and deflecting to output an electric signal; a frame body which has, on the pressure detecting portion, a cylindrical cavity along a film thickness direction of the supporting film, and is formed, in plan view when viewed from the film thickness direction of the supporting film, at a position where a cylindrical inner peripheral wall of the cavity overlaps with the opening, or outside of the opening; a sealing film which closes the frame body; and a silicone oil which is filled in an inner space formed of the cylindrical inner peripheral wall of the cavity, the sealing film, and the pressure detecting portion.

Owner:SEIKO EPSON CORP

Apparatus for sensing pressure fluctuations in a hostile environment

A pressure sensor (52) for a harsh environment such as the combustion chamber (58) of a gas turbine engine (50). The pressure sensor includes an acoustic waveguide (60) having a sensing portion (66) exposed to the combustion gas in the combustion chamber. Modulations in an acoustic signal passing through the acoustic waveguide are sensed and correlated to pressure fluctuations in the combustion gas. The sensing portion of the waveguide includes a core acoustic waveguide element (42) covered by a coating material (44). The coating material not only protects the core from the harsh environment, but it also improves the efficiency of the transfer of energy from the combustion gas into the waveguide because it provides a stepped transition from the acoustic impedance of the gas to the acoustic impedance of the core material. The protective coating may have a plurality of layers (46, 48) and / or it may include a graded material (78, 80) having an acoustic impedance value that varies across its depth.

Owner:SIEMENS ENERGY INC

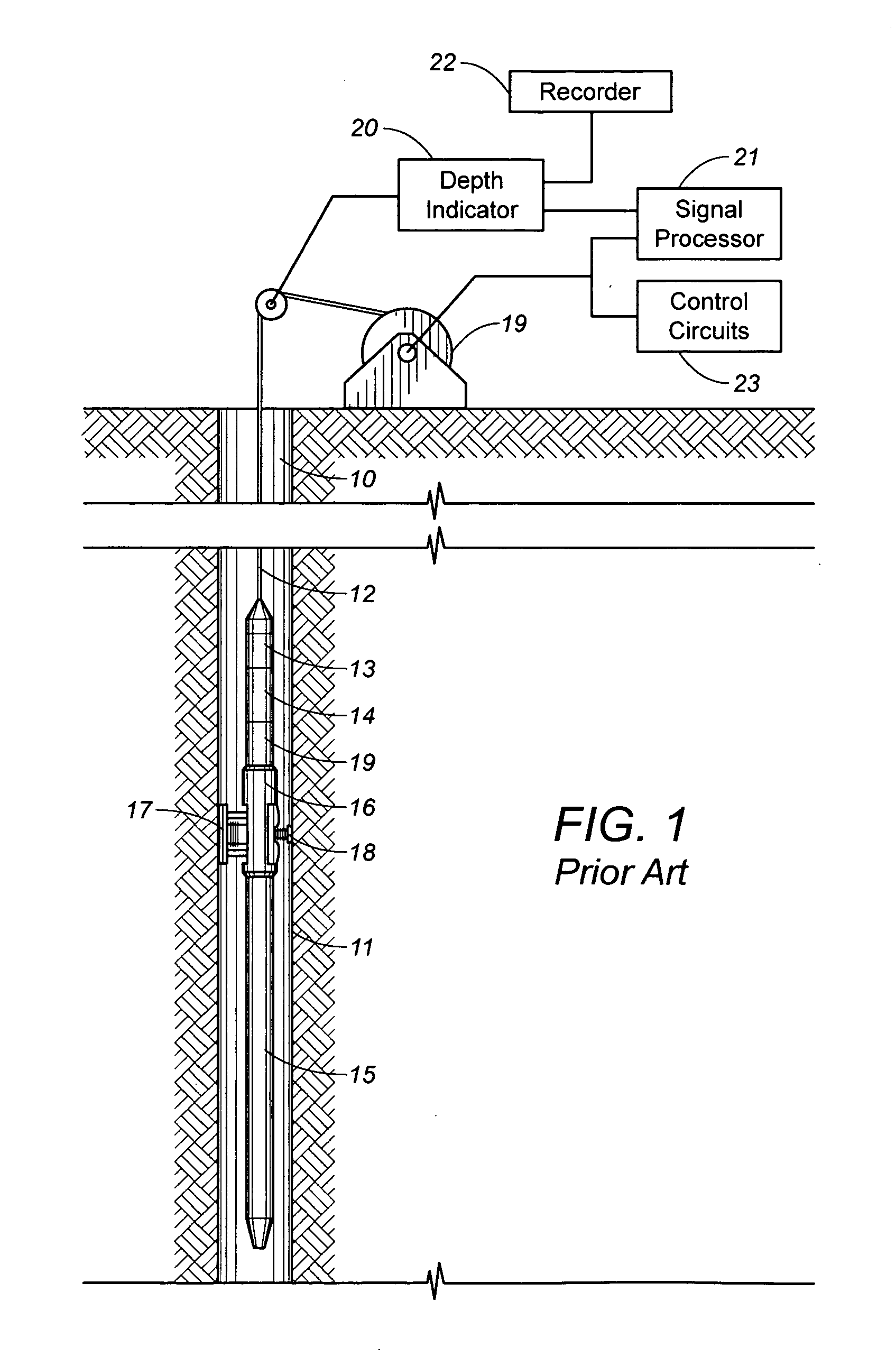

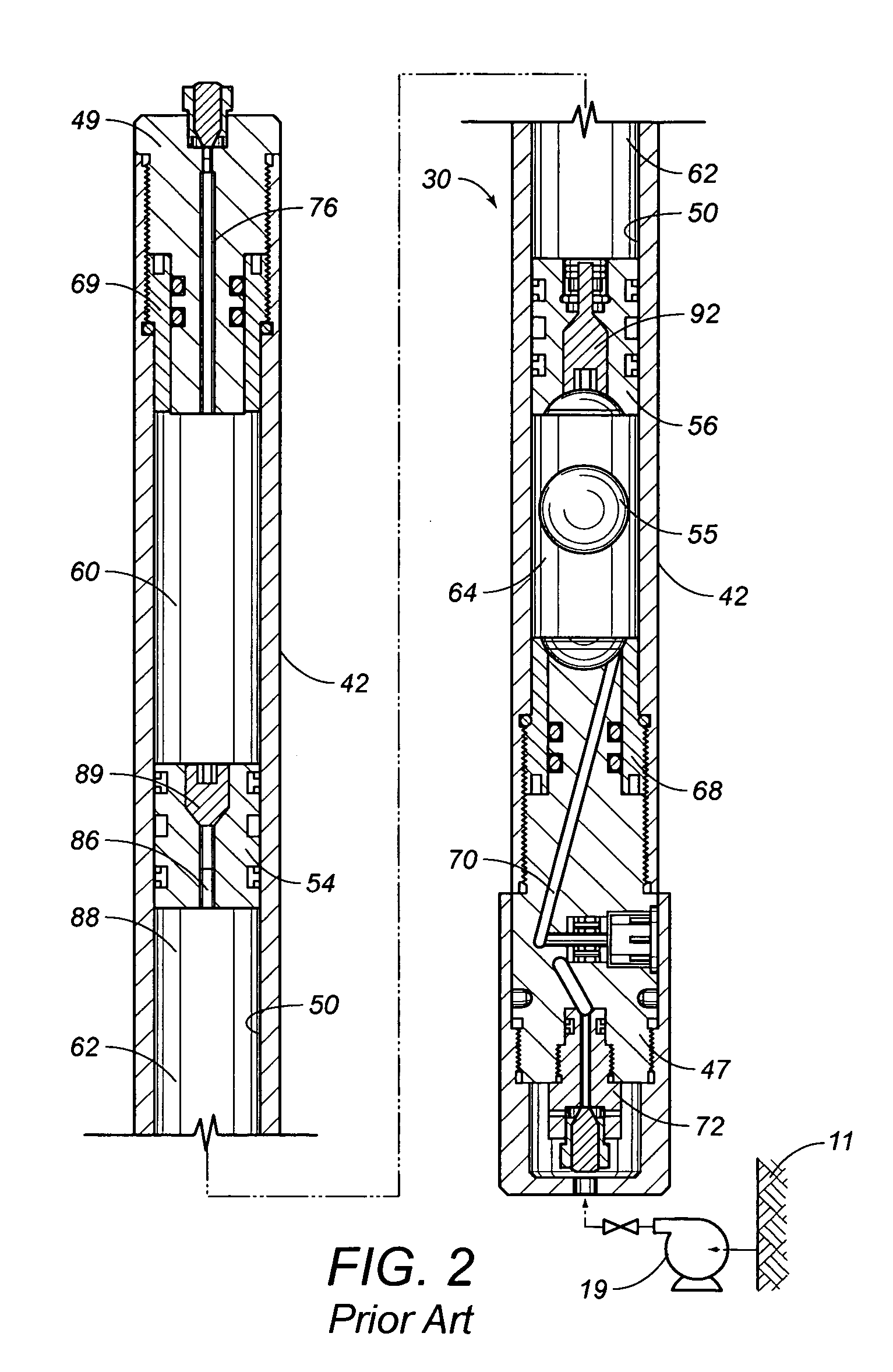

Wireless Logging of Fluid Filled Boreholes

ActiveUS20080239872A1Not easy to damagePropagate more efficientlySurveyConstructionsEngineeringWellbore

A predetermined condition in a fluid-filled wellbore system can be detected by generating at least one sound in the wellbore system in response to the condition, such that a detectable change is created in some characteristic of the emitted sound, and detecting the at least one sound and the change, the detection being indicative that the predetermined condition has occurred. Equipment for facilitating detection of the condition can include a trigger operable in response to the condition; a generator operable to emit sound in the borehole and to create a detectable change in some characteristic of the emitted sound in response to the trigger; and at least one sensor operable to monitor the sound and detect the change, the detection being indicative that the predetermined condition has occurred. It is also possible to estimate a value of a property of a fluid-filled wellbore system. This can be accomplished by recording data including at least one of pressure and rate of flow at one or more locations in the wellbore system, and then estimating the value of the property by employing a model for predicting at least one of pressure and rate of flow dependent upon parameters detailing at least one of wellbore system geometry, viscoacoustic properties of the fluid and entrained solids contained in the wellbore system, locations of boundaries and entrained solids, and characteristics and locations of disturbances to pressure and flow in the wellbore system, in order to determine a best prediction of some attribute of the recorded data.

Owner:SCHLUMBERGER TECH CORP

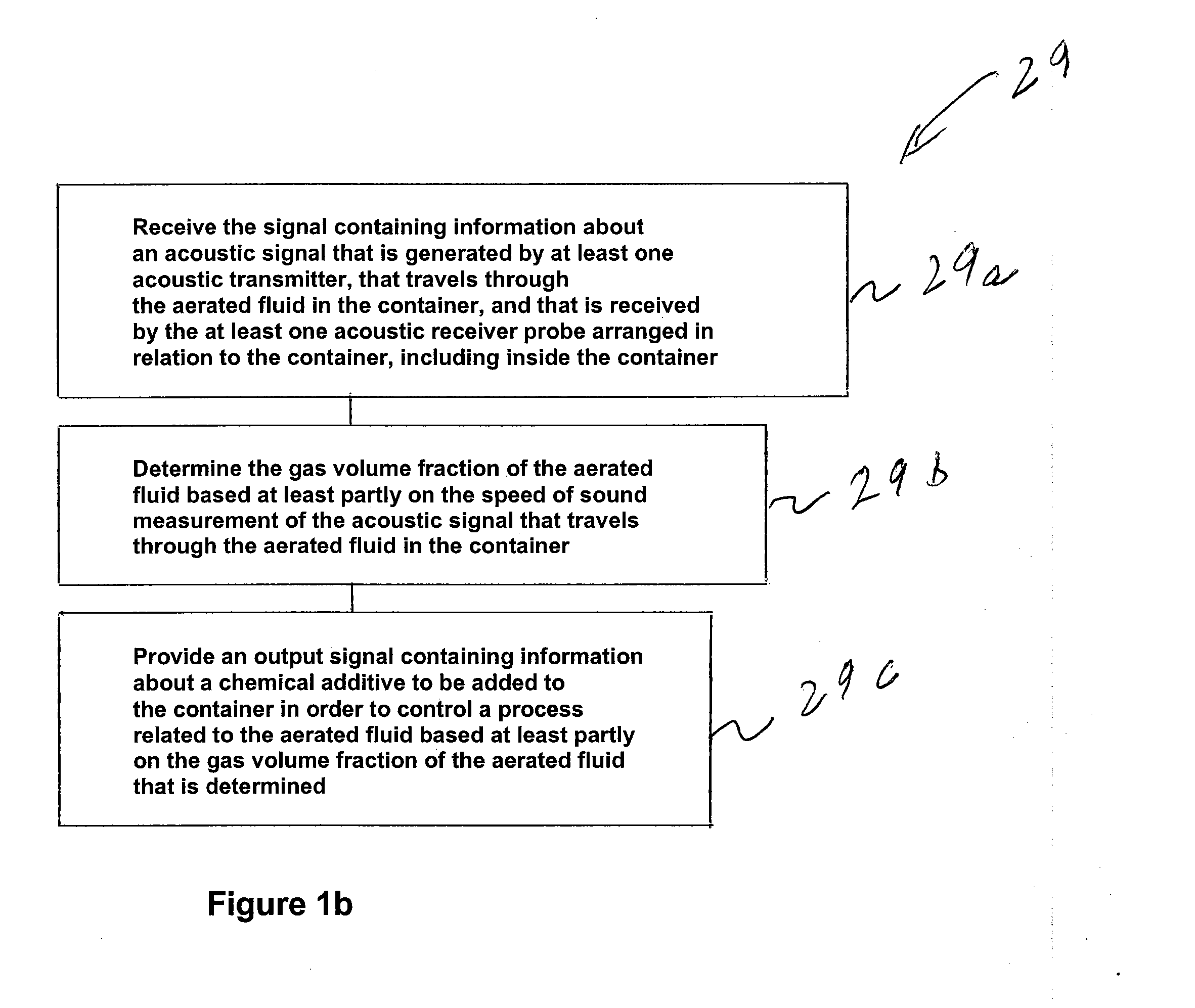

Method and apparatus for determining gvf (gas volume fraction) for aerated fluids and liquids in flotation tanks, columns, drums, tubes, vats

InactiveUS20130192351A1Effective controlImprove breathabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesRotating receptacle mixersEngineeringGas volume fraction

The invention provides a signal processor that receives a signal containing information about an acoustic signal that is generated by at least one acoustic transmitter, that travels through an aerated fluid in a container, and that is received by at least one acoustic receiver arranged in relation to the container, including inside the container; and determines the gas volume fraction of the aerated fluid based at least partly on the speed of sound measurement of the acoustic signal that travels through the aerated fluid in the container. The signal processor also sends an output signal containing information about the gas volume fraction of the aerated fluid. The signal processor may be configured together with at least one acoustic transmitter, the at least one acoustic receiver, or both.

