Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Fusion frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a fusion frame of a vector space is a natural extension of a frame. It is an additive construct of several, potentially "overlapping" frames. The motivation for this concept comes from the event that a signal can not be acquired by a single sensor alone (a constraint found by limitations of hardware or data throughput), rather the partial components of the signal must be collected via a network of sensors, and the partial signal representations are then fused into the complete signal.

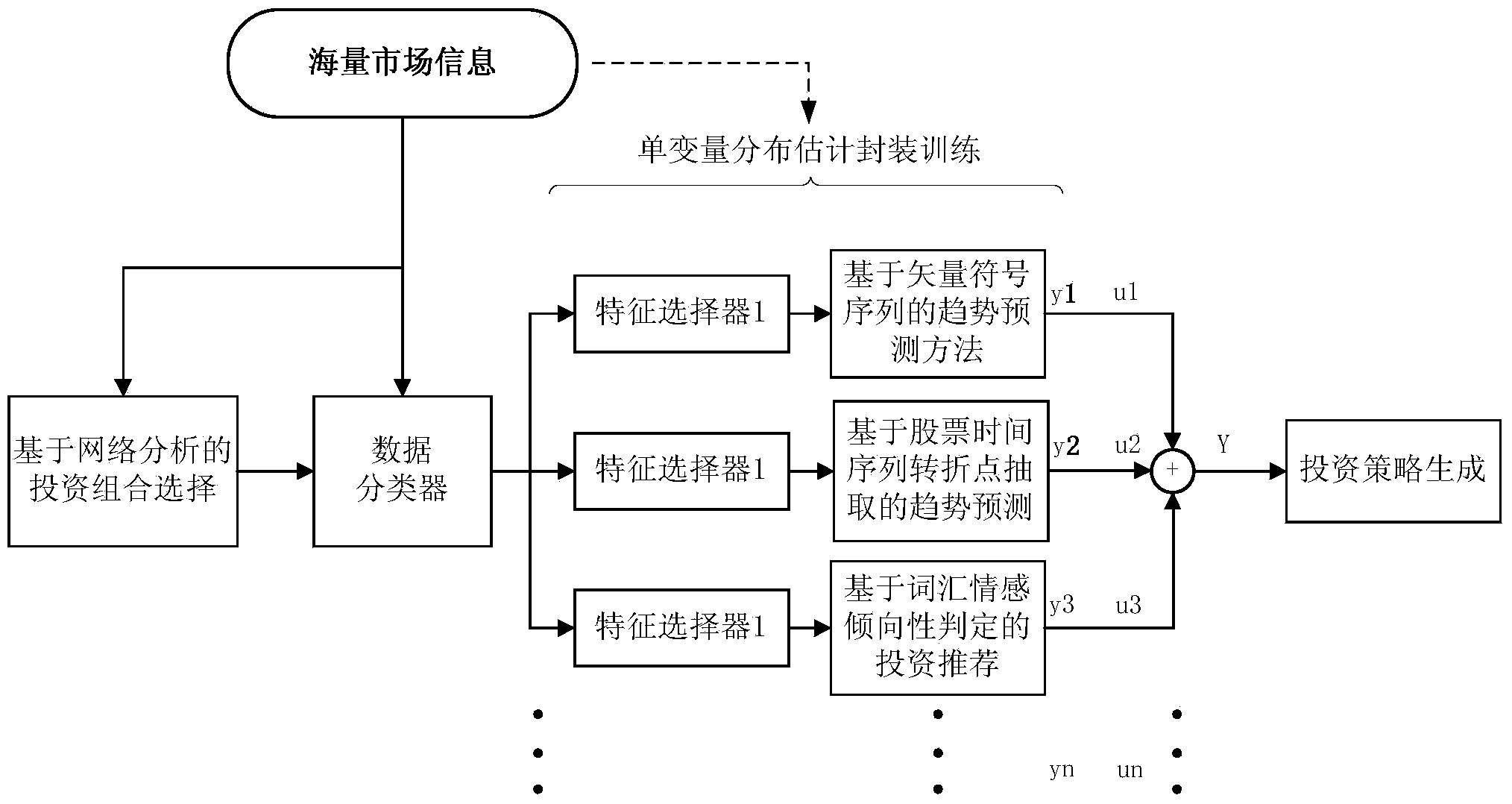

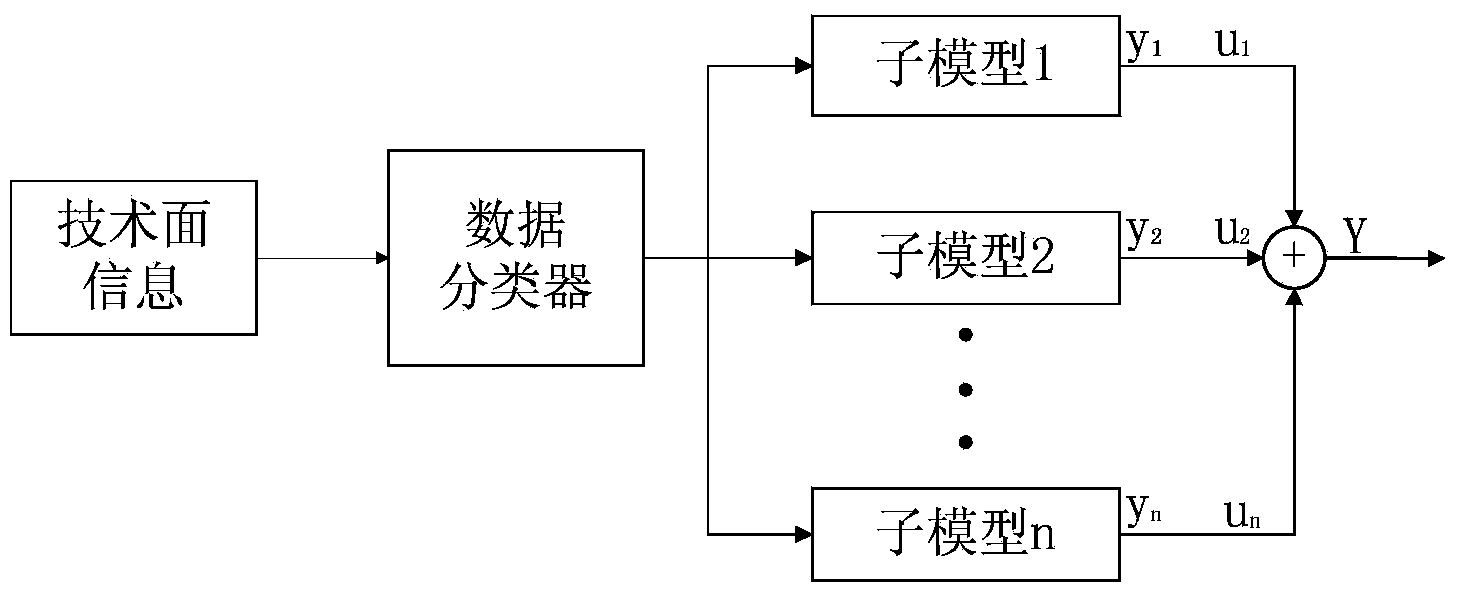

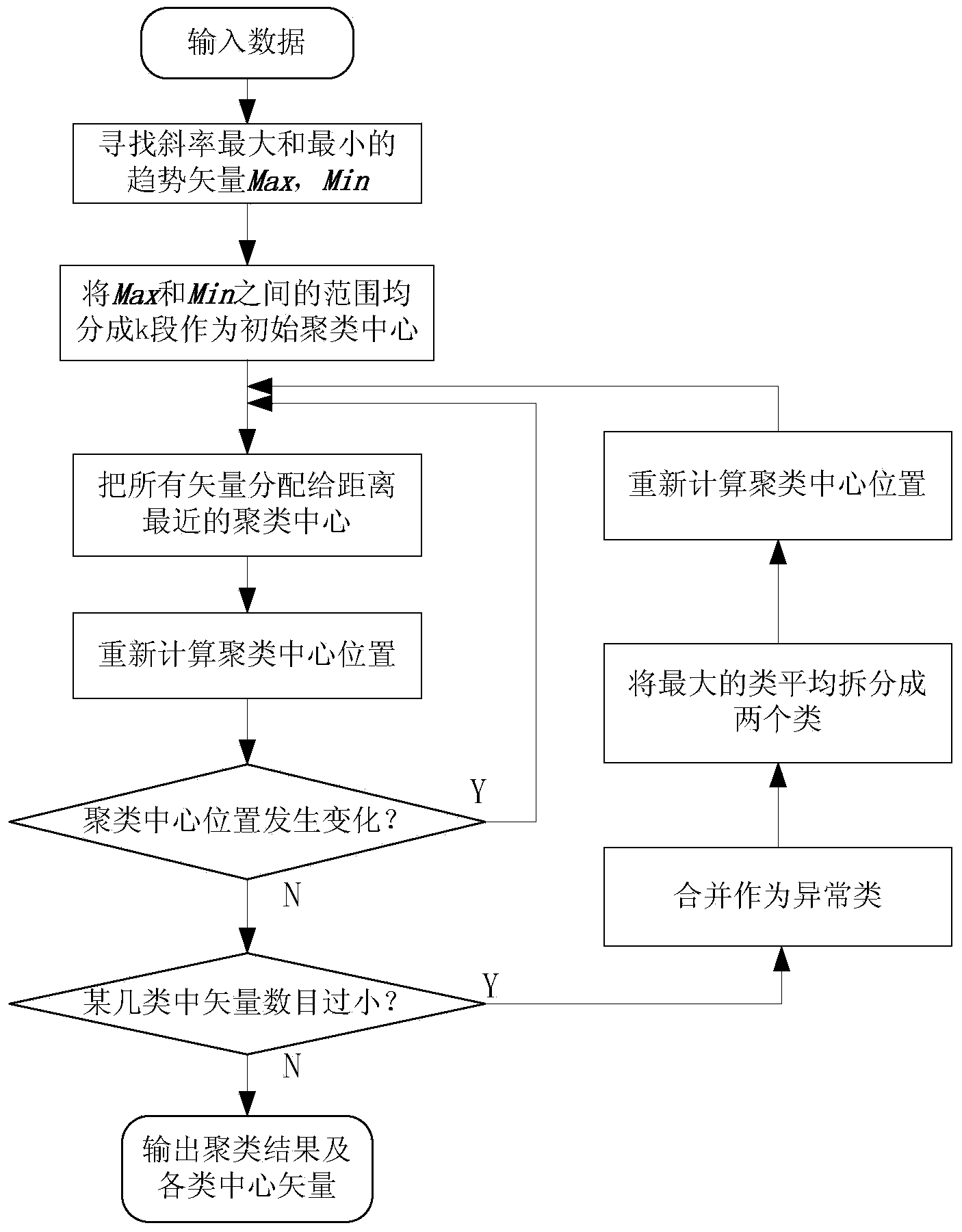

Stock market investment decision-making method based on network analysis and multi-model fusion

InactiveCN103985055AComplete and Comprehensive UtilizationEnsure real-time requirementsFinanceForecastingNODALNetwork connection

The invention discloses a stock market investment decision-making method based on network analysis and multi-model fusion. The method includes the steps that fundamental information is grabbed from a network and then network nodes and network connection are constructed; a complex social network model is constructed; an investment portfolio is selected by means of a network analysis method and then data involved in the investment portfolio are input into a multi-model fusion frame, wherein the multi-model fusion frame comprises a plurality of sub-models; all the sub-models conduct market trend prediction with different characteristics according to technical information of different characteristics grabbed in the network generate predicted values of the corresponding sub-models, the predicted values are weighted and summated to obtain a comprehensive market trend predicted value, and then corresponding investment strategies are generated according to the comprehensive market trend predicted value. According to the method, risk factors, which are ignored in general researches, of the investment portfolio are comprehensively considered from multiple angles, real-time requirements of the strategies are guaranteed through the methods such as dimension reduction data preselection of fundamentals and technical feature selection, and consequently the more reliable investment strategies are provided.

Owner:XI AN JIAOTONG UNIV

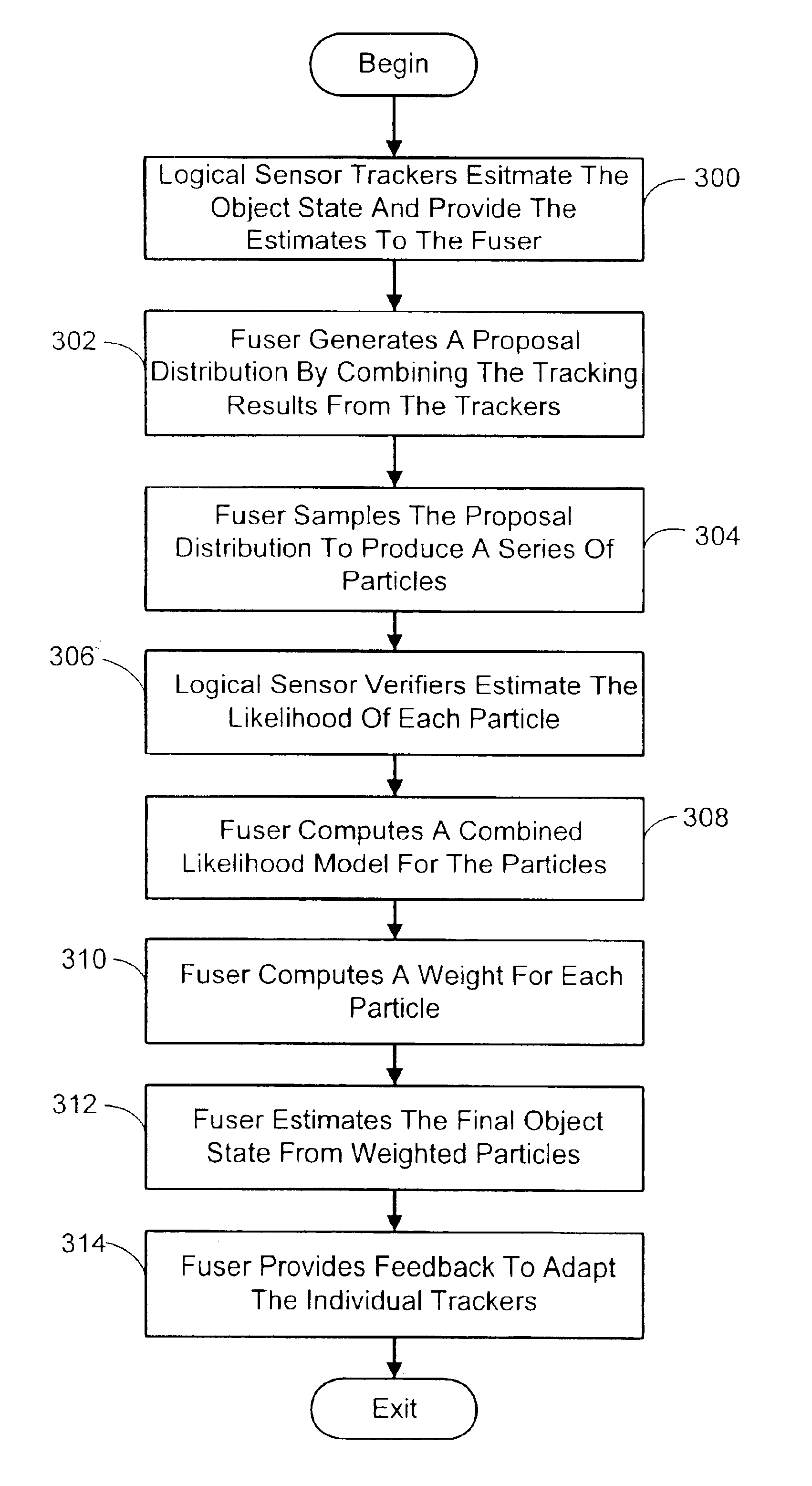

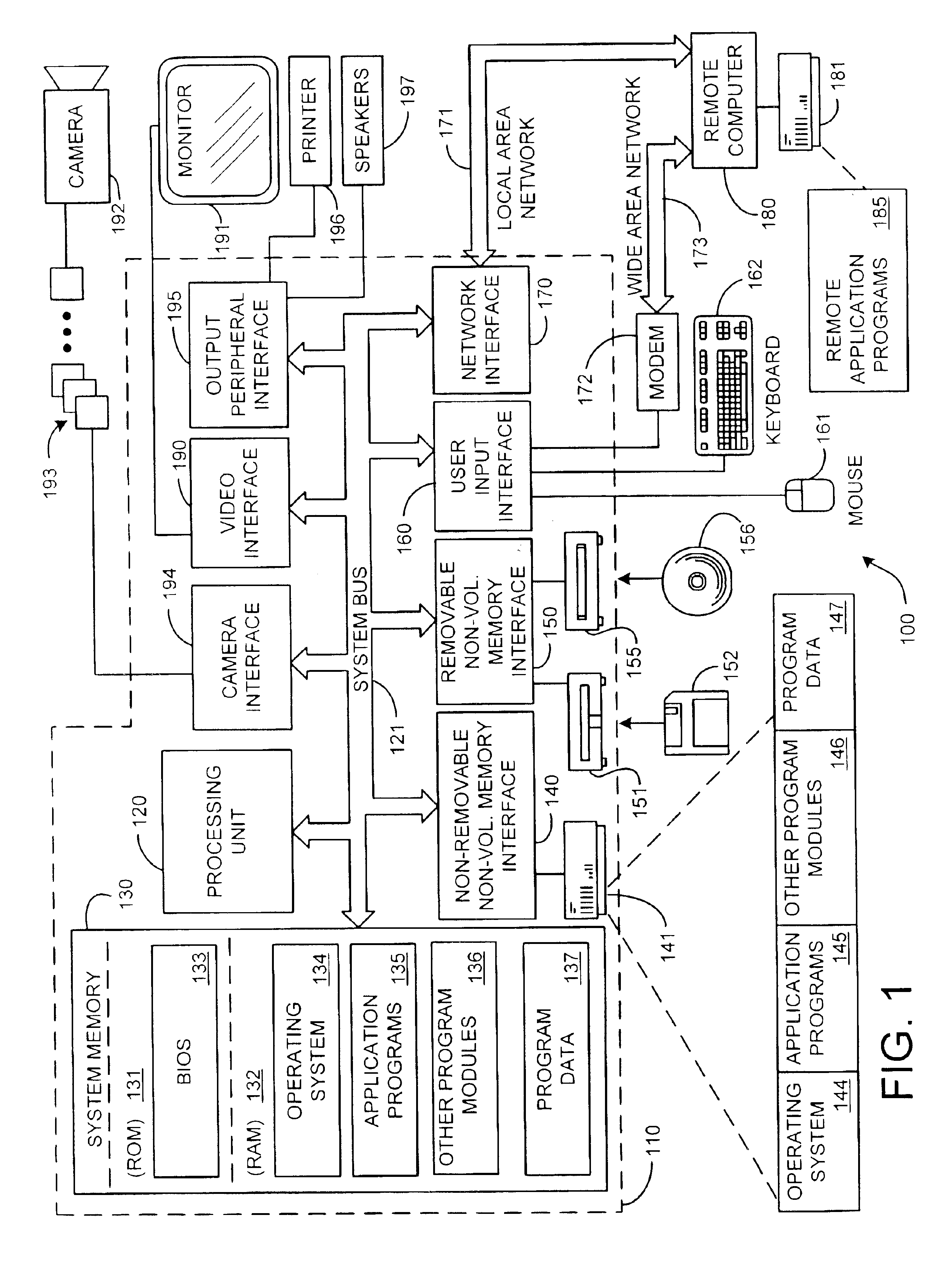

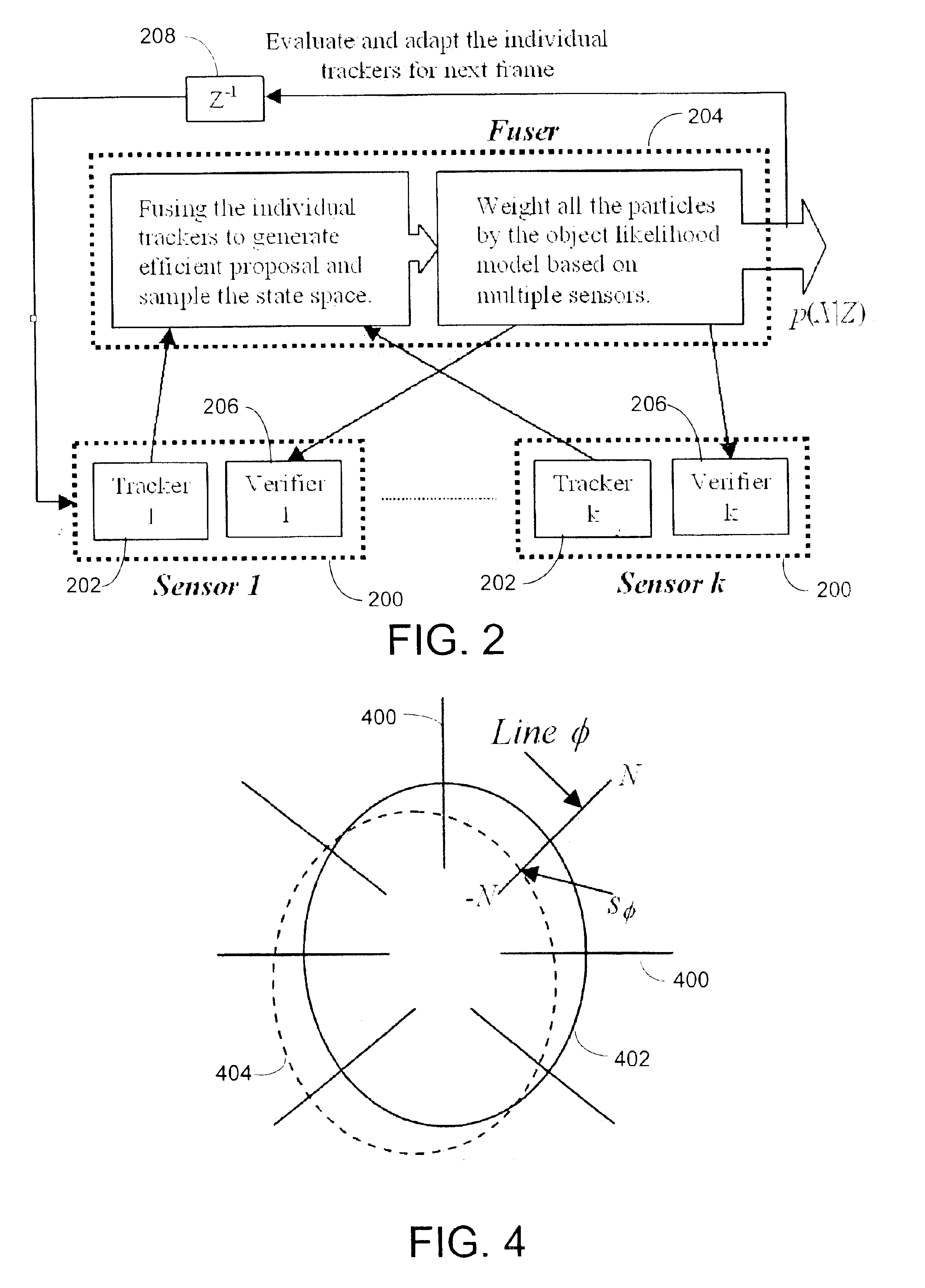

System and process for tracking an object state using a particle filter sensor fusion technique

