Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192 results about "Pipe in pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

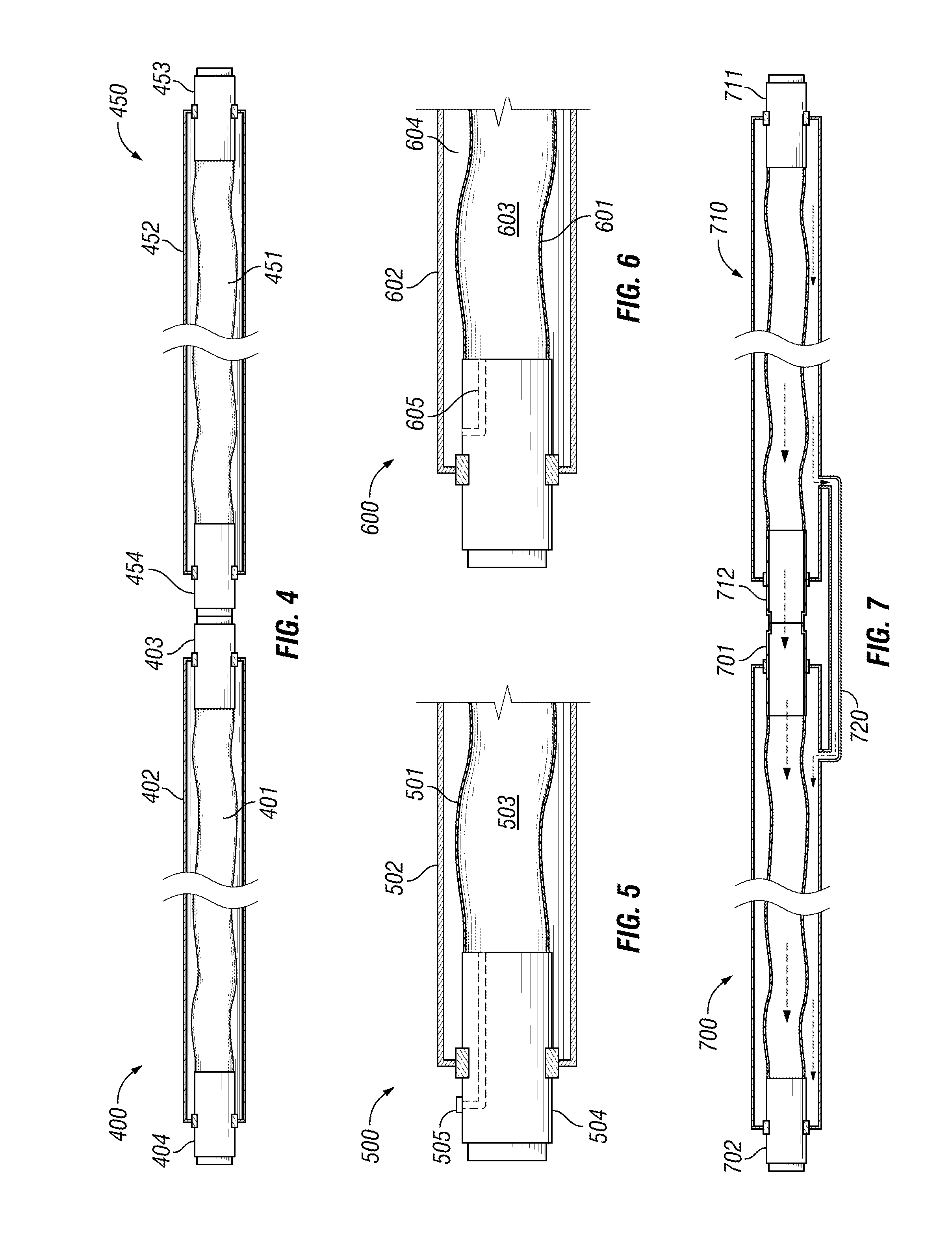

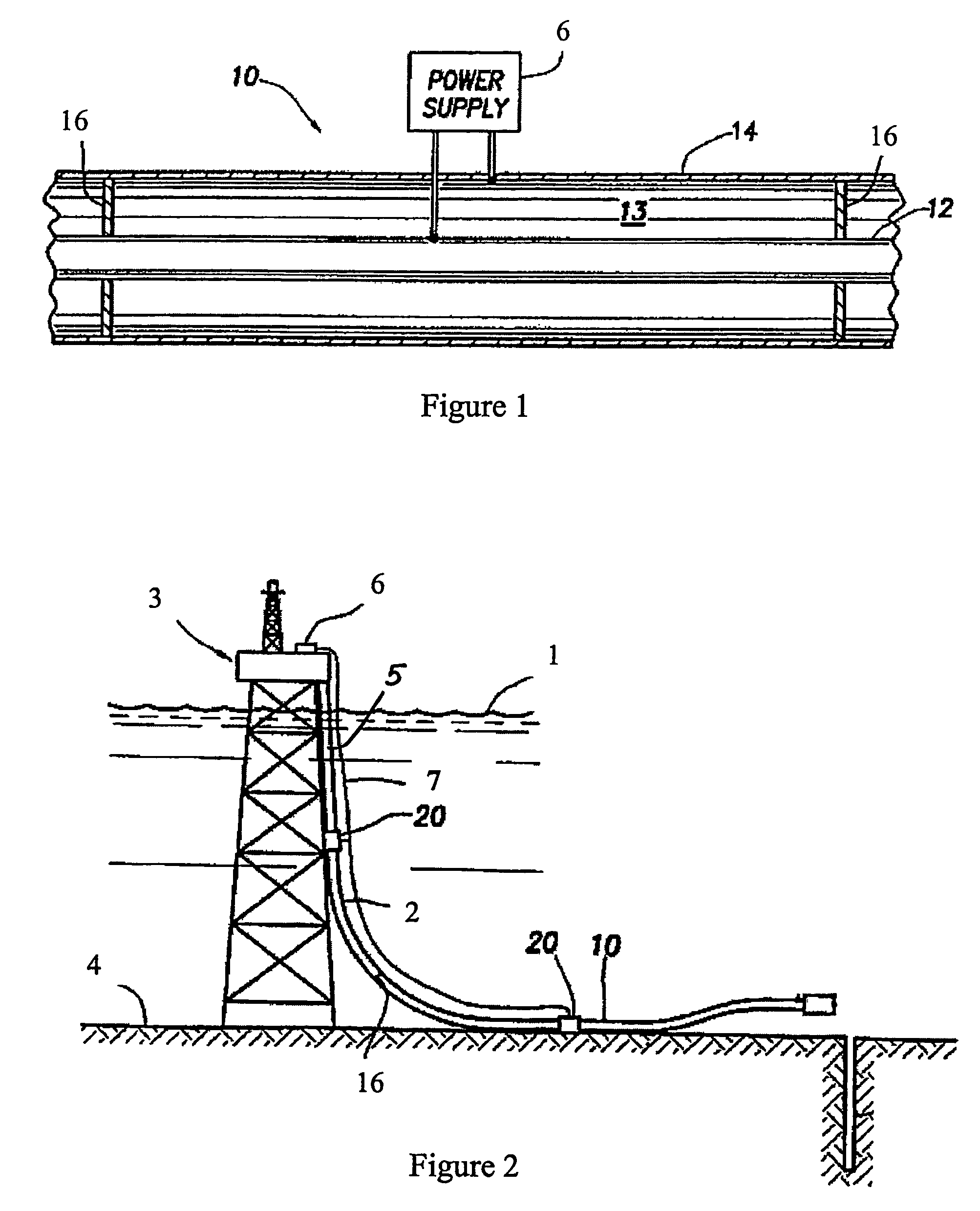

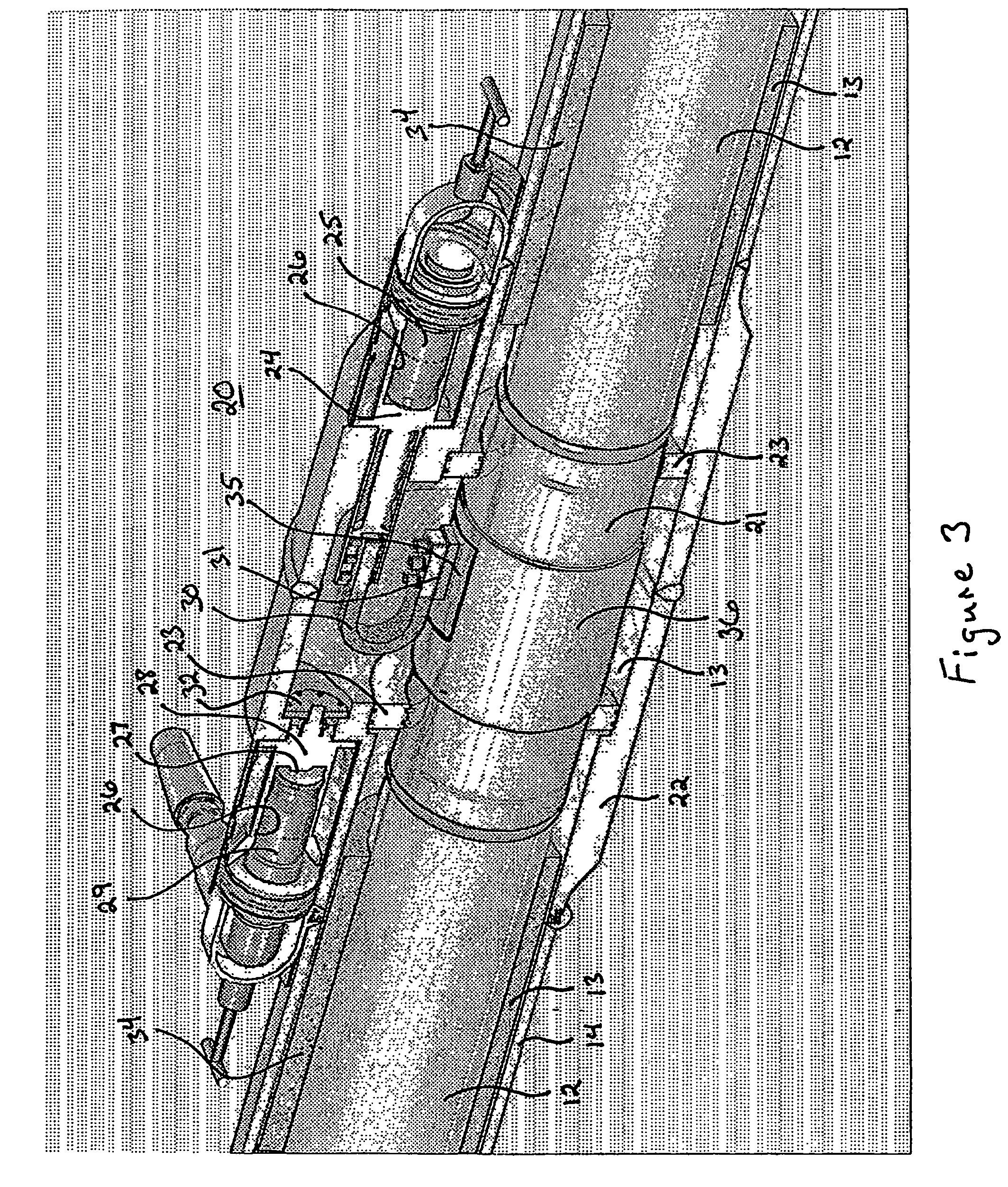

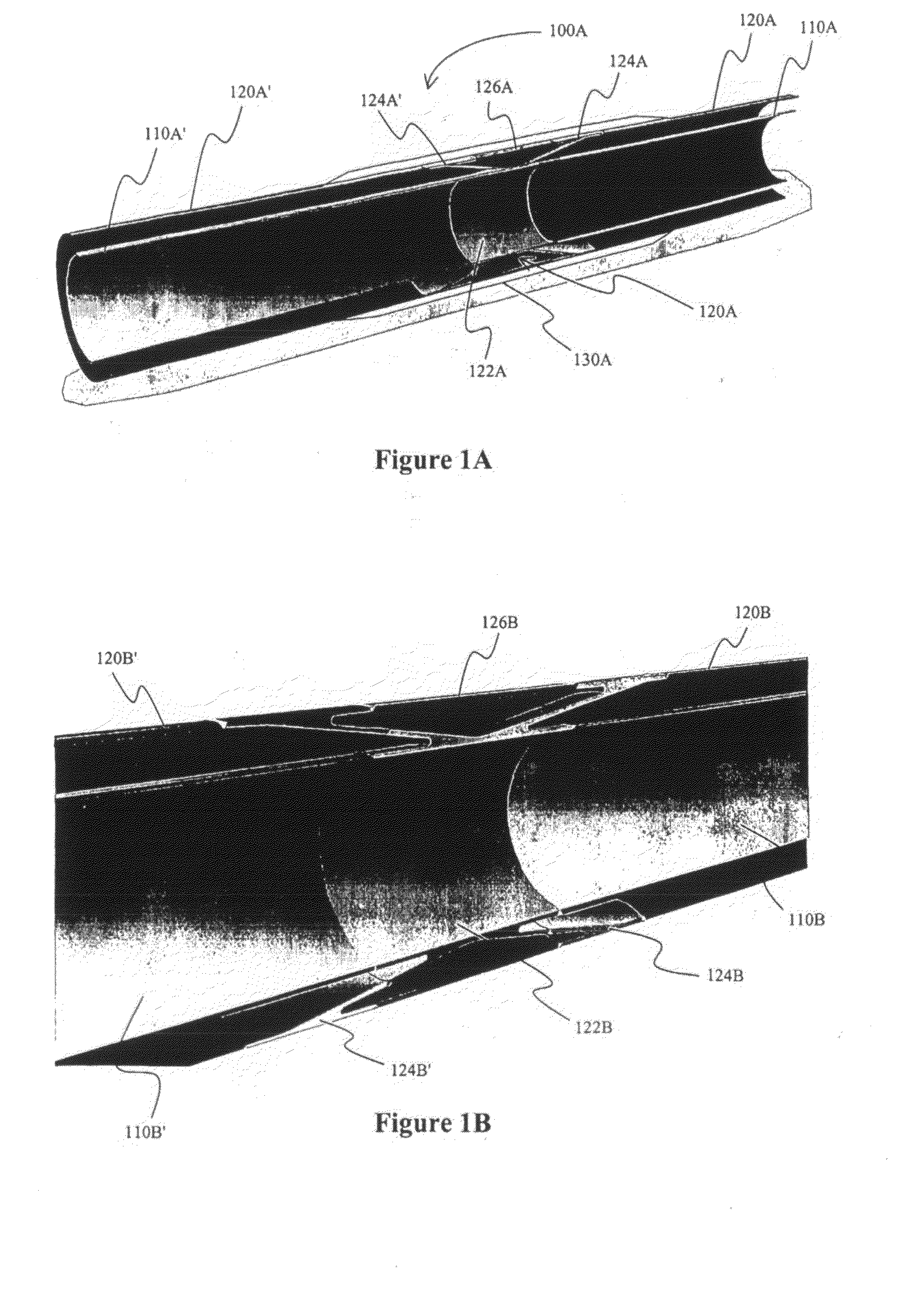

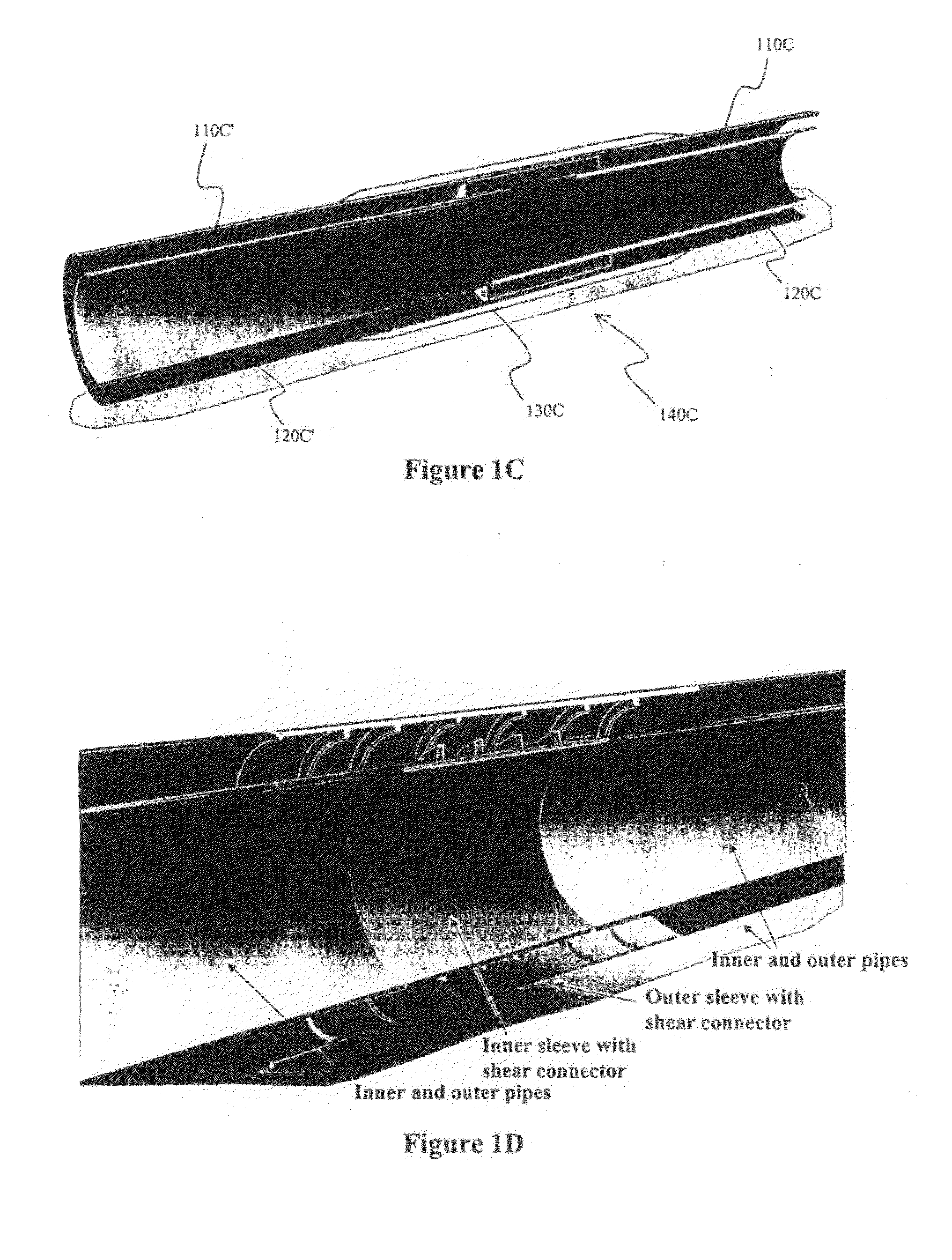

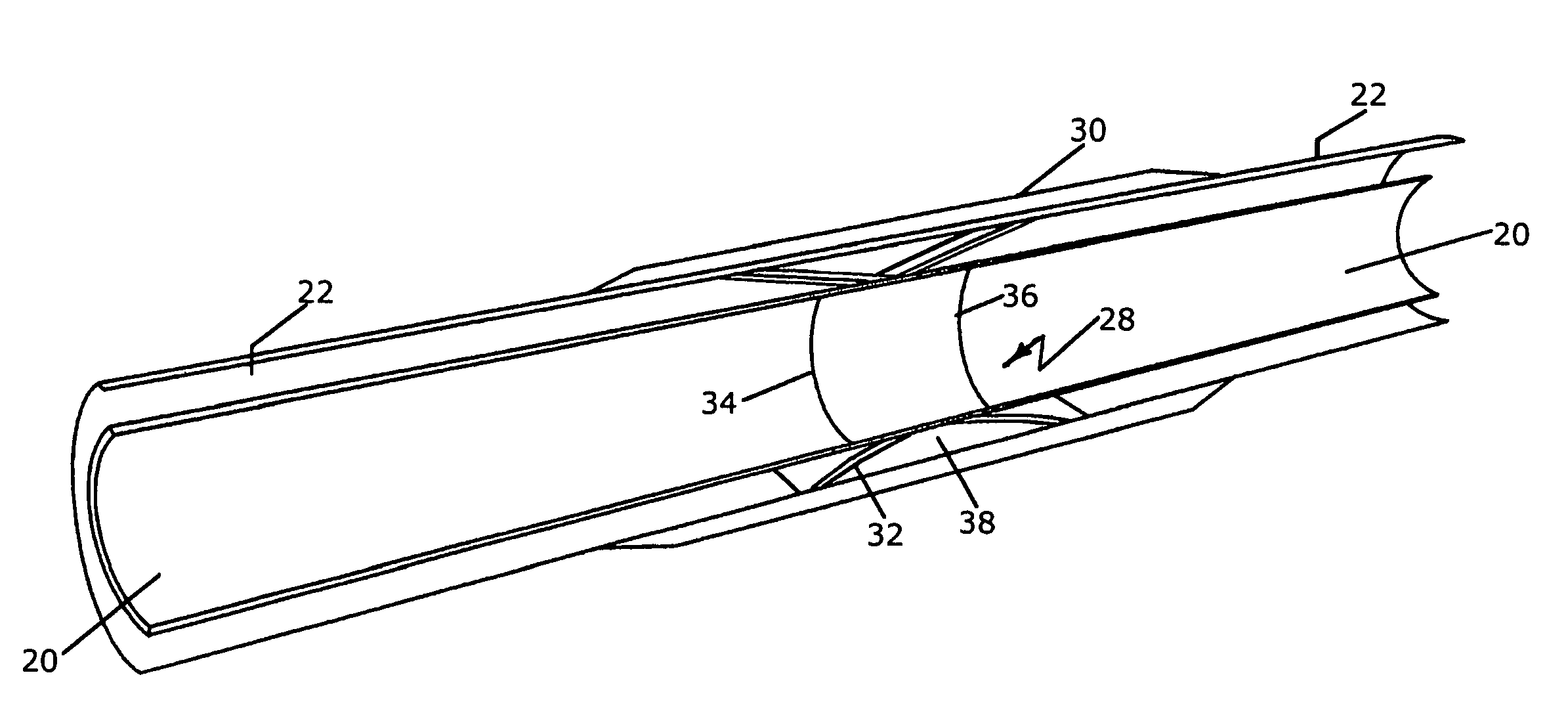

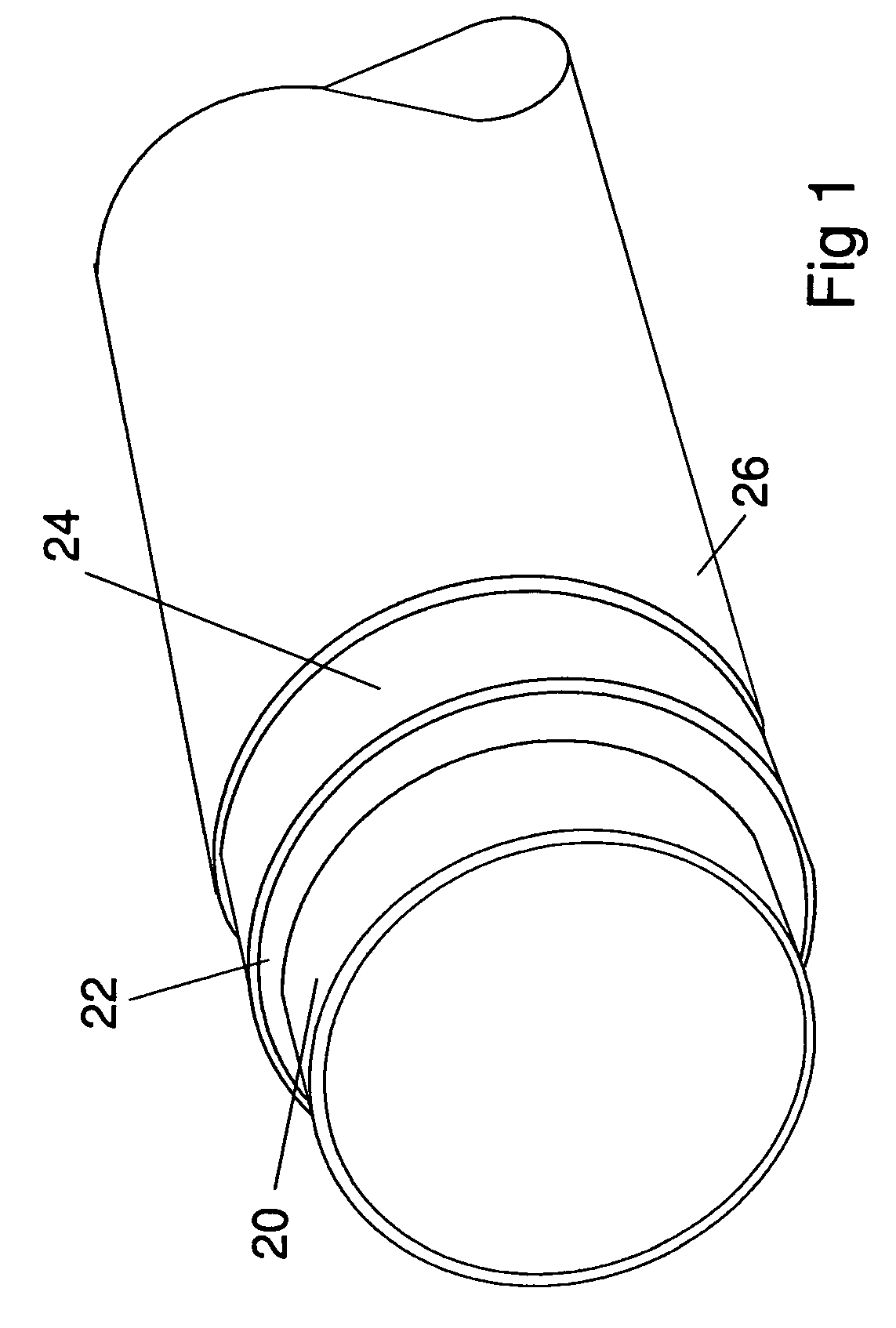

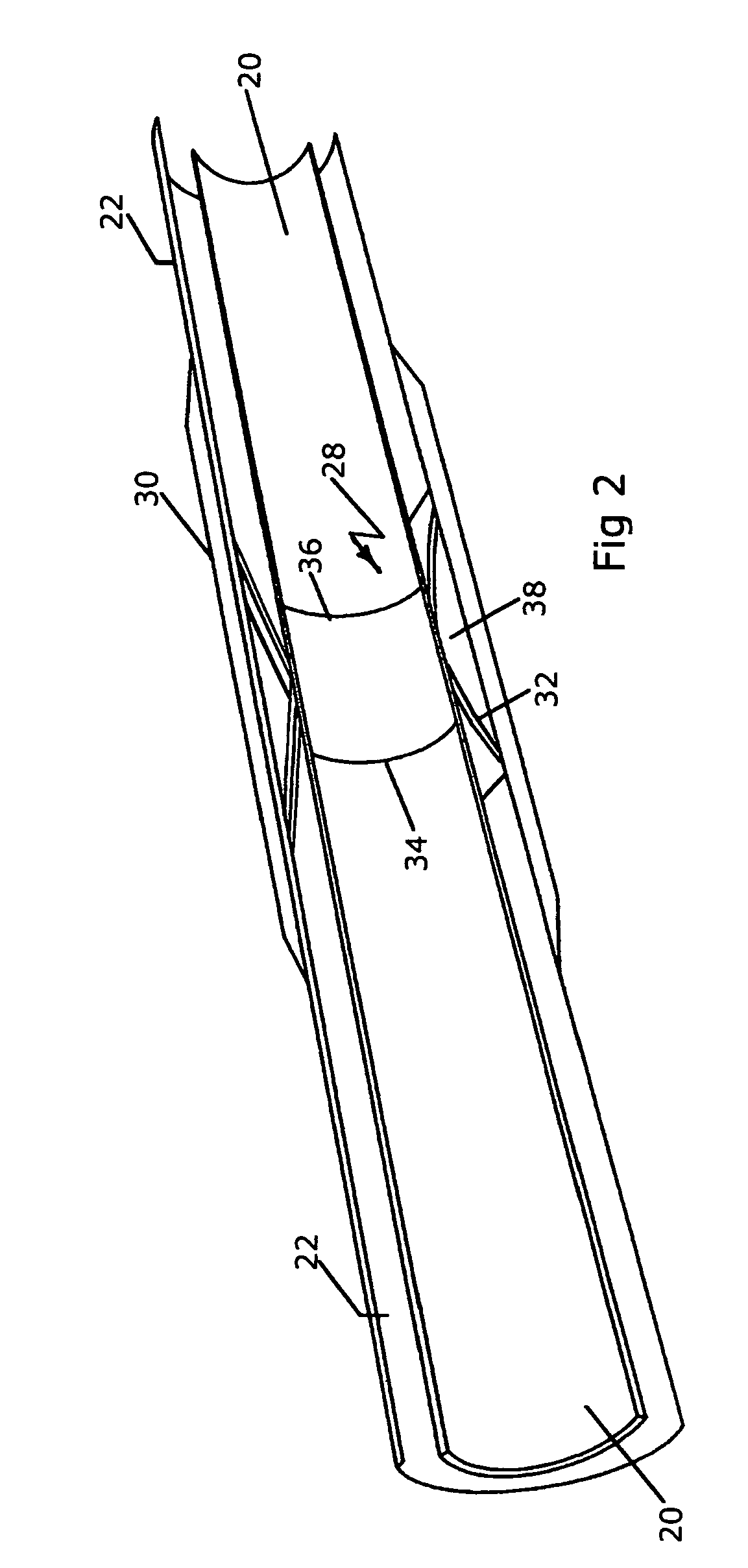

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS20050054228A1Increase axial loadAvoid local accumulationPipe heating/coolingPipe-jointsElectricityElectrical conductor

