Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about "Flexible/folding resistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

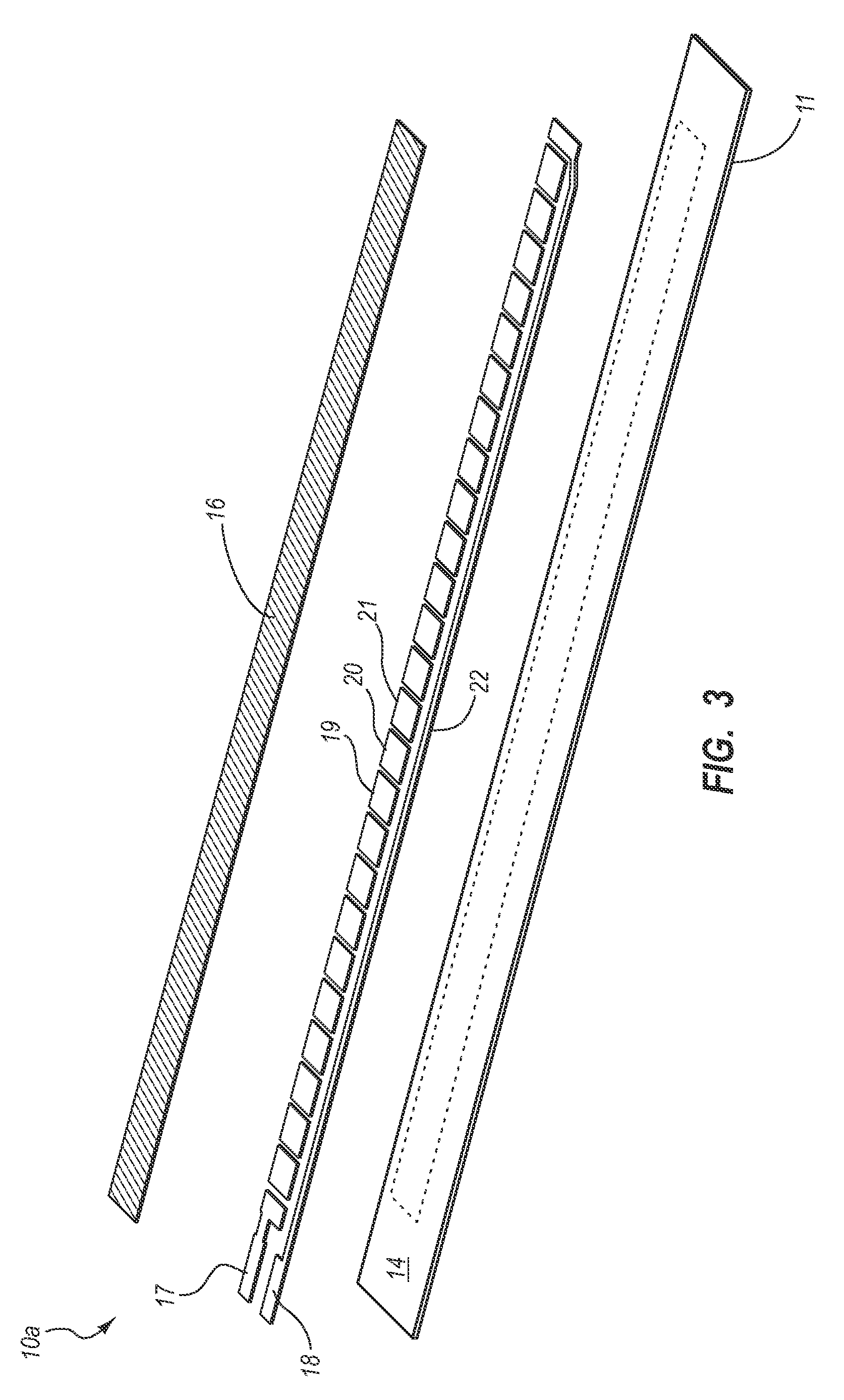

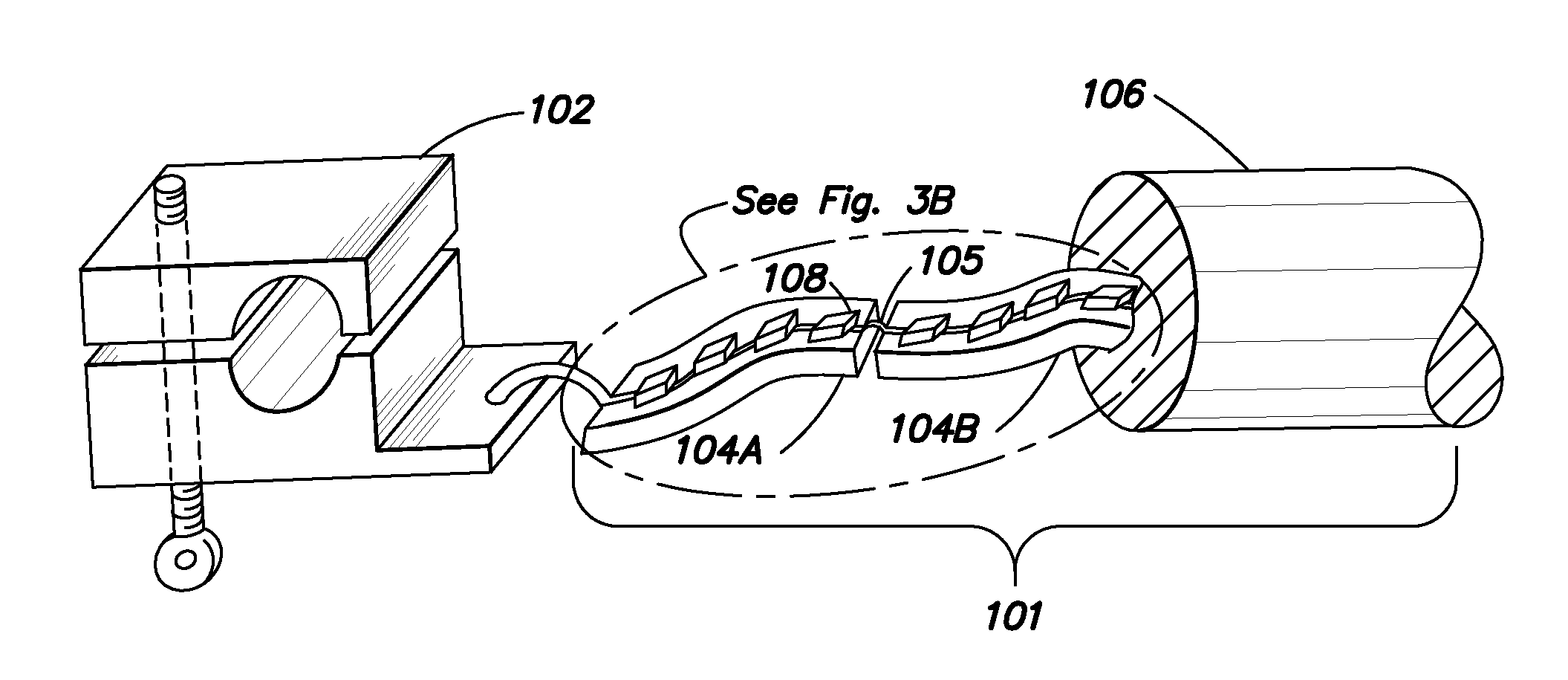

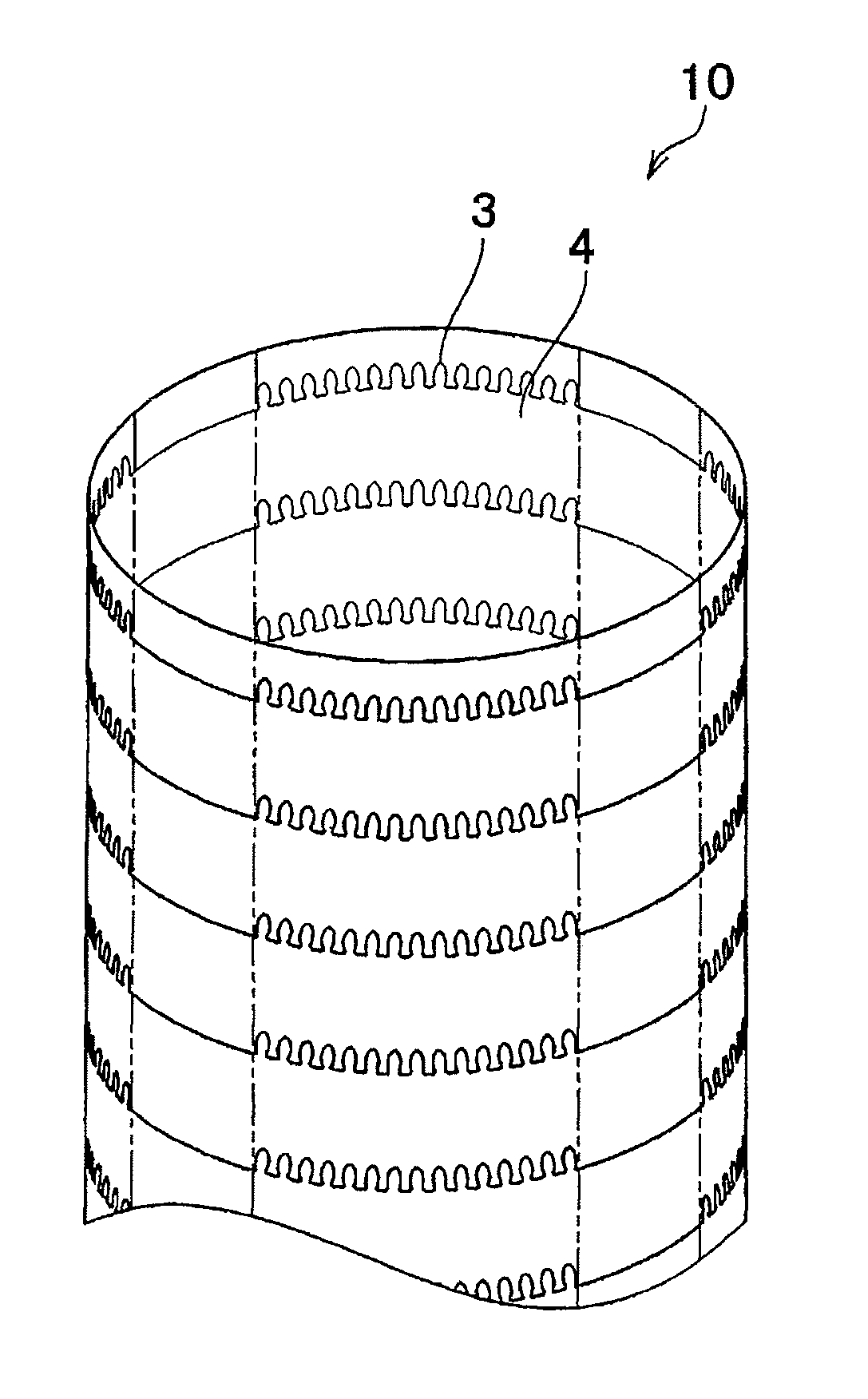

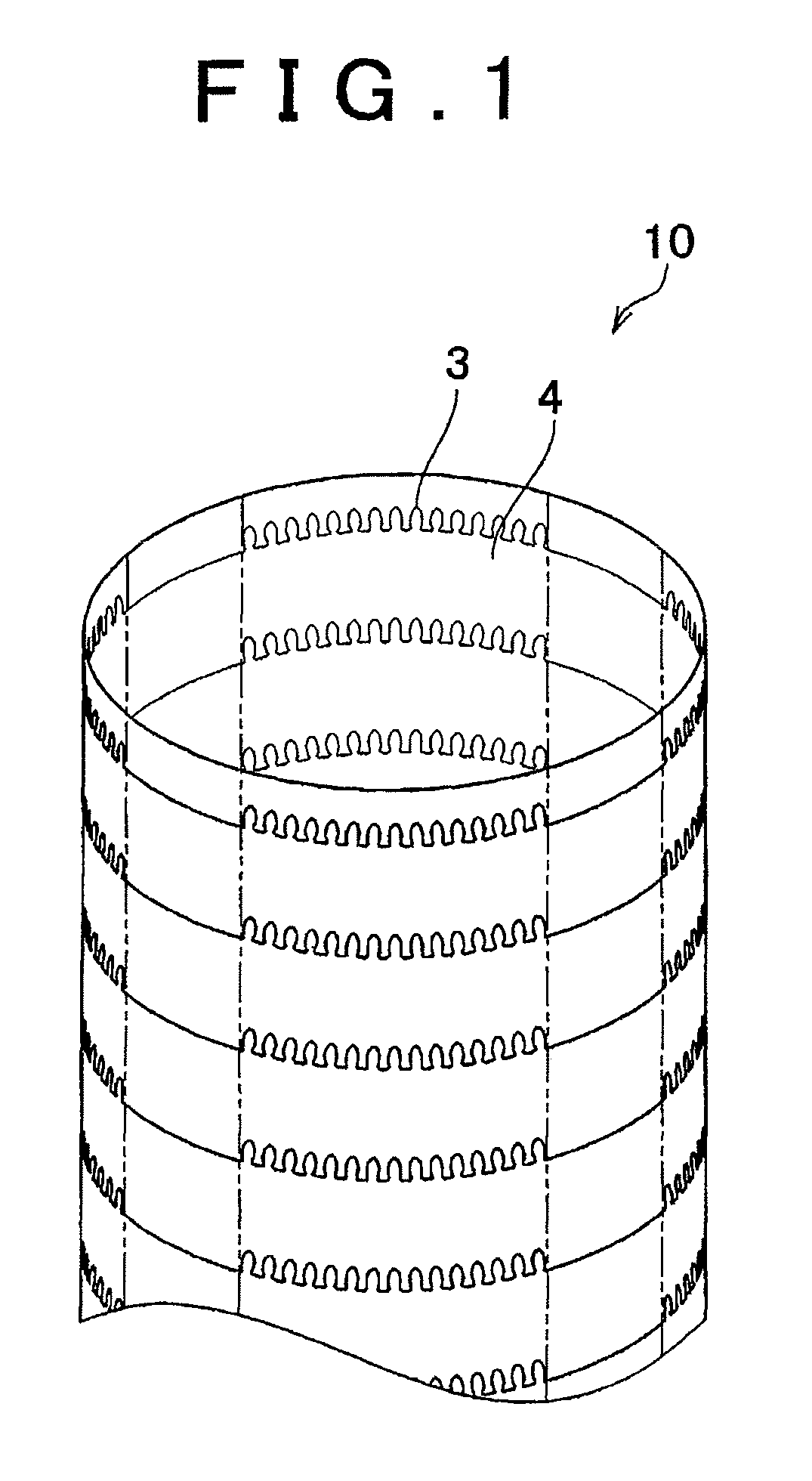

Method for producing a tube

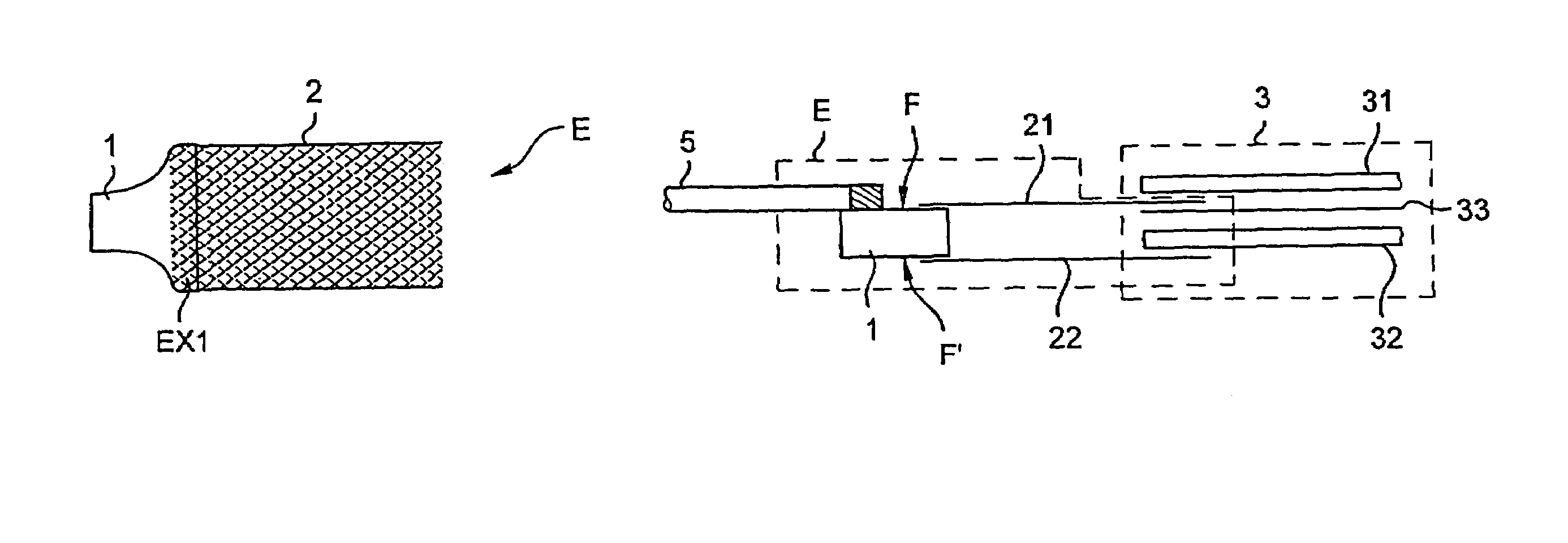

ActiveUS7155812B1Printed circuit assemblingLine/current collector detailsElectrical conductorDrift tube