Owner:CIDRA CONCRETE SYST INC

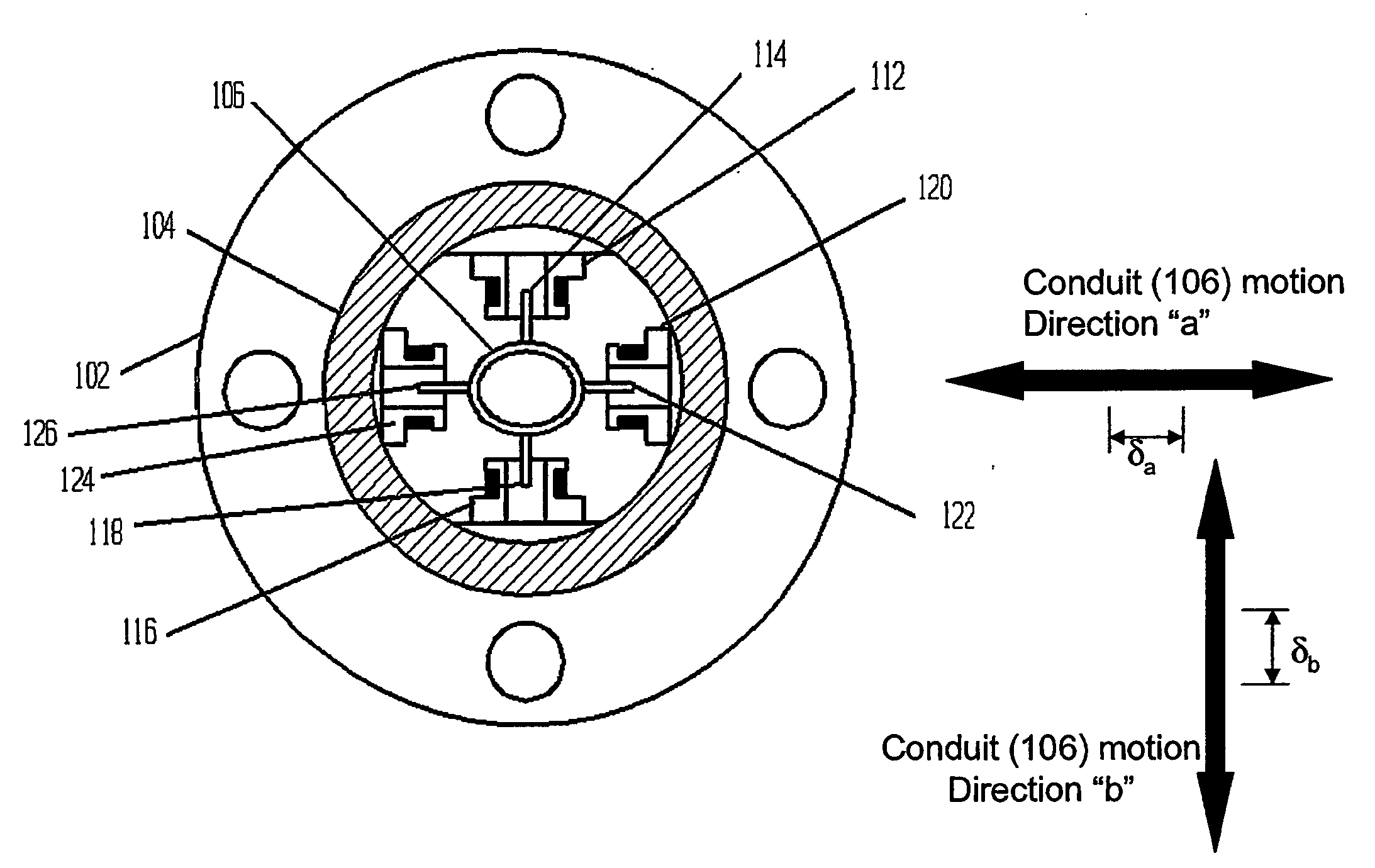

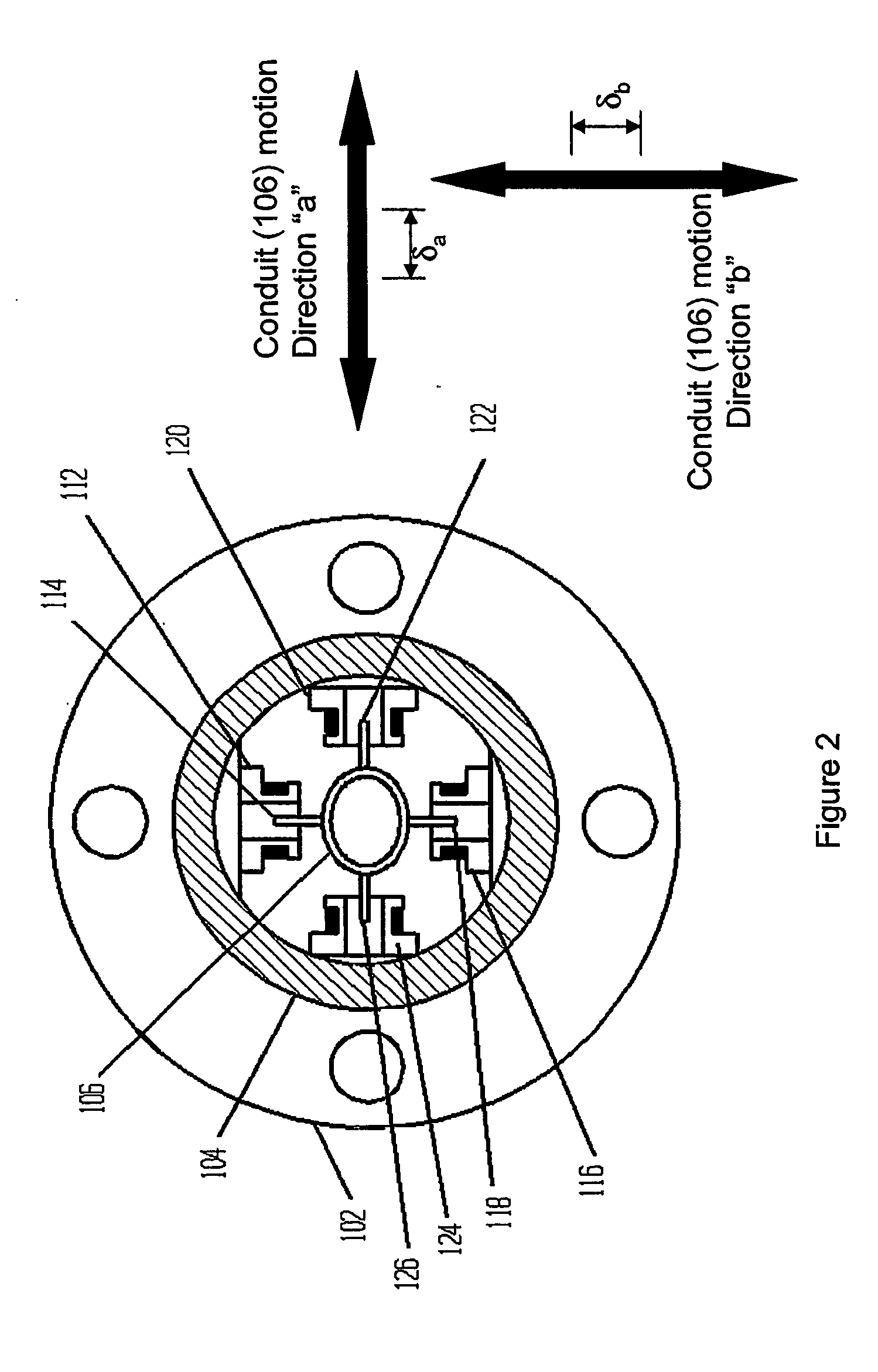

Precise pressure measurement by vibrating an oval conduit along different cross-sectional axes

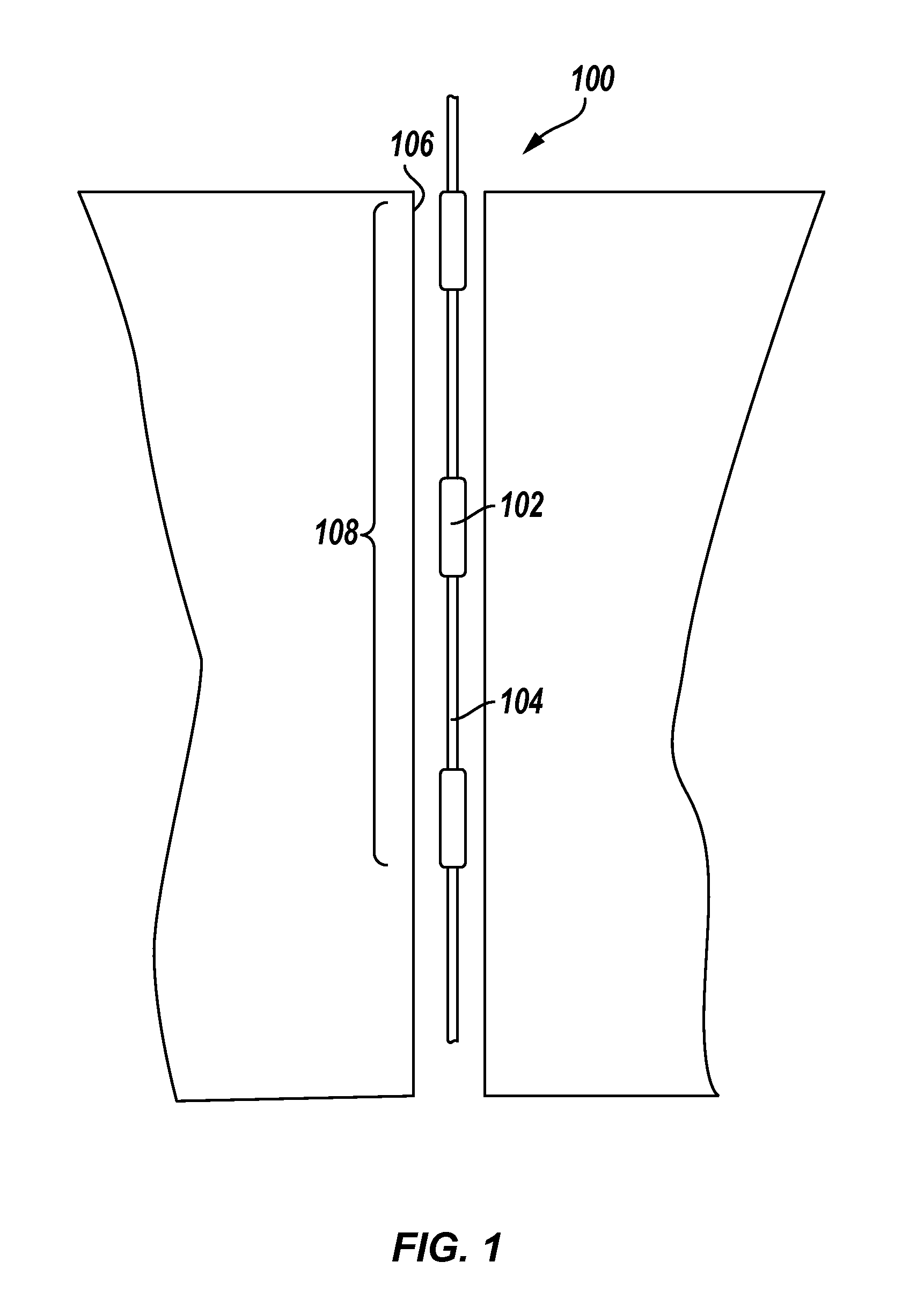

A conduit (106), with geometry designed to enhance pressure sensitivity, is vibrated at resonance in two modes along different cross-sectional axes (a, b). Measuring the change in the frequency ratio squared of the modes yields a substantially linear relationship to pressure that is substantially immune to other material properties and other environmental factors. Moments of inertia in different cross-sectional axes are related to pressure as a result of the elliptical or oral cross section of the conduit (106).

Owner:CARPENTER BRENT L

Saw transducer interface to pressure sensing diaphragm

InactiveUS20050109095A1Improve the ease of assemblyEasy alignmentThermometer detailsInflated body pressure measurementElectricityTransducer

A sensor assembly for monitoring physical parameters in a given environment, such as in a tire or wheel assembly, includes an improved interface between sensor components. The sensor assembly includes a piezoelectric substrate on which resonator elements, such as surface acoustic wave (SAW) resonators are provided. The resonators are configured to produce electrical output at predetermined resonator frequency ranges that can be monitored to determined such information as pressure and temperature to which such devices are subjected. A projection is formed on a surface of the piezoelectric substrate, which selectively interfaces with a recessed surface area in a flexible lid casing component. The lid casing component and a rigid base casing component combine to form an enclosed package for the sensor assembly. An antenna may be coupled to the sensor assembly to facilitate receipt and / or transmission of communicated signals.