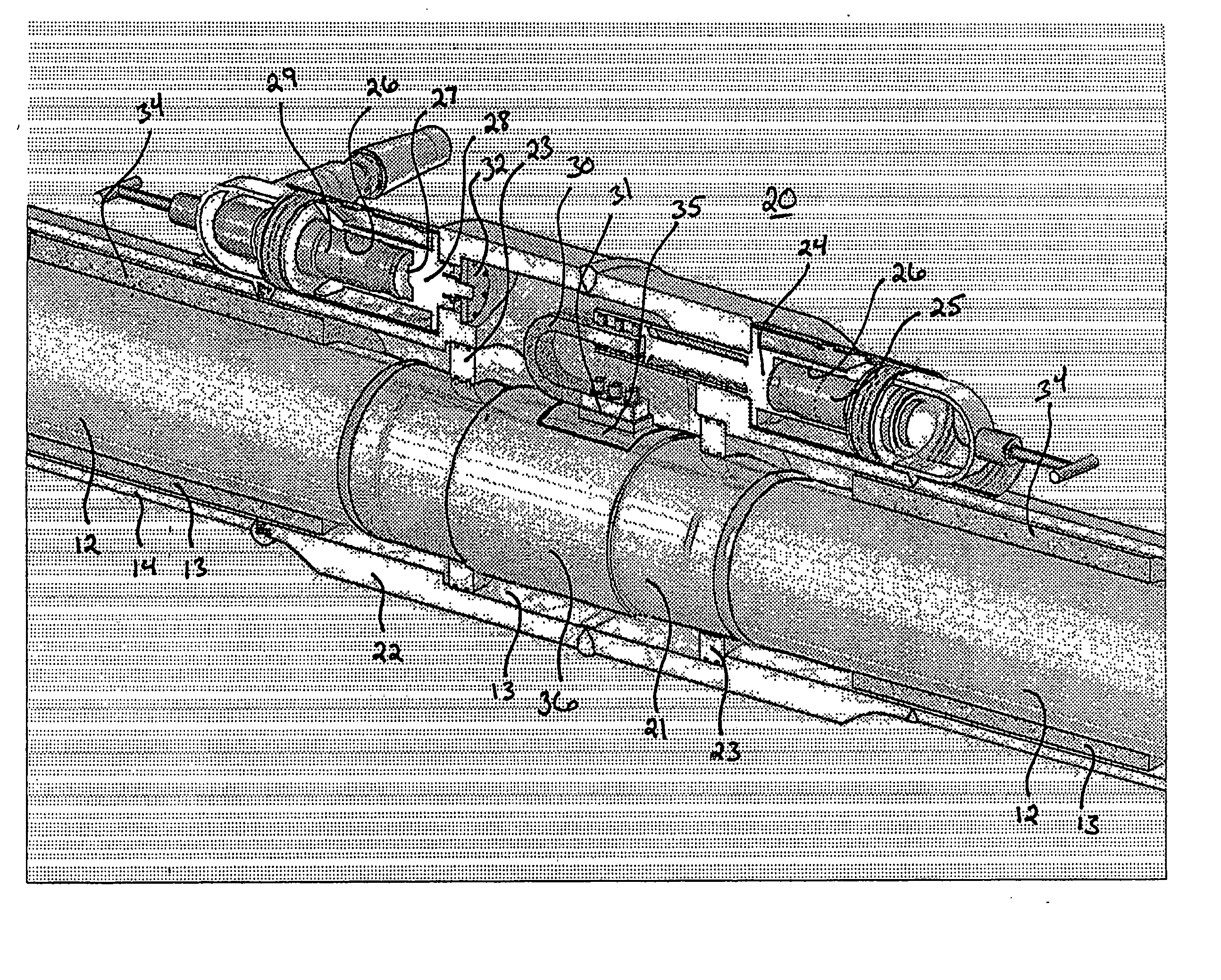

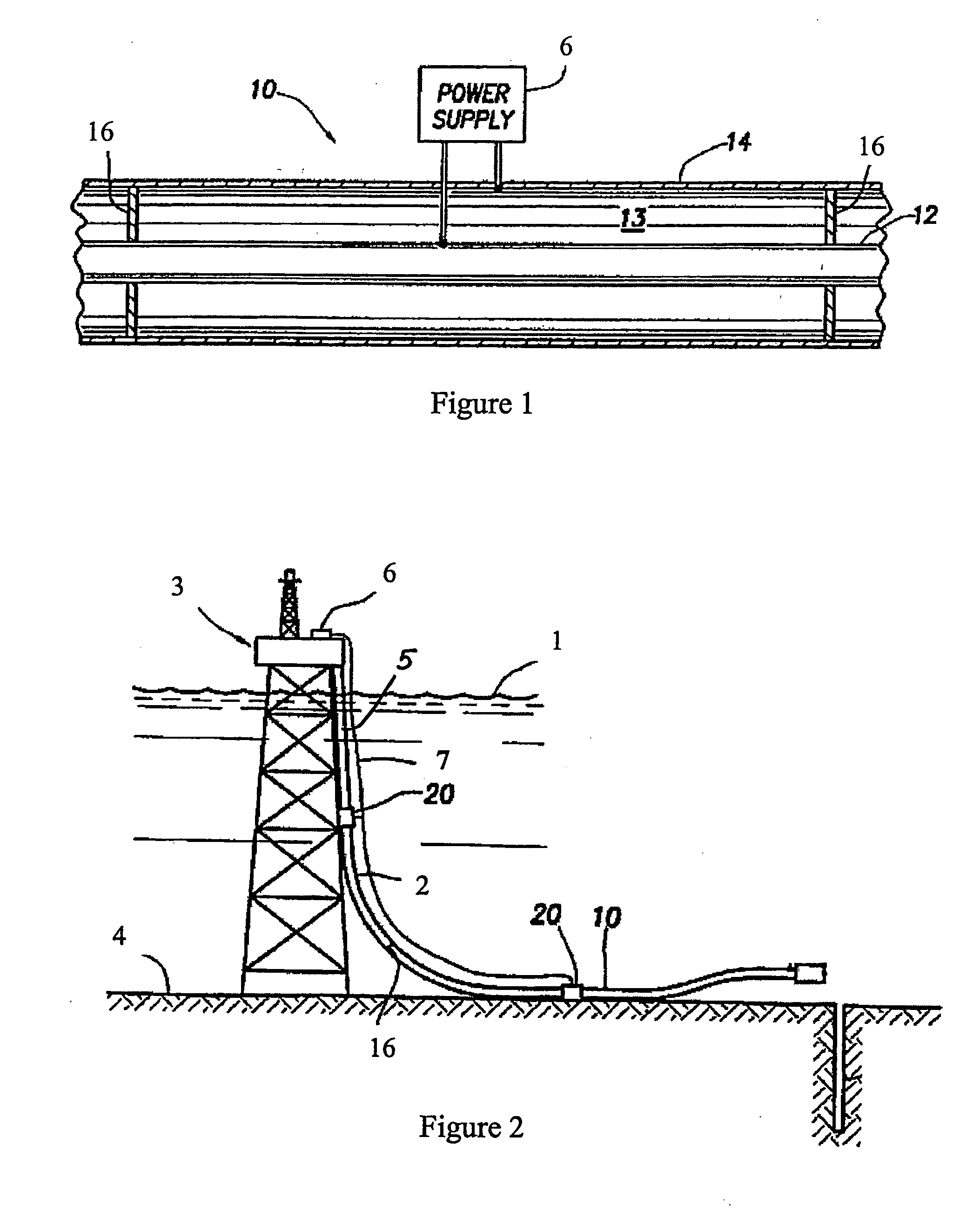

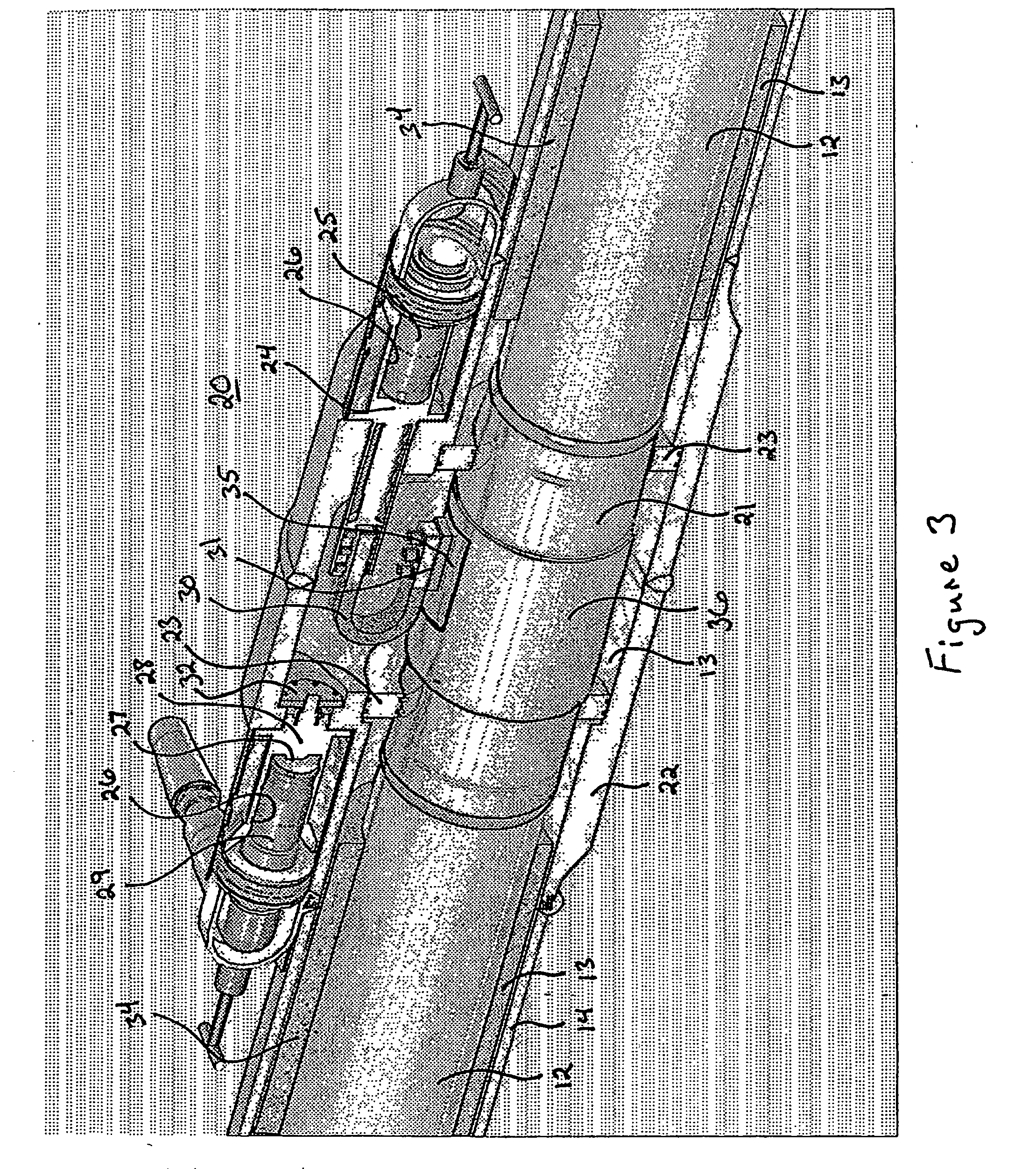

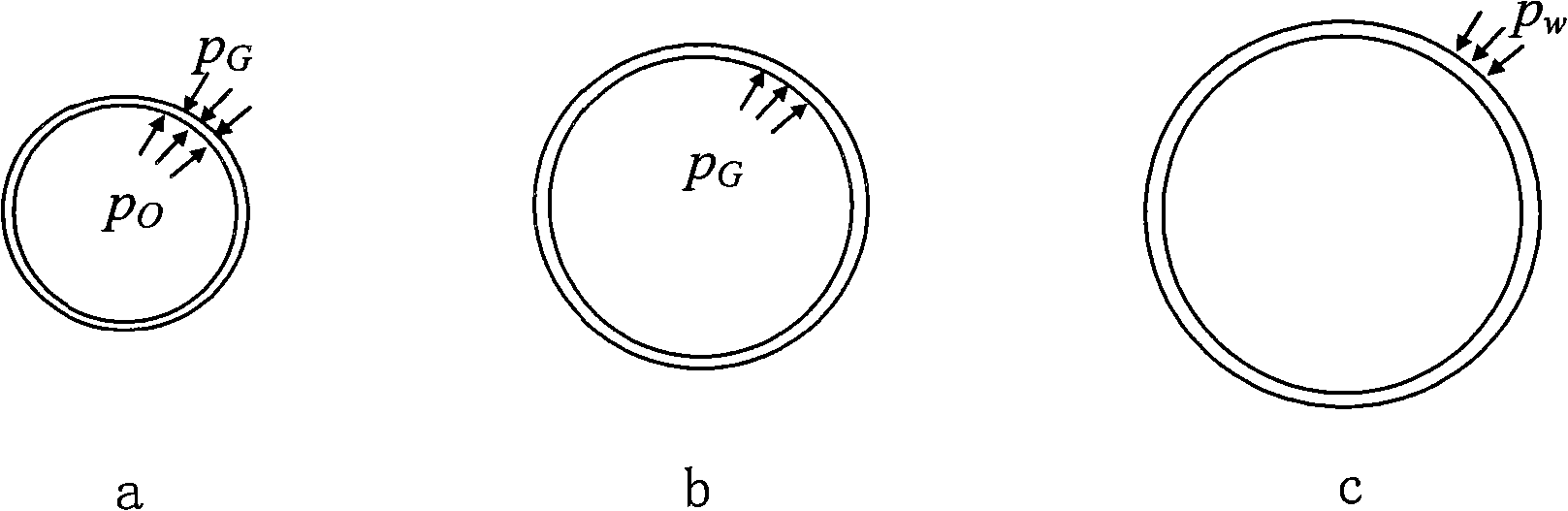

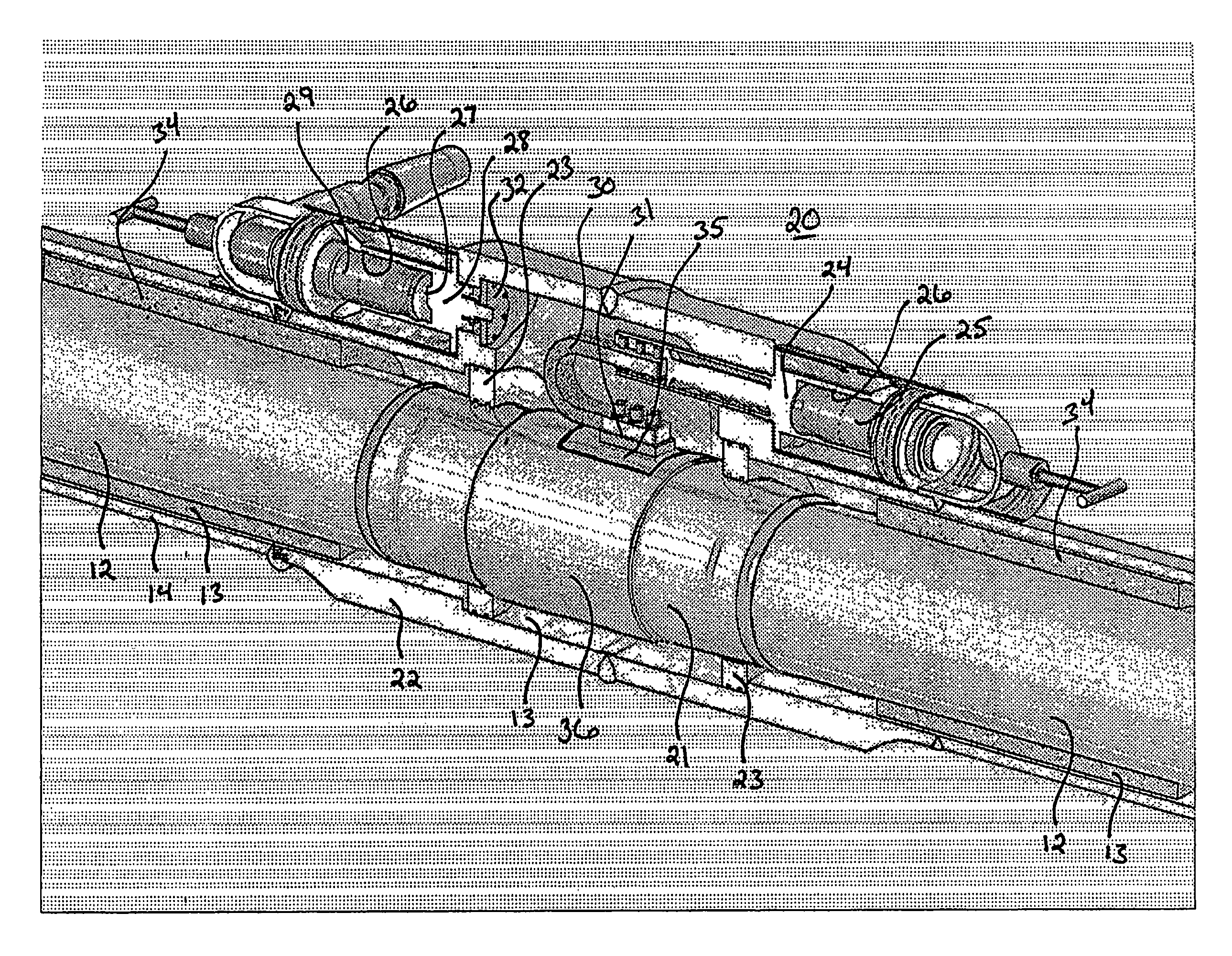

For heating a pipe-in-pipe pipeline with power provided through an electric cable, mid-line connector is provided including: a connector housing joinable to the outer pipe of the pipeline; a blank pipe positioned within the connector housing and joinable to the inner pipe of the pipeline; at least one pocket mounted in the connector housing, wherein the cable is mateable with the at least one pocket; a blank pipe conductor electrically coupled between the at least one pocket and the blank pipe; and an outer pipe conductor electrically coupled between the at least one pocket and the outer pipe.

Owner:SHELL OIL CO

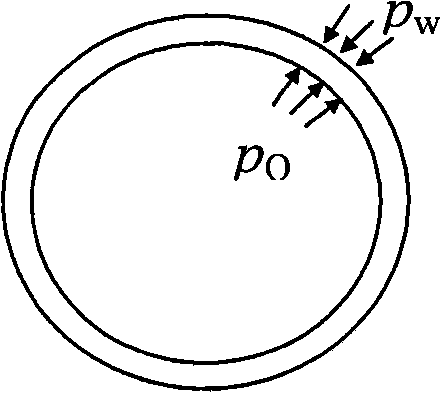

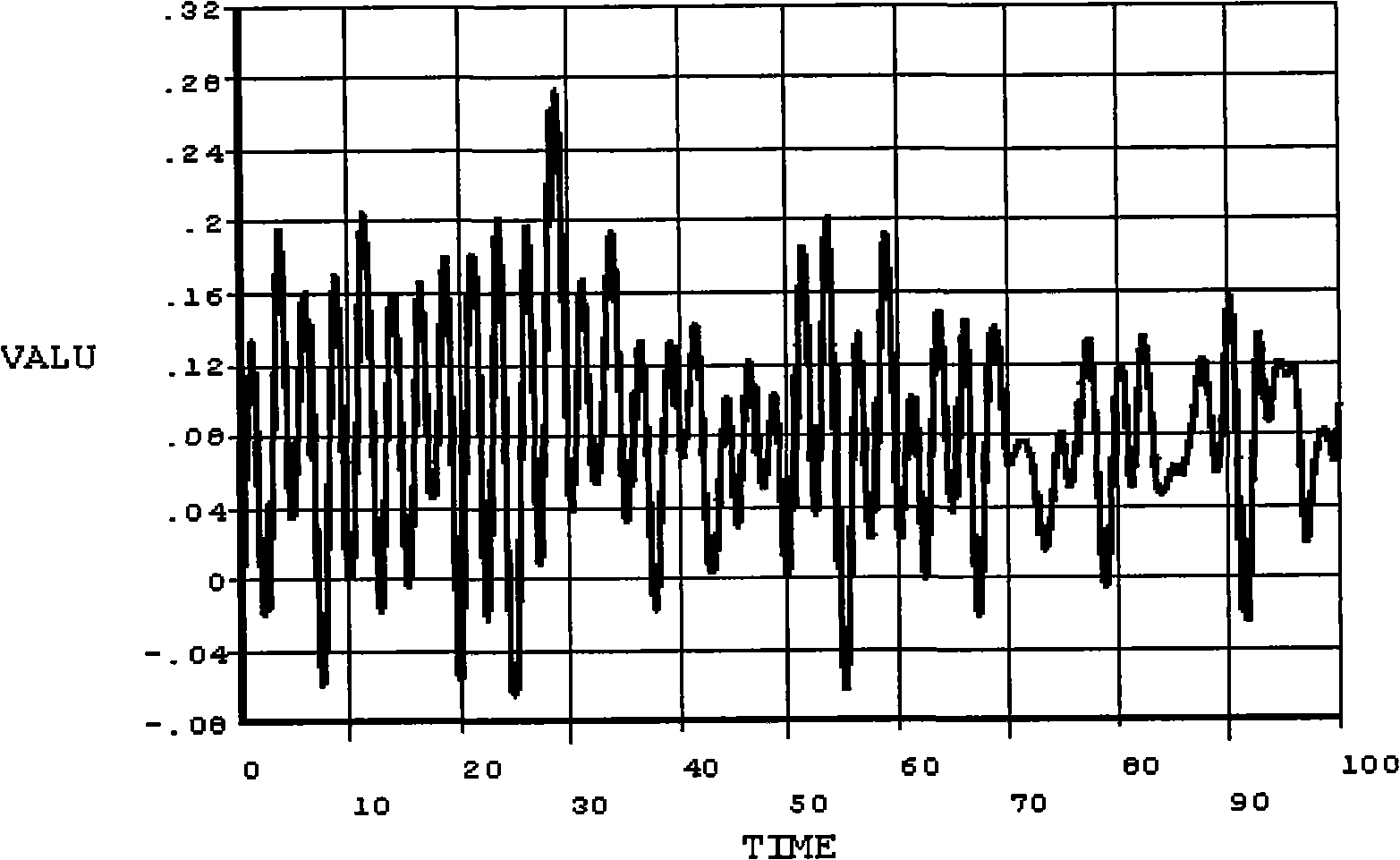

Method for analyzing vortex vibration and fatigue of depth tension-type vertical pipe

A method for analyzing vortex vibration and fatigue of a depth tension-type vertical pipe, which relates to the field of depth vertical pipe design, comprises the following specific steps of: step 1. obtaining flow field data; step 2. substituting the flow field data into vertical pipe vibration equations 6 and 7; step 3. solving the equations 6 and 7 by using a finite element method, and obtaining calculation results including displacement, velocity, accelerated velocity and stress time interval; and step 4. counting stress cycle number n(i) of an amplitude within a certain time by adopting a rain-flow counting method according to the calculation results, and substituting the n(i) into a fatigue damage calculation formula 8 to calculate the fatigue damage. The method for analyzing vortex vibration and fatigue of the depth tension-type vertical pipe improves the accuracy of stress calculation by adopting a practical pipe-in-pipe model and simultaneously considering direct flow vibration and cross flow vibration.

Owner:OCEAN UNIV OF CHINA

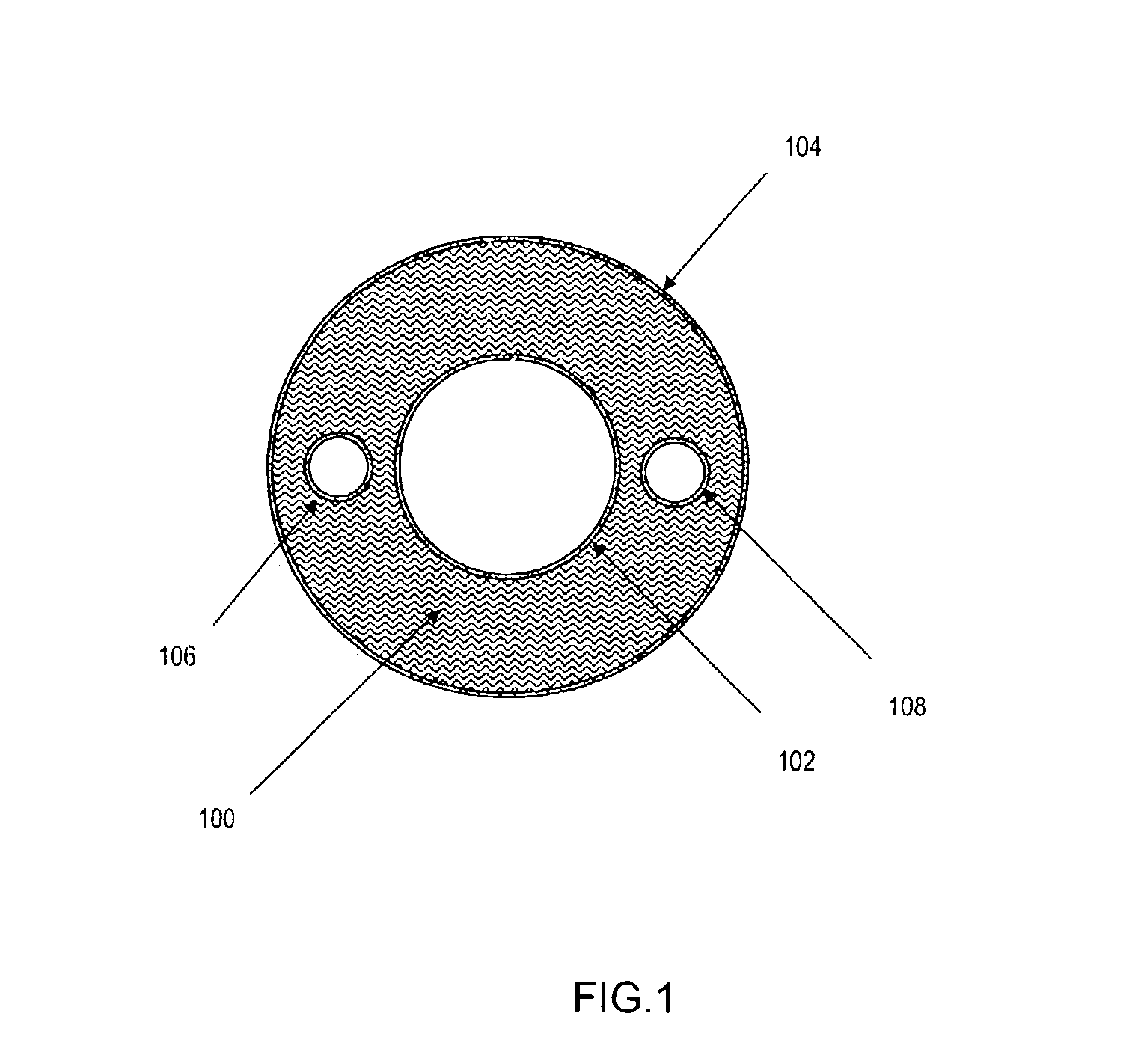

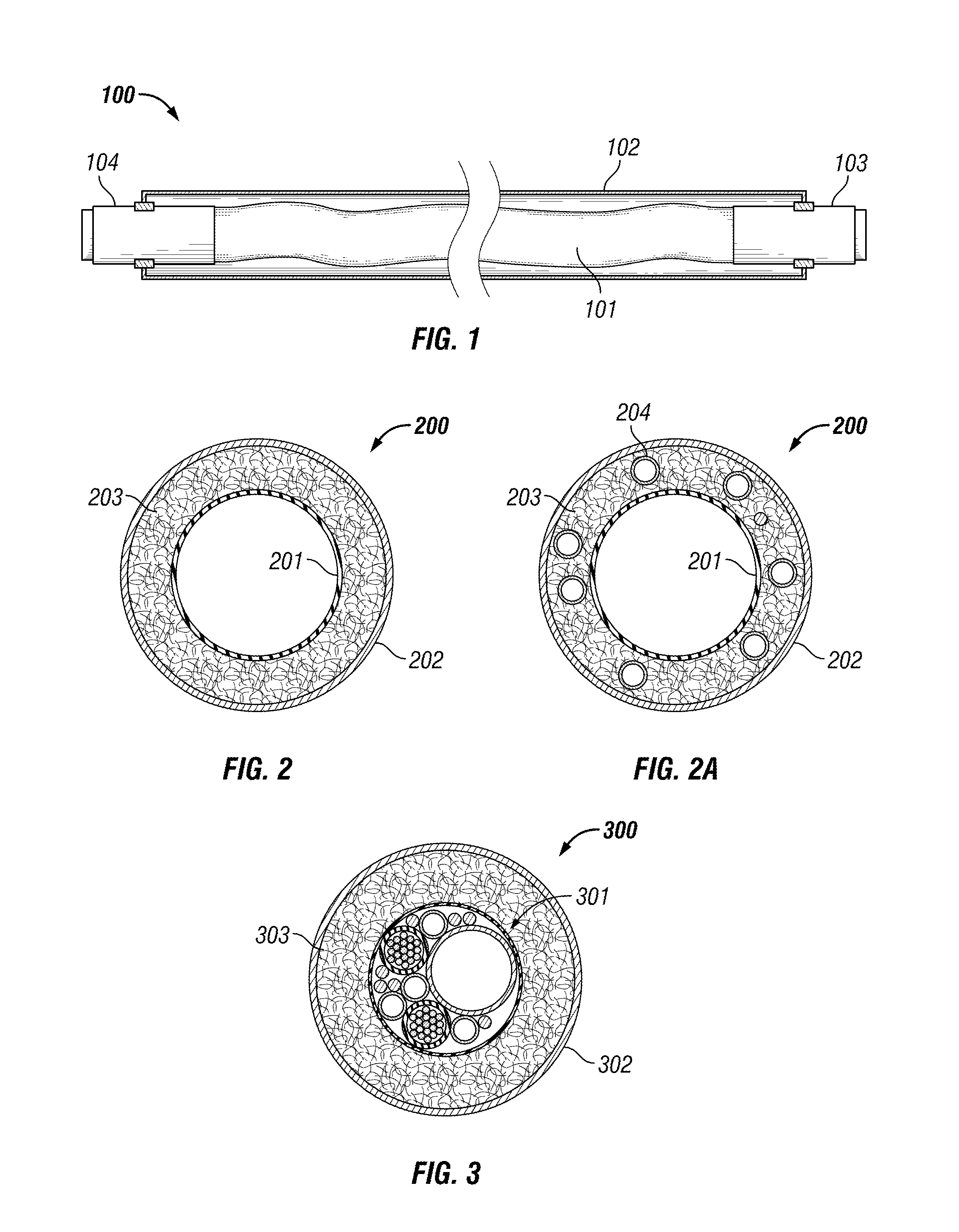

Instrumentation and Monitoring System For Pipes and Conduits Transporting Cryogenic Materials

InactiveUS20100229662A1Mechanically simpleCheap manufacturingThermal insulationPipe elementsTransfer systemMarine engineering

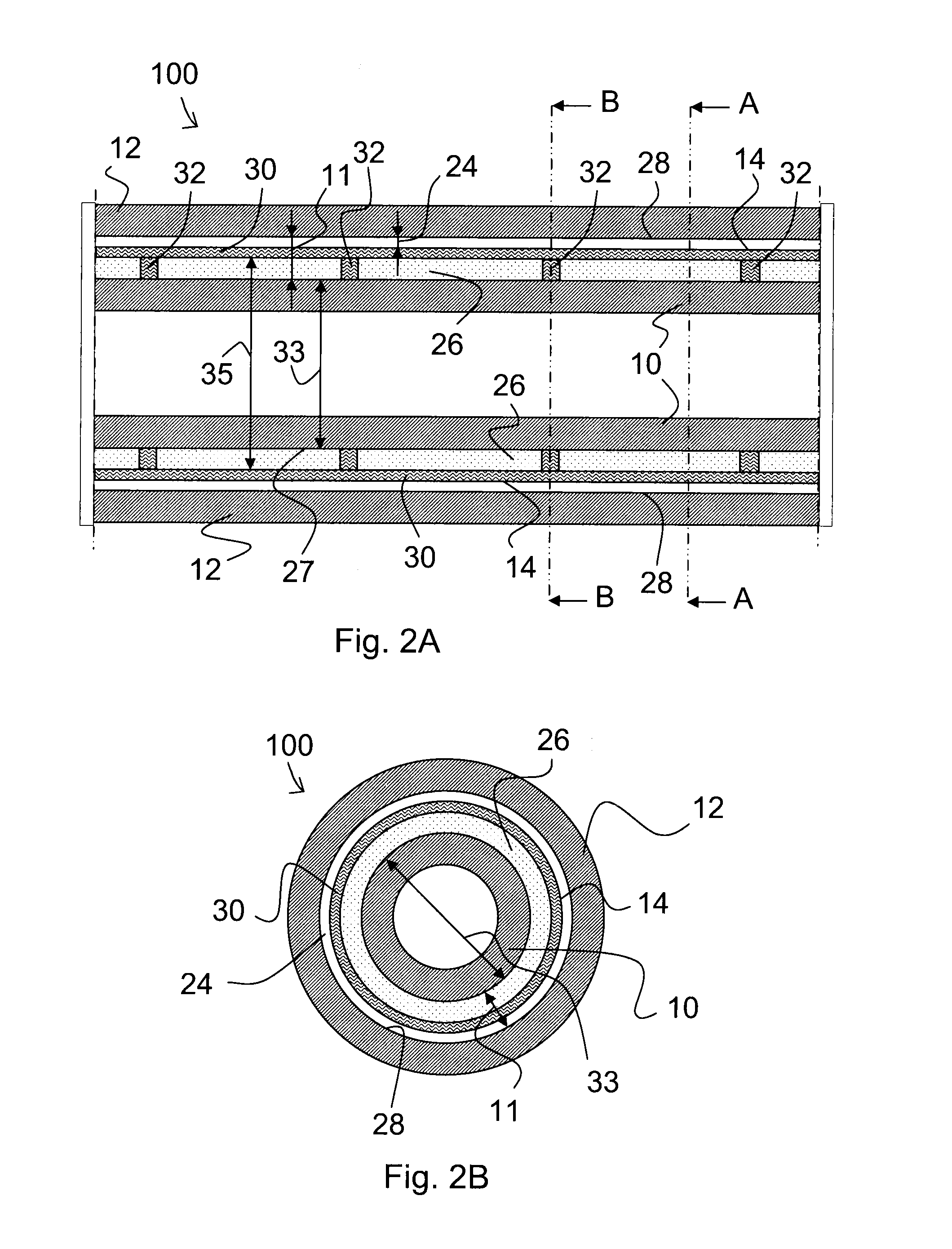

An instrumentation and monitoring system for a cryogenic material transfer system incorporates a pipe-in-pipe configuration with either a vacuum or a nanoporous or microporous insulating layer filling the annulus between the inner and outer pipe. The insulating layer is of sufficient flexibility to absorb the expansion or contraction of the inner pipe due to thermal effects from the flow of cryogenic material. The monitoring system typically includes a multitude of fiber optic sensors that measure leaks, temperature, pressure and strain. The invention includes the fiber optic sensors, conventional sensors, cabling, connectors / splice assembles, ingress / egress methods, ruggedization methods, data acquisition and analysis.

