S-P-doped g-C3N4 pipe-in-pipe and preparation method thereof

A g-c3n4, tube-in-tube technology, which is applied in the field of doped g-C3N4 preparation, can solve the problems of complex precursor pretreatment process and difficult removal of the template of the template method, and achieve great application value, uniform dispersion, and few types Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1.1 Mix 2.0g of melamine, 0.01g of ammonium dihydrogen phosphate and 0.01g of dibenzyl sulfide to obtain a uniform powder;

[0027] 1.2 Raise the mixture in step (1) to 650°C at a heating rate of 2°C / min, and calcinate at 650°C for 2 hours under an argon atmosphere;

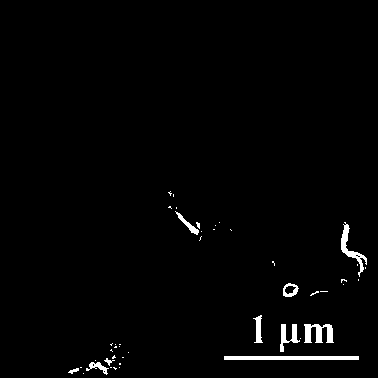

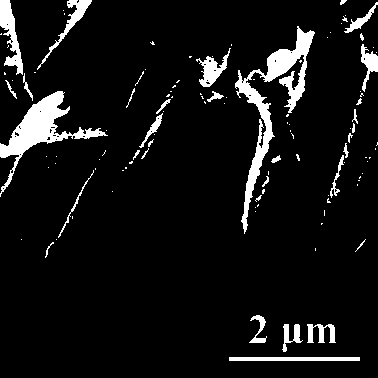

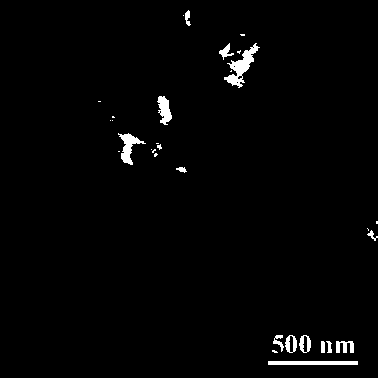

[0028] 1.3 The calcined product is S, P doped g-C 3 N 4 Tube-in-tube product. figure 1 It is the SEM picture of the obtained product. It can be clearly seen from the figure that the product is a tube-in-tube structure formed by nesting inner tubes and outer tubes. The number of inner tubes is one or two, and the inner tube wall and the outer tube wall Partial contact, where the inner tube has an inner diameter of 100-200 nm and a wall thickness of 5-10 nm, the outer tube has an inner diameter of 300-800 nm and a wall thickness of 5-10 nm, and the length of the tube-in-tube is 2- 10 microns. Figure 4 and Figure 5 The XPS photos of the P2p orbital and S 2p orbital in the obtained product, respectively...

Embodiment 2

[0030] 2.1 Mix 2.0g of melamine, 0.005g of ammonium dihydrogen phosphate and 0.005g of dibenzyl sulfide to obtain a uniform powder;

[0031] 2.2 Raise the mixture in step (1) to 650°C at a heating rate of 2°C / min, and calcinate at 650°C for 2 hours under an argon atmosphere;

[0032] 2.3 The calcined product is g-C doped with S and P 3 N 4 Tube-in-tube product. The product is a tube-in-tube structure in which inner tubes and outer tubes are nested. The number of inner tubes is one or two, and the inner tube wall is partially in contact with the outer tube wall. The inner diameter of the inner tube is 50-100 nanometers , the wall thickness is 4-7 nanometers, the inner diameter of the outer tube is 200-600 nanometers, the wall thickness is 4-7 nanometers, and the length of the tube in the tube is 2-10 microns. After the BET test, the specific surface area of the obtained product is 50 m 2 . g -1 .

Embodiment 3

[0034] 3.1 Mix 2.0g of melamine, 0.002g of ammonium dihydrogen phosphate and 0.002g of dibenzyl sulfide to obtain a uniform powder;

[0035] 3.2 Raise the mixture in step (1) to 650°C at a heating rate of 2°C / min, and calcinate at 650°C for 2 hours under an argon atmosphere;

[0036] 3.3 The calcined product is S, P doped g-C 3 N 4 Tube-in-tube product. The product is a tube-in-tube structure in which inner tubes and outer tubes are nested. The number of inner tubes is one or two, and the inner tube wall is partially in contact with the outer tube wall. The inner diameter of the inner tube is 10-50 nanometers , the wall thickness is 8-15 nanometers, the inner diameter of the outer tube is 300-900 nanometers, the wall thickness is 20-50 nanometers, and the length of the tube in the tube is 2-10 microns. After the BET test, the specific surface area of the obtained product is 35 m 2 . g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com