Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236 results about "L-Pyroglutamic Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyroglutamic acid (also known as PCA, 5-oxoproline, pidolic acid, or pyroglutamate for its basic form) is a ubiquitous but little studied natural amino acid derivative in which the free amino group of glutamic acid or glutamine cyclizes to form a lactam.

Method for preparing disubstituted piperidine and intermediates

ActiveUS20100197928A1Reduce functionOrganic chemistryBulk chemical productionL-Pyroglutamic AcidCarboxylic acid

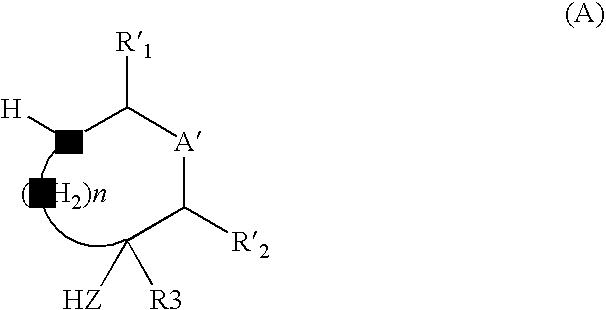

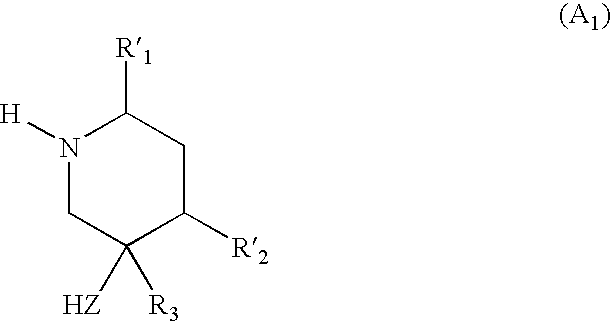

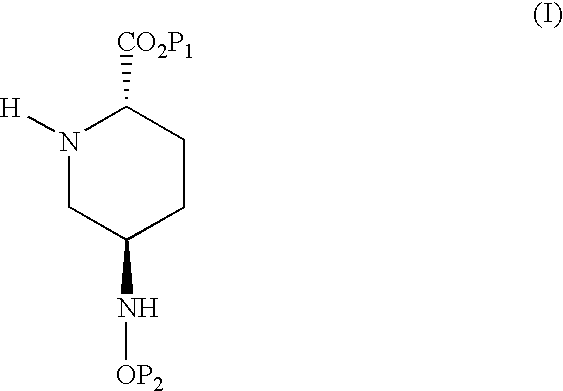

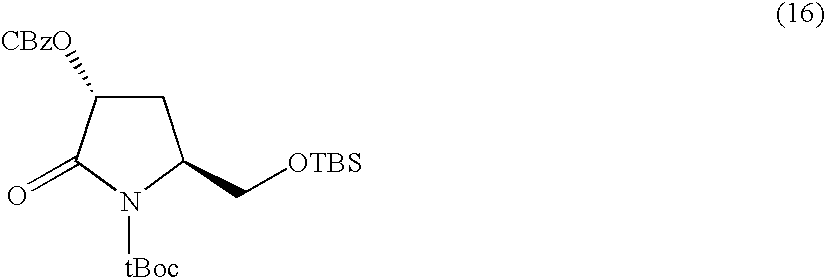

The disclosure relates to a method for preparing a compound of formula (I), wherein P1 and P2 are groups protecting the carboxylic acid and oxyamine functions, starting from pyroglutamic acid (S). The disclosure also relates to novel intermediates.

Owner:FOREST LAB HLDG LTD

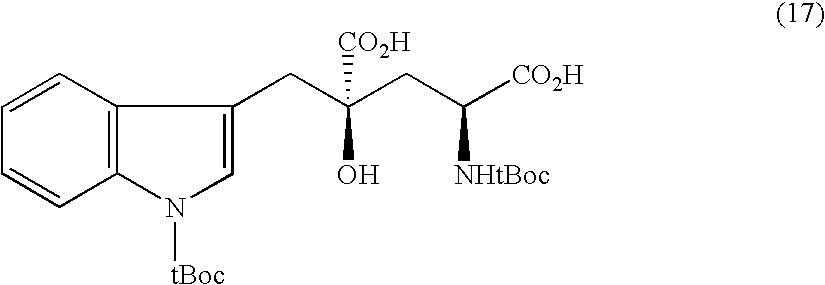

Process for manufacturing a glutamic acid derivative and a pyroglutamic acid derivative and a novel intermediate in the manufacture thereof

InactiveUS20060009394A1Easy to manufactureEfficient and easy manufactureNervous disorderOrganic compound preparationAlkylating antineoplastic agentHydroxyproline

Glutamic acid derivatives, in particular monatin, may be conveniently prepared by alkylating a 4-protected hydroxyl pyroglutamic acid derivative with an alkylating agent to prepare a 4-protected hydroxyl-4-alkylglutamic acid derivative, followed by the steps of hydrolysis and deprotection. The 4-protected hydroxyl pyroglutamic acid derivative is easy to produce from hydroxyproline. The 4-protected hydroxyl pyroglutamic acid derivative is particularly suitable for use in the efficient manufacture of monatin of high optical purity, since it can be alkylated selectively at the 4-position and stereoselectively and after its alkylation, it can easily be converted to a glutamic acid derivative.

Owner:AJINOMOTO CO INC

Compositions for improving mental performance

ActiveUS20050244510A1Improved mental performanceElimination of mental fatigueHeavy metal active ingredientsBiocidePoor focusAntioxidant

The present invention provides formulas for producing compositions for the structural / functional nutritional support for those who struggle with poor focus, concentration and / or memory. In addition, the present invention provides compositions comprising nutritional / botanical factors helpful to those who subjectively experience transient mental fatigue or poor cognitive function. The compositions of this invention consist primarily of the following ingredients B-complex vitamins, antioxidants, minerals, phosphatidyl serine (PS), choline, dimenthyl-aminoethanol (DMAE), docosahexaenoic acid (DHA), L-pyroglutamic acid, as well as herbal extracts from Bacopa monniera, Vinca minor, and Huperzia serrata. The present invention also relates to the administration of these compounds to alleviate mental fatigue or poor cognitive function.