Owner:MICHELIN RECH & TECH SA

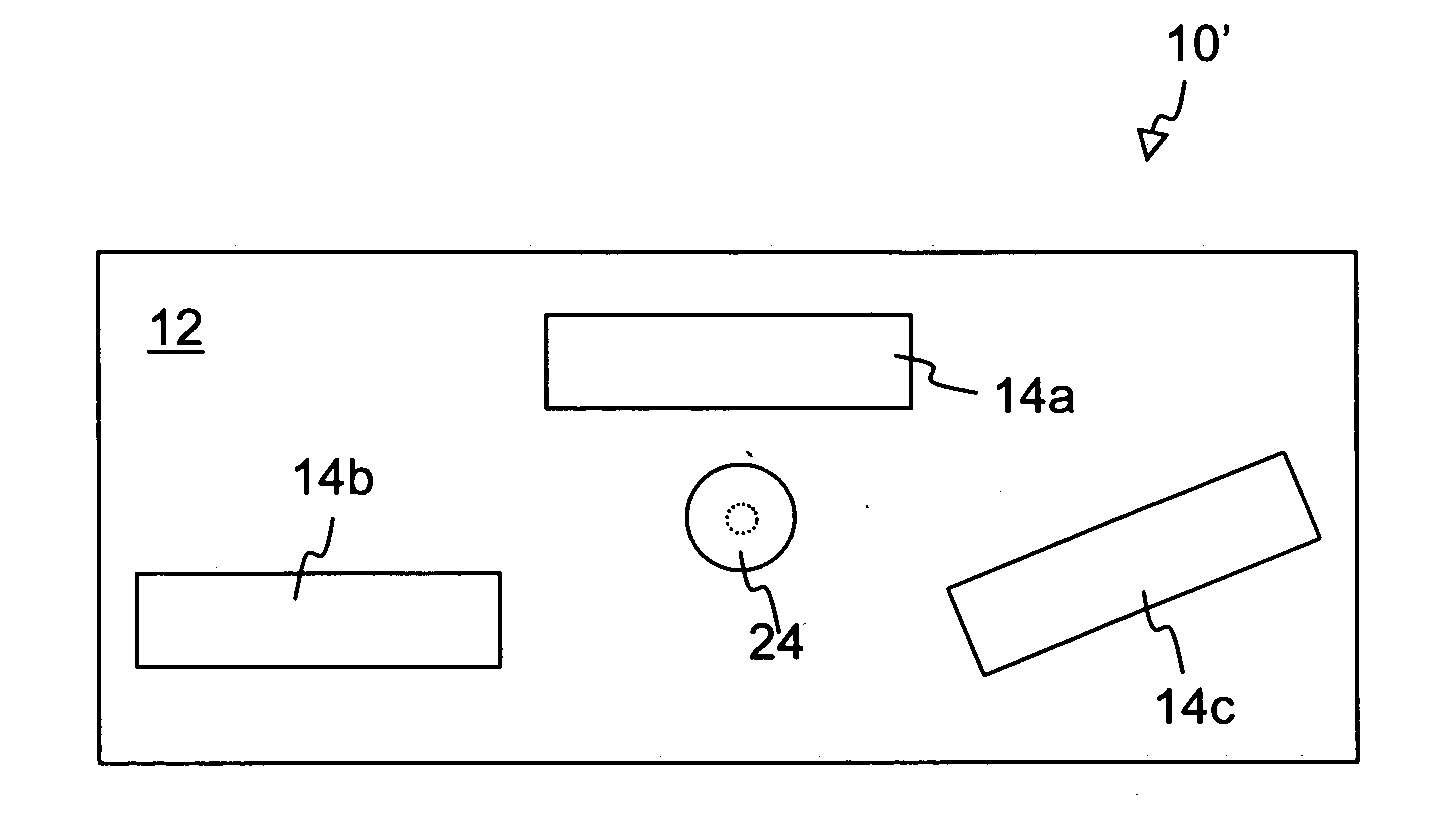

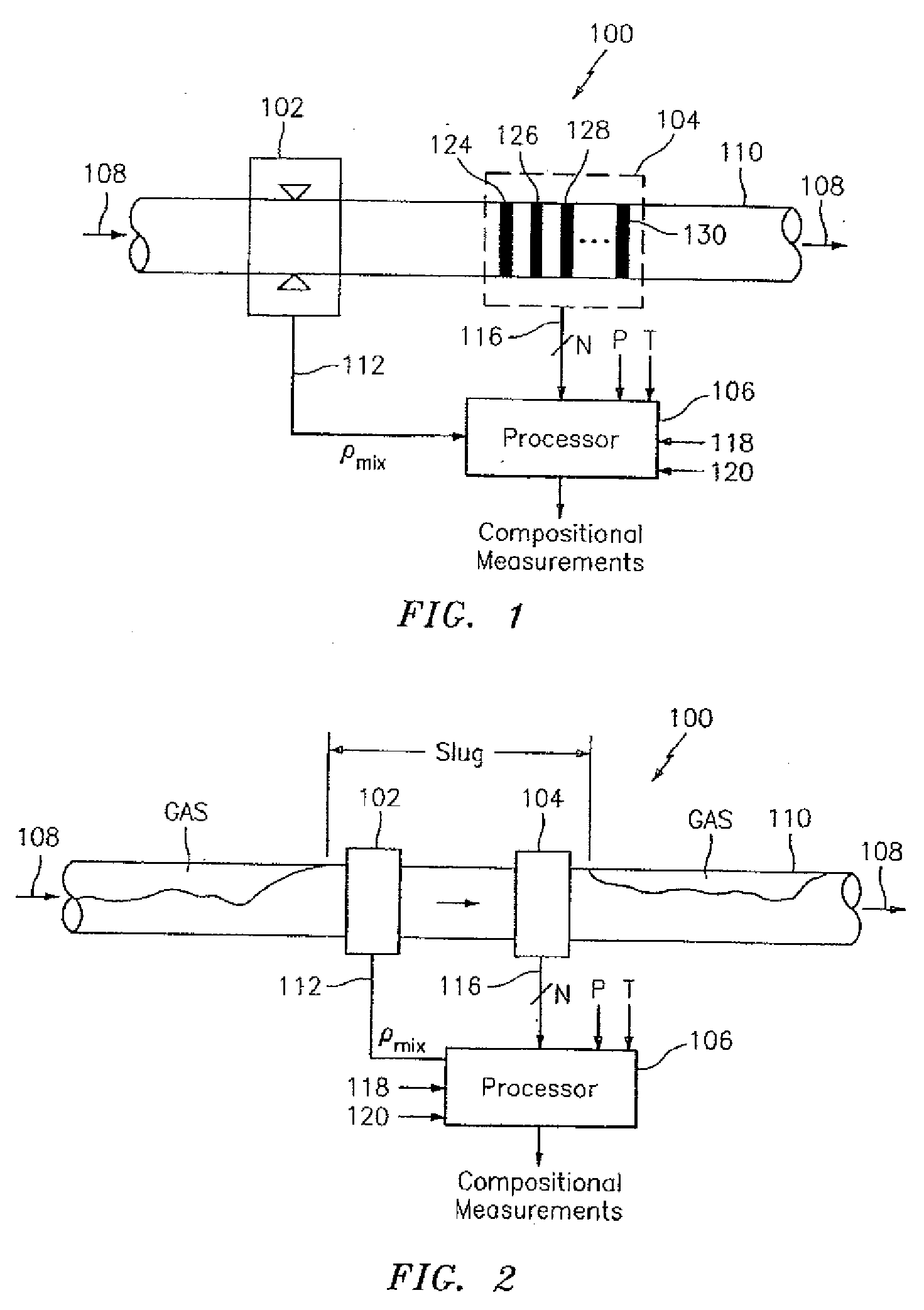

System and Method for Providing a Compositional Measurement of a Mixture Having Entrained Gas

ActiveUS20090241672A1Increase variabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesProduct gasEngineering

A method and apparatus for determining at least one characteristic of a fluid flowing within a pipe is provided. The fluid flow may include one or more liquid component bodies and one or more gas component bodies, which bodies occupy a substantial cross-sectional area of the pipe when passing a location in the pipe. The method includes, and the apparatus includes elements operable to perform, the steps of: 1) transmitting a signal into the fluid flow at the location within the pipe, and receiving the signal after it has traversed at least a portion of the fluid flow; 2) determining a time of flight of the signal traversing the fluid flow; 3) determining the presence of a liquid component body at the location in the pipe, using the determined time of flight; and 4) determining at least one characteristic of the fluid using fluid data generated if the liquid component body is present at the location.