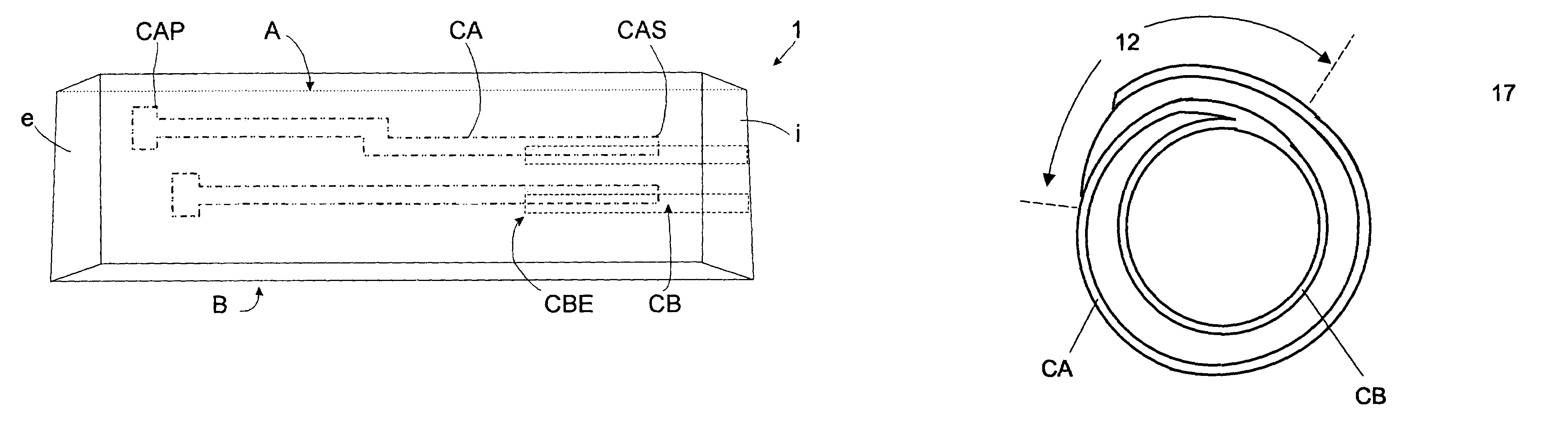

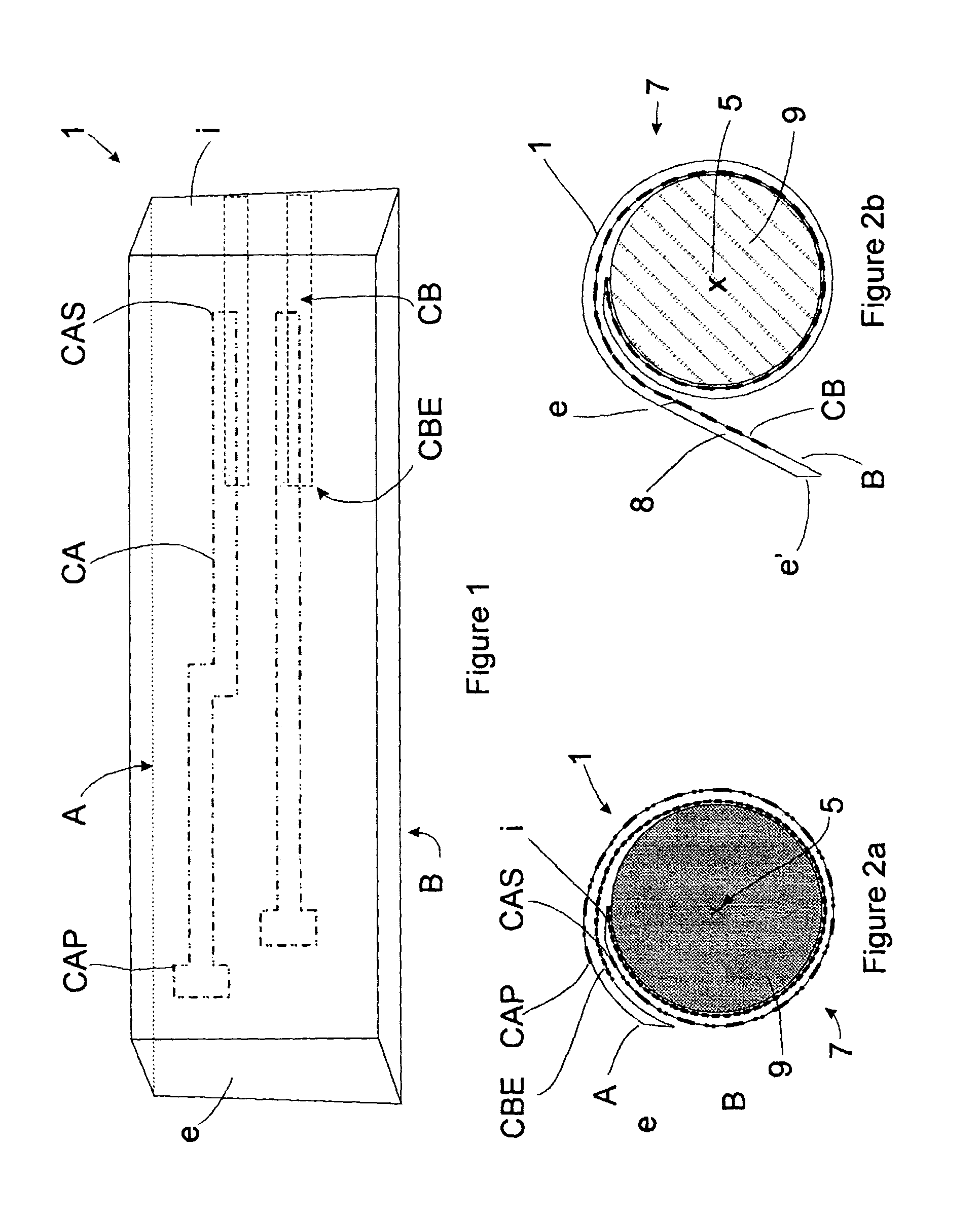

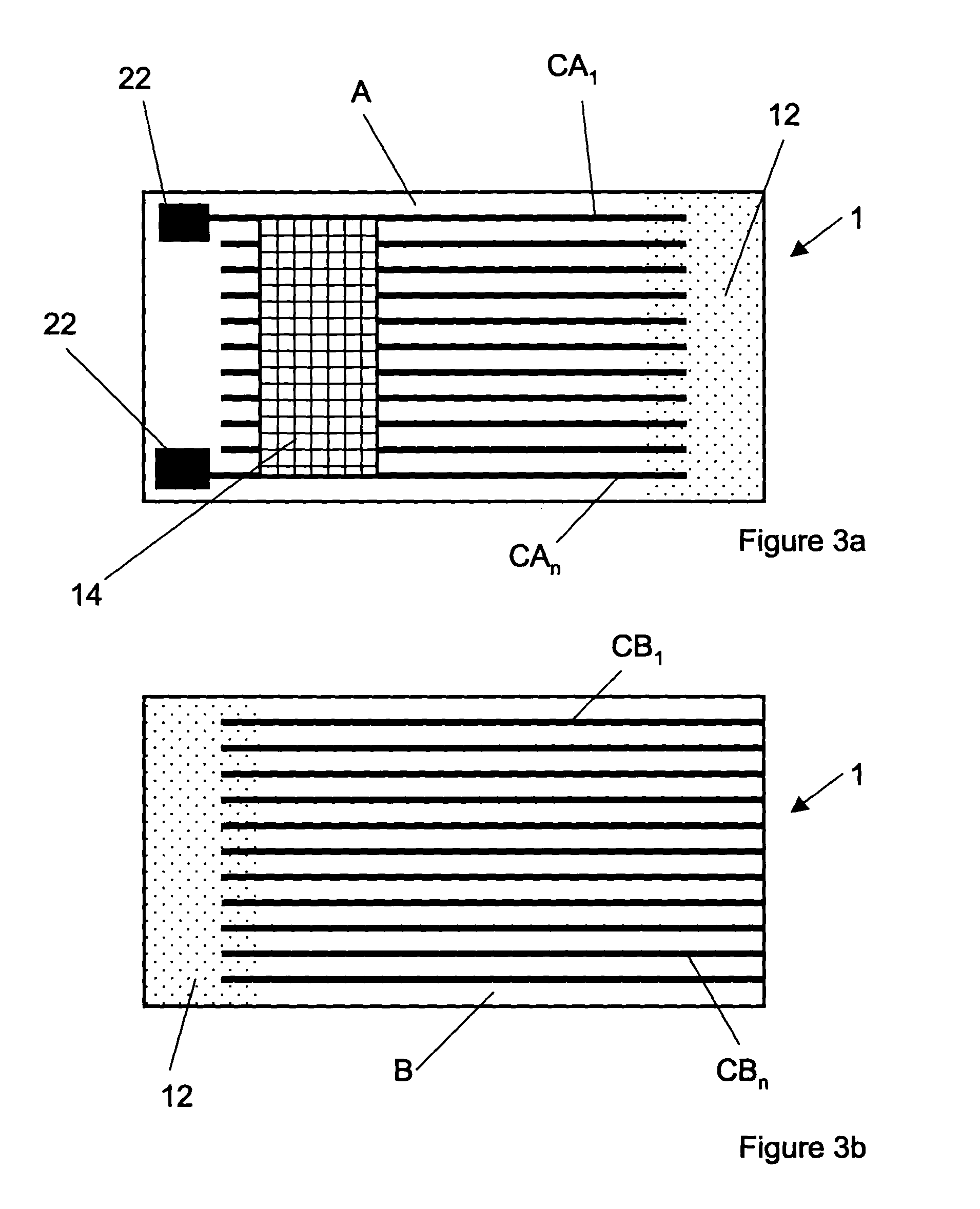

A method is described for producing tubular substrates having parallel spaced concentric rings of electrical conductors that can be used as the drift tube of an Ion Mobility Spectrometer (IMS). The invention comprises providing electrodes on the inside of a tube that are electrically connected to the outside of the tube through conductors that extend between adjacent plies of substrate that are combined to form the tube. Tubular substrates are formed from flexible polymeric printed wiring board materials, ceramic materials and material compositions of glass and ceramic, commonly known as Low Temperature Co-Fired Ceramic (LTCC). The adjacent plies are sealed together around the electrode.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

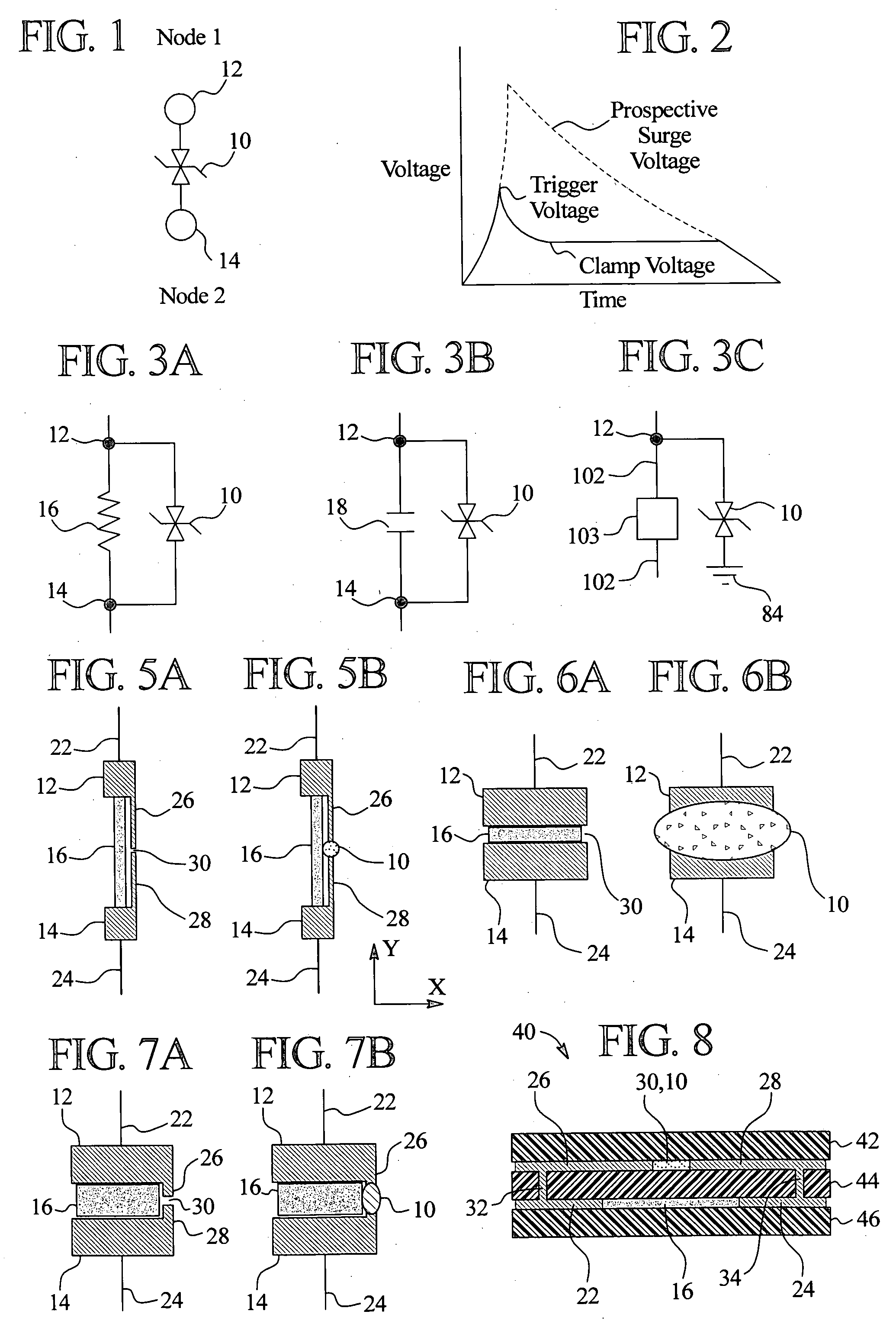

Electrostatic discharge protection for embedded components

InactiveUS20060152334A1Protection elementLow costPrinted circuit aspectsHigh voltage circuit adaptationsCapacitanceElectrical resistance and conductance

An improved electrical circuit that includes an embedded electrical component and an embedded voltage variable material (“VVM”) is provided. In one embodiment, the embedded VVM is provided as a voltage variable substrate, which is used in combination with an embedded electrical component, such as an embedded resistive material or an embedded capacitive material.

Owner:LITTELFUSE INC

Structure and method for attaching tactile sensor to curved surface

InactiveUS20130168336A1Good adhesionMass productionForce measurementElectrical apparatus contructional detailsTactile sensorBiomedical engineering

The present invention relates to a structure for attaching tactile sensors to a curved surface, comprising a sensor fixing unit configured to have at least part of one surface curved and to have a plurality of sensor insertion grooves, crossing each other, formed in the one surface in a matrix form; tactile sensor units formed in a matrix form, inserted into the respective sensor insertion grooves, and configured to detect external force; sealing units configured to seal the respective sensor insertion grooves; and a support unit configured to come in contact with one face of the sealing units or the sensor fixing units and to support the sensor fixing units. Accordingly, the tactile sensors can be easily attached to a curved surface, and mass production is possible.

Owner:KOREA RES INST OF STANDARDS & SCI

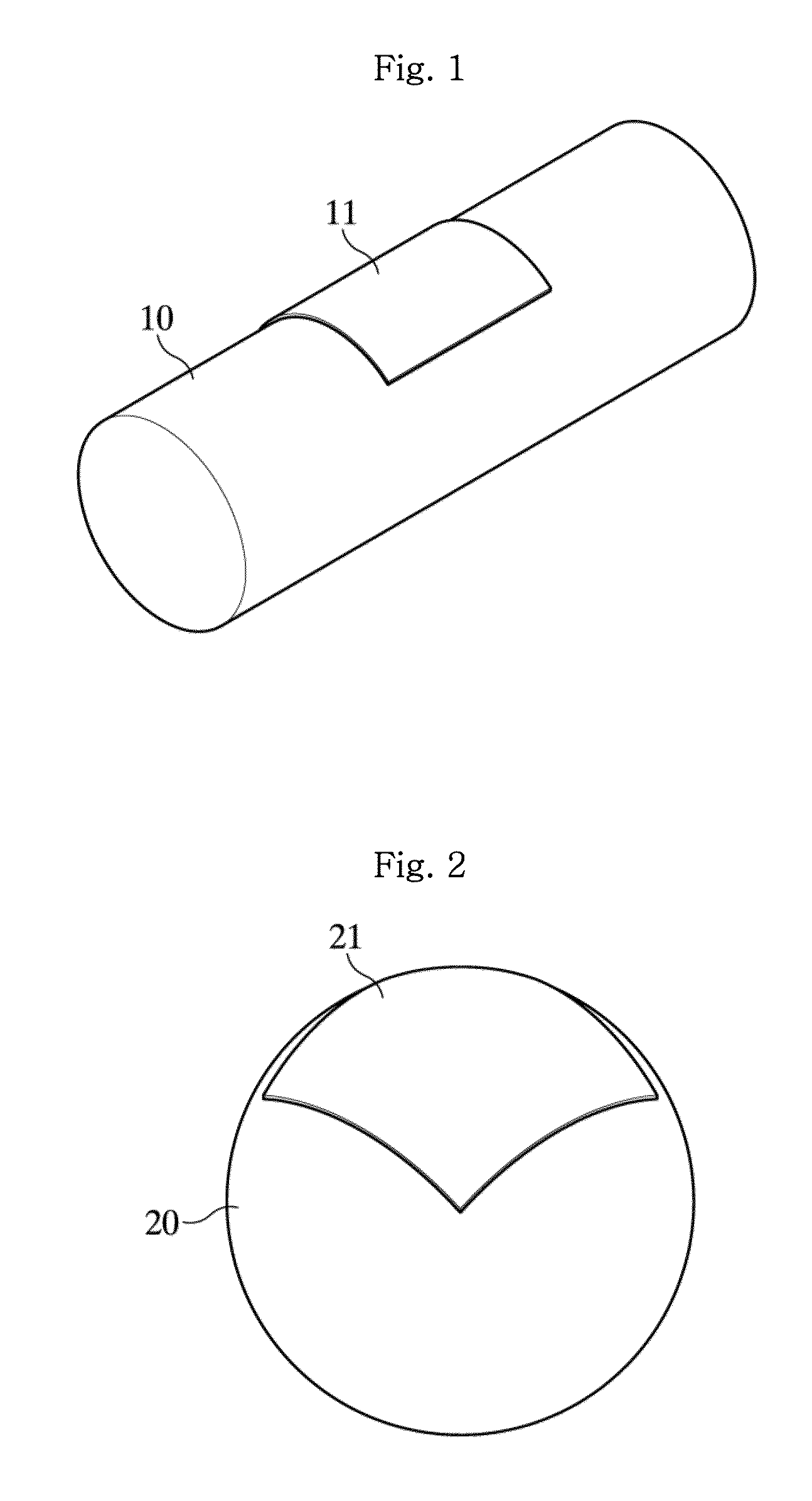

Method for igniting combustion of fuel in a combustion chamber of an engine, associated device and engine

ActiveUS7770551B2Combustion characteristic is optimizedReduce fuel consumptionSparking plugsCombustion enginesMicrowaveCombustion chamber

A method ignites the combustion of fuel in a combustion chamber (5) of engine (2), by introducing microwave radiation into the combustion chamber (5). The microwave radiation is produced in a microwave source (7) on the outside of the combustion chamber (5). The introduced microwave radiation is absorbed by the fuel distributed in the combustion chamber (5). The supply of energy, in the fuel, arising from absorption, distributes combustion in a large-volume in the combustion chamber (5), preferably in the entire combustion chamber (5) and in a homogenous manner, and is essentially simultaneously ignited. An associated ignition device (1) and an associated engine (2) are also provided.