Owner:SYNERGY STRIPS CORP

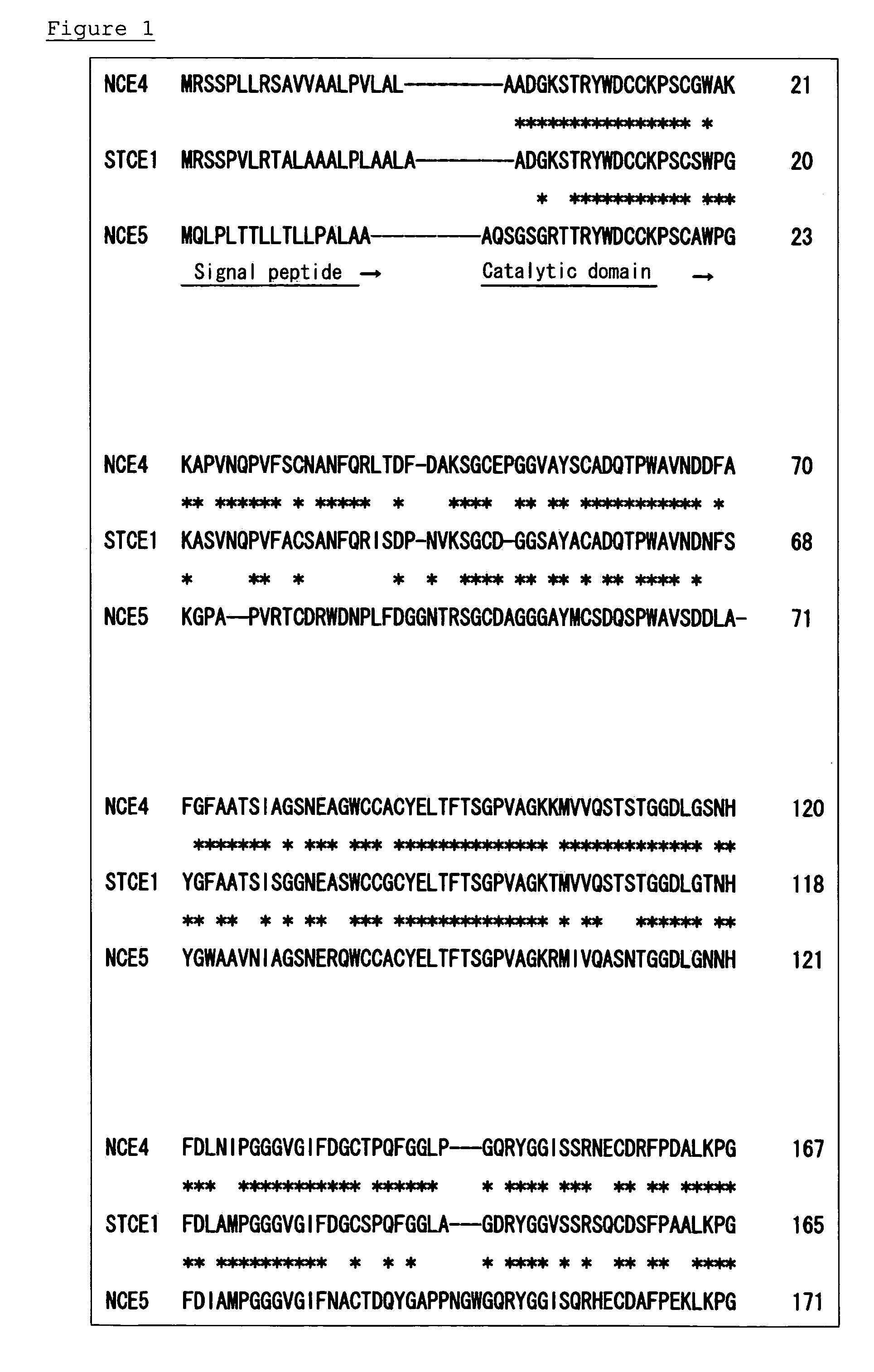

Surfactant tolerant cellulase and method for modification thereof

ActiveUS8569033B2Efficient productionReduce presenceSugar derivativesMicroorganismsNucleotideL-Pyroglutamic Acid

A method for suppressing a reduction in an endoglucanase activity in the presence of a surfactant, characterized by modifying a protein having the endoglucanase activity in which the N-terminus is an amino acid other than pyroglutamic acid, to a protein having the N-terminus of pyroglutamic acid, is disclosed. Further, a modified protein having an endoglucanase activity wherein the N-terminal amino acid is converted into pyroglutamic acid by an amino acid modification, a polynucleotide encoding the protein, an expression vector comprising the polynucleotide, a host cell transformed with the expression vector, and a process for producing the protein by cultivating the host cell, are disclosed.

Owner:MEIJI SEIKA KAISHA LTD

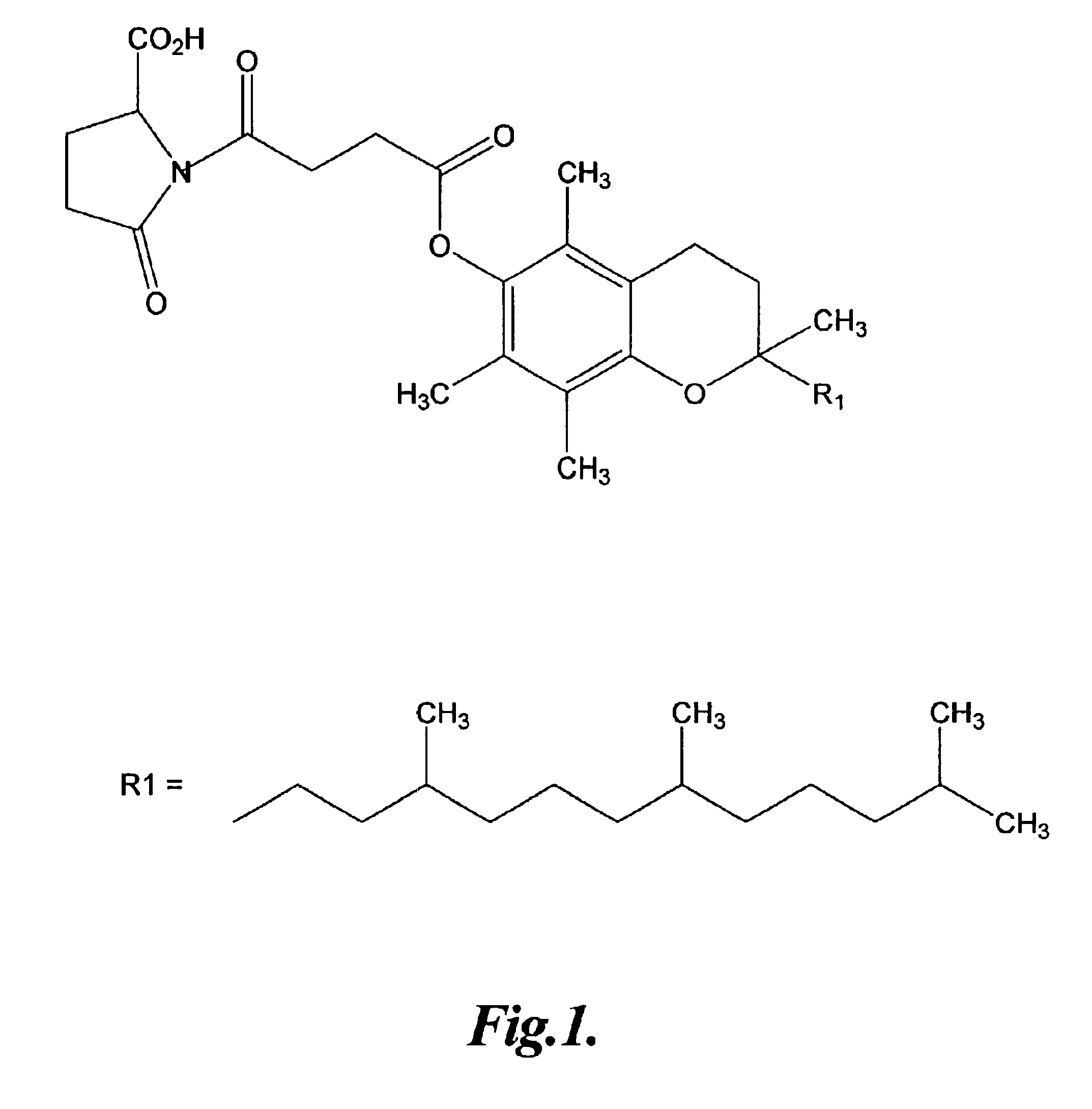

Vitamin E conjugates

Vitamin E conjugates, methods for their preparation, and compositions that include the conjugates. The vitamin E conjugates include a tocopherol moiety covalently coupled through a linker moiety to either a pyroglutamate moiety, a pyrrolidinone moiety, or a gentisic acid moiety.

