Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

967 results about "Outlet Port Valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

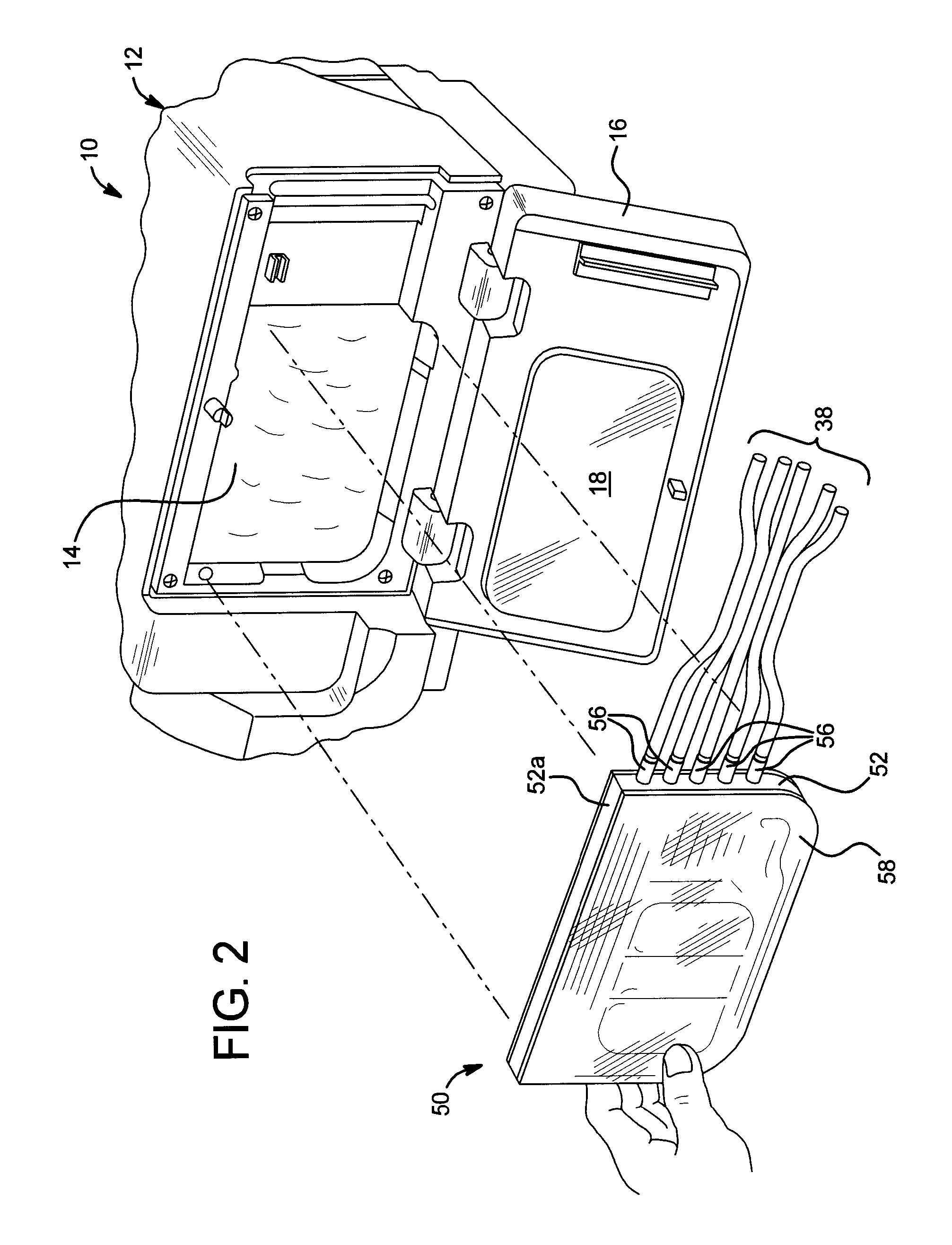

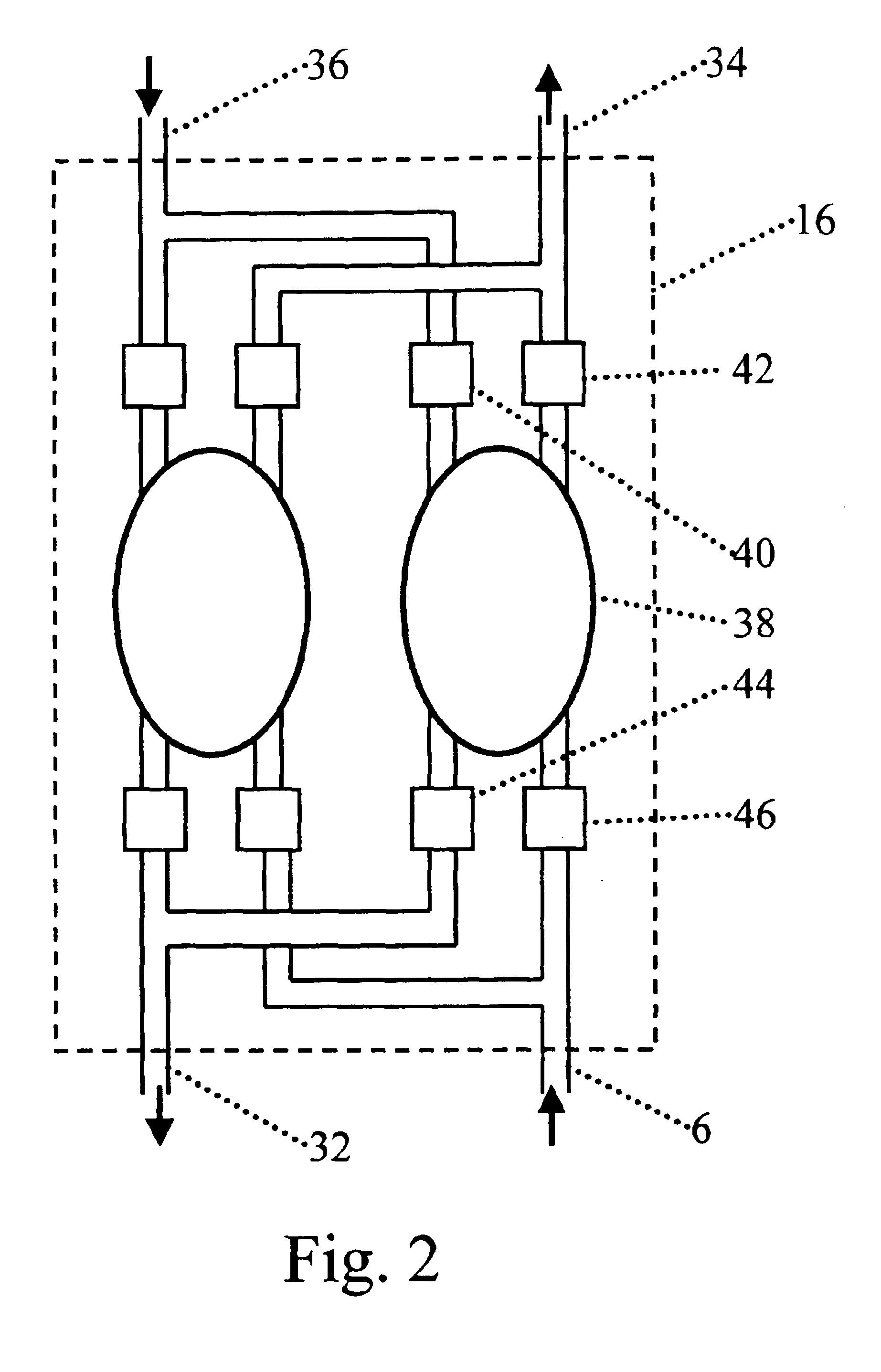

Dialysis cassette having multiple outlet valve

A disposable pumping cassette in one embodiment includes a pump chamber; and a valve chamber in communication with the pump chamber, the valve chamber including an inlet and first and second outlets. A disposable pumping cassette in another embodiment includes a first valve chamber including an inlet and first and second outlets; and a second valve chamber including an inlet and an outlet, the second valve chamber openable to allow dialysis fluid to flow through one of the first and second outlets of the first valve chamber, through the outlet of the second valve chamber. A disposable pumping cassette in a further embodiment includes a valve chamber including a fluid inlet and first and second fluid outlets; and a flexible sheet openable to open and close only one of the first and second outlets.

Owner:BAXTER HEALTHCARE SA +1

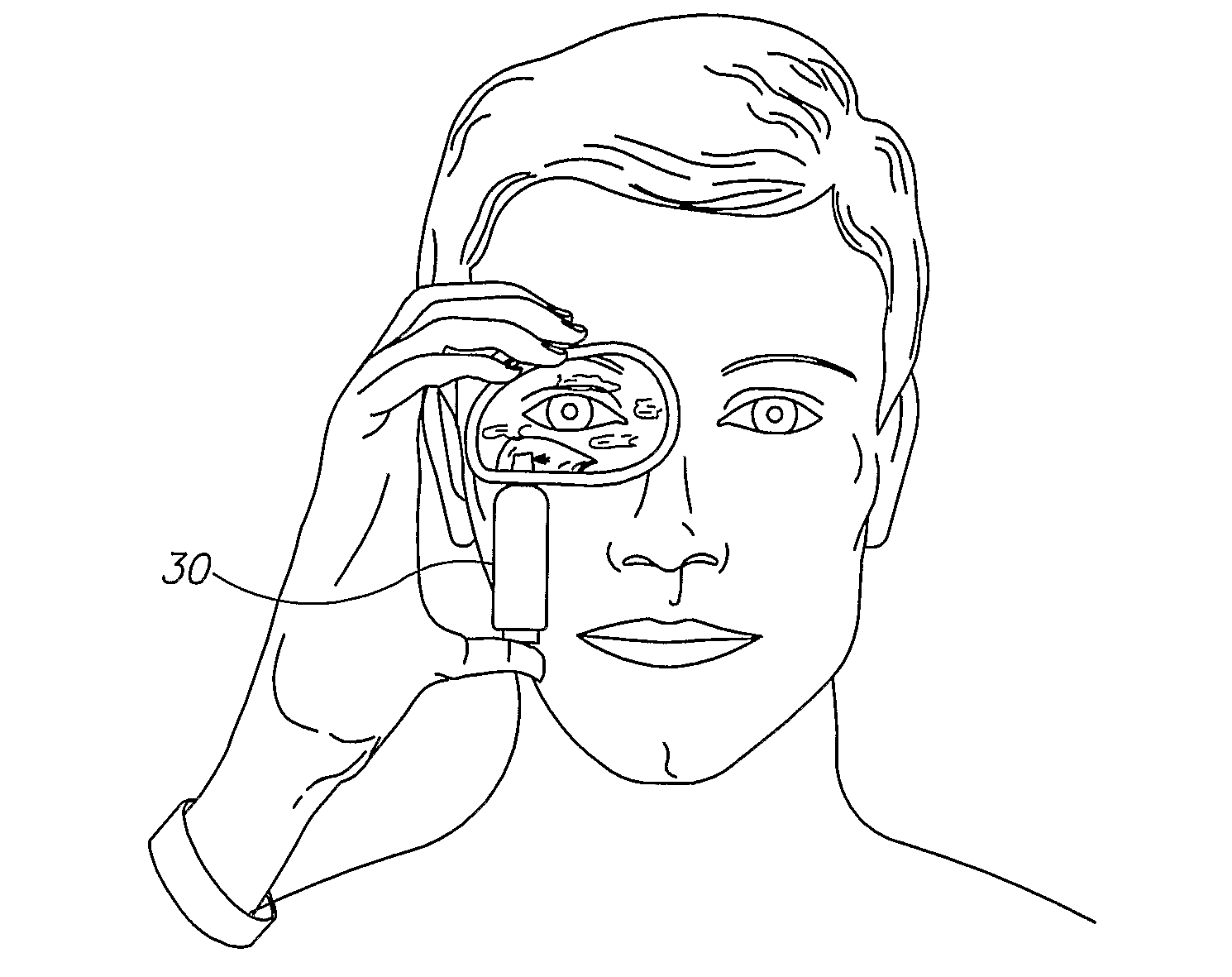

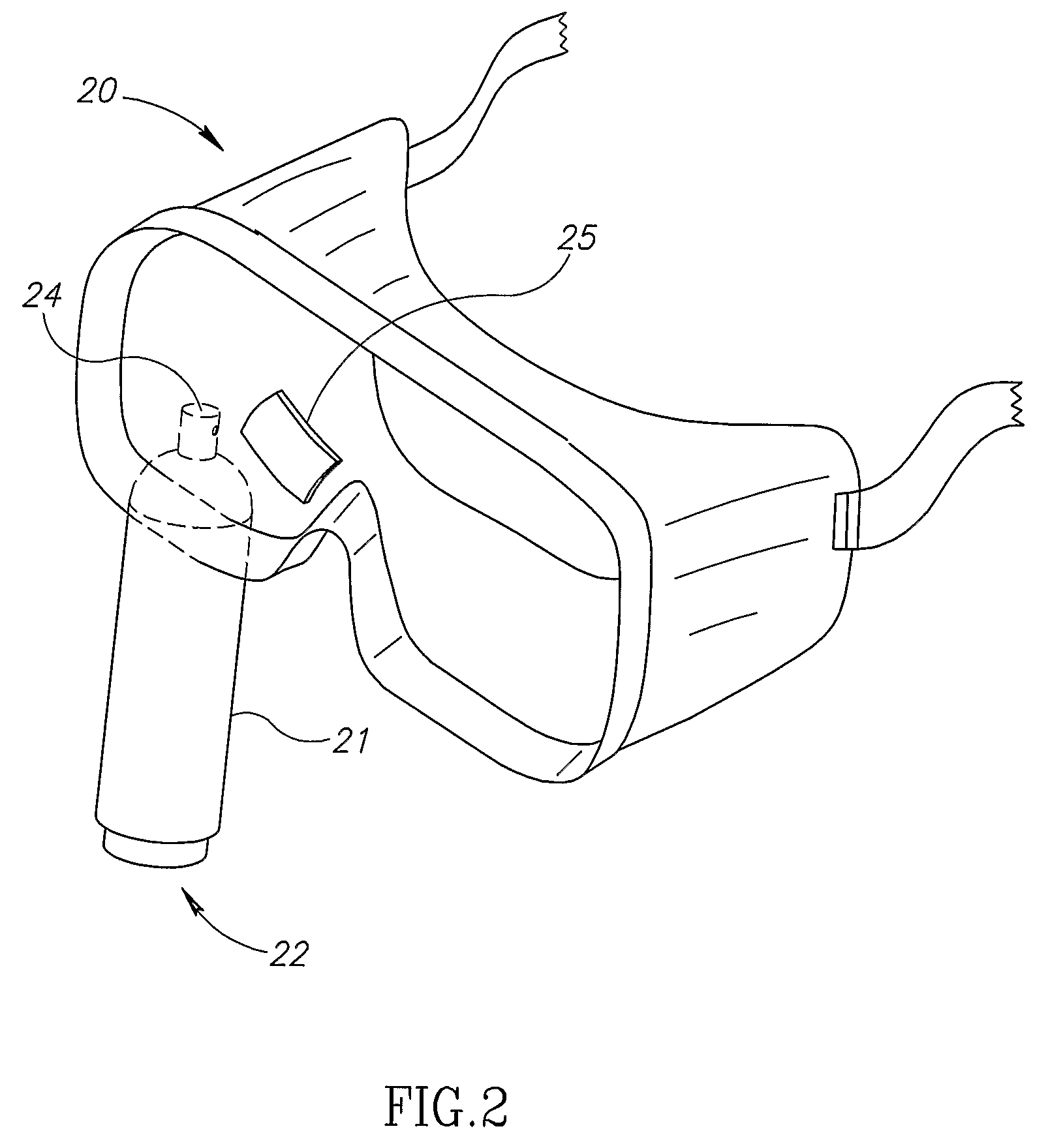

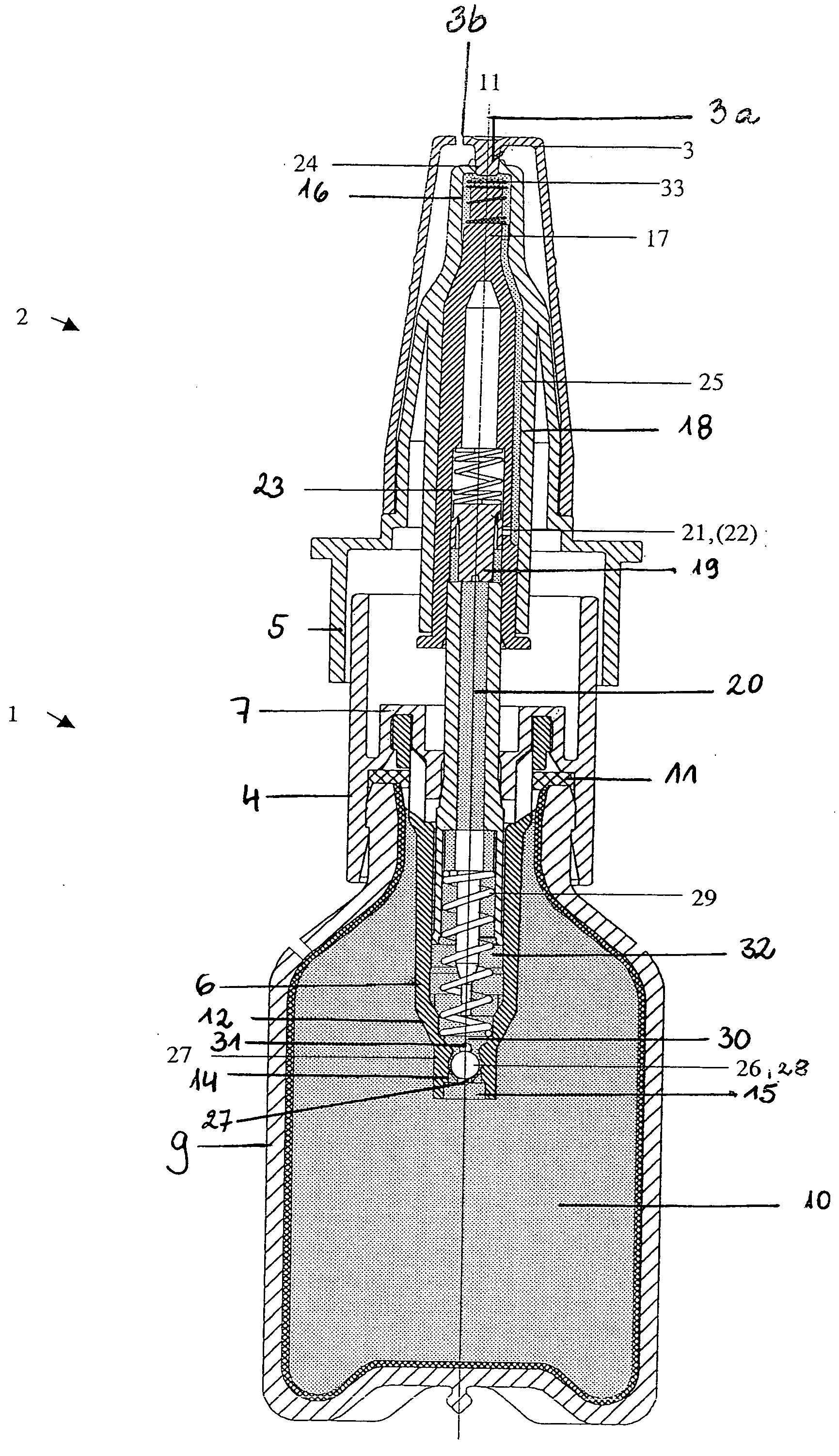

Eye medicament dispenser

InactiveUS20090182291A1Easy to keepReduced effectivenessGogglesBathing devicesPreservativeBiomedical engineering

A device for applying a medicament to the eye, consisting of a single or pair of eye goggles, into which is sprayed a fine mist or fog of the medicament. The medicament is contained in a canister attached to an aperture in the goggle or goggles, and the mist is generated either by the configuration of the outlet valve, or by means of a baffle disposed within the goggle volume opposite the outlet valve. The container may be a bag-on-valve type of device, with the aerosol propellant outside of the medicament bag, such that the medicament does not come into contact with the propellant. Alternatively, the container may be a metered-dose inhalator type of container operated by manual pressure. Because of the one-way flow operation, and the separation of propellant and medicament, formulation of the medicament with a potentially harmful preservative is not necessary.