Owner:MWI MICRO WAVE IGNITION

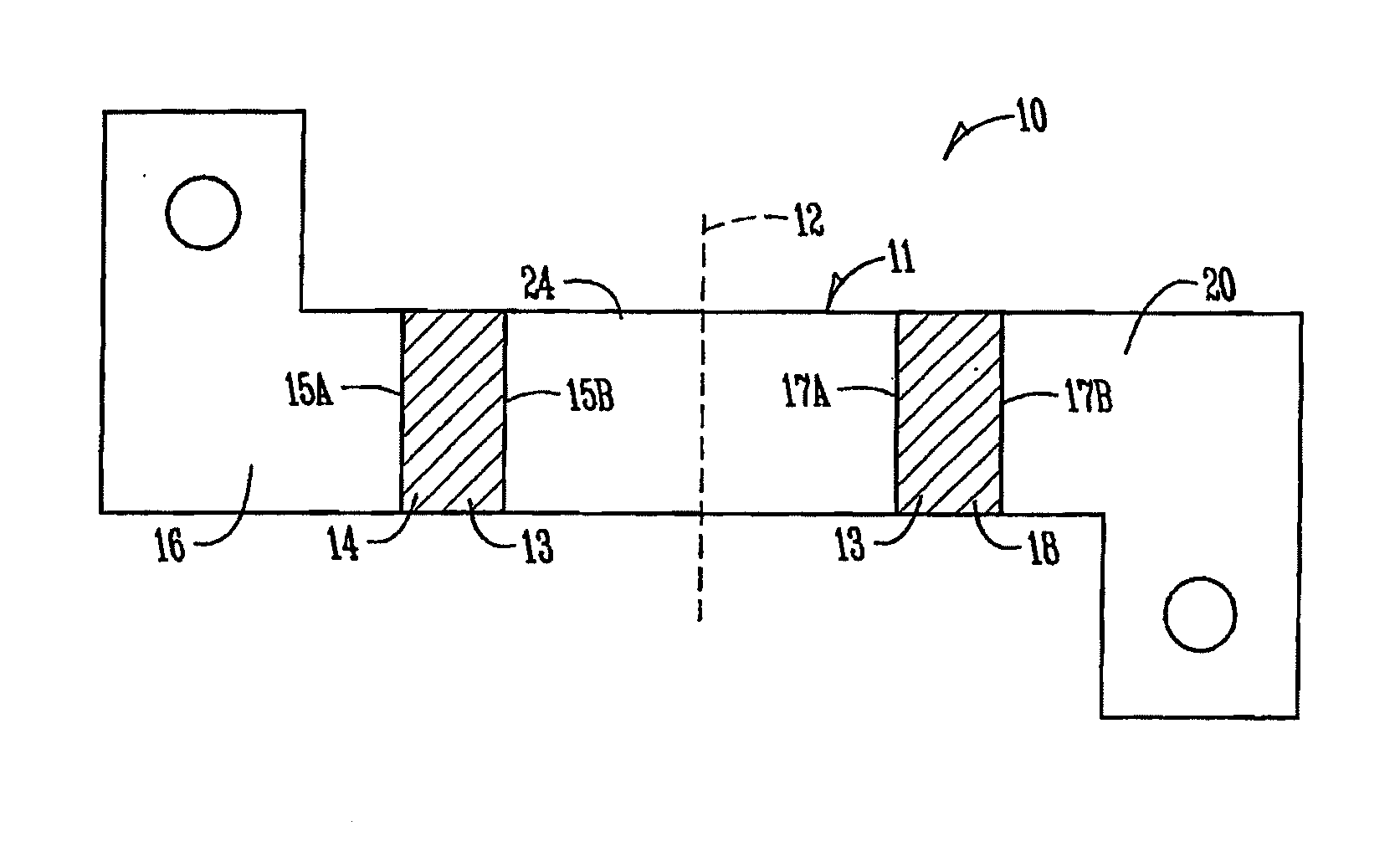

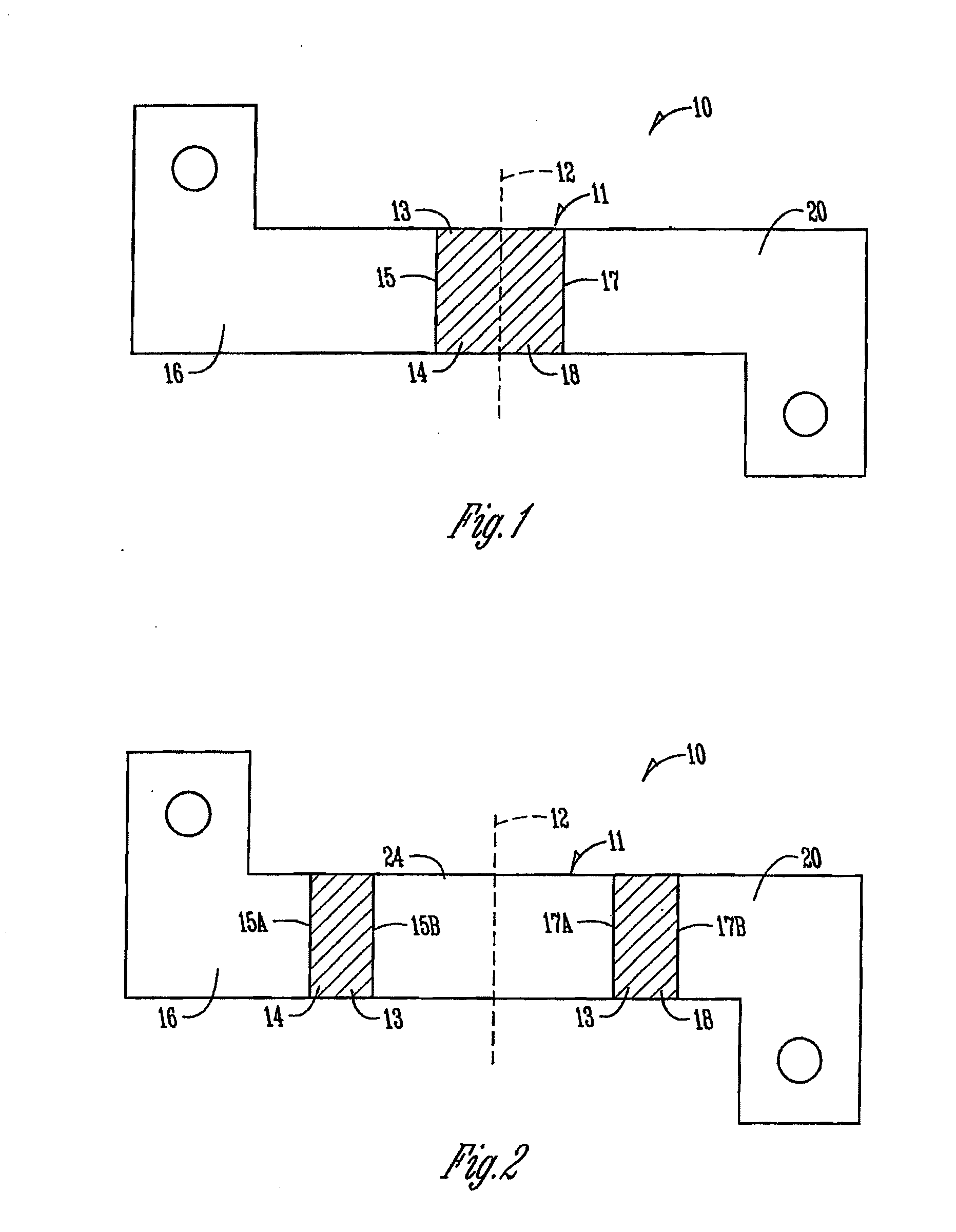

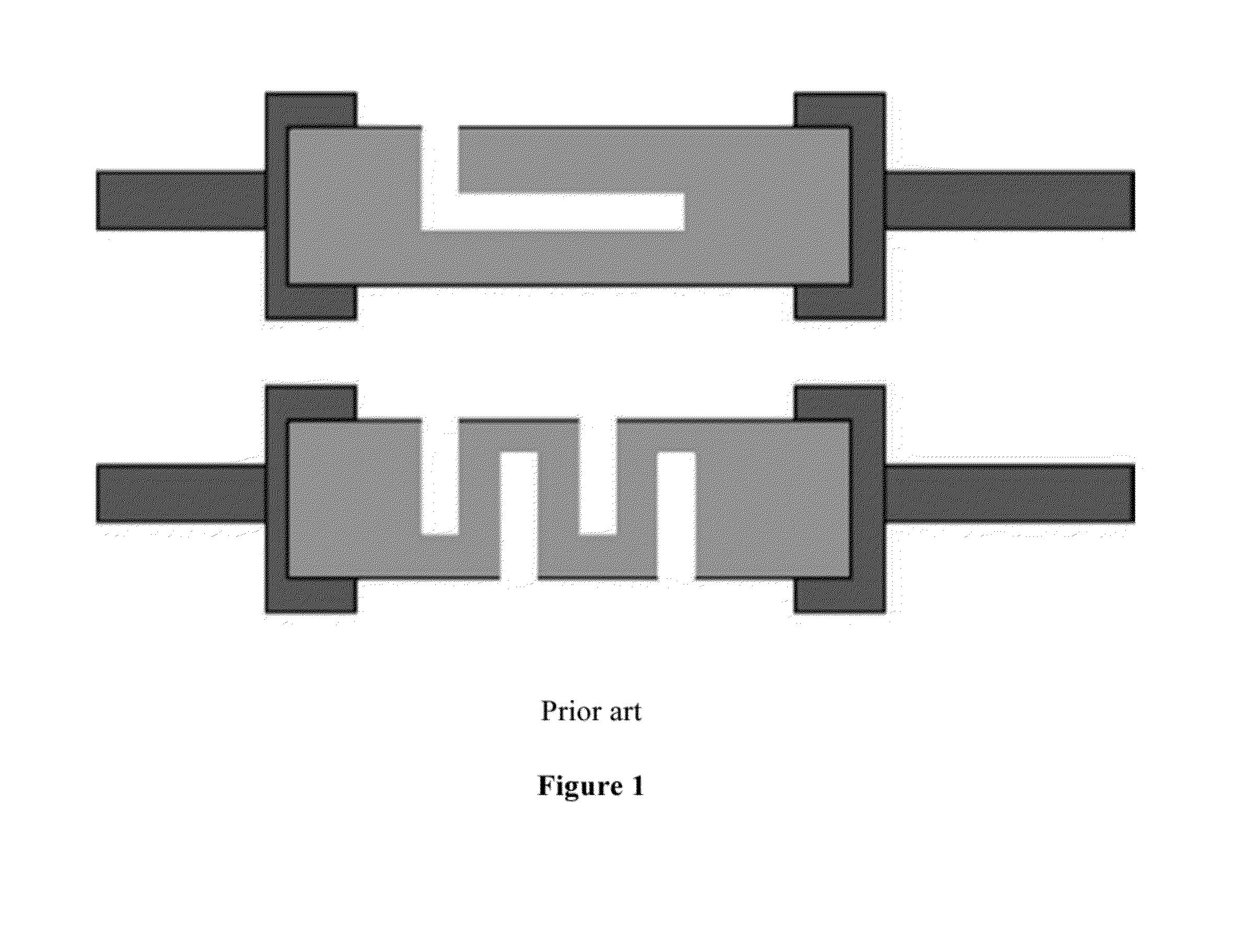

Metal strip resistor for mitigating effects of thermal emf

InactiveUS20100237982A1Reduce the impactReduce impactResistor terminals/electrodesResistor manufactureMetal stripsEngineering

A metal strip resistor includes a resistor body having a resistive element formed from a strip of an electrically resistive metal material and a first termination electrically connected to the resistive element to form a first junction and a second termination electrically connected to the resistive element to form a second junction, the first termination and the second termination formed from strips of electrically conductive metal material. The resistive element, the first termination, and the second termination being arranged mitigate thermally induced voltages between the first junction and the second junction.

Owner:VISHAY DALE ELECTRONICS INC

Voltage probe systems having improved bandwidth capability

InactiveUS7053750B2Resistance/reactance/impedenceElectrical measurement instrument detailsElectricityElectrical resistance and conductance

A resistive pin for use in a voltage probe includes a pin-head that is configured to contact a test point in a device under test, and a resistor that is attached to the pin-head. Other systems are also provided for establishing electrical connections between testing instruments and devices under test.

Owner:AGILENT TECH INC

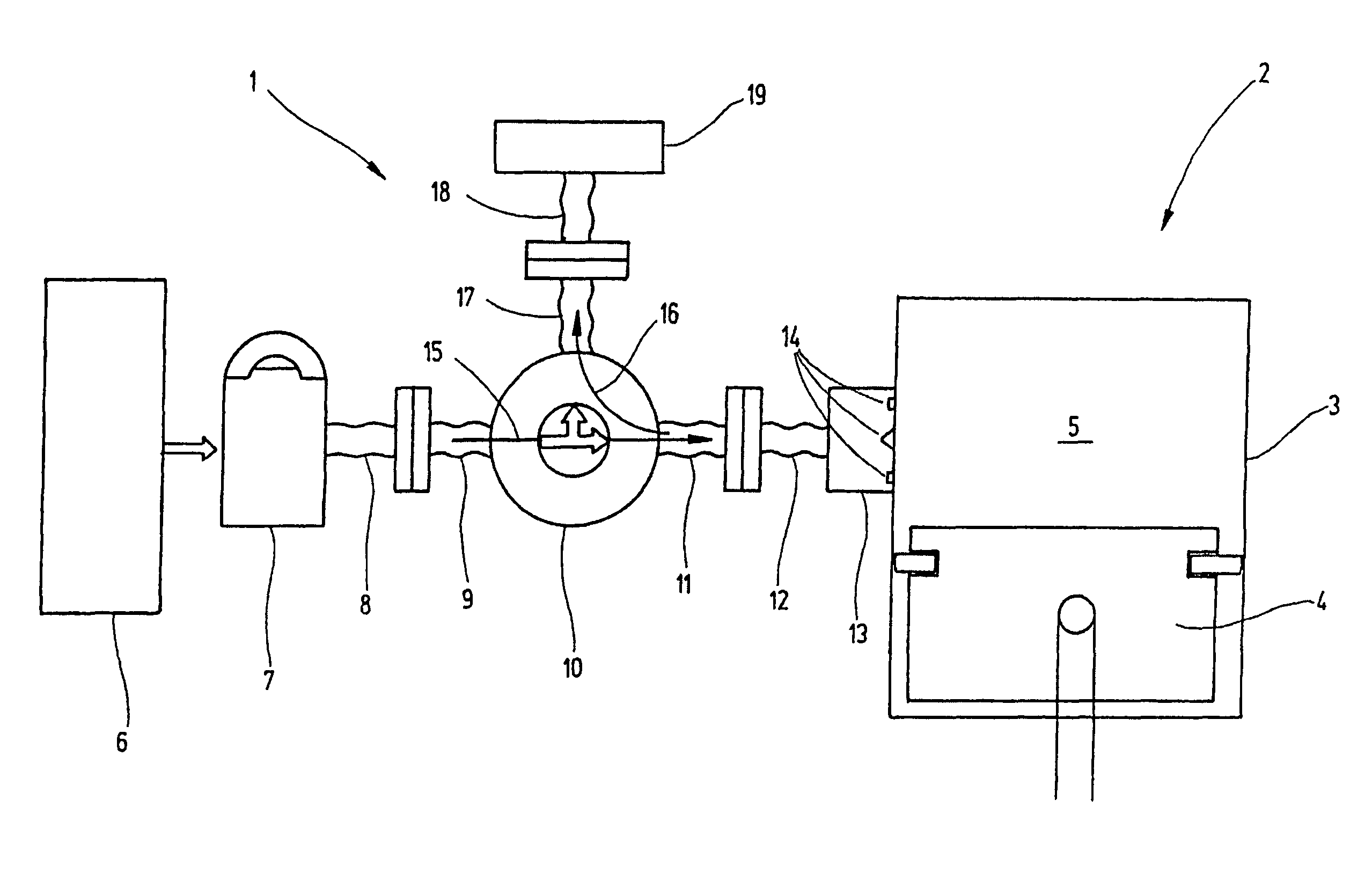

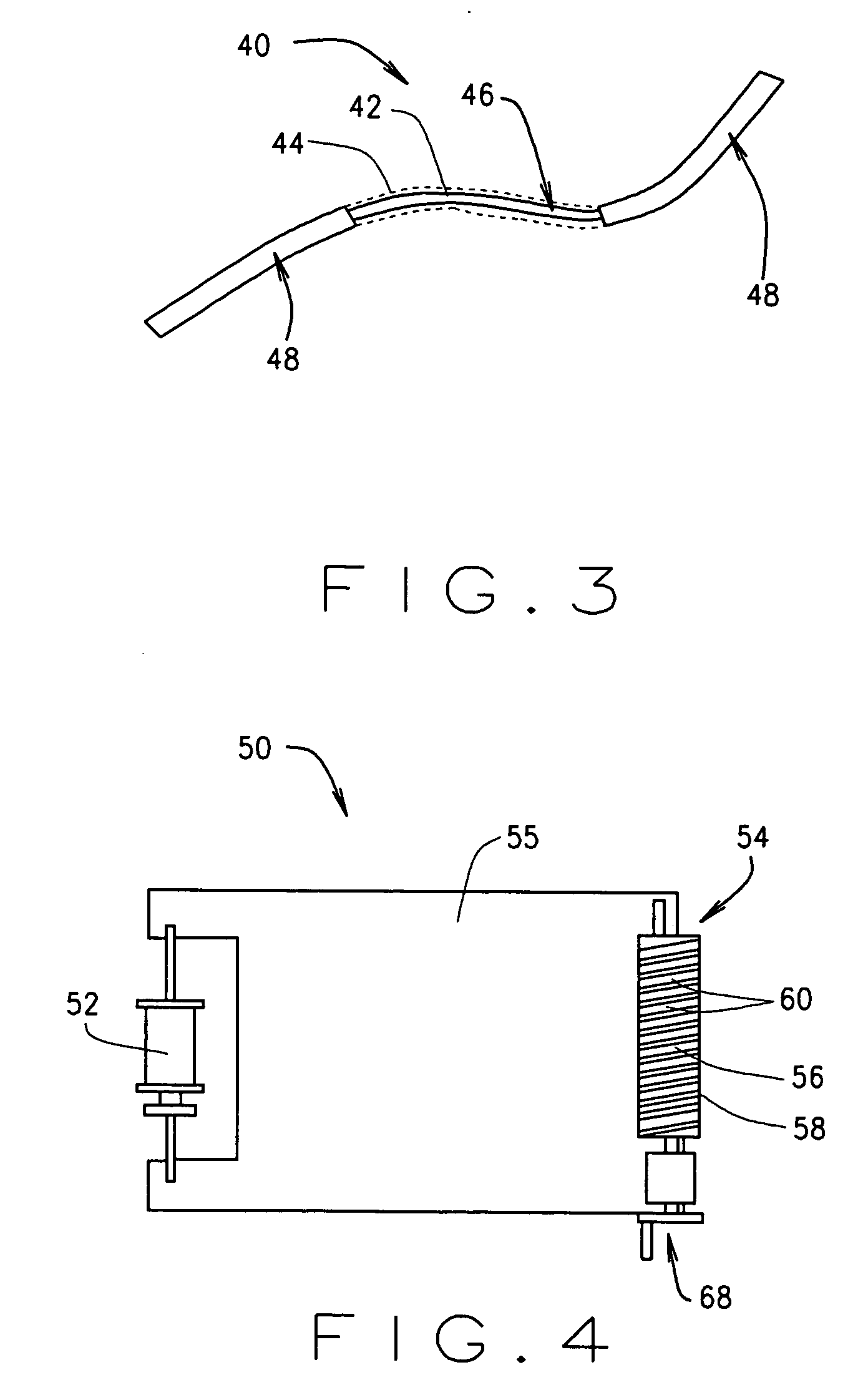

Bi-directional bend resistor

InactiveUS20100171583A1Flexible/folding resistorsAdjustable resistorsElectrical resistance and conductanceEngineering

A system and method for a bi-directional bend resistor are disclosed. The bidirectional deflectable resistor has a variable resistance stack on a top surface of a substrate having a resistance that changes predictably when an electrical signal is applied thereto. The change of resistance of the variable resistance stack reflects an amount of deflection of the bi-directional bend resistor. The variable resistance stack allows for the measurement of deflection of the bi-directional bend resistor in all directions.

