Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Texture measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

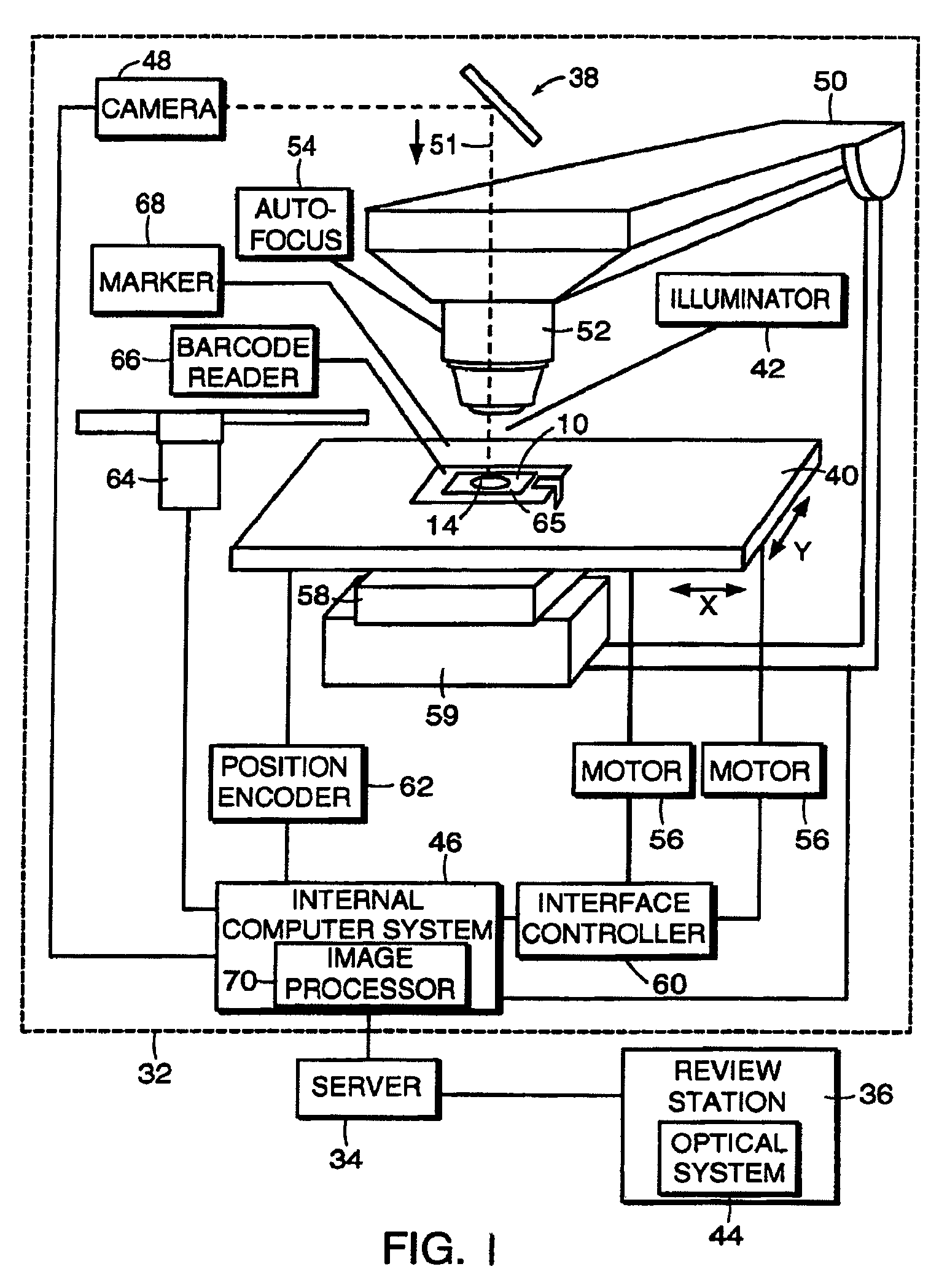

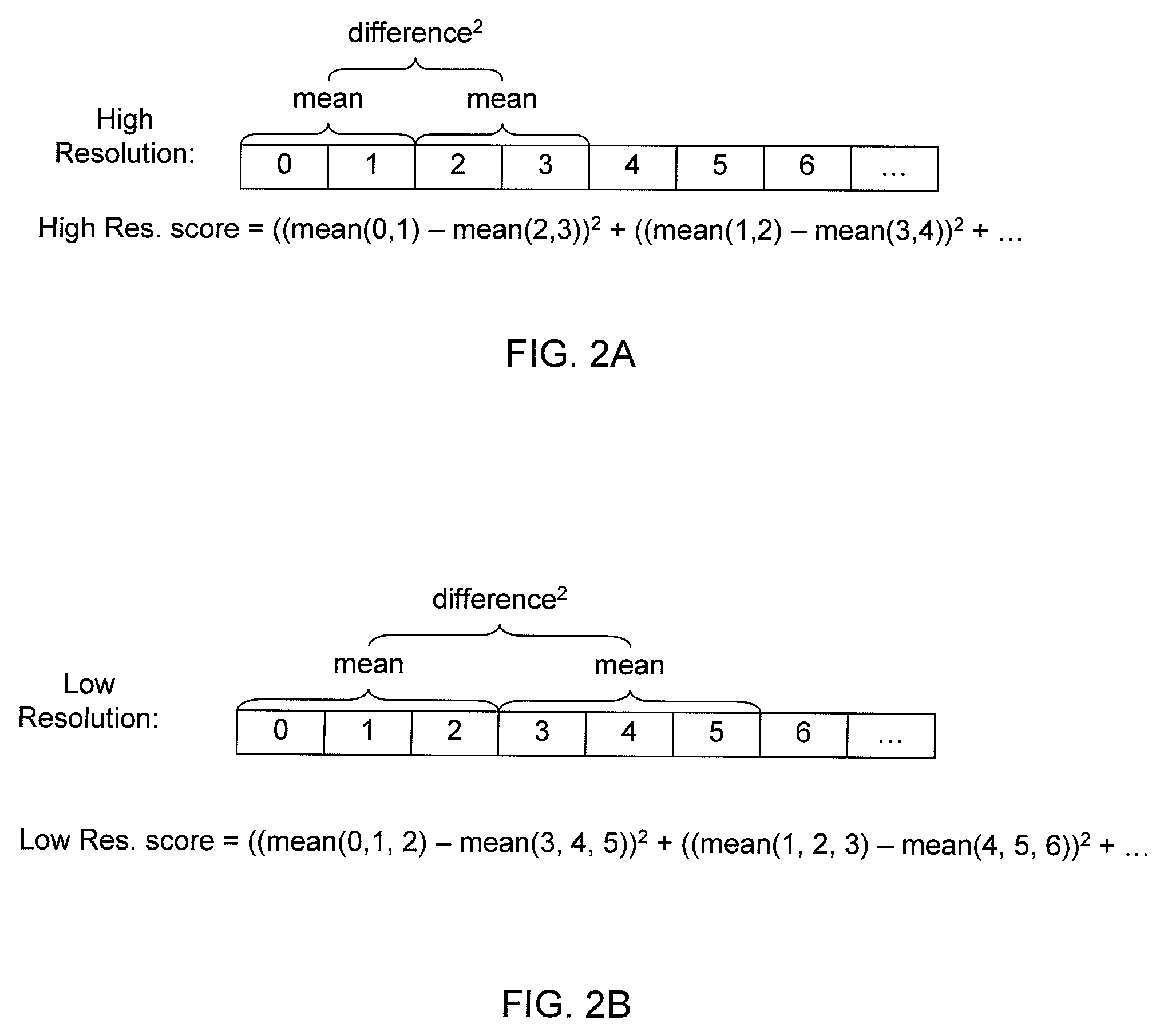

Method for assessing image focus quality

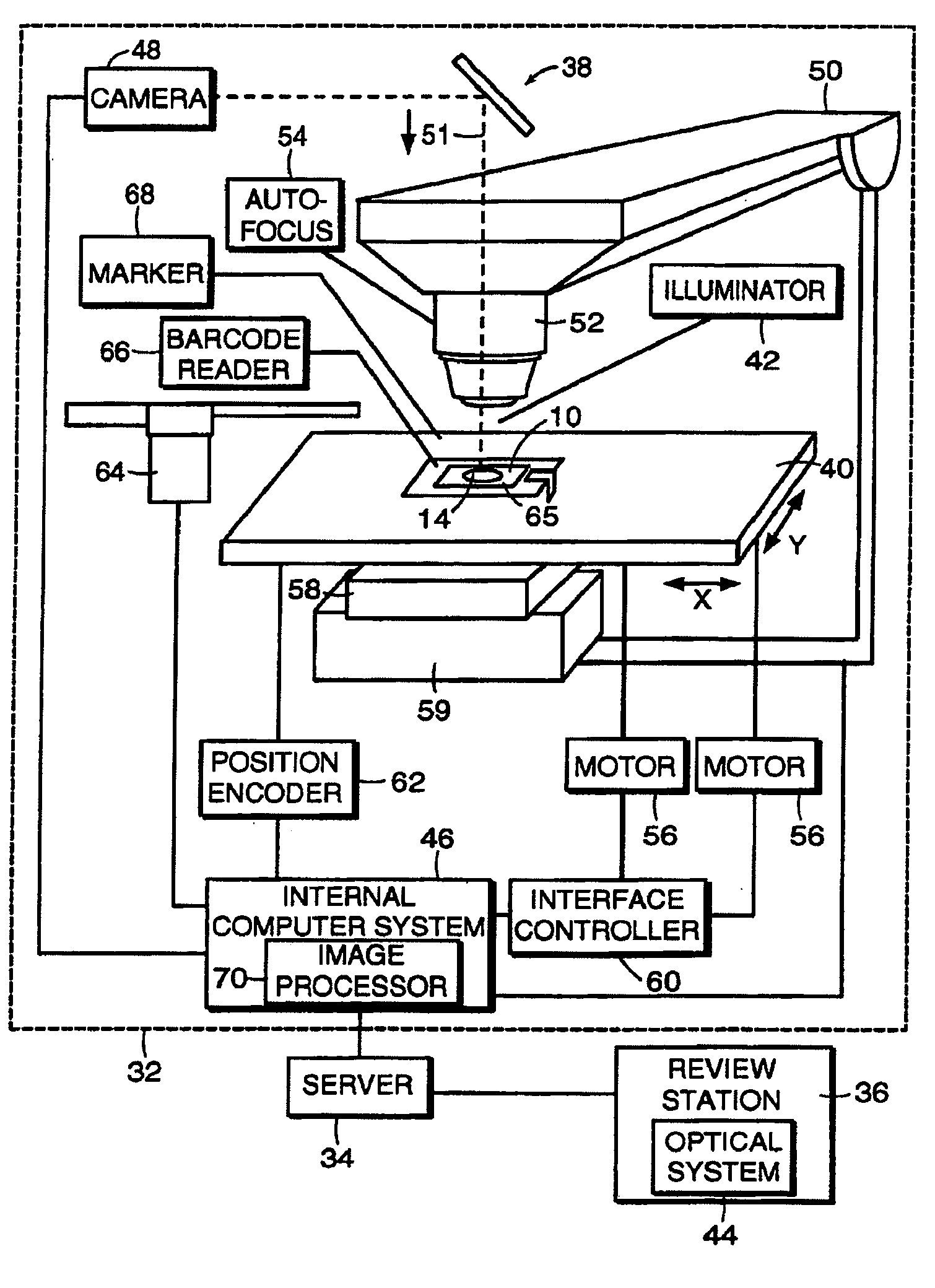

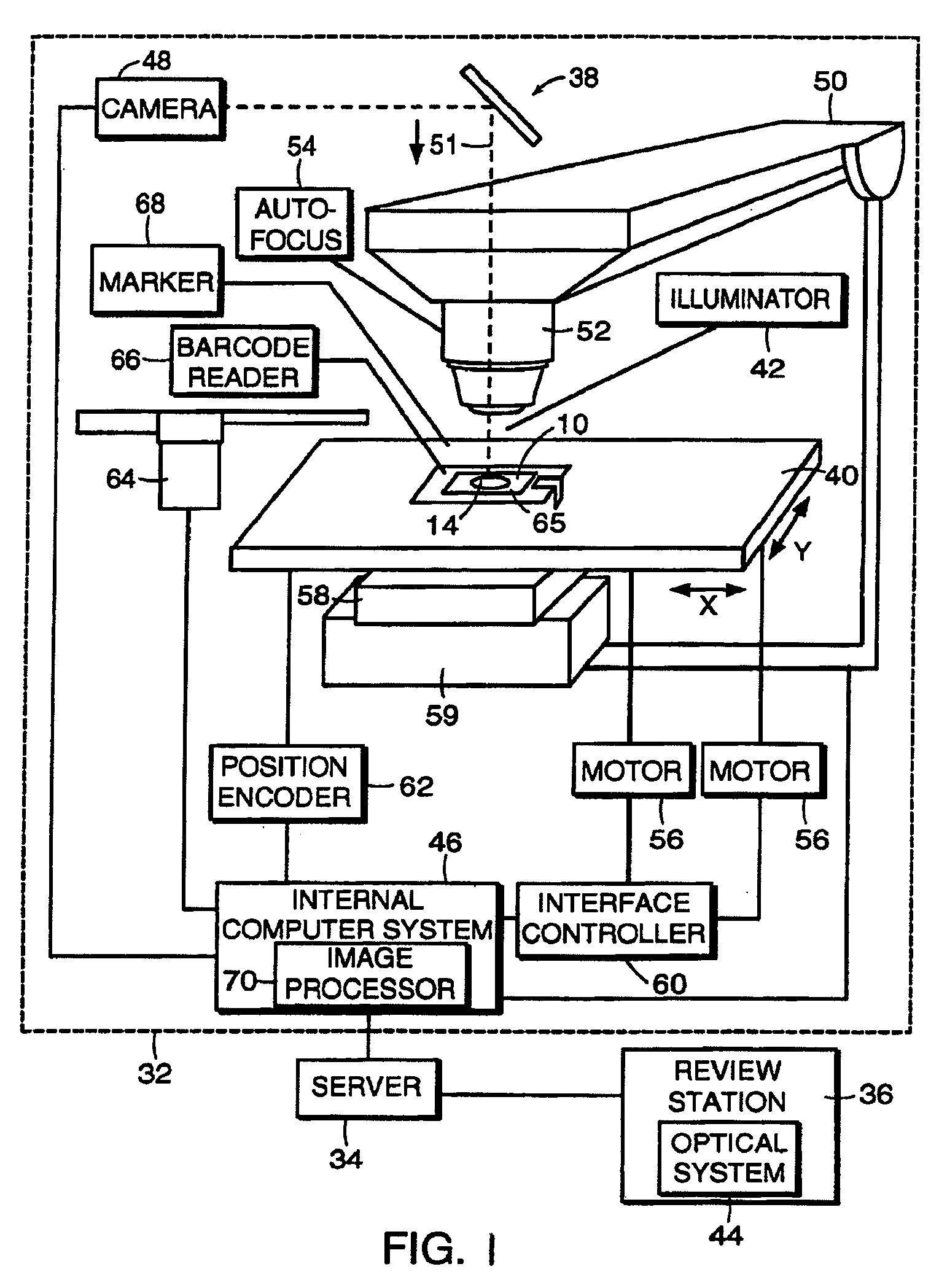

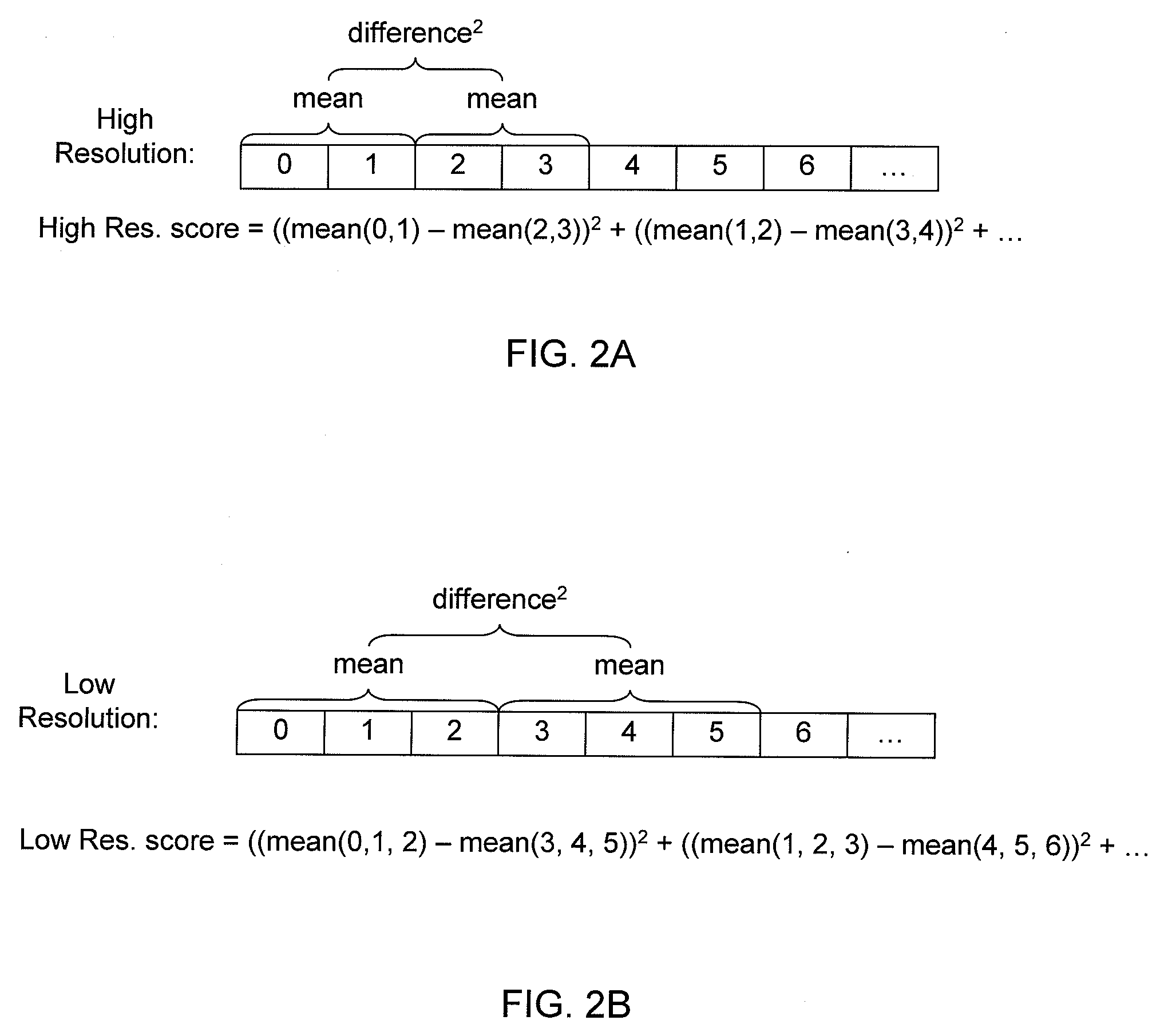

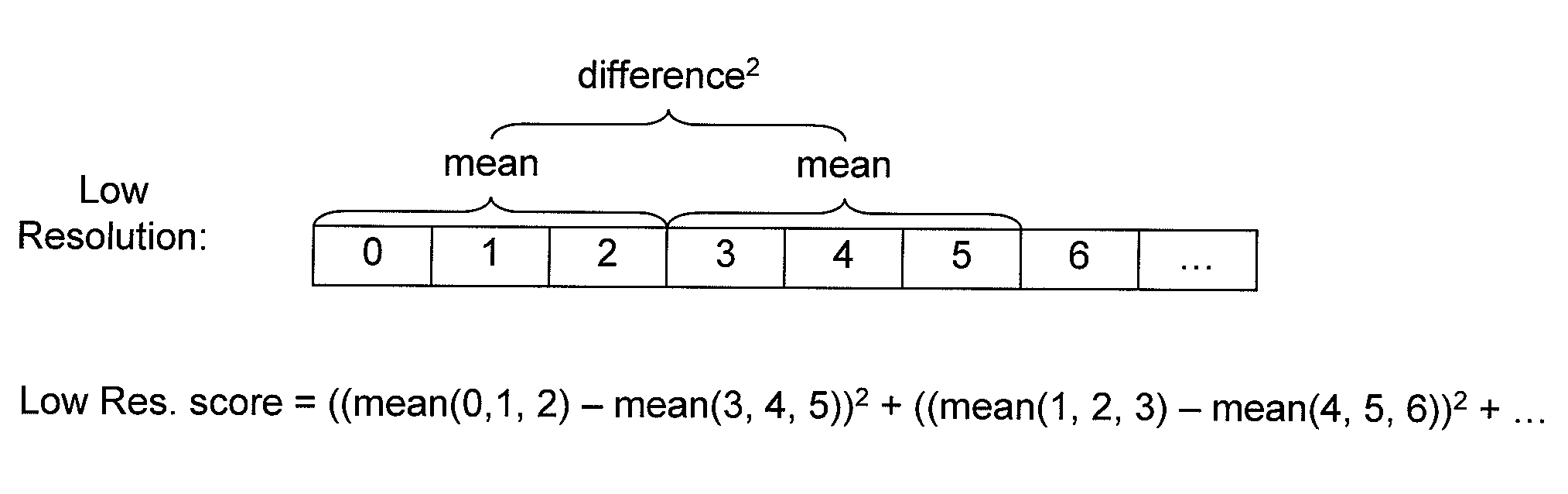

A method for determining the quality of focus of a digital image of a biological specimen includes obtaining a digital image of a specimen using a specimen imaging apparatus. A measure of image texture is calculated at two different scales, and the measurements are compared to determine how much high-resolution data the image contains compared to low-resolution data. The texture measurement may, for example, be a Brenner auto-focus score calculated from the means of adjacent pairs of pixels for the high-resolution measurement and from the means of adjacent triples of pixels for the low-resolution measurement. A score indicative of the quality of focus is then established based on a function of the low-resolution and high-resolution measurements. This score may be used by an automated imaging device to verify that image quality is acceptable. The device may adjust the focus and acquire new images to replace any that are deemed unacceptable.

Owner:CYTYC CORP

Method for assessing image focus quality

A method for determining the quality of focus of a digital image of a biological specimen includes obtaining a digital image of a specimen using a specimen imaging apparatus. A measure of image texture is calculated at two different scales, and the measurements are compared to determine how much high-resolution data the image contains compared to low-resolution data. The texture measurement may, for example, be a Brenner auto-focus score calculated from the means of adjacent pairs of pixels for the high-resolution measurement and from the means of adjacent triples of pixels for the low-resolution measurement. A score indicative of the quality of focus is then established based on a function of the low-resolution and high-resolution measurements. This score may be used by an automated imaging device to verify that image quality is acceptable. The device may adjust the focus and acquire new images to replace any that are deemed unacceptable.

