Method and apparatus for desorbing material

A technology for desorption and target materials, applied in chemical instruments and methods, ion exchange treatment devices, improvement of process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

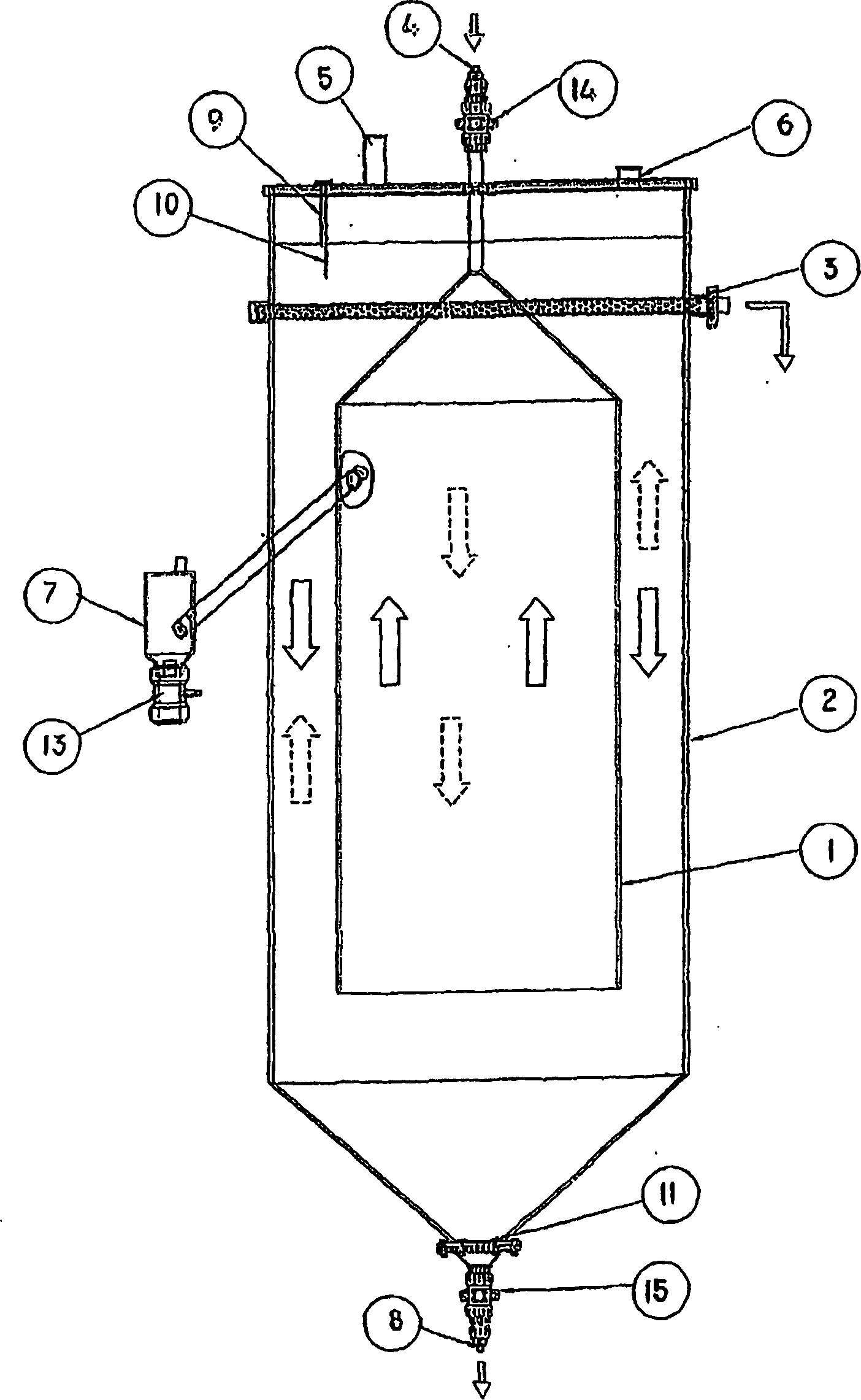

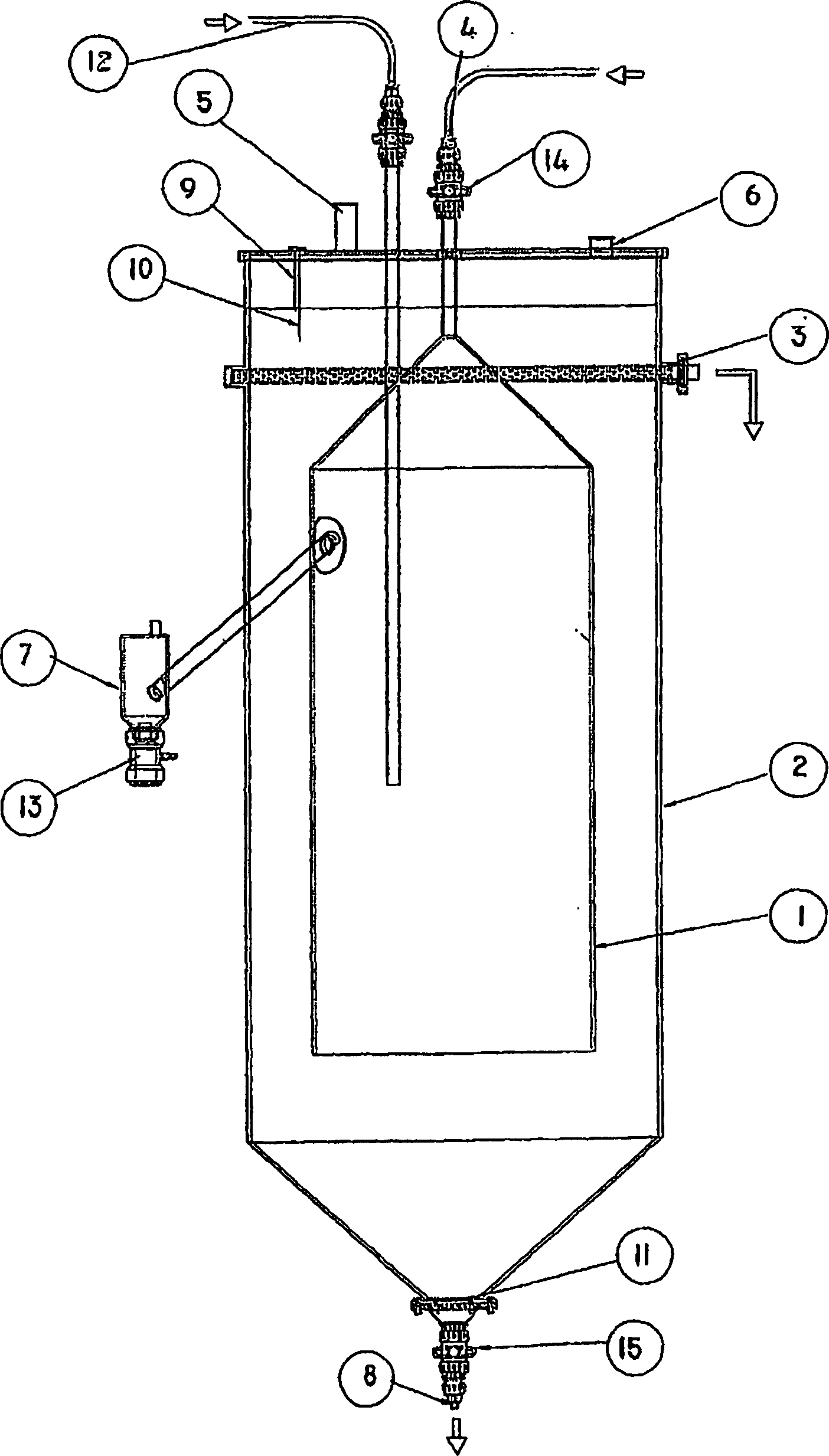

[0102] This example describes the desorption of copper from a resin that is saturated during the treatment of a wastewater stream from a copper electroplating plant. displayed by using the Figure 4 The device in is designed to perform this example.

[0103] The copper concentration in the wash water is about 50 to 80 ppm, and the loading capacity of the resin suction reaches 28 to 32 g / l.

[0104] according to Figure 4 In the example shown in , the desorption test was carried out in a 150L plastic U-shaped column tube, and the loaded resin entered the column tube through the sleeve 5 located on the cover of the column tube. After desorption, the completely desorbed resin is removed from the column via the transfer tube and the intermediate chamber 7 once an hour. The resin was passed through the column at a rate of 20 L / hr.

[0105] A 7% sulfuric acid solution was used as the desorption solution. A desorption stream was pumped at a rate of approximately 22 L / hr into the...

example 2

[0110] This example shows the desorption of nickel from resin that was loaded during the adsorption recovery of nickel from high pressure ferrovanadium leached slurry. by using Figure 4 The device shown in is used to perform this example.

[0111] The elemental composition analysis of the loaded resins is shown in Table 2.1.

[0112] The desorption equipment consists of a U-shaped plastic test column with a capacity of 750 ml. The resin flows through the column at a rate of 100ml / hr.

[0113] A 10% hydrochloric acid solution was used as the desorption solution. The solution was pumped into the column via cannula 4 and valve 14 and flowed through the desorption and resorption zones at a rate of approximately 160 ml / hr. The desorption solution stream is divided into two unequal parts:

[0114] i) The wastewater solution stream, which after desorption is collected in an amount of approximately 100 ml / hr from the discharge device 3 and fed to the adsorption stage together wi...

example 3

[0120] This example shows the desorption of copper from a saturated resin which had been previously loaded during the adsorption recovery of copper from bulk filtrate. The copper concentration is between 2g / l and 6g / l.