Owner:EILAT ERAN

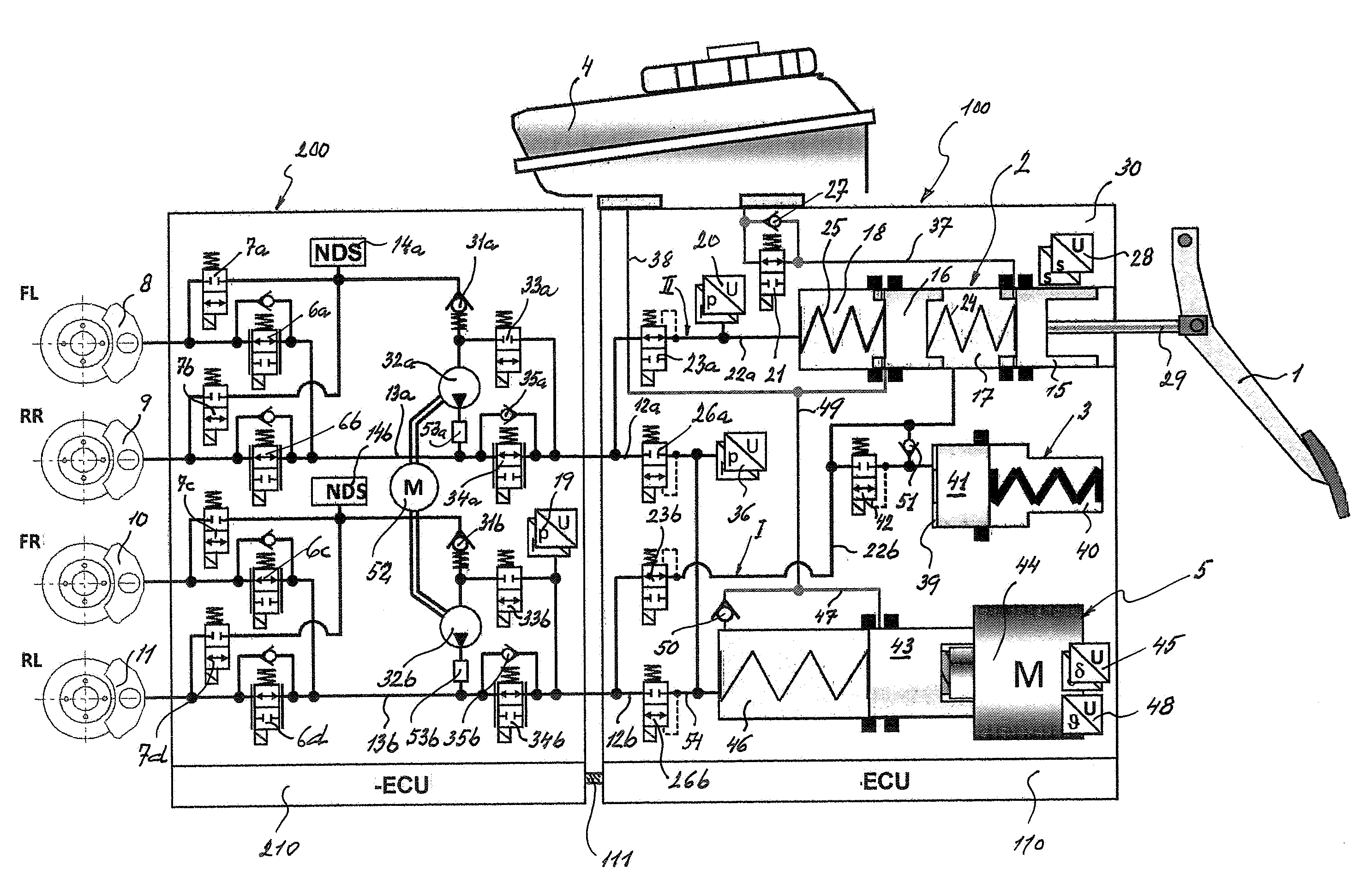

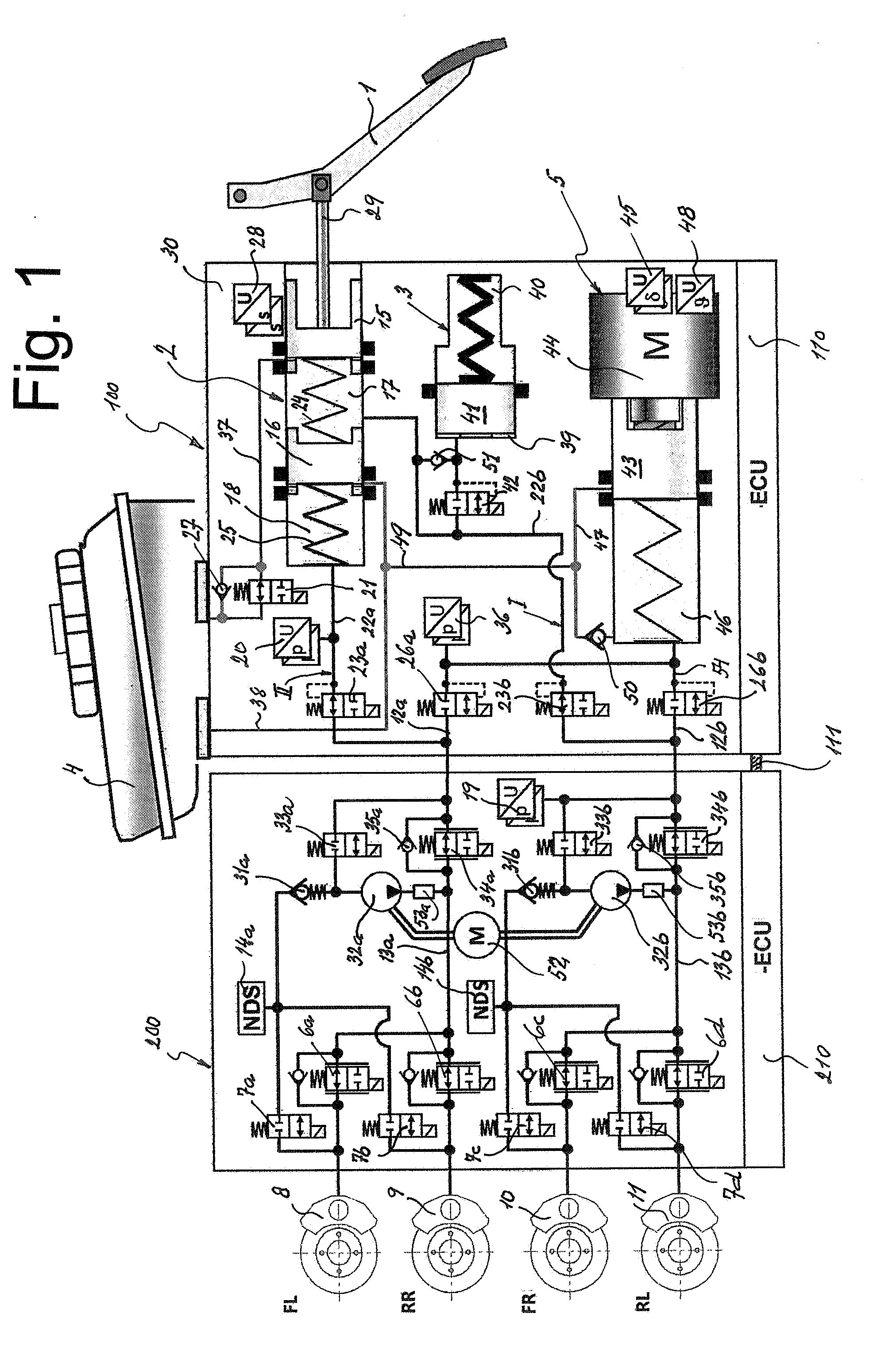

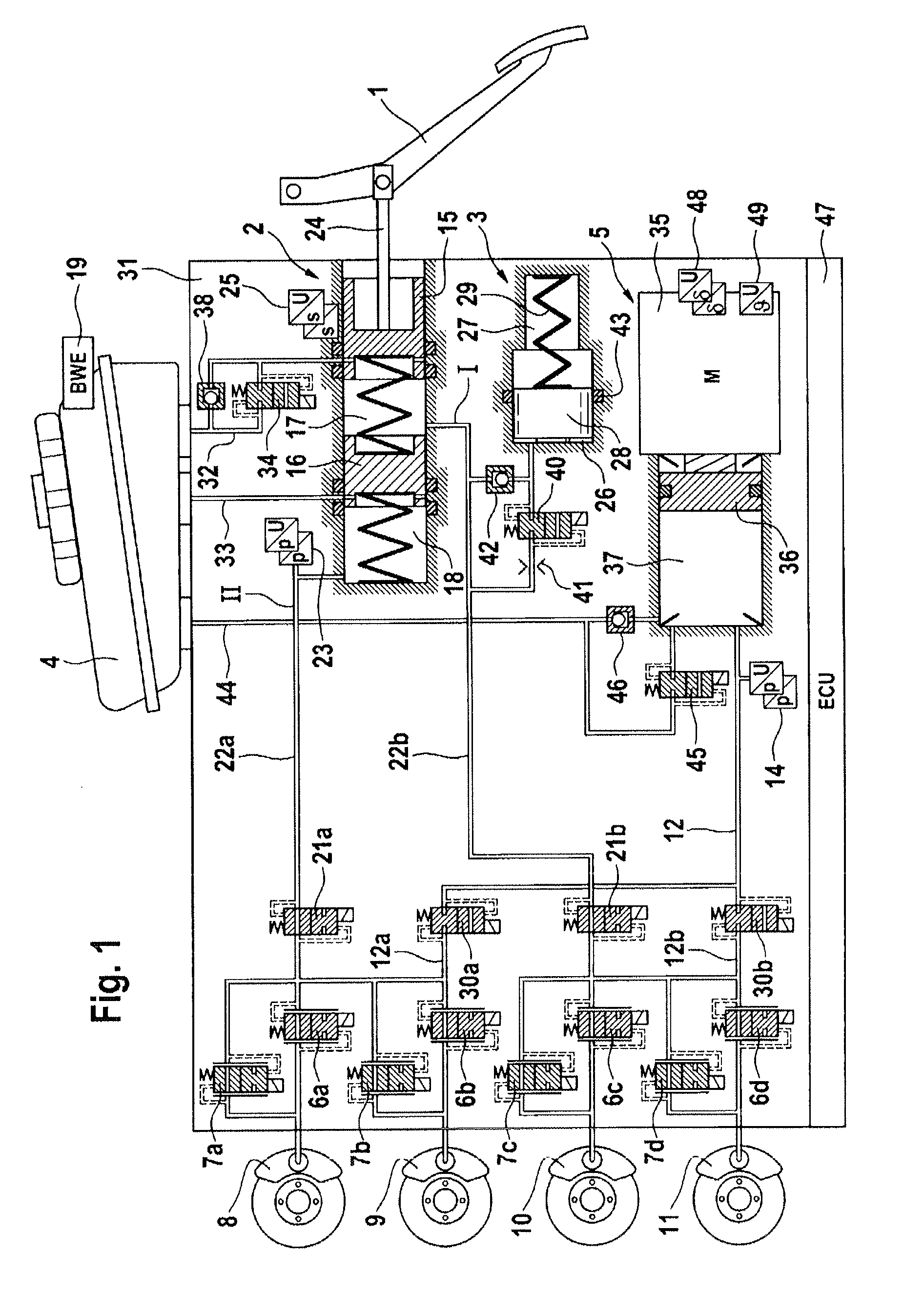

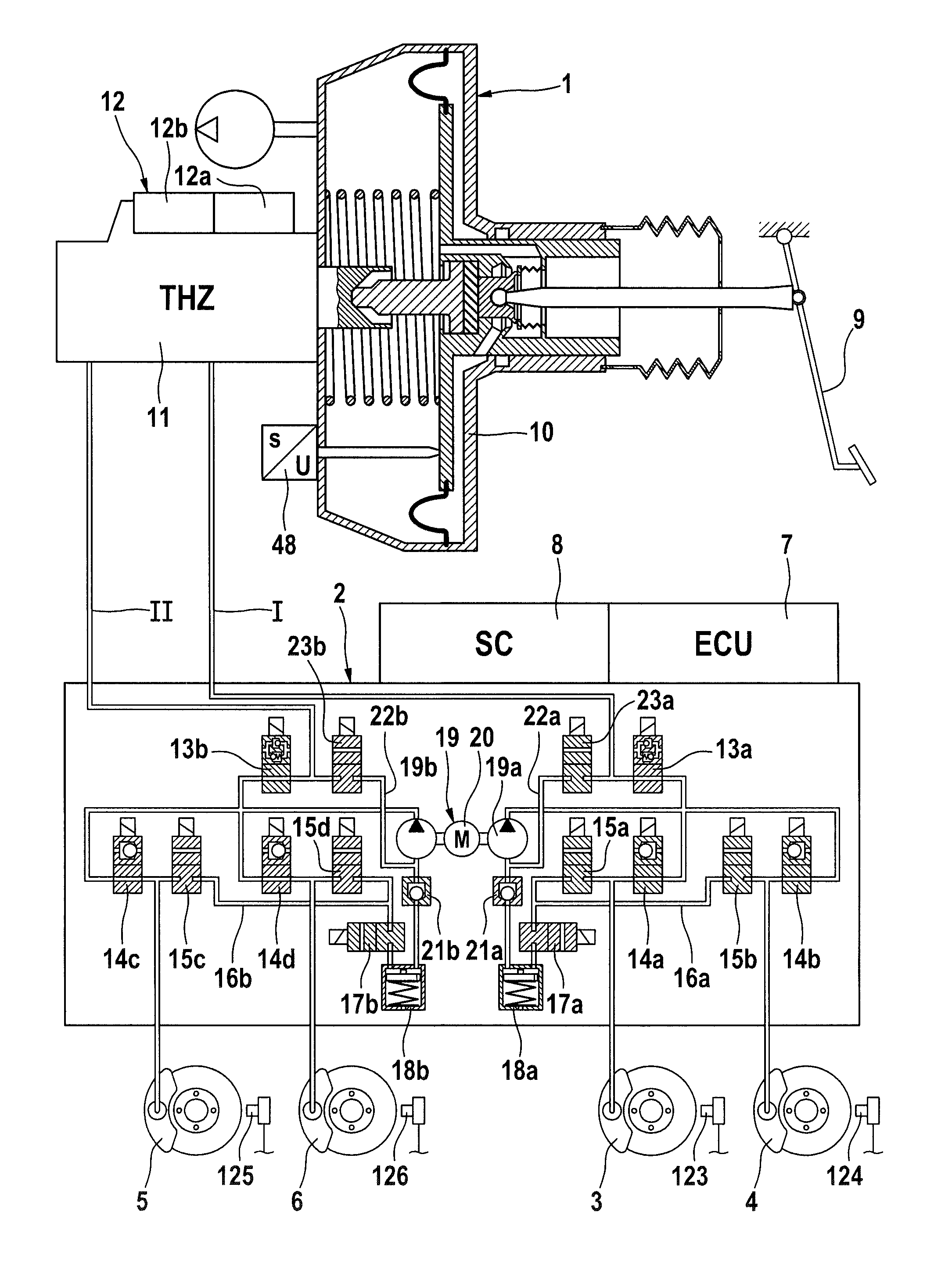

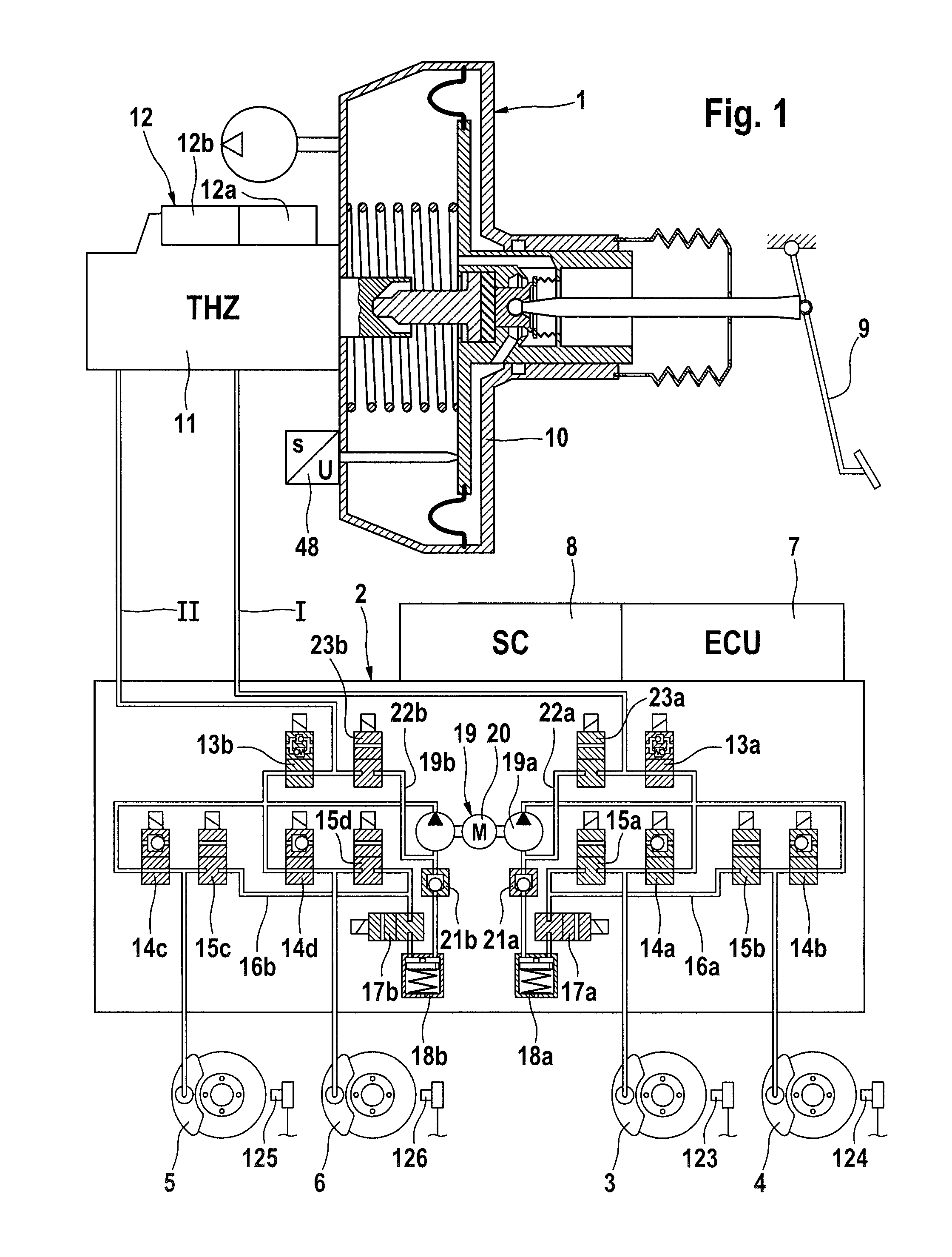

Brake System for Motor Vehicles

A motor vehicle brake system operable in a brake-by-wire and fallback modes. The system includes a brake pedal (1), a master cylinder (2), a reservoir (4), a travel simulator (3), an electrically controllable pressure source (5), isolation valves (23a, 23b) pumps (32a, 32b) and a low-pressure accumulator (14a, 14b), an inlet valve (6a-6d) and an outlet valve (7a-7d) for each wheel brake (8, 9, 10, 11), valves (34a, 34b; 134a, 134b) connected to the pumps (32a, 32b), and a control and regulation unit (110, 210). A valve arrangement (23a, 23b) establishes for each brake circuit (I, II) a connection from the pressure chamber (17, 18) of the master cylinder (2) to the modulator admission pressure line (13a, 13b; 113a, 113b) and disconnects the connection when unenergized, the valve arrangement (23a, 23b) preventing the pressure source (5) from being subjected to pressure from the pressure chambers (17, 18).

Owner:CONTINENTAL TEVES AG & CO OHG

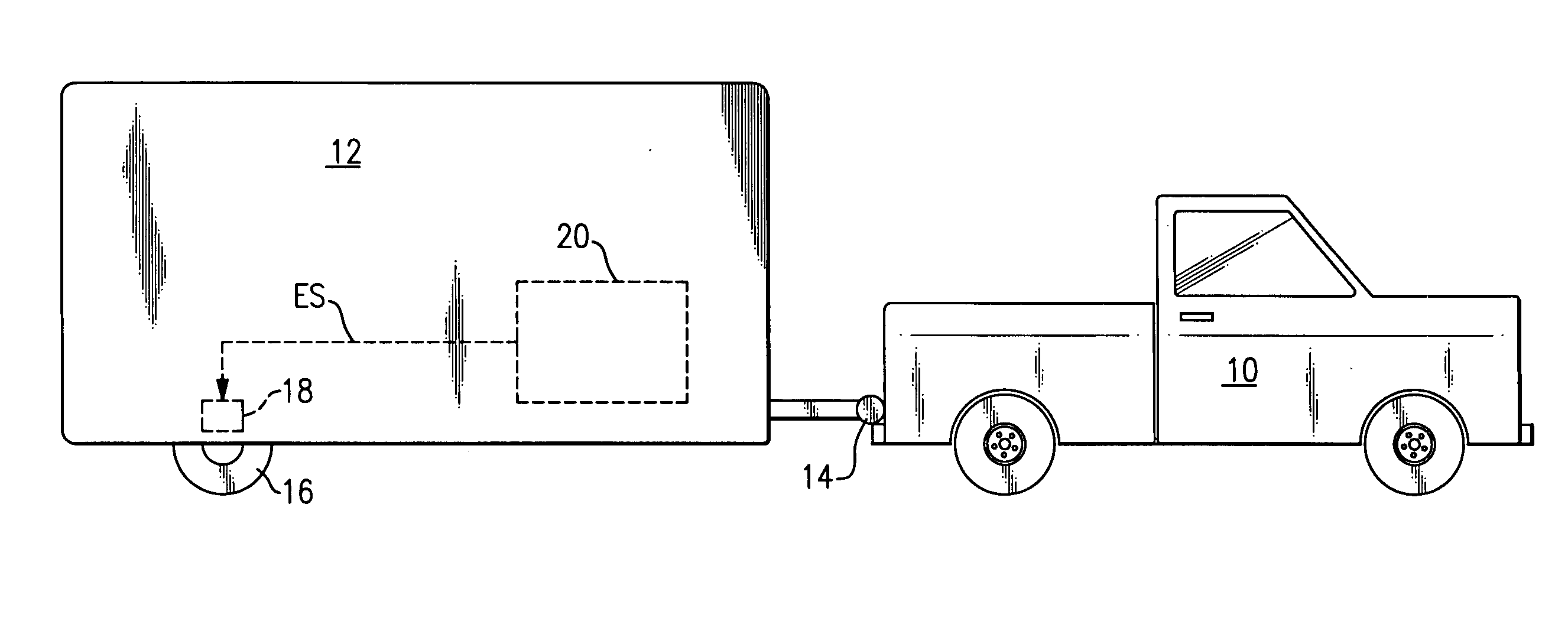

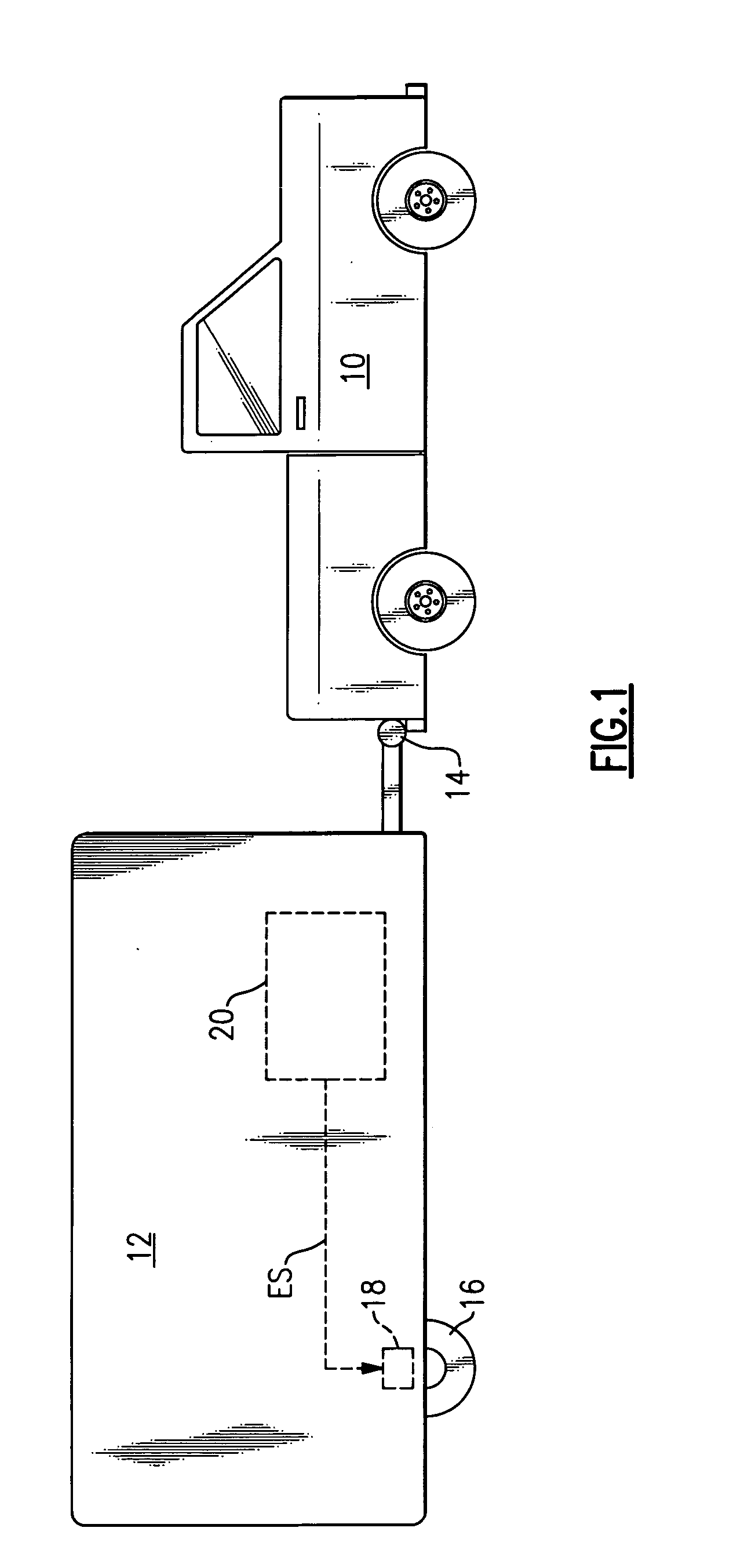

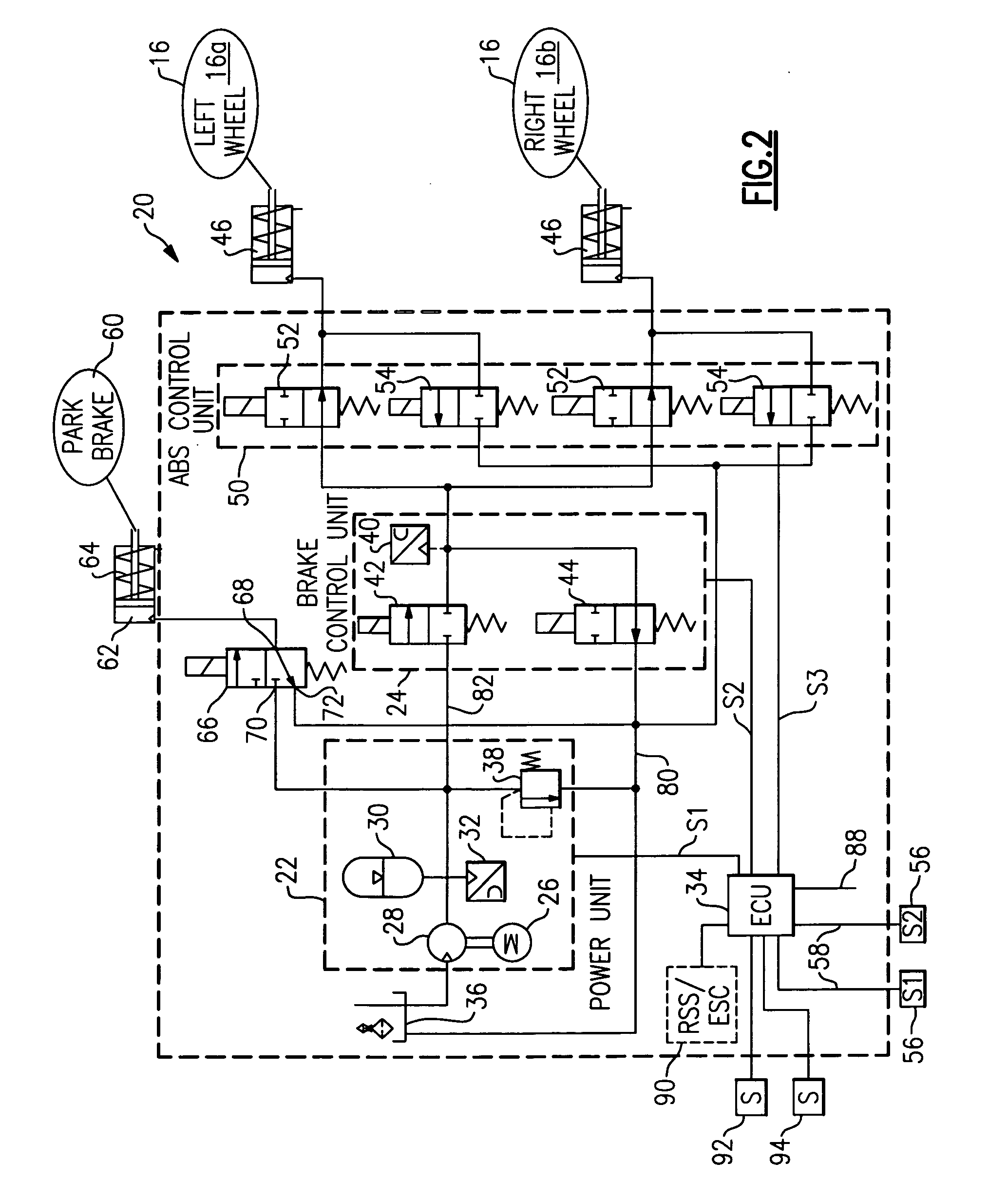

Hydraulic full power brake system for trailers

InactiveUS20070102996A1Prevents over-pressure conditionAvoid adjustmentBraking action transmissionAutomatic initiationsAutomotive engineeringPressure level

A trailer brake system includes a full power hydraulic brake system that is electrically controlled by a system control unit. The trailer brake system includes a power unit that maintains a pressurized supply of hydraulic fluid and a brake control unit that is fluidly connected between the power unit and trailer wheel brake components. The power unit includes an electric motor driven pump and accumulator that is in fluid communication with a trailer supply reservoir. The brake control unit includes an inlet valve that is fluidly connected to the accumulator and an outlet valve that is fluidly connected to the trailer supply reservoir. The system control unit generates control signals to the power unit and brake control unit to respectively maintain a desired pressure level in the accumulator, and to apply the trailer wheel brake components through the brake control unit.