Owner:EXPRO METERS

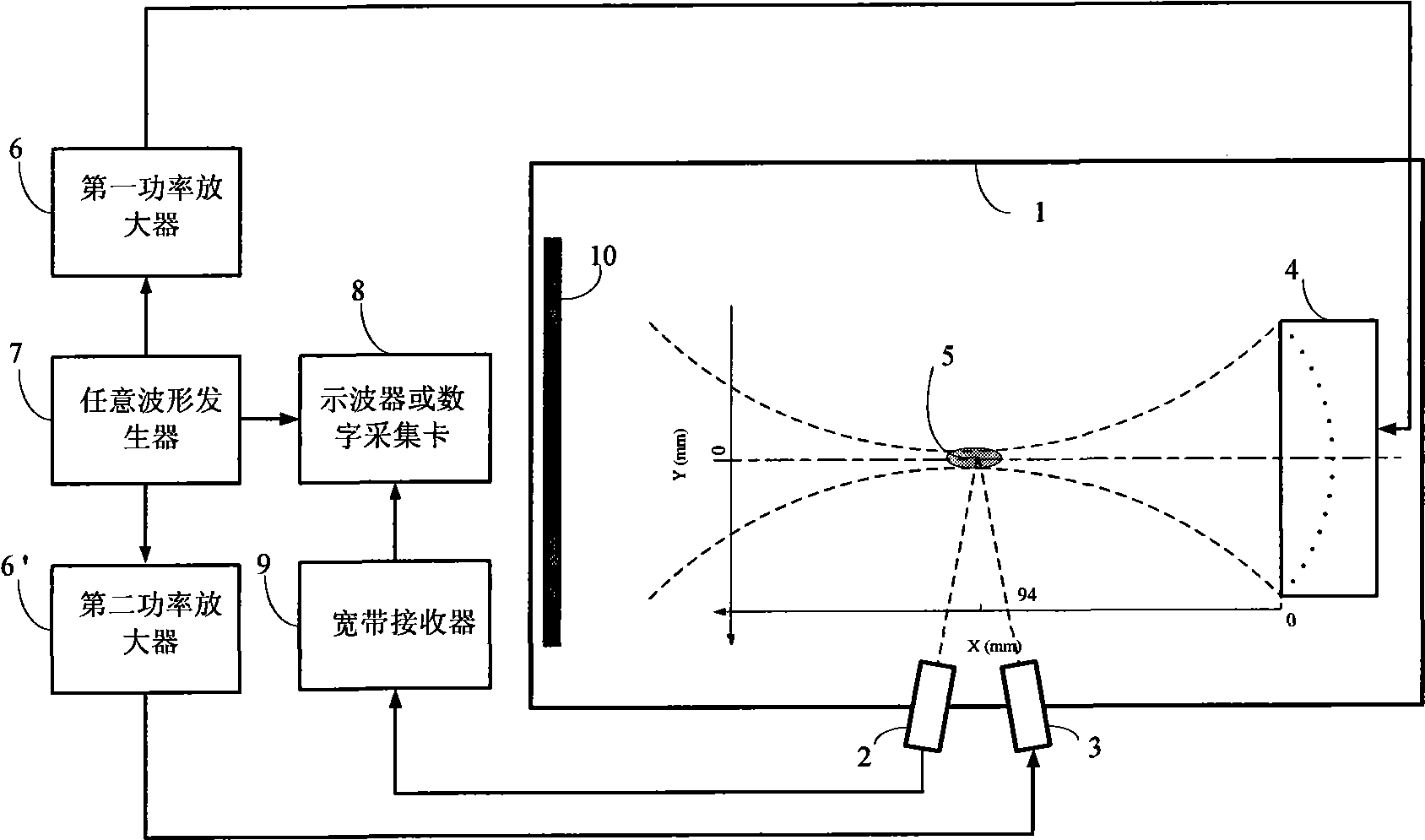

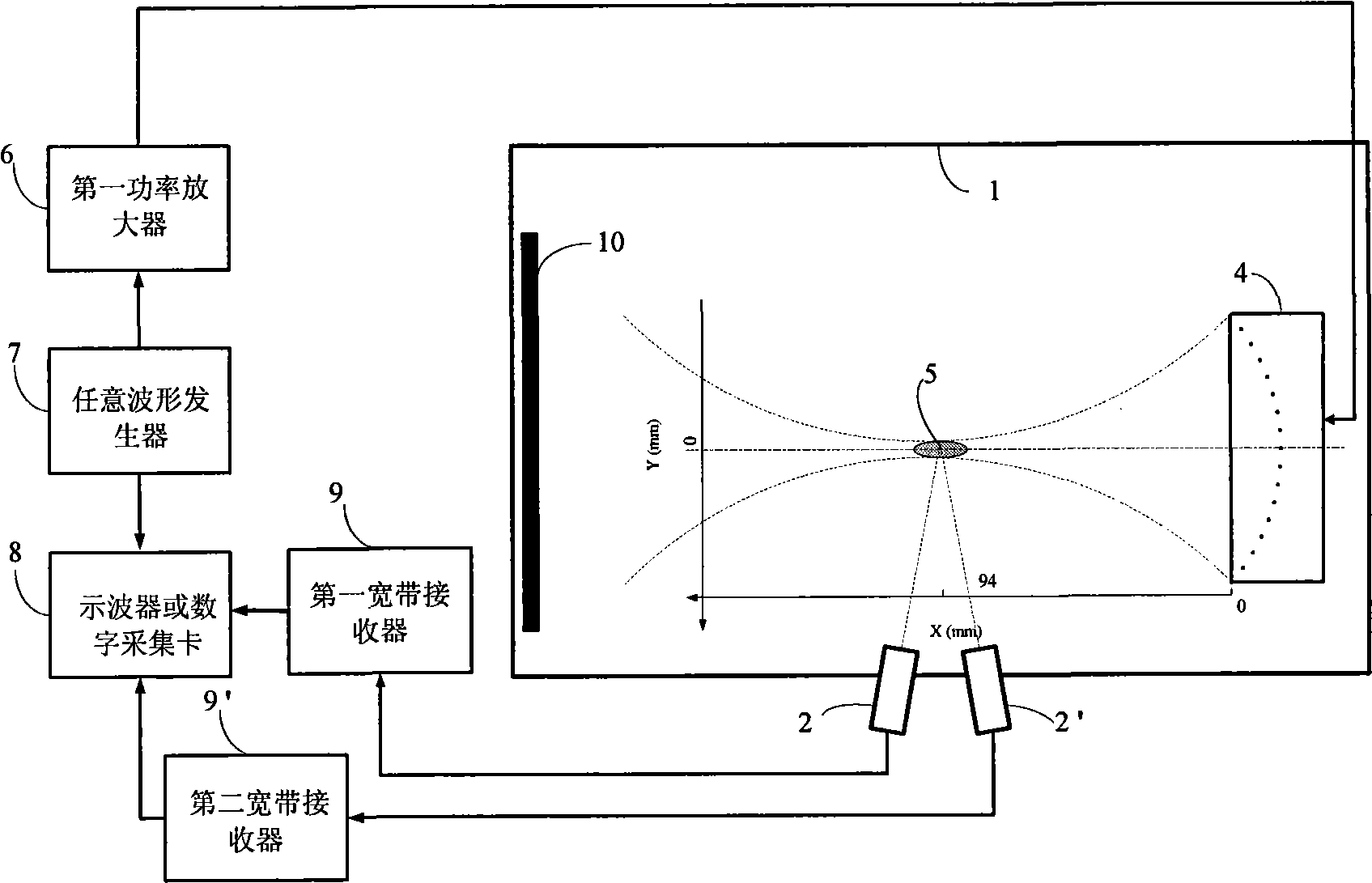

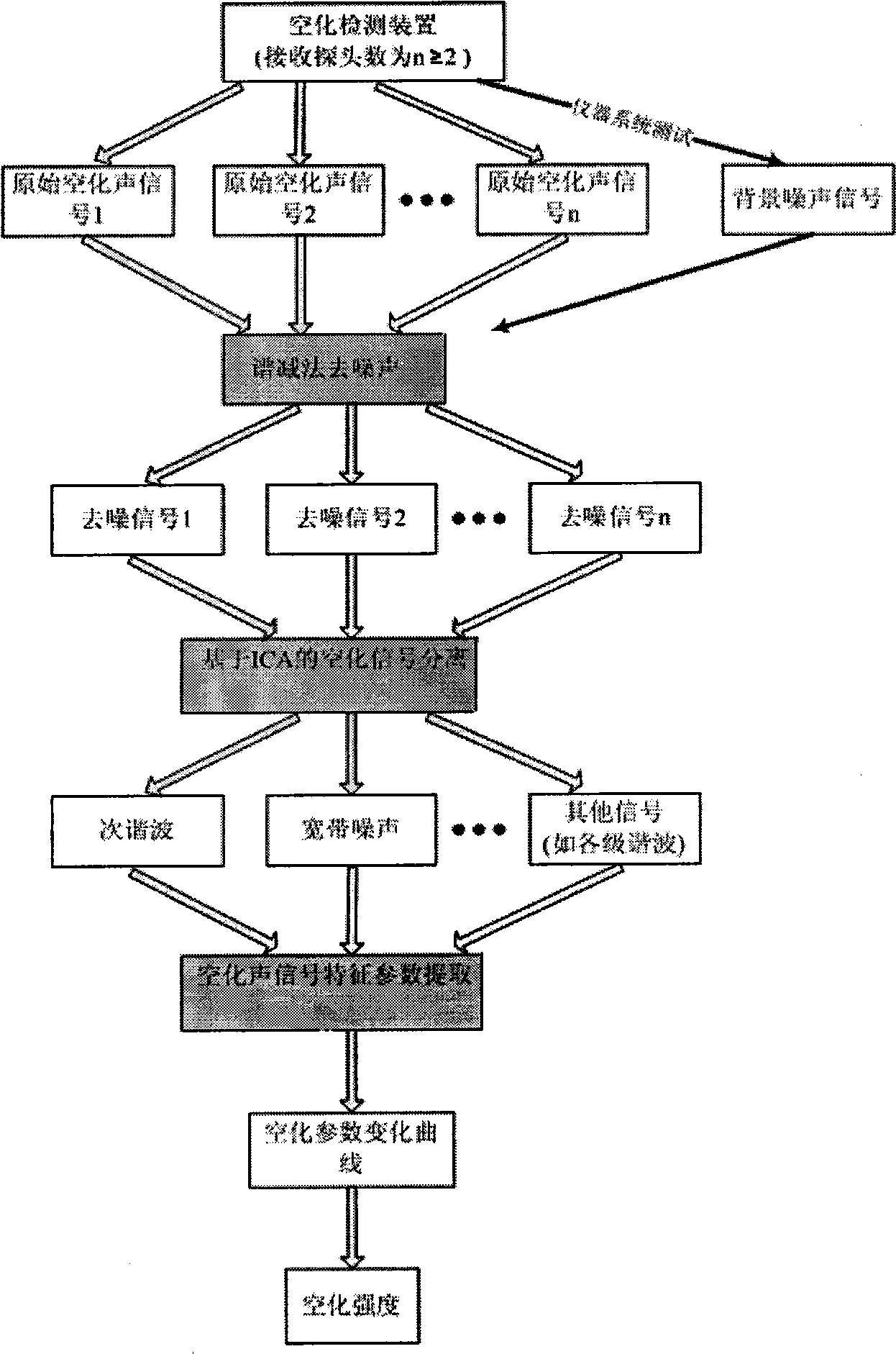

Real-time extracting device and detection method for focused ultrasonic cavitation and microbubbles thereof

InactiveCN101530320AAchieving real-time identification detectionHas inhibitory effectDiagnostic recording/measuringSensorsBroadband noiseUltrasonic cavitation

The invention belongs to the technical field of ultrasonic cavitation detection and signal analysis, and relates to a method and a device for separating and detecting focused ultrasonic cavitation signals. An ultrasonic transducer of a device emits cavitation detecting signals in a pulse-inversion mode, and another ultrasonic transducer receives acoustic signals diffused by ultrasonic cavitation and movement of microbubbles; a transducer of another device generates cavitation signals in the pulse-inversion mode; for each cavitation detecting experiment, the detection method extracts background signals when the cavitation does not happen, respectively calculates power spectrums of the acquired cavitation acoustic signals and the background signals, calculates the subtracted power spectrum estimation and phase position estimation, and converts the power spectrum estimation and the phase position estimation into time domain signals to filter noise of a system; and an ICA method separates target signals such as broadband noise component, subharmonic and the like in cavitation acoustic signals from other signal components and extracts characteristic parameters of the cavitation acoustic signals. The detection method has high sensitivity and can perform quantitative analysis.

Owner:XI AN JIAOTONG UNIV

Micro-electro-mechanical device and method for making the same

ActiveUS20140109680A1MicrophonesDecorative surface effectsCapacitance transducerElectrical and Electronics engineering

The invention provides a micro-electro-mechanical device which includes a substrate, an electrode, and a diaphragm. The electrode includes plural vent holes. The diaphragm is disposed above and in parallel to the electrode, to form a capacitive sensor with the electrode. The diaphragm includes plural ribs protruding upward and / or downward from the diaphragm; the ribs are respectively disposed in correspondence to the plural vent holes and do not overlap nor contact the electrode. A method for making the micro-electro-mechanical device is also provided according to the present invention.