Owner:IMAGES SCI INSTR

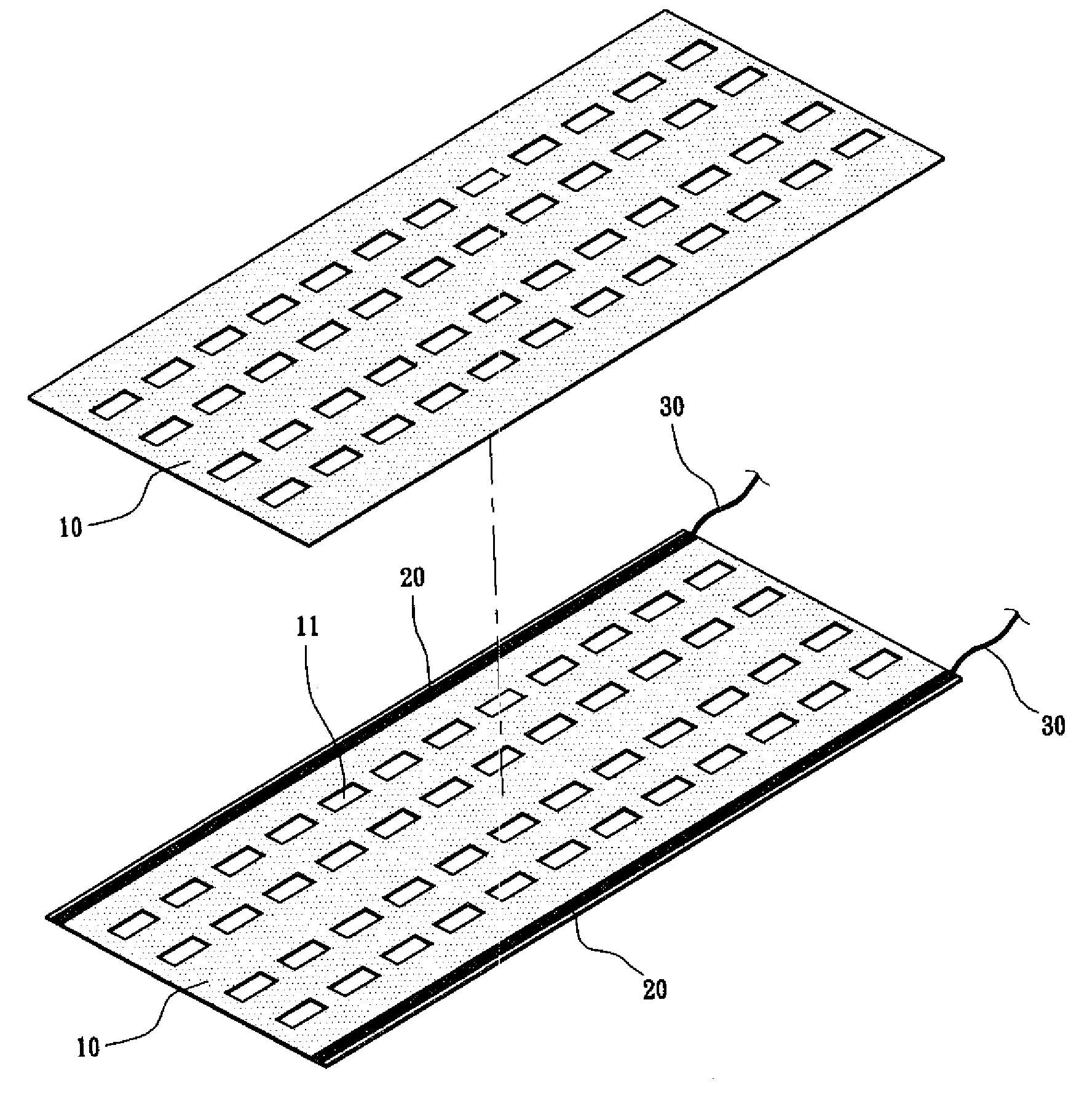

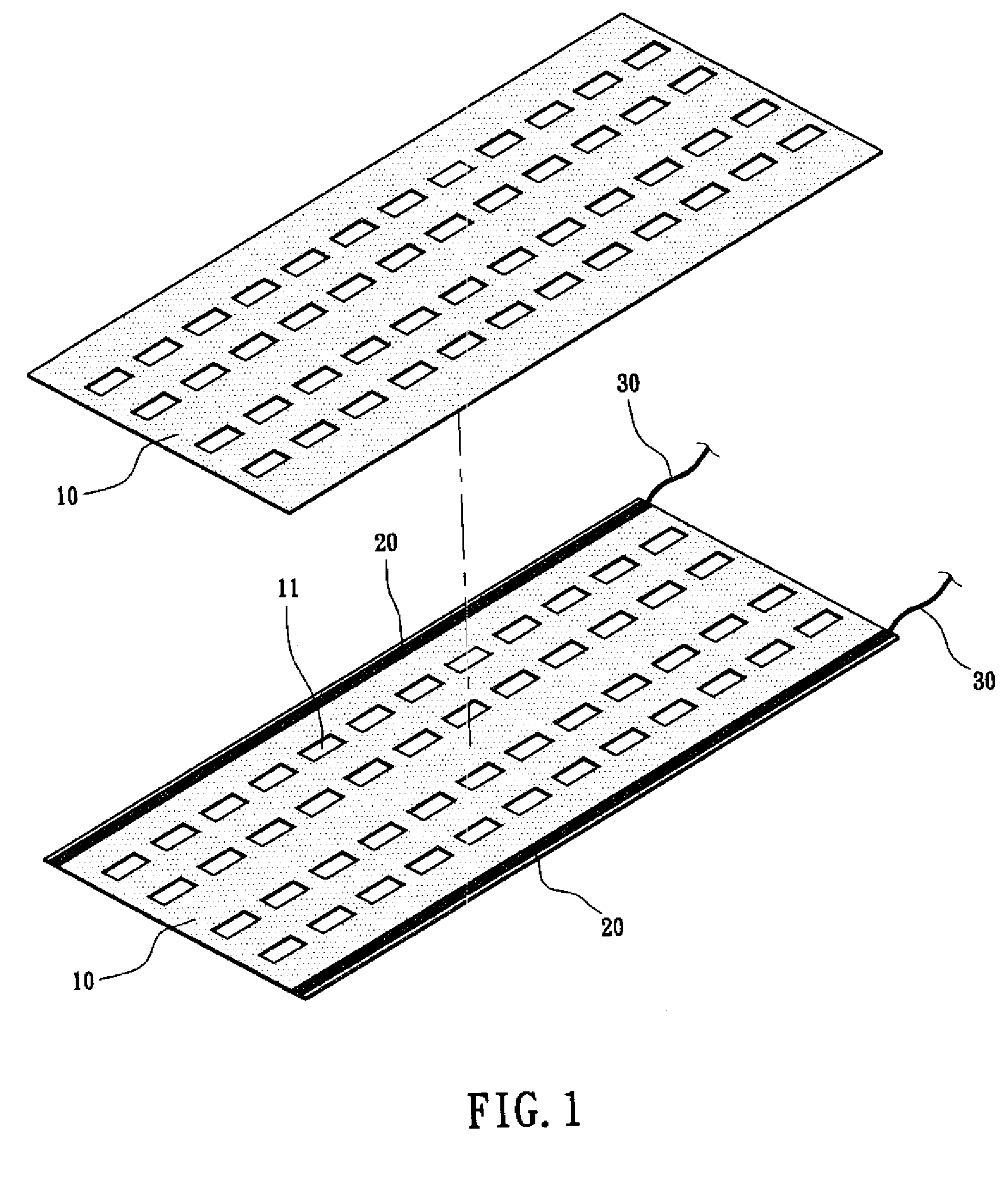

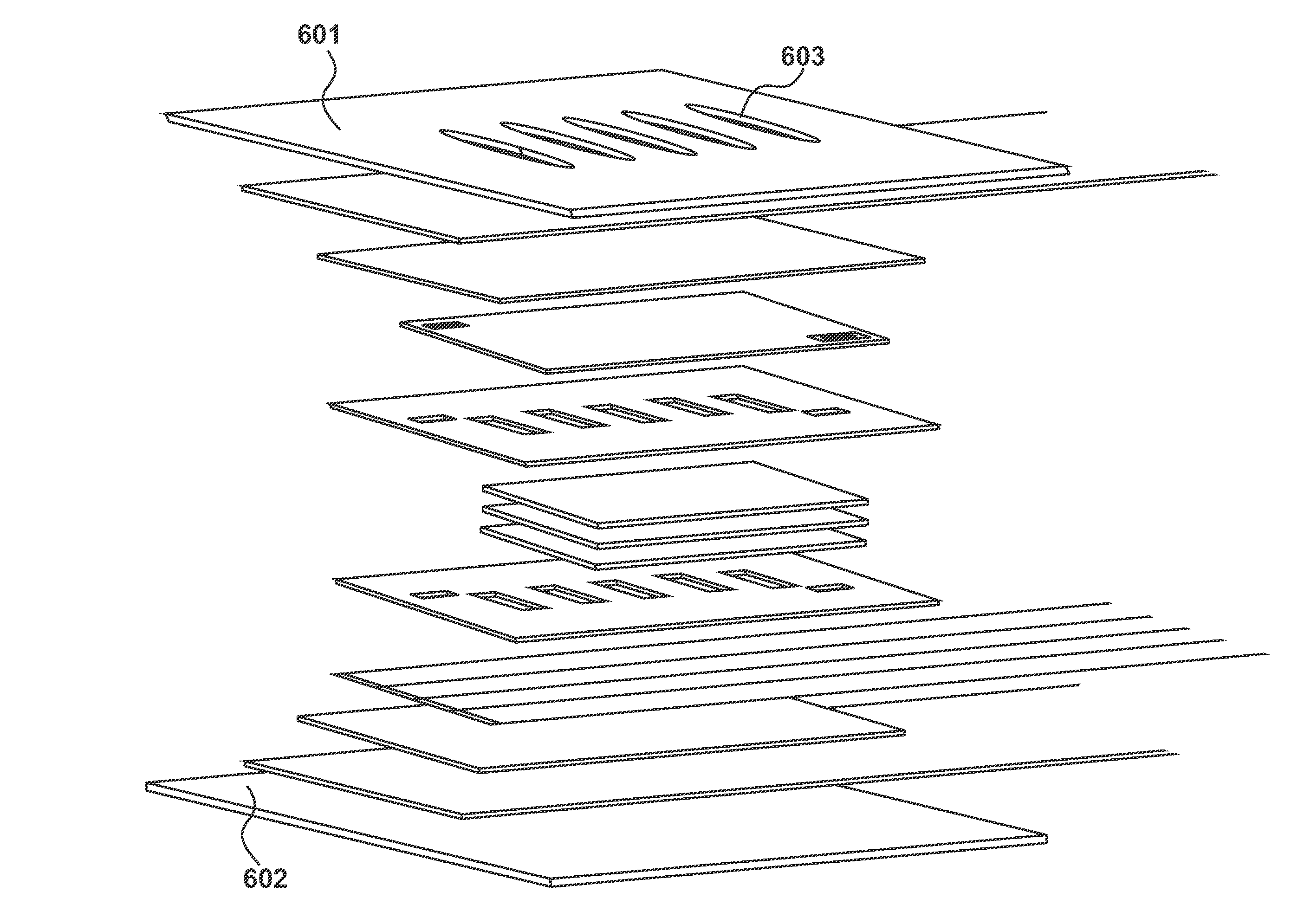

Flexible planar heating device

InactiveUS20090184106A1Reduce consumptionHeating evenlyHeating element shapesFlexible/folding resistorsElectrical conductorThin layer

A heating device which includes two first conducting members and at least a second conducting member, wherein the first conducting members are made of silicone rubber conductor and flexibly pressed into an upper thin layer and a lower thin layer between which is arranged the second conducting member. The first and second conducting members are formed into a whole unit by heat and pressure, which are provided holes at predetermined positions for increasing the contact area to disperse electrical current and conducting wires for connection in parallel or series with the power source. Voltages from 0.1V˜500V AC or DC are all applicable. Hence, the first and second conducting members can dissipate heat evenly. The increased temperature ranges from 1˜230° C. with respect to the environmental temperature thereby preventing the formation of high temperature points. Furthermore, the holes can reduced the electrical current required.

Owner:TOP BOUND ENTERPRISE

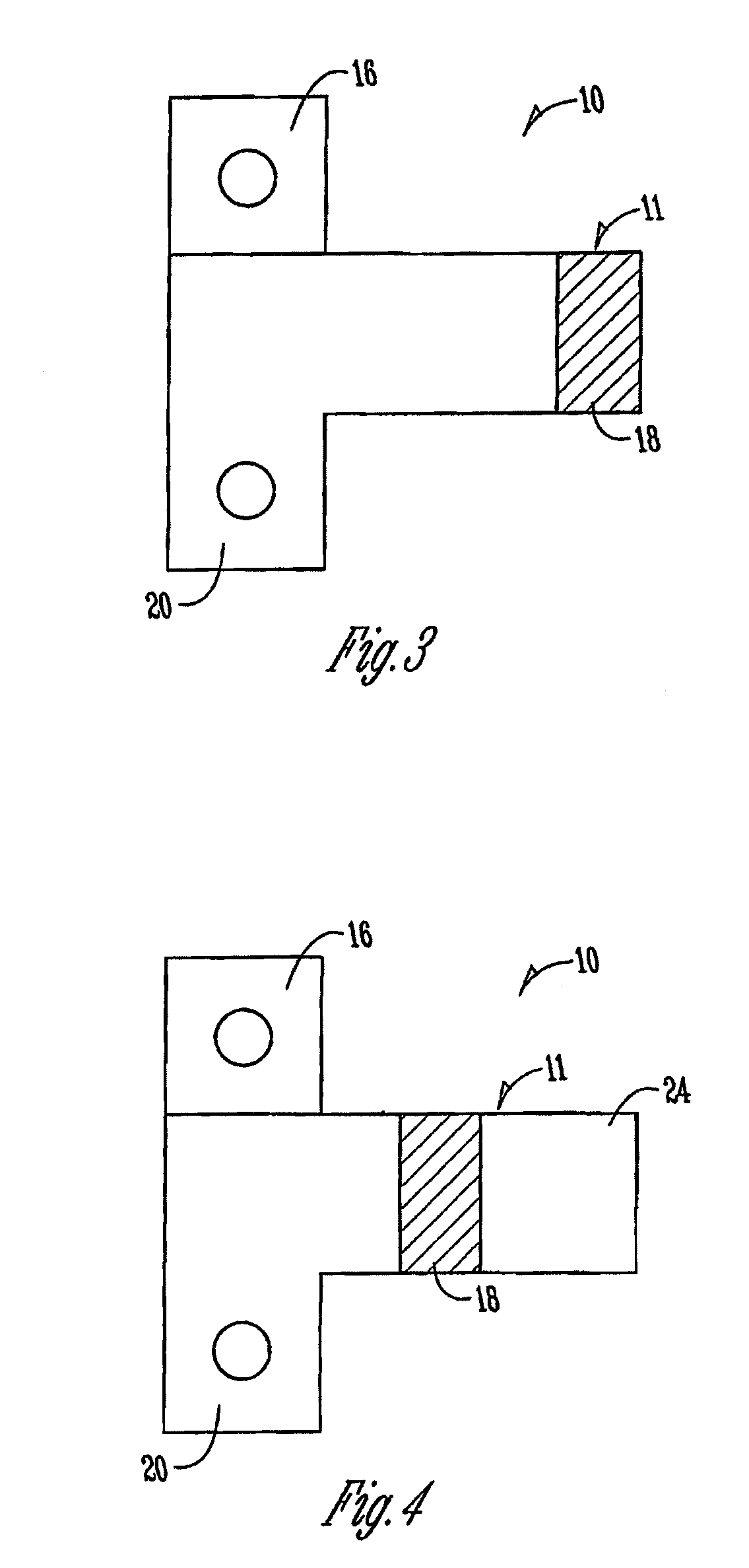

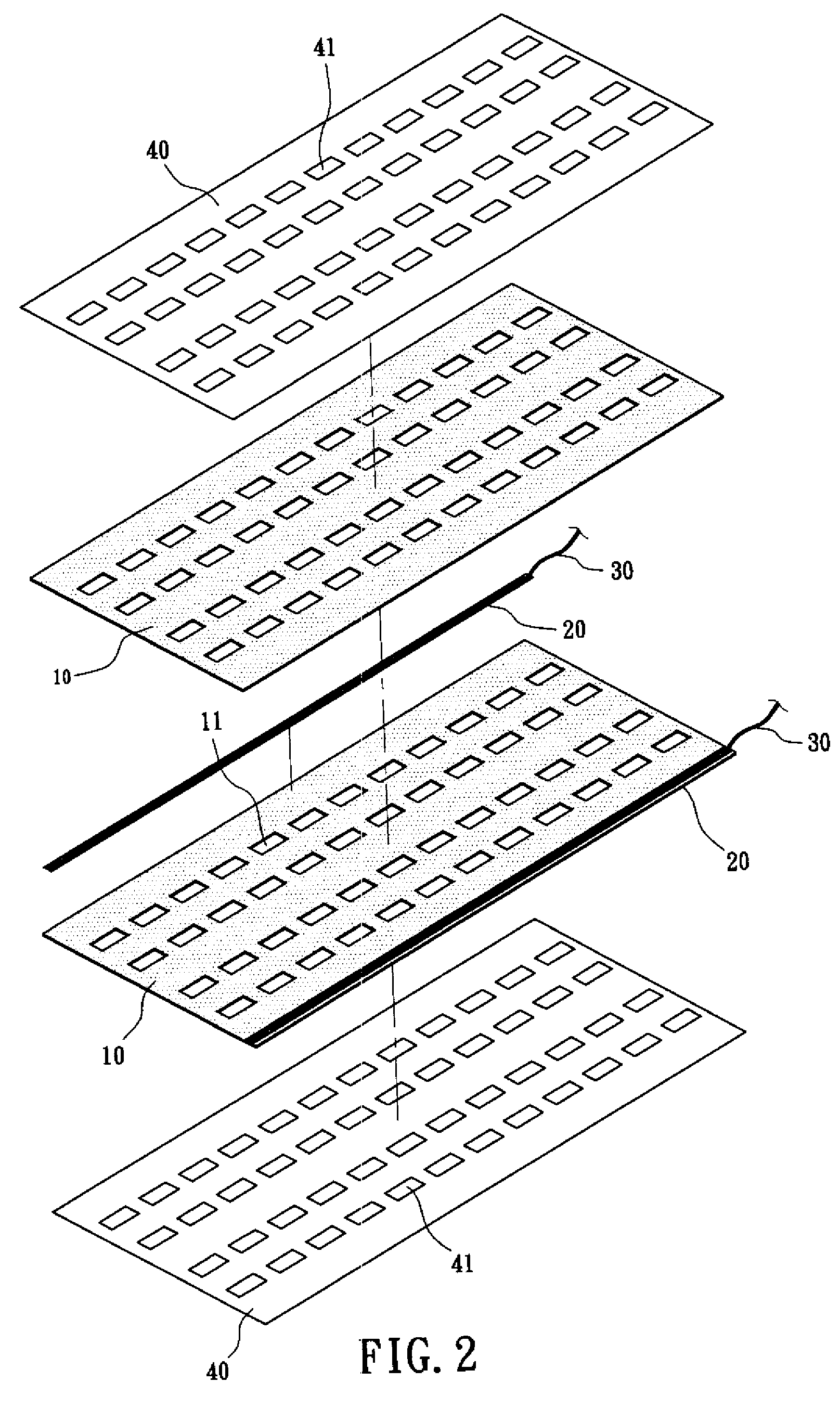

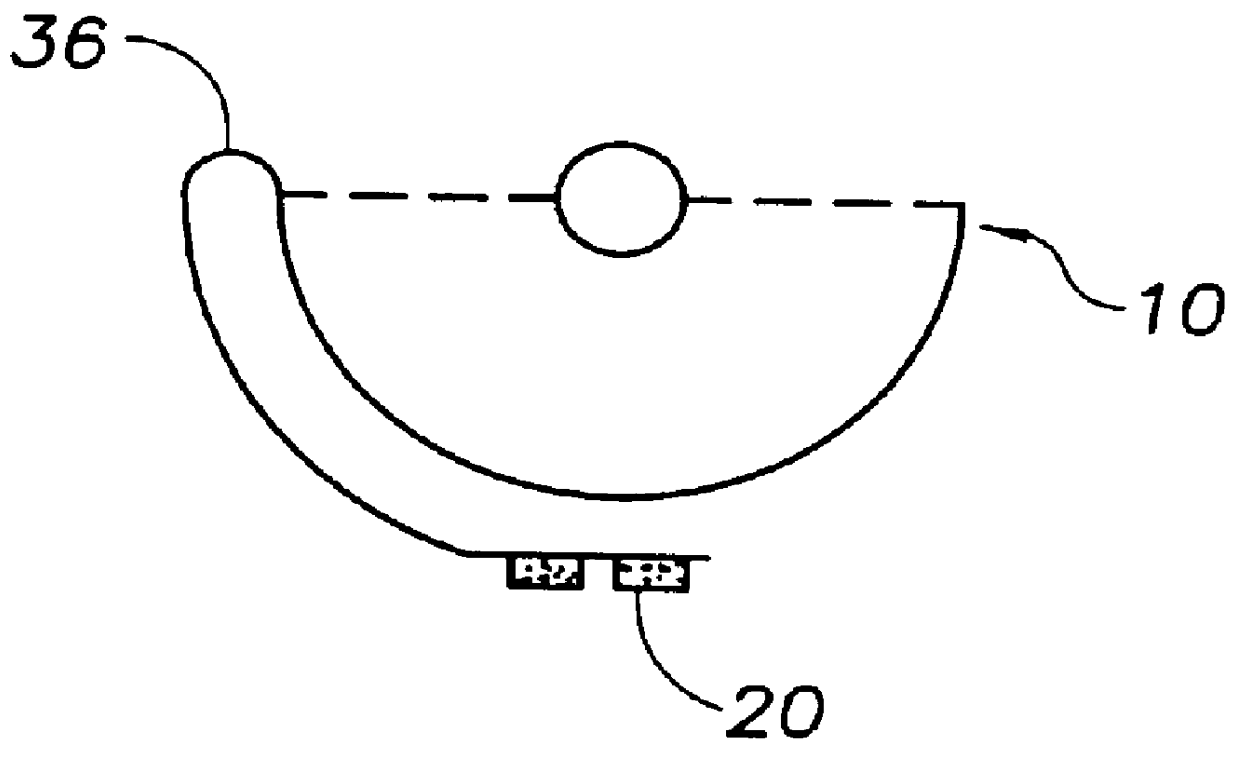

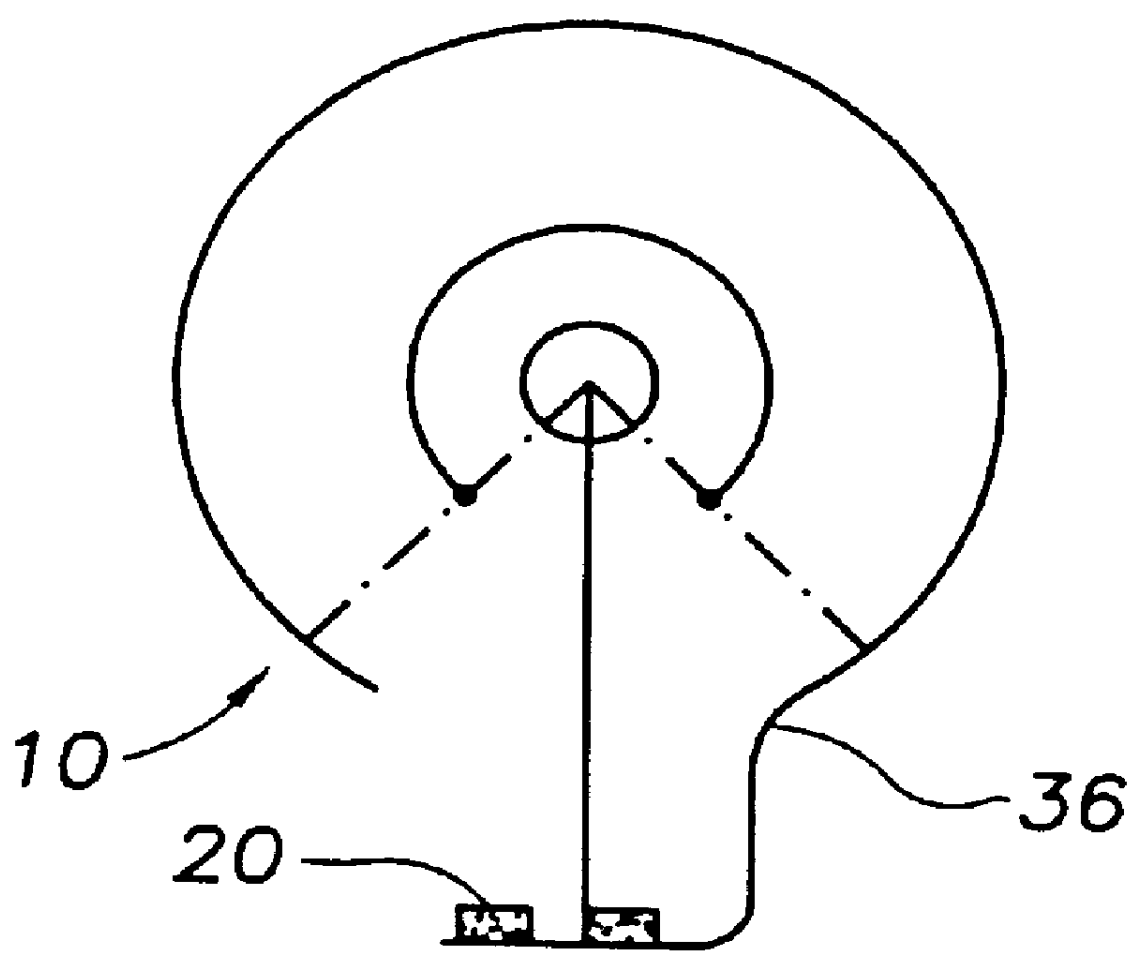

Heater for aircraft potable water tank

InactiveUS7277628B2Eliminates “cold-flows”Impairs handlingHeater elementsResistor cooling/heating/ventillationPotable waterMoisture

A heater (10) for installation on a potable water tank (12). The heater (10) comprises a blanket (14) including an electrical resistance heating element (16) and a connection pad (18) for electrically connecting the heating element (16) to lead lines (20) to an aircraft power source (22). The water tank (12) is typically positioned under the cabin floor or other locations on an aircraft which are susceptible to cold temperatures, moisture invasion, and pressure drops / rises caused by changing altitudes. The heater (10) maintains the tank (12) at an acceptable temperature range and prevents freezing of the water.