[0121] The resin loading capacity in this copper test was 55 to 64 g / l. The resin flowed through the desorption column at a rate of approximately 100 ml / hr during the test.

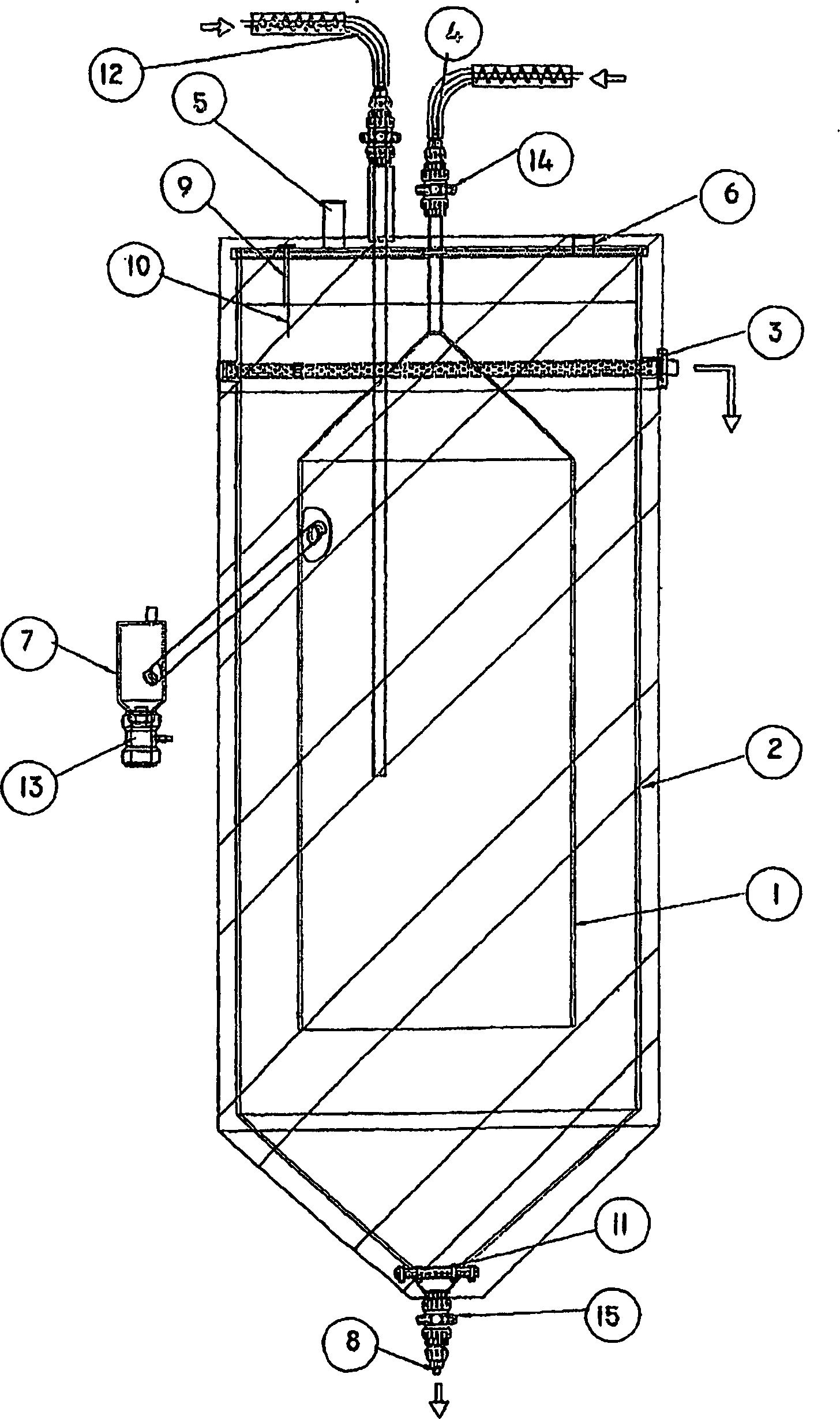

[0122] according to Image 6 For the apparatus shown in , desorption experiments were performed in 750 ml borosilicate glass column tubes. The U-shaped column was fully insulated to maintain the temperature in the column between 60 and 70°C.

[0123] 10% sulfuric acid solution is used as the desorption agent, and an electric heater is used at the inlet 4 of the desorption solution to preheat it to 60-70°C. The flow of desorbent was maintained at a rate of approximately 75ml / hr.

[0124] In addition, after copper sulfide is precipitated, the preheated mother liquor is pumped into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com