Owner:CYTYC CORP

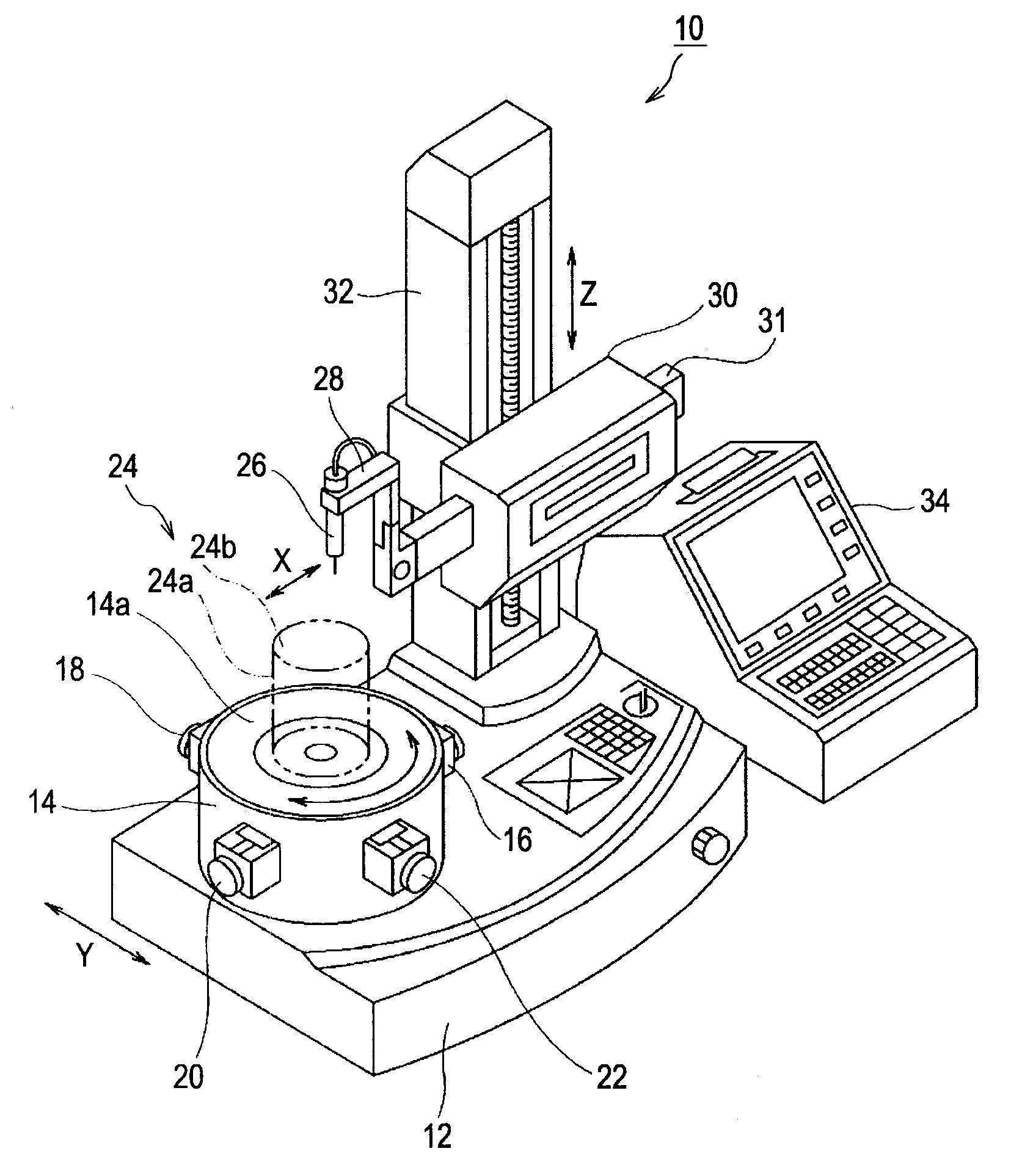

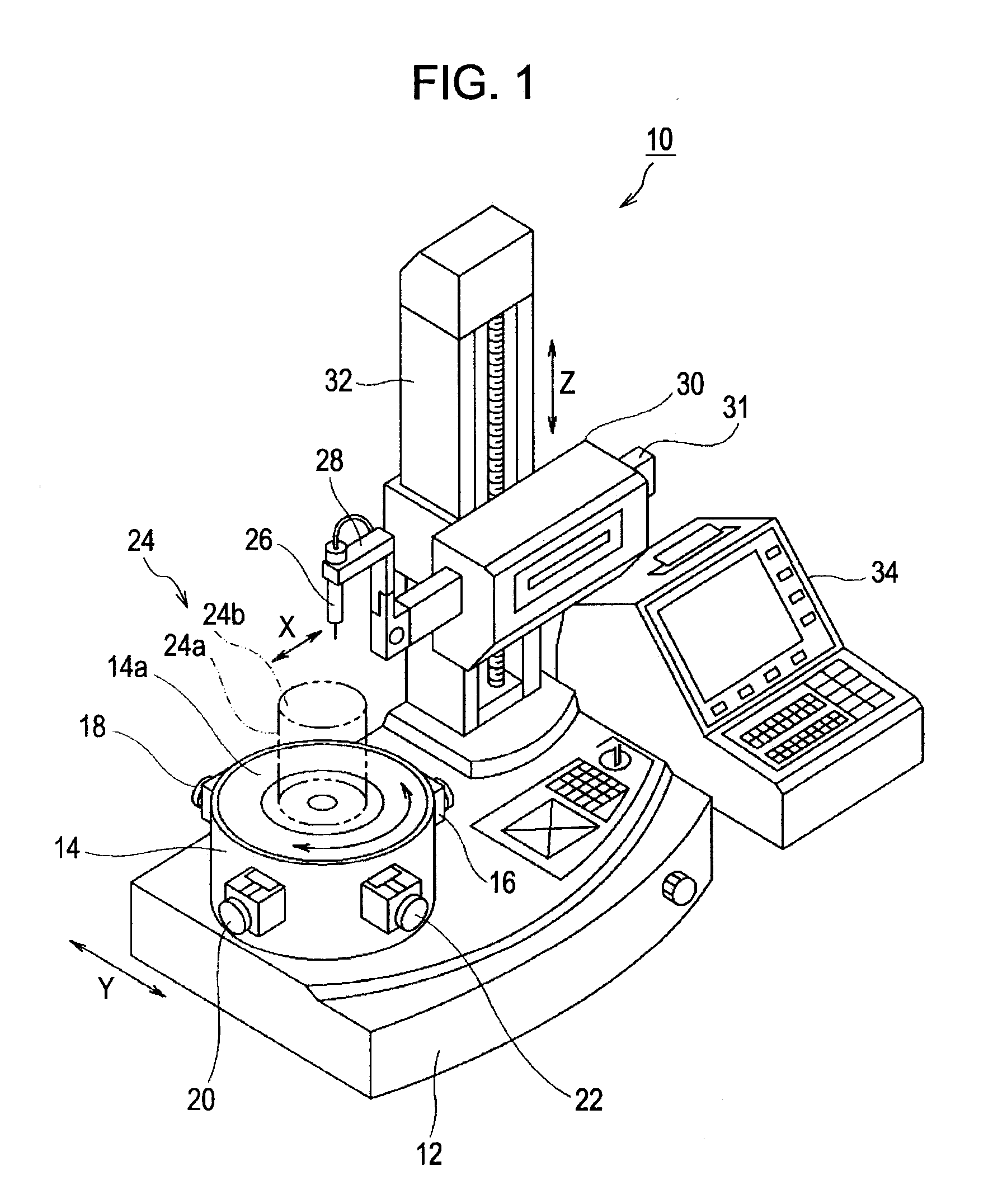

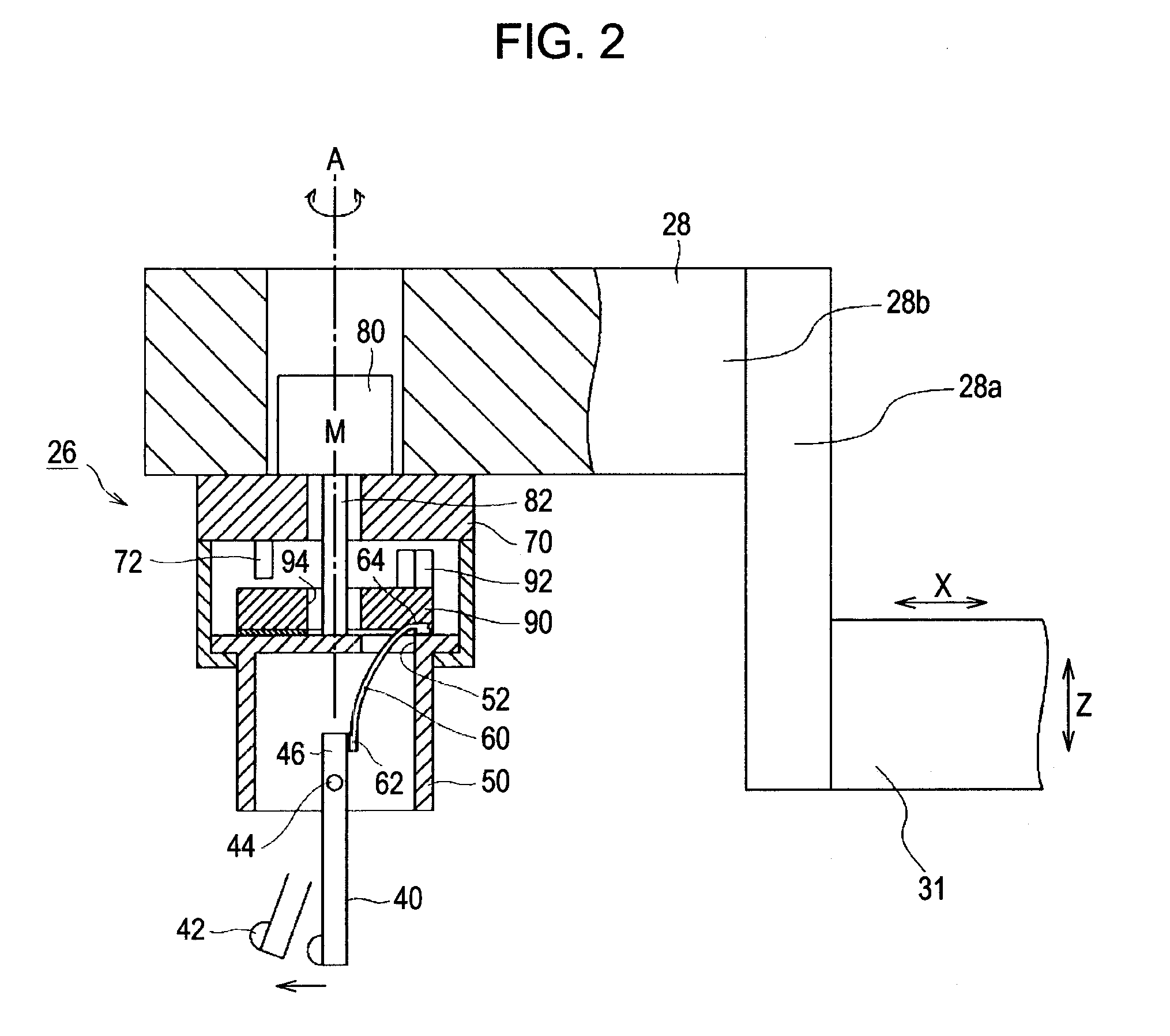

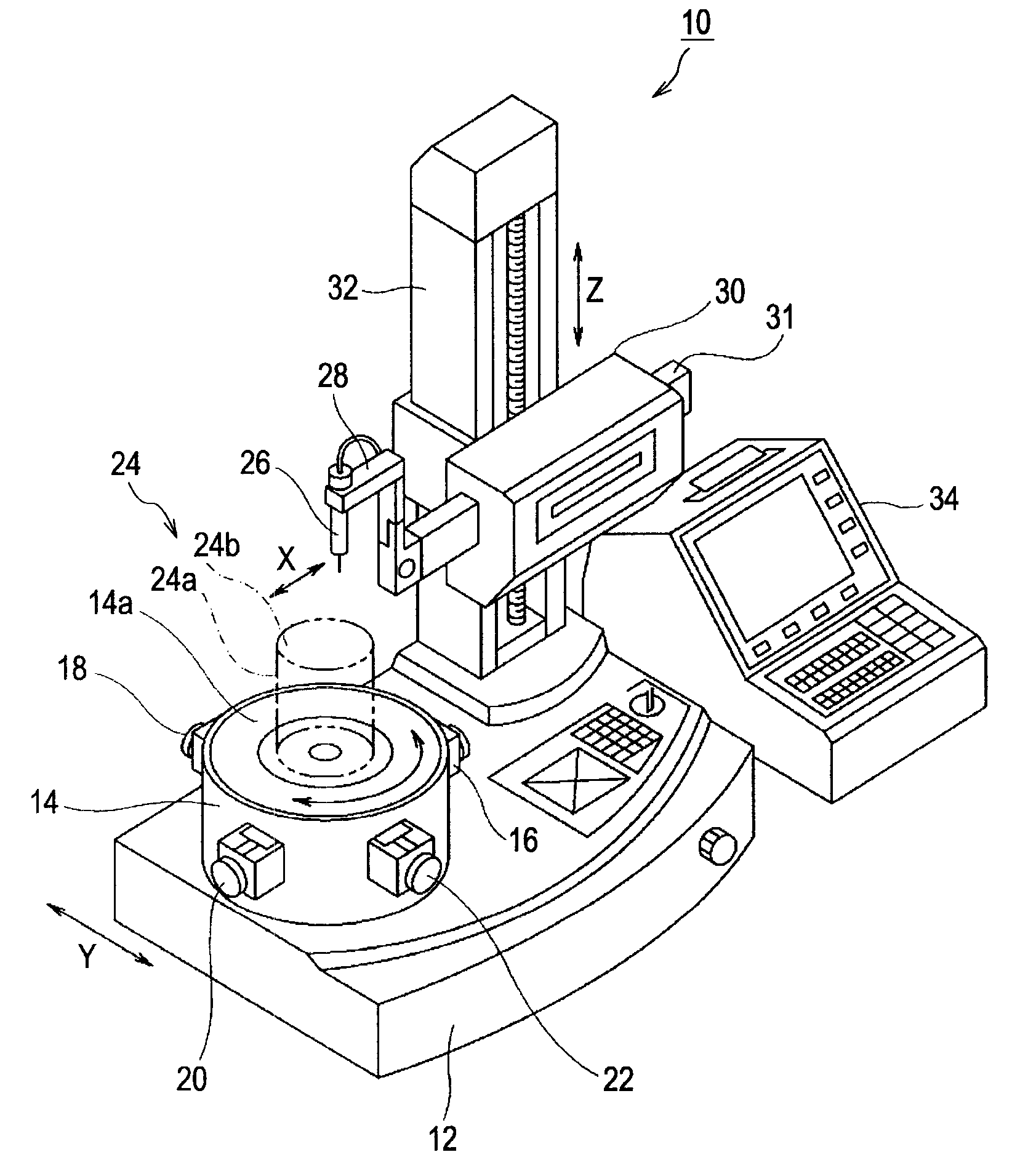

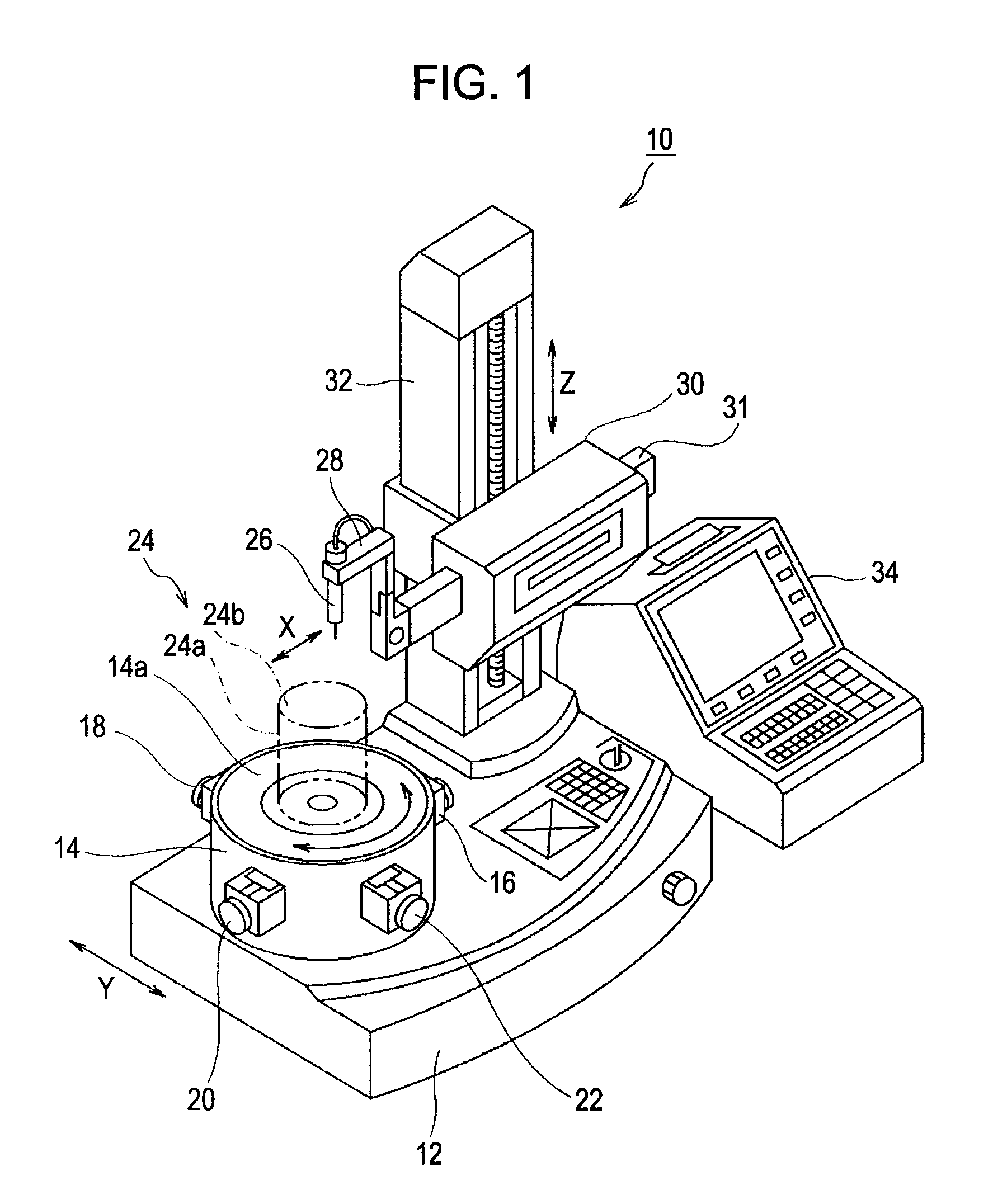

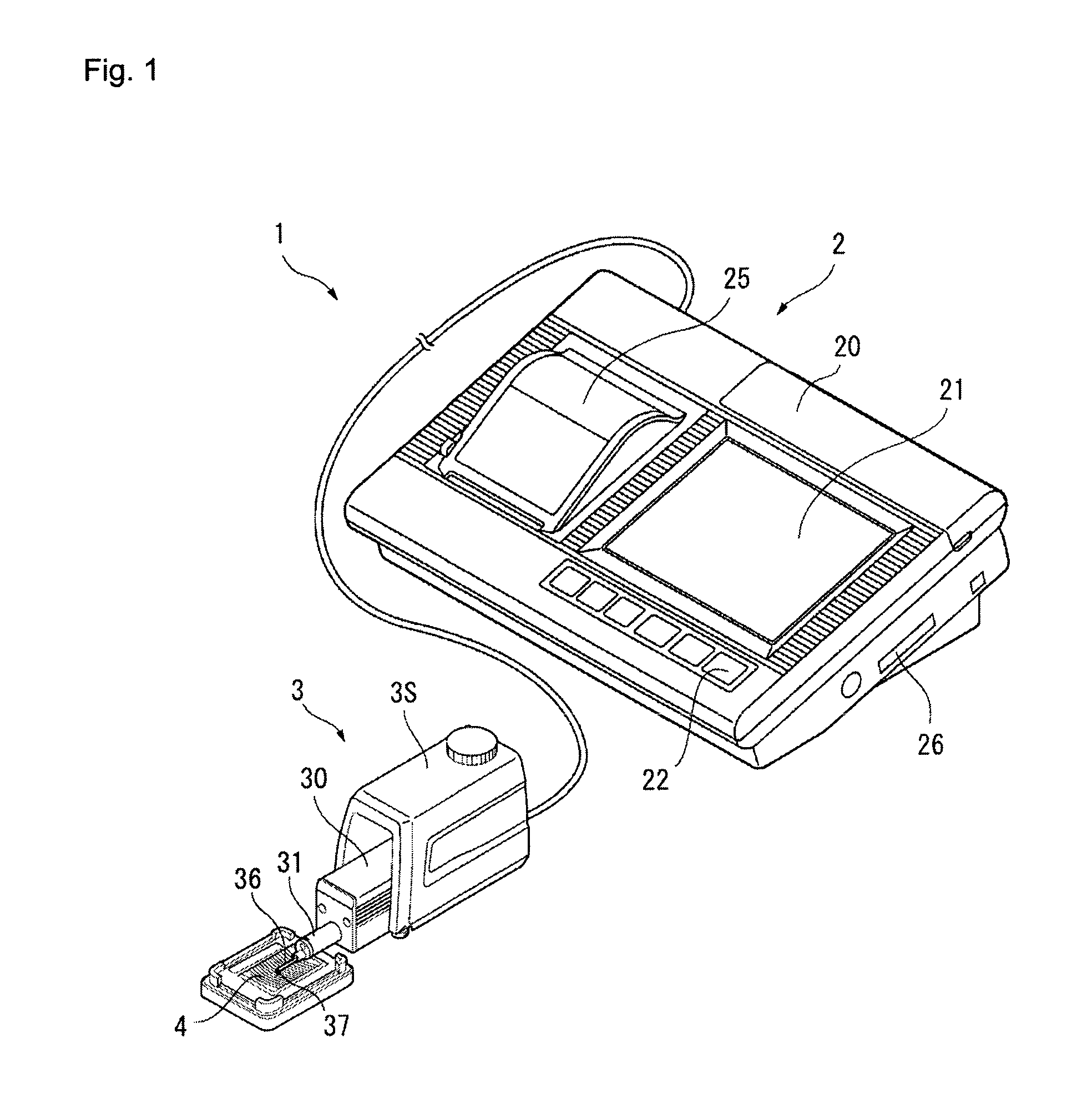

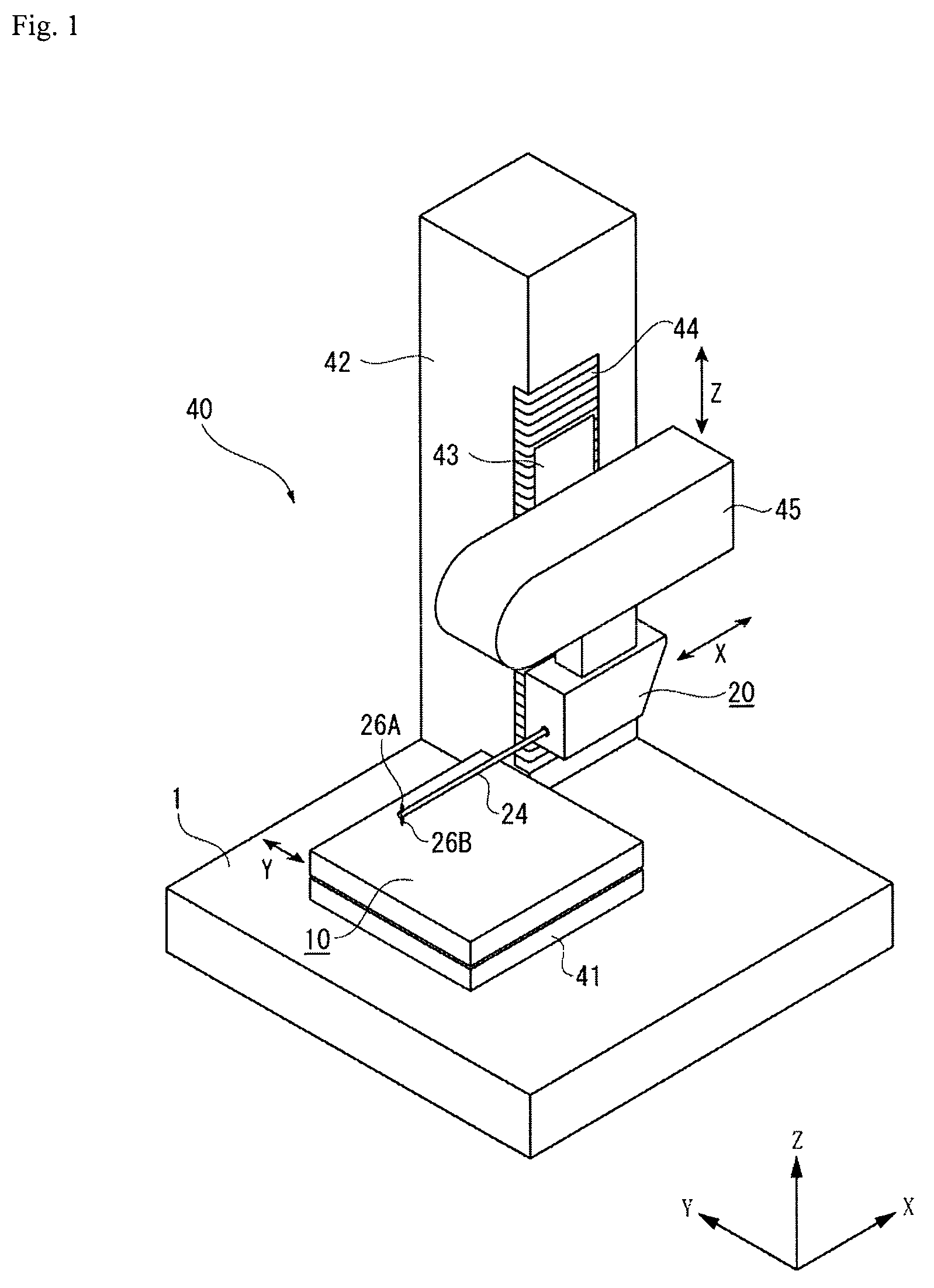

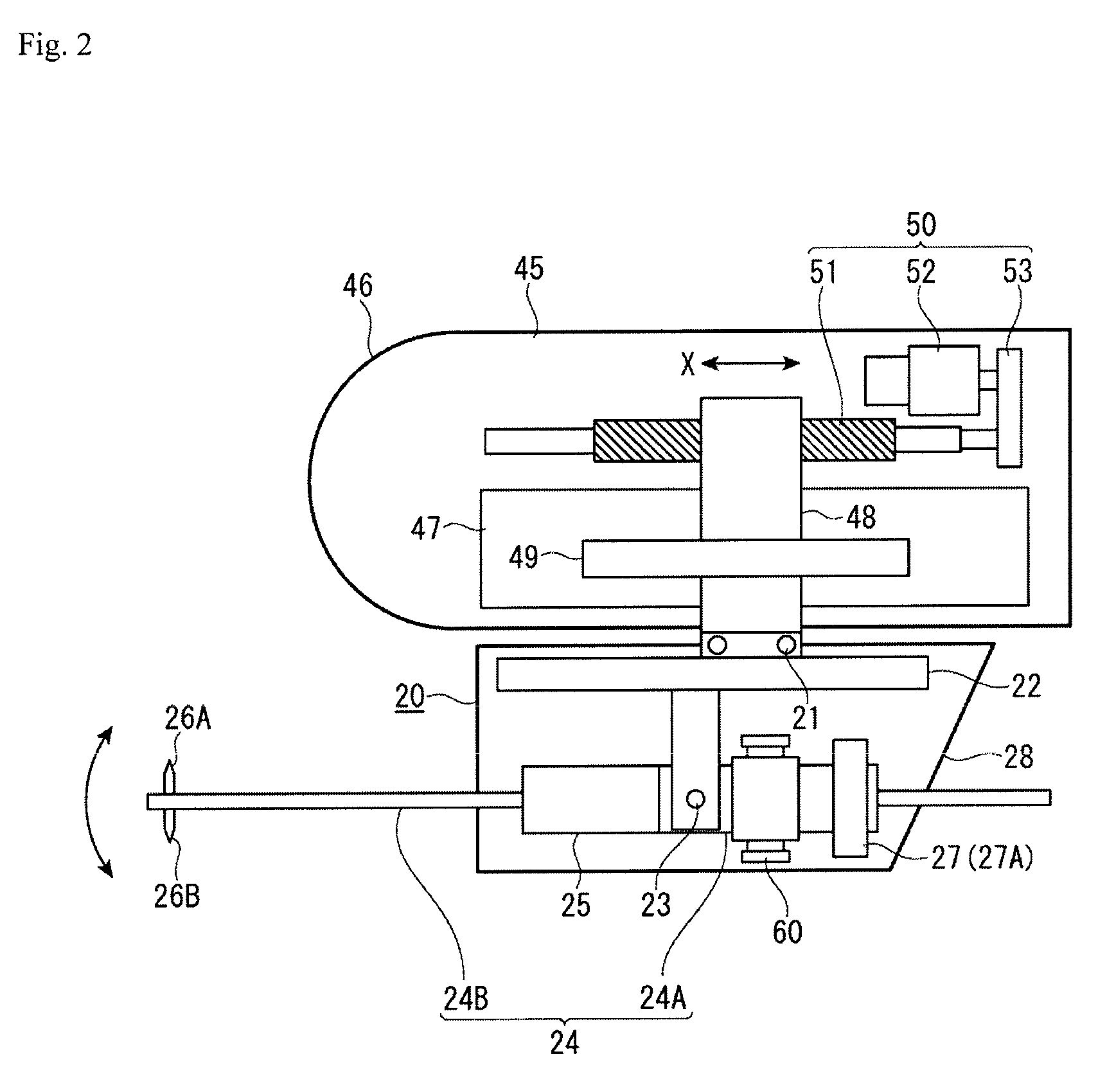

Surface texture measurement apparatus and roundness measuring apparatus

ActiveUS20110005095A1Small sizeContinuous measurementMechanical counters/curvatures measurementsMechanical roughness/irregularity measurementsMeasurement deviceEngineering

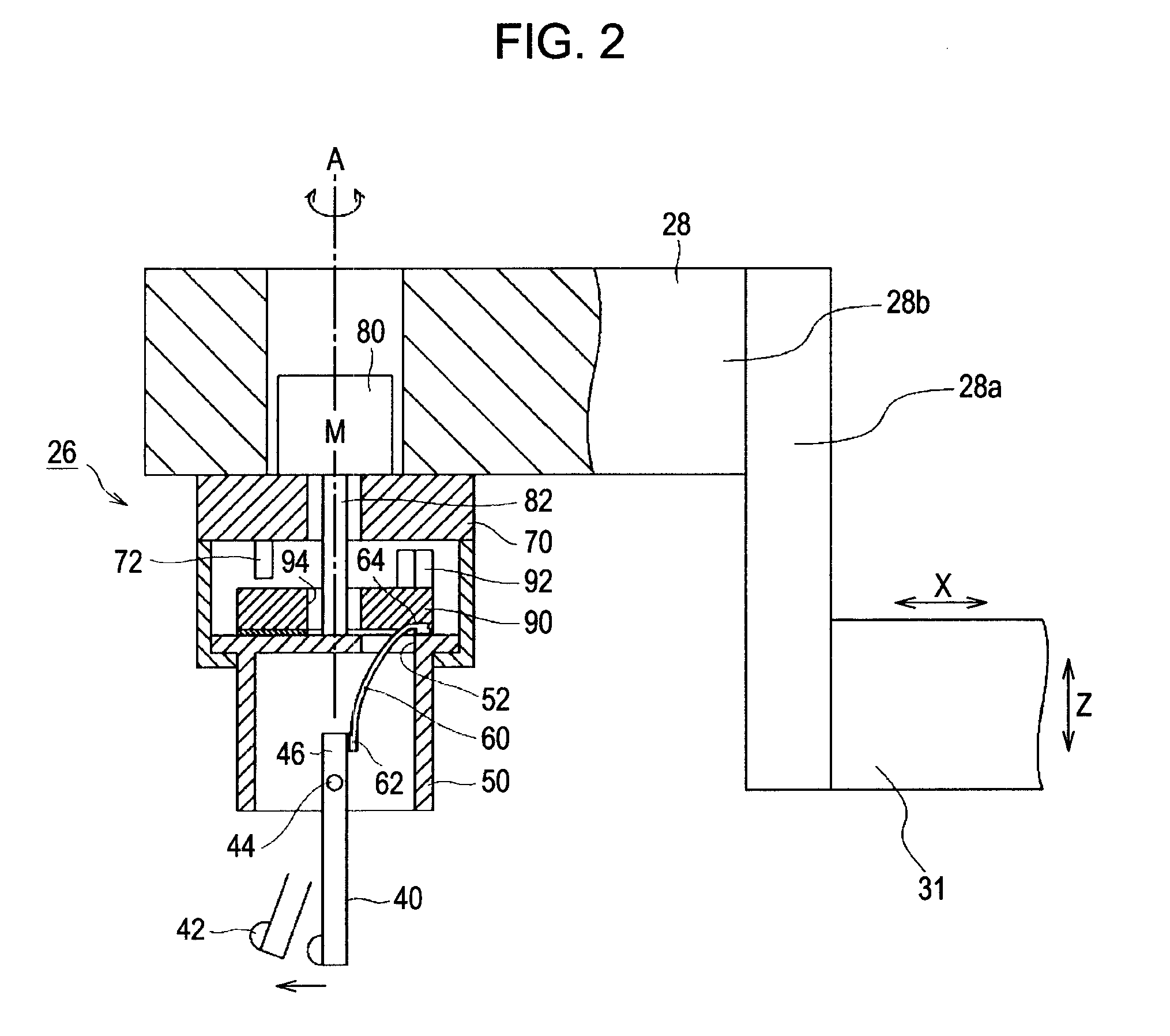

A roundness measuring apparatus includes: a stylus having a contact part; a holding member that holds the stylus while allowing displacement of the contact part; an elastic member that presses the contact part against a measurement target object; a detector holder that supports the holding member rotatably; a motor; an elastic force adjustment member that is rotatable and concentric with the holding member; a joining section that joins the elastic force adjustment member with the holding member to maintain relative rotational positions; and a restricting section that restricts rotation of the elastic force adjustment member at a predetermined rotational position. The displacement direction of the contact part is adjusted in a first rotation range. The rotational position of the holding member relative to the rotational position of the elastic force adjustment member changes with the rotation of the elastic force adjustment member being restricted in a second rotation range.

Owner:MITUTOYO CORP

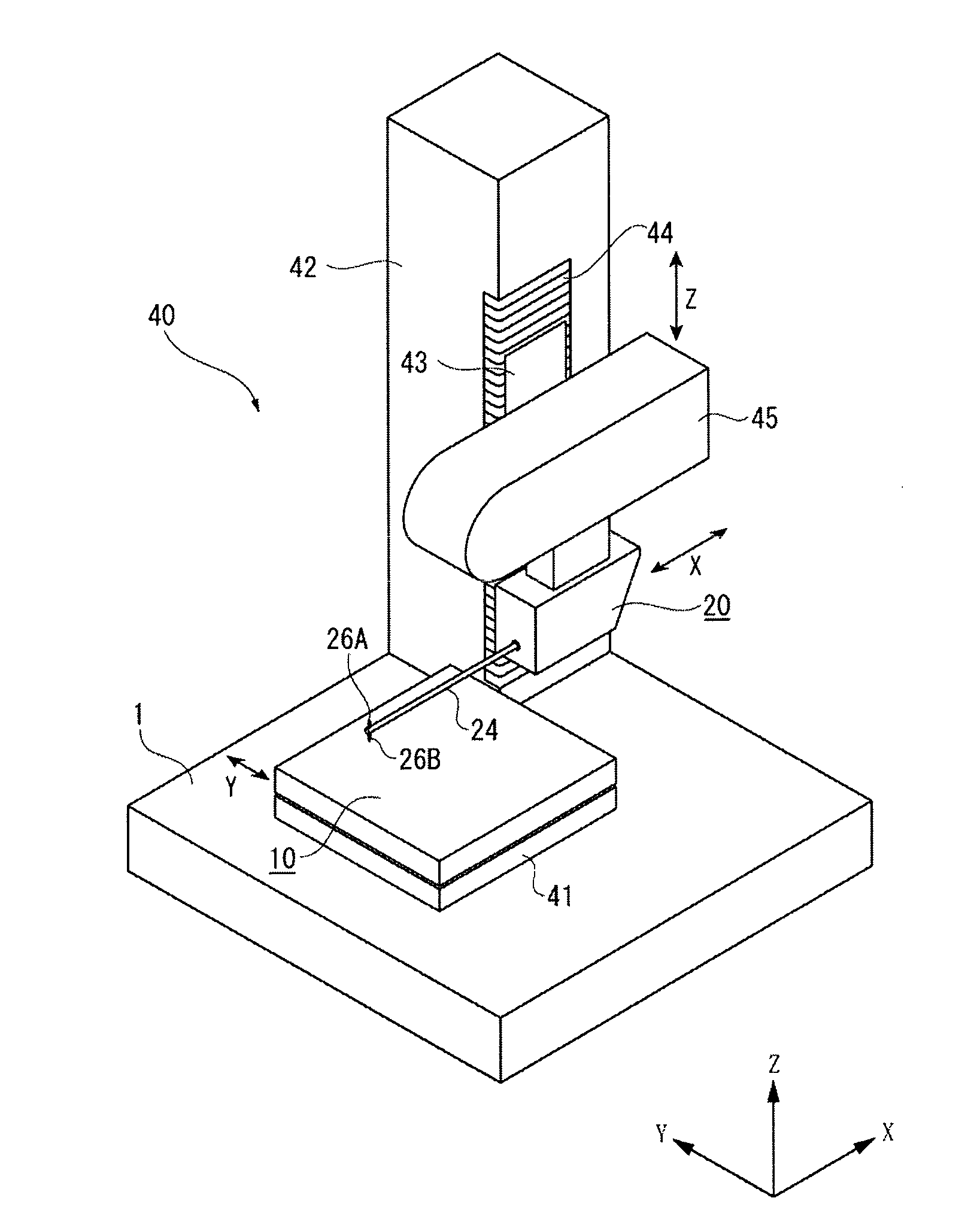

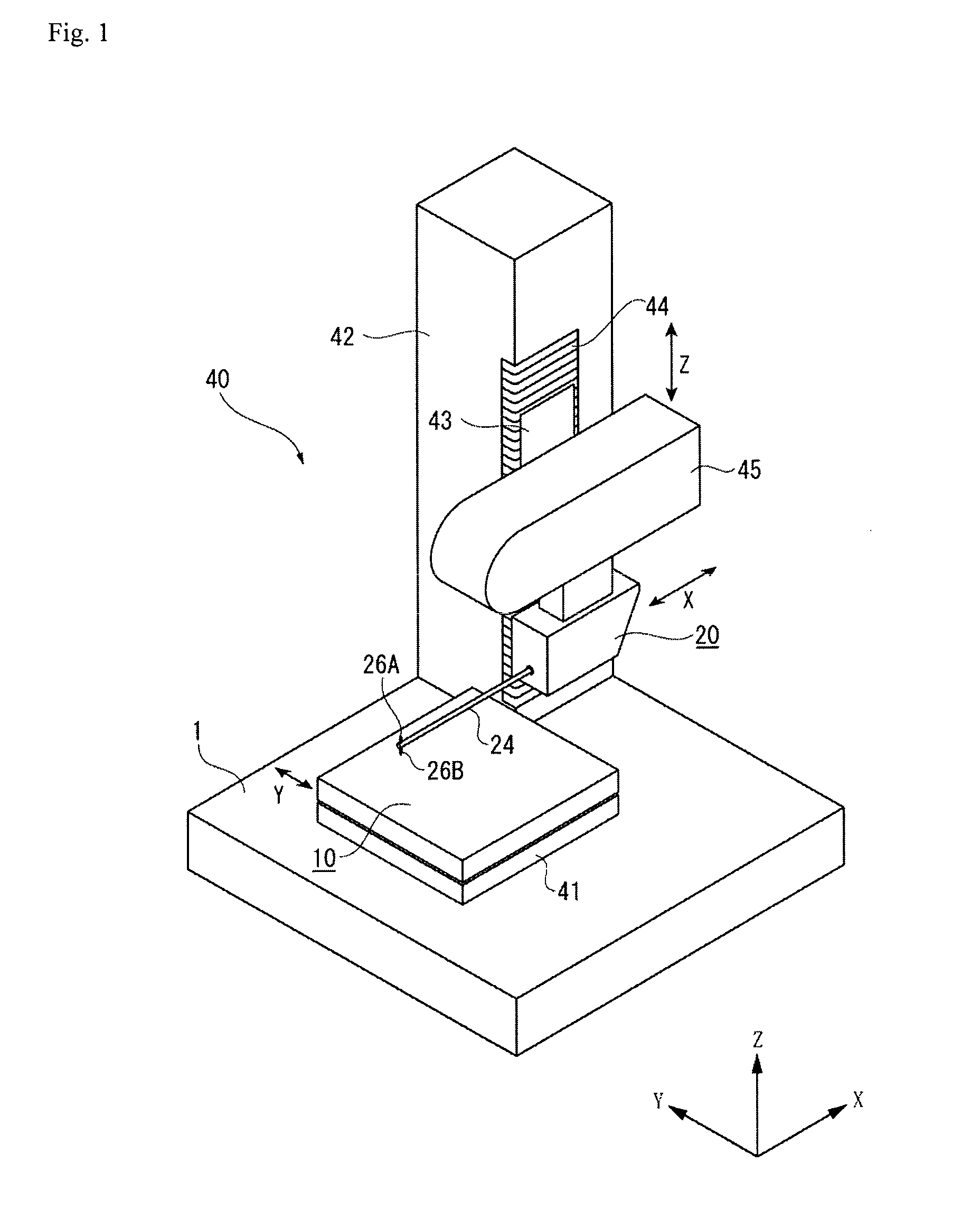

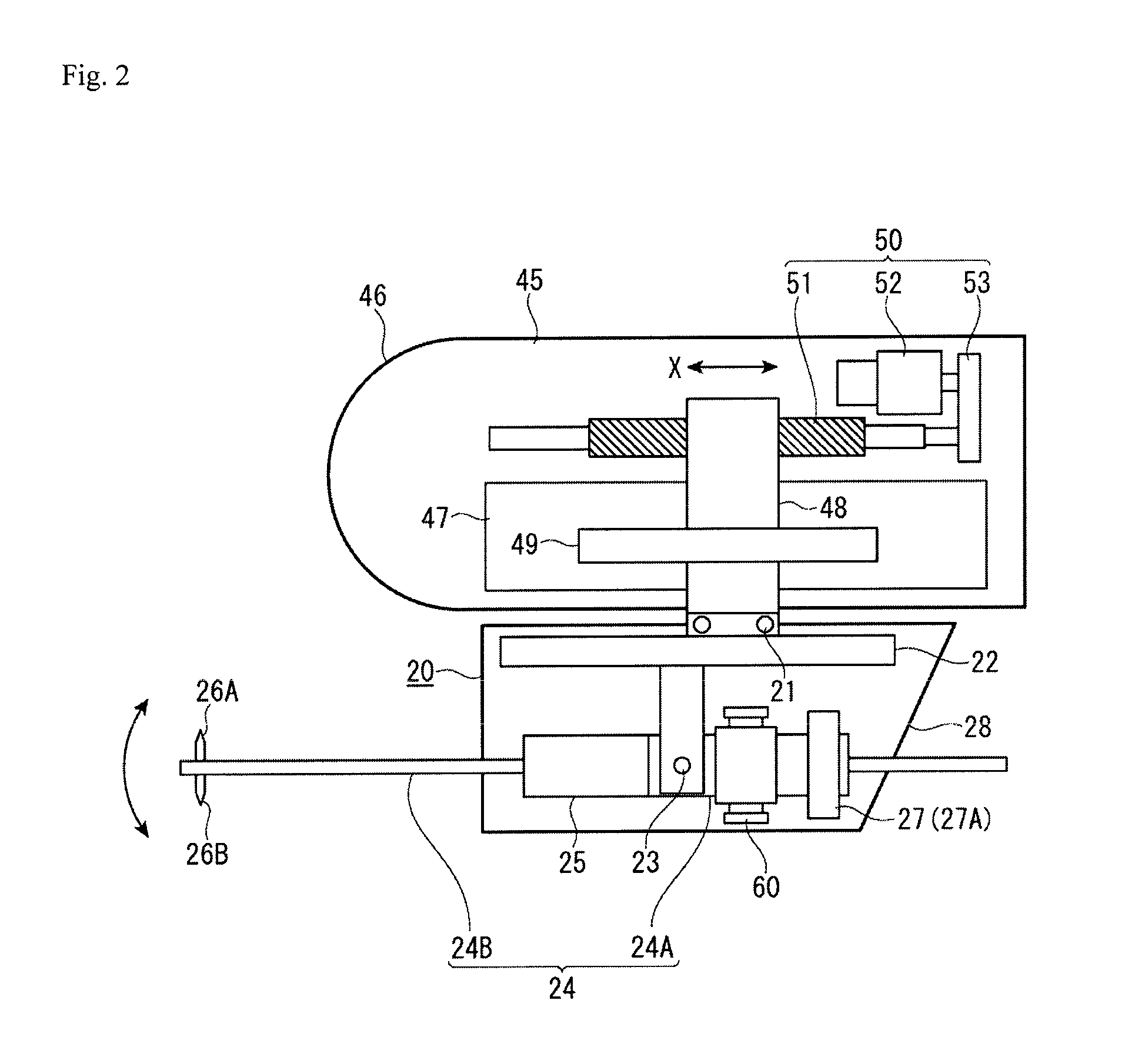

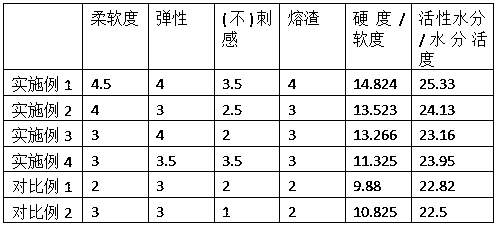

Method of calibrating surface texture measurement device

ActiveUS20120234075A1Accurate mutual positional relationshipAccurate assessmentMechanical roughness/irregularity measurementsStrength propertiesMeasurement deviceMaximum diameter

A method of calibrating a surface texture measurement device includes obtaining Y-axis shape measurement data and a maximum diameter portion to obtain upper and lower maximum diameter portions of a reference sphere from Y-axis upper and lower shape data obtained by relatively moving in the Y-axis direction while a downward and an upward styluses are in contact with an upper and a lower surfaces, respectively, of the reference sphere; obtaining X-axis shape measurement data to obtain X-axis upper and lower shape data of the reference sphere by relatively moving in the X-axis direction while the downward stylus is in contact with the upper diameter portion and the upward stylus with the lower diameter portion of the reference sphere; and calculating offset amounts Δx and Δz of the upward and downward styluses from center coordinates O3 and O4 obtained from the shape data.