ActiveUS6882959B2Quick and computationally inexpensive estimateLess computing powerImage analysisSpeech analysisSound source locationHypothesis

A system and process for tracking an object state over time using particle filter sensor fusion and a plurality of logical sensor modules is presented. This new fusion framework combines both the bottom-up and top-down approaches to sensor fusion to probabilistically fuse multiple sensing modalities. At the lower level, individual vision and audio trackers can be designed to generate effective proposals for the fuser. At the higher level, the fuser performs reliable tracking by verifying hypotheses over multiple likelihood models from multiple cues. Different from the traditional fusion algorithms, the present framework is a closed-loop system where the fuser and trackers coordinate their tracking information. Furthermore, to handle non-stationary situations, the present framework evaluates the performance of the individual trackers and dynamically updates their object states. A real-time speaker tracking system based on the proposed framework is feasible by fusing object contour, color and sound source location.

Owner:MICROSOFT TECH LICENSING LLC

Multisource navigation information fusion method based on factor graph

InactiveCN106197408AHigh precisionImprove fault toleranceNavigational calculation instrumentsNavigation by speed/acceleration measurementsInformation integrationFusion frame

The invention discloses a multisource navigation information fusion method based on a factor graph. The multisource navigation information fusion method comprises the following steps: firstly obtaining a track meeting the actual environment and task requirement by carrying out track setting, obtaining sensor measurement information by virtue of various sensors, obtaining inertial navigation IMU data by virtue of an inertia measurement unit, constructing a multisource navigation information fusion frame by virtue of the factor graph, and finally obtaining navigation information through multisource information filtering fusion. The multisource navigation information fusion method disclosed by the invention has the advantages that the factor graph and a multisource information fusion algorithm are combined together and processing on asynchronous measurement information and requirement on navigation accuracy are realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

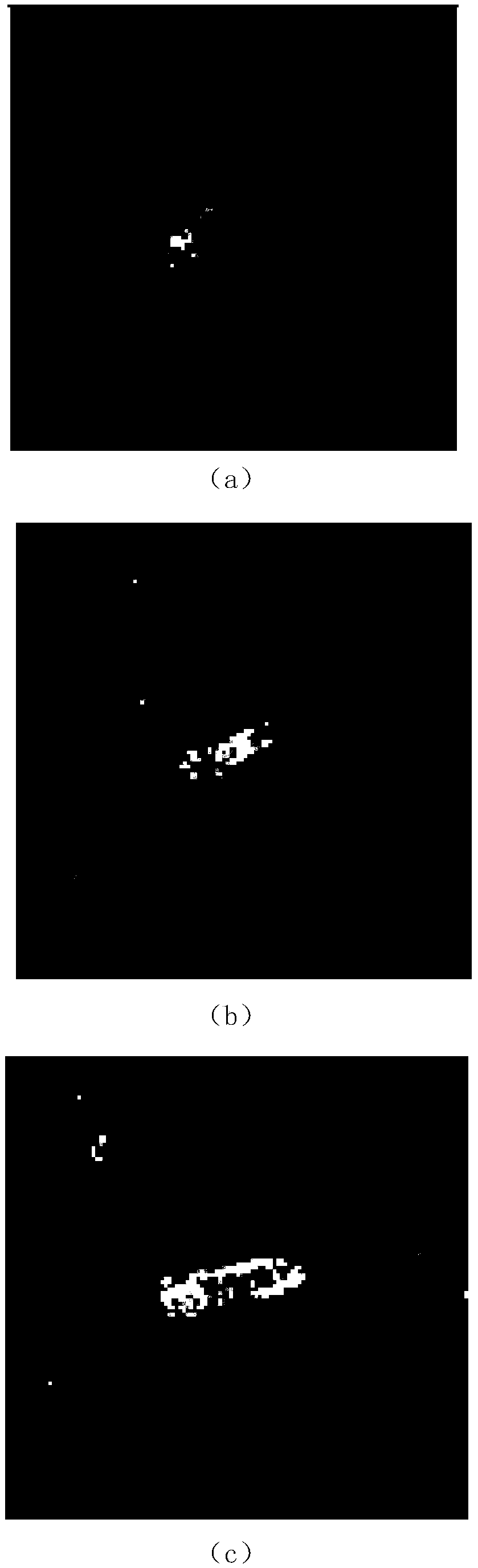

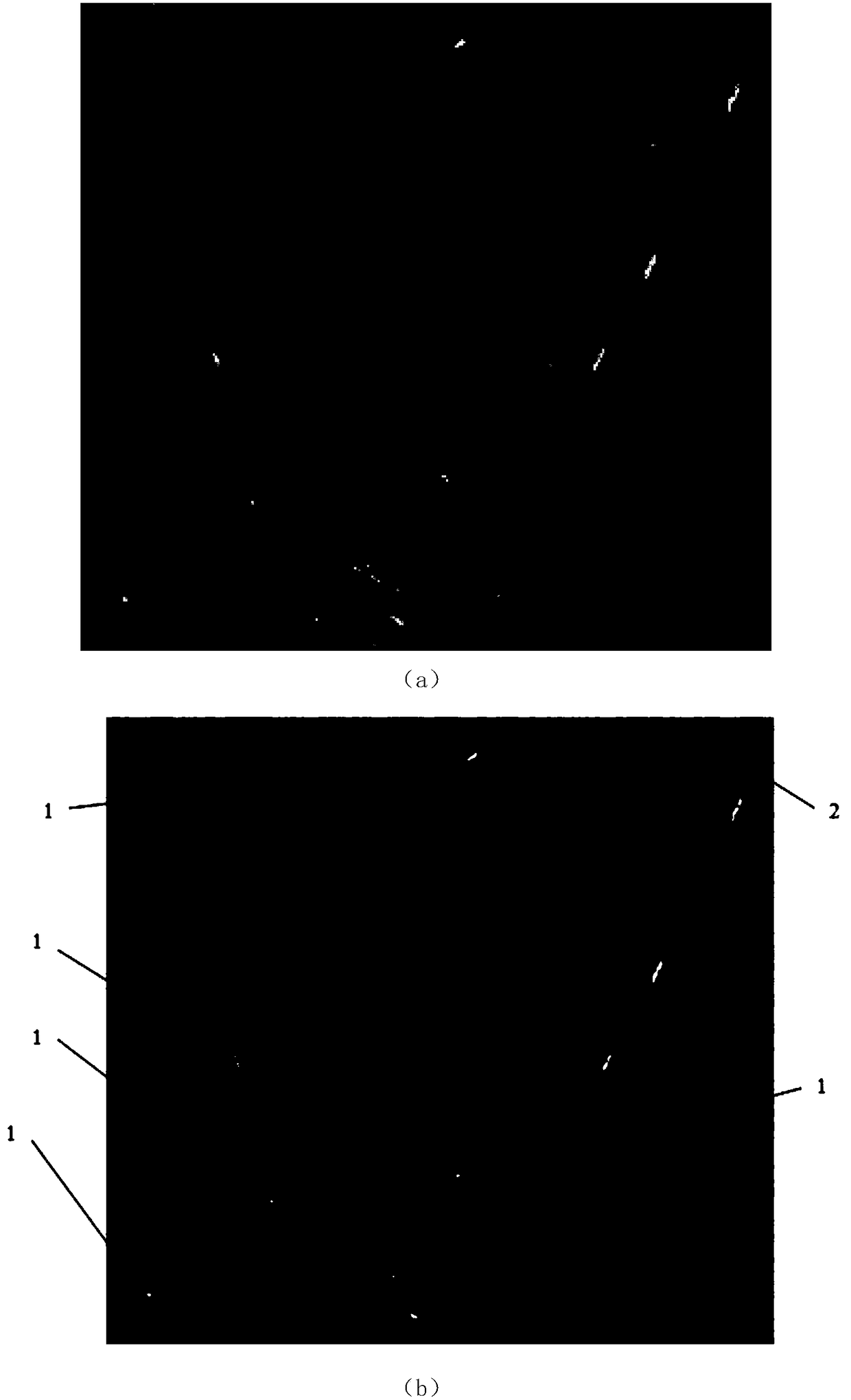

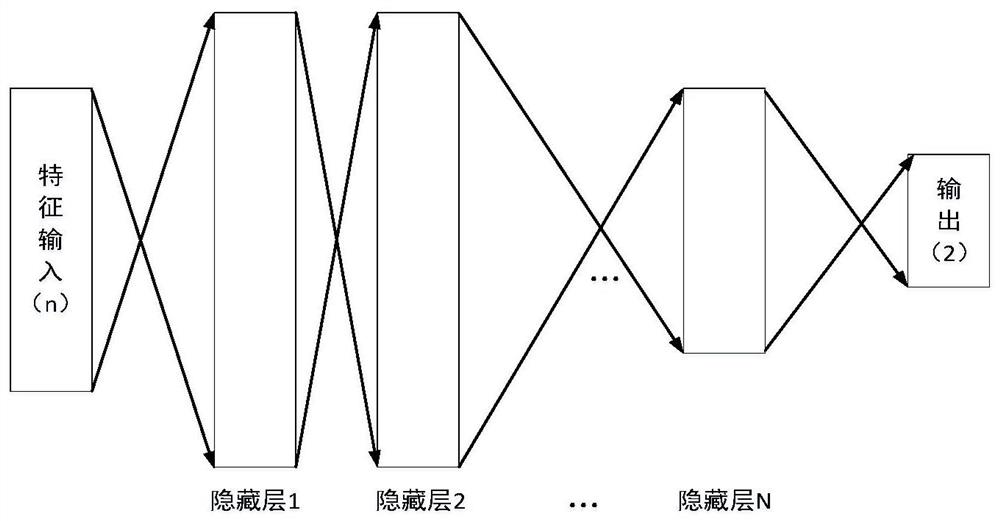

Complex background SAR vehicle target detection method based on CNN

InactiveCN109284704ASolve the degradation problemAvoid the phenomenon of gradient disappearanceScene recognitionNeural architecturesPattern recognitionData set

The invention discloses a complex background SAR vehicle target detection method based on CNN, comprising the following steps: S1, collecting pattern data and processing to obtain sample data set; S2,ResNet and Faster-RCNN framework is fused to form a fusion framework, and the fusion framework is retrained on the basis of pre-training weights; S3, adopting the fusion frame after retraining to carry out target detection and recognition on the pattern data; the invention combines ResNet and Faster-RCNN framework, using Faster-RCNN framework realizes the end-to-end target detection process to realize the full automation of target detection, which is convenient for engineering application. At the same time, the residual network model is used to solve the problem of network model degradation in depth convolution network model, and the phenomenon of gradient disappearance in depth convolution network model is avoided.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

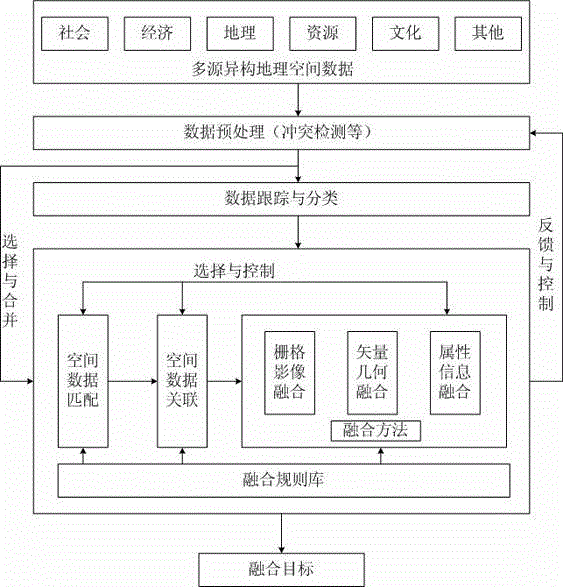

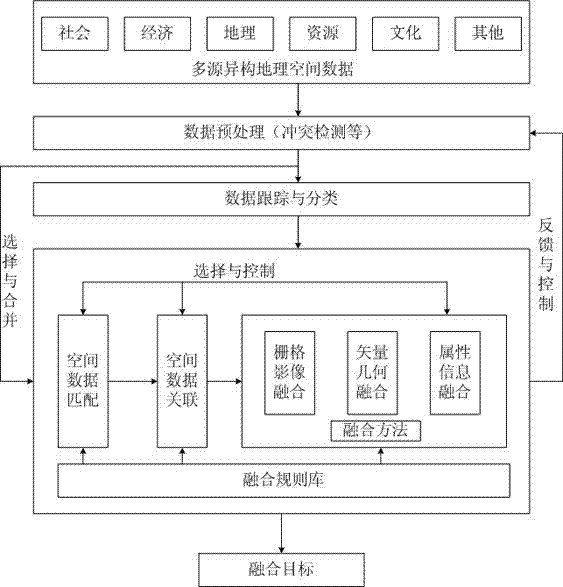

Subject-oriented large-scale geographic spatial data dynamic fusion method

ActiveCN104699734ASolve runnabilitySolve the comprehensive fusion of multi-source heterogeneous informationGeographical information databasesSpecial data processing applicationsAssociation modelFusion frame

The invention relates to a subject-oriented large-scale geographic spatial data dynamic fusion method. The method comprises steps as follows: Step a), firstly, establishing a matching model and an association model of geographic spatial data; Step b), then constructing a subject-oriented geographic spatial data fusion frame; Step c), establishing a subject-oriented geographic spatial data fusion rule base in combination with a geographical element matching technology of multi-source heterogeneous geographic spatial data; Step d), finally, realizing the subject-oriented large-scale geographic spatial data dynamic fusion method under the support of geographic raster data information fusion, geometric information fusion and attribute information fusion methods.

Owner:武汉图歌信息技术有限责任公司

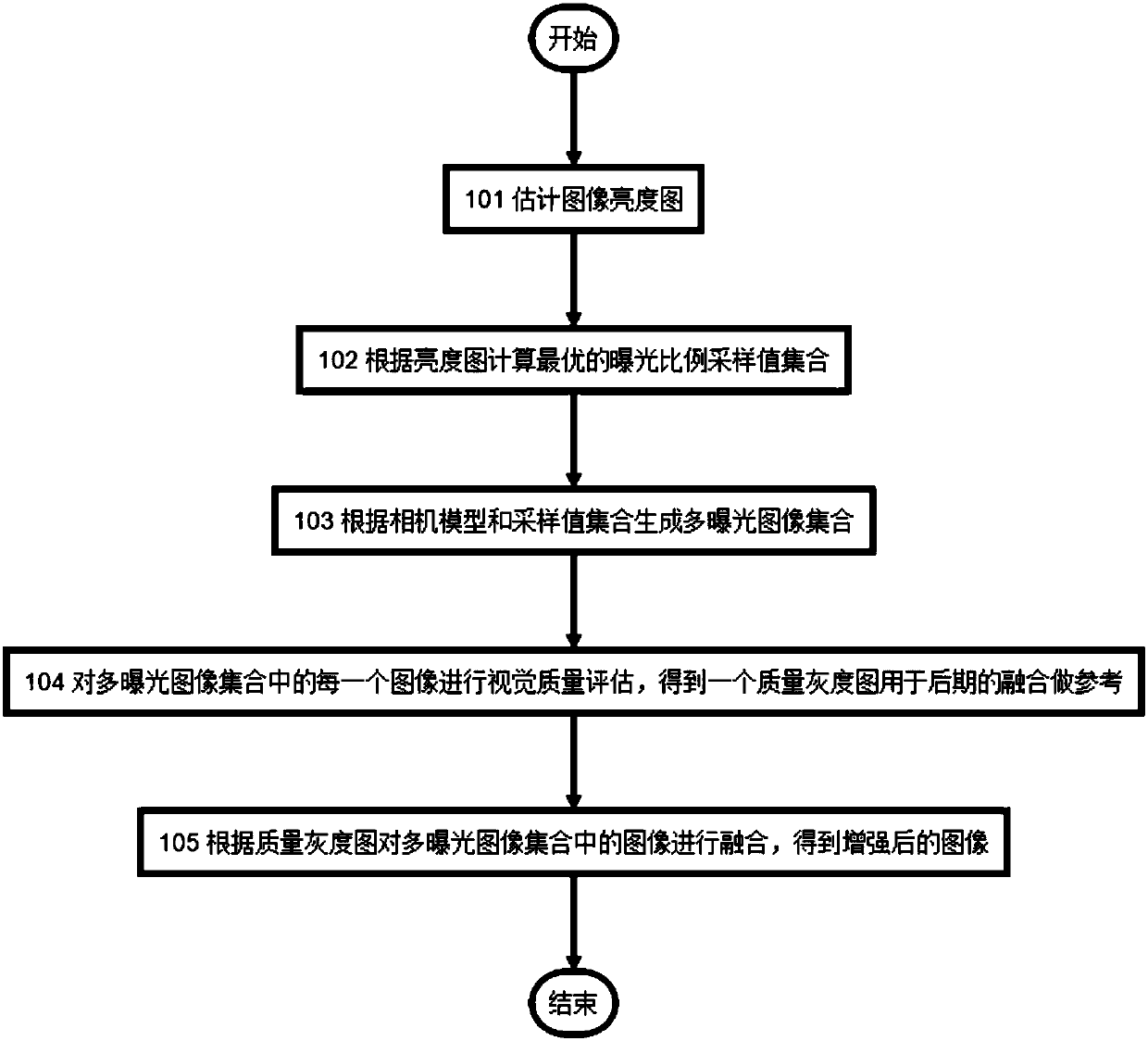

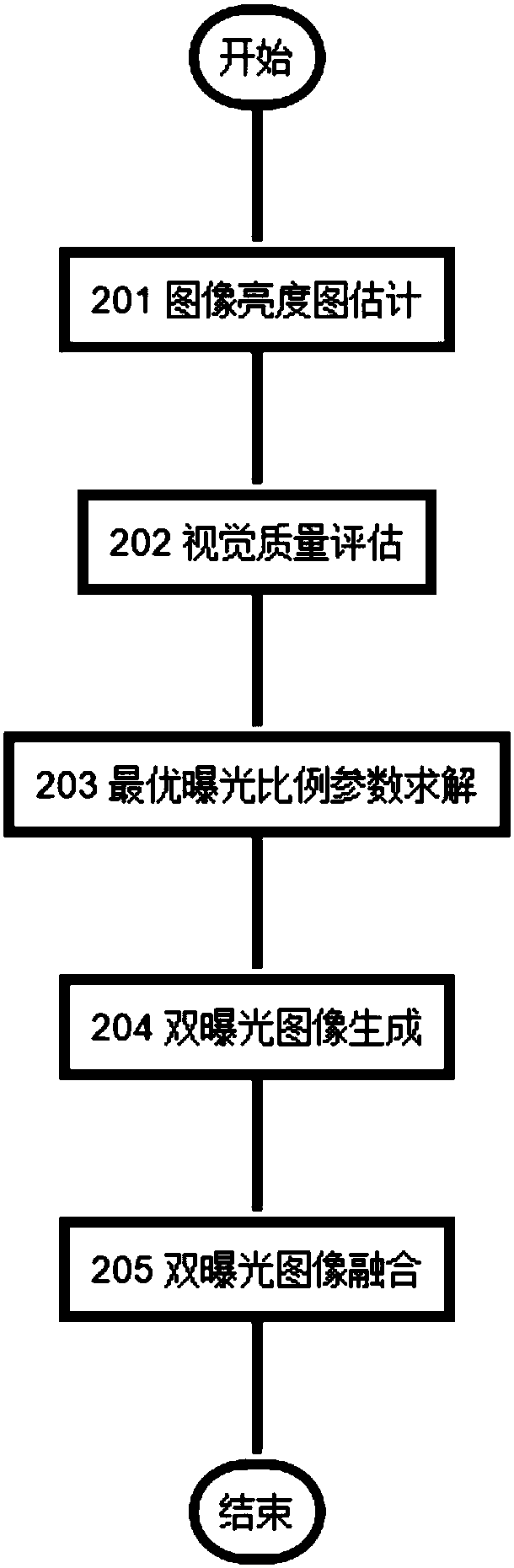

Image enhancement method based on multiple exposure generation and re-fusion frame