Owner:PIXART IMAGING INC

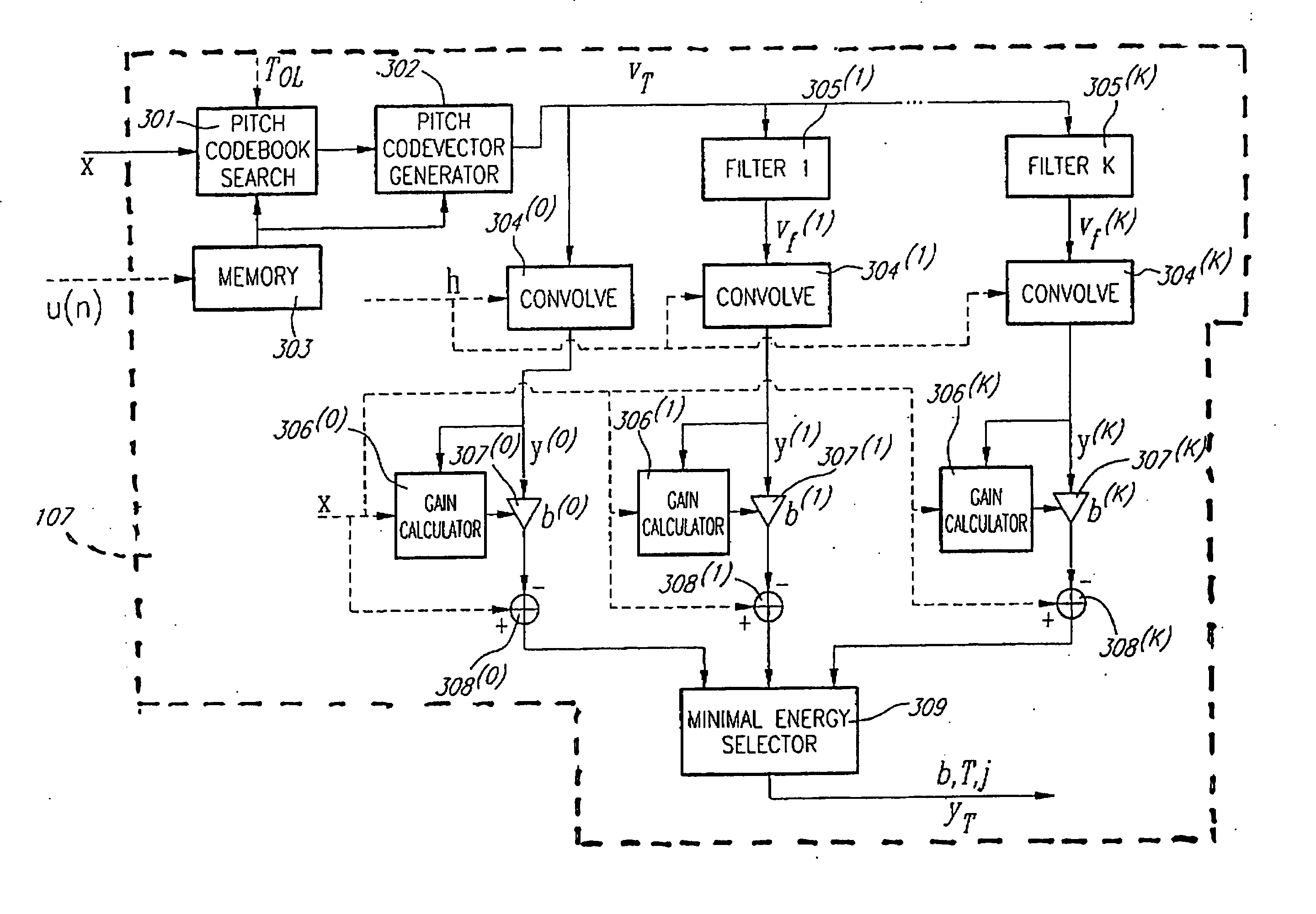

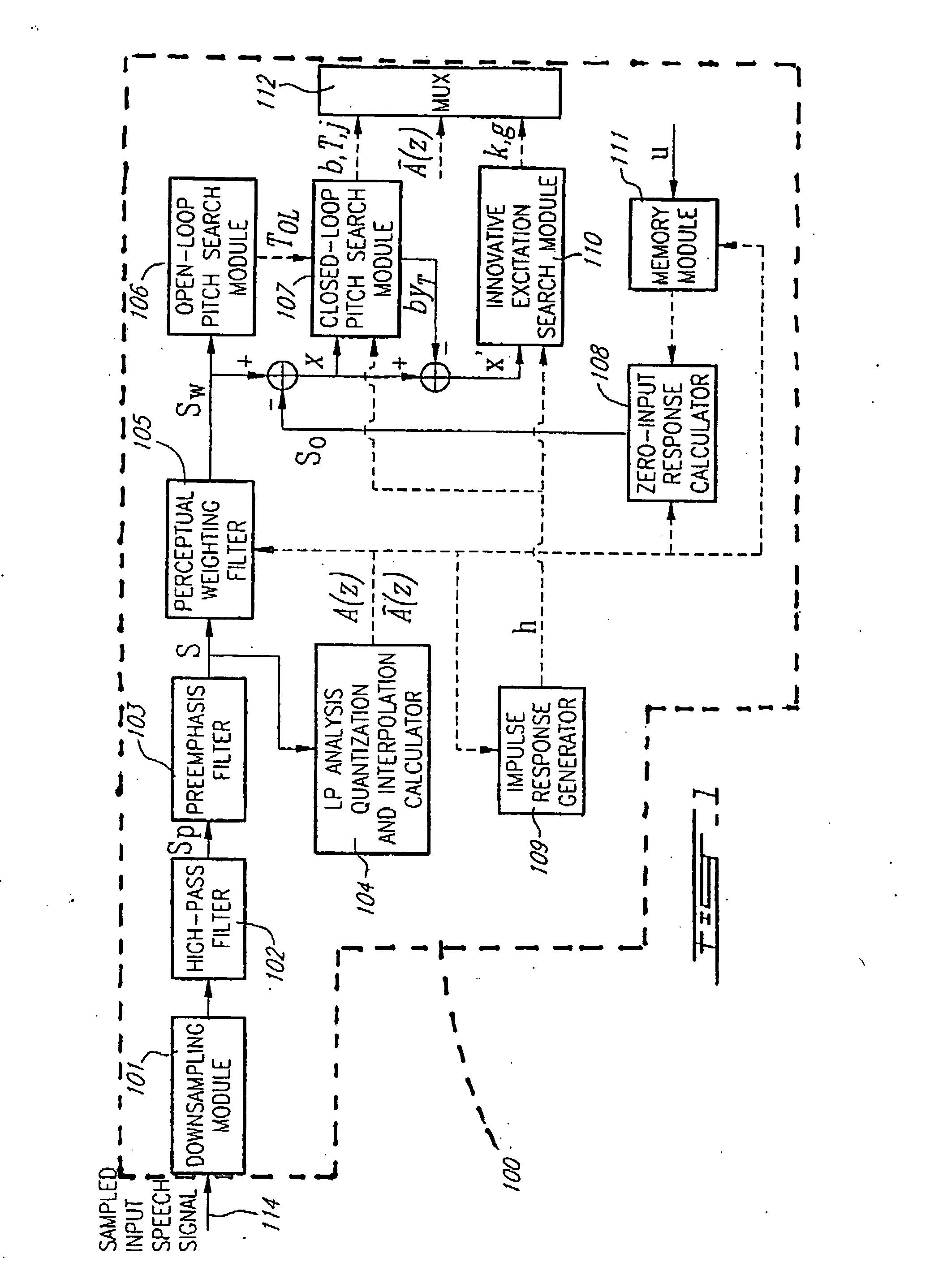

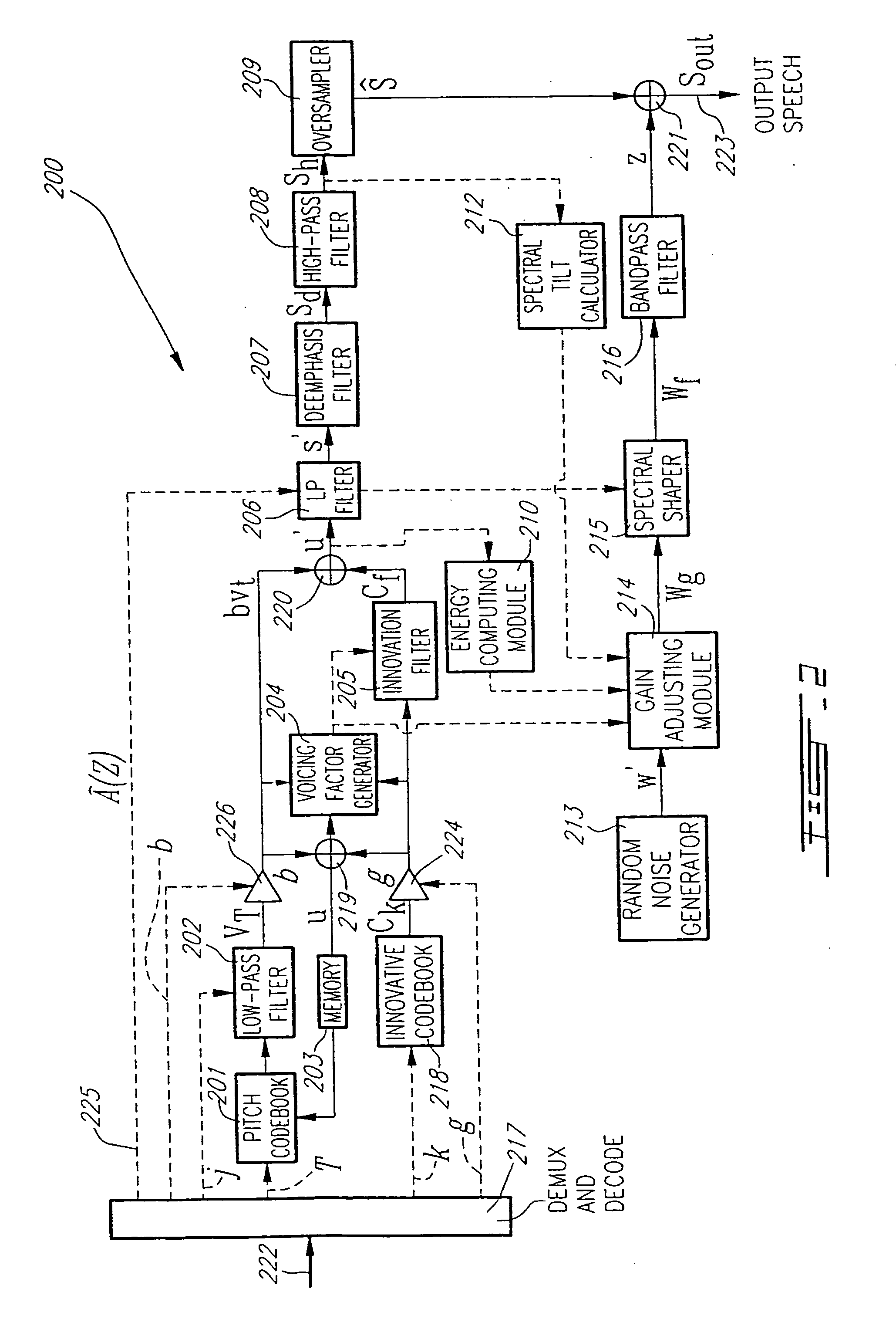

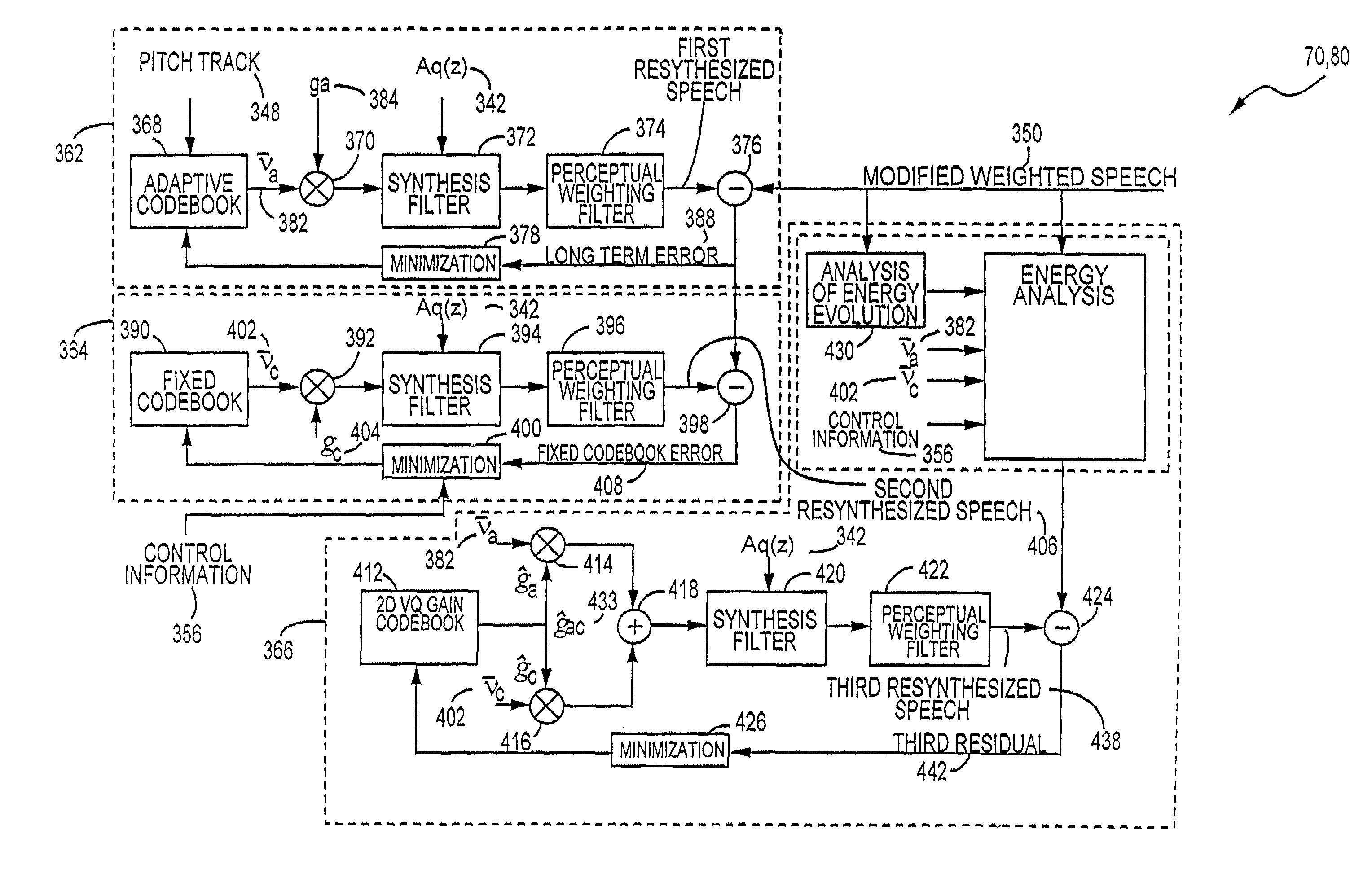

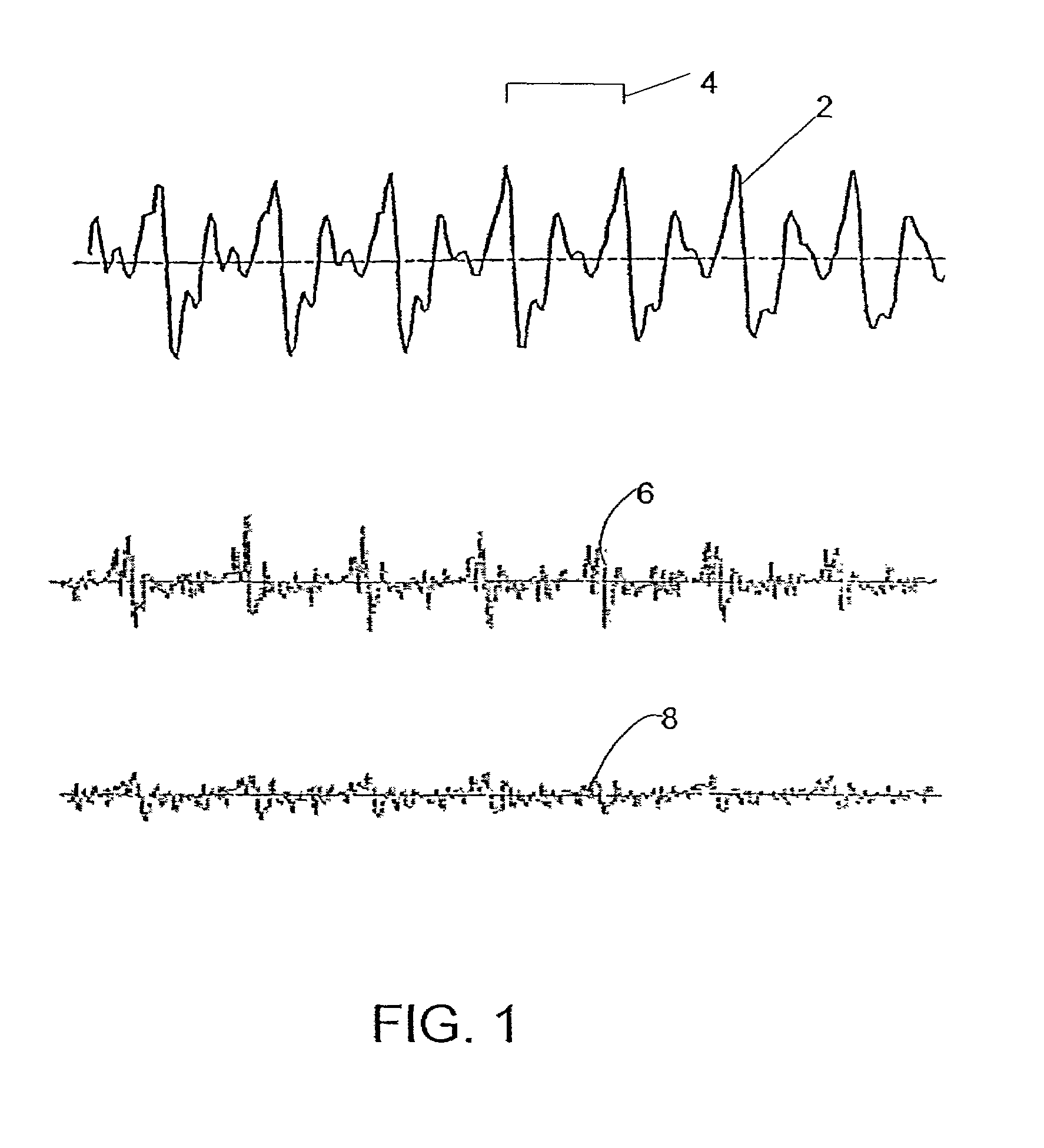

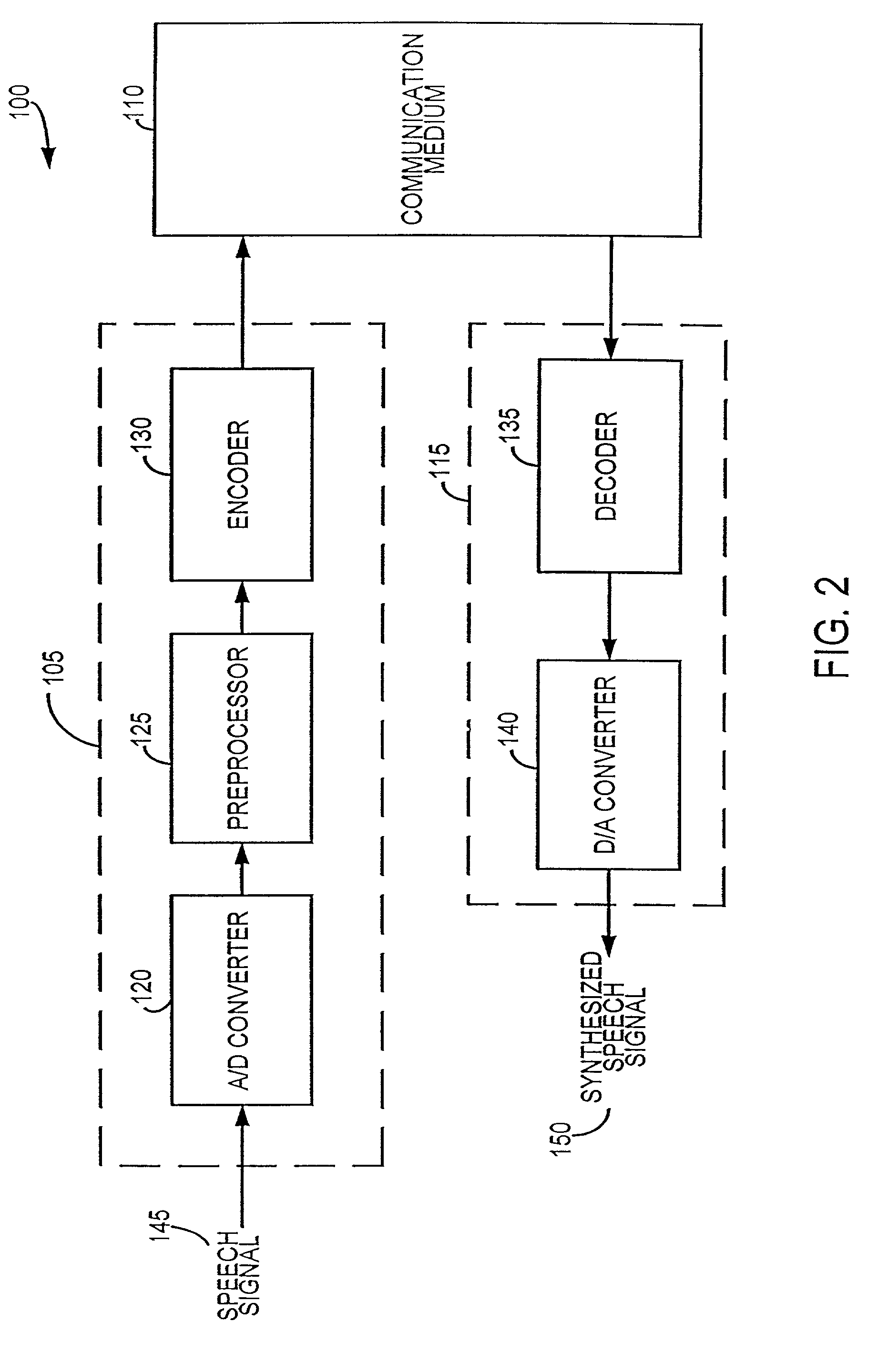

System for improved use of pitch enhancement with subcodebooks

ActiveUS7117146B2Easy to useCapture redundancySpeech analysisFluid pressure measurement by acoustic meansTyping ClassificationHalf Rate

A speech compression system capable of encoding a speech signal into a bitstream for subsequent decoding to generate synthesized speech is disclosed. The speech compression system optimizes the bandwidth consumed by the bitstream by balancing the desired average bit rate with the perceptual quality of the reconstructed speech. The speech compression system comprises a full-rate codec, a half-rate codec, a quarter-rate codec and an eighth-rate codec. The codecs are selectively activated based on a rate selection. In addition, the full and half-rate codec are selectively activated based on a type classification. Each codec is selectively activated to encode and decode the speech signals at different bit rates emphasizing different aspects of the speech signal to enhance overall quality of the synthesized speech. The overall quality of the system is strongly related to the excitation. In order to enhance the excitation, the system contains a fixed codebook comprising several subcodebooks. The invention reveals a way to apply a pitch enhancement efficiently and differently for different subcodebooks without using additional bits. The technique is particularly applicable to selectable mode vocoder (SMV) systems.