Owner:ASTRO TECH GRP LLC

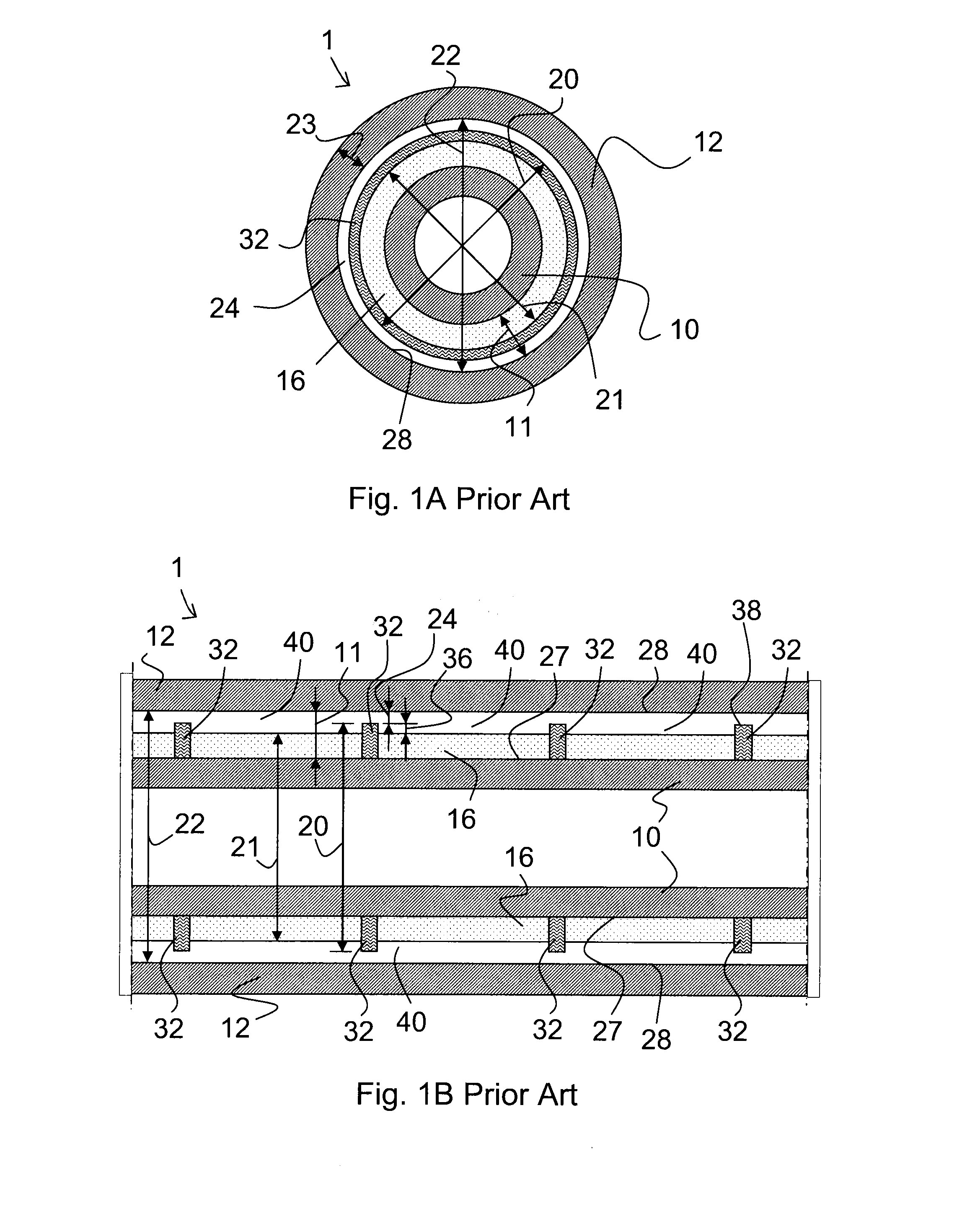

Active heating of thermally insulated flowlines

InactiveUS6955221B2Cost-effective and reliableCost-effectiveInsulationFluid removalEngineeringHot liquids

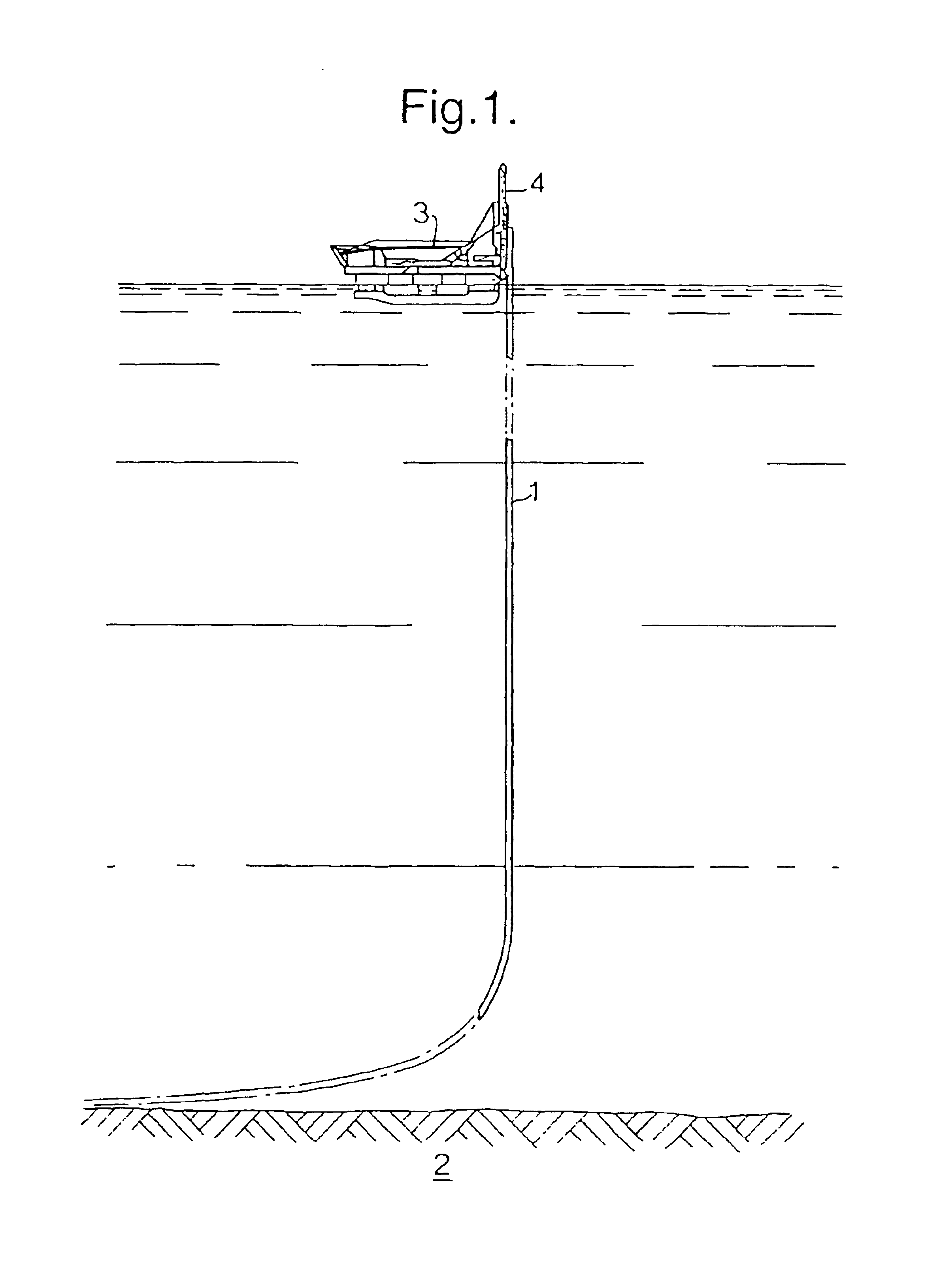

Hydrocarbon liquids are transported from a subsea welihead to an above-surface hydrocarbon processing facility along a pipe-in-pipe flowline. The flowline is a pipe placed coaxially within an outer carrier pipe and the annulus between the pipes is filled with thermally insulating material. The hydrocarbon liquids have their temperature maintained above solidification / precipitation temperature by heat from an active heating system. Hot liquid, preferably hot water, is passed along the annulus, either along a single pipe or multiple pipes installed in the insulation-filled annulus, or along an inner annulus formed by a water pipe added concentrically around the hydrocarbon-transporting inner pipe, inside the outer insulation-filled annulus. The water or other suitable liquid can be heated in a heater at or adjacent the subsea wellhead, or by a water heater in the above-surface hydrocarbon processing facility.

Owner:SUBSEA 7 US

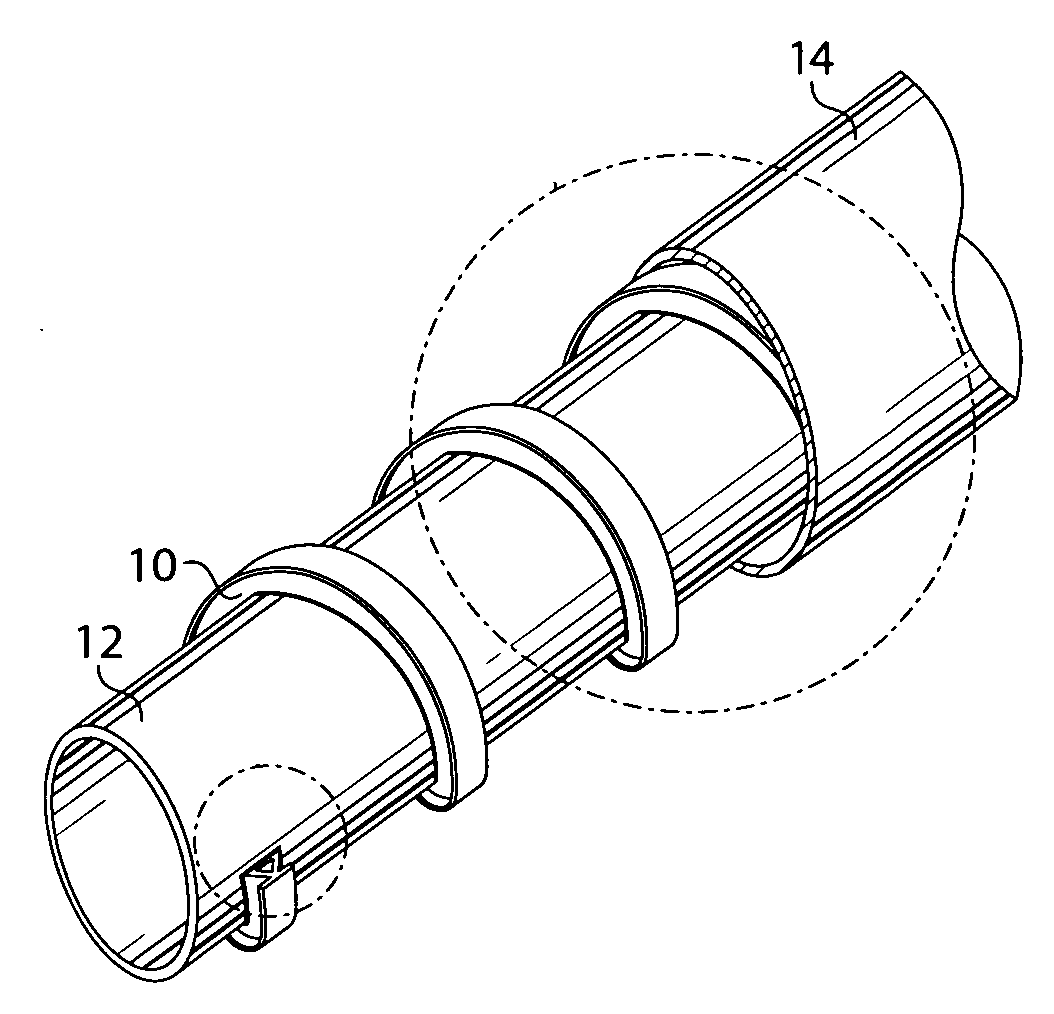

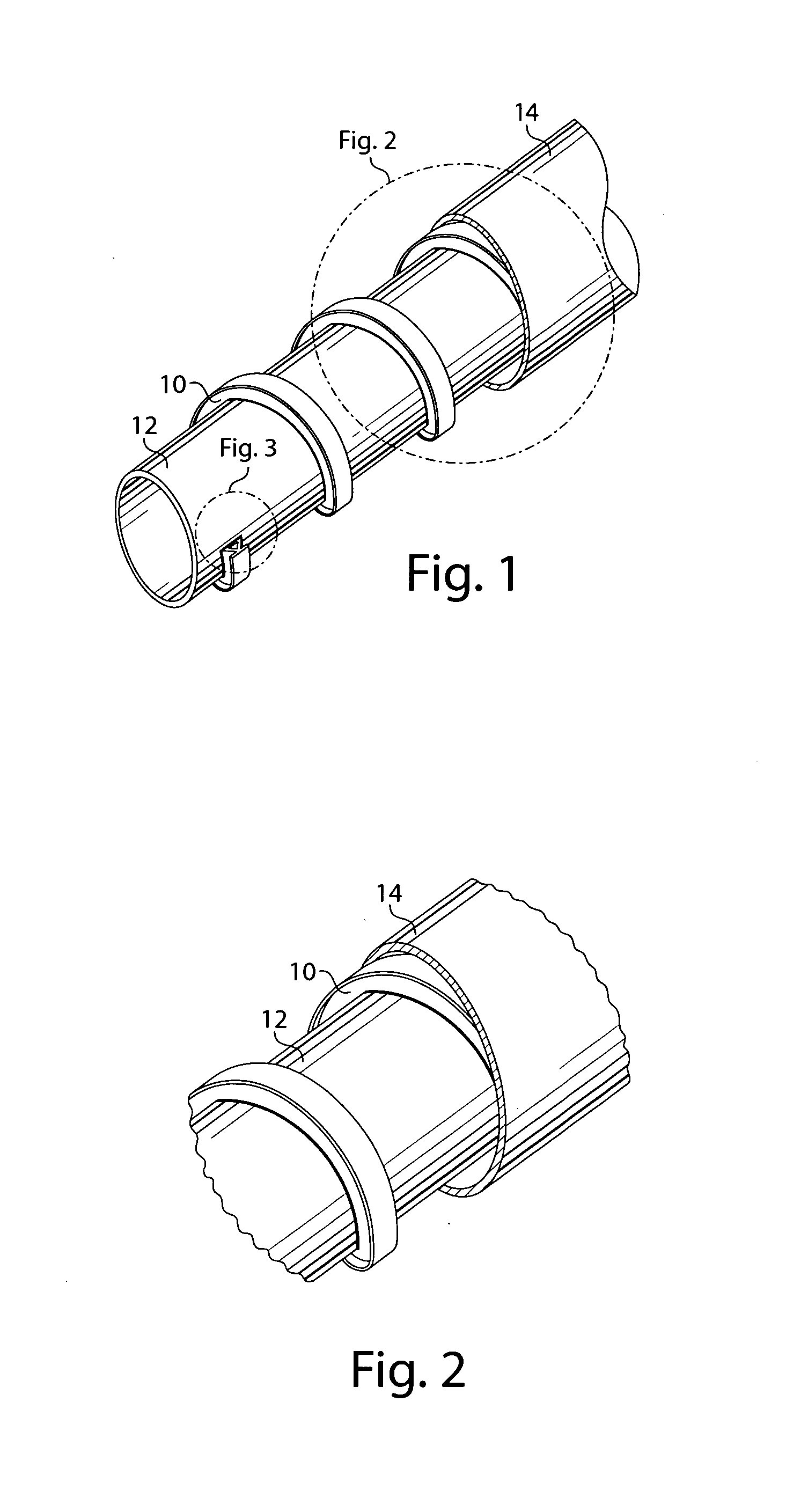

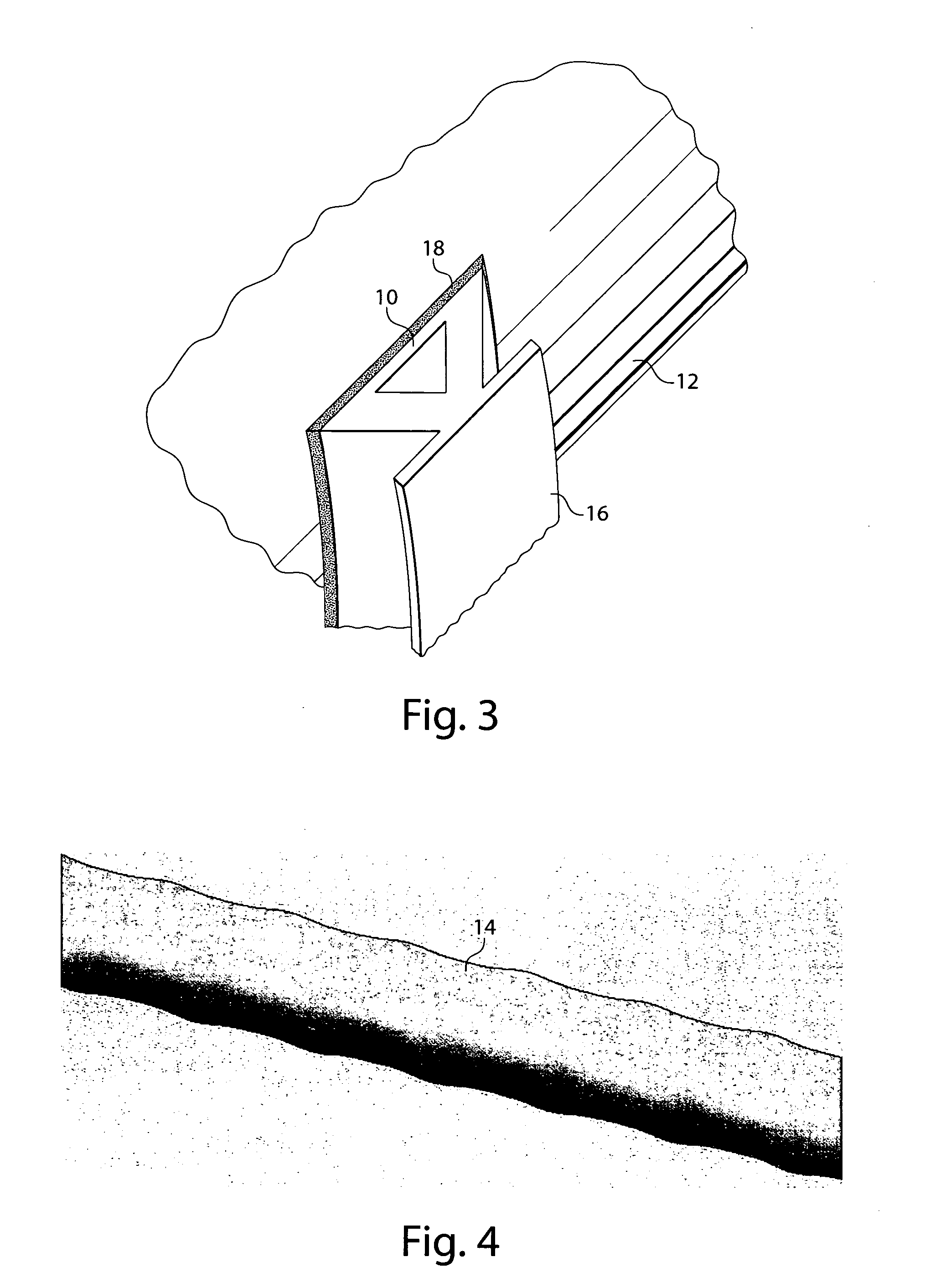

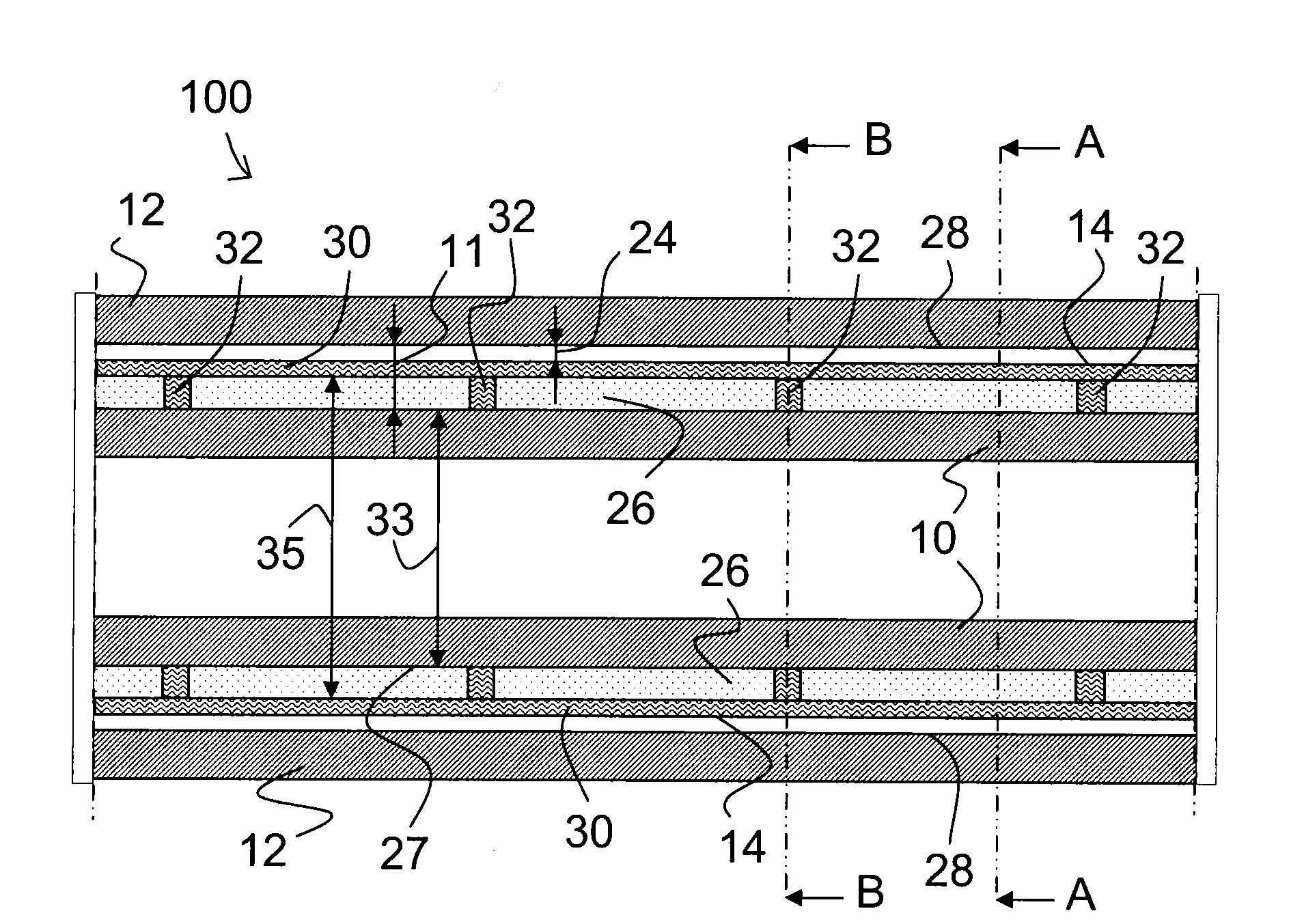

Load-bearing, lightweight, and compact super-insulation system

ActiveUS20050047871A1Easy to installEasy maintenanceDrilling rodsService pipe systemsEngineeringInsulation system

A lightweight and compact super-insulation system that is also capable of supporting a high level of compressive load is described. The system utilizes spacers to provide structural support and utilize controlled buckling of a thin protective outer skin supported by spacers to form strong catenary surfaces to protect insulation material underneath. The spacers may comprise an aerogel, or an aerogel may provide insulation separate from the spacer yet contained within the thin outer skin. The system will be useful for thermal management of variety of deep underwater structures such as pipe-in-pipe apparatus, risers or subsea trees for ultra-deep water oil-and-gas exploration.

Owner:ASPEN AEROGELS INC

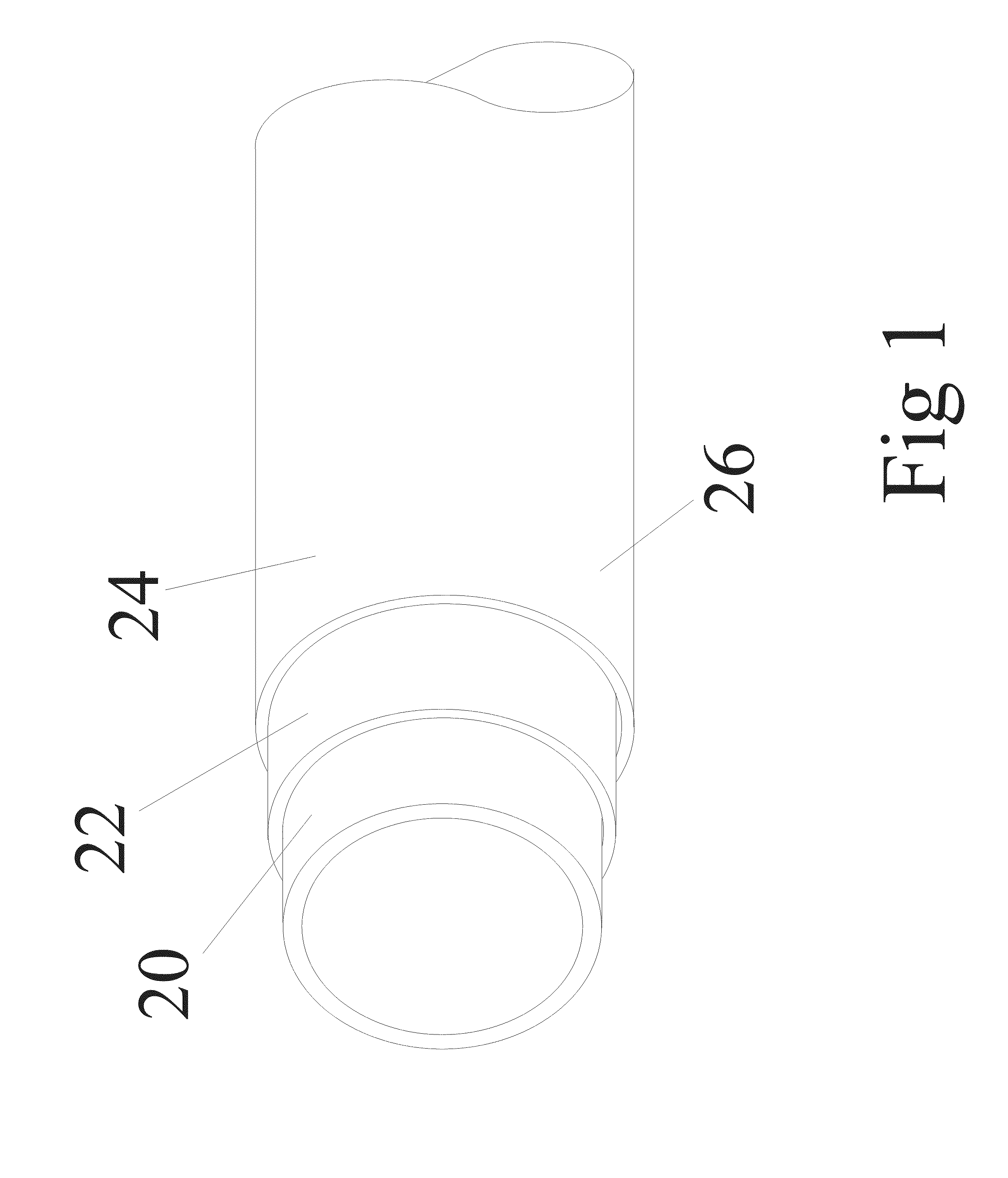

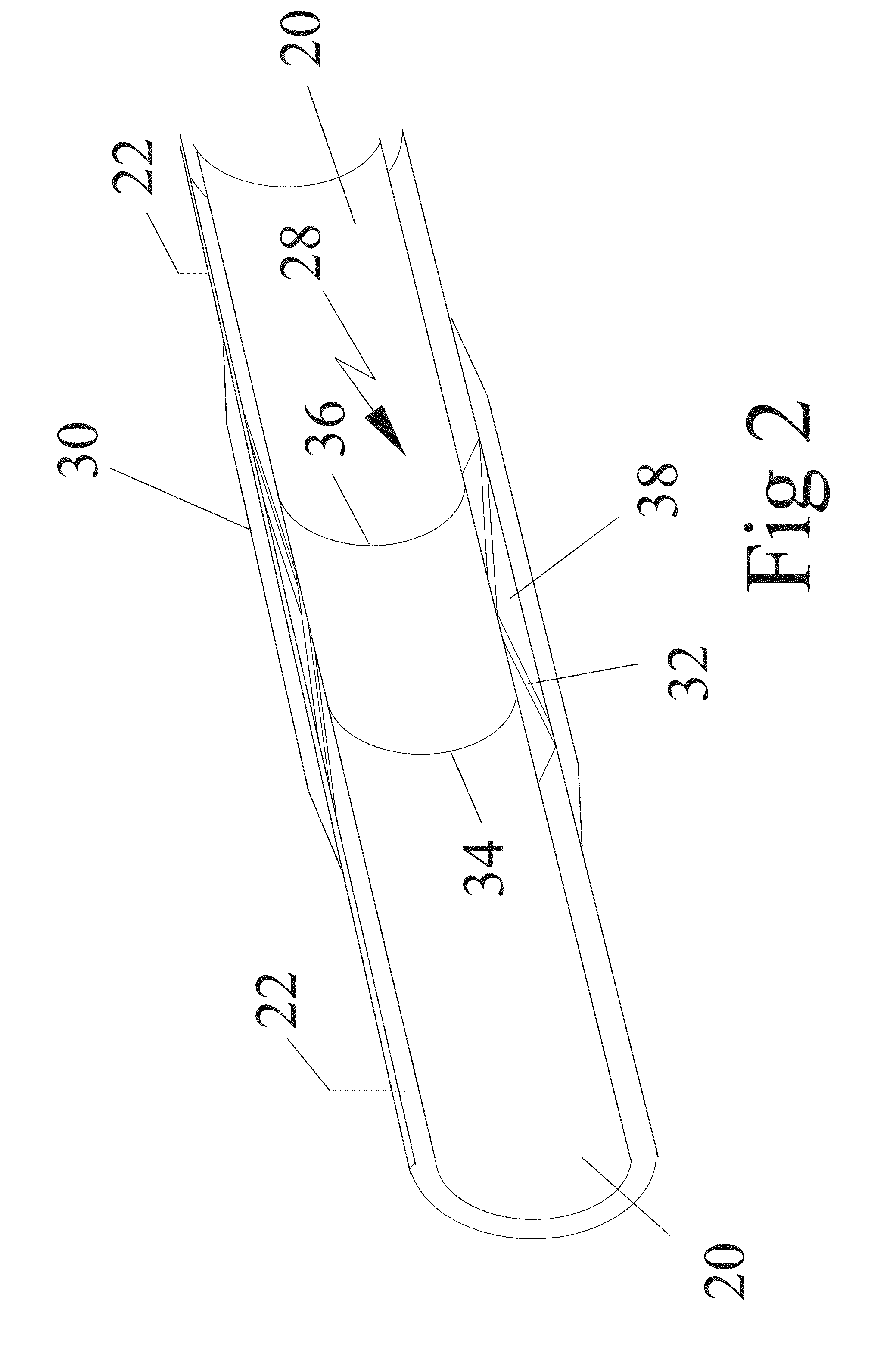

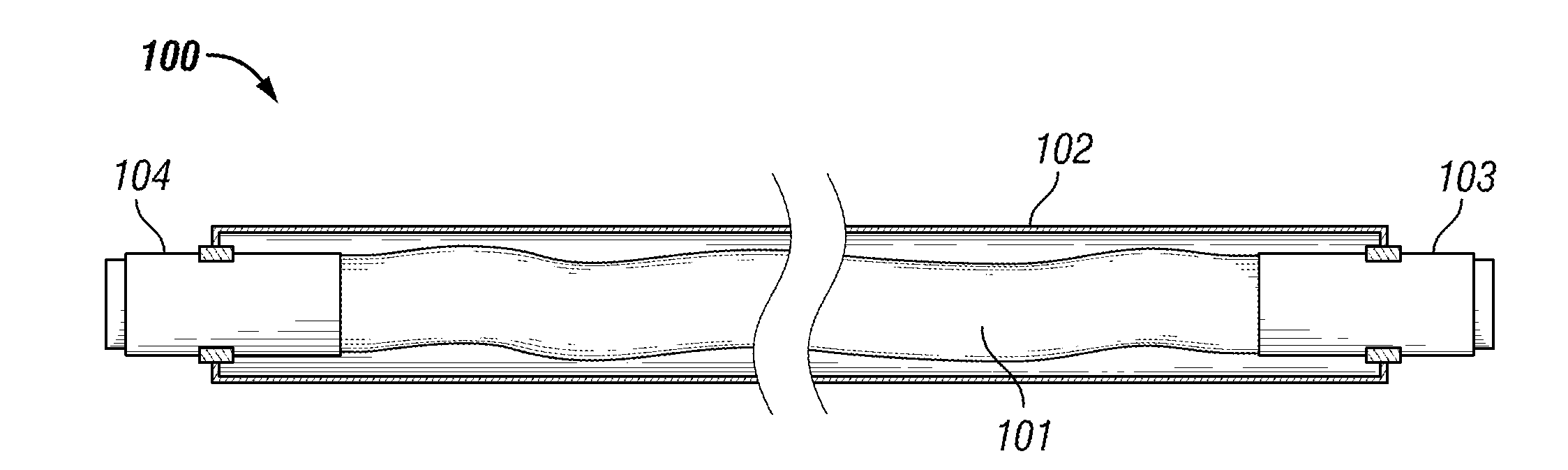

Pipe-in-pipe apparatus including an engineered pipe

ActiveUS20140116556A1Increased resistance to fatigue loadsAvoid undesired movementThermal insulationPipe elementsEngineeringRetrofitting

Disclosed is a pipe-in-pipe apparatus comprising an inner pipe disposed within an outer pipe wherein the inner pipe is an engineered pipe or umbilical. The outer pipe will shield the inner pipe. As a result, the design of the inner pipe only needs to address the functions required for the engineered pipe-in-pipe apparatus. The end fittings of the system are designed for enabling maximum operation and intervention flexibility. The engineered pipe-in-pipe apparatus will allow longer sections of the inner pipe to be used which will reduce the amount of field fabrication and streamline the installation process. The apparatus may be used for both new piping systems as well as the updating or retrofitting of an existing onshore or offshore piping system.