Owner:SONUS PHARM INC

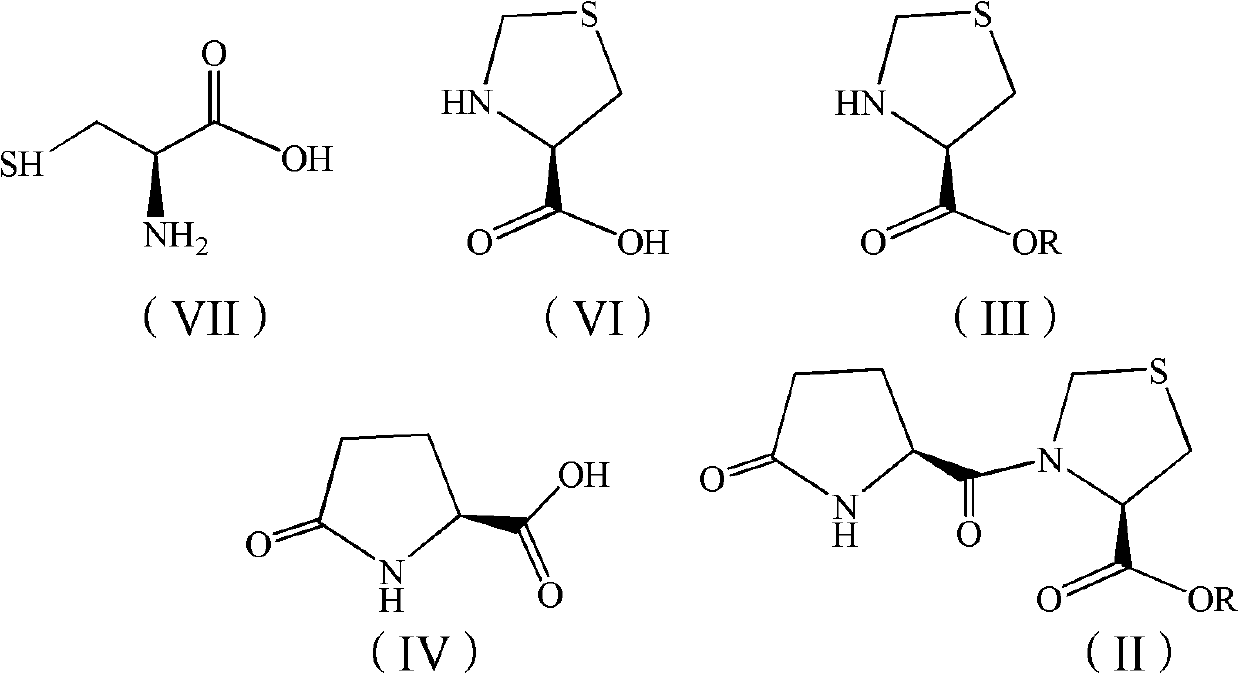

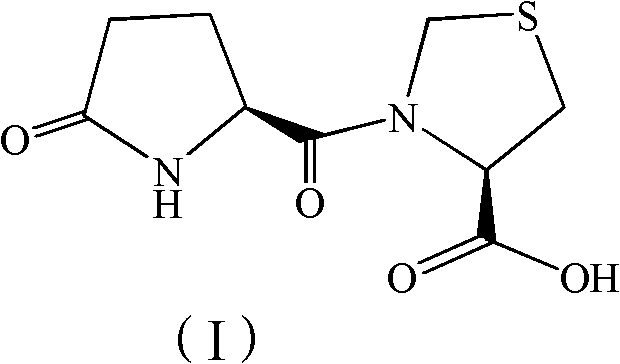

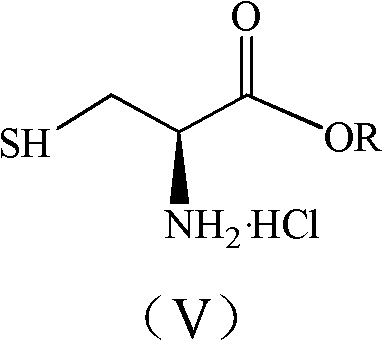

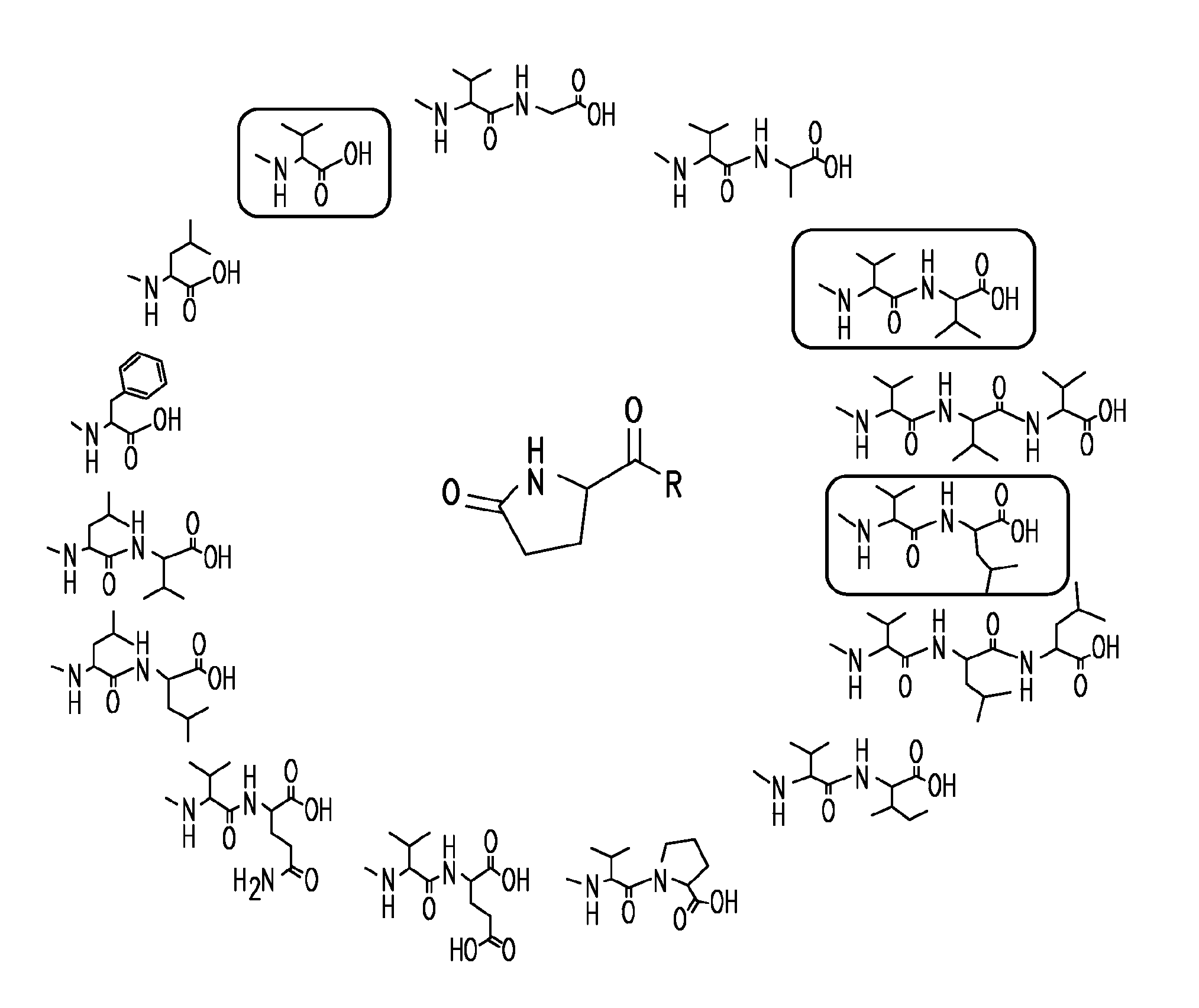

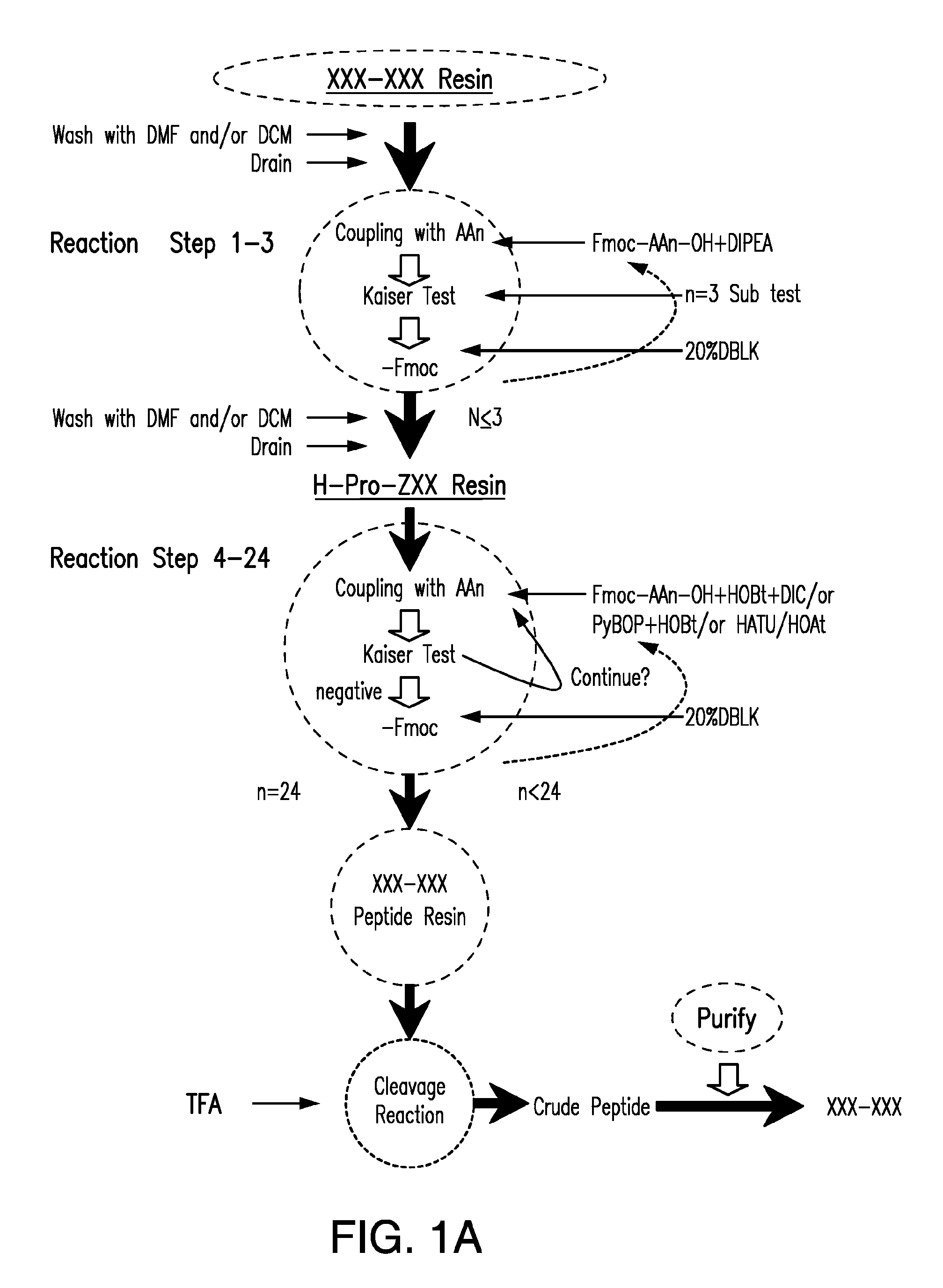

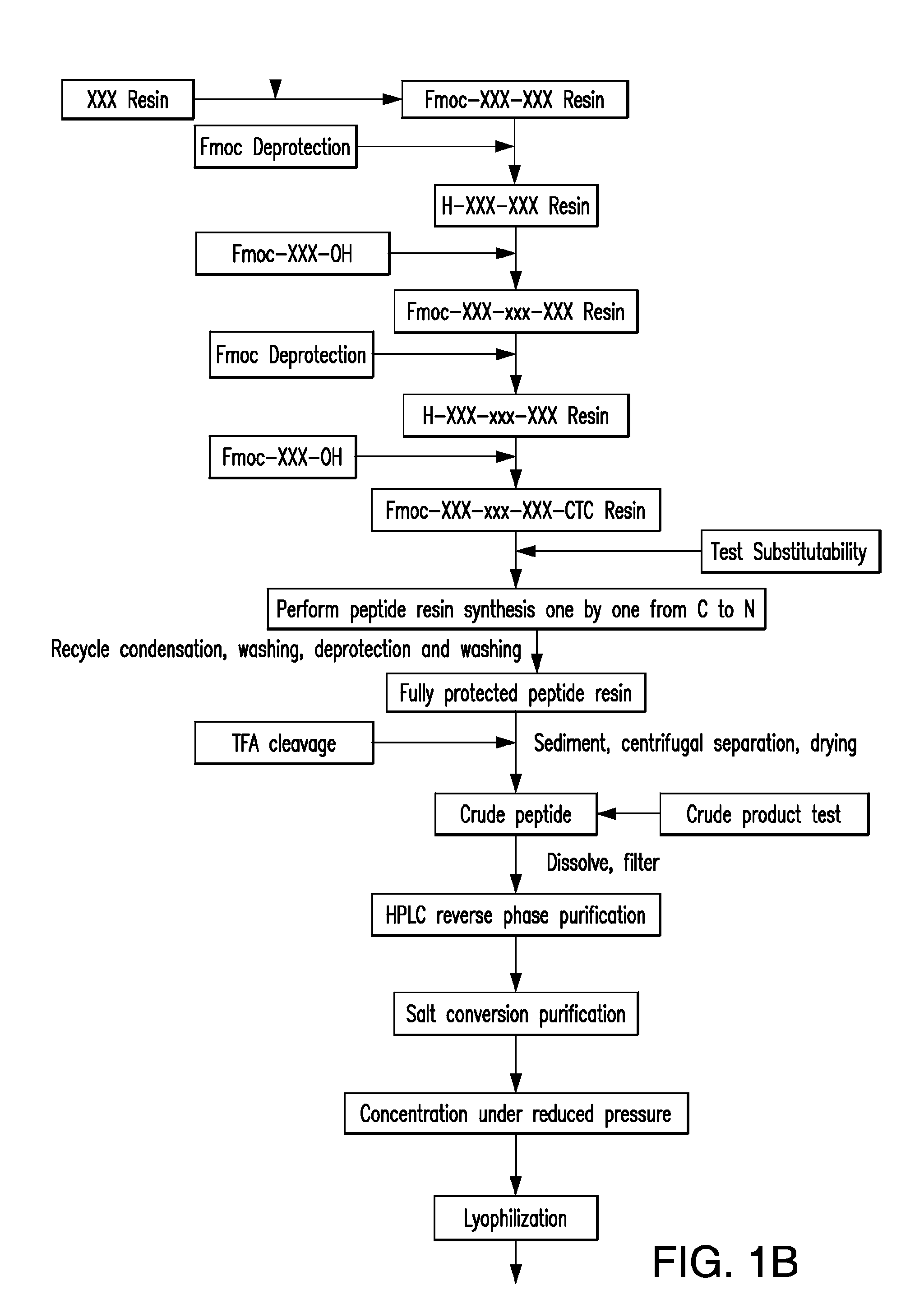

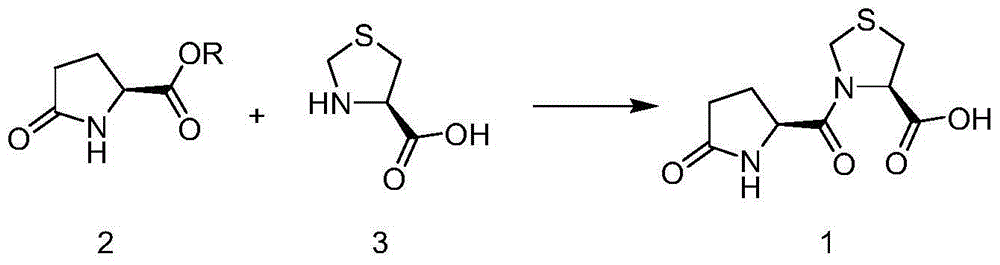

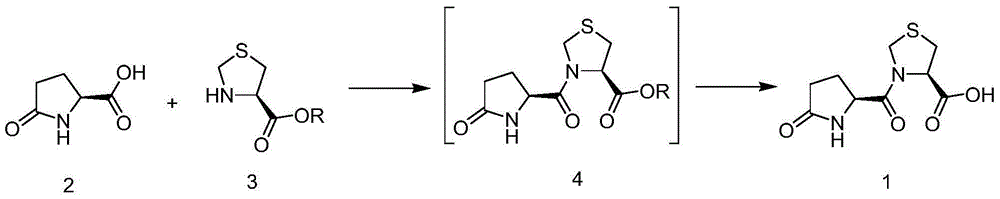

Synthesis method of pidotimod

InactiveCN102167727AThe synthesis process is simple and safeEasy to operatePeptidesSynthesis methodsThiazolidine carboxylate

The invention discloses a synthesis method of pidotimod. The synthesis method comprises the following steps: reacting L-cysteine with paraformaldehyde or formaldehyde to generate L-thiazolidine-4-carboxylic acid, performing esterification to generate L-thiazolidine-4-carboxylate, or reacting L-cysteine ester hydrochloride with paraformaldehyde or formaldehyde to generate L-thiazolidine-4-carboxylate; and then carrying out condensation reaction on L-thiazolidine-4-carboxylate and L-pyroglutamic acid to generate (4R)-3-[[(2S)-5-oxo-2-pyrrolidinyl]carbonyl]-4-thiazolidine carboxylate, and then synthesizing pidotimod through hydrolysis reaction. Compared with the prior art, the technology in the invention is simple, is easy to operate, has high product yield and low production cost, is environmentally friendly and is suitable for industrial production.

Owner:ZHEJIANG KINGLYUAN PHARMA

Method for preparing disubstituted piperidine and intermediates

The disclosure relates to a method for preparing a compound of formula (I),wherein P1 and P2 are groups protecting the carboxylic acid and oxyamine functions, starting from pyroglutamic acid (S). The disclosure also relates to novel intermediates.

Owner:FOREST LAB HLDG LTD

Method for increasing pyro-glutamic acid formation of a protein

ActiveUS20160060349A1Reduce or obtain desired product heterogeneityImmunoglobulins against cell receptors/antigens/surface-determinantsPeptide preparation methodsCrystallographyL-Pyroglutamic Acid