Owner:SAMSUNG ELECTRONICS CO LTD

Environmental sensor with tensioned wire exhibiting varying transmission characteristics in response to environmental conditions

ActiveUS20120325018A1Fluid pressure measurement by electric/magnetic elementsForce measurementSonificationEngineering

Systems and methods for measuring environmental conditions of a sensing location, where a sensor including a measuring surface and a wire coupled in tension to the measuring surface over which ultrasonic signals may be transmitted and sensed. Signal analysis of ultrasonic signals transmitted over the tensioned wire are analyzed to measure one or more environmental conditions acting on the measuring surface.

Owner:ETEGENT TECH

Apparatus and methods for acoustically determining fluid properties while sampling

ActiveUS7377169B2Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransmitterAcoustic property

An apparatus and methods for acoustically analyzing a fluid sample and determining one or more properties of the sample are disclosed by the present invention. The apparatus comprises a chamber, a transmitter positioned within the chamber for transmitting an acoustic signal through the fluid, a reflector movably positioned within the fluid inside the chamber for reflecting the acoustic signal, and a receiver positioned within the chamber for detecting reflections of the acoustic signal. The methods employ the use of a transmitter, a reflector movably positioned within the fluid inside the chamber, and a receiver to characterize the fluid sample based on one or more of its acoustic properties.

Owner:SHELL OIL CO

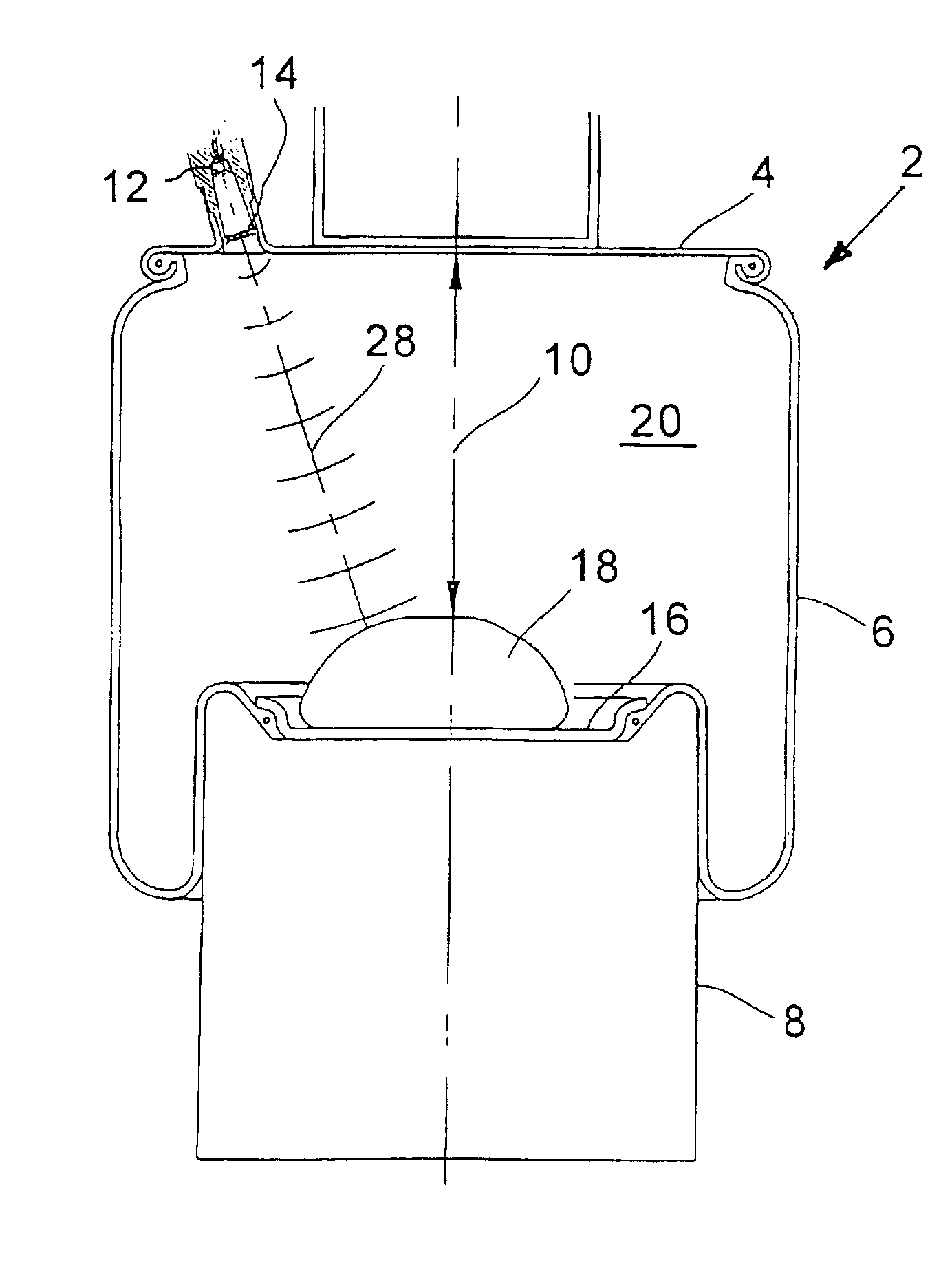

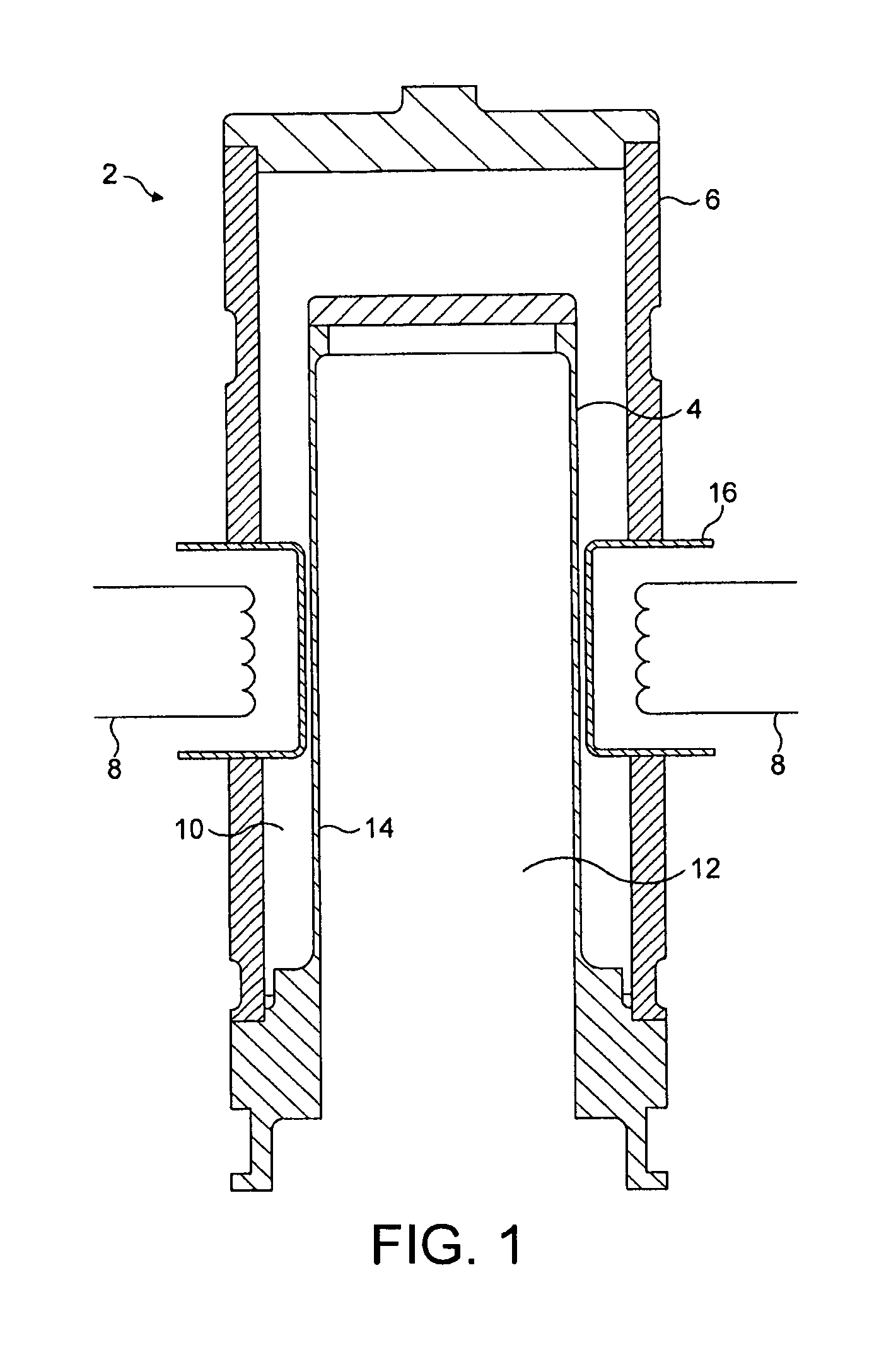

Method for determining the pressure present in the interior space of an air spring for a motor vehicle and apparatus for carrying out the method

InactiveUS6931930B2Cost-effective and precisely functioningReduce complexityVibration measurement in fluidMagnetic property measurementsUltrasonic sensorAmbient pressure

An ultrasonic pulse / echo measurement arrangement includes an ultrasonic transducer (12), which is mounted spatially fixed on an air spring cover plate (4). The arrangement further includes a fixedly mounted reference reflector (14), a target reflector (16) mounted on a roll-off piston (8) or on the bumper (18) as well as a transmitter / receiver evaluation electronic circuit (30). The running time as well as the amplitude of the reference signal is evaluated to precisely determine the pressure present in the interior space of the air spring. The ultrasonic transducer (12) has a λ / 4-adaptation layer (22), whose impedance does not correspond to the geometric mean of the impedances of the ultrasonic transducer (12) and the ambient air of the interior space (20) of the air spring, but rather, is a mismatch. The evaluation electronic circuit (30) can be calibrated at ambient pressure for the determination of the inner pressure of the air spring. Preferably, the pressure measuring method according to the invention is also used to determine the running-time dependent spring height in an air spring (2) of a motor vehicle.

Owner:VAHRENWALDER STRASSE 9

Pressure sensor utilizing a low thermal expansion material

InactiveUS20070277974A1SurveyFluid pressure measurement by electric/magnetic elementsAcoustic waveThermal expansion

A pressure sensor for use in measuring the pressure within fluids. The sensor comprises a medium whose material has a low coefficient of thermal expansion. The pressure can be measured by observing how signals pass through the medium at some unknown pressure and then comparing the observations to how the signals pass through the medium at a known pressure. The signals can be acoustic waves or light waves.

Owner:BAKER HUGHES INC

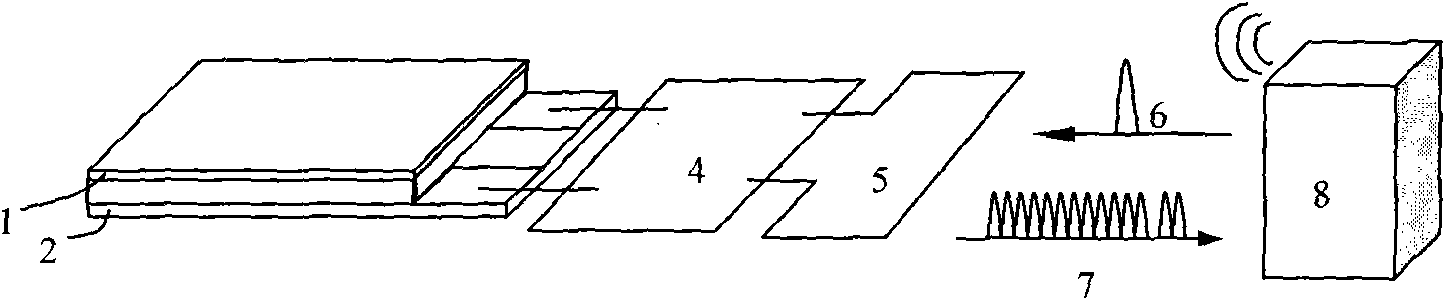

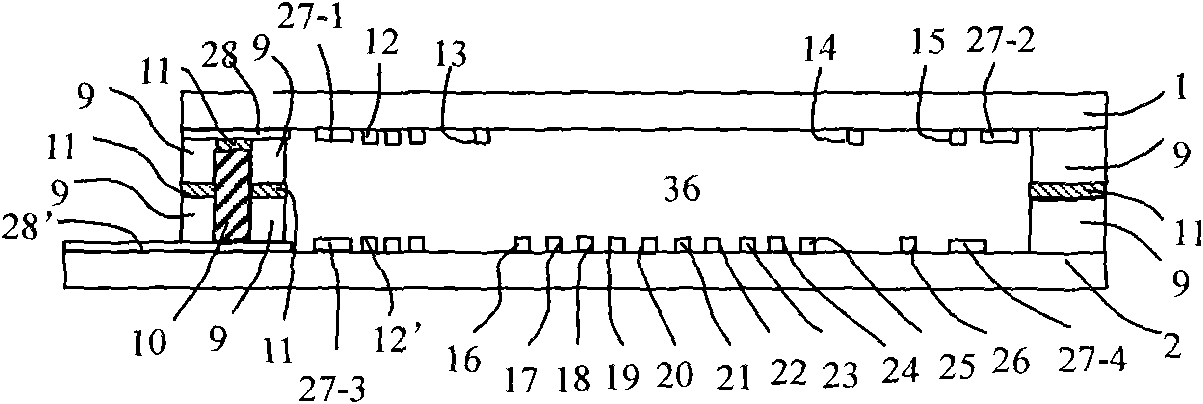

Integrated surface acoustic wave wireless pressure sensor applied to TPMS

InactiveCN101644616AImprove signal-to-noise ratioGood signal to noise ratioThermometers using physical/chemical changesTyre measurementsAdhesiveEngineering

The invention relates to an integrated surface acoustic wave wireless pressure sensor applied to a TPMS, comprising two SAW reflection delay lines which are encapsulated for integration with a JSR membrane by a nickel conducting cylinder and a conducting adhesive, and a matched network connected with a wireless antenna, wherein, the first SAW reflection delay line comprises a single-phase unidirectional energy converter for controlling electrode width, and 3 short-circuit gate reflectors applied to pressure detection; and the second SAW reflection delay line comprises 11 short-circuit gate reflectors, wherein, 8 reflector are used for 8-bit electronic tags, and the other 3 reflectors are used for temperature detection. In the sensor, an EWC / SPUDT receives an electromagnetic wave signal from a wireless reading unit by the wireless antenna and transforms the signal into an SAW signal which is propagated along the surface of a piezoelectric substrate and is respectively reflected by the reflectors, the reflected acoustic wave is retransformed into the electromagnetic wave signal by the EWC / SPUDT and is returned to the wireless reading unit by the wireless antenna, and finally temperature and pressure detection in a tire is realized at the same time by evaluation of a phase change of time-domain response via a signal processing method.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