Owner:MITUTOYO CORP

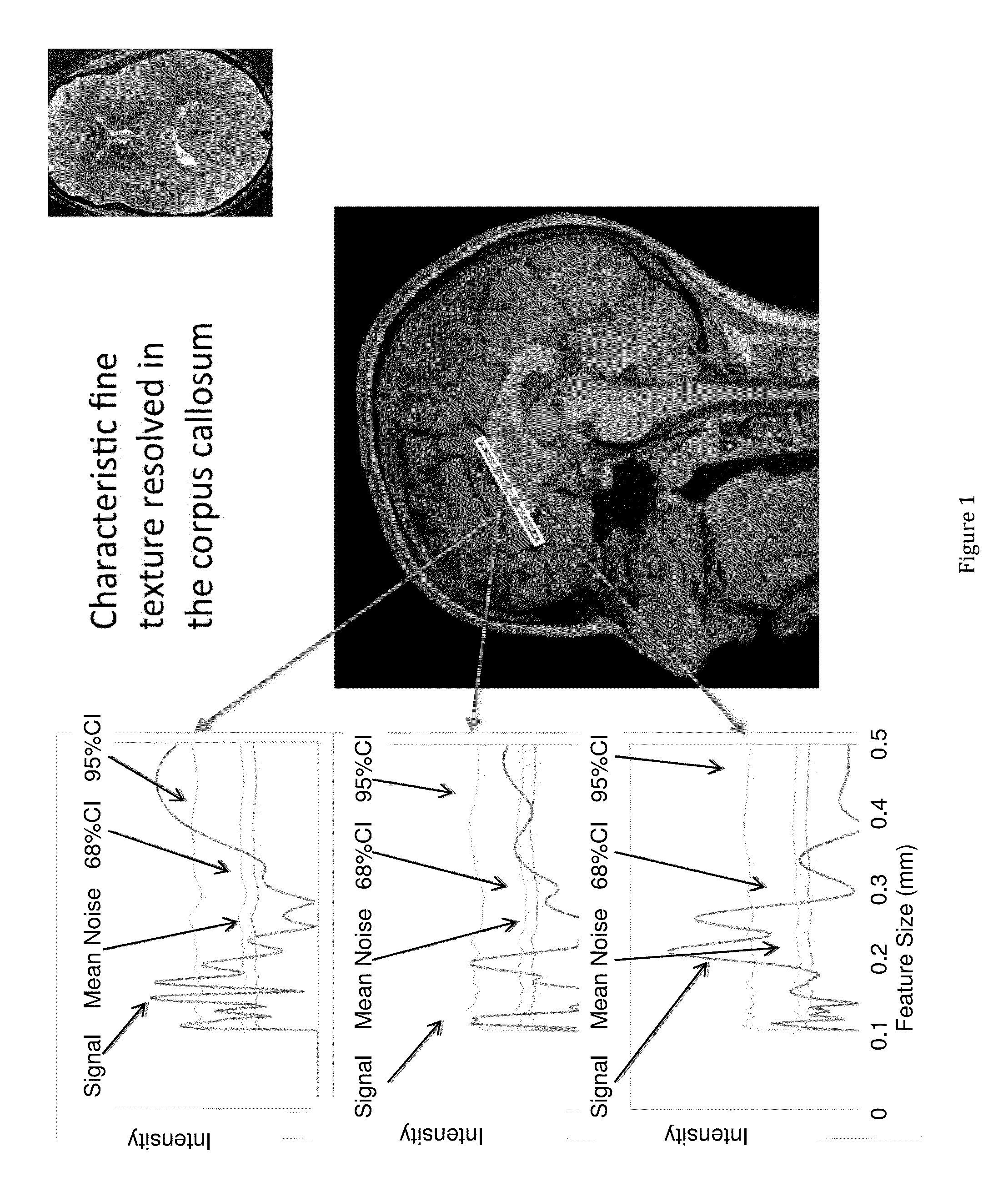

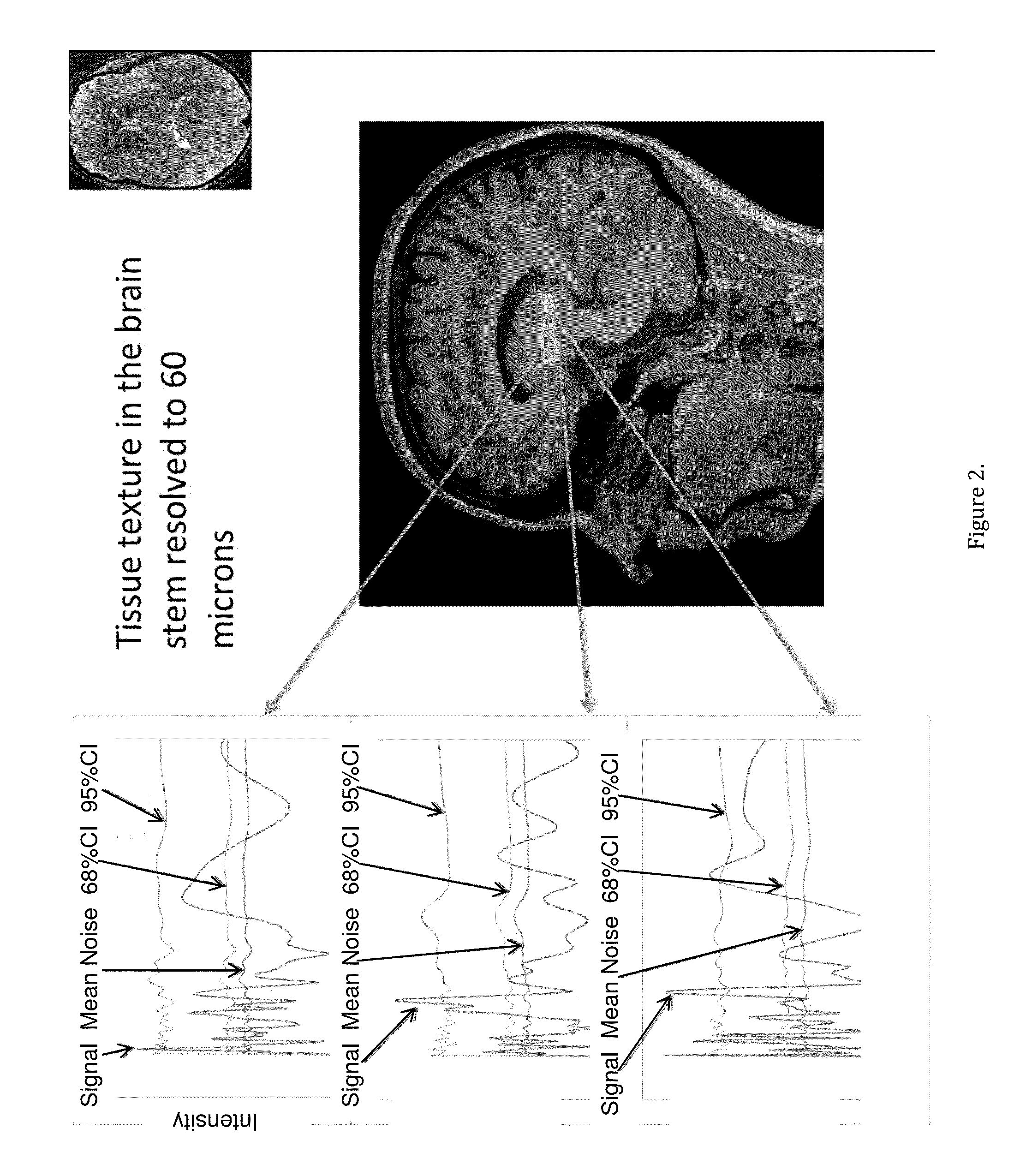

Magnetic Resonance Based Method for Assessing Alzheimer's Disease and Related Pathologies

The disclosed invention is a method for detecting indications of the presence of Alzheimer's disease (AD) and related dementia-inducing, motor-control-related pathologies, and other diseases in the human brain using a magnetic-resonance based technique for measuring fine tissue and bone textures. Specifically, the invention focuses on refinements / adaptations to a prior art magnetic resonance fine texture measurement technique that facilitates / enables pushing the detection limits closer to the cellular level, so as to be able to measure the fine scale structures and tissue changes that are known to be characteristic of the neurodegenerative processes involved in the development of these diseases.

Owner:OSTEOTRONIX MEDICAL PTE LTD

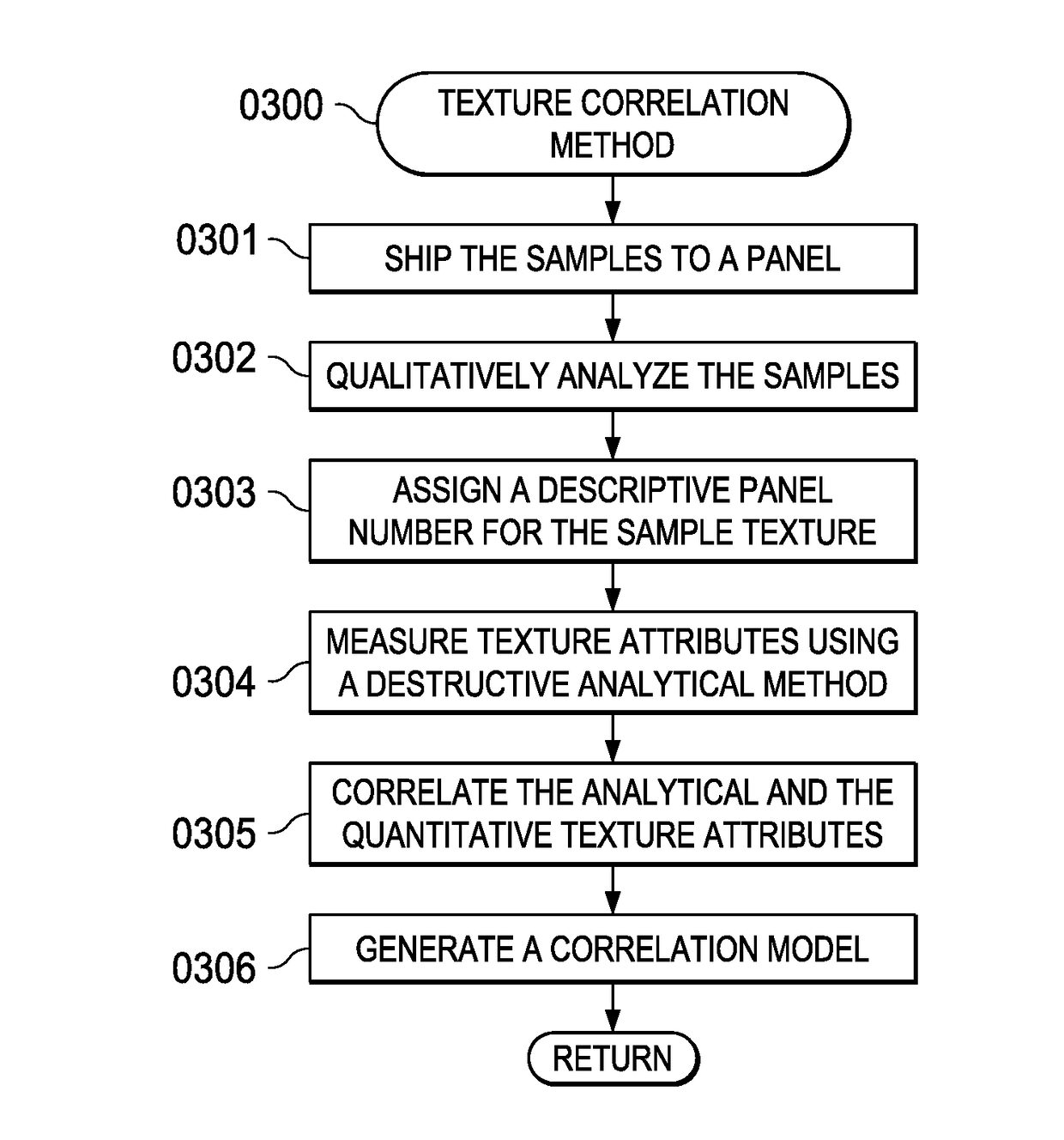

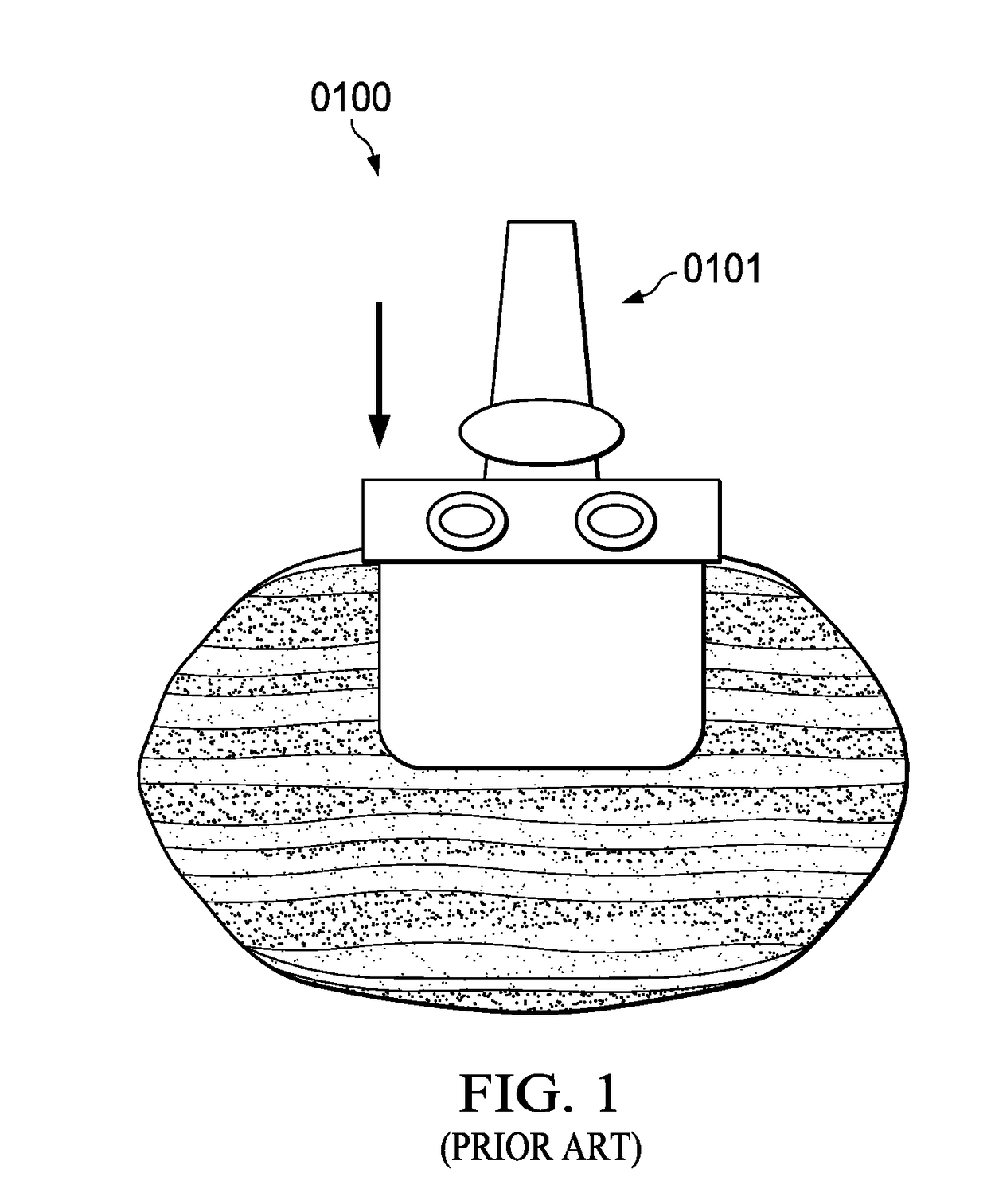

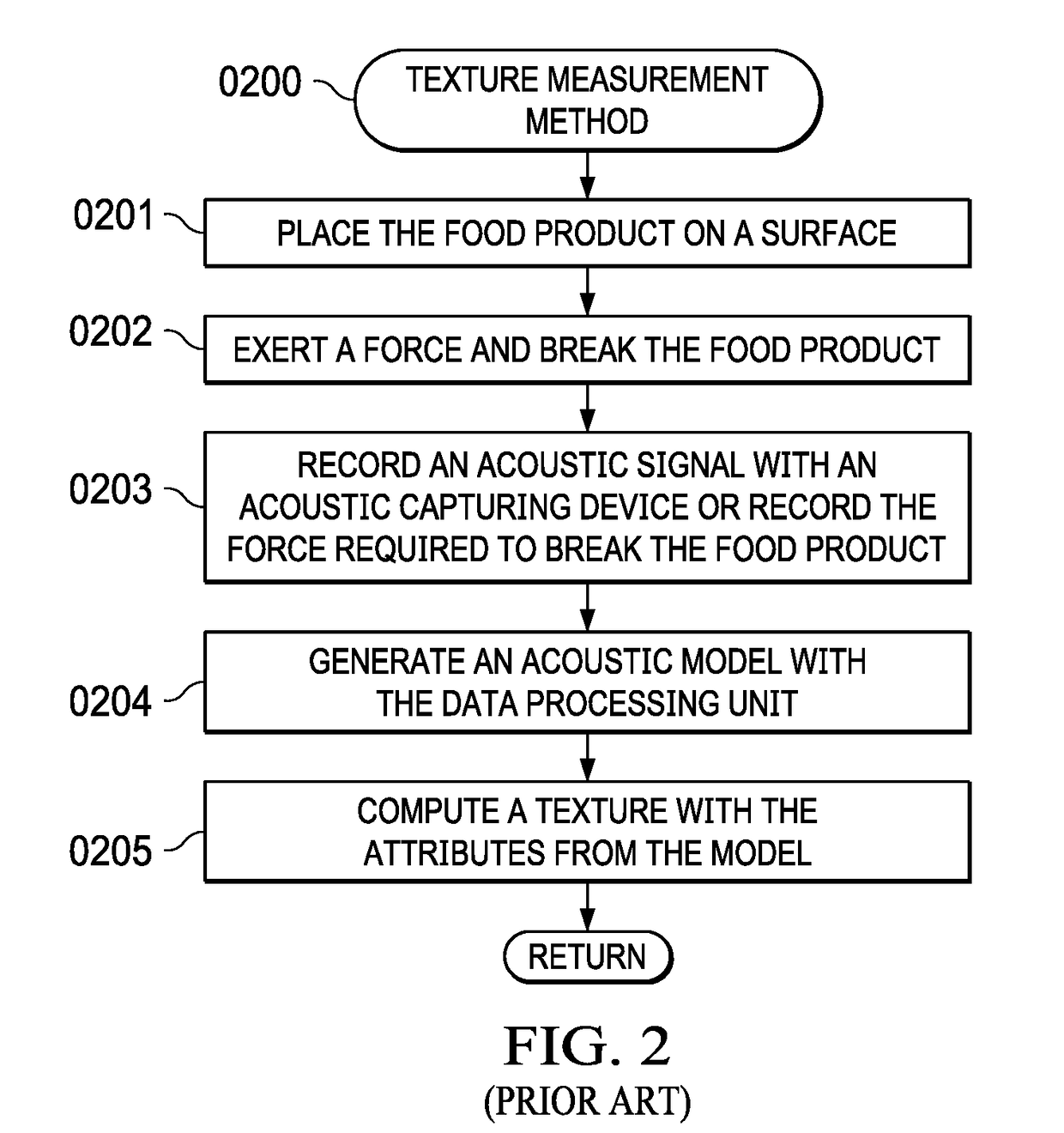

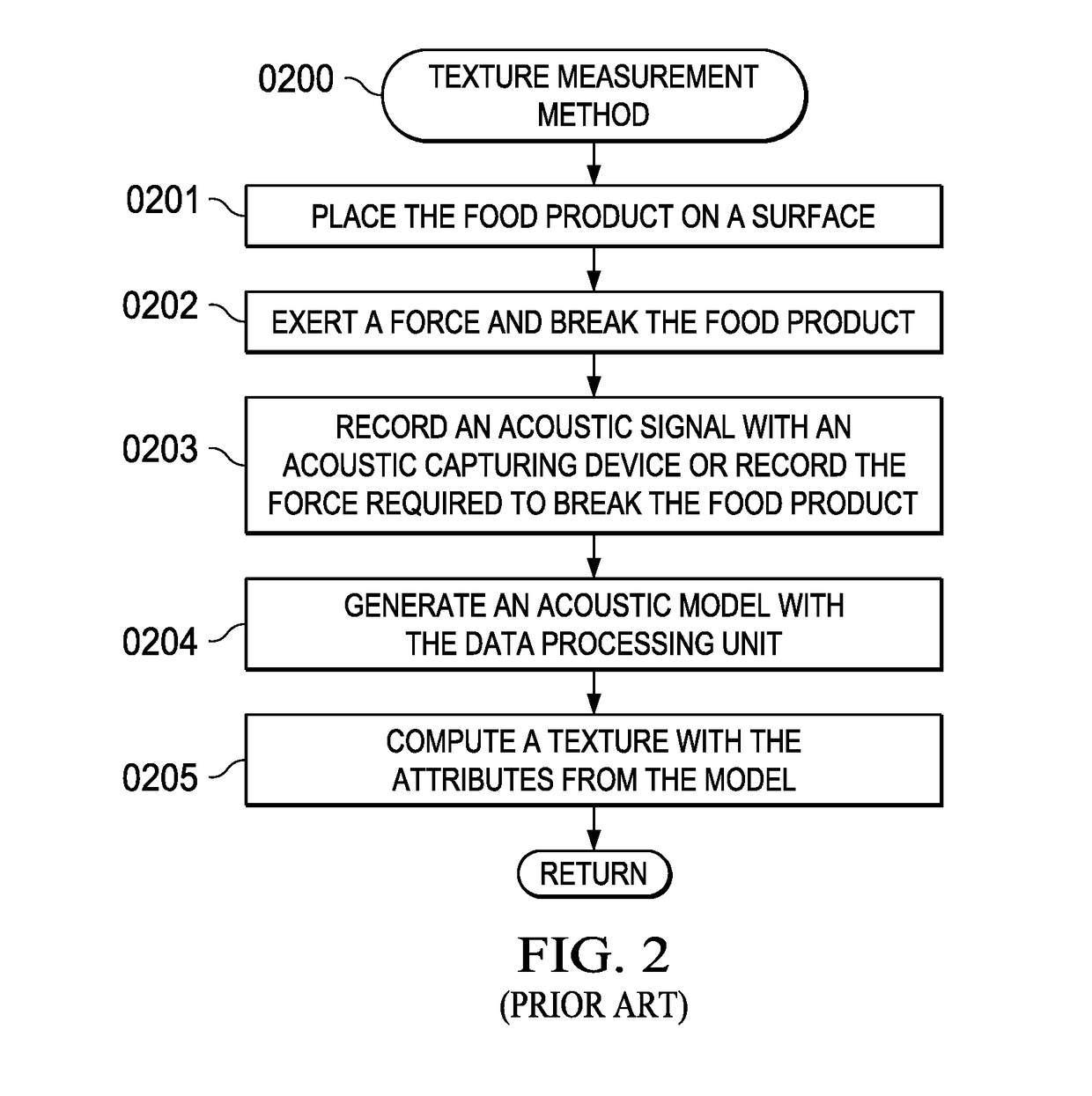

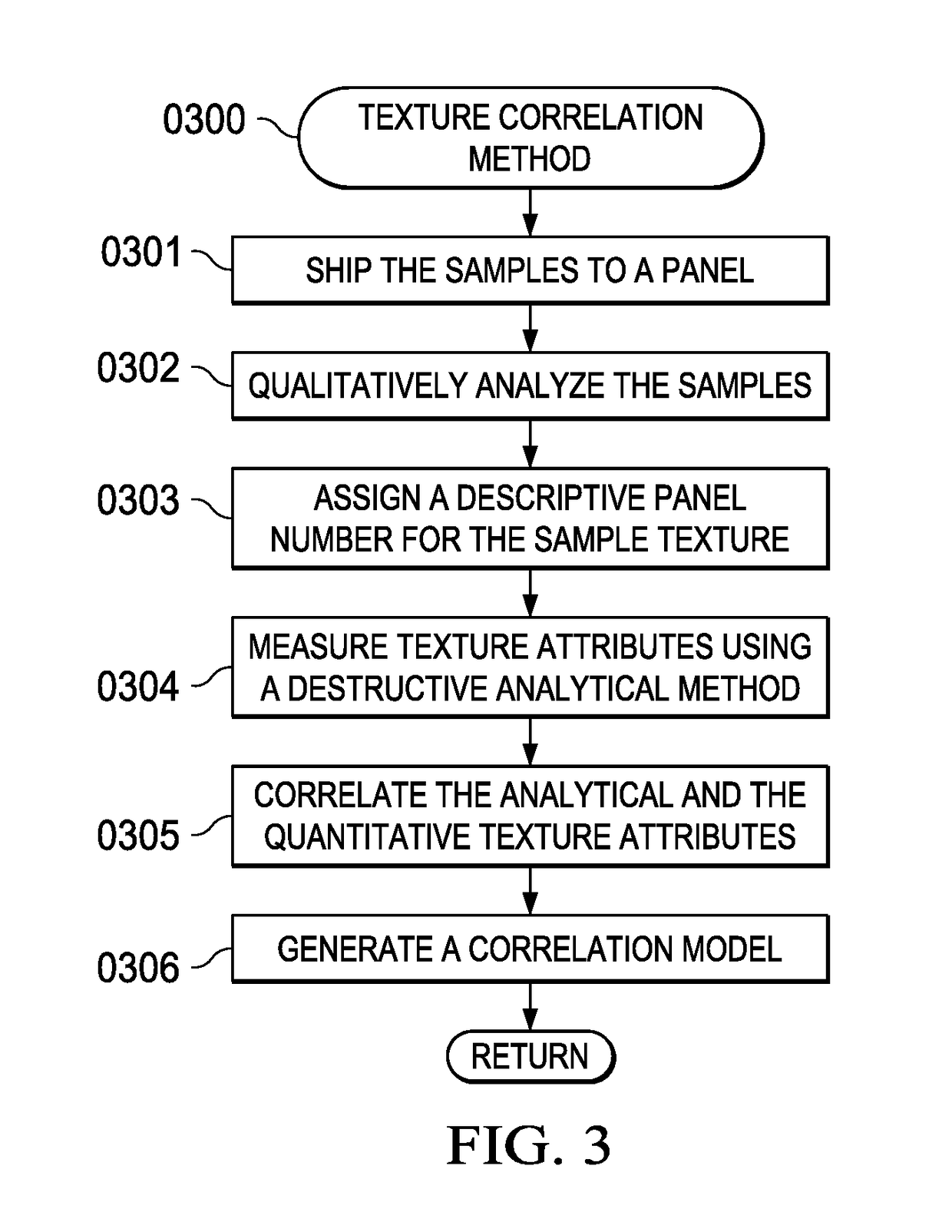

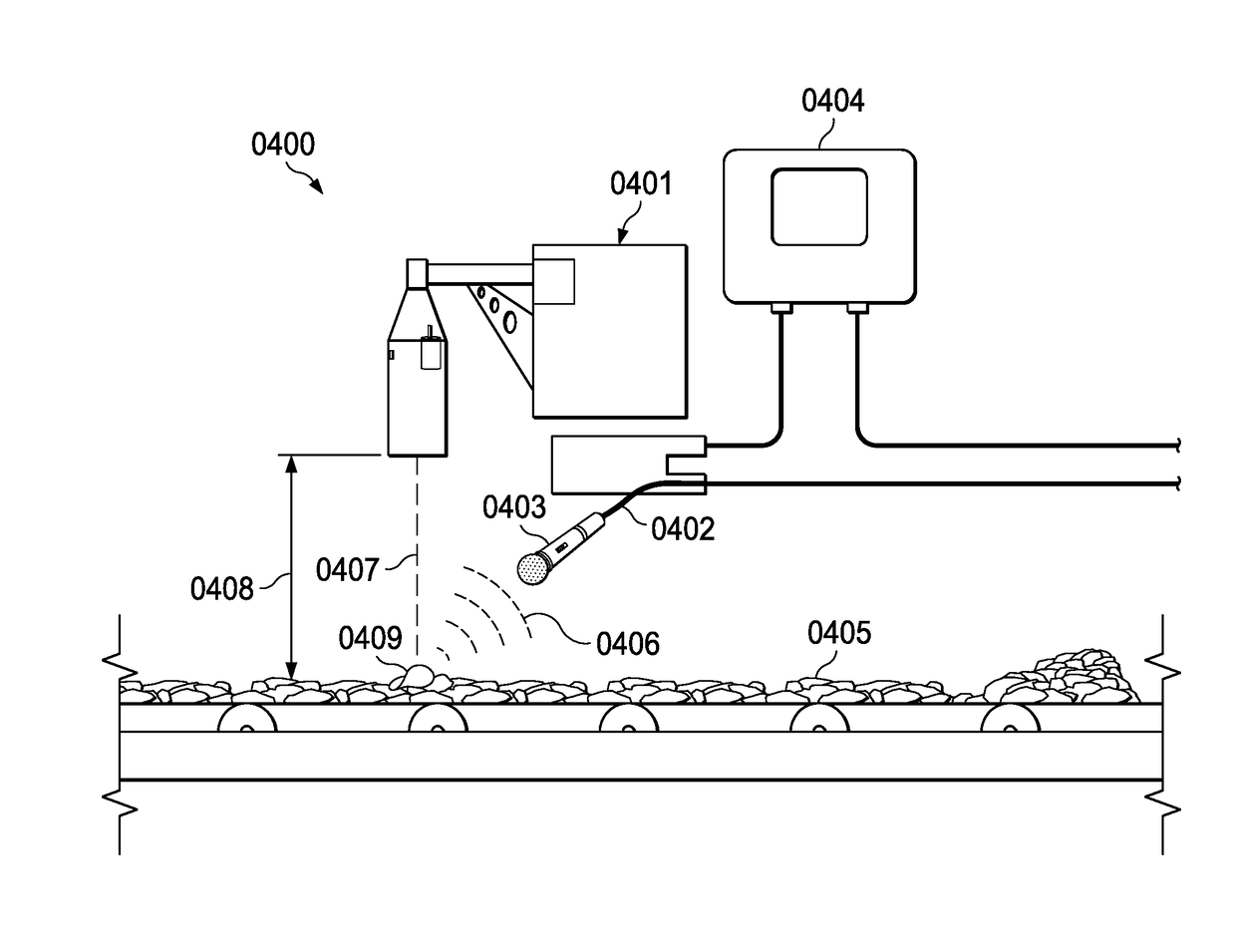

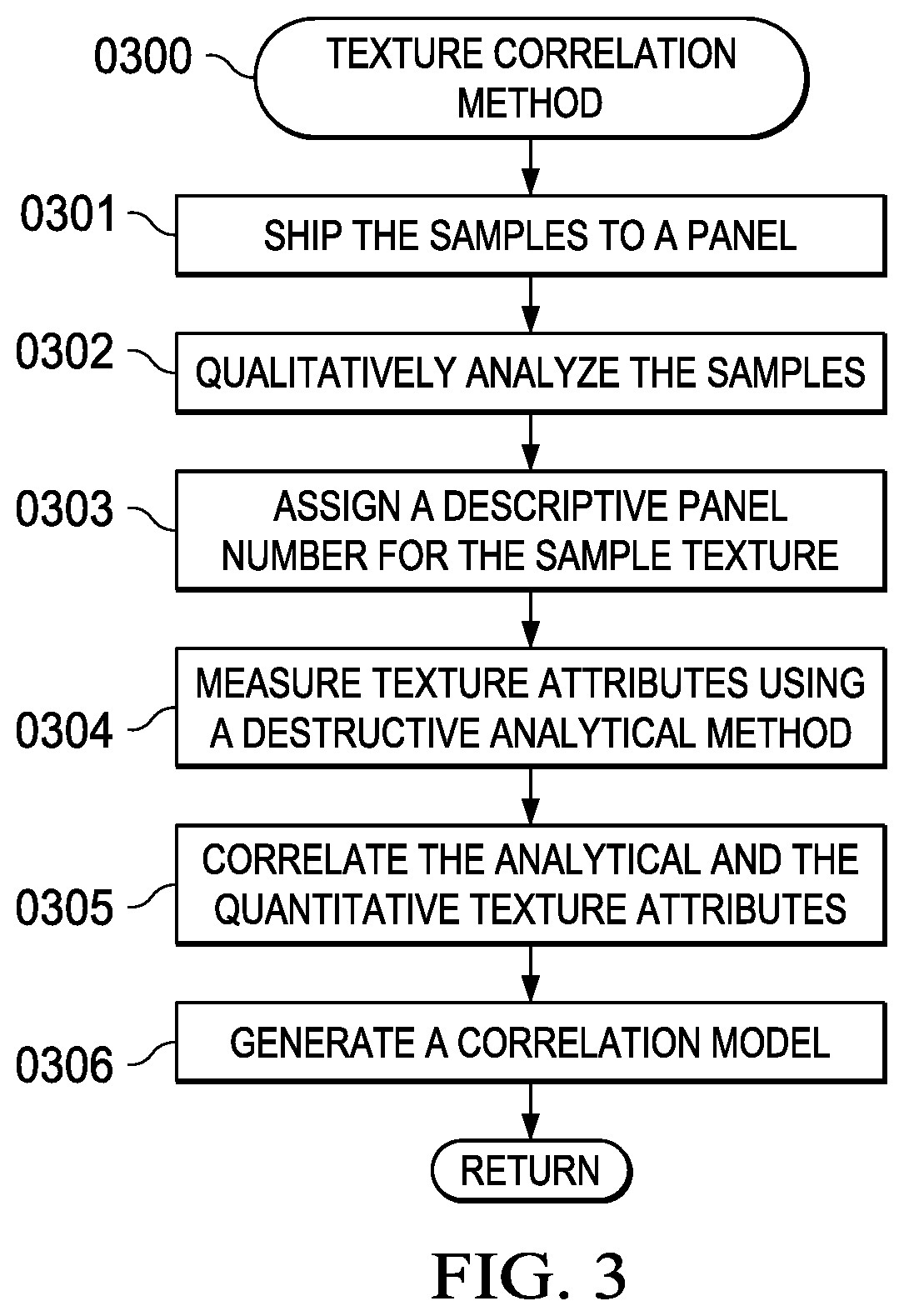

Quantitative Liquid Texture Measurement Apparatus and Method

ActiveUS20170184551A1Testing starch susbtancesAnalysing fluids using sonic/ultrasonic/infrasonic wavesNon destructiveDigital signal processing

A photo acoustic non-destructive measurement apparatus and method for quantitatively measuring texture of a liquid. The apparatus includes a laser generating tool, an acoustic capturing device, and a data processing unit. The laser generating tool directs a laser towards a surface of a liquid contained in a container and creates pressure waves that propagate through the air and produce an acoustic signal. The acoustic capturing device records and forwards the signal to a data processing unit. The data processing unit further comprises a digital signal processing module that processes the received acoustic signal. A statistical processing module further filters the acoustic signal from the data processing unit and generates a quantitative acoustic model for texture attributes such as hardness and fracturability. The quantitative model is correlated with a qualitative texture measurement from a descriptive expert panel. Textures of liquids are quantitatively measured with the quantitative acoustic model.