Owner:CHEVROU USA INC

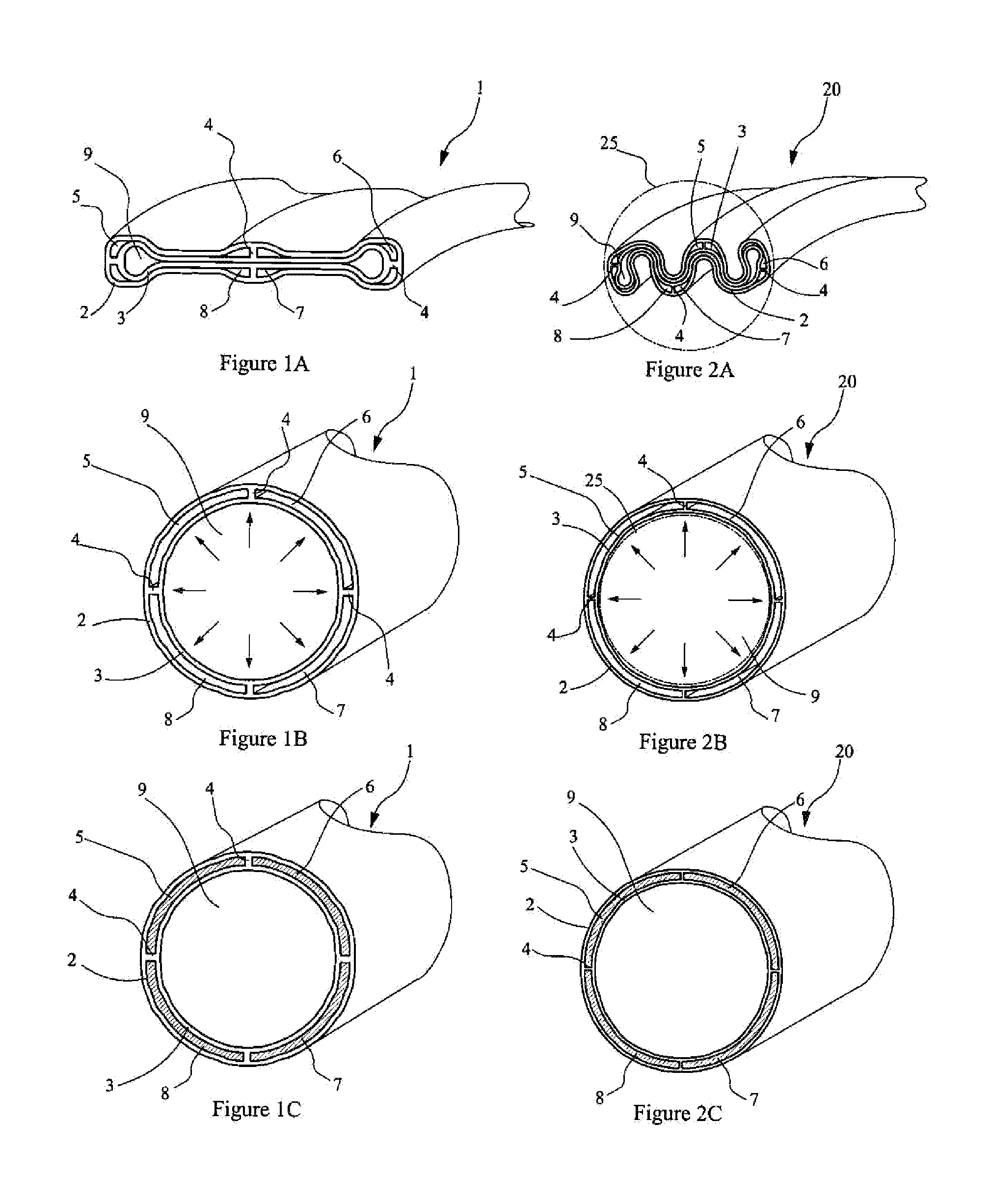

Insulation for pipe-in-pipe systems

InactiveUS20090301596A1Big cost advantageQuick assemblyThermal insulationFlexible pipesThermal insulationThick wall

A method of providing an insulated pipe-in-pipe assembly includes providing an inner pipe; providing a thermal insulation layer of a highly porous solid formed from a gel, the highly porous solid having pores smaller than 100 nanometre, the thermal insulation layer being provided around the inner pipe for thermal insulation of the inner pipe; providing a protective layer on the outer surface of the thermal insulation layer for protecting the thermal insulation layer, and providing a thick walled outer pipe around the protective layer. A Pipe-in-pipe assembly and a pipe-in-pipe section made by the method are also provided.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND

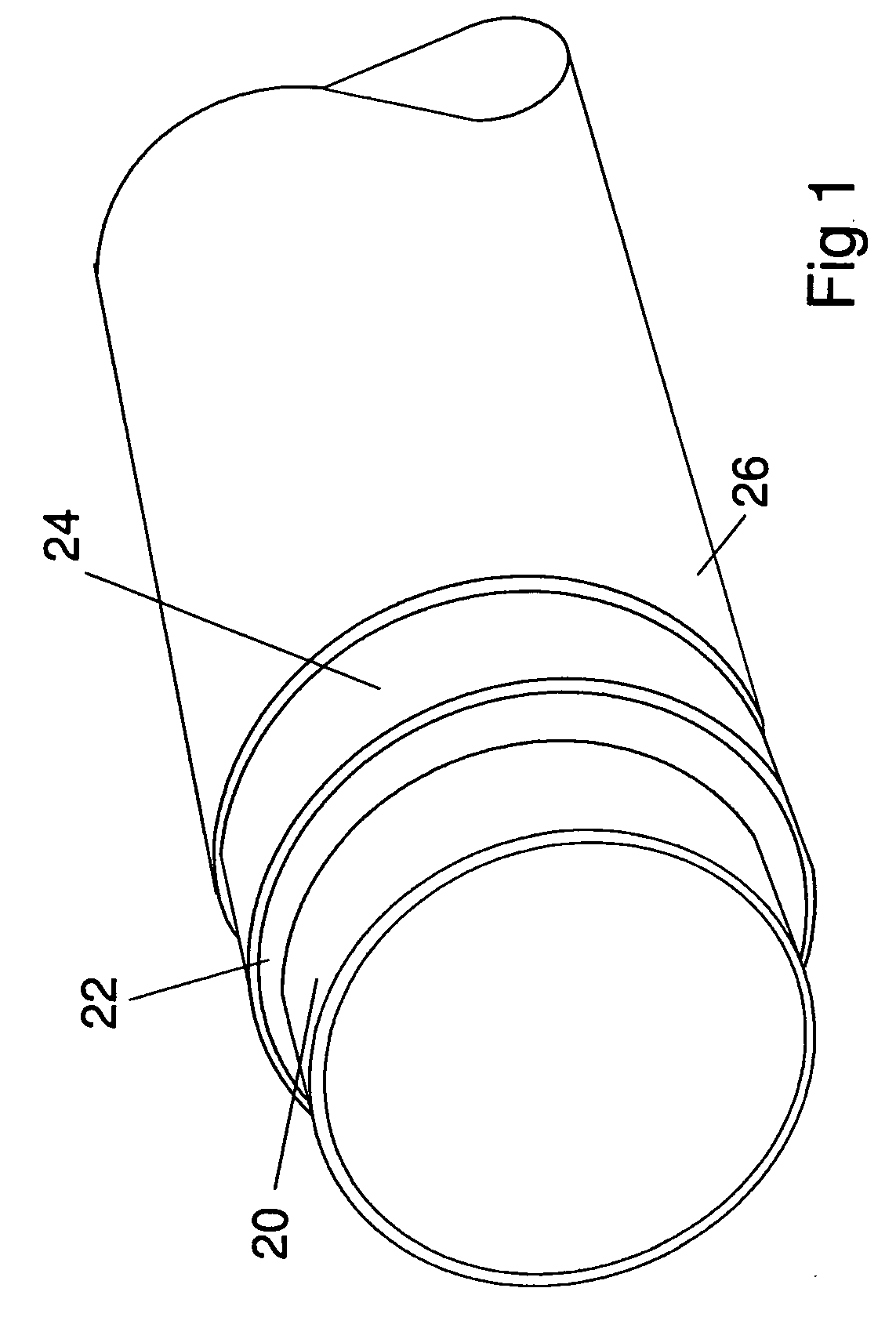

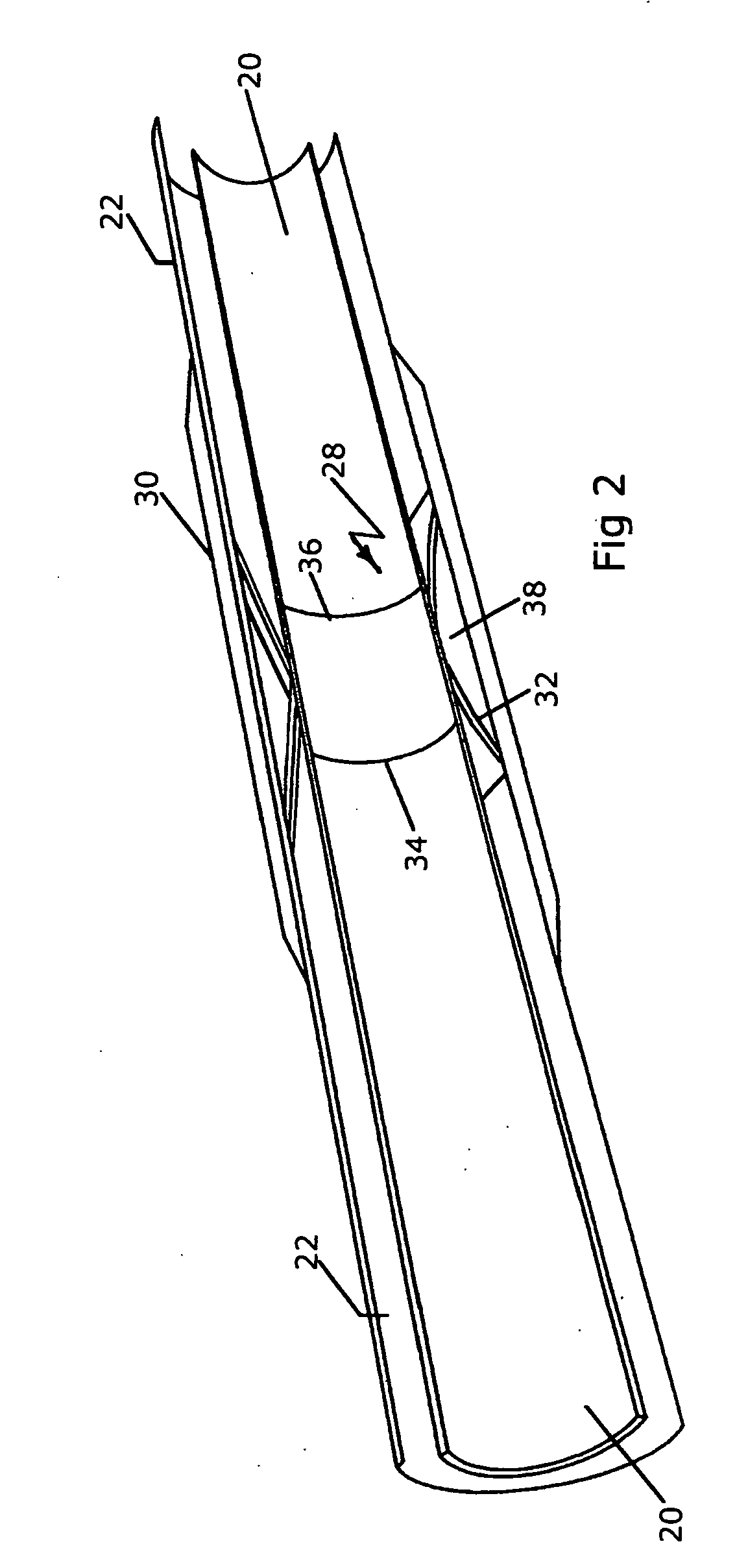

Foldable Composite Tubular Structure

InactiveUS20120145381A1Easy to deployImprove mechanical propertiesPipe laying and repairDrilling rodsCasing stringEngineering

Foldable pipe-in-pipe composite tubular structure having between pipes after rounding and hardening a filling material associating the layers to enhance the structure mechanical performance mostly in collapse resistance. Improvements are related to increase foldability by having at least one of the pipe made of two layers and in case of transportation on a reel in continuous length the capability of circulating most of the hardenable filling material when the pipe is still on the reel and in case of wellbore casing application the capability of connecting sealingly successive strings of casing

Owner:NOBILEAU PHILIPPE CONSTANT

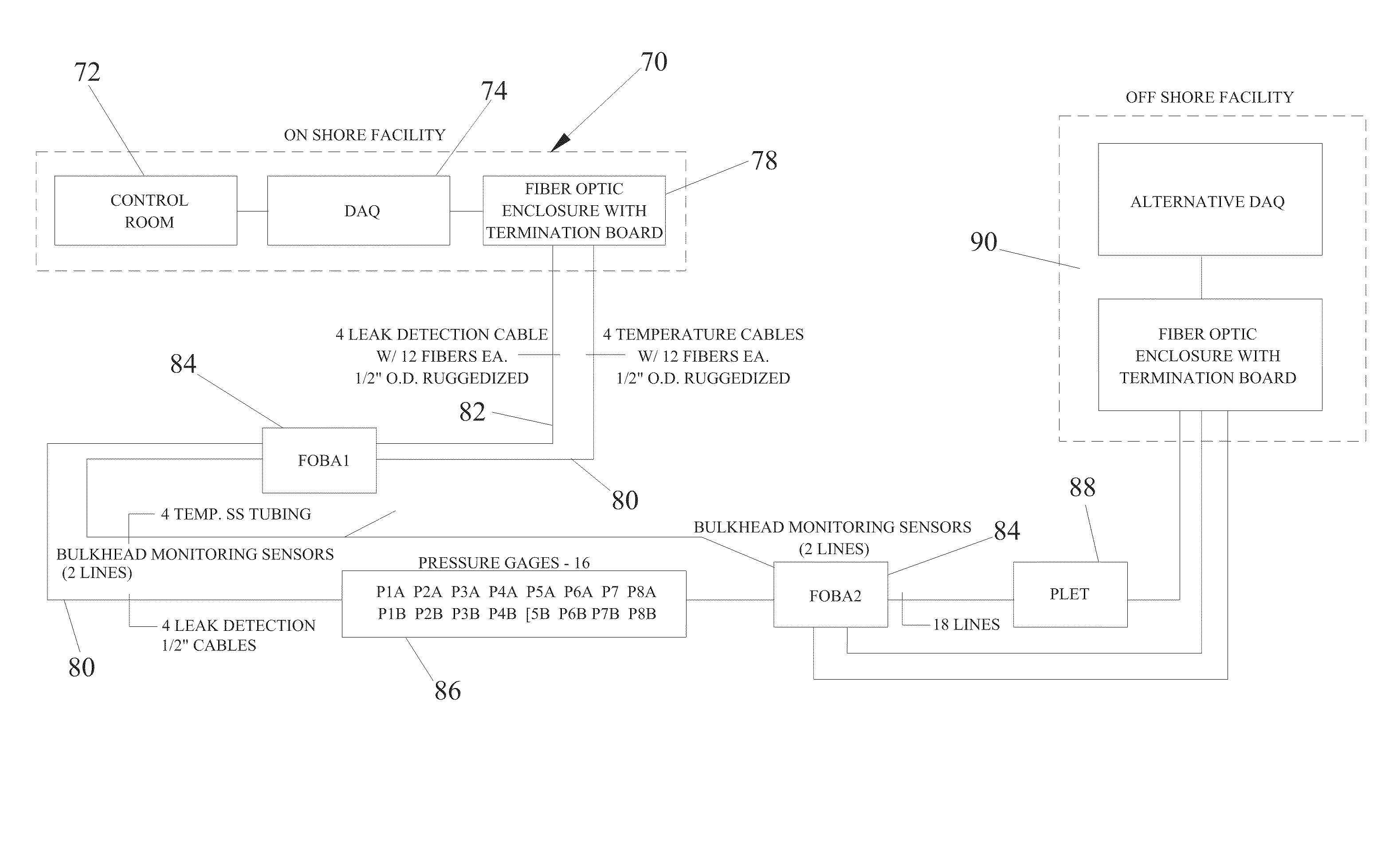

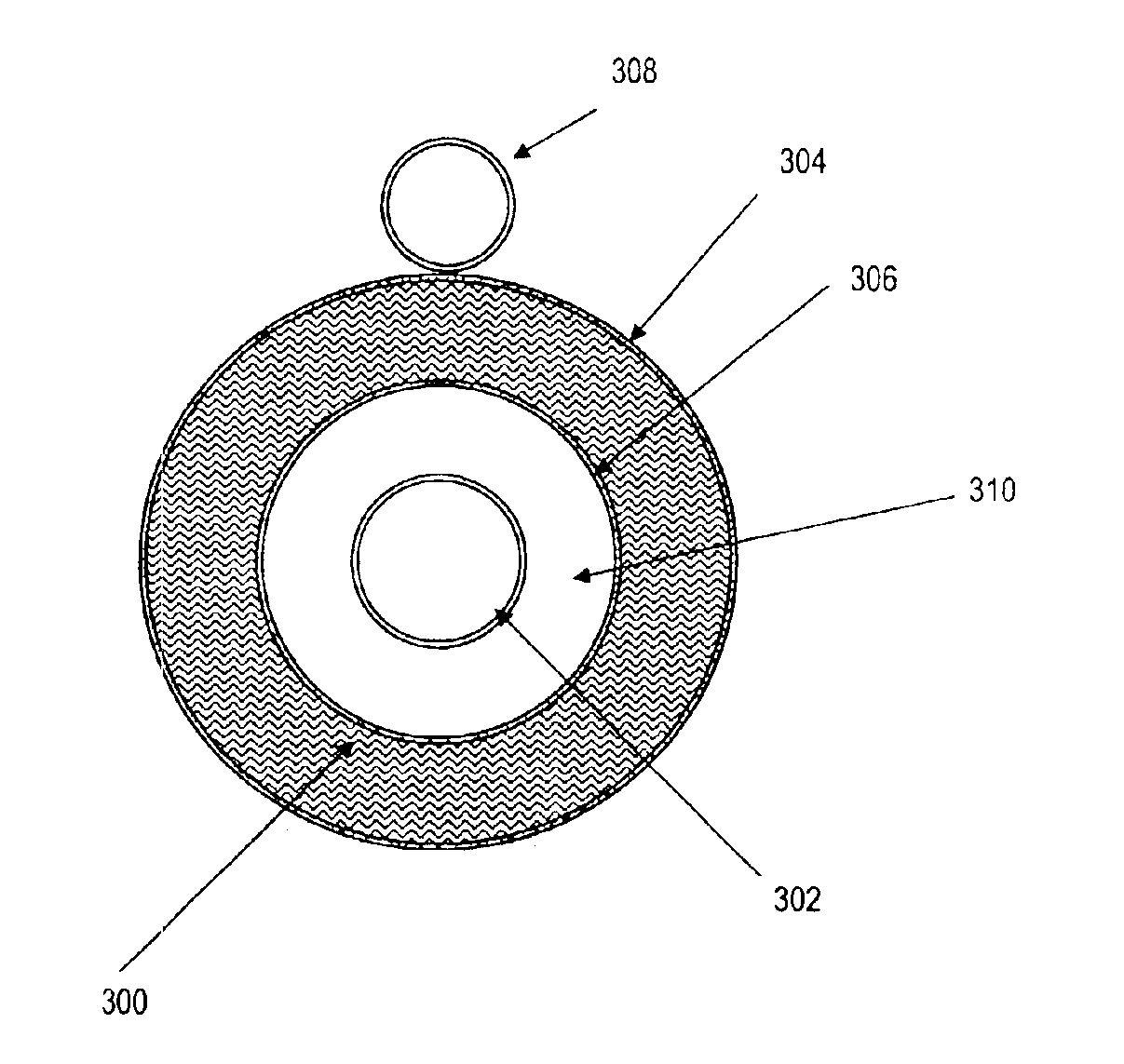

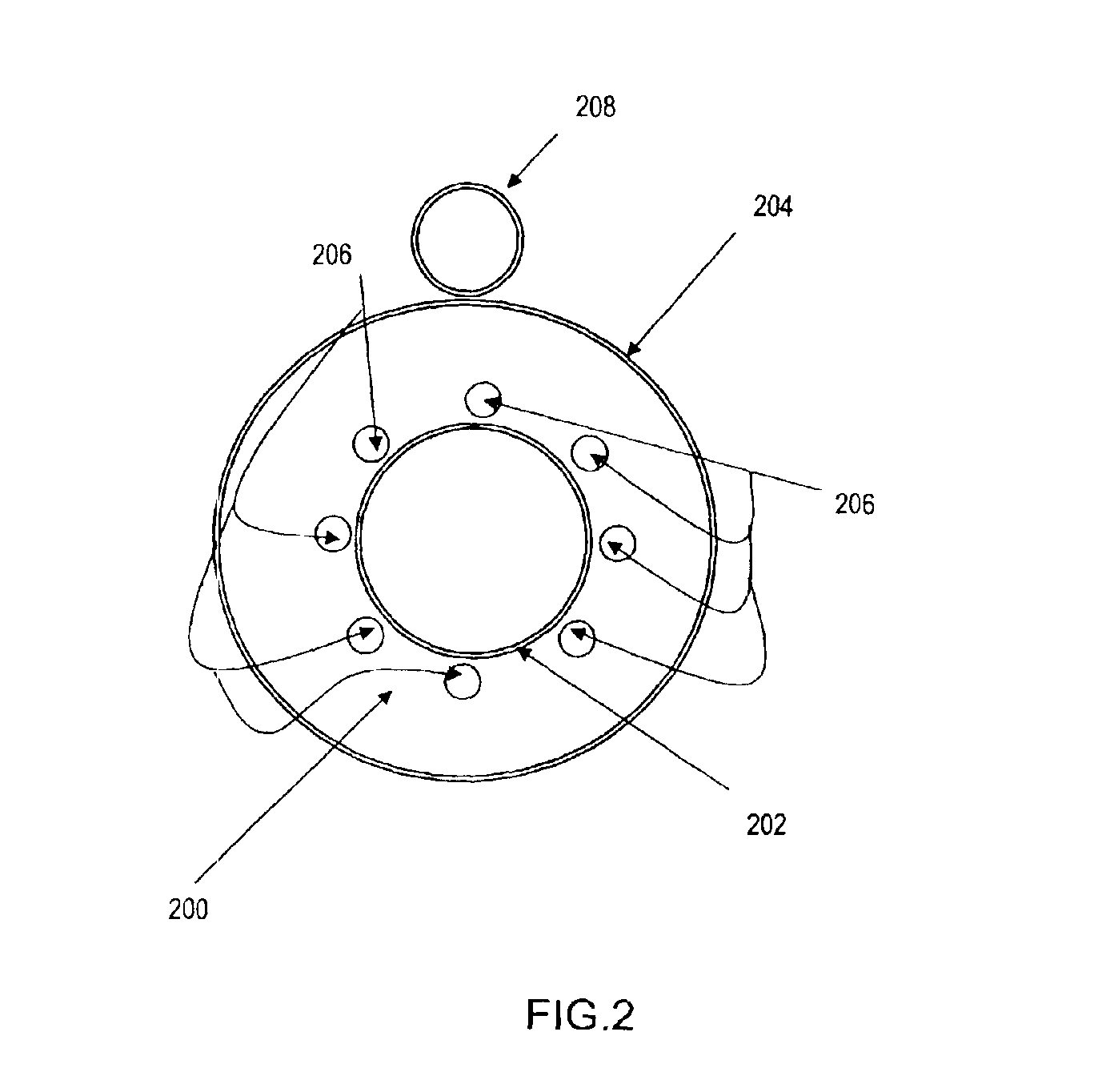

Advance instrumentation methods for pipes and conduits transporting cryogenic materials

A cryogenic material transfer system incorporates a pipe-in-pipe configuration with a nanoporous or microporous insulating layer filling the annulus between the inner and outer pipe. The insulating layer is of sufficient flexibility to absorb and expansion or contraction of the inner pipe due to the flow of cryogenic material therethrough. For longer transfer systems a bulkhead is provided between adjacent pipe joints. Intermediately of the pipe joints an additional bulkhead may be employed to provide additional sealing or water stops and for providing provide additional load transfer. A fiber optic sensor system is installed in the annuals between the inner and outer pipe.

Owner:ASTRO TECH GRP LLC

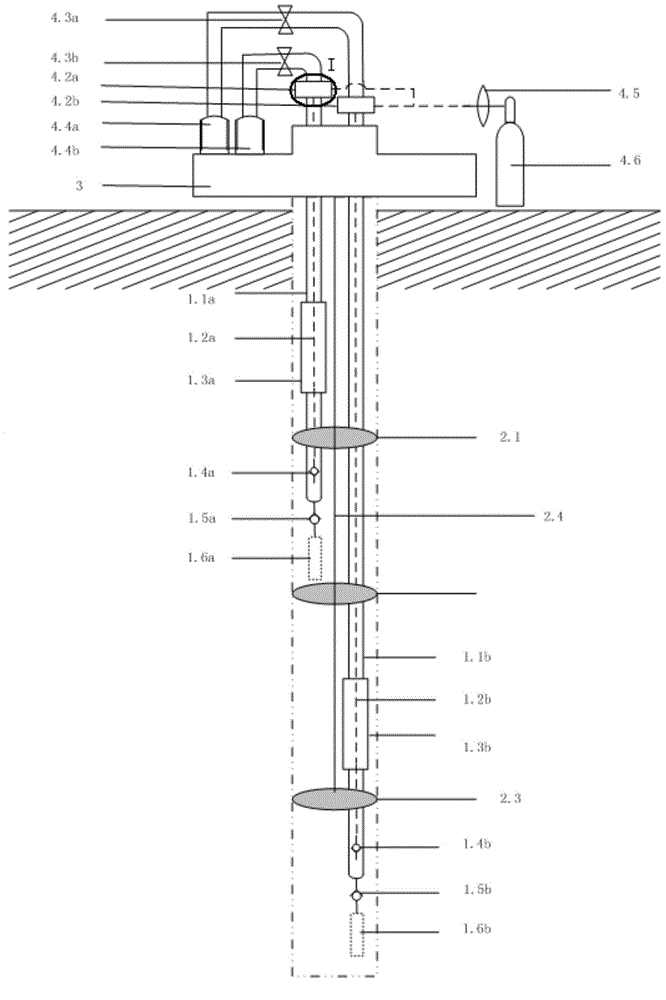

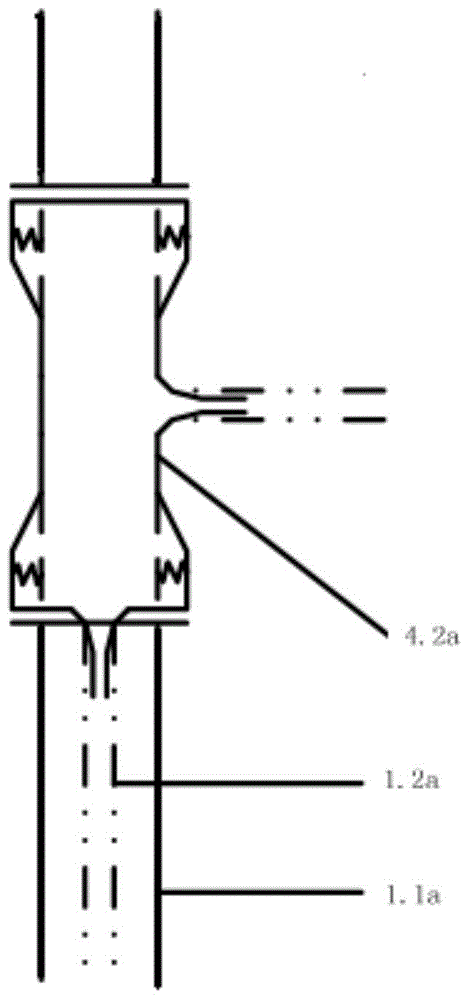

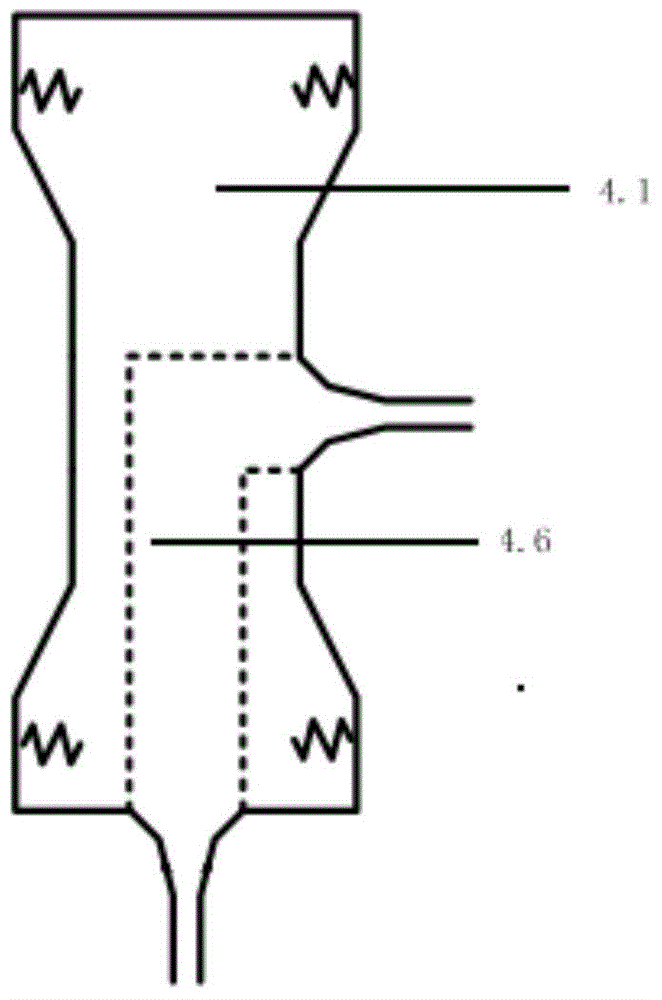

Pipe-in-pipe underground fluid stratified sampling device

ActiveCN104929629AReduce the number of perforationsIncrease sampling depthBorehole/well accessoriesTransmitted powerEngineering

The invention provides a pipe-in-pipe underground fluid stratified sampling device. The pipe-in-pipe underground fluid stratified sampling device at least comprises a pressure source, a well head fixing frame, a pipe-in-pipe underground sample introducing mechanism, a packing mechanism and a ground sampling mechanism, wherein the well head fixing frame is used for fixing the device. The pressure source provides sampling power. The pipe-in-pipe underground sample introducing mechanism is a pipe-in-pipe system and performs pipeline arrangement for underground fluid sampling. The ground sampling mechanism transmits power of a power source to the pipe-in-pipe underground sample introducing mechanism and pumps underground fluid to the ground, and then the underground fluid is collected and sampled. The gas push type sampling principle is still adopted for the device, a U-shaped pipe system is upgraded into a pipe-in-pipe system, the number of stratified sampling layers is doubled, bearing force is doubled, sampling depth is extended from a -30 m level to a -200 m level, the structure of the device is greatly simplified, stability and operability are greatly improved, and therefore the competitive advantage of the device in the field of underground fluid sampling devices is further enhanced.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