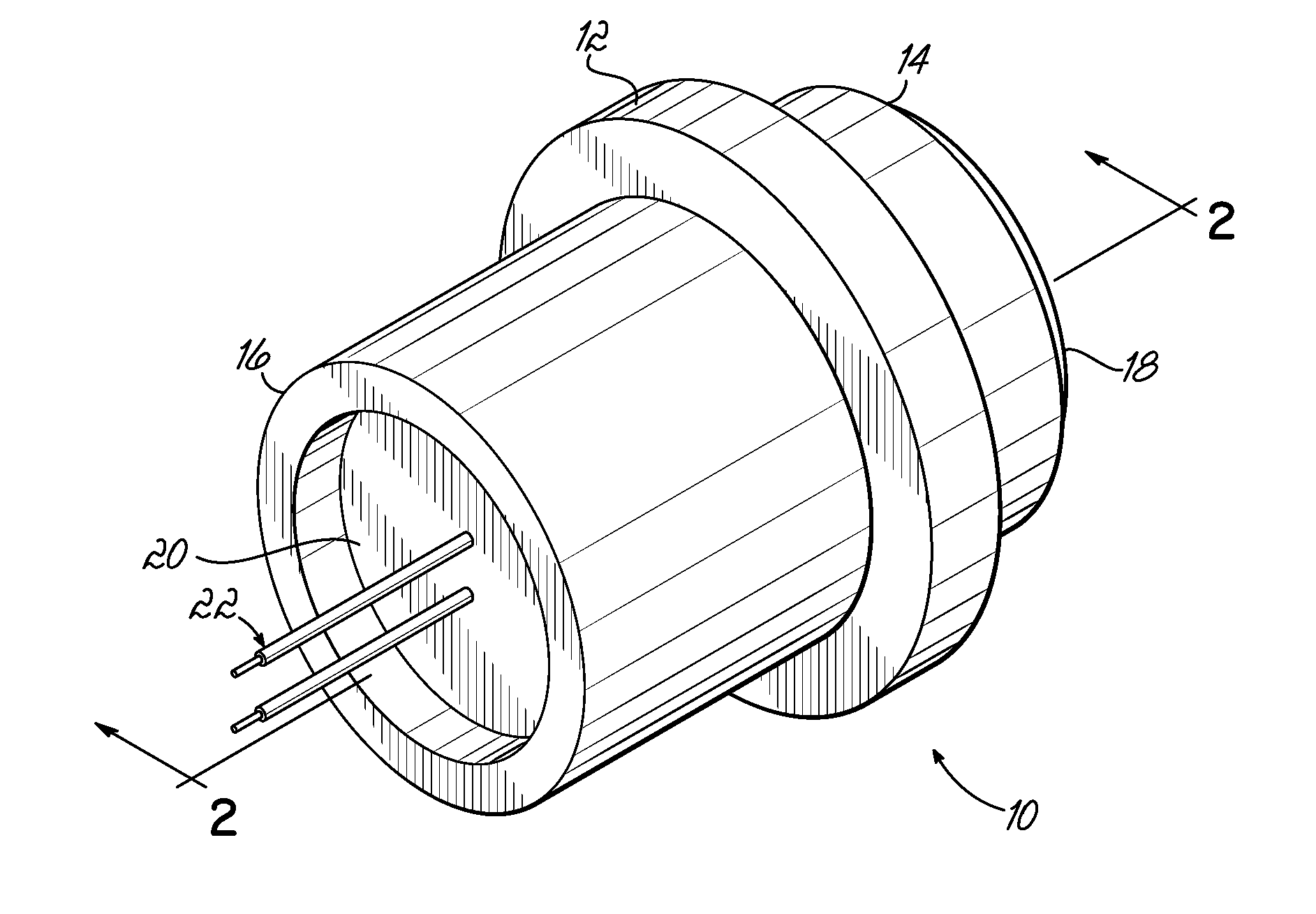

Vibrating cylinder transducer with protective coating

InactiveUS20110252884A1Corrosion resistanceImprove the harsh environmentOther chemical processesFluid pressure measurement by electric/magnetic elementsParyleneTransducer

The invention provides a vibrating cylinder transducer for measuring the pressure or density of a fluid medium comprising: a cylindrical vibrator, in use having at least one surface coupled to a fluid medium to be measured; a drive means for vibrating the cylindrical vibrator; a sensor for detecting the resonant frequency of the cylindrical vibrator; and an output coupled to the sensor, the output configured to provide an output signal indicative of the pressure and / or the density of the fluid medium; wherein the surface coupled to the fluid medium is coated in a corrosion resistant polymer layer. Preferably the corrosion resistant polymer layer is formed from parylene.

Owner:WESTON AEROSPACE

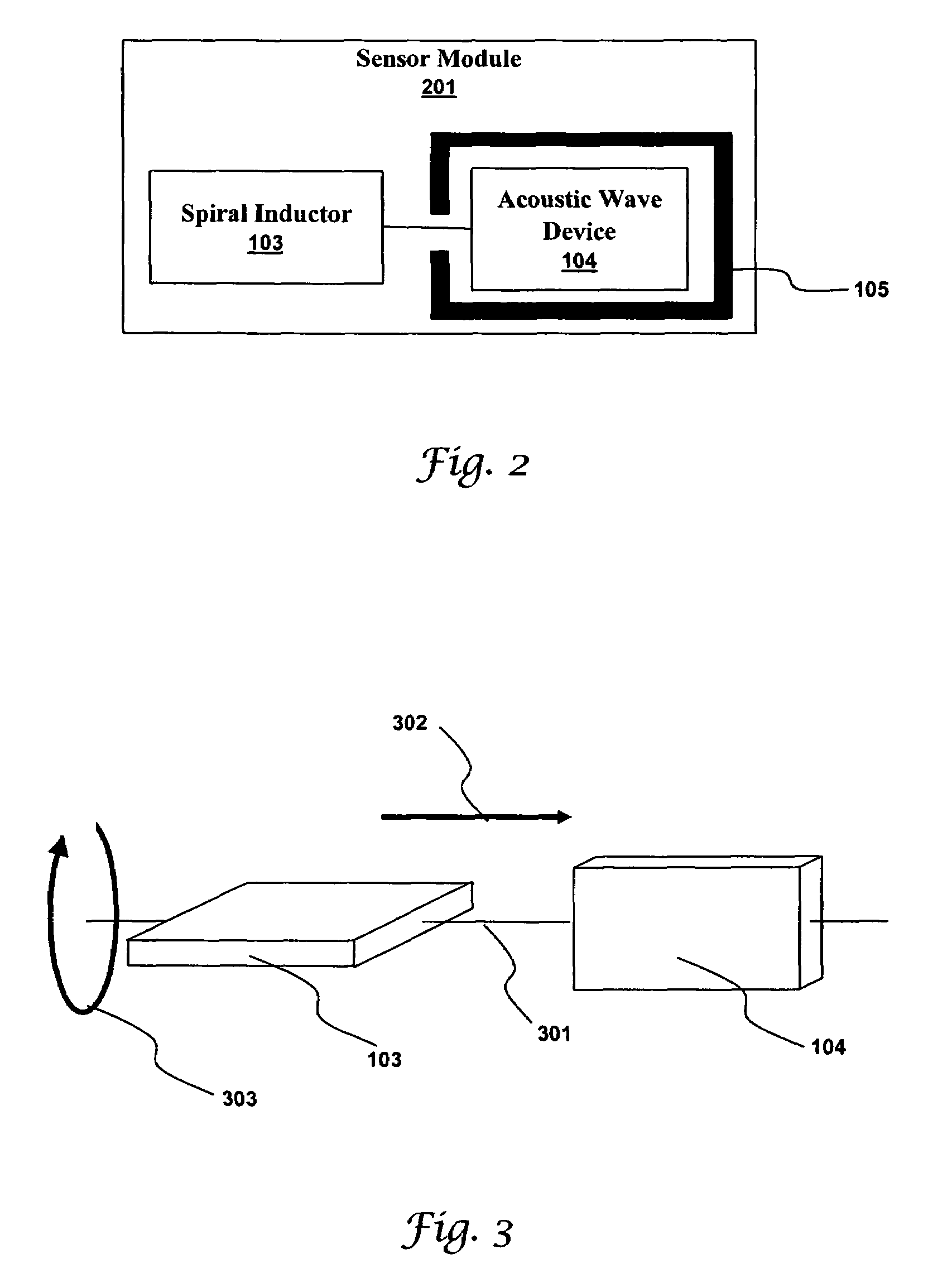

Wireless sensor antenna configuration

InactiveUS7377168B2Avoid noiseMaximum couplingVibration measurement in solidsElectric signal transmission systemsElectricityLine sensor

Many sensors could be used in a passive wireless mode. These include RLC, acoustic wave and magneto-elastic sensors. These types of sensors are designed to exhibit a change in fundamental frequency when exposed to environmental factors such as temperature, pressure, or chemicals. An interrogation circuit can inductively couple to the sensor and measure the change in fundamental frequency. The change can be used to measure the environmental factor. Sensor sensitivity and inductive coupling efficiency can be competing design constraints. A driver, electrically connected to the sensor and inductively coupled to the interrogation circuit, can relax the constraints. The driver, however, can introduce noise into the sensor. The sensor can be shielded using physical and geometric techniques to reduce the noise.

Owner:HONEYWELL INT INC

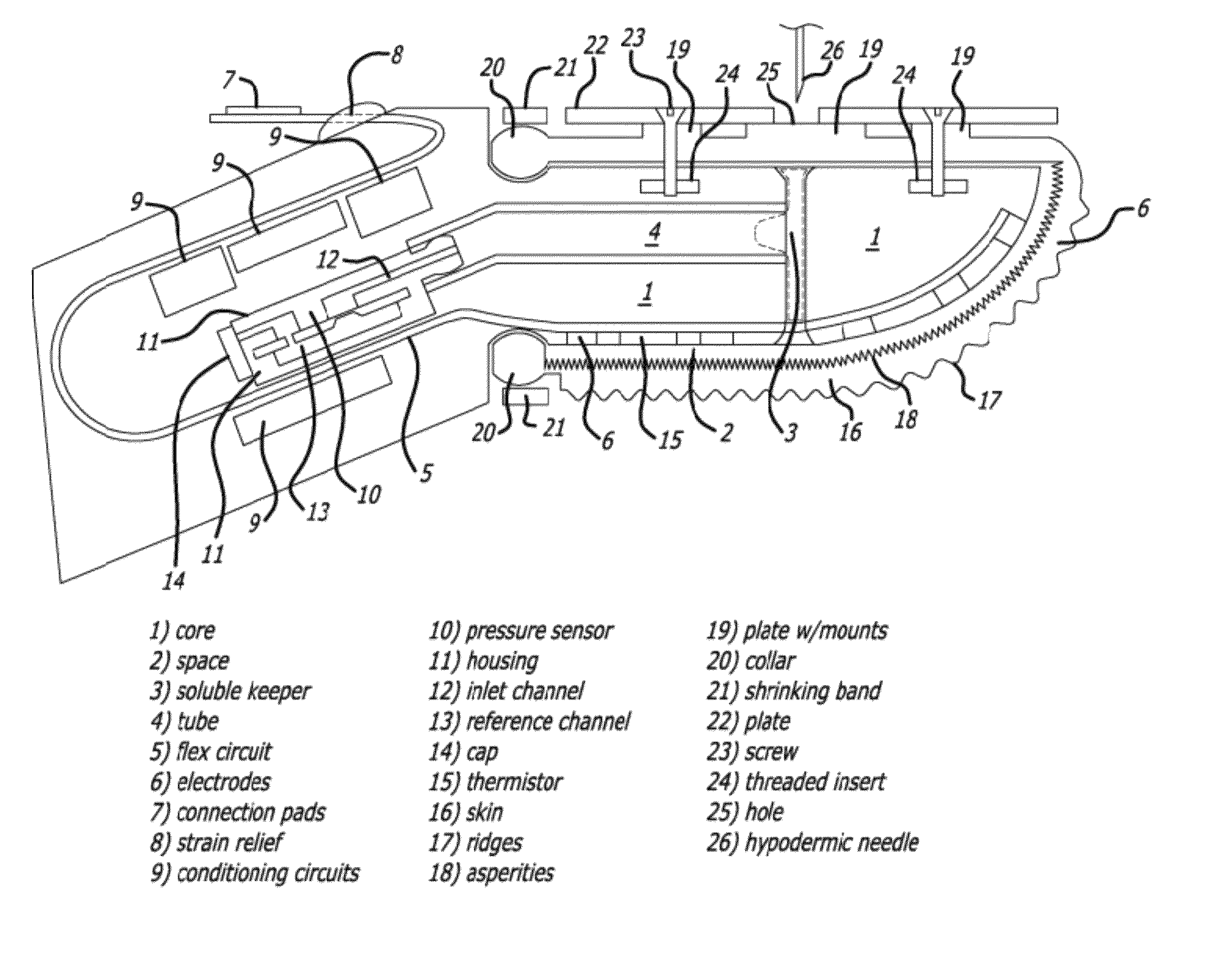

Measurement of sliding friction-induced vibrations for biomimetic tactile sensing

ActiveUS8181540B2Stable and efficient graspEasy to detectVibration measurement in solidsForce measurement by measuring frquency variationsElastomerGrip force

Owner:UNIV OF SOUTHERN CALIFORNIA

Method and systems for exhaust gas recirculation valve diagnosis based on crankcase pressure

Various methods and systems are provided for diagnosing an exhaust gas recirculation valve based on crankcase pressure. In one example, a method comprises indicating a condition of a valve disposed in a first exhaust passage downstream from a cylinder exhaust valve based at least in part on a crankcase pressure.

Owner:GE GLOBAL SOURCING LLC

Downhole distributed pressure sensor arrays, downhole pressure sensors, downhole distributed pressure sensor arrays including quartz resonator sensors, and related methods

Downhole distributed pressure sensor arrays include sensor housings each comprising at least one pressure sensor in a pressure housing. Downhole pressure sensors include a housing, at least one pressure sensor in a pressure housing portion of the housing, and at least one isolation element positioned at an outer wall of the housing.