Owner:THE BF GOODRICH CO

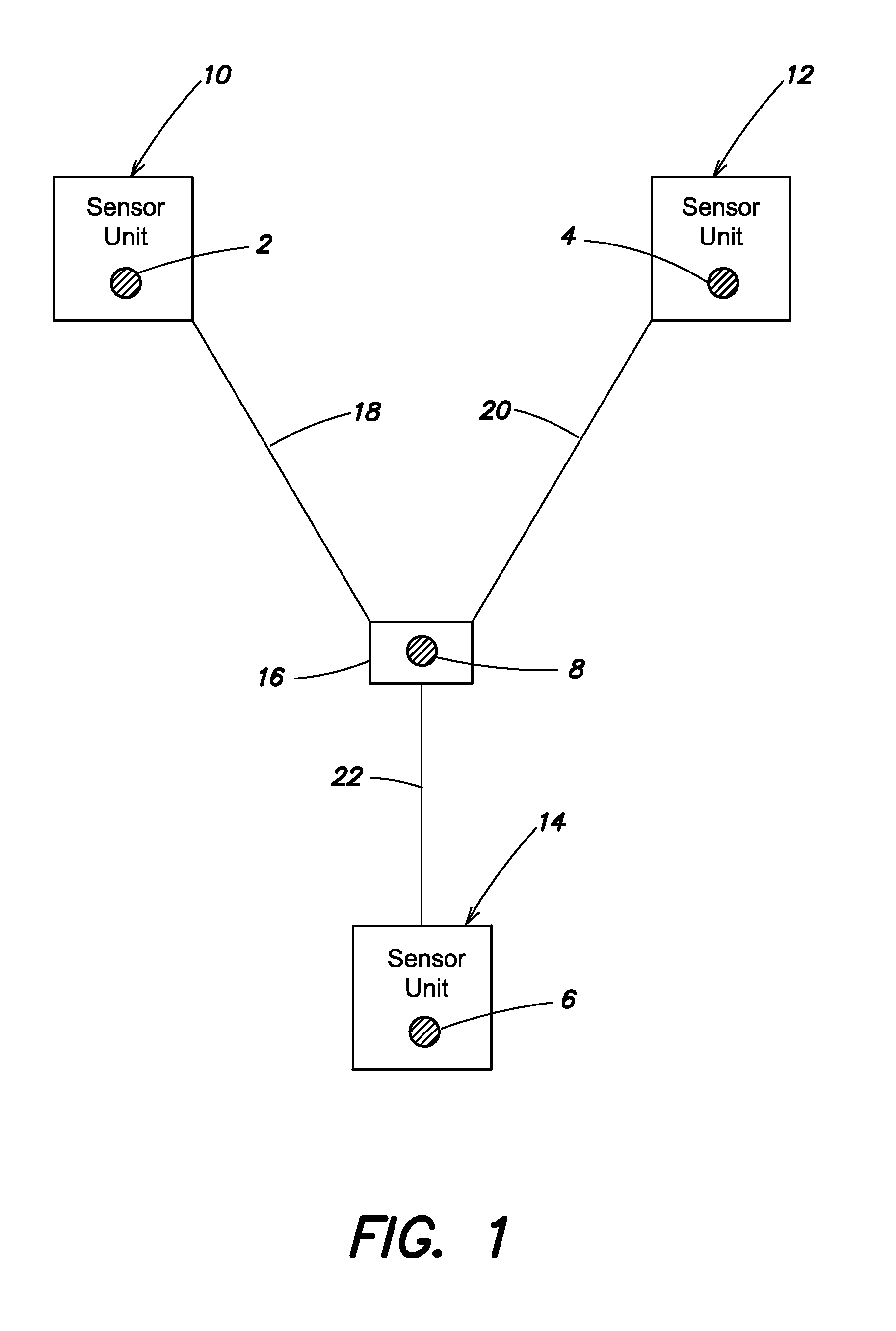

Power line voltage measurement using a distributed resistance conductor

InactiveUS20130134998A1Easy to manageAccurately electrical propertyResistance/reactance/impedenceElectrical measurement instrument detailsElectrical resistance and conductanceElectrical conductor

A system for measuring electrical properties of a power line comprising a first wire and a second wire. The system comprises a sensor unit configured for connection to the first wire; and an elongated resistive element comprising a first end configured for connection to the sensor unit and a second end configured for connection to the second wire, the elongated resistive element having a distributed resistance. The first wire may be a hot wire and the second wire may be a hot wire or a neutral wire.

Owner:TOLLGRADE COMM INC

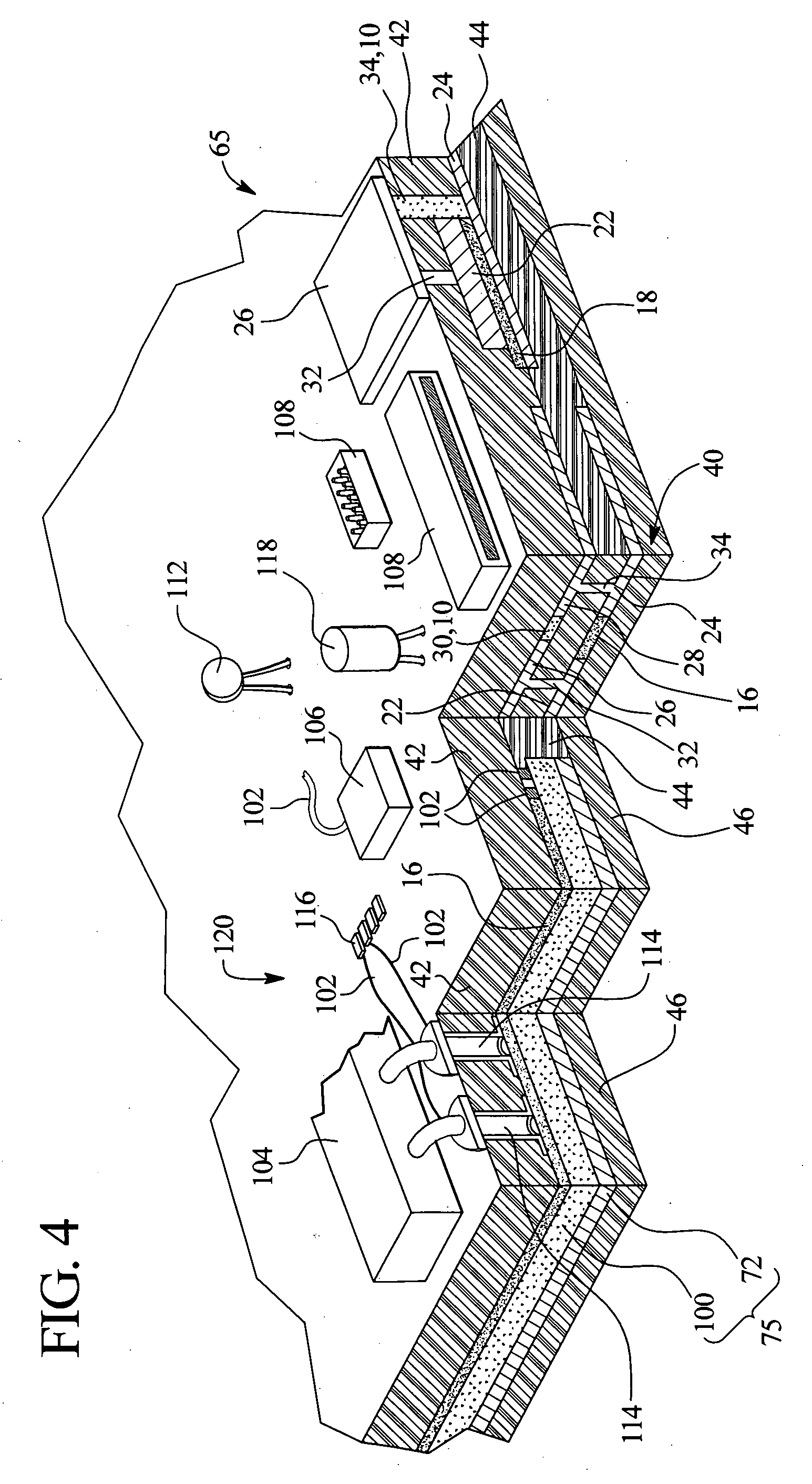

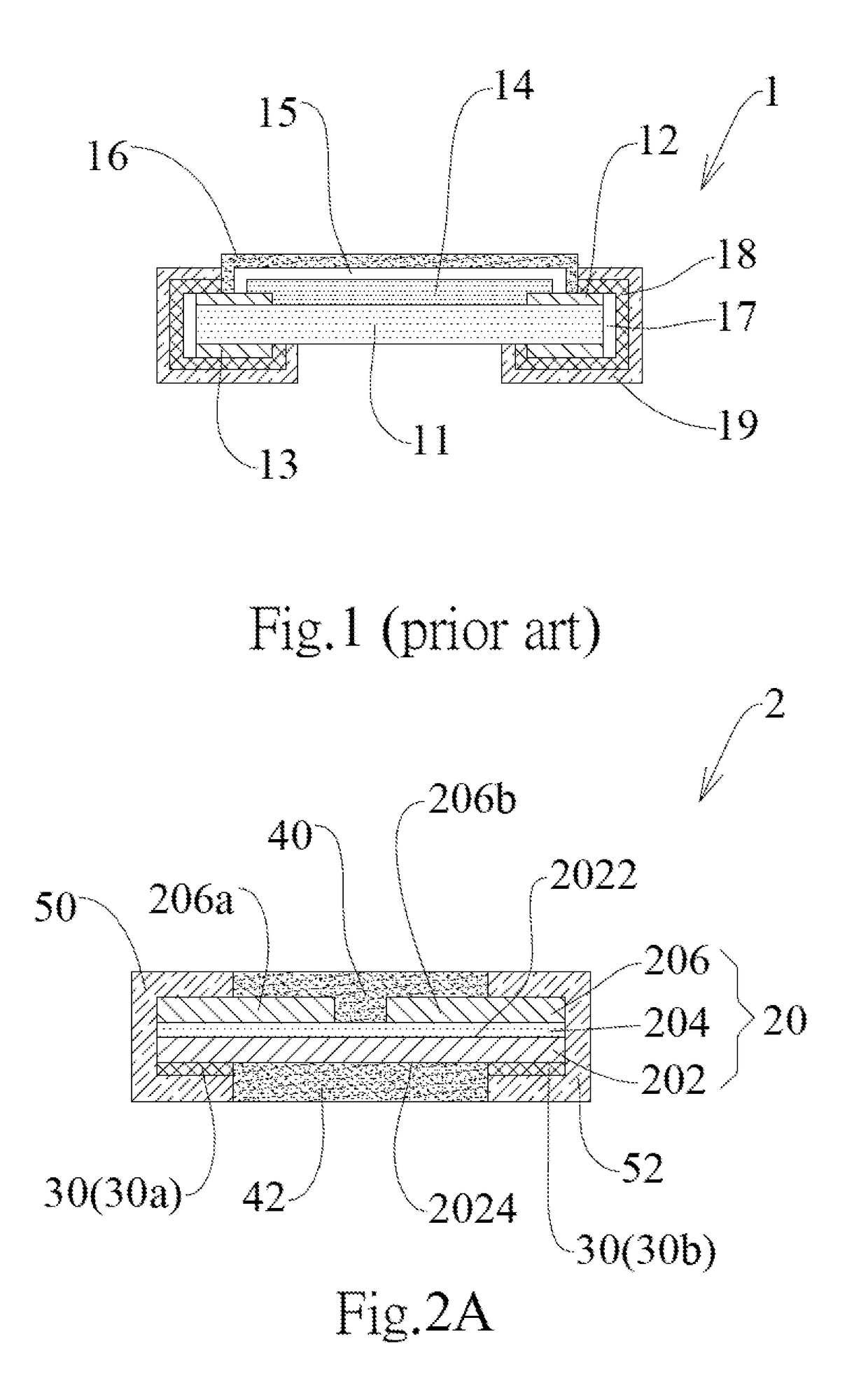

Micro-resistance structure with high bending strength, manufacturing method and semi-finished structure thereof

ActiveUS9728306B2Improve bending strengthImprove bending performanceEnvelope/housing resistor manufactureFlexible/folding resistorsFlexural strengthWork in process

Owner:VIKING TECH CORP

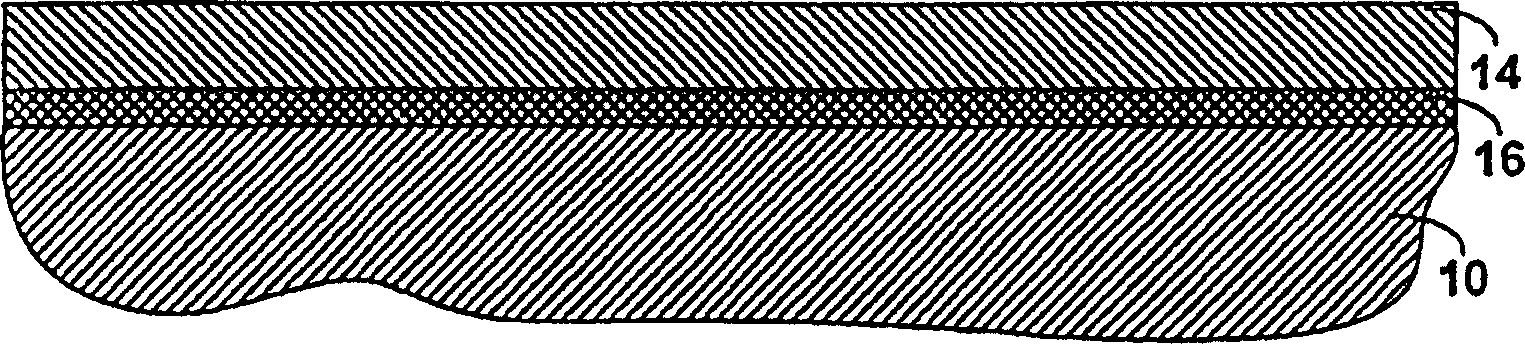

Techniques for fabricating a resistor on a flexible base material

InactiveCN1695209AInsulating substrate metal adhesion improvementPrinted circuit aspectsPolyimide substrateCarbide

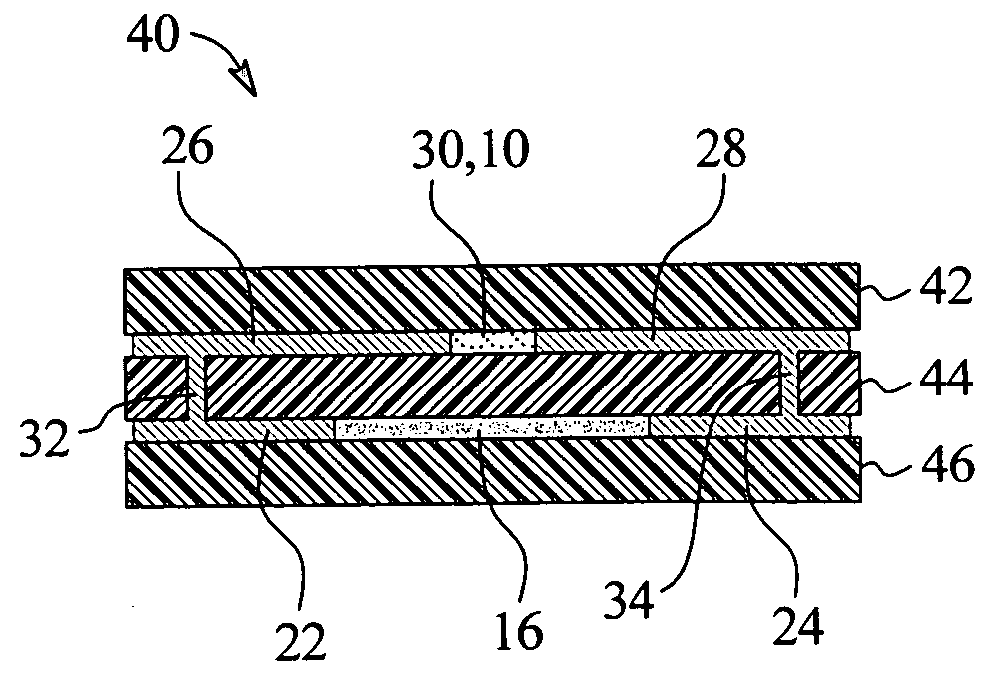

A technique for fabricating a resistor on a flexible substrate (10) (28). Specifically, at least a portion of a polyimide substrate (10) (28) is activated by exposure to a ion sputter etch techniques. A metal layer (14) (36) is depositing over the activated portion (12) (34) of the substrate (10) (28), thereby resulting in the formation of a highly resistive metal-carbide region (16) (38). Interconnect layers (18, 20) (40, 42) are deposited over the metal-carbide region (16) (38) and patterned to form terminals (24, 26) (44, 46) at opposite ends of the metal carbide region (l6) (38). The metal-carbide region (16) (38) is patterned to form a resistor between the terminals. Alternatively, only a selected area of the polyimide substrate (10) (28) is activated. The selected area forms the area in which the metal-carbide region (16) (38) is formed. Interconnect layers (18, 20) (40, 42) are disposed over the metal-carbide region (16) (38) and patterned to form terminals (24, 26) (44, 46) at opposite ends of the metal-carbide region (16) (38).

Owner:GENERAL ELECTRIC CO

Power Semiconductor Module

ActiveUS20080192437A1Reduce surge voltageSemiconductor/solid-state device detailsSolid-state devicesSurge voltageCapacitor

A power semiconductor element and a capacitor have their electrodes joined to each other in a module. The power semiconductor element is formed on a semiconductor substrate having first and second main surfaces. A power semiconductor module includes an electrode through which a main current flows, joined to the first main surface, an electrode through which the main current flows, joined to the second main surface, and a resin portion sealing the semiconductor substrate, the capacitor and the electrodes. The capacitor includes electrodes. The electrode of the capacitor and the electrode of the semiconductor element are joined to each other by solder such that surfaces exposed through the resin portion are arranged on one continuous surface on which a cooler can be attached. Therefore, a power semiconductor module can be provided in which the capacitor and the power semiconductor element can effectively be cooled and the surge voltage can be reduced.

Owner:TOYOTA JIDOSHA KK

Heater member for chair and method for producing the same

A heater member for a chair, of which the dimension as measured in the width direction is not constant, includes a fabric of a weft knitting structure having a plurality of conductive threads woven into the fabric as a part of constituent yarn. Each of the conductive threads has substantially the same length.