InactiveCN107833184ASolve the problem of too bright and too darkThe authenticity index is largeImage enhancementImage analysisValue setVisual perception

The invention discloses an image enhancement method based on a multi-exposure generation and re-fusion frame and belongs to the technical field of image processing. The image enhancement method includes the steps of performing image illumination estimation based on images to obtain an image illumination map L; calculating an optimal exposure ratio sampling value set [kappa]* according to the imageillumination map L; generating a multi-exposure image set according to the camera model g and the sampling value set [kappa]*; performing visual quality evaluation on each image in the multi-exposureimage set to obtain a quality grayscale map; and performing fusion of the multi-exposure image set to obtain an enhanced image. According to the invention, the over bright or dark problems in a single exposure image during the process of camera taking an image can be solved, the obtained enhancement result has less contrast distortion, the visual information authenticity index VIF is larger, theillumination sequence error index LOE is smaller, with no obvious aperture or stroke marks, and a better visual experience can be obtained.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

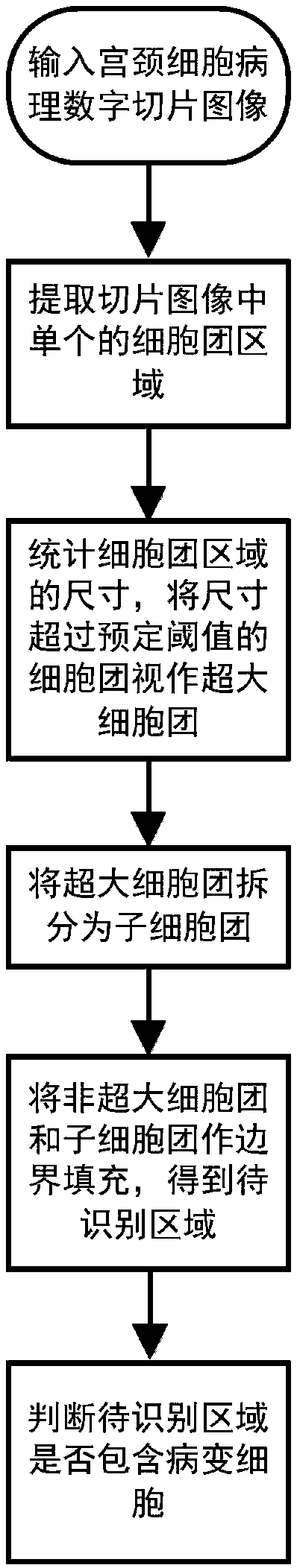

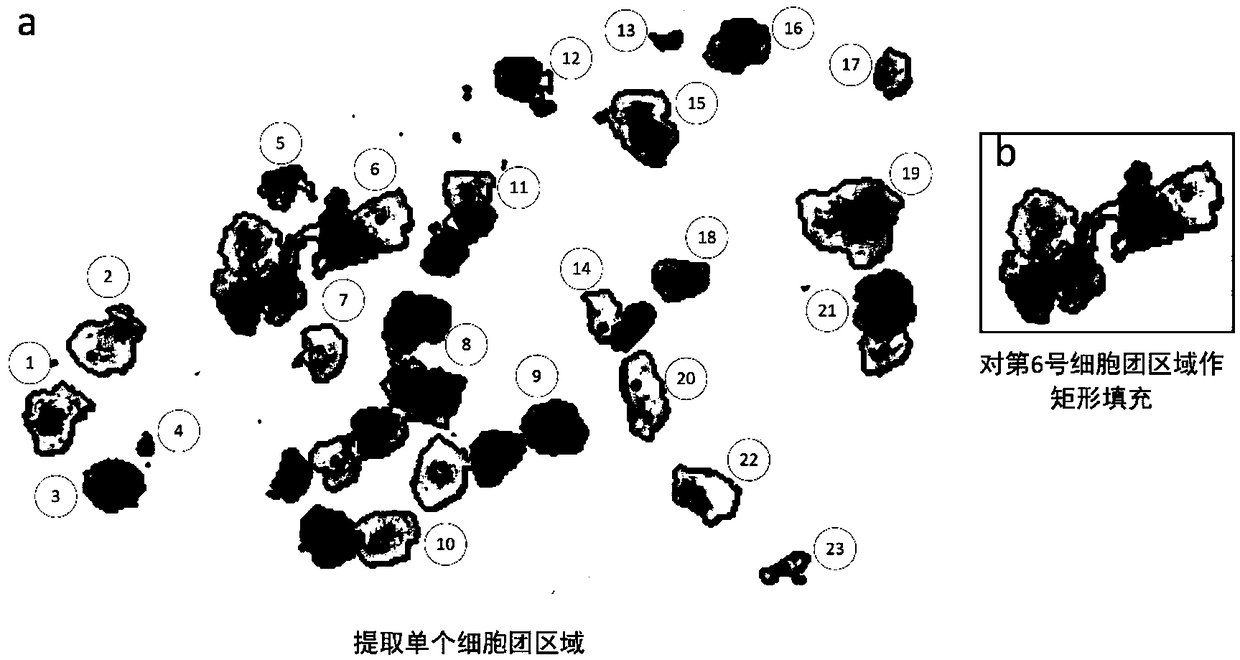

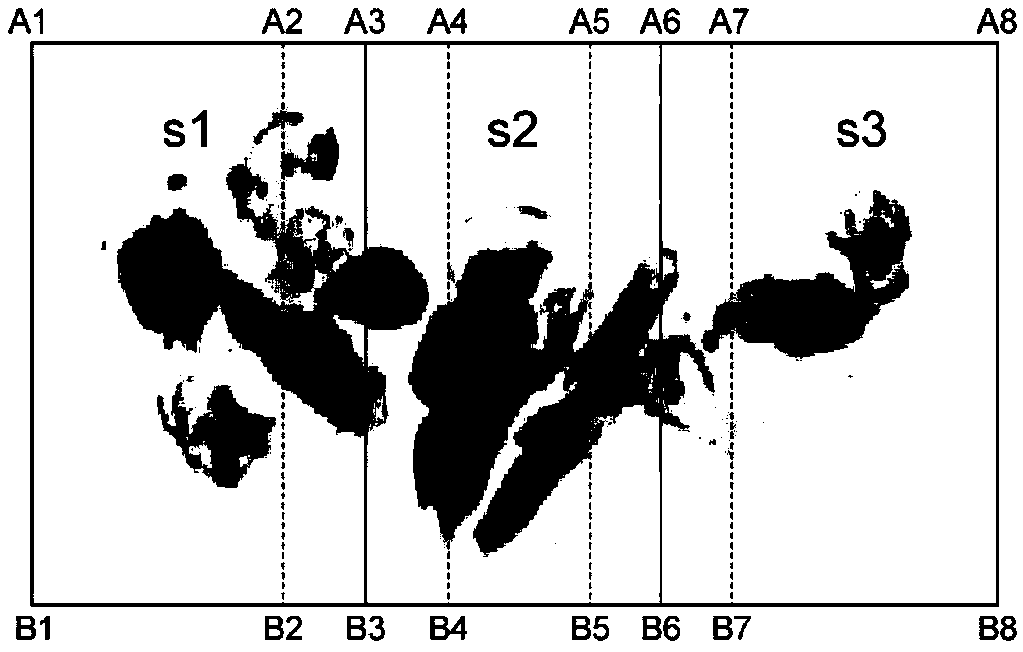

Method and system for recognizing pathological cells of cervical cell pathological section based on cell mass

ActiveCN109087283ANo loss of recognition accuracyWithout loss of representationImage enhancementImage analysisCervical cellLarge cell

The invention discloses a cervical cell pathological slice image pathological cell identification method and system based on cell mass, which comprises the following steps: extracting a single cell mass region on the cervical pathological slice image; extracting the single cell mass region on the cervical pathological slice image; counting the size of the cell mass region, and treating the cell mass whose size exceeds a predetermined threshold value as a super-large cell mass; the superlarge cell mass being divided into daughter cell mass; the region to be recognized being obtained by boundaryfilling treatment of the cell cluster region other than the super-large cell cluster and the daughter cell cluster obtained by splitting; a lesion cell being identified in that region to be identified. The invention aims at the whole slice image of the massive pixels, takes the cell cluster as the processing and recognition unit, instead of the conventional image partition and fusion frame, whichis more suitable for the characteristics of the cervical cell pathological slice image, and improves the efficiency and the precision at the same time.

Owner:怀光智能科技(武汉)有限公司

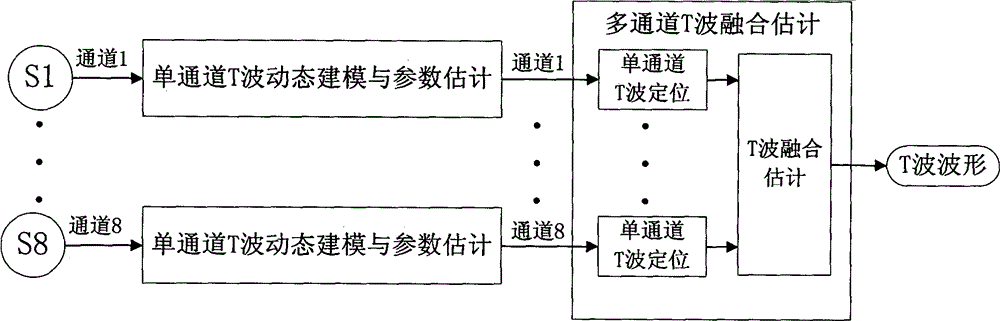

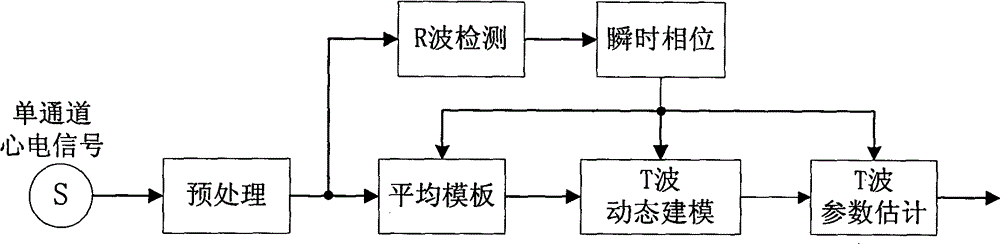

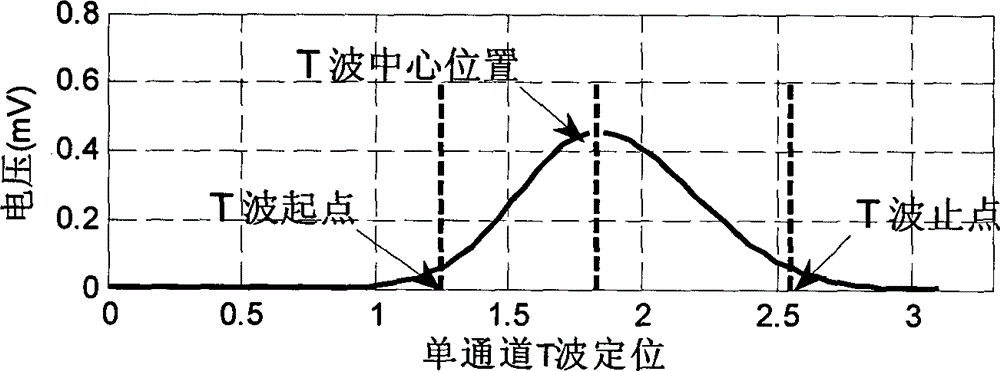

T wave dynamic modeling and multi channel estimation fusion method

InactiveCN104462867AAutomate analysisImplement extractionDiagnostic recording/measuringSensorsEcg signalDynamic monitoring

The invention discloses a T wave dynamic modeling and multi channel estimation fusion method. Aiming to solve the problems of T wave asymmetry, beat-to-beat dynamic change, myoelectricity pulses in highly dynamic monitoring environment and electrode pulse noise interference, a T wave state space model adaptive to the beat-to-beat dynamic estimation is provided, on the basis of extended Kalman filter, a multi-channel T wave estimation fusion frame is established, T wave parameters with eight independent channels are combined, and T wave robustness estimation in strong noise background can be implemented. The method has the advantages that the sectional characteristics of electrocardiosignals are utilized completely, an analysis module adaptive to asymmetrical T wave estimation is established, the T wave analysis presentation is utilized, the T wave data with eight independent channels are fused completely, the robustness of the T wave beat-to-beat dynamic estimation is improved, and necessary theoretical and technical basis is provided for beat-to-beat detection and estimation of T wave alternating signals in the highly dynamic monitoring environment.

Owner:CHONGQING TELECOMMUNICATION INSTITUTE

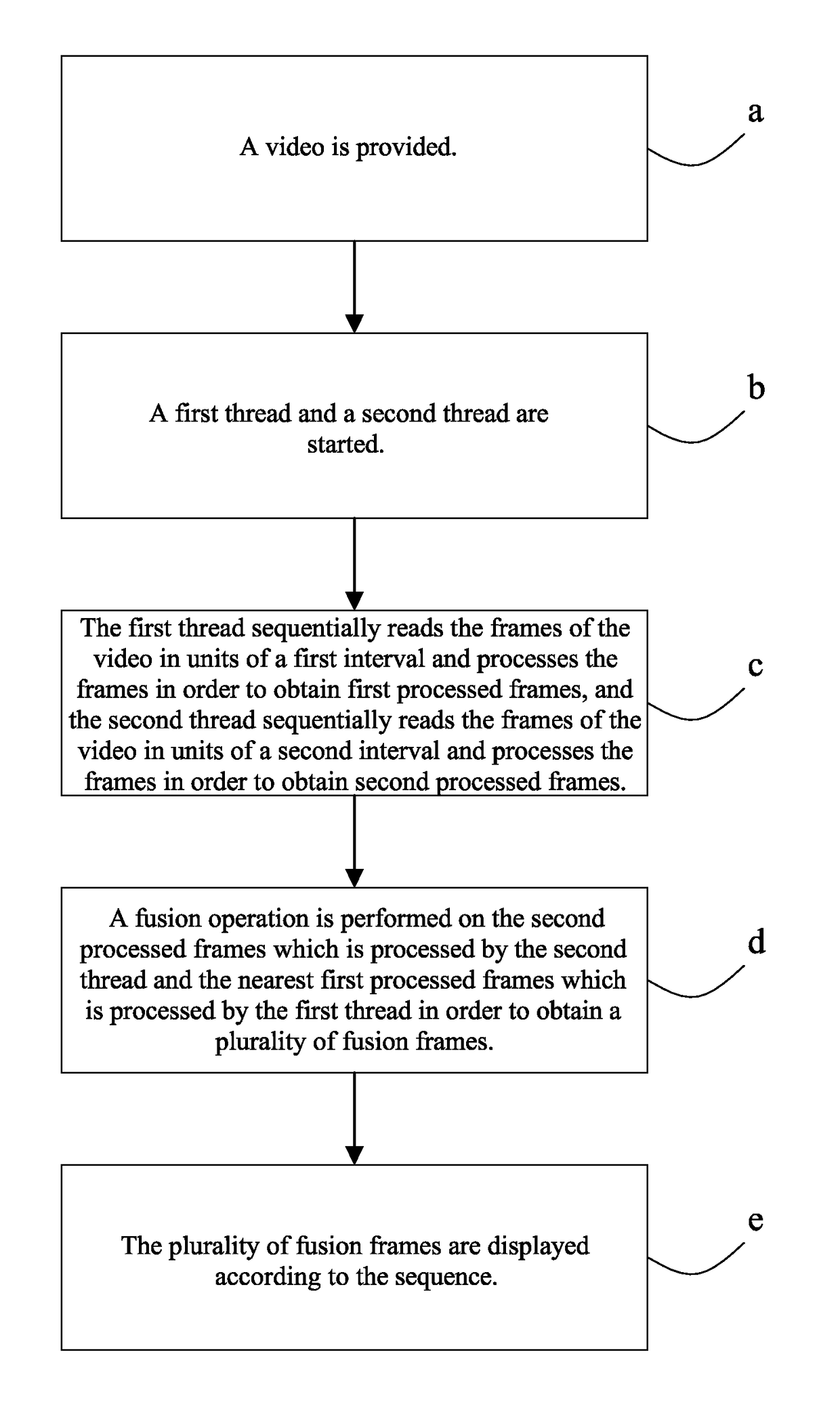

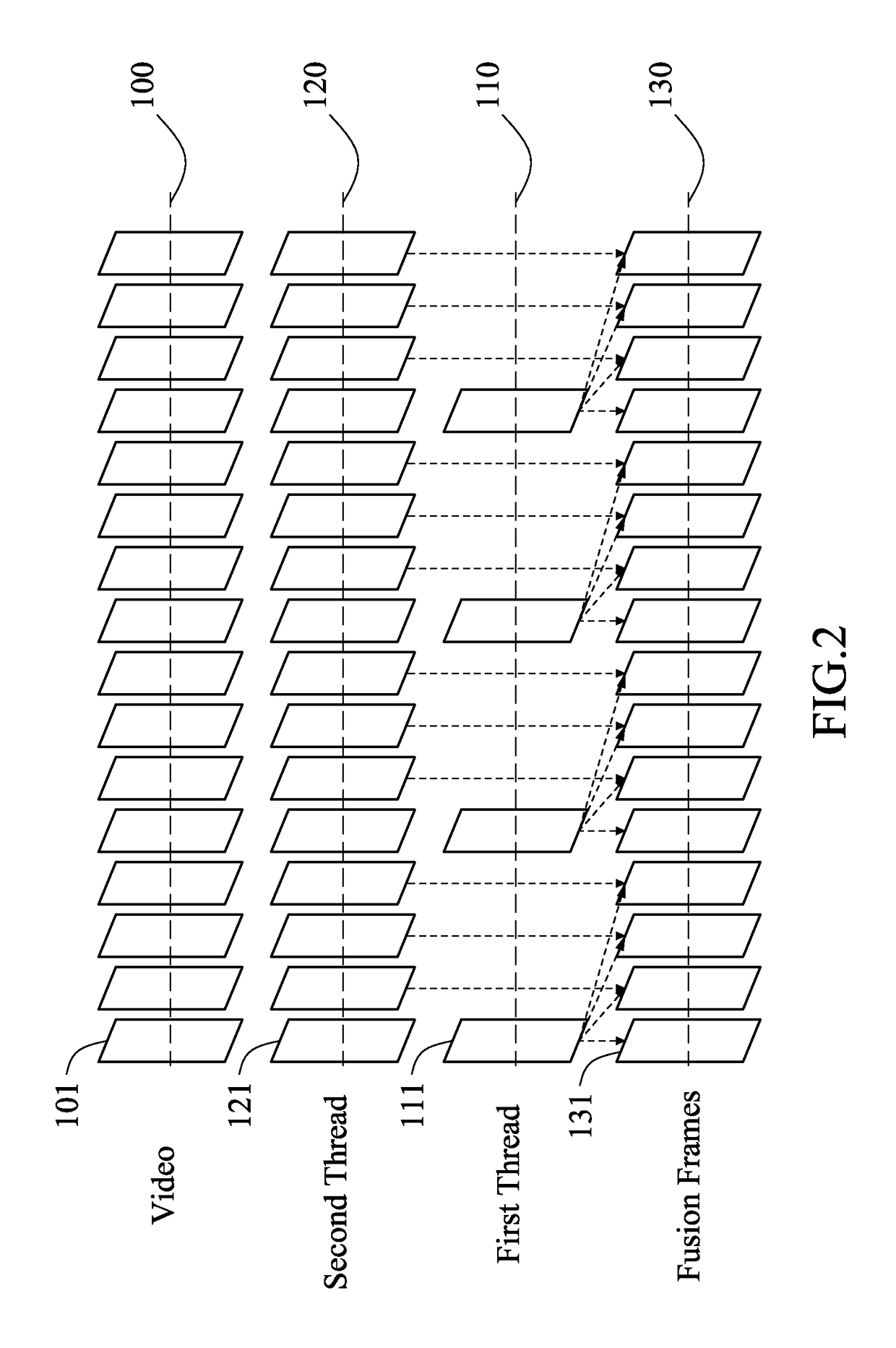

Method and system of reconstructing videos by using super-resolution algorithm

A method of reconstructing videos by using super-resolution algorithm includes the steps: (a) providing a video, wherein the video is composed of a plurality of frames having a sequence; (b) starting a first thread and a second thread, the first thread performing a first algorithm and the second thread performing a second algorithm for improving resolution, wherein a time complexity of the first algorithm is greater than a time complexity of the second algorithm; (c) the first thread sequentially reading the frames of the video in units of a first interval and processing the frames in order to obtain first processed frames, and the second thread sequentially reading the frames of the video in units of a second interval and processing the frames in order to obtain second processed frames, wherein a value of the first interval is an integer greater than 1, and a value of the second interval is 1; (d) performing a fusion operation on the second processed frames which is processed by the second thread and the nearest first processed frames which is processed by the first thread in order to obtain a plurality of fusion frames; and (e) displaying the plurality of fusion frames according to the sequence. The present disclosure can solve the problem that video super-resolution in real-time, computing time and resolution are difficult to be taken into account simultaneously.