A method for conversion of an N-terminal glutamine and / or glutamic acid residue of a protein to pyro-glutamic acid within a purification process.

Owner:MABXIENCE RES SL

Flavor composition and edible compositions containing same

ActiveUS20150342231A1Increase and decrease clean salty tasteTaste saltyFrozen sweetsCocoaL-Pyroglutamic AcidUmami

Owner:MARS INC

Method for synthesizing pyroglutamic calcium glutamate with shells serving as calcium sources

The invention relates to a method for synthesizing pyroglutamic calcium glutamate with shells serving as calcium sources. Processing steps comprise shell pretreatment, synthesis, crystallization and drying. The method includes immersing the shells with 0.05M hydrochloric acid, drying, smashing and processing the shells with elutriation to obtain calcium shell powder, compounding pyroglutamic acid with the shell powder (the calciumcontent of calcium carbonate is calculated by 95%) according to a molar ratio of 2: (1.0-1.2), adding distilled water 20 to 25 times of the weight of the shell powder, stirring and heating the mixture to 55 DEG C to 60 DEG C, keeping the temperature for 1.5 to 2.0 hours, and performing cooling and suction filtration; performing pressure reduction and concentration on the obtained filtrate to enable the volume to be1 / 10, adding 95% of edible alcohol until the ethanol saturation degree is 90%, performing stirring, standing and filtering; and performing suction filtration, and drying the obtain crystals in a drying oven of 90 DEG C to obtain the pyroglutamic calcium glutamate product. According to the method, the process is simple, the product water solubility is good, various shells can be utilized highly, and the product can serve as calcium supplement, dietary supplement for improving the brain health level and the like.

