Inner-power-up electrostatic rotating cup for automatically spraying agricultural machine type cockpit and operation method of inner-power-up electrostatic rotating cup

An electrostatic cup, automatic spraying technology, used in liquid spraying equipment, spray booths, spraying devices, etc., can solve the problems of high investment, floor space and operating costs, and achieve the effect of economical paint consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the drawings and embodiments.

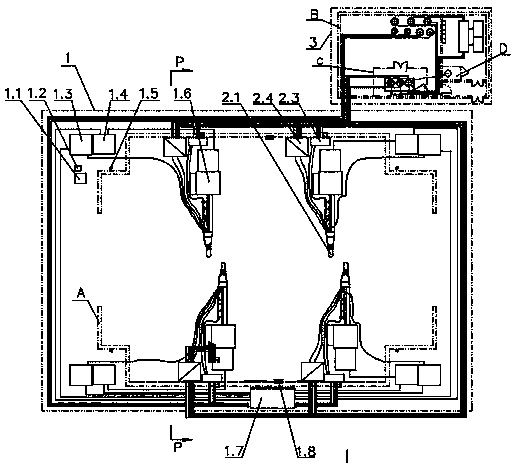

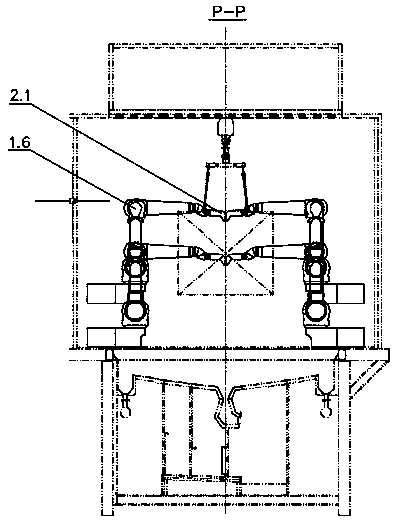

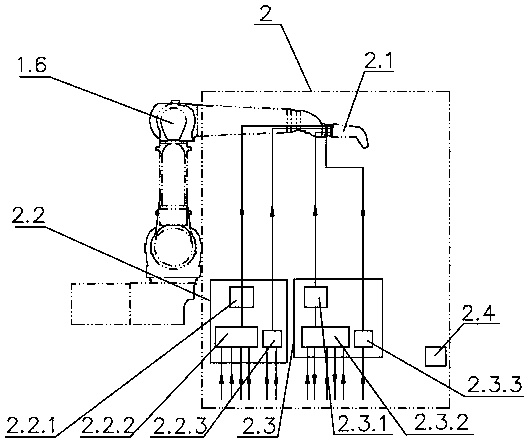

[0033] Combine figure 1 , figure 2 , A cockpit for automatic spraying of agricultural machinery with an internally powered electrostatic spinning cup, comprising a robot system 1, an internally powered electrostatic spinning cup system 2 and a two-component water-based paint centralized supply system 3; the coating robot of the robot system 1 1.6 Installed in spray booth A, and the remaining parts of robot system 1 are installed outside spray booth A; the inner electrostatic spin cup in the inner electrostatic spin cup system 2 2.1 The coating robot 1.6 arm installed in the robot system 1 Front end; the two-component water-based paint centralized supply system 3 that provides paint to the inner electrostatic spin cup 2.1 is installed in the paint mixing room A, and the two-component water-based paint centralized paint supply system 3 is connected by the pipeline Cup sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com