Owner:MERITOR WABCO VEHICLE CONTROL SYST

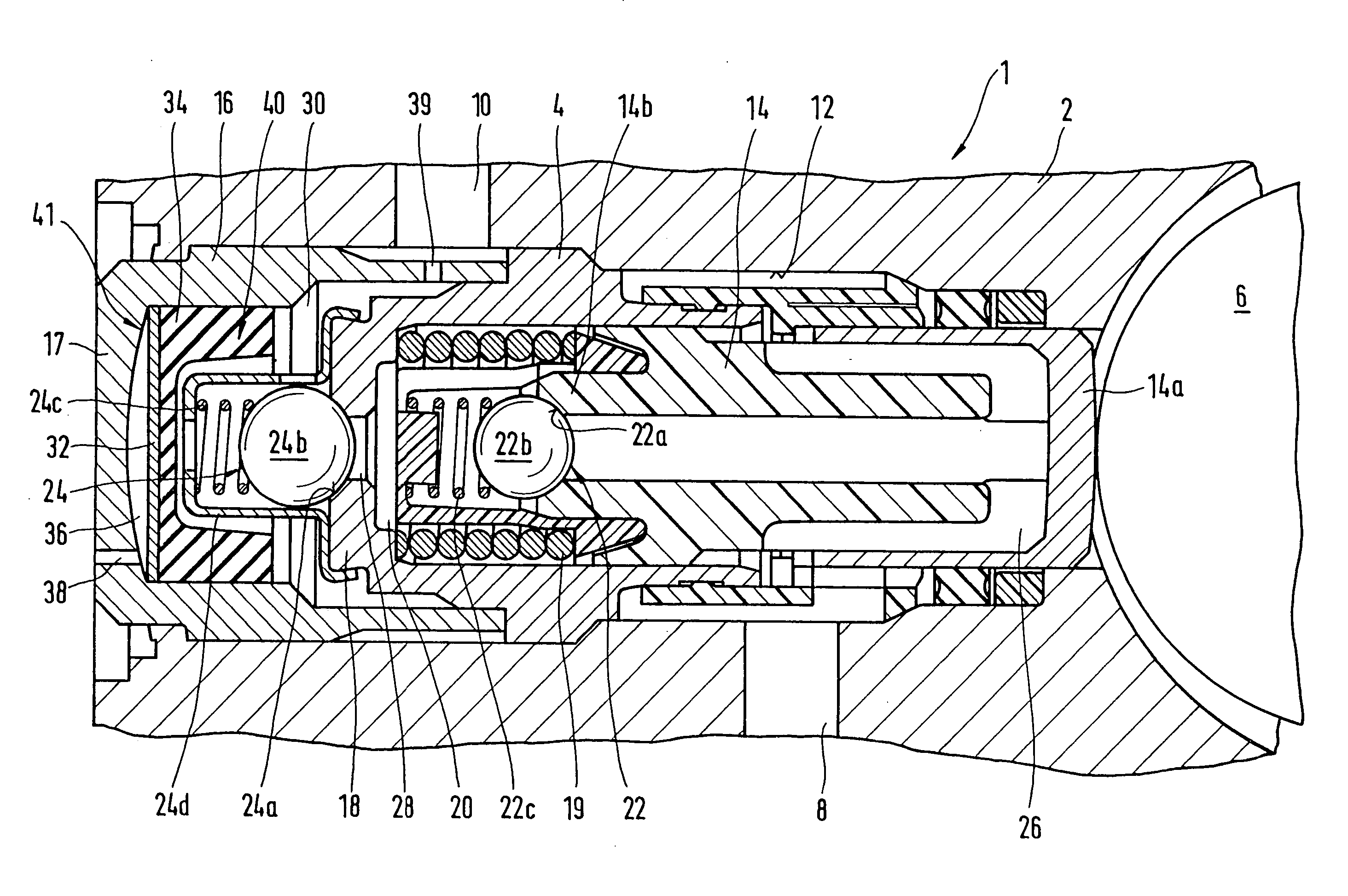

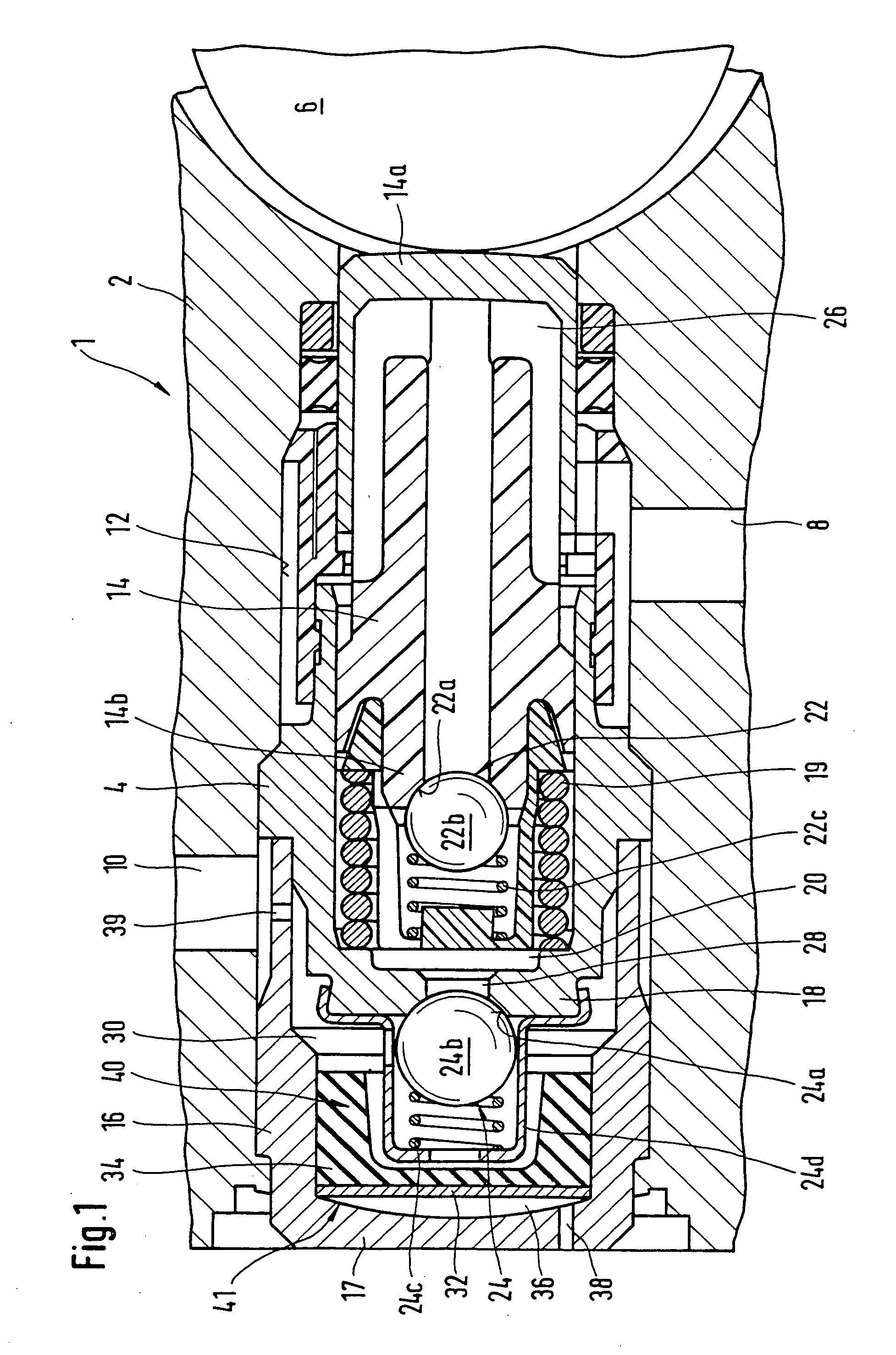

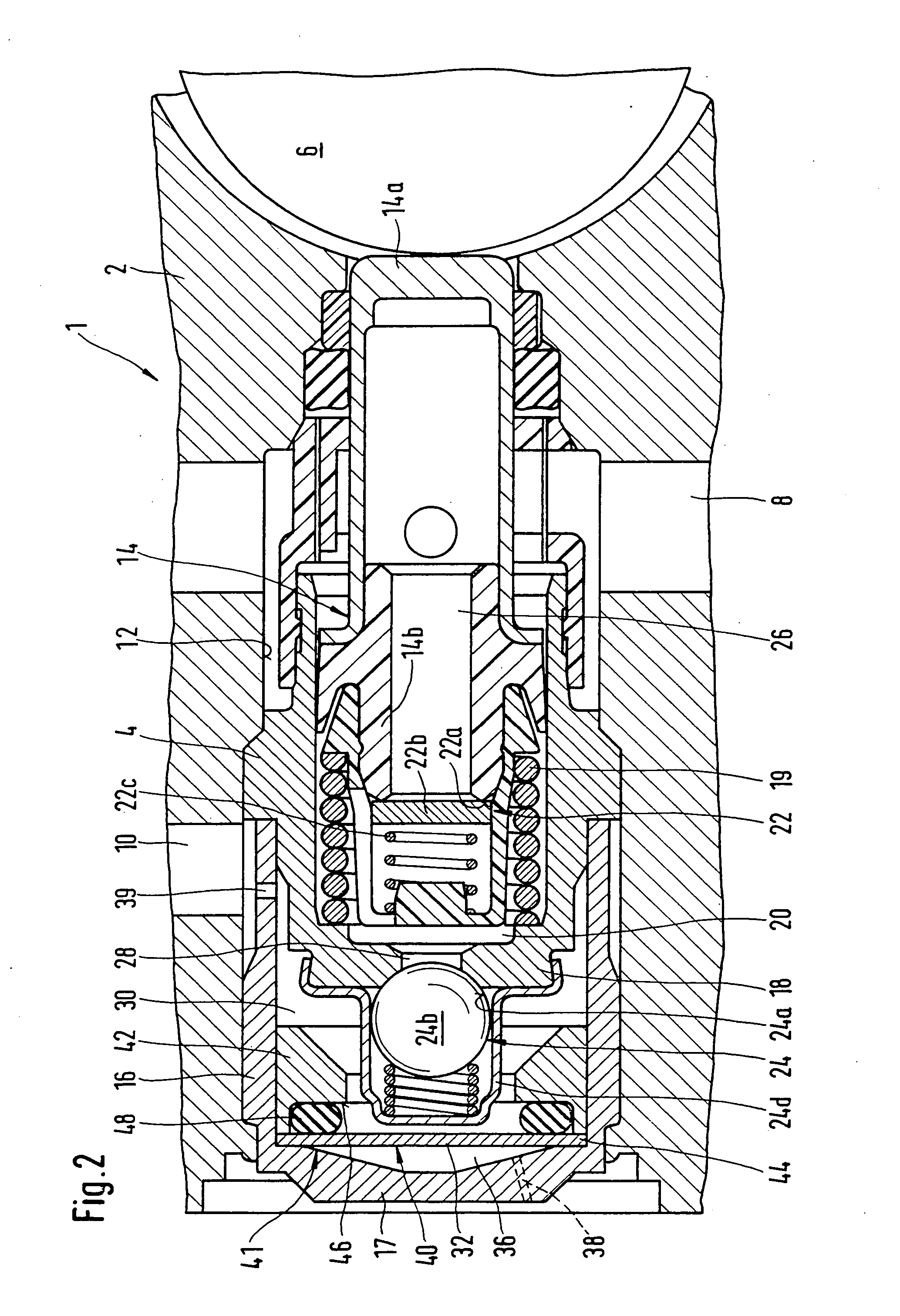

Piston pump

InactiveUS20040166004A1Improve effectivenessImprove efficiencyPositive displacement pump componentsPipe elementsMobile vehicleControl theory

In piston pumps for brake systems used until now, there were often noise problems, from pressure pulsations. In the piston pump for brake systems proposed here, a pulsation-smoothing device (40) that functions effectively well is provided in the region of the outlet valve (24). As a result, substantially less noise occurs, and the durability of the piston pump (1) is substantially better. The piston pump is used essentially in traction-controlled motor vehicle brake systems.

Owner:ROBERT BOSCH GMBH

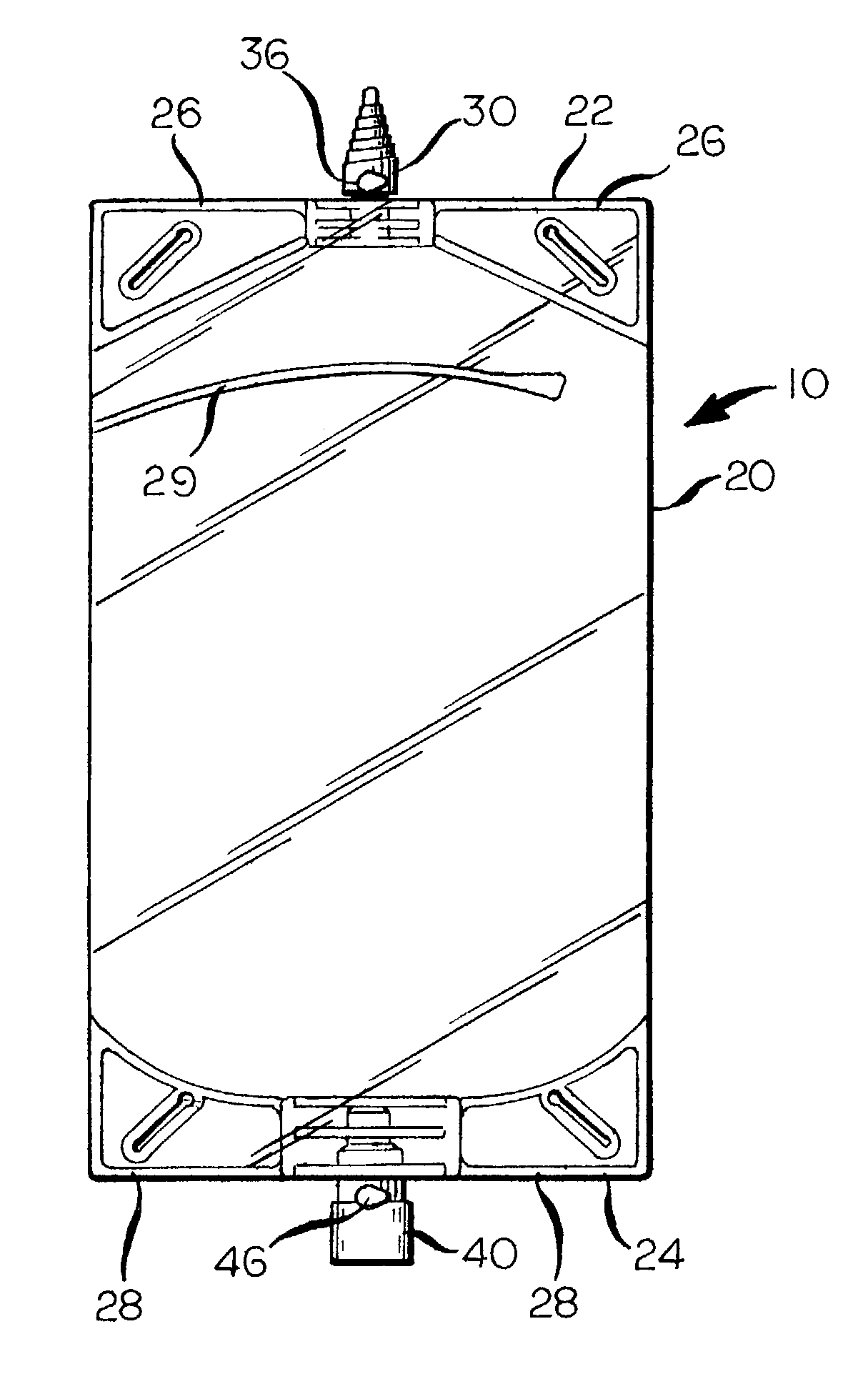

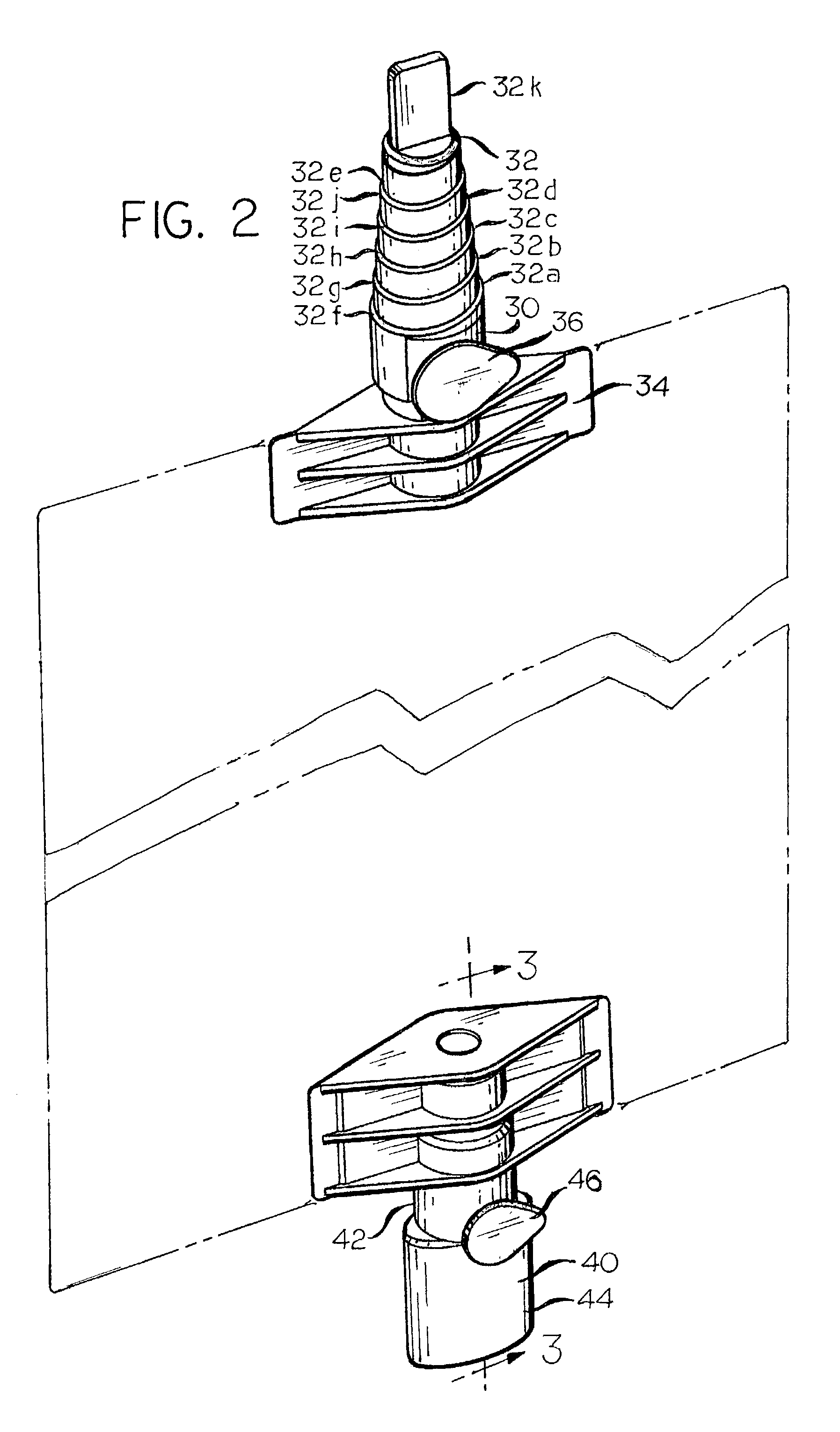

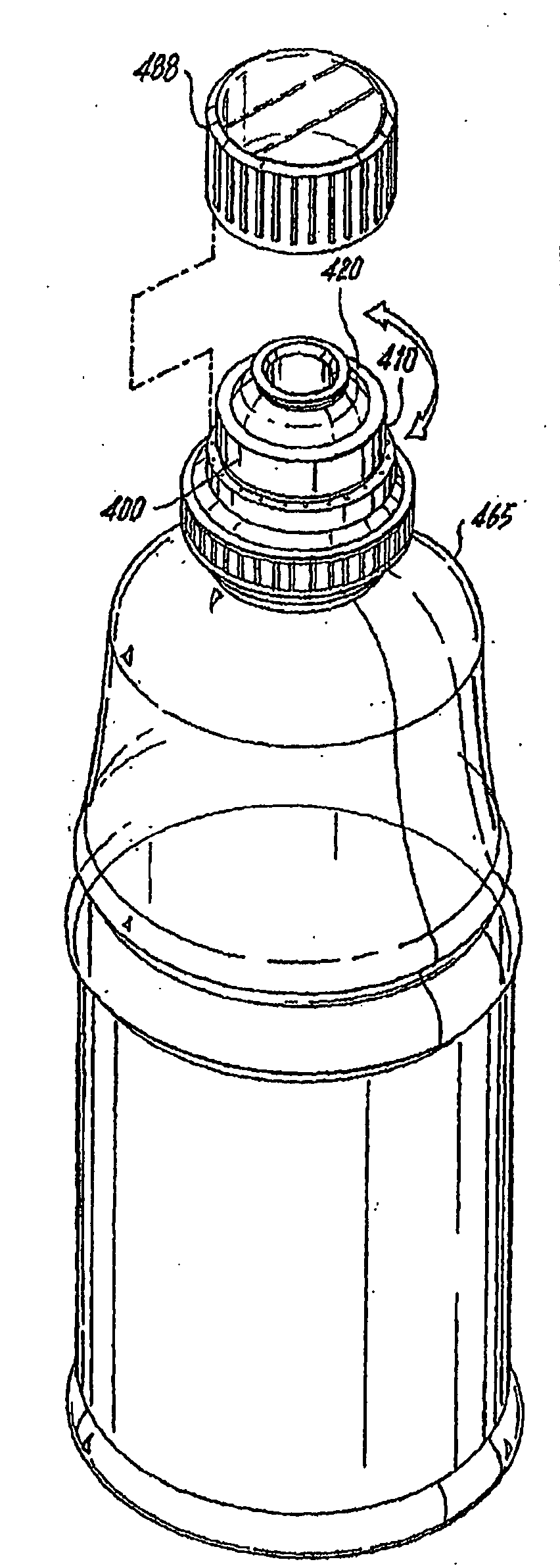

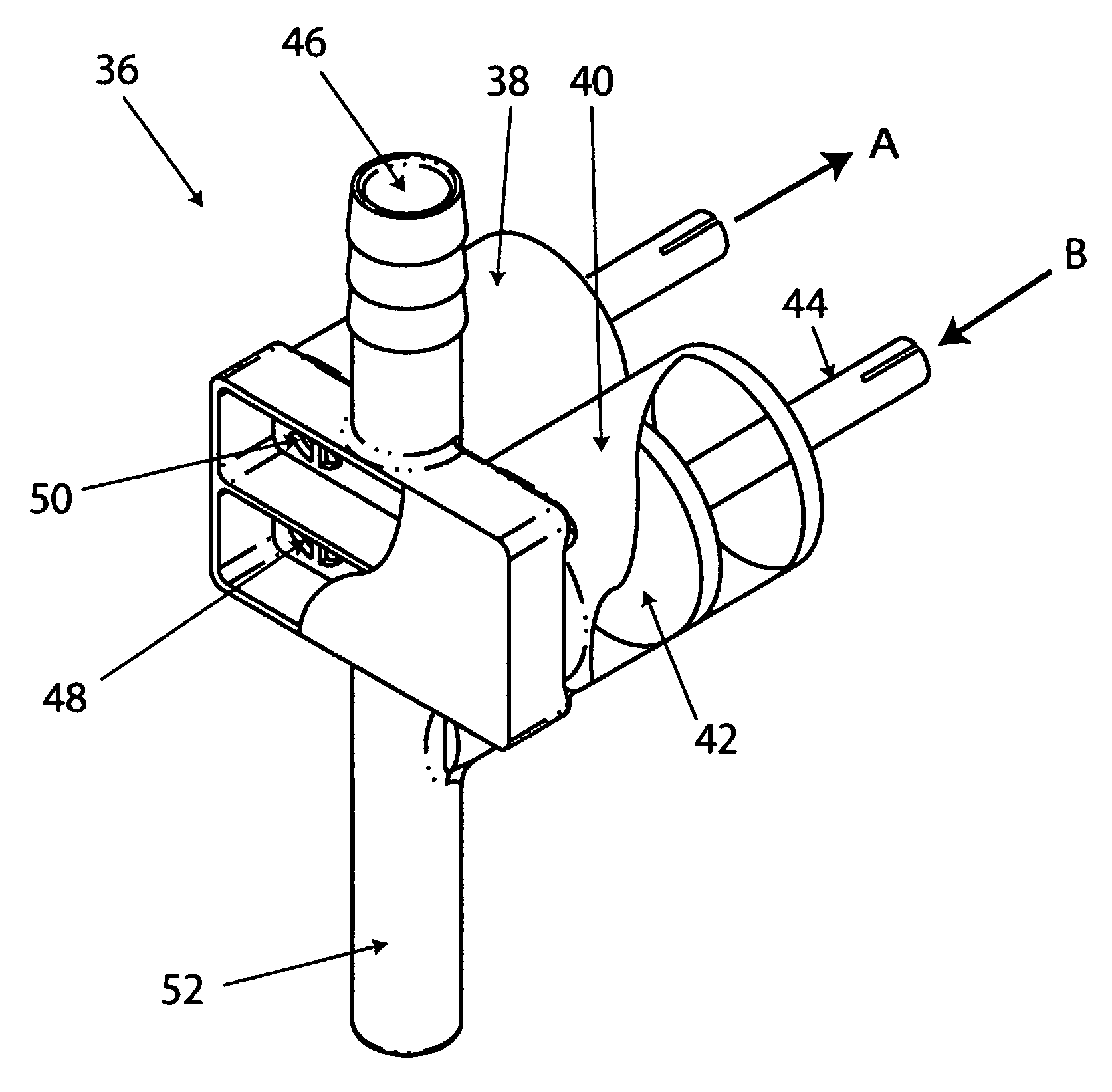

Urine collection method and apparatus

InactiveUS7008407B1Easy constructionPrevent backflowSuction devicesBodily discharge devicesUrine collection deviceCheck valve

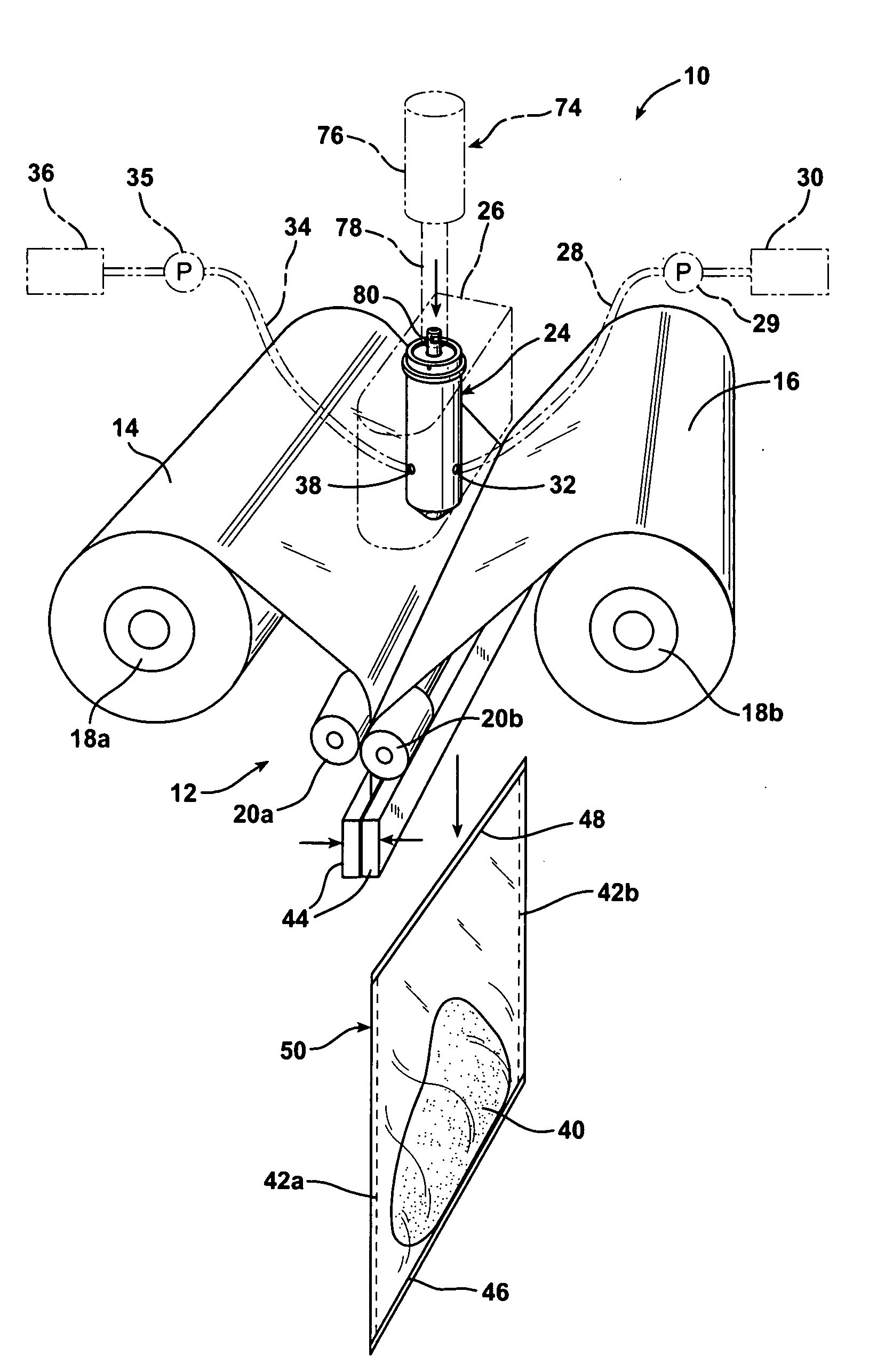

A urine collection device (10) that is made up of a flexible, thermoplastic urine collection bag (20), which receives urine through a molded plastic inlet fitment (30) that is secured to an upper end of the bag 5 and discharges urine through a two-piece molded plastic valve fitment (40) at a lower end of the bag. The inlet fitment, which has no check valve therein, has a series of steps gradually reducing lateral extent as it extends longitudinally from the bag to a free end thereof, and each of the steps extends at a non-perpendicular angle to the longitudinal central axis of the inlet fitment. The bag is also free of any check or flutter valve. The outlet valve fitment has a fixed outer element (42) surrounding an inner element (44) that is rotatable with respect to the outer element to selectively open or close the outlet valve fitment to flow.