Owner:QINGDAO UNIV

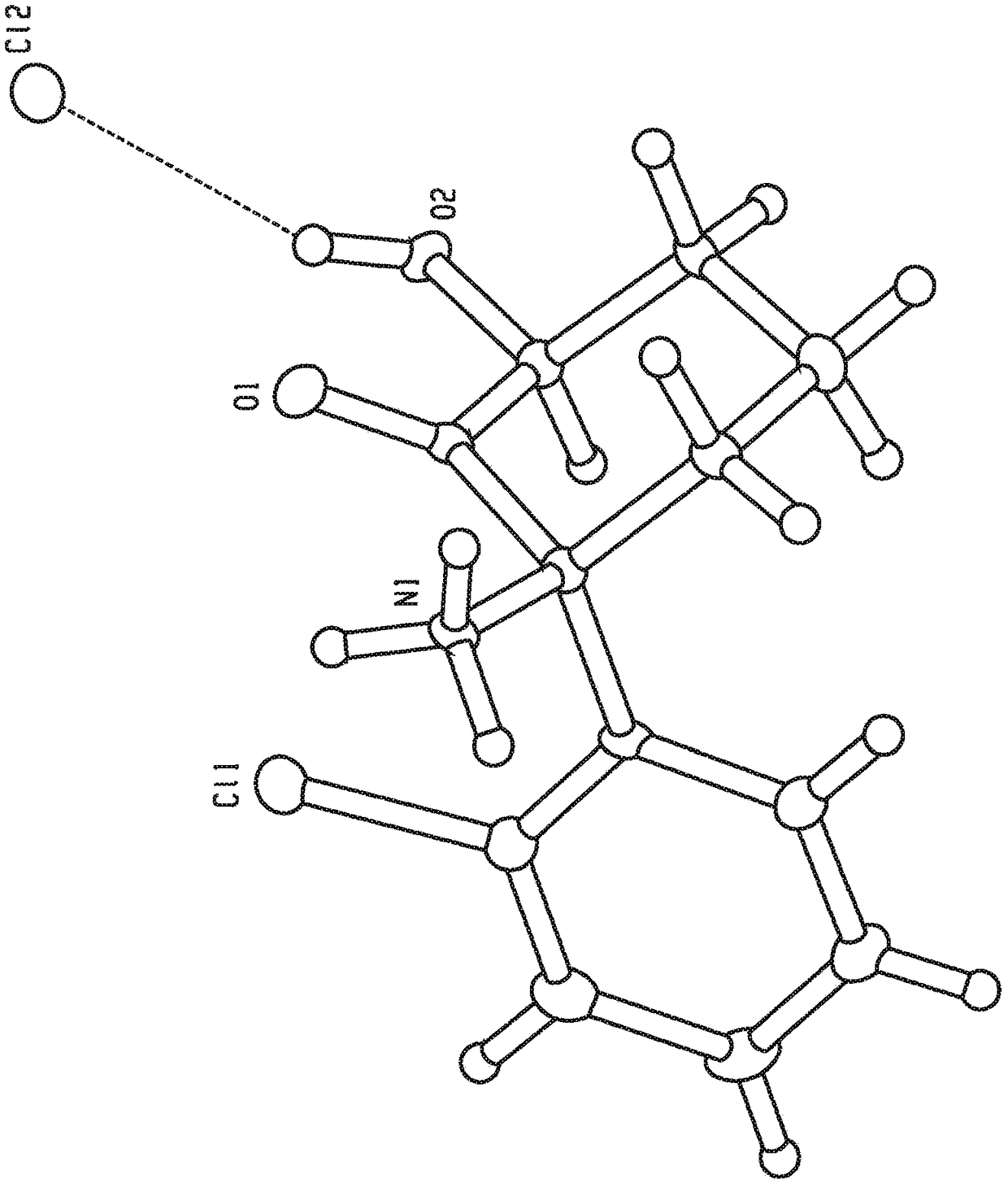

Crystal forms and methods of synthesis of (2r, 6r)-hydroxynorketamine and (2s, 6s)-hydroxynorketamine

ActiveCN109311801AOrganic active ingredientsCarbamic acid derivatives preparationL-Pyroglutamic AcidNorketamine

The disclosure provides a method for synthesizing free base forms of (2R,6R)-hydroxynorketamine (HNK) and (2S,6S)-hydroxynorketamine. In an embodiment synthesis of (2R,6R)-hydroxynorketamine (HNK) includes preparation of (R)-norketamine via chiral resolution from racemic norketamine via a chiral resolution with L-pyroglutamic acid. The disclosure also provided crystal forms of the corresponding (2R,6R)-hydroxynorketamine (HNK) and (2S,6S)-hydroxynorketamine hydrochloride salts.

Owner:US DEPT OF HEALTH & HUMAN SERVICES +1

Process for manufacturing a glutamic acid derivative and a pyroglutamic acid derivative and a novel intermediate in the manufacture thereof

InactiveUS7674915B2Efficient and easy manufactureEasy to manufactureOrganic compound preparationAmino-carboxyl compound preparationAlkyl transferHydroxyproline

Glutamic acid derivatives, in particular monatin, may be conveniently prepared by alkylating a 4-protected hydroxyl pyroglutamic acid derivative with an alkylating agent to prepare a 4-protected hydroxyl-4-alkylglutamic acid derivative, followed by the steps of hydrolysis and deprotection. The 4-protected hydroxyl pyroglutamic acid derivative is easy to produce from hydroxyproline. The 4-protected hydroxyl pyroglutamic acid derivative is particularly suitable for use in the efficient manufacture of monatin of high optical purity, since it can be alkylated selectively at the 4-position and stereoselectively and after its alkylation, it can easily be converted to a glutamic acid derivative.

Owner:AJINOMOTO CO INC

Process for manufacturing a glutamic acid derivative and a pyroglutamic acid derivative and a novel intermediate in the manufacture thereof

InactiveUS20100010234A1Efficient and easy manufactureEasy to manufactureSilicon organic compoundsOrganic compound preparationAlkyl transferHydroxyproline

Glutamic acid derivatives, in particular monatin, may be conveniently prepared by alkylating a 4-protected hydroxyl pyroglutamic acid derivative with an alkylating agent to prepare a 4-protected hydroxyl-4-alkylglutamic acid derivative, followed by the steps of hydrolysis and deprotection. The 4-protected hydroxyl pyroglutamic acid derivative is easy to produce from hydroxyproline. The 4-protected hydroxyl pyroglutamic acid derivative is particularly suitable for use in the efficient manufacture of monatin of high optical purity, since it can be alkylated selectively at the 4-position and stereoselectively and after its alkylation, it can easily be converted to a glutamic acid derivative.

Owner:AJINOMOTO CO INC

Process for producing pidotimod

InactiveCN104447947AReduce complexityReduce labor intensityPeptidesL-Pyroglutamic AcidCondensation reaction

The invention discloses a process for producing pidotimod and belongs to the technical field of medicines. A pidotimod crude product is prepared by a one-pot method which mainly comprises the following steps: (1) in the presence of a condensing agent as a catalyst, carrying out condensation reaction on L-pyroglutamic acid and L-4-thiazolidine formate to produce pidotimod ester and after the reaction is completed, filtering solid to obtain a mother liquid; and (2) adding an appropriate amount of acid into the mother liquid for hydrolyzing pidotimod ester, after the reaction is completed, separating liquid, retaining an aqueous phase, precipitating solids in an ice bath and filtering to obtain pidotimod. The yield is greatly increased, the process is simple, no special device is needed and pidotimod is suitable for large-scale production. According to the preparation process of pidotimod, by preferably selecting the process parameters, the yield and purity are greatly improved. Compared with the prior art, the yield of the pharmaceutical-grade pidotimod pure product is increased by 10-20%.

Owner:CHENGDU YILUKANG MEDICAL TECH & SERVICE

Heterocylcic derivatives as inhibitors of glutaminyl cyclase

ActiveCN102695546ALasting effectOrganic active ingredientsNervous disorderCyclaseL-Pyroglutamic Acid

The invention relates to novel pyrrolidine derivatives of formula (I), wherein R1, R2 and R3 are as defined herein, as inhibitors of glutaminyl cyclase (QC, EC 2.3.2.5). QC catalyzes the intramolecular cyclization of N-terminal glutamine residues into pyroglutamic acid (5-oxo-prolyl, pGlu*) under liberation of ammonia and the intramolecular cyclization of N-terminal glutamate residues into pyroglutamic acid under liberation of water.