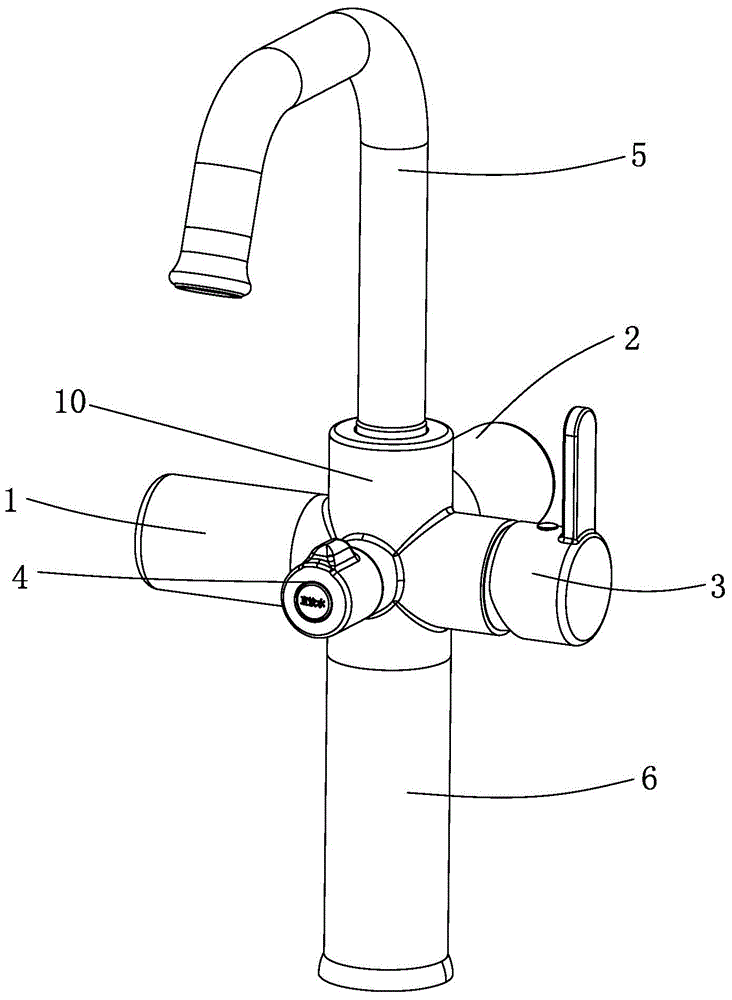

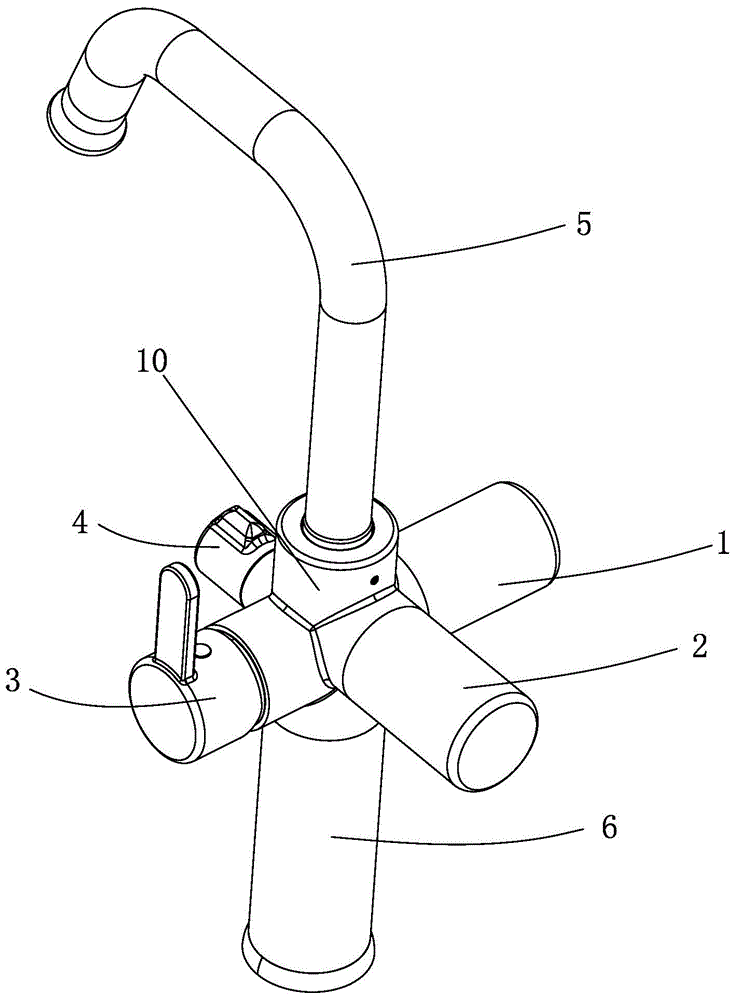

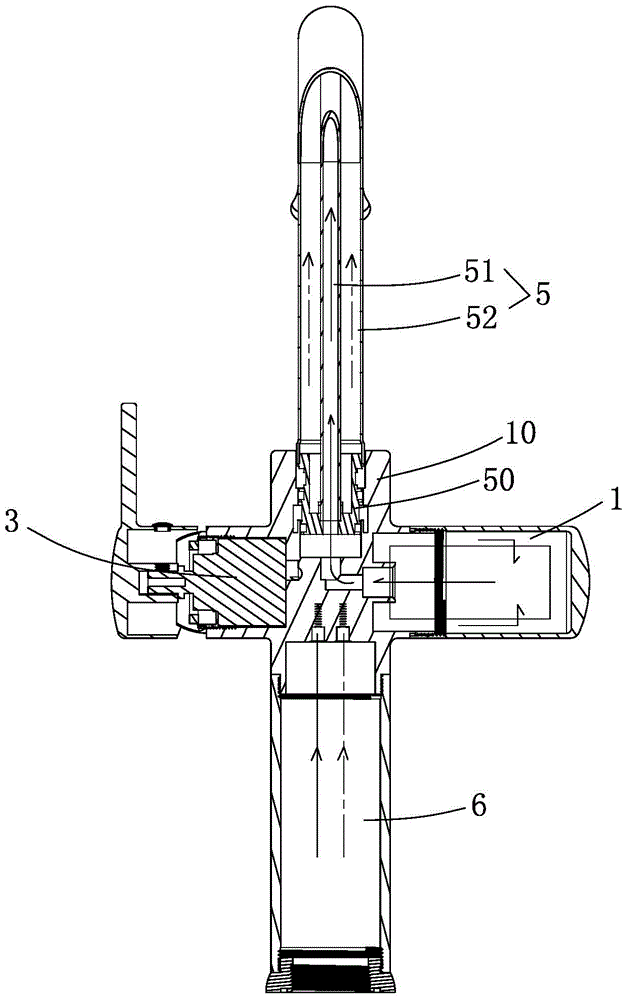

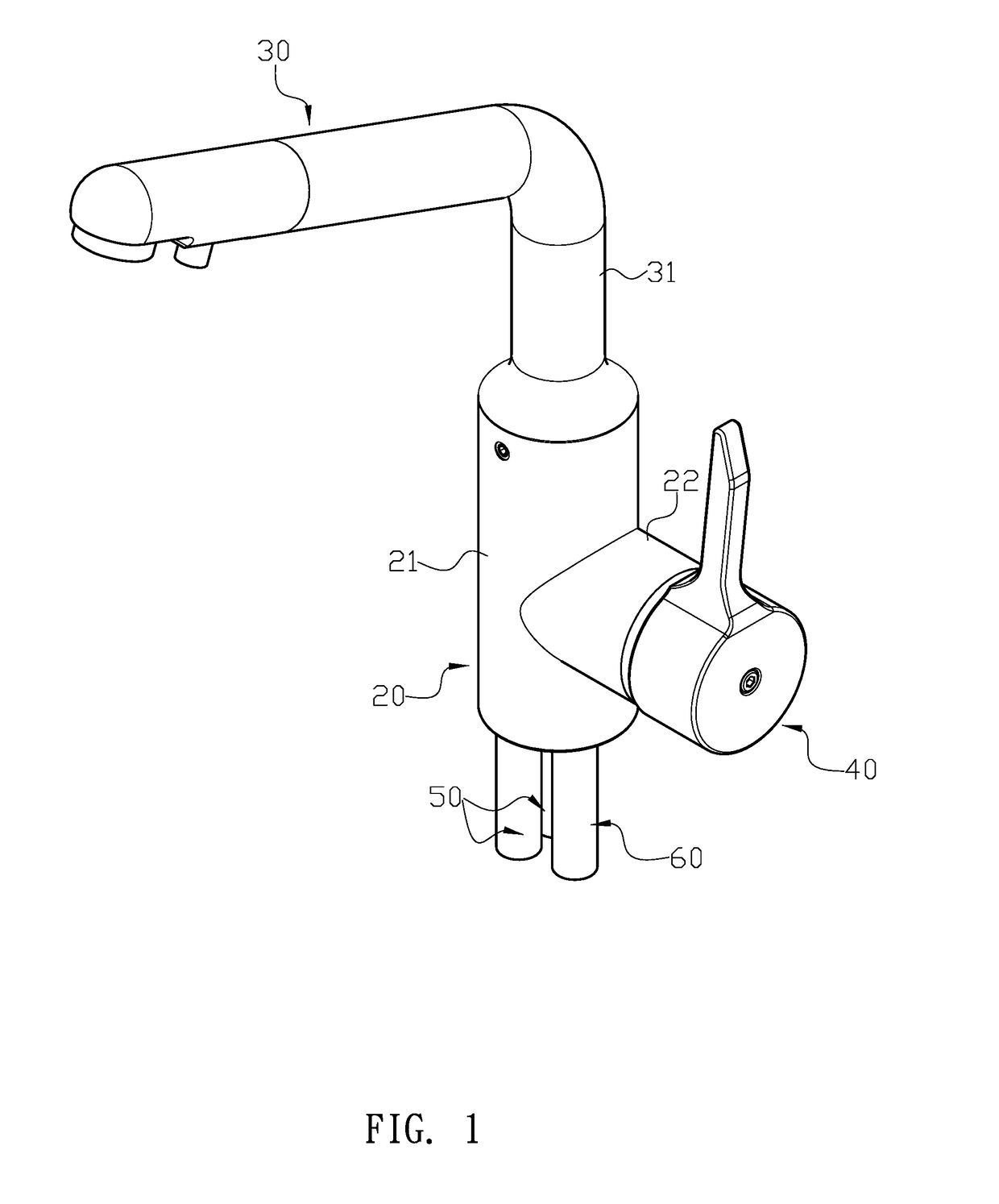

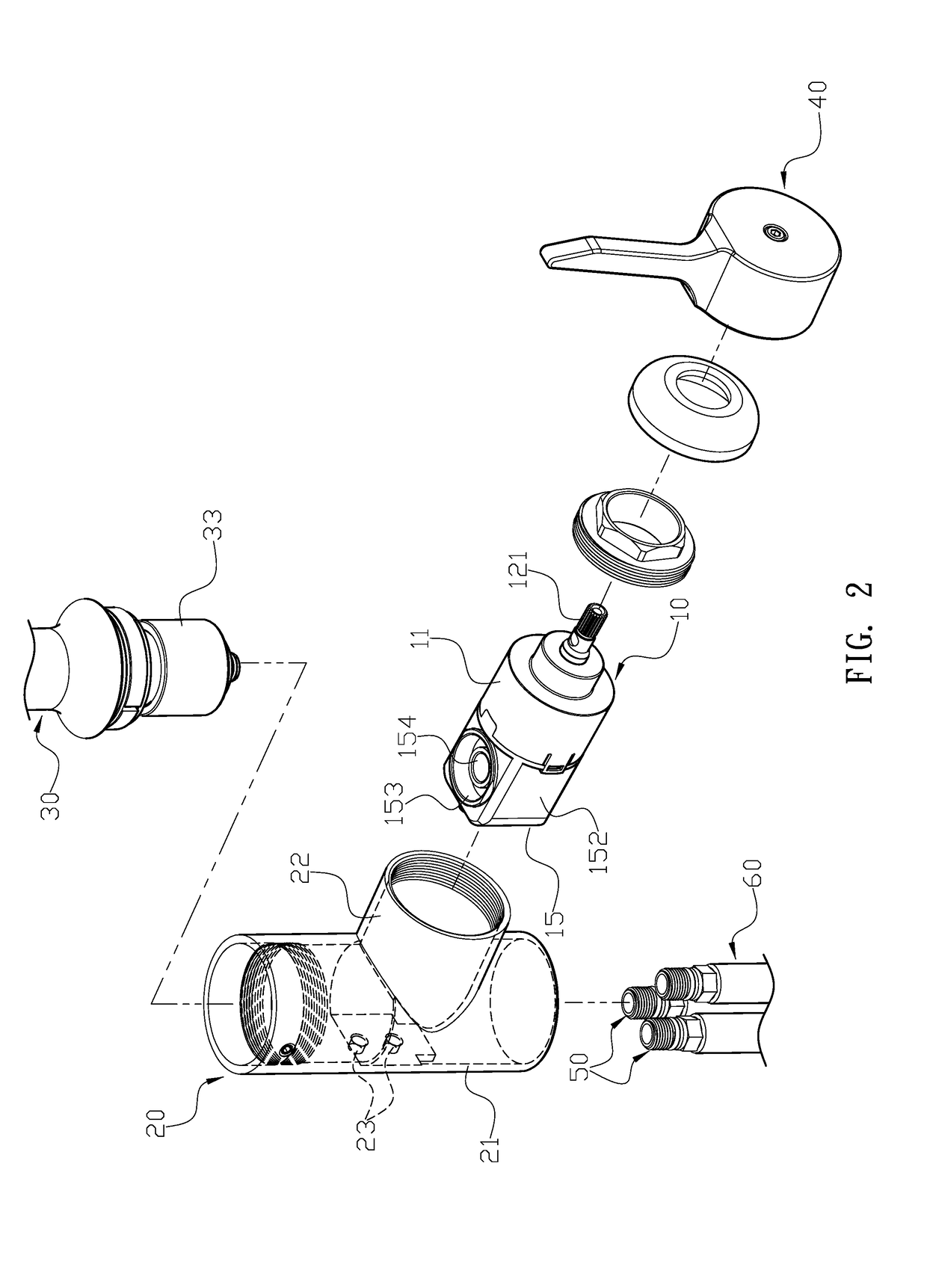

Multifunctional integrated water filtering faucet

ActiveCN104976400AMeet different water needsEasy to replaceMultiple way valvesFiltration separationWater useWater filter

The invention discloses a multifunctional integrated water filtering faucet. The multifunctional integrated water filtering faucet comprises a faucet body, a first filter, a second filter, a direct drinking water valve and a cold and hot water valve. The first filter, the second filter, the direct drinking water valve and the cold and hot water valve are installed on the faucet body. The direct drinking water valve and the cold and hot water valve are matched. The faucet body is provided with a vertical pipe portion. Two filtering connectors and two water valve connectors are arranged on the peripheral side of the vertical pipe portion. The filters are transversely arranged. The upper end and the lower end of the vertical pipe portion of the faucet body are provided with a water outflow connector and a water inflow connector. Direct drinking water use and cold and hot filtering water use are achieved through the integrated faucet structure, different water use requirements of users are met, a direct drinking water path and a cold and hot water path are controlled through the two water valves and the corresponding filters respectively, and finally water is drained outwards through the pipe-in-pipe water outflow structure. The multifunctional integrated water filtering faucet has the advantages that the structure is reasonable, and filter elements are convenient to replace.

Owner:福建滤冠新型材料科技有限公司

Apparatus and method for connecting pipes during underwater pipe-laying

InactiveUS6939083B2Reduce decreaseDeleterious effectPipe supportsPipe laying and repairEngineeringFlange

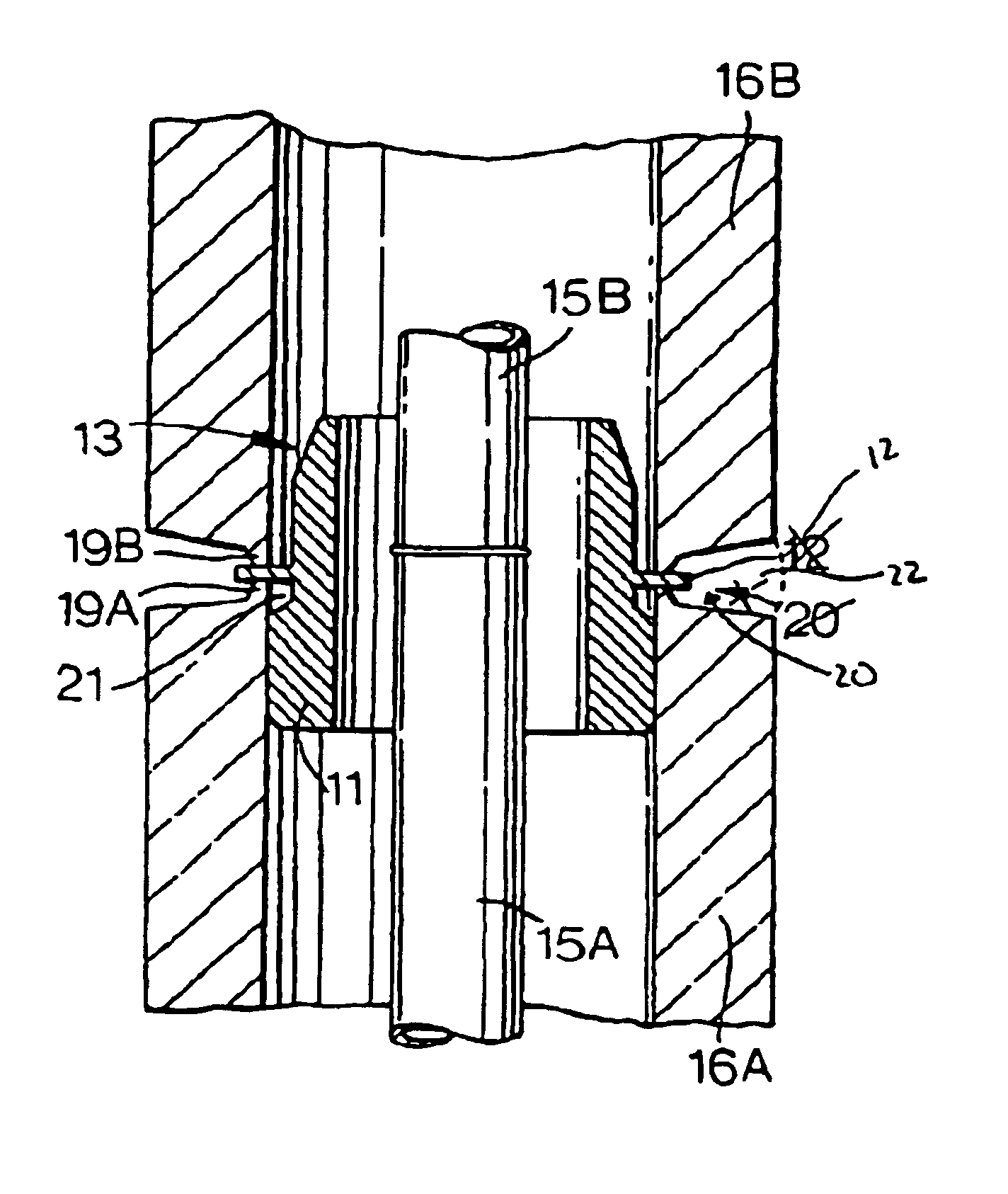

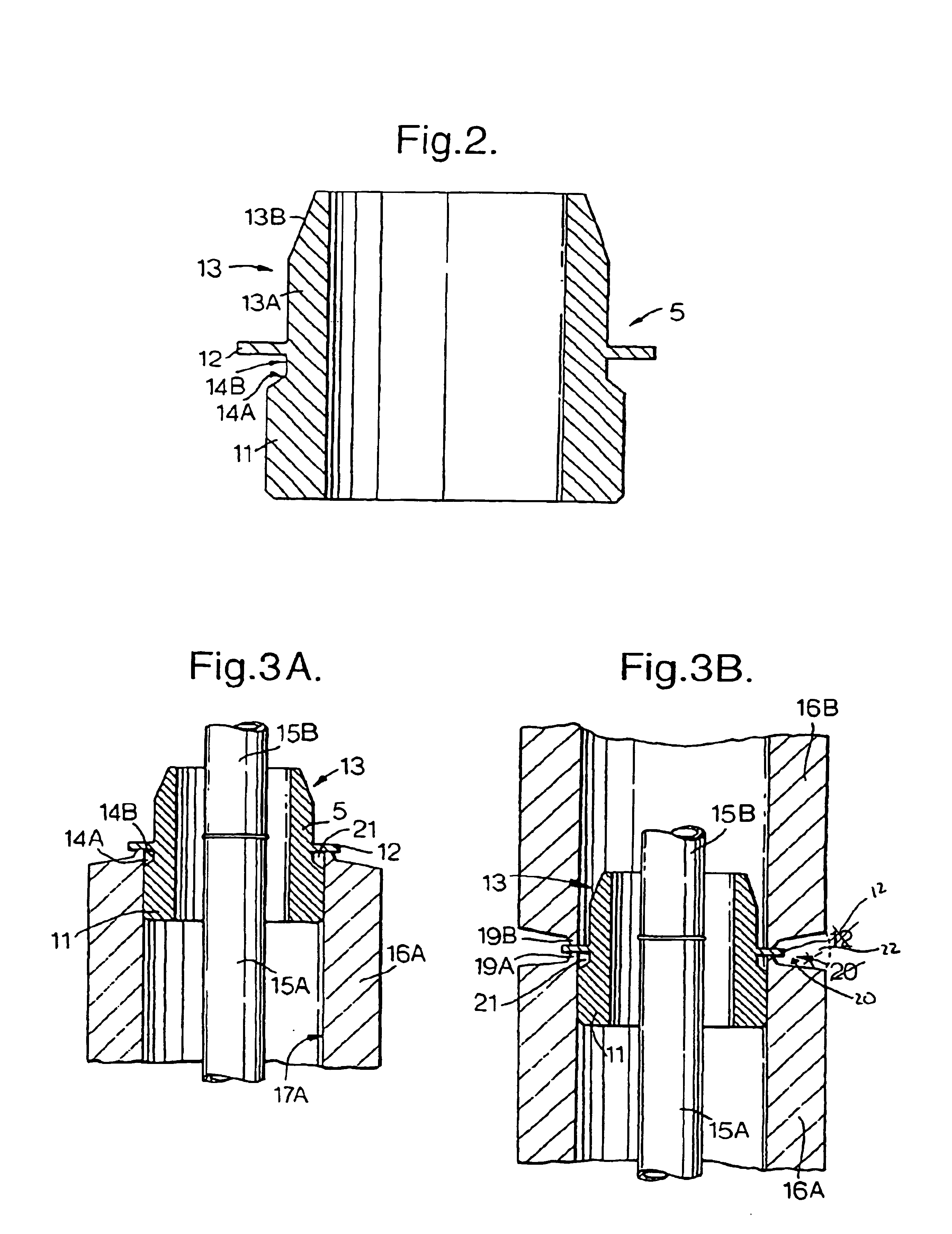

A method of welding together the ends of outer pipe sections (16A, 16B) of pipe-in-pipe pipeline to be laid on a seabed employs an annular member (5) interposed between adjacent lengths of pipe. The annular member comprises a first axial part (11) which fits within the end of the first outer pipe section, and a flange part (12) which is interposed between the adjacent ends of the two lengths of outer pipe sections (16A, 16B) to be joined. The flange part (12) of the annular member (5) projects radially outwardly beyond the inside of the outer pipe sections (16A, 16B) and terminates radially inwardly of the outside of the outer pipe sections (16A, 16B), and provides some of the welding material for the joint.

Owner:SAIPEM SPA

Mid-line connector and method for pipe-in-pipe electrical heating

ActiveUS7033113B2Increase axial loadAvoid local accumulationPipe laying and repairWaterborne vesselsElectricityElectrical conductor

Owner:SHELL OIL CO

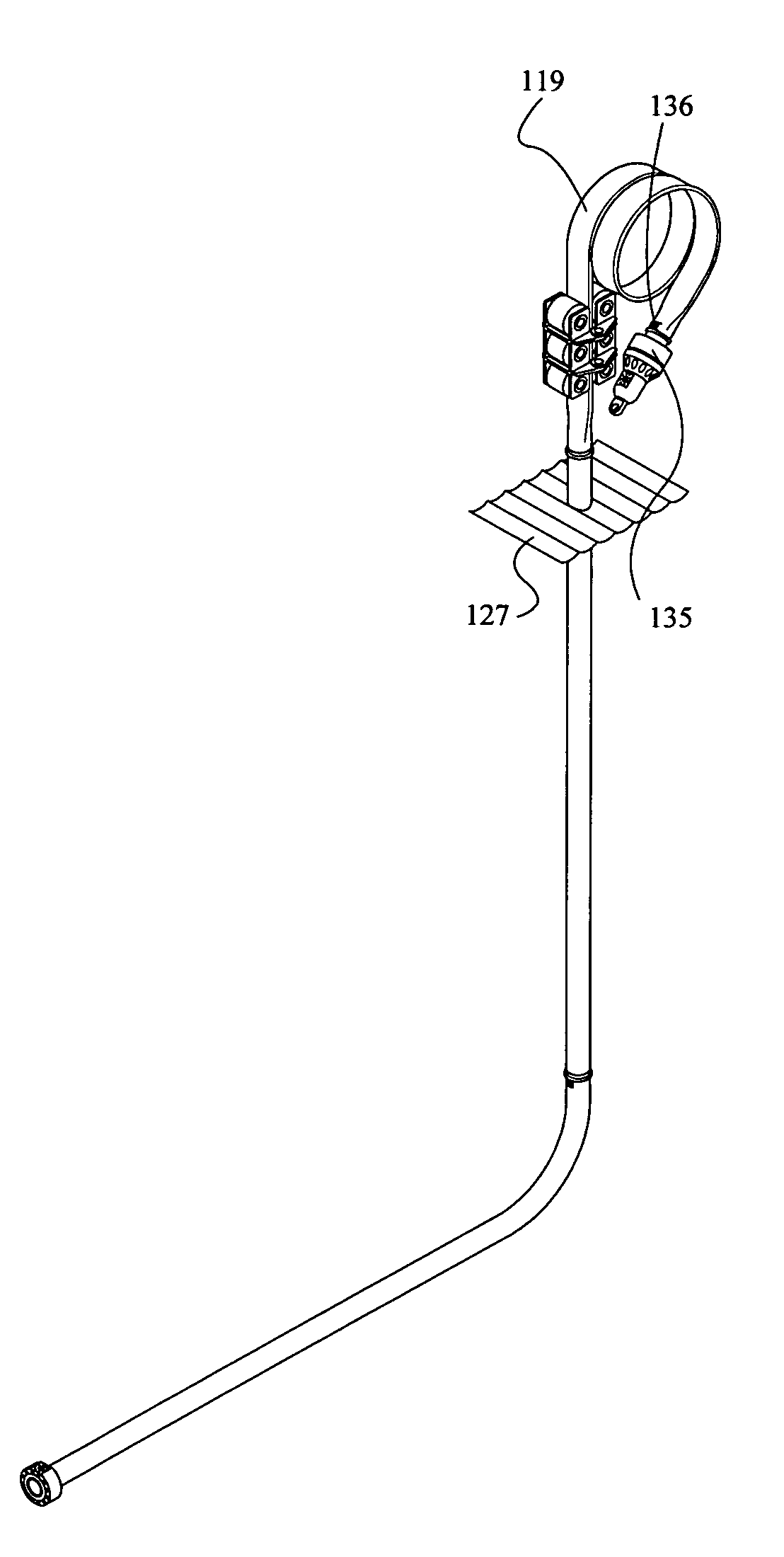

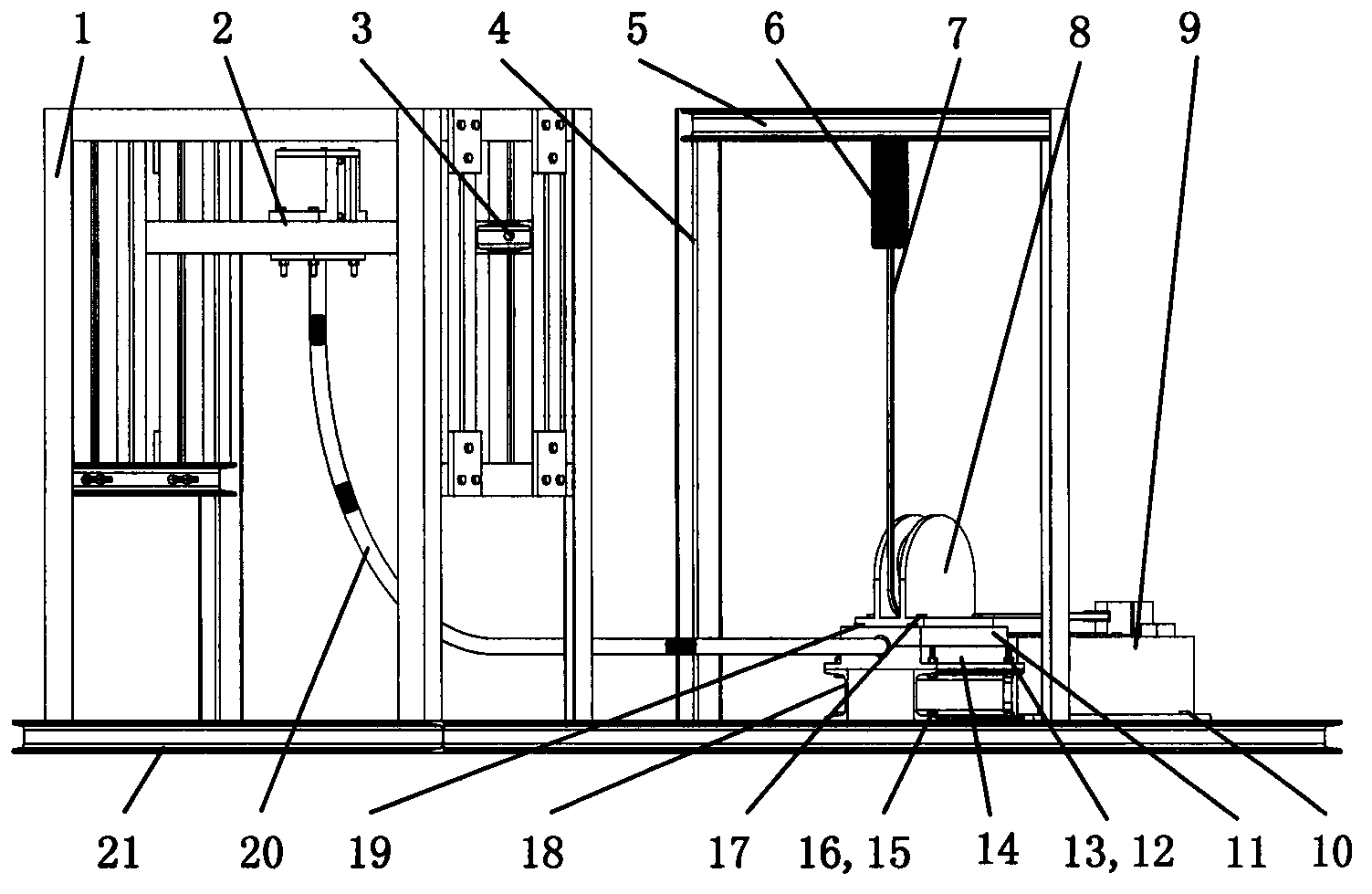

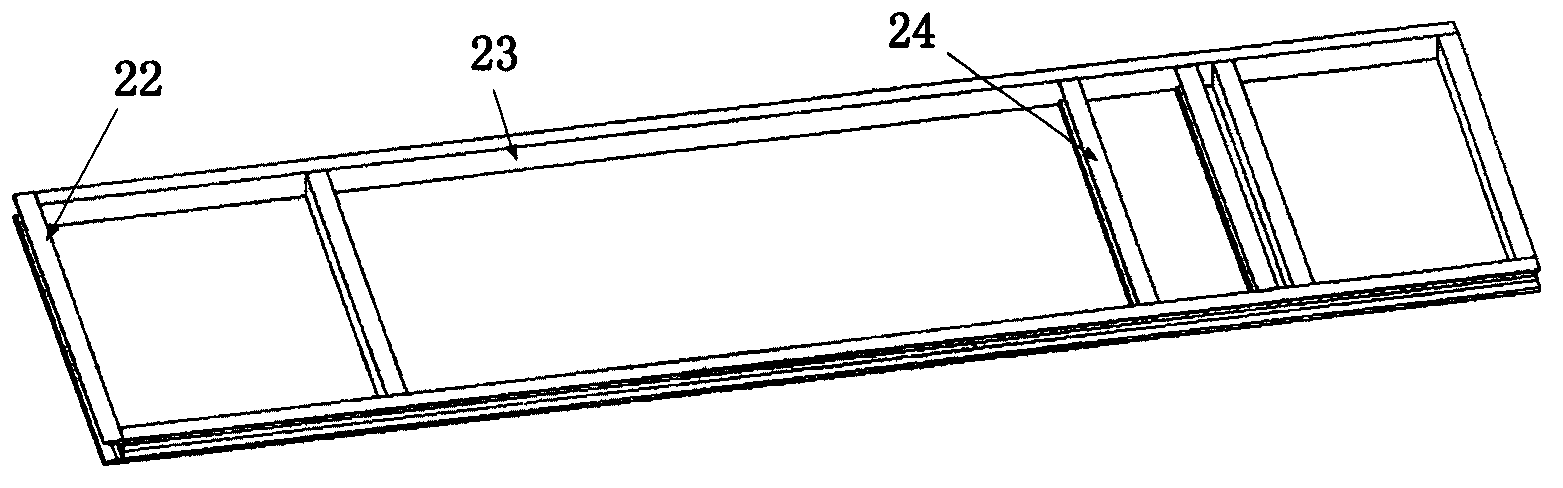

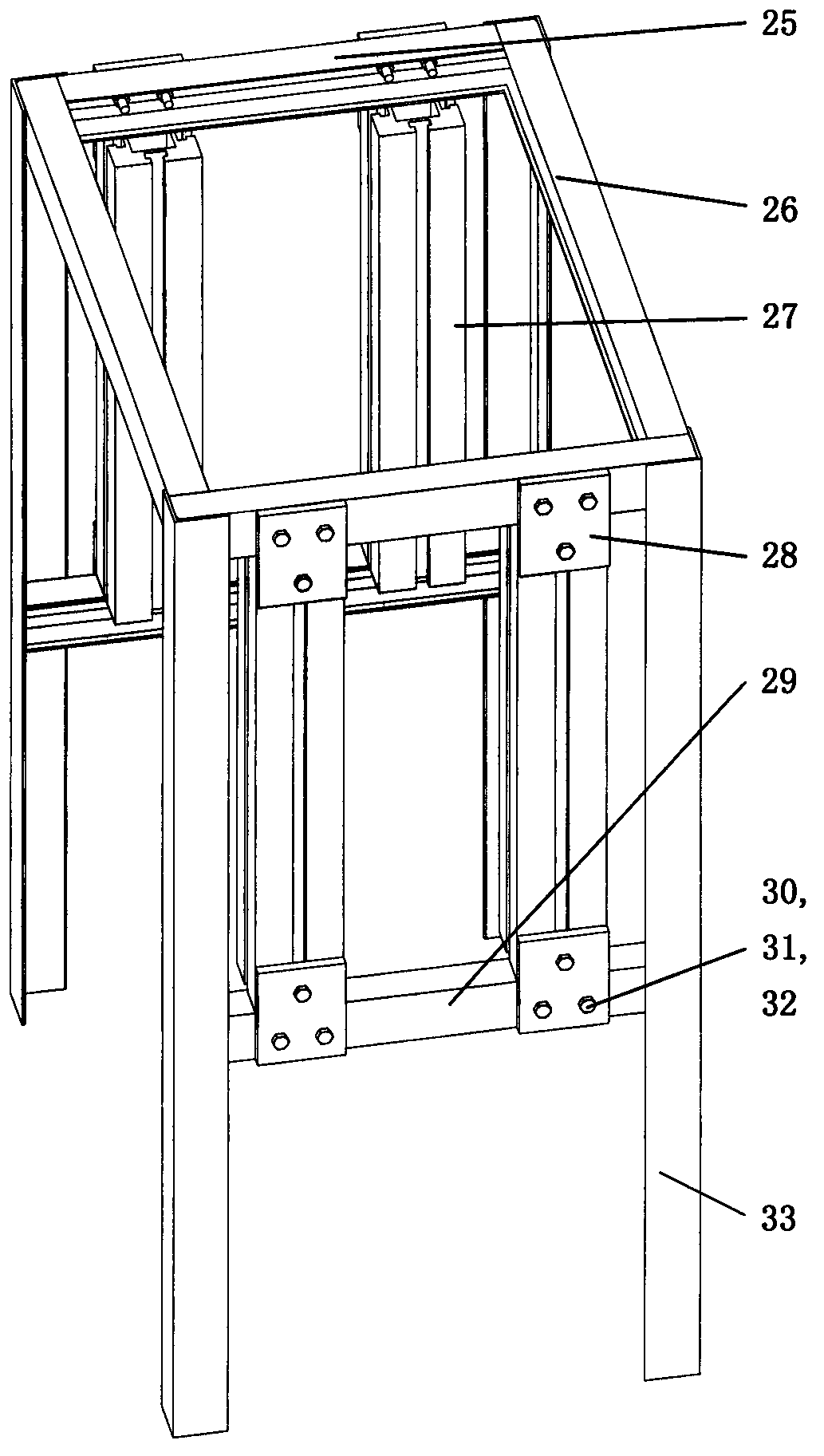

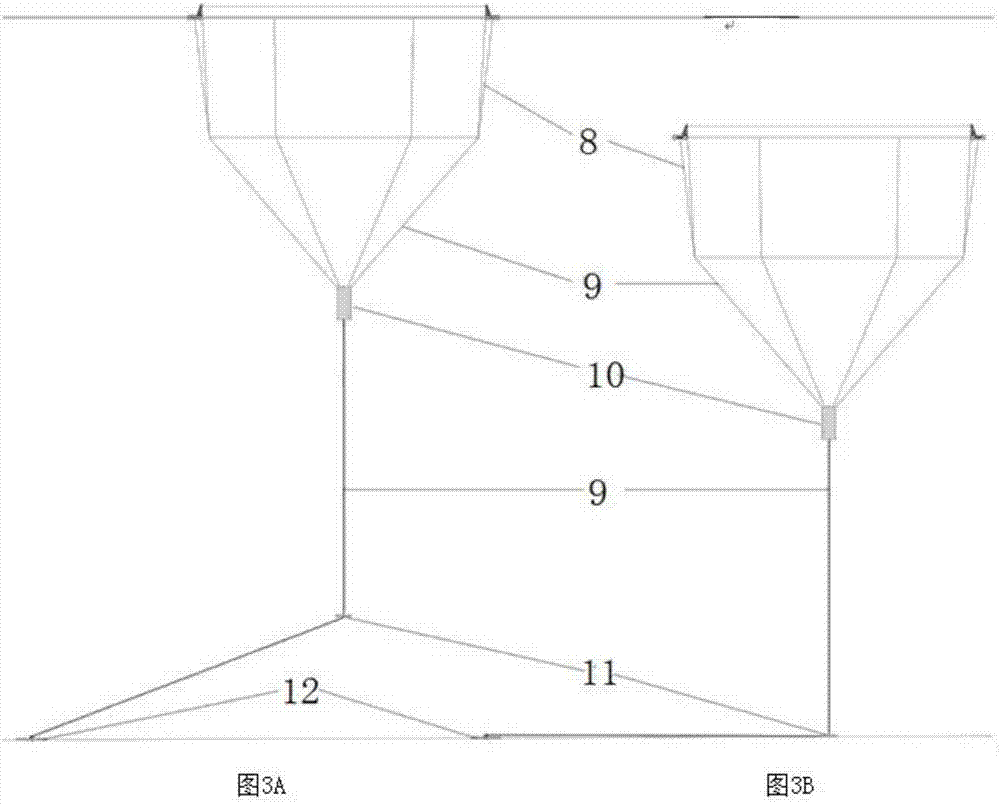

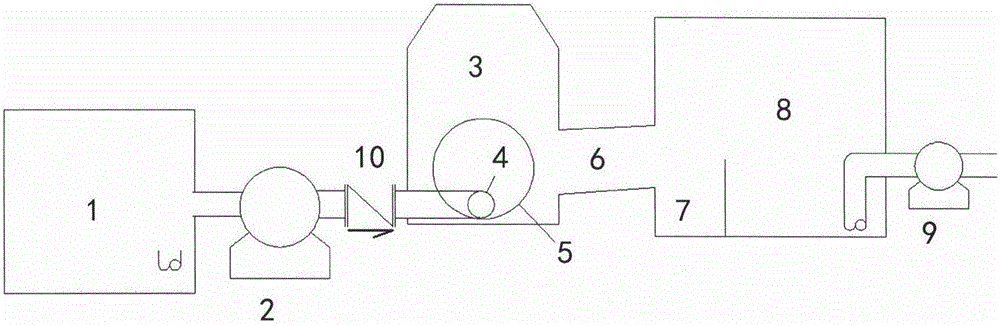

Deep-sea pipe-in-pipe mechanical transfer characteristic analysis experiment device