Owner:ULSEE

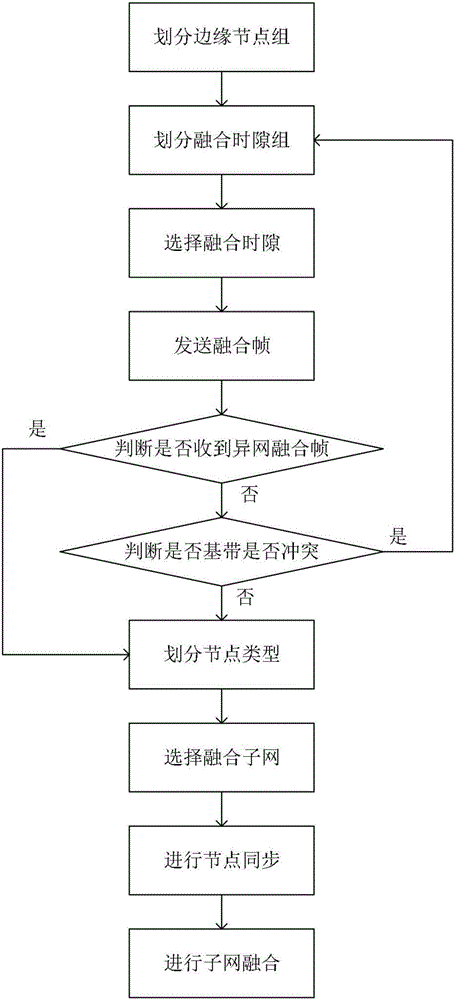

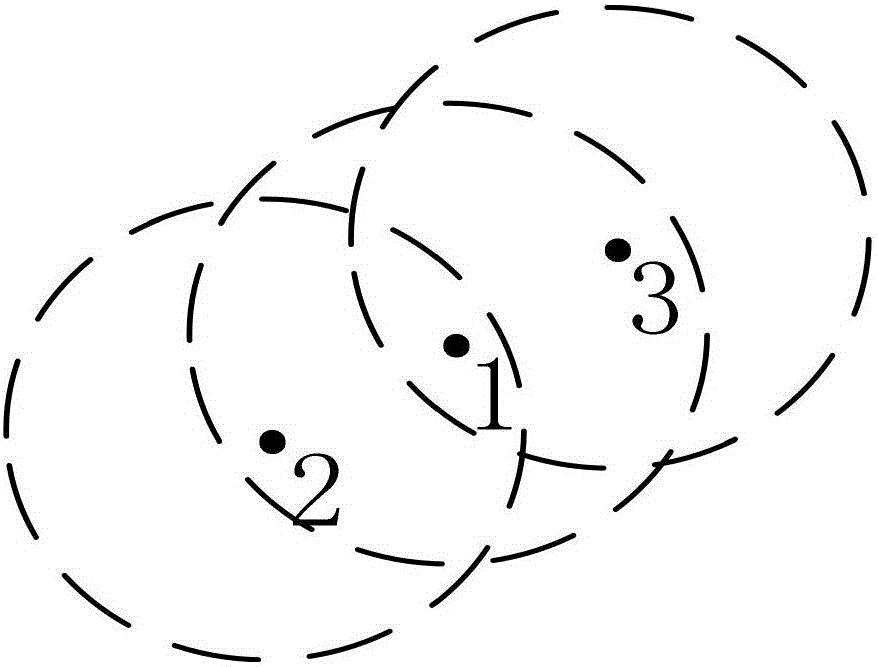

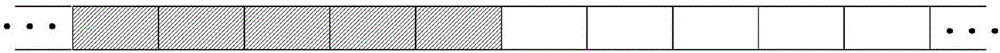

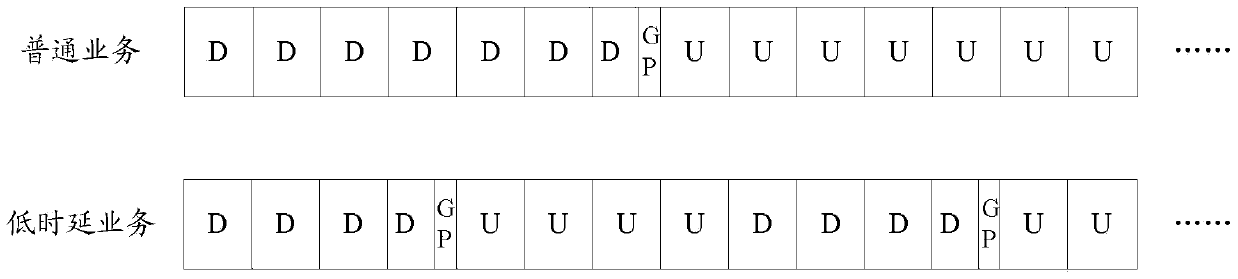

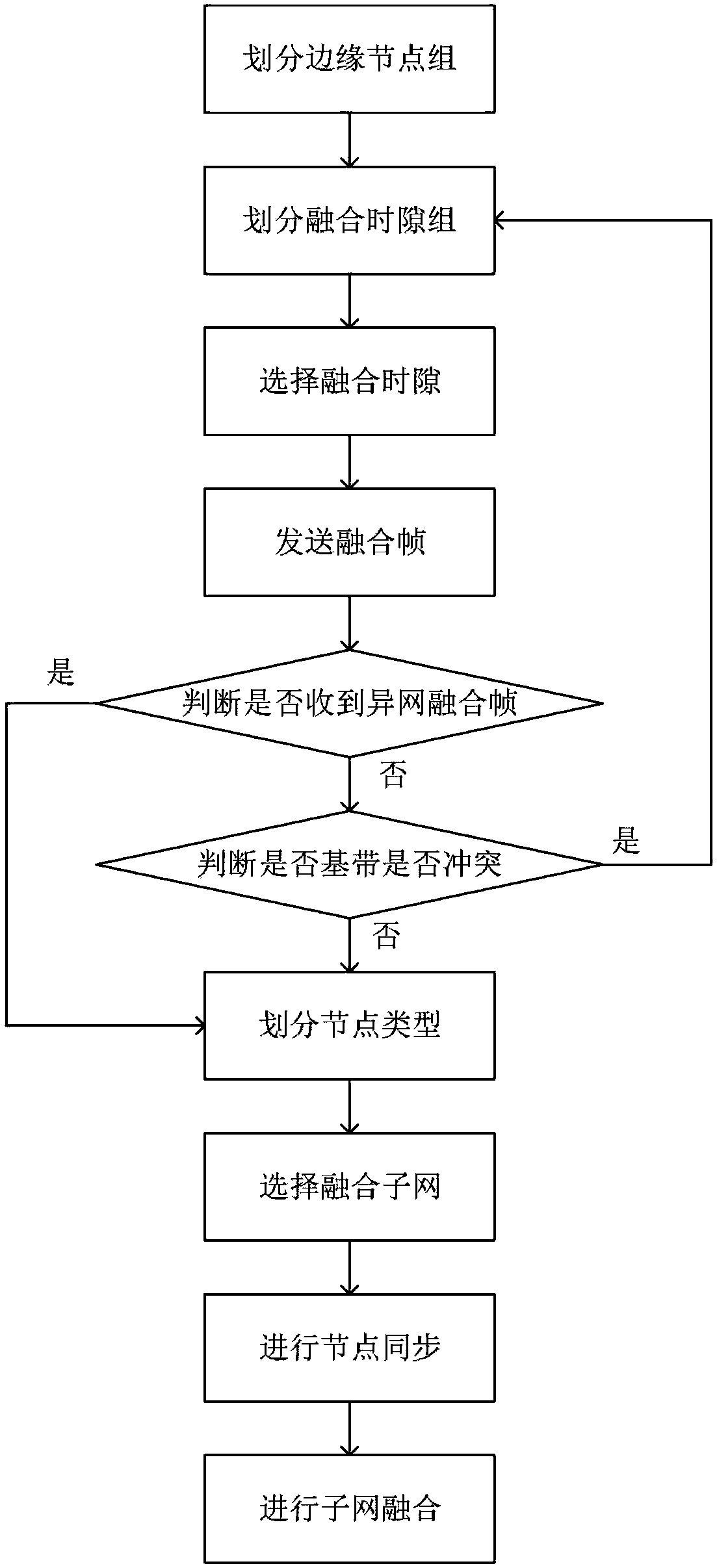

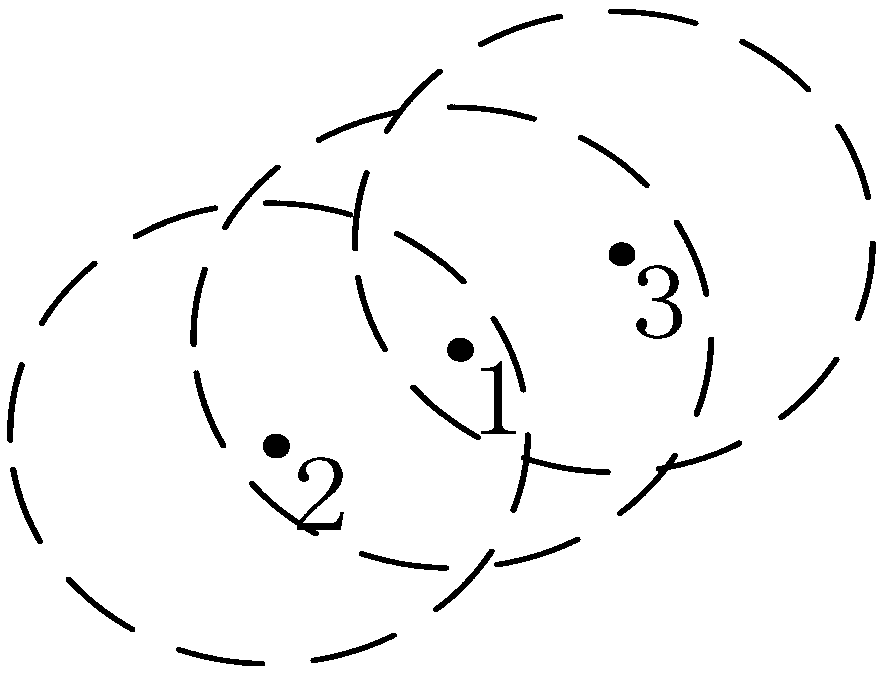

Subnet fusion method for single-channel time division multiple access (TDMA) ad-hoc network

ActiveCN107437972AReduce the probability of mutual discoveryReduce energy consumptionTime-division multiplexGeographic siteTime division multiple access

The invention discloses a subnet fusion method for a single-channel time division multiple access (TDMA) ad-hoc network, and solves problems that subnets of a single-channel time division multiple access (TDMA) ad-hoc network in the prior art needs a control channel for communication and carry out the communication through a gateway node. The thinking of the invention is that the method comprises the steps: carrying out the dividing of an edge node group according to the geographic position information and the topological information of the subnets, and carrying out the dividing of a fusion time slot group, wherein the edge nodes select fusion time slots in the fusion time slot group, transmits fusion frames at the occupied fusion time slots, and judging whether to carry out the fusion with other subnets or not after receiving the fusion frames from other subnets; selecting the fusion subnets and then carrying out the node synchronization; selecting data time slots, and completing the fusion process of the subnets. Through the employing of different unoccupied time slot occupying methods and the dividing of the edge node group, the method can effectively reduce the energy consumption of a system, reduces the fusion time, and improves the stability of the fusion process.

Owner:XIDIAN UNIV

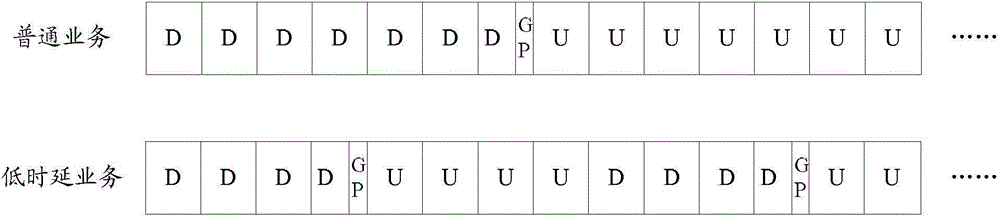

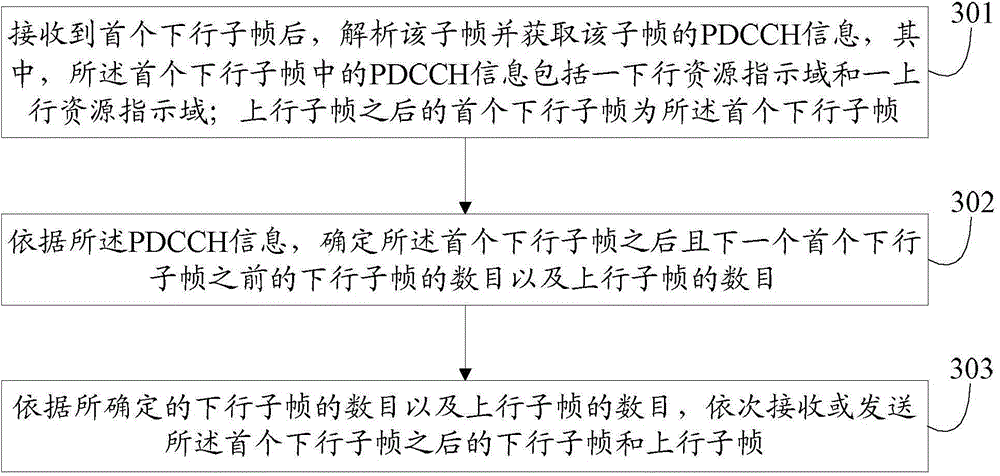

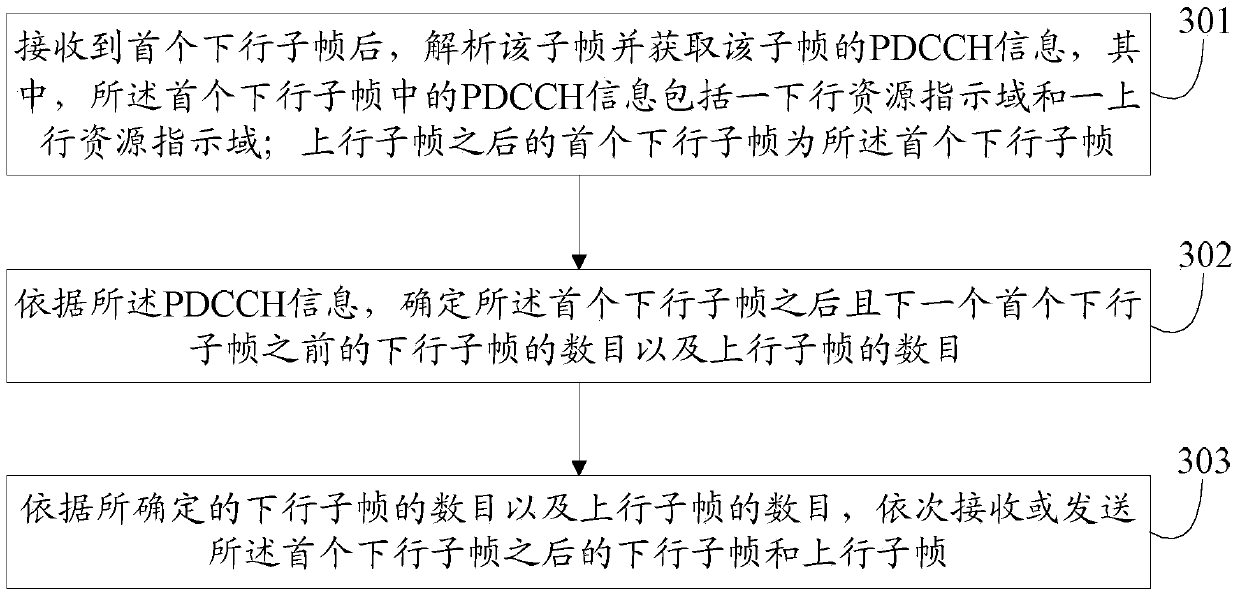

Fusion frame processing method and terminal

ActiveCN106160984AFlexible ratioSatisfy latency requirementsError preventionTransmission path multiple useFusion frameComputer science

The invention discloses a fusion frame processing method and terminal. The method comprises the following steps: after a sub-frame is received, analyzing the sub-frame, and acquiring PDCCH information of the sub-frame, wherein the PDCCH information contains types of one or more sub-frames behind the sub-frame; determining the types of one or more sub-frames behind the sub-frame according to the PDCCH information, wherein the type of the sub-frame is used for indicating the sub-frame as an uplink sub-frame or a downlink sub-frame; and sequentially sending or receiving the uplink / downlink sub-frames behind the sub-frame according to the types of the one or more sub-frames behind the sub-frame.

Owner:CHINA MOBILE COMM GRP CO LTD

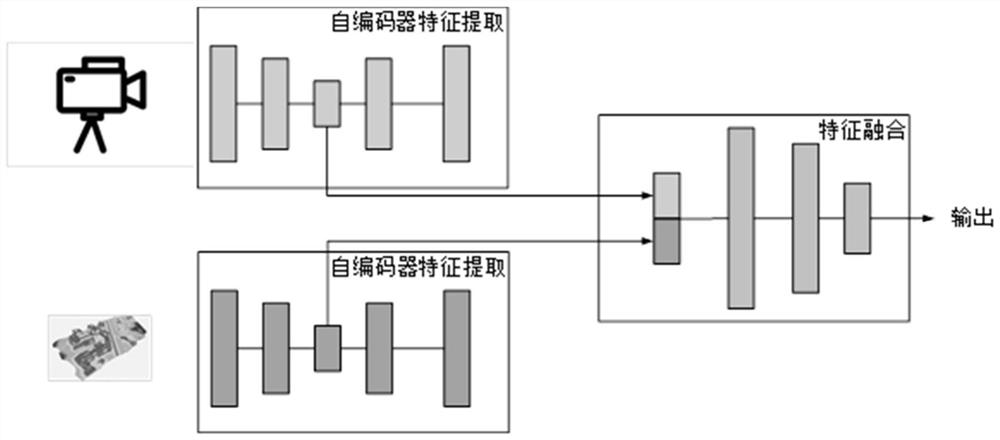

Autonomous system sensing method and system based on multi-modal fusion

PendingCN113988172AImprove performanceAddressing field of view limitationsCharacter and pattern recognitionNeural architecturesGoal recognitionEngineering

The invention discloses an autonomous system sensing method and system based on multi-modal fusion, and the method comprises the steps: obtaining data collected by sensors of a plurality of vehicles, processing the data collected by the sensors through employing a trained multi-modal data fusion frame, fusing the processed results, obtaining a primary fusion result, processing the primary fusion result based on a target recognition service, retaining region-of-interest information, constructing a cooperation-level fusion architecture by using an existing multi-view fusion algorithm, performing secondary fusion on the region-of-interest information uploaded by a plurality of vehicles to obtain a secondary fusion result, and issuing the secondary fusion result to the vehicles so that the vehicles can make control decisions according to the secondary fusion result. According to the method and system, the vehicle cascade cooperation data fusion framework is constructed, the environment view can be improved and expanded through the cascade framework, the view limitation of a single automatic driving vehicle is solved, the uncertainty is reduced, and the performance of a sensing algorithm is improved.