Owner:维沃永治疗公众有限公司

Process for synthesis of L-glutamine

InactiveCN1569820AEasy to separateAvoid racemizationOrganic compound preparationCarboxylic acid amides preparationAcetic anhydrideL-Pyroglutamic Acid

Disclosed is a process for synthesis of L-glutamine which consists of, reacting ortho-phthalic anhydride and excess L-glutamine at 120-180 deg. C, obtaining phthaloyl-L-glutamine and L-pyroglutamic acid, separating to obtain L-pyroglutamic acid and phthaloyl-L-glutamine, subjecting the latter and acetic anhydride to azeotropy 3-30 minutes to form phthaloyl-L-glutamic acid anhydride, acting with stronger ammonia water directly at room temperature, obtaining phthaloyl-L-glutamine, charging hydrazine hydrate solution, dispensing 48 hours to remove the protective groups.

Owner:NANJING UNIV

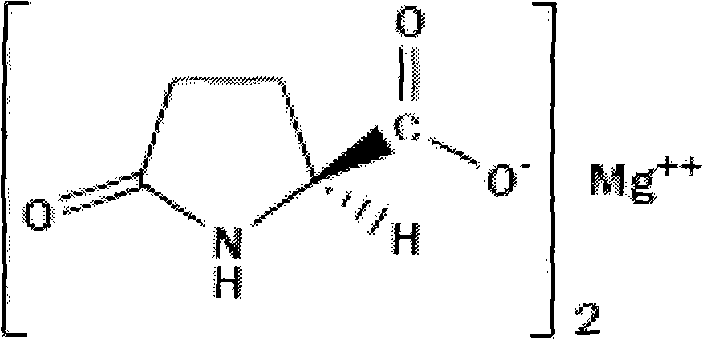

Method for preparing magnesium L-pyroglutamate

The invention discloses a method for preparing magnesium L-pyroglutamate. The preparation process is as follows: a, preparing L-pyroglutamic acid by dehydration, wherein L-glutamic acid and deionized water are put into a reaction kettle, stirred, heated to 100 to 128 DEG C and kept at the temperature for 6 to 12 hours; b, separating and extracting the L-pyroglutamic acid, wherein after pyrogenation is finished, the reaction solution is cooled to room temperature, deionized water is added to dilute the reaction solution, and the L-pyroglutamic acid and the non-pyrolyzed L-glutamic acid are separated by a cation exchange resin column; c, preparing the magnesium L-pyroglutamate, wherein the solution of the L-pyroglutamic acid obtained by the step b is stirred and heated and added with magnesium carbonate or magnesium oxide; and d, separating and extracting the magnesium L-pyroglutamate, wherein a sample is made after the reaction solution obtained by the step c is clear to test the pH value of the reaction solution, the pH value of the reaction solution is adjusted to 6.5 to 7.5, the reaction solution is concentrated till supersaturated solution is obtained, the supersaturated solution is stirred and cooled for crystallization, the solution is subjected to vacuum filtration and the crystals are subjected to vacuum drying to obtain the magnesium L-pyroglutamate. The method is simple in operation, high production efficiency and low in cost and is suitable for industrial production.