The invention relates to a deep-sea pipe-in-pipe mechanical transfer characteristic analysis experiment device, in particular to a device for analyzing mechanical transfer characteristics in the process of coiled tubing tripping into a deep-sea riser. When in experiment, a chain hoist 6 is opened, and an injection test assembly 9 clamps simulated coiled tubing to perform injection operation under the traction effect of a steel wire rope 7. The injection force of the simulated coiled tubing can be obtained by reading parameters of a tension compression sensor on the injection test assembly 9 in the injection process, the injection depth of the simulated coiled tubing can be obtained by reading parameters of a displacement sensor on the injection test assembly 9, the stress of the end of the simulated coiled tubing can be obtained by reading parameters of a pressure sensor inside a pipe end fixing test assembly 2, and the stress of a simulated riser can be obtained by reading parameters of a strain gauge on a pipe-in-pipe system 20. Finally obtained results can be used for analyzing mechanical characteristics of the coiled tubing tripping into the marine riser.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

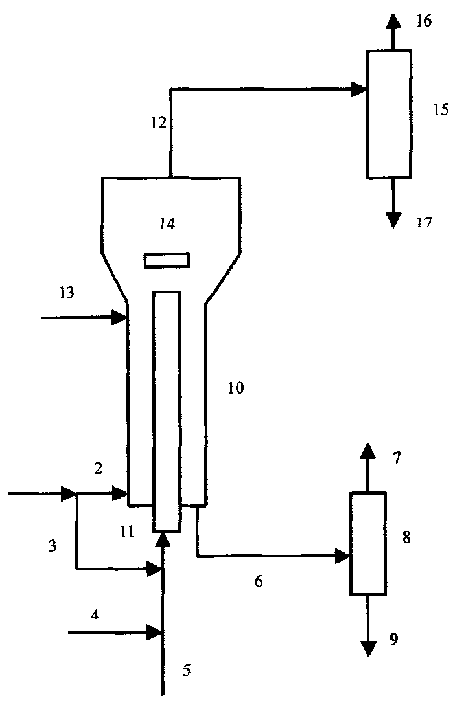

Poor residuum hydroconversion method

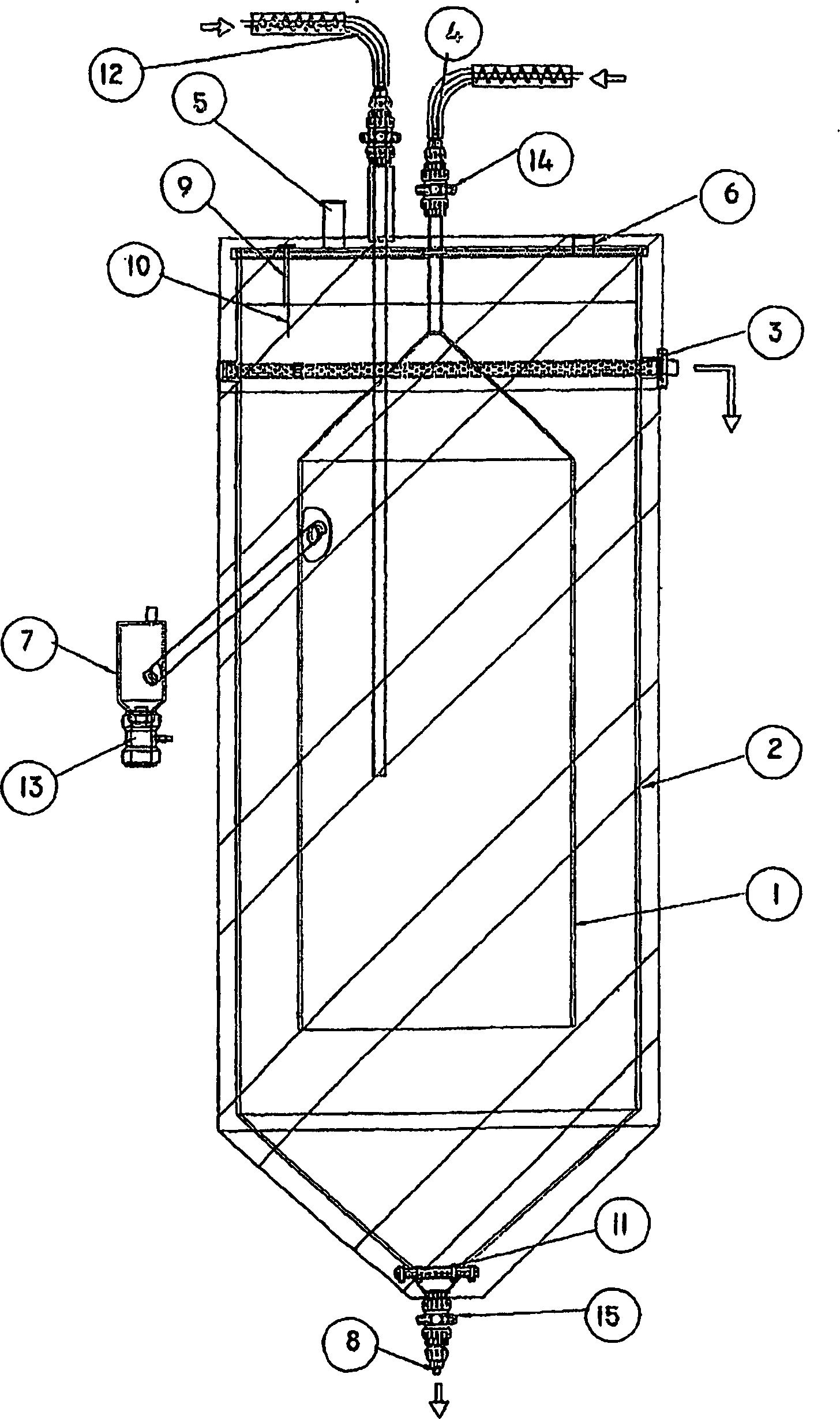

InactiveCN1488727AImprove conversion rateLow yieldHydrocarbon oil crackingHydrogenVapor–liquid separator

The present invention provides a residuum hydrocracking method, which adopts a pipe-in-pipe tye reactor, the top of internal pipe is equipped with gas-liquid separator, firstly, the raw material and hydrogen gas are fed into internal pipe reaction section in the upward-flowing mode, then they are separated at the upper gas-liquid separator place, the gas phase can be discharged from the reactor, and the liquid phase can be fed into the ring pipe reaction section together with added hydrocarbon oil containing more heavy aromatics, at the same time the hydrogen gas is added in the bottom of ring pipe reaction section. Said invention is mainly applicable to the hydrogenation cracking reaction of the heavy oil and residuum, specially applicable to the hydrogenation cracking reaction of poor heavy oil and residuum.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cryogenic Pipeline Configurations and Methods

A pipe-in-pipe pipeline has a bulkhead that transfers thermal stress from an inner pipe to an outer pipe, wherein at least part of the bulkhead forms a conduit for a product traveling through the inner pipe. Most preferably, the pipeline is a cryogenic pipeline for transport of liquefied natural gas. Where desirable, insulating material may be disposed between the inner pipe and outer pipe, while spacers may maintain the distance between the pipes.

Owner:FLUOR TECH CORP

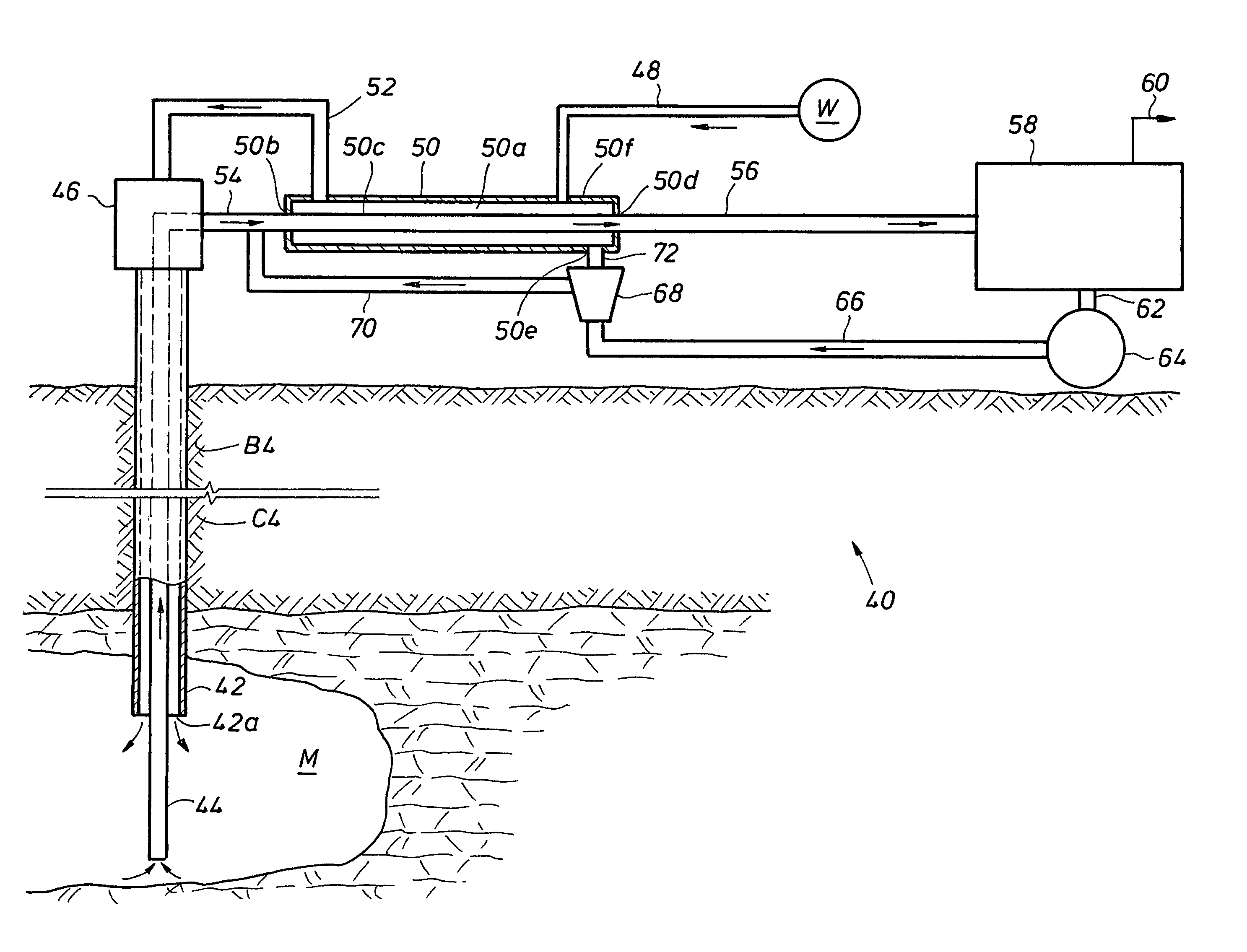

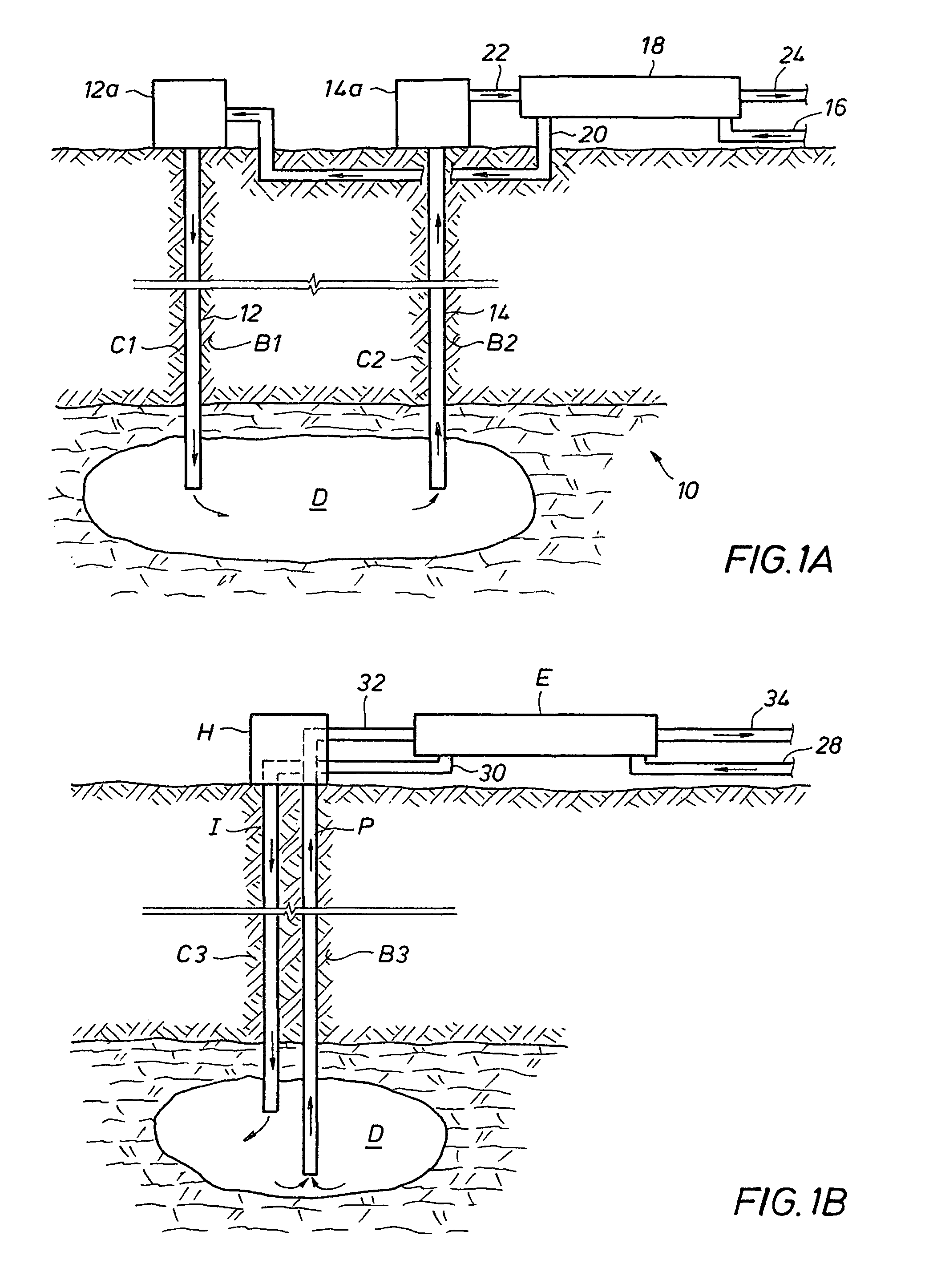

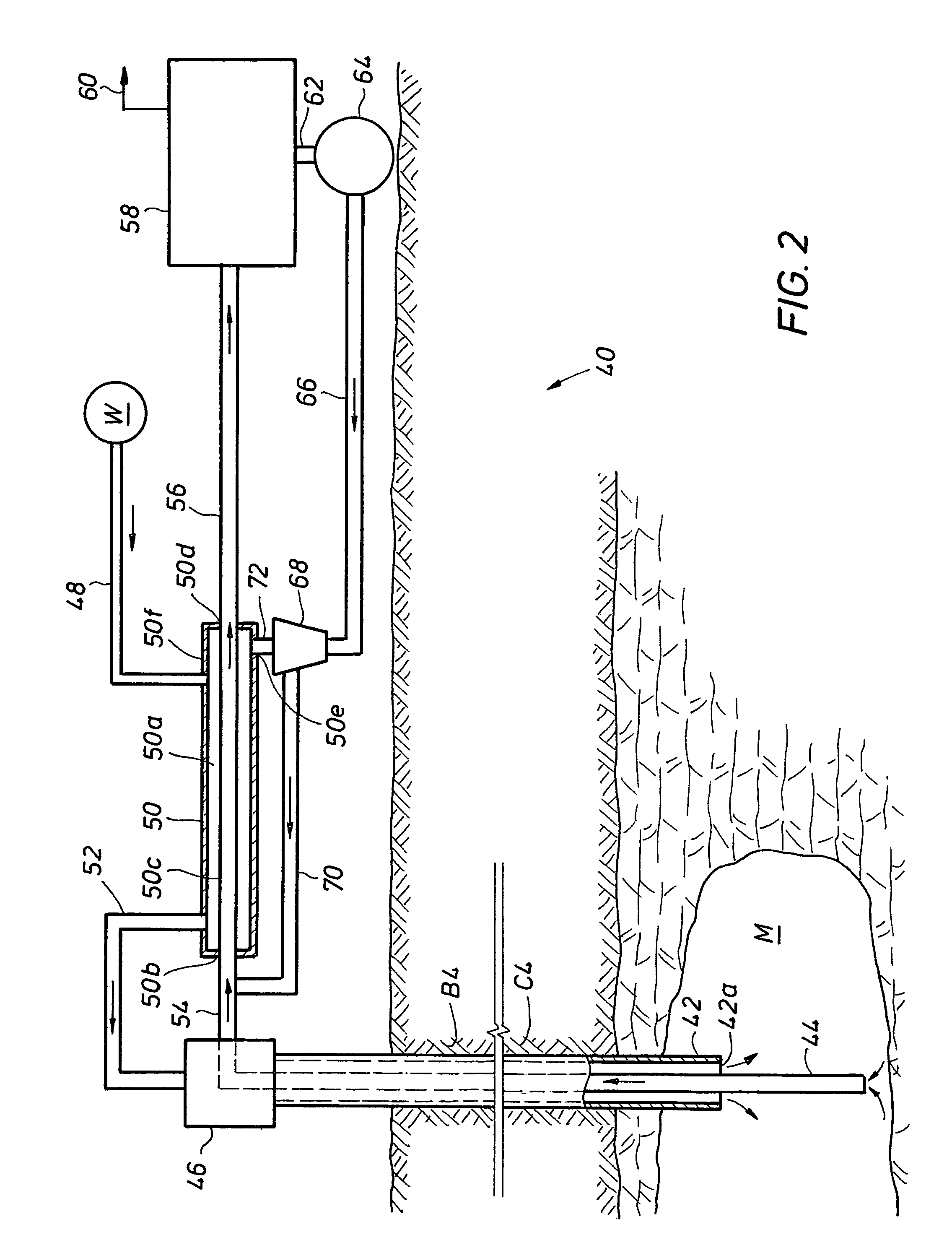

Method and system for solution mining

Owner:PINNACLE POTASH INT

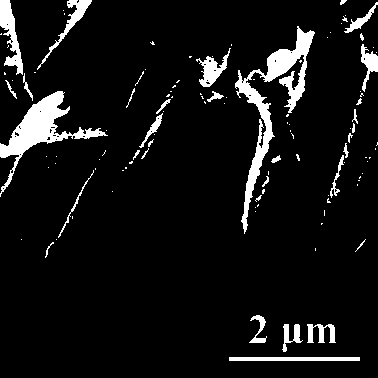

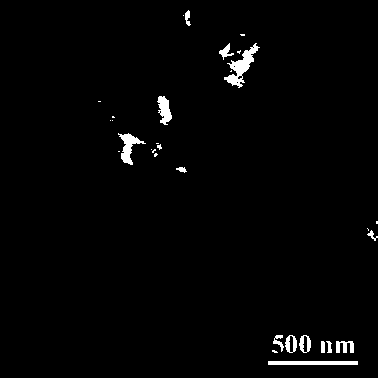

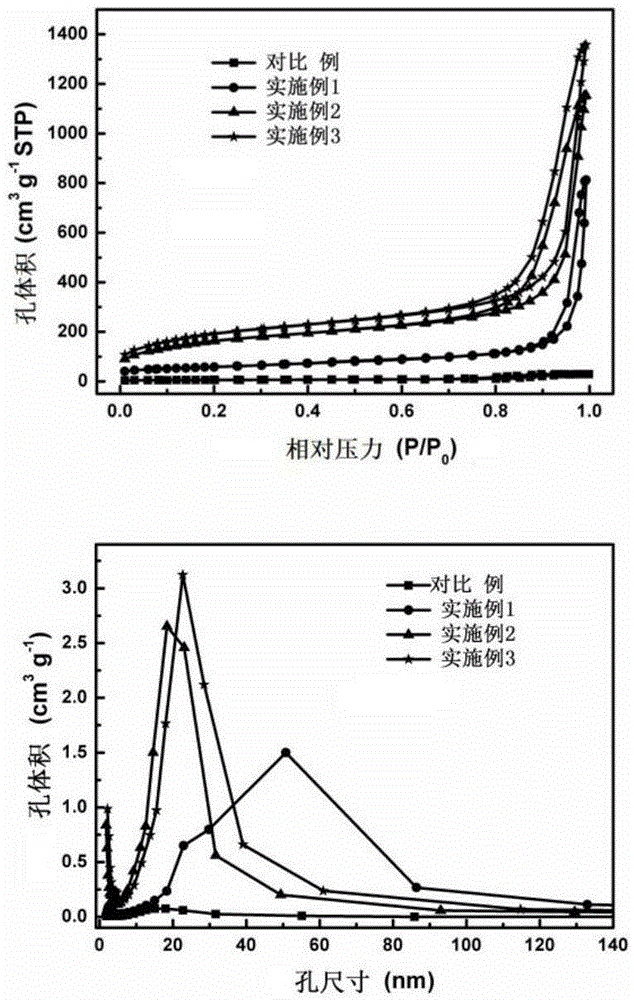

S-P-doped g-C3N4 pipe-in-pipe and preparation method thereof

ActiveCN108383091AReduce typesHollow degree can be adjustedNanotechnologyNitrogen and non-metal compoundsMelamineRepeatability

The invention discloses an S-P-doped g-C3N4 pipe-in-pipe and a preparation method thereof. The preparation process comprises; mixing melamine, ammonium dihydrogen phosphate and dibenzyl sulfide to obtain a uniform mixture; and heating the mixture to a temperature of 550-700 DEG C, and calcining to obtain the product, wherein the obtained product has the special morphology of the pipe-in-pipe, andhas the component of S, P-doped g-C3N4. According to the present invention, the preparation process is simple and has good repeatability; and g-C3N4 has good stability, such that the prepared g-C3N4 pipe-in-pipe product has characteristics of controllable hollow degree and large specific surface area, and has great application values in the fields of microelectronics, catalysis, photocatalysis, electrocatalysis and the like.

Owner:UNIV OF JINAN

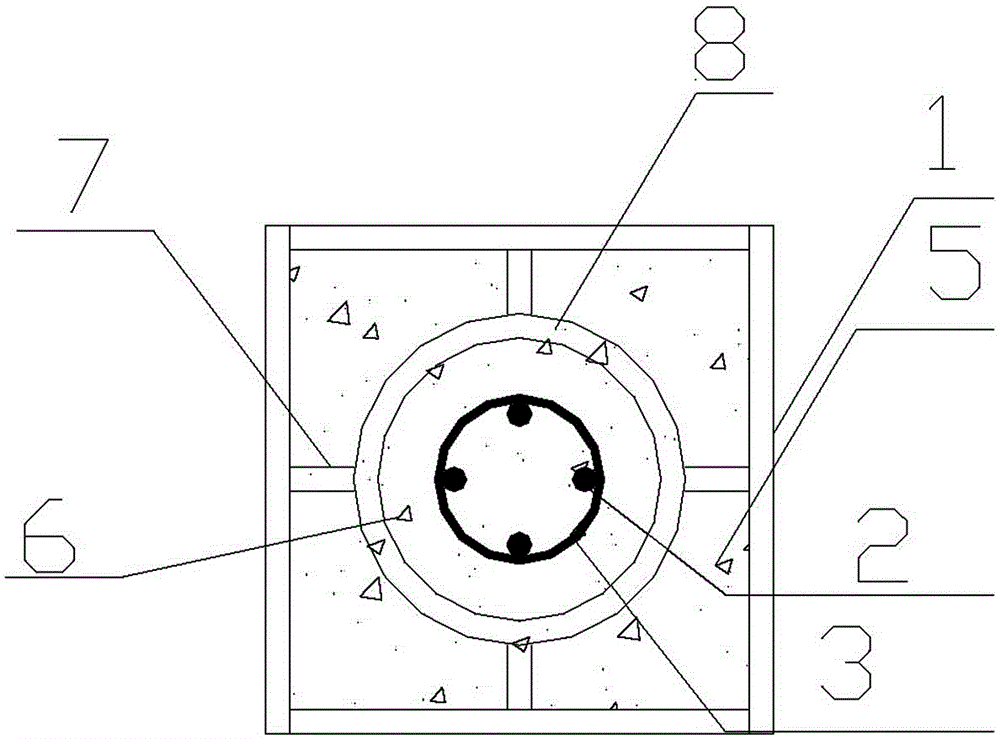

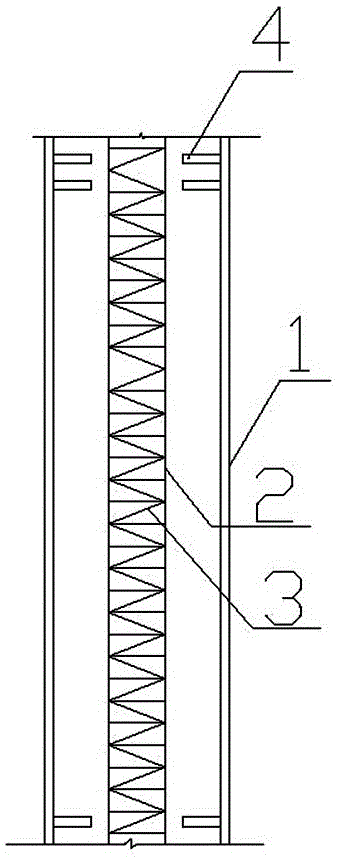

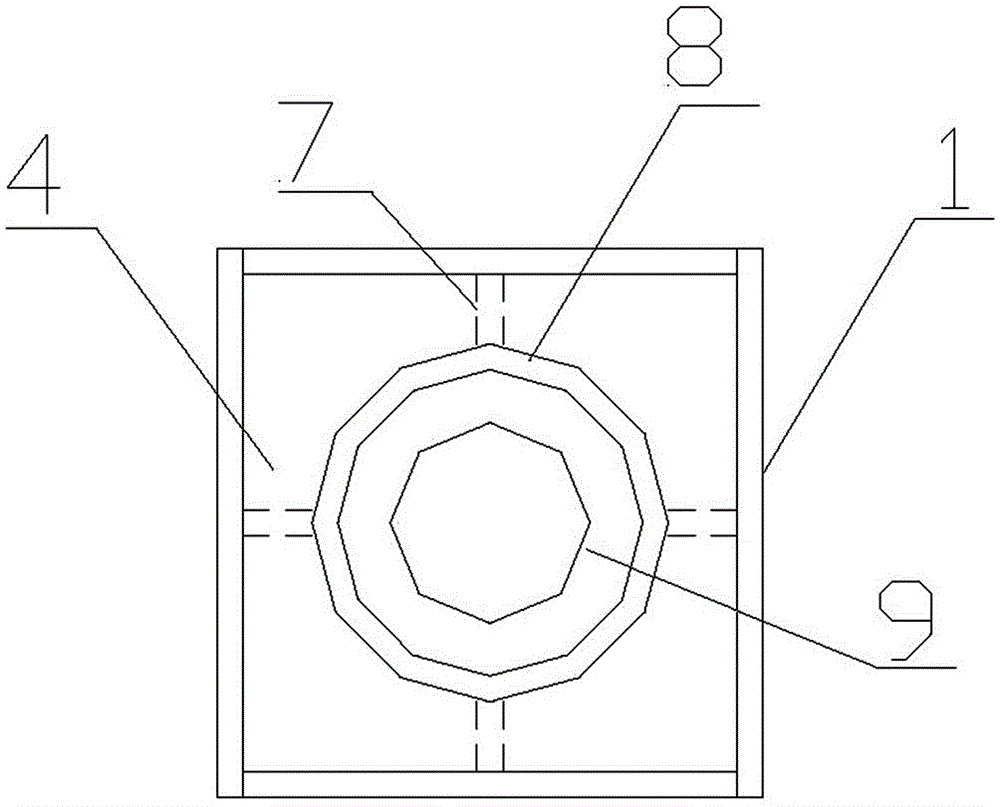

Space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and construction method

ActiveCN105133793AImprove mechanical performanceWide range of sizesStrutsBuilding material handlingRebarMaterials science

The invention relates to a space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and a construction method. A huge column comprises a core steel pipe concrete part and a steel-encased pipe concrete part. A core steel pipe forms an inner cavity. The inner cavity is filled with inner cavity concrete, and a steel bar frame is arranged through the middle part of the inner cavity. The core steel pipe and the steel-encased pipe form an outer cavity. The outer cavity is filled with outer cavity concrete, and at least a steel bar frame is arranged through the outer cavity. The core steel pipe and the steel-encased pipe are connected through a vertical connection plate and form a space steel pipe structure. The outer steel pipe of the huge column is connected with the inner steel pipe through the vertical connection plate, the space steel pipe structure is formed, and the force bearing performance of traditional steel pipe concrete can be raised effectively. The huge column has a strong anti-pressure capability, steel and concrete combined action performances are good under action of long-term load. The huge column has good earthquake resistant behavior, fireproof performance and construction convenience.

Owner:姚攀峰

Advance instrumentation methods for pipes and conduits transporting cryogenic materials

Owner:ASTRO TECH GRP LLC

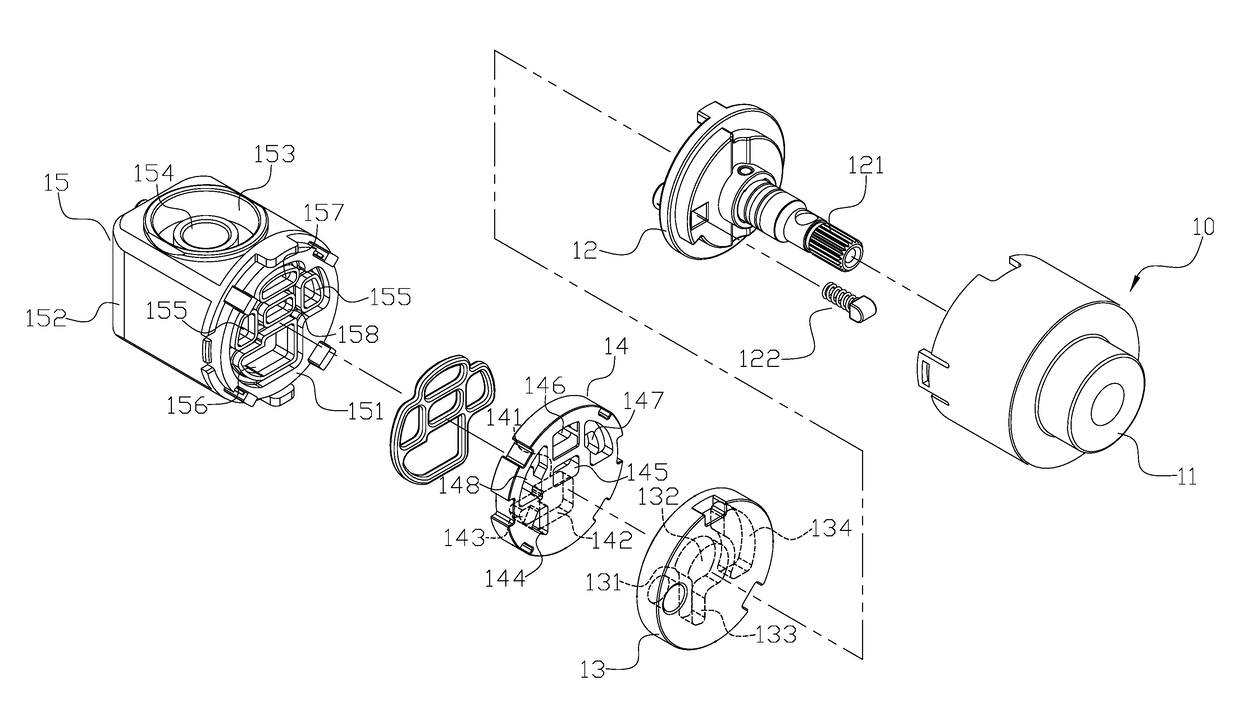

Faucet with pipe-in-pipe structure

InactiveUS9644353B1Efficient separationSimplify structural complexityDomestic plumbingMultiple way valvesWater flowEngineering

A faucet with pipe-in-pipe structure may include a control valve and a valve shell, and a rotating base, a sliding valve piece, and a fixing valve piece are sequentially formed inside the valve shell. The rotating base has a valve rod outwardly sticking out of the valve shell to connect to a handle. The valve rod operated by a handle can rotate the rotating base with the sliding valve piece, so that relative positions between the sliding valve piece and the fixing valve piece are controlled to operate the on / off operation of the faucet, the mixing ratios of hot water and cold water, and the amount of water flow. A valve base connected to a lower end of the valve shell is configured to prevent the fixing valve piece, the sliding valve piece and the rotating base from falling out of the valve shell.