Owner:REXAM HEALTHCARE PACKAGING +1

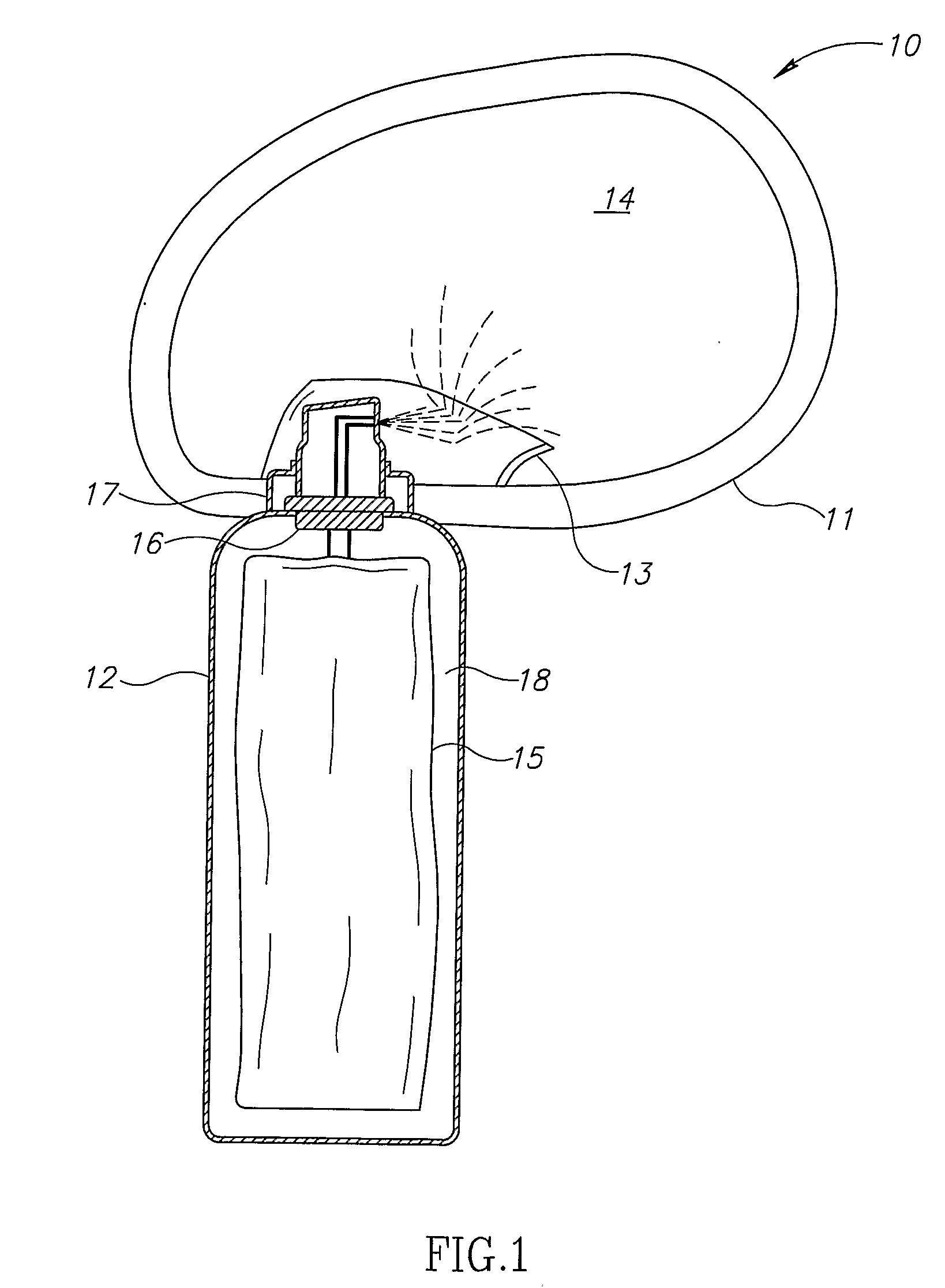

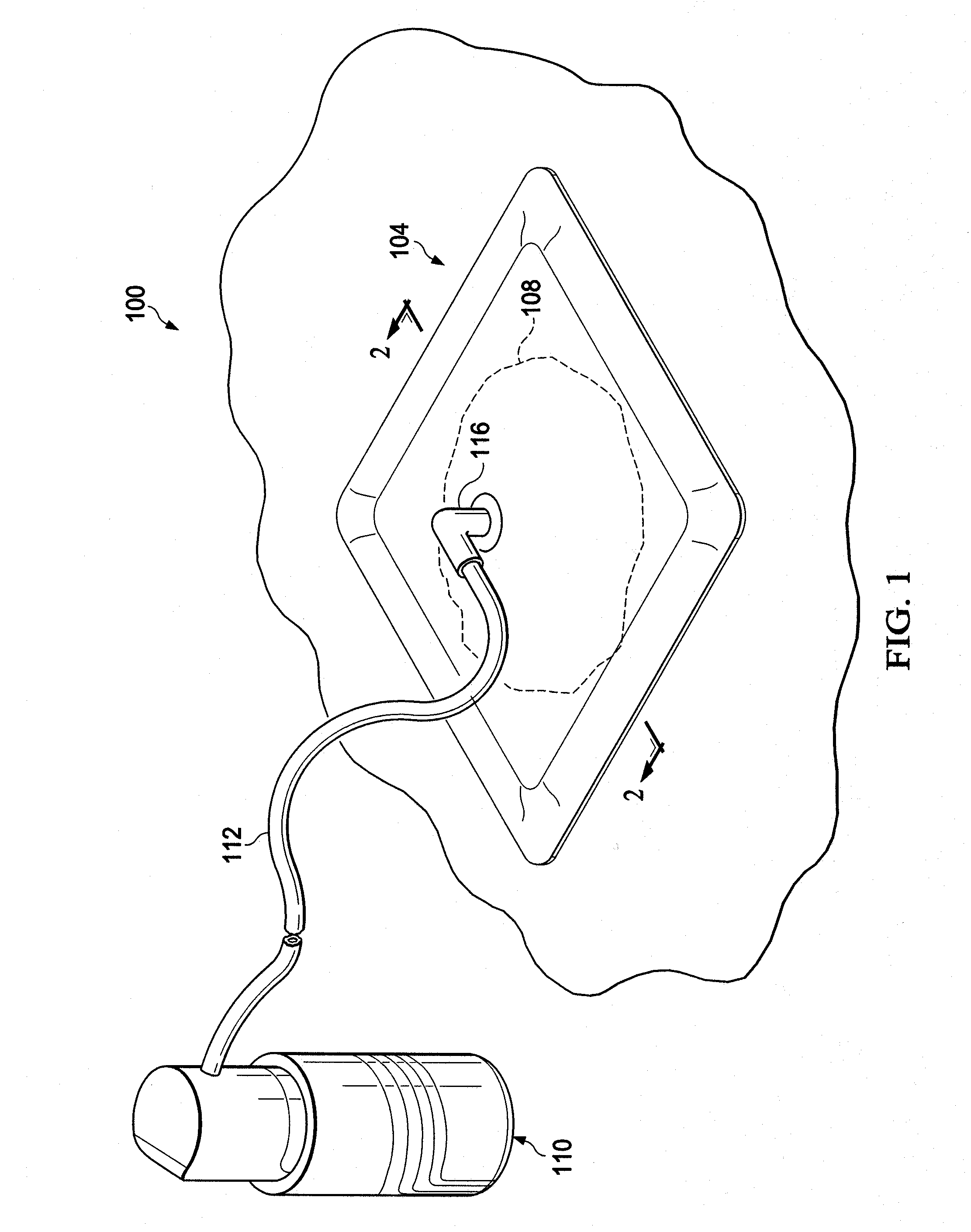

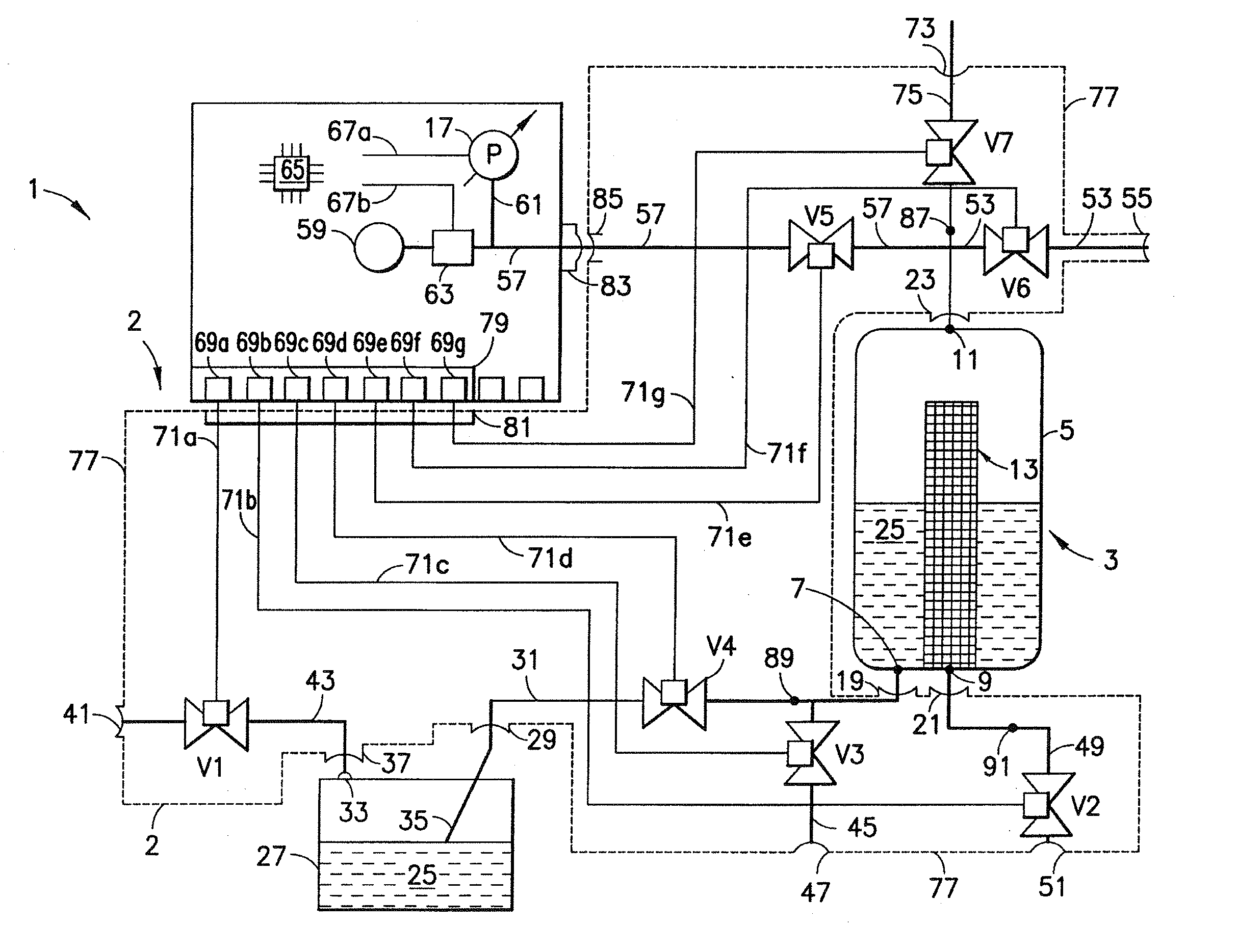

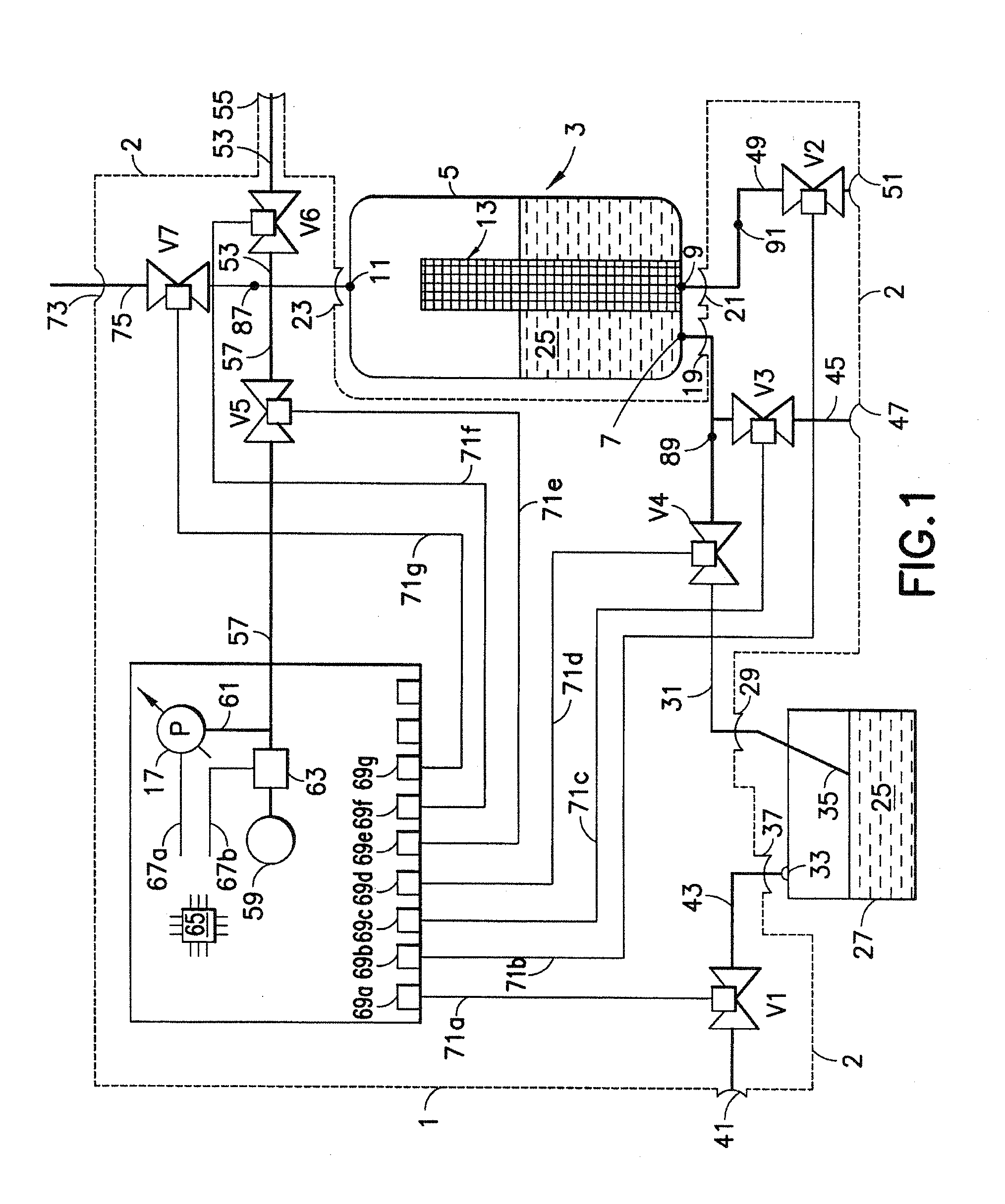

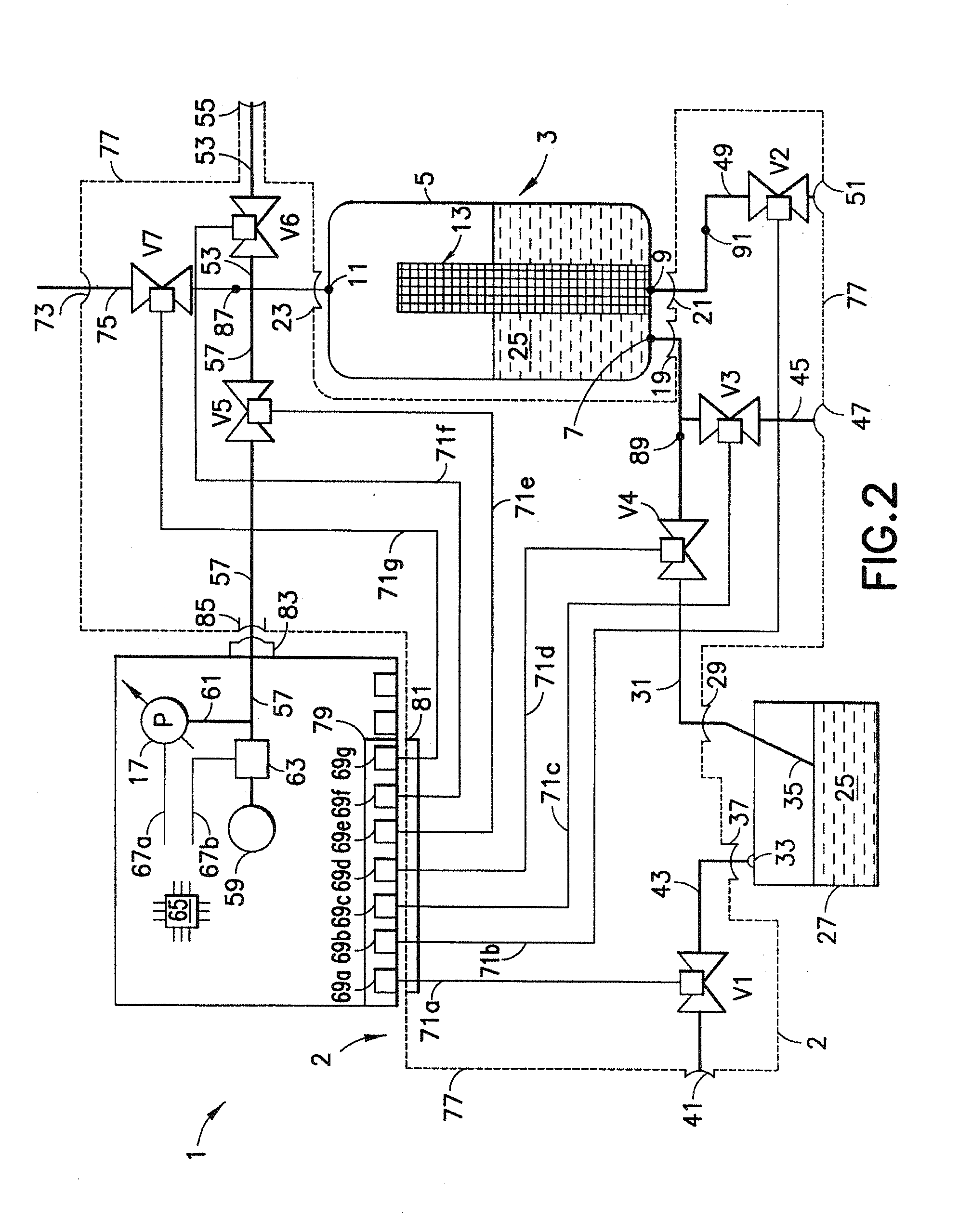

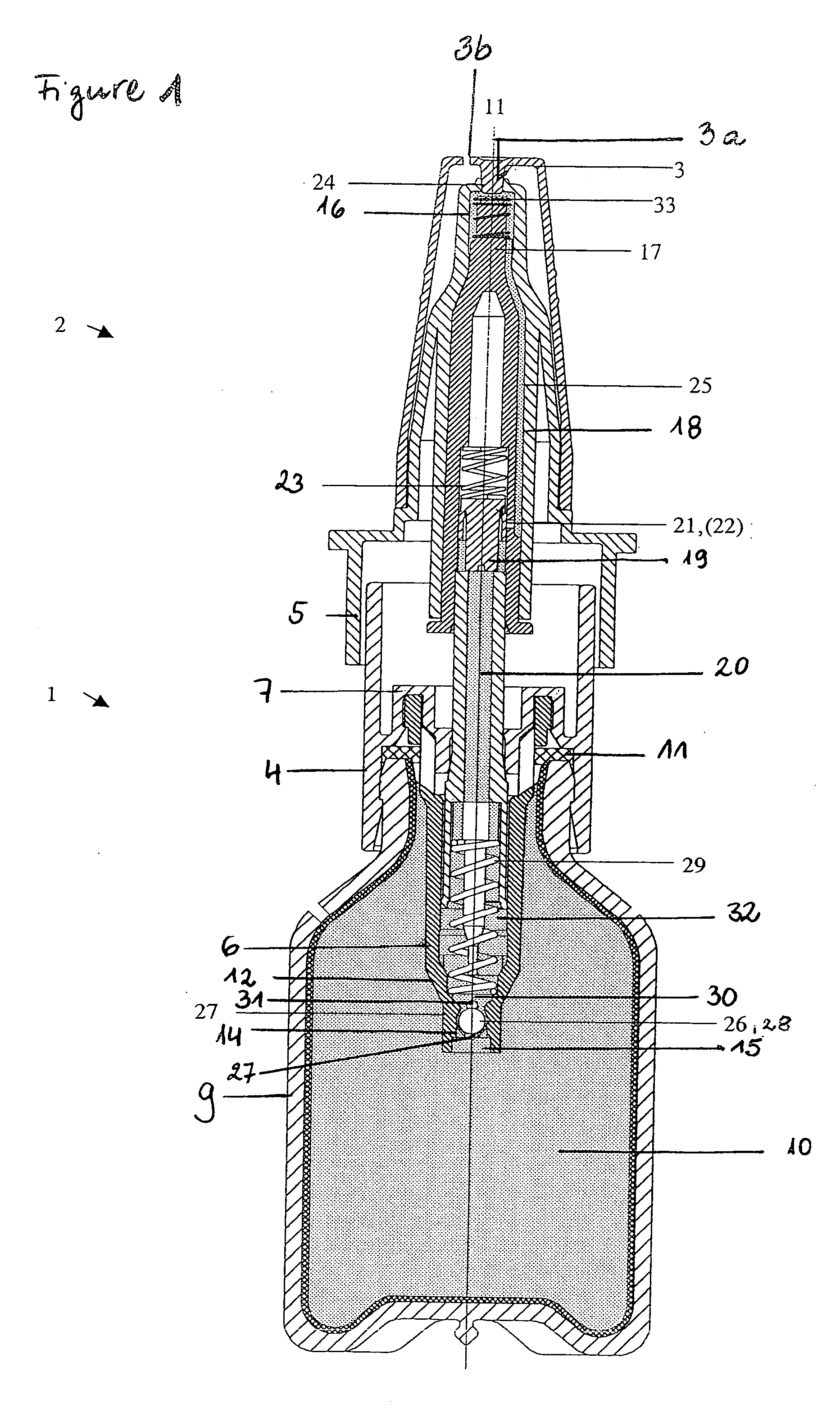

Manually powered, regulated, negative pressure pump with adapter for external pressure source

ActiveUS20150018784A1Reduce pressureAvoid chargingMedical devicesIntravenous devicesAmbient pressureMechanical engineering

A manually-actuated pump for applying reduced-pressure therapy includes a charging chamber and a regulated chamber. The charging chamber has a closed end. A regulator passage extends between the charging chamber and the regulated chamber, and a valve body is adapted to control fluid communication through the regulator passage. A regulator spring is engaged with the valve body to bias the valve body against a differential between a pressure in the regulated chamber and an ambient pressure. The manually-actuated pump also includes an outlet port coupled to the regulated chamber; and a valve assembly coupled to the charging chamber to permit fluid flow through the closed end of the charging chamber.