Owner:宜兴市前成生物有限公司

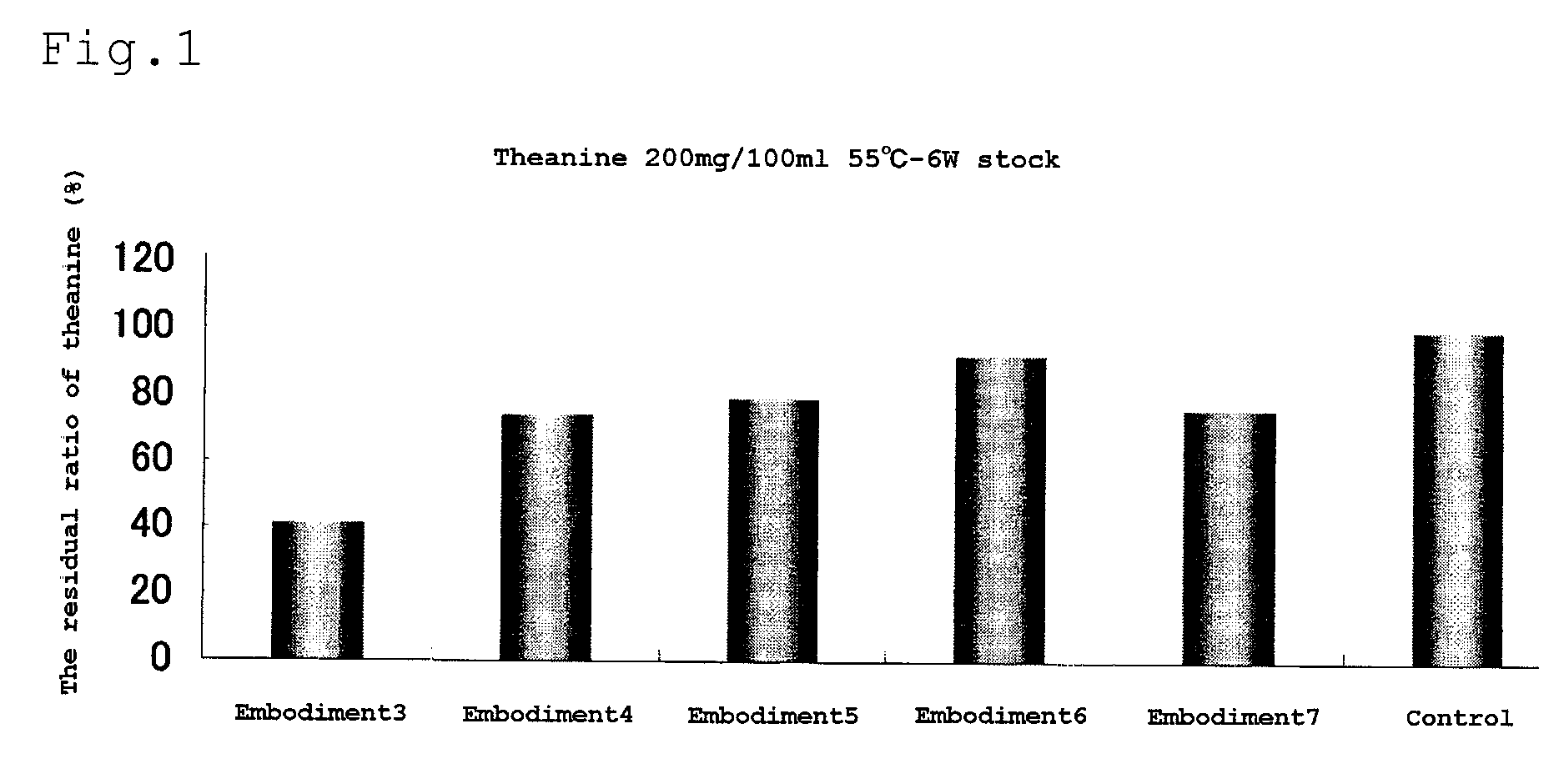

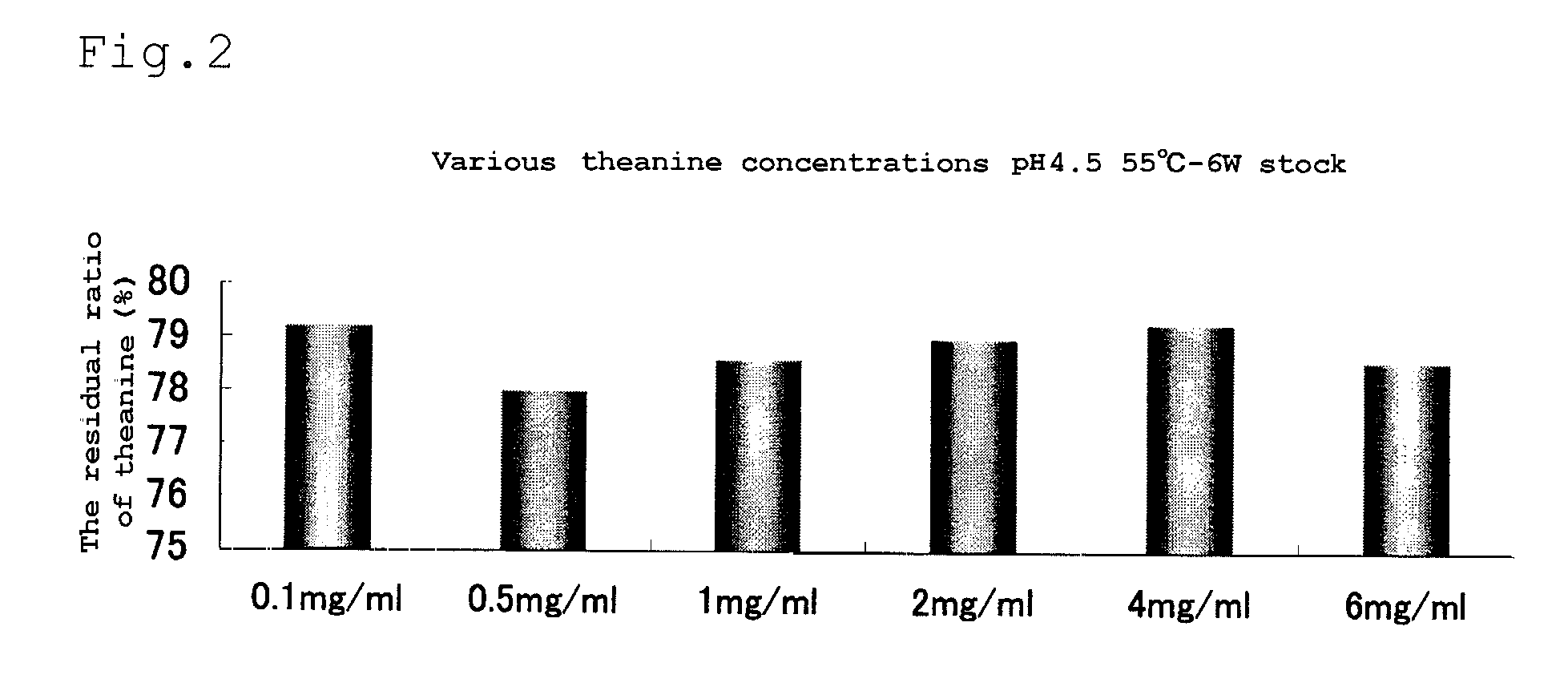

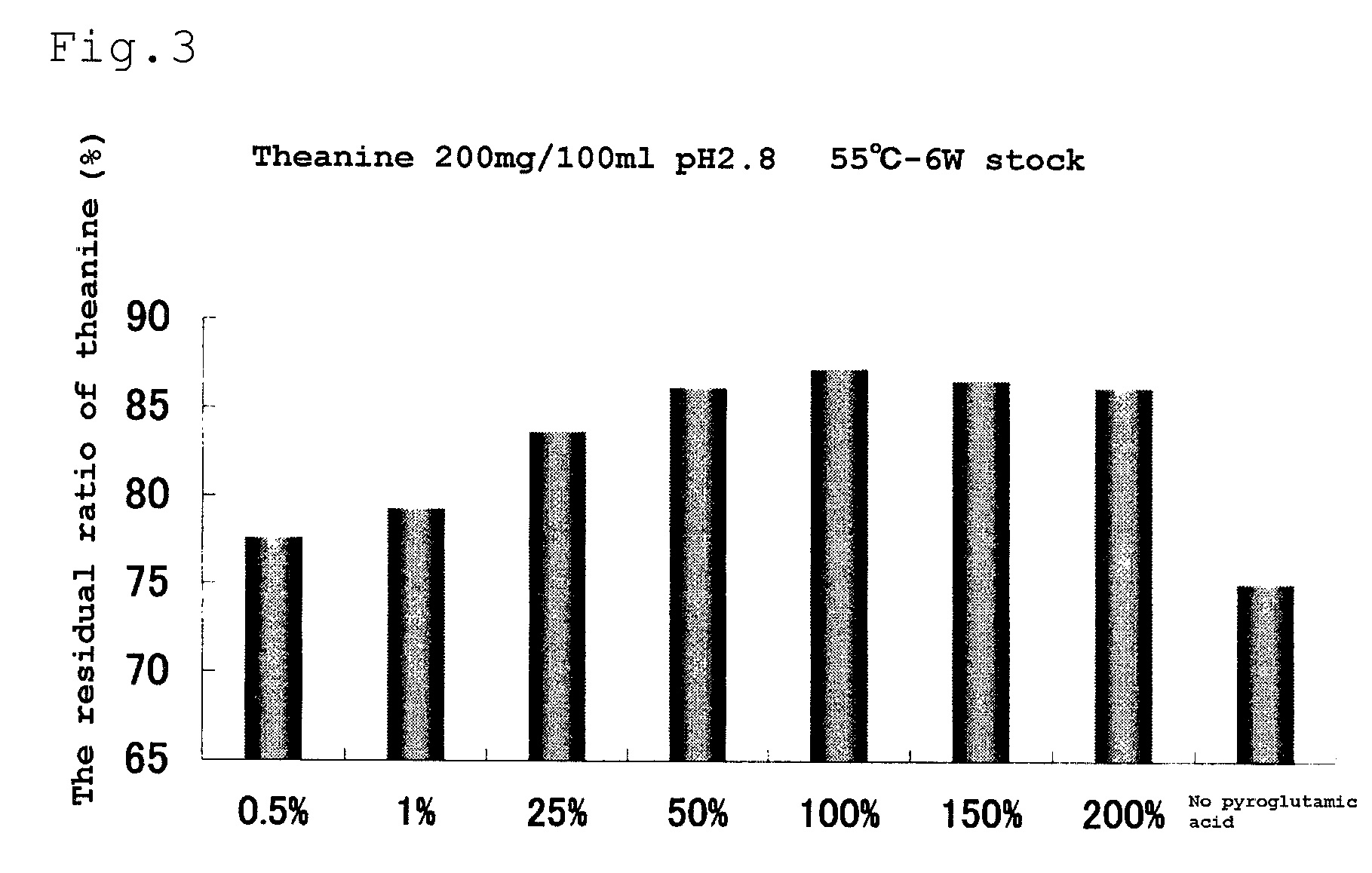

Hydrated Food

InactiveUS20090011108A1Improve taste thresholdLong preservationOrganic active ingredientsPharmaceutical non-active ingredientsL-Pyroglutamic AcidTheanine

Providing a hydrated food which contains theanine and in which theanine content can stably be maintained even when the hydrated food is preserved for a long period of time and the taste threshold of the food can be improved and the peculiar taste can be flavored. The problem can be overcome by a hydrated food containing theanine and pyroglutamic acid. In this case, it is preferable that pH ranges from about 2.8 to about 7.5. Furthermore, it is preferable that a content of pyroglutamic acid ranges from about 1% to about 20% relative to a content of theanine.

Owner:TAIYO KAGAKU CO LTD

Preparation method for L-pyroglutamic acid

ActiveCN102558015AIncrease production costReduce manufacturing costOrganic chemistryL-Pyroglutamic AcidGlutamic acid

The invention relates to a preparation method for L-pyroglutamic acid. The preparation method comprises the following steps of: melting glutamic acid serving as a raw material at a high temperature, and purifying; and concentrating and crystalizing to obtain the L-pyroglutamic acid. The method for the L-pyroglutamic acid, disclosed by the invention, is easy to operate, and has low cost and high yield.

Owner:BENGBU BBCA MEDICINE SCI DEV

Methods for improving health in animals

A method of improving health in an animal includes administering to the animal a nutritional supplement comprising an amino acid secretagogue composition, which stimulates the pituitary gland in the animal to produce growth hormone. The nutritional supplement may be administered orally. The nutritional supplement may comprise L-arginine hydrochloride, L-pyroglutamic acid, L-lysine hydrochloride, and cysteine. When desired, the nutritional supplement may consist essentially of L-arginine hydrochloride, L-pyroglutamic acid, L-lysine hydrochloride, N-acetyl-L-cysteine, L-glutamine, and schizonepeta powder.

Owner:IP INVESTMENT

Chemical synthesis method of pyroglutamic acid alcohol and intermediates thereof

The invention provides a chemosynthesis method of pyroglutamic acid alcohol and intermediates thereof, i.e., pyroglutamic acid and pyroglutamic acid ester, wherein, glutamic acid is used as raw material which is dehydrated and cyclized in a heating environment to generate pyroglutamic acid which is then reacted with absolute alcohol under the effect of catalyst to generate pyroglutamic acid ester; finally, pyroglutamic acid ester is dissolved in organic solvent to be reduced by reducing agent to generate pyroglutamic acid alcohol. The chemosynthesizing method has the advantages that the raw material is easy to get, the process route is short, catalyst and acid consumption are little, the operation environment is good, the yield coefficient is high, the cost is low, the purity is high and the method is easy for industrialization.

Owner:SICHUAN TONGSHENG AMINO ACID CO LTD

Antimicrobial compositions comprising pyroglutamic acid and optionally metal salts

InactiveCN1411372AGood for healthReduce absenteeismInorganic/elemental detergent compounding agentsAntibacterial agentsL-Pyroglutamic AcidAnti bacterial

The present invention relates to antimicrobial compositions that provide enhanced immediate as well as residual antiviral and antibacterial efficacy. When used, the antimicrobial composition of the present invention provides residual efficacy against Gram-negative bacteria, Gram-positive bacteria, viruses, and fungi not found in the prior art, as well as improved immediate germ reduction effects. The compositions of the present invention comprise: a) a safe and effective amount of pyroglutamic acid; b) a safe and effective amount of a metal salt; and c) a skin-acceptable carrier of the acid and salt, wherein the pH of the composition is About 1-about 7. The invention also relates to methods of using the compositions of the invention and antimicrobial products comprising the compositions of the invention.