Owner:HAIN YO ENTERPRISES

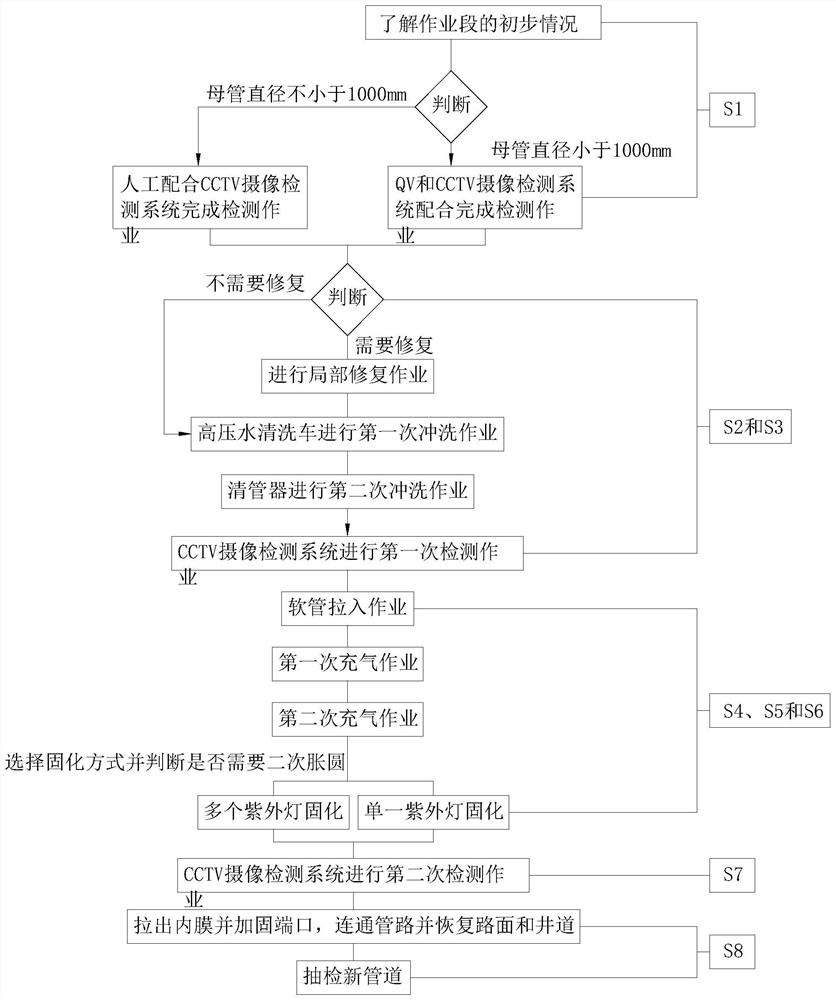

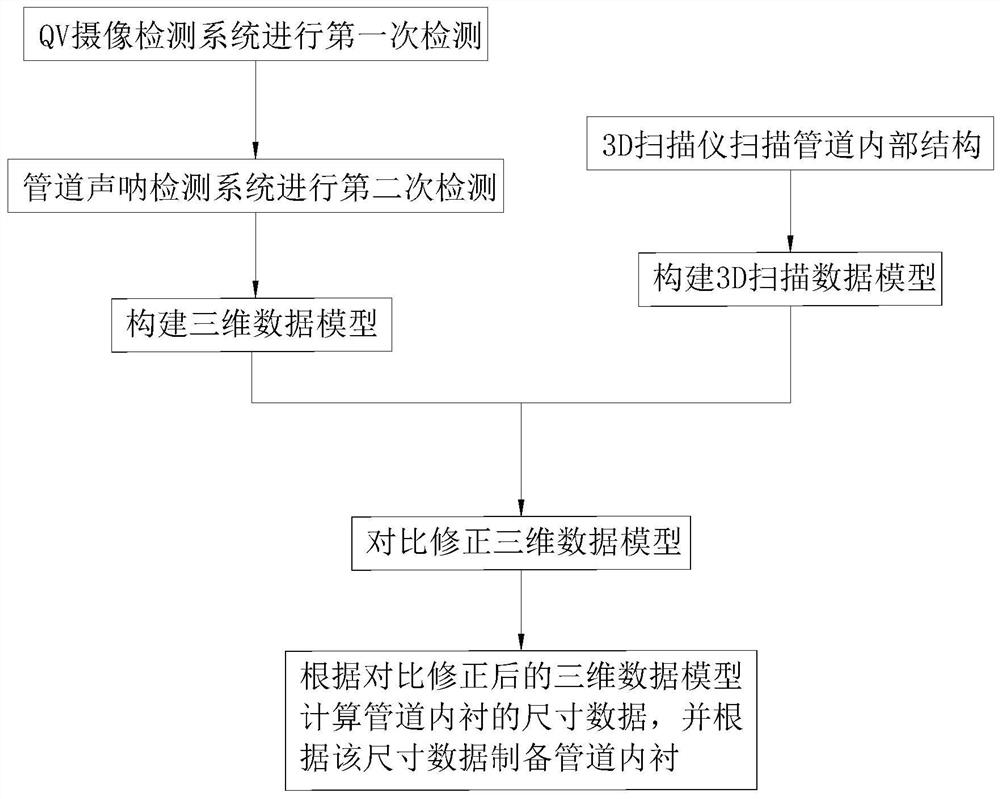

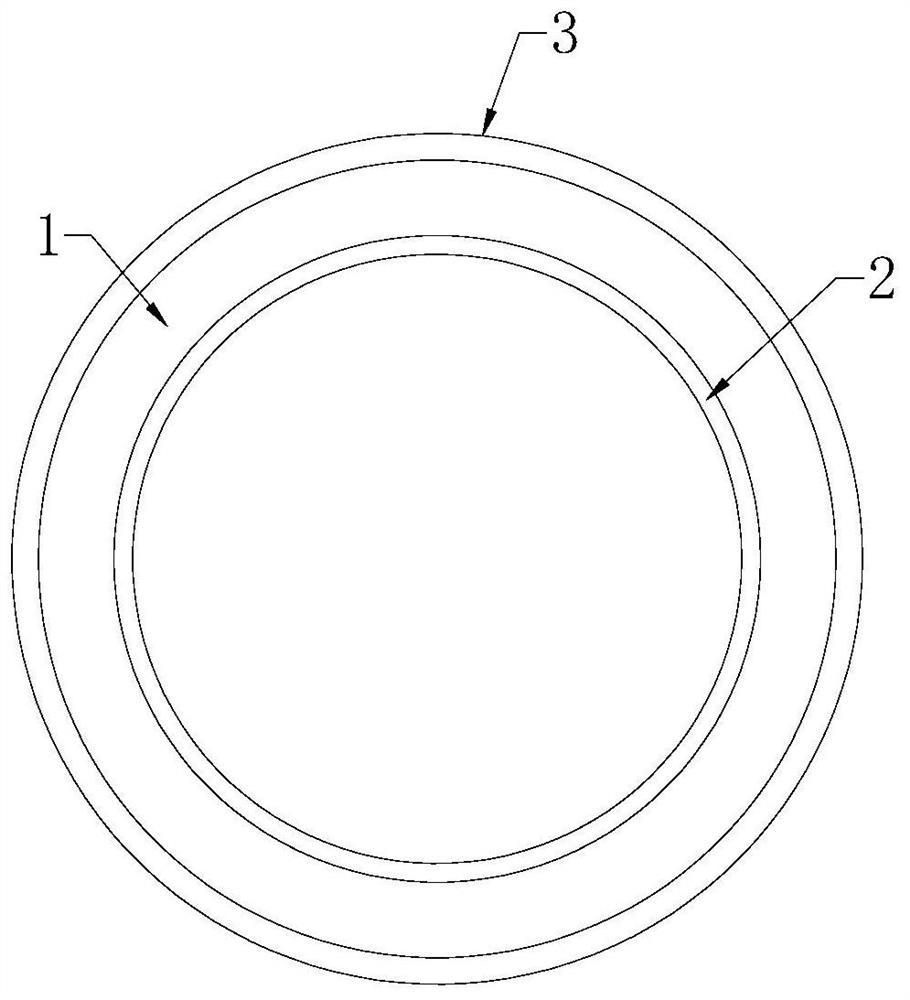

Ultraviolet lamp light curing pipeline repairing method

InactiveCN111750206ATo achieve the purpose of non-excavation repair of municipal pipelinesReduce the impactPigs/molesUltravioletRoad surface

The invention relates to an ultraviolet lamp light curing pipeline repairing method, and relates to the technical field of municipal pipeline repairing. The method comprises the steps of S1, investigating and detecting, specifically, old pipeline data and positions are determined and a pipeline lining is prepared; S2, ventilating and cleaning, specifically, an old pipeline is cleaned twice; S3, cleaning detection, specifically, the inner wall of the cleaned pipeline is determined by adopting a pipeline CCTV television camera detection system; S4, pulling in operation, specifically, the pipeline lining is pulled into the old pipeline; S5, inflating operation, specifically, the pipeline inner lining is inflated and expand around, and the pipeline lining is tightly adhered the inner wall of the old pipeline to form an integrated pipe-in-pipe structure; S6, curing, specifically, irradiating and curing are carried out on the the pipeline lining by using an ultraviolet lamp; S7, repairing and detecting, specifically, a new pipeline is detected by adopting the CCTV television camera detection system; and S8, post-treatment and pavement restoration. According to the repairing operation method of the ultraviolet curing pipeline lining, the pipeline lining is cured on the inner wall of the old pipeline, the old pipeline does not need to be replaced or the road surface is excavated, and the purpose of trenchless repairing of municipal pipelines is achieved.

Owner:上海懿诚市政工程有限公司

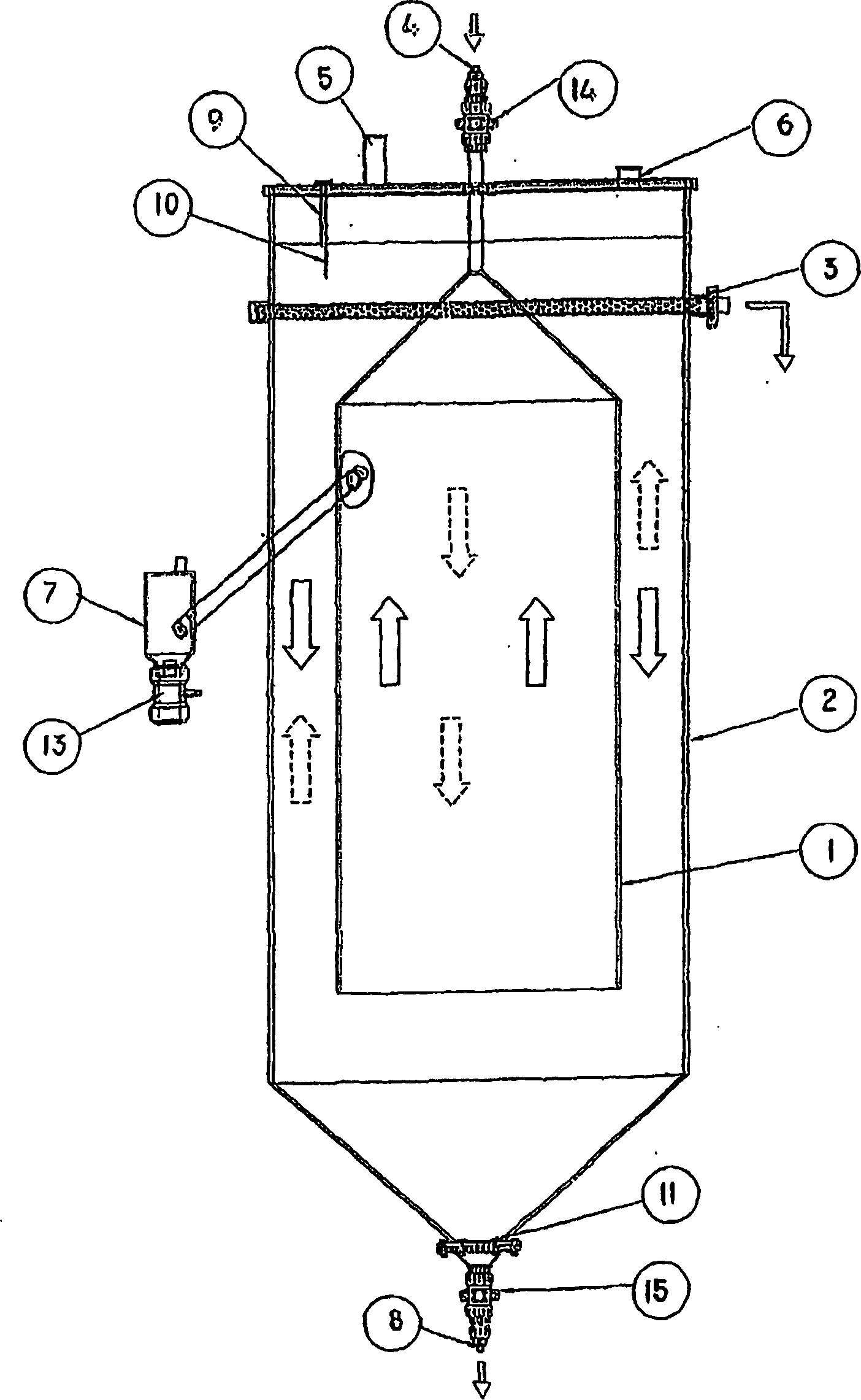

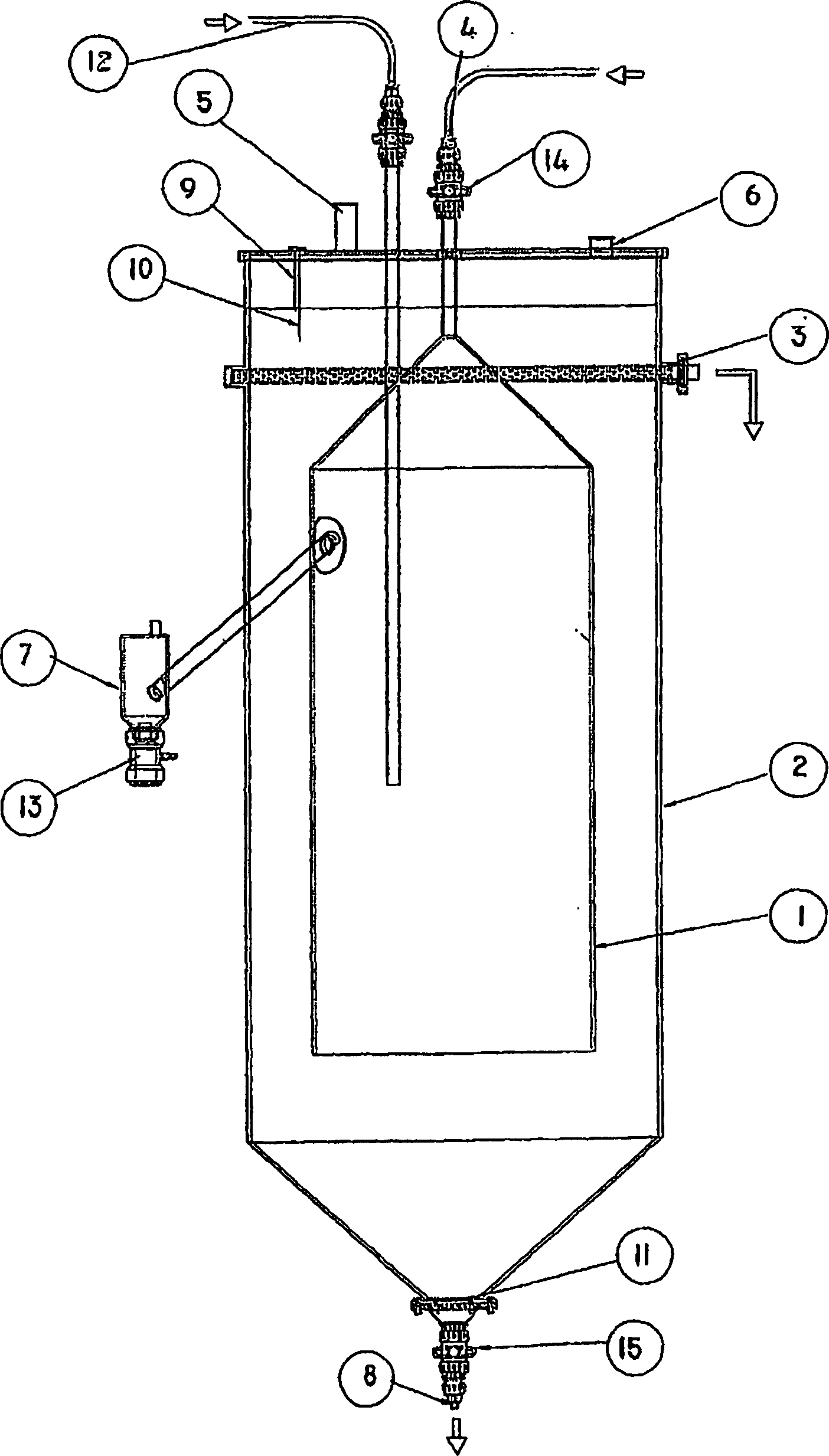

Method and apparatus for desorbing material

InactiveCN1805794AIon-exchange process apparatusIon-exchanger regenerationChemical compositionSorbent

The present invention relates to a method and apparatus for the continuous countercurrent desorption of targeted materials including metals, non-metals and inorganic and / or organic compounds of thereof, wherein the desorption method is divided to the two modes namely: (I) desorption and (II) re-absorption. The desorption of the target material from the loaded resin using the fresh desorbent takes place in mode (I). According to mode (I) loaded resin moves upwardly in a chamber. According to mode (II) impurities are desorbed from resin and targeted material in solution can be re-absorbed. The resin moves downwardly in another chamber during mode (II). Concentrated eluates, which are suitable for the direct economical recovery of chemical elements and / or compounds thereof, can be produced using the present invention. The apparatus of the present invention includes desorption and re-absorption zones that are configured using a ''pipe-in-pipe'' construction or a U-shape construction.

Owner:CLEAN TEQ HLDG

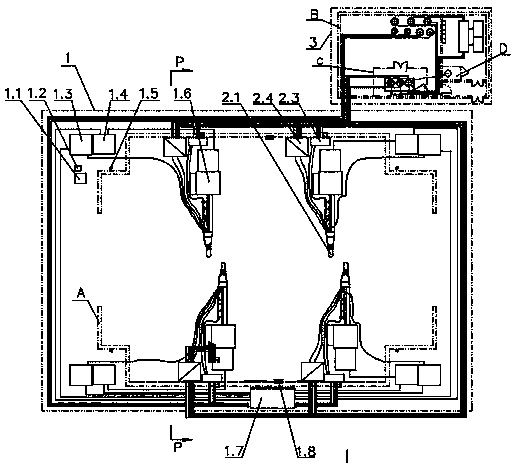

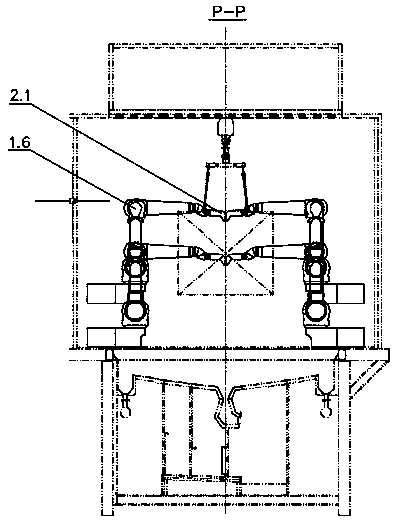

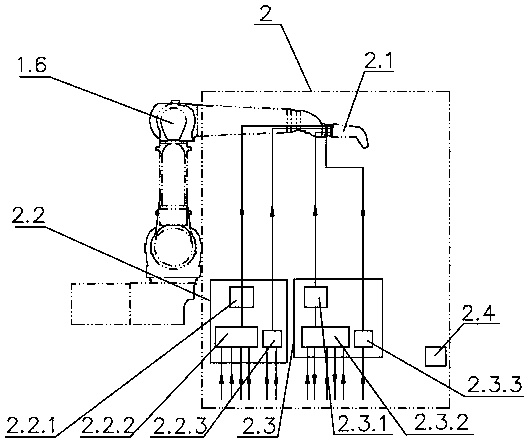

Inner-power-up electrostatic rotating cup for automatically spraying agricultural machine type cockpit and operation method of inner-power-up electrostatic rotating cup

PendingCN108620246ARealize automatic identificationEconomical paintingLiquid spraying plantsLiquid supply arrangementsWater basedEnvironmental resistance

The invention relates to an inner-power-up electrostatic rotating cup for automatically spraying an agricultural machine type cockpit and an operation method of the inner-power-up electrostatic rotating cup. A robot system, an inner-power-up electrostatic rotating cup system and a double-component water-based paint centralized paint supplying system are included. The robot system and the inner-power-up electrostatic rotating cup system are installed in a paint spraying chamber, and remaining parts of the robot system are installed outside the paint spraying chamber; the double-component water-based paint centralized paint supplying system is installed in a paint mixing chamber; and the double-component water-based paint centralized paint supplying system is connected to the inner-power-upelectrostatic rotating cup system through a pipeline. According to the inner-power-up electrostatic rotating cup for automatically spraying the agricultural machine type cockpit and the operation method of the inner-power-up electrostatic rotating cup, the inner-power-up electrostatic rotating cup is adopted and achieves that a robot can perform spraying on the inner and outer surfaces of the cockpit at the same time, and it is achieved that double-component water-based paint environment-friendly coating and the robot inner-power-up electrostatic rotating cup are integrated to achieve automatic spraying of the cockpit. A color changing and cleaning module is adopted, and automatic color changing and cleaning for different cockpit colors are achieved; an insulating platform technology is adopted, and electrification of the water-based paint coating and application of the inner-power-up rotating cup are achieved; and a pipe-in-pipe temperature control device is adopted and the paint conveying temperature control precision of water-based paint and construction characteristics are guaranteed.

Owner:FIRST TRACTOR

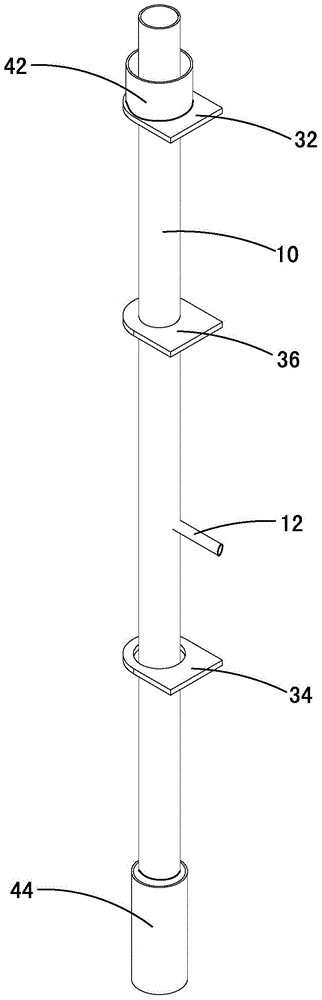

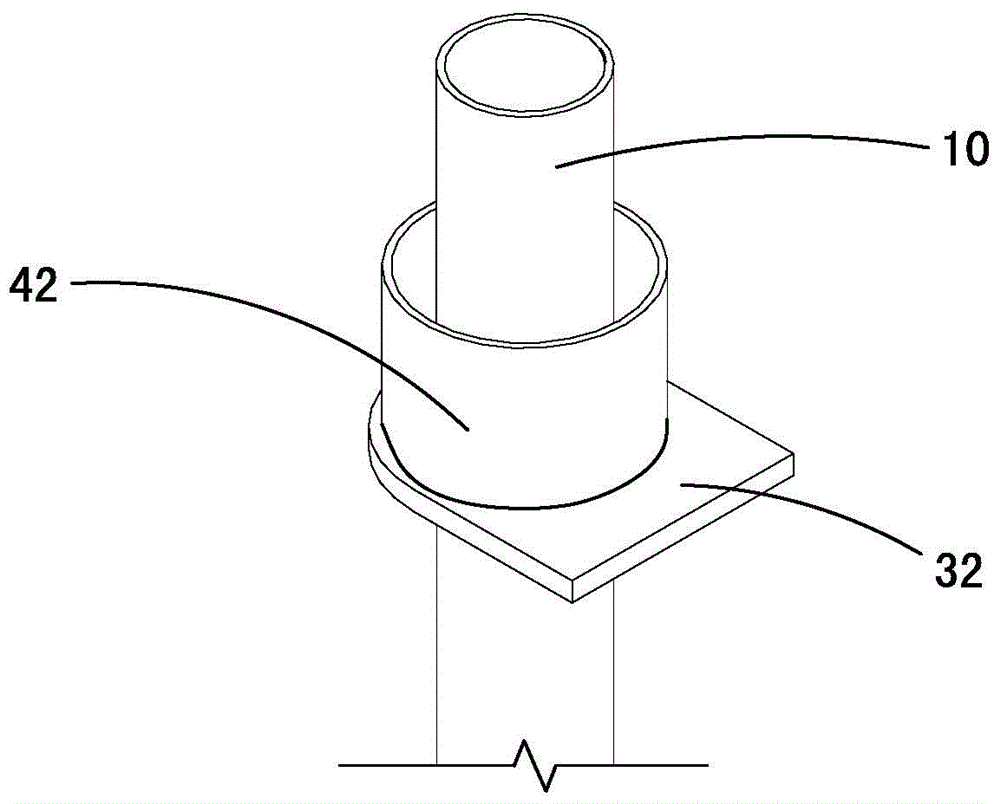

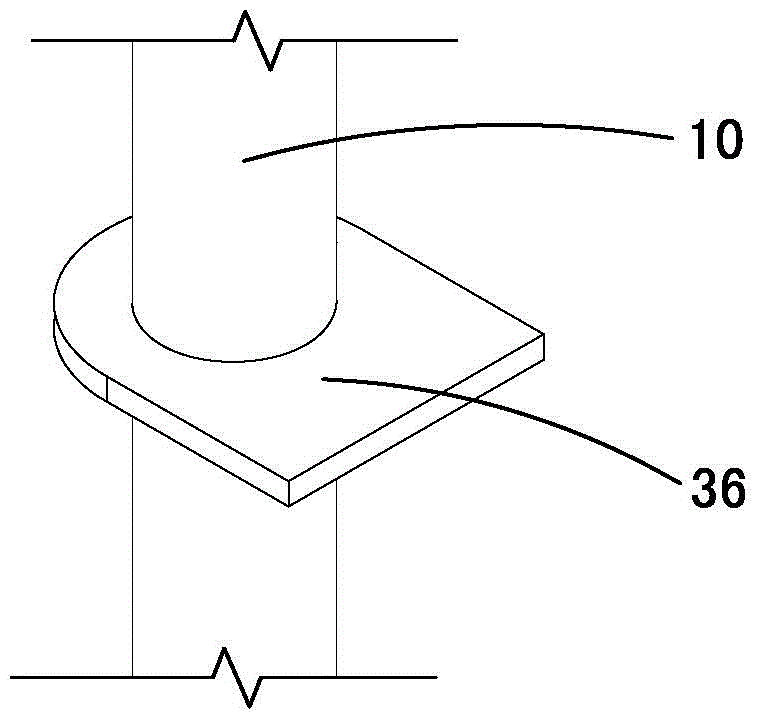

Pipe-in-pipe structure and machining method and installing method thereof

ActiveCN103603467AEasy dockingImprove machining accuracyRoof drainageBuilding material handlingAgricultural engineeringEngineering

The invention relates to a pipe-in-pipe structure which comprises an outer pipe and an inner pipe arranged in the outer pipe, wherein a plurality of connection plates are sleeved on the inner pipe and fixed in the outer pipe, a column top sleeve and a column bottom sleeve are arranged on the inner pipe, the column top sleeve is sleeved at the top end of the inner pipe, the inner diameter of the column top sleeve is larger than the outer diameter of the column bottom sleeve, the column bottom sleeve is sleeved at the bottom end of the inner pipe, and the inner diameter of the column bottom sleeve is larger than the outer diameter of the inner pipe; the top end of the inner pipe protrudes out of the column top sleeve, and the column bottom sleeve protrudes out of the bottom end of the inner pipe. The pipe-in-pipe structure has the advantages of being high in machining precision and convenient in butt joint. The invention further provides a machining method and an installing method of the pipe-in-pipe structure.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

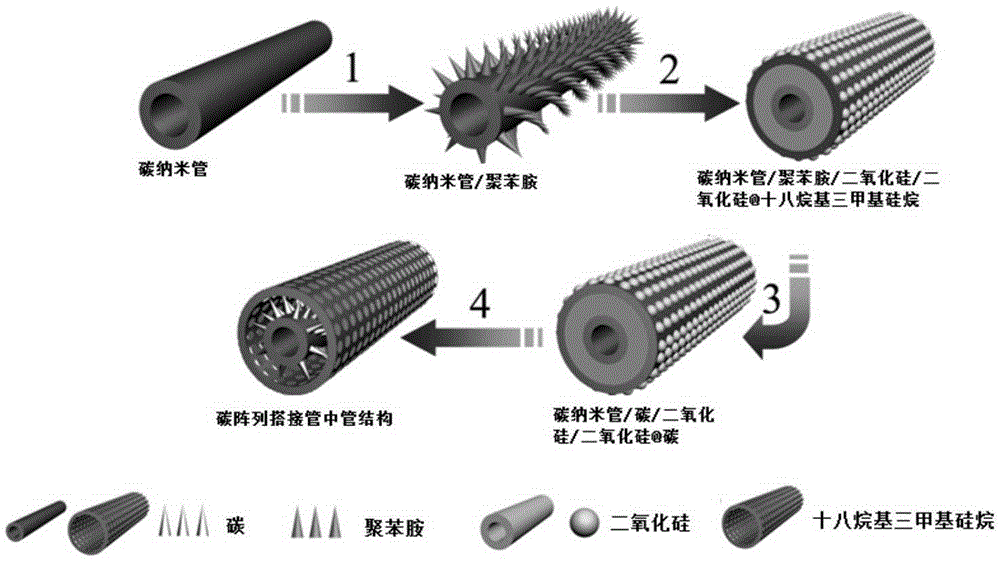

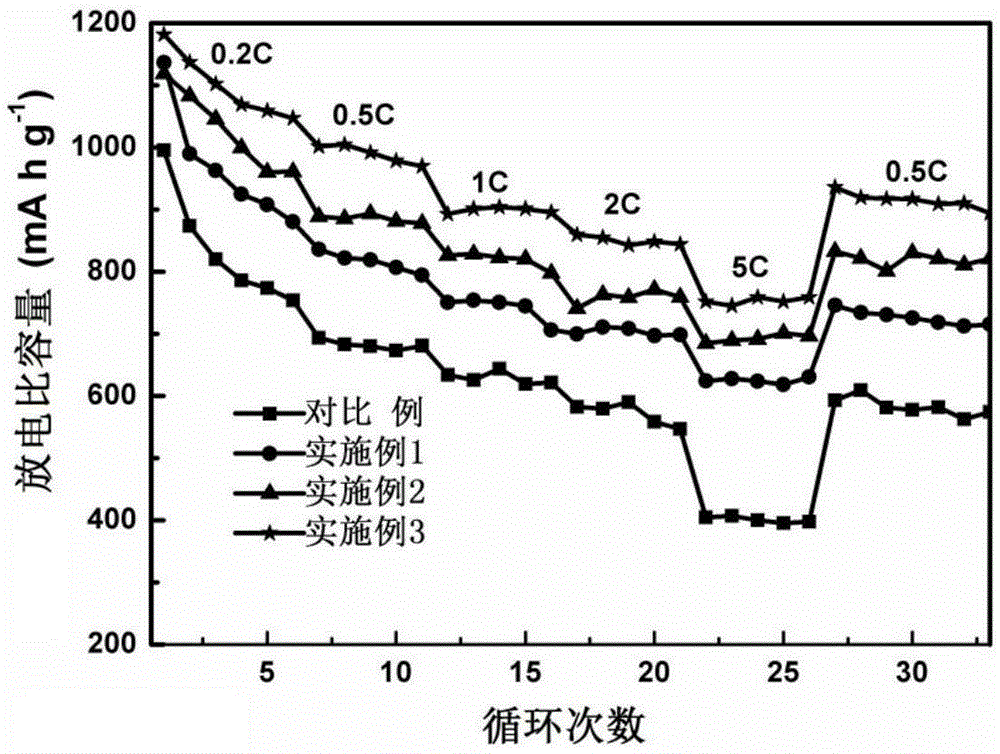

Porous carbon material for lithium-sulfur battery and preparation method and application thereof

ActiveCN106549159AAperture size adjustableControllable pore size distributionElectrode carriers/collectorsLi-accumulatorsEnvironmental resistancePore distribution

The invention relates to a porous carbon material for a lithium-sulfur battery and a preparation method and application thereof. The preparation method of the porous carbon material comprises forming carbon bosses on the surface of a one-dimensional carbon material as a matrix in situ so that a carbon array is formed, and coating the carbon array with a porous carbon layer. The carbon array lap joint pipe-in-pipe structure utilizes sufficient porous carbon raw materials. The preparation method has eco-friendly processes. The porous carbon material has controllable sizes and adjustable pore size, pore distribution and porosity. The porous carbon material as a lithium-sulfur battery positive pole material has great advantages in a raw material utilization rate, conductivity and sulfur resistance, and has a good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