Owner:3M INNOVATIVE PROPERTIES CO

Filter device test apparatus, filter integrity testing method and computer program product

ActiveUS20120059603A1Reduce probabilityEasy to operateSemi-permeable membranesDispersed particle filtrationExhaust valveDraining tube

An apparatus automatically carries out an integrity test on a filter device having a fluid inlet, a fluid outlet and a venting port. The apparatus includes a filter integrity testing device having a pressure sensor and / or a flowmeter. An inlet connector is connectable to the fluid inlet, is connected via a wetting liquid supply valve to a wetting liquid supply, and is connected via a drainage valve to a first drain. An outlet connector is connectable to the fluid outlet and via an outlet valve to the first or a second drain. A venting port connector is connectable to the venting port and via a measurement valve to the pressure sensor and / or flowmeter. The venting port connector also is connected via a venting valve to a venting pipe, and via a measurement gas valve to a measurement gas source. The valves are controlled by the filter integrity testing device.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Airless dispensing pump with tamper evidence features

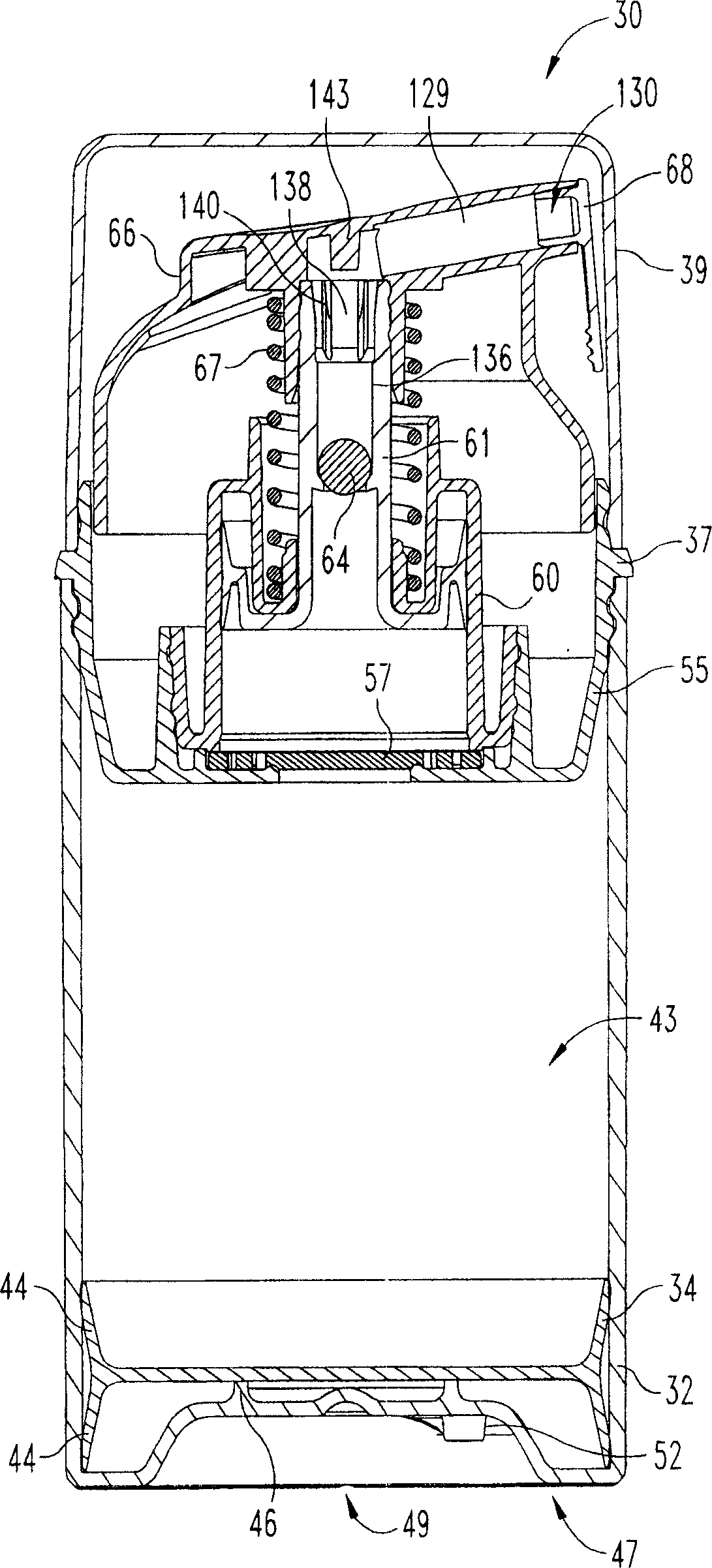

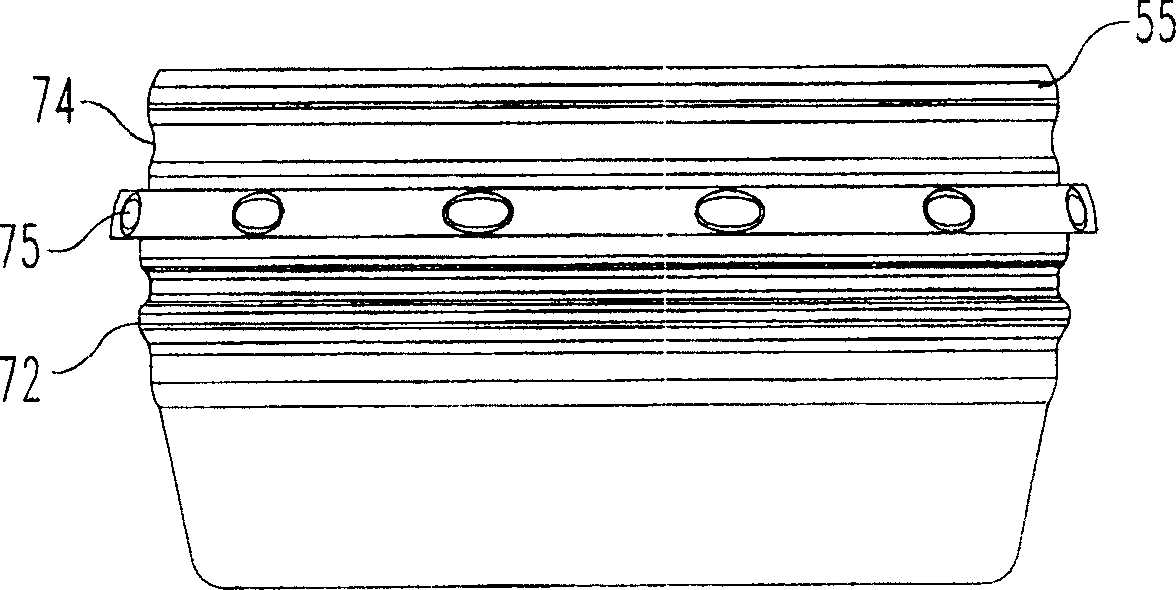

An airless dispenser pump assembly (30) includes a pump mechanism with an inlet valve (57) that is configured to efficiency pump viscous fluids and that is able to be pre-primed when the pump mechanism is attached to a container. In one form, the inlet valve includes a seal member that seals an inlet port of the pump and an outer support member that secures the inlet valve to the rest of the pump mechanism. Two or more legs (88) generally extend in a circumferential direction between the support member and the seal member in order to create a large flow opening for fluid flow through the inlet valve when opened and to rapidly dose the inlet valve. The pump mechanism further includes an outlet valve (64) that is configured to draw fluid back from a nozzle of the pump after dispensing in order to minimize build up around the nozzle.

Owner:RIEKE

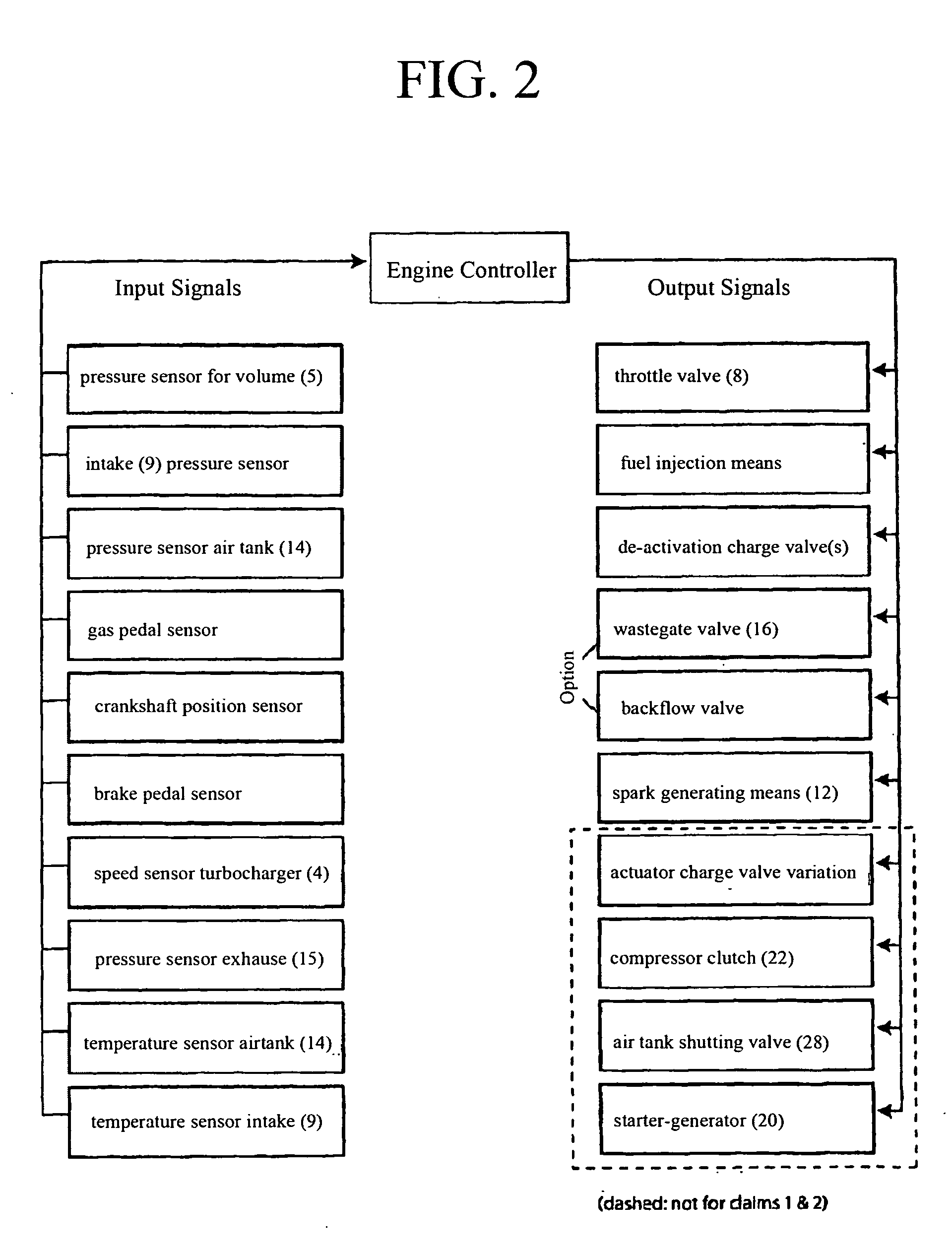

Turbocharged reciprocating piston engine having a connected pressure tank for bridging turbo lag, and method for operating said engine

InactiveUS20120186249A1Decrease in cubic capacityReduce capacityElectrical controlInternal combustion piston enginesCombustion chamberTurbocharger

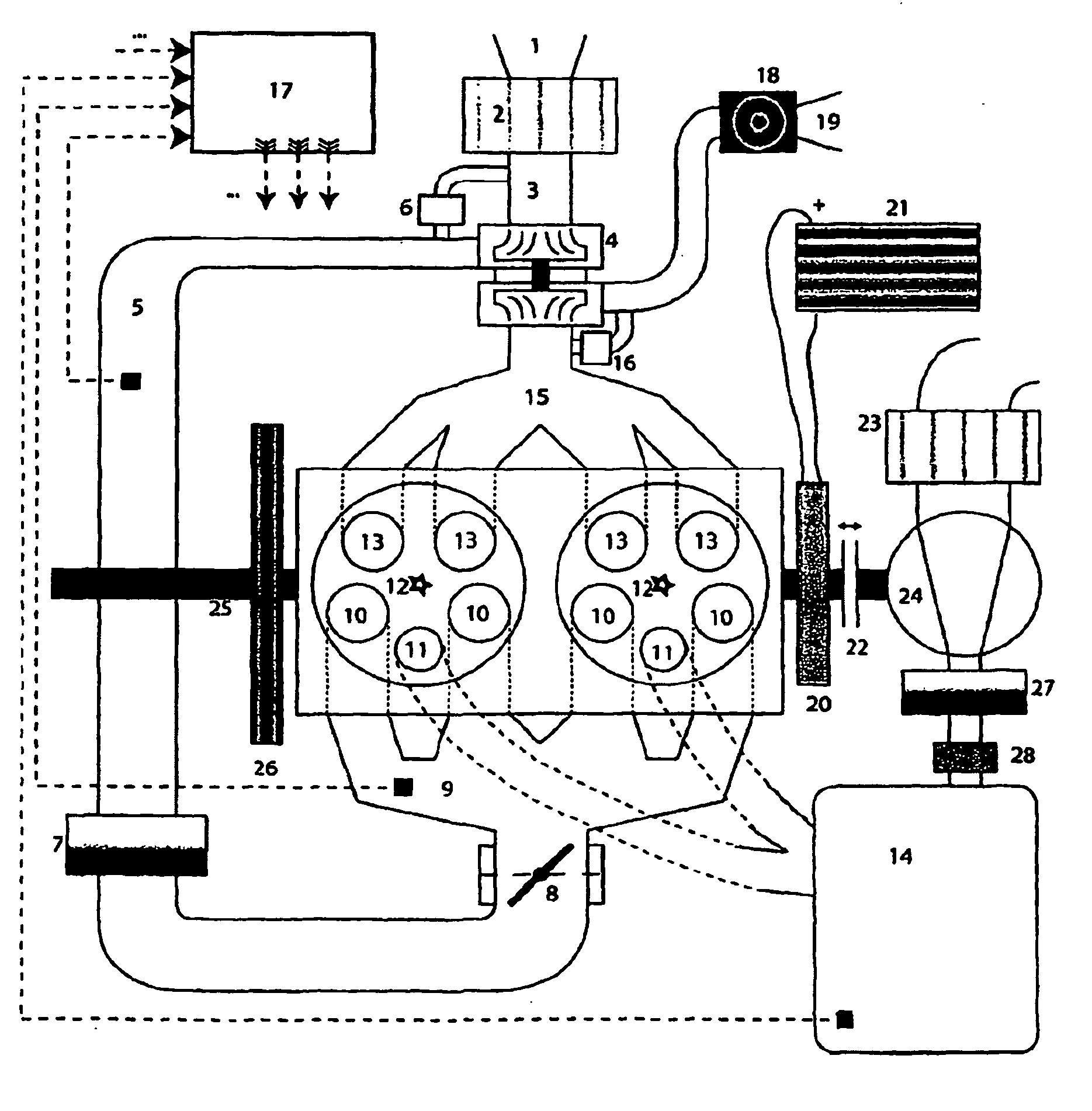

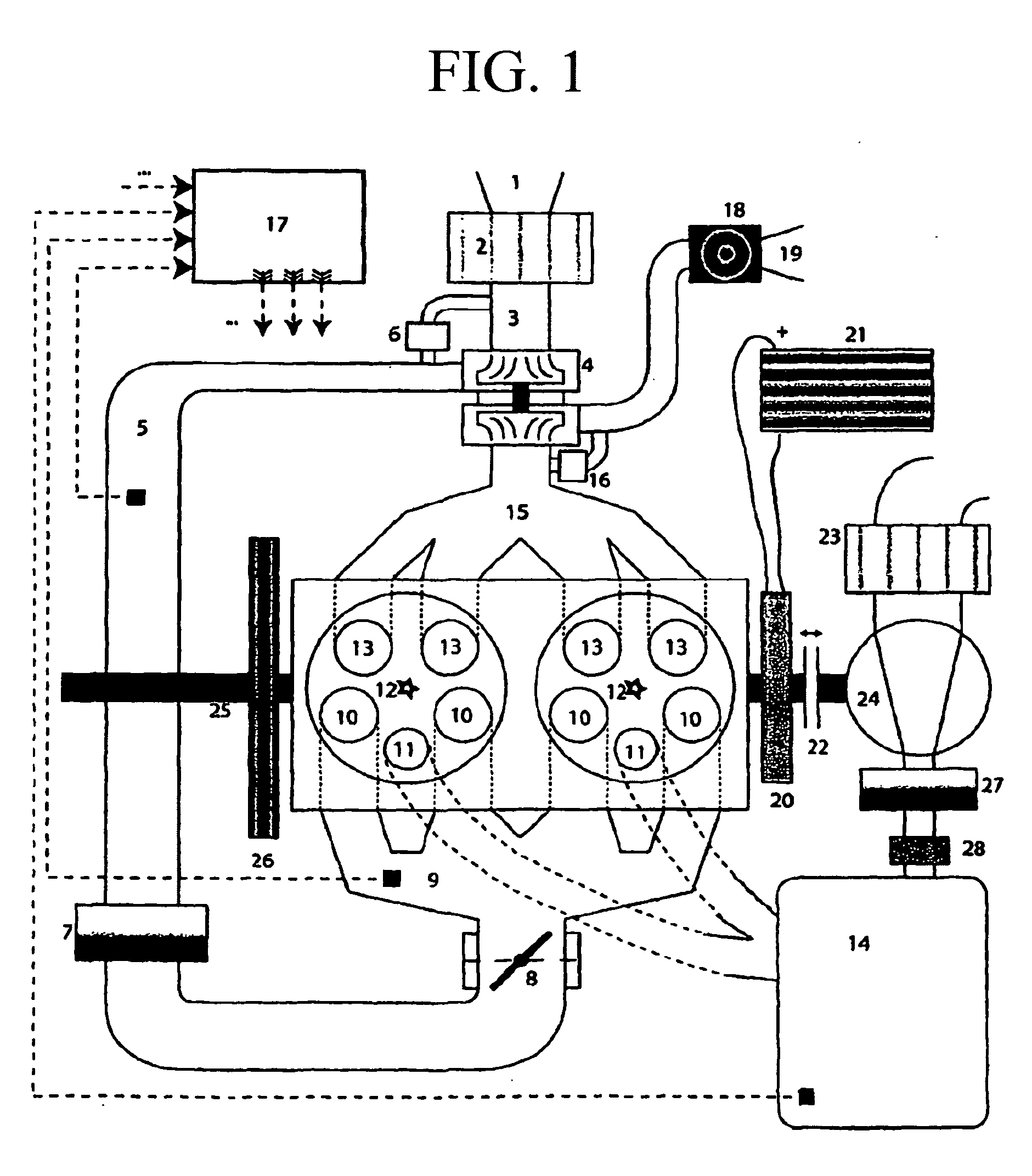

The present invention relates to a turbo-charged reciprocating piston engine having a combustion chamber, and to a method for operating said engine. The combustion chamber has at least one inlet valve (10), one outlet valve (13) and at least one additional charging valve (11), for the additional feed of compressed air to bridge the turbo lag. All the valves (10, 11, 13) are operatively connected to the crankshaft via a camshaft and the operative connection of the charging valves to the crankshaft can be deactivated, with the result that the at least one charging valve (11) remains closed. The correct metering of the air for a stoichiometric or approximately stoichiometric combustion mixture is additionally achieved by a turbocharger (4) and a throttle valve (8). By displacement of the opening instant of the charging valves (11), air can be pumped from the cylindrical combustion chambers into the compressed air tank (14), instead of removing said air from the latter. Furthermore, an additional compressor (24), driven by the crankshaft, can likewise deliver air into the compressed air tank (14) if required.