Owner:TOYOTA BOSHOKU KK

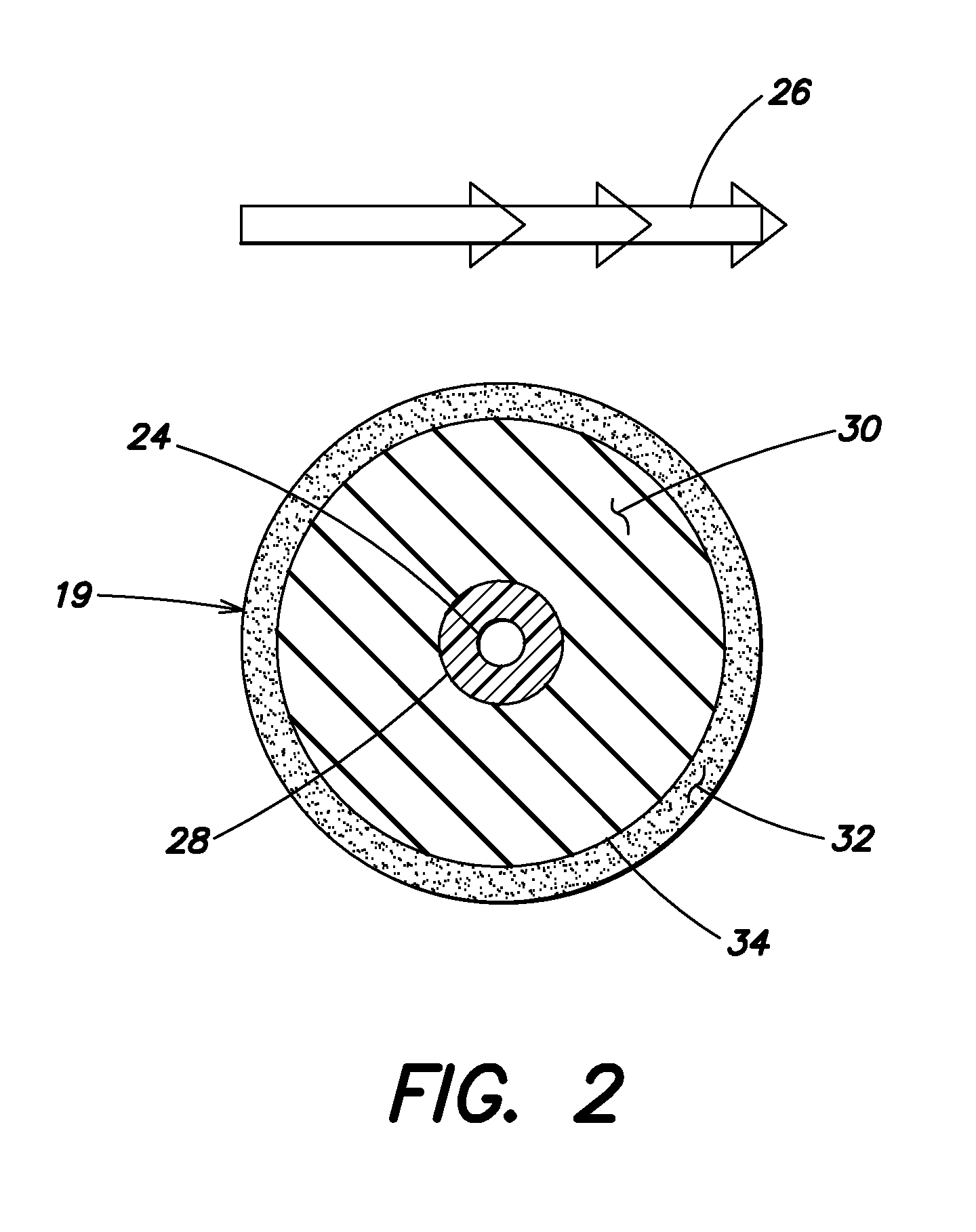

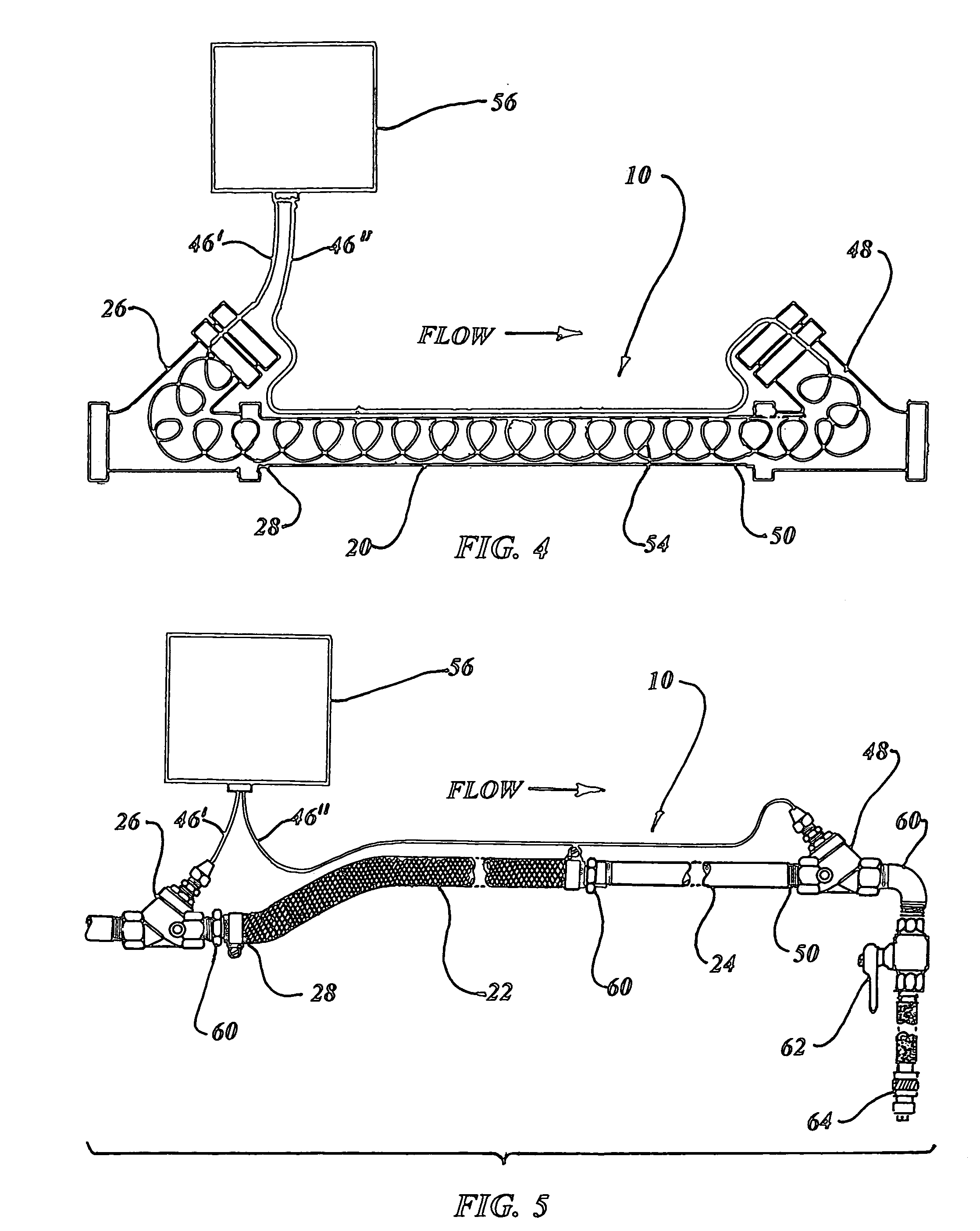

In-pipe heat trace system

ActiveUS7449661B1Eliminates broken and damaged heating elementEasy can be approvedHelicopter landing platformHeater elementsLow voltageAirplane

A heat trace system (10) is used for heating water to prevent freezing in a conduit (20) while servicing an aircraft positioned at a passenger loading bridge (52). An upstream fitting (26) is attached onto the conduit adjacent to a building structure and a downstream fitting (48) is attached onto the conduit adjacent to the cab of the passenger loading bridge. A coated retractable coiled wire disposed within the conduit and cold lead wires (46) enter through the upstream fitting and leave through the downstream fitting. A low voltage solid state power control box (56) is in communication with the cold lead attached to the coiled wire inside providing regulated electrical energy for heating the coiled wire thus preventing freezing the water within in the conduit.

Owner:BENCH STEVEN D

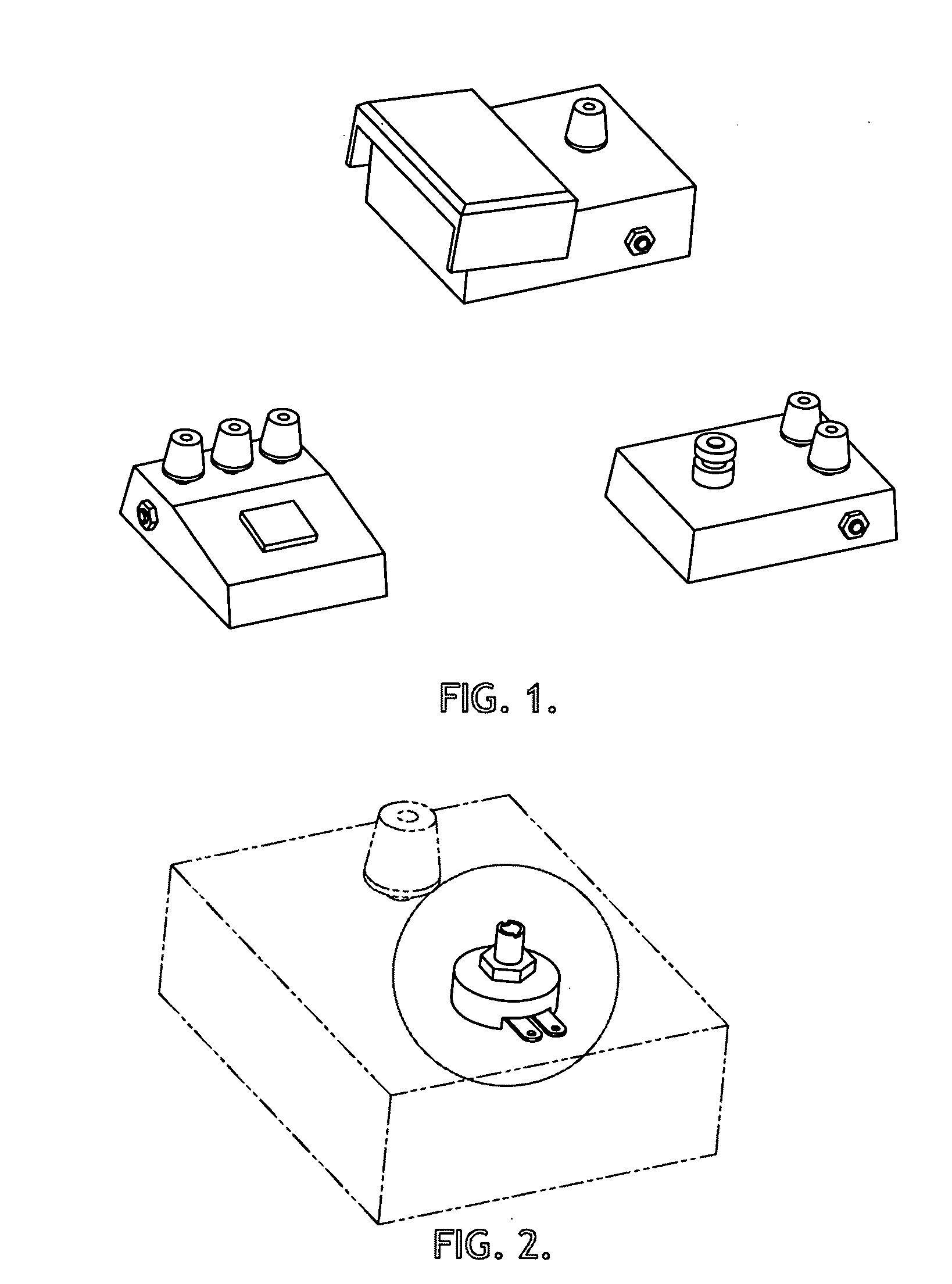

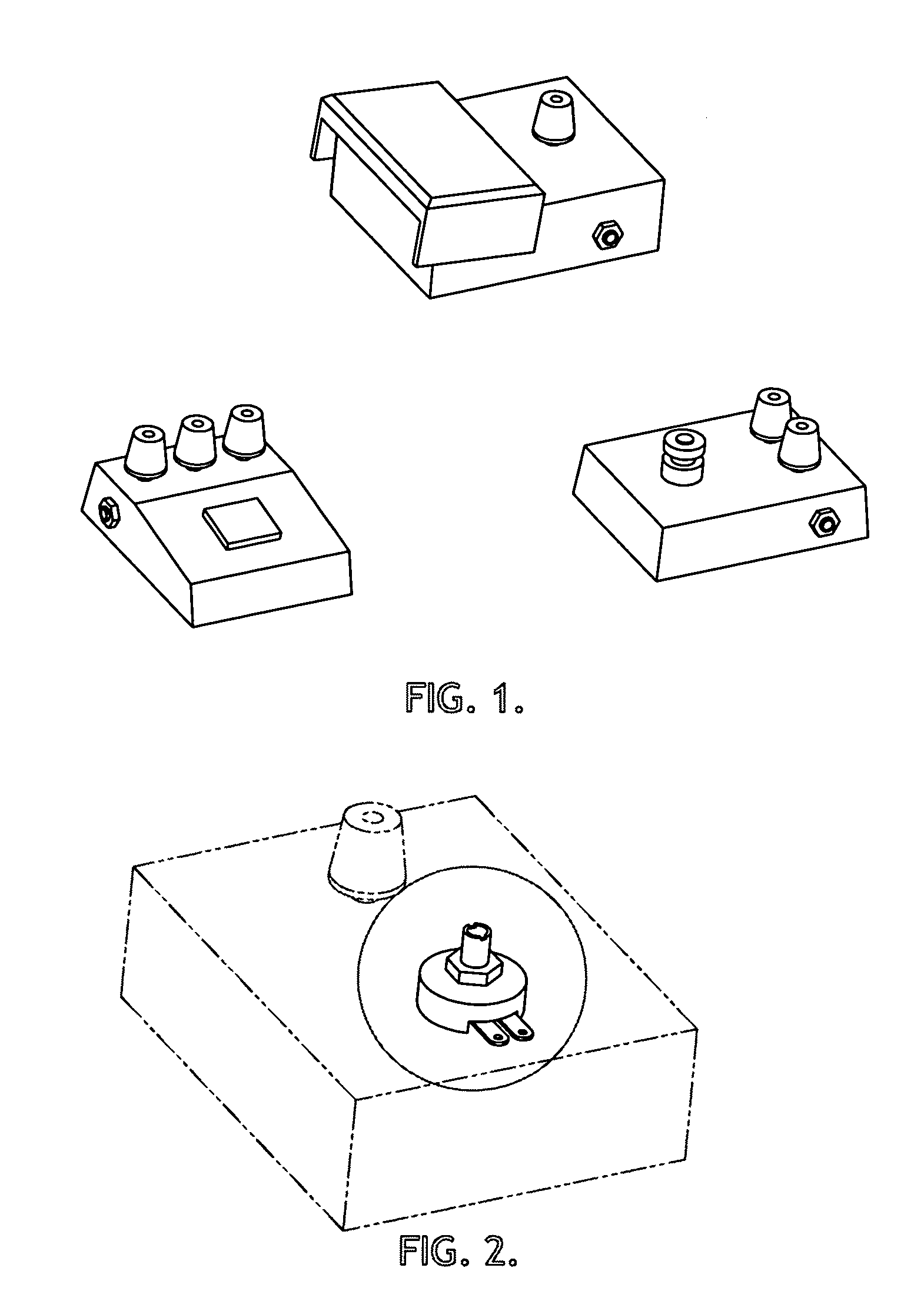

Remote controller for rotary potentiometer

InactiveUS20070176729A1Current collector arrangementsResistors adjusted by auxillary driving meansUniversal jointDrive shaft

Device for remote operation of rotary potentiometers consisting of a mounting bracket 10 supporting a flexible drive shaft 24 which has affixed to its supported end a control knob 2 and at its unsupported end a universal joint 26 which houses a thumb-screw 30 for capture of a rotary potentiometer shaft. Thus allowing the user to operate floor-mounted effects devices from a more natural standing position during a musical performances, rather than having to crouch down during said performance.

