Fuel alcohol dewatering apparatus and process

A dehydration device, fuel ethanol technology, applied in the chemical industry, sustainable manufacturing/processing, preparation of organic compounds, etc., can solve the problem of high energy consumption for solvent regeneration, achieve low energy consumption, high overall efficiency, and recycling rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

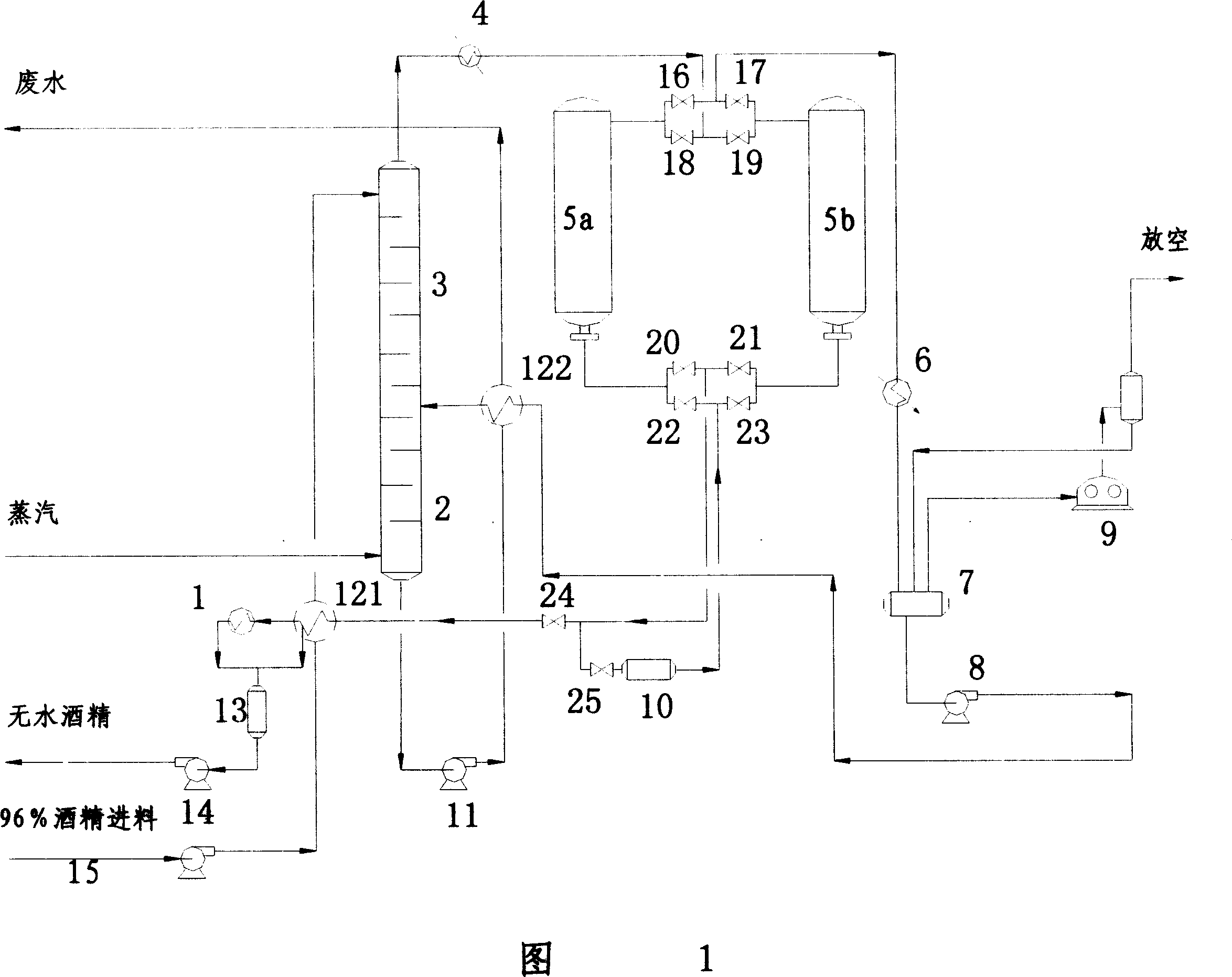

[0028] Embodiment: as shown in Figure 1, the fuel ethanol dehydration device with an annual output of 50,000 tons comprises a rectifying tower 3 and a stripping tower 2 arranged in series up and down, a first molecular sieve 5A and a second molecular sieve 5B arranged in parallel, a superheated 4, product cooler 1, feed preheater 121, feed pump 15, light wine tank 7, regeneration condenser 6, light wine pump 8, regeneration regulator wastewater pump 11, light wine preheater 122, middle The tank 13, the product pump 14 and the vacuum pump 9, wherein the top of the first molecular sieve 5A and the second molecular sieve 5B pass through the first inlet valve 18 and the second inlet valve 19 and the first regeneration outlet valve 16 and the first regeneration outlet valve 16 and the second inlet valve respectively arranged in parallel in series. The two regeneration outlet valves 17 communicate, and the bottom of the first molecular sieve 5A and the second molecular sieve 5B pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com