Pipe-in-pipe underground fluid stratified sampling device

A subsurface fluid and sampling device technology, applied in the direction of wellbore/well components, earthwork drilling, etc., can solve the problem of increasing the cross-sectional area of the sampling system, drilling diameter, increasing control difficulty and system failure rate, sealing system and formation Problems such as difficulty in layer sealing, achieve clear and stable system control, good interlayer sealing effect, and improved stability and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The tool of the present invention will be described in detail below in conjunction with the accompanying drawings.

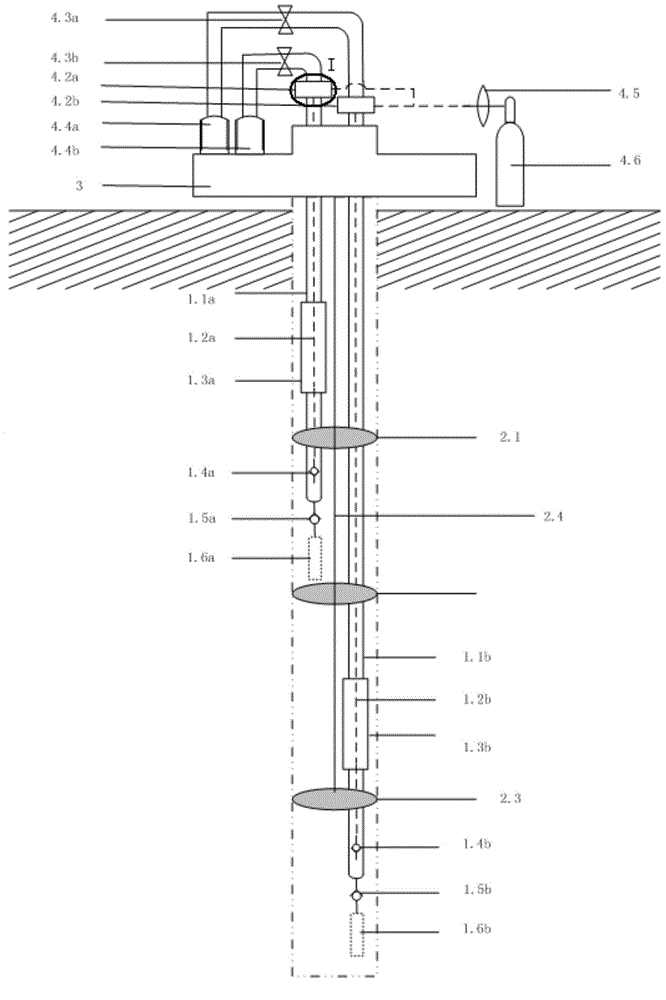

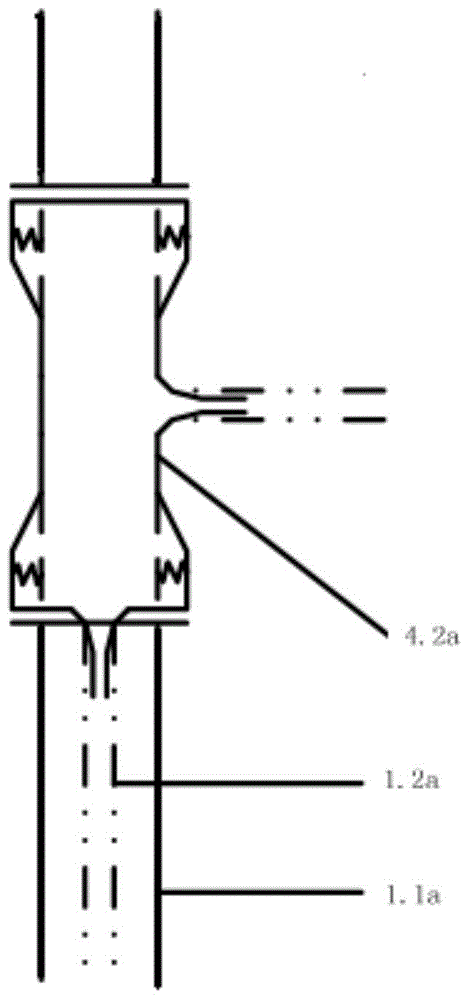

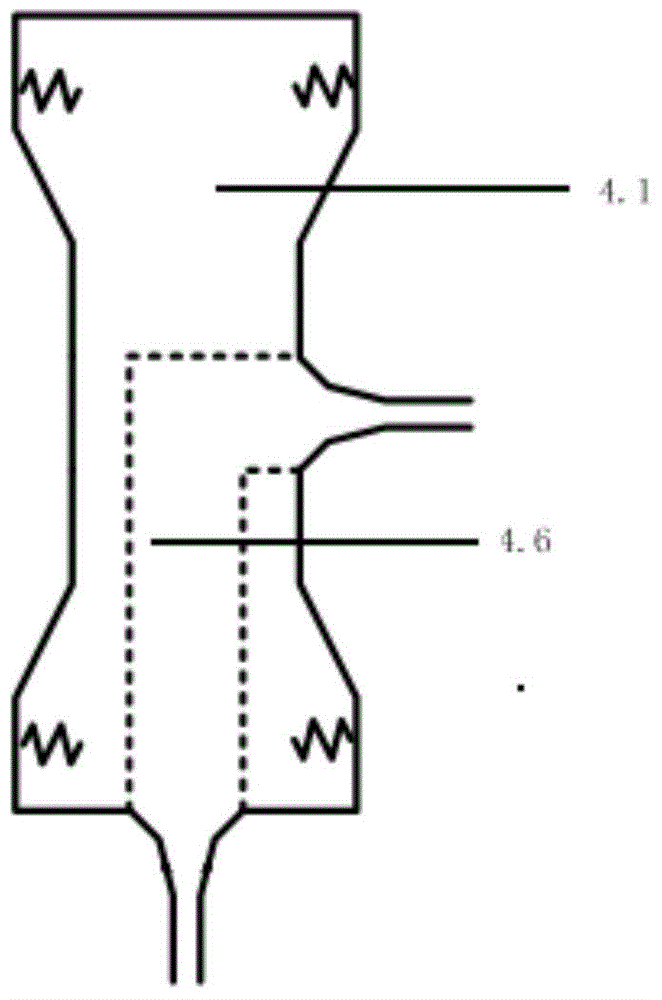

[0030] The structure of the pipe-in-pipe underground fluid layered sampling device provided by the present invention is as follows: figure 1 As shown, the device at least includes a pressure source 5, a wellhead fixing frame 3, a tube-in-tube downhole sampling mechanism 1, an isolation mechanism and a surface sampling mechanism. The well head holder 3 is used to fix the device when sampling.

[0031] Tube-in-tube downhole sampling mechanism 1 includes a first tube-in-tube sampling mechanism and a second tube-in-tube sampling mechanism. The first tube-in-tube sampling mechanism includes a first outer tube 1.1a, a first inner tube 1.2a, The first flow storage container 1.3a, the first gas phase one-way valve 1.4a, the first liquid phase one-way valve 1.5a and the first filter element 1.6a. The first inner tube 1.2a is located inside the first outer tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com