Owner:QUARTZDYNE

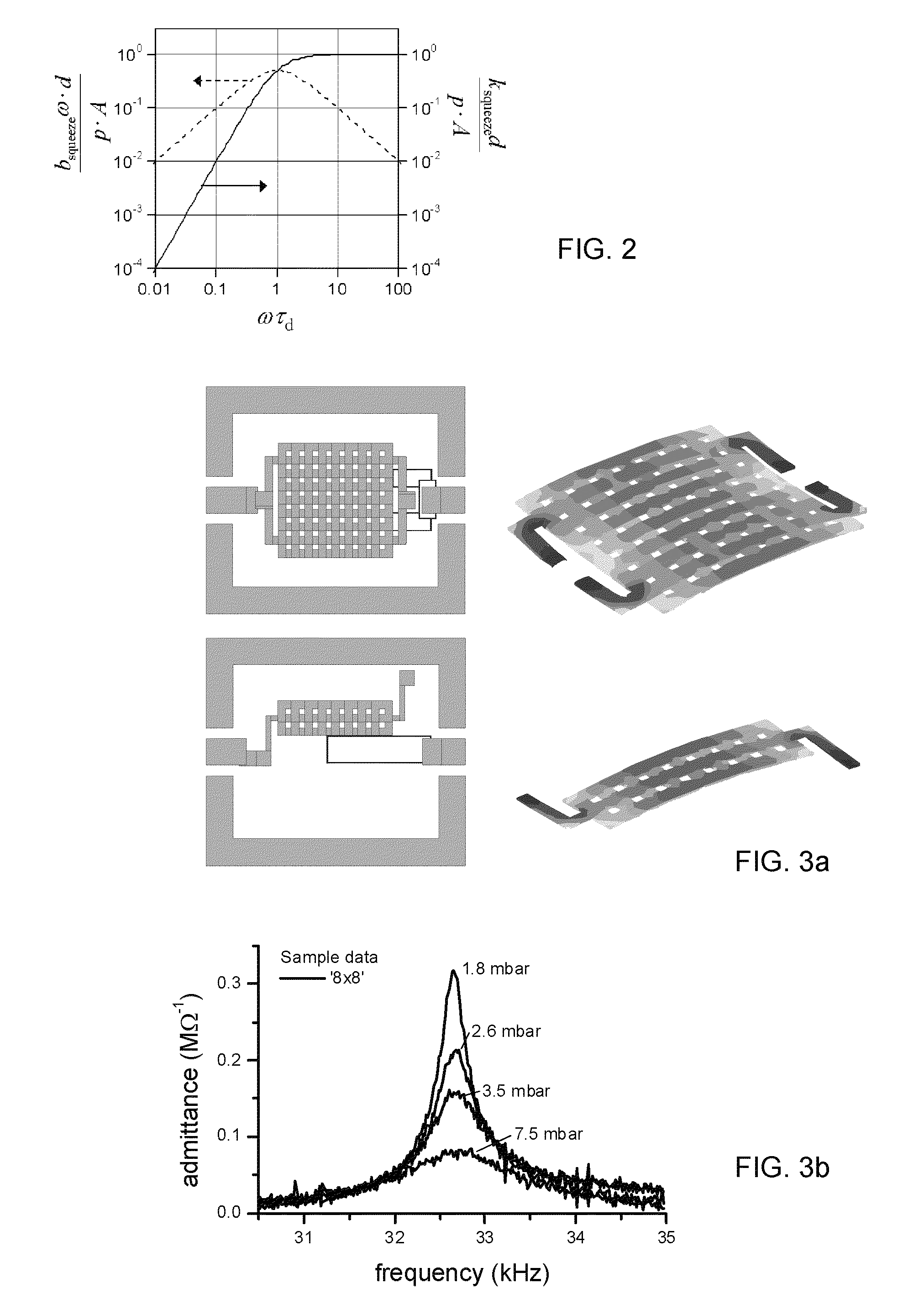

MEMS pressure sensor

ActiveUS8256298B2Fluid pressure measurement by electric/magnetic elementsVacuum gauge using gaseous frictional resistance variationMems pressure sensorResonance

A MEMS pressure sensor for sensing the pressure in a sealed cavity of a MEMS device, comprises a resonant MEMS device having a pressure sensor resonator element which comprises an array of openings. The resonant frequency of the resonant MEMS device is a function of the pressure in the cavity, with resonant frequency increasing with pressure. Over the pressure range 0 to 0.1 kPa, the average change in frequency is at least 10−6 / Pa. The invention is based on the recognition that for fast oscillation, the elastic force causes the resonance frequency to shift. Therefore, it is possible to sense the pressure by a device with resonance frequency that is sensitive to the pressure.

Owner:SCIOSENSE BV

Double-ended tuning fork type piezoelectric resonator and pressure sensor

InactiveUS20090151461A1Buildup of pressureImpedence networksPiezoelectric/electrostriction/magnetostriction machinesTuning forkEngineering

To provide a double-ended tuning fork type piezoelectric resonator that includes: a piezoelectric element having two arm portions disposed in parallel, a first supporting portion that support one ends of each of the arm portions, a second supporting portion that support the other ends of each of the arm portions; and an exciting electrode formed on a surface of each of the arm portions, and has a structure suitable for being built into a pressure sensor as a pressure sensitive element.A double-ended tuning fork type piezoelectric resonator includes: a piezoelectric element 3 having two arm portions 4 disposed in parallel and apart from each other, and a first supporting portion 5 and a second supporting portion 6 that respectively support one ends and the other ends of each of the arm portions; and an exciting electrode 7 formed on a surface of each arm portion. In the resonator, an annular linking piece 8 is provided to link the first and the second supporting portions to dispose the two arm portions in an internal space of the annular linking piece.

Owner:SEIKO EPSON CORP

Device for measuring pressure, variation in acoustic pressure, a magnetic field, acceleration, vibration, or the composition of a gas

ActiveCN101970339AEffective shieldingLength effectTelevision system detailsAcceleration measurement using interia forcesSonificationResonance

The invention relates to a sensor (1) and a method for measuring pressure, variation in sound pressure, a magnetic field, acceleration, vibration, or the composition of a gas. The sensor (1) comprises an ultrasound transmitter (2), and a cavity (4) arranged in connection with it. According to the invention, the sensor (1) comprises a passive sensor element (3, 3') located at the opposite end of the cavity (4) to the ultrasound transmitter (2), the distance of which from the ultrasound transmitter (2) is selected in such a way that the resonance condition is met at the ultrasound frequency used, the ultrasound transmitter (2) comprises a light-construction diaphragm oscillator (9), which is thus well connected to the surrounding medium, and the sensor includes means for measuring the interaction between the ultrasound transmitter (2) and the cavity (4).

Owner:VALTION TEKNILLINEN

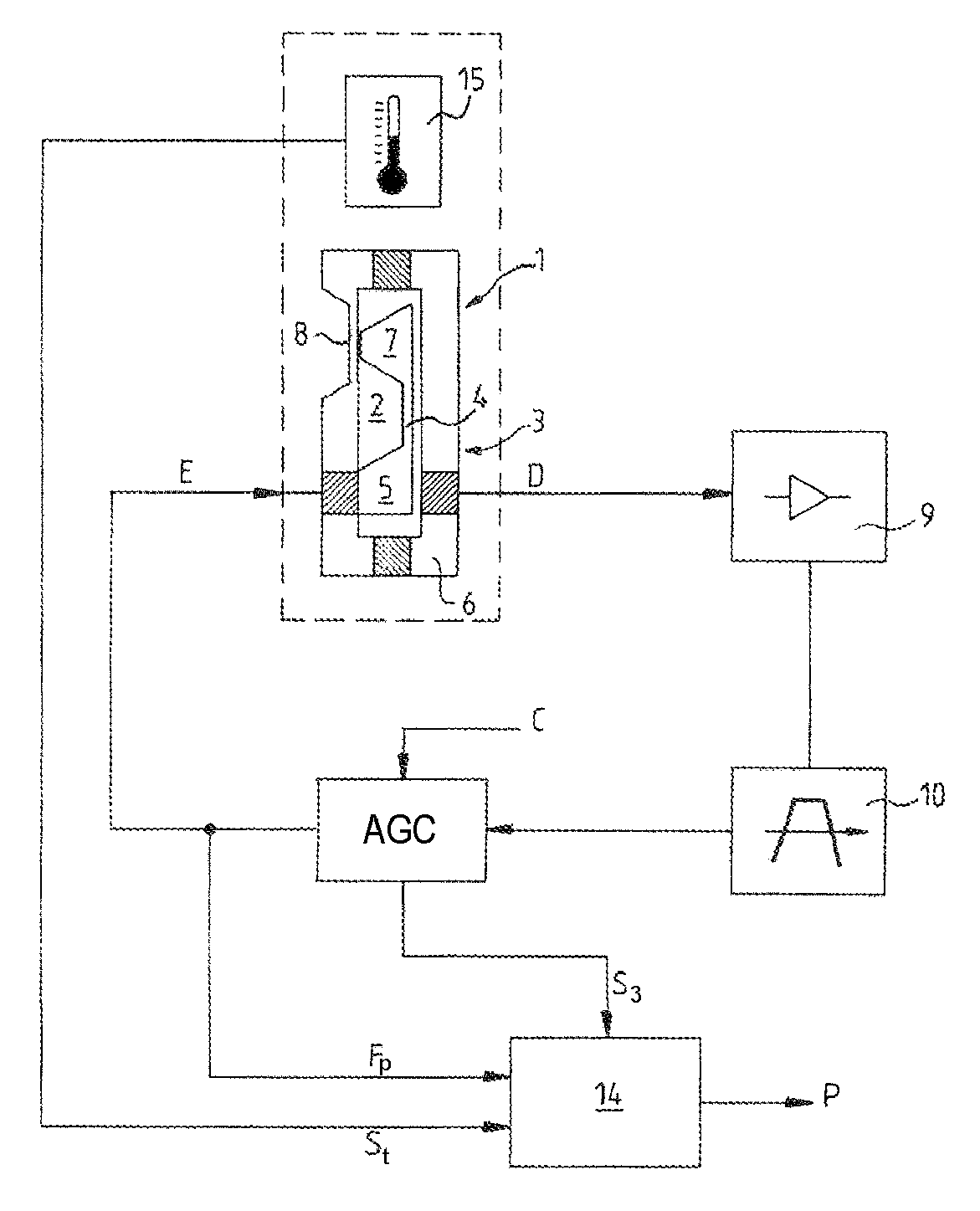

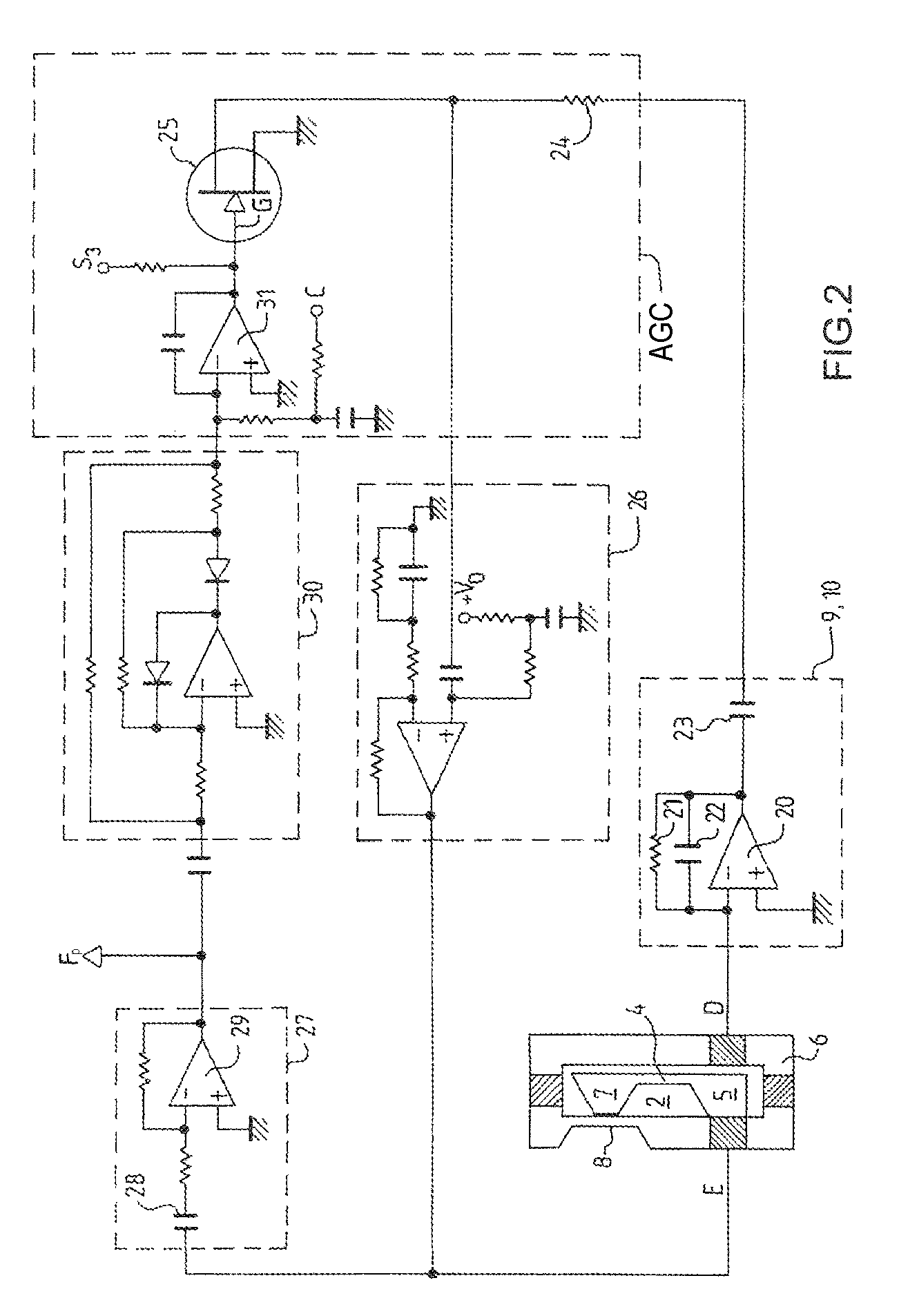

Resonator Measurement Device and Method Employing the Device

ActiveUS20080184804A1Broaden their knowledgeLeveling precisionVibration measurement in solidsAcceleration measurement using interia forcesMeasurement deviceCondensed matter physics

The invention relates to a device and a method for detecting a fault in a measurement device comprising a resonator and means for measuring a resonant frequency of the resonator. According to the invention, the device further includes means delivering information (S3) representative of the quality factor of the resonator (3) at the resonant frequency.

Owner:THALES SA

Popular searches

Weather/light/corrosion resistance Cathode-ray/electron-beam tube vessels/containers Response signal detection Processing detected response signal Material analysis by using resonance Indication of measured values Measurements using magnetic resonance Specific gravity measurement Automatic control for drilling Counting objects on conveyors

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com