Owner:西安电子科技大学广州研究院

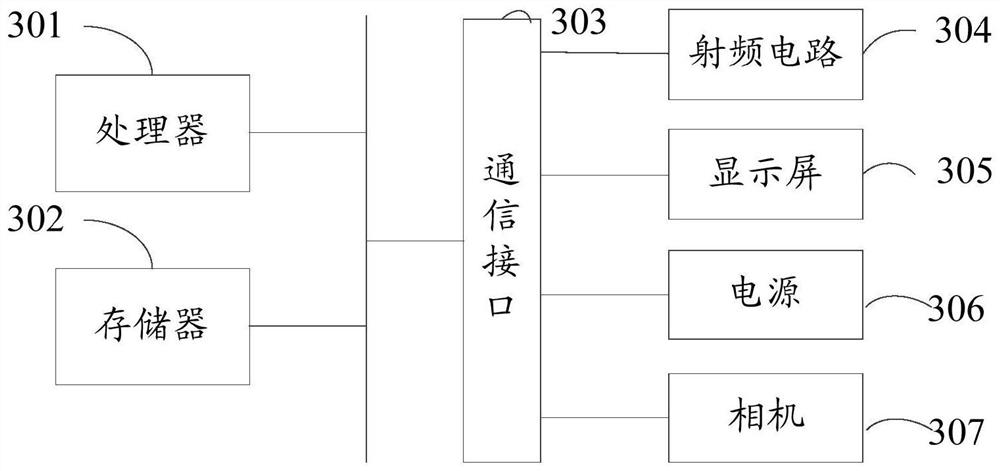

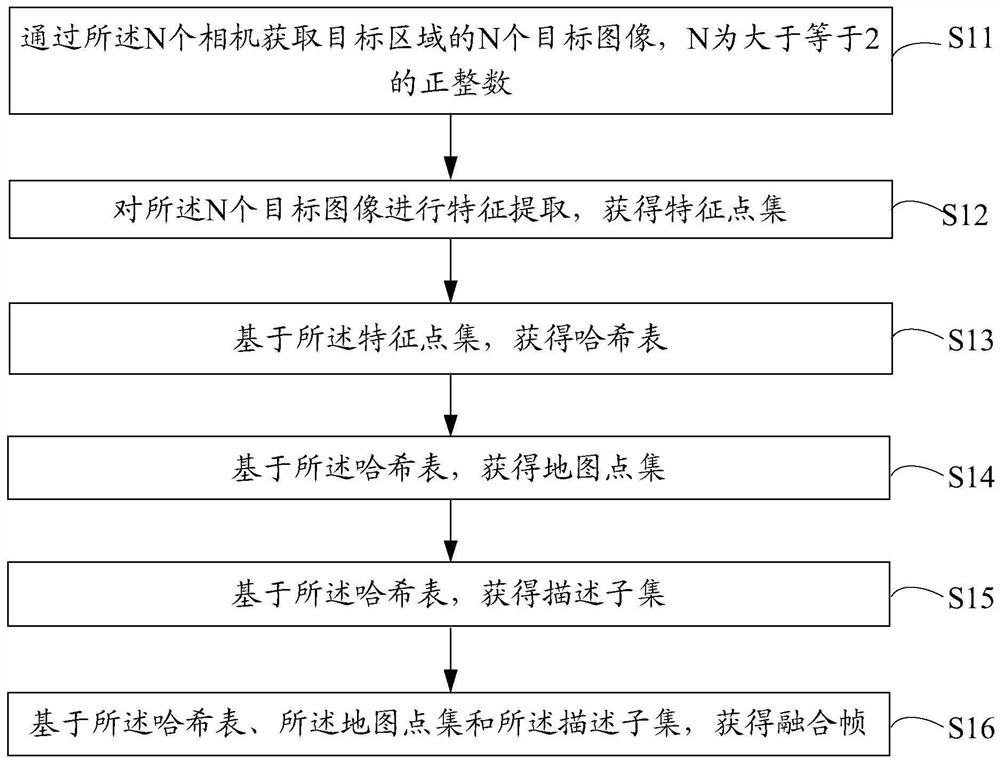

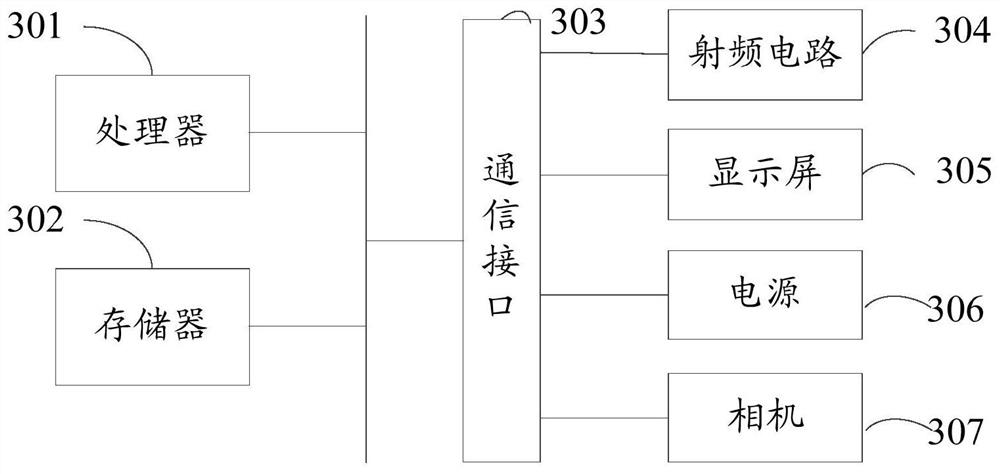

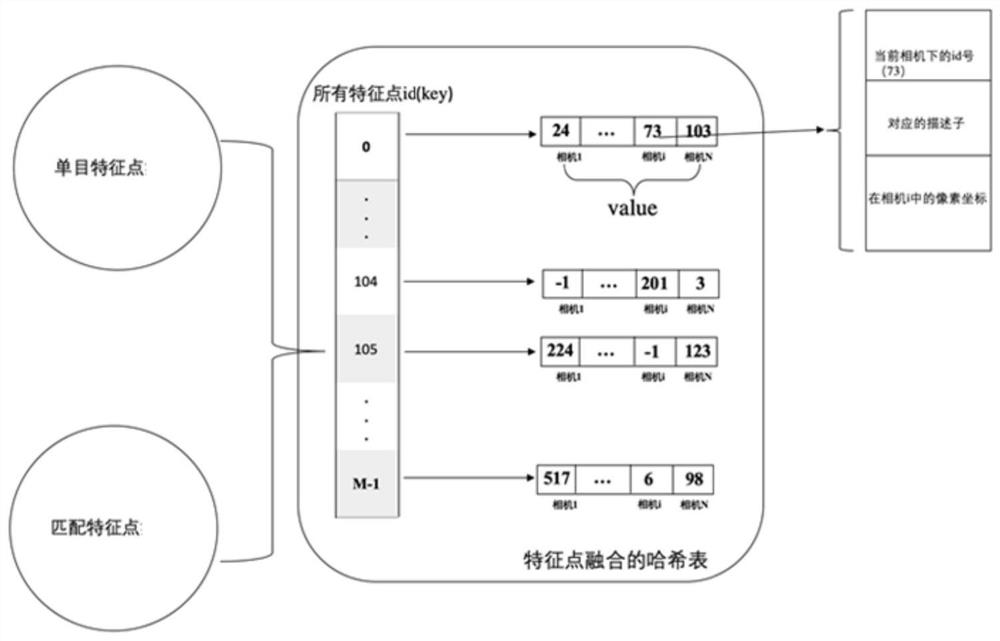

Fusion frame obtaining method and device, SLAM system and storage medium

PendingCN112446846AImprove accuracyImage enhancementImage analysisFeature extractionComputer graphics (images)

The invention discloses a fusion frame obtaining method, and the method comprises the following steps: obtaining N target images of a target region through N cameras, N being a positive integer greater than or equal to 2; performing feature extraction on the N target images to obtain a feature point set; obtaining a hash table based on the feature point set; obtaining a map point set based on thehash table; obtaining a description subset based on the hash table; and obtaining a fusion frame based on the hash table, the map point set and the description subset. The invention further disclosesa fusion frame obtaining device, an SLAM system and a storage medium. The fusion frame obtained through the method comprises more visual feature information, so that the accuracy of the fusion frame is better.

Owner:PENG CHENG LAB +1

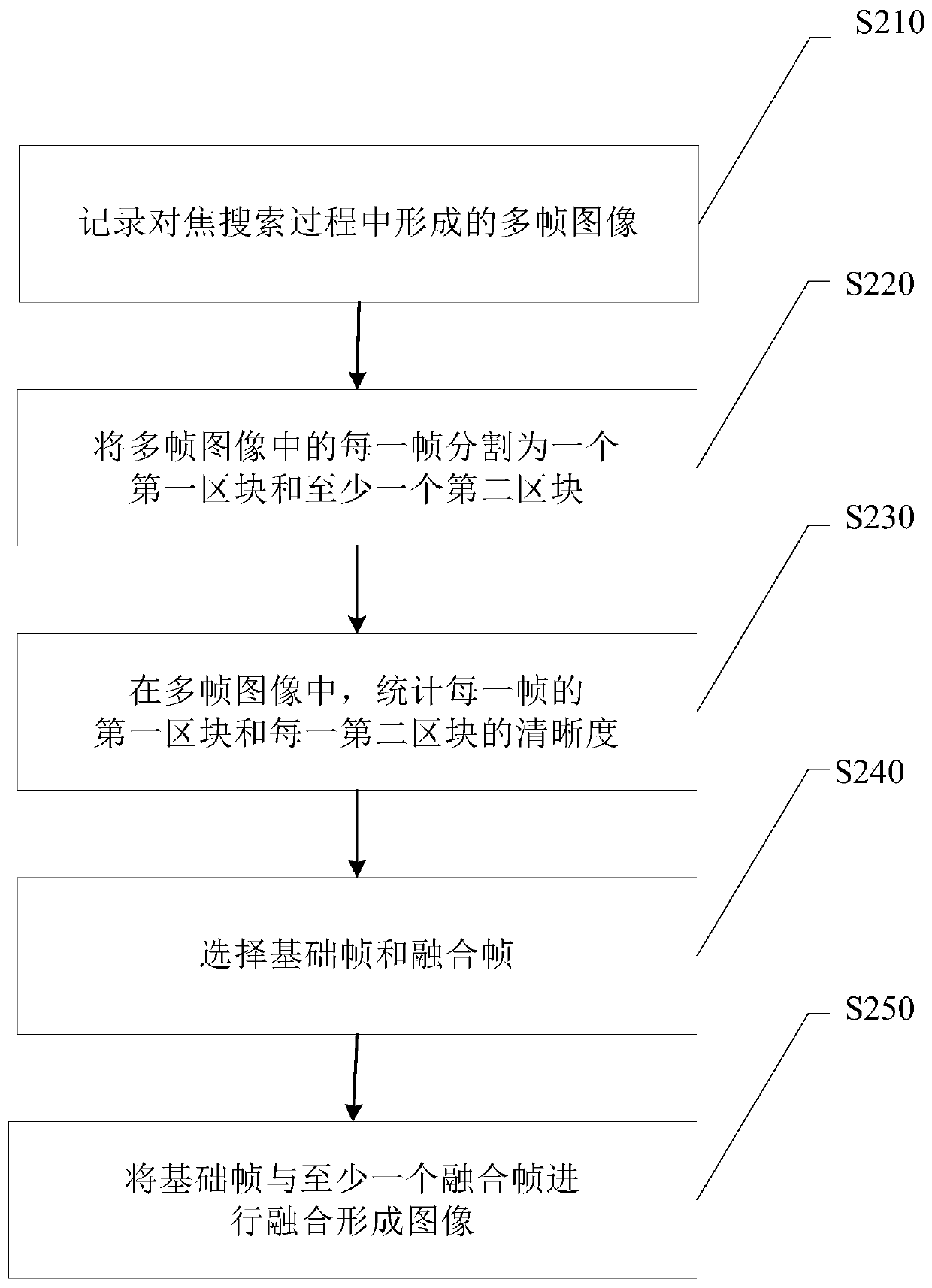

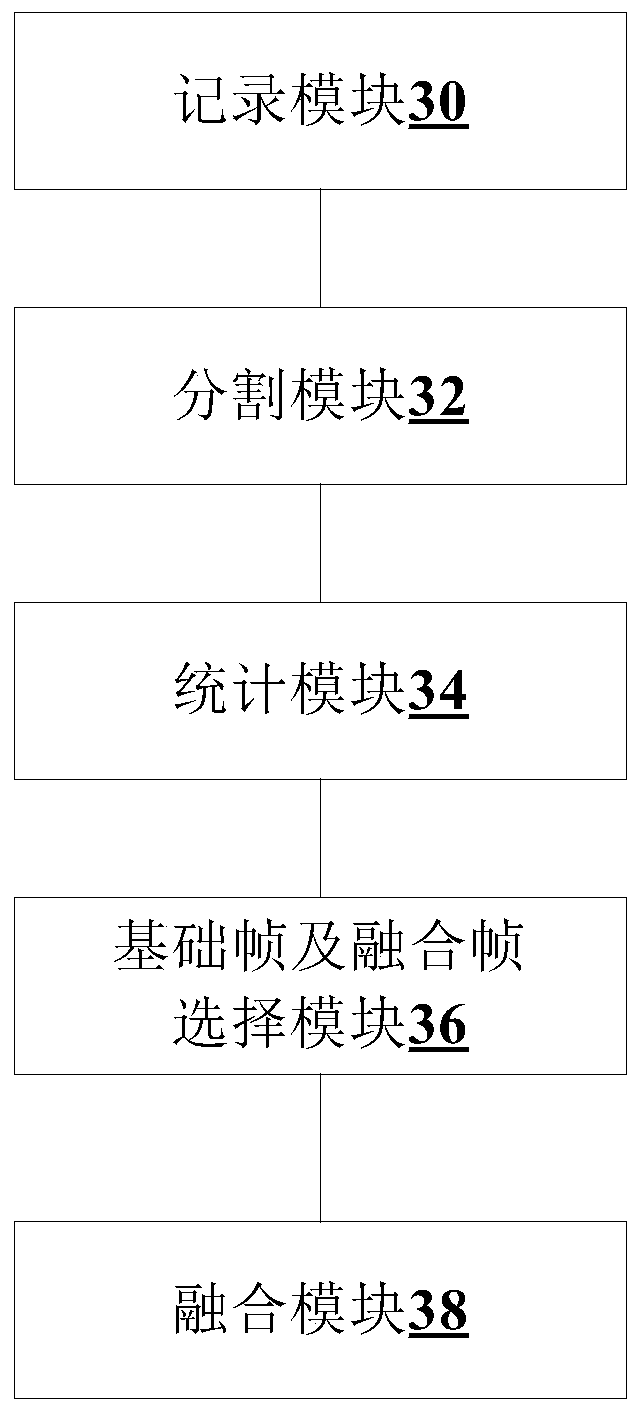

Method and device for improving definition of static photographing picture of camera and electronic equipment

InactiveCN110581953ARaise the level of clarityTelevision system detailsColor television detailsMultiple frameFrame time

The invention relates to a method and device for improving the definition of a static photographing picture of a camera and electronic equipment. The method comprises: recording multiple frames of images formed in the focusing search process; dividing each frame in the multiple frames of images into a first block and at least one second block; counting the definition of the first block and the definition of each second block of each frame in the multi-frame image; selecting a frame with the highest definition of the first block as a base frame; in the second blocks at the same position in different frames, selecting the frame with the highest definition as a fusion frame of the second block at the position; and fusing the basic frame and the at least one fusion frame to form an image. According to the present invention, based on the existing hardware capability, through the fusion of the base frame and the fusion frame, the definition level of static image shooting is improved.

Owner:CHANGSUO SOFTWARE TECH SHANGHAI CO LTD

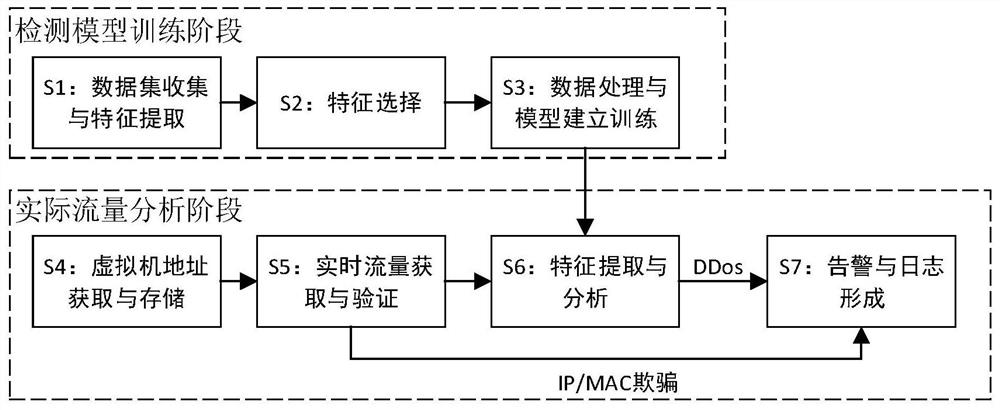

Intrusion detection method and device based on deep learning under hyper-fusion architecture

ActiveCN113660273AReduce overheadReduce redundant informationArtificial lifeNeural architecturesData setAlgorithm

The invention provides an intrusion detection method and device based on deep learning under a hyper-converged architecture and a storage medium, and relates to the technical field of intrusion detection.The detection method is applied to a virtualization kernel layer of the hyper-converged architecture and comprises the steps that network traffic entering and exiting a virtual machine is captured, IP / MAC address verification is conducted on the network traffic, then related traffic features are extracted, a deep learning model trained by a CICIDS2017 data set is utilized to analyze feature values, so that low-overhead and high-precision DDoS attack detection under the hyper-fusion architecture is realized. Particularly, in order to reduce redundant information, an improved binary cuckoo algorithm is adopted to select features, and while the detection precision is ensured, the size of a deep learning model is reduced, and the extraction time of network traffic features is shortened.

Owner:国家电网公司东北分部 +1

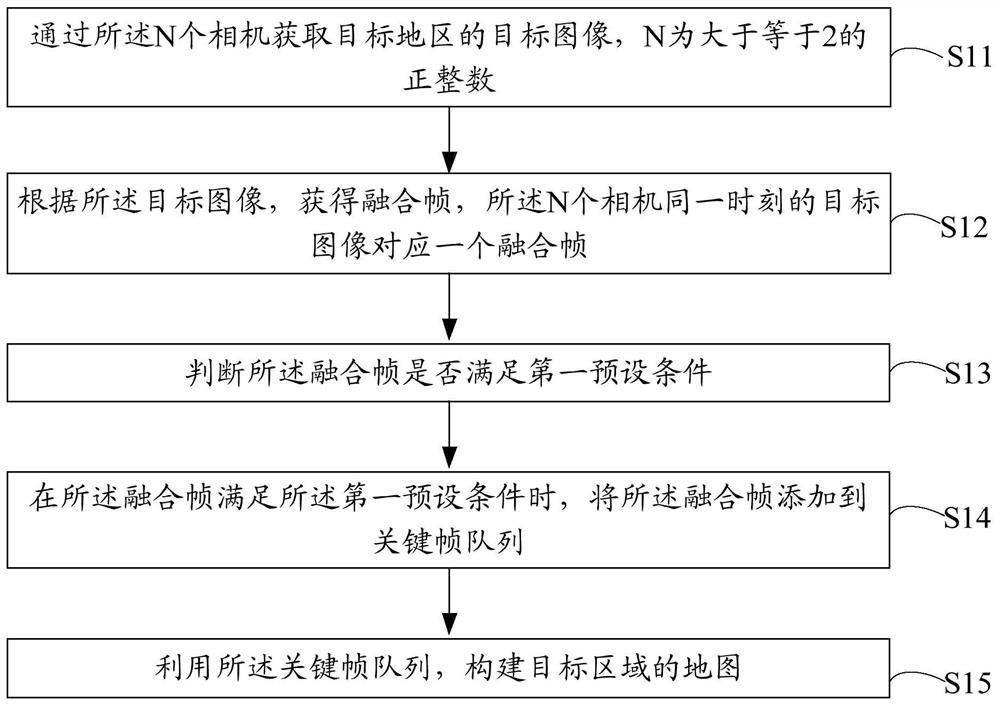

Map construction method and device, SLAM system and storage medium

PendingCN112446845AReduce data processingImprove mapping efficiencyImage enhancementImage analysisPattern recognitionKey frame

The invention discloses a map construction method which is applied to an SLAM system comprising N cameras, and the method comprises the following steps: obtaining target images of a target region through the N cameras, N being a positive integer greater than or equal to 2; according to the target images, obtaining fusion frames, wherein the target images of the N cameras at the same moment correspond to one fusion frame; judging whether the fusion frames meet a first preset condition or not; when the fusion frames meet the first preset condition, adding the fusion frames to a key frame queue;and constructing a map of the target region by utilizing the key frame queue. The invention further discloses a map construction device, an SLAM system and a storage medium. When the method is used for constructing the map of the target area, the data processing amount is small, and the mapping efficiency is high.