Owner:GOLDEN MARY ELIZABETH

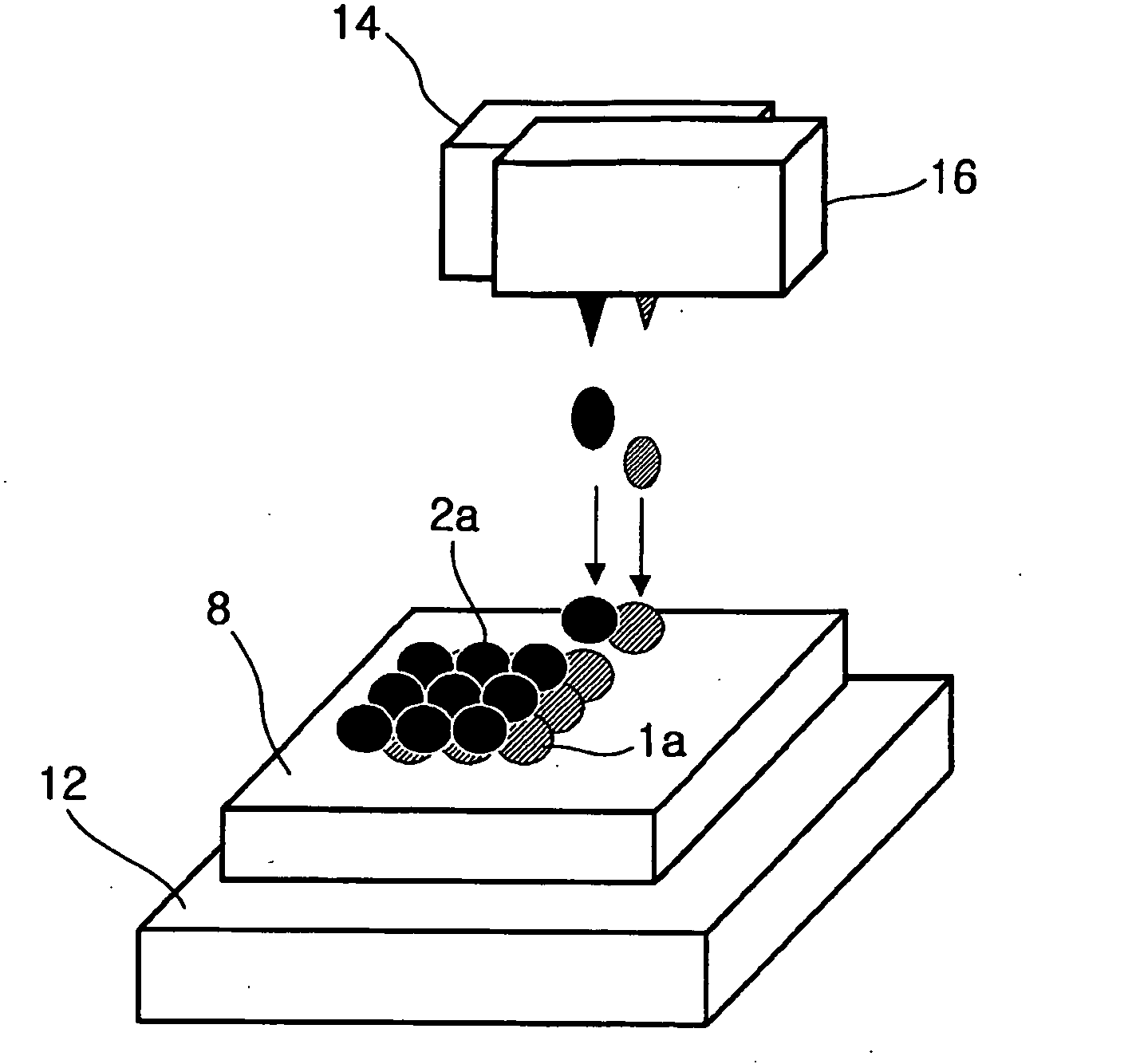

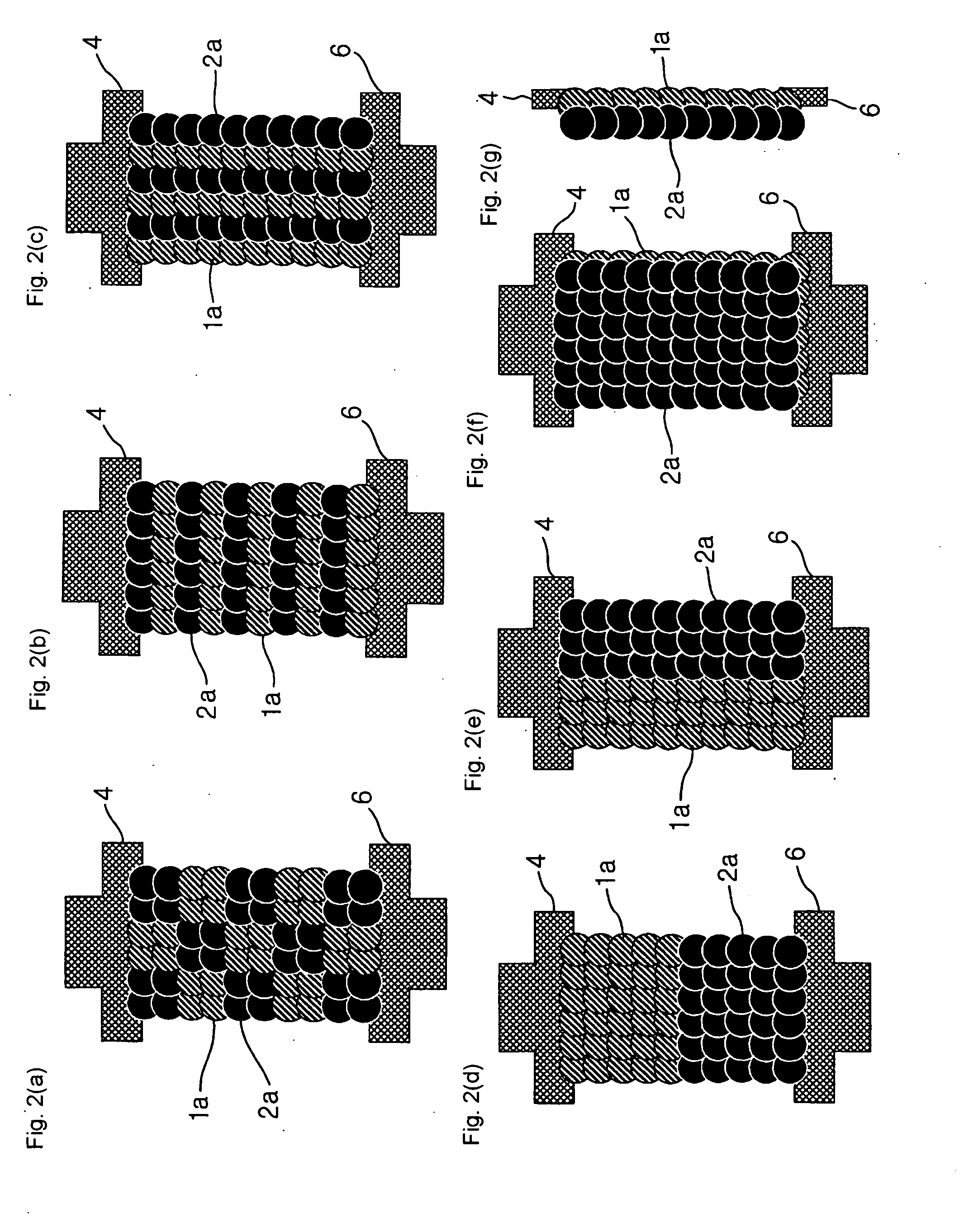

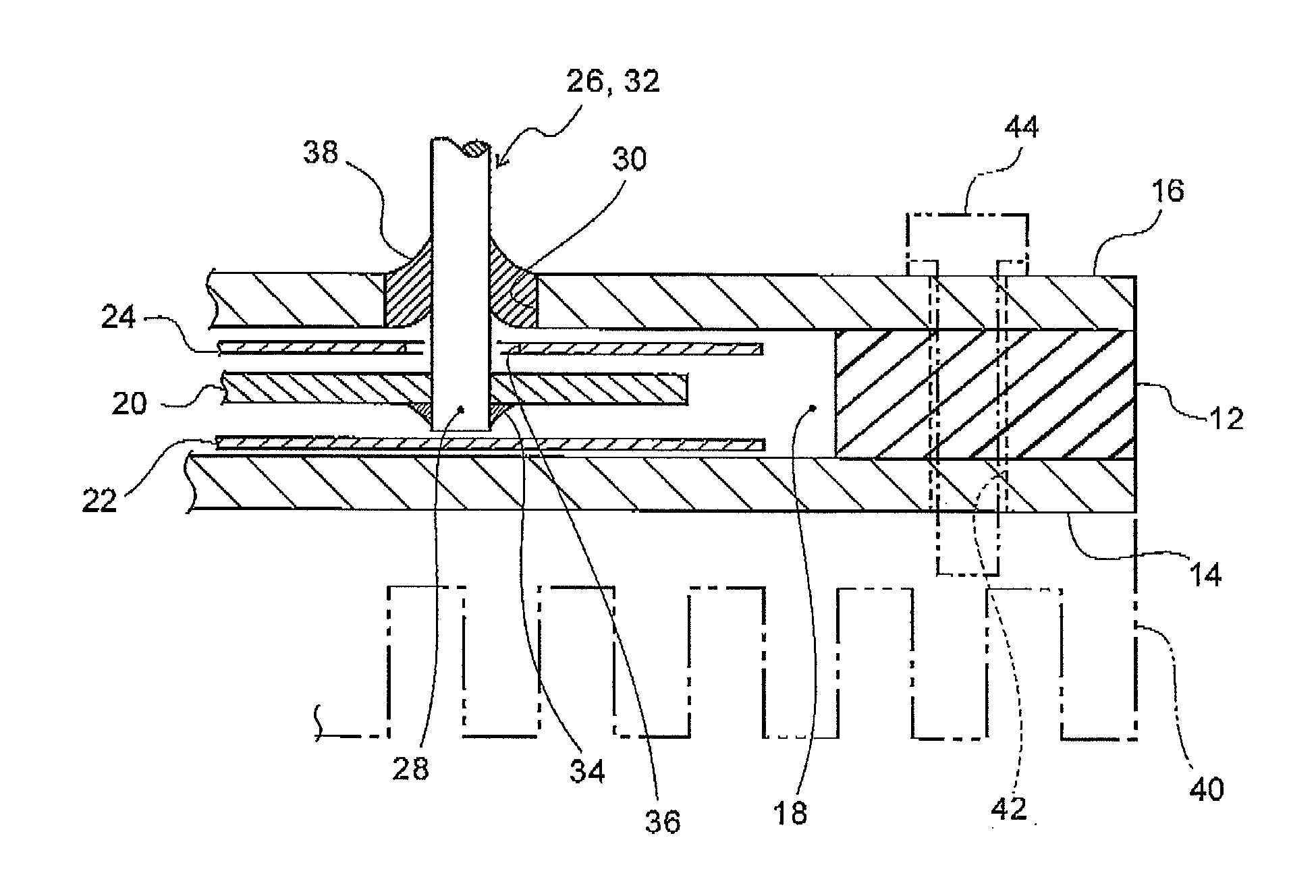

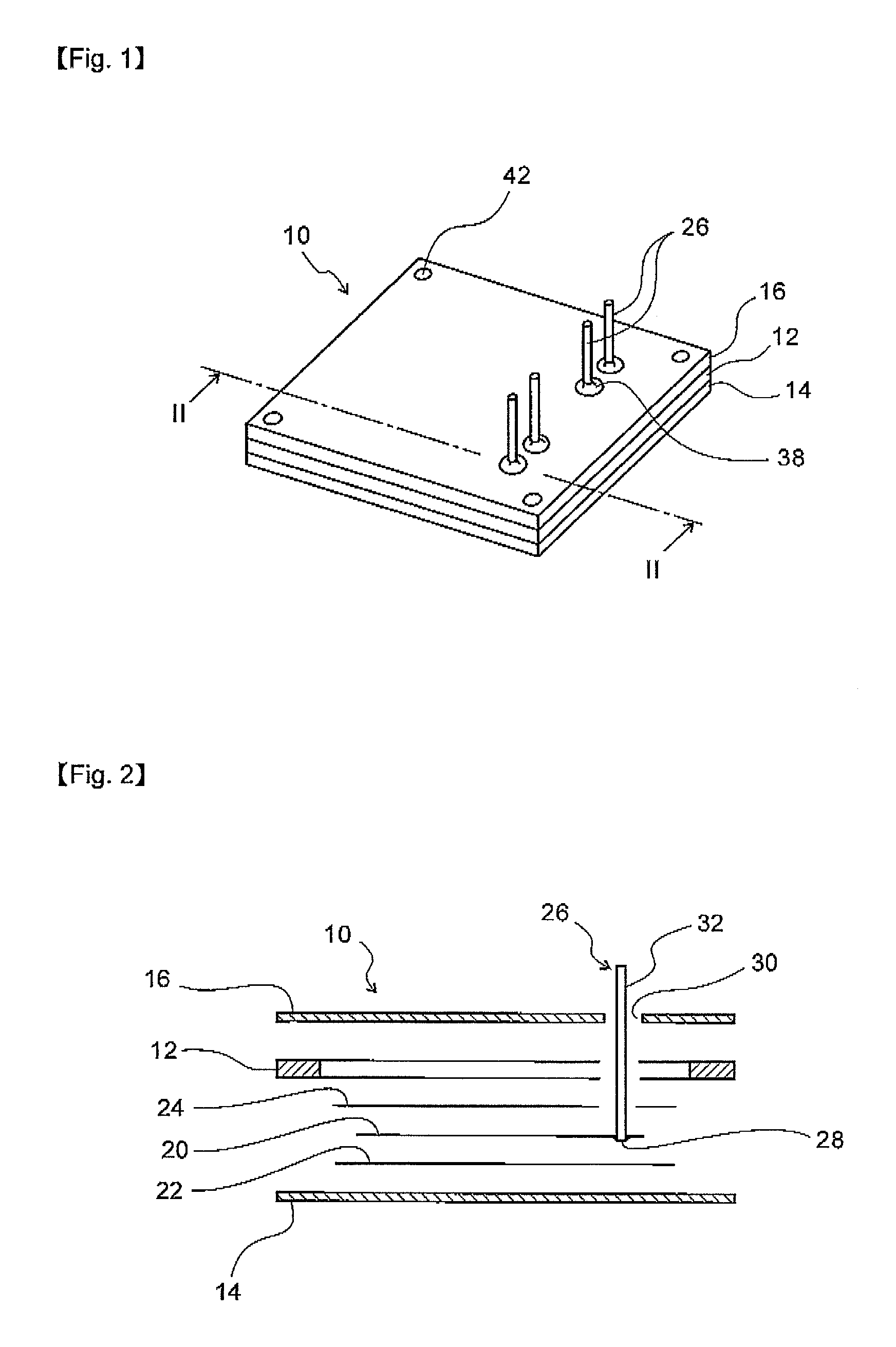

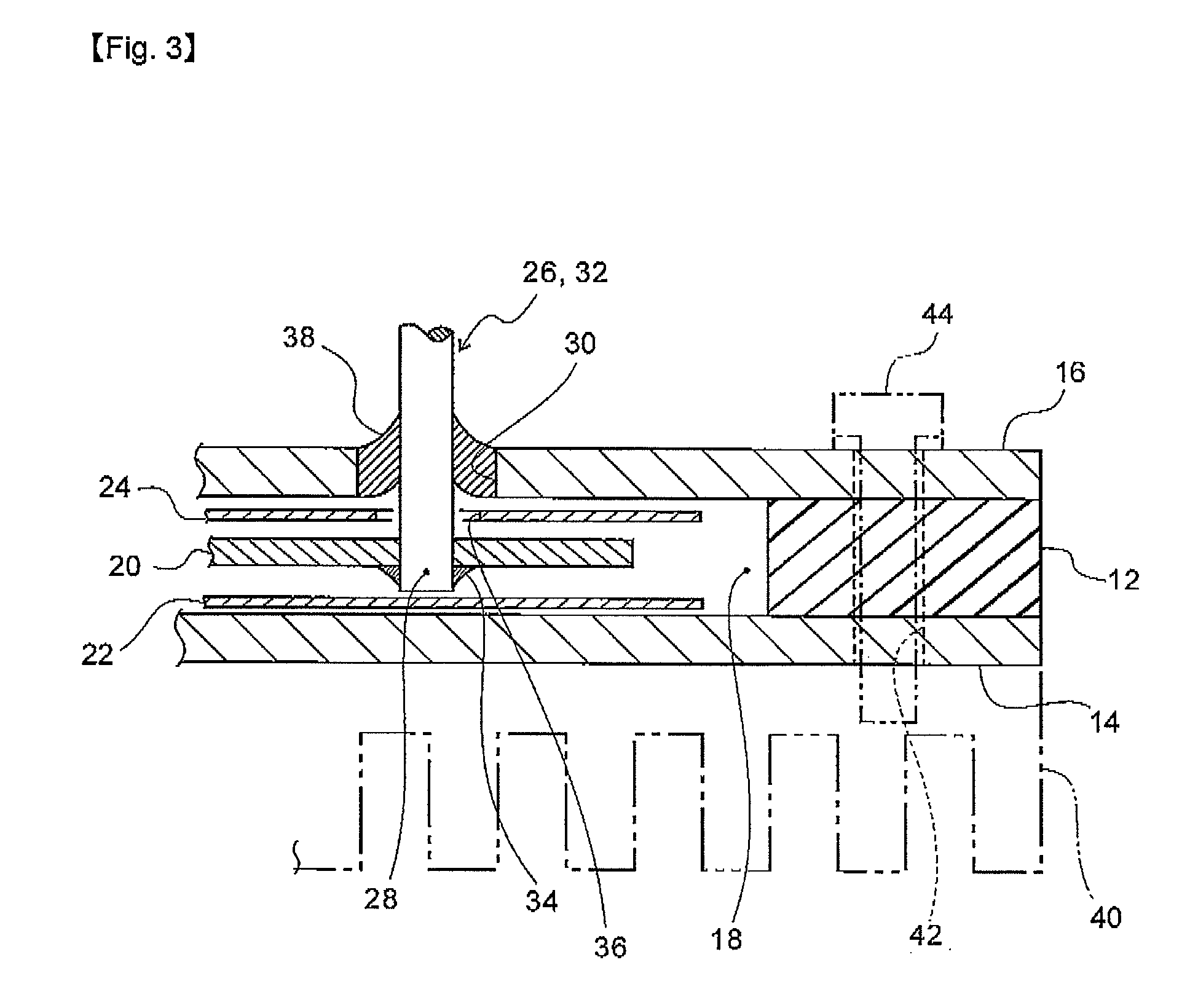

Electronic component and method for manufacturing the same

ActiveUS7595716B2Efficient productionFlexible/folding resistorsResistor detailsElectronic componentElectron

To provide an electronic component including a resistor element that can be efficiently produced with a range of resistances, and a method for manufacturing the electronic component, the electronic component includes a pair of terminals, and a resistor element disposed between the terminals. The resistor element includes at least two resistive portions (hereinafter referred to as a first resistive portion and a second resistive portion) that are continuously disposed. The first resistive portion includes a plurality of first dots overlapping one another. The second resistive portion includes a plurality of second dots having a different electric resistance from that of the first dots overlapping one another.

Owner:MURATA MFG CO LTD

Manually operable position sensor

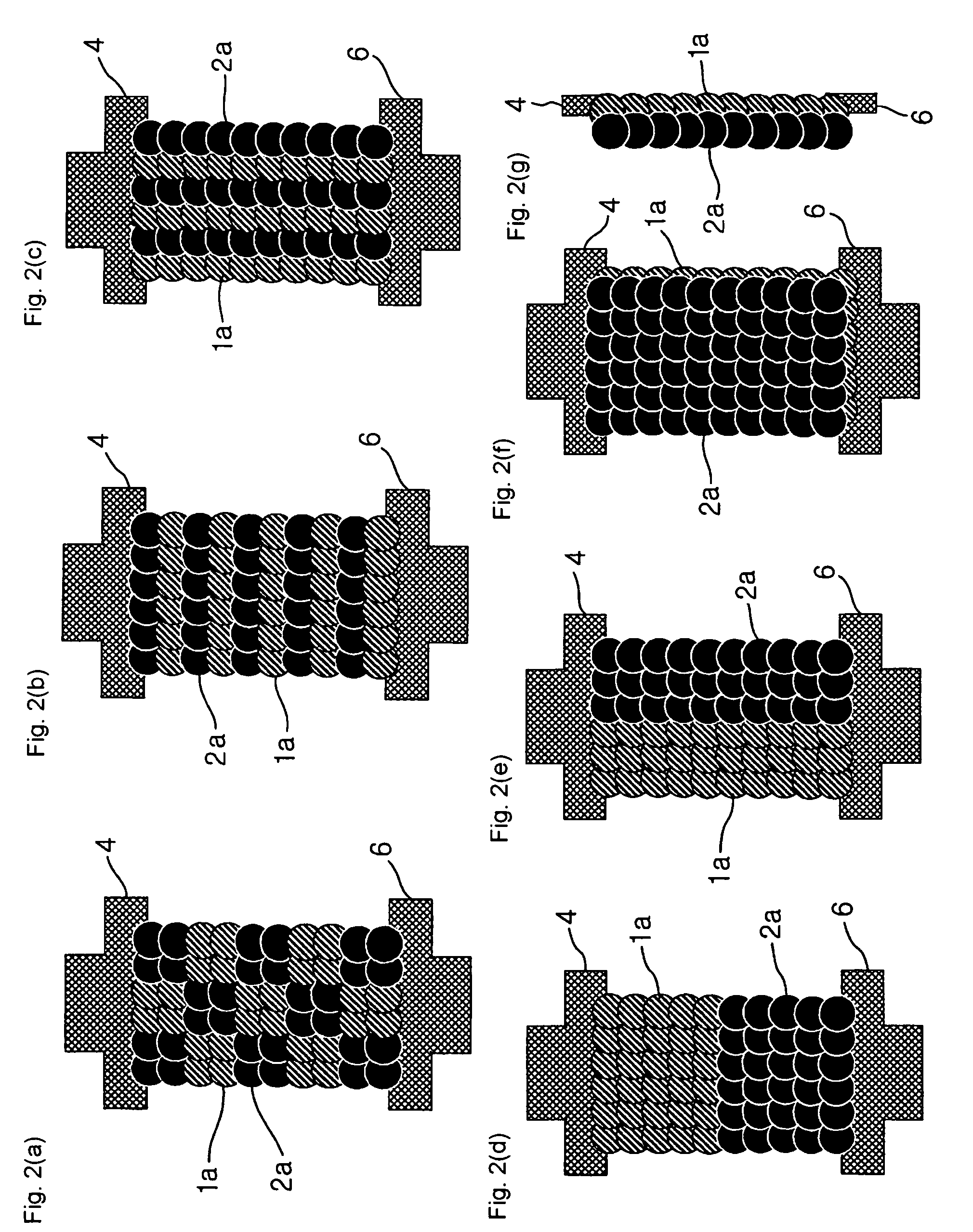

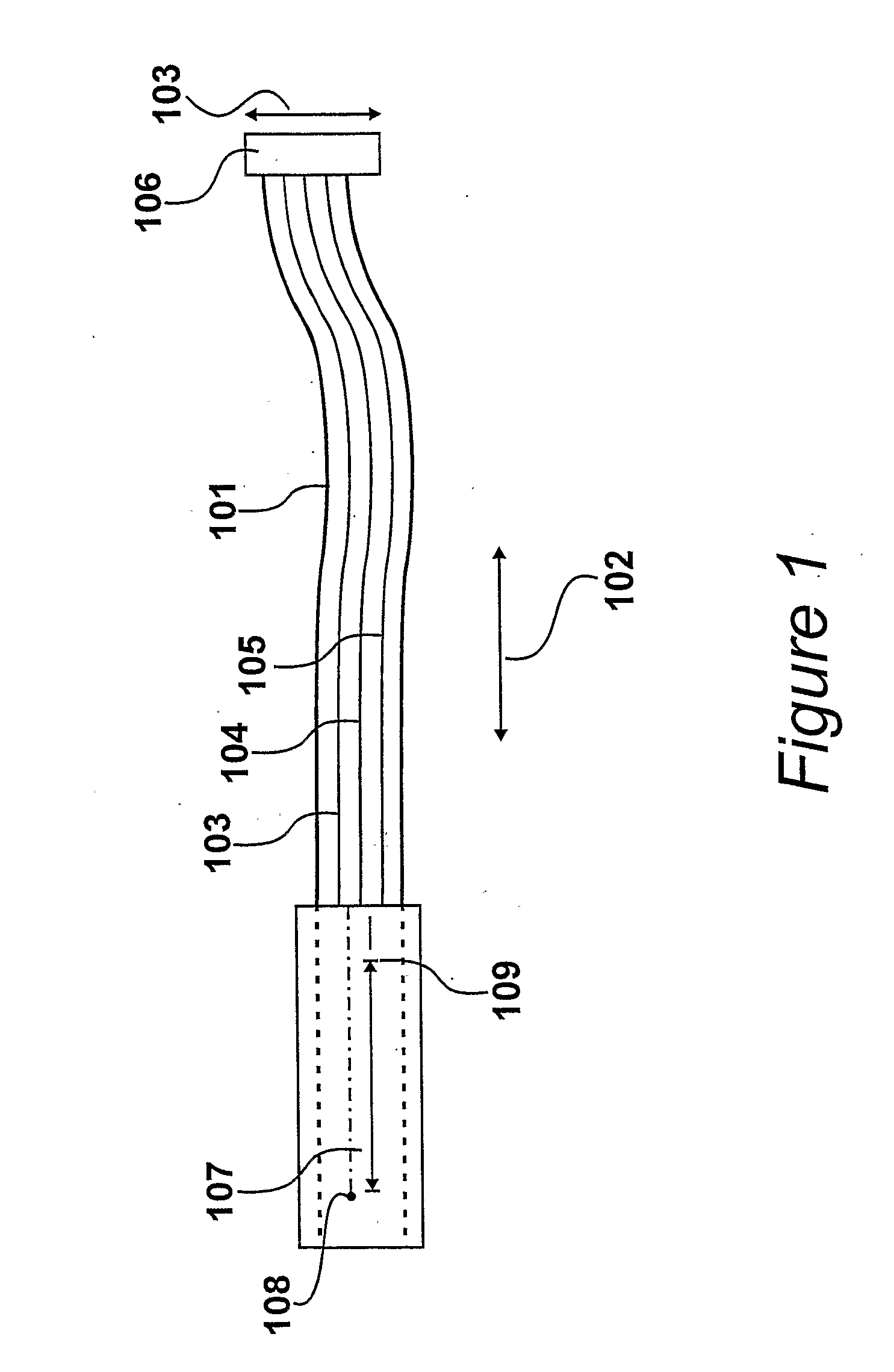

A manually operable position sensor is shown, for providing control signals to an electronic device, such as an audio player. A fabric ribbon (101) has a length substantially longer than its width with insulating yarns and electrically conducting yarns included therein. The conducting yarns define three conductive tracks (103, 104, 105) running the length of the fabric. The conductive tracks are configured to interface with an electronic device at a first end. At a second end, an active region of the fabric forms part of a sensor assembly that is receptive to a manually applied pressure.