Owner:FRITO LAY NORTH AMERICA INC

Surface texture measurement apparatus and roundness measuring apparatus

ActiveUS7950164B2Small inexpensive detectorIncrease volumeMechanical counters/curvatures measurementsMechanical roughness/irregularity measurementsMechanical engineeringTexture measurement

Owner:MITUTOYO CORP

Texture automatic monitoring system

InactiveUS20150153167A1Efficient detectionUsing optical meansRoads maintainenceMeasuring instrumentMonitoring system

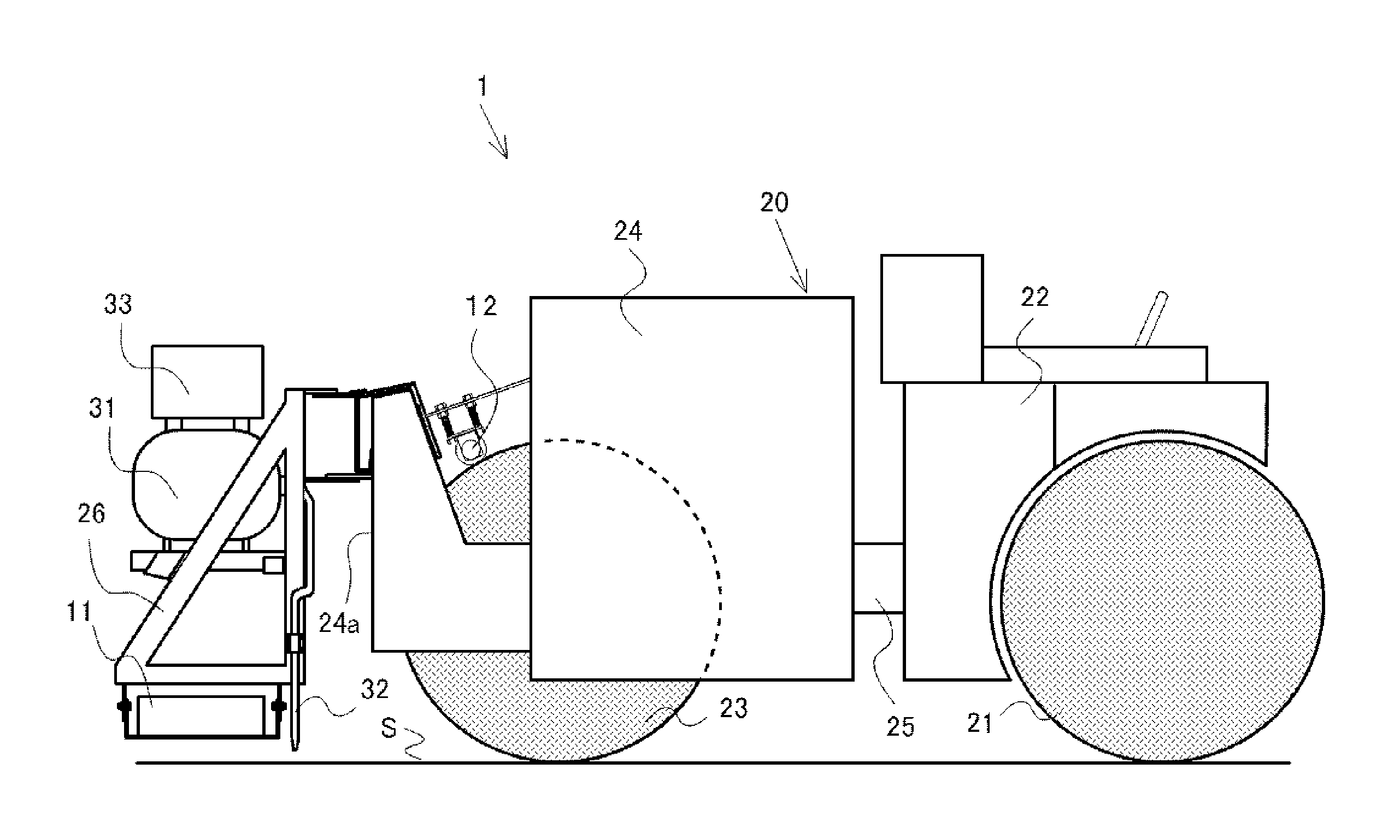

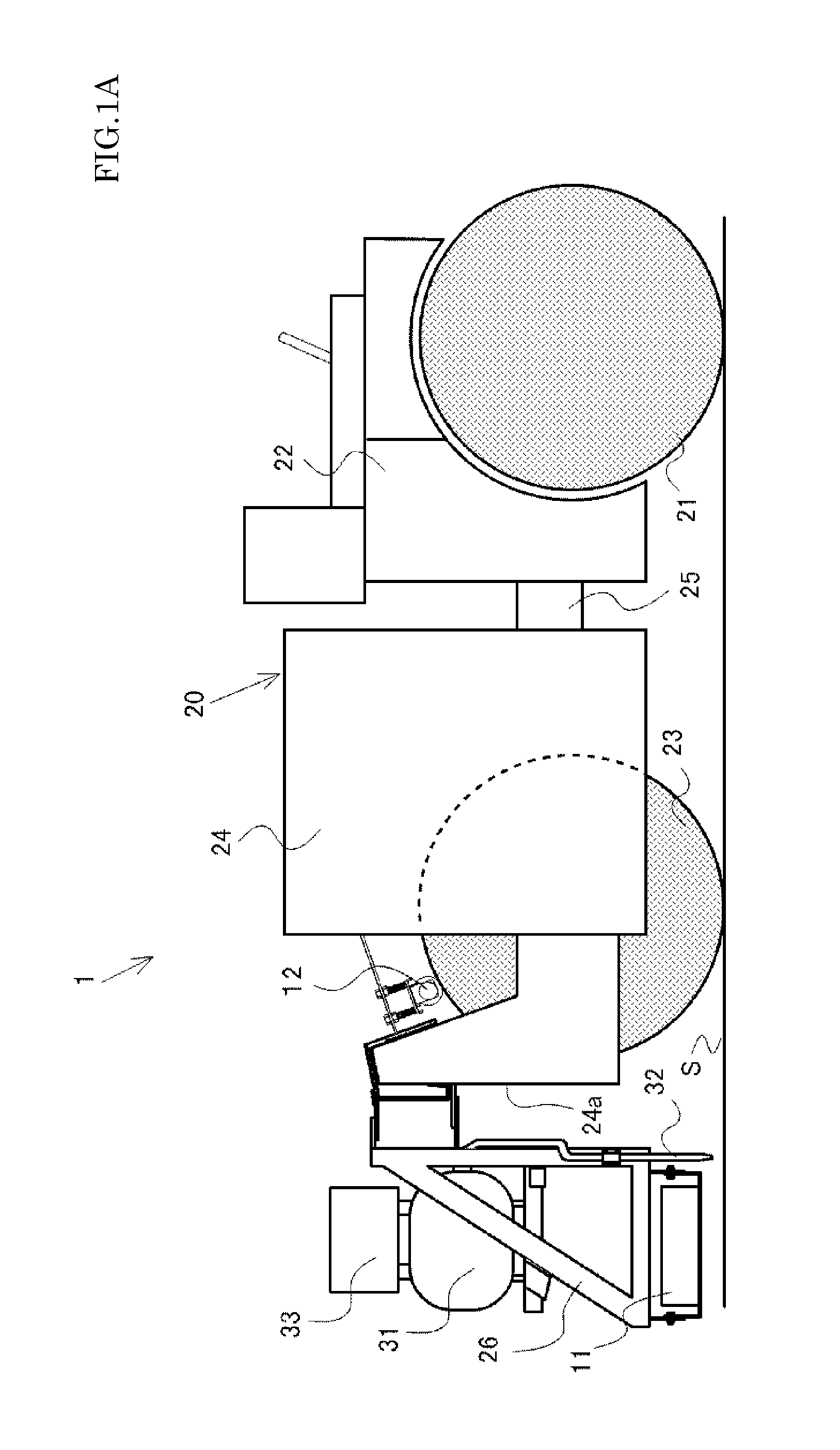

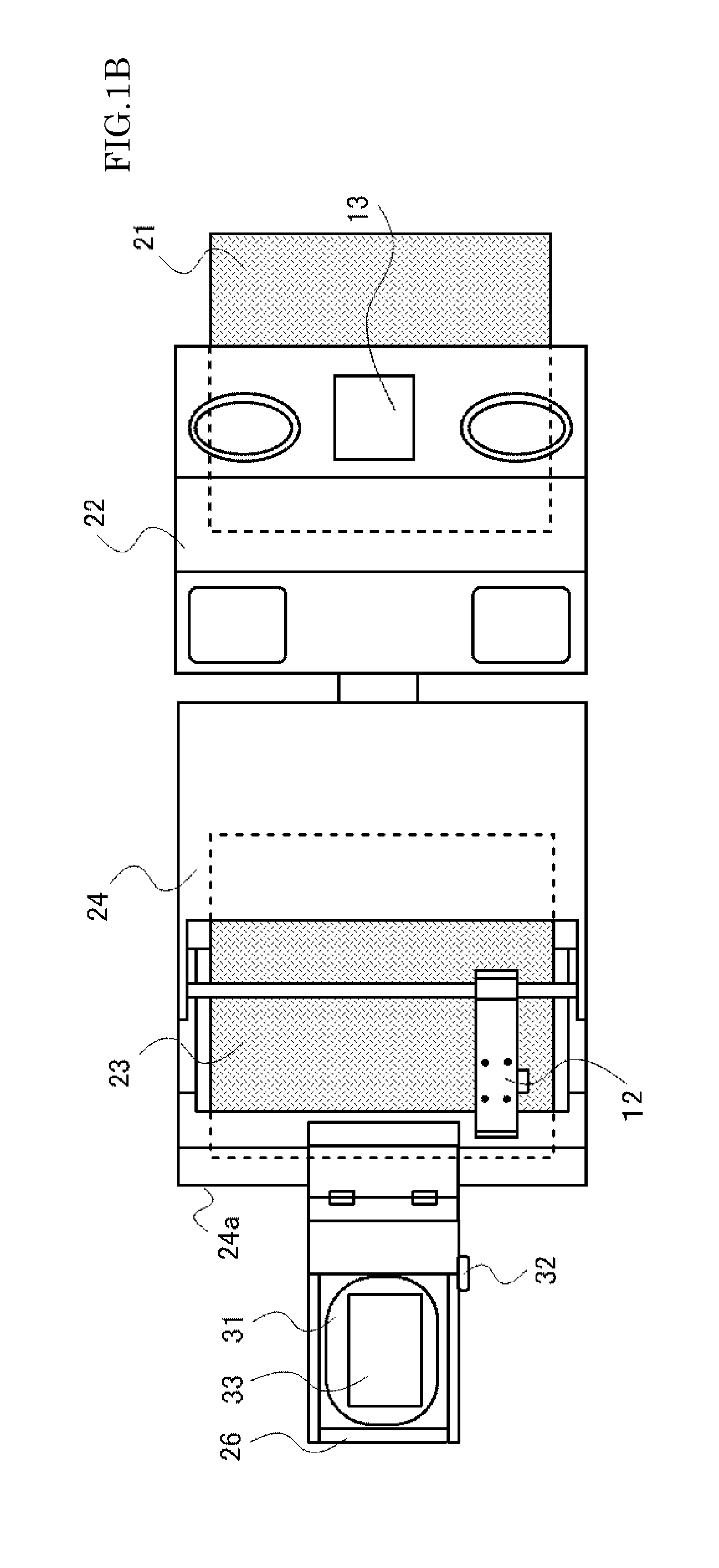

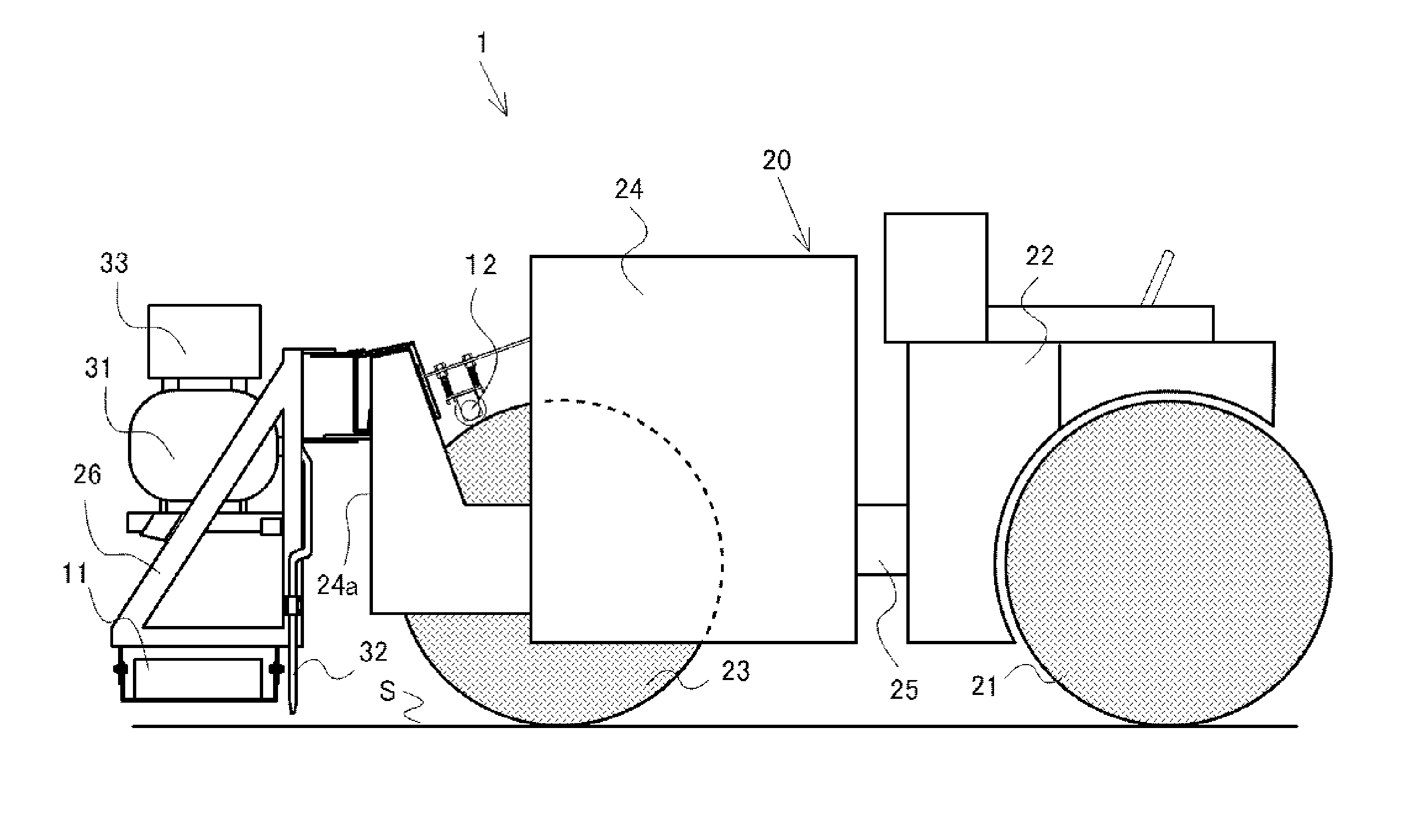

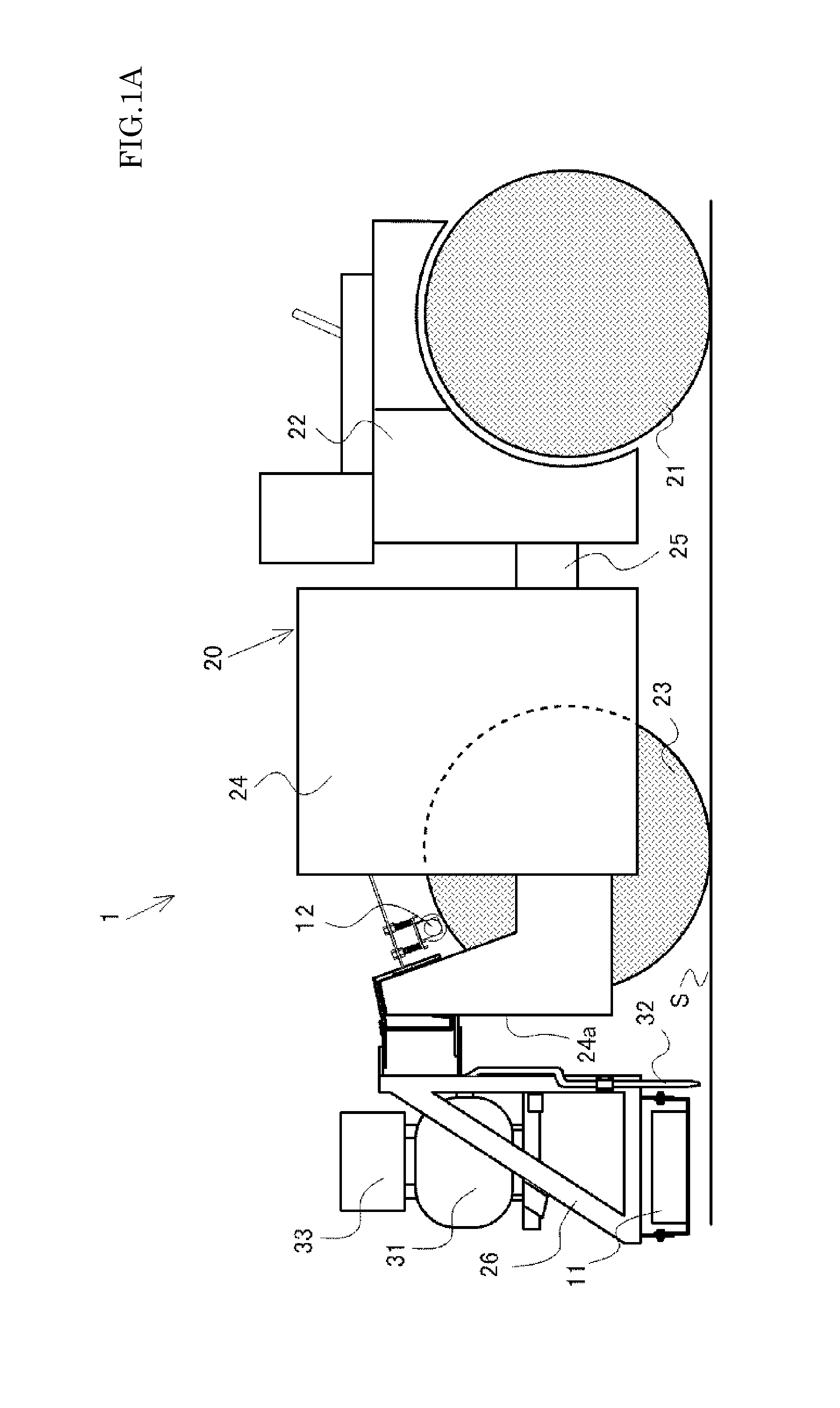

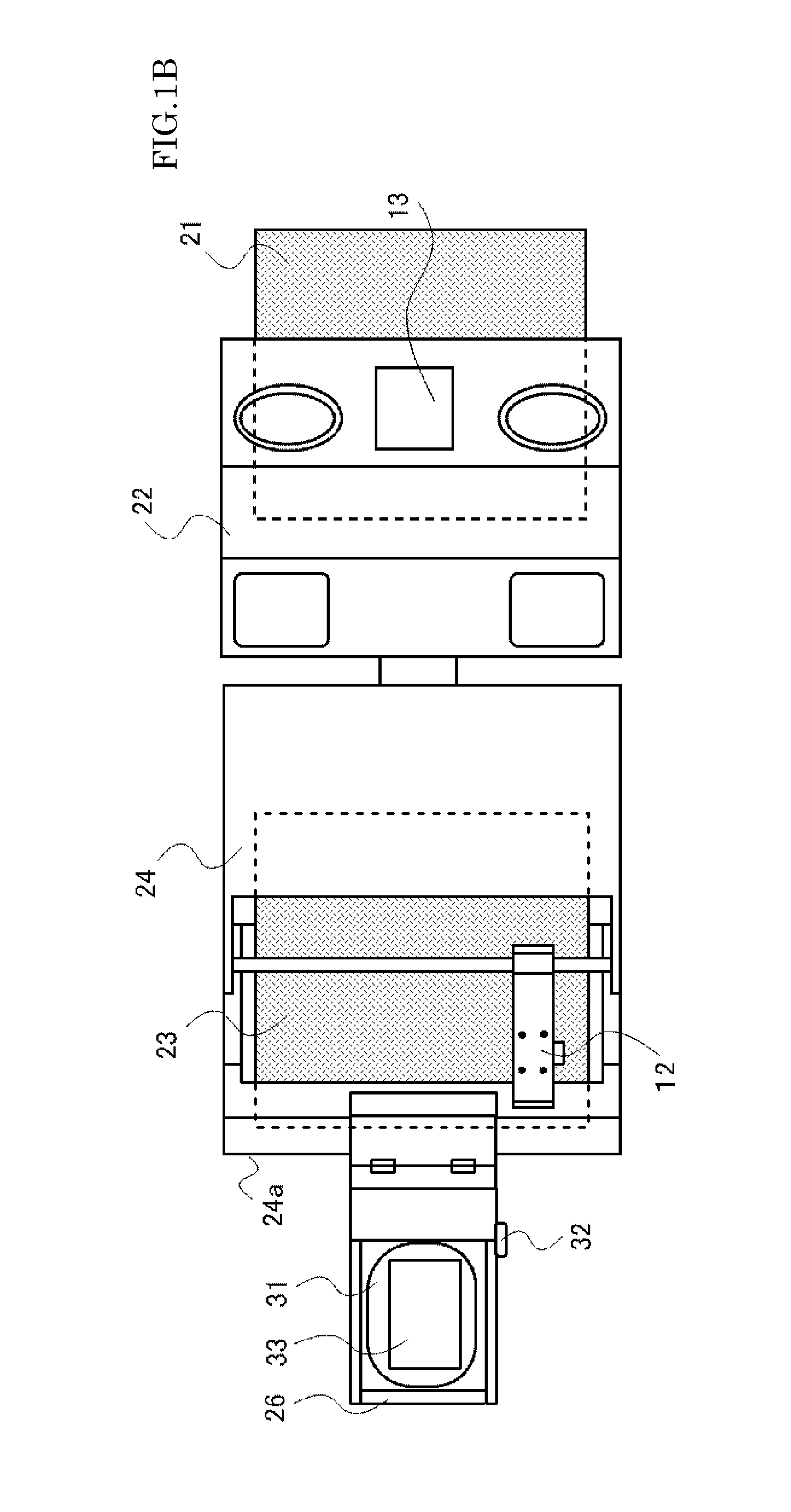

A texture automatic monitoring system for measuring surface texture of a road surface compacted by a road roller is measured by texture measurement equipment mounted on the road roller. The road surface texture measurement equipment comprises a height measurement instrument disposed on the compaction roller that measures height from the road surface, a moving distance detecting instrument that generates a signal corresponding to the moving distance of the road roller, a data processing unit that calculates the moving distance of the road roller based on the moving distance detecting signal, and calculates one or more road surface property values indicating the road surface texture by using the measured value of the height acquired from the height measurement instrument and the calculated moving distance, and a displaying unit which displays the calculated road surface property value.