Owner:PENG CHENG LAB +1

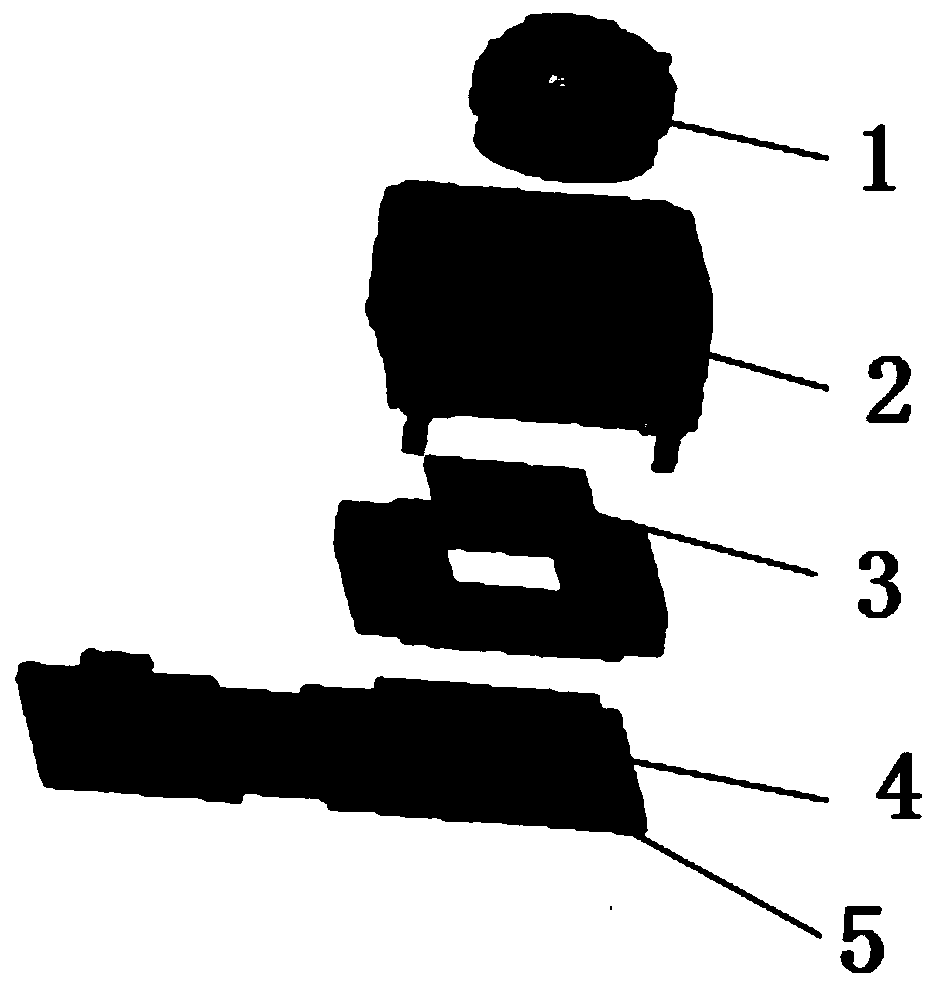

PCB lamination and fusion anti-wrinkling method

InactiveCN107708338AImprove bindingReduce lossesMultilayer circuit manufactureEngineeringCopper foil

The invention relates to a PCB lamination and fusion anti-wrinkling method, which comprises the steps of lamination: laminating and fixing various layers of boards required to be pressed-fit for a PCBonto an operation table of a press machine; fusion frame arrangement: placing a fusion frame on the side of the laminated boards; fusion block arrangement: arranging fusion blocks in a mesh form in aclosed area formed by the fusion frame and the side of the boards; prepreg arrangement: arranging prepregs on the surface of the fusion blocks; copper foil laying: laying a whole piece of copper foilon the surfaces of the boards, fusion frame and the prepregs; press-fit process; and cutting: after the press-fit is completed, cutting the edge of the boards and cutting the fusion frame and the fusion blocks and the prepregs in the fusion frame partially to complete the PCB lamination and fusion. Through the mesh graphic design with a specific effect, the heat loss is reduced, meanwhile, the support area is increased to avoid wrinkling of the copper foil, a large support area cooperates with the prepregs and increases the integration of the fusion zone at the same time, and the fusion graphic frame adopts the copper sheet design to avoid wrinkled extension.

Owner:广州广合科技股份有限公司

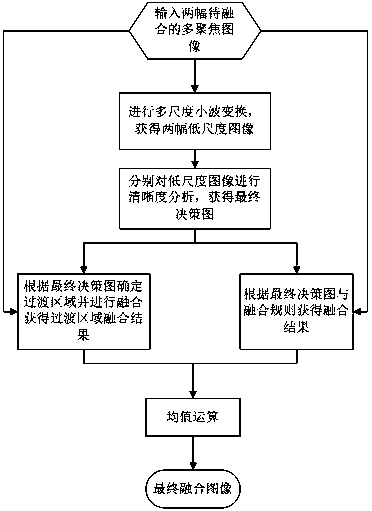

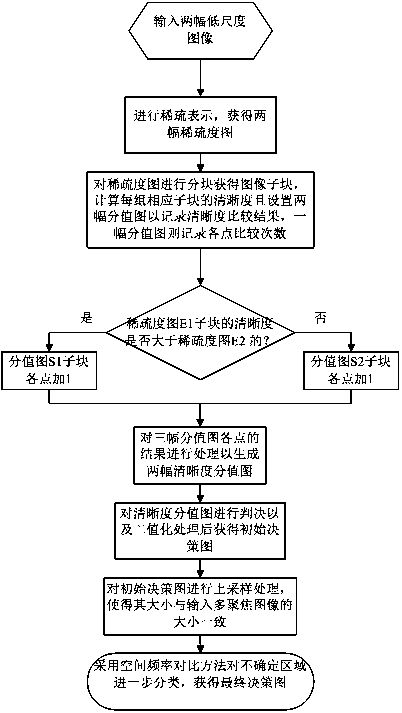

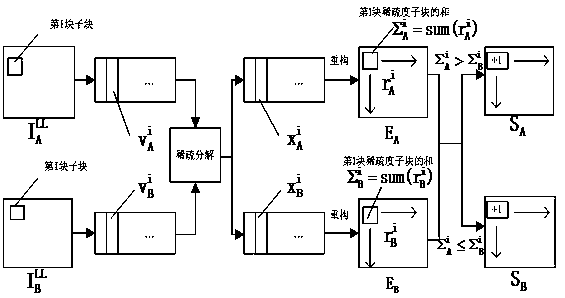

A Multi-Focus Image Fusion Method Based on Decision Graph and Sparse Representation

InactiveCN106228528BQuality improvementReduce mistakesImage enhancementImage analysisImage fusion algorithmDecision graph

The invention discloses a multi-focus image fusion method based on a decision graph and sparse representation. This method proposes a multi-focus image fusion framework different from previous multi-focus image fusion algorithms based on the characteristics of the human visual system. Analyze and study the transition area of the image to avoid its influence on the fusion result and improve the quality of the fusion image. Implementation process: On the basis of sharpness analysis of low-scale images of multi-focus images, a decision map is generated, and the fusion result is obtained according to the decision map; considering that there is a deviation in the sharpness judgment of the transition area, it will lead to the generated decision map If there is an error, it is necessary to determine the transition area and process it with a multi-focus image fusion algorithm based on sparse representation to obtain the fusion result of the transition area; finally, the fusion result based on the decision map and the fusion result of the transition area are averaged to obtain the final fused image.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A processing method and terminal for fused frames

ActiveCN106160984BFlexible ratioSatisfy latency requirementsError preventionTransmission path multiple useFusion frameComputer science

The invention discloses a fusion frame processing method and terminal. The method comprises the following steps: after a sub-frame is received, analyzing the sub-frame, and acquiring PDCCH information of the sub-frame, wherein the PDCCH information contains types of one or more sub-frames behind the sub-frame; determining the types of one or more sub-frames behind the sub-frame according to the PDCCH information, wherein the type of the sub-frame is used for indicating the sub-frame as an uplink sub-frame or a downlink sub-frame; and sequentially sending or receiving the uplink / downlink sub-frames behind the sub-frame according to the types of the one or more sub-frames behind the sub-frame.

Owner:CHINA MOBILE COMM GRP CO LTD

A subject-oriented large-scale geospatial data dynamic fusion method

ActiveCN104699734BGeographical information databasesSpecial data processing applicationsAssociation modelFusion frame

The invention relates to a subject-oriented large-scale geographic spatial data dynamic fusion method. The method comprises steps as follows: Step a), firstly, establishing a matching model and an association model of geographic spatial data; Step b), then constructing a subject-oriented geographic spatial data fusion frame; Step c), establishing a subject-oriented geographic spatial data fusion rule base in combination with a geographical element matching technology of multi-source heterogeneous geographic spatial data; Step d), finally, realizing the subject-oriented large-scale geographic spatial data dynamic fusion method under the support of geographic raster data information fusion, geometric information fusion and attribute information fusion methods.

Owner:武汉图歌信息技术有限责任公司

Subnet Convergence Method for Single Channel Time Division Multiple Access Ad Hoc Network

ActiveCN107437972BReduce the probability of mutual discoveryReduce energy consumptionTime-division multiplexTime division multiple accessEdge node

The invention discloses a subnet fusion method for a single-channel time division multiple access (TDMA) ad-hoc network, and solves problems that subnets of a single-channel time division multiple access (TDMA) ad-hoc network in the prior art needs a control channel for communication and carry out the communication through a gateway node. The thinking of the invention is that the method comprises the steps: carrying out the dividing of an edge node group according to the geographic position information and the topological information of the subnets, and carrying out the dividing of a fusion time slot group, wherein the edge nodes select fusion time slots in the fusion time slot group, transmits fusion frames at the occupied fusion time slots, and judging whether to carry out the fusion with other subnets or not after receiving the fusion frames from other subnets; selecting the fusion subnets and then carrying out the node synchronization; selecting data time slots, and completing the fusion process of the subnets. Through the employing of different unoccupied time slot occupying methods and the dividing of the edge node group, the method can effectively reduce the energy consumption of a system, reduces the fusion time, and improves the stability of the fusion process.

Owner:XIDIAN UNIV

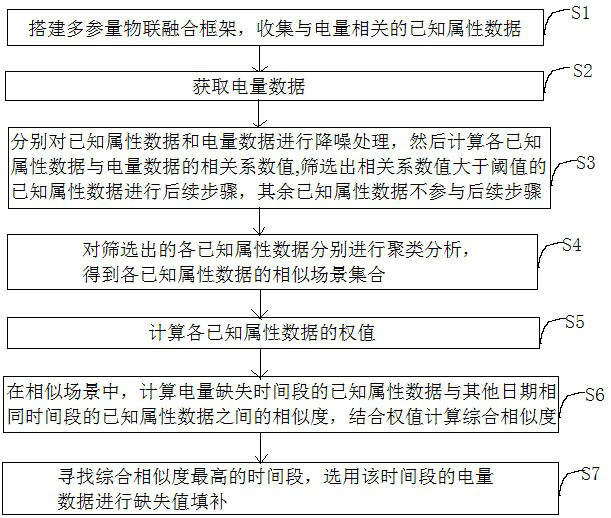

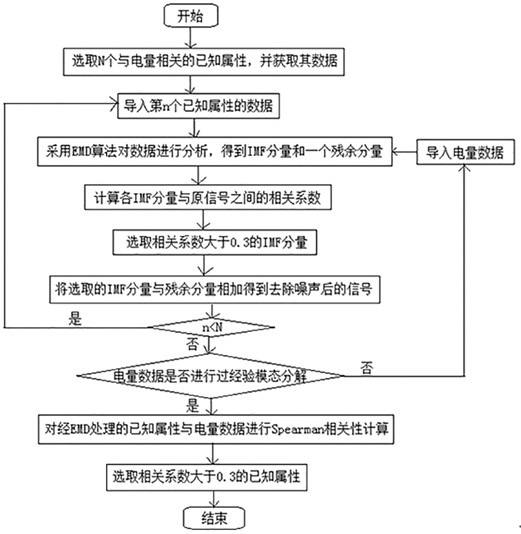

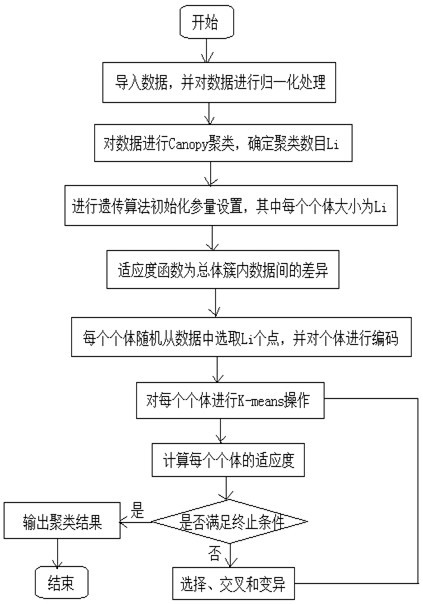

Electric quantity missing value filling method based on multi-parameter Internet of Things fusion technology

InactiveCN114065878AReduce filling errorImprove accuracyData processing applicationsCharacter and pattern recognitionCorrelation coefficientEngineering

The invention provides an electric quantity missing value filling method based on a multi-parameter internet-of-things fusion technology, and relates to the technical field of electric power metering. The method comprises the following steps: building a multi-parameter internet-of-things fusion frame, and collecting known attribute data related to the electric quantity; acquiring electric quantity data; performing noise reduction on the data, then calculating a correlation coefficient value between each piece of known attribute data and the electric quantity data, screening out the known attribute data of which the correlation coefficient value is greater than a threshold value and performing subsequent steps, and enabling the rest of the known attribute data not to participate in the subsequent steps; performing clustering analysis on the known attribute data to obtain a similar scene set of the known attribute data; calculating the weight of each piece of known attribute data; calculating the similarity, and calculating the comprehensive similarity by combining the weights; and searching a time period with the highest comprehensive similarity, and selecting the electric quantity data of the time period to carry out missing value filling. The accuracy of missing value filling is improved by fully utilizing the electric quantity related attribute data.

Owner:TAIAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

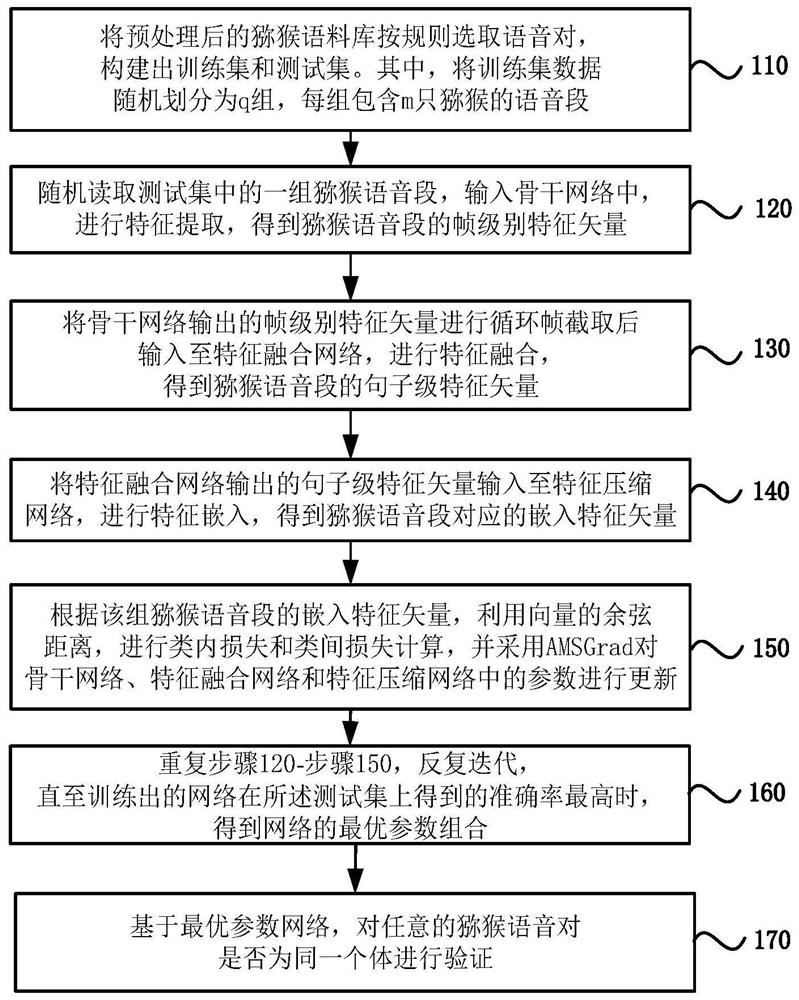

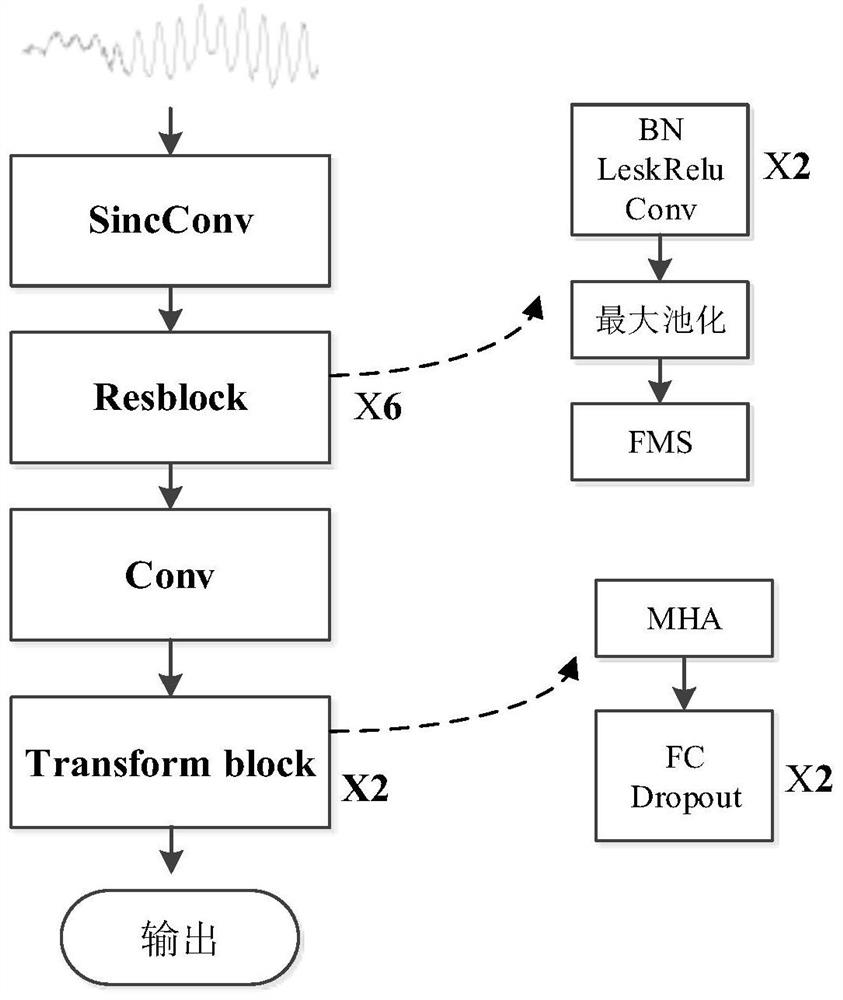

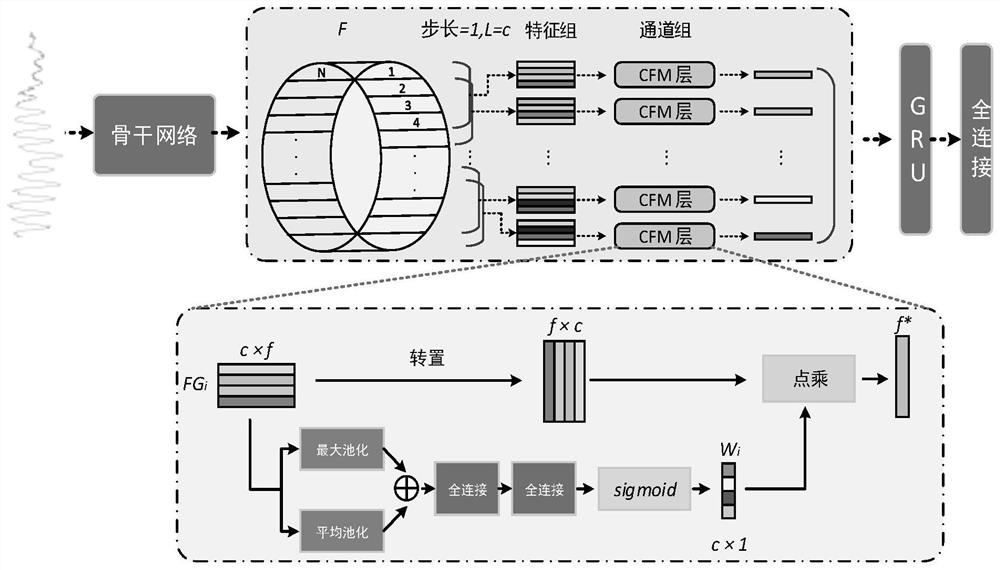

End-to-end macaque voiceprint verification method and system based on cyclic frame-level feature fusion

ActiveCN113129908AImprove accuracyComprehensive and effective speech characteristicsSpeech analysisAlgorithmEngineering

The invention discloses an end-to-end macaque voiceprint verification method and system based on cyclic frame-level feature fusion. The method comprises the following steps of preprocessing a to-be-verified macaque voice pair; the macaque voice pair comprising two macaque voice segments; inputting the preprocessed macaque voice pair into a pre-trained macaque voiceprint verification model to obtain a conclusion whether the macaque voice pair to be verified belongs to the same macaque, and realizing voiceprint verification; the macaque voiceprint verification model comprising a backbone network, a feature fusion network and a feature compression network which are connected in sequence; wherein the backbone network is used for carrying out frame-level feature extraction; the feature fusion network is used for performing cyclic frame interception and grouping on the frame-level feature vectors subjected to feature extraction, and mapping the frame-level features into fusion frame features based on a channel weighted fusion mechanism; and the feature compression network is used for compressing the fused frame features to obtain sentence-level features corresponding to the macaque voice segments.

