Method for analyzing vortex vibration and fatigue of depth tension-type vertical pipe

A vortex-induced vibration and fatigue analysis technology, which is used in the testing of mechanical components, the testing of machine/structural components, and measuring devices. casing stress and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below with reference to the accompanying drawings.

[0052] The purpose of this invention is to:

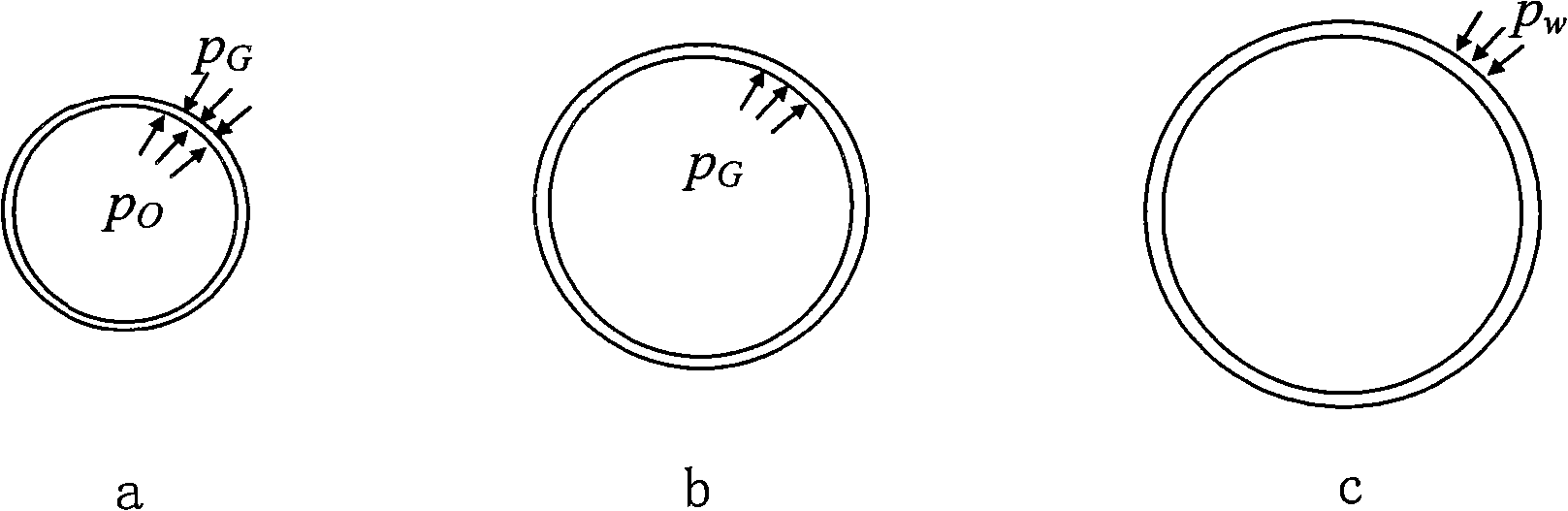

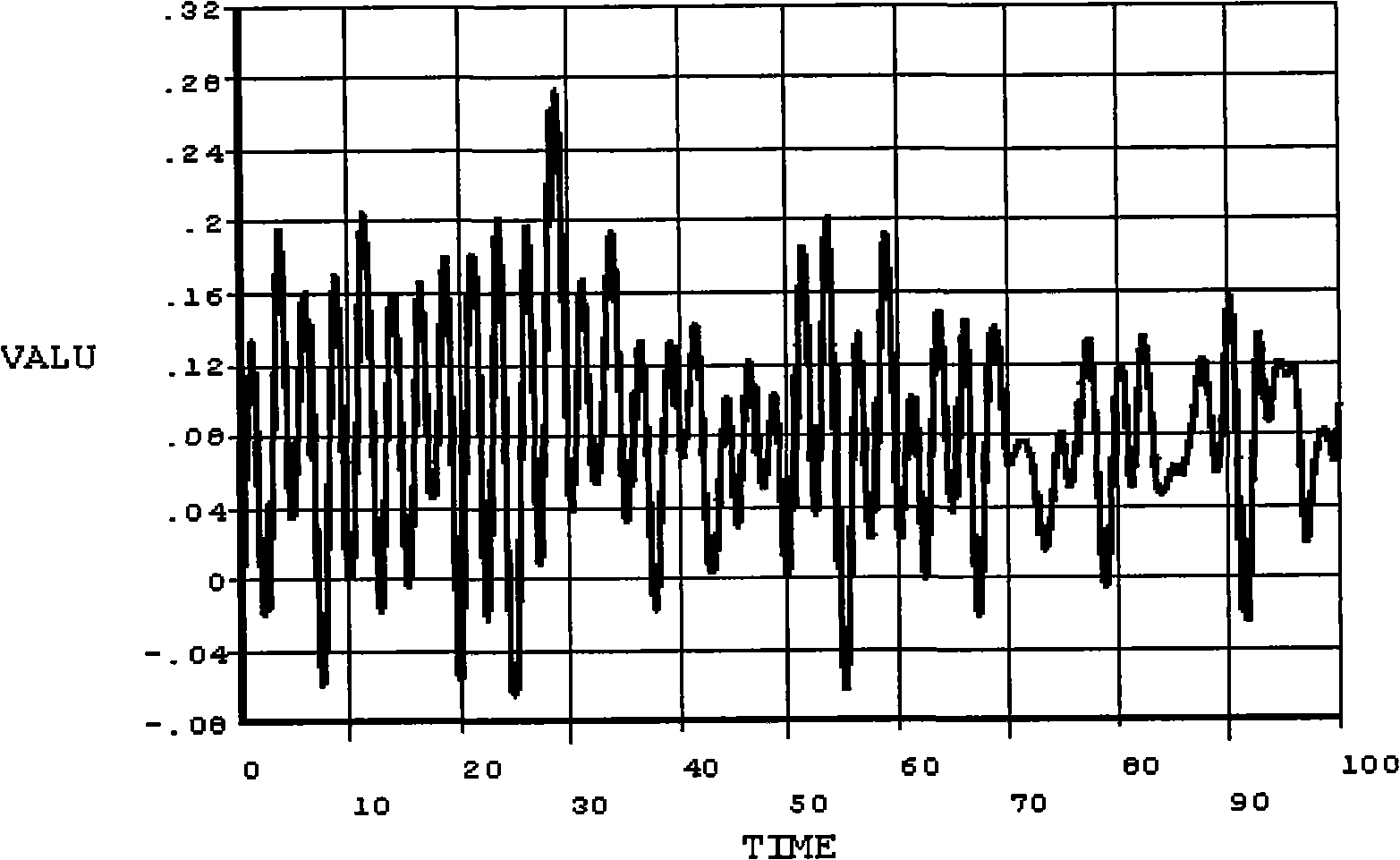

[0053] 1. In the VIV analysis of the deepwater riser, the downstream vibration is considered, so that the analysis model and results are more consistent with the actual engineering problems.

[0054] 2. Improve the existing vortex-induced lift model, consider the influence of the fluid-structure interaction effect on the vortex-induced lift, and improve the VIV analysis accuracy.

[0055] 3. Improve the calculation model of the existing vortex discharge frequency so that it is not only applicable to the locked area, but also to the non-locked area.

[0056]4. Using the time domain analysis method, the maximum amplitude of the riser VIV and its stress and fatigue damage can be analyzed intuitively.

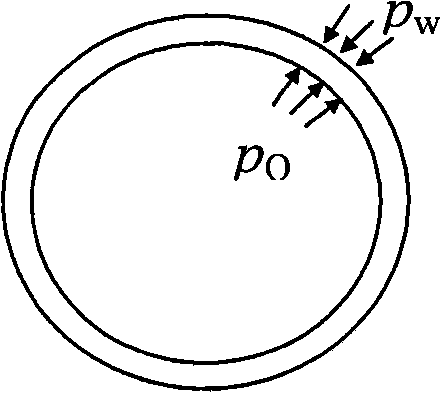

[0057] 5. Calculate the stress by using the actual structure of the riser (tube-in-tube), so that the calculation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com