Owner:KUMATAKA ENG +2

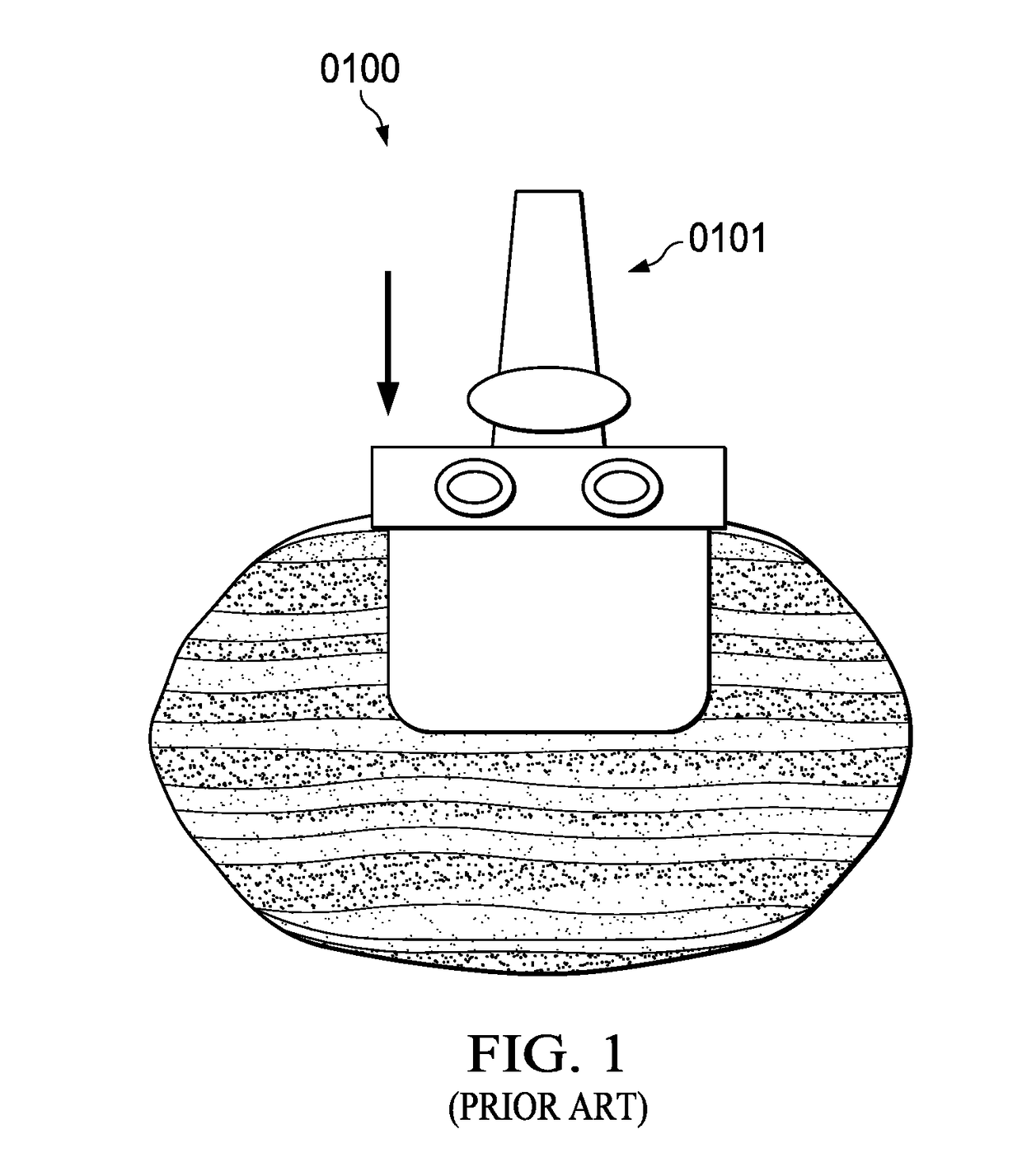

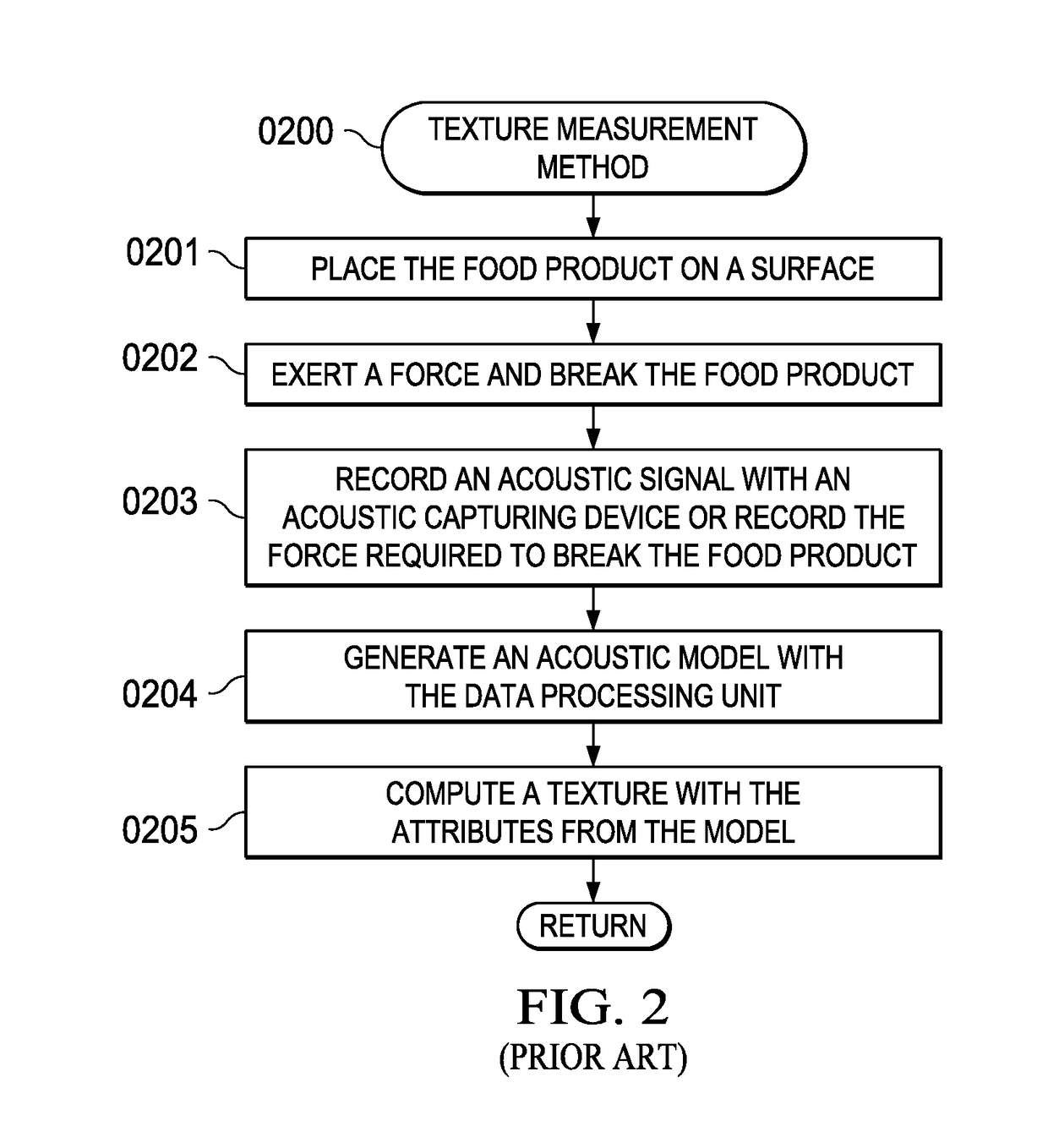

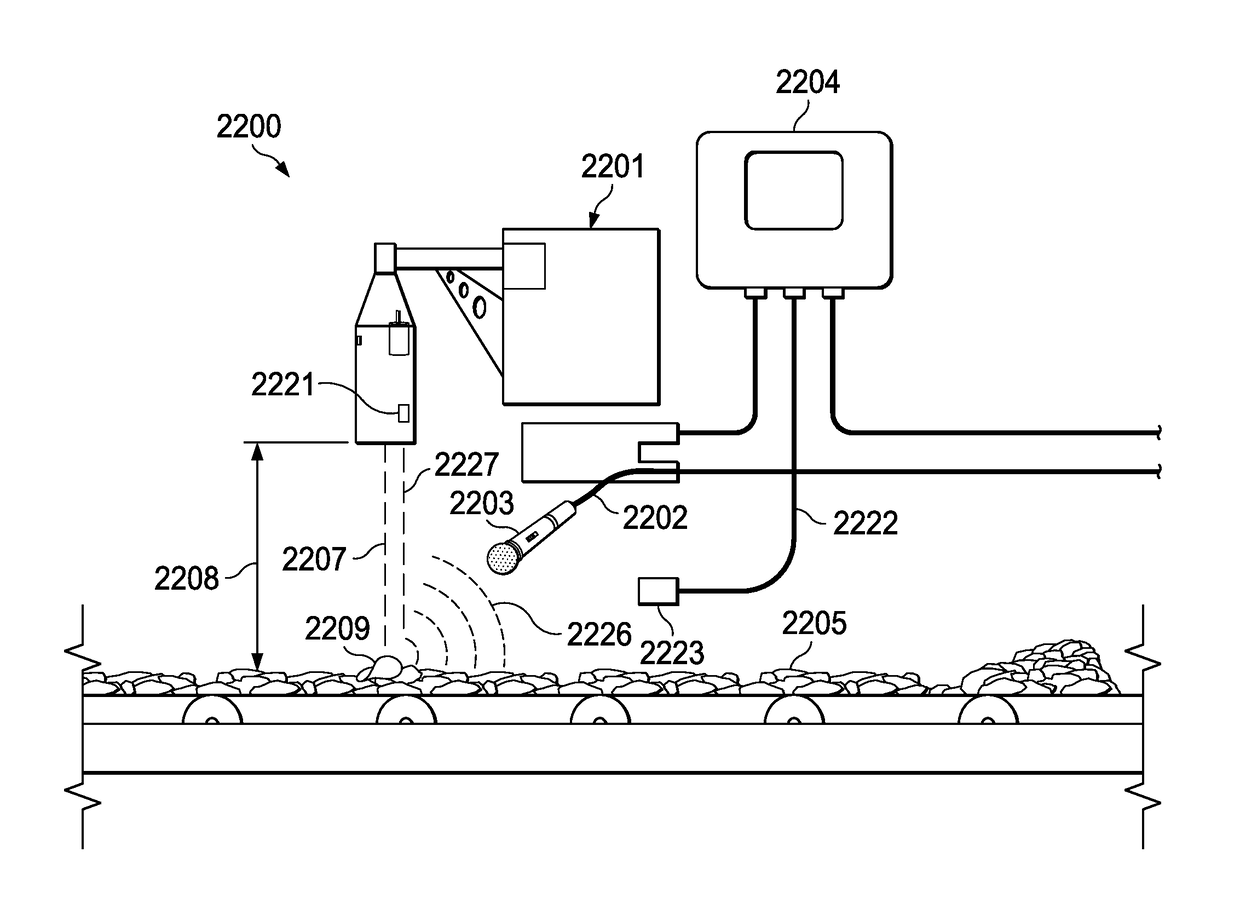

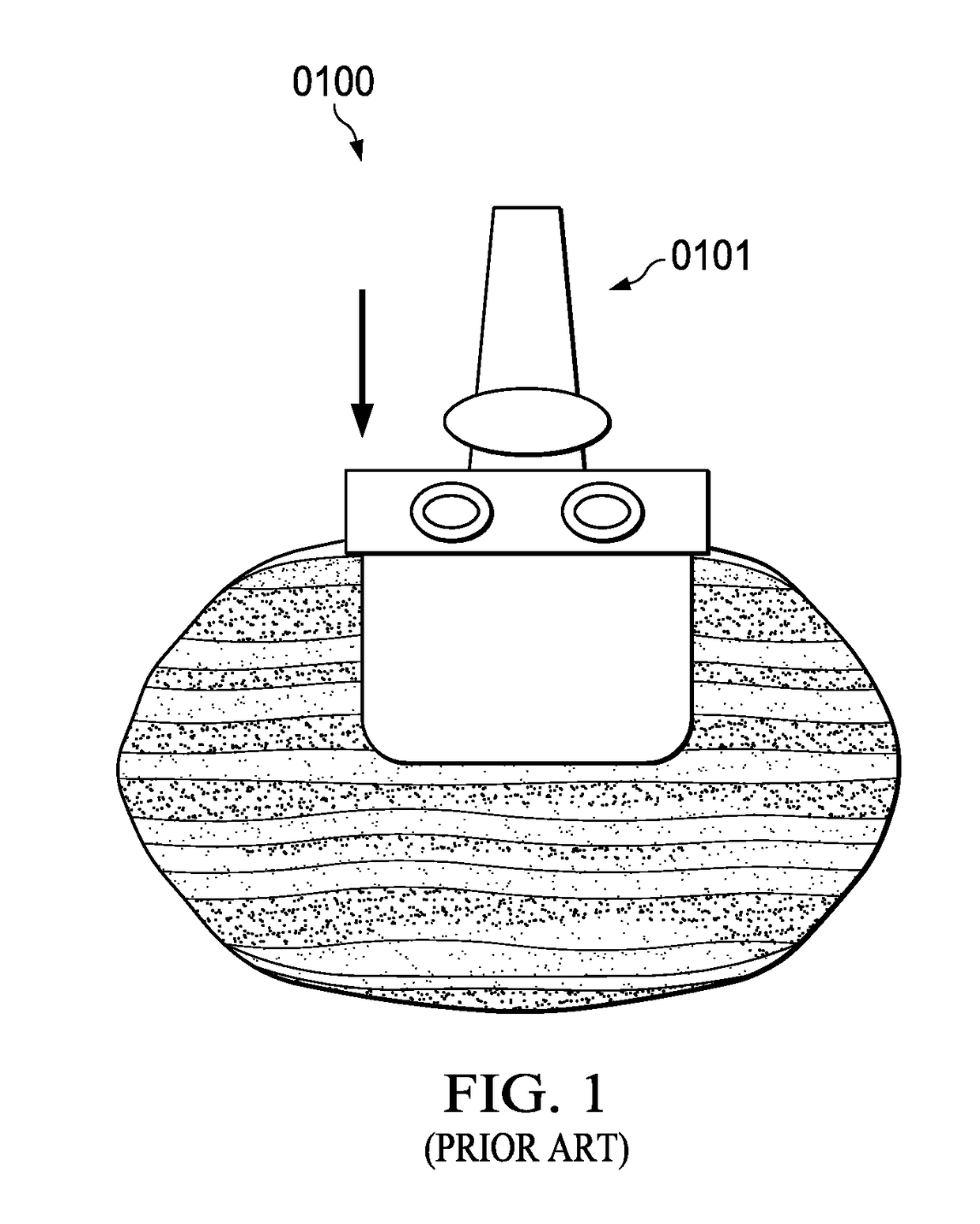

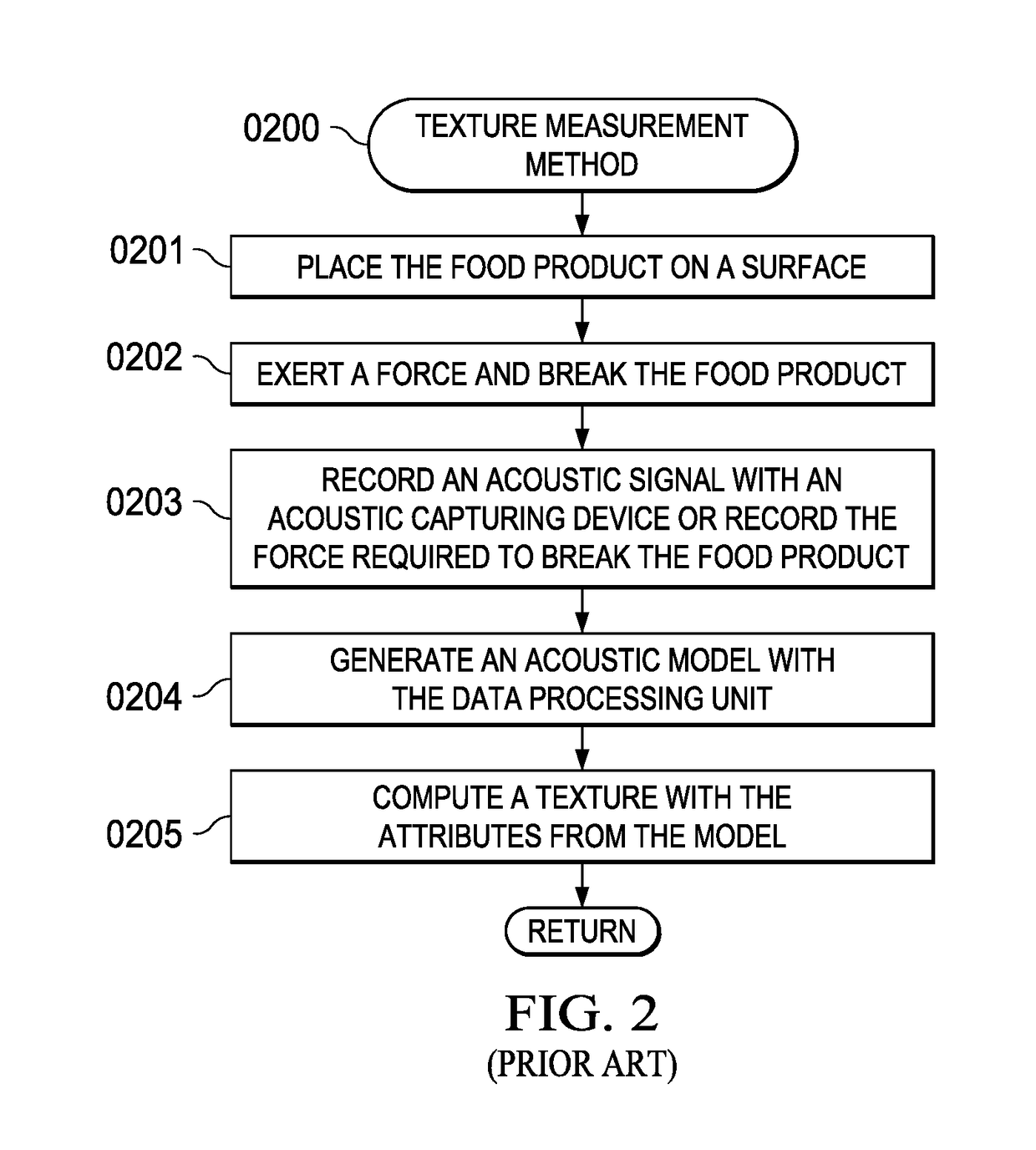

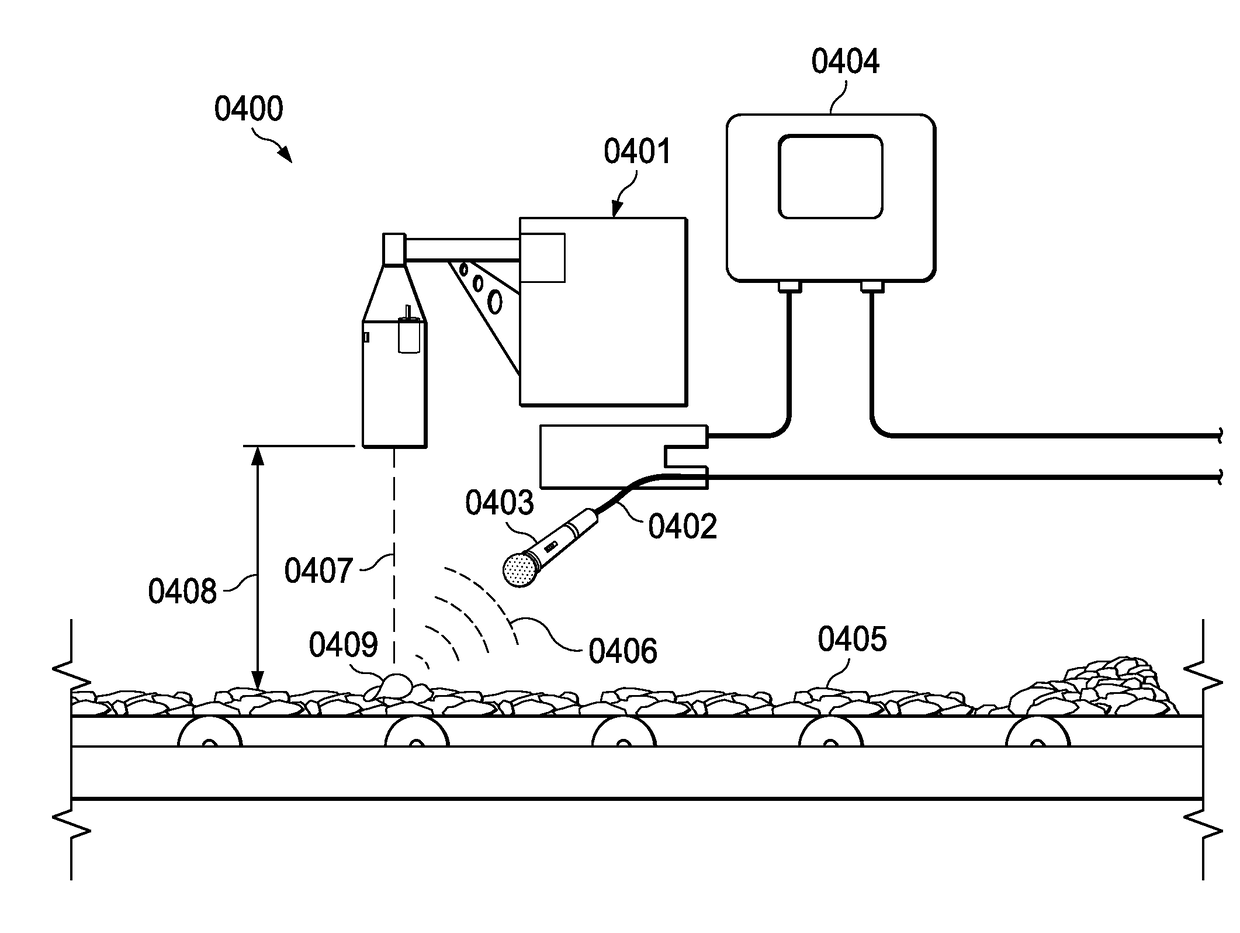

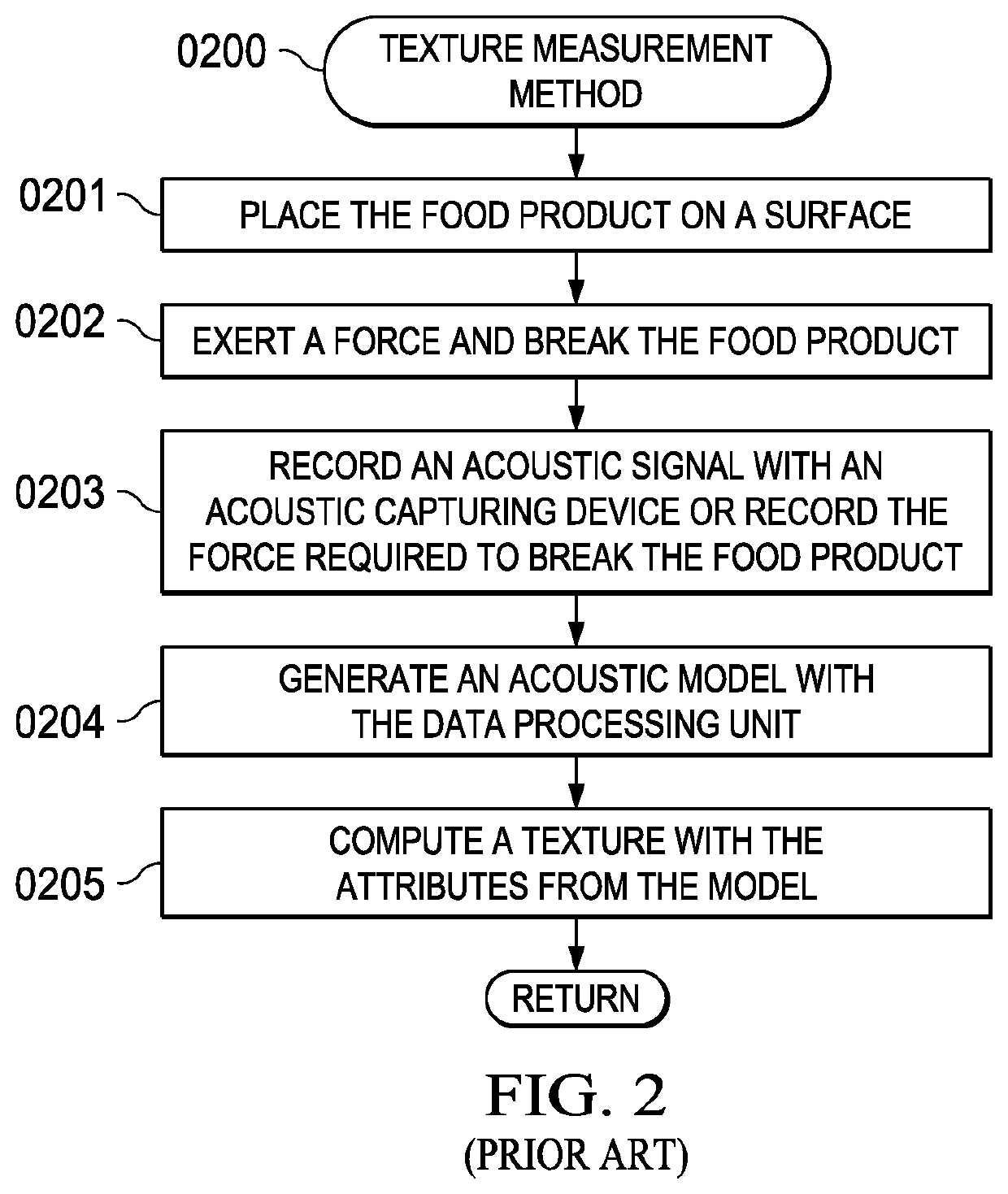

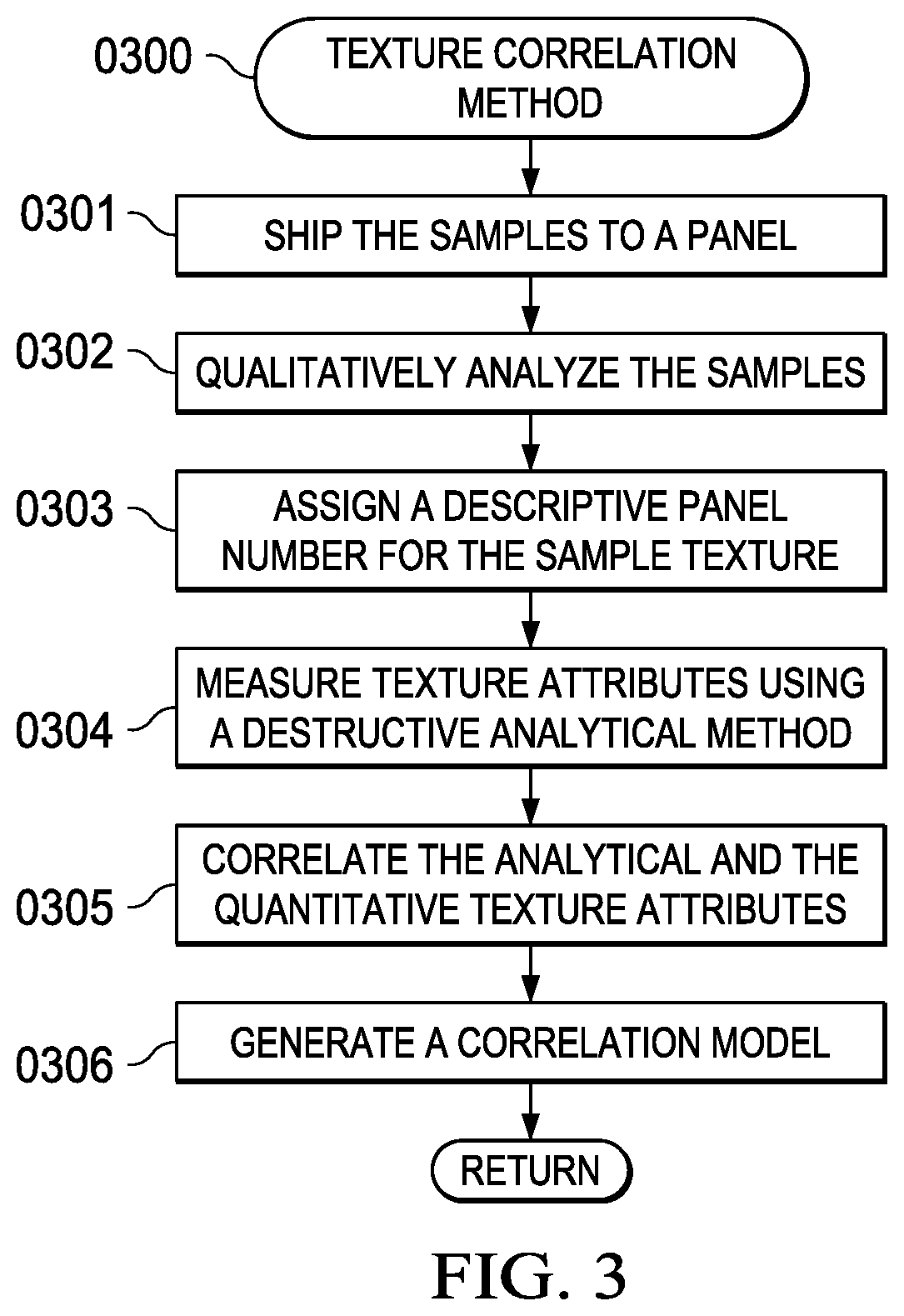

Quantitative Texture Measurement Apparatus and Method

ActiveUS20180011069A1Testing starch susbtancesAnalysing solids using sonic/ultrasonic/infrasonic wavesDigital signal processingNon destructive

A non-destructive measurement apparatus and method for quantitatively measuring texture of a food snack is disclosed. The apparatus includes a laser generating tool, an ultrasound excitation device, an acoustic capturing device, an ultrasound capturing device and a data processing unit. The laser generating tool and the ultrasound excitation tool direct energy towards a food snack placed on a surface and produce an acoustic signal and an ultrasound signal. The data processing unit further comprises a digital signal processing module that processes the received acoustic signal and ultrasound signal. A statistical processing module further filters the acoustic signal from the data processing unit and generates a quantitative acoustic model for texture attributes such as hardness and fracturability. The quantitative model is correlated with a qualitative texture measurement from a descriptive expert panel. Texture of food snacks are quantitatively measured with the quantitative acoustic model.

Owner:FRITO LAY NORTH AMERICA INC

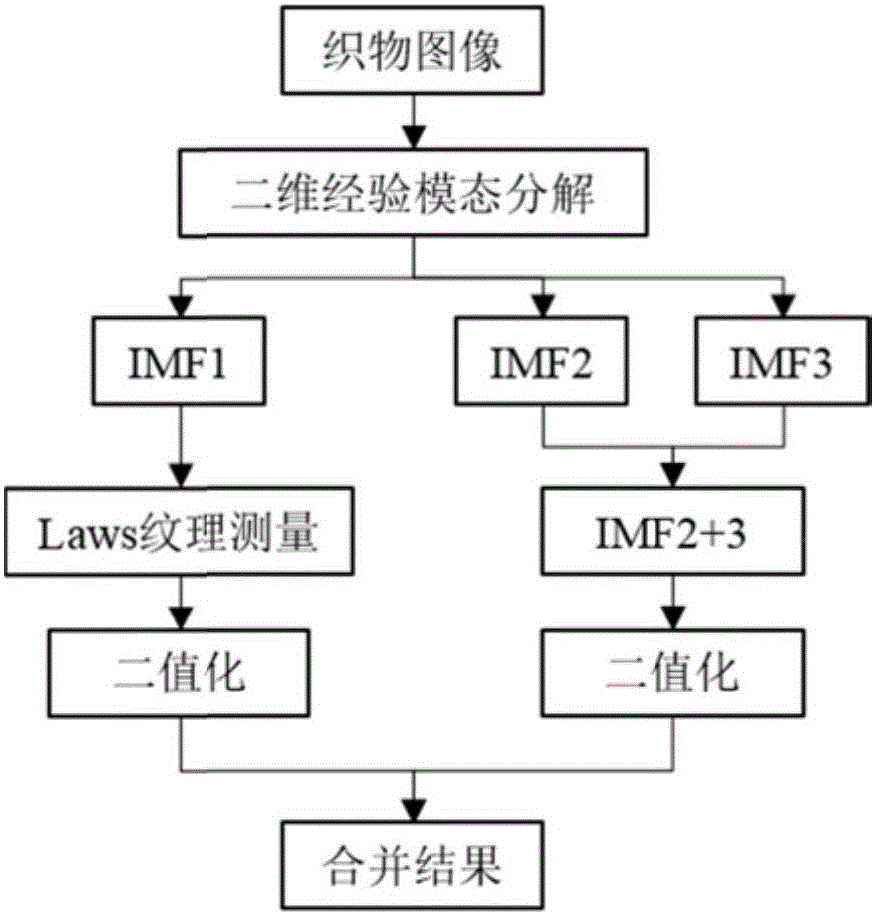

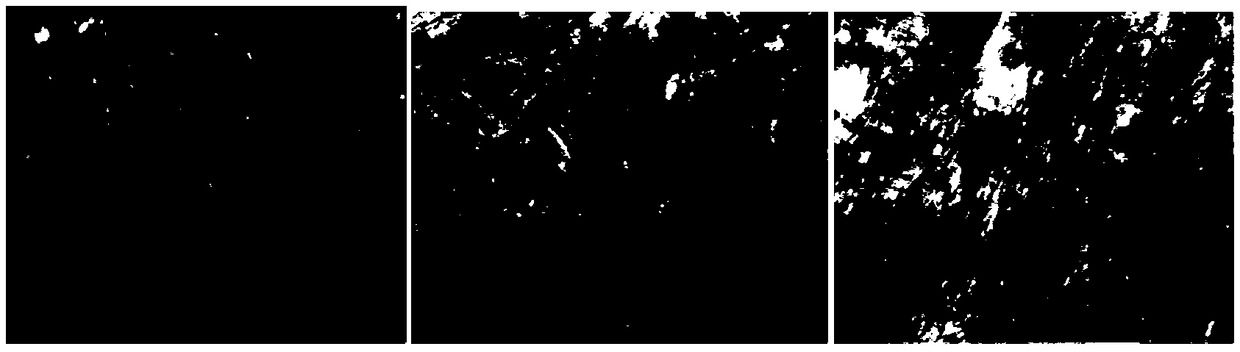

Dual-channel fabric fault detection method based on two-dimensional empirical mode decomposition

ActiveCN105844657AImprove detection adaptabilityPromote decompositionImage enhancementImage analysisPattern recognitionDecomposition

The present invention relates to a dual-channel fabric fault detection method based on two-dimensional empirical mode decomposition. Aiming at each step method and parameters in the fabric image feature two-dimensional empirical mode decomposition, an optimal decomposition method is employed to obtain IMFI consisting of fabric texture information and IMF2+3 consisting of rough scale gray information; the texture energy is extracted by using optimal Laws texture measurement, the binaryzation operation is performed, and a texture detection channel result is obtained; the binaryzation operation of the IMF2+3 is carried out, and a gray detection channel result is obtained; and the texture detection channel result and the gray detection channel result are fused, and the fabric fault detection result is obtained, wherein the pixel with the value of 255 in the result represents a faultless region, and the pixel with the value of 0 in the result represents a fault region. The dual-channel fabric fault detection method based on the two-dimensional empirical mode decomposition solve the problem that the two-dimensional empirical mode decomposition is short of the scheme of fabric image decomposition, and on the basis, provides a dual-channel fabric fault detection method according with a human eye work mode.

Owner:JIANGNAN UNIV

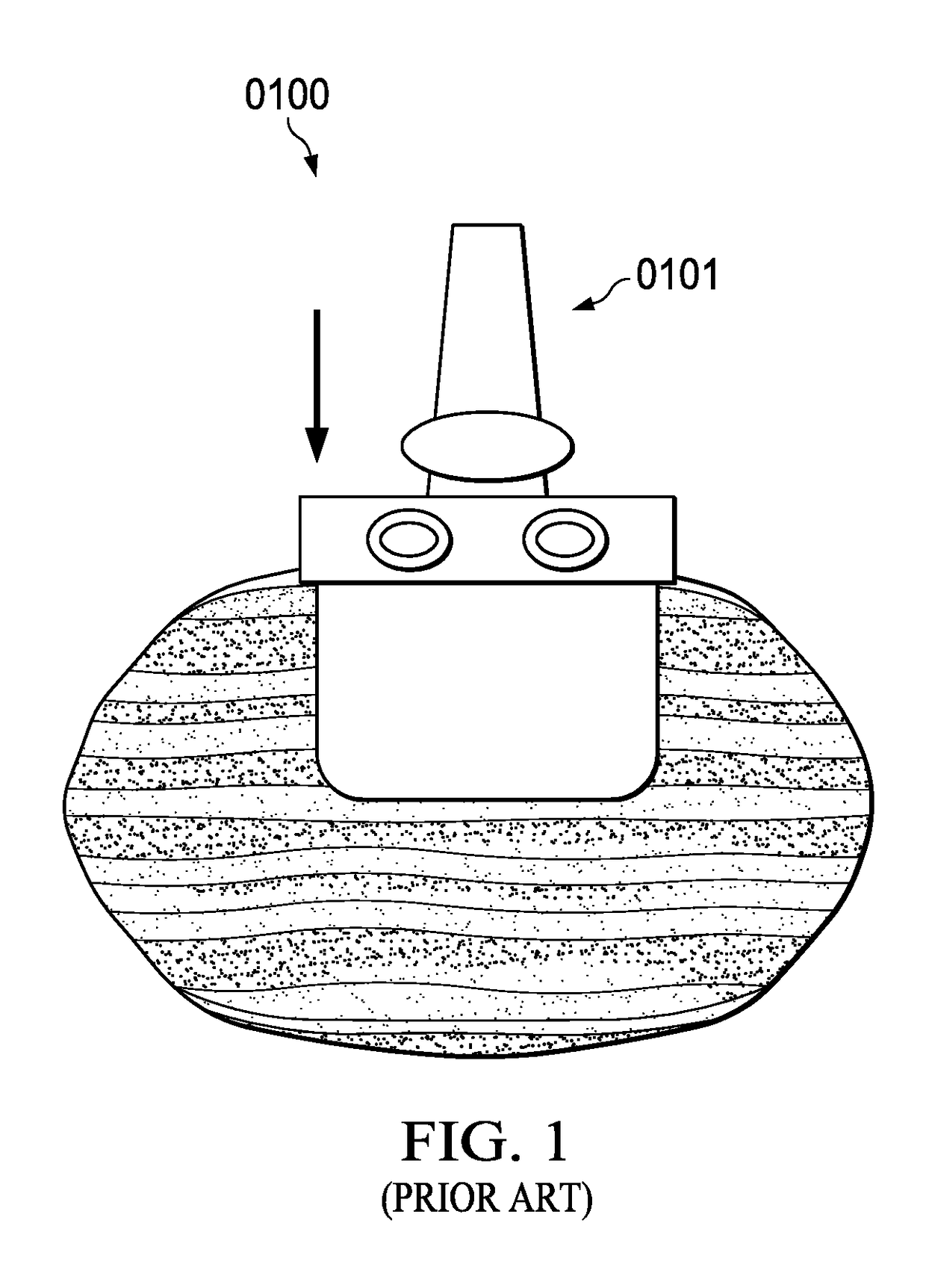

Quantitative In-Situ Texture Measurement Apparatus and Method

ActiveUS20170176309A1Analysing solids using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementDigital signal processingMeasurement device

A measurement apparatus and method for in-situ quantitative texture measurement of a food snack. The apparatus includes an acoustic capturing device and a data processing unit. The physical interaction in the mouth with saliva, when a human being eats / drinks a food snack, sends pressure waves that propagate through the ear bone and produce an acoustic signal. The acoustic capturing device records and forwards the signal to a data processing unit. The data processing unit further comprises a digital signal processing module that smoothens, transforms and filters the received acoustic signal. A statistical processing module further filters the acoustic signal from the data processing unit and generates a quantitative acoustic model for texture attributes such as hardness and fracturability. The quantitative model is correlated with a qualitative texture measurement from a descriptive expert panel. Another method includes a food snack fingerprinting using an in-situ quantitative food property measurement.

Owner:FRITO LAY NORTH AMERICA INC

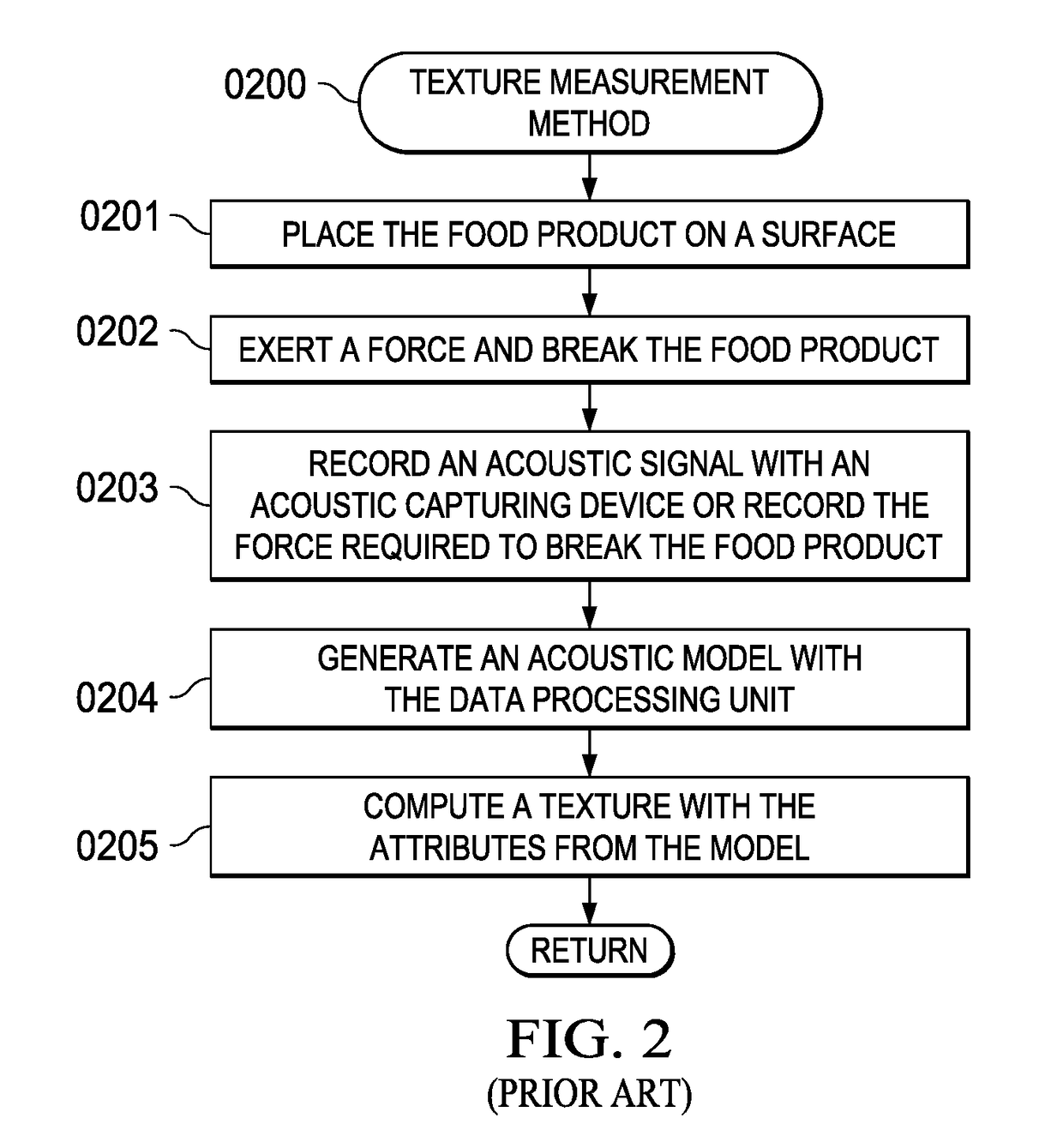

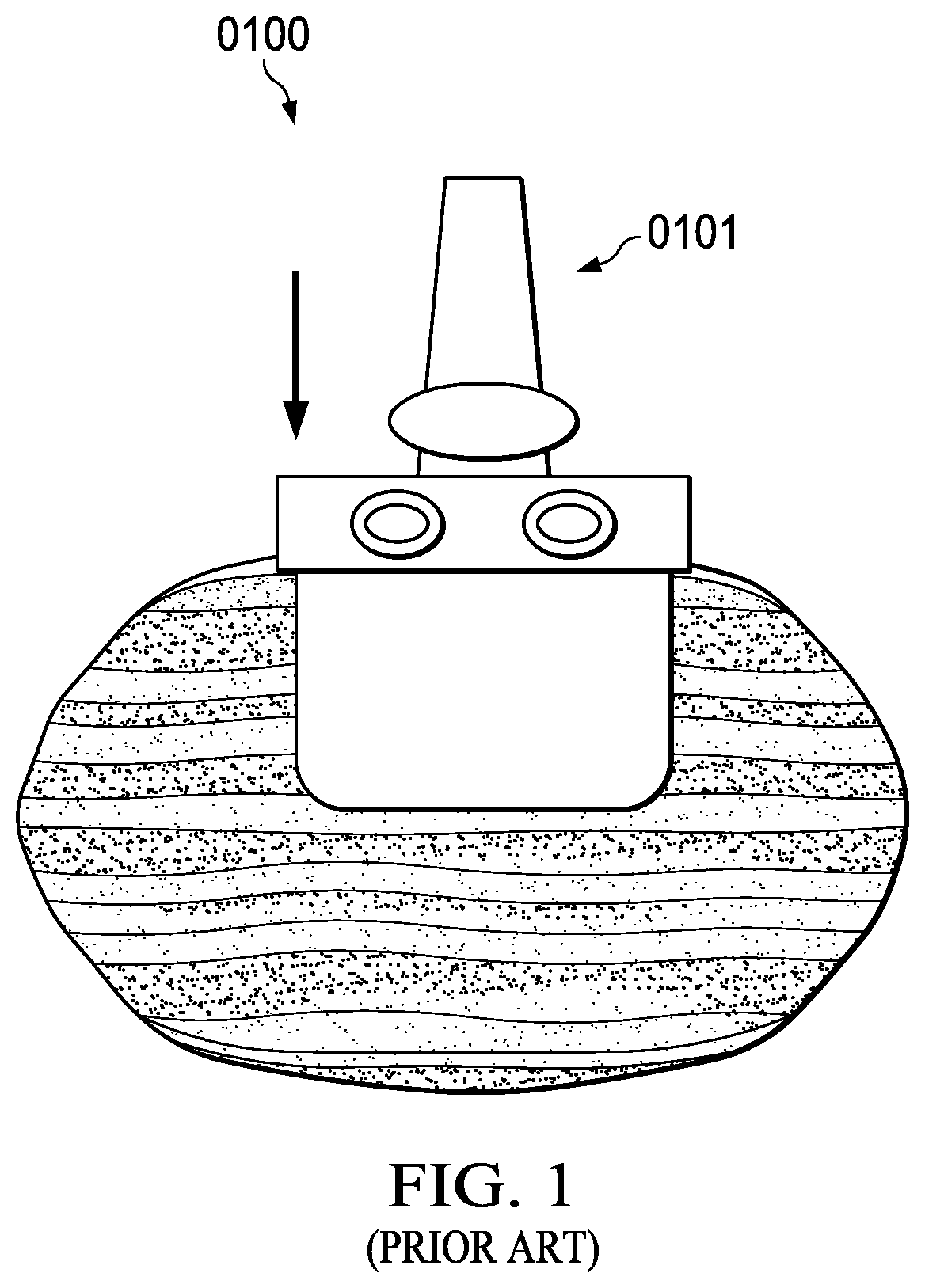

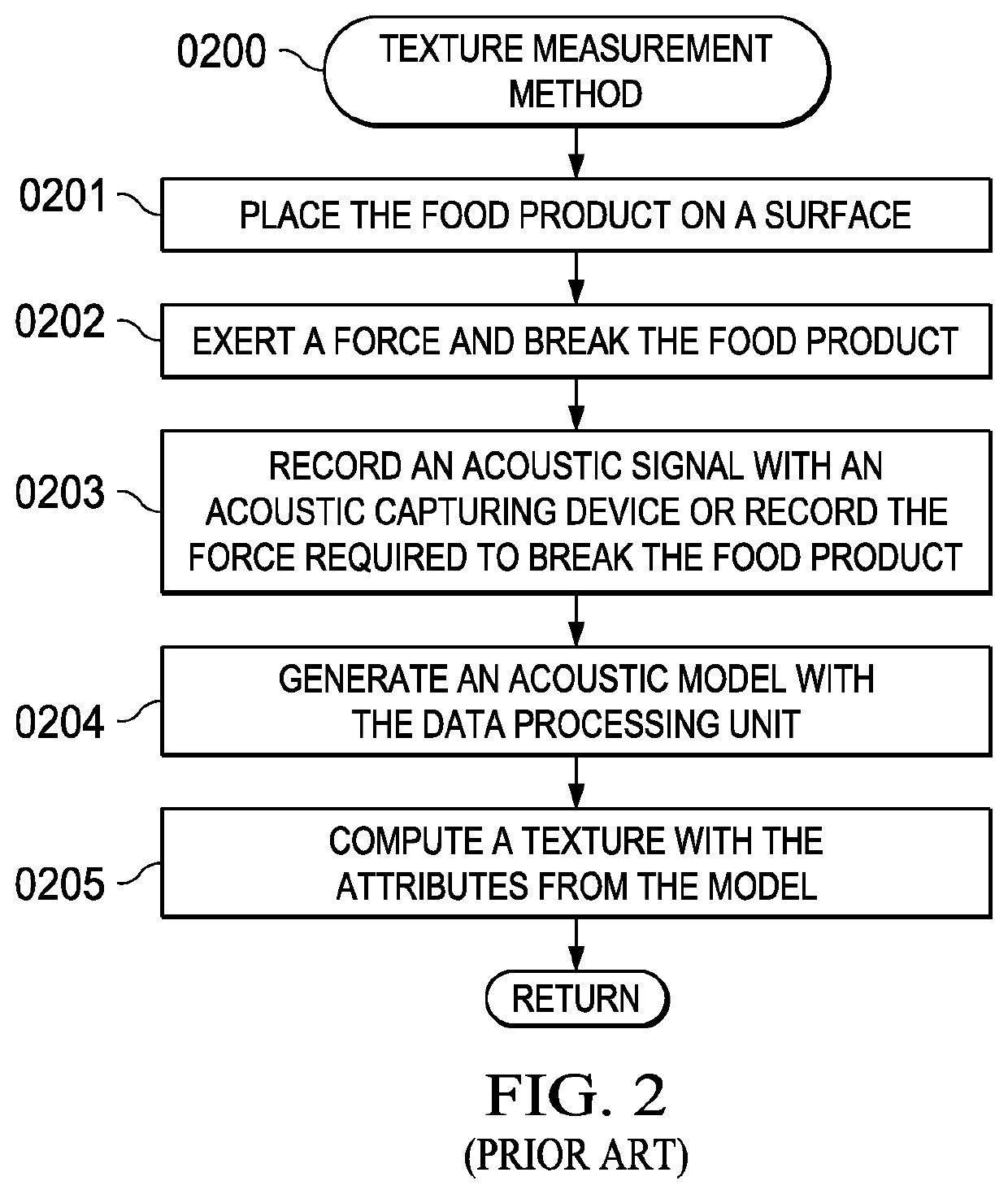

Quantitative texture measurement apparatus and method

ActiveUS20170097324A1Testing starch susbtancesAnalysing solids using sonic/ultrasonic/infrasonic wavesDigital signal processingNon destructive

A photo acoustic non-destructive measurement apparatus and method for quantitatively measuring texture of a food snack is disclosed. The apparatus includes a laser generating tool, an acoustic capturing device, and a data processing unit. The laser generating tool directs a laser towards a food snack placed on a surface and creates pressure waves that propagate through the air and produce an acoustic signal. The acoustic capturing device records and forwards the signal to a data processing unit. The data processing unit further comprises a digital signal processing module that processes the received acoustic signal. A statistical processing module further filters the acoustic signal from the data processing unit and generates a quantitative acoustic model for texture attributes such as hardness and fracturability. The quantitative model is correlated with a qualitative texture measurement from a descriptive expert panel. Texture of food snacks are quantitatively measured with the quantitative acoustic model.