Owner:NANHAI RES STATION OF INST OF ACOUSTICS CHINESE ACADEMY OF SCI

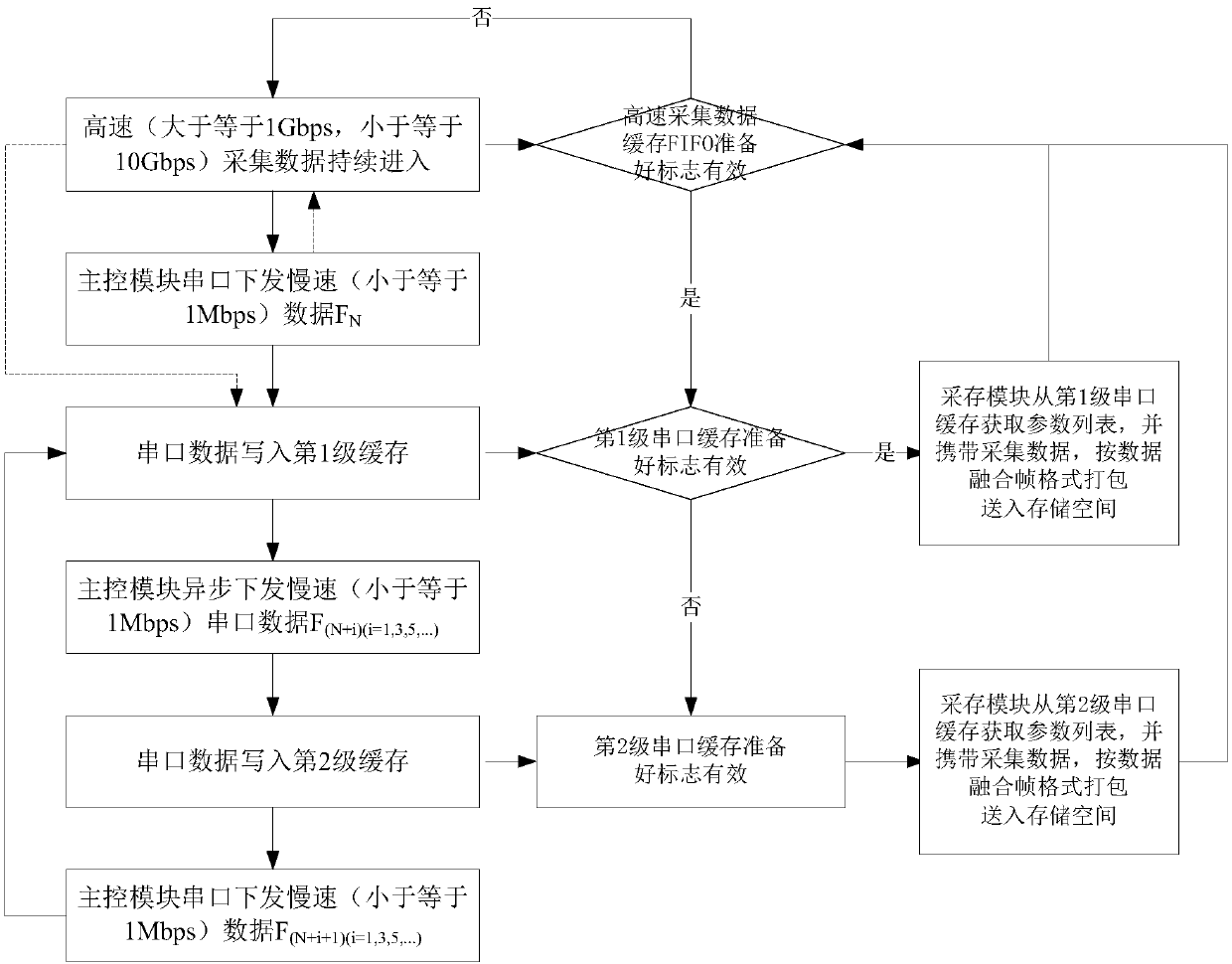

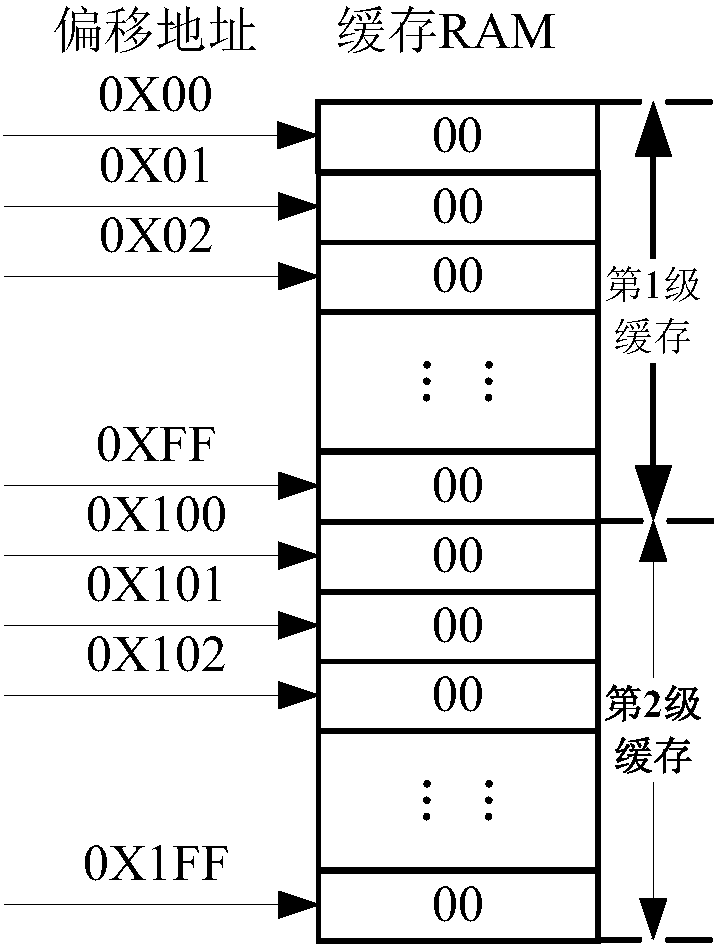

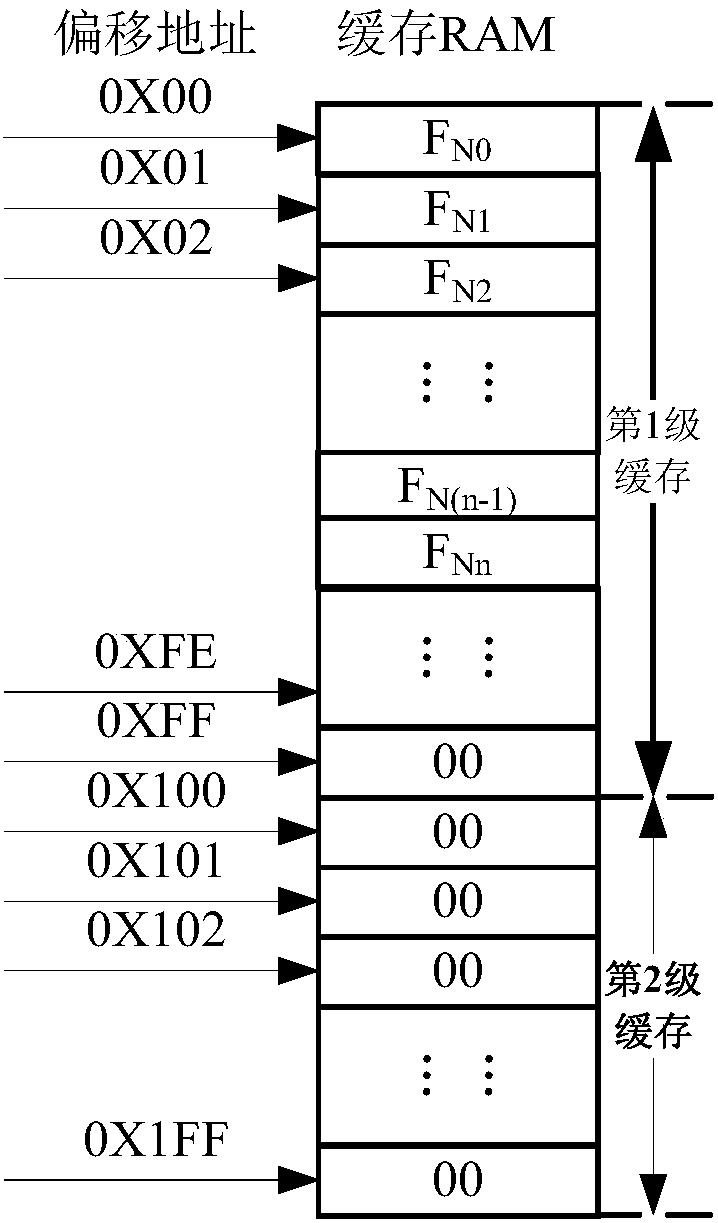

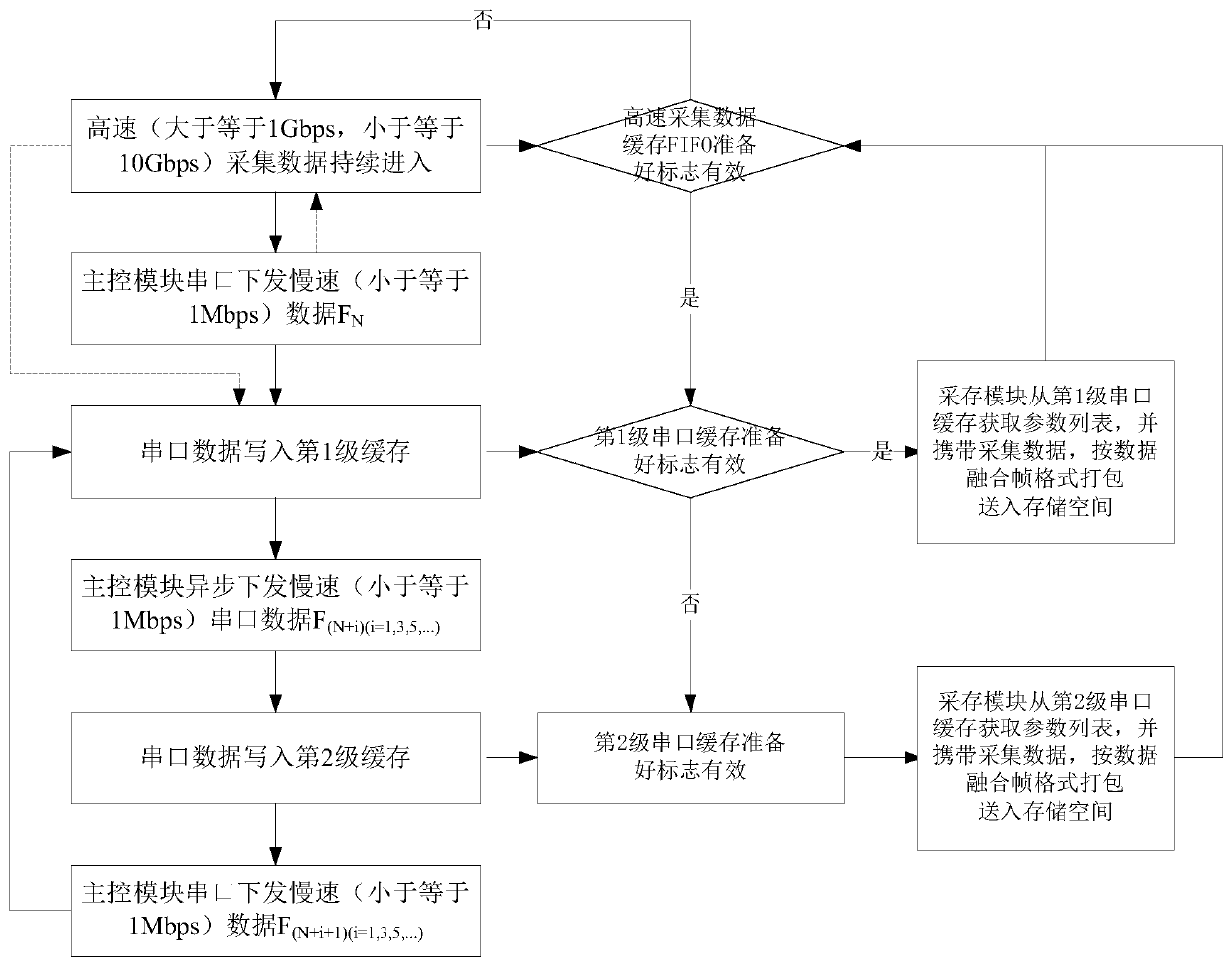

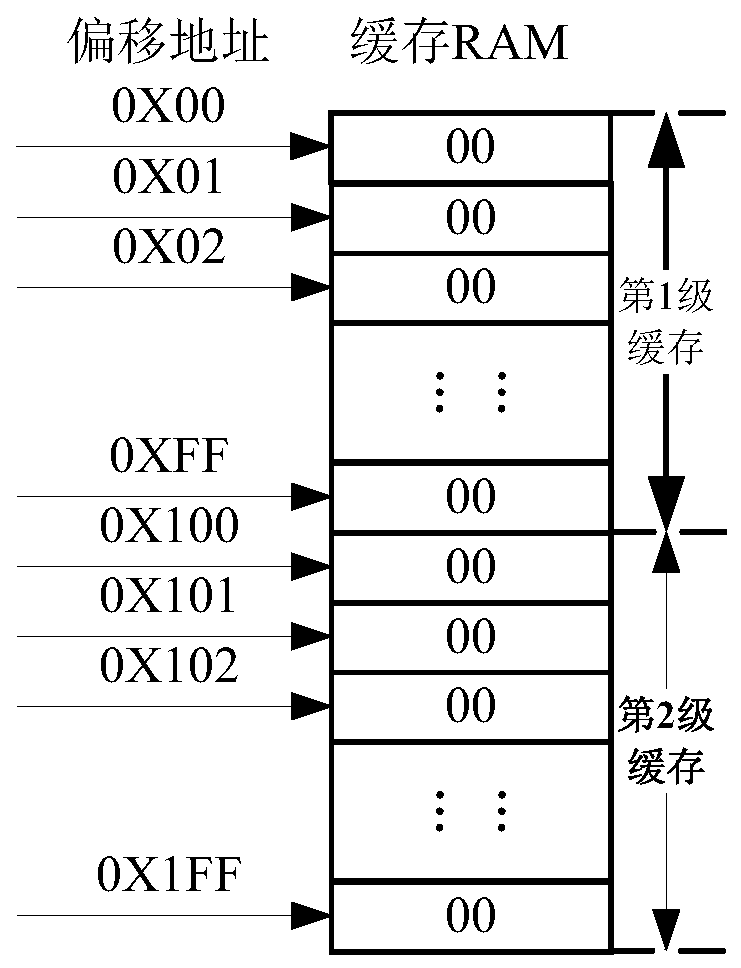

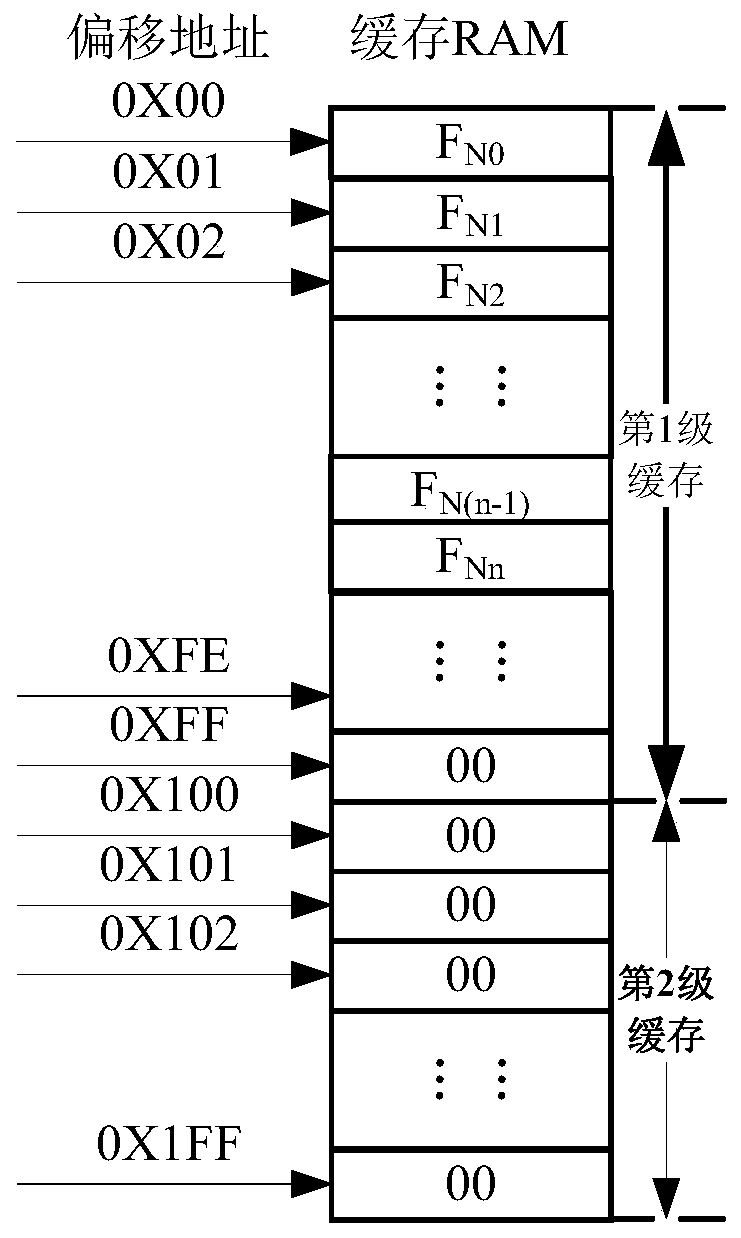

Method for performing fusion storage on low-speed serial data and high-speed collection data

The invention discloses a method for performing fusion storage on low-speed serial data and high-speed collection data. The method comprises the steps that 1, initialization setting is performed on adata collection and storage system; 2, a master control module sends the high-speed collection data to a collection and storage module; 3, the master control module sends the low-speed serial data tothe collection and storage module; and 4, the collection and storage module performs fusion storage on the low-speed serial data and the high-speed collection data. The method can meet the applicationdemand of serial online asynchronous update and adapt to sending of a new parameter list by the master control module at any moment in any cycle, the new parameter list can be updated to a frame header of each data fusion frame to be sent into a storage space with minimum time delay, and the information completeness of the parameter list is ensured. The method also achieves the function of performing reliable fusion storage on the low-speed serial data and the high-speed collection data, and the data instantaneity, completeness and reliability of data collection and storage equipment are effectively improved.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

A Method of Fusion Storage of Slow Serial Port Data and High Speed Acquisition Data

The invention discloses a method for performing fusion storage on low-speed serial data and high-speed collection data. The method comprises the steps that 1, initialization setting is performed on adata collection and storage system; 2, a master control module sends the high-speed collection data to a collection and storage module; 3, the master control module sends the low-speed serial data tothe collection and storage module; and 4, the collection and storage module performs fusion storage on the low-speed serial data and the high-speed collection data. The method can meet the applicationdemand of serial online asynchronous update and adapt to sending of a new parameter list by the master control module at any moment in any cycle, the new parameter list can be updated to a frame header of each data fusion frame to be sent into a storage space with minimum time delay, and the information completeness of the parameter list is ensured. The method also achieves the function of performing reliable fusion storage on the low-speed serial data and the high-speed collection data, and the data instantaneity, completeness and reliability of data collection and storage equipment are effectively improved.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