Owner:ETH ZZURICH

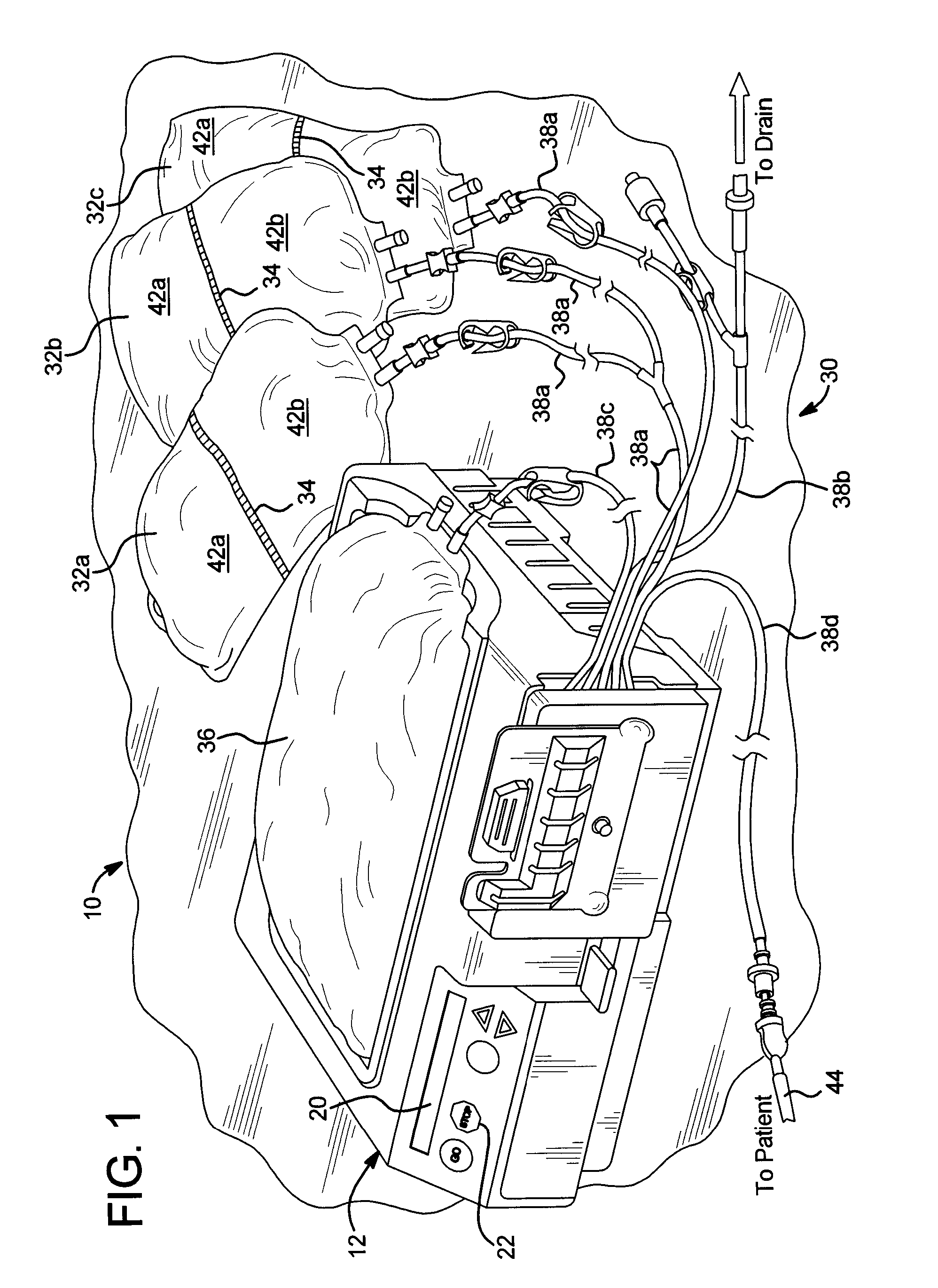

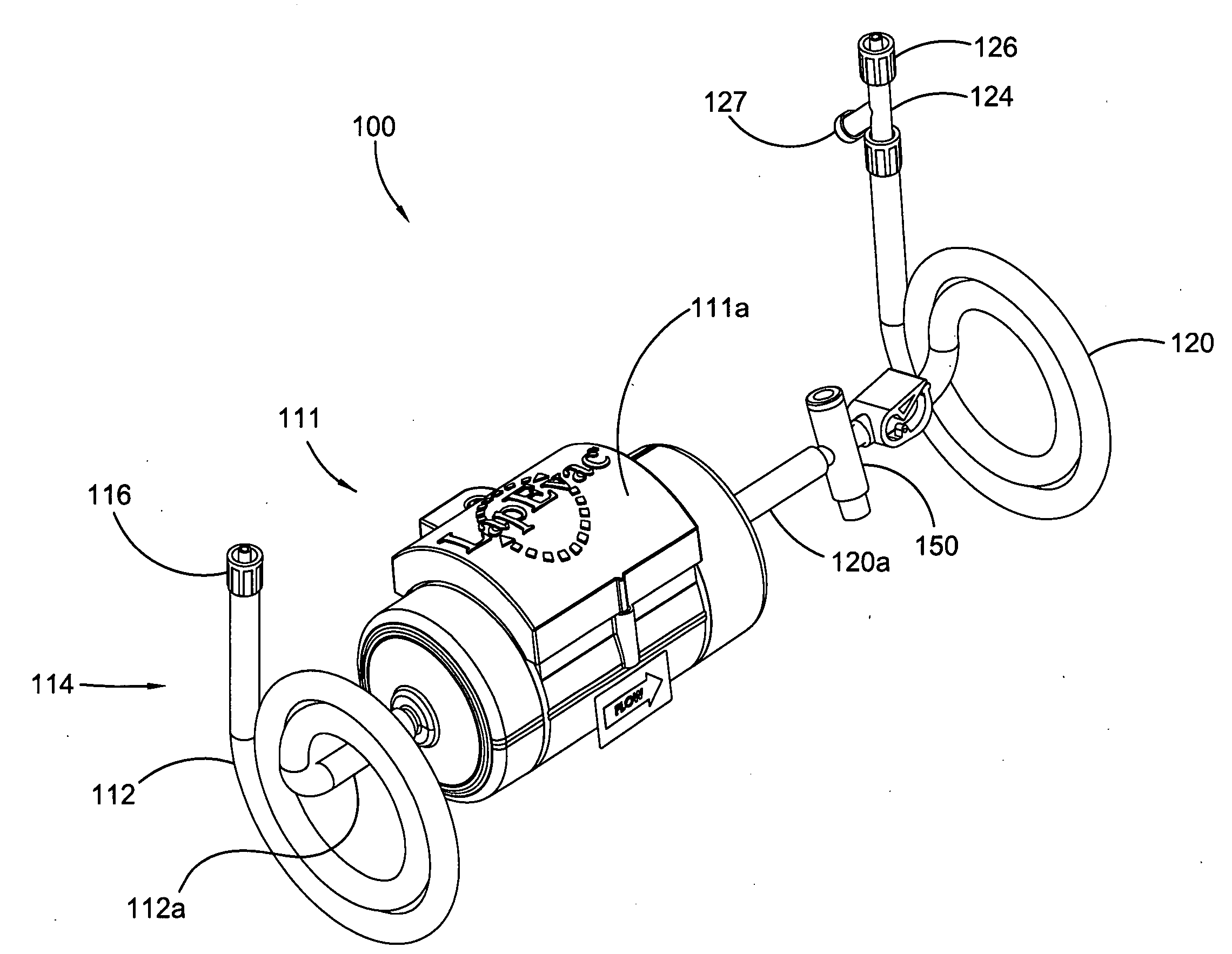

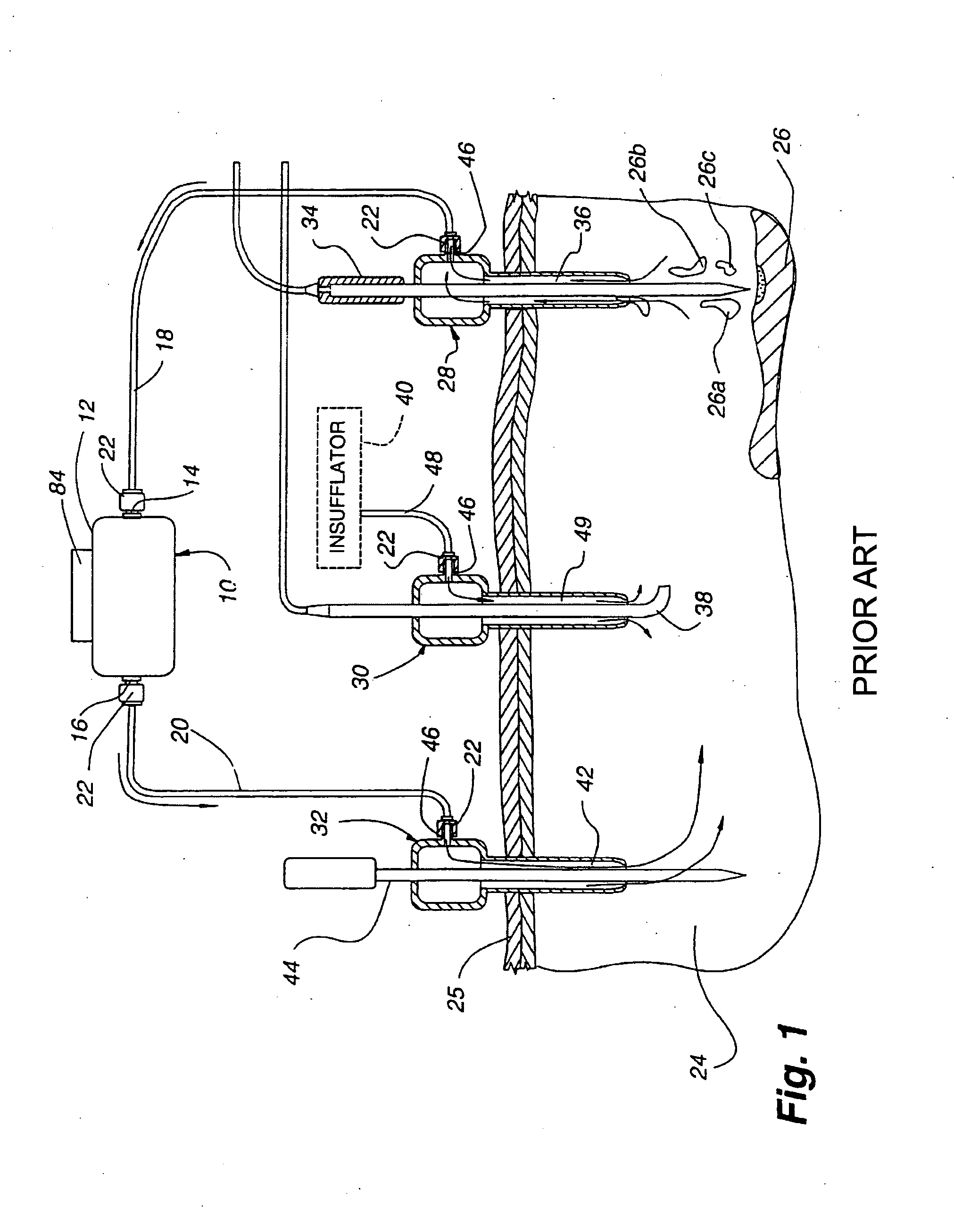

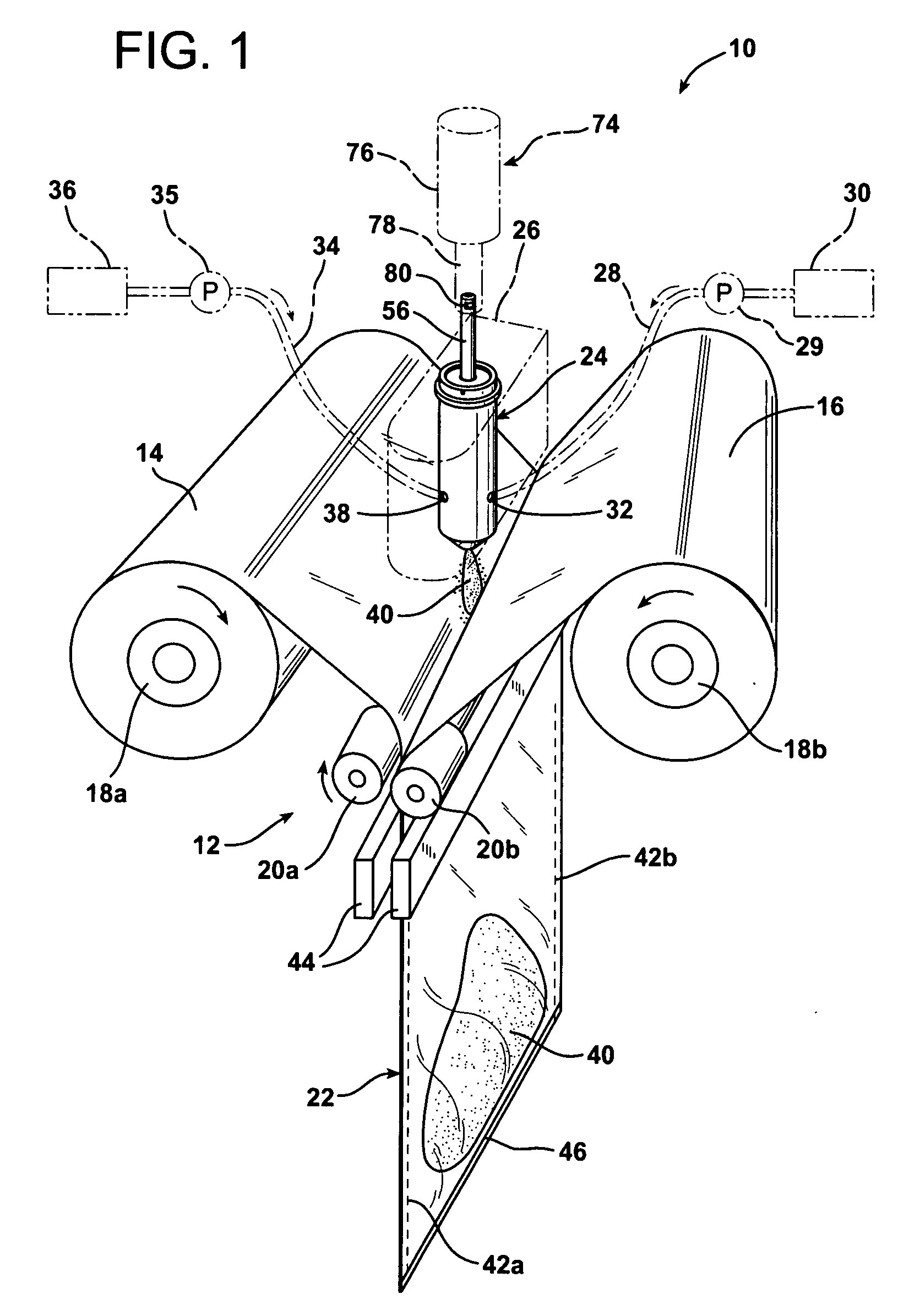

Wick and relief valve for disposable laparoscopic smoke evacuation system

ActiveUS20100094200A1Reduce and eliminate blockingReduce eliminate stratificationCombination devicesDispersed particle filtrationPERITONEOSCOPESurgical site

The present invention relates to an improved smoke evacuation device for use in laparoscopic surgeries. One improvement is a hydrophilic wick positioned within the inlet system of the smoke device for absorbing moisture and trapping surgical waste entering the smoke evacuation device. The second improvement is a multi-outlet valve inserted into the outlet system of the smoke evacuation device to enable quick depressurization of the surgical site.

Owner:BUFFALO FILTER

Fluid dispenser

ActiveUS20050173459A1Inhibition formationExcellent decontaminationLarge containersLiquid transferring devicesEngineeringMetering pump

A fluid dispenser for germ-free fluid is described incorporating at least one material being capable of interacting via an oligodynamically active substance. The dispenser includes a metering pump and inlet and outlet valves. The fluid coming into contact with at least one oligodynamically active substance is present in the region of the outlet valve, of the inlet thereto and / or the outlet therefrom.

Owner:URSAPHARM ARZNEIMITTEL

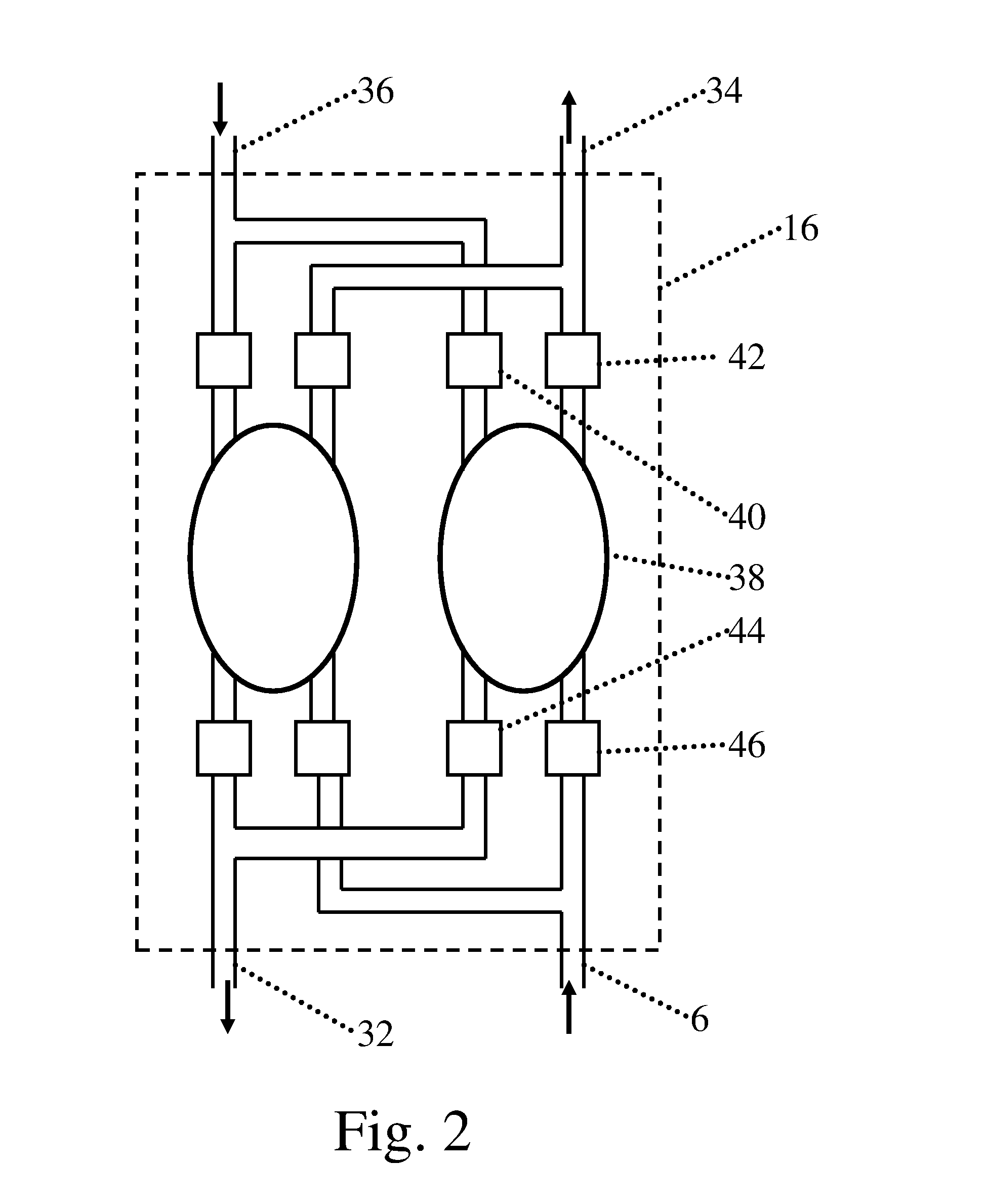

Device and method for pumping a fluid

InactiveUS7257940B1Reduce weightMass of system-byFlexible member pumpsPressure pumpsEngineeringMechanical engineering

A method of pumping a fluid includes: providing a pressurizer for pressurizing the fluid, the pressurizer including at least two storage tanks, where, for each storage tank, the pressurizer includes a propellant entrance valve, a propellant exit valve, a pressurant entrance valve, and a pressurant exit valve, where each of the storage tanks is configured to be filled with the fluid under a low pressure and drained of the fluid under a high pressure by the force of a pressurant; and for each storage tank, opening and closing its associated valves in cycles to sequentially fill and drain the storage tank of the fluid, the cycles each having a cycle time between approximately 1 and 500 milliseconds.

Owner:KNIGHT ANDREW F

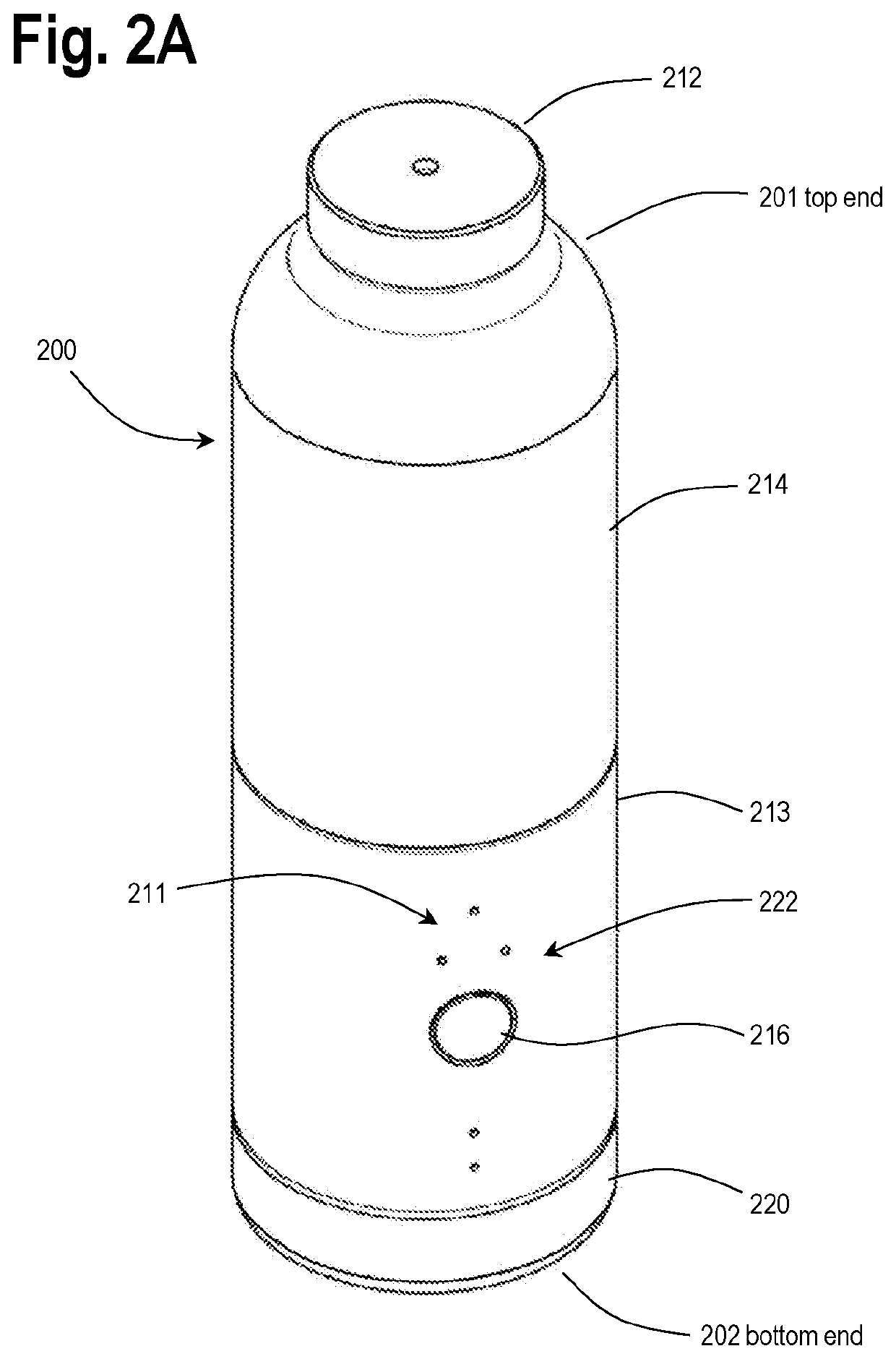

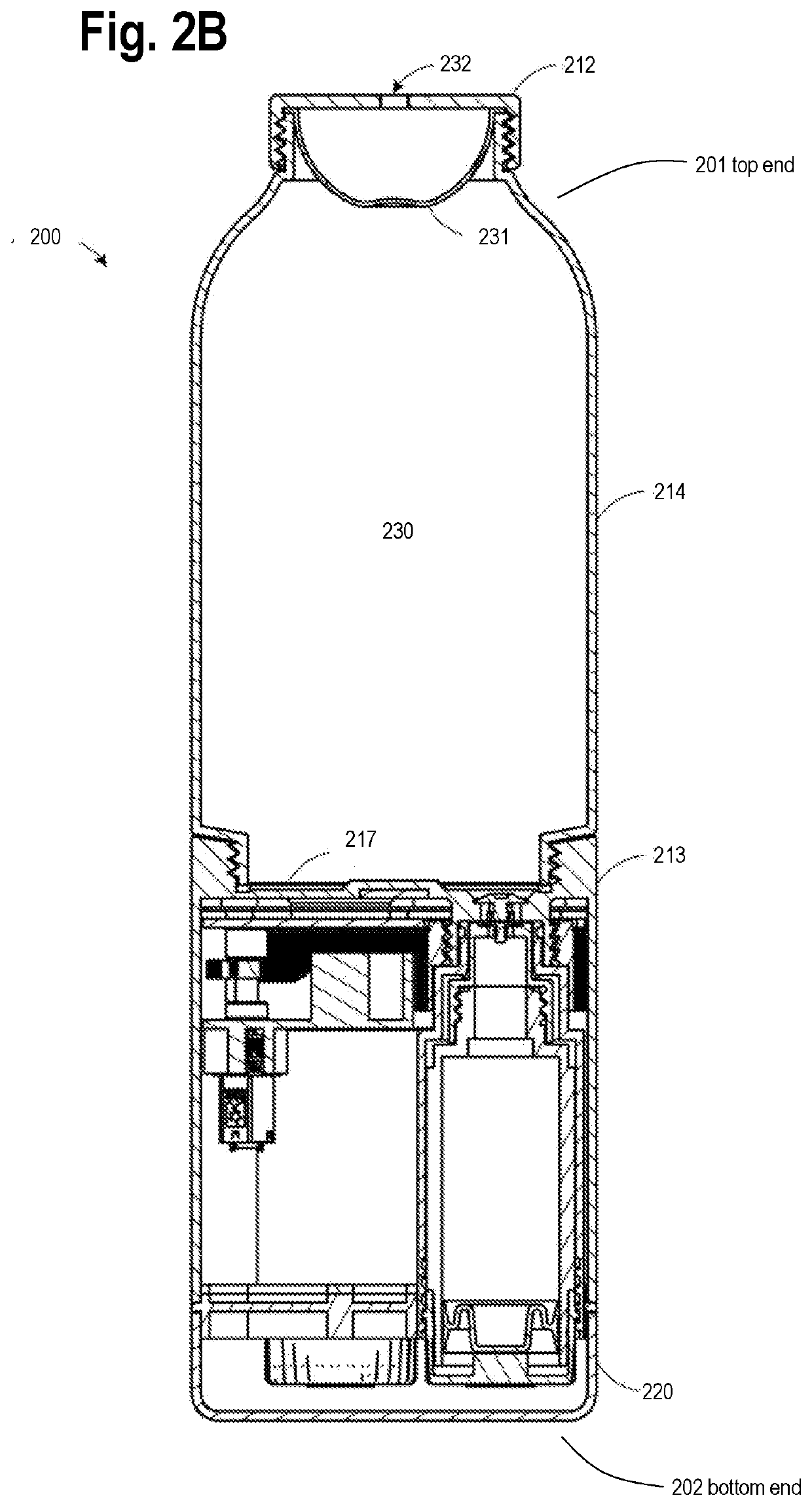

Portable systems and methods for adjusting the composition of a beverage

The systems and methods provide a container assembly comprising: a container having a known storage capacity for storing a liquid; an additive dispensing assembly, the additive dispensing assembly dispensing variable, non-zero quantities of one or more additives into the liquid stored in the container; one or more vessels that each contain one of the additives, of the one or more additives, to be dispensed into the liquid; and a gas dispensing assembly, the gas dispensing assembly releasing a gas into the liquid stored in the container, and the gas dispensing assembly including: an onboard gas tank; a valve assembly; and a gas outlet, and the valve assembly controlling flow of gas from the onboard gas tank, through the valve assembly, and to the gas outlet so as to output the gas into the liquid; and wherein the valve assembly, to perform the controlling the flow of gas, is movable between: an open position, in which flow of gas is allowed to flow from the onboard gas tank to the gas outlet; and a closed position in which the flow of gas is prevented to flow from the onboard gas tank to the gas outlet.

Owner:CIRKUL INC

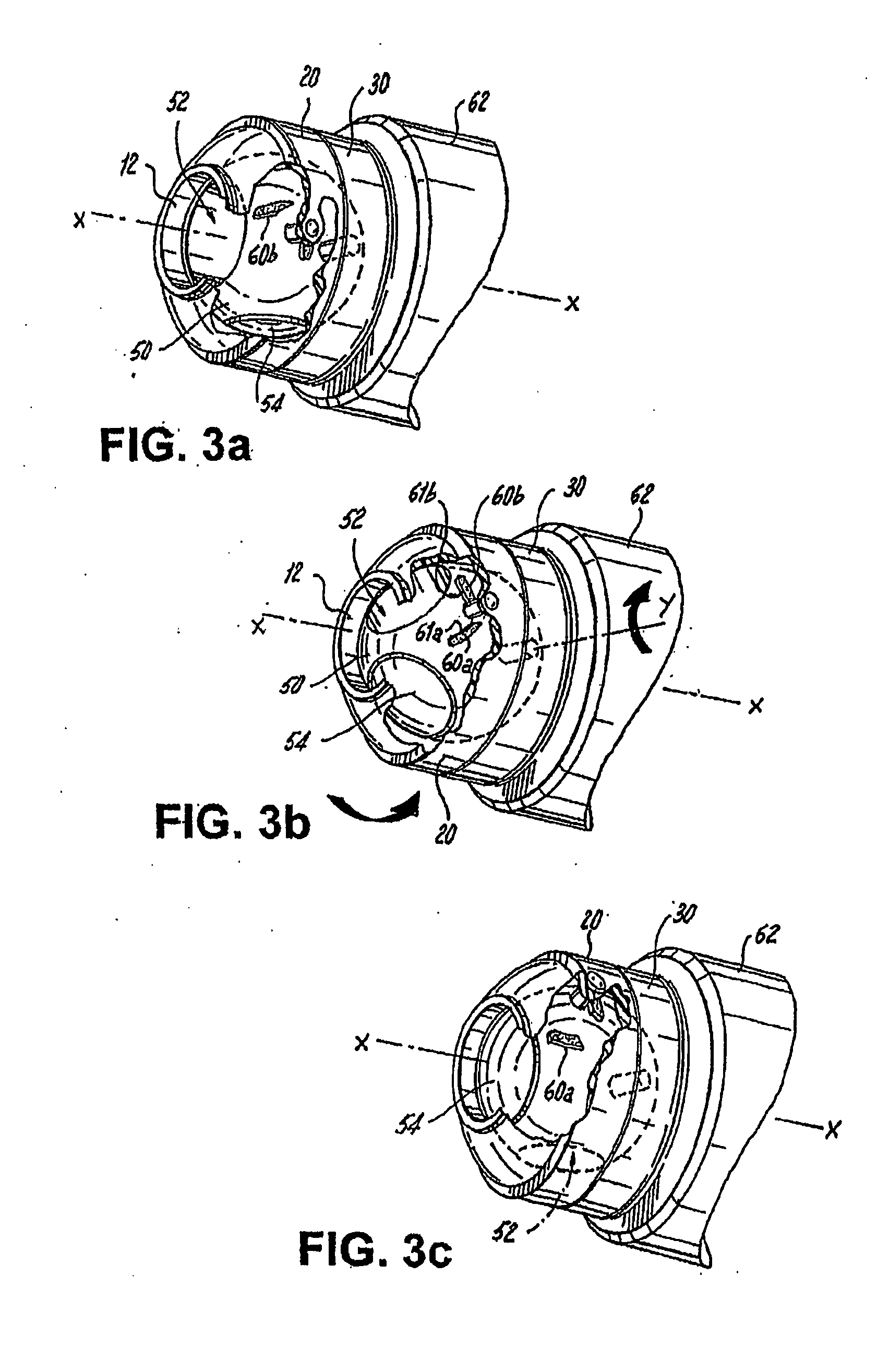

Flow switch and container

InactiveUS20090032533A1Smooth rotationAvoid displacementPlug valvesOperating means/releasing devices for valvesEngineeringCam

A flow switch assembly which includes a valve housing that includes an upper body portion and a lower body portion that are rotatably engaged relative each other. The upper and lower body portions define a chamber. The housing includes an inlet and outlet to the chamber. A valve member seated in the chamber of the valve housing for movement between an open position establishing at least one passage between the inlet and the outlet and a closed position wherein the at least one passage between the inlet and the outlet is non-established. Interactive cam elements are associated with at least one of the upper body portion and the lower body portion, and associated with the valve member, are provided for moving the valve member between the open position and the closed position when the upper body portion of the housing is rotated relative to the lower body portion.