Owner:FRITO LAY NORTH AMERICA INC

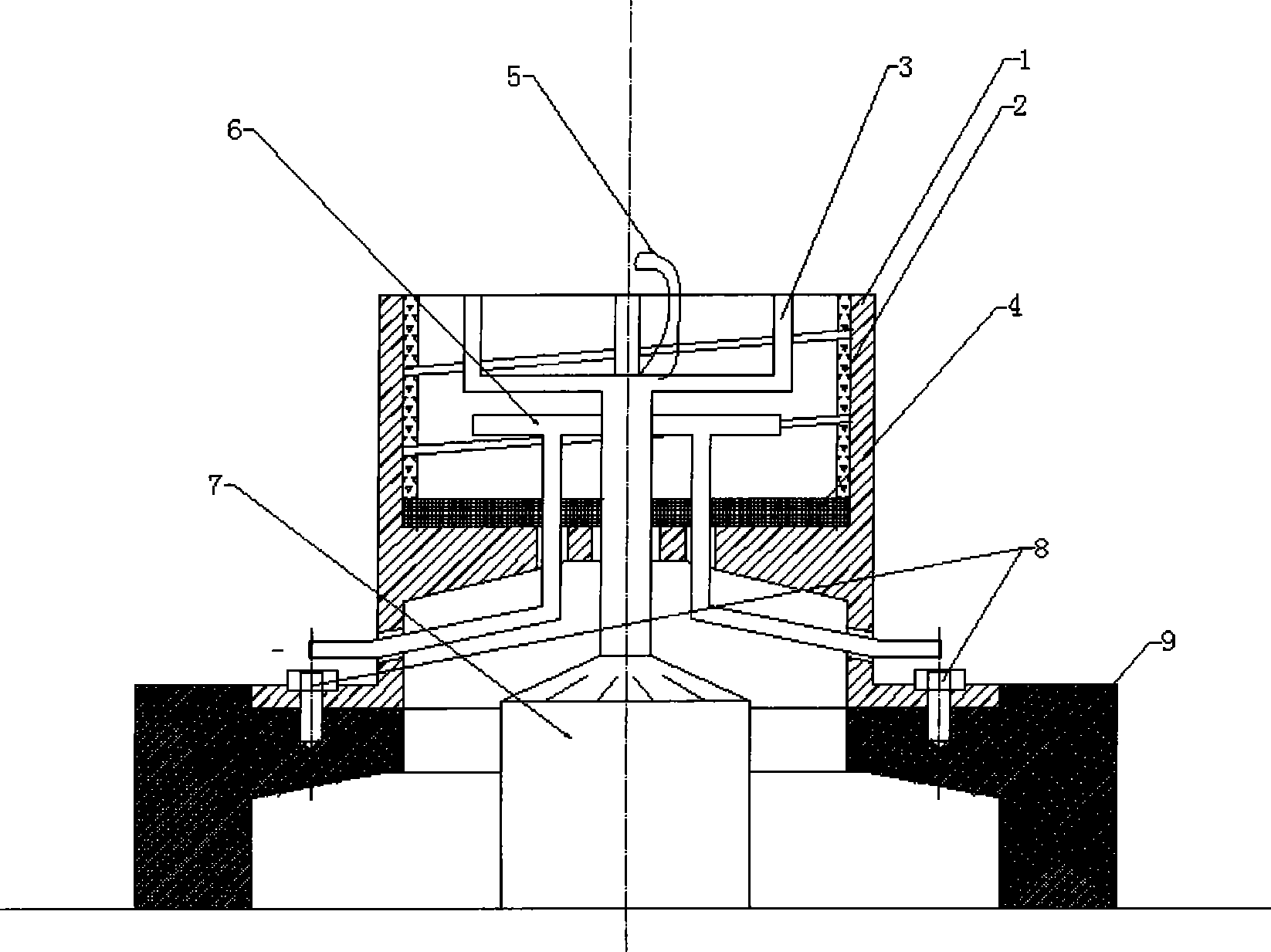

High-temperature heating equipment used for orientation texture measurement

InactiveCN101482525AEvenly heatedGuaranteed Texture MeasurementsMaterial analysis using radiation diffractionTemperature stressElectric machinery

The invention relates to a high-temperature heating device for measuring the orientation texture in a measurement technical field, comprising a heating furnace, a heating element, a sample stage, a sample rack, a thermocouple, a water cooling pipe, a step motor, wherein the exterior of the heating furnace is a ceramics socket sleeve and a spiral drum type heating element is embedded into the heating furnace and the heating furnace is set on the sample stage; and the sample rack is set in the step motor and separated from the heating furnace, capable of rotating along the self-axle in the heating furnace; a water cooling pipe is set at the lower part of the sample rack and coils in parallel with the sample undersurface to form a cooling plane; and the thermocouple is set in the heating furnace. During heating process, the sample can rotate and the uniform heating of sample can be ensured; at the same time the rotation is consistent with the Phi rotation in general texture measurement, thereby ensuring the texture measurement at high-temperature; in addition, the whole of the heating furnace is set on the texture measurement stage, thus Psi rotation of stress rolling method, therefore the high-temperature stress measurement can be performed.

Owner:SHANGHAI JIAO TONG UNIV

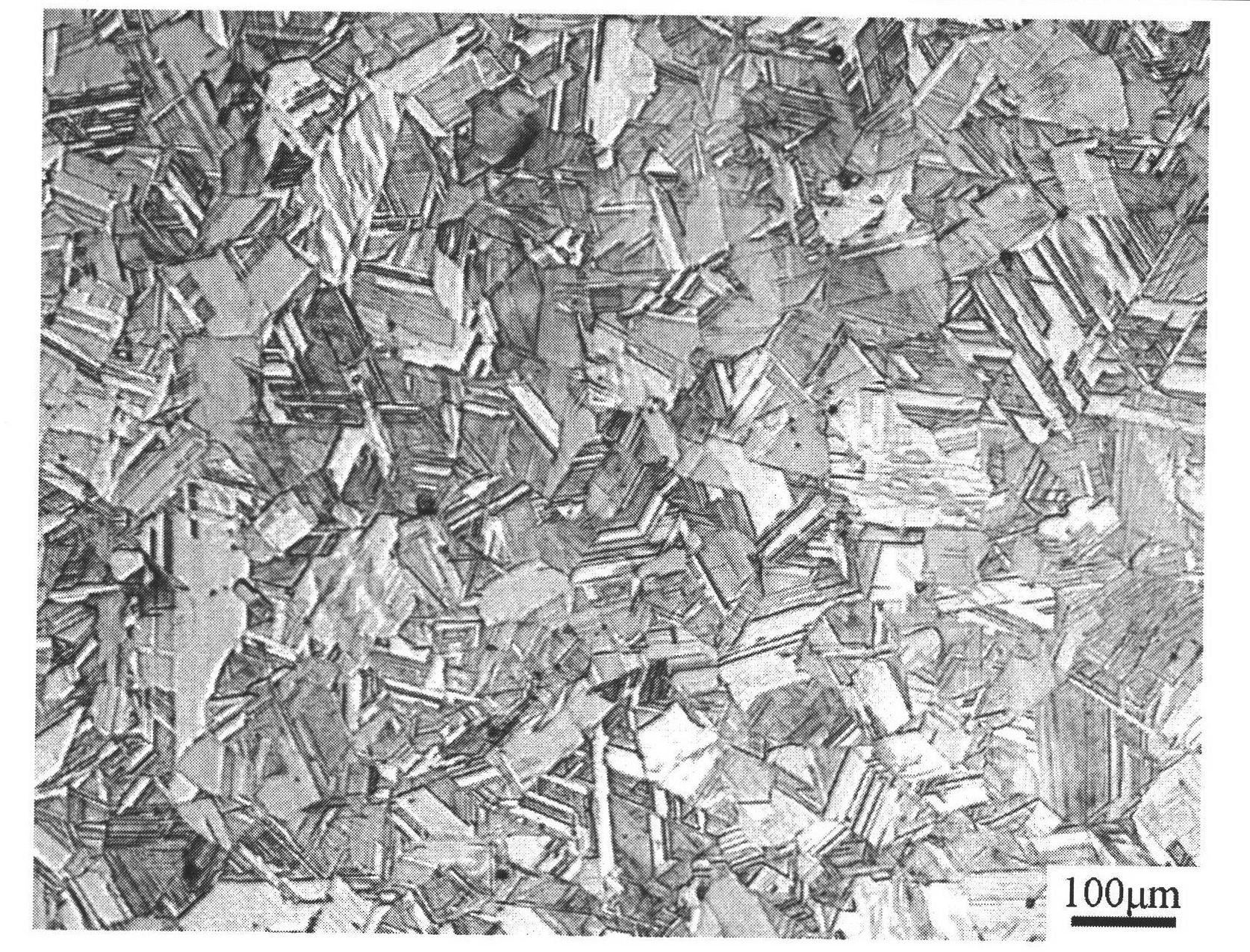

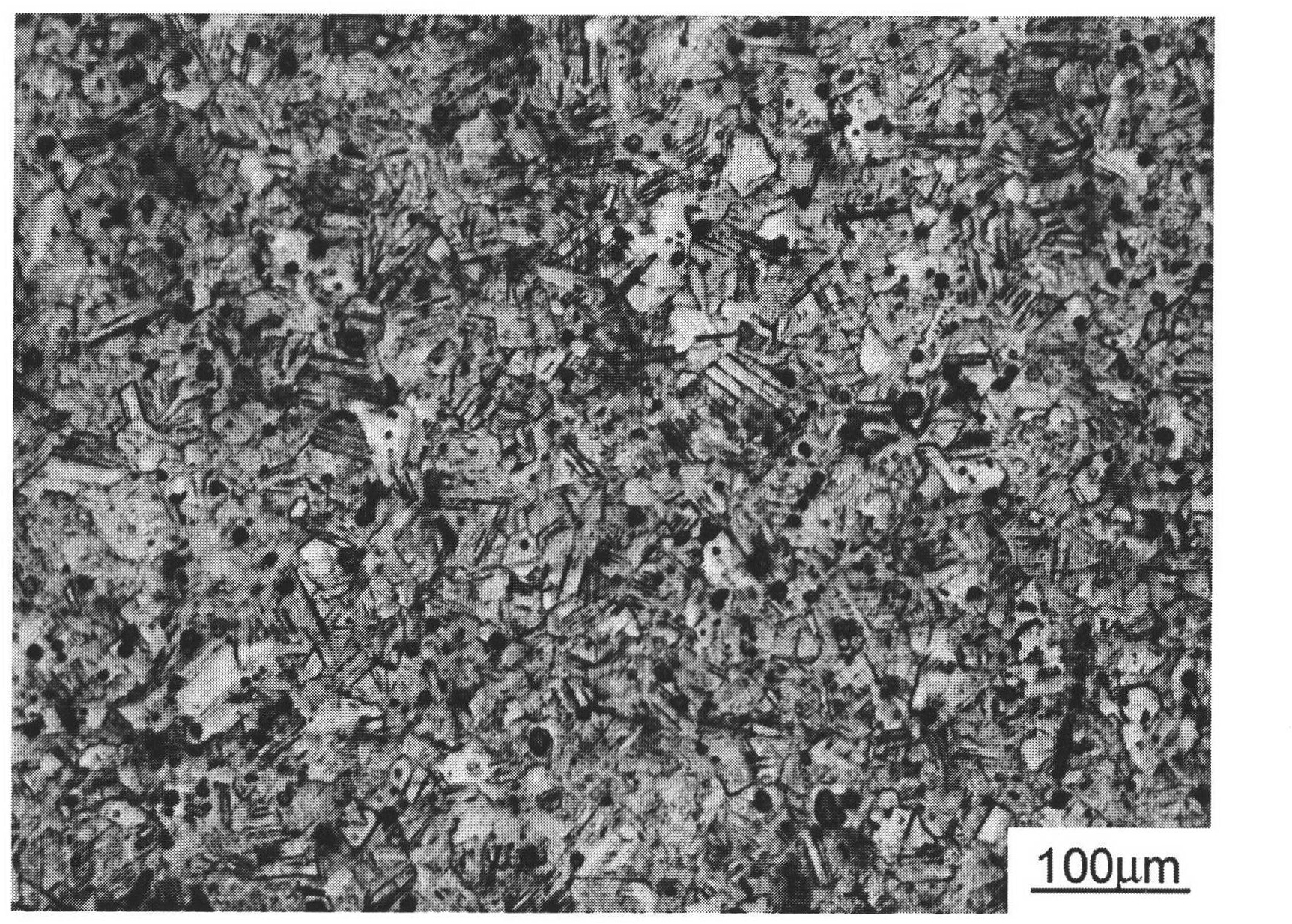

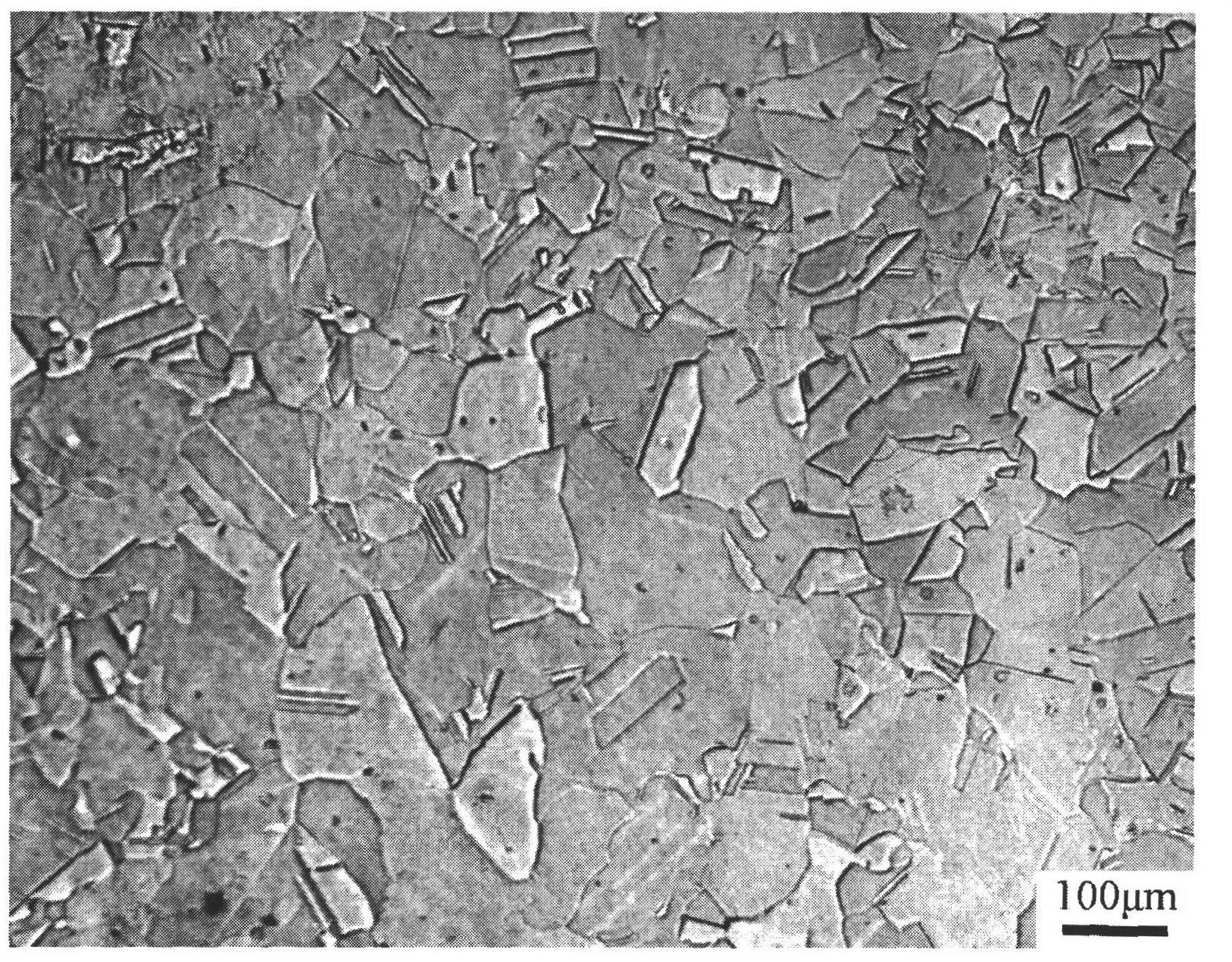

Electrolytic corrosion method of high strength and high toughness Fe-Mn-C series twinning induced plasticity steel

The invention discloses an electrolytic corrosion method of high strength and high toughness Fe-Mn-C series twinning induced plasticity (TWIP) steel. The steel is the second generation of the TWIP steel and is suitably used in the car impact resistant structural component and in other fields. The steel contains the following chemical components by weight percent: 0.2-0.7% of C, 17-24% of Mn and the balance Fe and inevitable impurities generated by the smelting process. The electrolytic corrosion method is characterized in that the electrolytic corrosion liquid is the mixed solution of 10% of perchloric acid, 80%-90% of glacial acetic acid and 0-10% of glycerol by volume, the working voltage is 30-45V; the current density is 0.5-1.5A / cm<2>, the corrosion time is 30-120s, the temperature of the corrosion liquid is 10-50 DEG C and the distance between the cathode and the anode is 1-5cm. The method of the invention is simple and practical and has good repeatability; the surface of the prepared TWIP steel does not have scratches and the surface deformations caused by polishing deformation such as the disturbing layer and the deformation twin, and the TWIP steel of the invention can satisfy the experimental requirements of the metallurgical phase, the type analysis of grain boundary, the strain test and the texture measurement on different sizes of Fe-Mn-C series TWIP steel samples.

Owner:CHINA JILIANG UNIV

Quantitative texture measurement apparatus and method

ActiveUS20170097222A1Testing starch susbtancesAnalysing solids using sonic/ultrasonic/infrasonic wavesDigital signal processingMeasurement device

A photo acoustic non-destructive measurement apparatus and method for quantitatively measuring texture of a food snack is disclosed. The apparatus includes a laser generating tool, an acoustic capturing device, and a data processing unit. The laser generating tool directs a laser towards a food snack placed on a surface and creates pressure waves that propagate through the air and produce an acoustic signal. The acoustic capturing device records and forwards the signal to a data processing unit. The data processing unit further comprises a digital signal processing module that processes the received acoustic signal. A statistical processing module further filters the acoustic signal from the data processing unit and generates a quantitative acoustic model for texture attributes such as hardness and fracturability. The quantitative model is correlated with a qualitative texture measurement from a descriptive expert panel. Texture of food snacks are quantitatively measured with the quantitative acoustic model.

Owner:FRITO LAY NORTH AMERICA INC

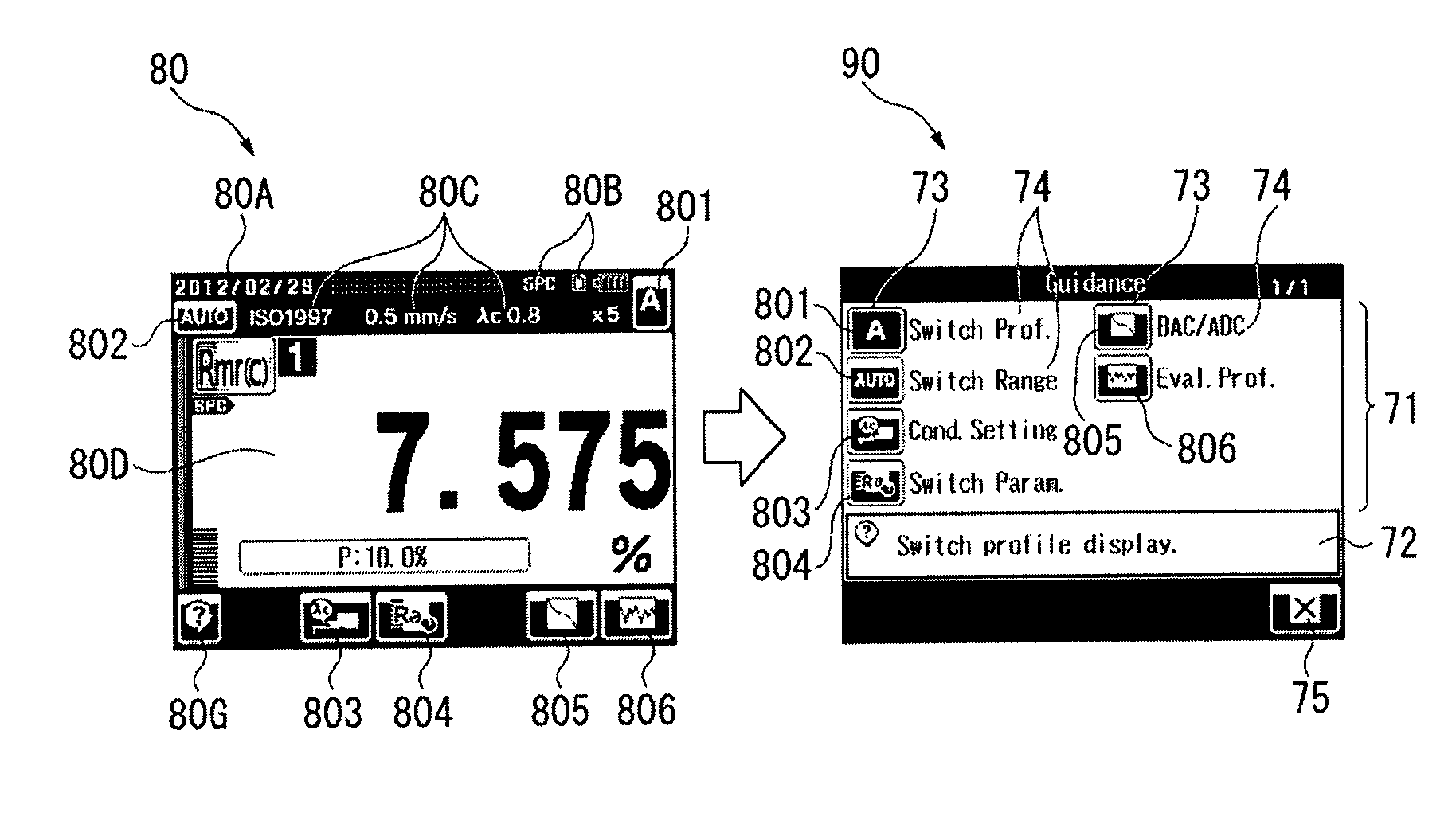

Surface texture measurement device

ActiveUS20130246959A1Effective displaySmall display screenProgramme controlElectric/magnetic roughness/irregularity measurementsComputer graphics (images)Display device

A surface texture measurement device displays in a display an operation screen based on display information of a current operation screen, and displays in the display a guidance screen when guidance display is requested by pressing a guidance screen display button on the operation screen. The operation screen has icon display for one or more buttons that activate predetermined functions. The guidance screen has a button list field that displays a list of icon display and function name display for the buttons included in the current operation screen and a description display field that displays a function description for any of the buttons included in the current operation screen.

Owner:MITUTOYO CORP

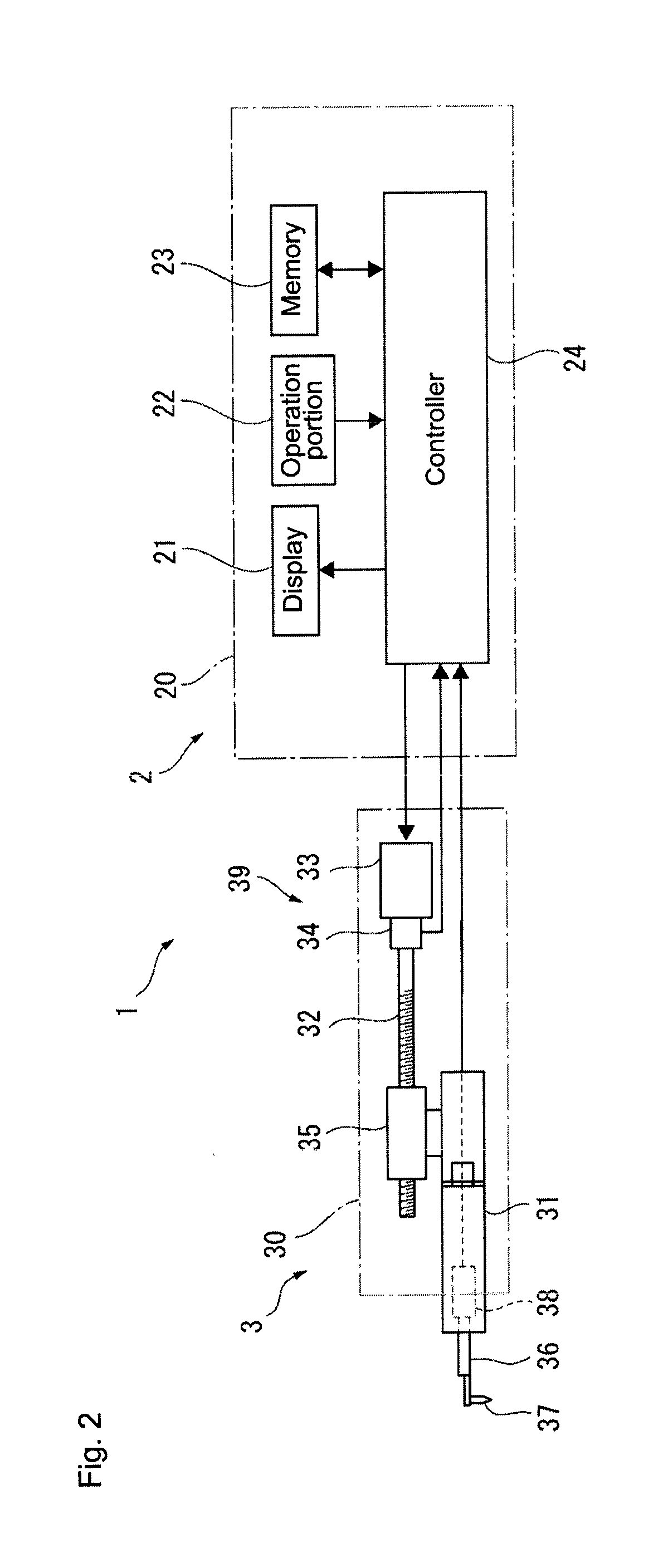

Preparation and method for improving texture of areca seeds

The invention relates to a preparation and method for improving texture of areca seeds. The preparation comprises 20-60% of xylanase, 10-40% of proteases, 10-40% of amylases, 10% or less of pectinaseand 10% or less of beta-glucanase based on the total weight. During texture improvement, an areca seed texture improvement preparation is added at the seed fermentation stage for production of areca seeds. The preparation and method disclosed by the invention solve the problems that softening which only aims at hardness improvement is realized, and texture improvement pursues balance among the hardness, the scratchability and the elasticity. The later-listed data indicates assessment for the hardness, the scratchability the elasticity, chewing sense, stimulation and the like, and texture measurement data is listed. The preparation has high practical value, and can be applied to processing of edible areca seeds.

Owner:捷行(上海)生物科技有限公司

Method of calibrating surface texture measurement device

ActiveUS8925367B2Accurate mutual positional relationshipMechanical counters/curvatures measurementsElectric/magnetic roughness/irregularity measurementsMeasurement deviceMaximum diameter

A method of calibrating a surface texture measurement device includes obtaining Y-axis shape measurement data and a maximum diameter portion to obtain upper and lower maximum diameter portions of a reference sphere from Y-axis upper and lower shape data obtained by relatively moving in the Y-axis direction while a downward and an upward styluses are in contact with an upper and a lower surfaces, respectively, of the reference sphere; obtaining X-axis shape measurement data to obtain X-axis upper and lower shape data of the reference sphere by relatively moving in the X-axis direction while the downward stylus is in contact with the upper diameter portion and the upward stylus with the lower diameter portion of the reference sphere; and calculating offset amounts Δx and Δz of the upward and downward styluses from center coordinates O3 and O4 obtained from the shape data.

Owner:MITUTOYO CORP

Quantitative Liquid Texture Measurement Apparatus and Methods

ActiveUS20200110058A1Testing starch susbtancesAnalysing fluids using sonic/ultrasonic/infrasonic wavesDigital signal processingMeasurement device

A photo acoustic non-destructive measurement apparatus and method for quantitatively measuring texture of a liquid. The apparatus includes a laser generating tool, an acoustic capturing device, and a data processing unit. The laser generating tool directs a laser towards a surface of a liquid contained in a container and creates pressure waves that propagate through the air and produce an acoustic signal. The acoustic capturing device records and forwards the signal to a data processing unit. The data processing unit further comprises a digital signal processing module that processes the received acoustic signal. A statistical processing module further filters the acoustic signal from the data processing unit and generates a quantitative acoustic model for texture attributes such as hardness and fracturability. The quantitative model is correlated with a qualitative texture measurement from a descriptive expert panel. Textures of liquids are quantitatively measured with the quantitative acoustic model.