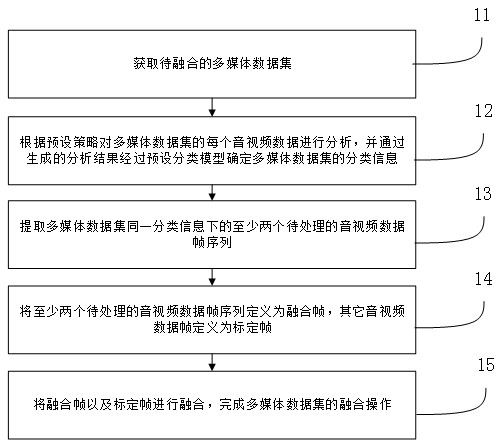

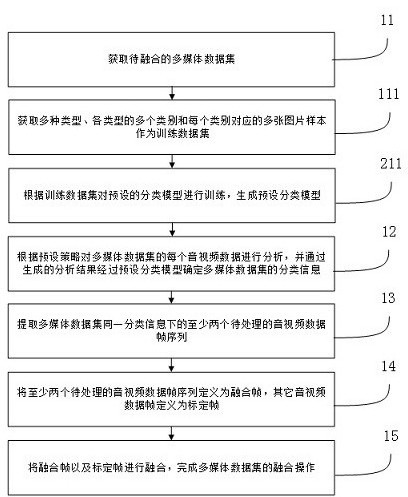

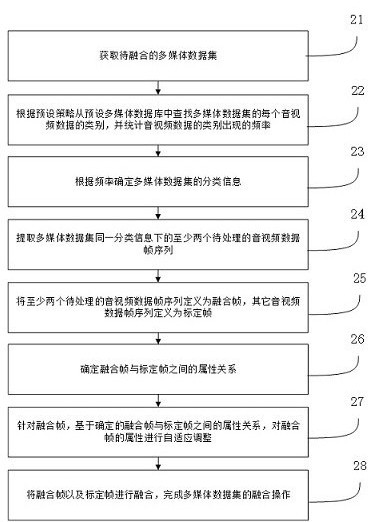

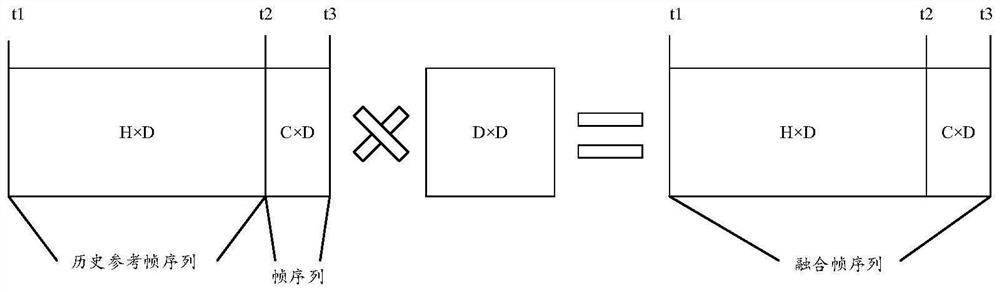

A multimedia digital fusion method and device

ActiveCN111246124BFusion operation is preciseFusion operation is fastTelevision system detailsMultimedia data clustering/classificationData setFrame sequence

The disclosure provides a multimedia digital fusion method, which acquires a multimedia data set to be fused; analyzes each audio and video data of the multimedia data set according to a preset strategy, and determines the multimedia data through a preset classification model through the generated analysis results The classification information of the collection; extract at least two audio and video data frame sequences to be processed under the same classification information of the multimedia data set; define at least two audio and video data frame sequences to be processed as fusion frames, and define other audio and video data frame sequences is the calibration frame; fuse the fusion frame and the calibration frame to complete the fusion operation of the multimedia data set. The method can accurately and quickly complete the multimedia digital fusion operation, and has the ease of use and practicability of the fusion operation. The disclosure also proposes a multimedia digital fusion device.

Owner:海南风语筑数字科技有限公司

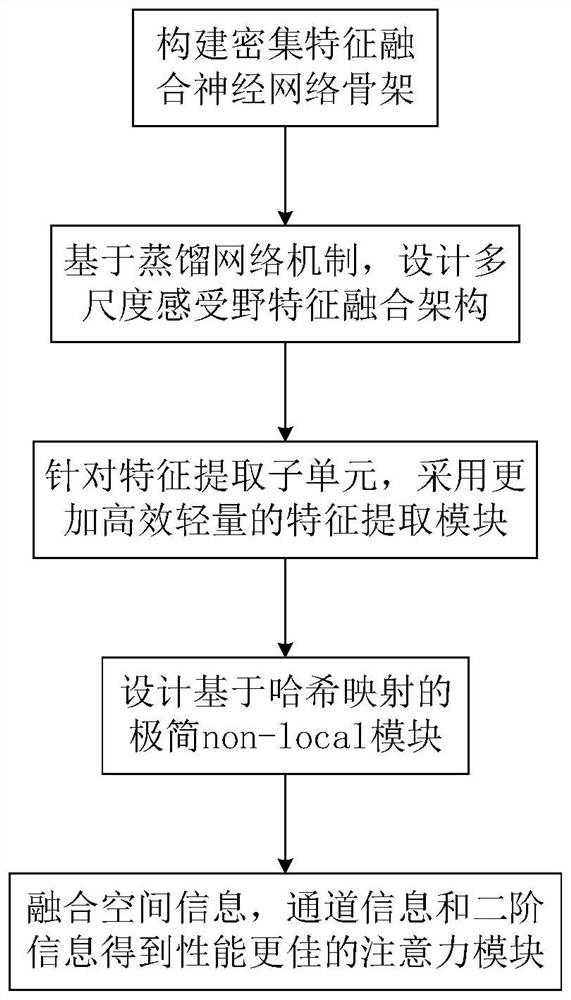

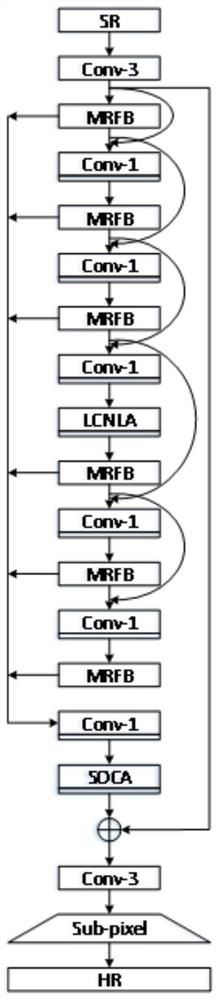

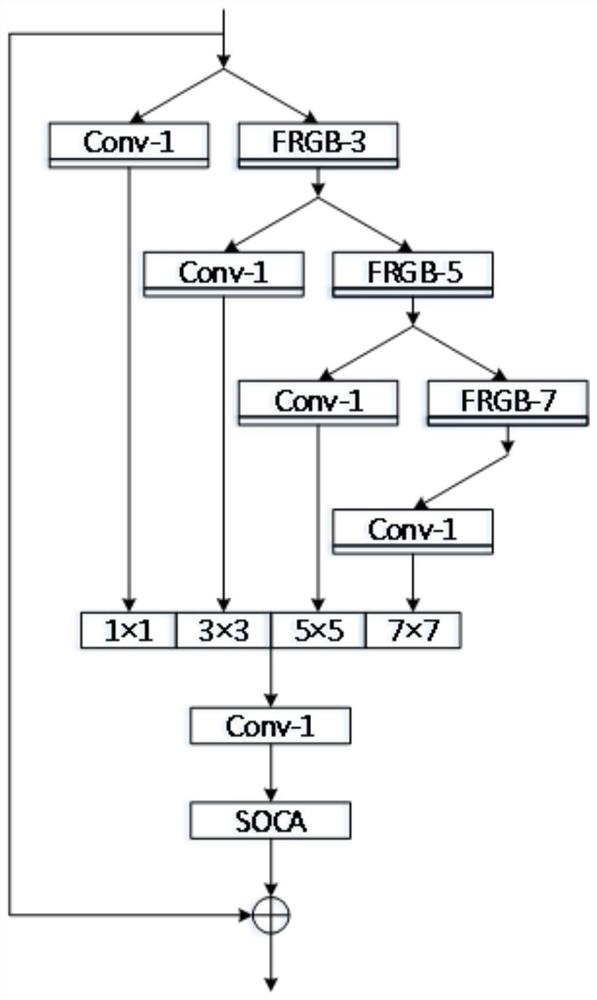

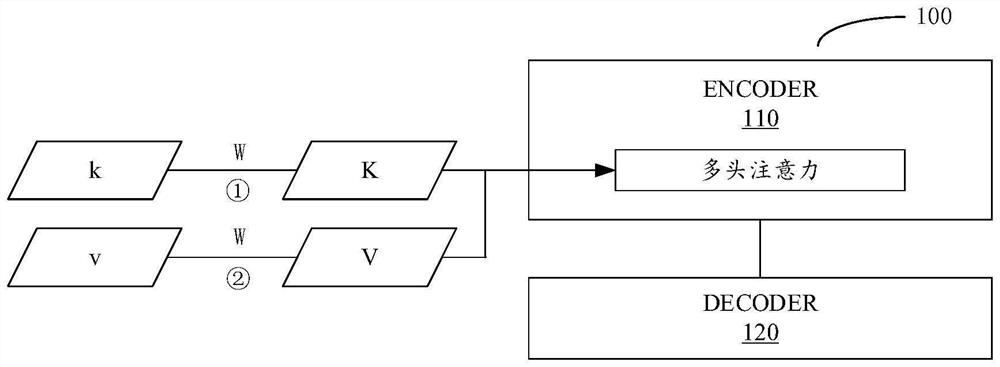

Ultra-light image super-resolution reconstruction method

PendingCN114677277AImprove efficiencyLoss mitigationGeometric image transformationNeural architecturesImage resolutionReconstruction method

The invention discloses an extremely light image super-resolution reconstruction method, which effectively alleviates the problem of shallow information loss by constructing a dense feature fusion neural network skeleton. According to the invention, based on a distillation network mechanism, a multi-scale receptive field feature fusion architecture is designed, and richer and more diversified features can be extracted; for the feature extraction subunits, a feature extraction module which is more efficient and lighter is adopted, so that the efficiency of the whole network is greatly improved; according to the method, a very simple non-local module based on Hash mapping is designed, and the correlation between points is deeply mined at very low cost; in addition, spatial information, channel information and second-order information are ingeniously fused, and an attention module with better performance is obtained. The method provided by the invention is small in parameter quantity, small in calculation amount and high in precision, and exceeds all image super-resolution reconstruction methods below 800K at present.

Owner:杭州图科智能信息科技有限公司

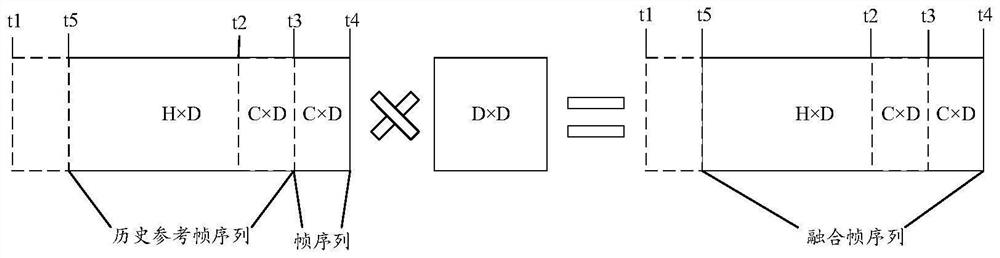

Streaming coding and speech recognition method and device, electronic equipment and storage medium

PendingCN114530144AReduce processingImprove processing efficiencySpeech recognitionFrame sequenceEngineering

The embodiment of the invention provides a streaming coding and speech recognition method and device, electronic equipment and a storage medium. The streaming coding method comprises the following steps: determining a third transformation sequence of a historical reference frame sequence based on a second transformation sequence of a previous fused frame sequence; performing splicing processing based on the first transformation sequence and the third transformation sequence to obtain a fourth transformation sequence of the current fusion frame sequence; determining at least one of a source sequence and a context sequence for an attention mechanism based on the fourth transformed sequence; and performing streaming coding on the current frame sequence based on the source sequence and the context sequence. The third transformation sequence of the historical reference frame sequence is determined based on the second transformation sequence of the previous fusion frame sequence, so that the data processing amount required by the change processing of the historical reference frame sequence in the linear transformation processing process is reduced, the data processing efficiency is improved, and the computing power requirement of equipment is reduced.

Owner:C SKY MICROSYST CO LTD

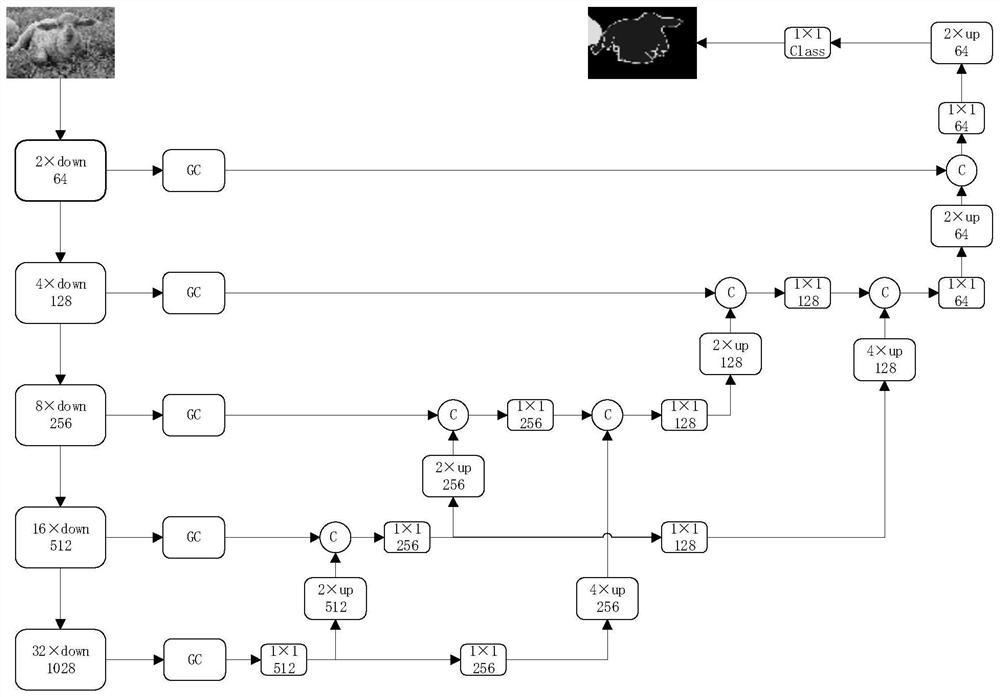

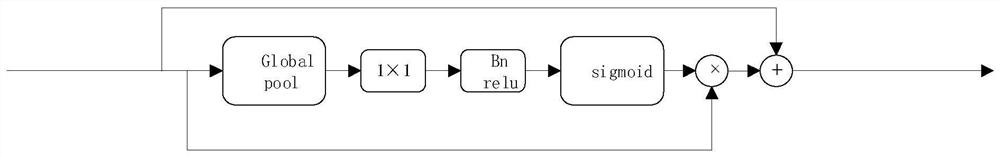

A Real-time Semantic Segmentation Approach with Gated Multilayer Fusion

ActiveCN110569851BGuaranteed timelinessGuaranteed accuracyCharacter and pattern recognitionAlgorithmEngineering

Owner:深圳万知达科技有限公司

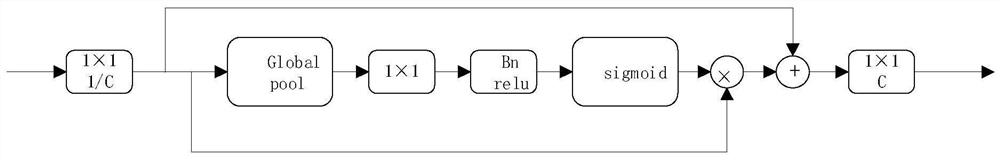

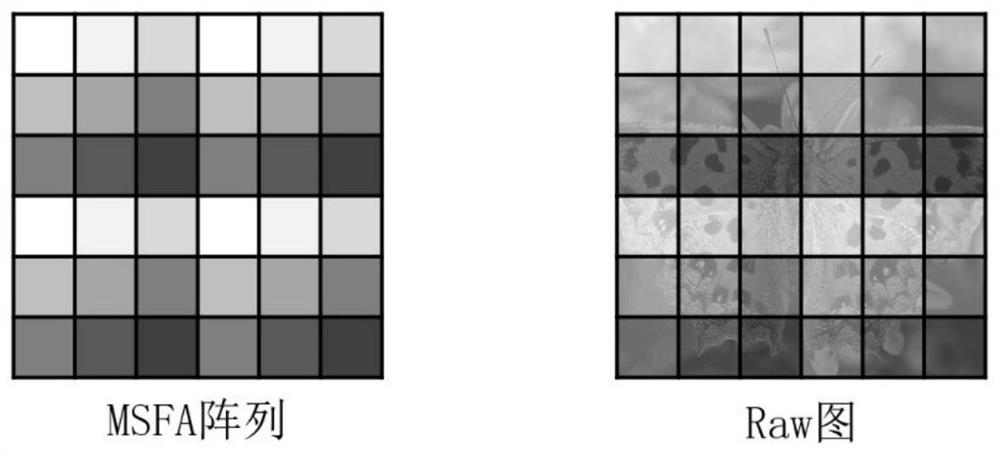

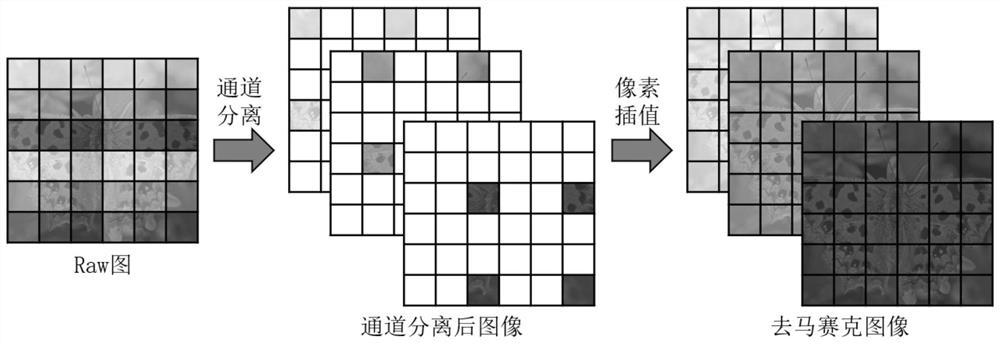

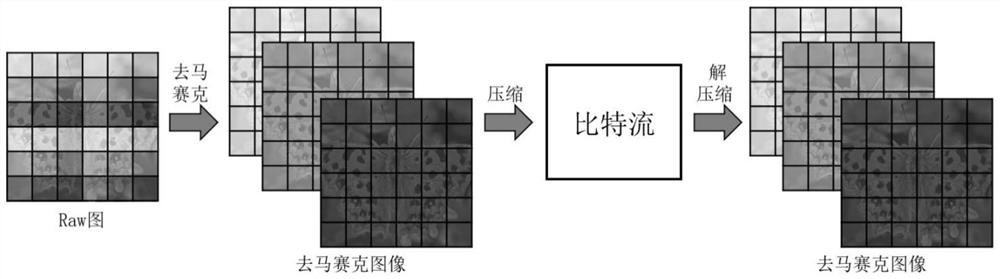

Demosaicing and compression fusion frame for MSFA hyperspectral image

PendingCN114240776AIncrease the compression ratioIncrease image sizeImage enhancementImage analysisComputer graphics (images)Algorithm

The invention discloses a demosaicing and compression fusion frame for an MSFA hyperspectral image. The demosaicing and compression fusion frame comprises a PPI image generation module, a compression and decompression module and a rapid demosaicing module. The PPI image generation module obtains various features in the Raw image by using a DPG-Net network, carries out image reconstruction according to the features, outputs the reconstructed image and generates a PPI image; the compression and decompression module is used for compressing and decompressing the Raw graph and the PPI graph and reducing the size of a compressed file and the complexity of an algorithm; the rapid demosaicing module firstly separates spectrum channels of the Raw graph and the PPI graph; subtracting the separated Raw graph from the PPI graph; and carrying out convolution on the difference between the two images, and adding the image after convolution with the PPI to obtain a final demosaiced image. The frame provided by the invention has the characteristics of high compression rate and high demosaicing speed at the decompression end.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com