Owner:AXIAL TECH

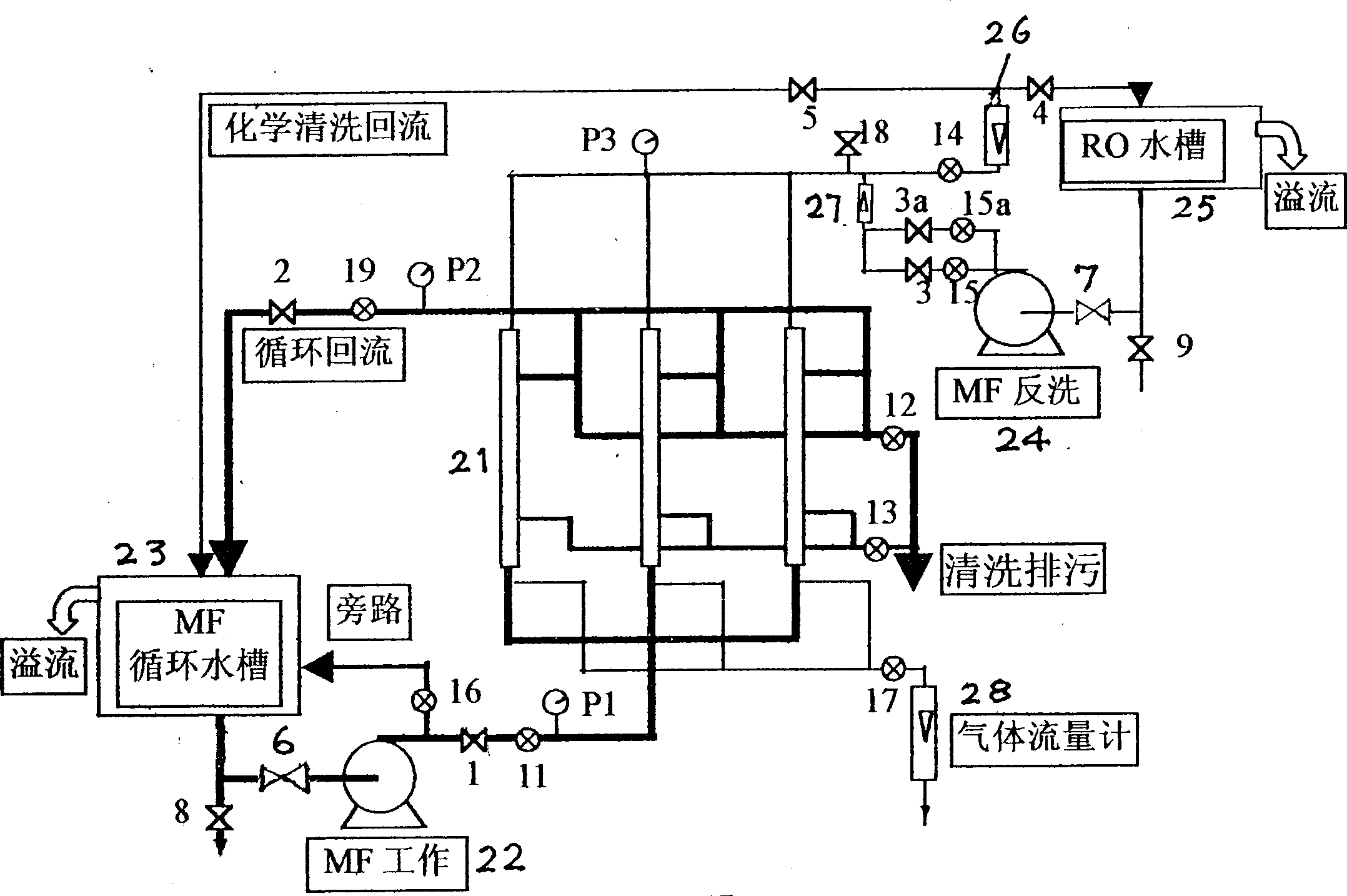

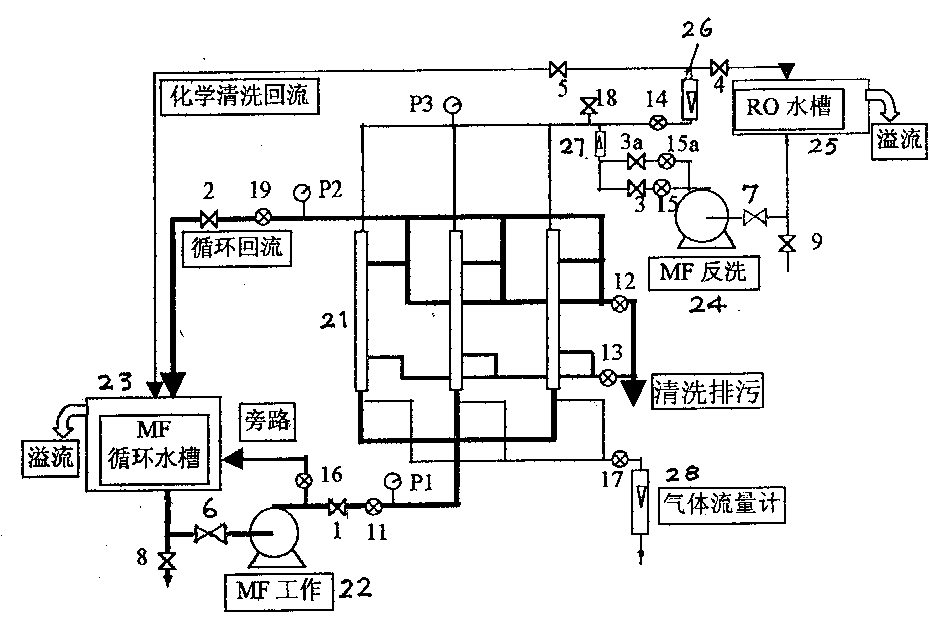

Hollow fiber membrane separator and its running process

InactiveCN1347752AImprove completenessGuaranteed stabilityMembranesUltrafiltrationHollow fibre membraneInlet valve

The hollow fiber membrane separator includes membeane assembly, control valve, pressure gauge, pump, air compressor, water tank, connecting pipes and other parts; and features that the upper mouth ofthe membrane assembly is connected via a back washing flow meter as well as a back washing regulating valve in one channel and a back washing automatic valve to the back washing pump pipe and the back washing pump via its inlet valve is connected to back washing water tank pipe in one channel and discharge valve pipe in the other channel; that the back water tank is connected to the filtering liquid outlet valve pipe via change-over valve and filtering liquid flow meter with the change-over valve being connected to circular water tank. The running process includes two steps in different cleaning states. The present invention makes it possible to realize ideal membrane separation and membrane cleaning.

Owner:TIANJIN MOTIMO MEMBRANE TECH

Fluid dispenser

ActiveUS7249693B2Inhibition formationExcellent decontaminationLarge containersLiquid transferring devicesMetering pumpBiomedical engineering

A fluid dispenser for germ-free fluid is described incorporating at least one material being capable of interacting via an oligodynamically active substance. The dispenser includes a metering pump and inlet and outlet valves. The fluid coming into contact with at least one oligodynamically active substance is present in the region of the outlet valve, of the inlet thereto and / or the outlet therefrom.

Owner:URSAPHARM ARZNEIMITTEL

Method for Controlling an Electrohydraulic Braking System and Electrohydraulic Braking System

A method and system for controlling an electrohydraulic braking system for a motor vehicle having an antilock braking control function and an electrically controllable pressure generating device having a cylinder-piston arrangement having a hydraulic pressure chamber and a piston displaceable by an electromechanical actuator so that a predetermined pressure can be set in the chamber, and having a number of hydraulically wheel brakes connected to the hydraulic pressure chamber by an electrically actuatable inlet valve and to a pressure medium reservoir by means of an electrically actuatable outlet valve. The cylinder-piston arrangement is actuated in case of antilock controlling at all wheel brake for setting an individual wheel target pressure at each wheel brake, such that the pressure in the hydraulic pressure chamber is set to the greatest wheel target pressure.

Owner:CONTINENTAL TEVES AG & CO OHG

Device for mixing and dispensing fluids

ActiveUS20090038270A1Avoid mixingPaper/cardboard articlesSolid materialEngineeringMechanical engineering

One aspect of the invention pertains to a device for mixing and dispensing fluids, which generally includes a housing; a mixing chamber having a first inlet for introducing a first fluid into the mixing chamber, a second inlet for introducing a second fluid into the mixing chamber, and an outlet through which fluid may exit the mixing chamber; and a valving rod received within the mixing chamber and movable between an open position, in which the first and second inlets are in fluid communication with the mixing chamber, a cleaning position, in which the valving rod substantially seals closed the first inlet but does not seal closed the second inlet, and a closed position, in which the valving rod substantially seals closed the first and second inlets.

Owner:SEALED AIR U S

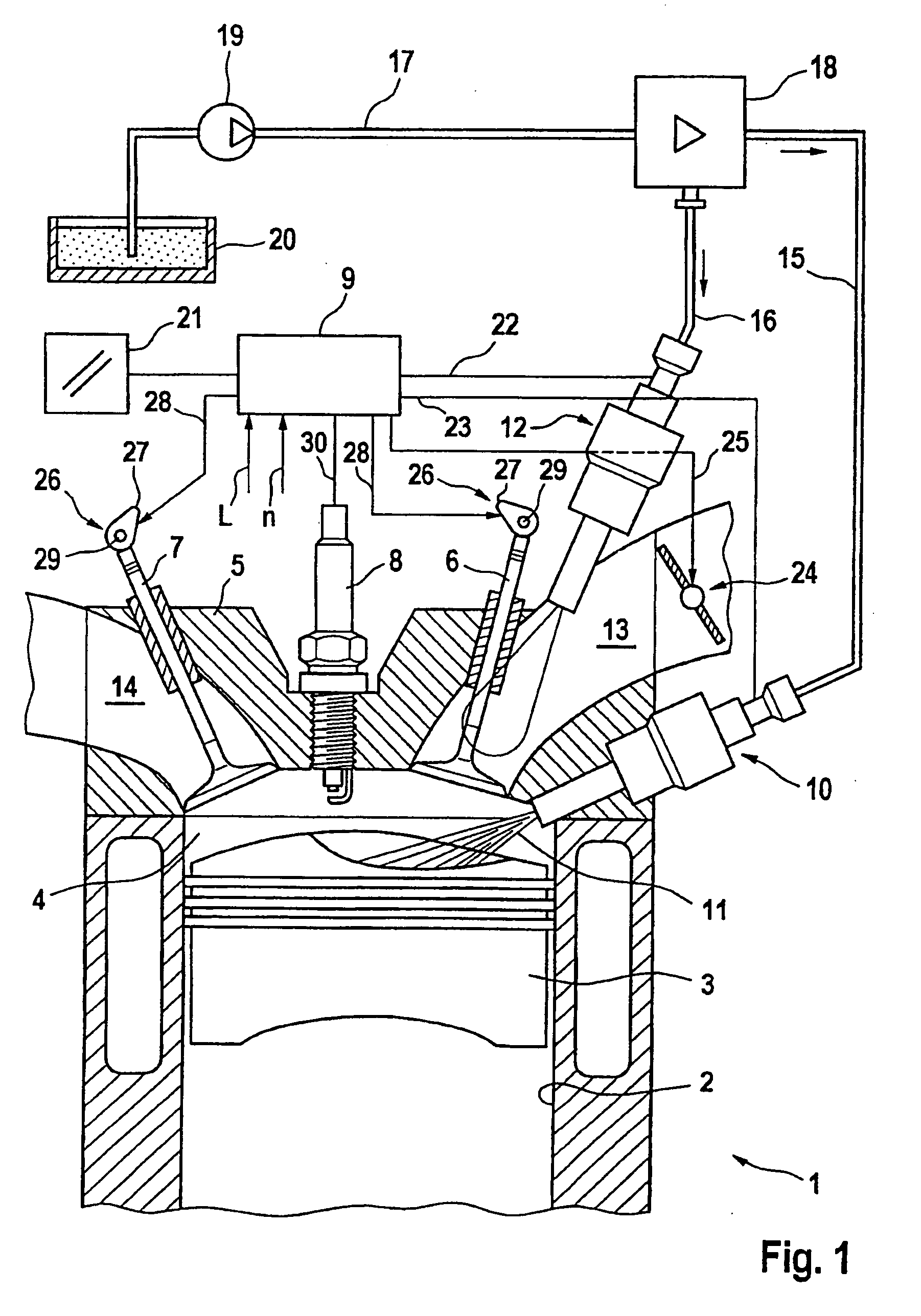

Method of operating an internal combustion engine

ActiveUS20070144480A1Smooth engine operationOptimal exhaust gas emissionElectrical controlInternal combustion piston enginesValve openingEngineering

In a method of operating an internal combustion engine with a switch-over capability between a compression ignition mode of operation and a spark ignition mode of operation in higher load ranges which includes a cam-operated valve drive with a valve control providing, in the compression ignition mode of operation, for an increased valve overlap of the valve opening times, smooth engine operation and optimal exhaust gas emissions are obtained also during rapid load changes upon changing the engine operating mode as the change-over is accompanied by changes of the injection parameters, the throttling parameter and the valve control, which are coordinated with respect to one another as the valve control is switched over by changing the amplitude and phase position of the valve stroke of at least one of the inlet and outlet valves.

Owner:DAIMLER AG

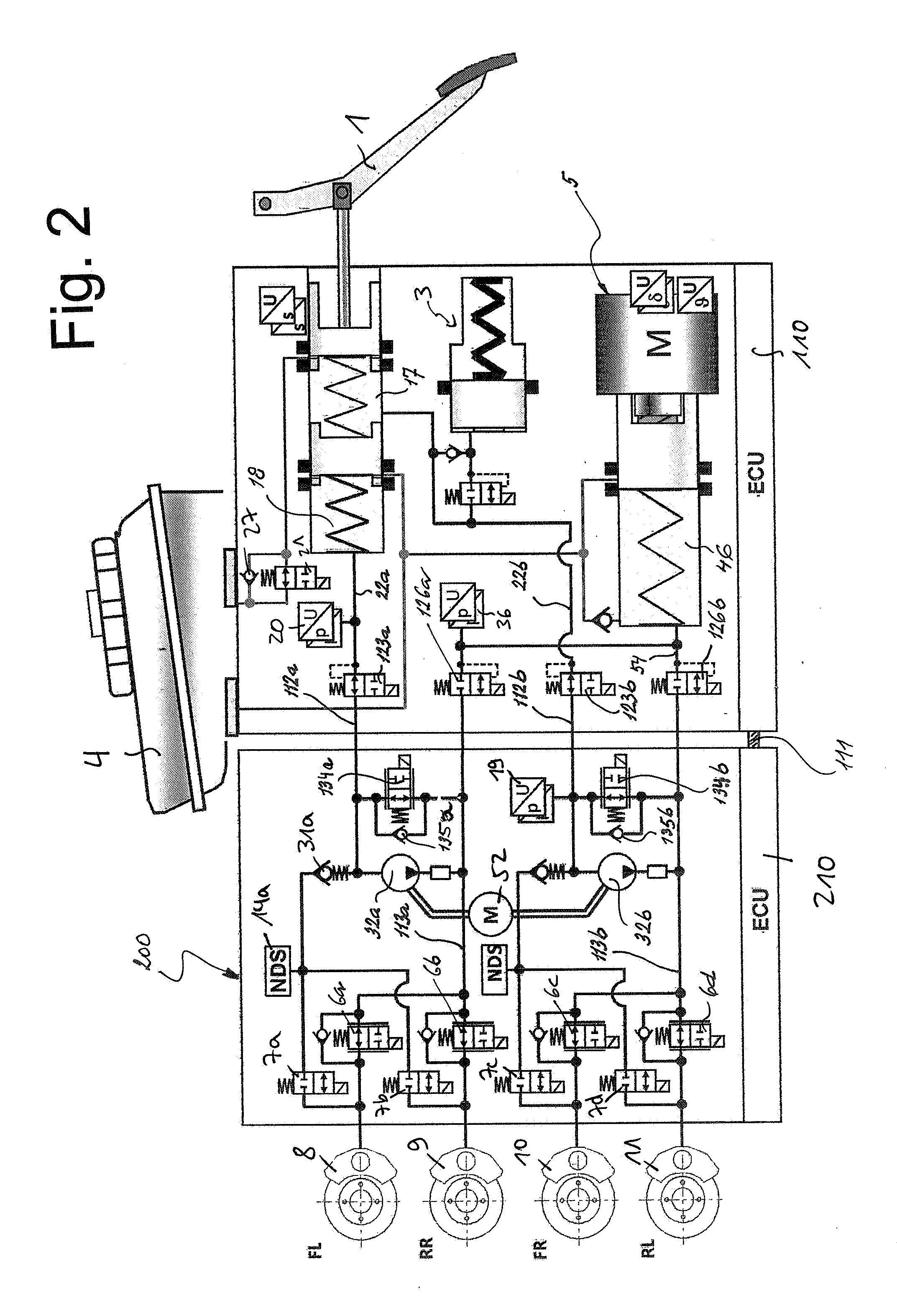

Braking system with two pressure sources, and method for operating a braking system with two pressure sources

PendingUS20210053540A1Control is possibleShort maintenance periodBraking action transmissionVehicle sub-unit featuresInlet valveControl theory

A braking system including four hydraulically actuatable wheel brakes. A normally closed outlet valve is assigned to each wheel brake and a normally open inlet valve is assigned to each wheel brake. Two pressure supply devices are provided for active pressure build-up in the wheel brakes. A first and a second brake circuit are hydraulically configured with two wheel brakes respectively, wherein in each brake circuit a respective pressure supply device is hydraulically connected to two wheel brakes. A first and a second control and regulating unit are provided, wherein the first control and regulating unit electrically controls the pressure supply device of the first brake circuit, and wherein the second control and regulating unit hydraulically controls the pressure supply device of the second brake circuit, and the two control and regulating units are connected together via a data interface.

Owner:CONTINENTAL TEVES AG & CO OHG

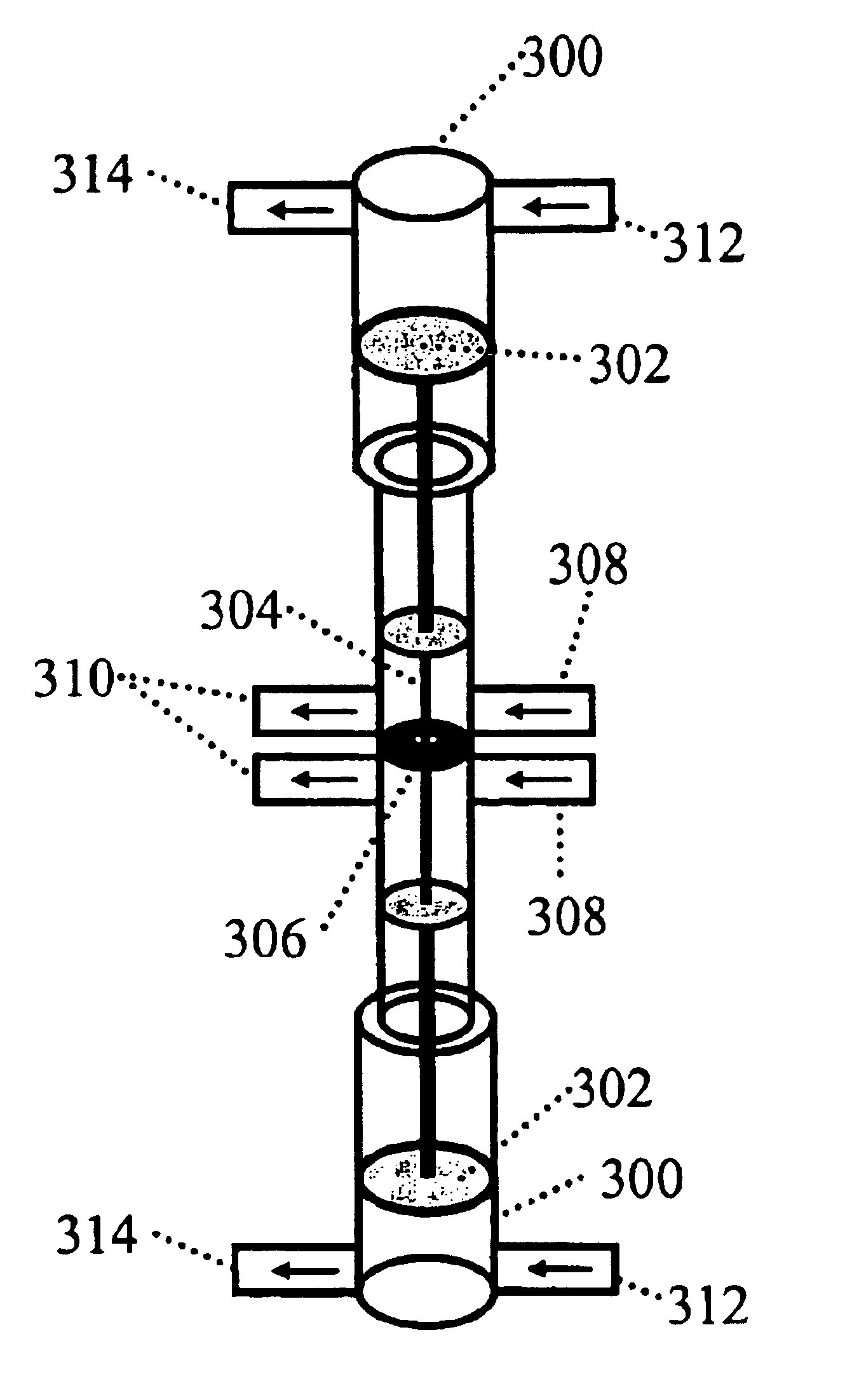

Pressurizer for a rocket engine

InactiveUS7082750B2Control flowPiston pumpsPositive-displacement liquid enginesEngineeringHigh pressure

A pressurizer for pressurizing a fluid includes: at least two storage tanks, where, for each storage tank, the pressurizer further includes: a propellant entrance valve, a propellant exit valve, a pressurant entrance valve, and a pressurant exit valve, where each of the storage tanks is configured to be filled with the fluid under a low pressure when its propellant entrance and pressurant exit valves are open and its propellant exit and pressurant entrance valves are closed, and to be drained of the fluid under a high pressure by the force of a pressurant when its valves are reversed, where its valves are configured to be opened and closed in a cycle to sequentially fill and drain the storage tank of the fluid, the cycle having a cycle time of between 1 and 500 milliseconds, and where the cycles of the valves of the storage tanks are out of phase with each other such that at some time in which one storage tank is being filled with the fluid, at least one other storage tank is being drained of the fluid. The pressurizer may be used as a propellant pump in a rocket engine.

Owner:KNIGHT ANDREW F

Method for calibrating analog-controlled hydraulic valves and brake system comprising an electronic control and regulating unit in which the method is carried out

ActiveUS20150020520A1Rapid assessmentRotary clutchesFluid braking transmissionInlet valveHydraulic brake

A method for determining a driving characteristic of an analogized or analog-controlled hydraulic valve of a motor vehicle hydraulic brake system in which a brake pressure generated with the aid of an electrically controllable, electric-motor-driven pressure supply device, is conducted to a wheel brake via an inlet valve and can be conducted via an outlet valve from the wheel brake into a pressure medium container. The pressure supply device and the inlet valves, and outlet valves, can be controlled by an electronic control unit. For determining the control characteristic of an analogized or analog-controlled inlet or outlet valve, a brake pressure is generated by the control unit via the pressure supply device, and the brake pressure is determined by a pressure sensor associated with the pressure supply device. The determined brake pressure and an associated valve control variable are stored as a calibration point of the control characteristic.

Owner:CONTINENTAL TEVES AG & CO OHG

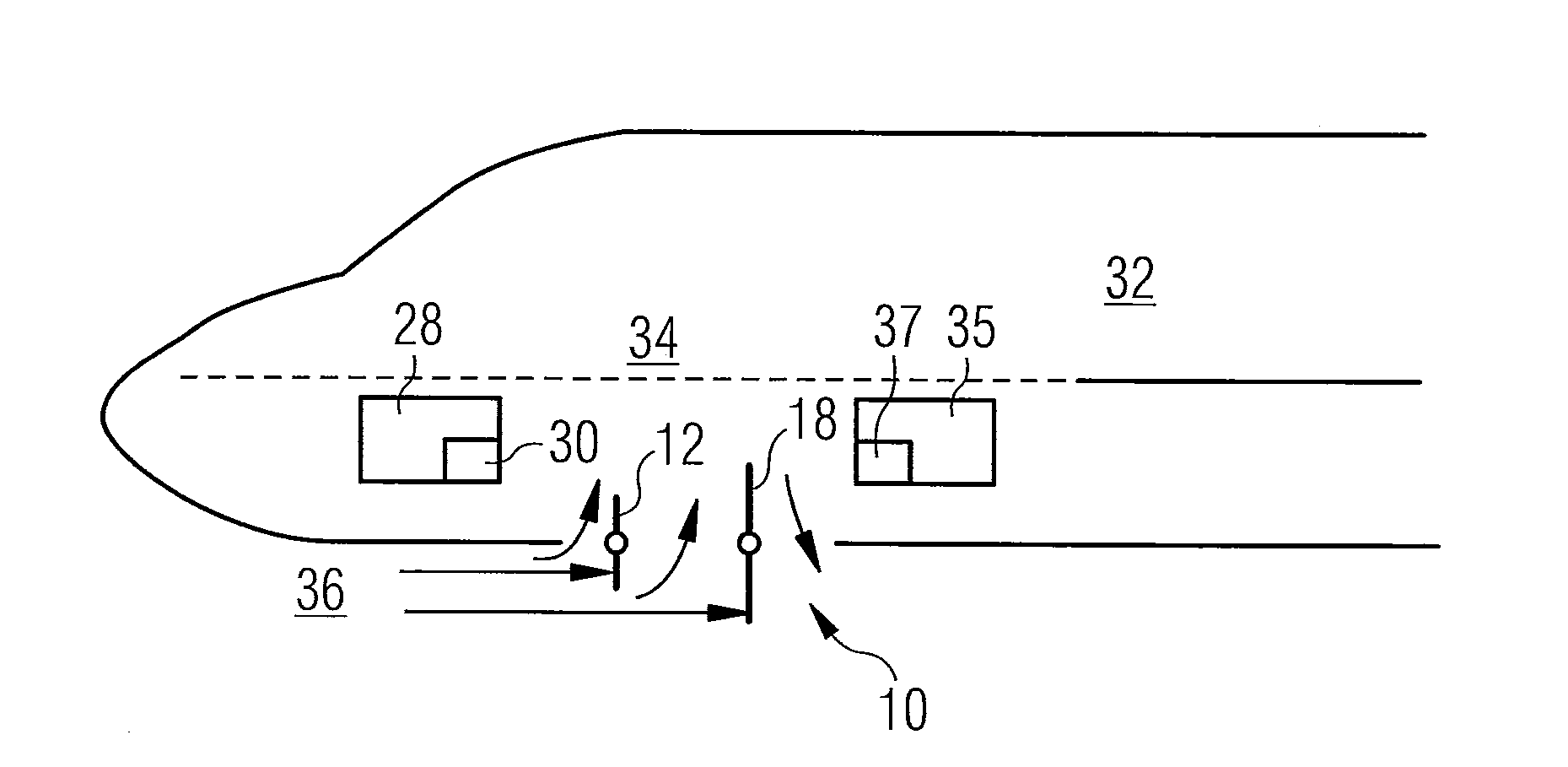

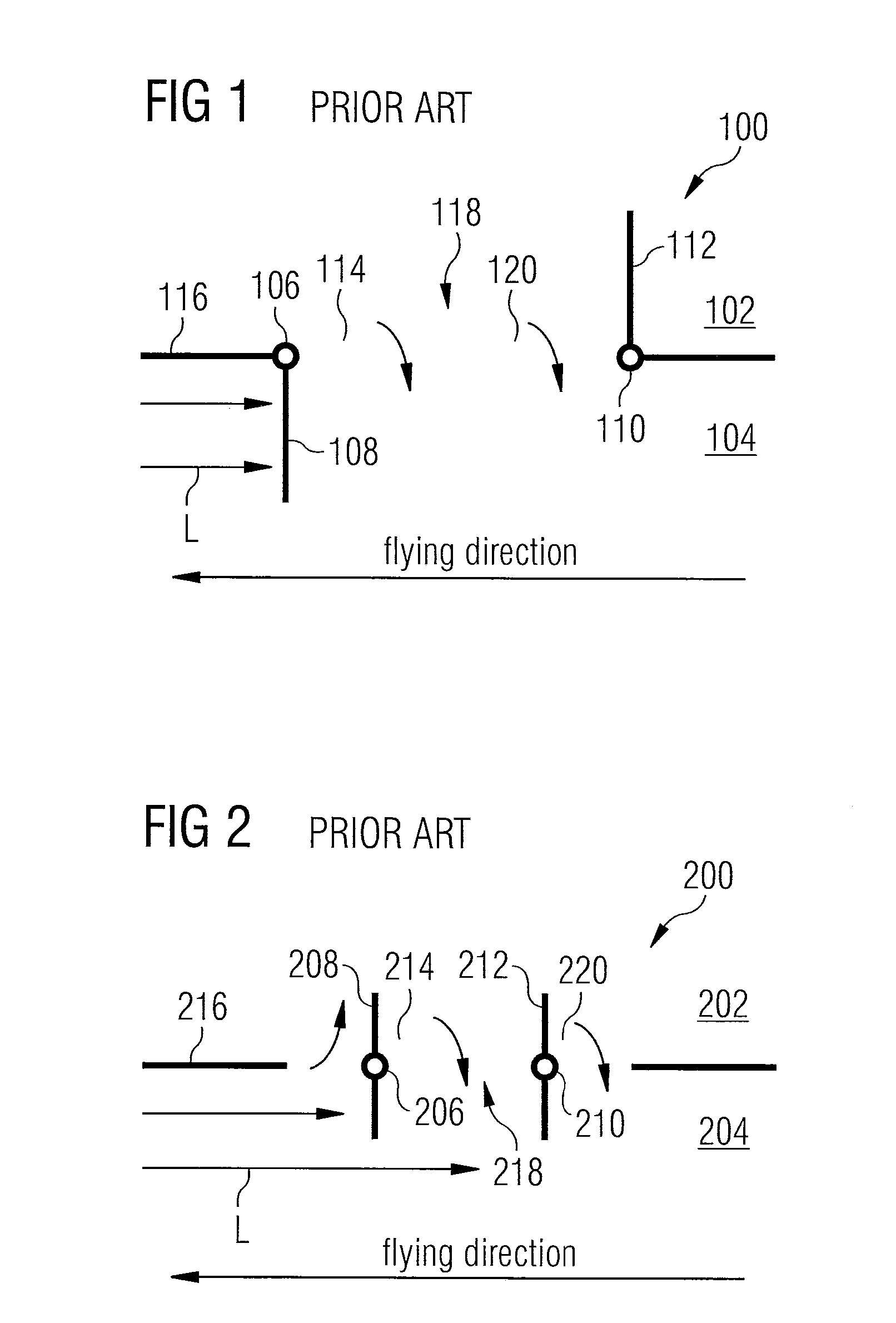

Air Outlet Valve As Well As a System and Method for Emergency Ventilation of An Aircraft Cabin

ActiveUS20100216385A1Increase floor area ratioImprove functional propertiesDucting arrangementsSpace heating and ventilation safety systemsExhaust valveControl system

An air outlet valve for use in an aircraft is adapted during normal operation of the aircraft as a component of a cabin pressure control system for adjusting a desired pressure level in an aircraft cabin to remove air from an interior of the aircraft into the environment around the aircraft. The air outlet valve is further adapted during emergency ventilation operation of the aircraft as a component of a system for emergency ventilation of the aircraft cabin to introduce air from the environment around the aircraft into the interior of the aircraft. The air outlet valve comprises a nose-side valve flap, which is pivotable about an axis and is adapted to open or close a nose-side portion of an air outlet valve aperture, and a tail-side valve flap, which is pivotable about an axis and is adapted to open or close a tail-side portion of the air outlet valve aperture. A portion of the tail-side valve flap that in the open state of the tail-side valve flap projects into an air stream flowing around an aircraft skin during cruising of the aircraft is greater than a portion of the nose-side valve flap that in the open state of the nose-side valve flap projects into the air stream flowing around the aircraft skin during cruising of the aircraft.