Owner:WEARABLE TECH LTD

Resistive current limiter

InactiveUS7760067B2Superconductors/hyperconductorsMagnetic/electric field switchesElectrical resistance and conductanceElectrical conductor

Owner:THEVA DUENNSCHICHTTECHN

Belt type large-power resistor

InactiveCN104091662AEasy to assembleIncrease productivityFlexible/folding resistorsElectrical resistance and conductanceEngineering

The invention relates to a belt type large-power resistor. The belt type large-power resistor comprises a left bracket and a right bracket which are located at the left and right sides, wherein a plurality of resistor belts are arranged between the left bracket and the right bracket. The belt type large-power resistor is characterized in that each resistor belt is formed by wholly bending a stainless steel belt; a ceramic part with a bayonet is arranged between the adjacent two layers of resistor belts; the adjacent two layers of resistor belts are respectively fixedly arranged on an opening of the corresponding ceramic part; the corresponding two layers of resistor belts are insulated by the ceramic part and a screw rod is arranged in each ceramic part in a penetrating manner; the two ends of the screw rods are respectively connected and fixed with the left bracket and the right bracket. Compared with the prior art, the belt type large-power resistor has the following beneficial effects of safe and reliable product performances, large capacity, high electric conductivity, strong flow capacity, high temperature resistance, stable resistance value, corrosion resistance, long service life and simple structure; the belt type large-power resistor is convenient to combine and can be combined into a resistor with larger power.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

Position sensor cord, position sensor and planar position sensor

ActiveUS8395474B2Increase freedomLengthy structureFlexible/folding resistorsResistors adjusted by mechanical pressure/forcePosition sensorElectrical contacts

A position sensor cord includes a hollow insulator formed of a restorable rubber or a restorable plastic, and two linear resistive members. Each of the two linear resistive members includes a linear insulator and a conductive layer provided around a circumference of the linear insulator. The conductive layer is formed of a conductive rubber or a conductive plastic. The two linear resistive members are arranged in no electrical contact with each other and along an inner surface of the hollow insulator. One of the two linear resistive members may be replaced with one linear conductive member.

Owner:HITACHI CABLE

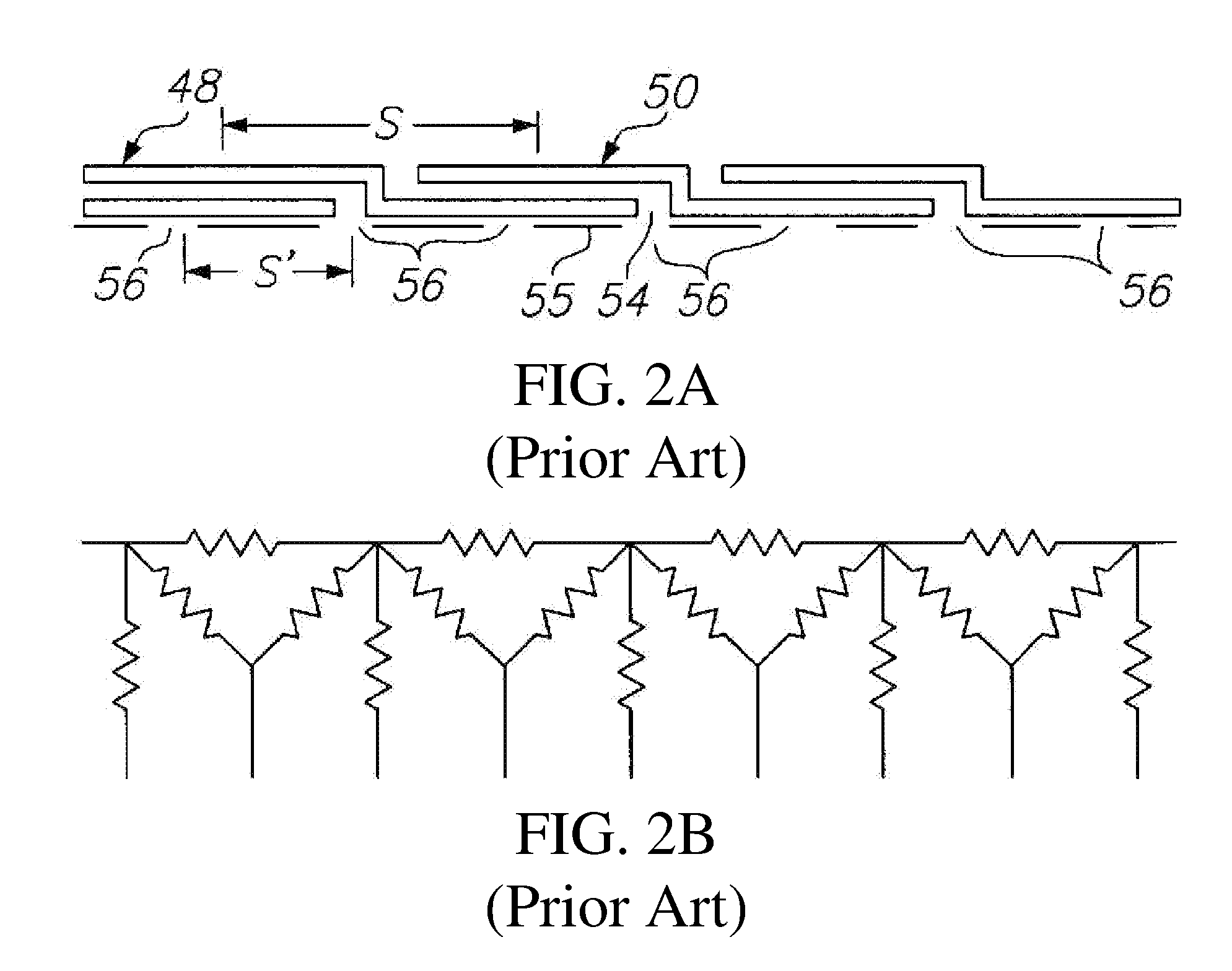

Touch panel with discontinuous chain of resistances

ActiveUS20100214263A1Improve linear accuracyImprove accuracyFlexible/folding resistorsInput/output processes for data processingElectrical resistance and conductanceVoltage drop

The disclosure is related to a touch panel with discontinuous chain of resistances. It is formed by an internal series of electrodes of the conducting layer formed by a chain of discontinuous resistances. The design of the chain of discontinuous resistances can compensate for the voltage compensation by the voltage drop generated by the distance of chain of electrodes wherein the chain of discontinuous resistances is located at the interface of the series electrodes, and the length chain of discontinuous resistances is calculated by the specific equation.

Owner:HIGGSTEC

Manually operable position sensor

A manually operable position sensor is shown, for providing control signals to an electronic device, such as an audio player. A fabric ribbon (101) has a length substantially longer than its width with insulating yarns and electrically conducting yarns included therein. The conducting yarns define three conductive tracks (103, 104, 105) running the length of the fabric. The conductive tracks are configured to interface with an electronic device at a first end. At a second end, an active region of the fabric forms part of a sensor assembly that is receptive to a manually applied pressure.

Owner:WEARABLE TECH LTD

Flexible film with a non-tensioned electrical circuit mounted thereon

InactiveUS6052049AChange directionResisitors with sliding contactResistor housing/enclosing/embeddingEngineeringMechanical engineering

A flexible element for use in a rotary position sensor or the like having the direction of electrical traces on one surface of the element altered without putting the traces into tension. The directional change is accomplished by partially splitting the flexible element and continuing an electrical trace from one side of the split back along the other side. The invention makes it possible to decrease the size for a given operational angle of mechanically variable resistors without sacrificing quality or reliability.

Owner:CTS CORP ELKHART

Electronic component and method for manufacturing the same

ActiveUS20090040009A1Stable resistanceExtend the mixing timeFlexible/folding resistorsResistor detailsEngineeringElectronic component

To provide an electronic component including a resistor element that can be efficiently produced with a range of resistances, and a method for manufacturing the electronic component, the electronic component includes a pair of terminals, and a resistor element disposed between the terminals. The resistor element includes at least two resistive portions (hereinafter referred to as a first resistive portion and a second resistive portion) that are continuously disposed. The first resistive portion includes a plurality of first dots overlapping one another. The second resistive portion includes a plurality of second dots having a different electric resistance from that of the first dots overlapping one another.

Owner:MURATA MFG CO LTD

Methods for fabricating fuse elements

InactiveUS20060230606A1Reducing first electrical resistivityIncrease resistanceFuse device manufacturePrinted circuit manufactureHigh resistanceConductive materials

A method for fabricating wire fuse elements is provided. The method includes providing a continuously extending high resistance fuse wire having a first electrical resistivity. The method also includes applying a conductive material to the wire, and reducing the first electrical resistivity of the wire to a second electrical resistivity lower than the first electrical resistivity. The method also includes selectively removing a portion of the conductive material from the wire, and forming at least one high resistance portion having the first electrical resistivity wherein the conductive material is removed, and the wire having the second electrical resistivity in portions thereof wherein the conductive material remains.

Owner:COOPER TECH CO

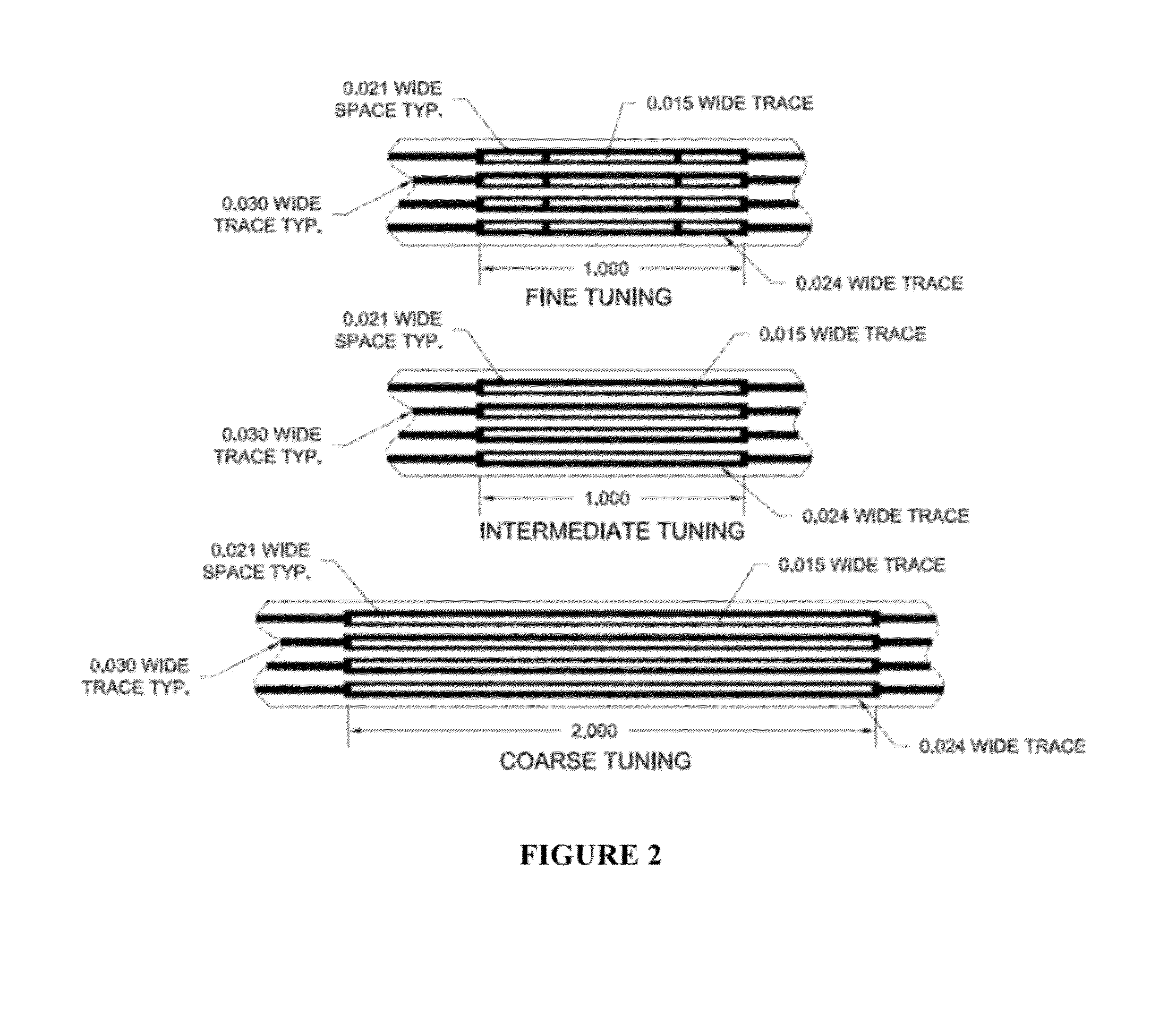

Tunable resistance conductive ink circuit

InactiveUS8686292B2Improve the immunityEnvelope/housing resistor manufacturePlastic/resin/waxes insulatorsElectrical resistance and conductanceHigh resistance

The method and system of high-resistance, multiple-conductor flat cables which contain integral tunable resistance sections suitable for fine tuning the resistance of a conductor to match the resistance of the conductors to one another within a specified target value. The method involves the design and creation of the high-resistance, multiple-conductor flat cables and the tuning of the resistance of the conductor.

Owner:MIRACO

Metal foil resistor

ActiveUS7982579B2Avoid distortionAvoid strainResistor cooling/heating/ventillationFlexible/folding resistorsElectricityMetal foil

The metal foil resistor having a metal foil resistive element 20 composed of a metal foil whereupon a resistance circuit pattern is formed. The metal foil resistor comprises: a package 10 which contains the metal foil resistive element 20 in an electrically insulated state so that the resistive element can be expandable and contractible in a spreading direction of the metal foil; and a relay terminal 26 which is held in the package 10 in the electrically insulated state and is connected to an electrode 20a of the metal foil resistive element 20. A temperature coefficient of resistance can be reduced and stabilized. Control factors can be reduced to increase degrees in freedom in designing. Further, an external stress applied to a package is prevented from transmitting to the metal foil resistive element, and therefore the package can be easily attached to a discretionary heat sink.

Owner:ALPHA ELECTRONICS

Electrical connection for a resistor element made of electrically-conductive fibers

ActiveUS7064302B2Line/current collector detailsElectrically conductive connectionsFiberElectrical connection

A connection endpiece placed on a resistor element provided with at least one layer of electrically-conductive fibers, the endpiece serving to connect a power supply wire electrically to the resistor element. The endpiece includes at least one metal plate having a top face for connection to the power supply wire, and provided with at least one rigid metal connector member of substantially flat shape arranged at a first end of the metal plate and connected to at least one layer of electrically-conductive fibers of the resistor element, the top face of the metal plate being covered in a removable anti-adhesive covering.

Owner:EUROCOPTER

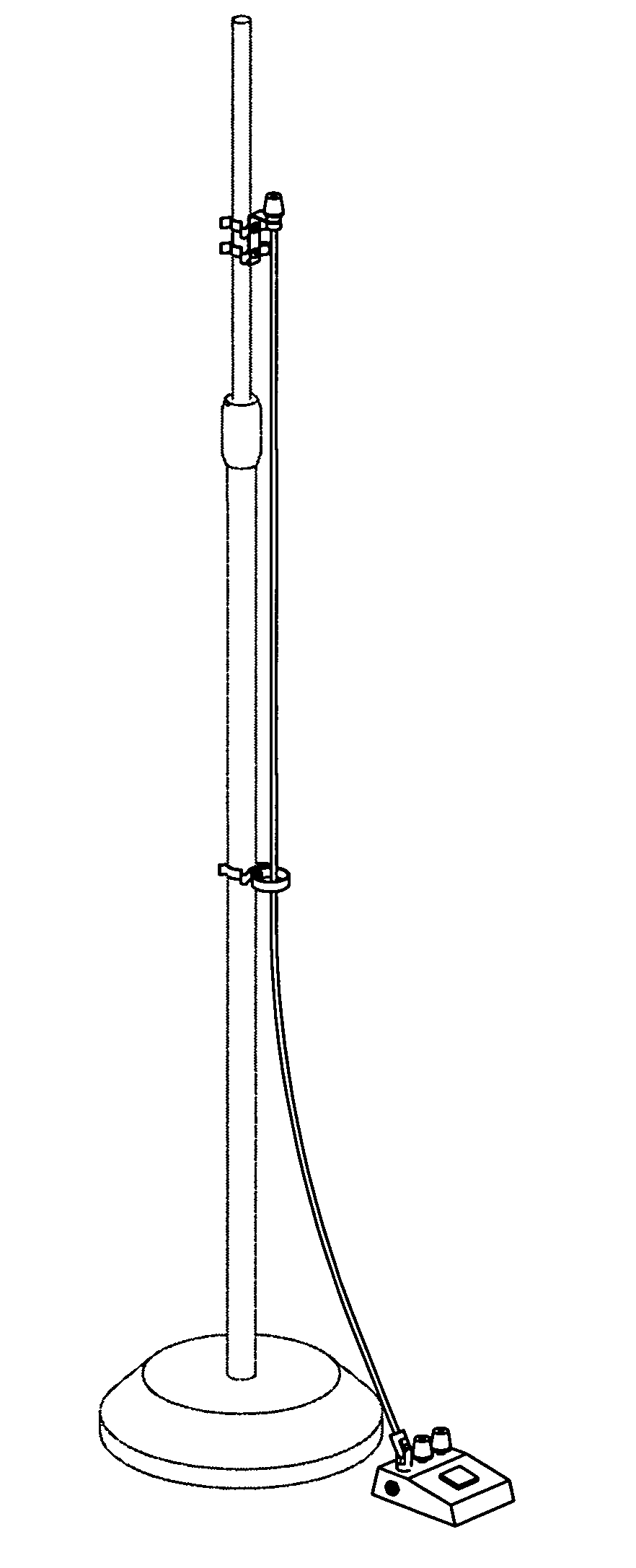

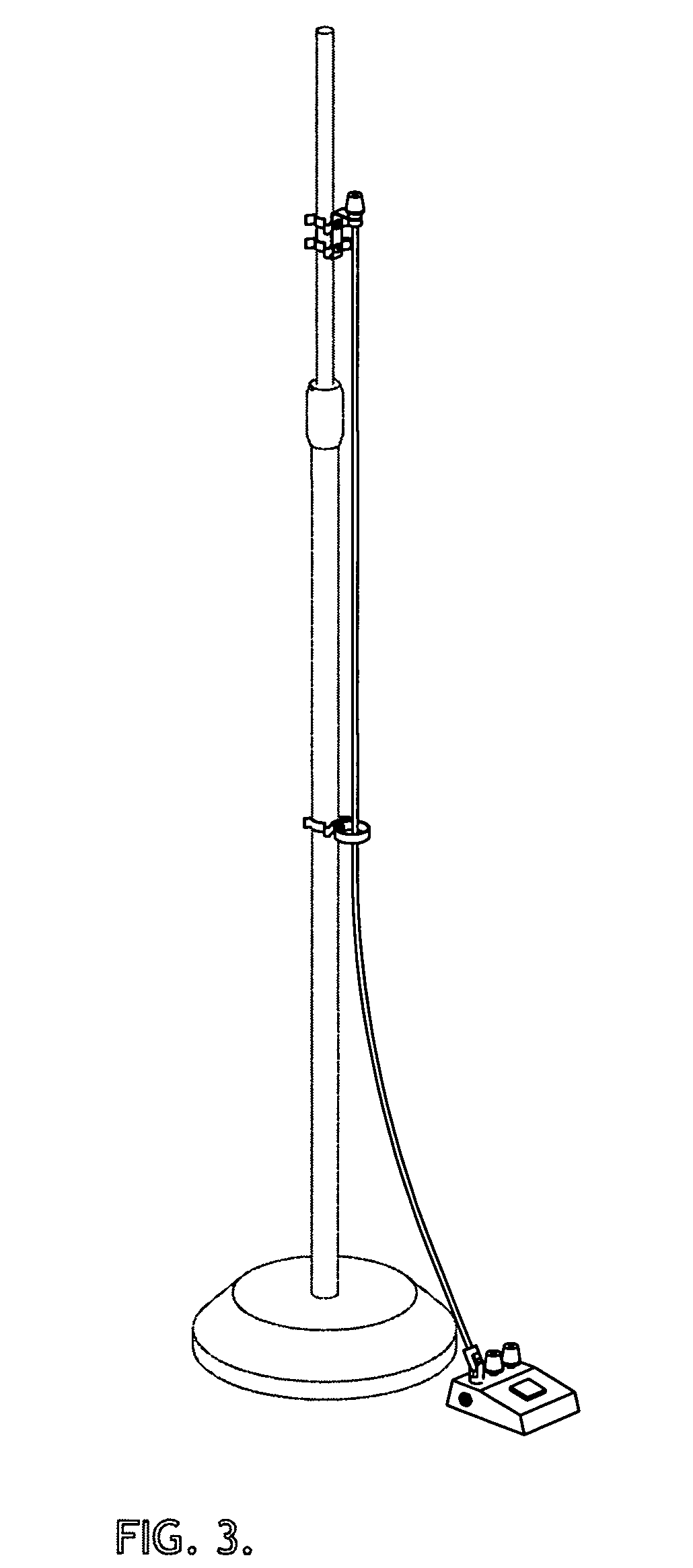

Remote controller device and method for hand operation of floor-mounted audio effects processors

InactiveUS7675399B2Current collector arrangementsResistors adjusted by auxillary driving meansRotary switchEngineering

Disclosed is a device for the remote operation of the variable audio controls of floor-mounted audio effects devices, such devices typical of those used by performing artists on stage. The vast majority of devices of this type are operated by a foot pedal-controlled on / off switch and rotary operated potentiometer switch(es) to vary the audio output. The present inventive concept uses a variety of mechanical connectors, which couple the rotary switches of the floor device to a hand-operated controller mounted on a microphone or accessory stand. In this manner a performer is able to operate the effects device, with his / her hand, from a more natural standing position during a musical performance, rather than having to crouch down during said performance.

Owner:GOLDEN MARY ELIZABETH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com