Owner:PROCTER & GAMBLE CO

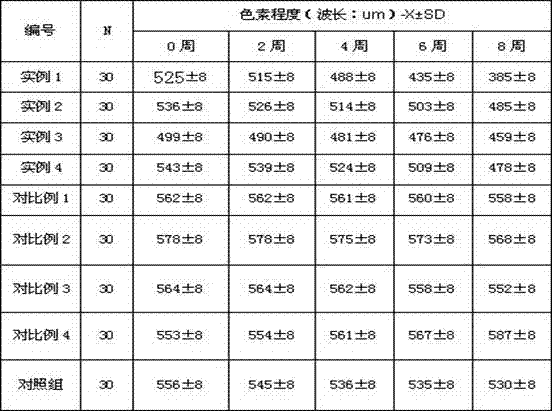

Whitening cosmetic composition

InactiveCN107149578AGood conditionRestore evenlyCosmetic preparationsToilet preparationsWrinkle skinL-Pyroglutamic Acid

The invention discloses a whitening cosmetic composition, mainly comprising PCA (pyroglutamic acid) zinc, chlorella / white lupin protein fermented product, watercress flower / leaf / stem extract, vitamin C ethyl ether and other components. The whitening cosmetic composition can brighten and white the skin and can also moisturize the skin and fade wrinkles.

Owner:广东创美抗衰老研究有限公司

Creatine pyroglutamic acid salts and methods for their production and use in individuals

The present invention relates to a method of production and the use of a compositional ingredient. Specifically, the present invention relates to hydrosoluble stable organic salts of creatine and pyroglutamic acid. The compositional ingredient may be useful for the regulation of athletic and cognitive functions.

Owner:NORTHERN INNOVATIONS HLDG

Theanine preparing process

InactiveCN1706816AReduce pollutionLow reaction conditionsOrganic chemistryL-Pyroglutamic AcidReaction temperature

The present invention provides theanine preparing process. Under closed condition, L-pyroglutamic acid and anhydrous ethylamine react directly to produce theanine at temperature of 30-55 deg.c and pressure of 2-4 MPa. The preparation process uses marketable materials, and has safe and relaxed reaction condition, product yield over 20 %, product purity over 98 %, low production cost, less investment in apparatus, and is suitable for industrial production. What is more important is that all the side products of different steps may be reused in the next circulation, resulting in high comprehensive utilization and few environmental pollution.

Owner:郑国斌

Preparation method of inflaming retarding type aqueous polyurethane coating

ActiveCN104031544AFlame retardant and cost-effectiveImprove toughnessFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a preparation method of an inflaming retarding type aqueous polyurethane coating. Under the condition that dibutylboron trifluoromethanesulfonate catalysts exist, 1,4-Bis(hydroxydimethylsily)benzene and hexamethylene diisocyanate are mixed by a weight ratio of 2:1 and react for 2-4 hours at 80-110 DEG C, then parathion is added into a reaction system, the reaction temperature is 80-110 DEG C, the reaction time is 40-60 minutes, and a polyurethane prepolymer is obtained; chain extenders and butanone are added into the polyurethane prepolymer and are stirred for 3-5 hours at 65-85 DEG C, trithylamine is added for neutral reaction for 10-40 minutes, water is added for emulsification, and aqueous polyurethane is formed; aluminum salt dispersion liquid, L-pyroglutamic acid, screw ring phosphoryl nafoxidine ester and N-aminoethyl-3-aminopropyl triethoxysilane are added into the aqueous polyurethane and are sheared and stirred for 40-80 minutes under the condition of pH being 7, and the inflaming retarding type aqueous polyurethane coating is obtained. The flammability and mechanical property of the obtained polyurethane coating are greatly improved.

Owner:广东新灏元科技有限公司

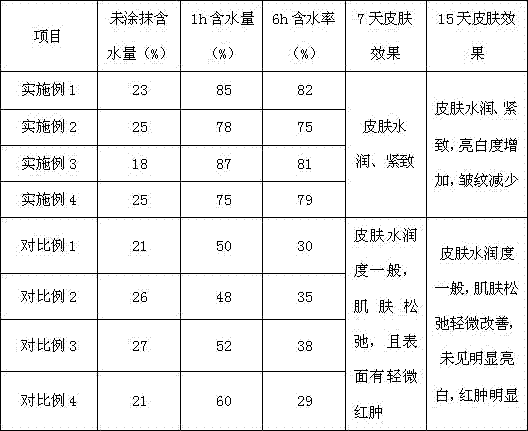

Amino acid compound and antibacterial composition and application thereof

ActiveCN107573271ASimple structureRaw materials are easy to getBiocidePlant growth regulatorsPlant diseaseBlight

The invention discloses an amino acid compound. The amino acid compound is formed through coordination of L-pyroglutamic acid and copper ions, and is of a structure with a formula I. The invention also provides an amino acid antibacterial compound, and antibacterial active components of the amino acid antibacterial compound comprise the amino acid compound. The compound disclosed by the inventioncan be prepared into soluble powder allowed to be used in agriculture. The invention also provides application of the amino acid compound for preventing and controlling crop diseases, and has better prevention and control effects for cucumber downy mildew, potato late blight and grape downy mildew.

Owner:吴文君 +2

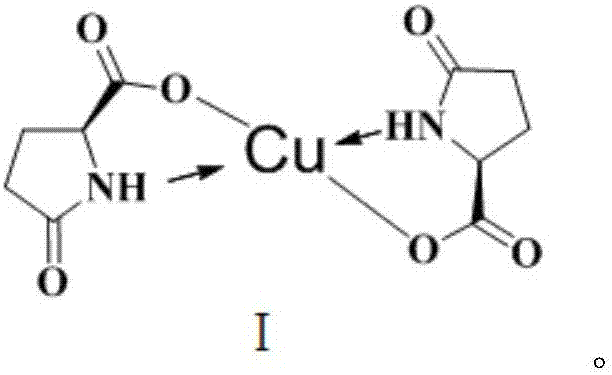

Anti-platelet aggregation peptide and application thereof

ActiveCN102020699AStrong anti-platelet aggregation effectHigh activityAntipyreticAnalgesicsDiseaseAnti platelet

The invention provides an anti-platelet aggregation optically active polypeptide compound. The compound consists of three amino acids, namely levorotatory or dextrorotatory tryptophan, asparagine and pyroglutamic acid, and is used for treating platelet aggregation-related heart cerebrovascular diseases, such as ischemic stroke, inflammation, asthma and the like.

Owner:JIANGSU CAREFREE PHARM CO LTD

Glutamic acid rotating crystal method

ActiveCN101550088AHigh purityAvoid damageOrganic compound preparationAmino-carboxyl compound preparationThermal insulationDissolution

The present invention discloses a glutamic acid rotating crystal method. the method includes following steps: adding transformation mother liquor to alpha-glutamic acid crystal to make crystal suspension; heating up to 55-85 DEG, washing water, agitating, thermal insulation; centrifugal separation to obtain glutamic acid; mixing glutamic acid and water to make glutamic acid suspension; adding sodium hydroxide or gourment powder mother liquor, controlling sodion concentration as 0.2-2.0% in volume percent concentration, heating up to 70-95 DEG, rotating crystal for 0.5-3 hours; cool down, agitation for producing crystal. Technics of the invention is simple, which greatly improved crystal rotating speed and glutamic acid purity; reducing loss of crystal, reducing dosage of sodion and transformation temperature, reducing dissolution of the glutamic acid and generation of the pyroglutamic acid, improving products quality and yield; saving a great amount of processing cost for gourment powder refining, and reducing consumption of electric, water, vapor and generation of sewerage in gourment powder production.

Owner:重庆飞亚实业有限公司

Flame retardant waterborne polyurethane coating capable of being used for building

The invention discloses a preparation method of an inflaming retarding type aqueous polyurethane coating. Under the condition that dibutylboron trifluoromethanesulfonate catalysts exist, 1,4-Bis(hydroxydimethylsily)benzene and hexamethylene diisocyanate are mixed by a weight ratio of 2:1 and react for 2-4 hours at 80-110 DEG C, then parathion is added into a reaction system, the reaction temperature is 80-110 DEG C, the reaction time is 40-60 minutes, and a polyurethane prepolymer is obtained; chain extenders and butanone are added into the polyurethane prepolymer and are stirred for 3-5 hours at 65-85 DEG C, trithylamine is added for neutral reaction for 10-40 minutes, water is added for emulsification, and aqueous polyurethane is formed; aluminum salt dispersion liquid, L-pyroglutamic acid, screw ring phosphoryl nafoxidine ester and N-aminoethyl-3-aminopropyl triethoxysilane are added into the aqueous polyurethane and are sheared and stirred for 40-80 minutes under the condition of pH being 7, and the inflaming retarding type aqueous polyurethane coating is obtained. The flammability and mechanical property of the obtained polyurethane coating are greatly improved.

Owner:广州市见微化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com