Owner:AIRBUS OPERATIONS GMBH

Method for operating a brake system and a brake system

ActiveUS9365199B2Quality is easy to controlFoot actuated initiationsFluid braking transmissionPower flowDriver/operator

A method and system for operating a motor vehicle brake system, actuated in a “Brake-by-Wire” operating mode both by the vehicle driver and also independent of the vehicle driver, preferably operated in the “Brake-by-Wire” operating mode, and which can be operated in at least one fall-back operating mode, in which only operation by the vehicle driver is possible. The brake system has an electrohydraulic pressure and volume setting device, which electronically emits a brake system pressure under control, and a pressure modulation unit having, for each wheel brake, inlet and outlet valves for setting wheel-specific brake pressures. For setting wheel-specific brake pressures, the inlet and outlet valves are actuated analogously by being energized by different electrical currents, in order to assign a pressurizing agent volume flow provided by the pressure and volume setting device to the wheel brakes that have a pressure change requirement.

Owner:CONTINENTAL TEVES AG & CO OHG

Beverage dispenser

InactiveUS7472805B2Positive displacement pump componentsLarge containersReciprocating motionEngineering

A disposable pump cartridge for use in conjunction with a pump driver characterized in the disposable pump unit containing a pair of piston pumps and inlet and outlet valves positioned at one end of each piston. The piston pump has a pair of pistons arranged for reciprocal motion and which are retained by a retainer adjacent the inlet and outlet valves during transit.

Owner:IMI VISION LTD

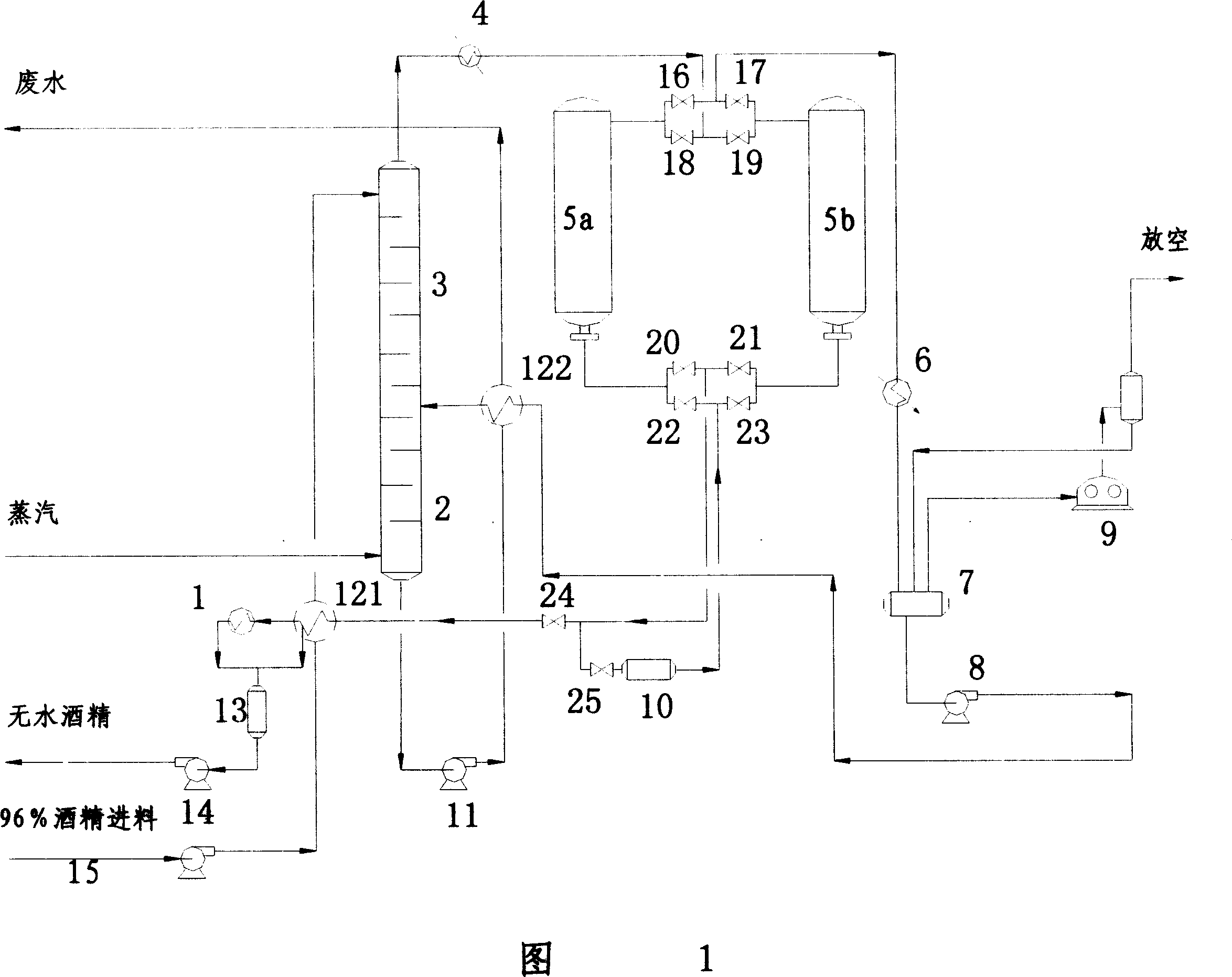

Fuel alcohol dewatering apparatus and process

InactiveCN101088975AReduce consumptionImprove recycling ratesOrganic compound preparationChemical industryMolecular sieveAlcohol

The fuel alcohol dewatering apparatus a rectification tower and a stripping tower connected serially, two parallel molecular sieves with valves in the inlets and the outlets, an overheater, a product cooler, a material preheater, a feeding pump, a waste water pump and a vacuum pump. The present invention has low power consumption, high energy recovering rate, no environmental pollution and high production efficiency.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Slip-Controlled Hydraulic Vehicle Brake System

InactiveUS20120043806A1Braking action transmissionApplication and release valvesInlet valveBrake fluid

A hydraulic vehicle brake system and method of operating same. The system includes an electrohydraulic wheel brake pressure modulation unit, a master brake cylinder (11) which has a pressure medium storage reservoir (12) for hydraulic brake fluid and which can be actuated by means of a brake pedal (9) and to which first and second brake circuits (I, II) are connected. Wheel brakes (3, 4, 5, 6) are connected to the first and second brake circuits (I, II). Each of the first and second brake circuits have a pair of inlets valves (14a-d, 114a-b) and a pair of outlet valves (15a-d, 115a-b) connected to the wheel brakes (3, 4, 5, 6). The outlets of the outlet valves (15a-d, 115a-b) of each of the first and second brake circuits (I, II) are connected to one another by means of jointly used hydraulic line sections (16a, 16b). A safety valve (17a, 117a; 17b, 117b) is provided by means of which an outflow of brake fluid medium out of the line section (16a, 16b) via an outlet port of the safety valves (17a, 117a; 17b, 117b) can be monitored as a means of checking the leak-tightness of the outlet valve and the safety valve.

Owner:CONTINENTAL TEVES AG & CO OHG

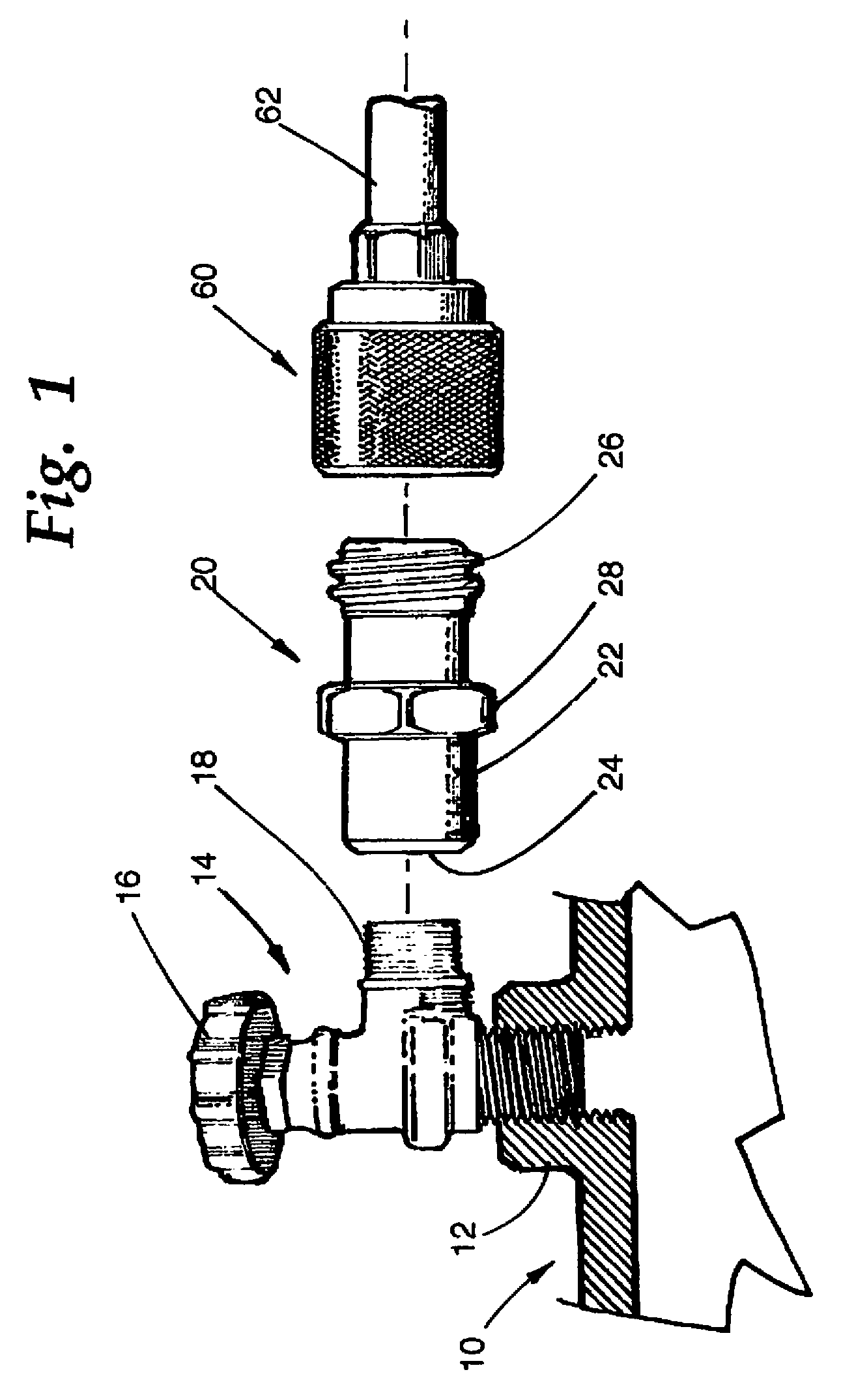

Motor fuel connector with replaceable tip seal

An improved fuel line connector for connecting a fuel line connection valve to a fuel cylinder outlet valve includes an improved, replaceable tip seal mounted on the tip or nose of the connector valve. The tip seal provides an additional, effective face seal between the connector body and the cylinder outlet valve. The tip seal, being on the fuel line connector, can be maintained and replaced by the party using the vehicle or filling the fuel cylinder.

Owner:MARSHALL EXCELSIOR CO

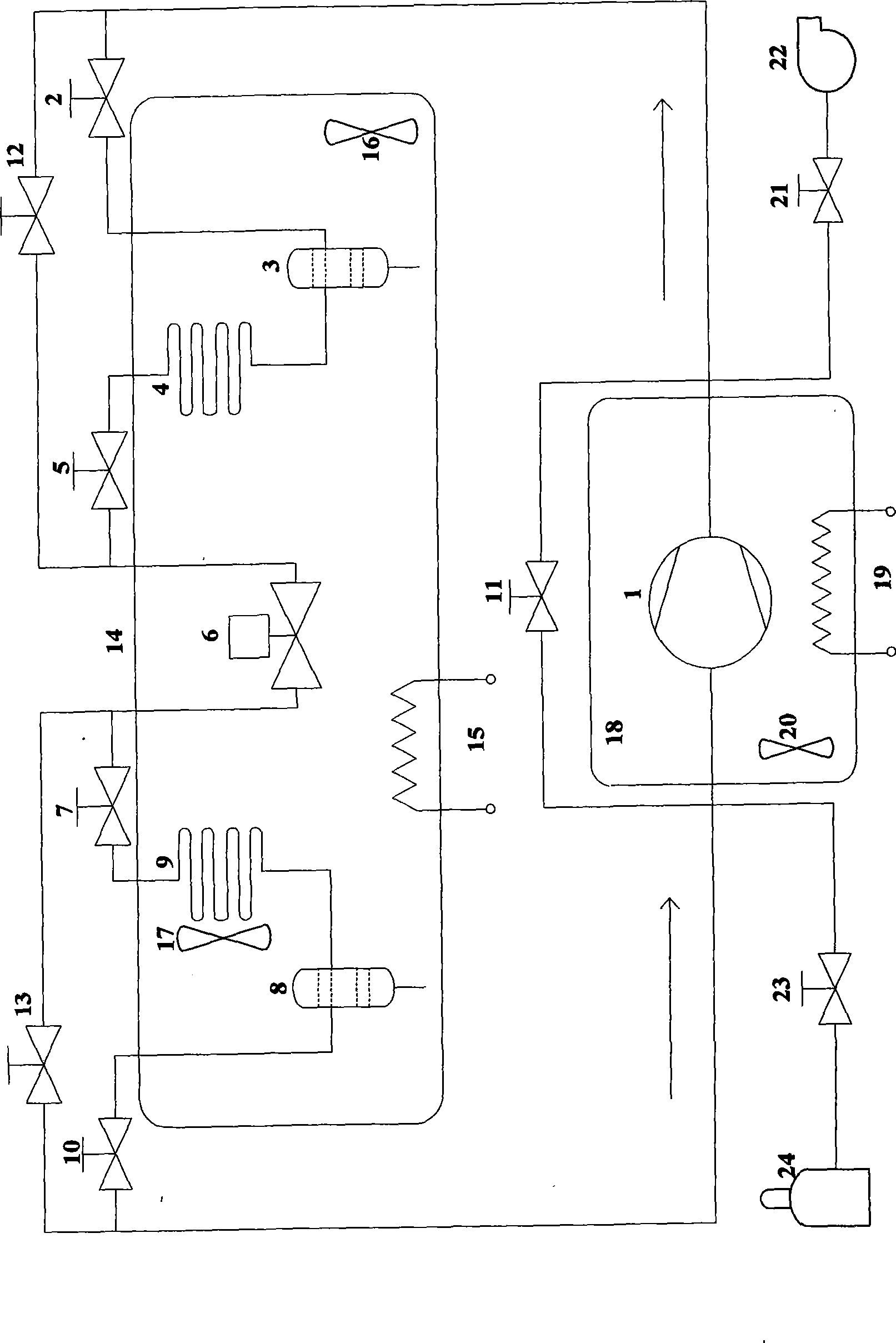

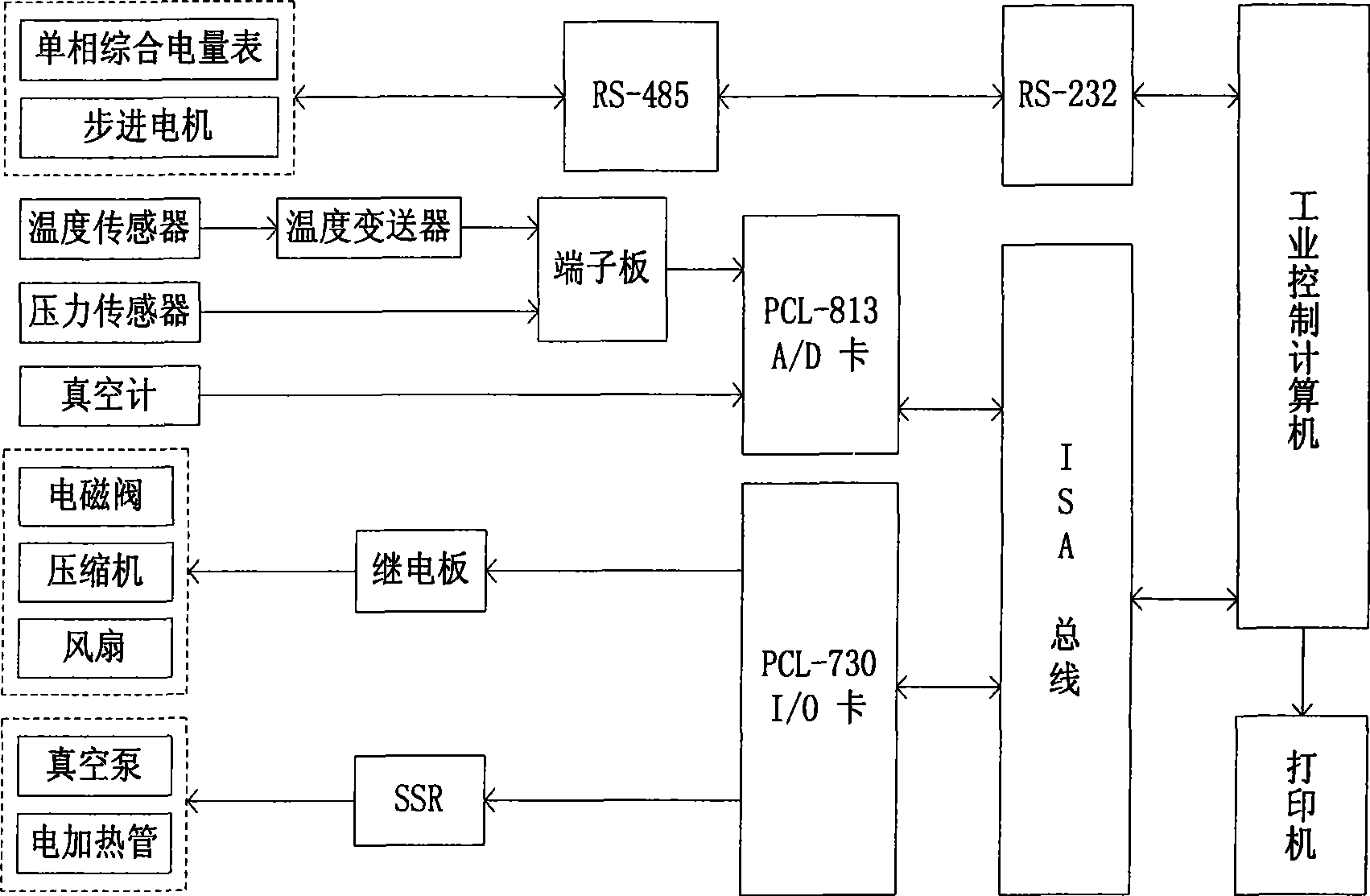

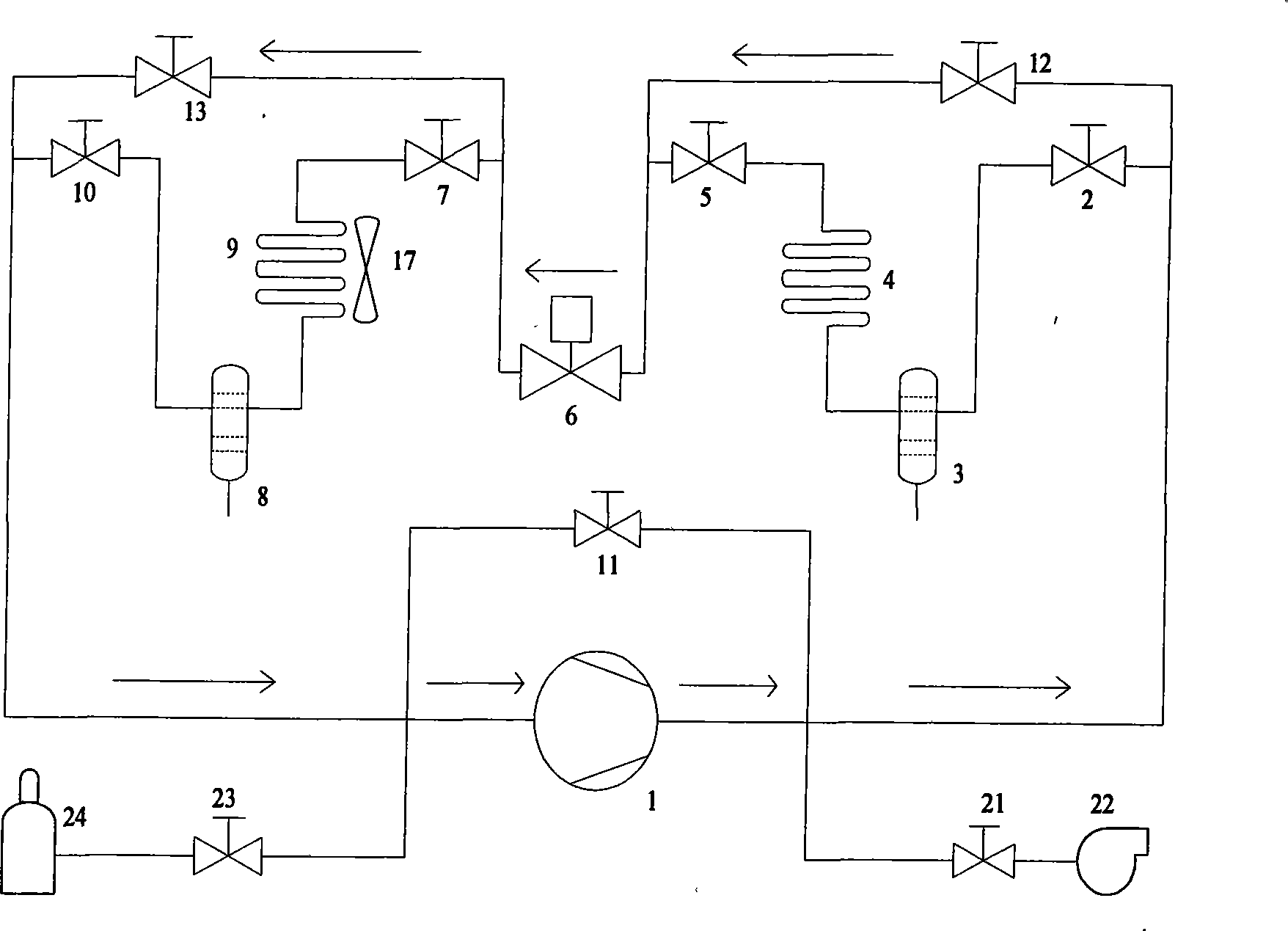

Apparatus and method for measuring small-sized cold compressor oil circulation amount

ActiveCN101498298APump testingPositive-displacement liquid enginesRefrigeration compressorHeating oil

The invention relates to a device and a method for measuring the oil circulating load of a small-sized refrigeration compressor. The device replaces a refrigeration subsystem to adopt a two-stage heating oil separating structure. In a refrigerating and operating unit, an exhaust hole and an inhalation hole of a measured compressor are respectively sequentially connected with an exhaust oil content inlet valve, an exhaust oil and gas separator, a condenser pipe, an exhaust oil content outlet valve, an expansion valve, an inhalation oil content inlet valve, an evaporating pipe, an inhalation oil and gas separator and an inhalation oil content outlet valve through an exhaust interface and an inhalation interface to form a loop, exhaust bypass valves are connected with both ends of the exhaust oil content inlet valve and the exhaust oil content outlet valve in parallel, inhalation bypass valves are connected with both ends of the inhalation oil content inlet valve and the inhalation oil content outlet valve in parallel, and balanced valves are connected with both ends of the exhaust interface and the inhalation interface. The device and the method carry out two-stage heating oil separation for the refrigerating loop by mainly using a method that the compressor is operated in a continuous and discontinuous circulation stopping and starting mode under a variable working condition state.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com