Owner:FRITO LAY NORTH AMERICA INC

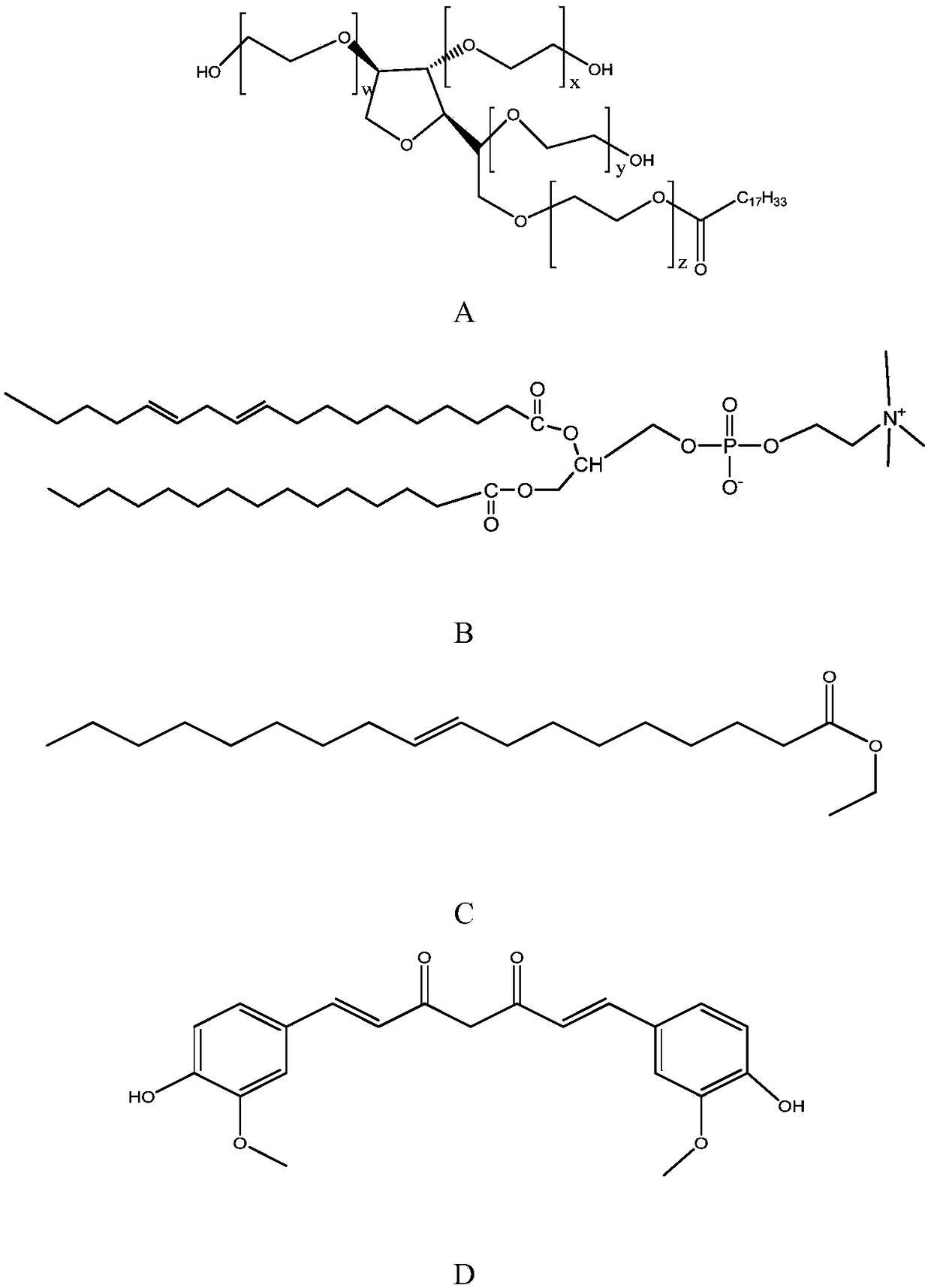

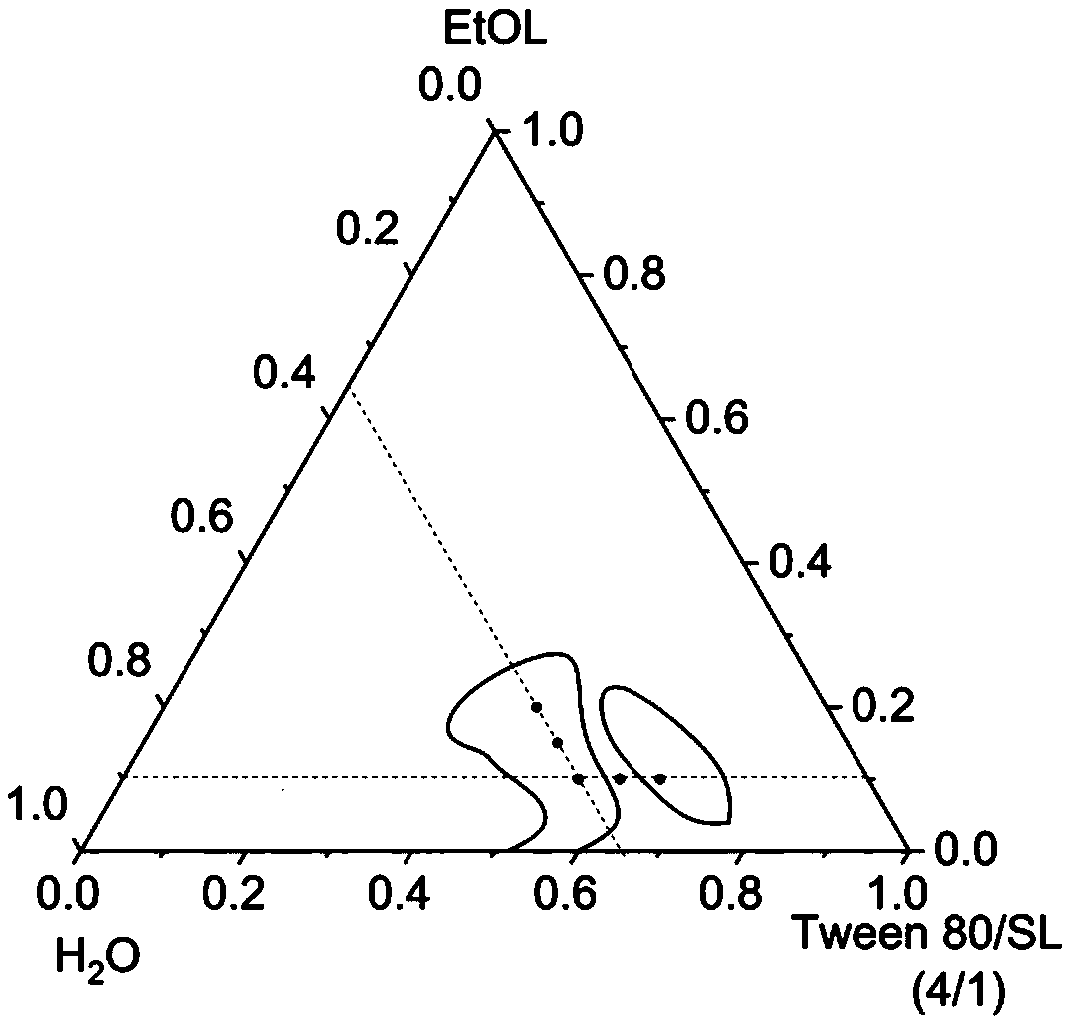

A lyotropic liquid crystal drug carrier and a preparation method and application thereof

ActiveCN109172526AMeet the needs of a variety of applicationsImprove solubilityAntipyreticAnalgesicsDrug releasePharmaceutical formulation

The invention belongs to the field of pharmaceutical preparations, in particular to a lyotropic liquid crystal drug carrier and a preparation method and application thereof. Twain-80, soybean lecithin, ethyl oleate and water in a certain proportion can obtain lyotropic liquid crystal phase, further adjusting that proportion of reagent, and confirm that hexagonal phase lyotropic liquid crystal andlamellar phase lyotropic liquid crystal are also prepared by polarizing texture measurement. It is found that the hexagonal and layered phases have good shear viscosity, which means that the crystalline phase has good stability and can be used as drug carrier. Curcumin is encapsulated in hexagonal phase and drug release is investigated. The results showed that hexagonal phase had good sustained-release effect and the release curve of layered phase fitted the first-order kinetic equation well. The suitable release dosage form could be selected according to the clinical application.

Owner:海生健康科技(青岛)有限公司

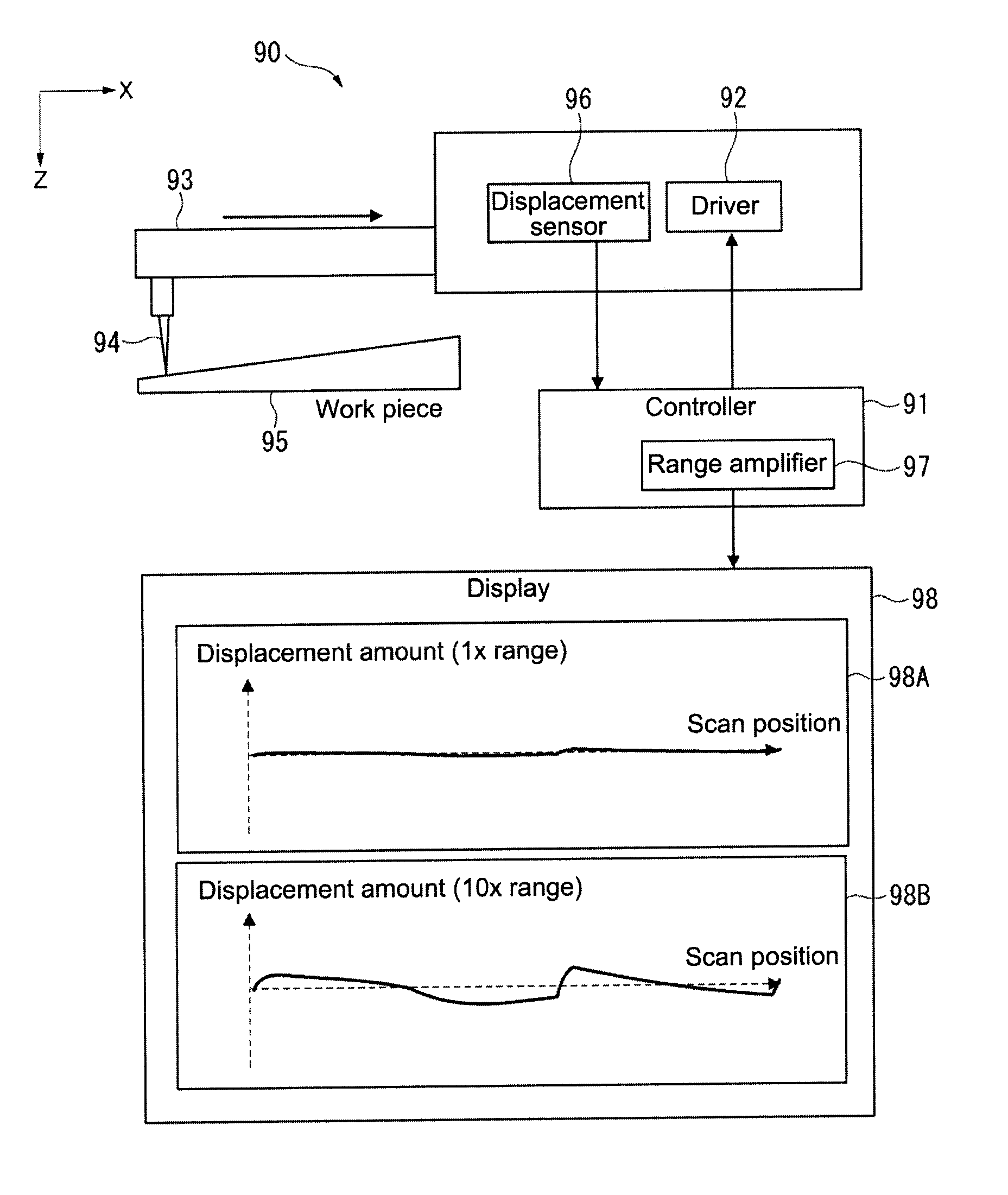

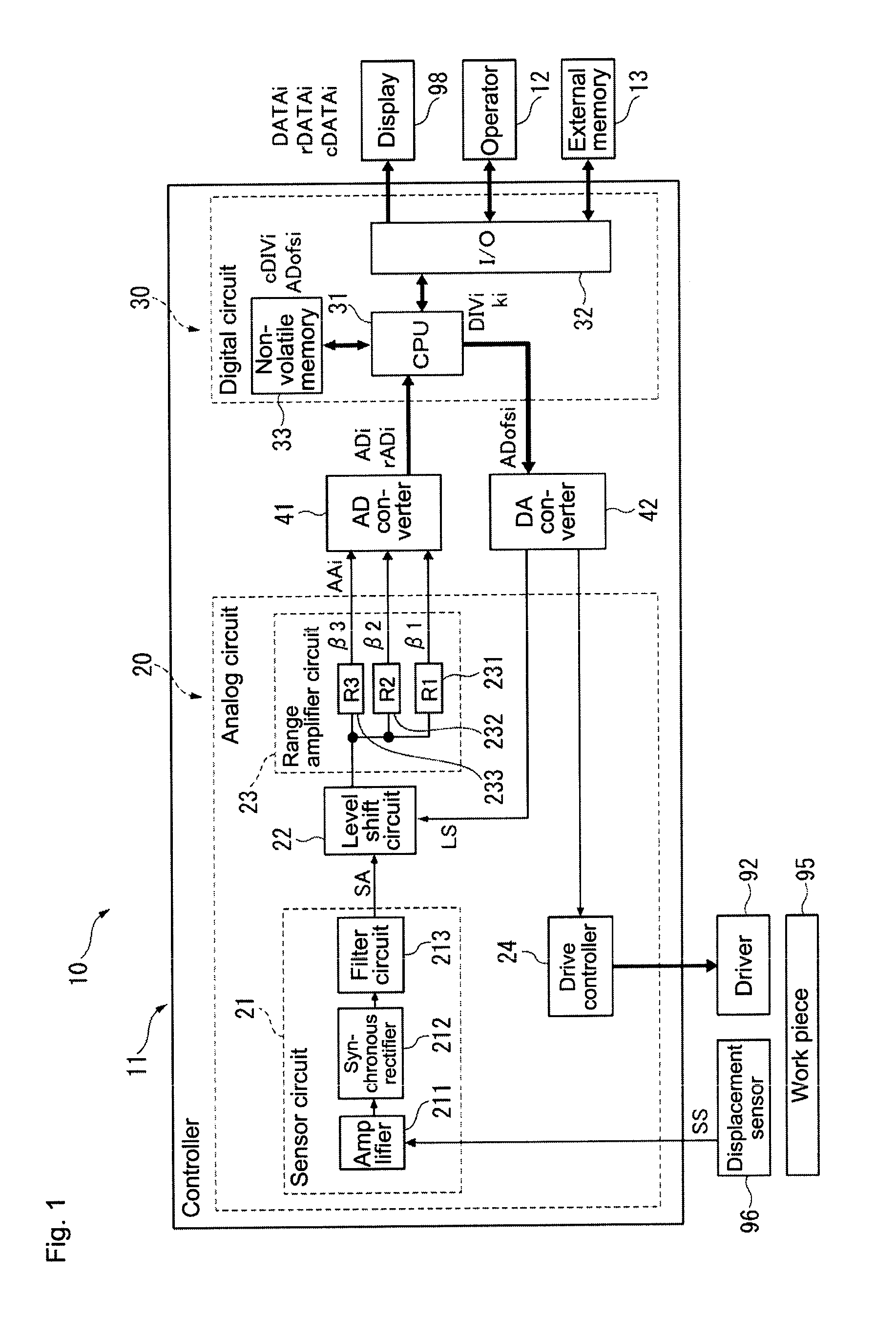

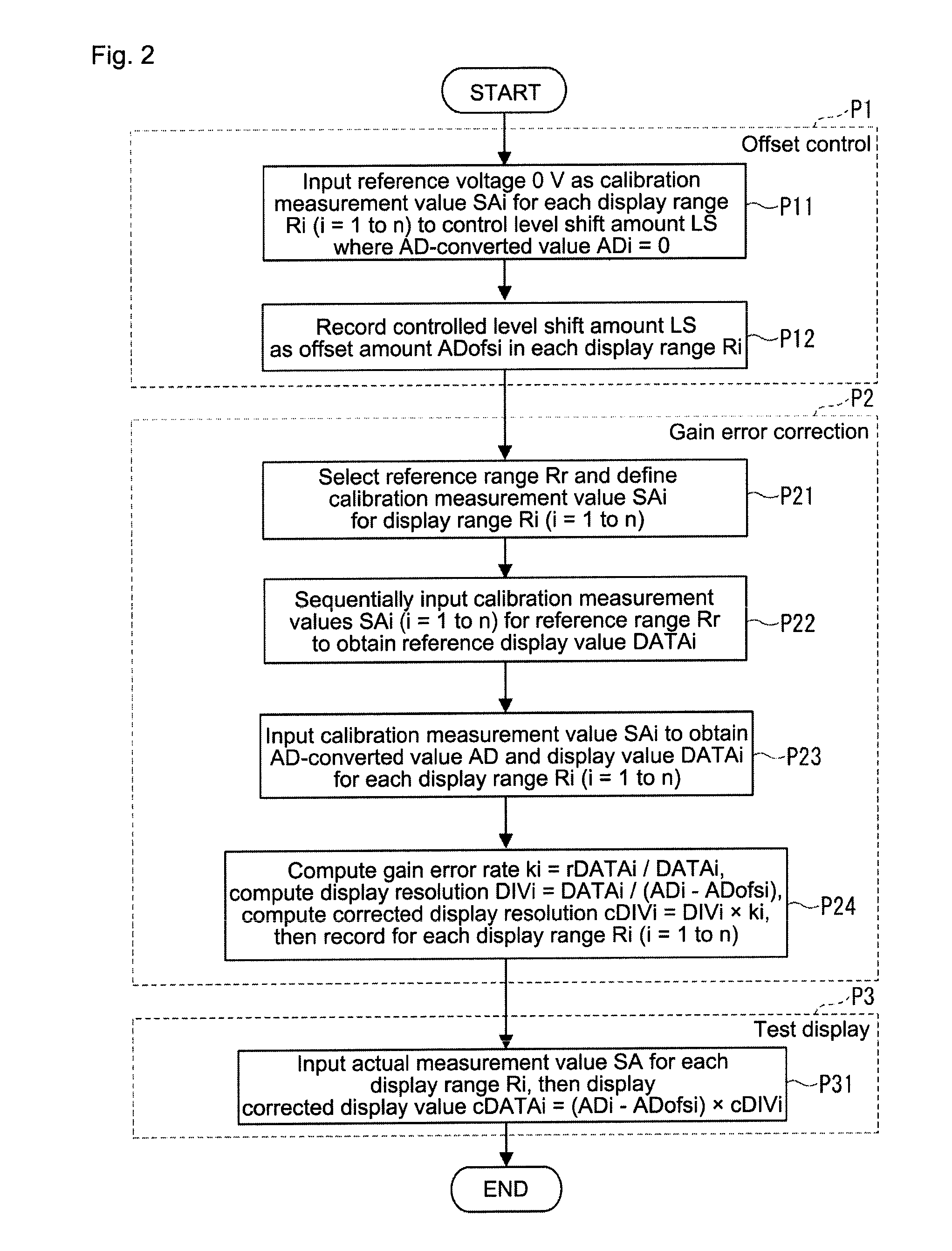

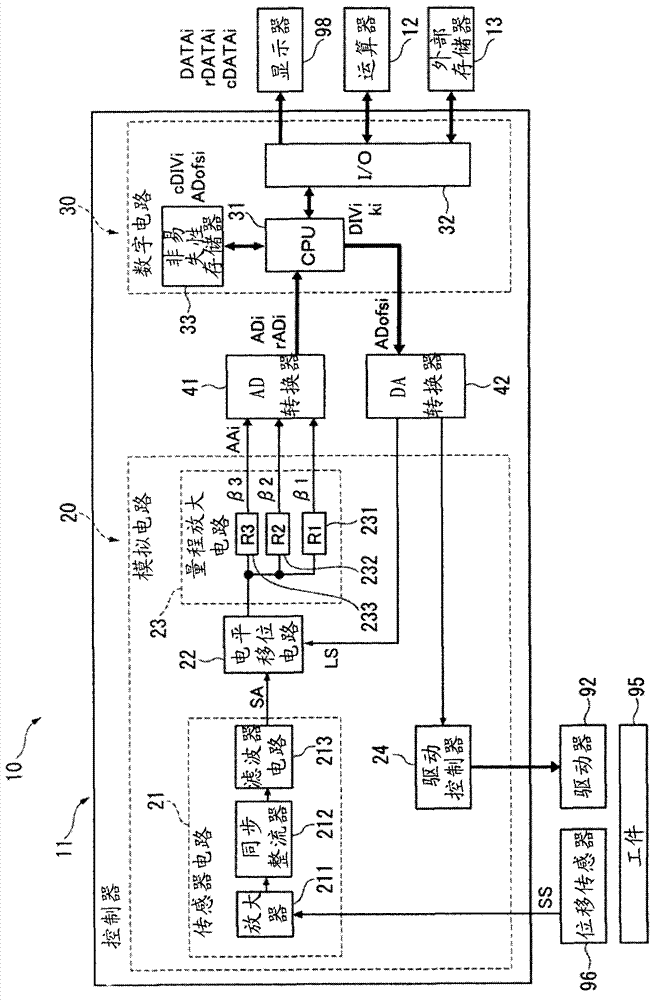

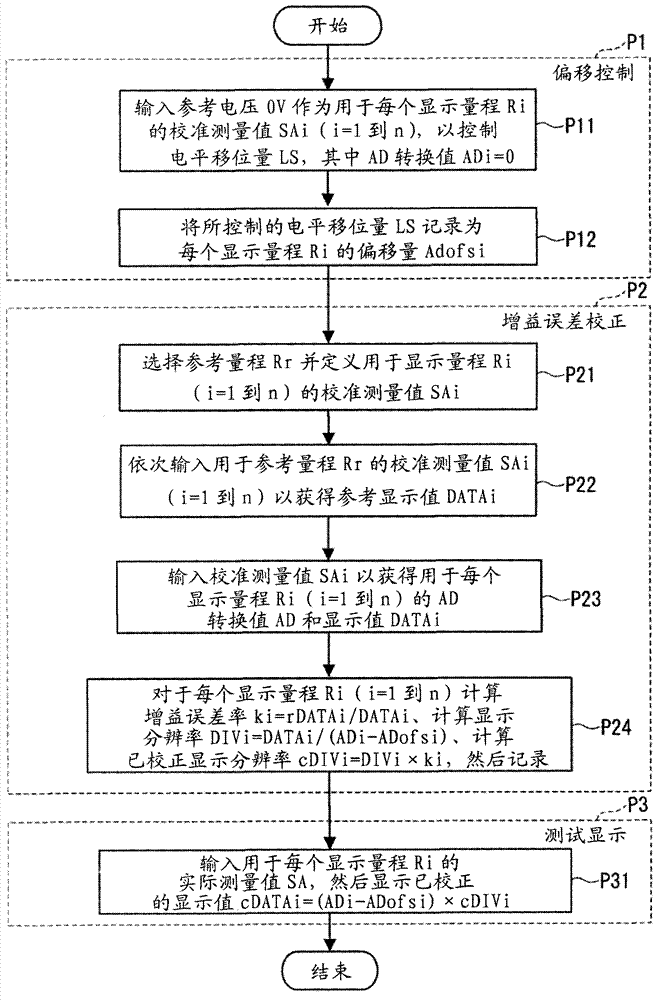

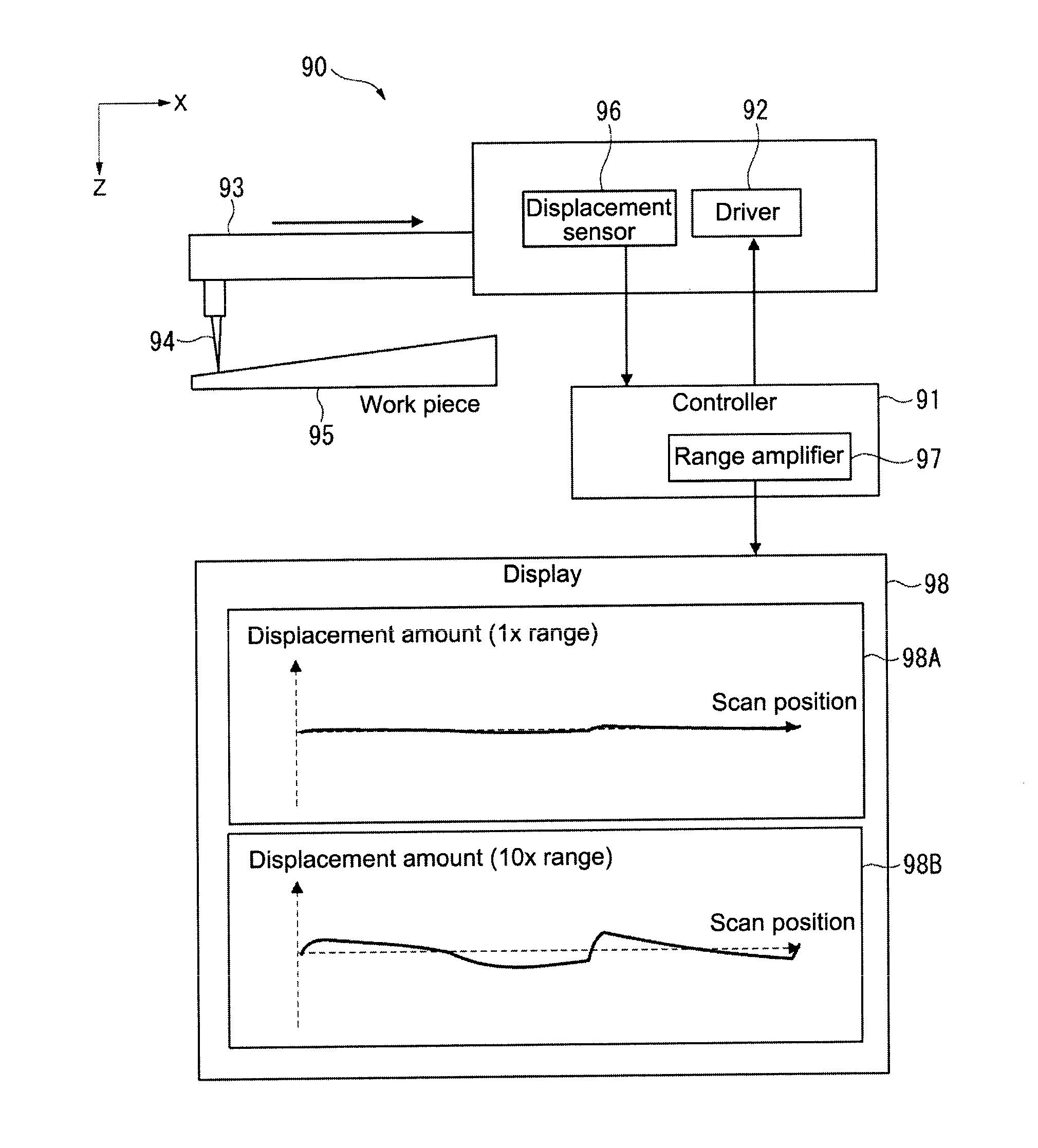

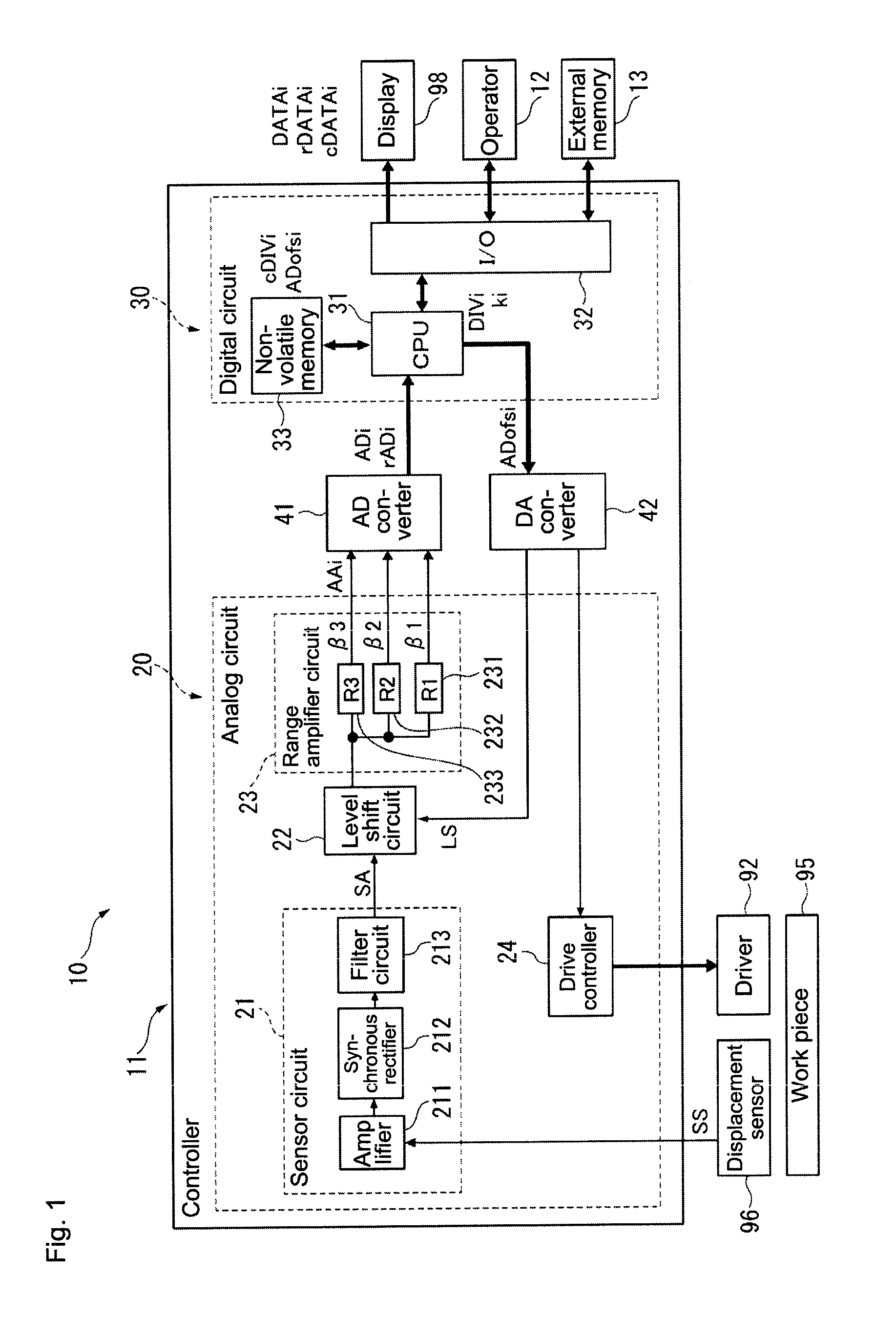

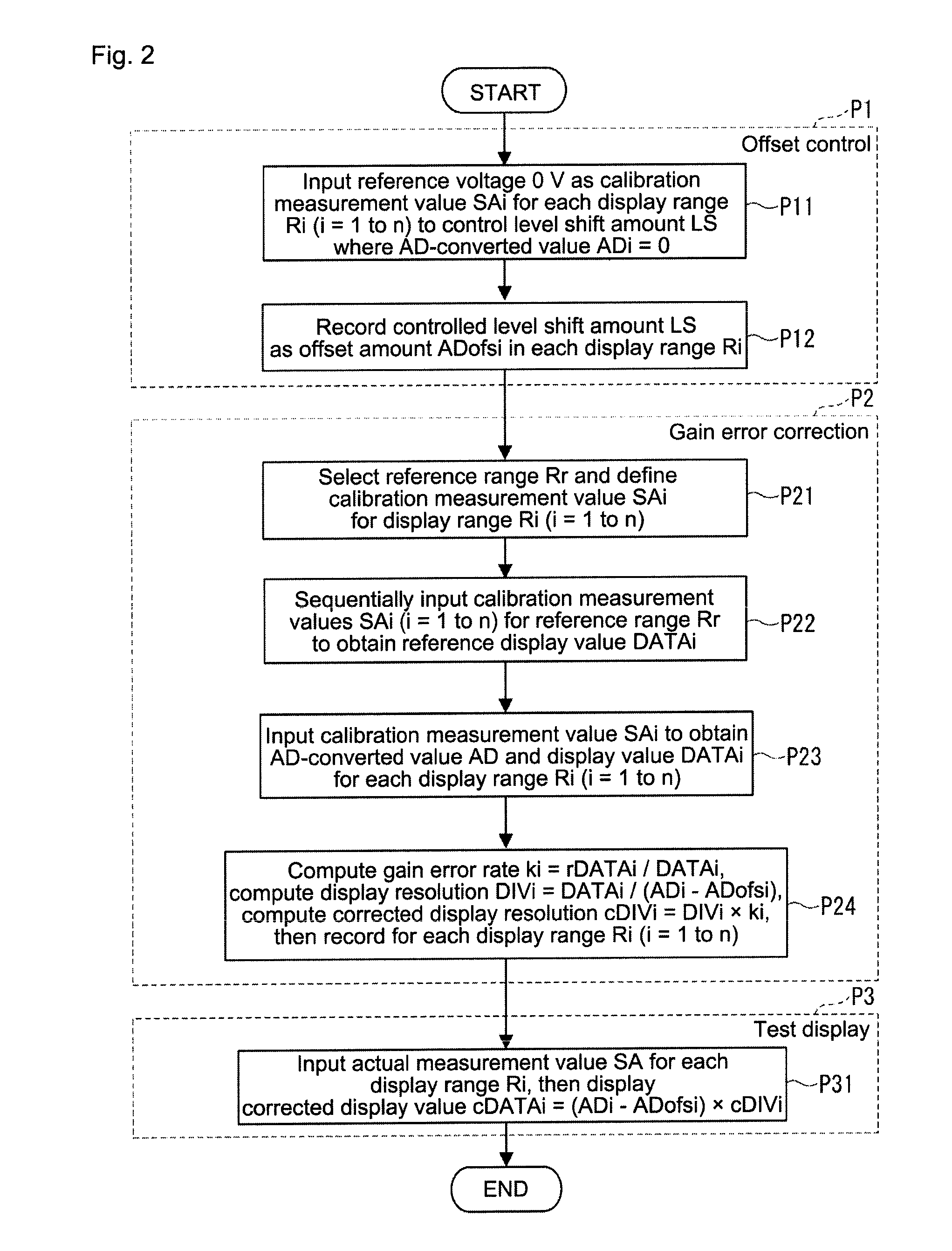

Surface texture measurement device, controller for surface texture measurement device, and method for controlling the same

ActiveUS9151589B2Measurement resultImprove errorFeeler-pin gaugesMechanical counters/curvatures measurementsAudio power amplifierMeasurement device

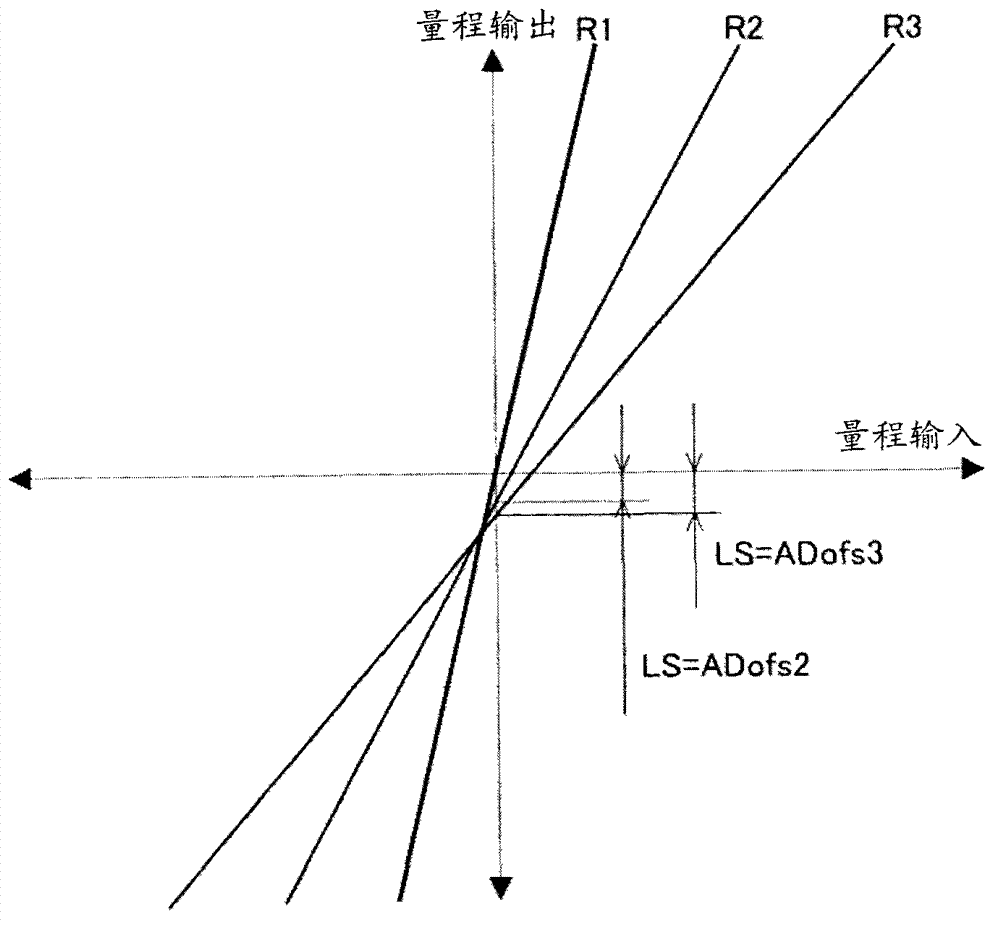

A surface texture measurement device capable of resolving errors for each entire display range, a controller for the surface texture measurement device, and a method for controlling the surface texture measurement device that includes selecting any one of the display ranges as a reference range and defining a calibration measurement value for each display range; sequentially inputting the calibration measurement values in place of the measurement values to the range amplifier corresponding to the reference range to obtain a reference display value rDATAi; inputting the calibration measurement values to the range amplifiers corresponding to each display range, then obtaining an AD-converted value ADi and a display value DATAi; computing a gain error rate ki=rDATAi / DATAi, a display resolution DIVi=DATAi / ADi, and a corrected display resolution cDIVi=DIVi×ki; and displaying the corrected display value cDIVi=DIVi×ki.