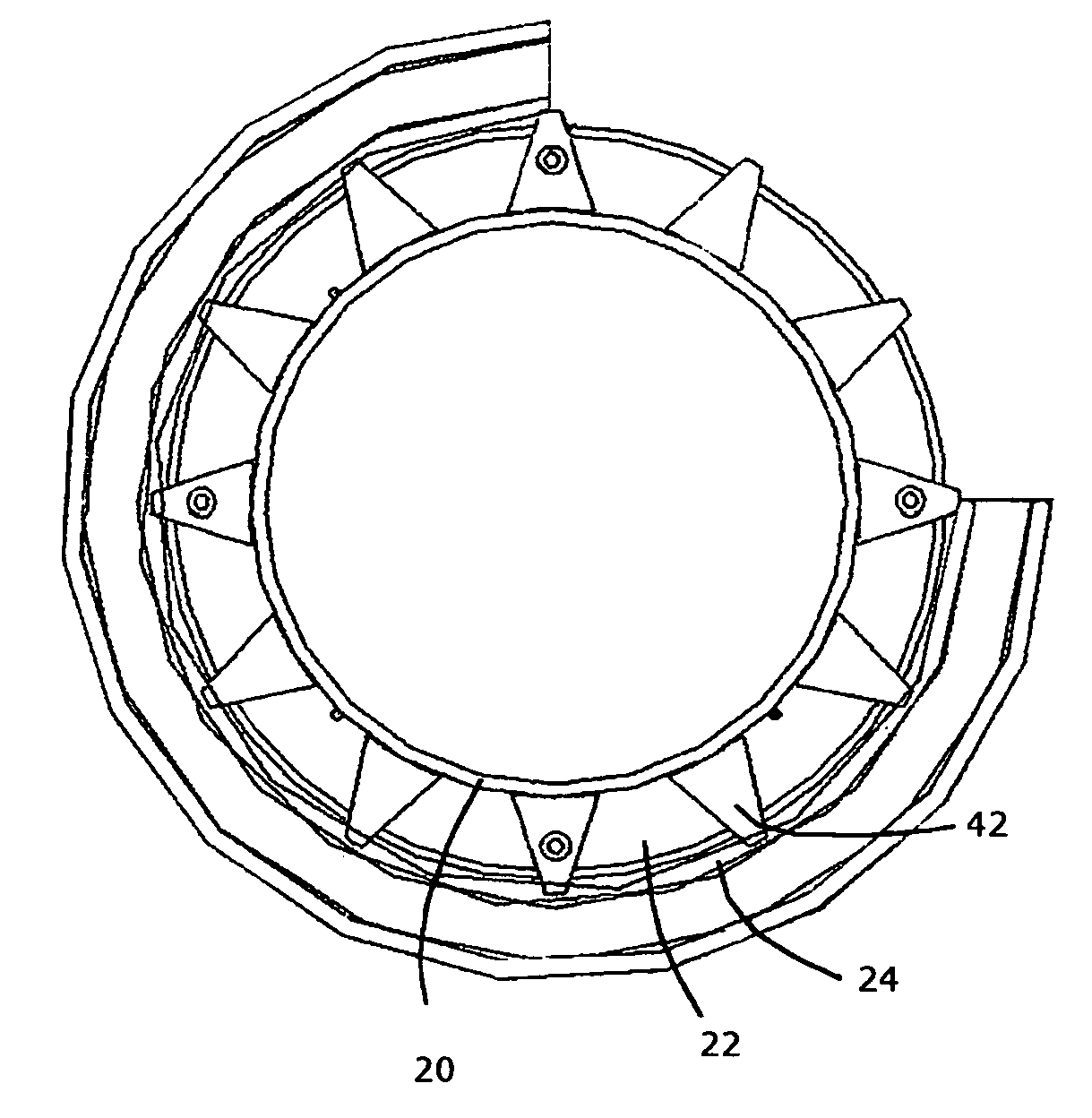

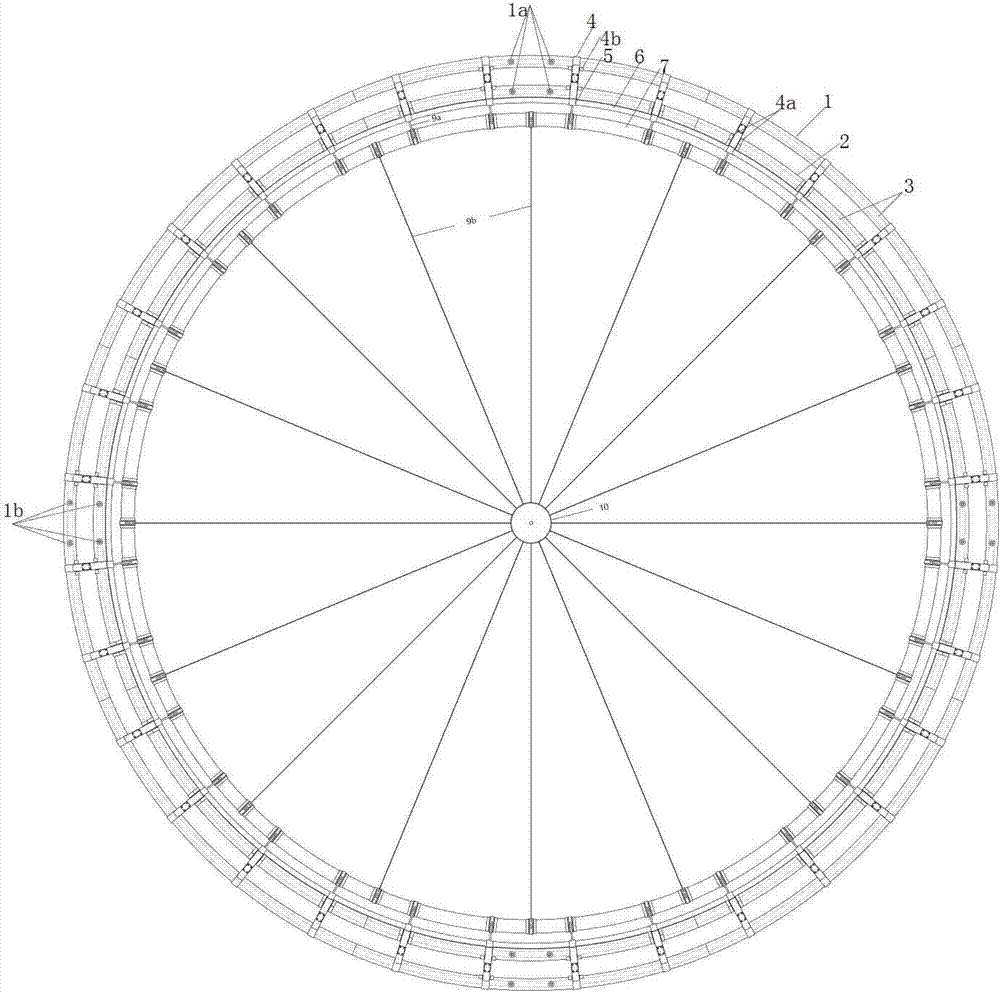

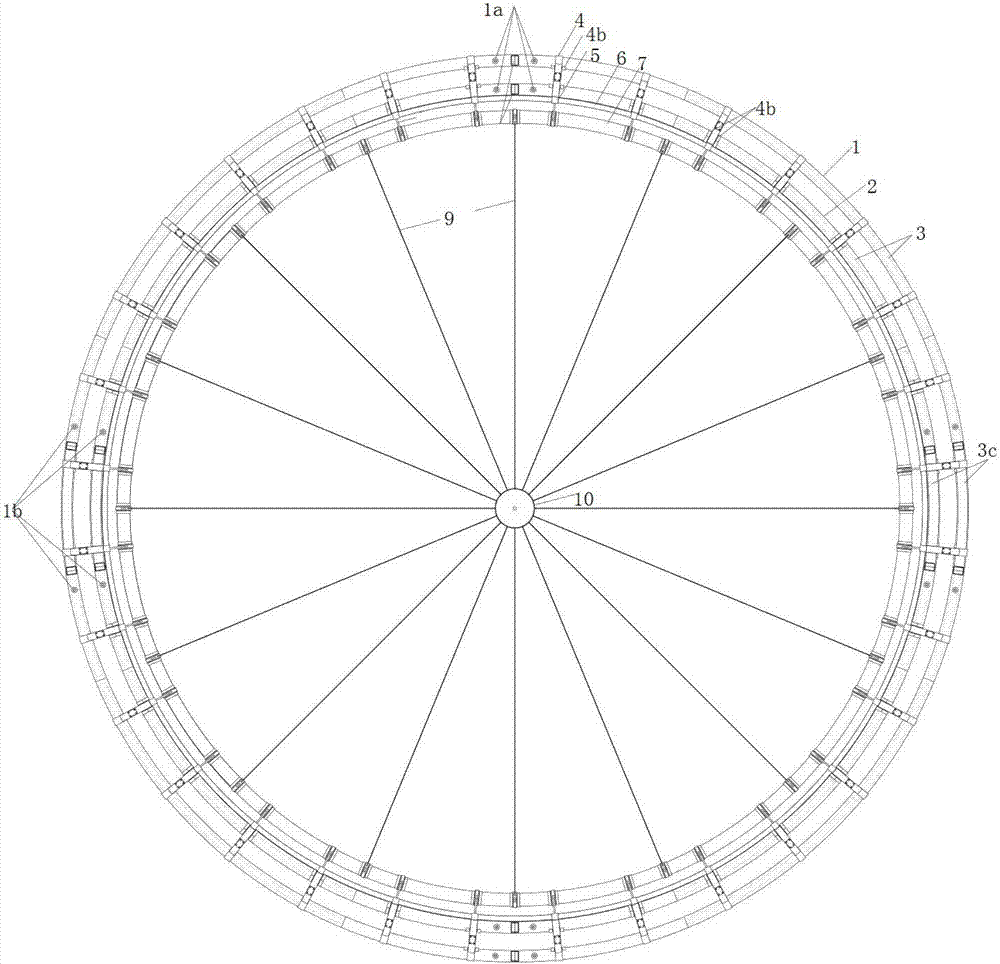

Sinking and floating type net cage

ActiveCN107148930AEasy accessAvoid destructionClimate change adaptationPisciculture and aquariaWater flowEngineering

The invention relates to a sinking and floating type net cage. The sinking and floating type net cage comprises at least two floating pipes, multiple floating pipe connection pieces, multiple handrails, at least one set of net, at least one net base rack, at least one sinker, at least one wire collector, at least one anchor, multiple sets of chains or ropes and at least one pipe-in-pipe. The floating pipes are used as floating bodies of the sinking and floating type net cage and are enclosed into two circles. The floating pipe connection pieces are used for fixing the floating pipes together. The handrails are arranged on the floating pipe connection pieces in an inward manner. The at least one sinker is arranged under the net base racks. The wire collectors are arranged between the net base racks and the sinkers. The anchors are arranged at the bottom of the sea and are used for fixing the net cage so that the net cage will not move along with the water flows. The chains or the ropes are used for connecting the floating pipe connection pieces to the net base racks, connecting the net base racks to the wire collectors, connecting the wire collectors to the sinkers and connecting the sinkers to the anchors. The pipe-in-pipes are sealed and filled with gas and arranged in the floating pipes. Adjusting assemblies are arranged on the floating pipes and / or the wire collectors, and are used for adjusting the sinking and floating of the net cage.

Owner:崔文亮

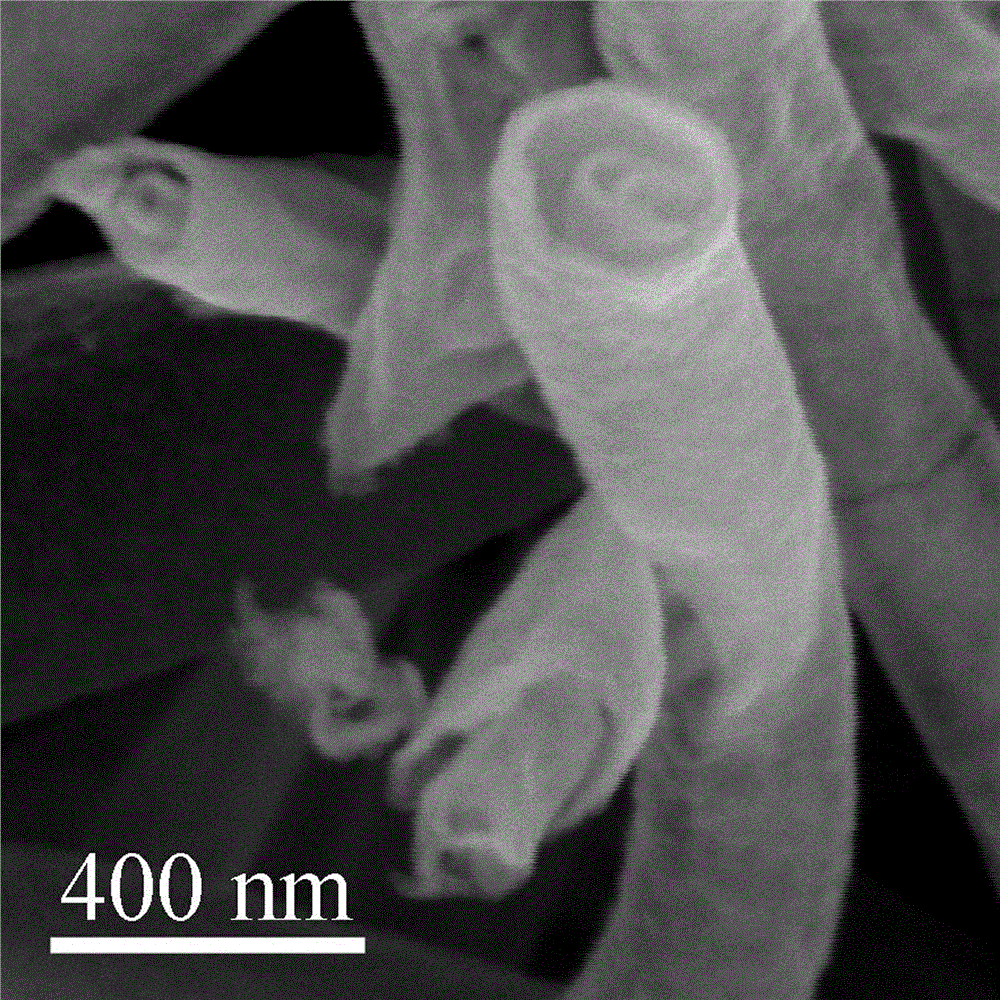

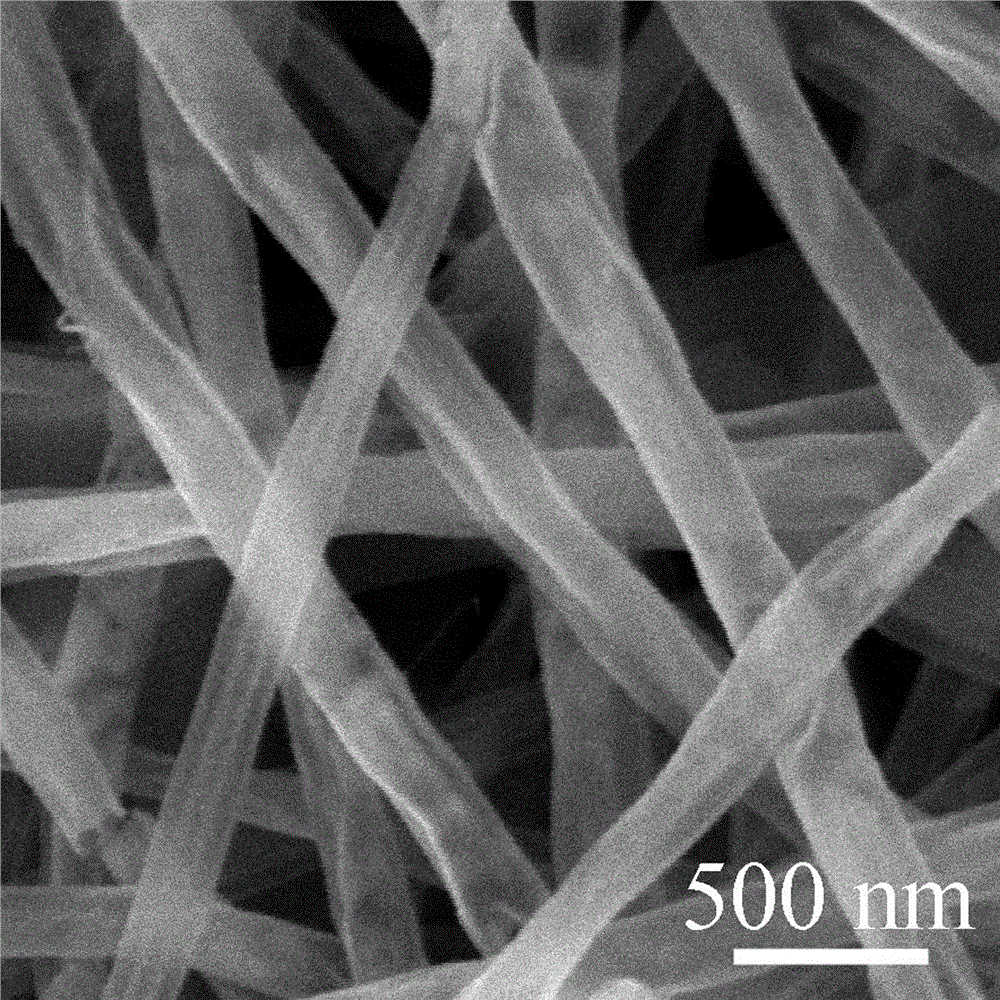

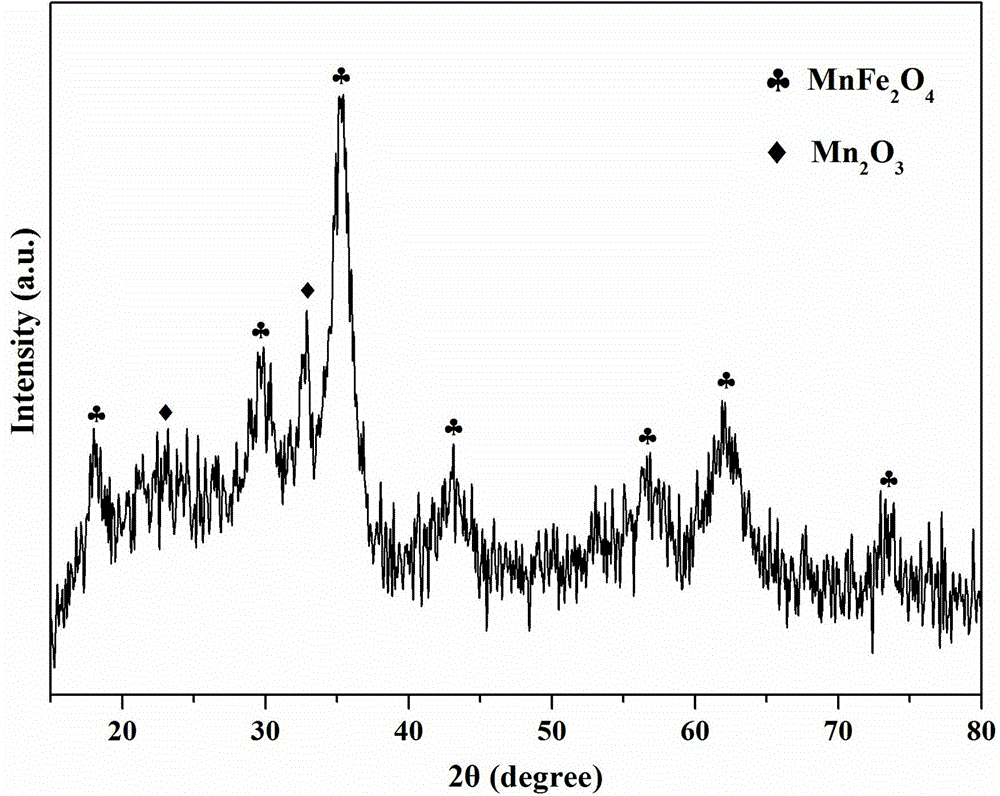

Ferrous-manganese combined metal oxide magnetic nanofiber with pipe-in-pipe structure and preparation method of ferrous-manganese combined metal oxide magnetic nanofiber

InactiveCN104928800AMagneticControl shapeInorganic material artificial filamentsFilament/thread formingFiberSpinning

The invention relates to a ferrous-manganese combined metal oxide magnetic nanofiber with a pipe-in-pipe structure and a preparation method of the ferrous-manganese combined metal oxide magnetic nanofiber. The nanofiber comprises manganous ferrite and manganese sesquioxide. The preparation method comprises the following steps: at first, preparing a spinning solution from polyvinylpyrrolidone (PVP), ferric salt, manganous salt and N,N-dimethylformamide (DMF), then preparing a composite fiber through an electrostatic spinning technology, and at last, calcining segment by segment to obtain the combined metal oxide magnetic nanofiber with the pipe-in-pipe structure. According to the combined metal oxide magnetic nanofiber and the preparation method, the technical route is simple, the operation is easy, the preparation process can be controlled relatively simply and conveniently, the raw materials are low in price, and wide in source, and the suitability for large-scale production is realized; through the adoption of a technology of calcining segment by segment, a nanofiber product, of which the appearance and the size are uniform, with the pipe-in-pipe structure can be obtained, the sample has certain magnetism, and can be independently applied to or compounded with other materials to be applied to the fields of sewage treatment and catalysis.

Owner:UNIV OF JINAN

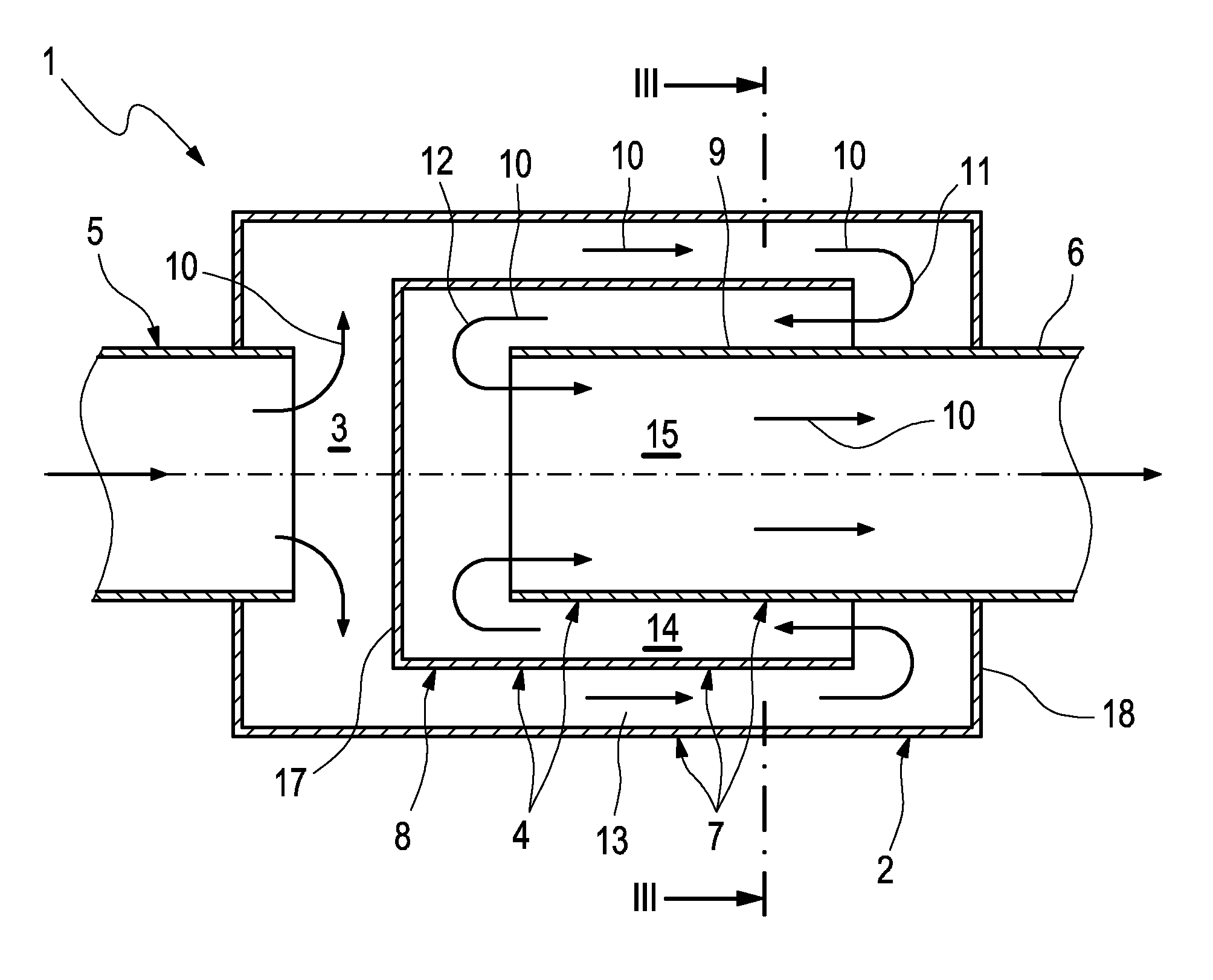

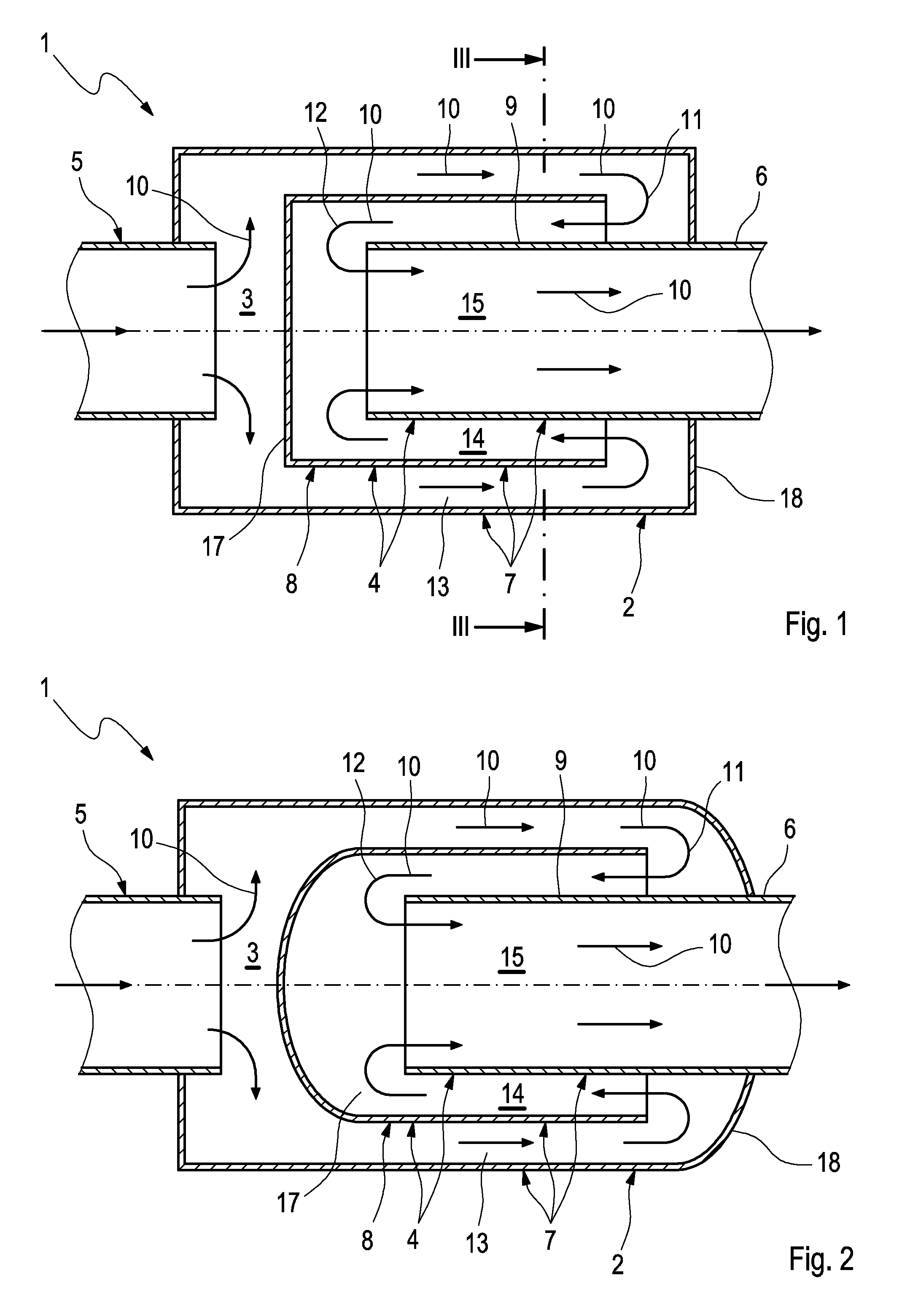

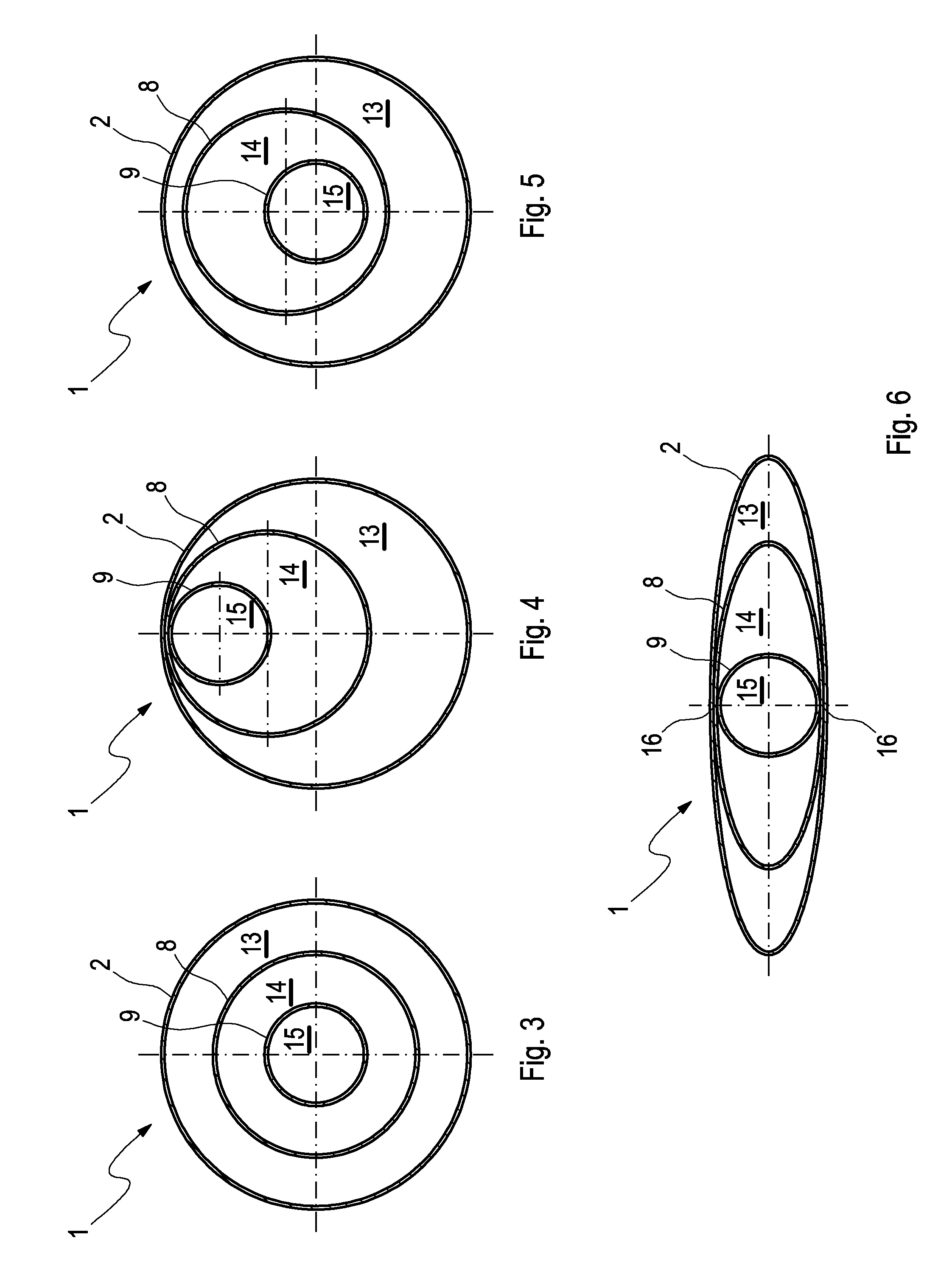

Silencer

ActiveUS8302732B2Improve shock absorptionShort structureExhaust apparatusSilencing apparatusCombustionEngineering

Owner:PUREM GMBH

Rain sewage diversion reforming system for old residential area

InactiveCN104405027ADoes not affect daily lifeIncrease flow rateSewage drainingSewer pipelinesPipeflowMunicipal sewage

The invention relates to a rain sewage diversion reforming system for an old residential area. An original combined pipe of the old residential area is taken as a rain water pipe, and a sewage pipe is arranged in the original combined pipe to form a pipe-in-pipe structure; a booster pump is arranged additionally to form a low-pressure flow sewage conveying system; one end of the rain water pipe is communicated with a rain water regulating pond, and the other end of the rain water pipe is communicated with an urban rain water pipe network; one end of the sewage pipe is communicated with a septic tank, and the other end of the sewage pipe is communicated with the urban rain water pipe network. By adopting the rain sewage diversion reforming system, the defects such as excavation operation, influence on the normal life of the residential area, high cost, the need of a sufficient construction site and the need of knowing the pipeline distribution situation in the residential area caused by the implementation of rain sewage diversion construction through large-scale diversion system reconstruction and a non-excavation technology are overcome. Rain sewage diversion is realized by using low-pressure flow conveying and pipe-in-pipe technologies, and the rain sewage diversion reforming system has the advantages of avoidance of the occupation of roads in the residential area during construction and avoidance of the influence on the daily life of residents; sewage is conveyed by adopting low-pressure flow, so that the sewage flow speed is increased, sedimentation is reduced, the discharge capacity is increased by over 50-100 percent, and the problem of overflow of rain water in case of storm is solved.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com