Owner:MITUTOYO CORP

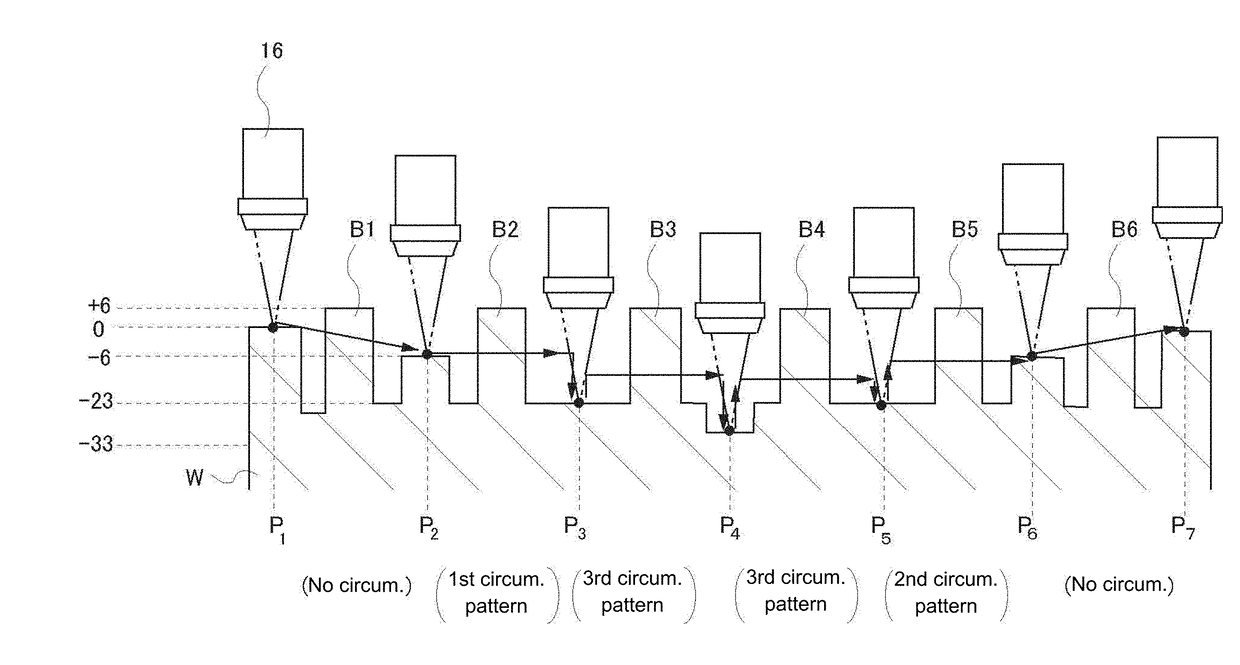

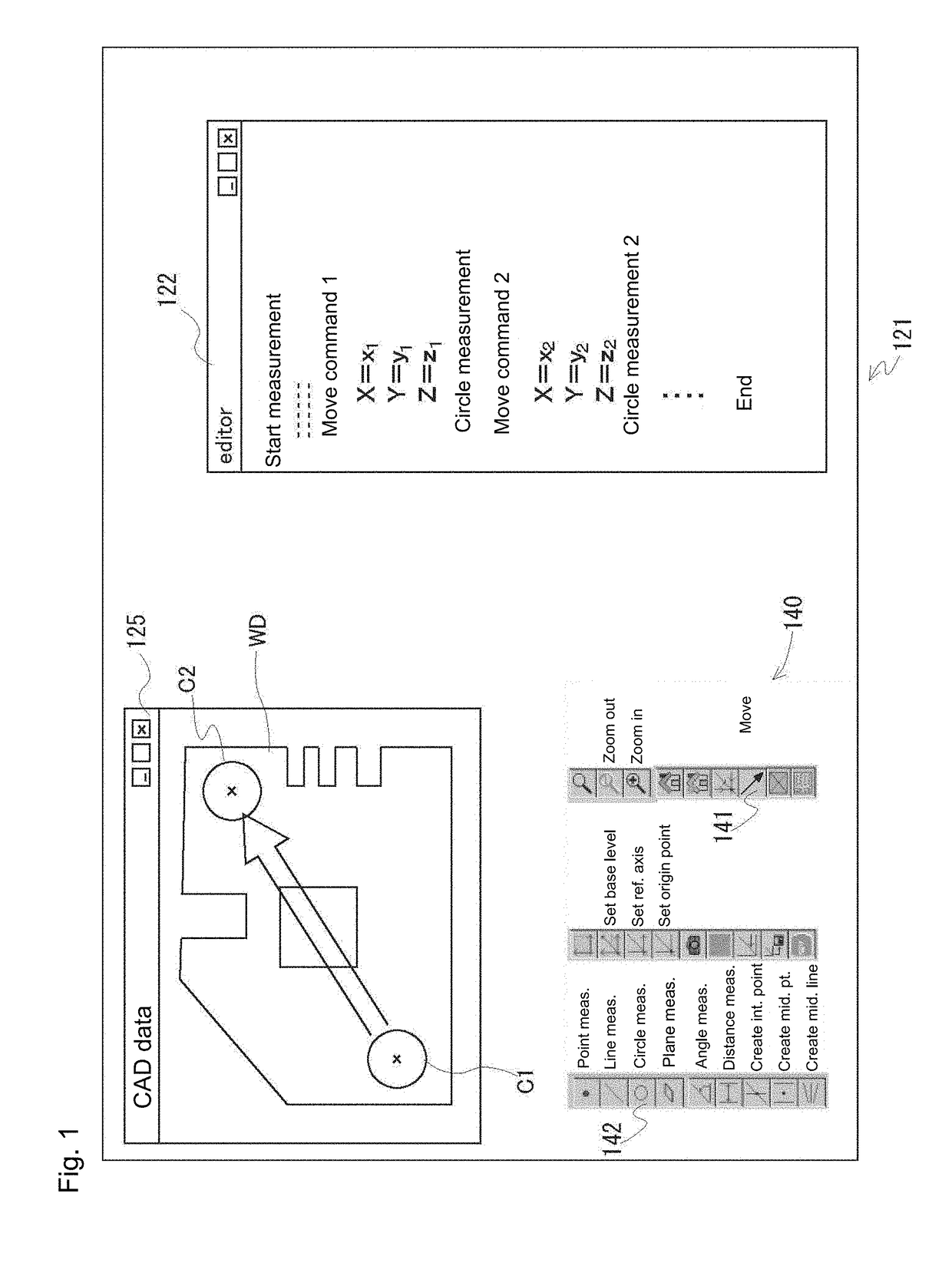

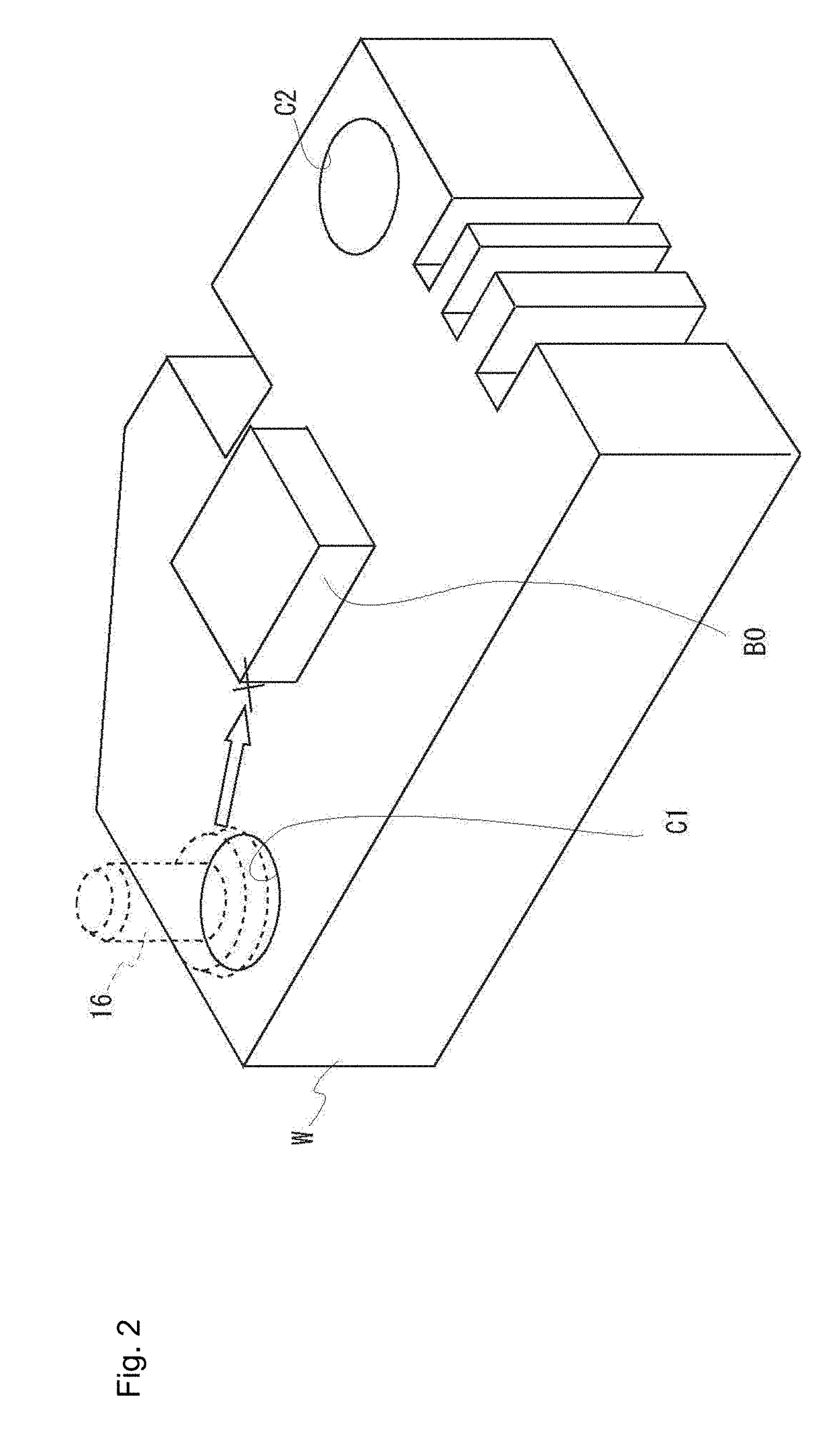

Part program generating device of surface texture measuring apparatus

ActiveUS20170270684A1Prevent sensor displacementProgramme controlImage analysisGraphicsGraphical user interface

A part program generating device includes a CAD data memory storing CAD data of a work piece, a measurement condition definer receiving an input operation performed by a user and defining a measurement procedure, and a part program generator converting the measurement procedure defined by the measurement condition definer into a part program language. The measurement condition definer provides the user with, as a graphical user interface, an editing window capable of editing the measurement procedure in an editing language and a command icon providing a command to be used for defining the measurement procedure as an icon. The command icon includes a circumvention move command icon instructing to overcome a barrier when displacing a sensor from a start point to a target point.

Owner:MITUTOYO CORP

Surface texture measurement device, controller thereof, and method for controlling the same

ActiveCN103308020AMechanical roughness/irregularity measurementsAudio power amplifierImage resolution

A surface texture measurement device capable of resolving errors for each entire display range, a controller for the surface texture measurement device, and a method for controlling the surface texture measurement device that includes selecting any one of the display ranges as a reference range and defining a calibration measurement value for each display range; sequentially inputting the calibration measurement values in place of the measurement values to the range amplifier corresponding to the reference range to obtain a reference display value rDATAi; inputting the calibration measurement values to the range amplifiers corresponding to each display range, then obtaining an AD-converted value ADi and a display value DATAi; computing a gain error rate ki = rDATAi / DATAi, a display resolution DIVi = DATAi / ADi, and a corrected display resolution cDIVi = DIViXki; and displaying the corrected display value cDIVi = DIViXki.

Owner:MITUTOYO CORP

Cold-roll steel sheet texture measurement method

ActiveCN107884429AAccurate quantitative characterizationAvoid depthMaterial analysis using wave/particle radiationPreparing sample for investigationSurface layerMetallurgy

The invention discloses a cold-roll steel sheet texture measurement method which comprises the following steps: S1, treating the surface of a cold-roll steel sheet so as to obtain a test sample 1; S2,measuring the <111> / / ND texture ratio within the maximum orientation deviation of 20 degrees so as to obtain a result A; S3, performing argon ion etching on a test sample 1 to be tested so as to obtain a test sample 2 to be tested; S4, detecting a surface argon ion etching depth T of the test sample 2 to be tested; and S5, measuring a <111> / / ND texture ratio within the maximum orientation deviation of 20 degrees so as to obtain a result B, and repeating steps S3 to S5 till the quotient of the absolute value of BN-AN divided by AN is greater than or equal to 50%, thereby obtaining a final argon ion etching depth TN, that is, the depth of a cold-roll steel sheet surface texture. By adopting the method disclosed by the invention, the depth of a micro-grade characteristic texture of the surface layer of a cold-roll sheet that the crystal orientation has differences from that of the central part of the cold-roll sheet can be accurately measured.

Owner:SHOUGANG CORPORATION

Texture automatic monitoring system

InactiveUS9366529B2Efficient detectionUsing optical meansRoads maintainenceDistance detectionMonitoring system

A texture automatic monitoring system for measuring surface texture of a road surface compacted by a road roller is measured by texture measurement equipment mounted on the road roller. The road surface texture measurement equipment comprises a height measurement instrument disposed on the compaction roller that measures height from the road surface, a moving distance detecting instrument that generates a signal corresponding to the moving distance of the road roller, a data processing unit that calculates the moving distance of the road roller based on the moving distance detecting signal, and calculates one or more road surface property values indicating the road surface texture by using the measured value of the height acquired from the height measurement instrument and the calculated moving distance, and a displaying unit which displays the calculated road surface property value.

Owner:KUMATAKA ENG +2

Surface texture measurement device, controller for surface texture measurement device, and method for controlling the same

ActiveUS20130238281A1Measurement resultImprove errorFeeler-pin gaugesMechanical counters/curvatures measurementsMeasurement deviceAudio power amplifier

A surface texture measurement device capable of resolving errors for each entire display range, a controller for the surface texture measurement device, and a method for controlling the surface texture measurement device that includes selecting any one of the display ranges as a reference range and defining a calibration measurement value for each display range; sequentially inputting the calibration measurement values in place of the measurement values to the range amplifier corresponding to the reference range to obtain a reference display value rDATAi; inputting the calibration measurement values to the range amplifiers corresponding to each display range, then obtaining an AD-converted value ADi and a display value DATAi; computing a gain error rate ki=rDATAi / DATAi, a display resolution DIVi=DATAi / ADi, and a corrected display resolution cDIVi=DIVi×ki; and displaying the corrected display value cDIVi=DIVi×ki.

Owner:MITUTOYO CORP

Quantitative liquid texture measurement method

ActiveUS11243190B2Testing starch susbtancesAnalysing fluids using sonic/ultrasonic/infrasonic wavesDigital signal processingEngineering

A photo acoustic non-destructive measurement apparatus and method for quantitatively measuring texture of a liquid. The apparatus includes a laser generating tool, an acoustic capturing device, and a data processing unit. The laser generating tool directs a laser towards a surface of a liquid contained in a container and creates pressure waves that propagate through the air and produce an acoustic signal. The acoustic capturing device records and forwards the signal to a data processing unit. The data processing unit further comprises a digital signal processing module that processes the received acoustic signal. A statistical processing module further filters the acoustic signal from the data processing unit and generates a quantitative acoustic model for texture attributes such as hardness and fracturability. The quantitative model is correlated with a qualitative texture measurement from a descriptive expert panel. Textures of liquids are quantitatively measured with the quantitative acoustic model.

Owner:FRITO LAY NORTH AMERICA INC

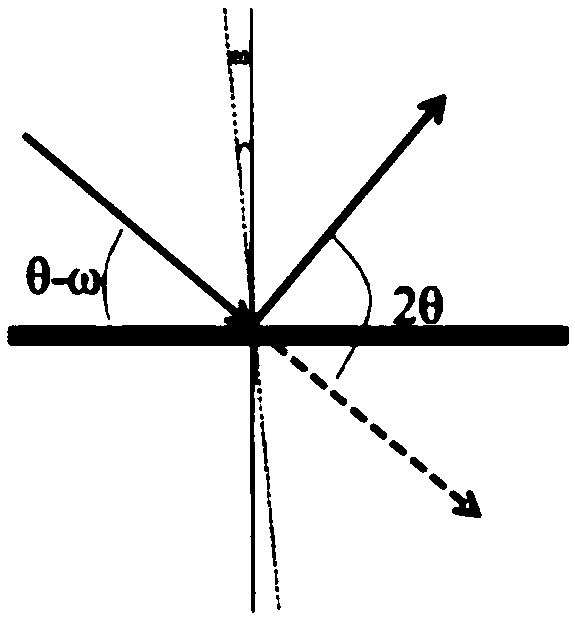

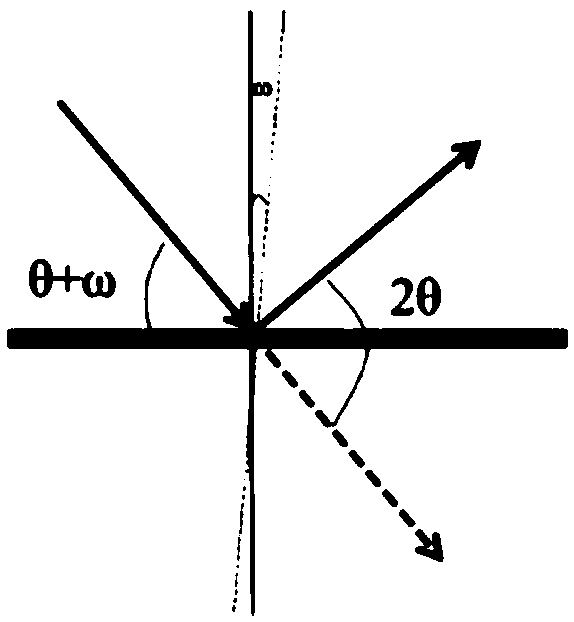

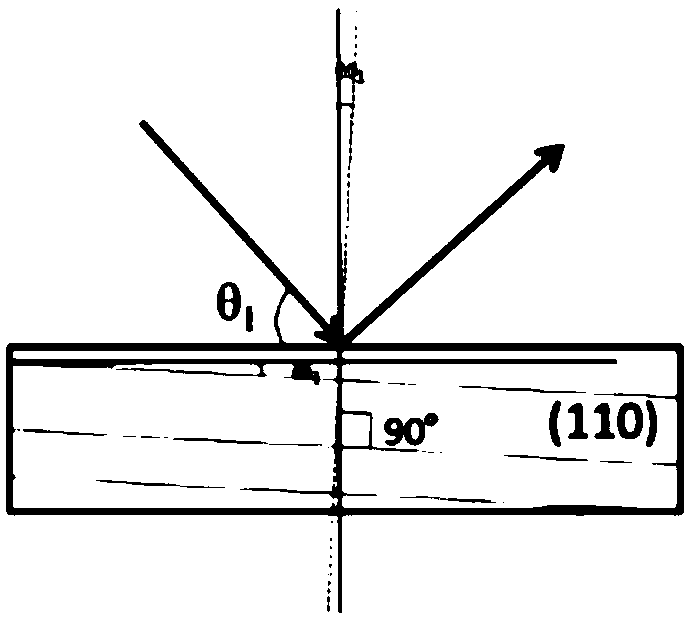

Method for measuring orientation deviation angle of oriented silicon steel through X-ray diffraction

ActiveCN109490346AAccurate angleSimple sample preparationMaterial analysis using radiation diffractionLight pipeX-ray

The invention belongs to the technical field of crystal texture measurement, and particularly relates to a method for measuring orientation deviation angle of oriented silicon steel through X-ray diffraction, including the steps of firstly, fixing a light pipe to the negative divergence of a theoretical diffraction angle, and utilizing a probe to scan to explore with large step to acquire probablediffraction angle by the standard of generating the diffraction peak; further, reducing the scanning range, gradually reducing scanning step, and finally determining the diffraction angle and deviation angle by the standard of the maximum diffraction peak intensity. By the method, accurate diffraction angle and orientation deviation angle of oversized-grain oriented silicon steel can be obtainedsimultaneously. Besides, the method has the advantages of simple sampling, low requirements on equipment, convenience in use and accuracy reaching 0.01 degrees.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

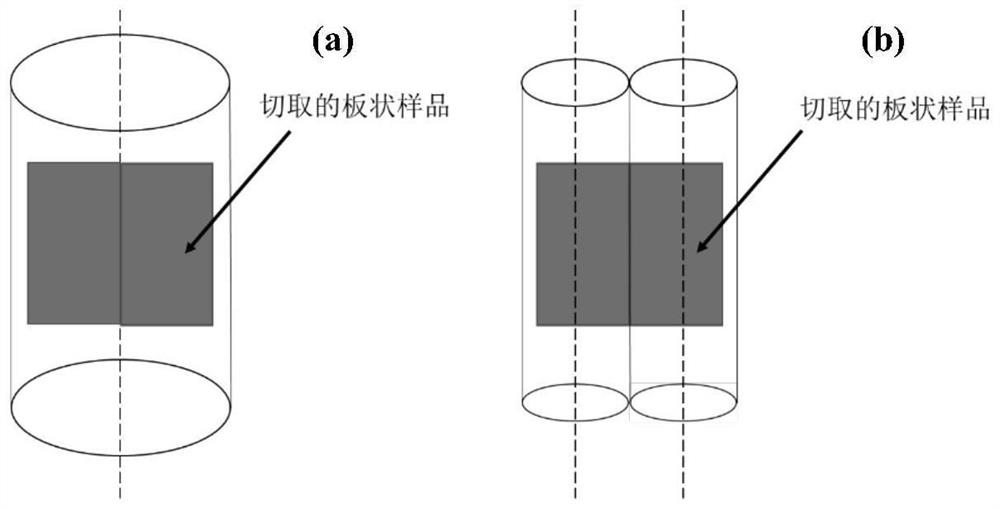

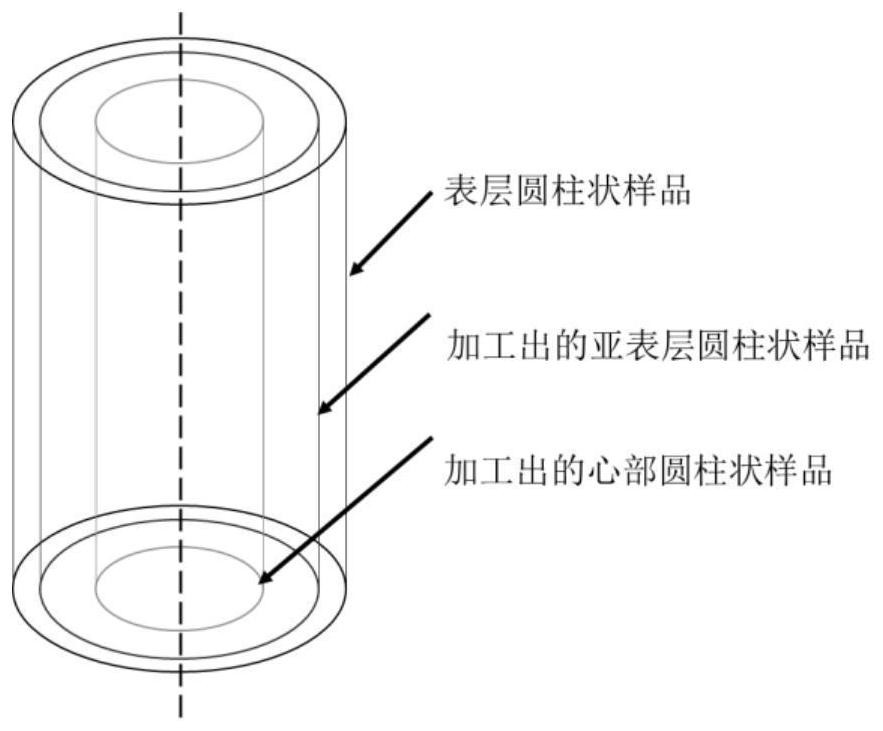

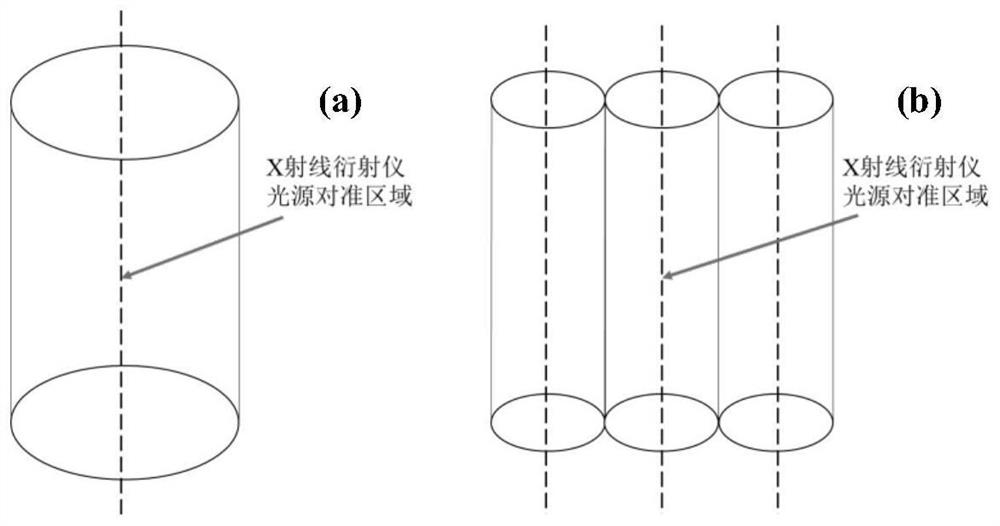

XRD (X-Ray Diffraction) method for determining wire texture

PendingCN113588695ADeformation state improvementSimple processMaterial analysis using wave/particle radiationWire rodTest sample

The invention discloses an XRD (X-Ray Diffraction) method for determining a wire texture, and belongs to the technical field of wire texture determination. The method comprises the following steps: processing a wire material and a blocky standard sample thereof into different layers of cylindrical samples during measurement, measuring textures of diffraction peaks of the samples, recording highest strength data and texture types of the textures of different layers, and calculating a highest strength average value max1 of the different layers; and respectively cutting a plate-shaped test sample and a standard sample, carrying out whole-body texture measurement on the test sample and the standard sample, recording the highest strength max and the texture type, judging the overall texture range of the wire rod, and comparing the maximum strength max and the texture type max in the same texture strength interval and the texture type matched with max1, thereby verifying that the method has extremely high accuracy. According to the determination method, the texture information integrity of the wire rod sample is guaranteed to a great extent, the texture change rule of the wire rod from the surface layer to the core part is accurately determined, and more research and guidance bases are provided for the deformation state, process improvement, mechanical property and microstructure analysis of the wire rod.

Owner:NORTHEASTERN UNIV

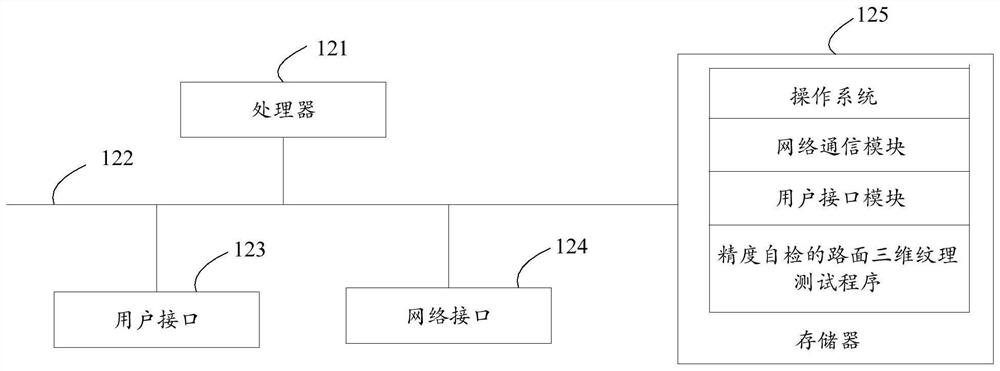

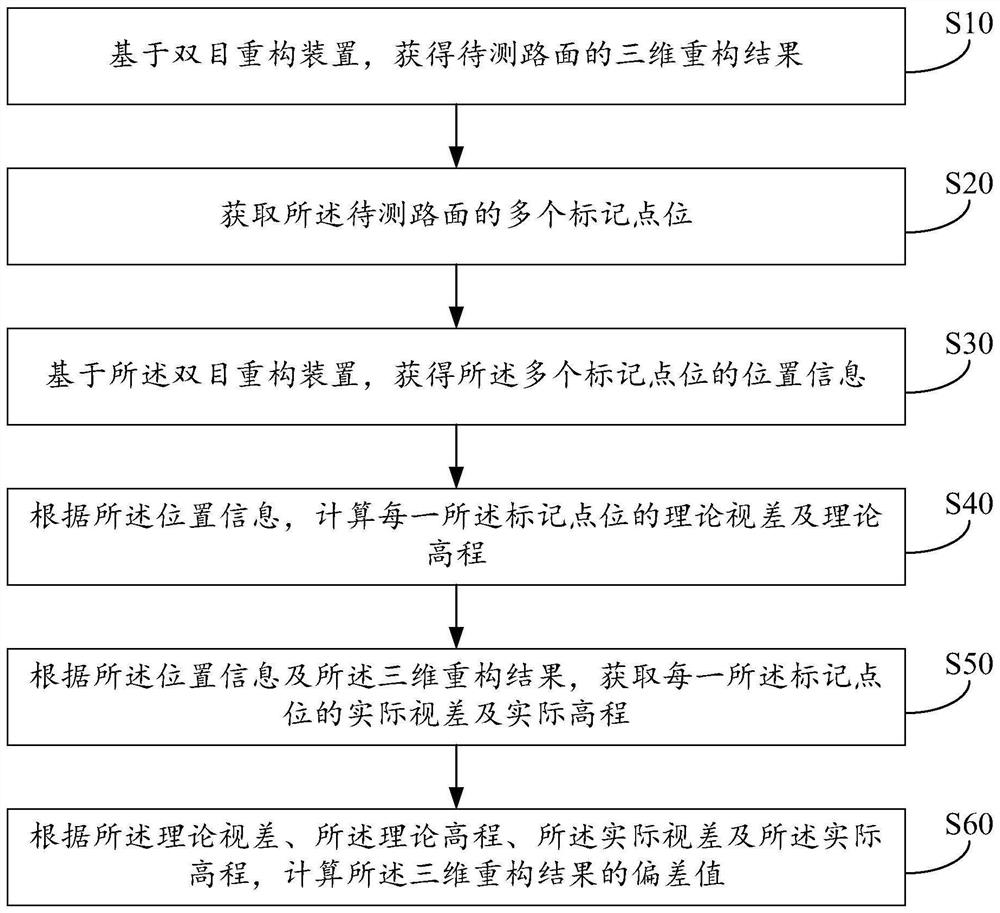

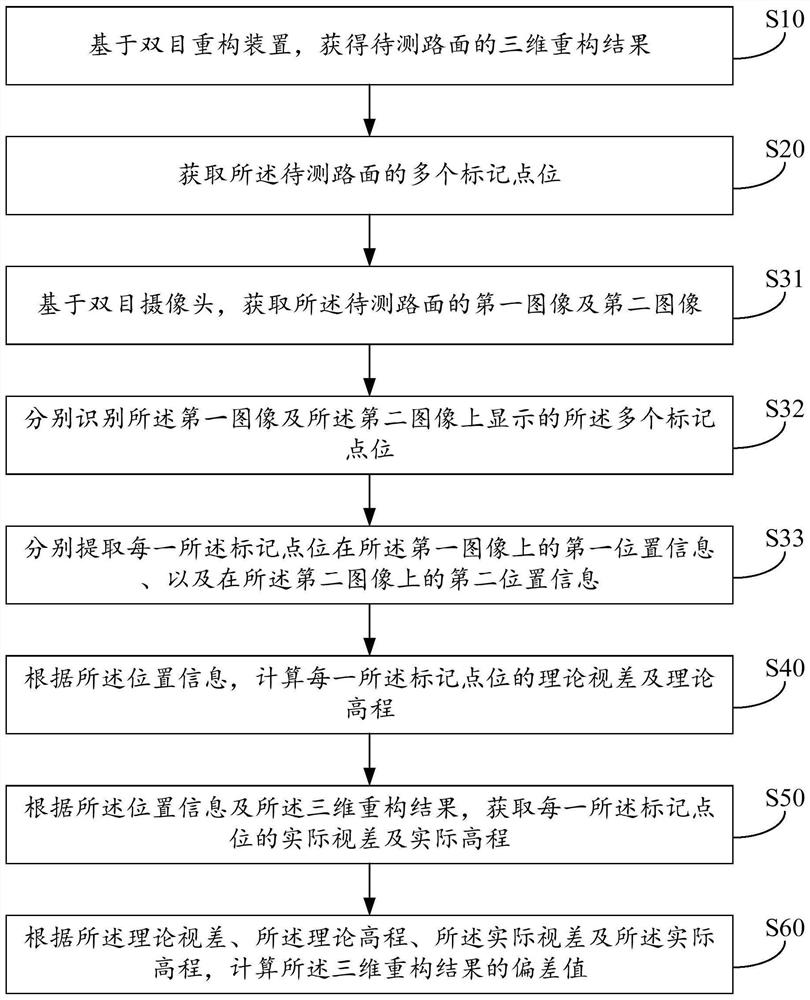

Precision self-checking pavement three-dimensional texture measurement method and system, and storage medium

The invention discloses a precision self-checking pavement three-dimensional texture measurement method and system, and a storage medium. The precision self-checking pavement three-dimensional texture measurement method comprises the following steps: obtaining a three-dimensional reconstruction result of a pavement to be measured based on a binocular reconstruction device; acquiring a plurality of marking points of the to-be-measured pavement; acquiring position information of a plurality of mark points based on a binocular reconstruction device; calculating a theoretical parallax and a theoretical elevation of each marking point according to the position information; according to the position information and the three-dimensional reconstruction result, obtaining the actual parallax and the actual elevation of each marking point position; and calculating a deviation value of the three-dimensional reconstruction result according to the theoretical parallax, the theoretical elevation, the actual parallax and the actual elevation. According to the invention, precision self-inspection can be carried out on the three-dimensional reconstruction result of the to-be-detected pavement, the structure is simple, the operation is convenient, the reconstruction technology of the three-dimensional texture of the to-be-detected pavement can be perfected according to the precision self-inspection result, and the accuracy of the detection result is improved.

Owner:HUBEI UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com